Food Processing Technology

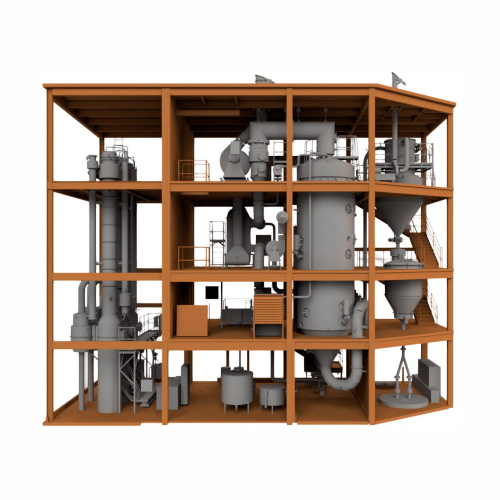

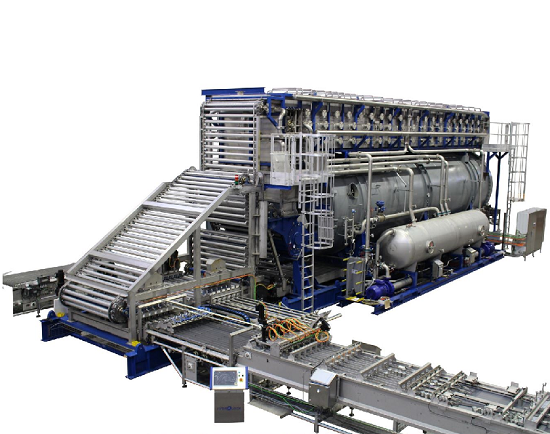

Find innovative food equipment and connect directly with world-leading technology suppliers

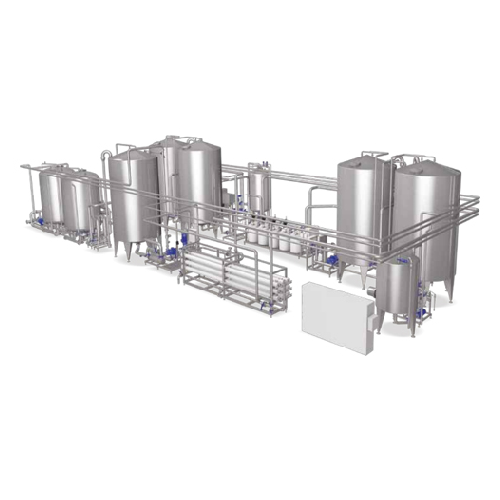

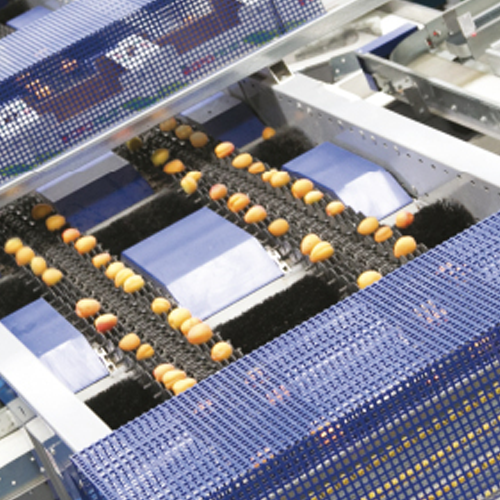

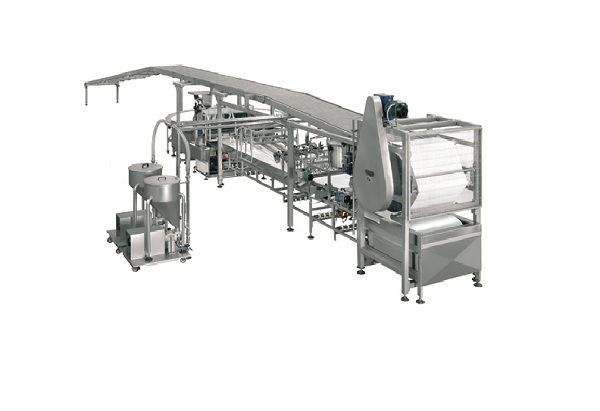

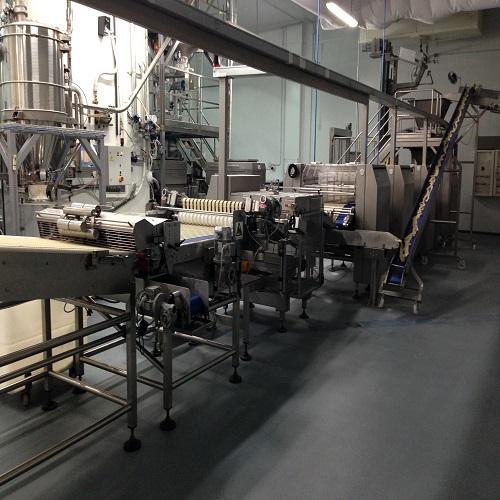

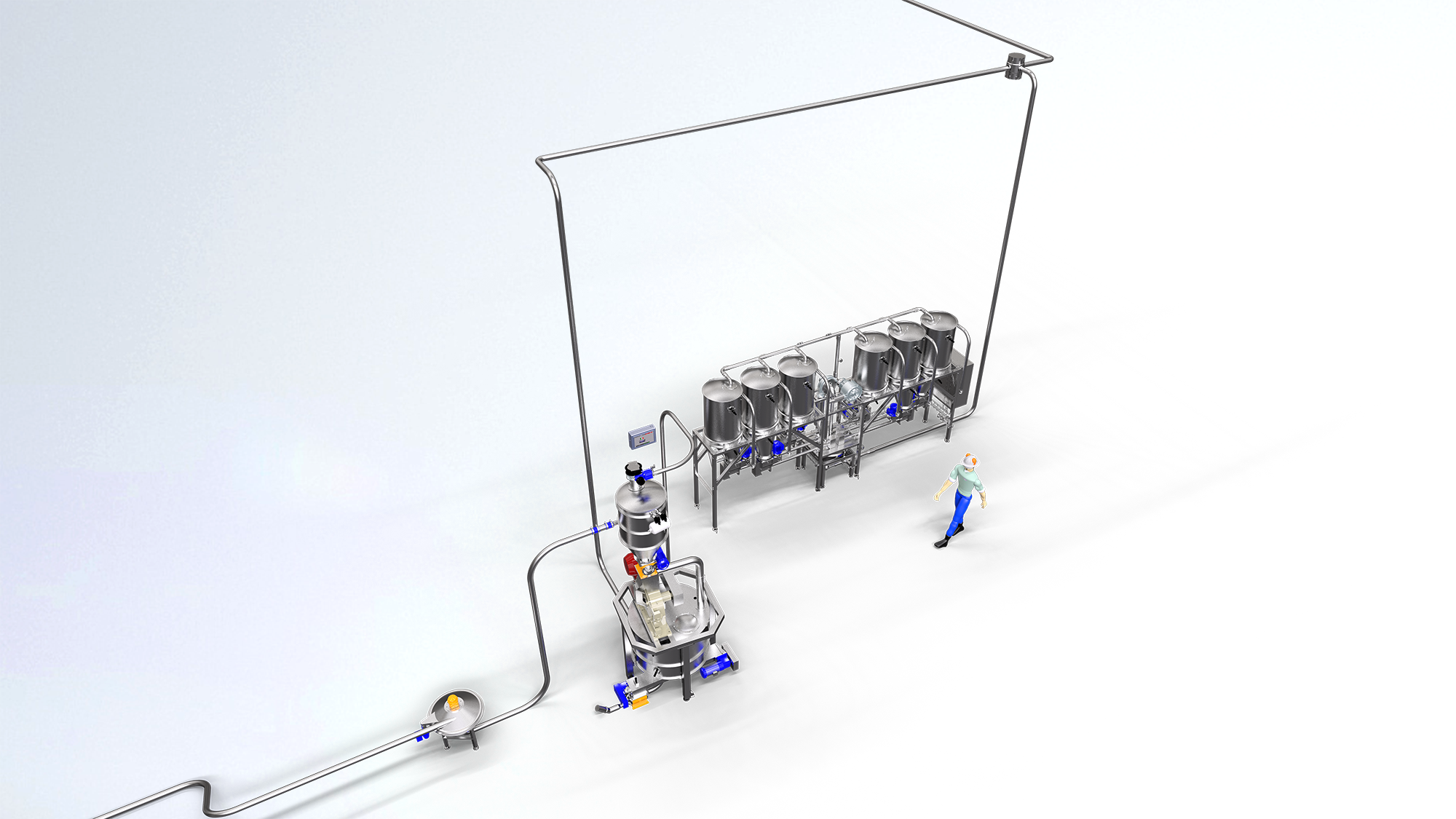

Our food chain starts in the soil, growing crops and livestock. But between the fields and the stores, there is a line of industrial food processing equipment. Processes may be as minimalistic as cleaning fruit and as complex as homogenizing milk alternatives made from pressed legumes. In each case, processing technology is an important link in the food production chain.

Top picks for food processing

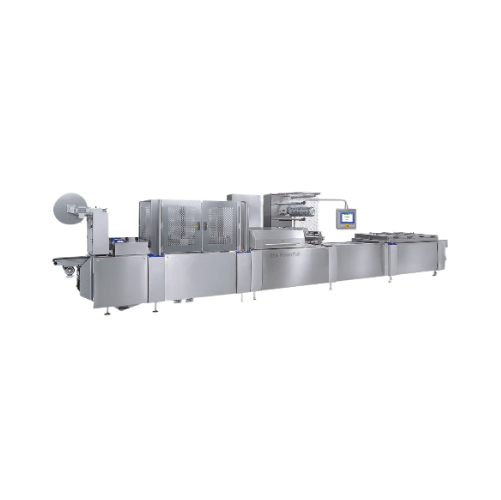

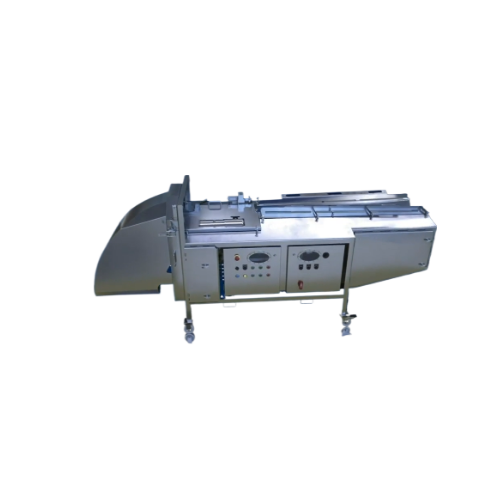

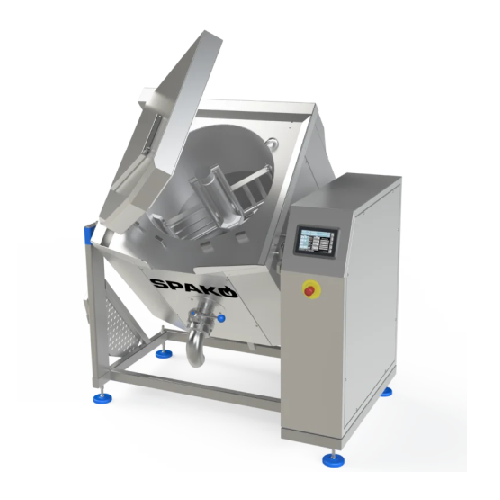

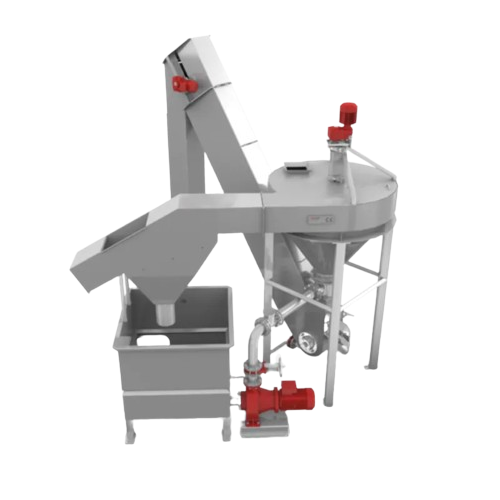

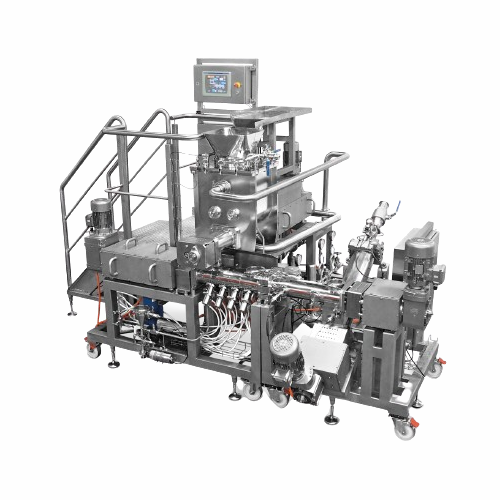

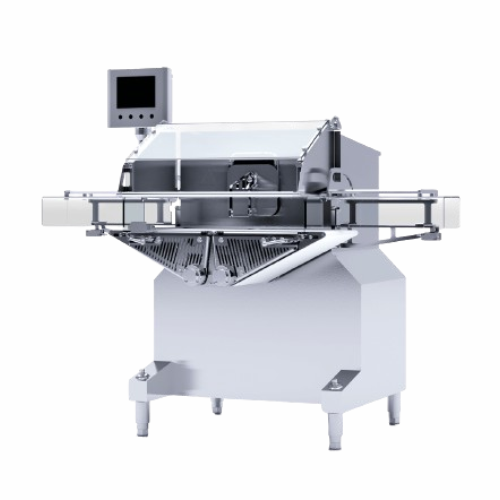

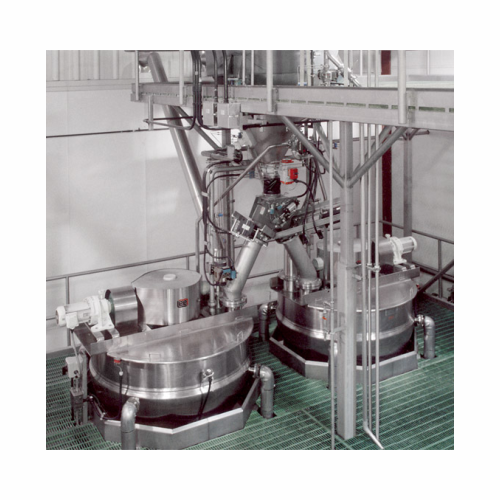

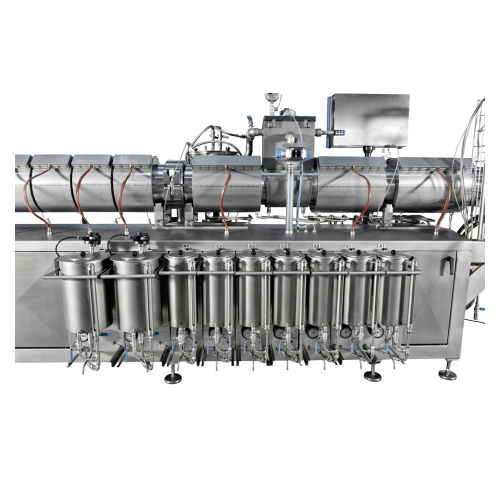

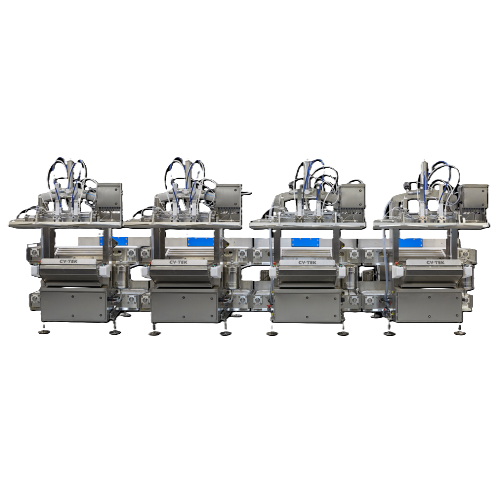

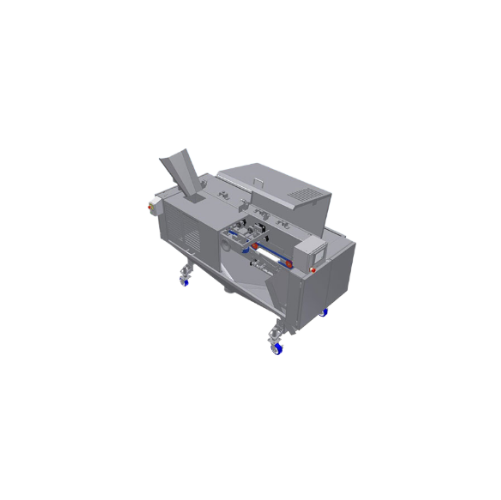

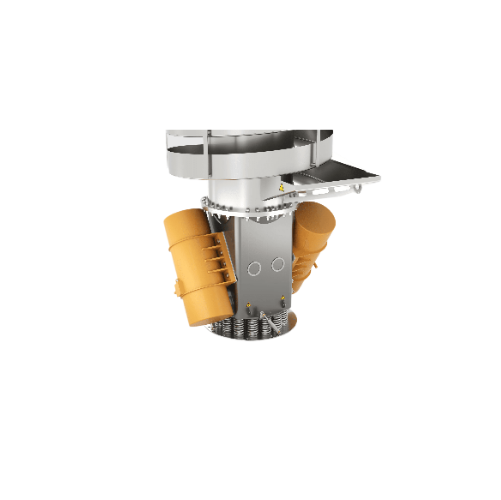

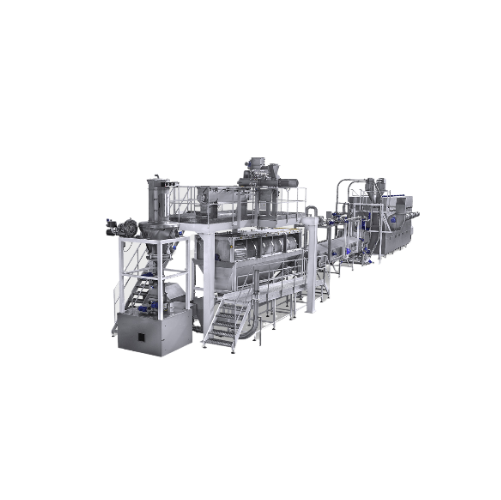

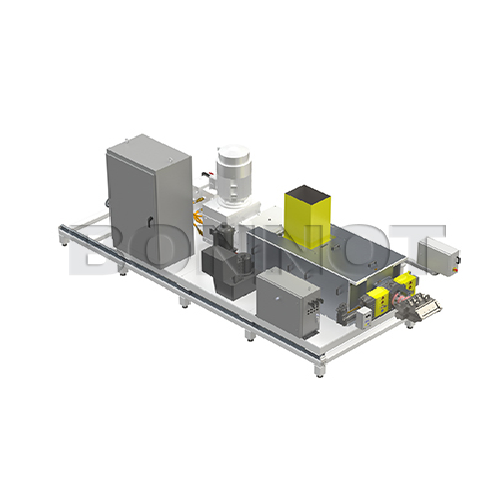

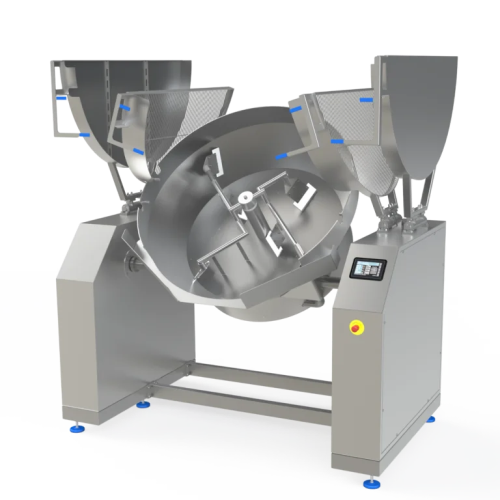

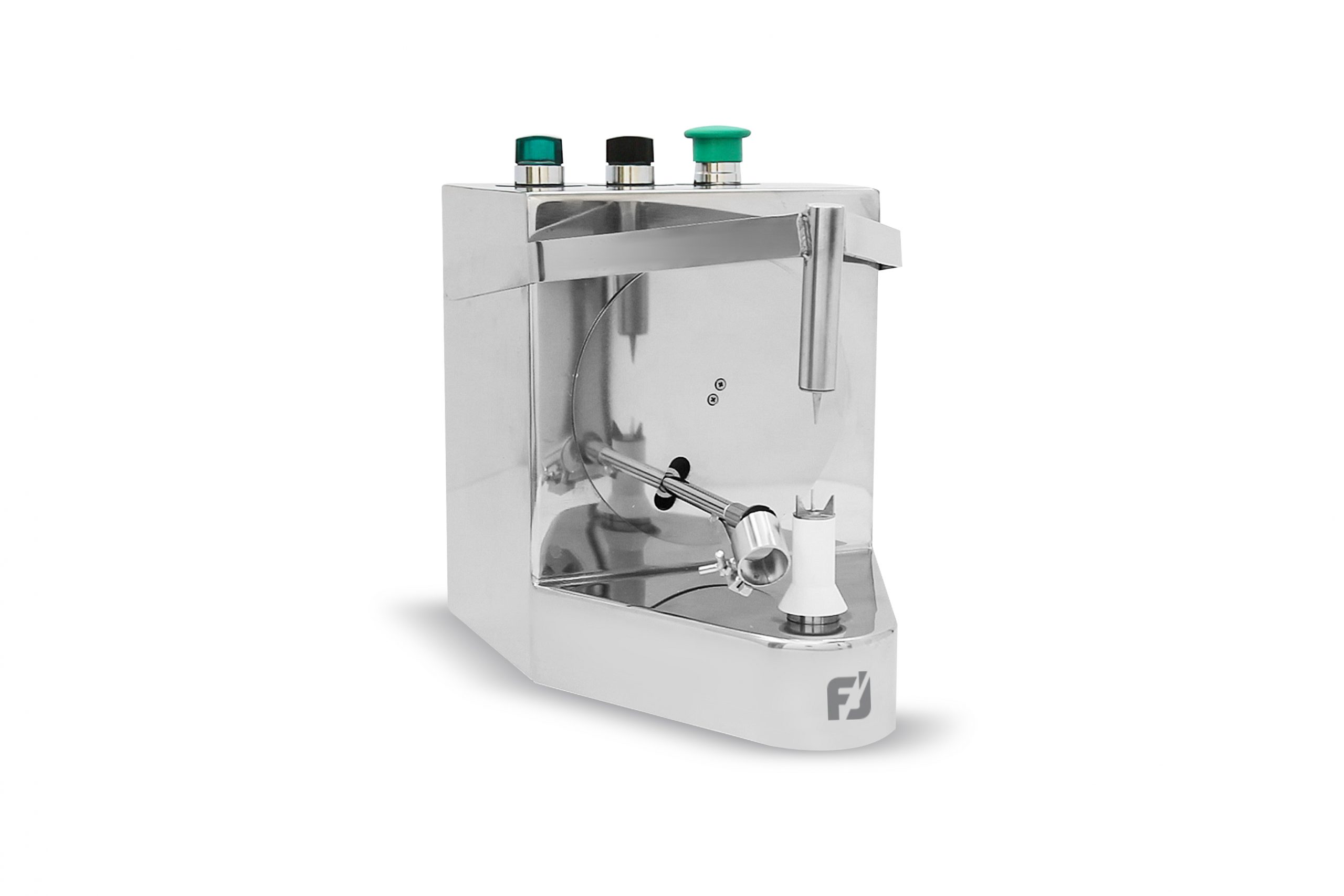

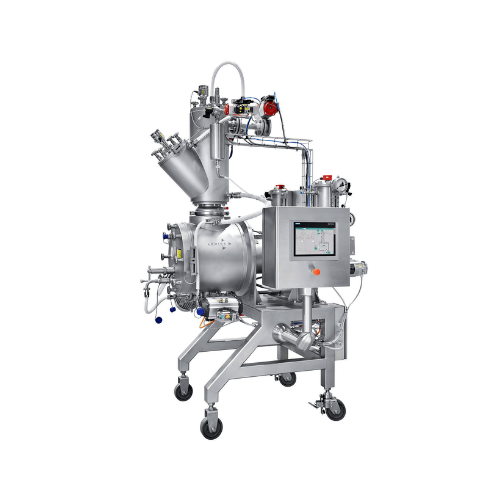

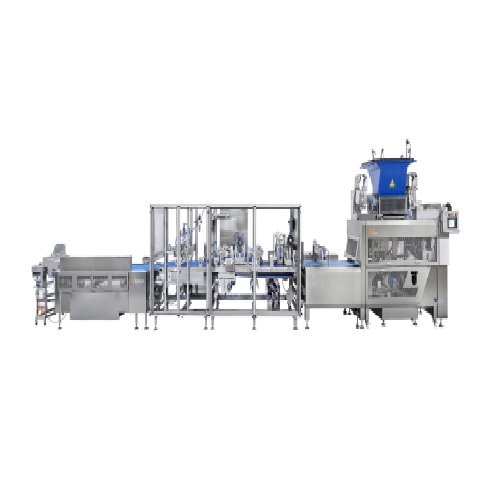

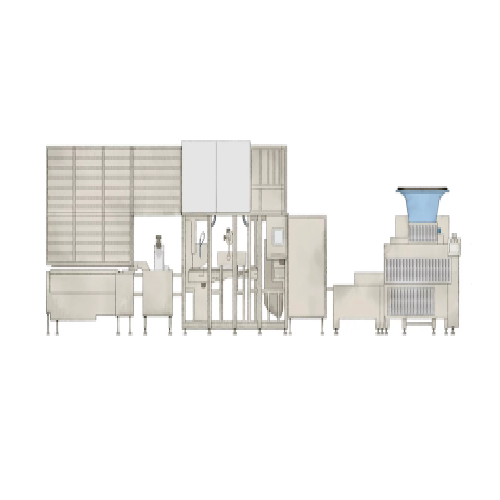

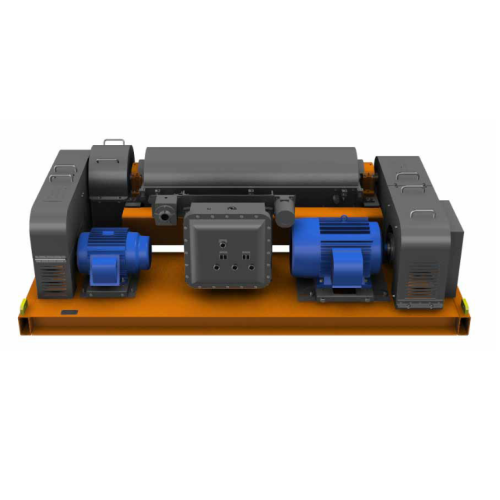

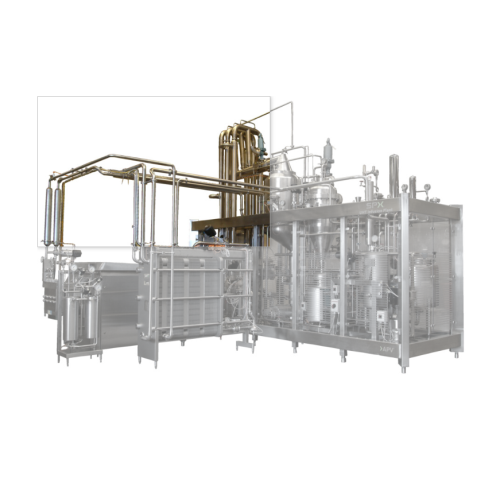

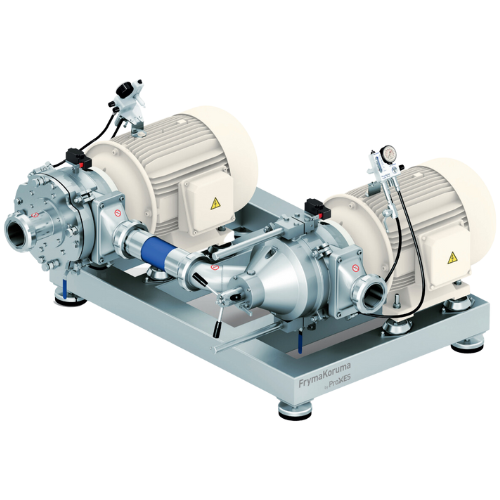

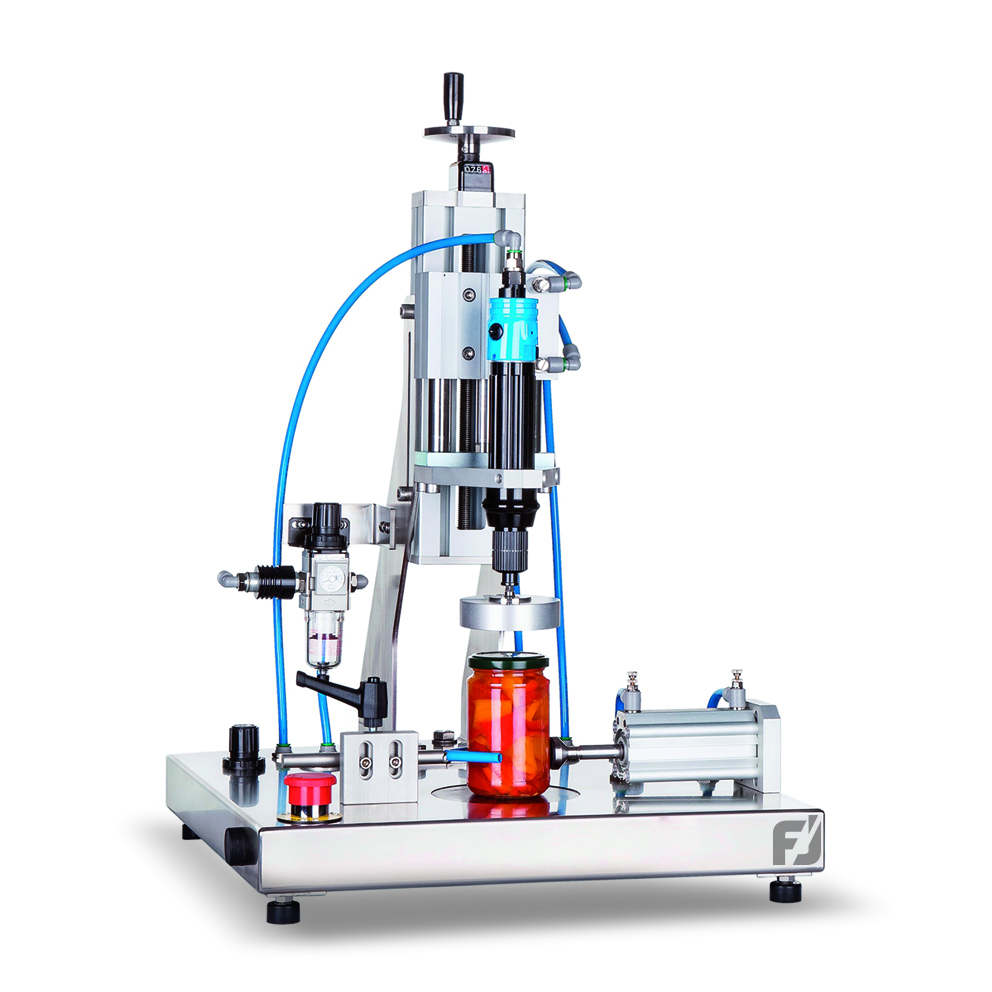

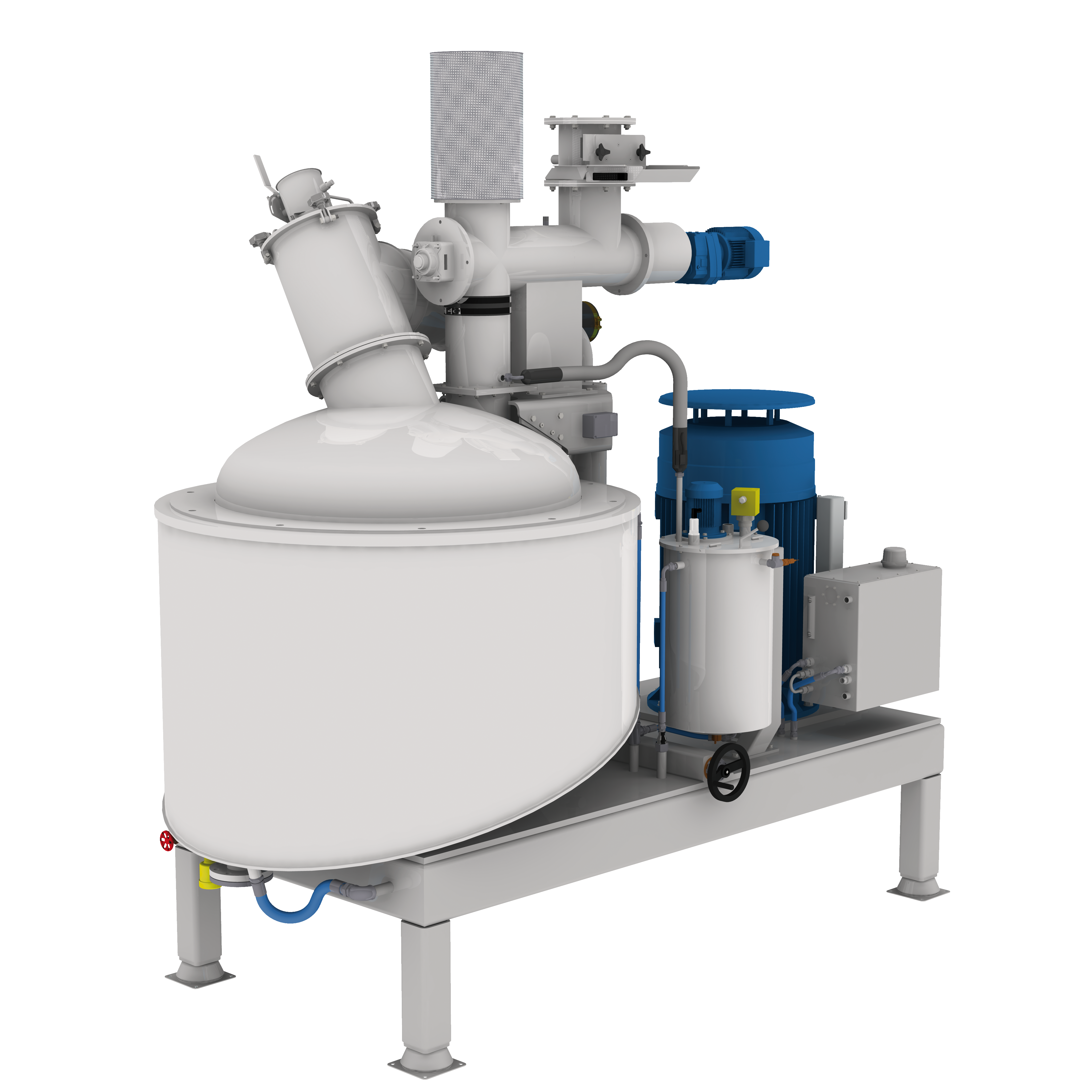

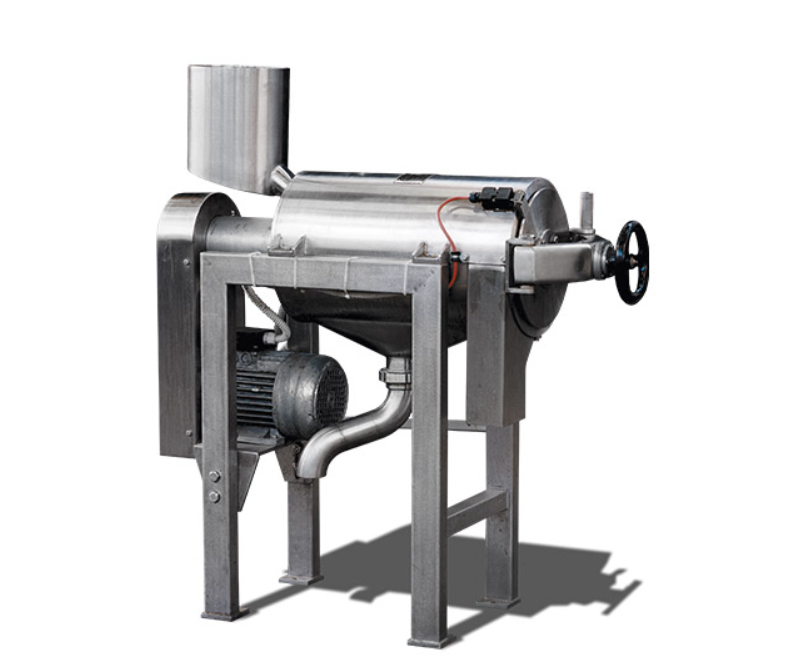

Food processor for high and low viscosity products

Achieve consistent recipe results and streamline your operations with ...

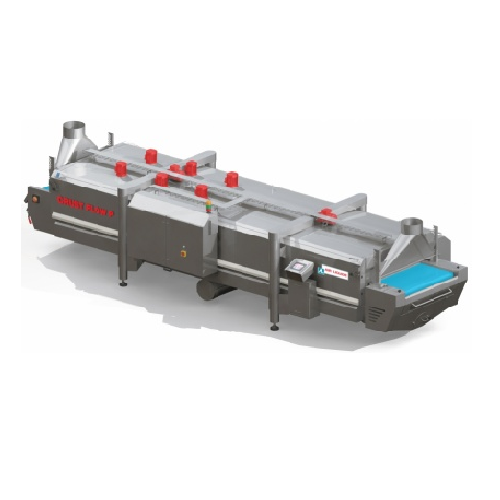

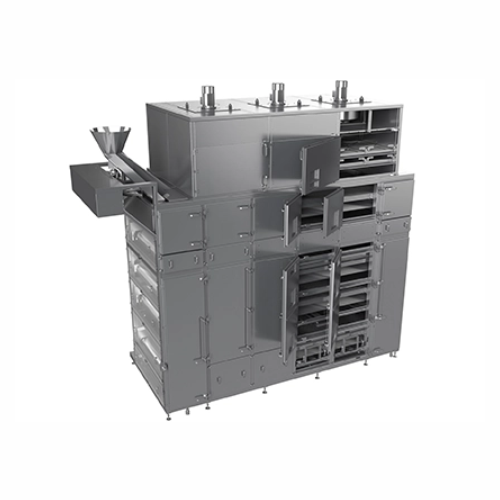

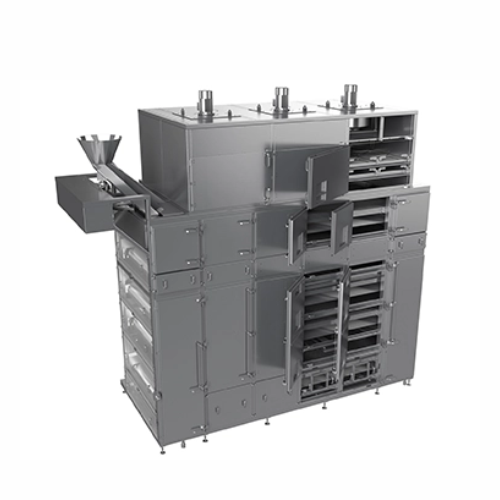

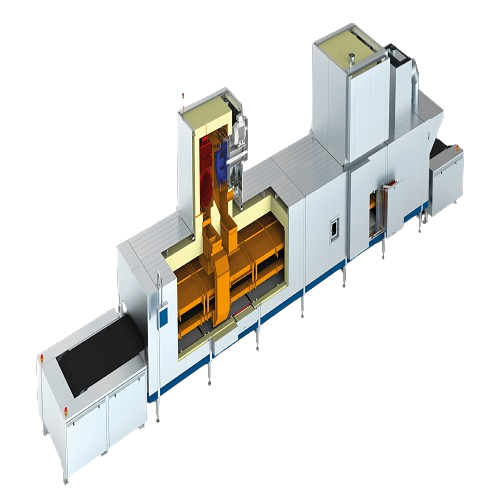

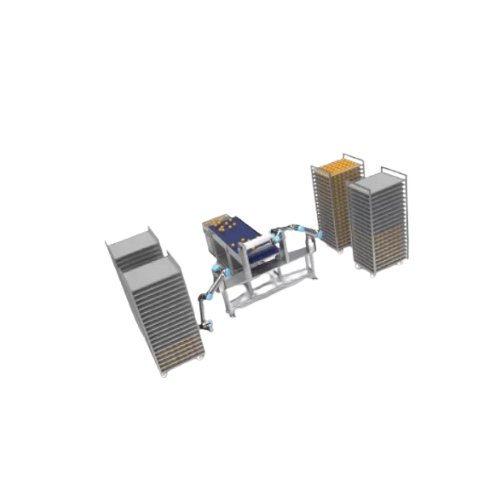

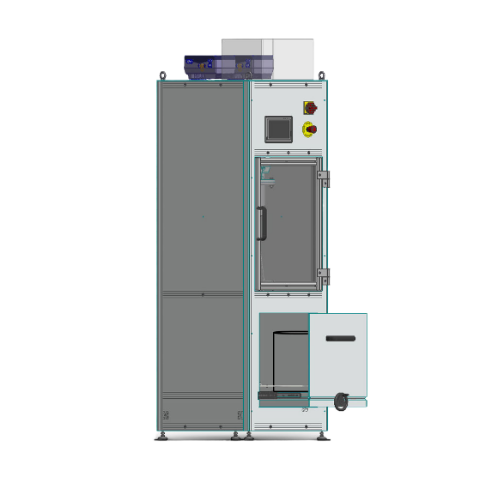

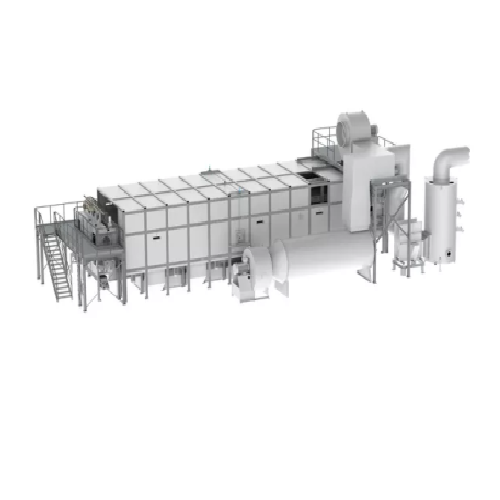

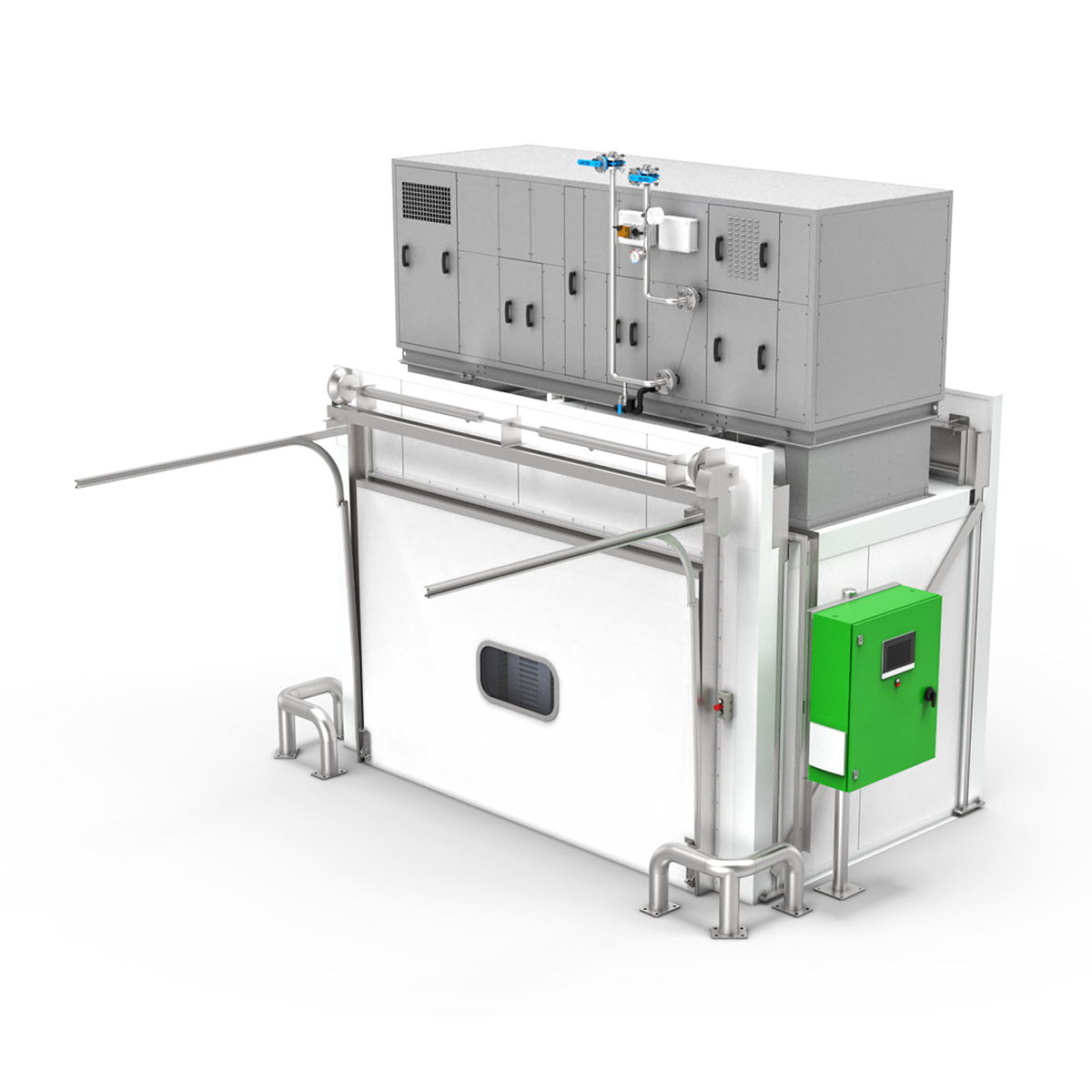

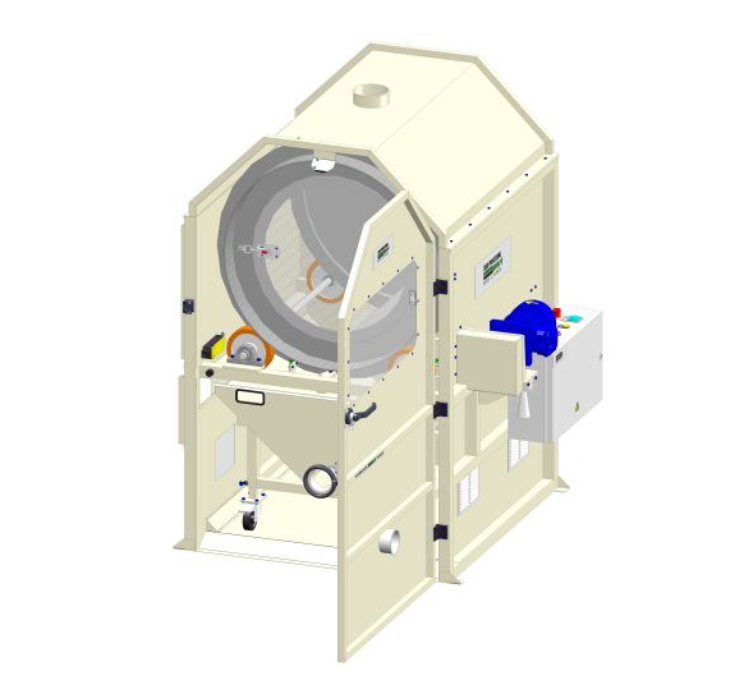

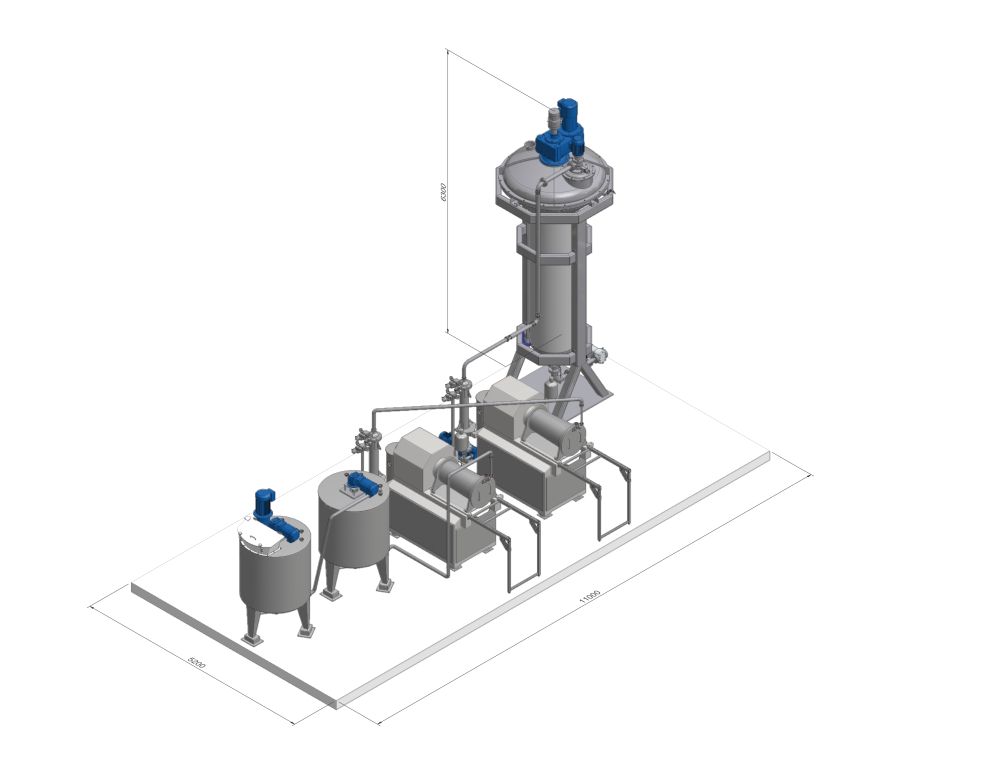

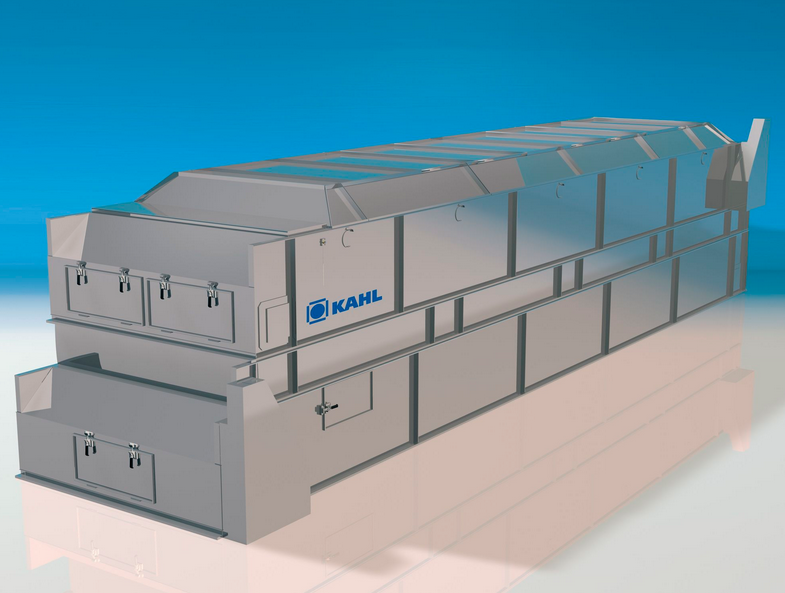

Energy saving cabinet dryer for food

Traditional drying systems use a lot of energy and take a long time to dry the product...

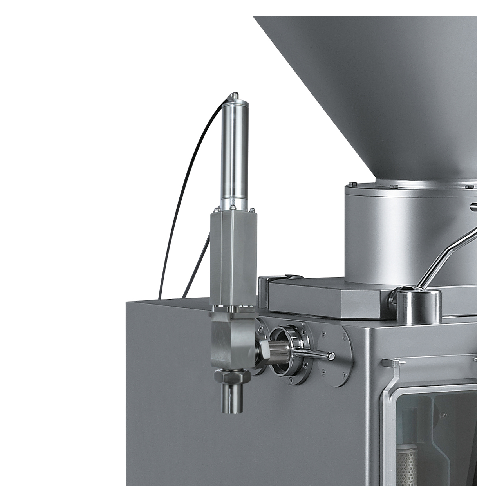

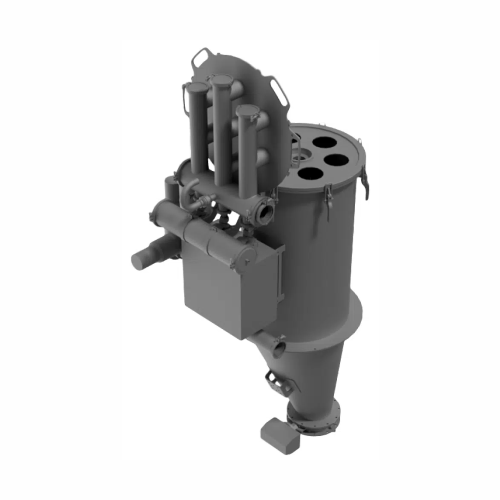

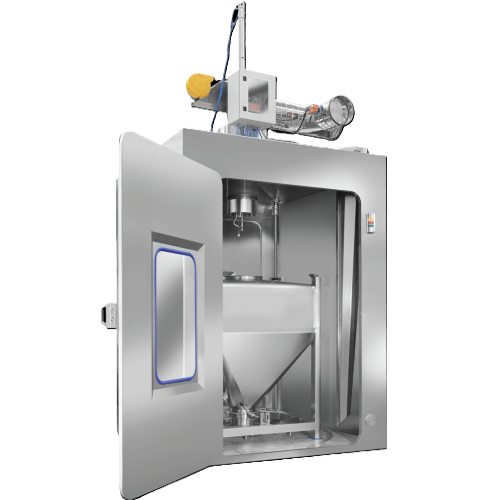

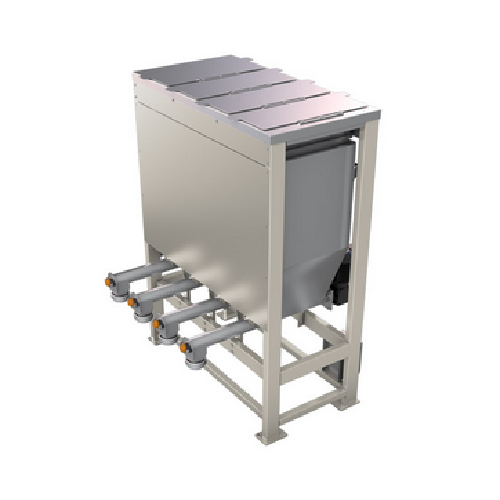

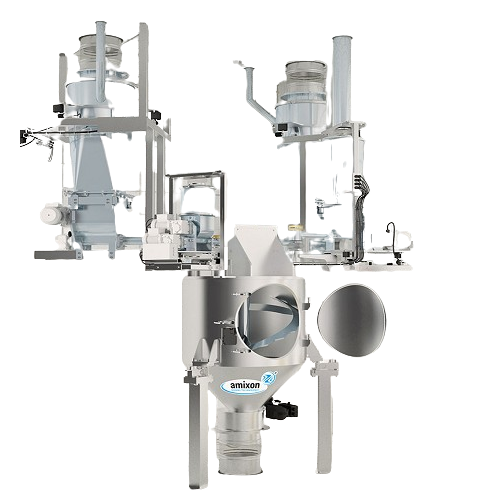

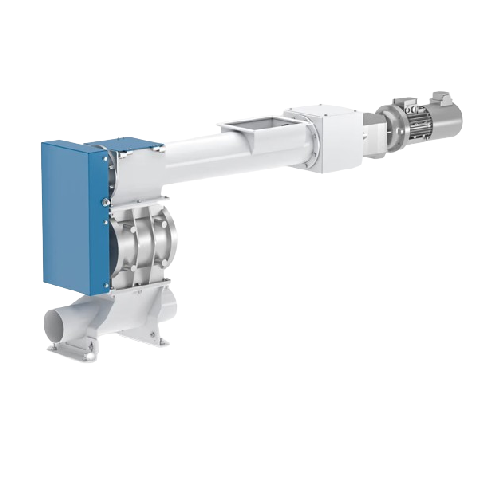

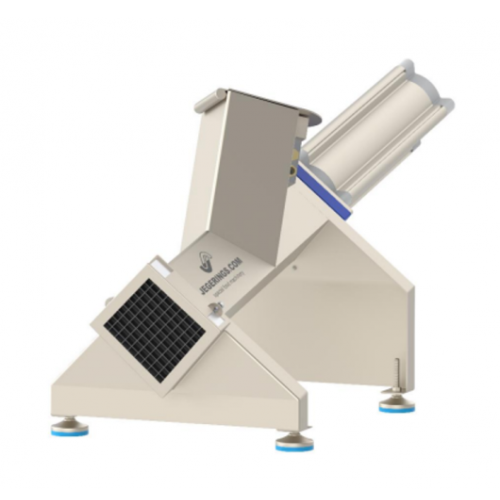

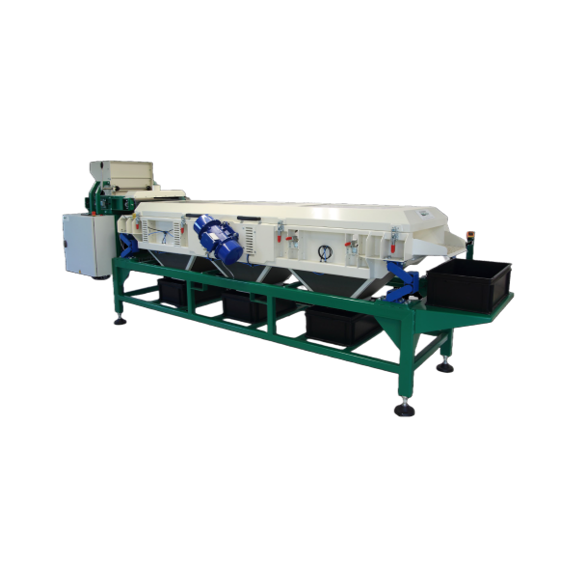

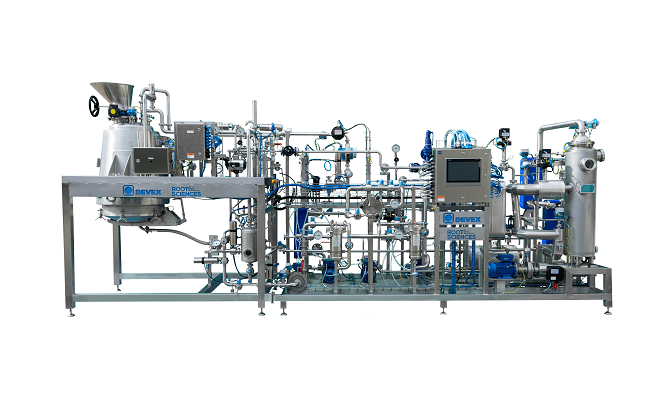

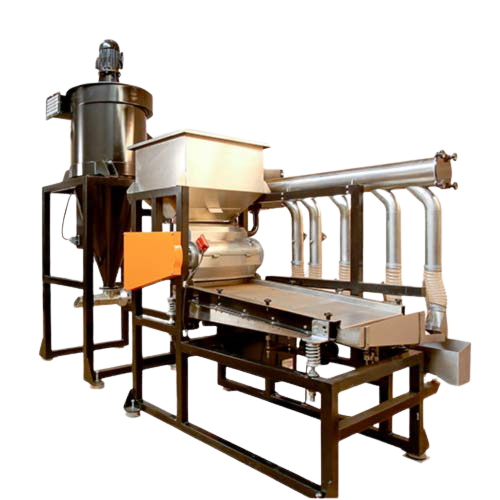

Food vacuum conveyor

Widely used in industries where a high rating in food quality is imperative.

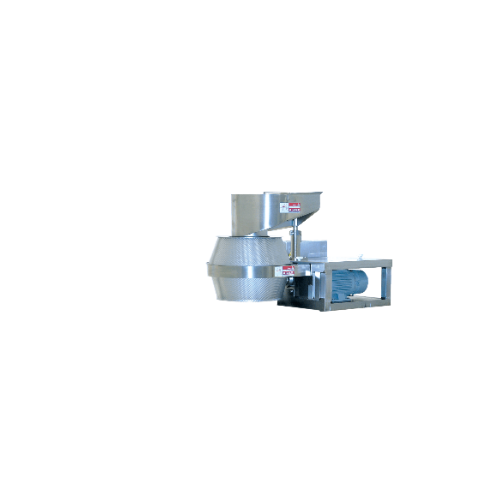

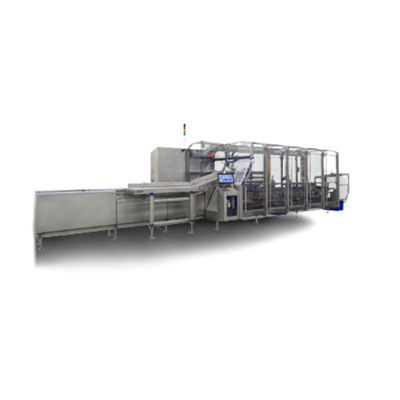

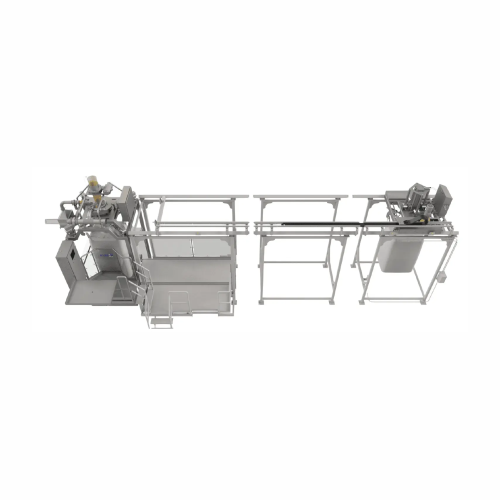

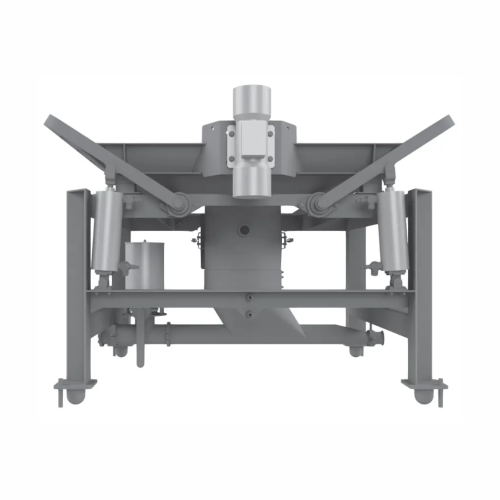

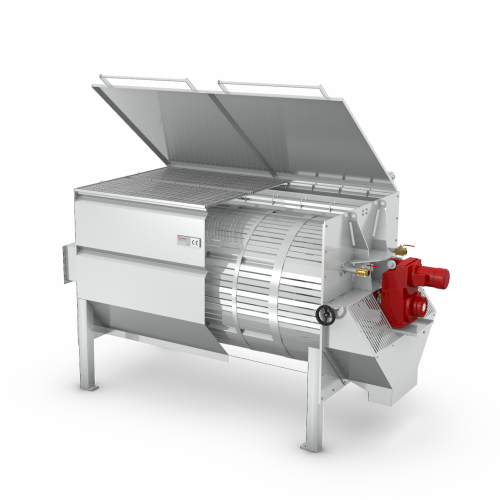

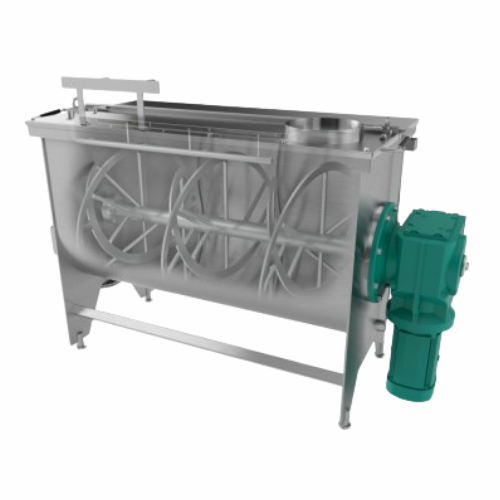

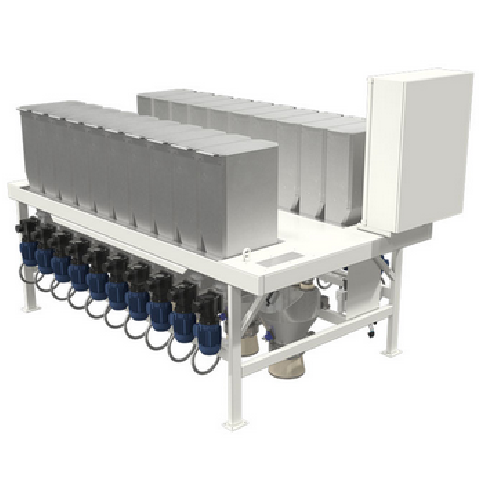

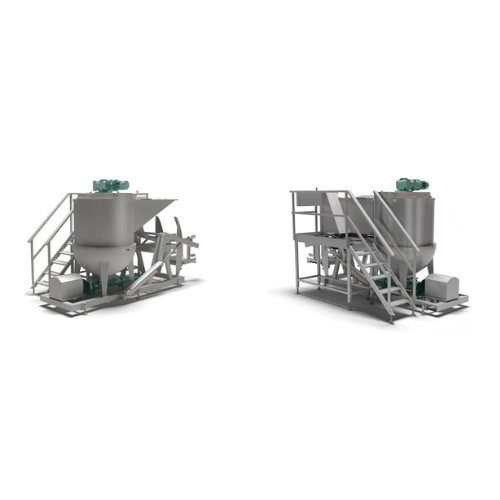

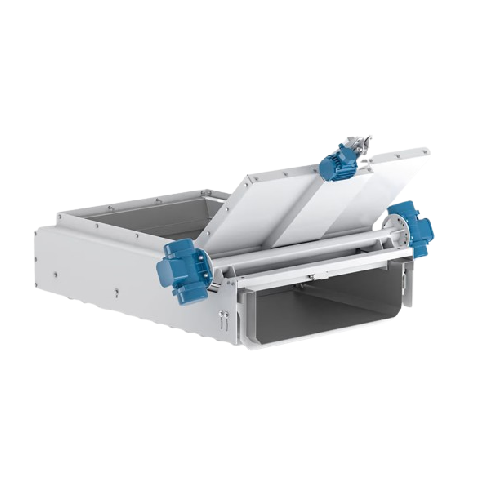

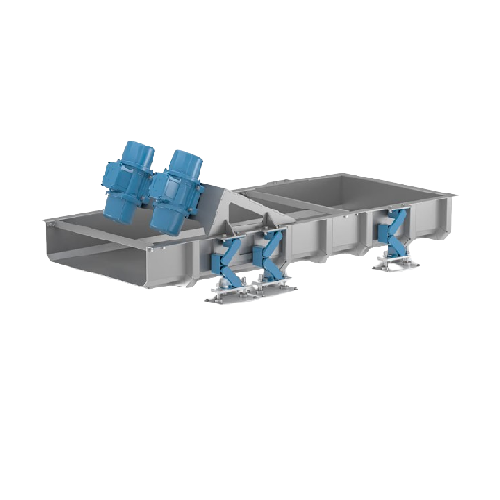

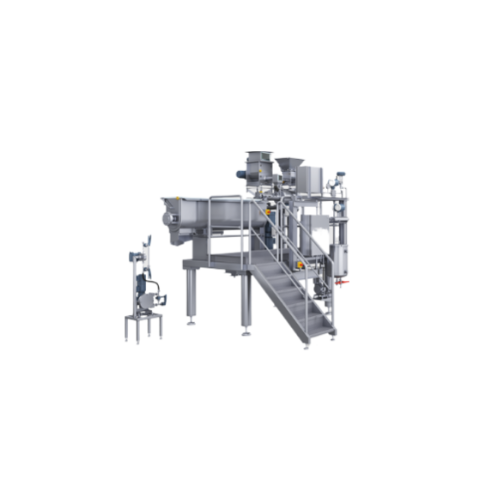

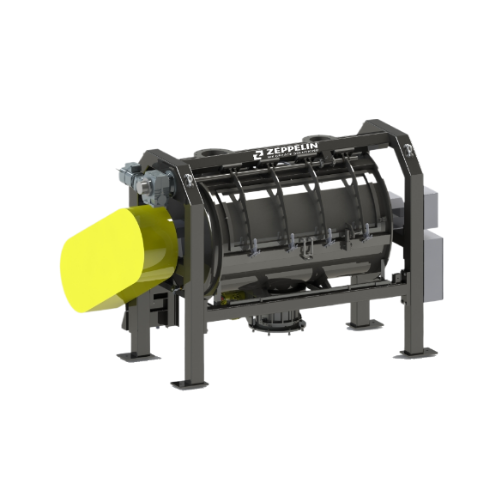

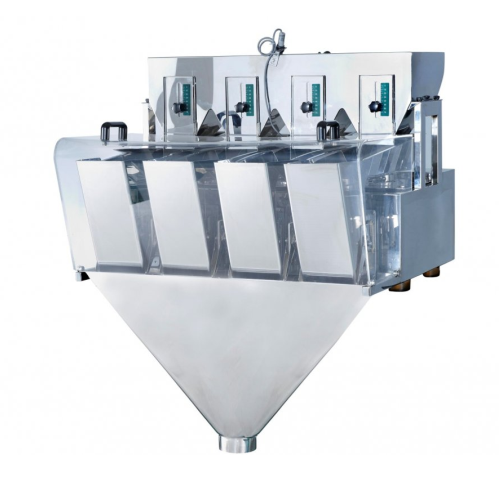

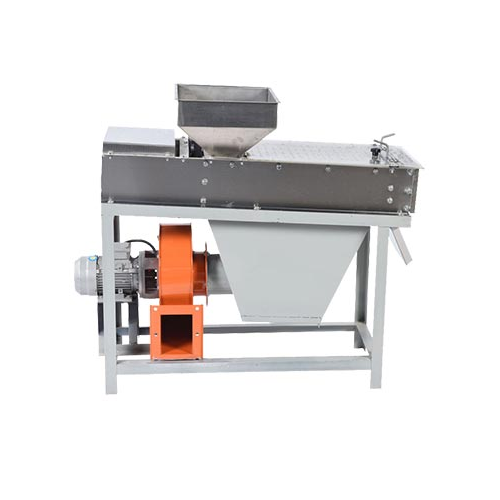

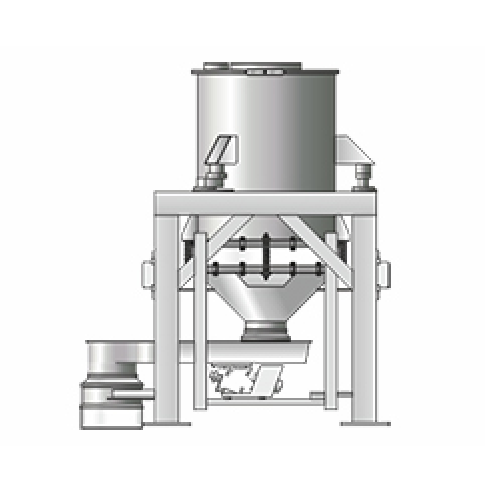

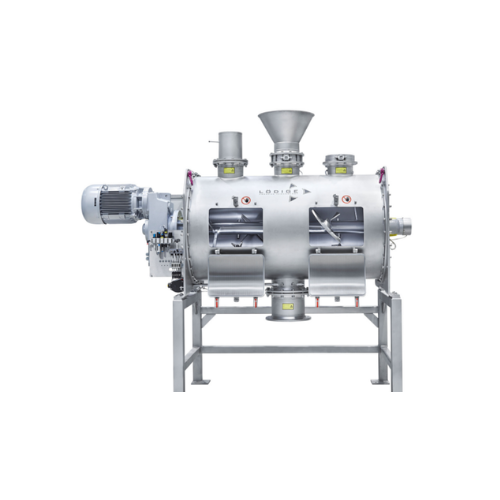

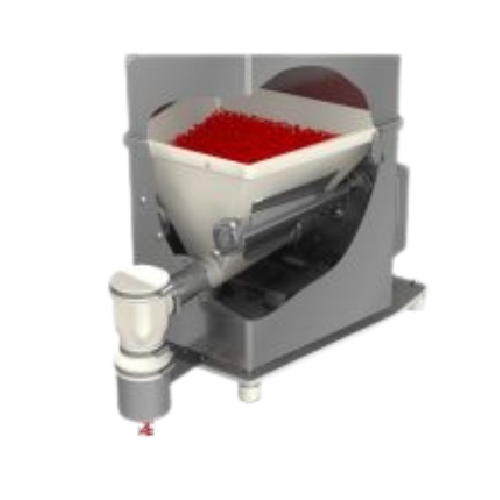

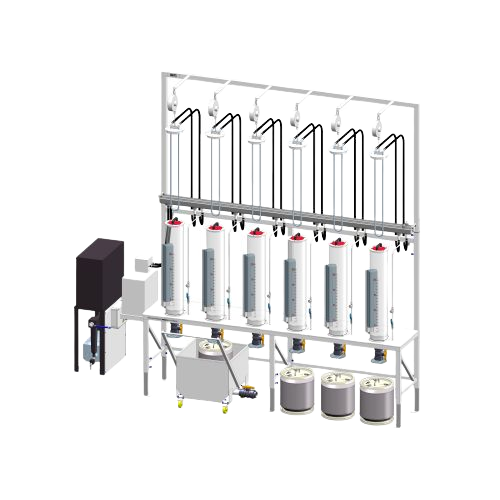

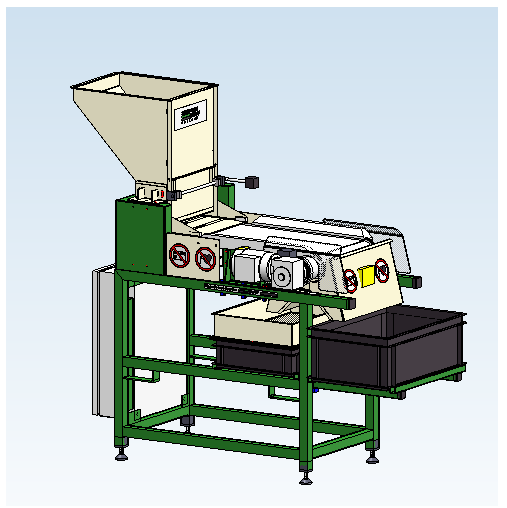

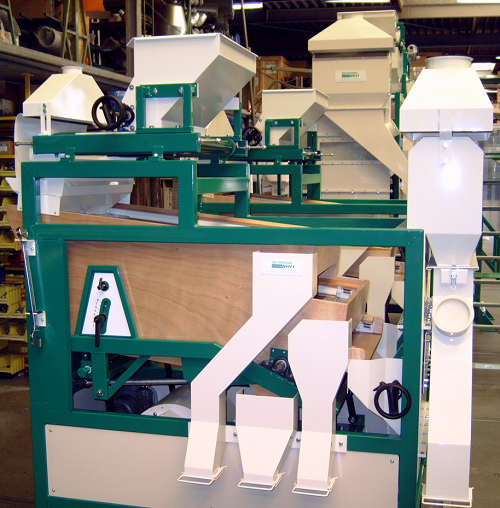

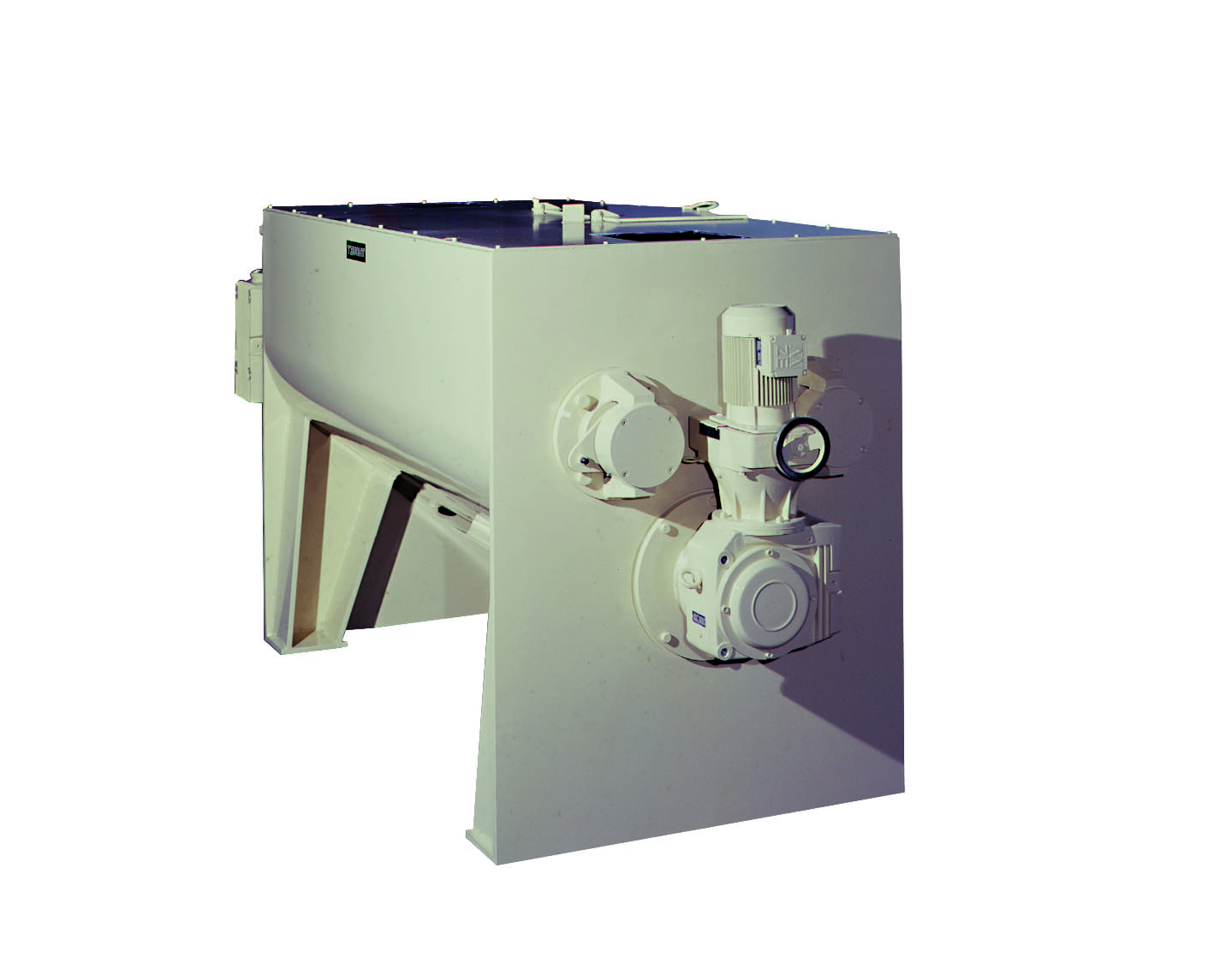

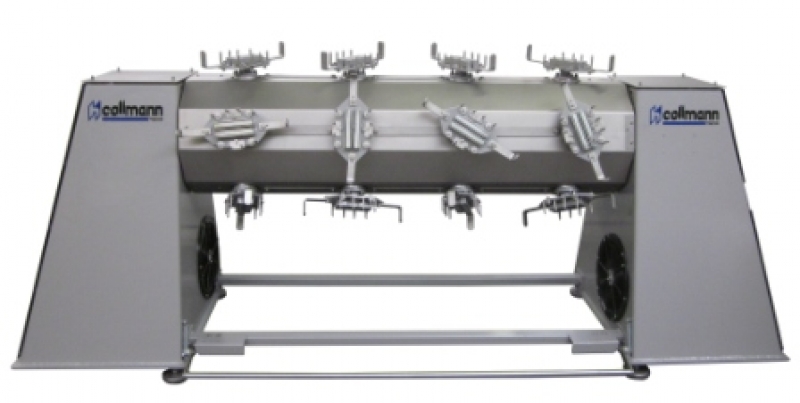

Basic mixer for granular foods

Straightforward blending solution for mixtures of beans, nuts, berries & powdered foods, ...

Stories about food

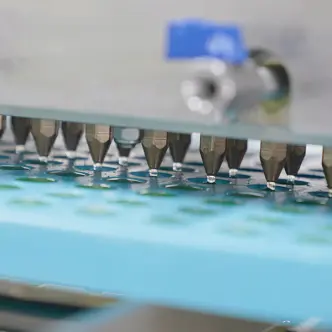

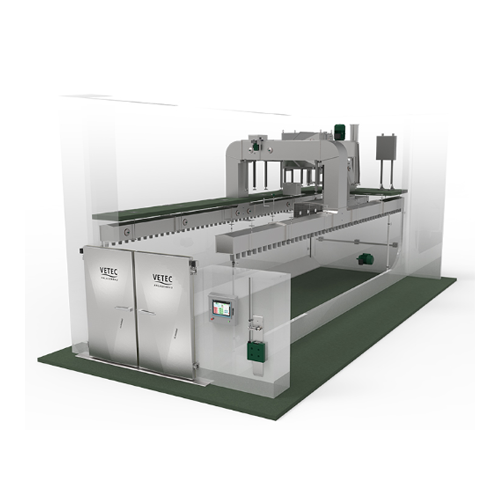

Starting up your OTC non-starch gummy production

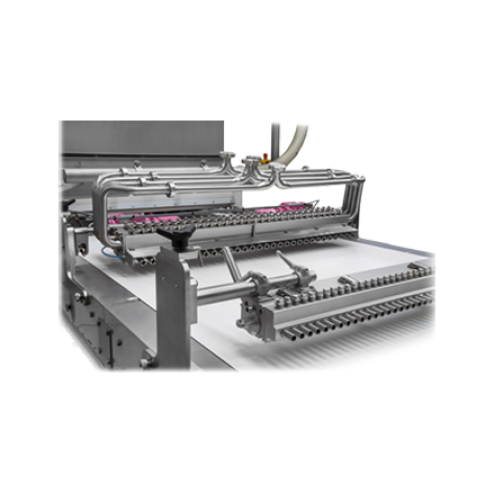

Starchless gummy depositing for limited risk on cross-contamination

Reinventing Tradition in Butter Production

#Changemaker: detect & reject truly low-density foreign bodies in your pumpable foods

#Changemaker: developing your recipe to success in the vegan market

How to turn a bag of sugar into a bag of scrumptious gummies

Find the perfect balance between sweets and wellness with vitamin candies

Streaming towards zero: minimizing freshwater in the dairy industry

Webinar: master mayo-making

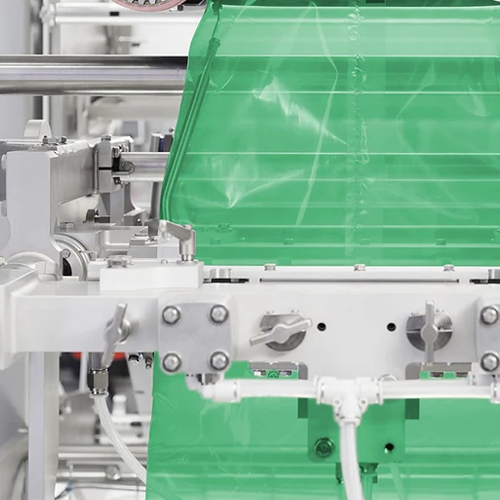

From big bags to compact bags: use MAP in both

Preserving gummy texture in low or no sugar confectionery

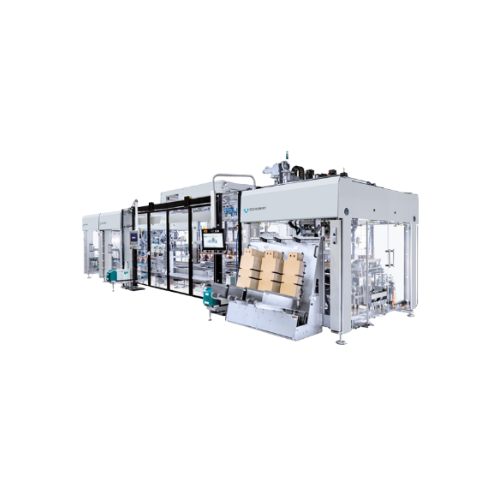

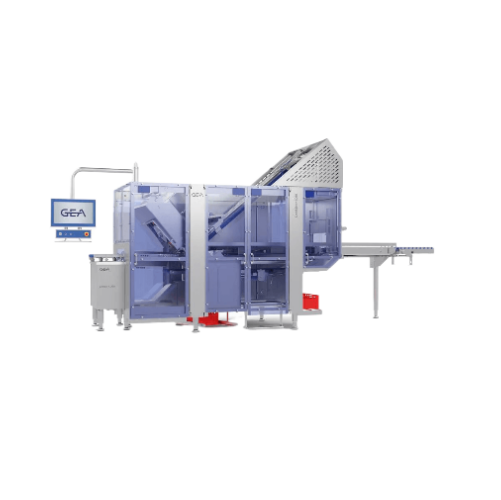

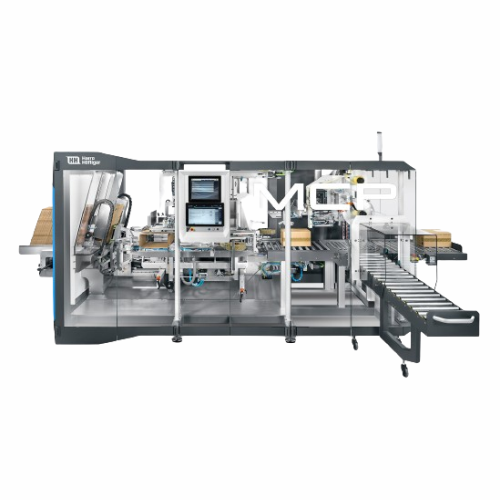

Keeping up with the trends: cartoning sustainable materials and utilizing AI all at once

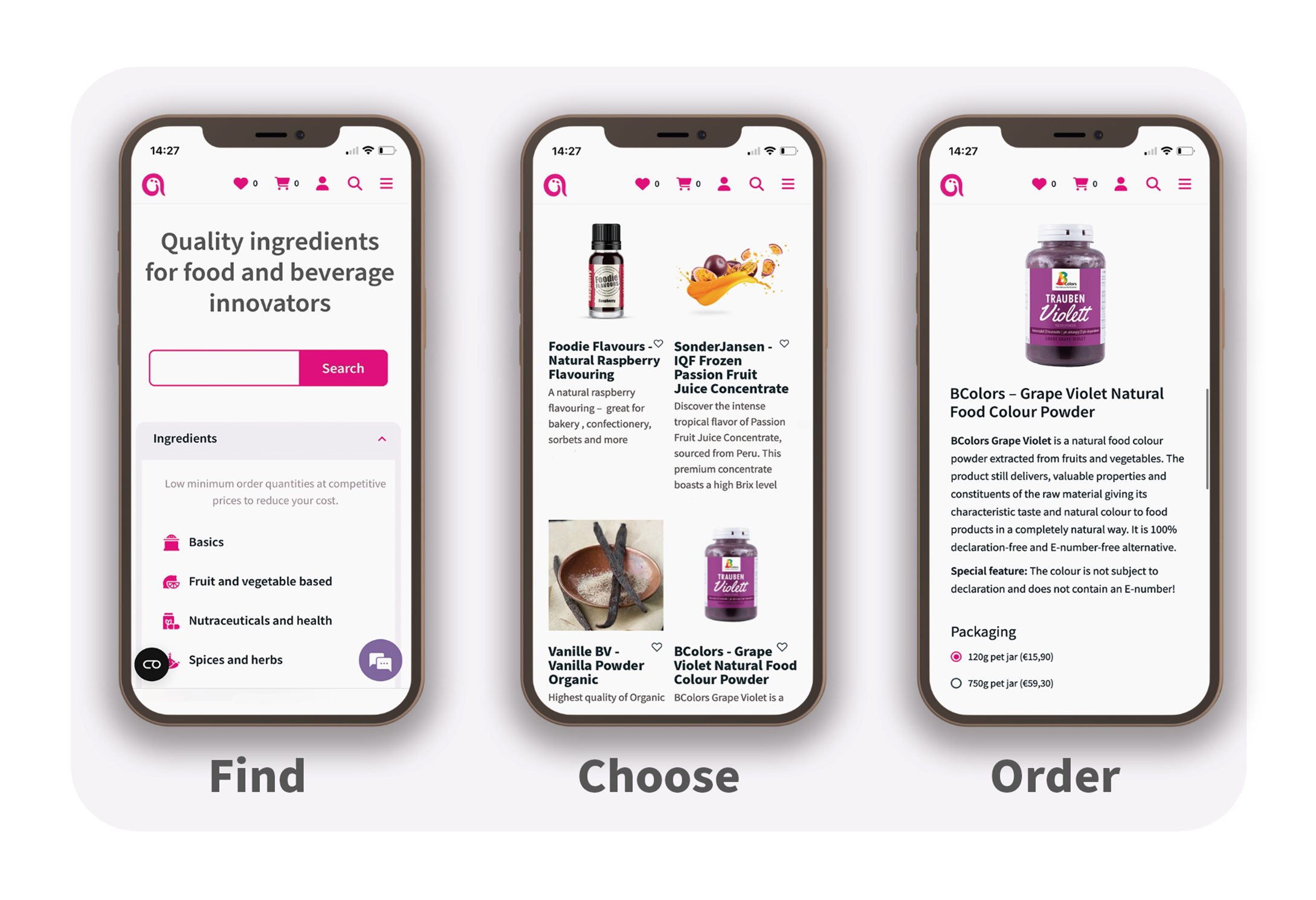

Order all your food Ingredients easily online at 1-2-Taste

#Changemaker: cellulose and hemp kicking the plastics out of packages

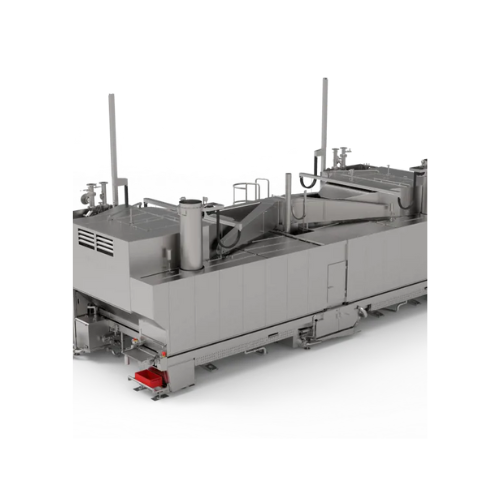

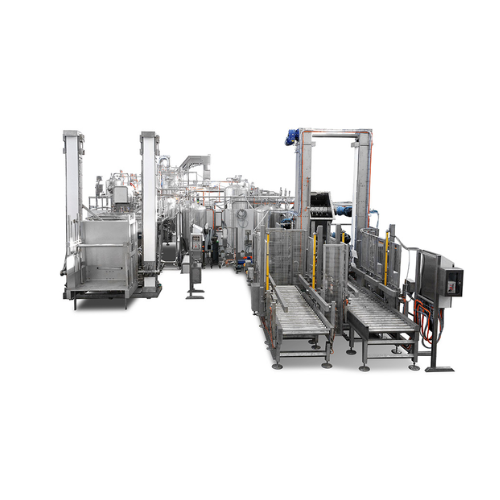

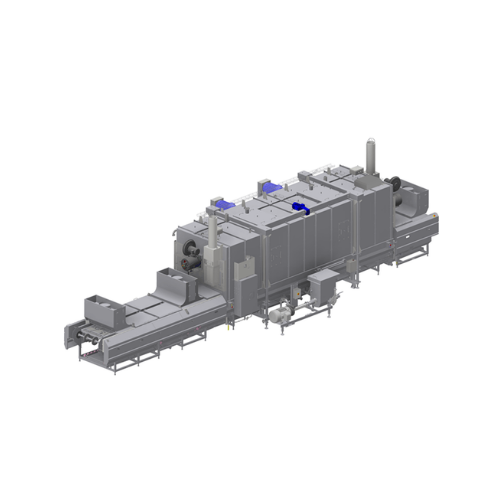

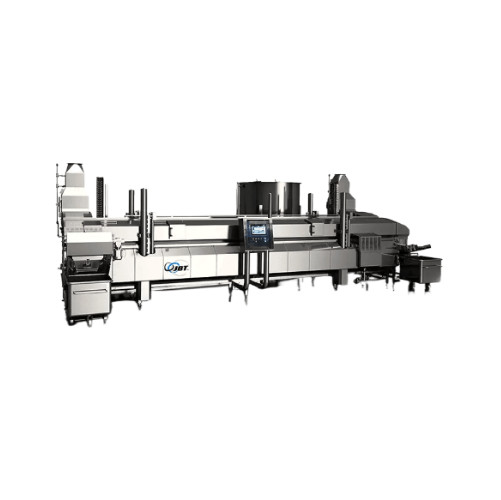

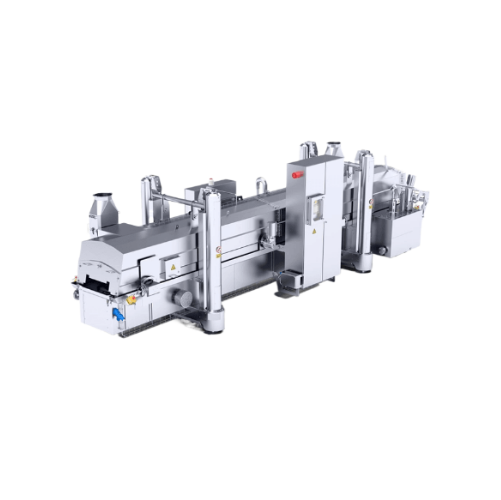

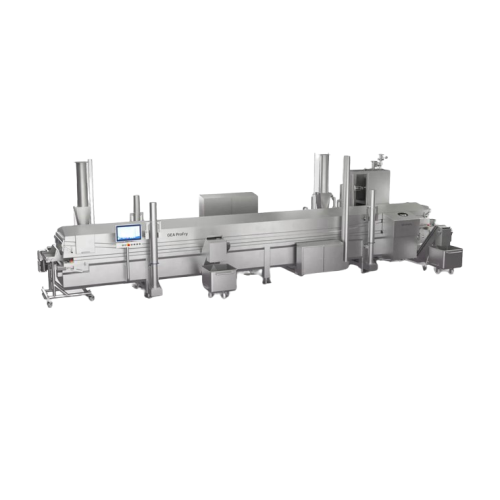

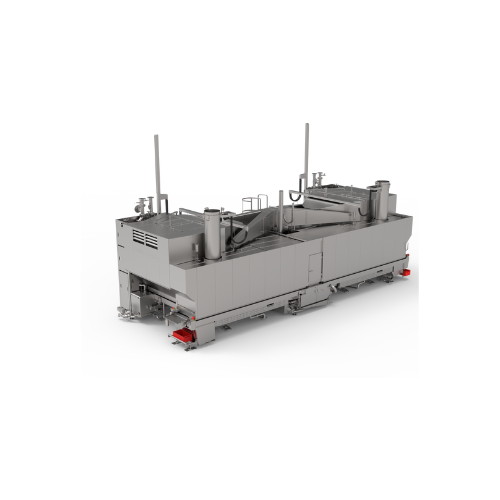

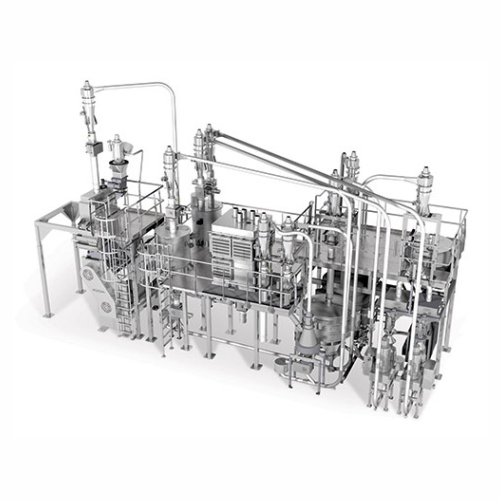

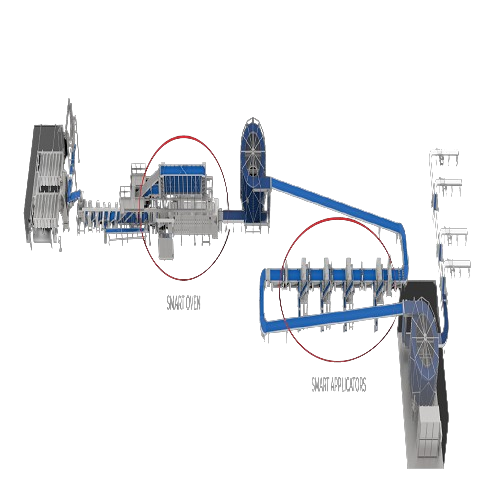

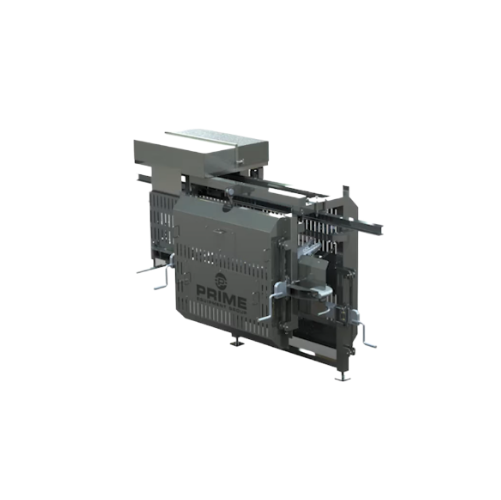

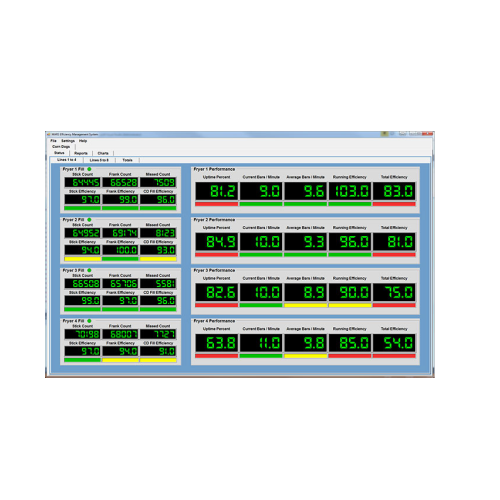

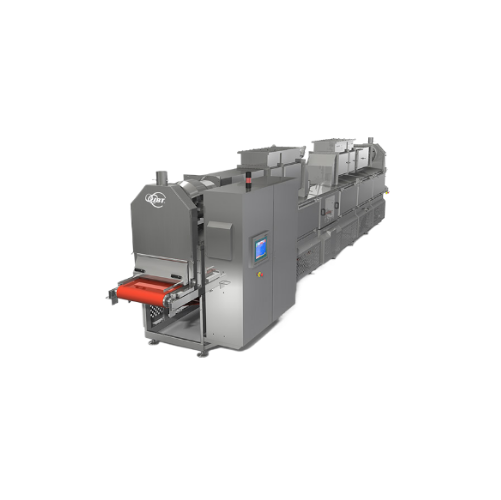

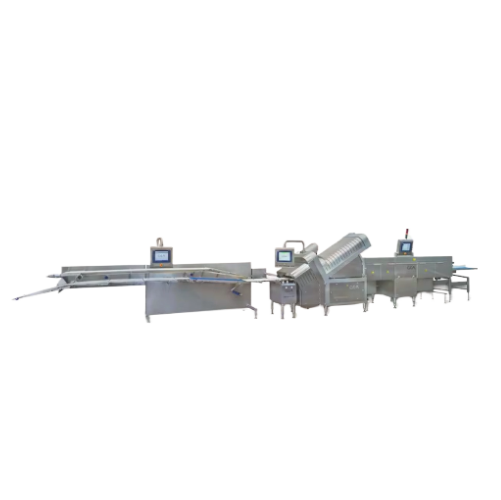

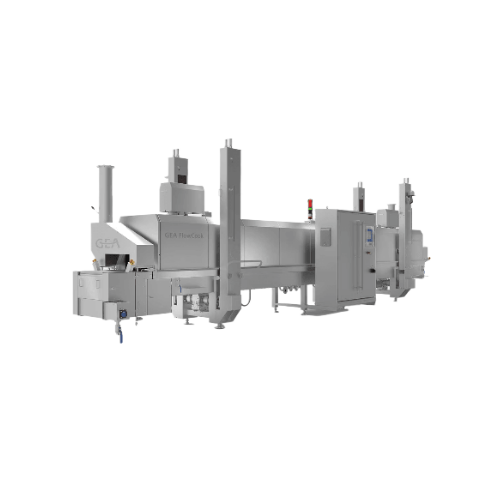

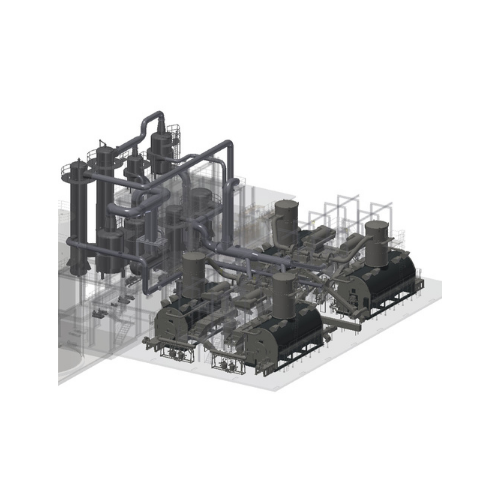

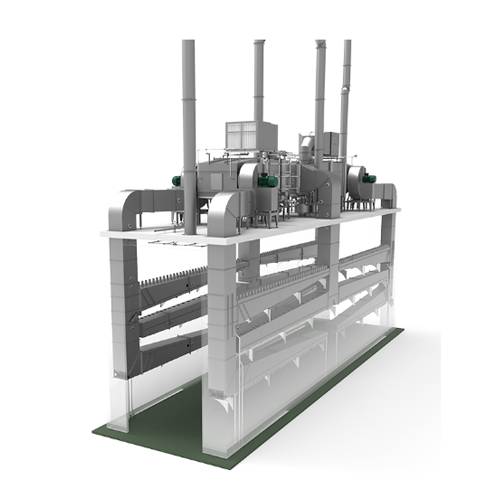

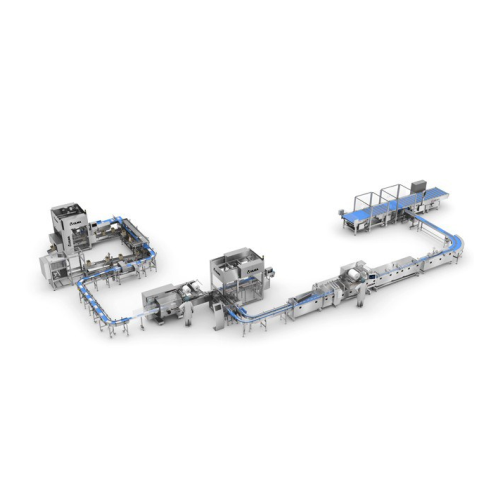

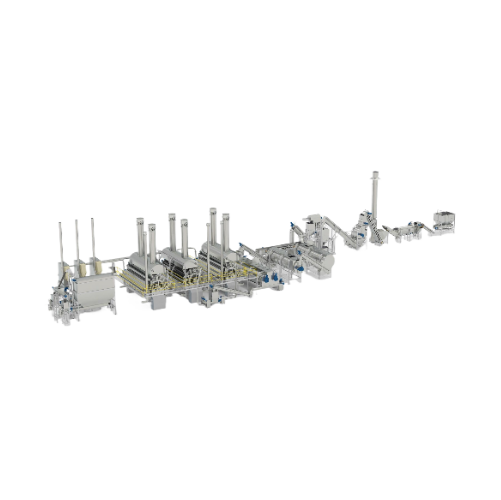

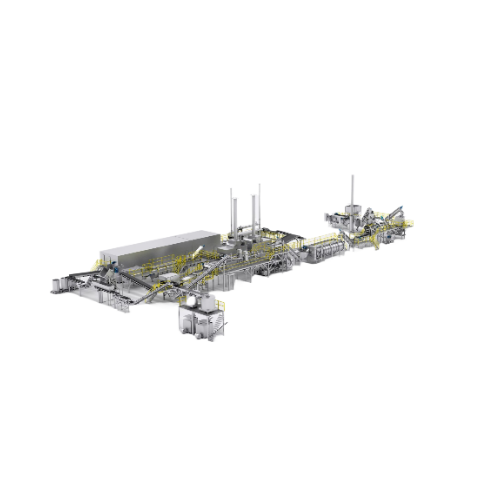

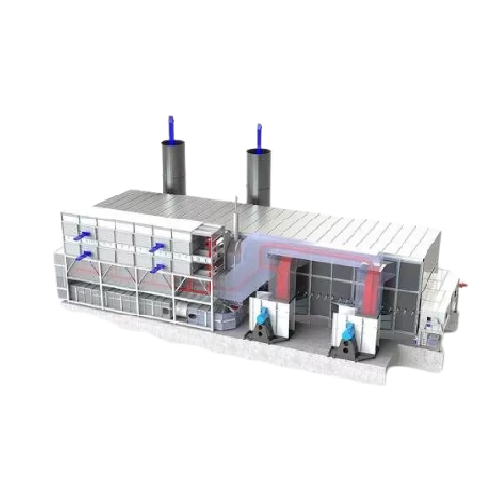

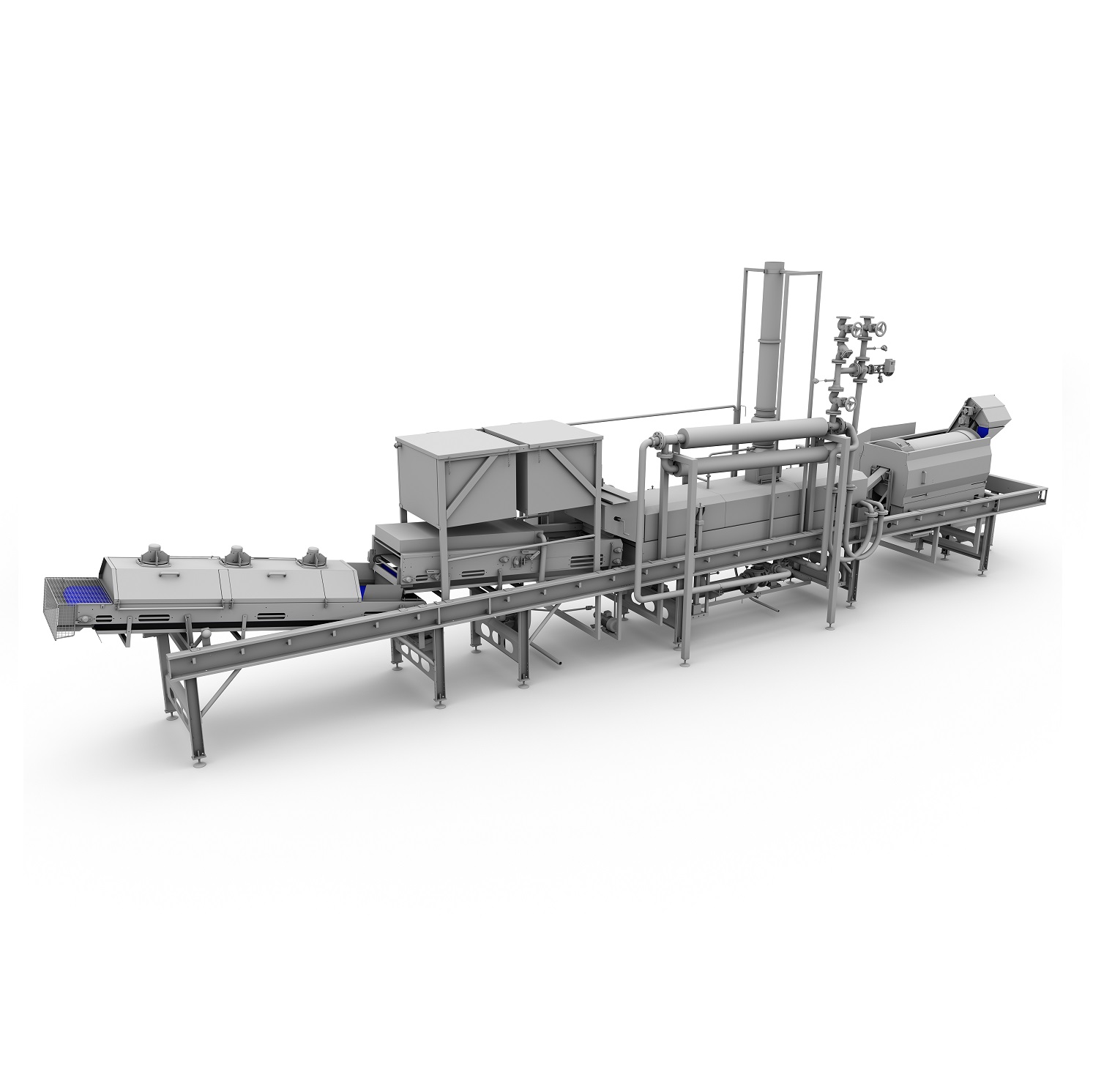

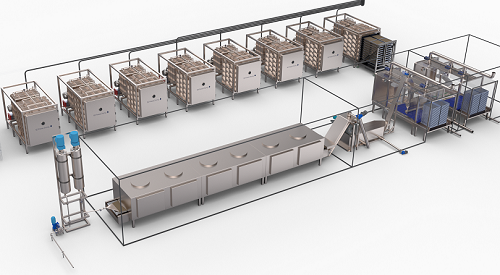

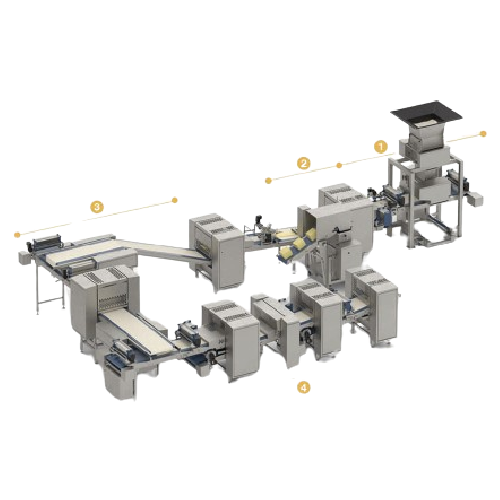

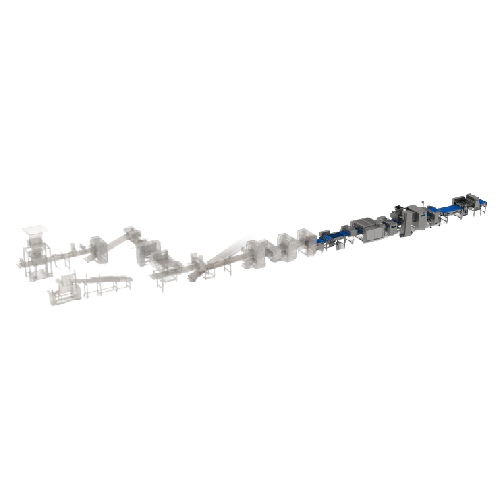

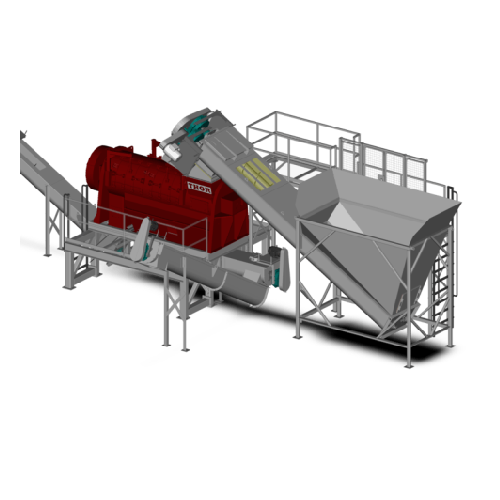

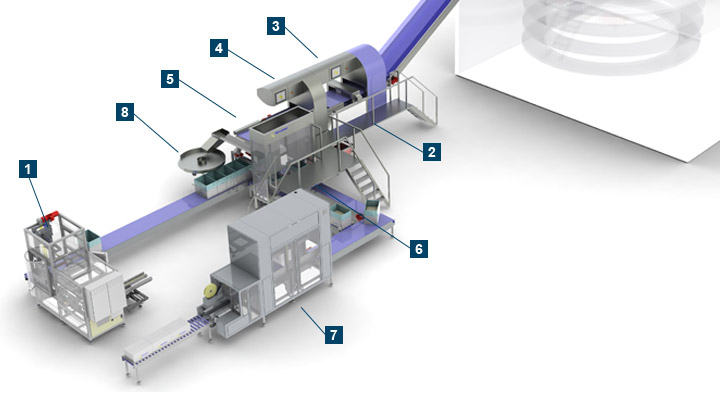

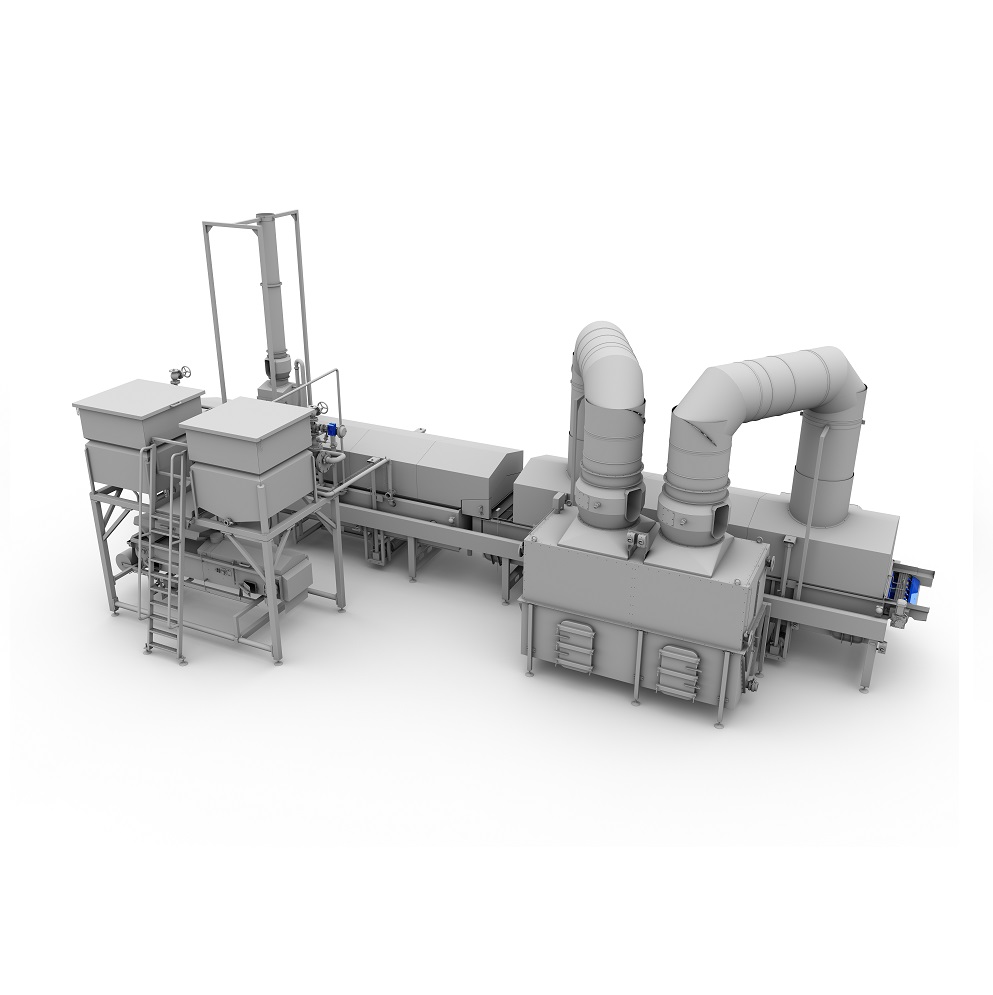

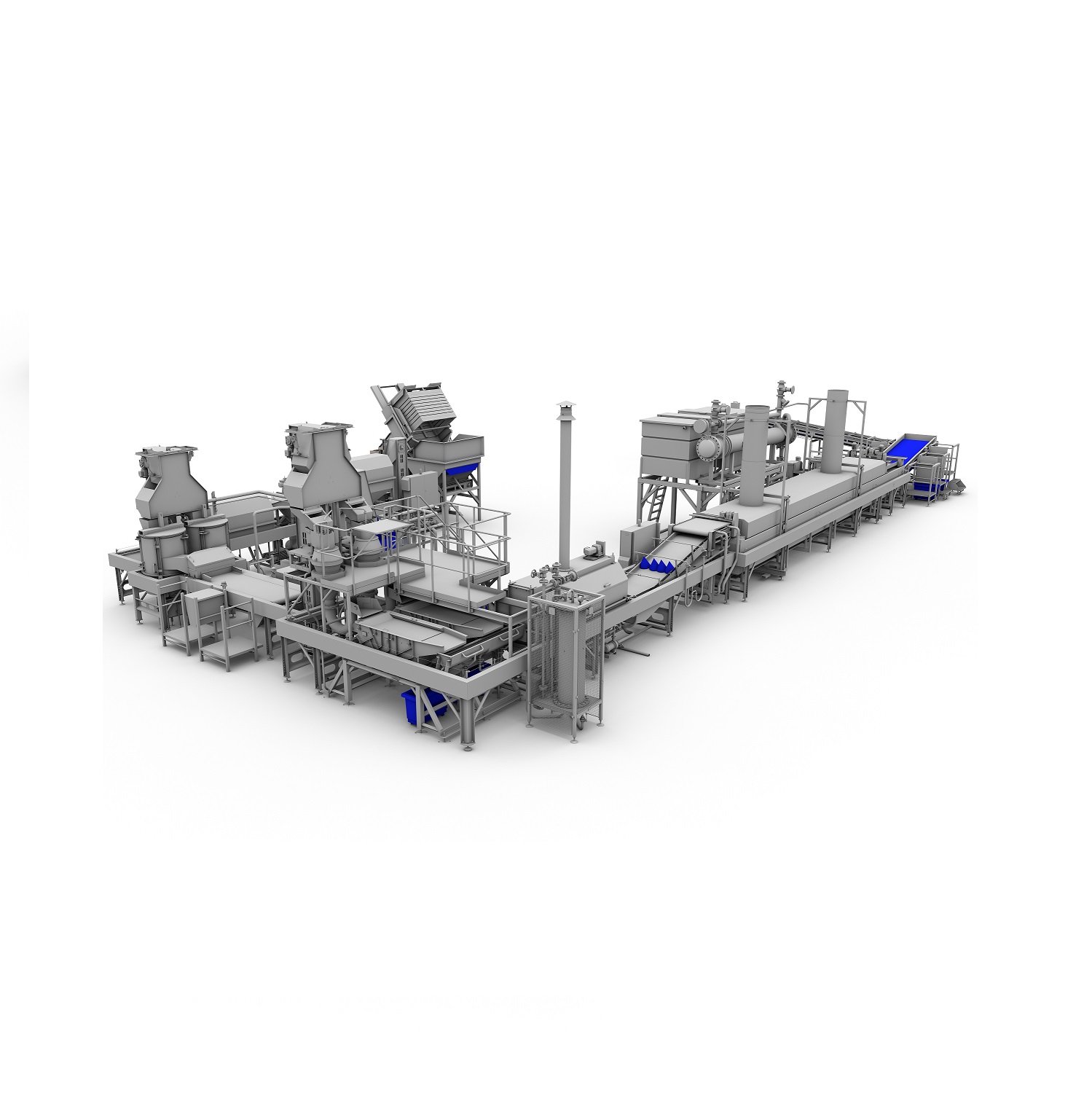

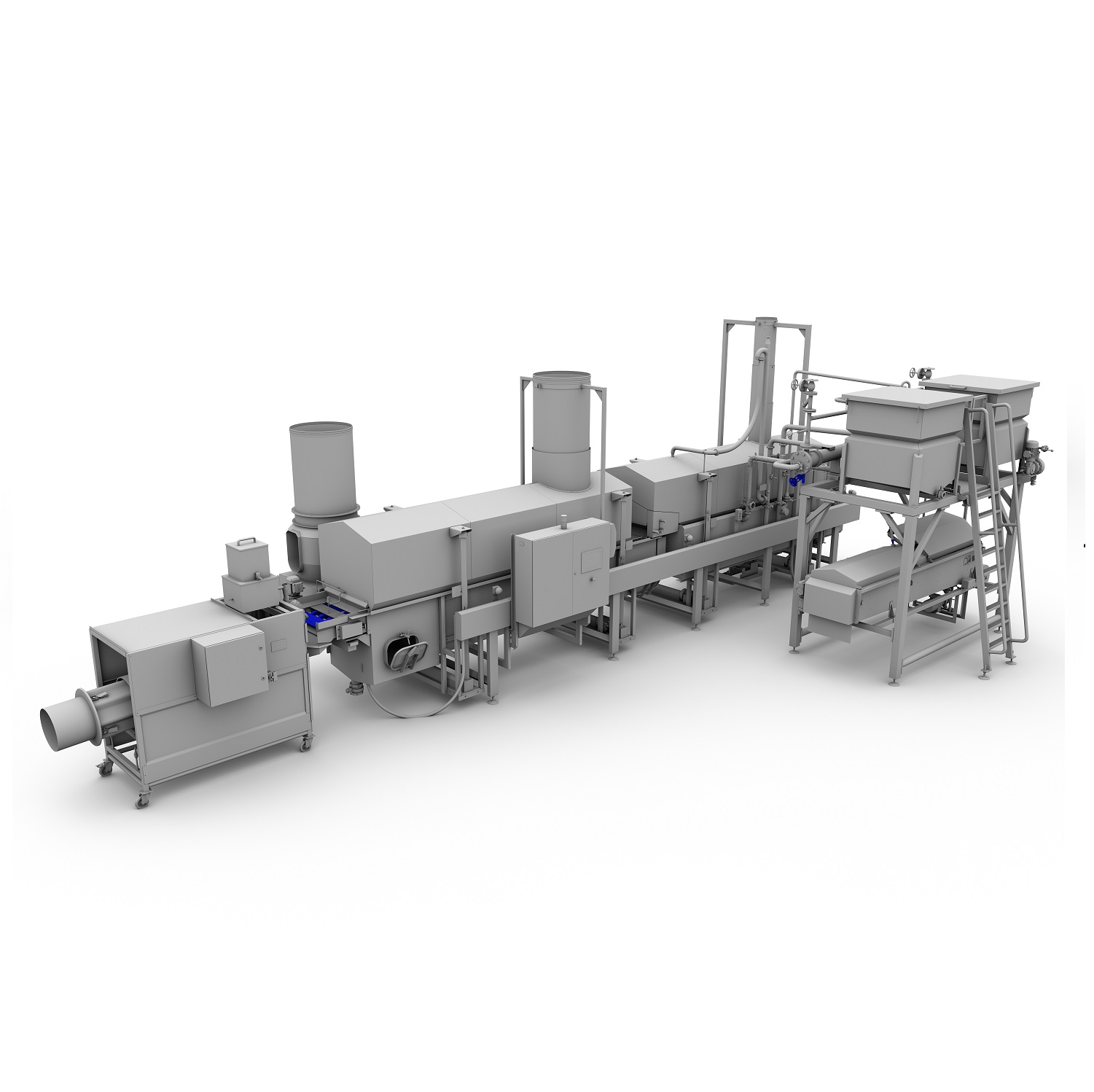

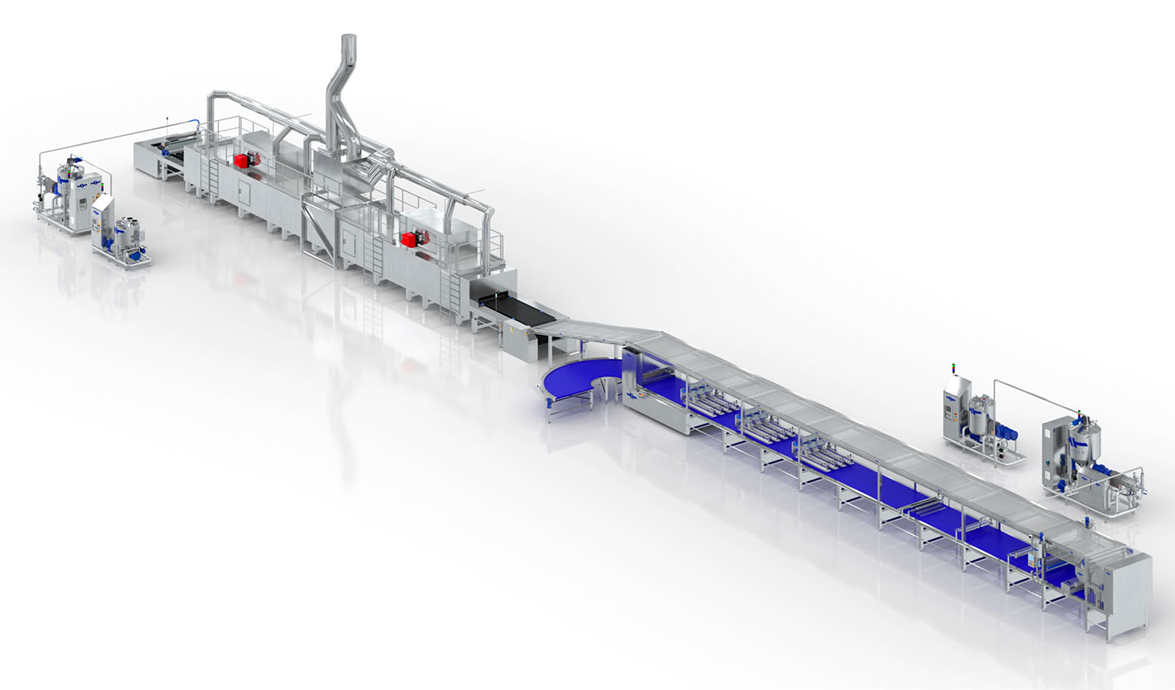

Modular design for a fast fryer plant startup

From flavorless to fabulous: unlocking the full potential of reaction flavors for tasty plant-based food

Whipping your cream at lower speeds for faster results

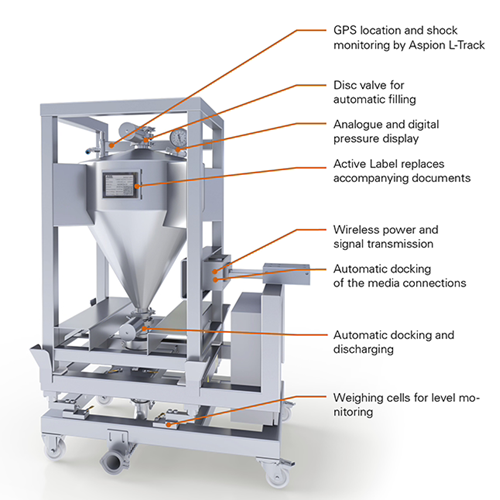

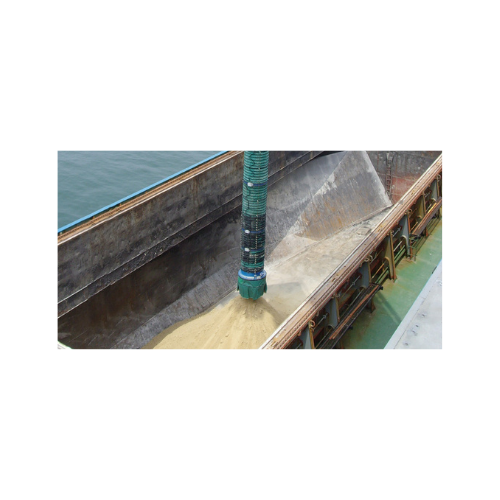

Preserve your milk powder during transportation. Big Bags: “Challenge accepted!”

Innovator or perfector – what kind of plant-based food maker are you?

Packaging solutions for meal kit and food delivery

Make a batch of mayo before you can finish a bag of fries

#Changemaker: The tastiest part of chicken is plant science

Giving aerated jelly some bite

#Changemaker: Make a positive change for the planet by choosing reusable tableware

#Changemaker: Edible coffee cups - a delicious addition to your morning routine

#Changemaker: Putting a label on sustainability

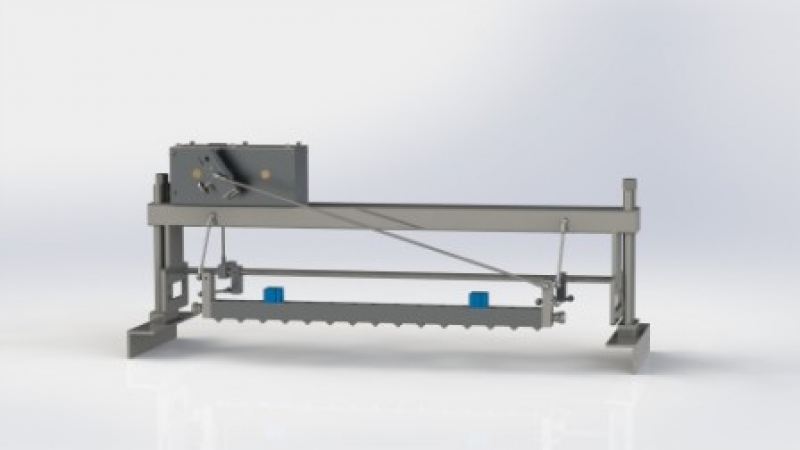

Down with gravity – how to make tea blends without breaking the leaves

#Changemaker: No-Leak No-Plastic packaging film is here

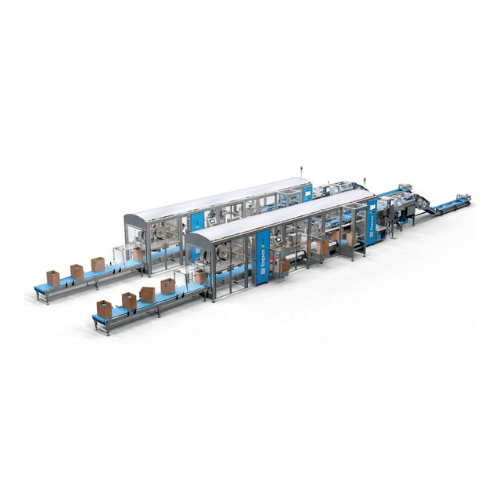

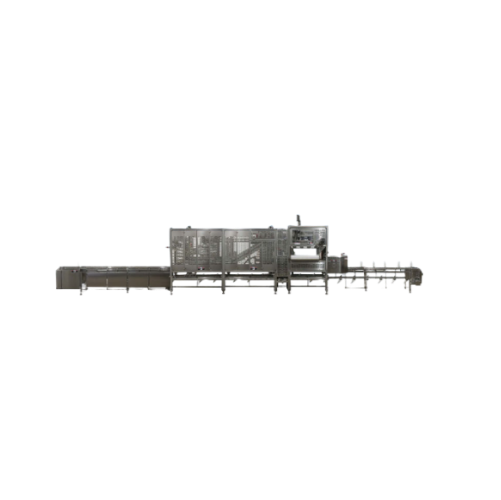

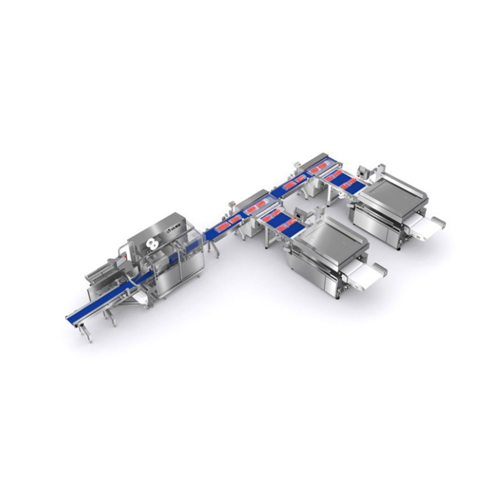

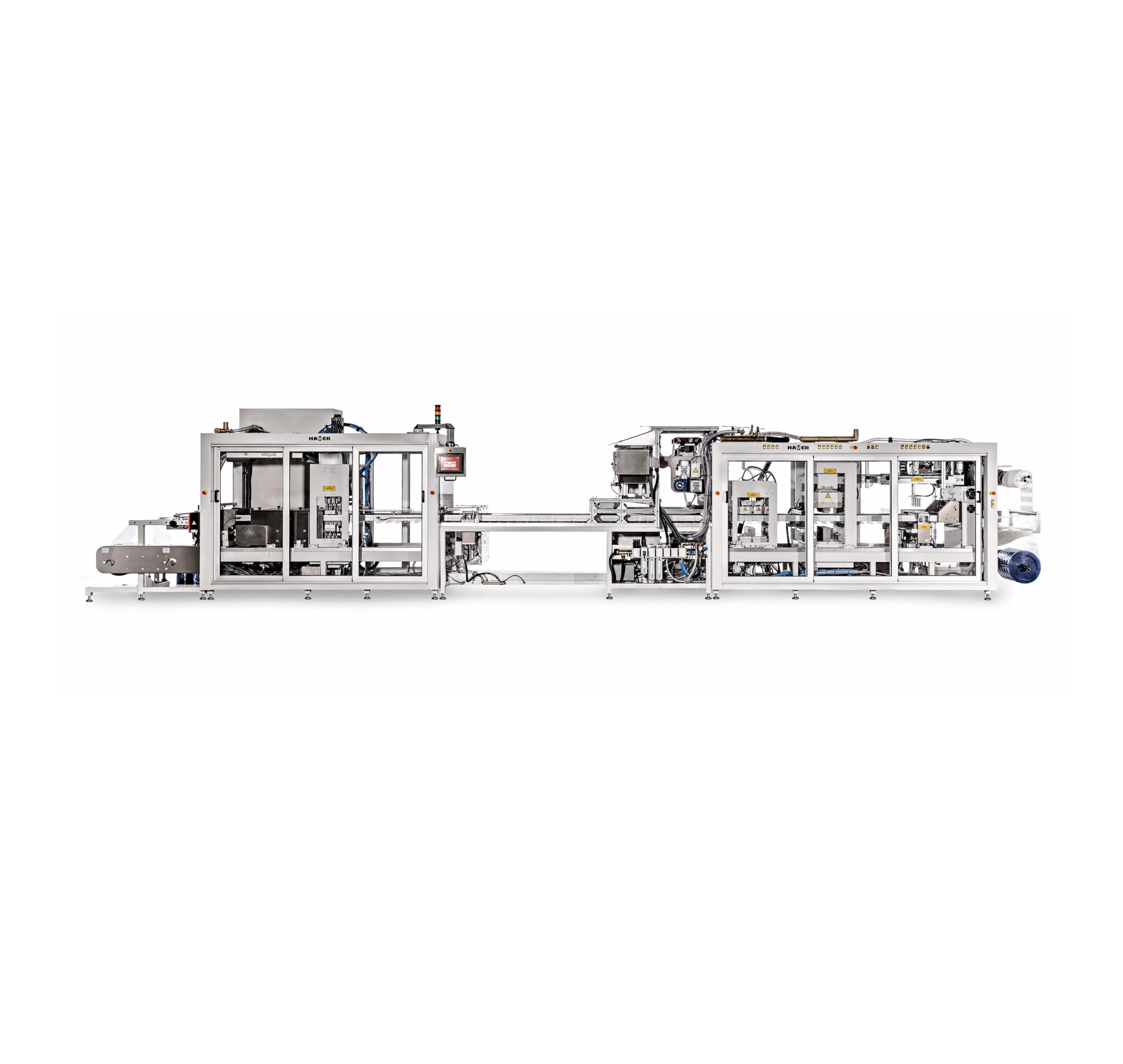

The need for speed - Let's pack 180 frozen pizzas a minute

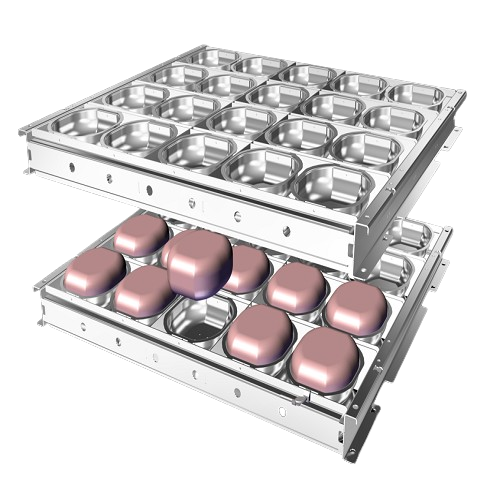

Remember when big biscuit producers still used thermoformed plastic trays?

Say no to food waste. How to protect your hazelnuts from going rancid along the supply chain

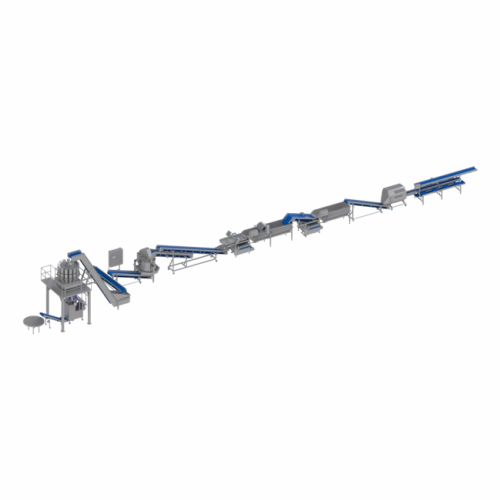

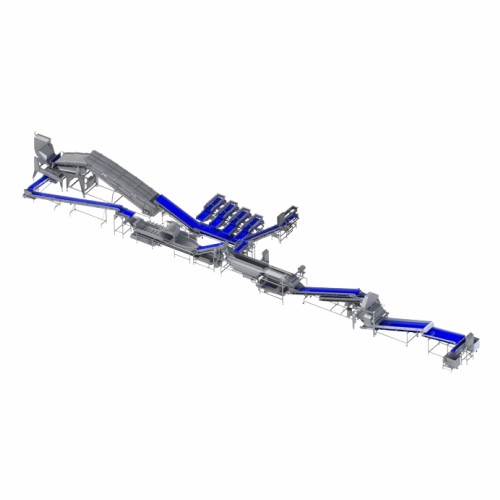

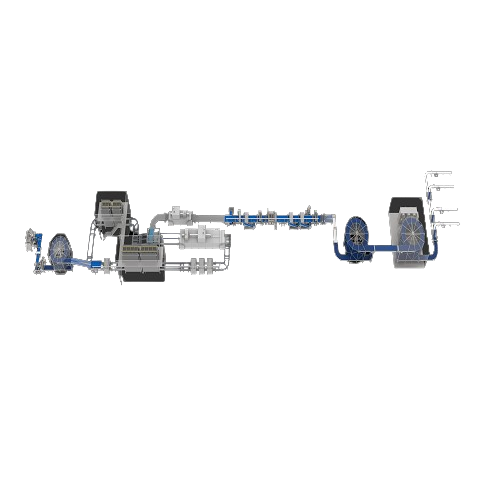

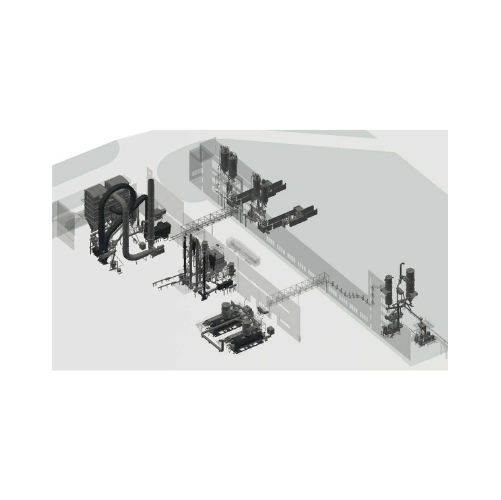

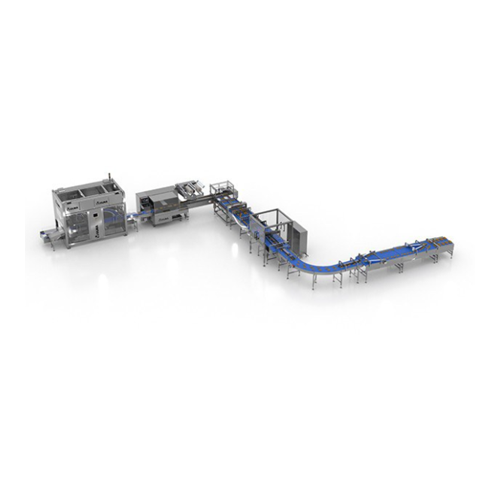

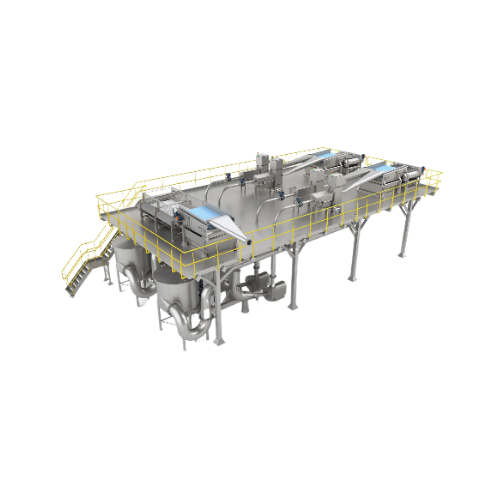

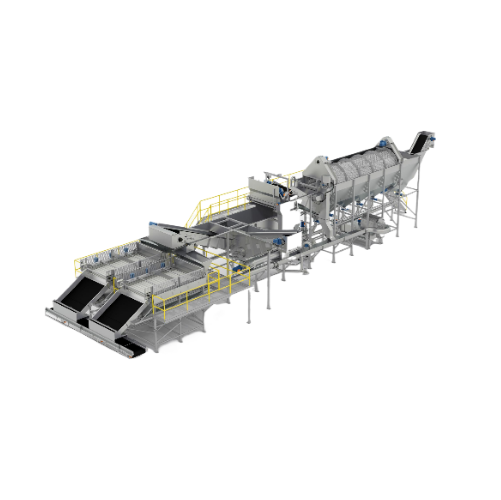

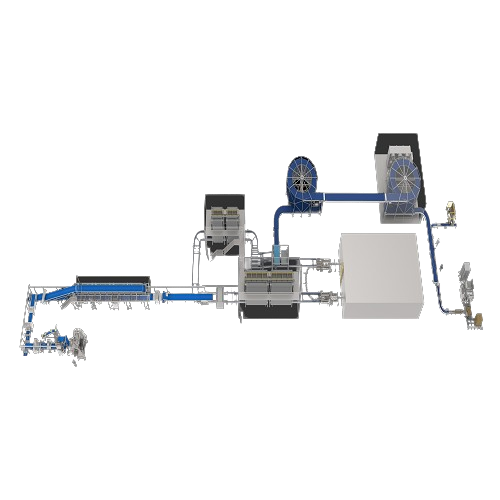

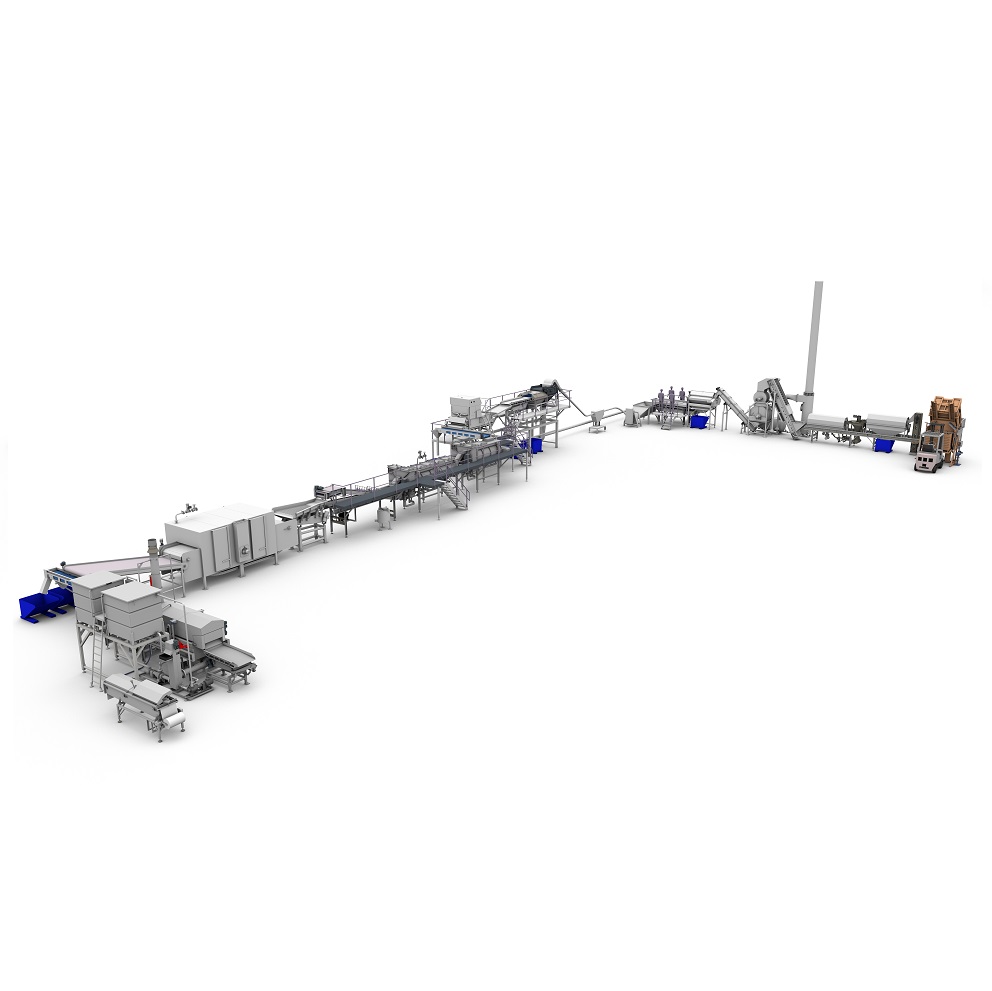

Joining the dots of a new French fries line

From the kitchen counter to industrial production: How to master texturing of vegan specialties

#Changemaker: The plant-based burger made of lentils you didn't know you needed!

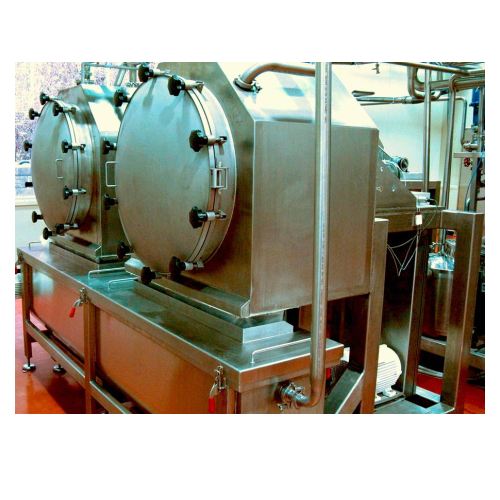

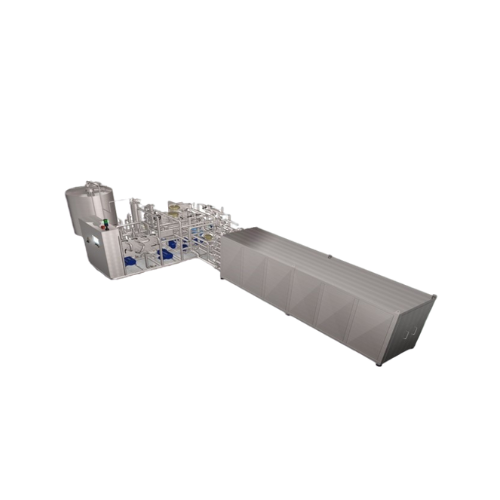

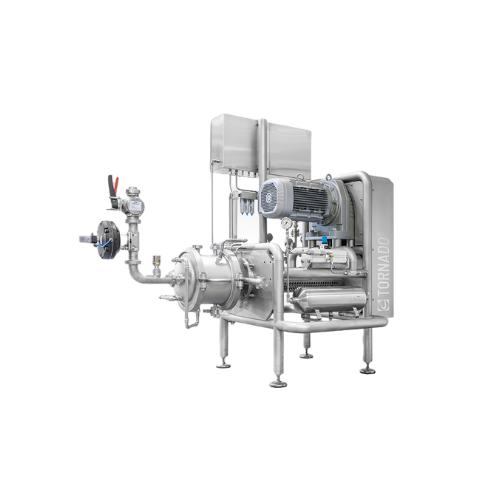

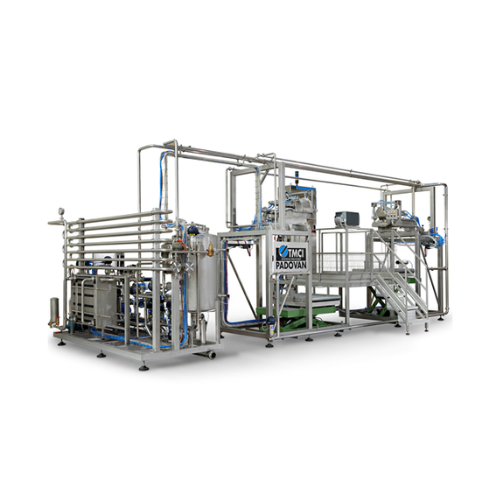

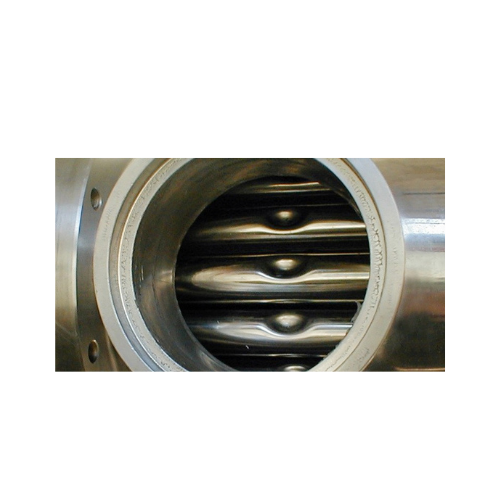

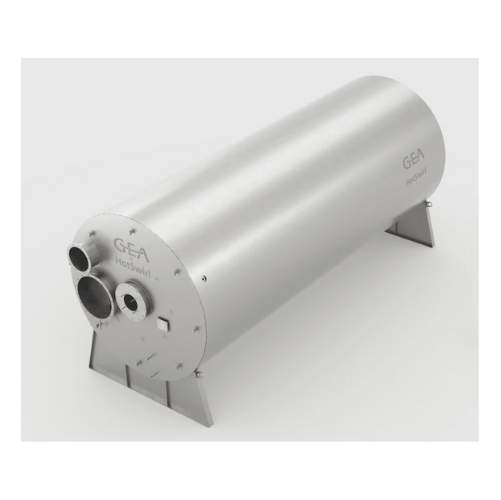

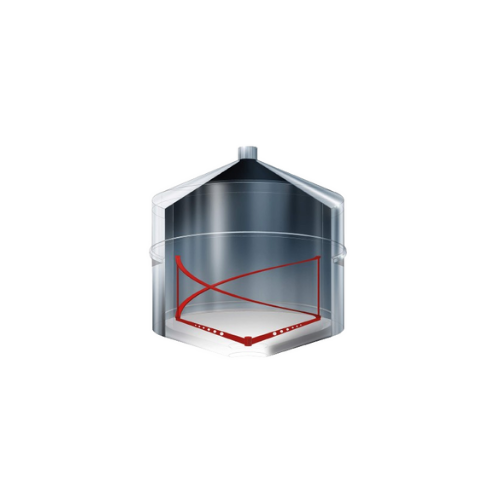

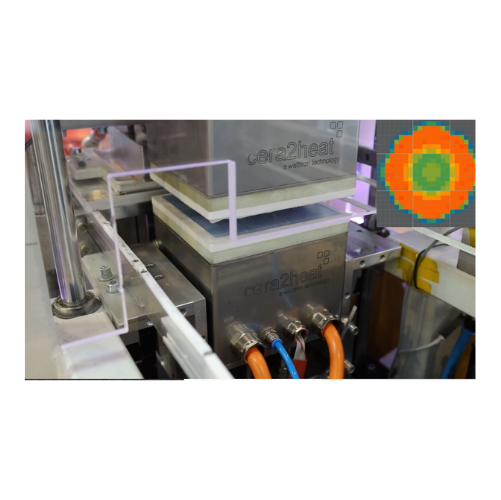

The power of zero - how to sterilize truffle cream without damaging it

Although not as highly regarded as their white or black winter varieties, summer truffles are the absolute first choice in preparing truffle cream. When making truffle cream, utmost attention must be paid to the sterilization step. Summer truffles are just as delicate as the more expensive varieties and could be ruined and lose 100% of their flavor if the temperature is too high.

Extraction of tomato seeds – take care of your red gold

Pork rind frying; from pigskin waste to tasty pellet snack

From granulated to invert sugar: the liquid therapy to prevent crystals in your jam processing line

How to reduce your water footprint when making potato chips

Gluten morgen… Temperature control in your sponge cake production

#Changemaker: Fava bean umami extract for your vegan diet!

Clean up your label, drying fruit extracts without using carriers

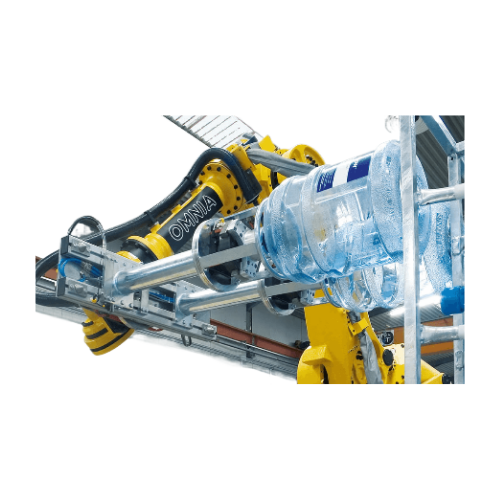

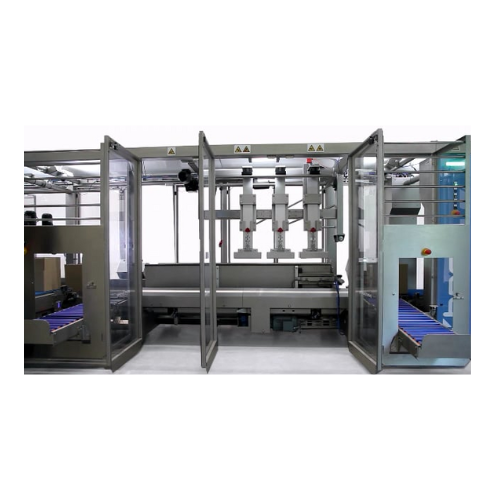

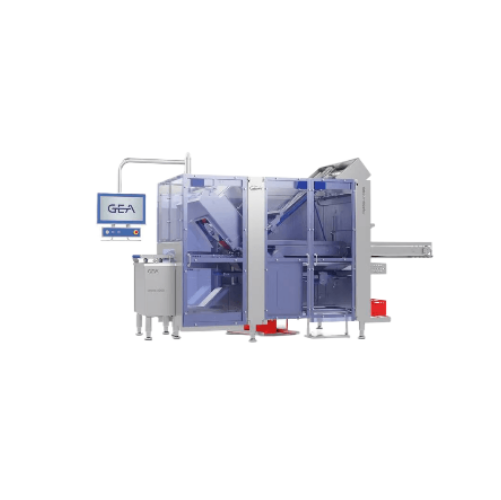

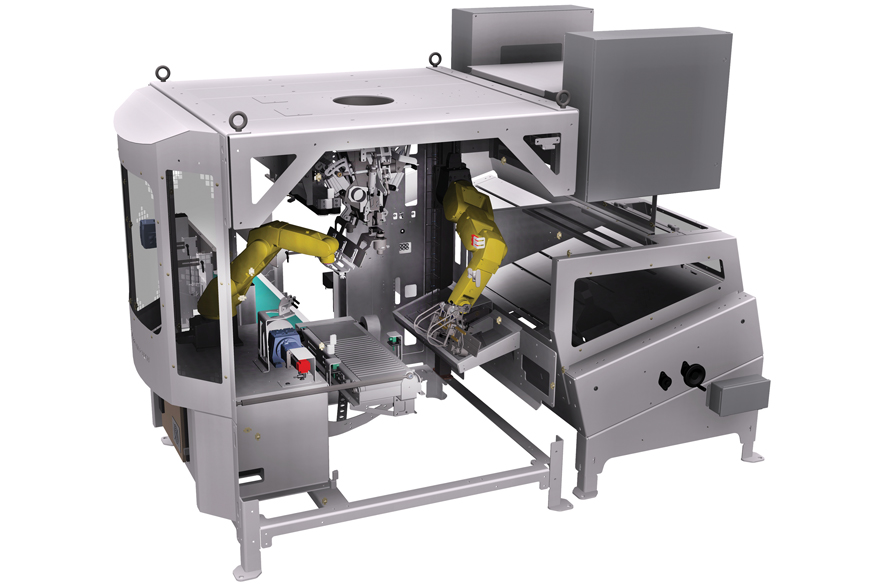

Advantage craft breweries: robots take the frothiness out of cartoning

Ketchup shows its true colors with vacuum cooking

#Changemaker: A divine alternative to synthetic preservatives

How to prevent untimely spoilage of canned vegetables by sterilization

#Changemaker: Vegan bacon is a co-man love match

How to detect the smallest leaks in your sandwich packaging

Liquorice: from root to candy

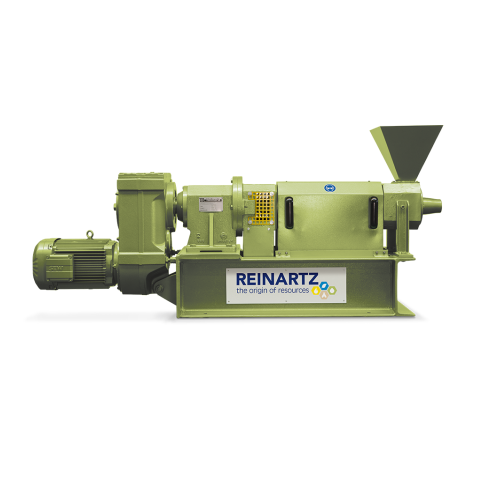

How to produce textured vegetable protein TVP?

#Changemaker: Trust nature. Paula ingredients, the company that produces dried fruits only from seasonal products

#Changemaker: white chlorella as your next protein source!

#Changemaker: Try this spoonful of fermented buckwheat snack!

#Changemaker: Marshmallow made out of seaweed?!

#Changemaker: Let's save "ugly" sweet potatoes with Batasta!

Infrared heating and drying organic herbs and spices

Second skin for your food products

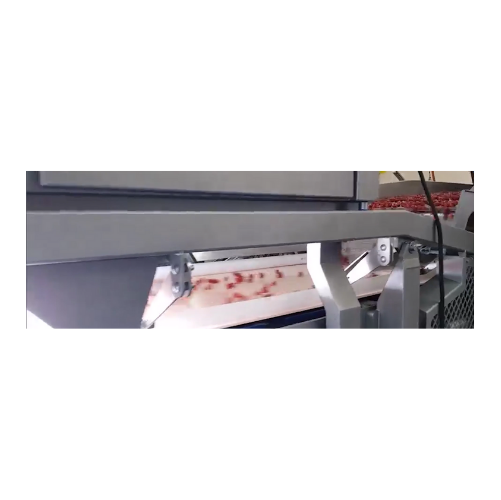

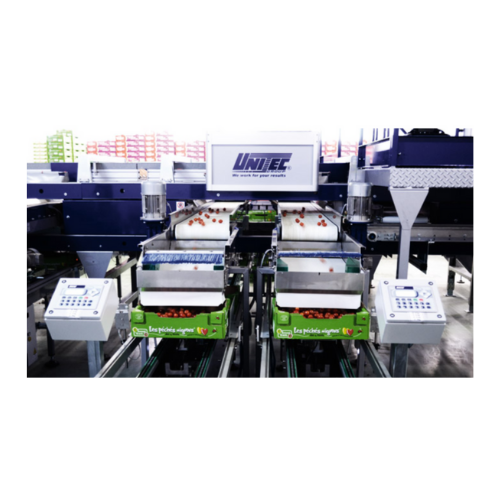

Inspect all types of tomatoes with speed up to 100 tons per hour.

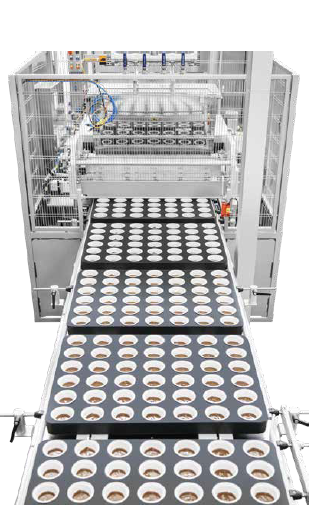

Chocolate surface filling for cup cakes

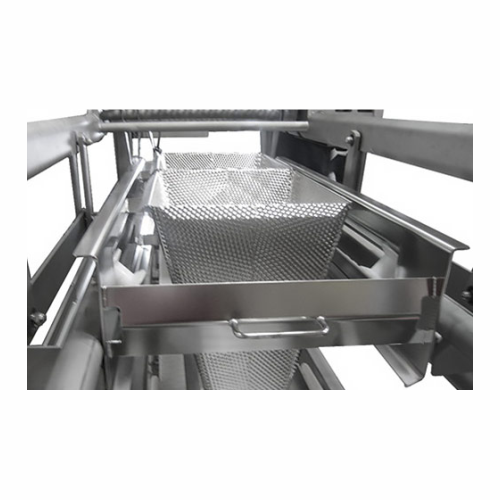

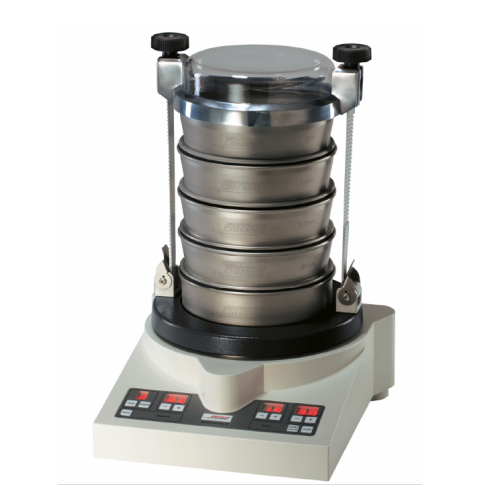

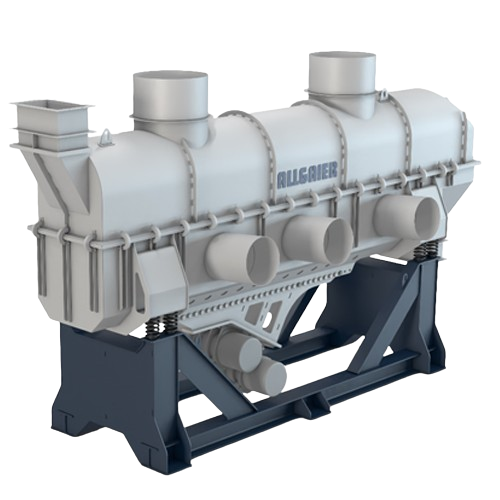

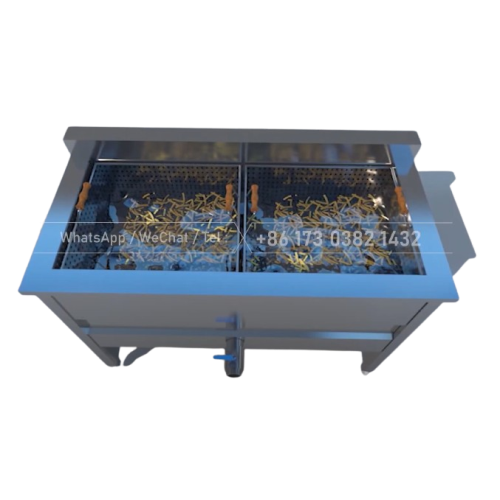

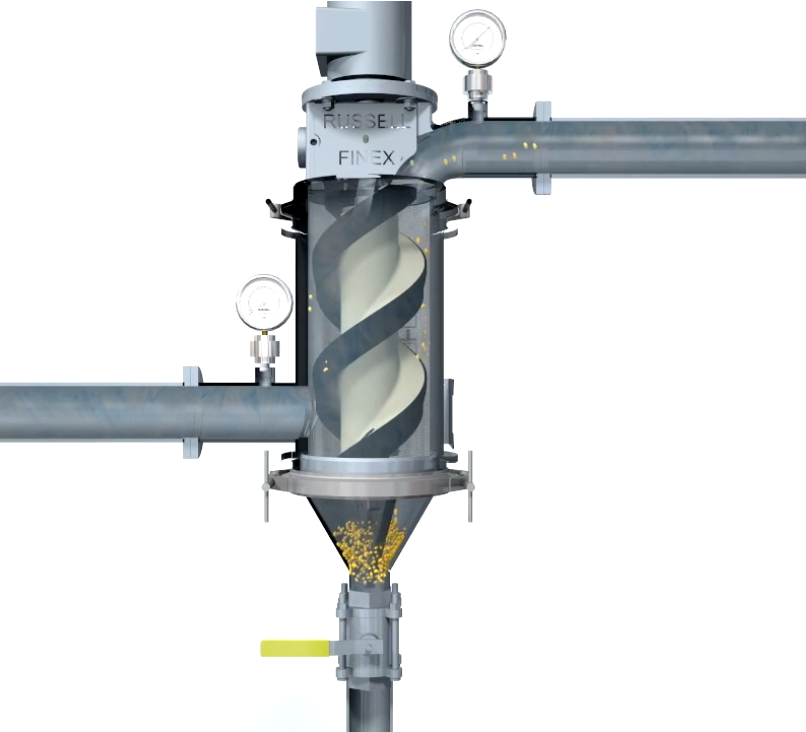

Sieving black soldier fly for insect-based feed

What are you making?

Yeast extract

Wheat starch

Wheat germ

Sushi rice

Pre-packaged salads

Pre-packaged meals

Pre-cooked meals

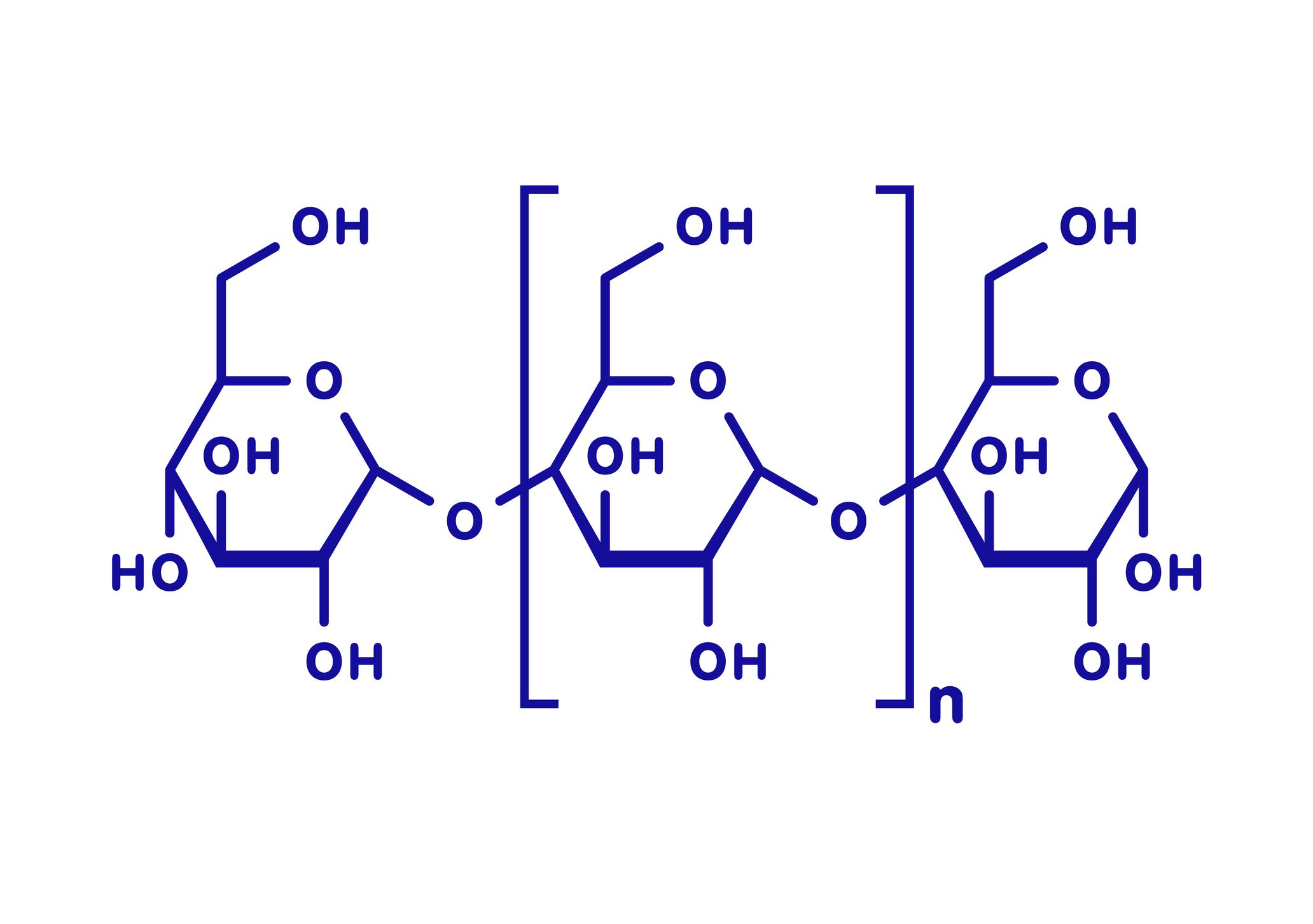

Polysaccharides

Pastes

Olive paste

Gluten-free flour

Ginger paste

Functional foods

Functional flours

Frozen mixed vegetables

Frozen food

Frozen dinners

Food-to-go

Food supplements

Food preservatives

Food ingredients

Food flavorings

Flakes

Dried foods

Fillings

Fast food

Desserts

Animal fats

Couscous

Alternative proteins

Almond milk powder

Almond flour

Convenience foods

Club sandwiches

Agricultural by-products

Longmoulded rolls

Multi-fruit solutions

Bran

Bagels

Pie

Flatbread

Cider

Vitamins

Bananas

Cassava

Lemons

Herbs

Bacteria

Fungi

Honey

Wheat

Vinegar

Tortillas

Semolina

Rice

Vegetable Puree

Potatoes

Nectar

Hash Browns

Eggs

Dumplings

Apples

Freeze dried berries

Tofu

Nutritional yeast

Plant-based yogurt

Pectin

Spirulina powder

Chlorella powder

Vodka

Chia seeds

Guacamole

Pesto

Tahini

Vegetable powder

Whipped cream

Potato wedges

Jelly

Frozen cakes

Ready meals

Craft beer

Instant noodles

Soy milk

Oat milk

Almond milk

Cashew milk

Corn seeds

French fries

Molasses

Brewers grain

Reaction flavors

Canola meal

Canned tuna

Halloumi

Cultivated meat

Agar-agar

Plant-based cheese

Kombucha

Sugar beet seeds

Probiotics

Plant-based meat

Truffle cream

Pellet snacks

Battered nuts

Cashews

Textured Vegetable Protein

Cocoa nibs

Salt

Yeast

Starch

Whey protein

Fondant

Chocolate fillings

Glycerine

Sugar

Cricket protein

Extruded cereal

Chocolate coatings

Ice cream

Protein powder

Vitamin C

Mixed nuts

Vegetable chips

Dried fruit

Protein bars

Dried oregano

Ground cinnamon

Curry powder

Black pepper

Chili powder

Vitamin gummies

Dragees

Dried meat

Shrimp crackers

Nougat

Corn nuts

Rice cakes

Caramel

Granola bars

Gummy Bears

Potato chips

Baby Food

Licorice

Frozen fruit

Marshmallows

Chewing gum

Lollipops

Fruit juice

Brittles

Fruit powder

Tomato seeds

Cannabis seeds

Hemp seeds

Fruit puree

Fruit concentrate

Sunflower seeds

Corn flakes

Granola

Cocoa beans

Flax seeds

Marmalade

Hummus

Muesli

Peanut butter

Jam

Oatmeal

Cereal bars

Rice Crispies

Chili sauce

Tomato sauce

Salad dressing

Mustard

Ketchup

Mayonnaise

Tea

Electrolyte drinks

Soft drinks

Mineral water

Wine

Beer

Pistachios

Hazelnuts

Peanuts

Nut oil

Nut butter

Roasted nuts

Sugar coated nuts

Soup liquids

Stock cubes

Broth

Instant soup

Grated cheese

Condensed milk

Cheese spread

Butter

Yogurt

Milk powder

Decaffeinated coffee

Coffee capsules

Instant coffee

Filter coffee

Ground coffee

Batter

Flour

Dough

Croutons

Croissants

Cookies

Biscuits

Frozen pizza

Bread

Chocolate milk

Cocoa liquor

Chocolate bonbons

Truffle balls

Hollow chocolate figures

Cocoa butter

Cocoa powder

Chocolate spread

Chocolate bars

Baking powder

Almonds

Compound chocolate

Tell us about your production challenge

Processing equipment prepares raw foods for consumption

Primary processing turns raw foods into digestible products. Harvested agricultural and farm produce is treated with heat or pressure to convert their natural compounds, making them safe for consumption.

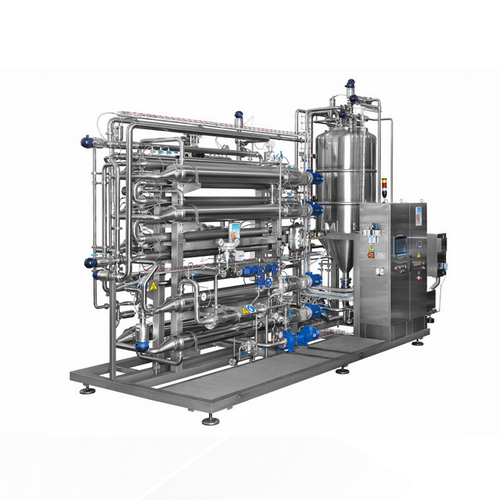

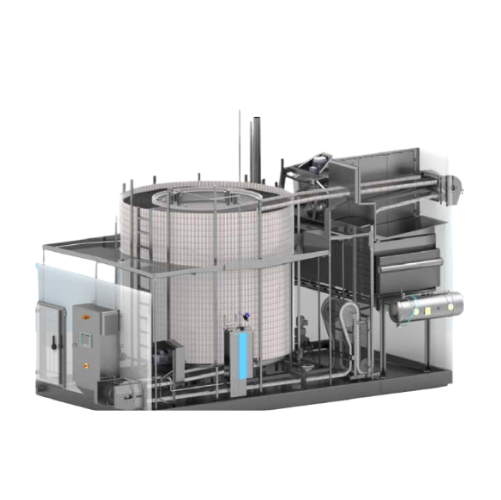

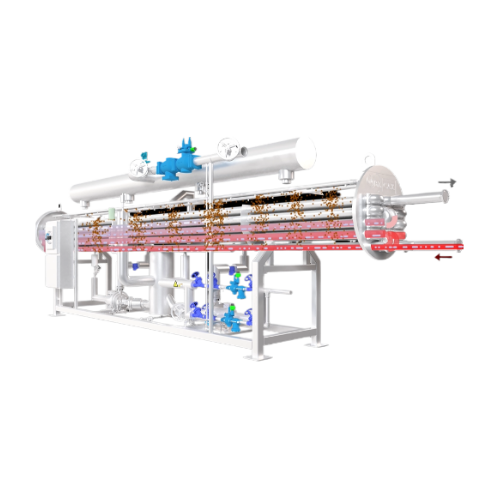

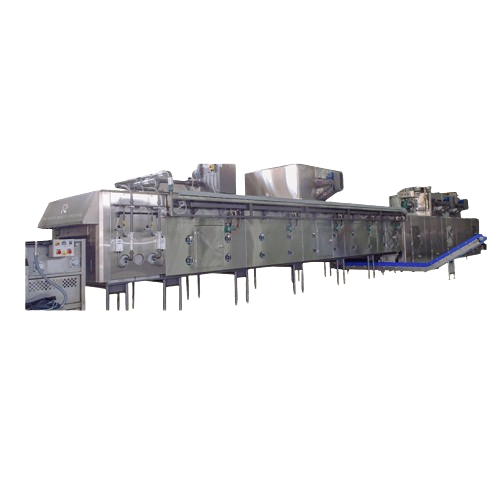

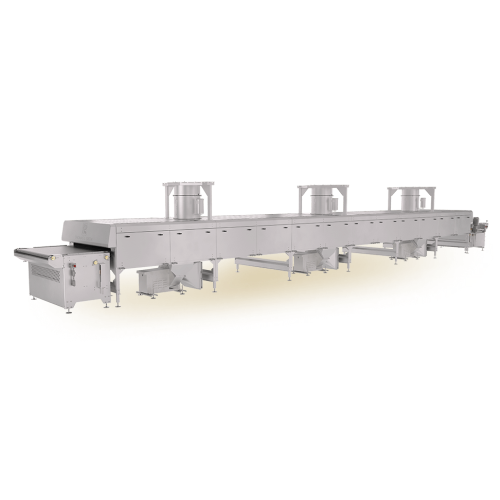

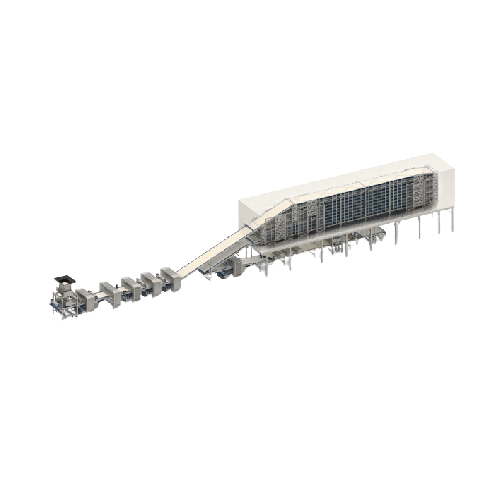

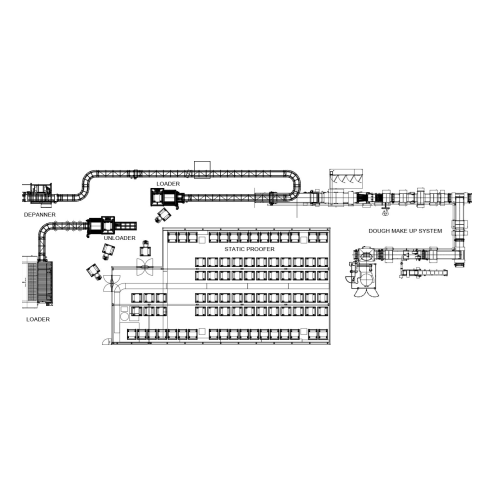

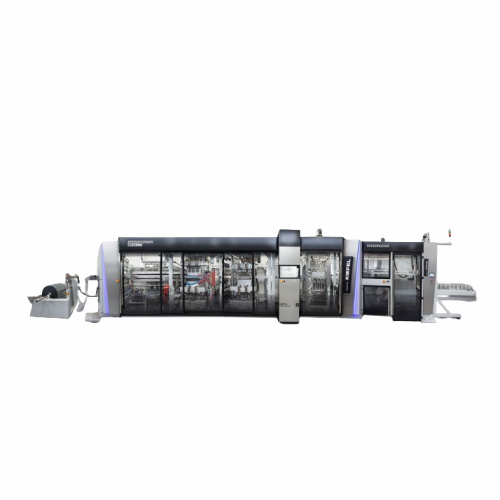

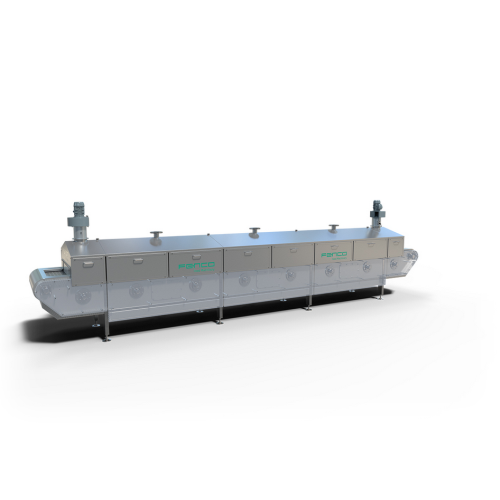

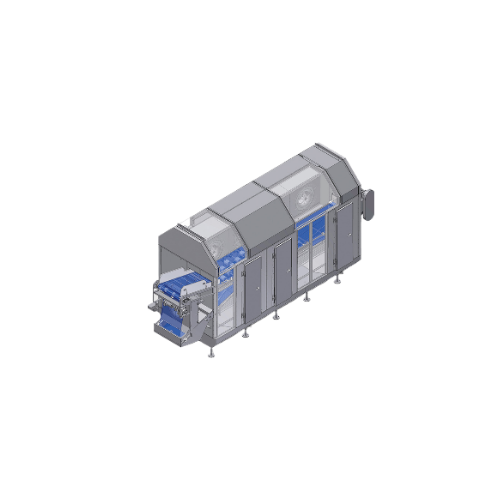

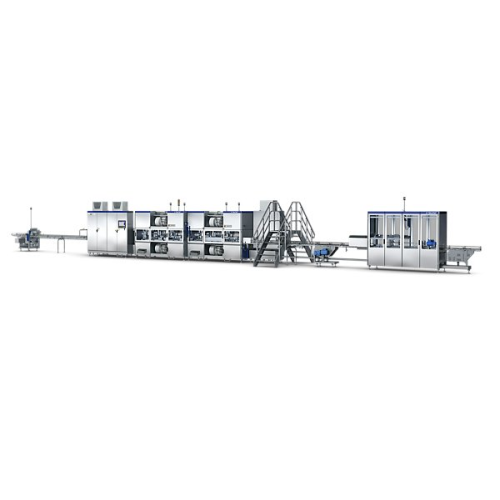

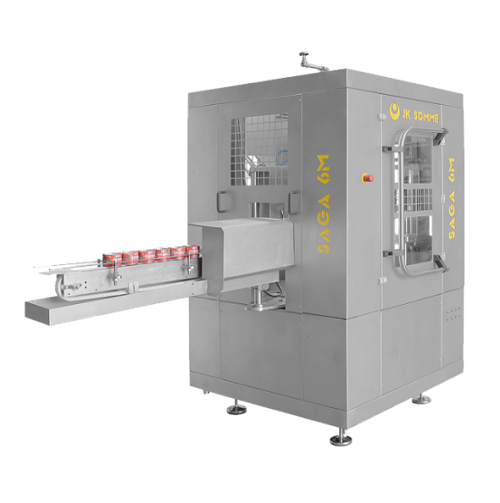

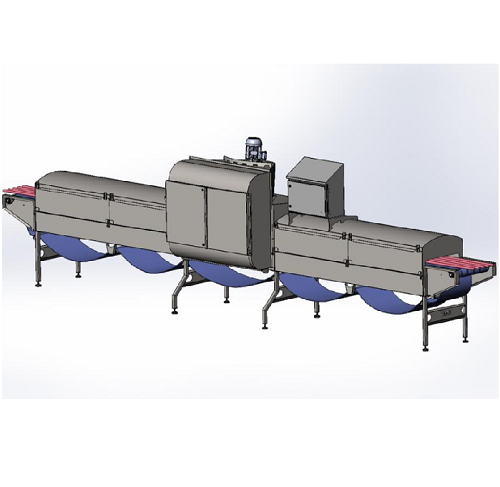

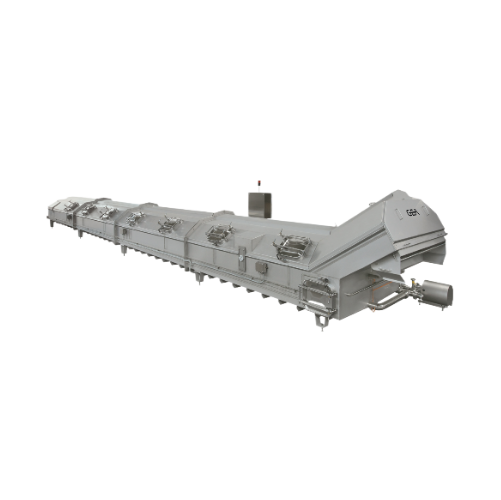

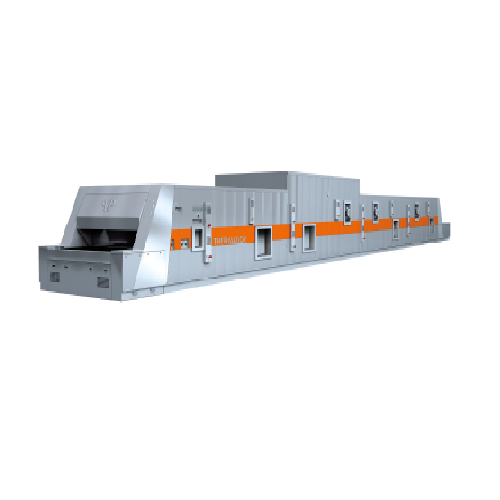

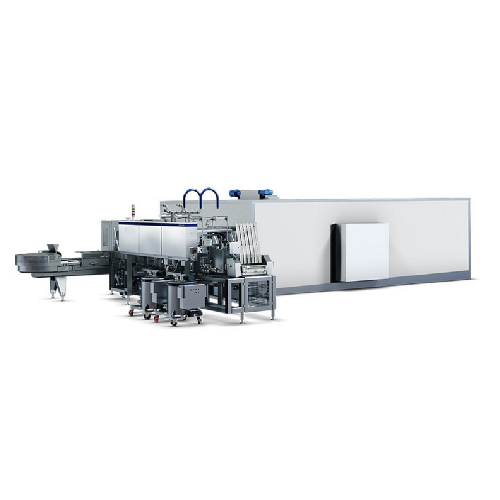

Some techniques, such as meat drying or milling wheat, predate industrial food processing equipment. But, as technology develops, methods become more refined. Pasteurization, for example, has come a long way since the original low-temperature long-time process (LTLT) of the nineteenth century. Tunnel pasteurizers make continuous processing possible, and the machines can be configured for a range of beverages, from beer to fruit juice.

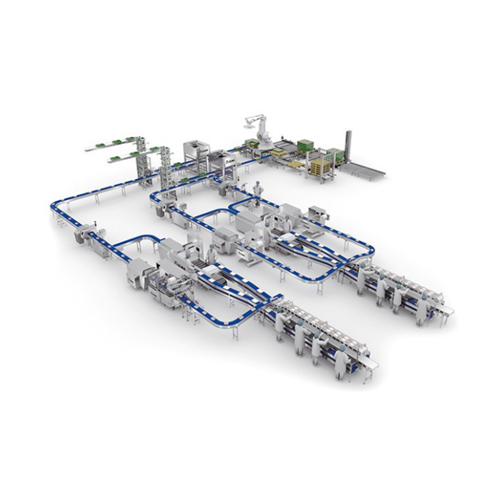

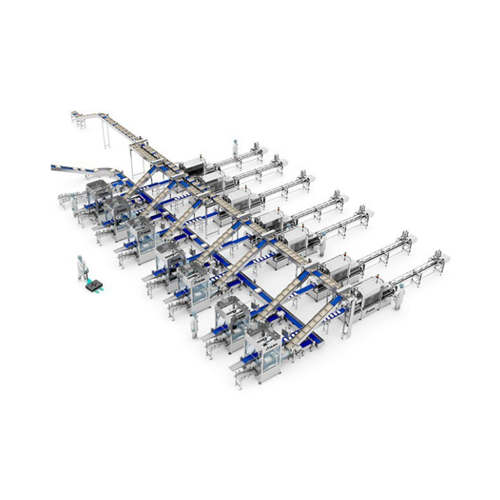

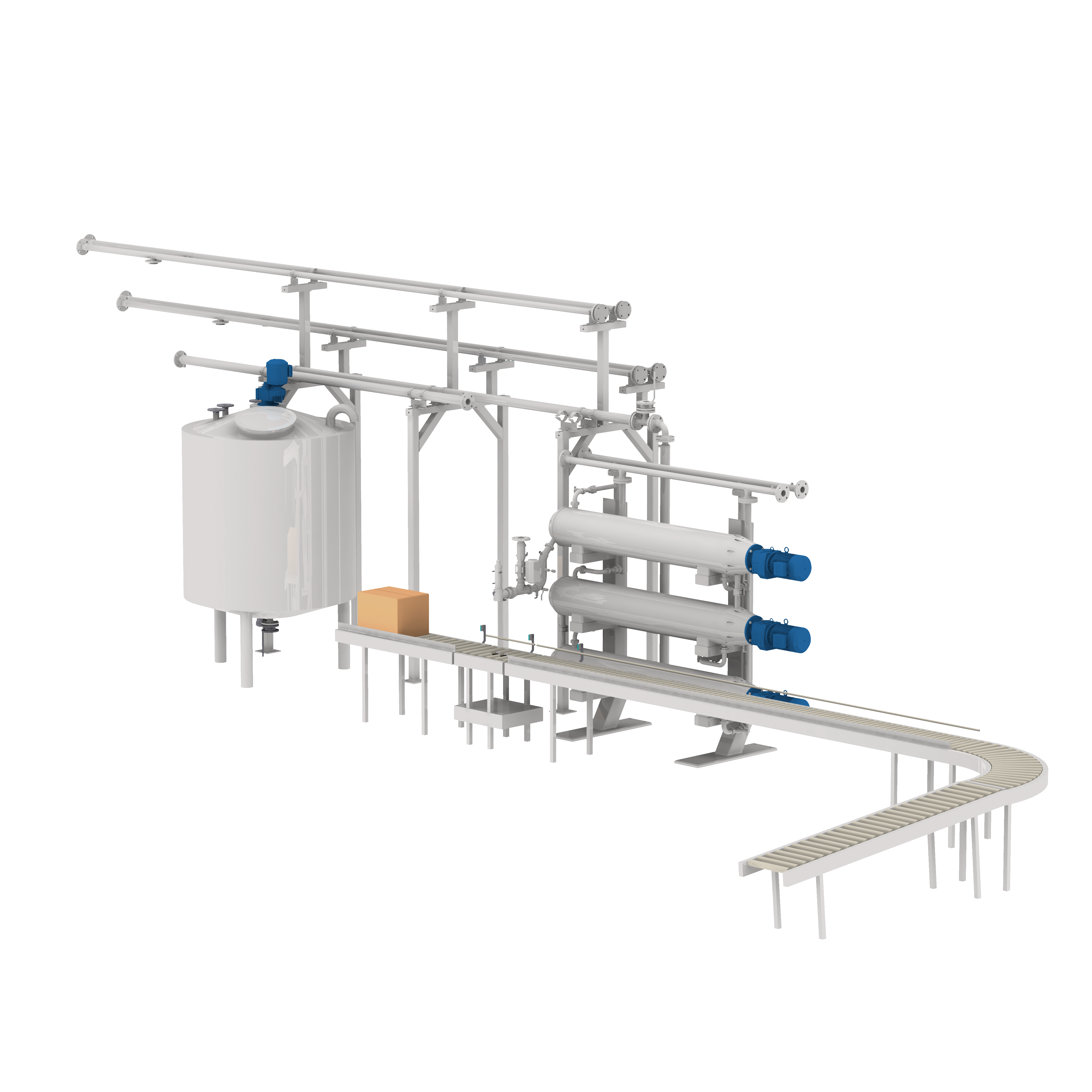

Turn ingredients into products with secondary food processing equipment

Food products often require further processing to be made into ready-to-eat products. To produce chocolate, the cocoa beans go through a long line of processes. The fermented beans are roasted, winnowed, and pressed to separate the oils from the nibs. The refined mixture is then prepared for conching to remove unwanted compounds. At the end of this chain of processes, the ingredient is ready to be formulated into chocolate products.

Chocolate is only one of the foods that undergo secondary processing. Bakery products, mustard, canned fruit, and most foods we consume are a blend of primary processed ingredients that are subsequently mixed, heated, chilled, or treated with other processing methods.

Food manufacturing applies mechanical and chemical processing methods

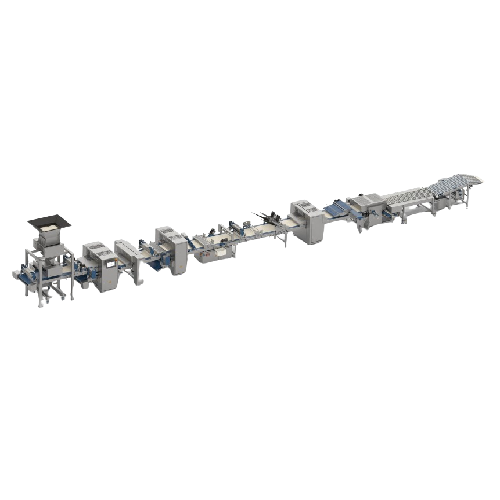

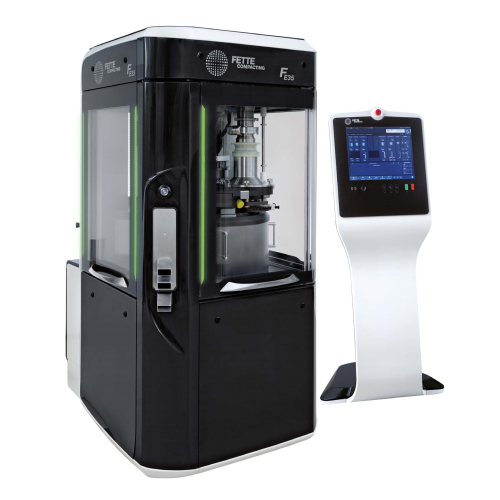

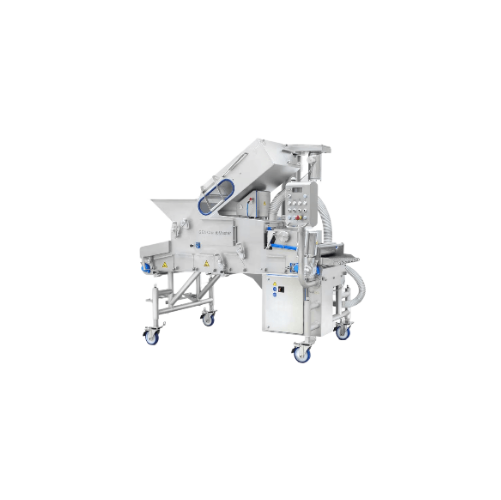

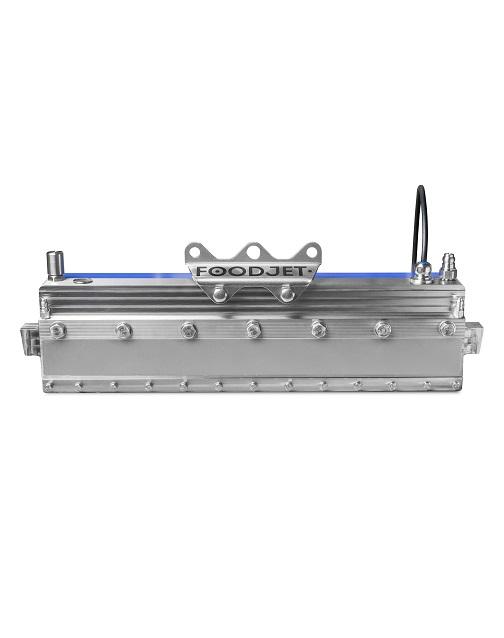

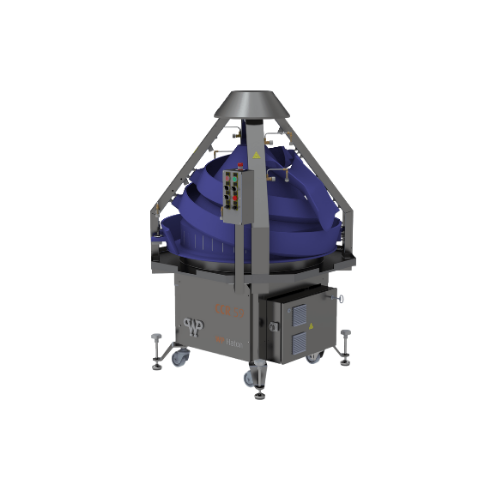

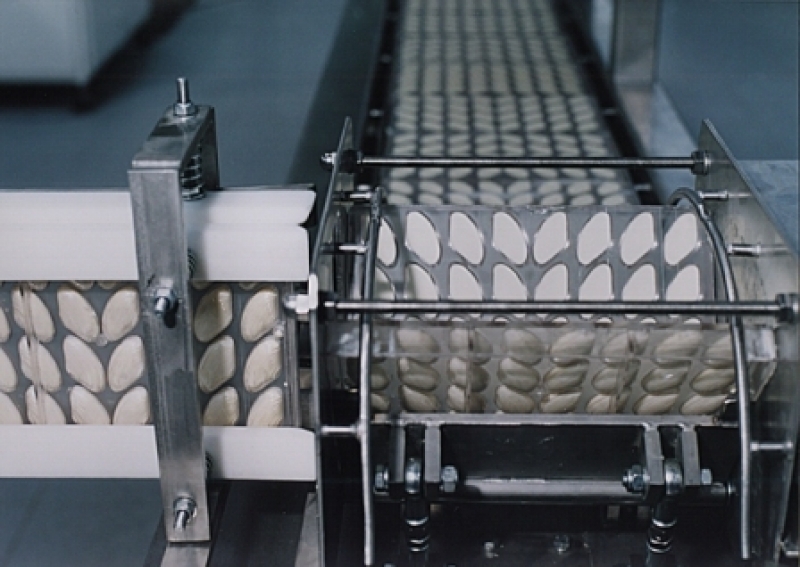

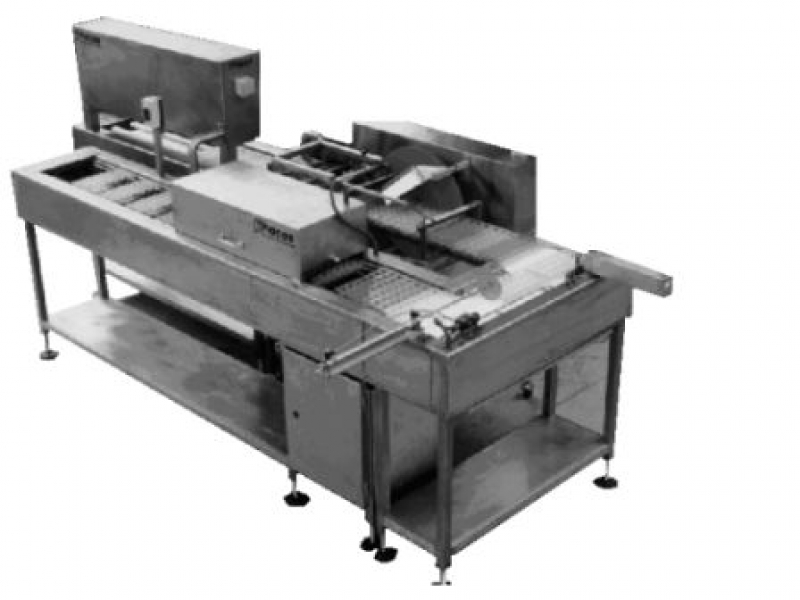

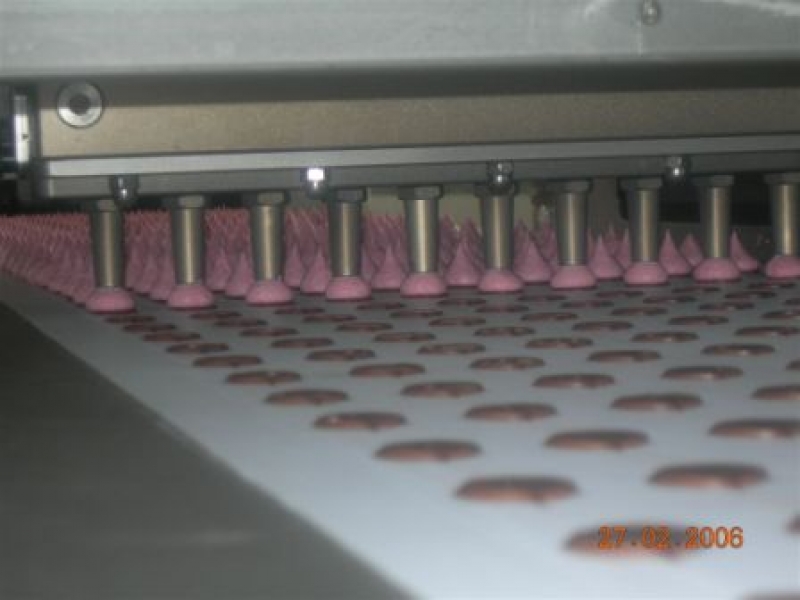

Secondary processing can either be mechanical or chemical. Mechanical food processes include a variety of methods, such as depositing gelatin formulations to make vitamin gummies or frying potato slices to make chips.

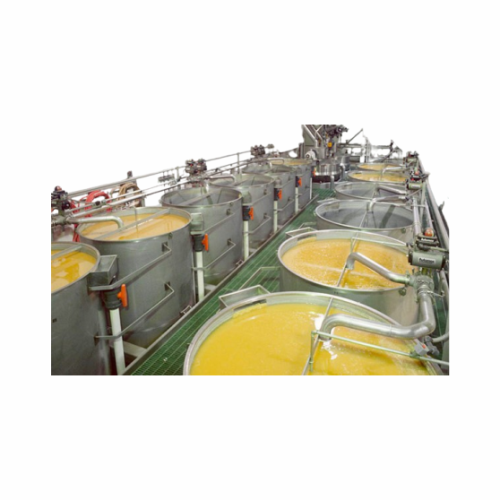

Chemical processing involves molecular transformation techniques, like hydrogenation to make edible oil or adding enzymes to milk in cheese-making.

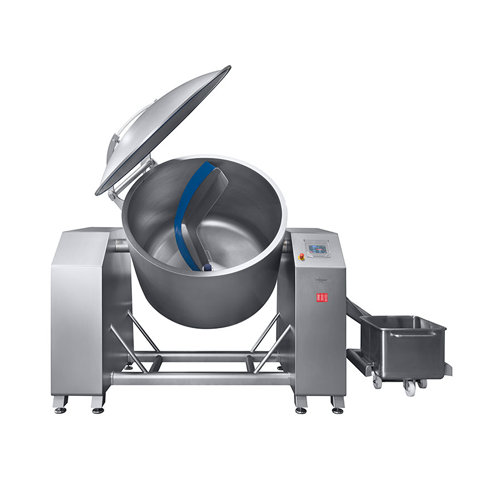

Choose the right industrial cooker for your food product

Cookers are ubiquitous food processing equipment in the food sector. Although the principle of heat distribution is the same, technologies adapt to the items they produce.

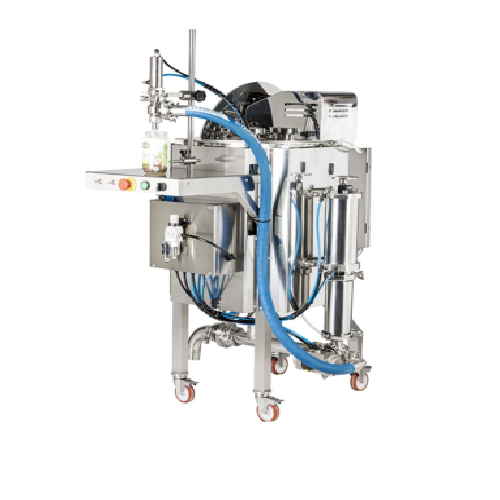

Industrial cooker systems designed for classic preparations like soups and purees take direct heat. Indirect heating methods are more suitable for delicate foods such as sauces and condiments. Some cookers apply vacuum technology to control the texture of the ingredients and are specially used for jams, creams, or ganache. Special formulations like baby foods or milk desserts are cooked in aseptic cookers to ensure a sterile environment.

Tertiary food processing extends the shelf-life of items

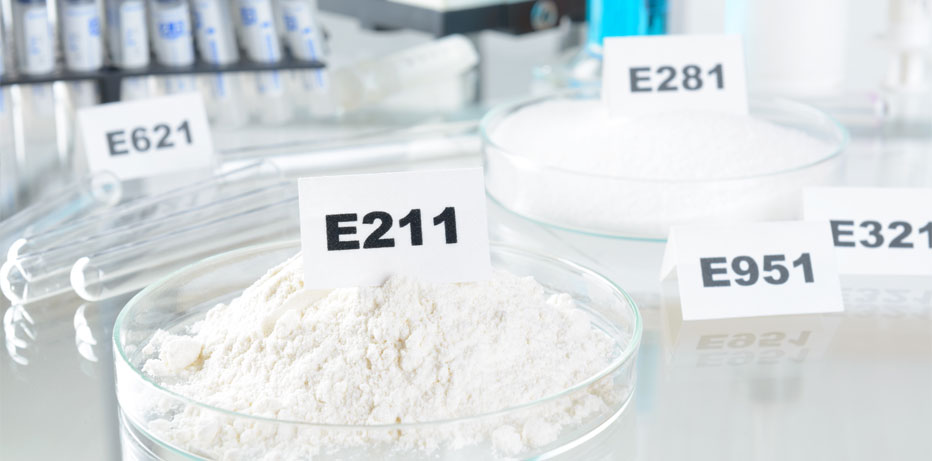

Convenience foods that are ready to be consumed with little or no preparation go through tertiary processing. These products are commonly formulated from starches, fats, and protein isolates and combined in a mixer with reaction flavors, emulsifiers, and colorants.

Snacks like extruded cereals or heat-and-serve meals like frozen pizzas are formulated for longer shelf-lives and contain higher quantities of additives such as salts and sugars. However, nutrition concerns are driving food manufacturers to reduce these ingredients from their formulations.

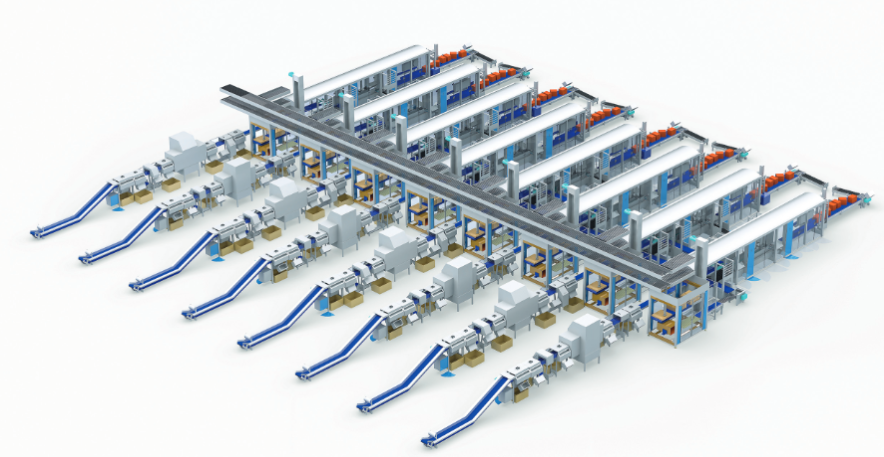

Applying processing techniques to create new food specialties

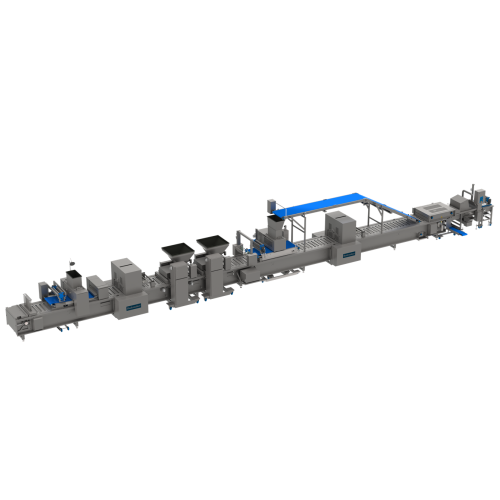

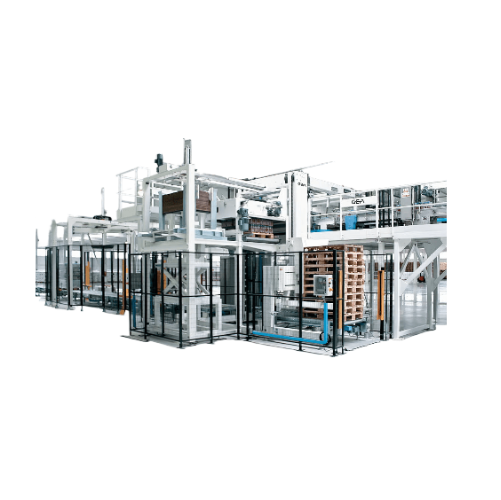

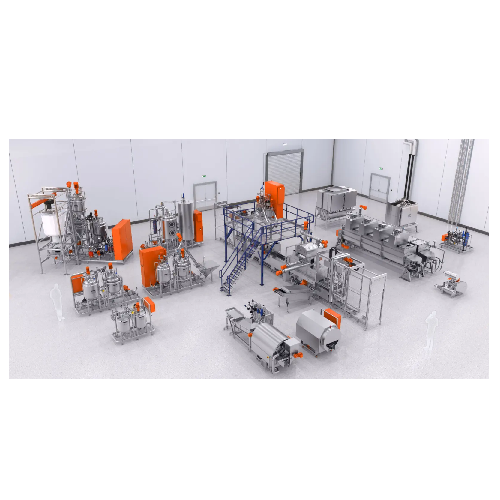

Food processing equipment makes traditional recipes easy to make on a large scale. But production technology also helps to develop new categories.

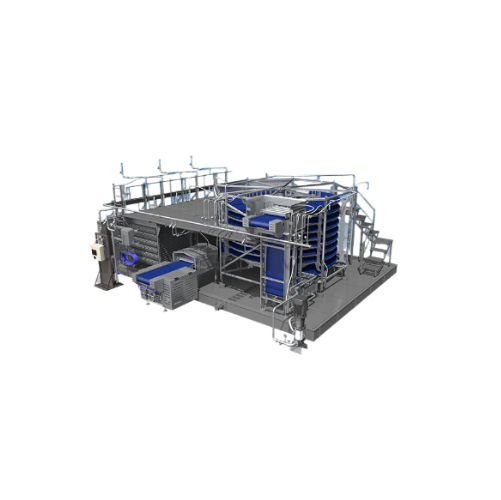

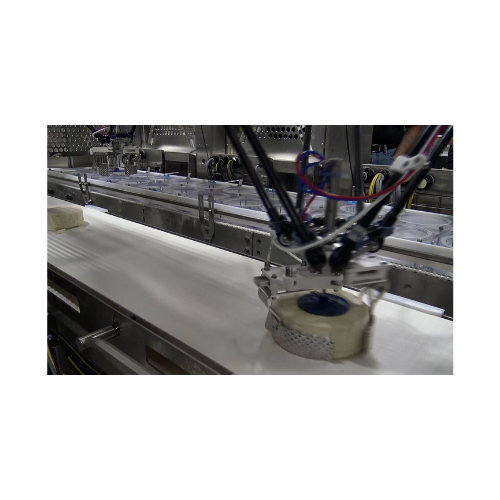

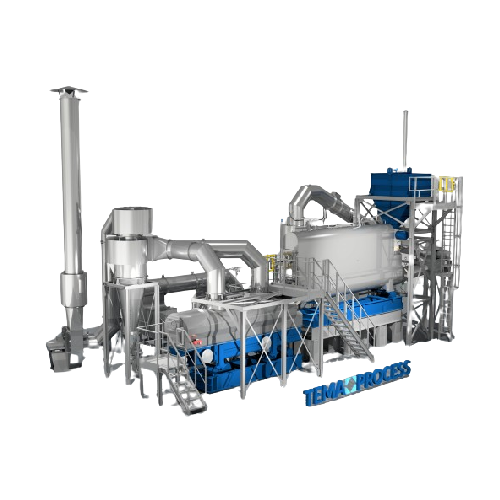

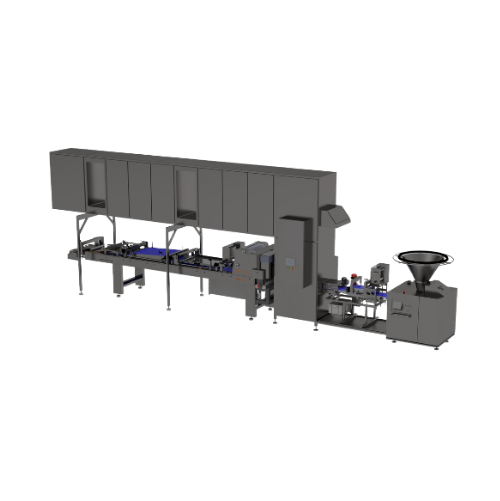

One example is the growing trend in plant-based foods supported by advanced manufacturing systems. A line of fine grinding, gentle mixing, and homogenizing technology is able to turn legumes into vegan cheese spreads or vegan salmon. Processing equipment opens up new possibilities for the food industry.

Which food technology do you need?

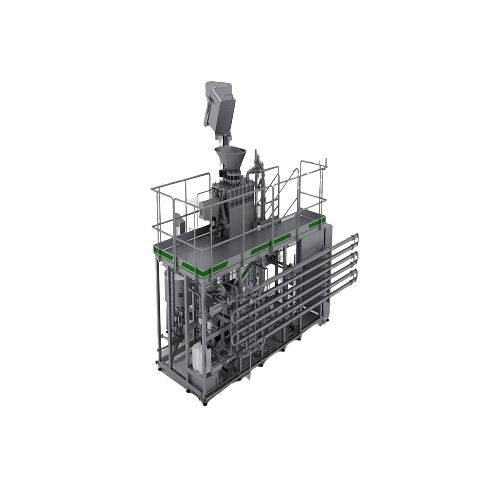

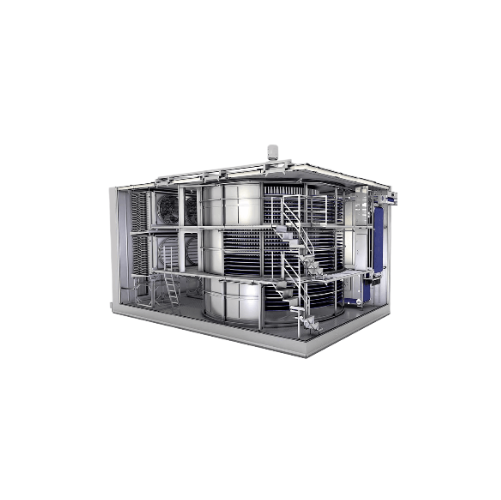

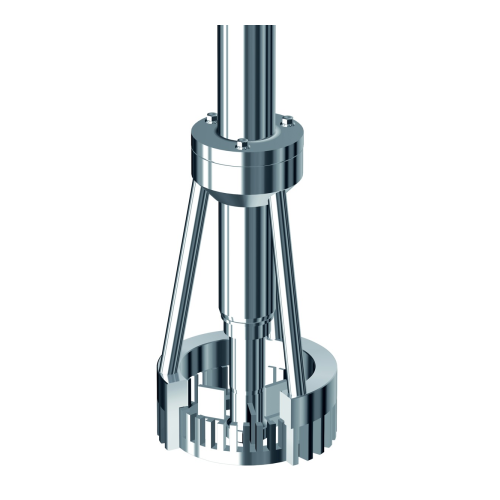

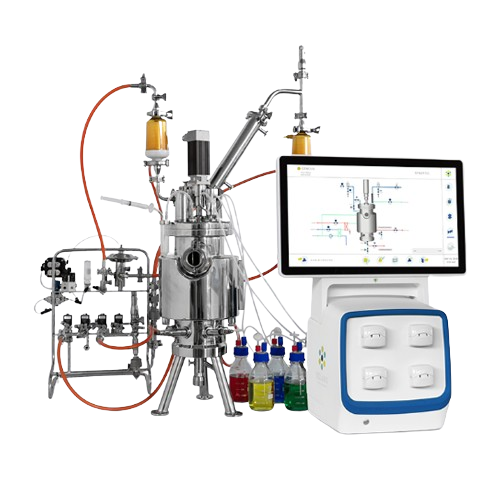

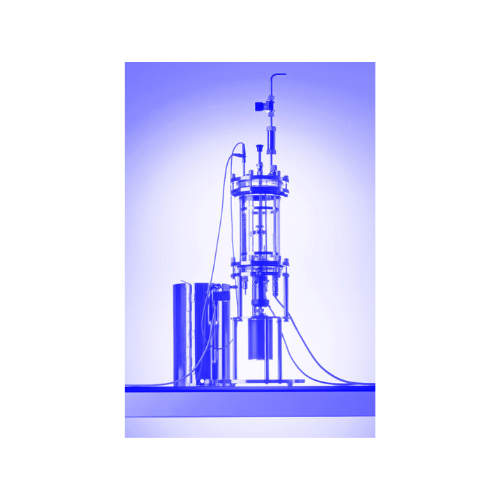

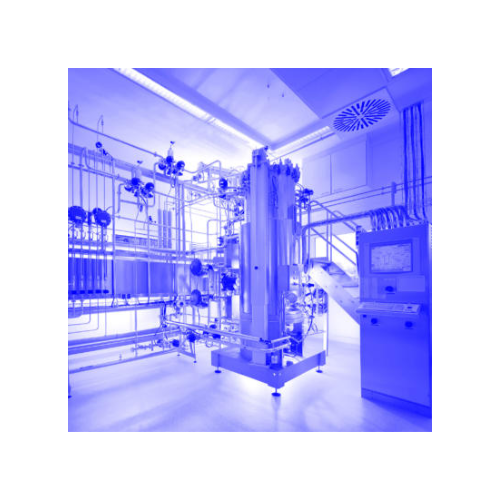

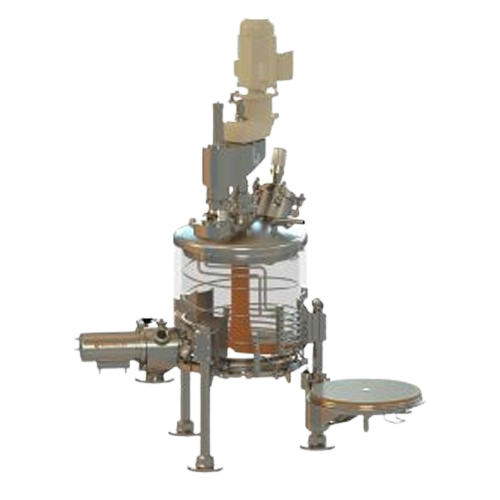

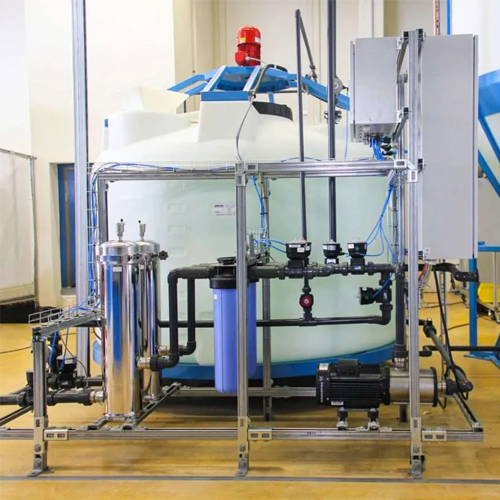

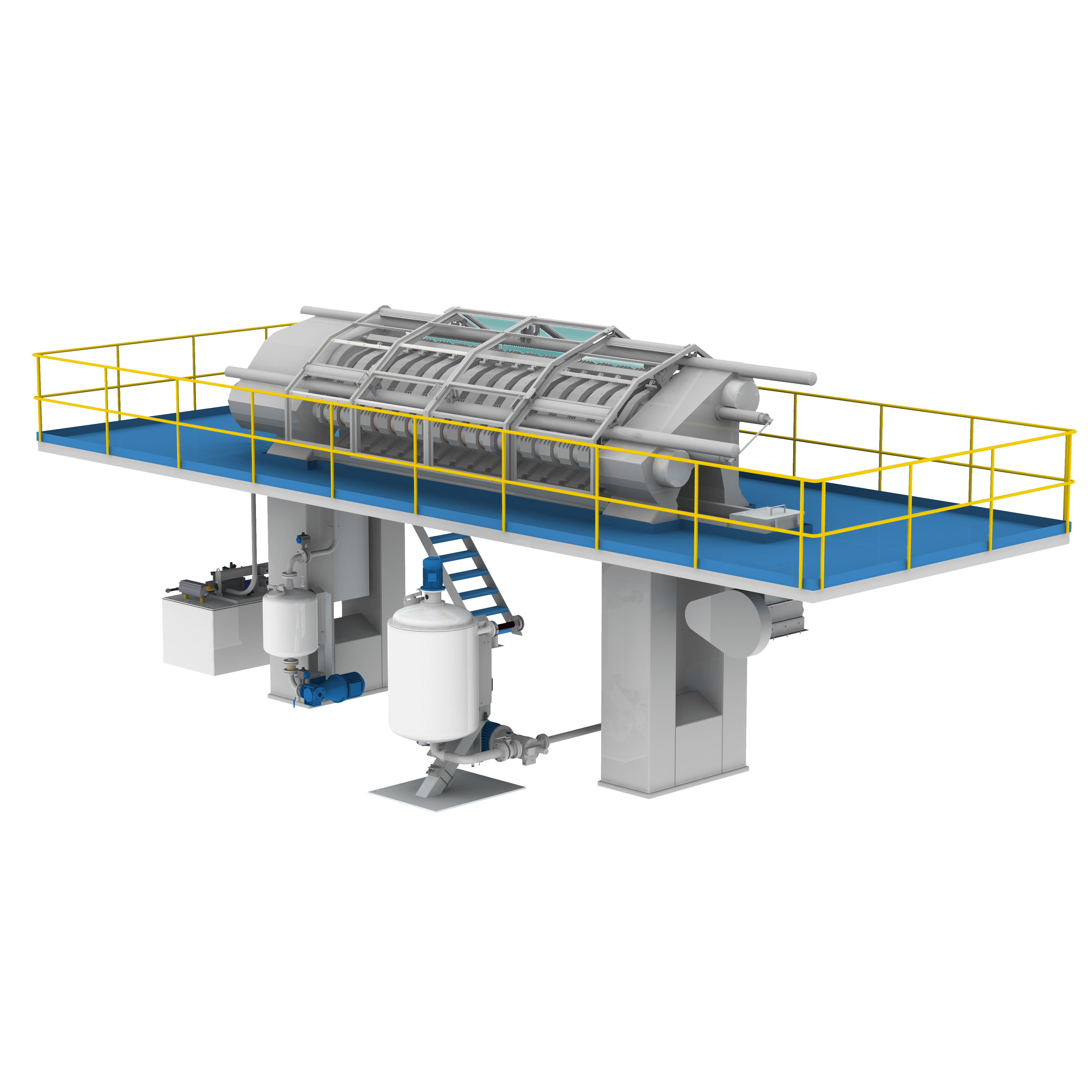

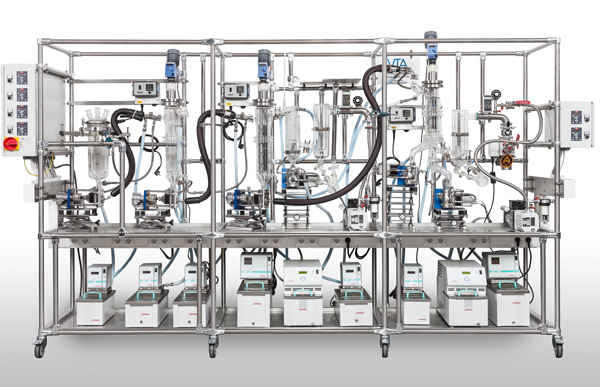

Industrial-scale bioreactor for new food applications

Unlock the potential of cultivated meats and alternative proteins w...

Industrial bioreactor for microbial food production

Enhance microbial food production with advanced bioreactor systems de...

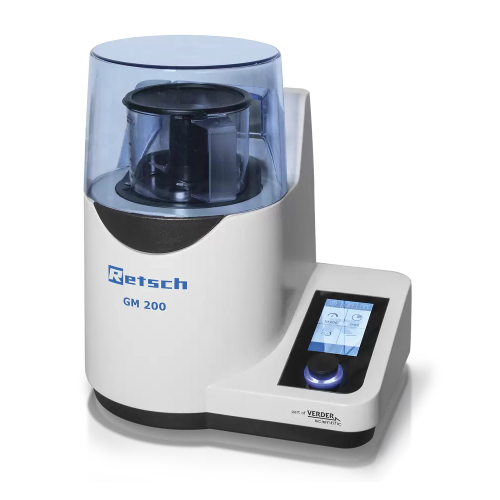

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

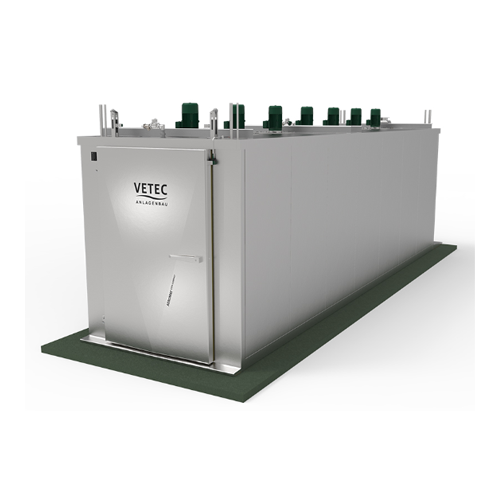

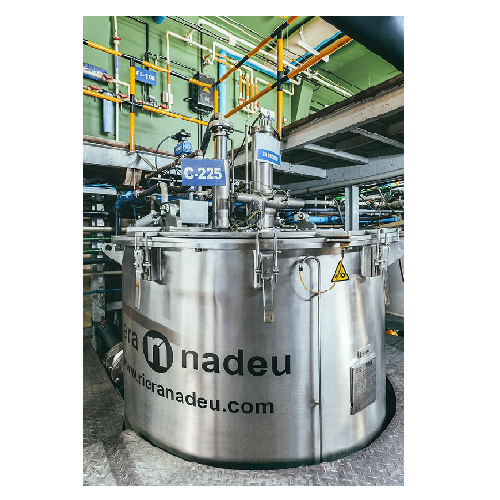

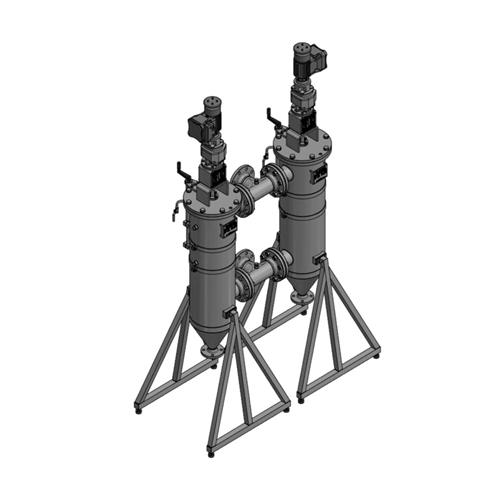

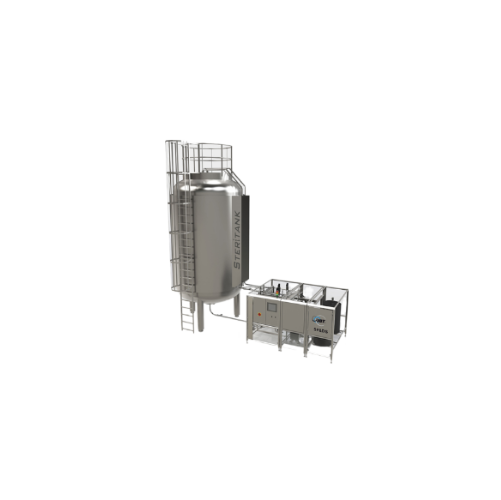

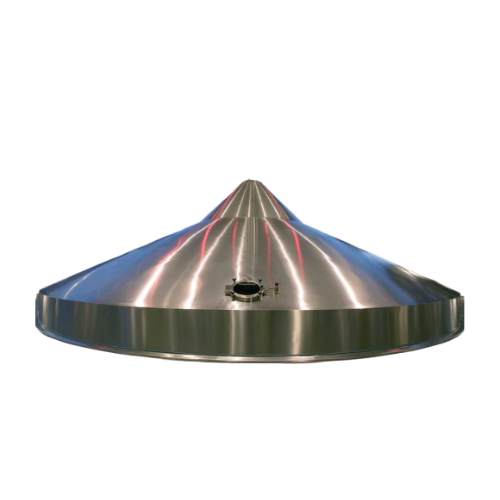

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

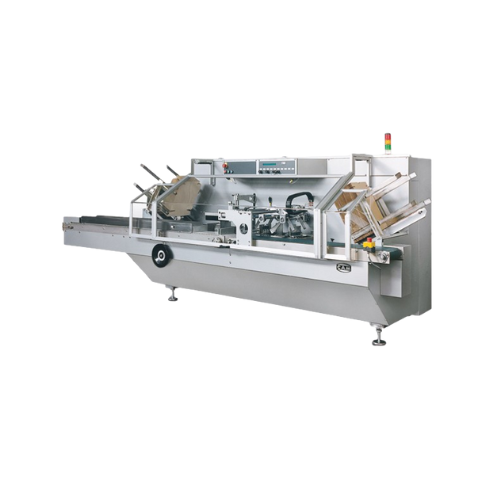

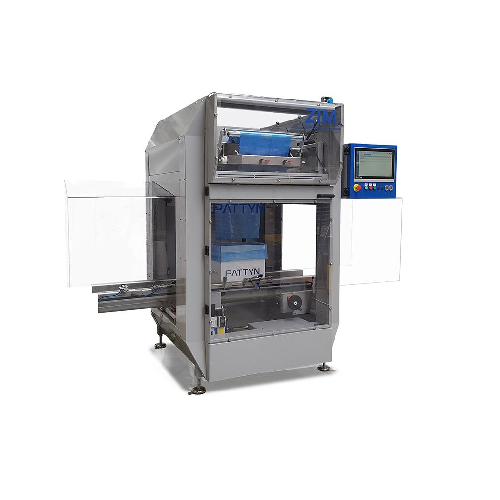

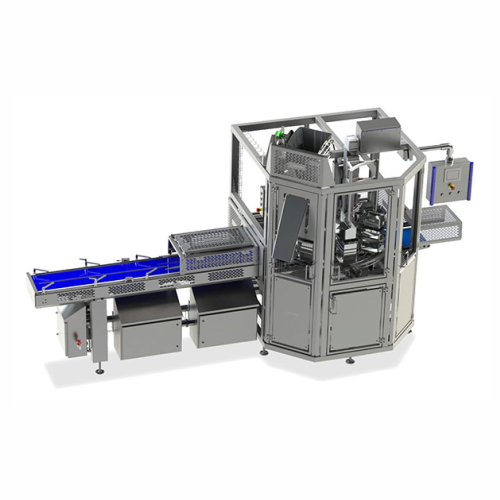

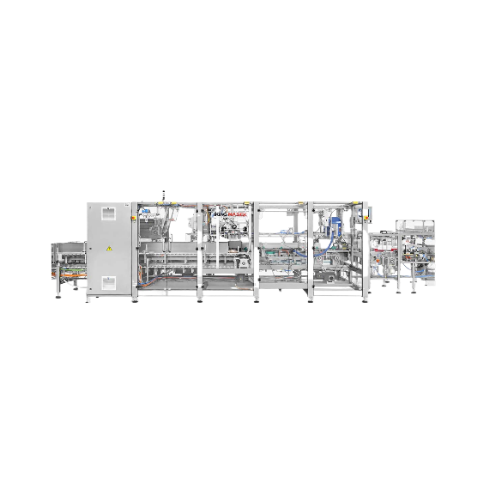

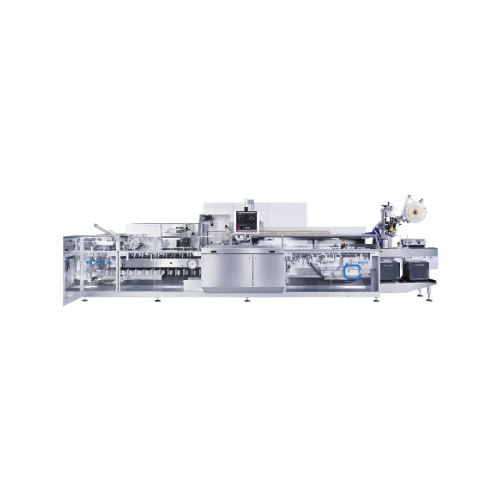

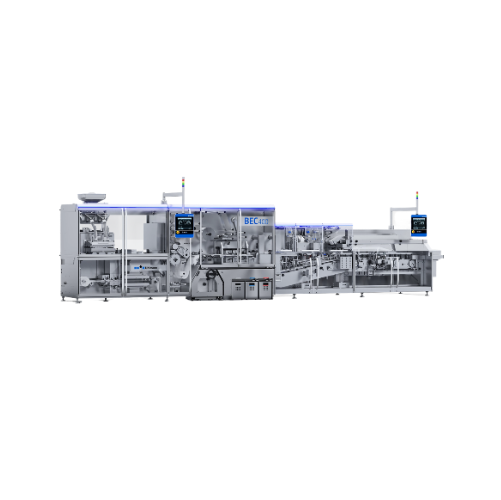

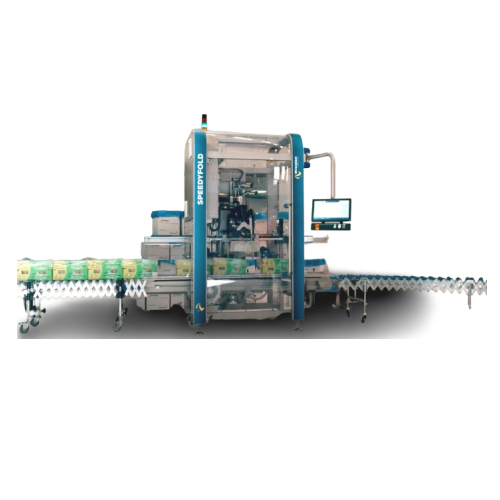

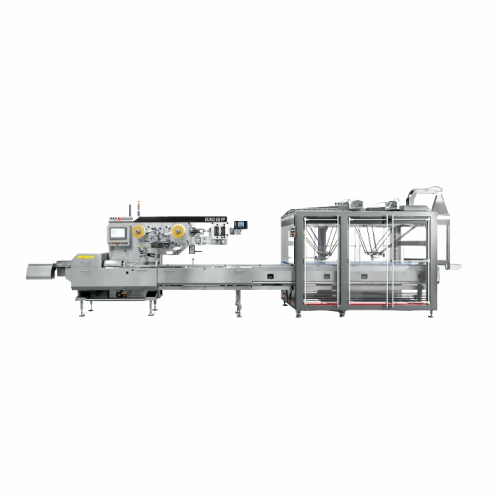

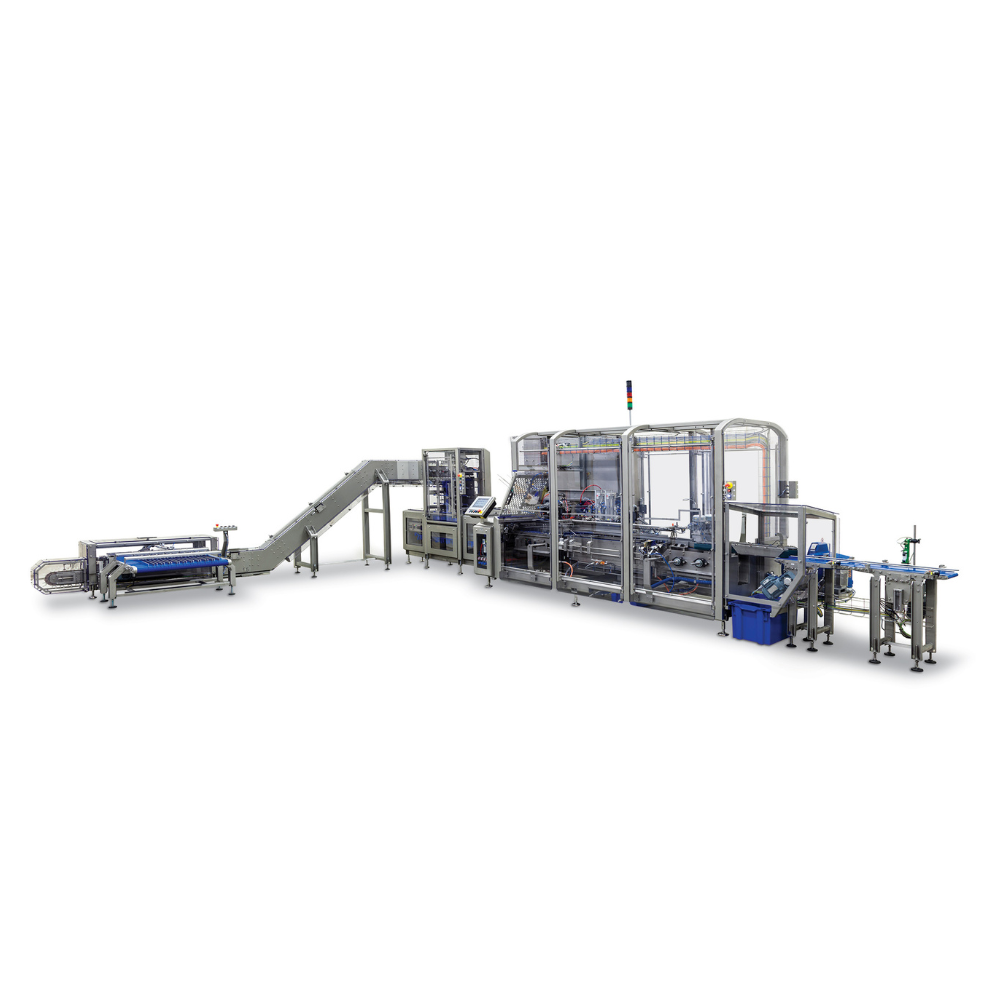

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

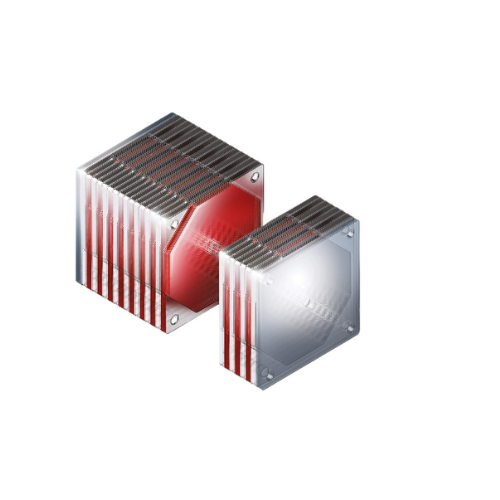

Pulsed electric field system for food preservation

Enhance your production line with technology that extends shelf life a...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

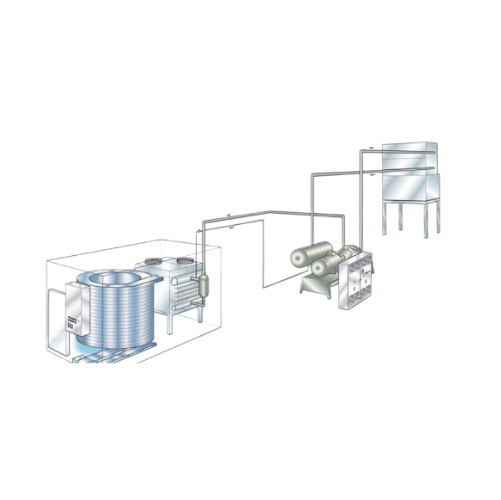

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

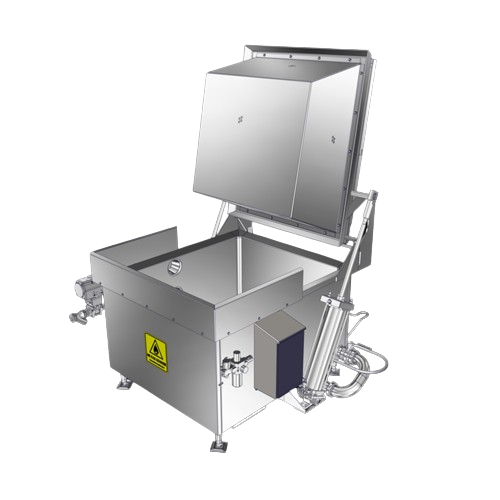

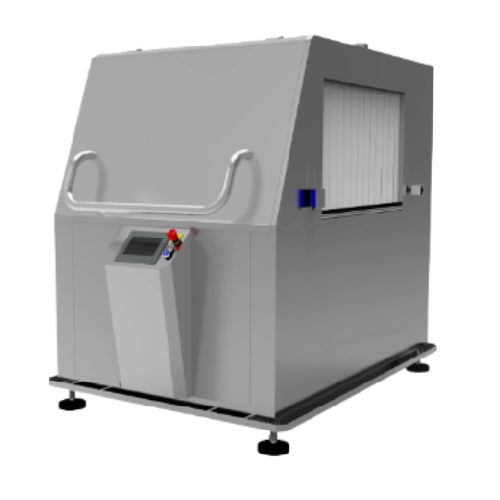

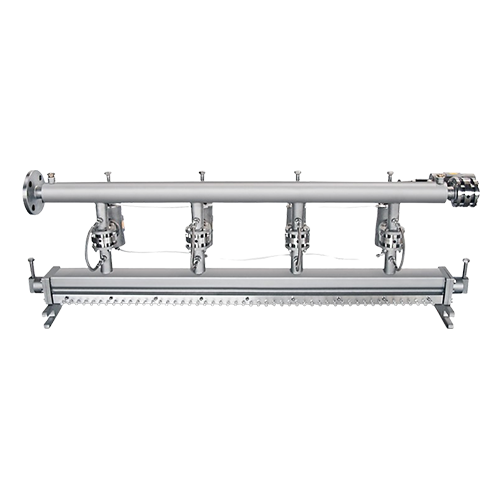

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

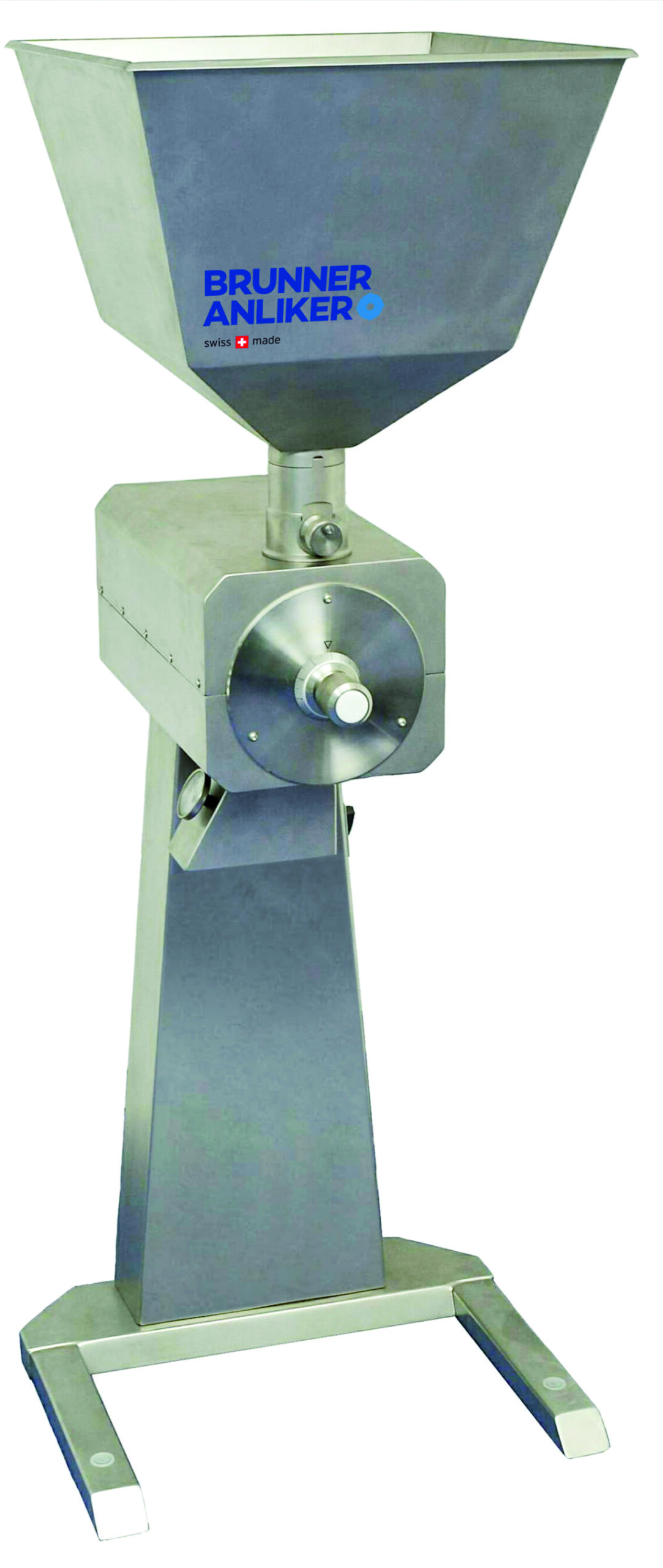

Perforated disc mill for food and chemical processing

Streamline your processing workflow with a versatile solution that ...

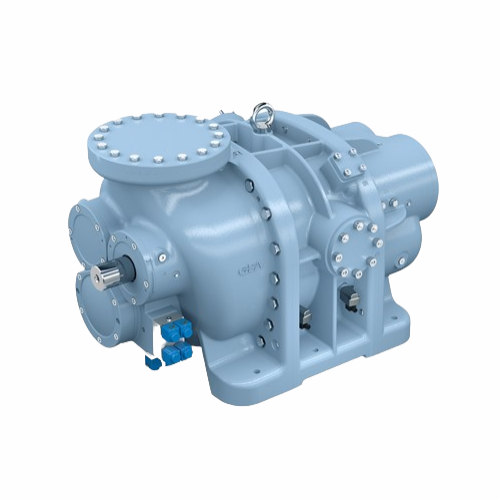

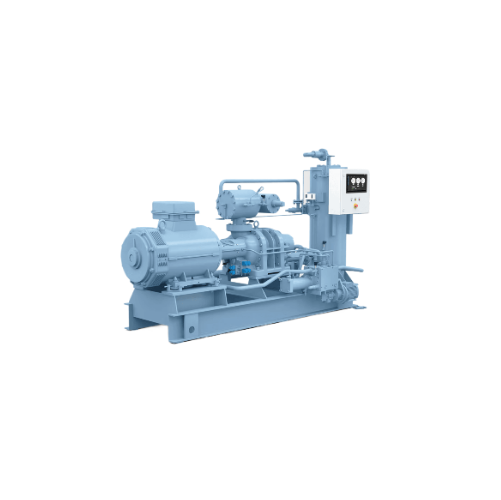

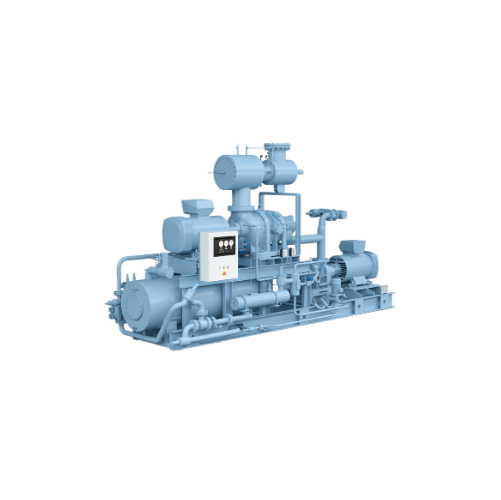

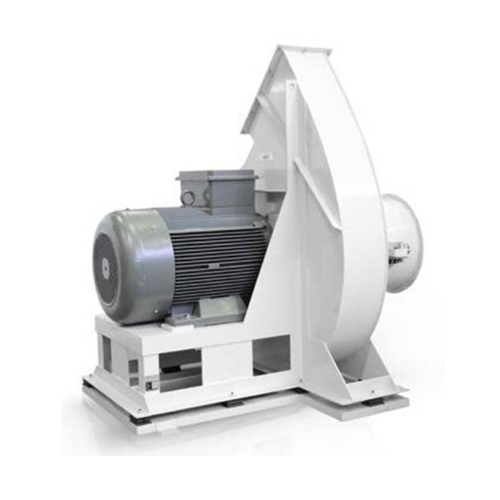

Food processing blower systems

Optimize your production line with precise air handling and moisture control to ensure qualit...

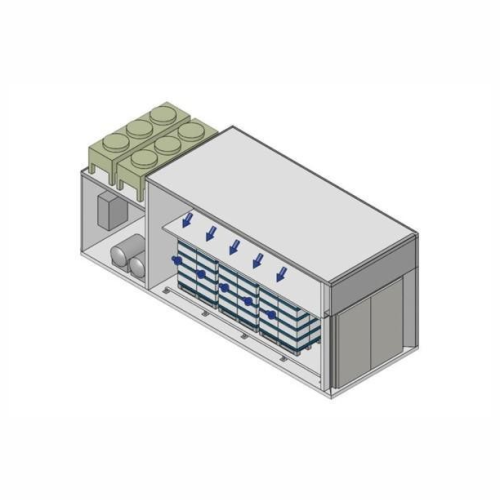

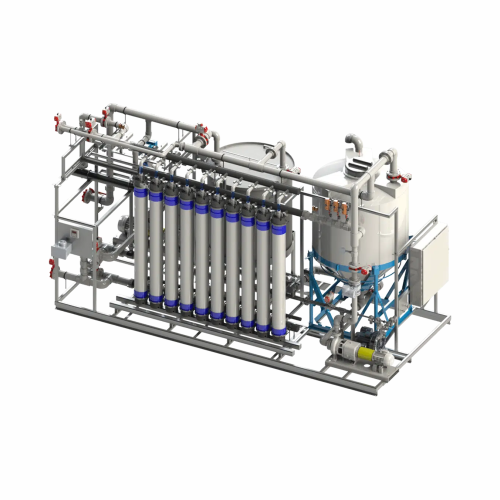

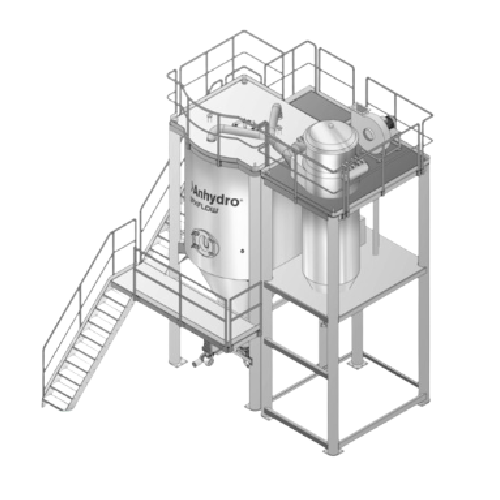

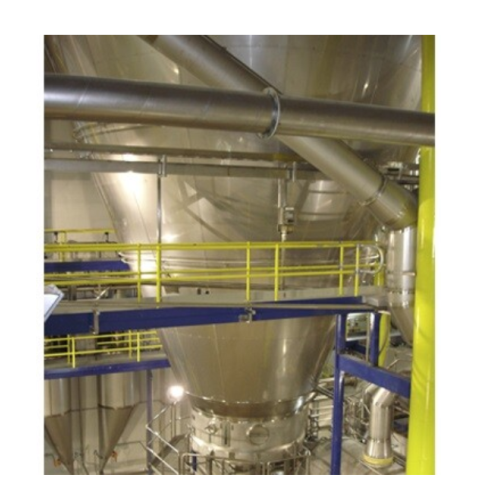

Air filtration system for dairy and food powder processing

Optimize powder processing with advanced air filtration, ensu...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

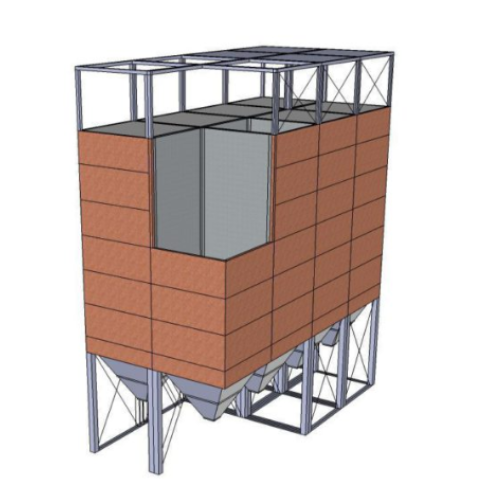

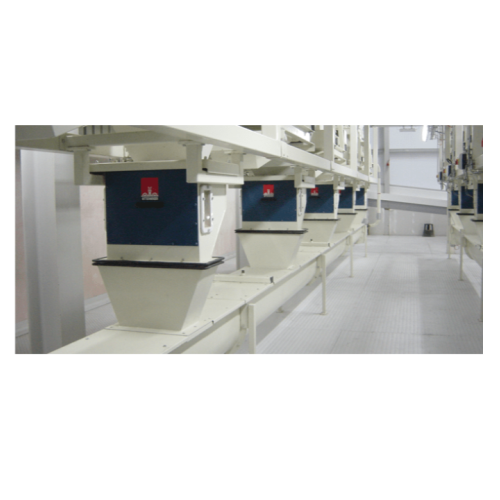

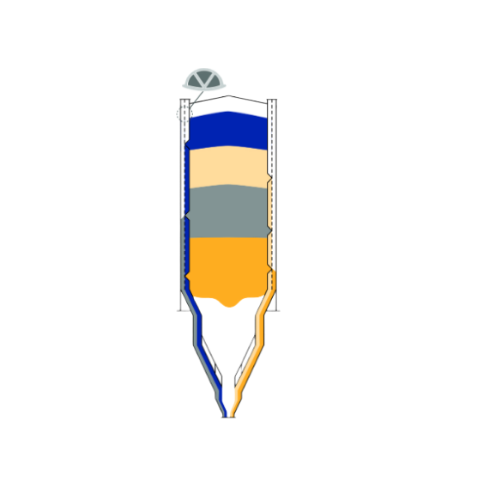

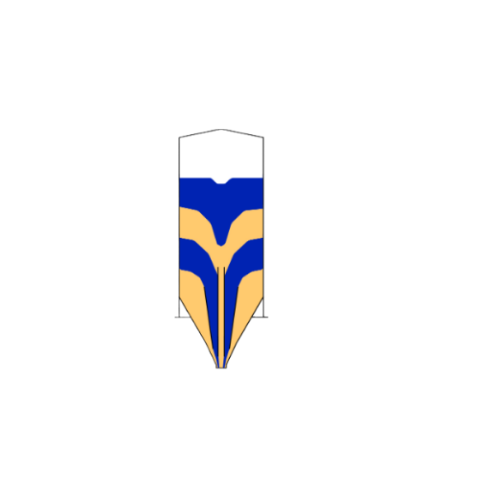

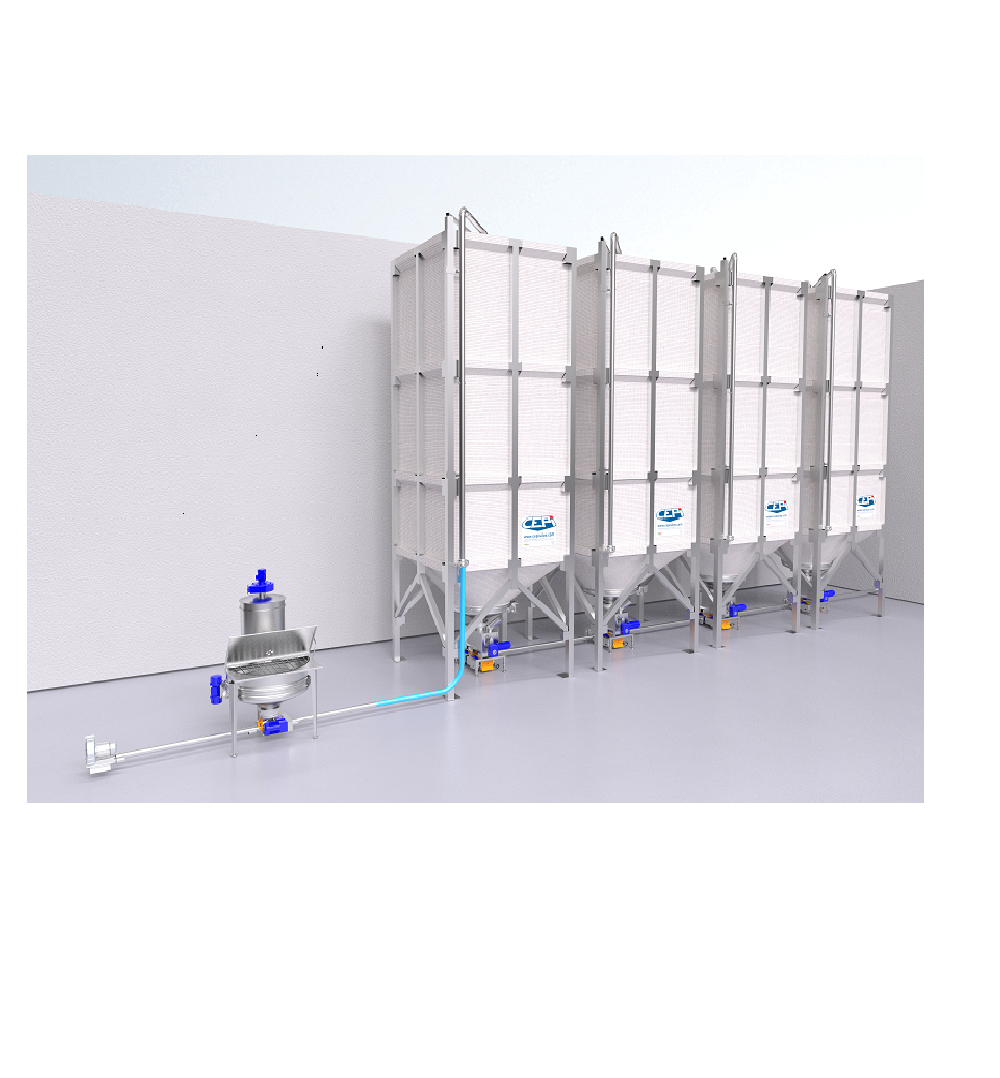

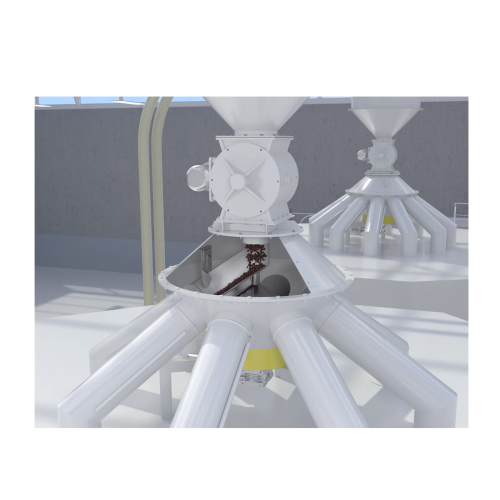

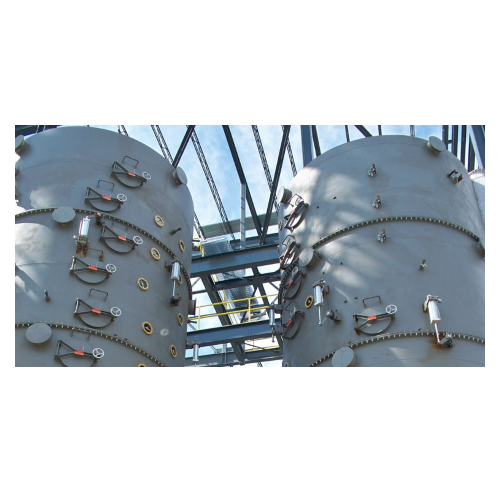

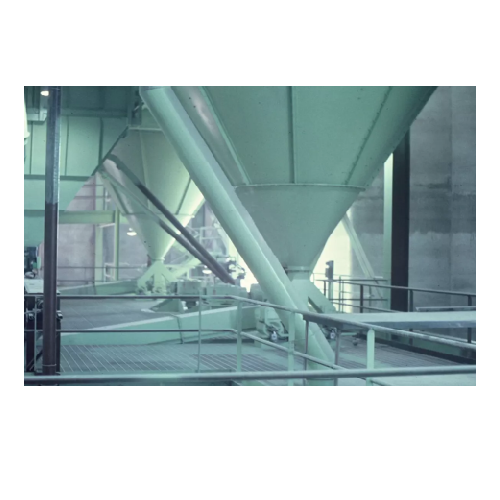

Storage silos and hoppers for food and dairy industries

Ensure optimal powder storage with solutions that enhance space e...

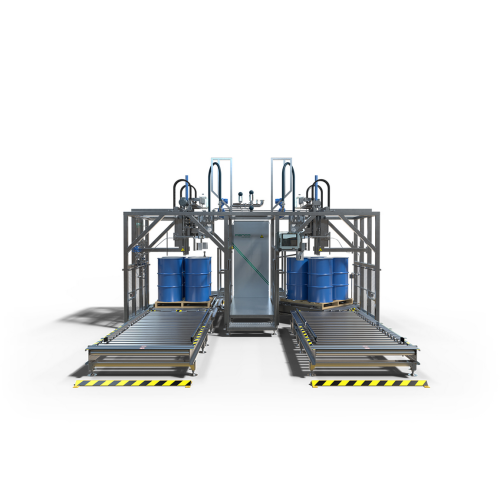

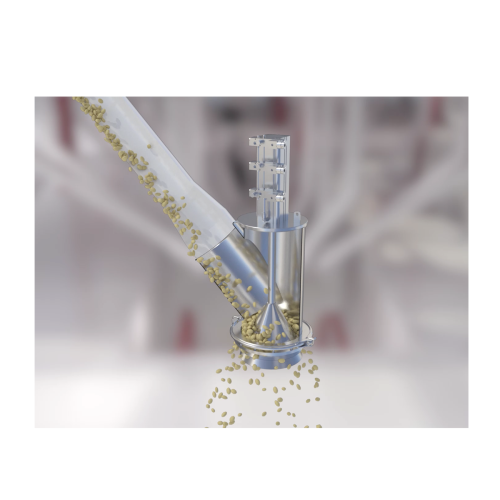

Powder unloading systems for food and dairy applications

Streamline your powder handling with customizable unloading syst...

Food product smoothing system for dairy and purees

Achieve unparalleled texture and fineness in viscous food products wit...

Centrifugal pumps for food & beverage and biopharmaceutical applications

Optimize your liquid transfer processes with p...

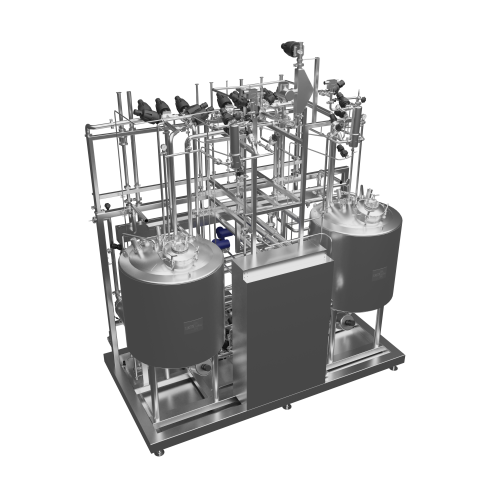

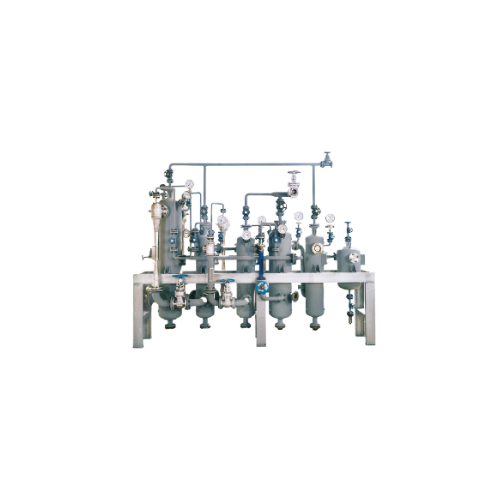

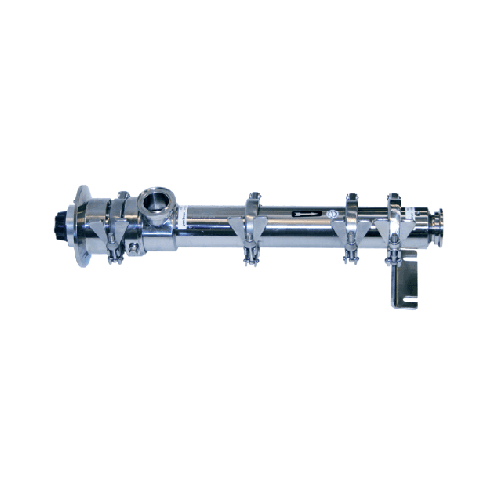

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

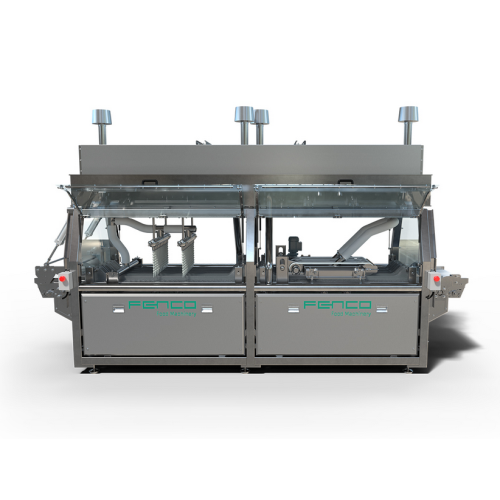

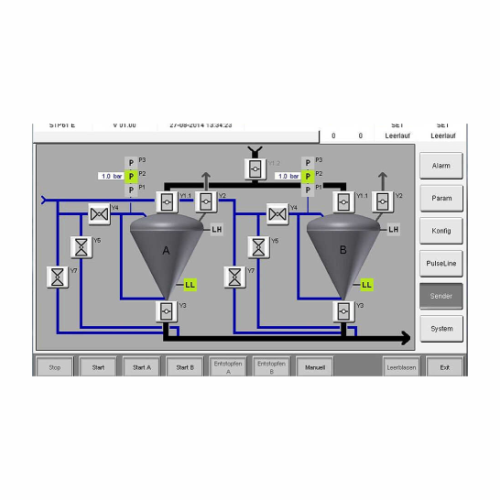

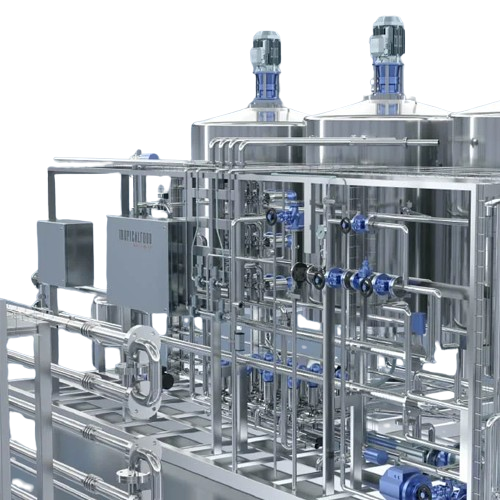

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Powder and liquid mixing system for food and life sciences

Achieve rapid and homogeneous dissolution of large quantities...

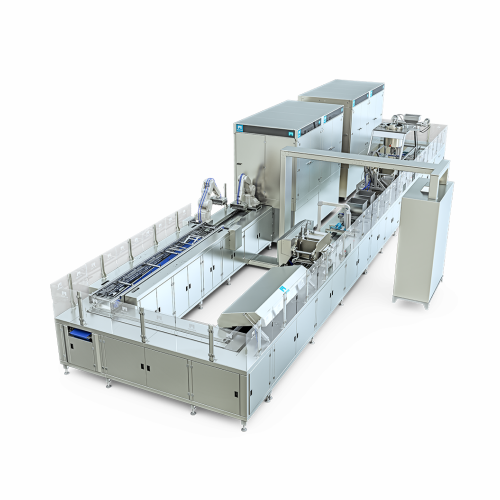

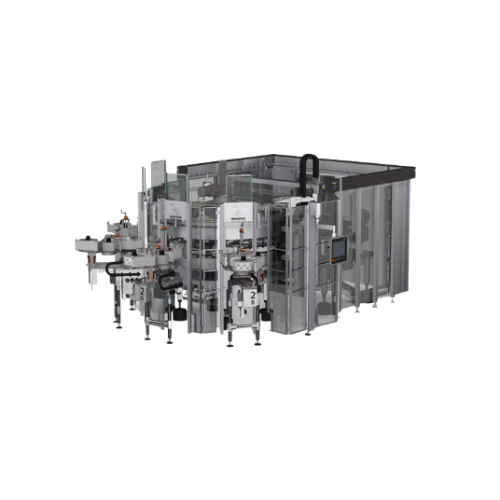

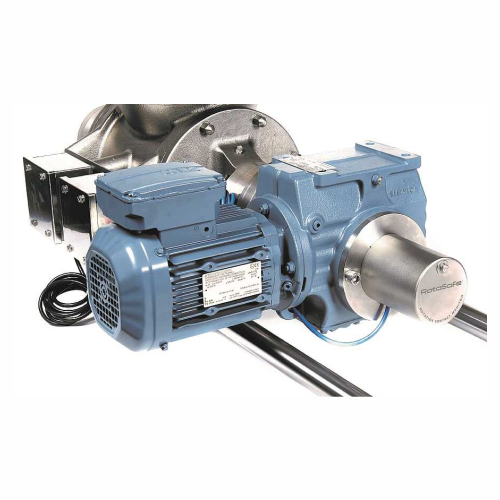

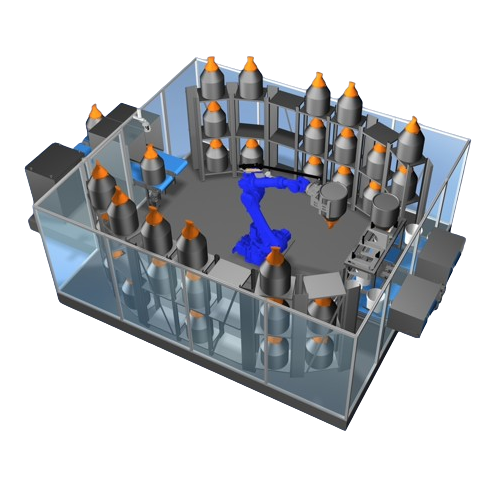

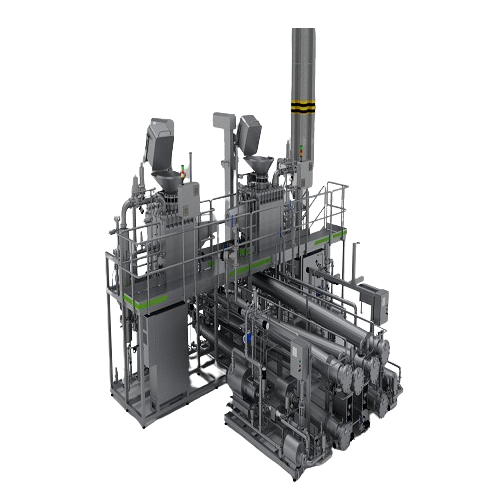

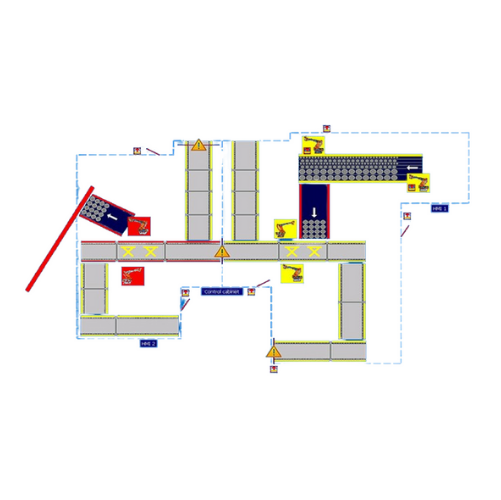

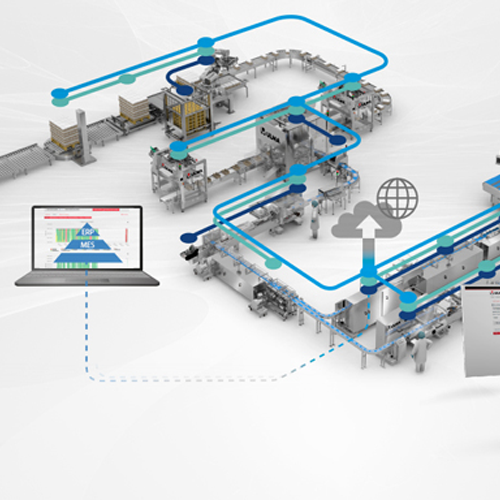

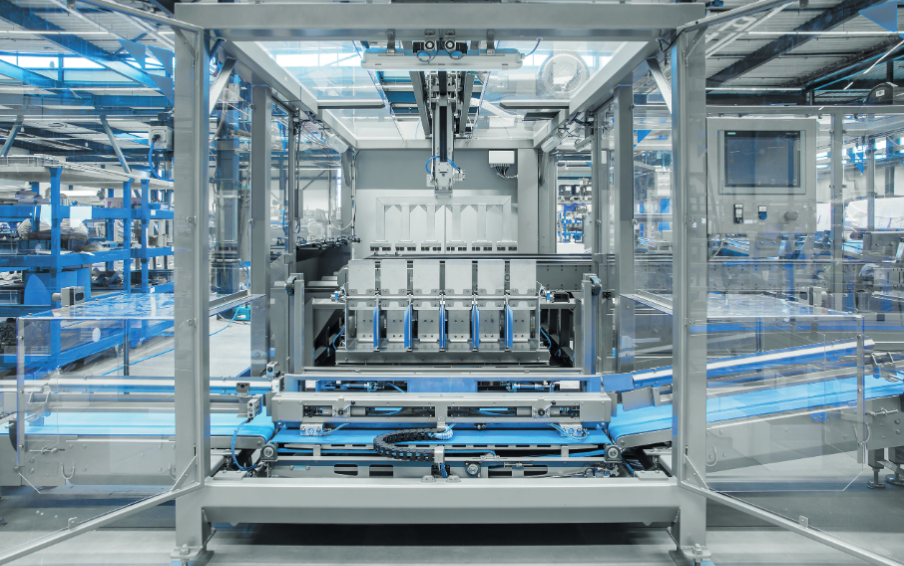

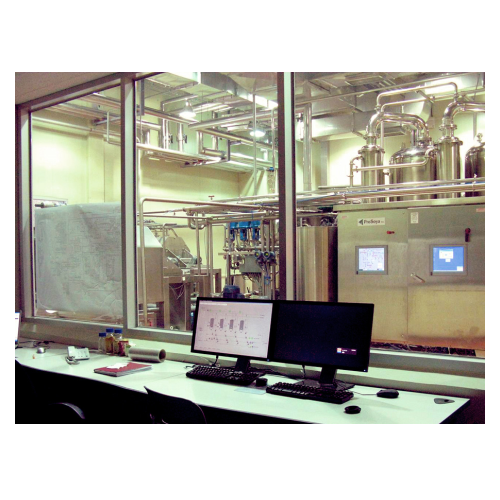

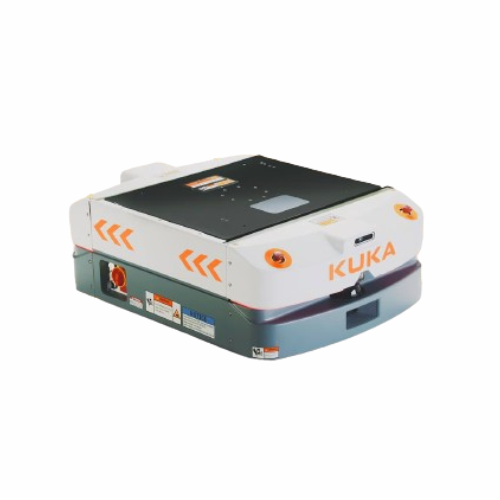

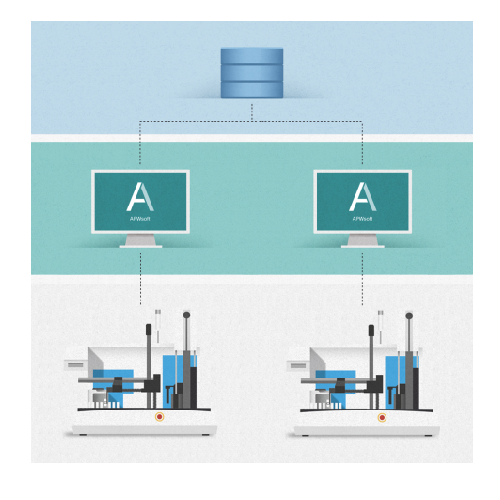

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Cip cleaning systems for food and beverage industry

Optimize your cleaning operations with seamless Clean-in-Place and St...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

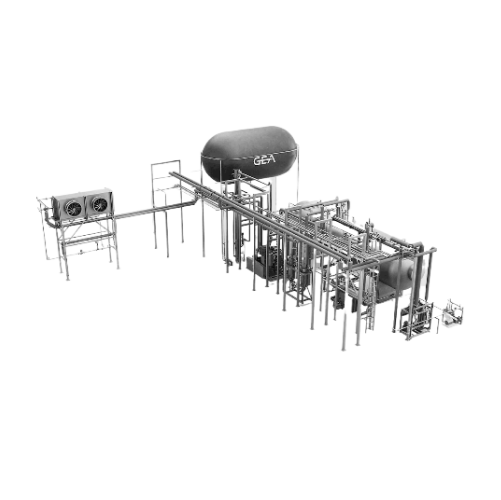

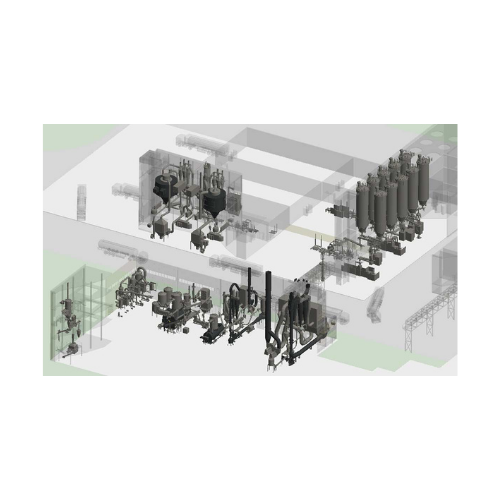

Turnkey food and beverage processing solutions

Optimize your production line with integrated processing systems designed t...

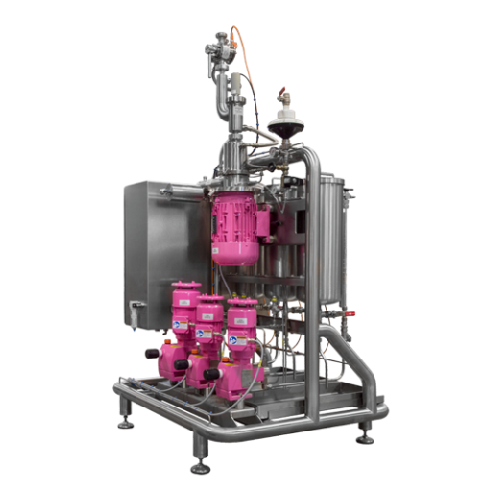

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

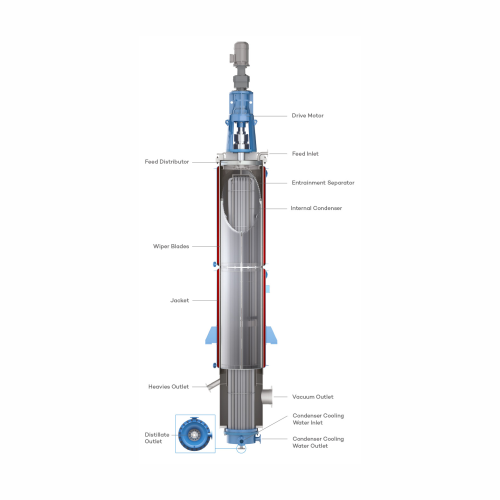

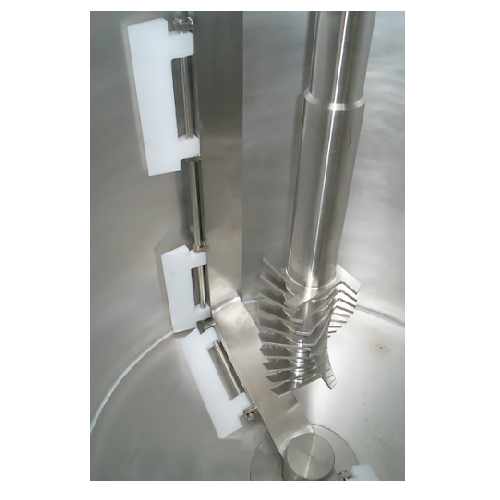

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

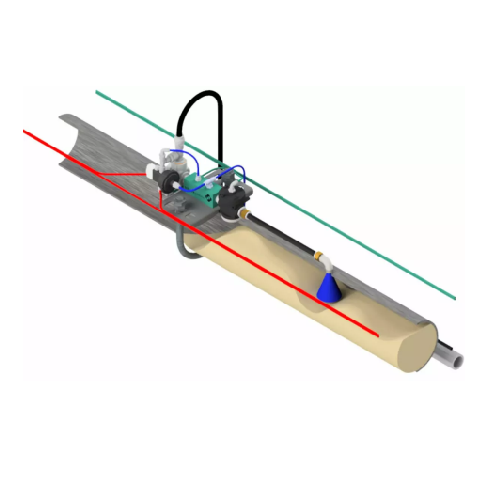

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

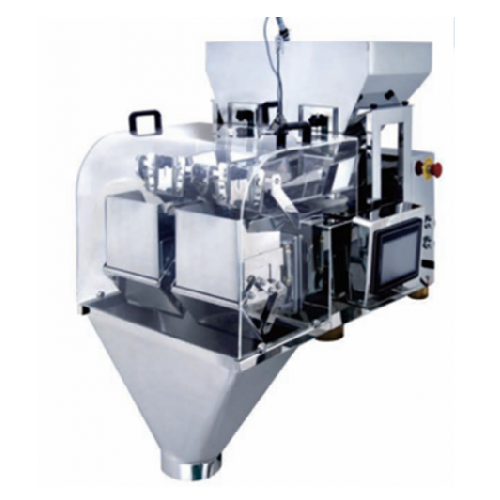

Linear vibratory weigh filler for fragile food products

Achieve precise and gentle filling of fragile food products with ...

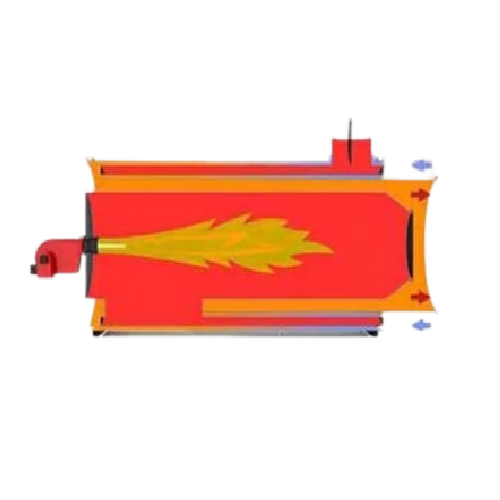

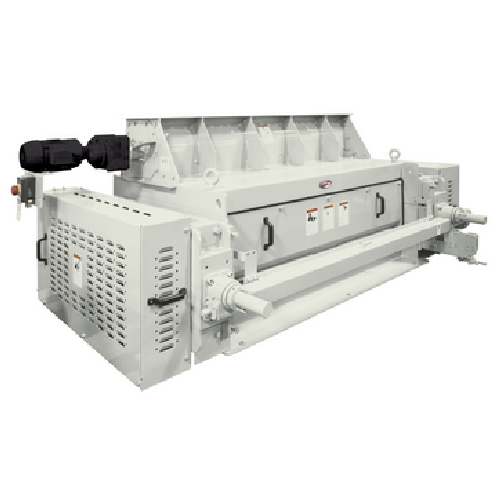

Hot start conditioner for feed and food processing

Enhance your production process with a high-efficiency thermal heating...

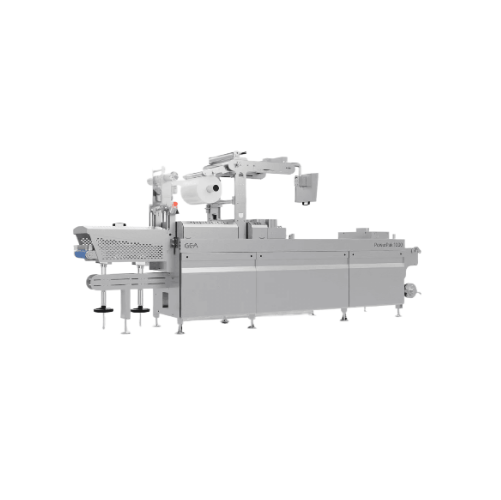

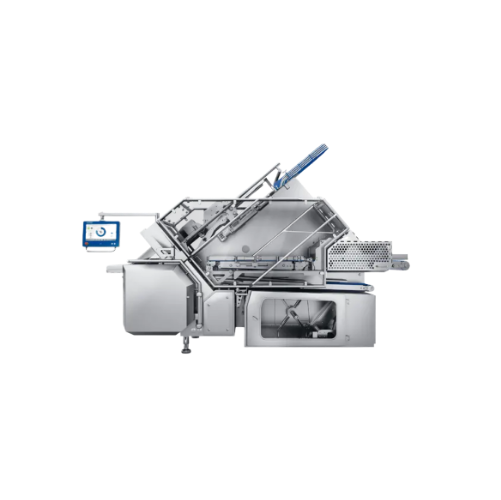

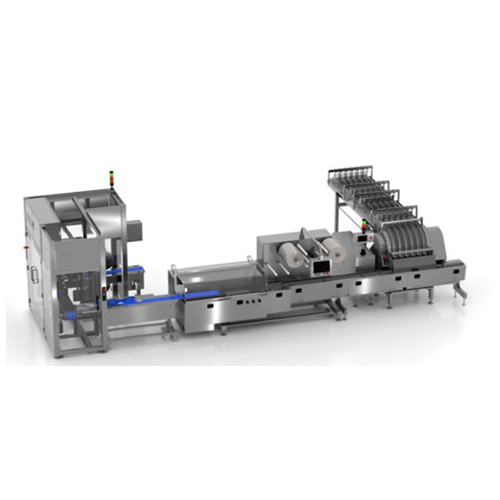

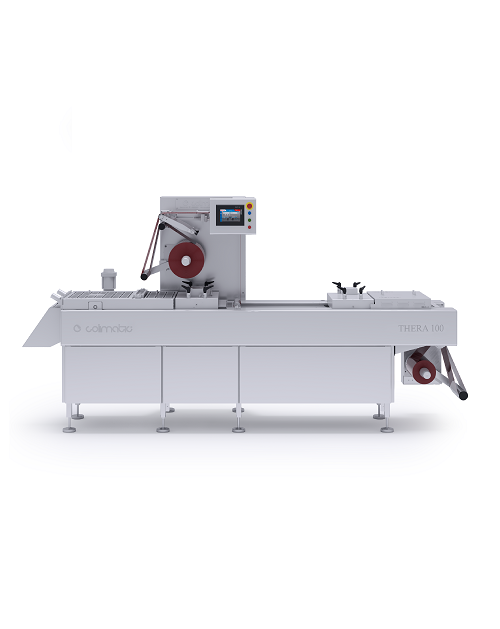

Vacuum packaging system for food products

Optimize your packaging process with high-speed vacuum technology designed to pr...

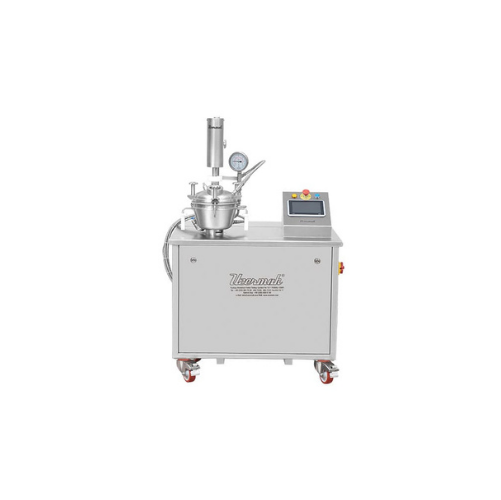

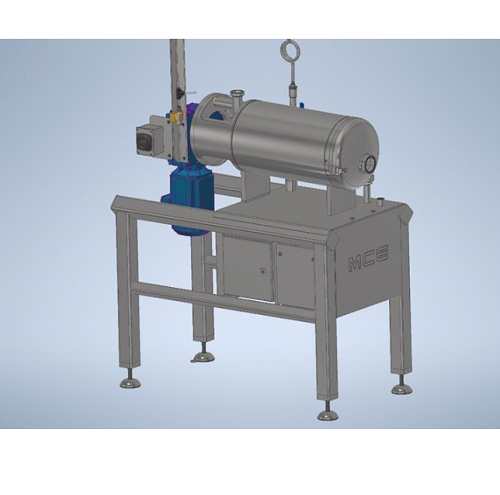

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

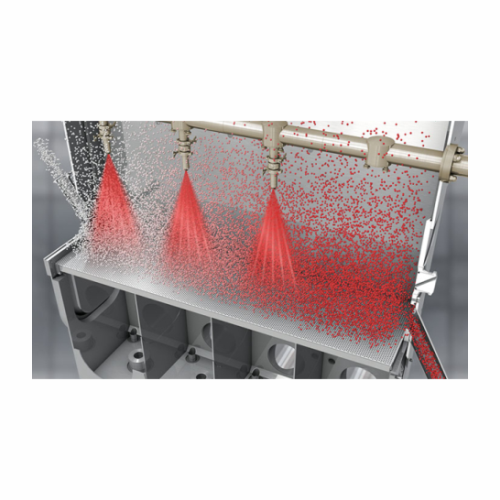

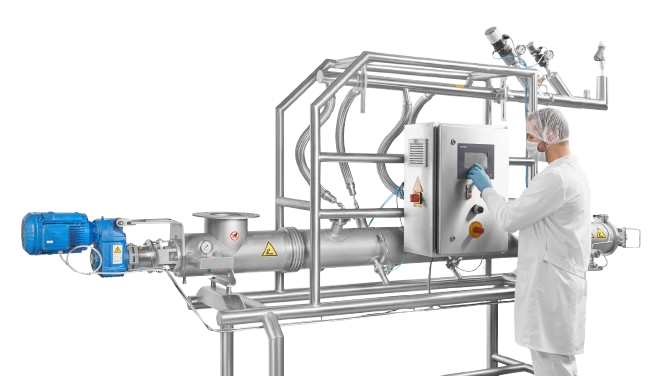

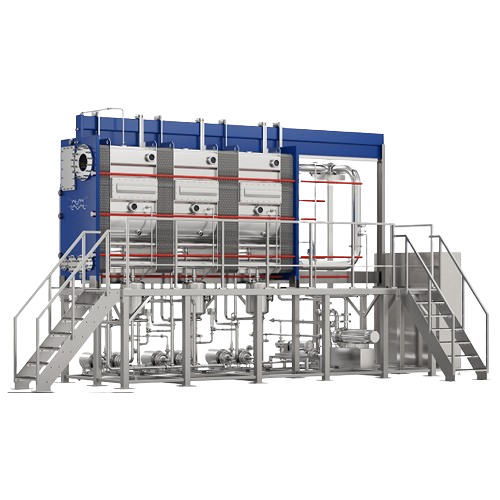

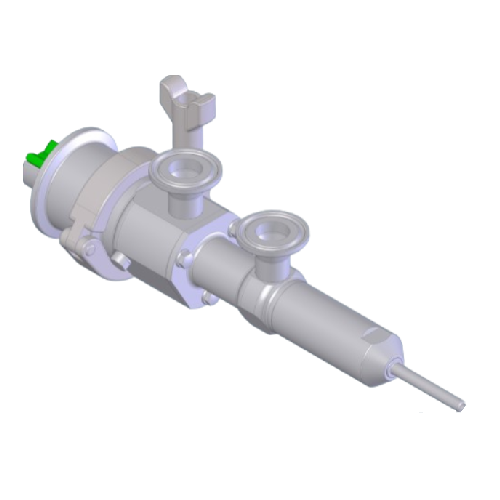

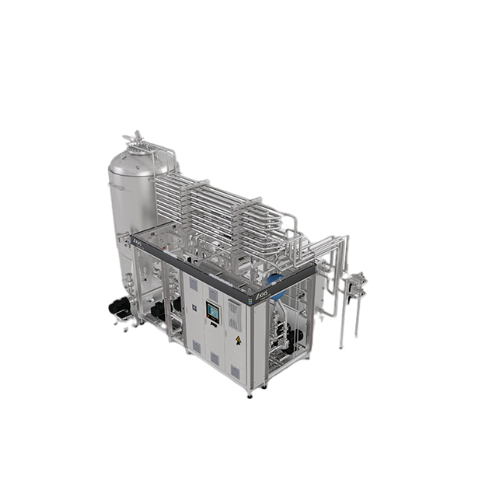

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Fully automated cleaning in place unit for food processing plants

Enhance food safety and streamline operations with a ...

Crown cork sealer for liquid food packaging

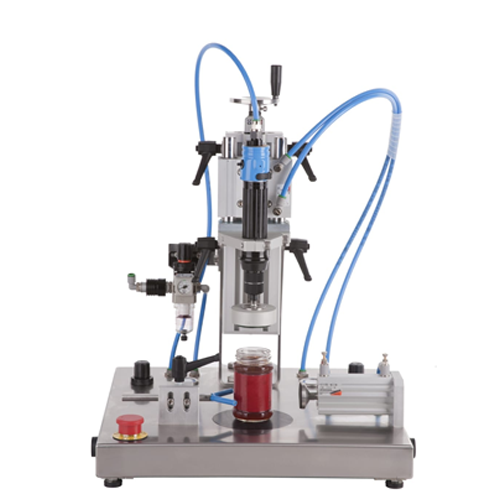

Ensure reliable sealing for bottled beverages and dairy with a compact, table-...

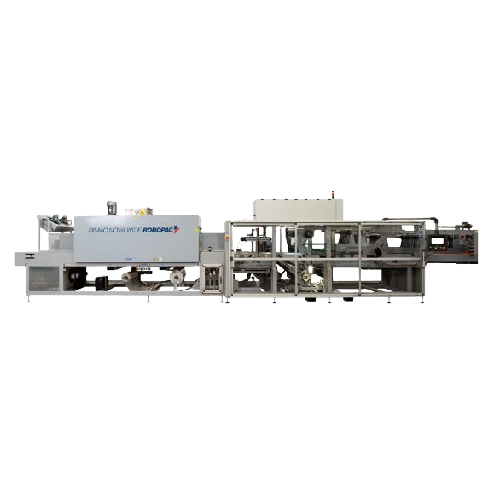

Shrink wrap packer for beverage and food industries

Optimize your production line efficiency with a versatile packer capa...

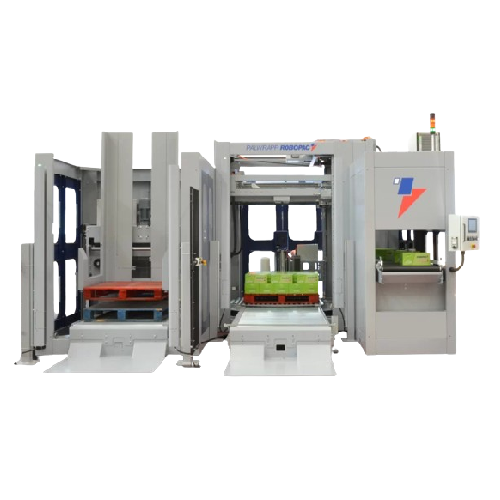

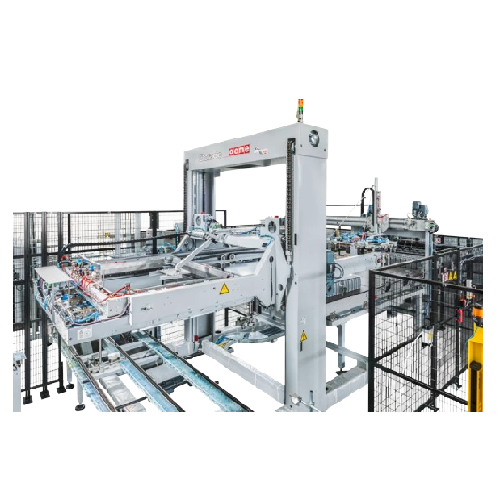

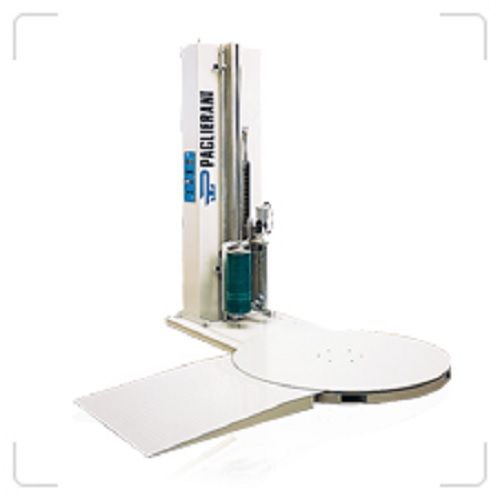

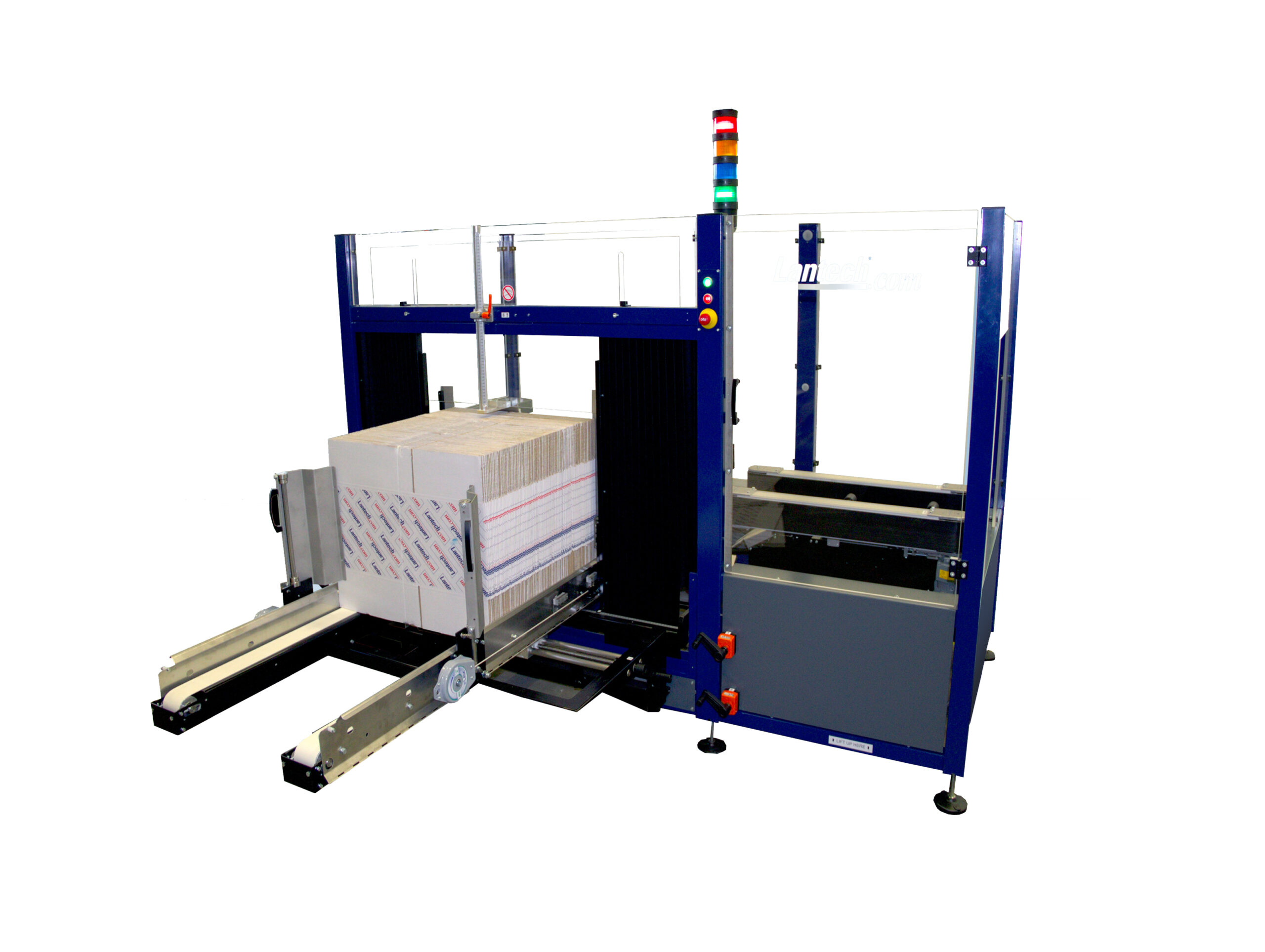

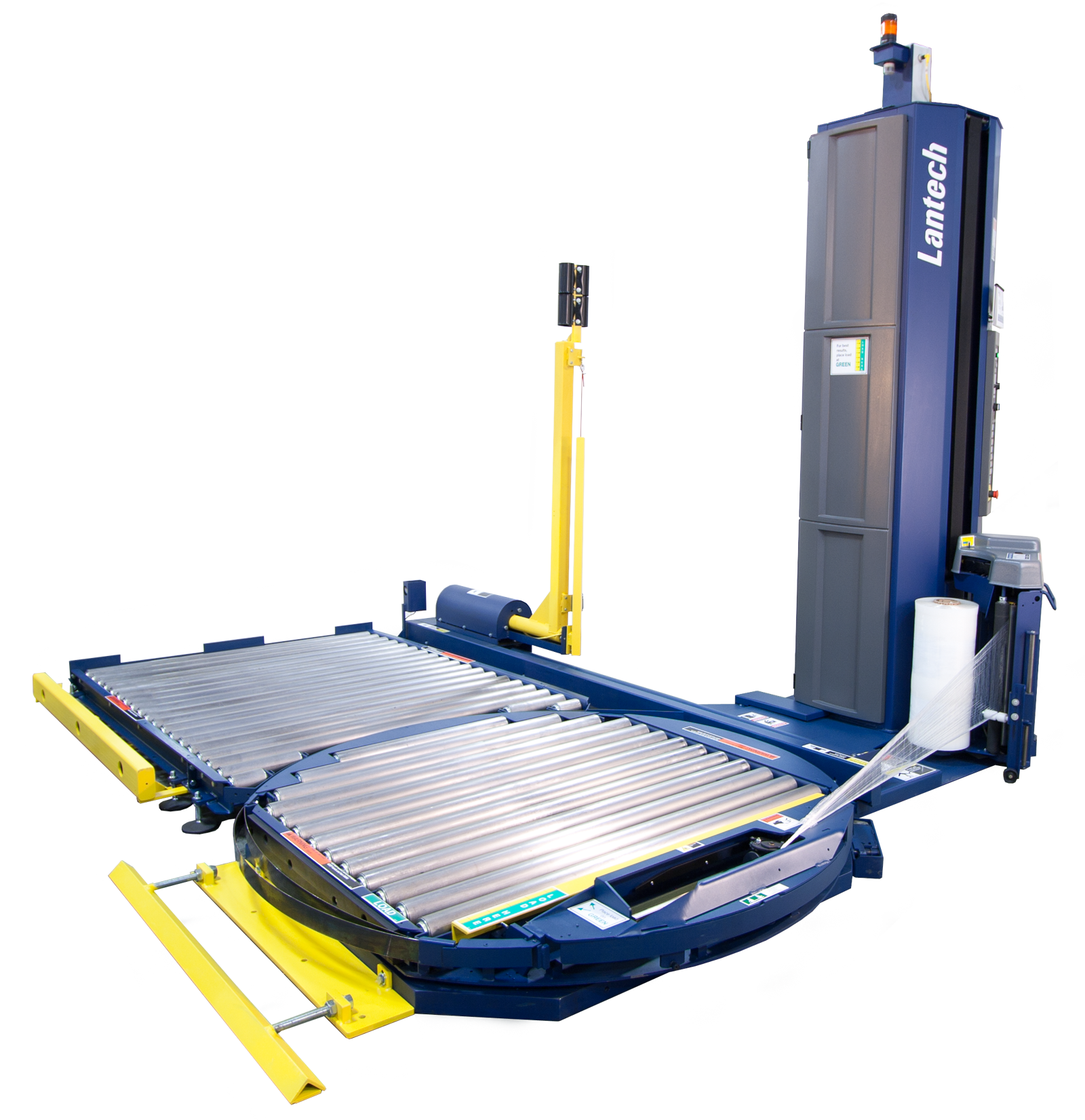

Automatic stretch wrapper for food and beverage industry

Optimize your packaging line with a high-speed stretch wrapper t...

Medium-speed shrink wrapper and case packer for food industry

Optimize your packaging line with a combined solution that...

Medium-speed automatic shrink wrapping systems for food and dairy

Optimize your packaging line with this flexible shrin...

Medium-speed wrap around case packer for food and dairy industries

Optimize your end-of-line efficiency with a reliable...

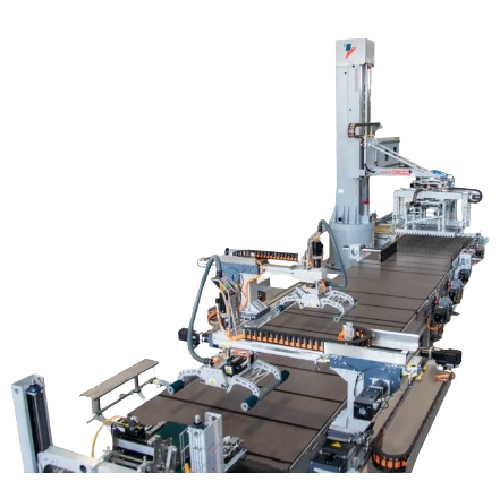

Compact and modular palletizer for food industry

Optimize your end-of-line efficiency with this modular palletizing soluti...

Horizontal stretch-film wrapping system for frozen food

Optimize your packaging line with a high-speed solution that secu...

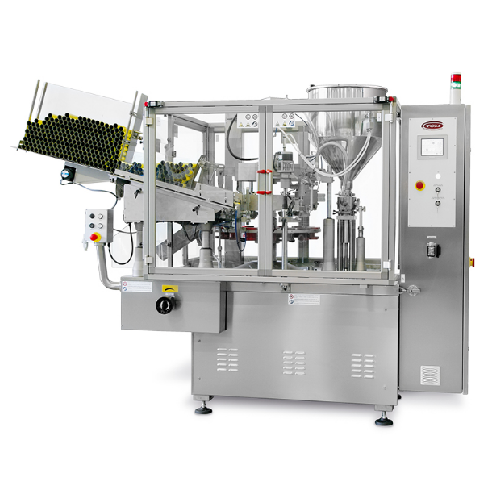

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

Automatic traysealer for food packaging

Optimize your packaging efficiency with this advanced traysealer, designed to enhan...

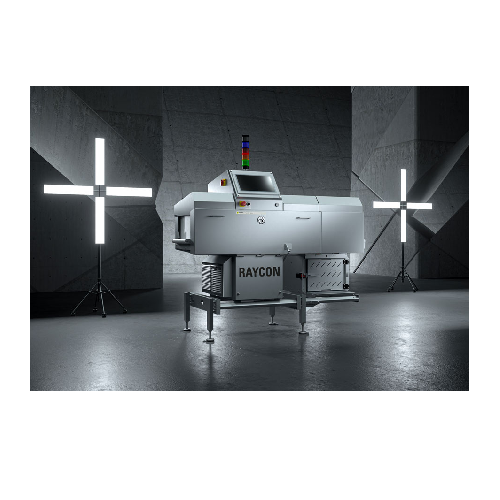

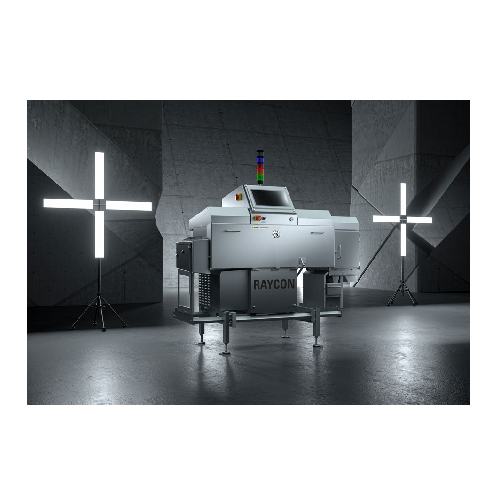

X-ray inspection system for food packaging

Ensure product integrity and safety with advanced detection of foreign bodies i...

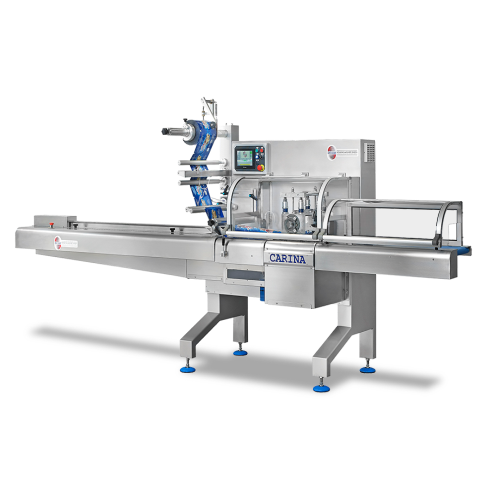

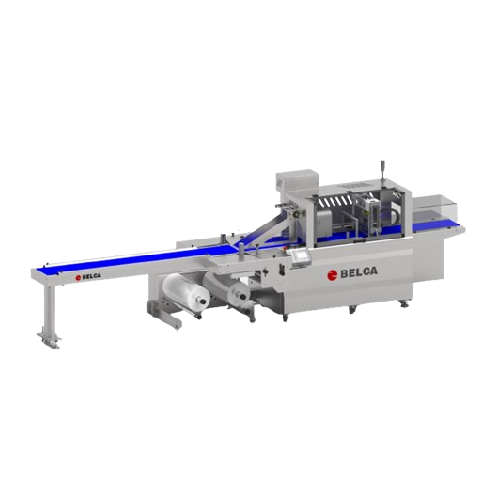

Flowpackers for efficient food packaging

Achieve seamless packaging with flowpackers designed for high-speed, sustainable o...

Industrial shrink and drying units for food products

Ensure optimal product integrity and extended shelf life by seamless...

Belt loaders for automated food packaging

Streamline your packaging line with precision-engineered belt loaders, designed ...

Automated conveyor systems for food packaging lines

Seamlessly integrate high-speed product transport and handling into y...

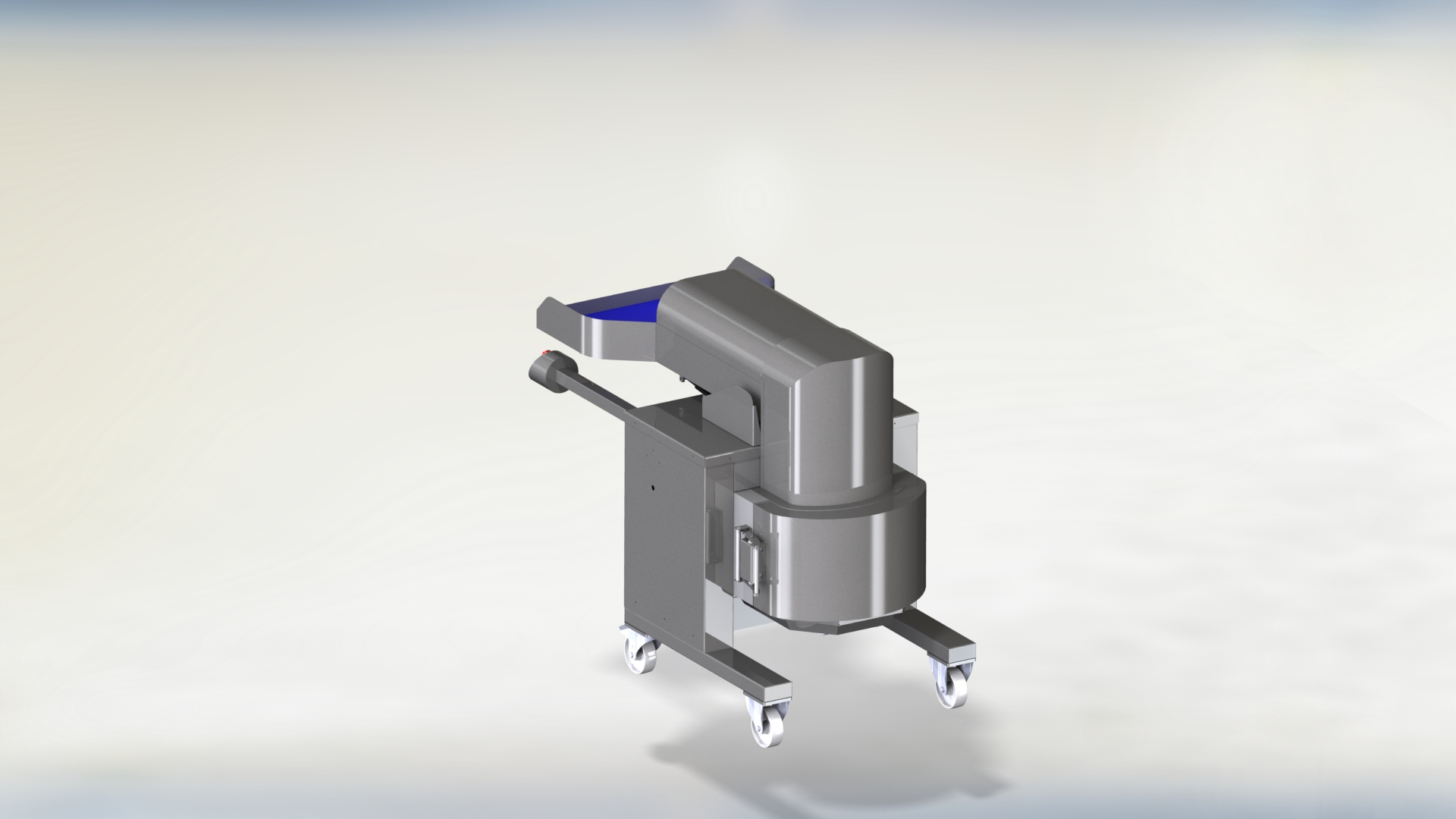

Food cutter for professional kitchens

Optimize your food preparation with precision mincing, cutting, and homogenizing, pre...

Professional food cutter for various ingredients

Streamline your food preparation with a versatile cutter designed to effi...

Automatic onion peeler for industrial food processing

Optimize your vegetable preparation process with this machine that ...

Flake ice maker for food processing applications

Ensure optimal product preservation and temperature control with precisio...

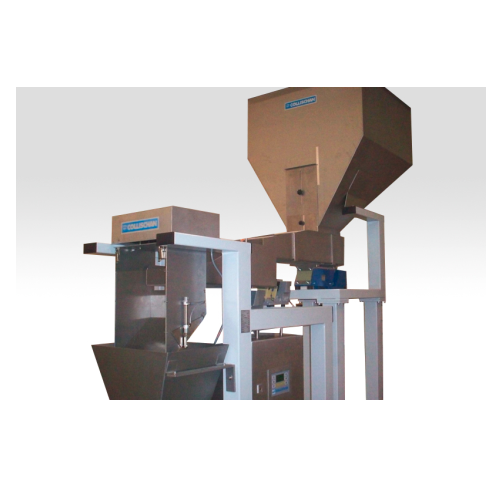

Accurate batching system for prepared foods

Streamline your food production with high-accuracy batching, minimizing rework...

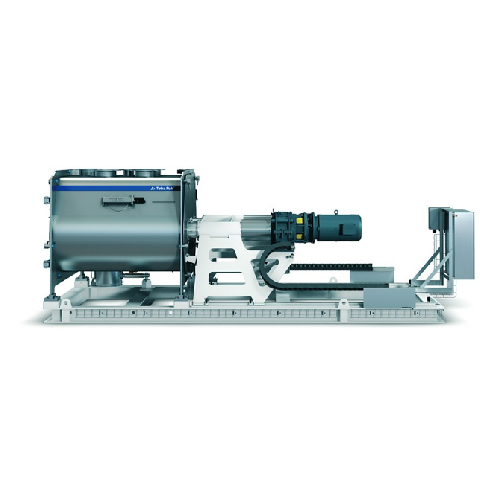

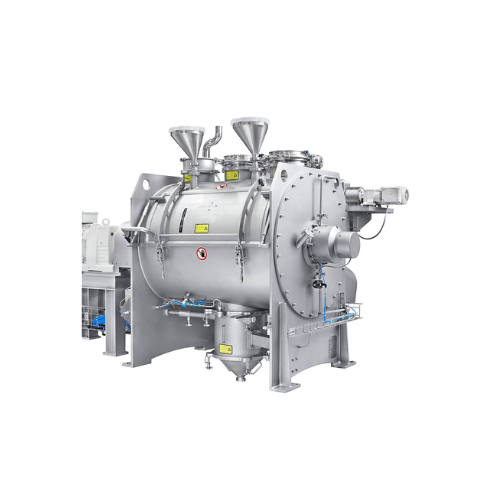

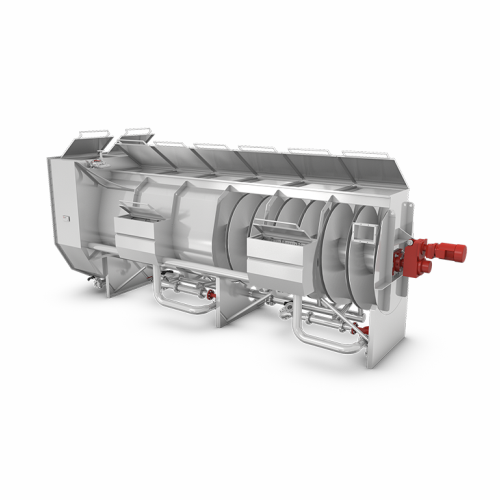

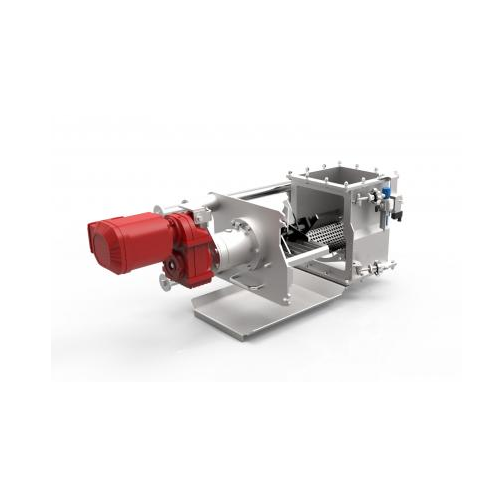

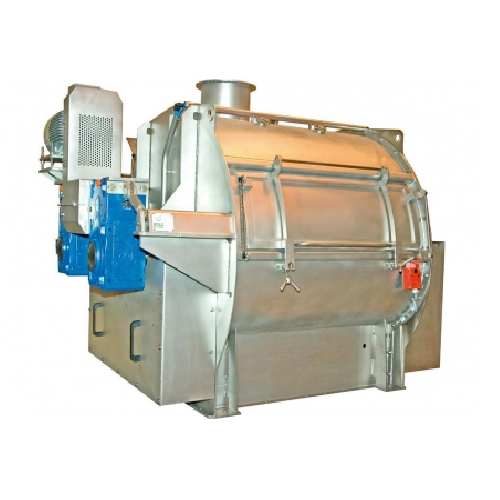

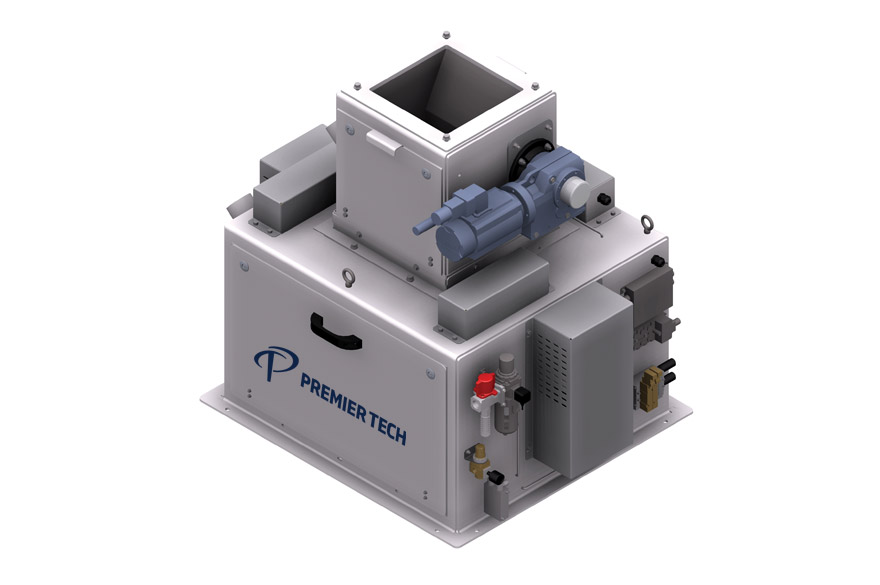

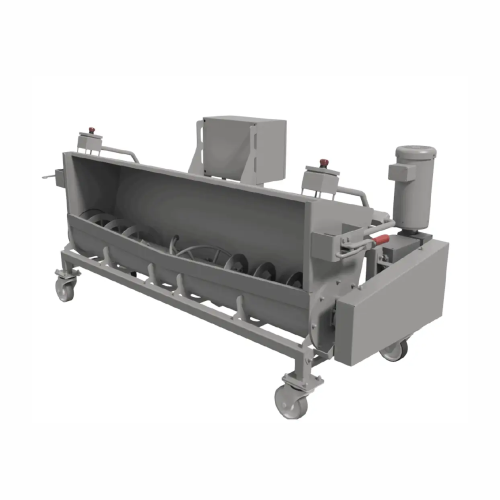

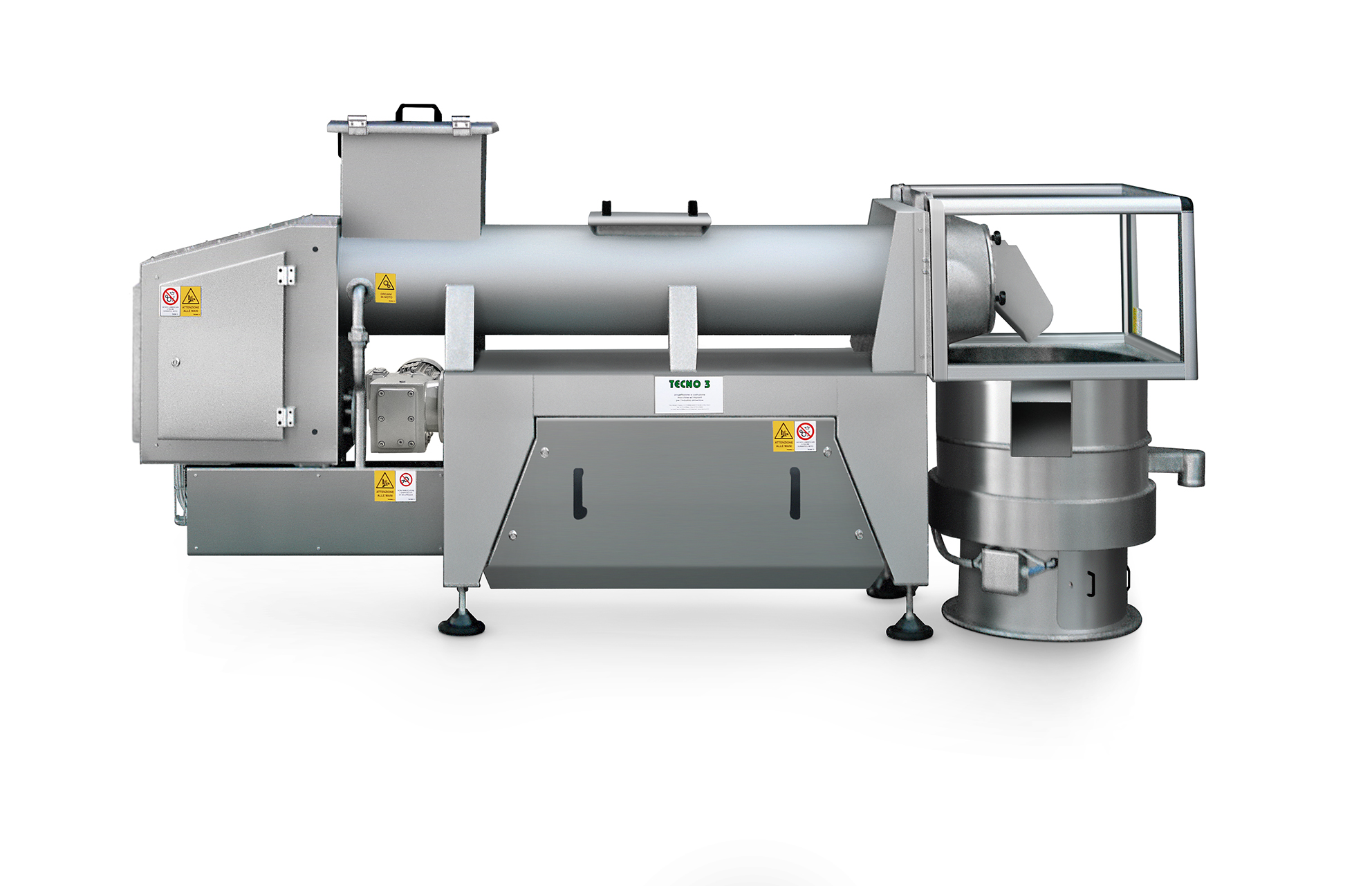

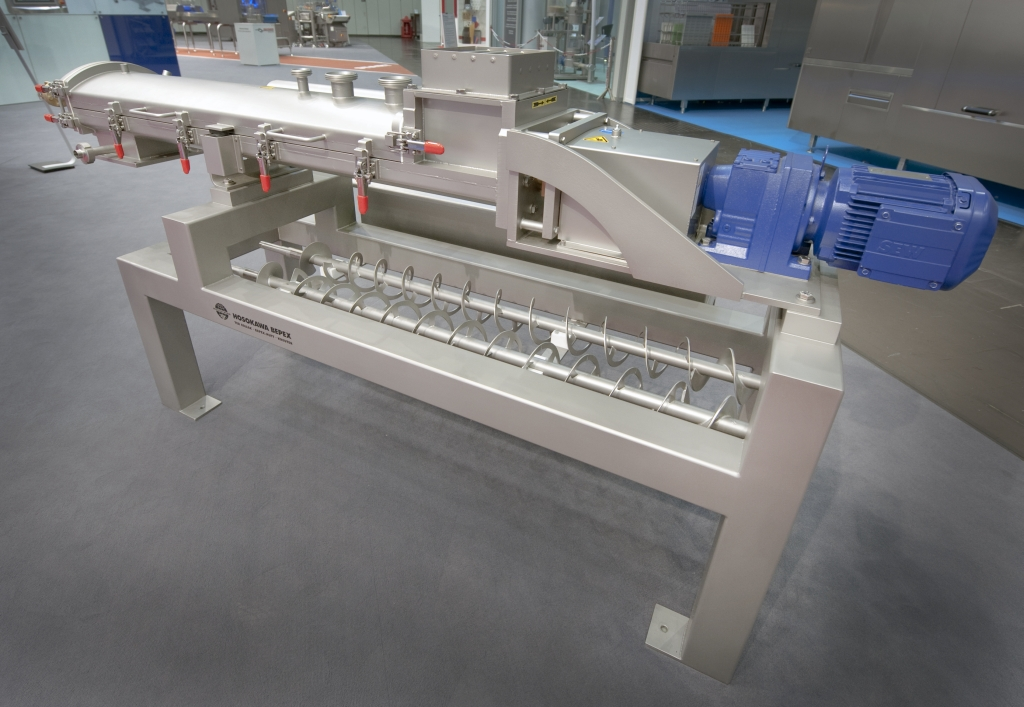

Industrial double shaft mixer for food processing

Ensure precise mixing in industrial food production with this double sh...

Flake ice producer for food-safe ice

Enhance your production line with hygienic flake ice, optimized for energy efficiency ...

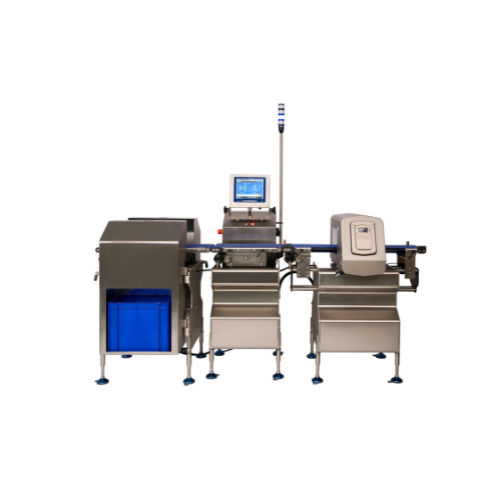

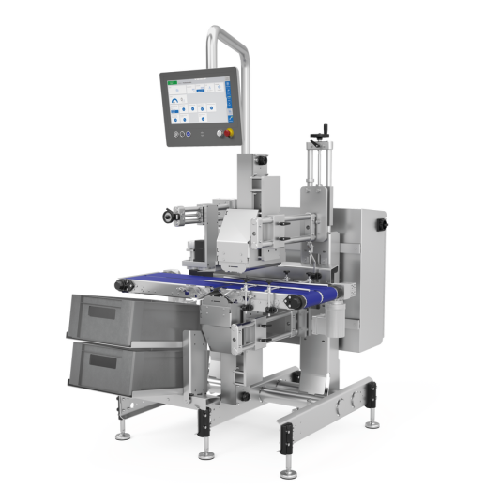

Checkweigher for food processing compliance

Ensure accurate package weights while preventing underweight or overweight pro...

Industrial mixer-grinder for food processing

Streamline your processing line with a robust mixer-grinder that combines eff...

Oven for high-yield cooking of prepared foods

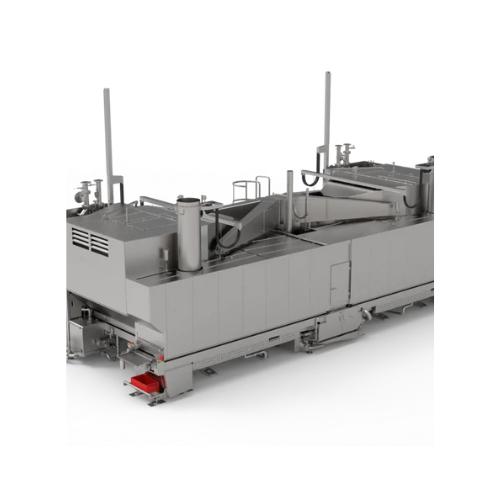

Achieve unparalleled consistency and enhanced yield in food production with ...

Modular industrial oven for high-yield food processing

Need a solution that offers high-yield roasting and precision cook...

Weigh price labeler for retail food products

Achieve consistent, high-speed labeling and pricing with precision—streamlini...

Industrial fryer for uniformly cooked convenience foods

Ensure perfectly fried textures and flavors with cutting-edge oil...

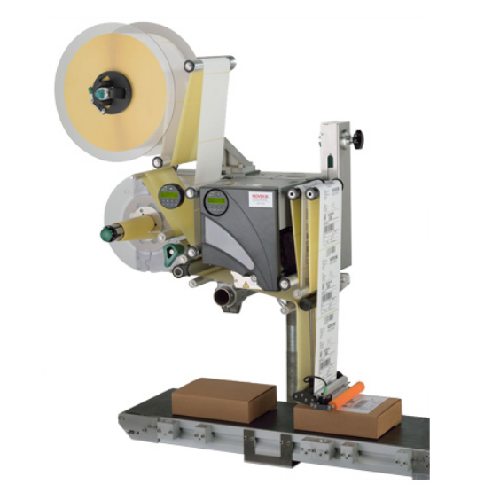

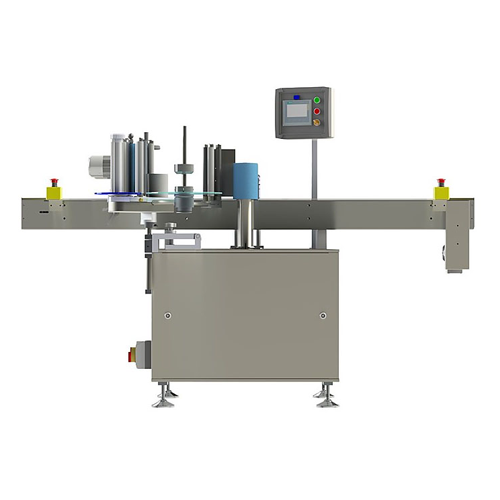

Automatic label applicator for food packaging

Enhance your packaging line with precise, high-speed labeling, ensuring your...

Flour applicator for convenience foods and snacks

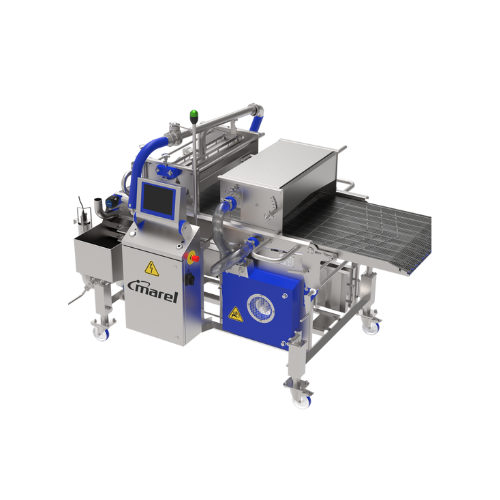

Achieve uniformly coated products, such as chicken nuggets and fish fil...

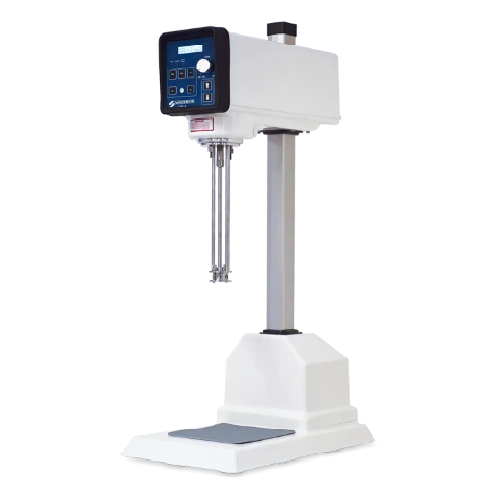

Semi-automatic batter mixer for prepared food production

Achieve consistent, high-quality batter for a variety of conveni...

Pouch cooling system for food processing

Experience rapid cooling for your pouched food products, minimizing time in the ba...

Industrial food cooler for pasta, rice, and vegetables

Rapidly reduce temperatures to halt cooking and preserve quality i...

Rapid food cooling solution for vegetables and pasta

Efficiently reduce the temperature of particulate foods with rapid p...

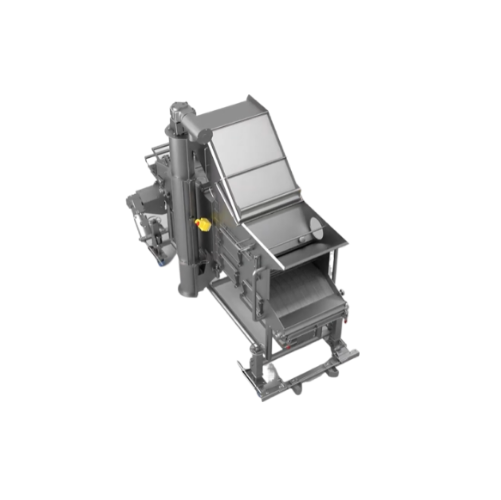

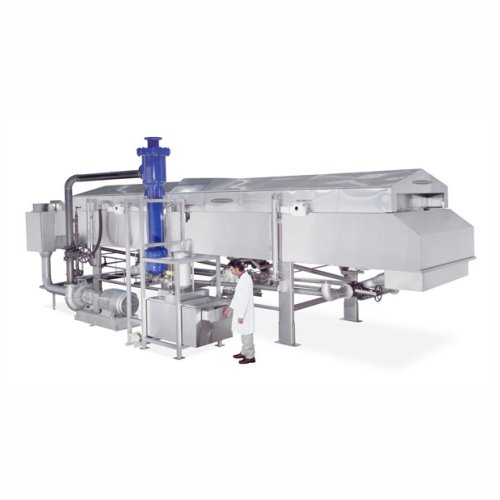

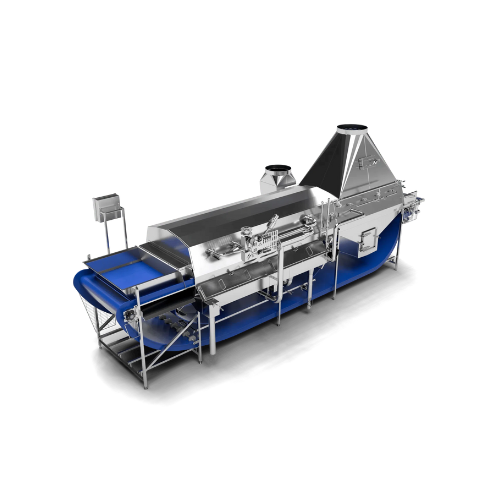

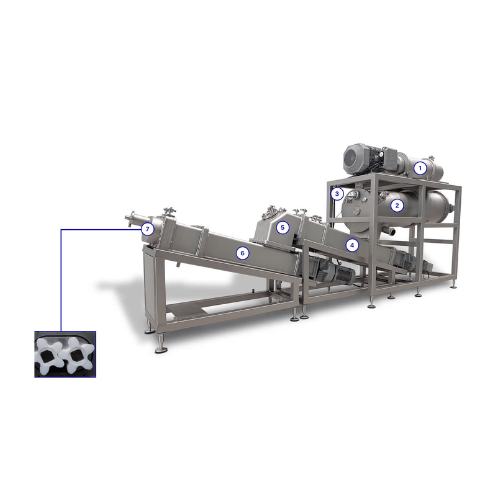

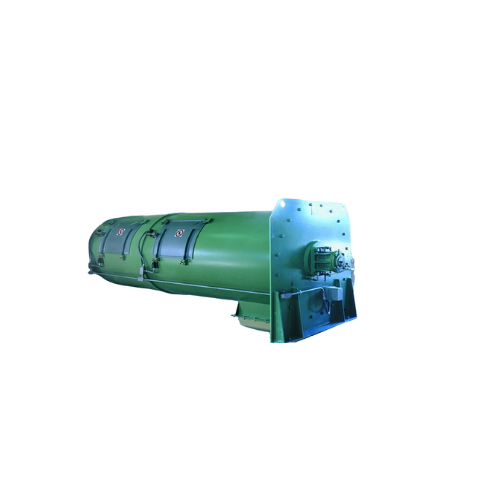

Rotary drum blancher for high volume food processing

Optimize your food production line with a versatile rotary drum blan...

Rotary drum blancher for industrial food processing

Optimize your food processing line with a robust solution that ensure...

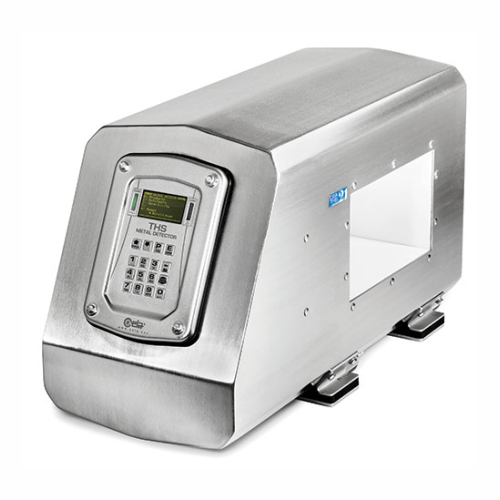

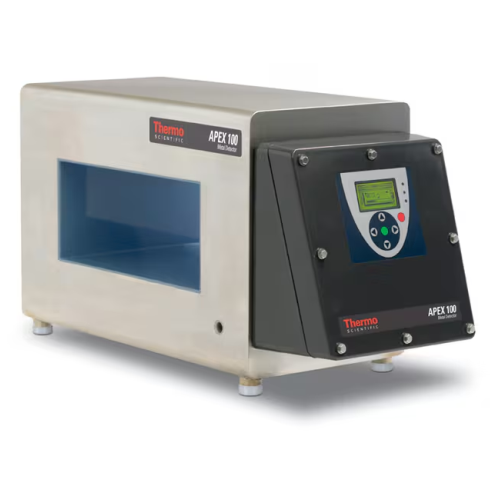

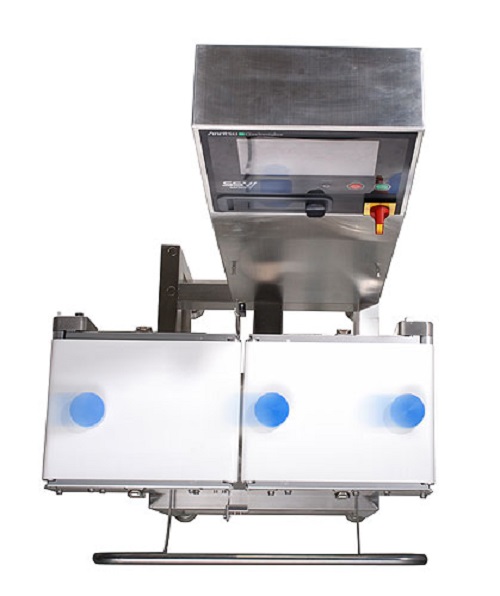

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Conveyorized food metal detector for high-care environments

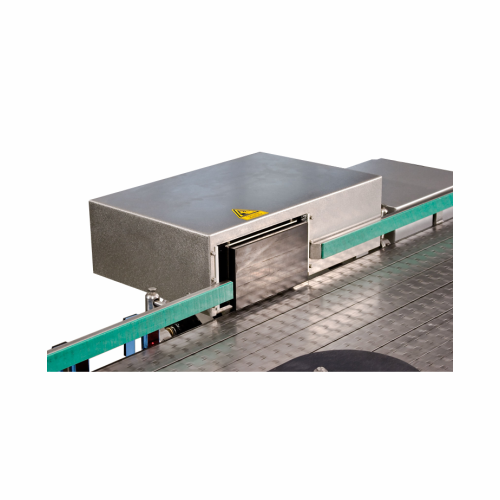

Ensure food safety with advanced metal detection tailored fo...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

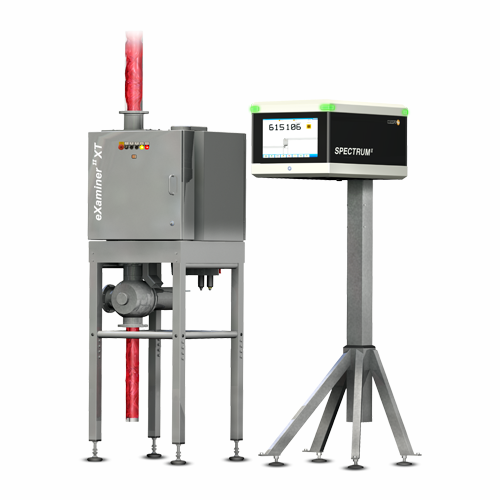

Ensure contaminant-free loose products by integrating a versatile inspecti...

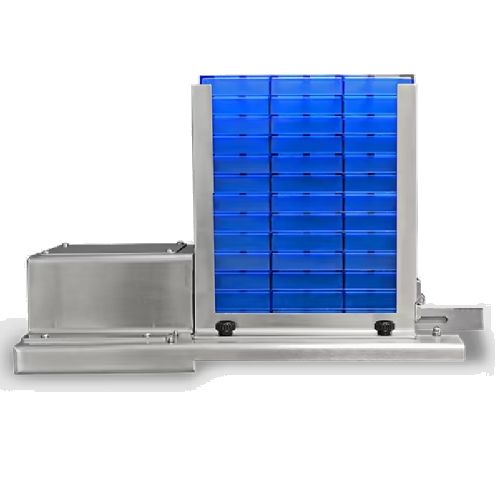

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

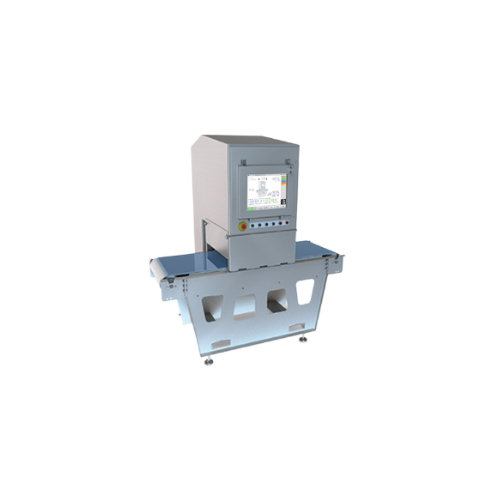

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

Checkweigher for high-care food environments

For facilities needing precision and hygiene, this high-care checkweigher ens...

High-care food processing combination system with metal detection

Optimize your high-care food environment with a robus...

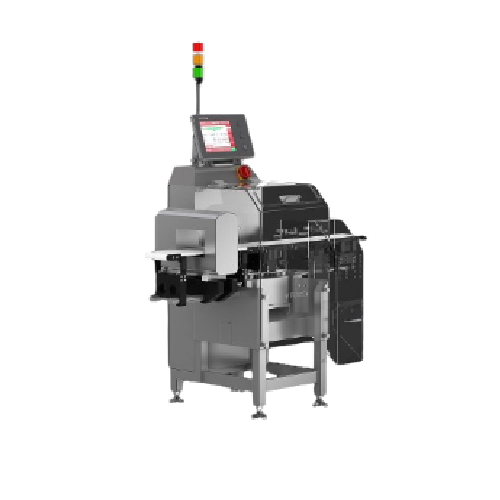

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Cryogenic freezer for food processing

Achieve rapid, precise freezing for your diverse food production needs, ensuring qual...

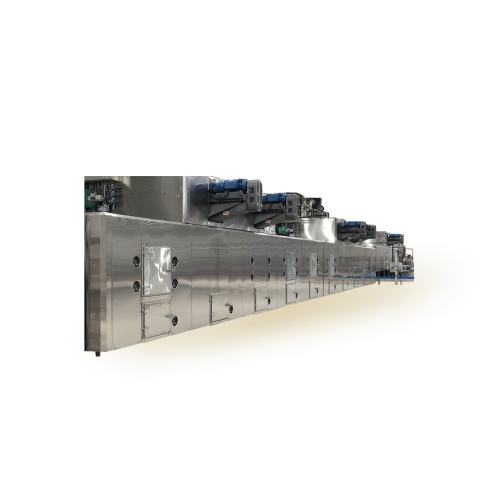

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

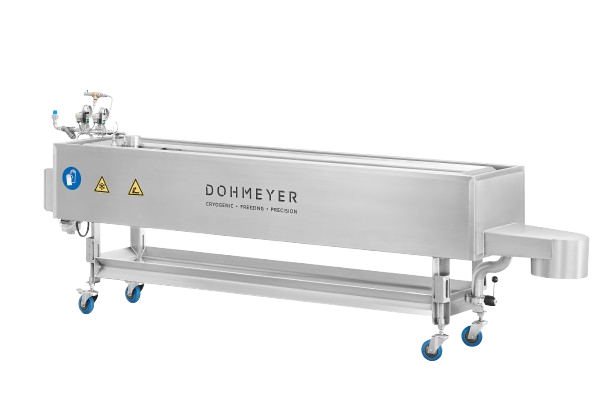

Cryogenic tunnel freezer for continuous food processing

Optimize product quality and retention with advanced cryogenic fr...

Cryogenic freezing systems for food processing

When you need precise and rapid freezing for diverse food products, these a...

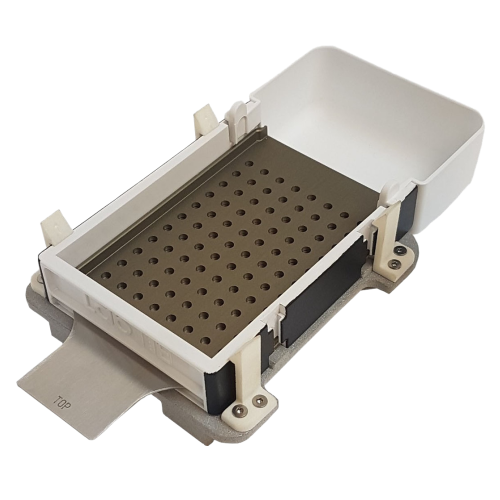

Film coater for Otc and food supplements

Achieve optimal film coating for tablets and capsules with precision-engineered so...

Cryogenic chilling systems for bulk food processing

Maintain optimal temperatures during high-volume food processing with...

Cryogenic food freezer

Achieve rapid and precise freezing for diverse food products, ensuring optimal texture and moisture re...

Cryogenic chilling systems for food processing

Efficiently maintain precise temperatures to enhance product quality and sa...

Cryogenic chilling for food processing

Optimize your food production line with cutting-edge cryogenic chilling solutions, d...

Cryogenic freezer for food industry applications

Efficiently tackle high-speed freezing and chilling challenges with a ver...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

Process mixer for food production

Optimize your production line with a versatile and adaptable process mixer that offers se...

Industrial mixer for baby food and dairy production

Optimize your production line efficiency with a versatile mixing solu...

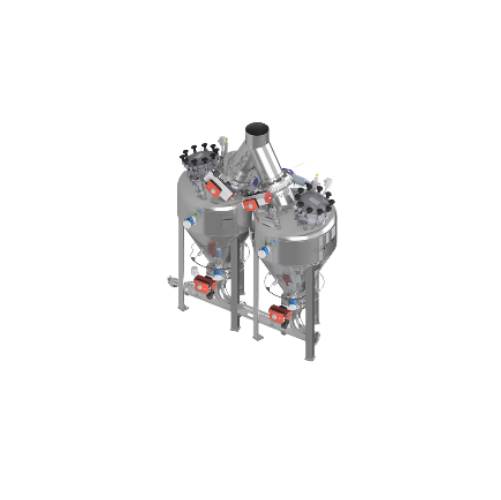

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

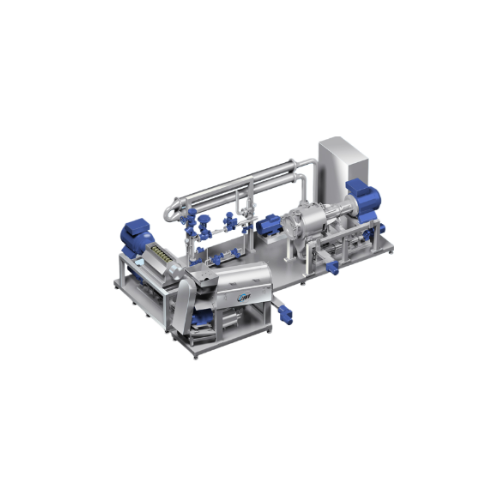

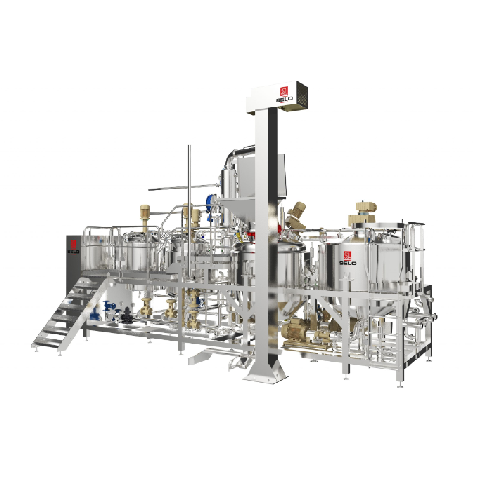

Emulsifying and blending system for liquid and semi-liquid food products

Efficiently emulsify and blend liquid and semi...

Food mixing and blending system

Enhance your production line with a versatile system designed for gentle processing needs, o...

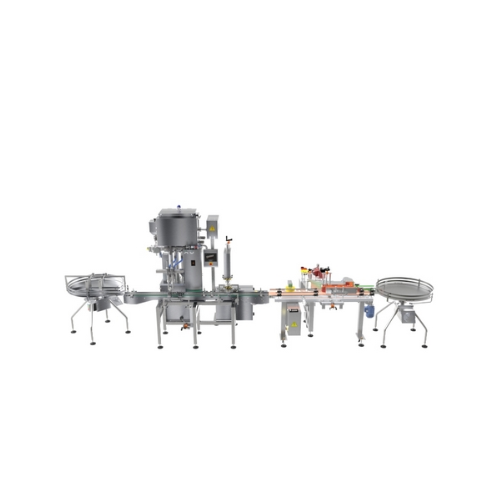

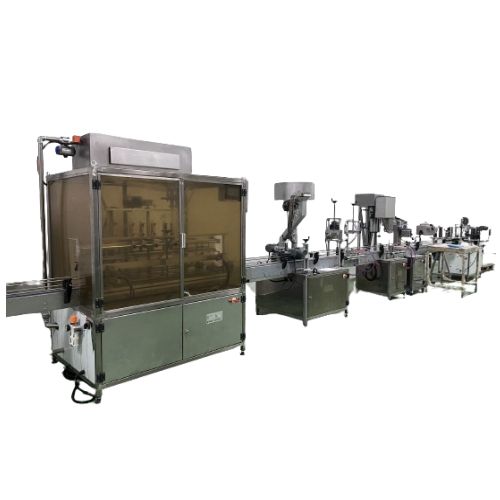

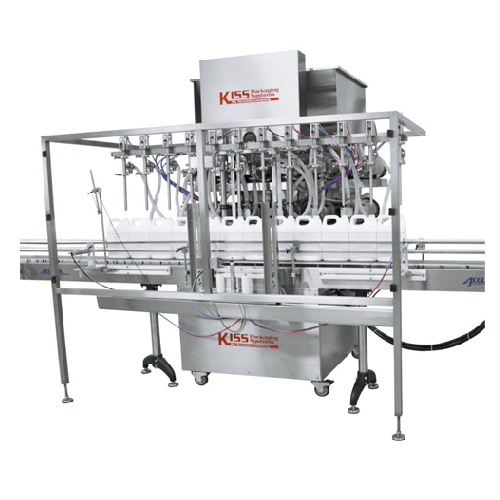

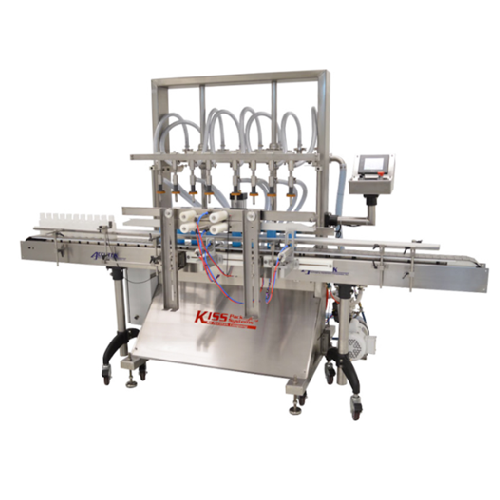

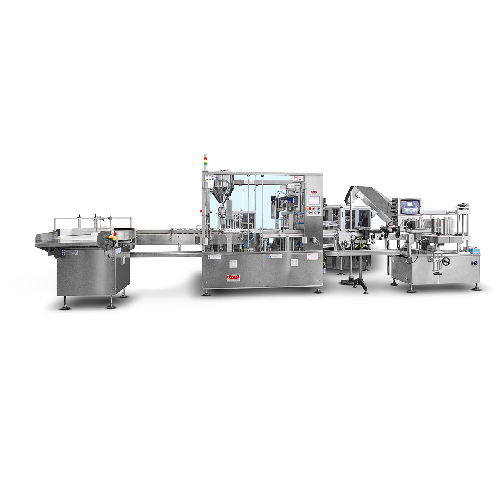

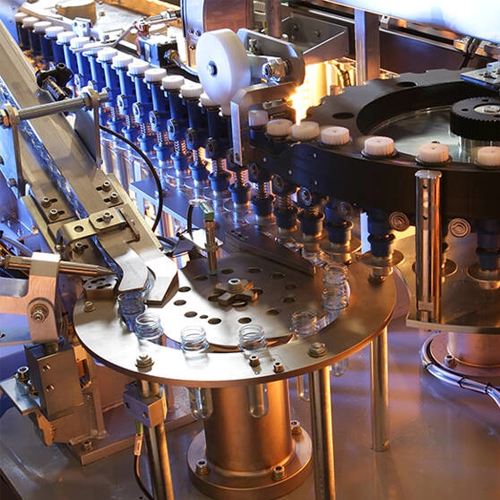

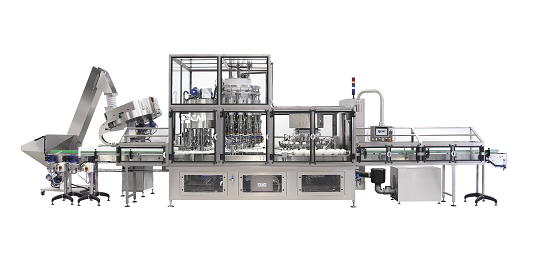

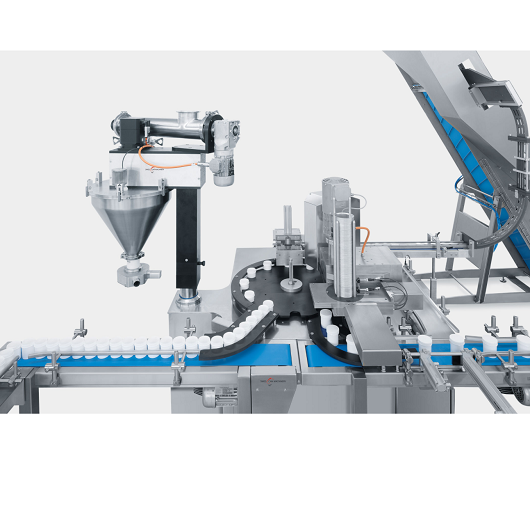

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

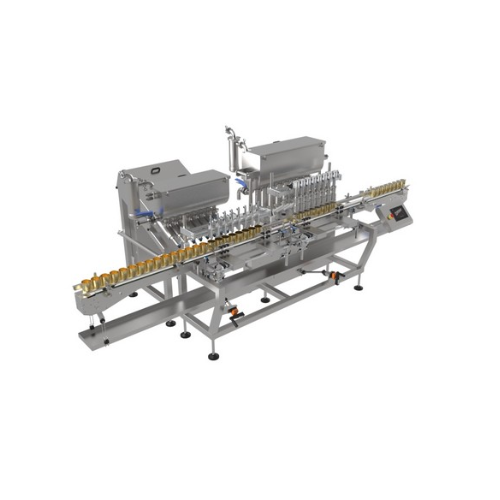

Two-component filling machines for food and beverage packaging

Streamline your filling process with precise two-componen...

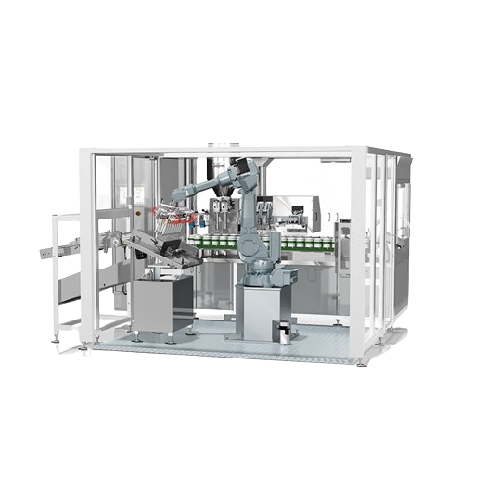

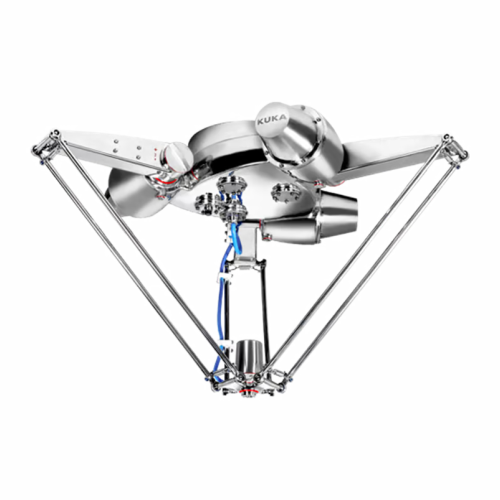

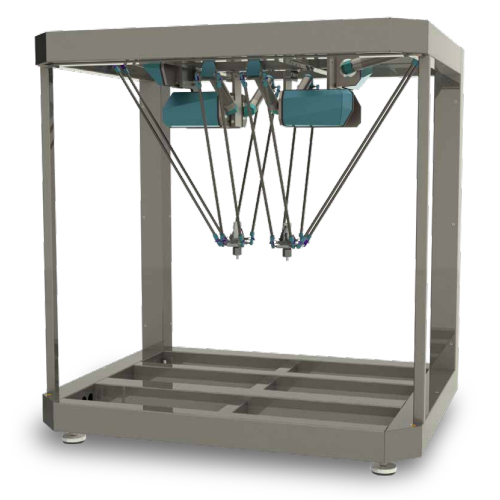

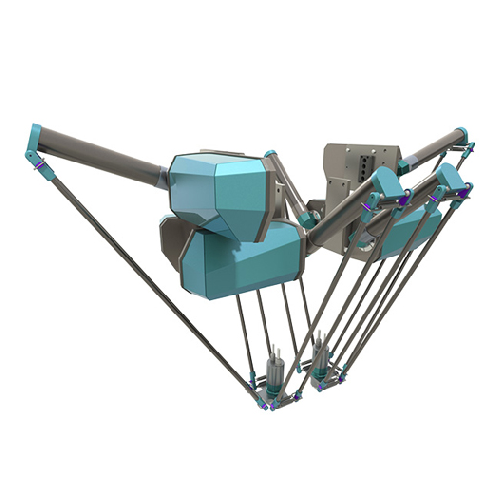

Hygienic design robot for food industry

Optimize your production line with a high-speed, hygienic design robot engineered f...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

Industrial food dehydrator for fruit and vegetables

Optimize your drying process with a high-temperature food dehydrator ...

Commercial food drum mixer for sauerkraut and salads

Streamline your batch production with this versatile commercial food...

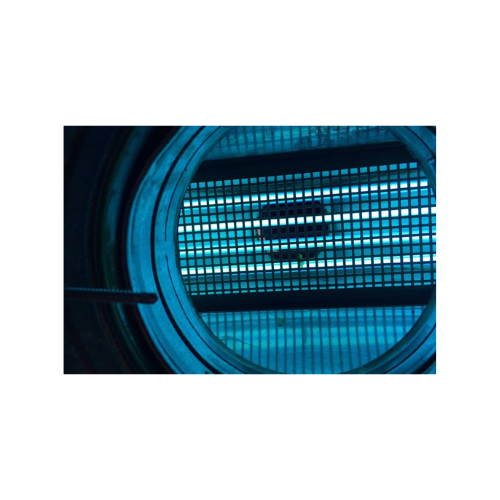

Uvc surface disinfection for food packaging and tools

Achieve fast and effective UVC disinfection of food products and pa...

Entry-level food packaging machine for pillow bags

Achieve space-saving packaging versatility with a machine designed for...

Continuous packaging solution for free-flowing food products

Streamline your production with a high-speed packaging mach...

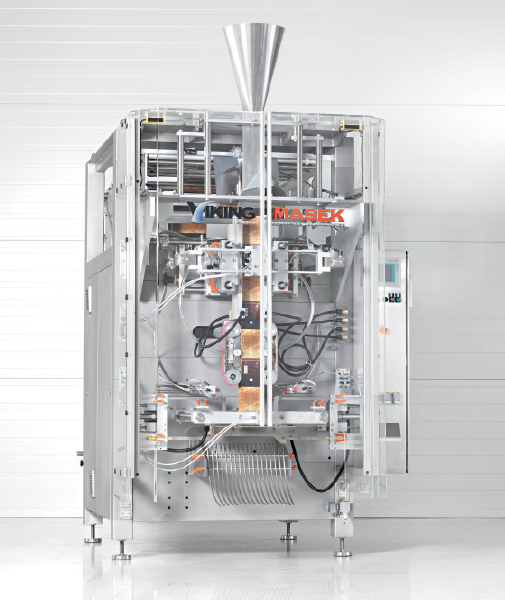

Flexible packaging solution for large food volumes

For high-volume food packaging, achieving consistent bag sizes and red...

Hollow fiber membranes for clarification in food and beverage industry

Optimize filtration and separation processes wit...

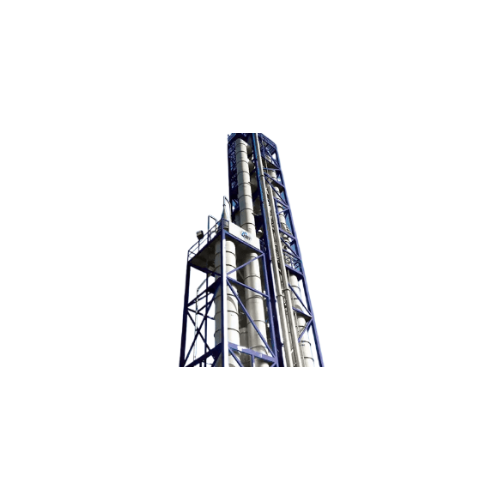

Tall form bustle dryer for dairy and food products

Experience efficient drying and precise moisture control with this inn...

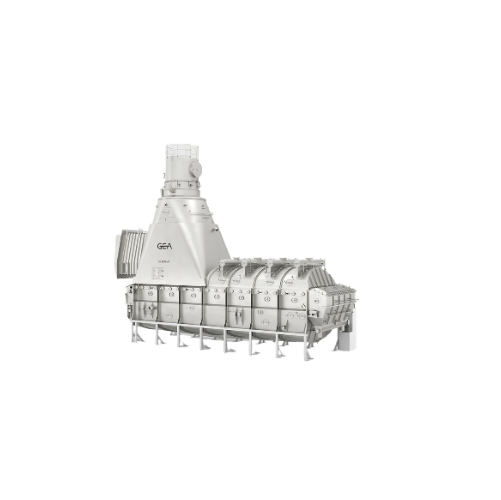

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy an...

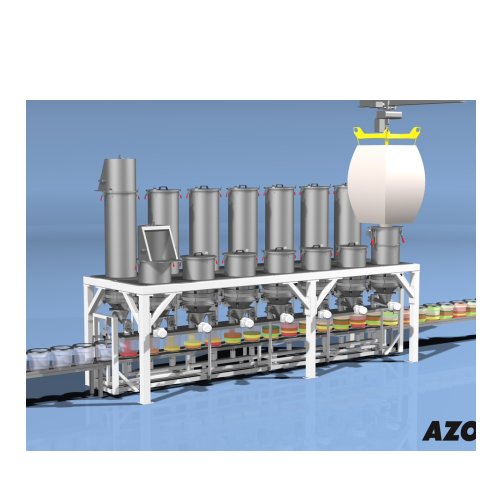

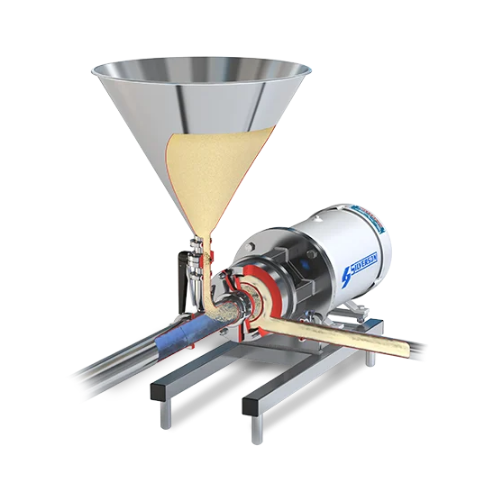

Food dosing systems for industrial applications

Optimize your food production efficiency by minimizing waste with precisio...

Industrial freezing tunnel for food products

Achieve rapid and precise freezing of diverse food products while maintaining...

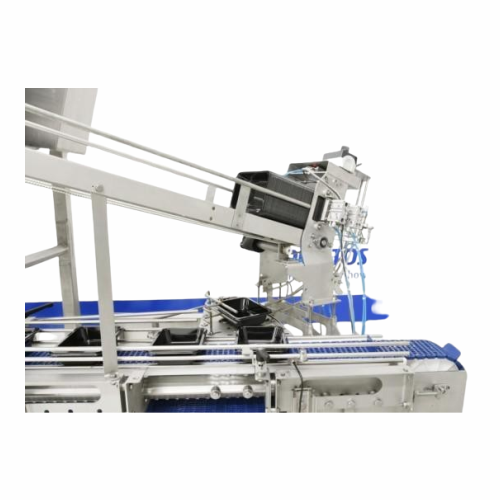

Tray handling equipment for food packaging

Optimize your food production with adaptable tray handling units that streamlin...

Cip cleaning system for food and beverage production lines

Ensure microbiological safety and maintain quality standards ...

Twin-column palletizer for beverage and food packaging

Achieve seamless operation with a flexible twin-column design that...

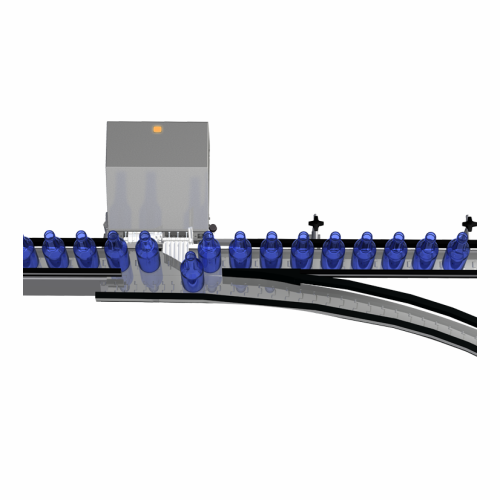

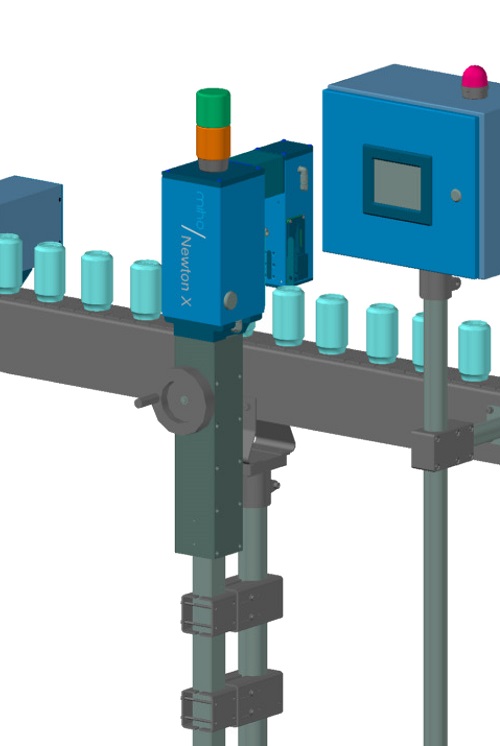

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

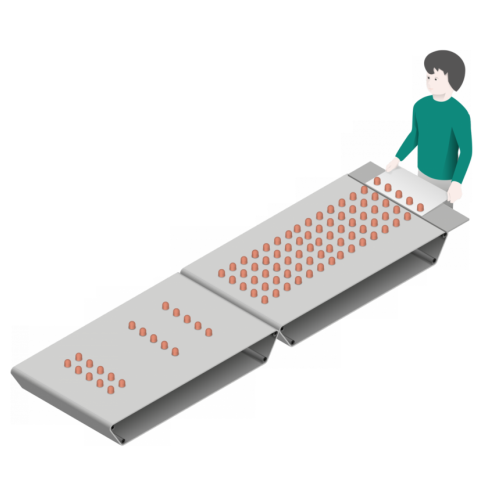

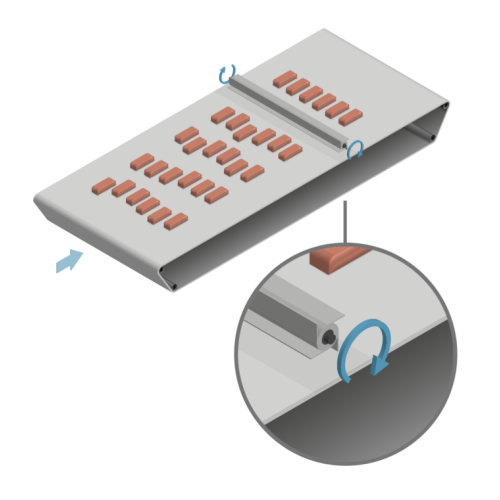

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

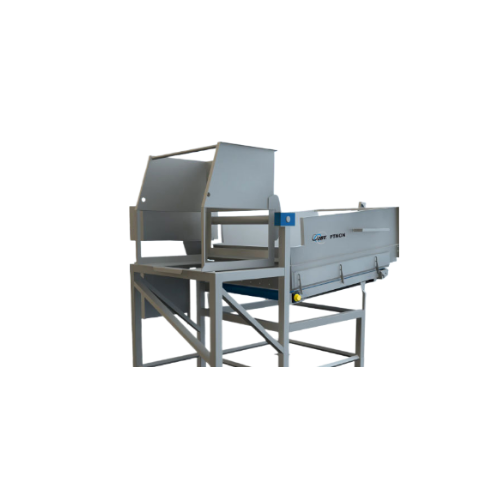

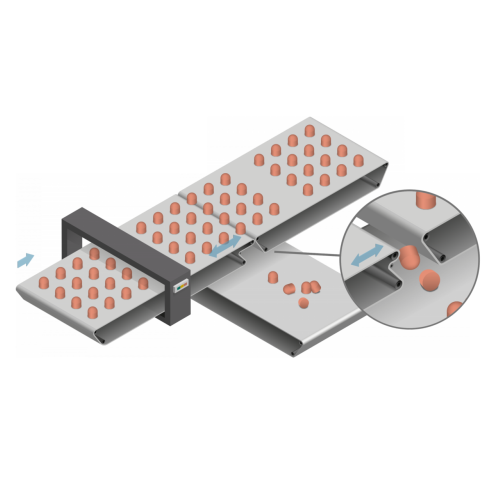

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

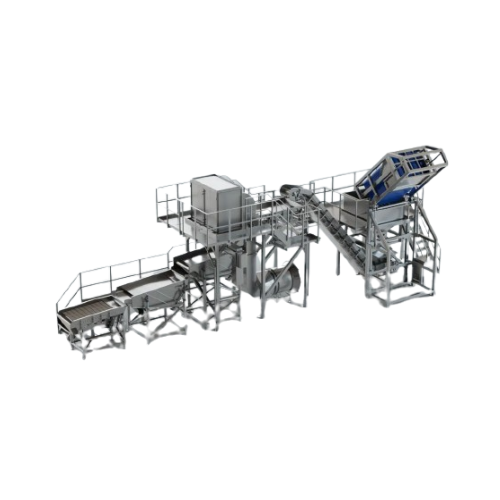

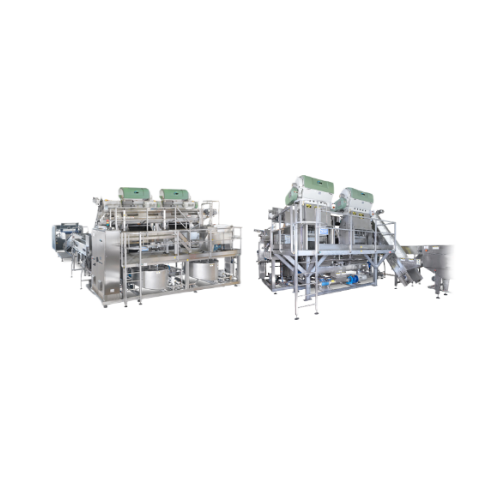

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

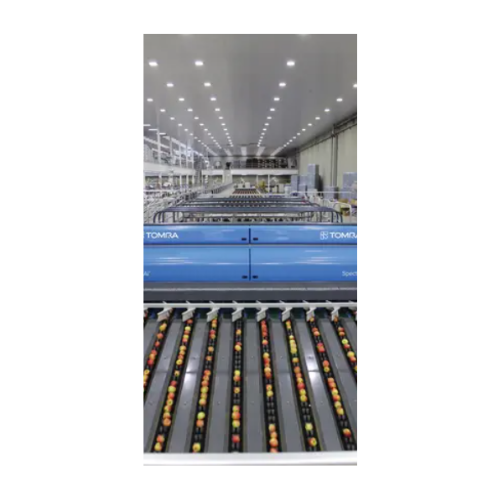

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

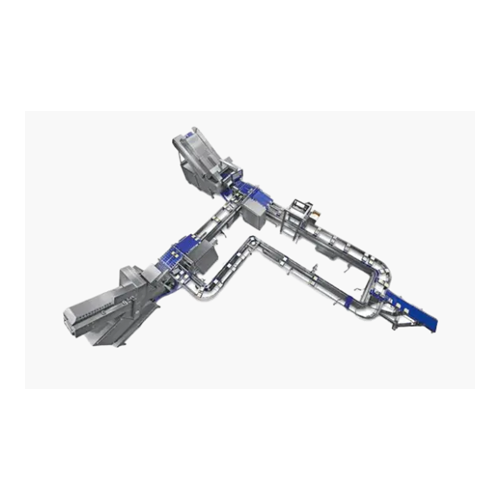

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

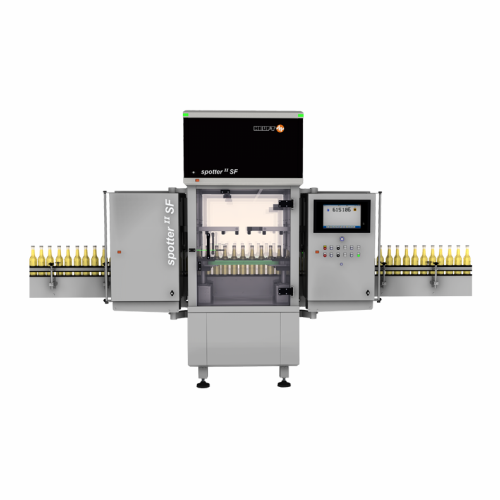

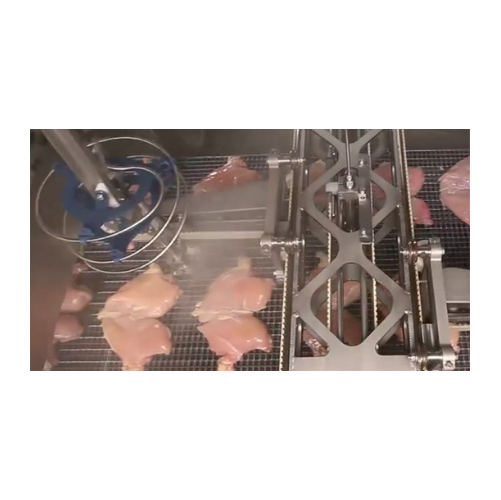

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

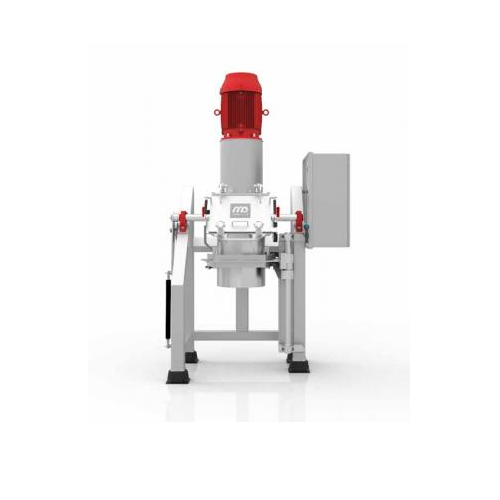

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

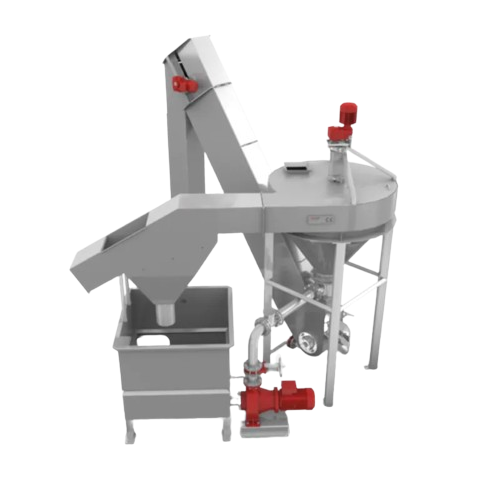

Bag dump station for handling solid foodstuffs

Efficiently manage manual dosing of solid foodstuffs and powders with this ...

Crossflow filter for liquid filtration in food industry

Enhance your liquid filtration process with a versatile crossflow...

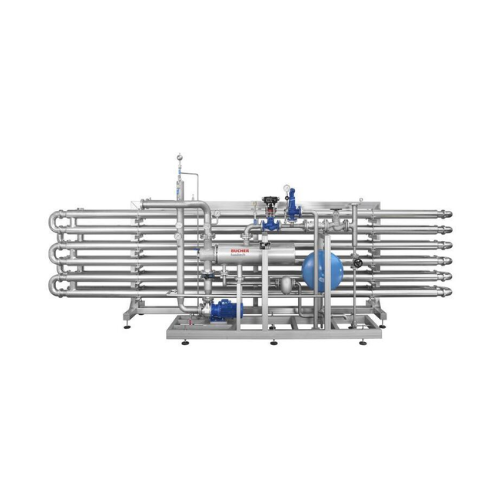

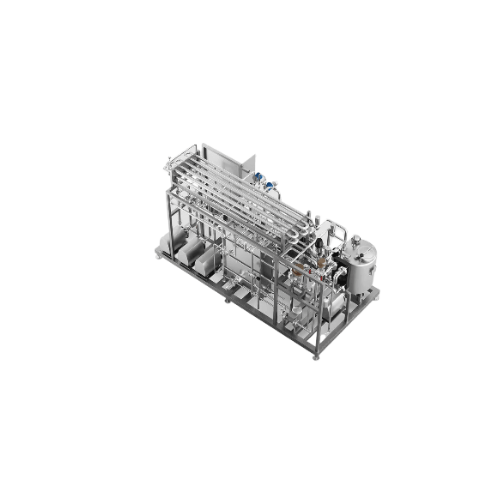

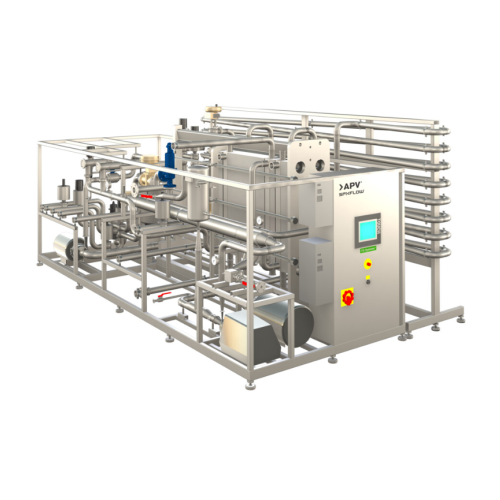

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

Powder liquid blender for food processing

Achieve seamless integration of solids into liquids with precision-engineered bl...

Manual Cip system for food processing hygiene

Designed for small-scale hygiene needs, this mobile clean-in-place system en...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

High-speed pouch filling and sealing system for food and dairy

Achieve precise spouted pouch filling with minimal waste ...

Flow wrapping system for hygienic food packaging

Enhance your packaging line with a modular flow wrapping solution that en...

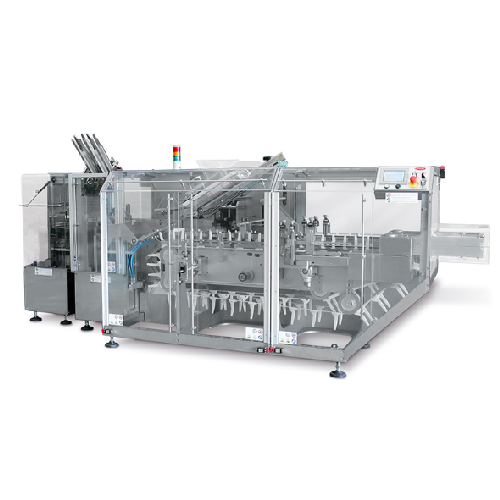

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

Map flow wrapper for chilled food packaging

Optimize your chilled food packaging with a flow wrapping solution that easily...

Over wrapping solution for foodstuffs and beverages

Optimizing film over wrapping for challenging thin materials, this co...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Traysealer for modified atmosphere packaging - food products

Optimize your packaging line with this semi-automatic trays...

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Traysealer for small scale food packaging

Improve your production efficiency with a compact traysealer designed for versat...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

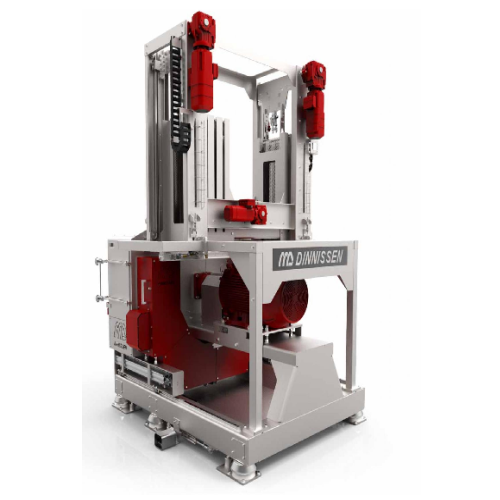

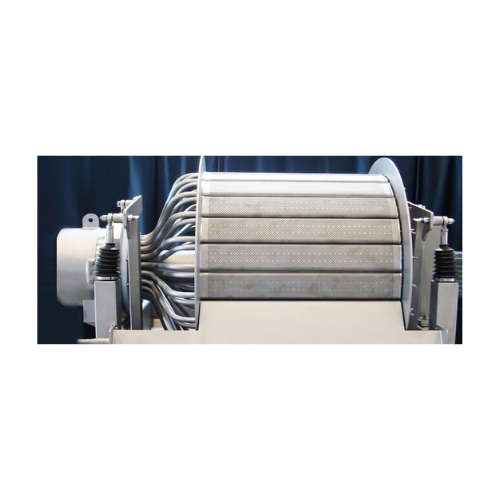

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Traysealer for food packaging with rotating table

Enhance your packaging line efficiency with a traysealer that simultane...

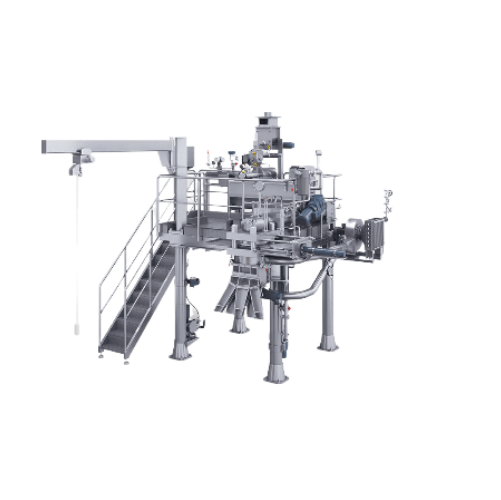

Multifunctional batch cooker for various food products

Optimize your production line with a versatile batch cooker design...

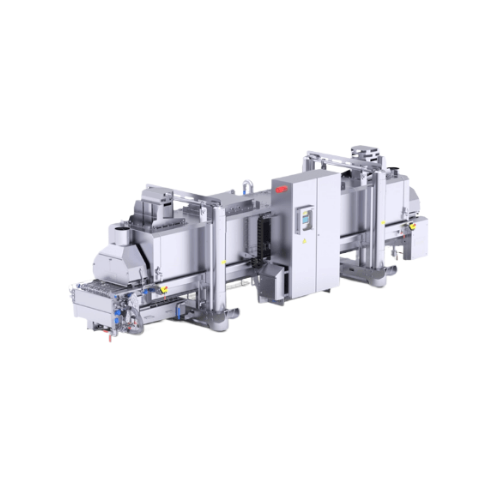

Continuous cooker for high-volume food processing

Elevate your production efficiency with a continuous cooker that ensure...

Batch processing system for processed cheese and various food products

Optimize your food production line with a multif...

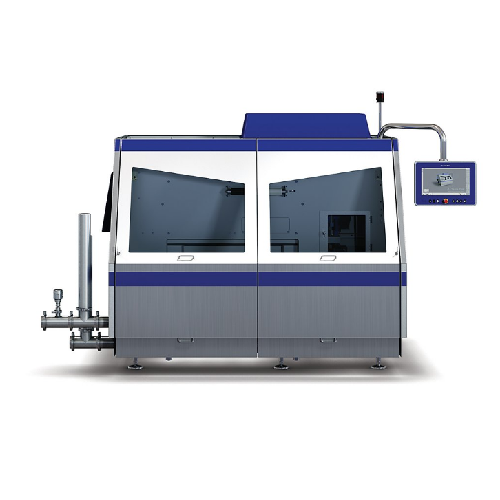

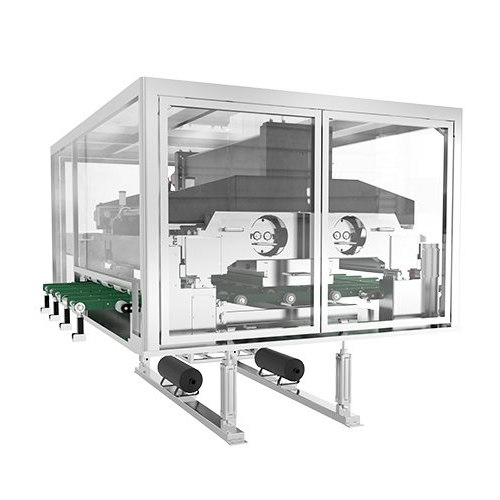

High pressure food processing system

Achieve extended shelf life and enhanced food safety with a cutting-edge high-pressure...

Hpp system for small-scale food production

Enhance food safety and prolong shelf life with this compact high pressure proc...

Hygienic conveyor belts for food manufacturing

Ensure bacteriological safety and boost productivity with hygienic conveyor...

Automated filter cleaning system for food production lines

Eliminate frequent production interruptions by utilizing an a...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...

Full case inspection for food, beverage, and pharma industries

Ensure flawless packaging integrity with this inspection ...

Top-down inspector for food and packaging

Ensure seamless product safety and quality assurance with advanced top-down insp...

Pulsed x-ray foreign object inspection for food packaging

Ensure your packaged goods are free from dangerous contaminant...

Foreign object detection for packaged and unpackaged food

Ensure the integrity of packaged and unpackaged foods by detec...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

Empty can inspection system for food industry

Ensure seamless production flow by detecting faulty cans before filling, pre...

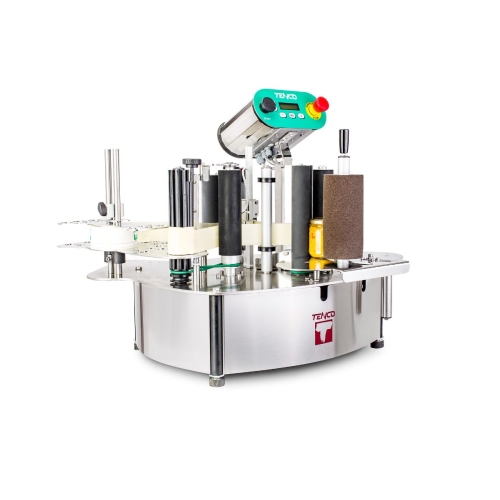

Versatile labeller for food industry

Enhance your packaging line with a versatile labelling machine capable of applying wra...

Labelling solution for food and beverage containers

Optimize your packaging line with precision labelling technology that...

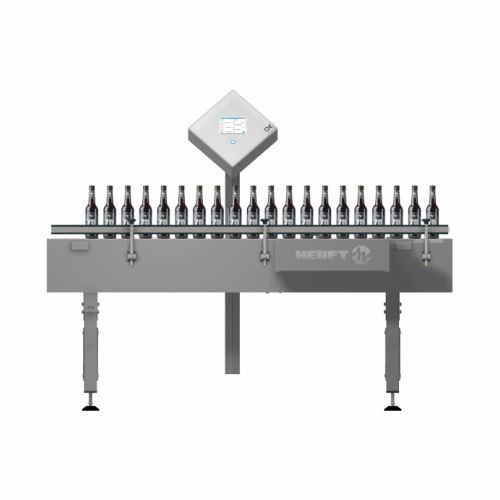

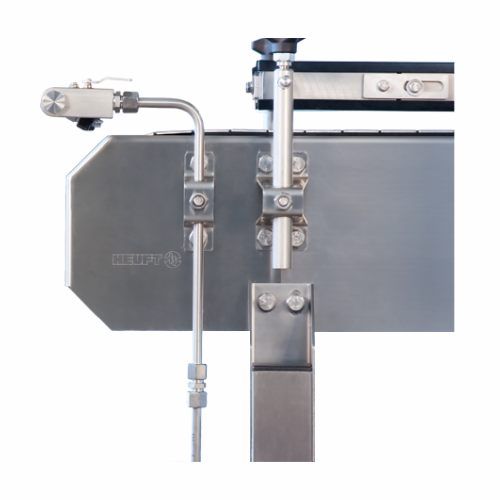

Heuft container rejector for beverage and food industries

Ensure flawless product flow by efficiently removing faulty or...

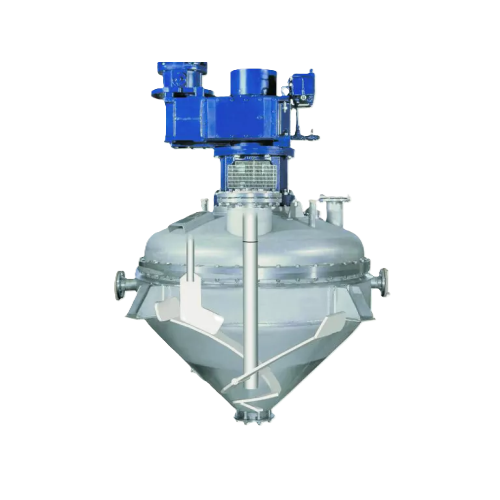

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Compact continuous fryer for food service applications

Streamline your frying operations with a compact continuous soluti...

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Rotary brander for industrial food processing

Achieve authentic grill marks and enhance product appeal on both sides of yo...

Semi-automatic weigher for fresh and sticky foods

Optimize your production line by effectively handling fresh and sticky ...

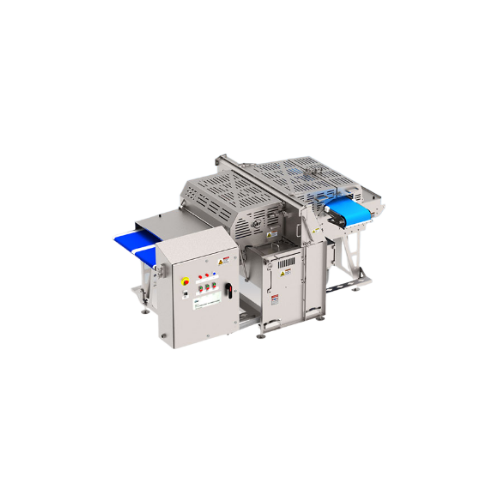

Batter applicator for poultry and seafood

Achieve consistent, even coating of batters and marinades for a variety of food ...

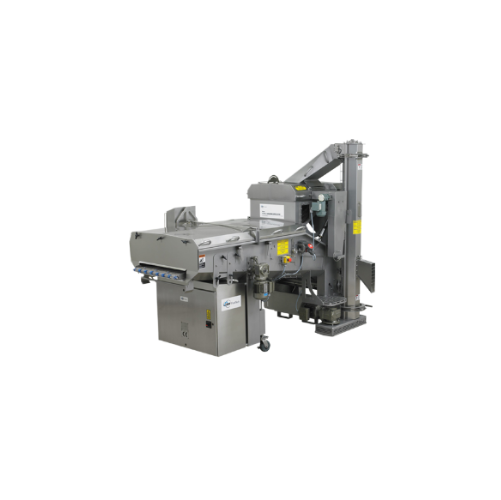

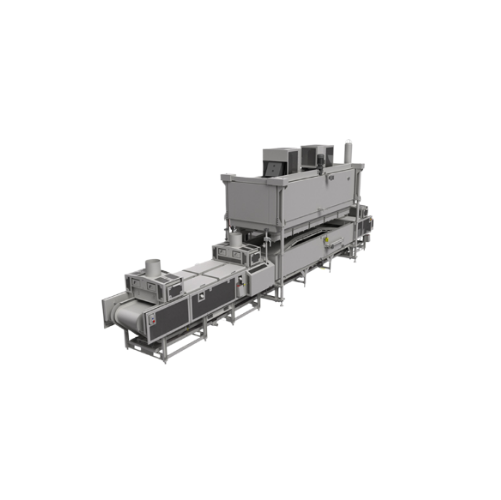

Continuous fryer for prepared foods

Effortlessly achieve uniform frying with precise temperature and conveyor speed control...

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this...

Thermal fluid heated fryer for prepared foods

Achieve precise, uniform frying with thermal fluid technology, ensuring each...

Compact breading applicator for meat and seafood

Optimize your production line with precise breading application, ensuring...

Multi-purpose oven for prepared foods

Ensure consistent cooking precision with this multi-purpose oven, designed to optimiz...

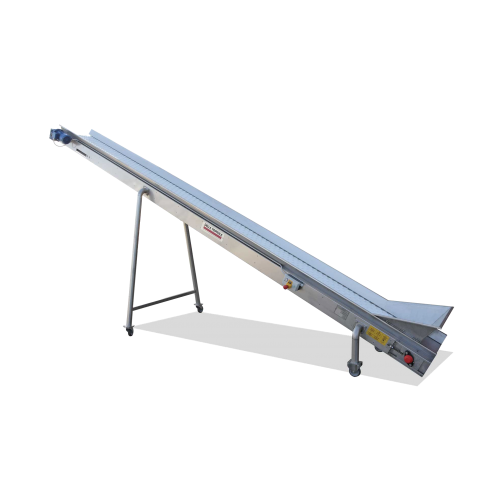

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

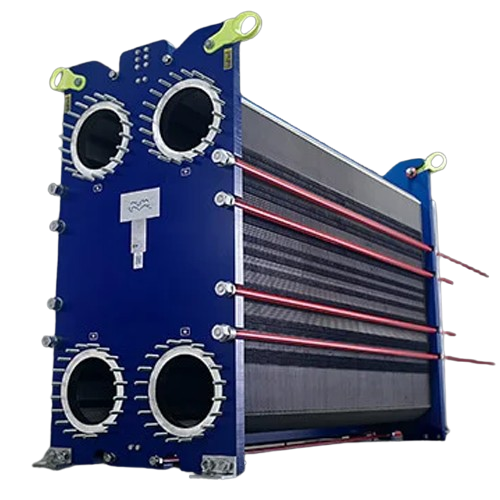

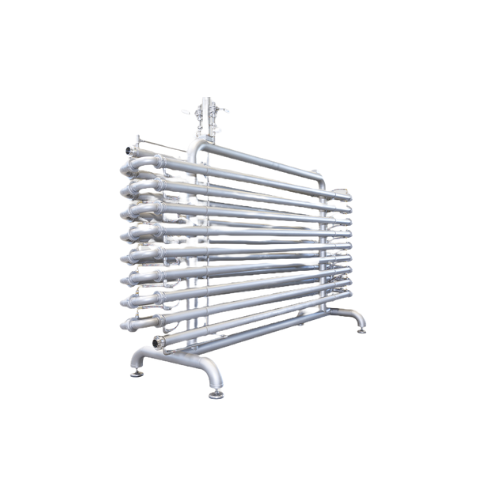

Energy recovery heat exchanger for fried food production

Harness otherwise wasted energy from your frying process to pre-...

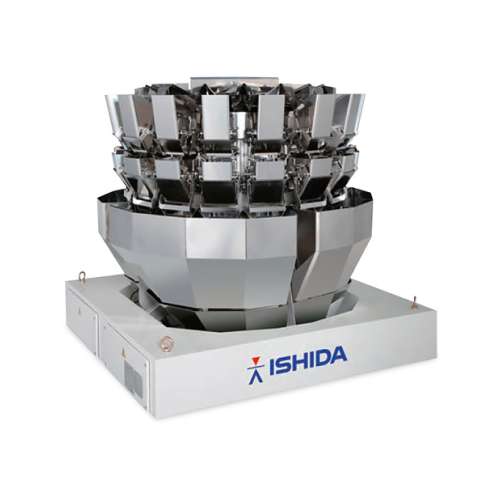

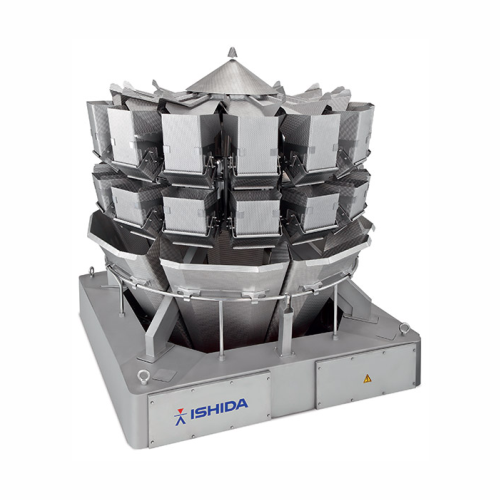

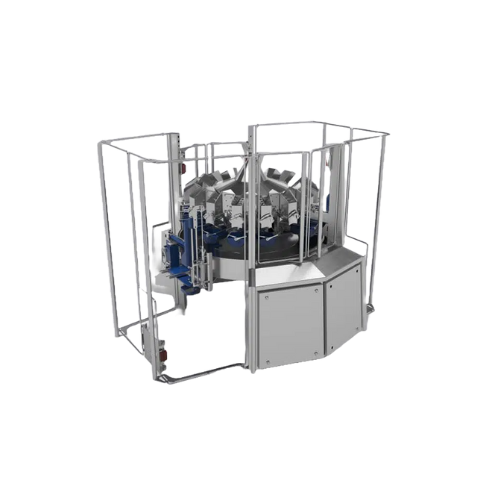

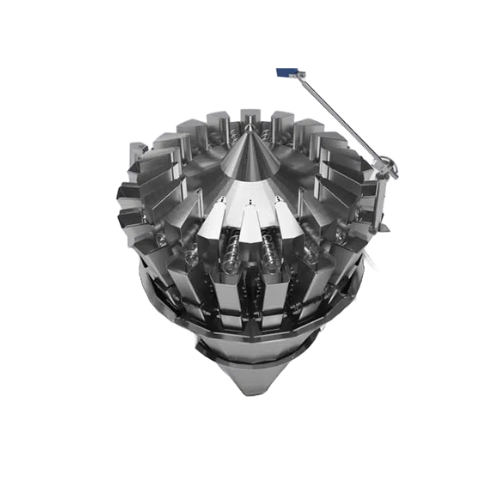

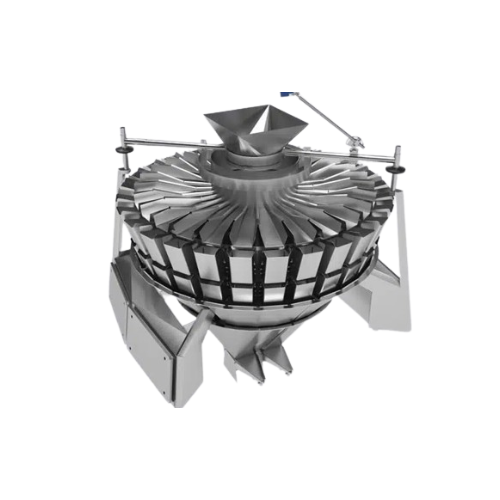

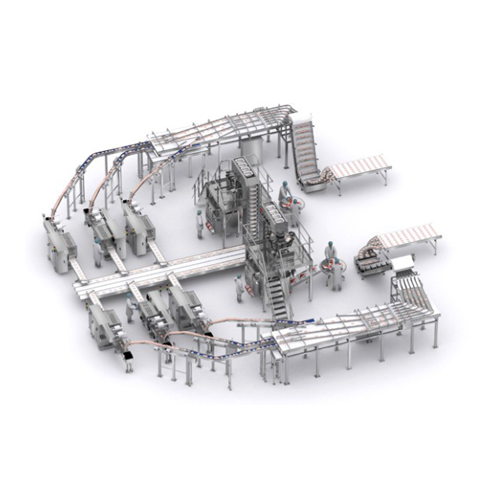

Multihead weigher for food processing

Enhance production efficiency and accuracy with multihead weighing technology, offeri...

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

Ambient air cooling system for food products

Achieve precise cooling control with high-speed ambient air cooling systems, ...

Compact food drying system

Achieve precise moisture control for product development and testing with this versatile compact ...

Food drying system for diverse products

Achieve precise moisture control and versatile drying for your diverse product line...

Batch drying system for food, pet feed, pharmaceuticals, and more

Optimize your drying needs with precision control for...

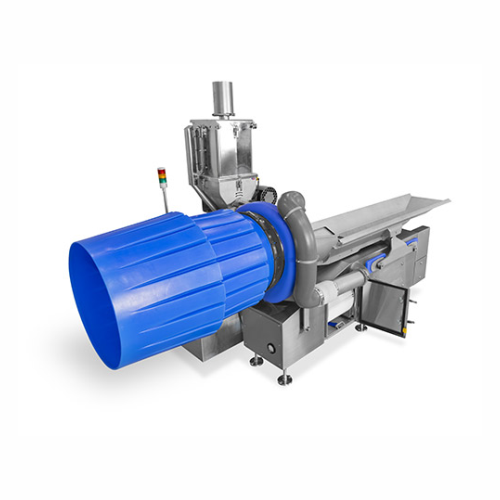

Rotary drum dryer for robust food products

Achieve uniform and gentle drying for sensitive and robust products alike with ...

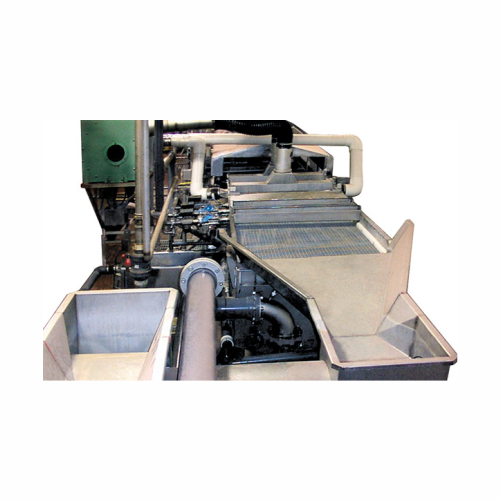

Continuous tunnel dryer for food products

Achieve precise moisture removal with adaptable drying technology, ensuring your...

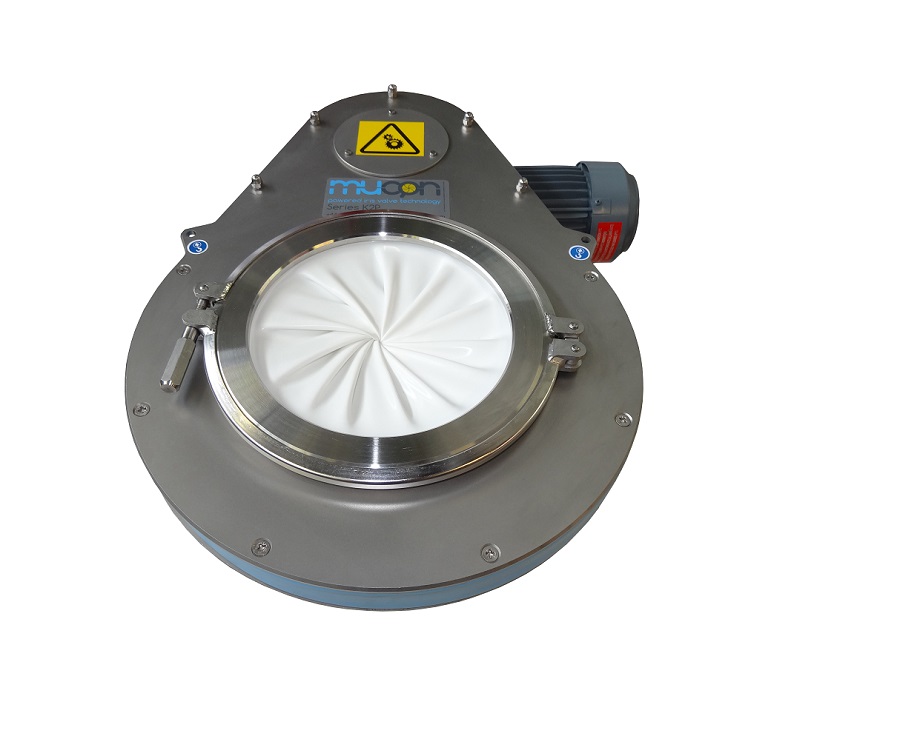

Ultra-hygienic vacuum conveyor for pharmaceutical and food industries

Streamline material handling with this ultra-hygi...

Hygienic vacuum conveyor for pharmaceutical and food industries

Optimize your material handling process with a vacuum co...

Industrial mixer for food and pet food production

Achieve precise and efficient mixing of viscous to highly viscous produ...

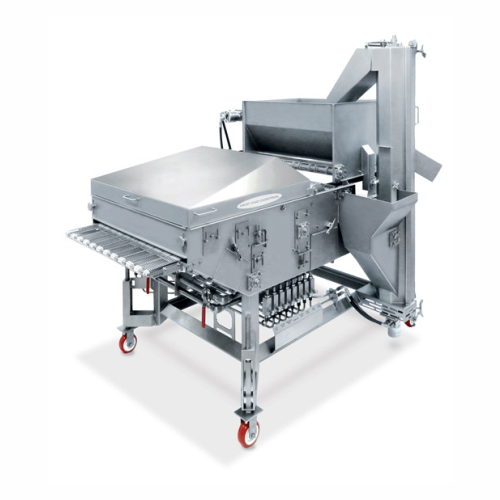

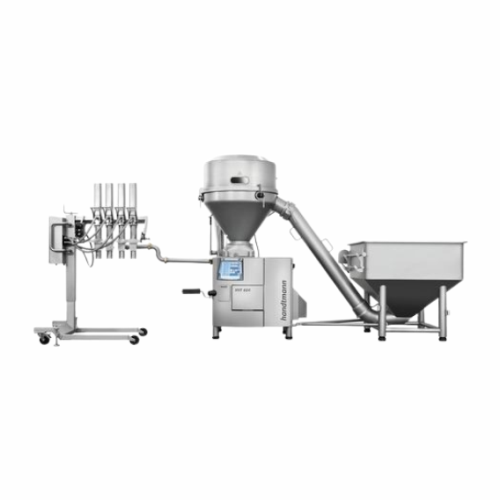

Compact vacuum filler for small to industrial scale food processors

Achieve precise portioning and high-speed productio...

Multi-lane forming system for 3d food product shapes

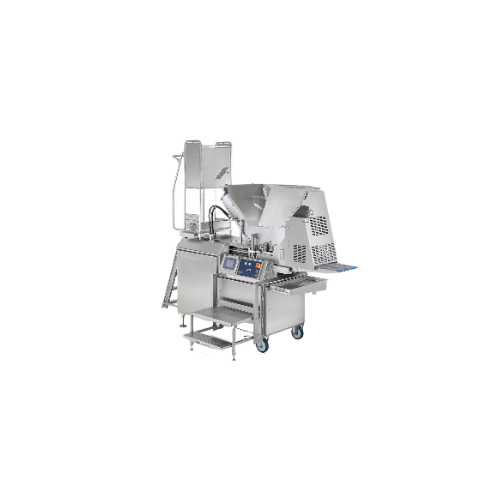

Achieve precise weight accuracy and high-speed production of diverse...

Forming system for multi-lane production of shaped foods

Streamline your production of uniform shaped foods with a multi-...

Filling flow divider for food and pet food applications

Optimize your production line with precision filling flow divider...

Cutting valve for chunky food portioning

Achieve precise portioning of chunky products, reducing waste and increasing effic...

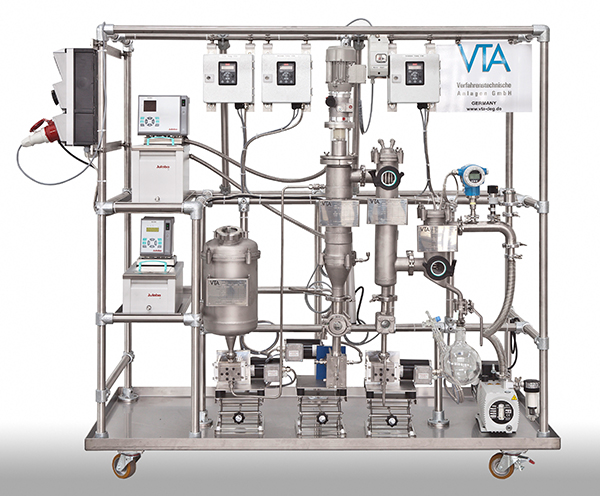

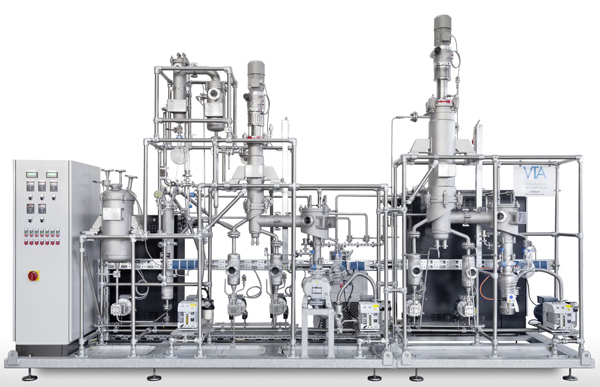

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel cooking kettle for food, pharma, and cosmetics

Efficiently streamline your production with versatile sta...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

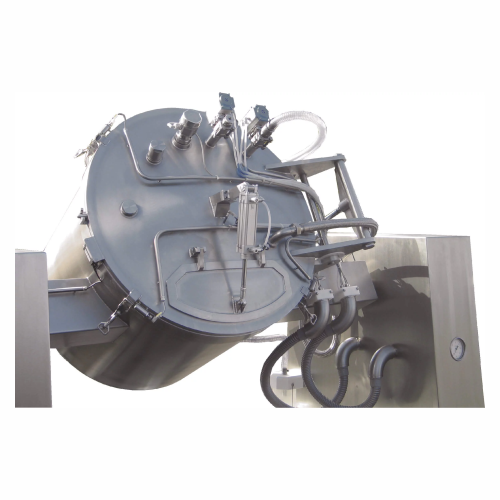

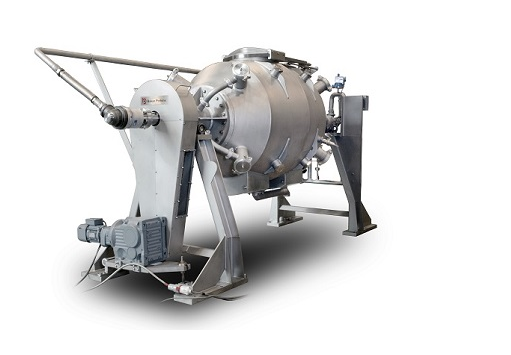

Vacuum tumblers for food processing

Optimize your production line with vacuum tumblers designed to enhance flavor infusion,...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Fluid bed granulation system for food and chemical industries

Achieve efficient granulation and drying of liquids with c...

Fluid bed granulator for food and chemical industries

Ensure consistent particle size and moisture control in your produc...

Spouted bed processing for food, feed, and fine chemicals

Tackle the challenge of processing temperature-sensitive and s...

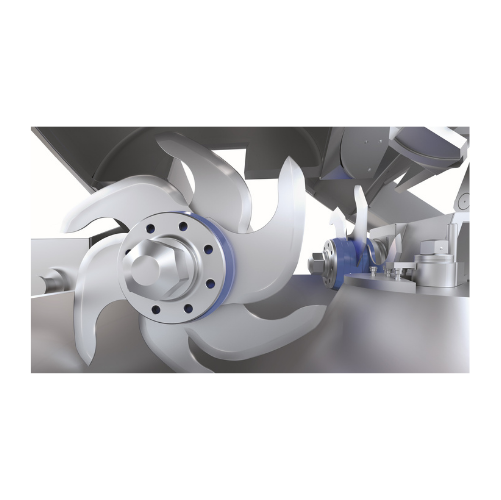

Precision emulsification equipment for food industry

Achieve precise comminution and emulsification for diverse food text...

Laboratory mixing plant for small scale food production

Achieve precise control over small batch food processing with a v...

Small batch free fall mixer for food industry applications

Efficiently handle diverse ingredient integration for plant-b...

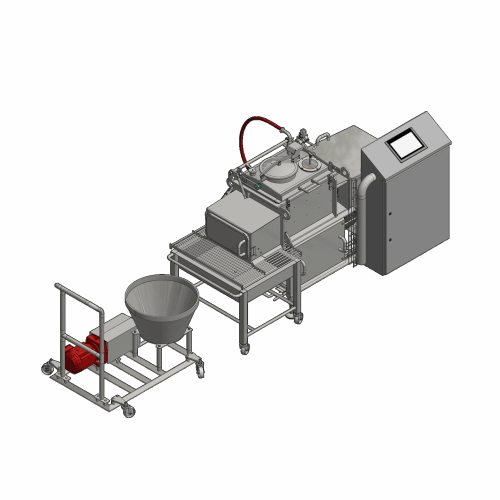

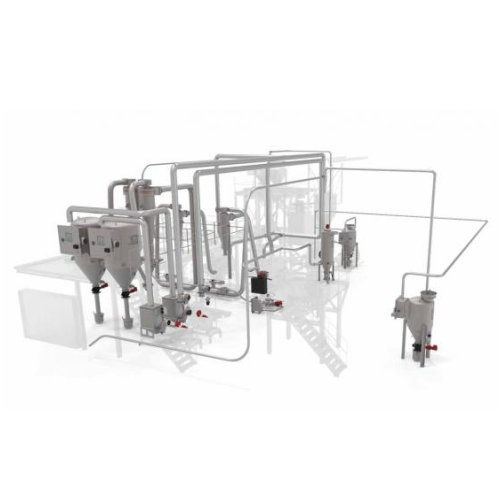

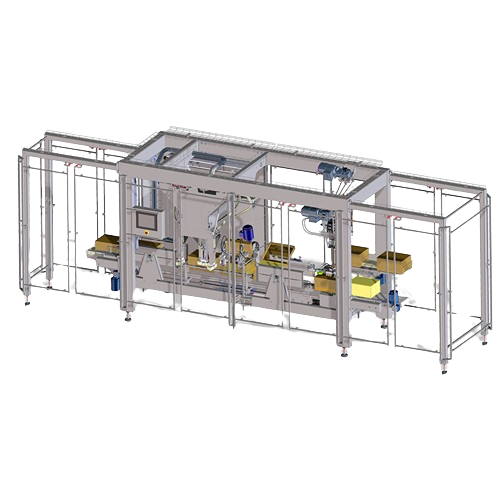

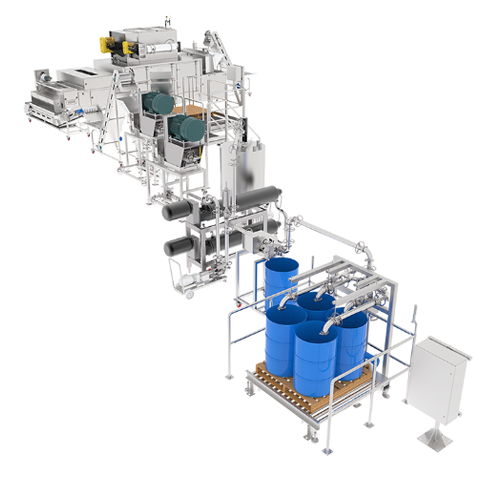

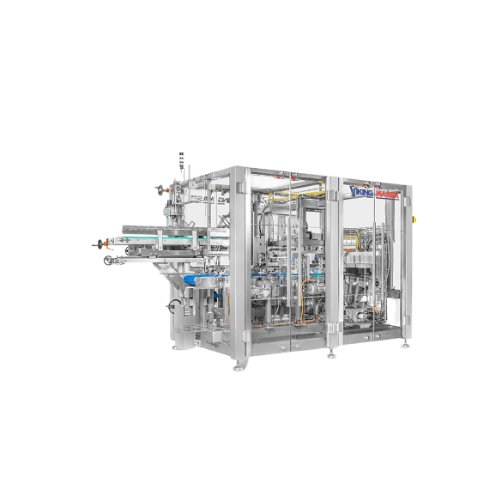

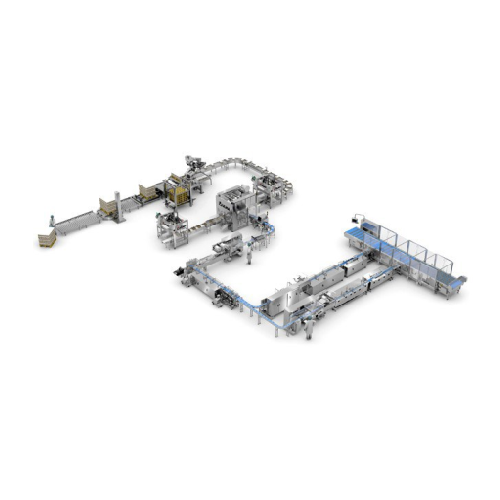

Integrated production system for food processing

Optimize your food production line with this versatile system, designed t...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Vacuum filling system for automated food production

Eliminate manual handling with an advanced system that automates the ...

Industrial vacuum stuffer for high-volume food production

Streamline your sausage production with precision filling and ...

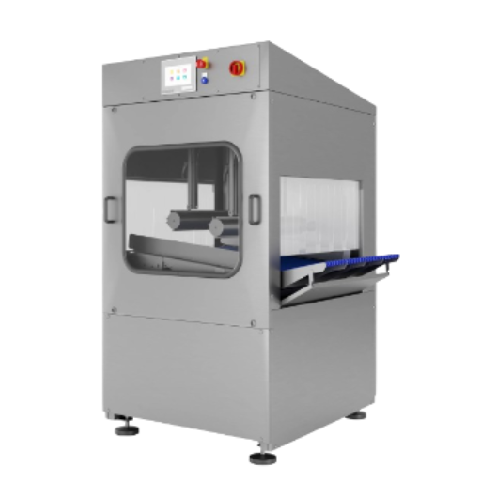

Industrial steam washer for pharmaceutical and food industry

For production lines requiring efficient and eco-friendly c...

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

Efficient drying solution for food packaging pouches

Optimize your packaging line with precise moisture control, ensuring...

Lab glassware washer for food and bio-pharmaceutical applications

Ensure precision cleaning of complex lab glassware us...

Radiofrequency sterilizer for delicate food products

Streamline your food processing with radiofrequency technology, offe...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

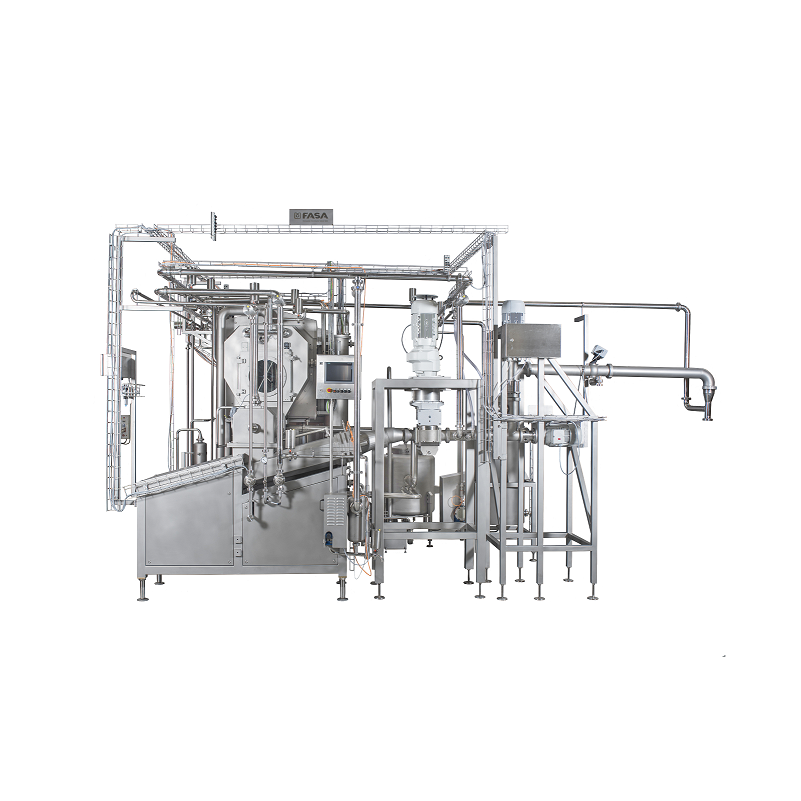

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

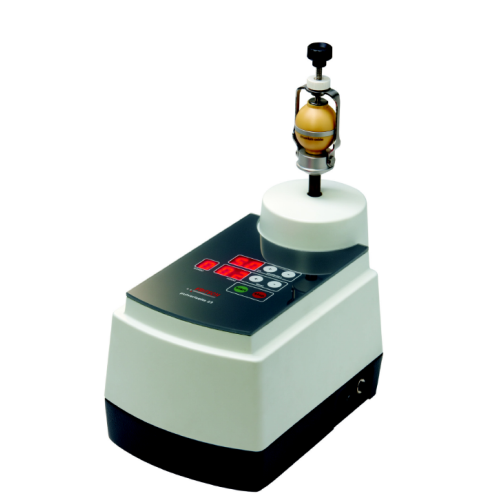

Cell disintegration measurement tool for food products

Ensure precise measurement of cell disintegration across food prod...

Modular pulsed electric field system for food processing

Enhance your food processing efficiency with a modular system th...

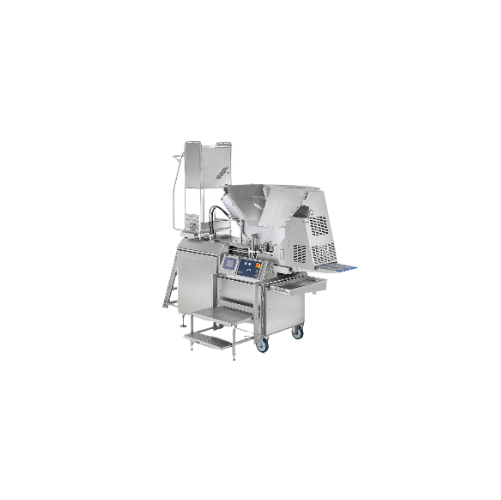

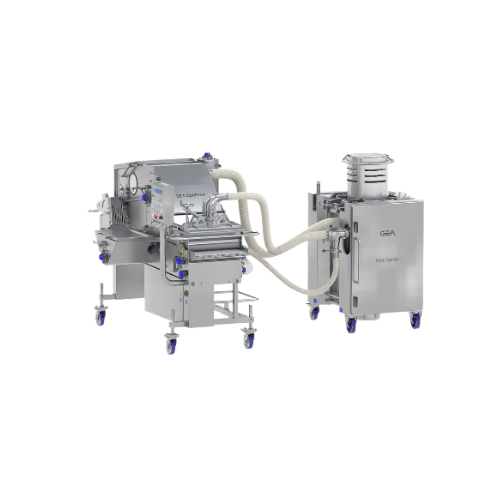

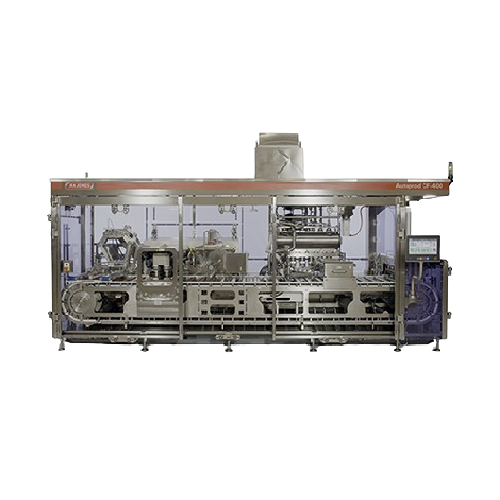

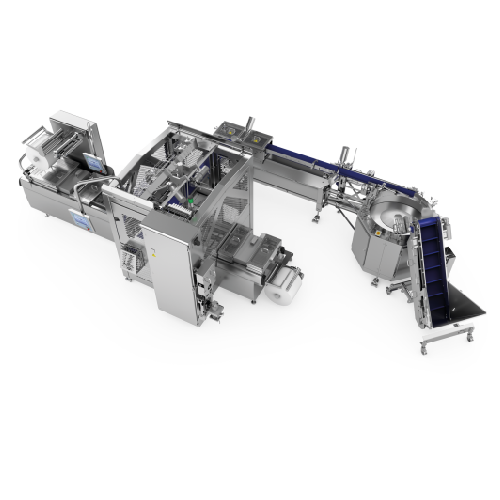

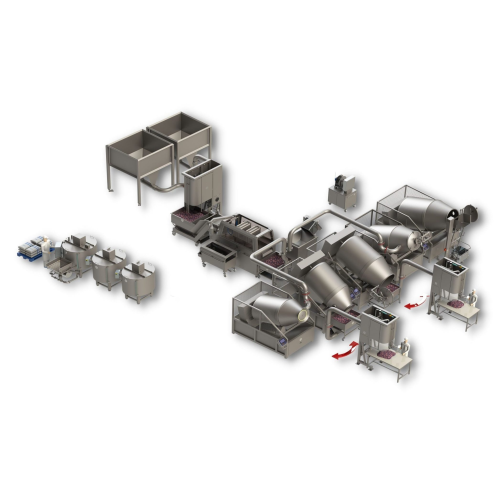

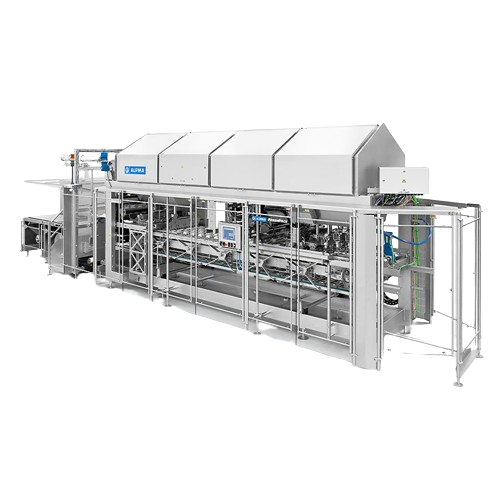

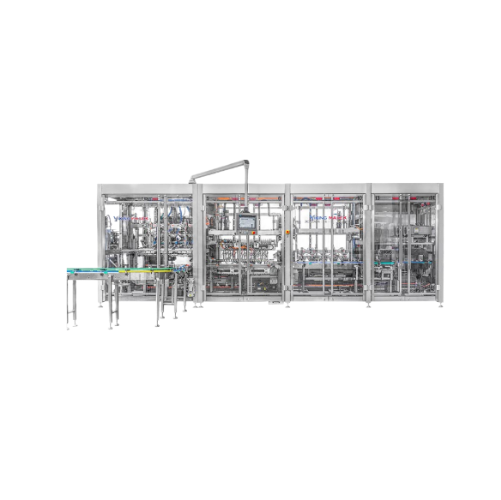

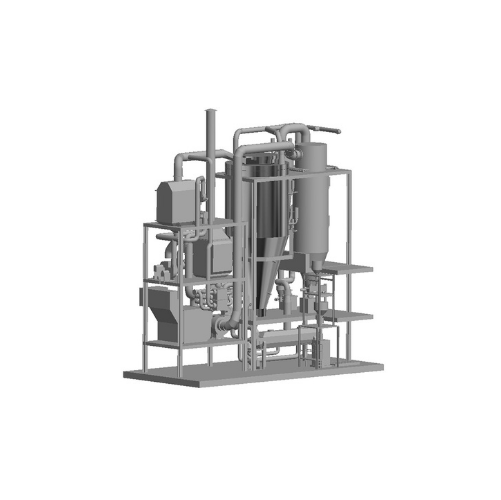

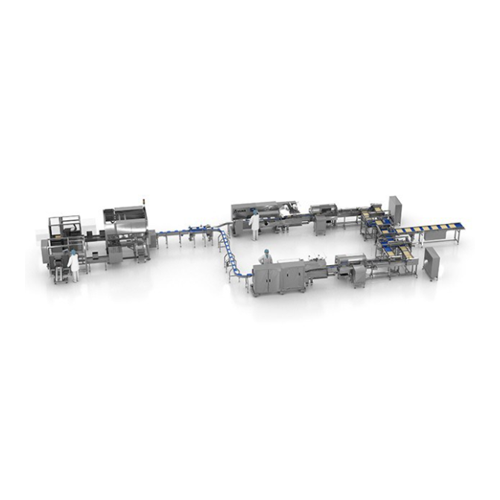

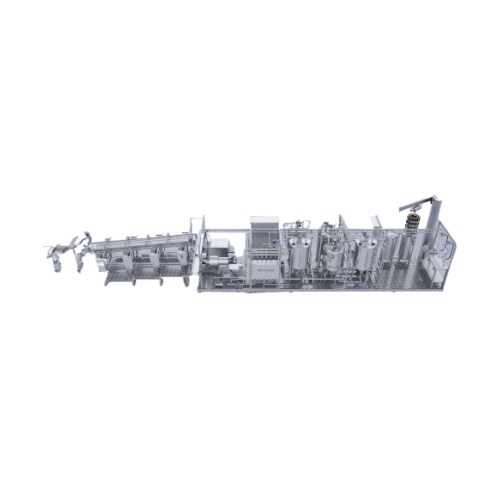

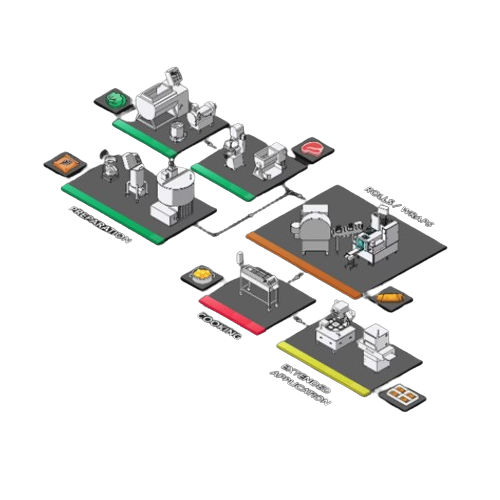

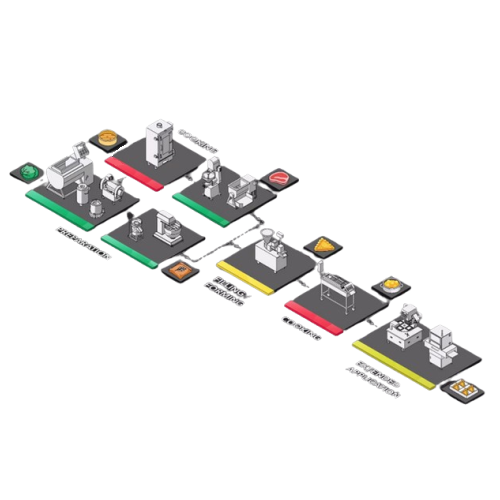

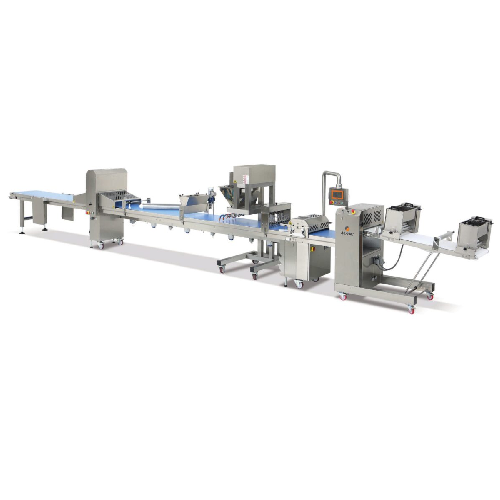

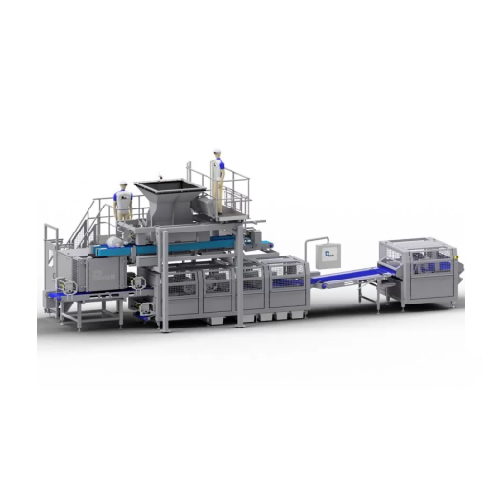

Production solutions for convenience foods

Effortlessly transform your innovative recipe ideas into consistent, high-quali...

Cleaning and sterilization system for food factories

Ensure optimal hygiene and safety in your production line with advan...

Cryogenic screw conveyor for food processing

Enhance your production line with a cryogenic screw conveyor that simultaneou...

In situ dry-ice snow generator for food and pharma applications

Achieve precise cooling and deburring with this versatil...

Cryogenic rotary drum freezer for Iqf foodstuffs

Optimize your freezing process with a rotary drum freezer that ensures ra...

High performance tunnel freezer for industrial food processing

Maximize your floor space while achieving rapid freezing ...

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Hygienic industrial grinder for food and pharma applications

Achieve optimal hygiene and efficiency in your grinding pro...

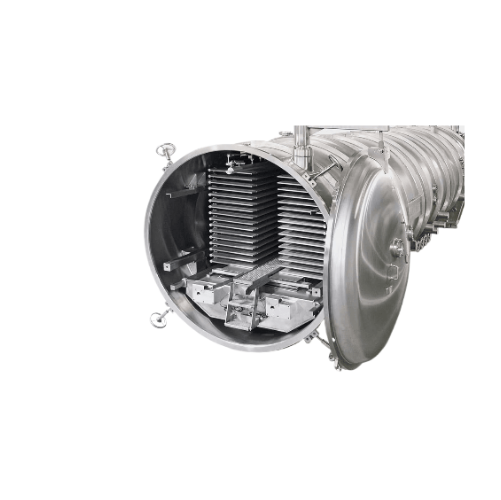

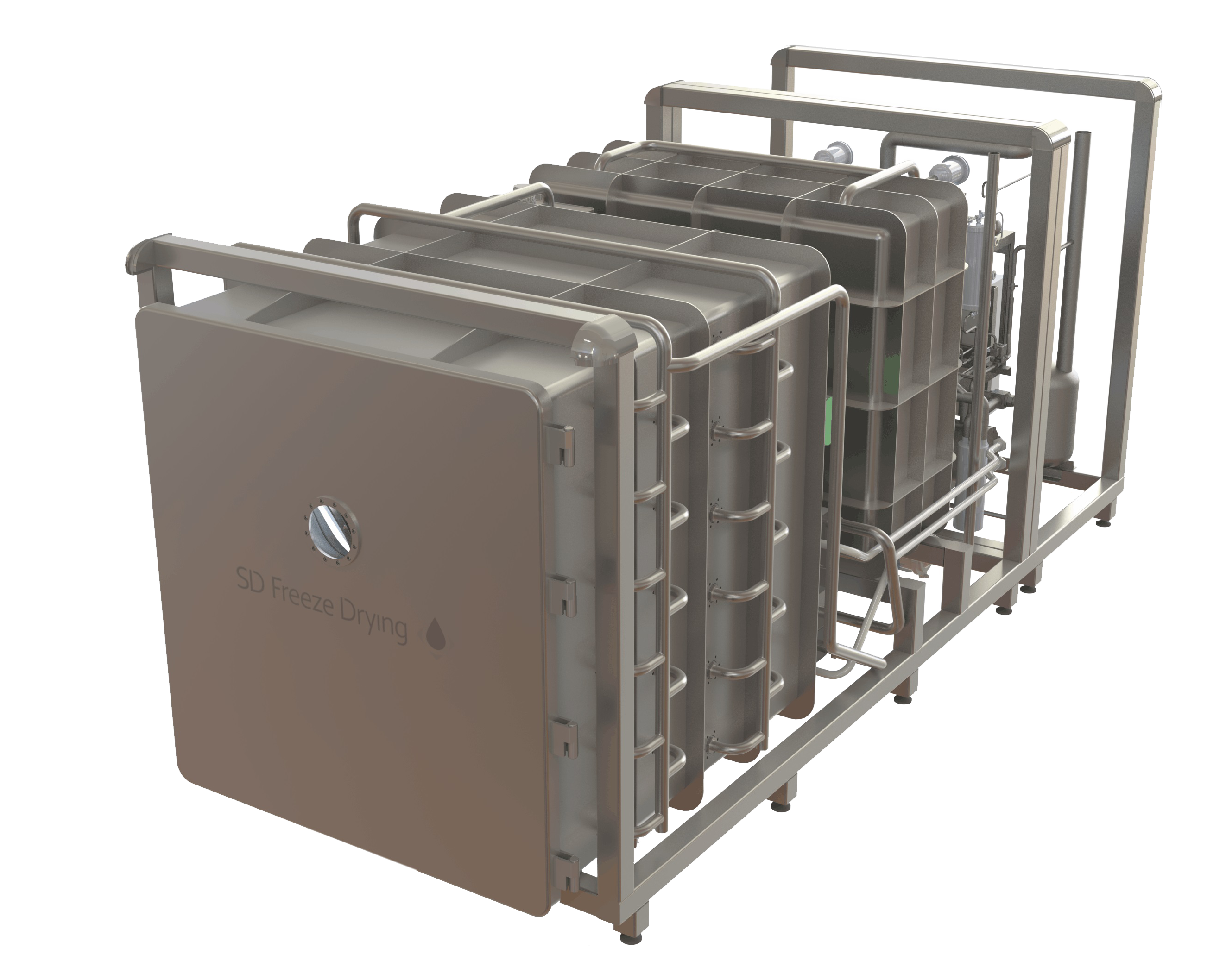

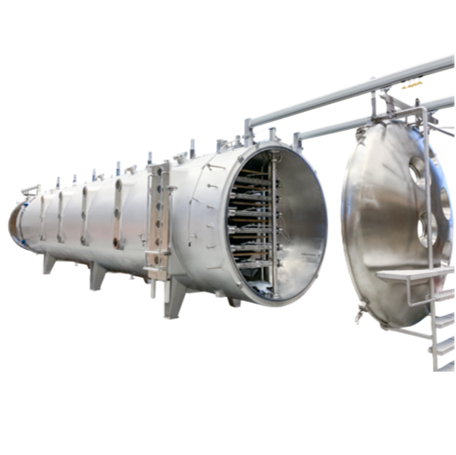

Vacuum and freeze drying plants for food and pharmaceuticals

Ensure high-quality, extended shelf-life products with inno...

Automated Cip systems for beverage and food industry

Ensure high hygiene standards in your production line with advanced ...

Pea fiber drying solutions for food or feed applications

Ensure top-tier product quality with precise drying of pea fiber...

Medium-low density food cooker

Streamline your cooking process for medium-low density foods with precision-controlled mixing...

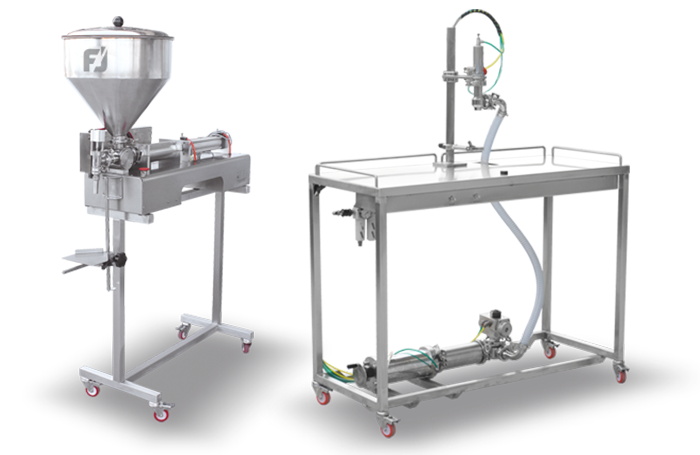

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

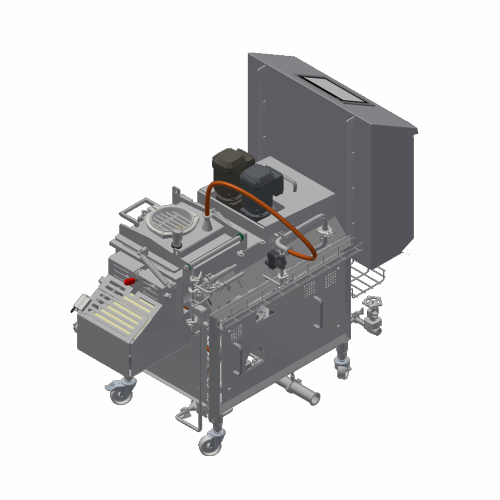

Combination cooker-dosing kit for food packaging

Optimize your small-scale food production with seamless cooking-to-packag...

Industrial cooker for food processing

Enhance your production line with versatile cooking solutions designed for precise te...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

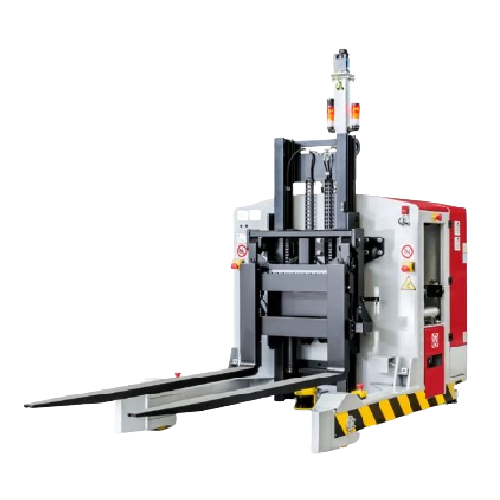

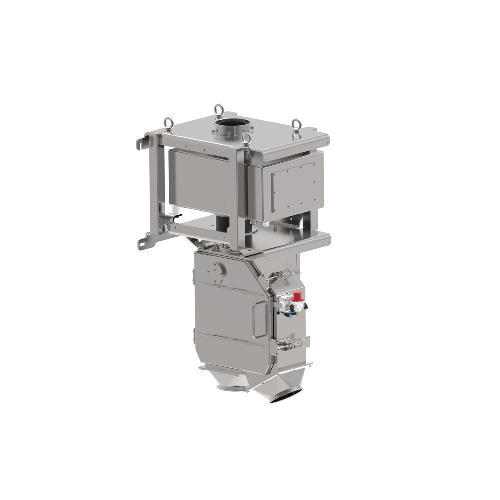

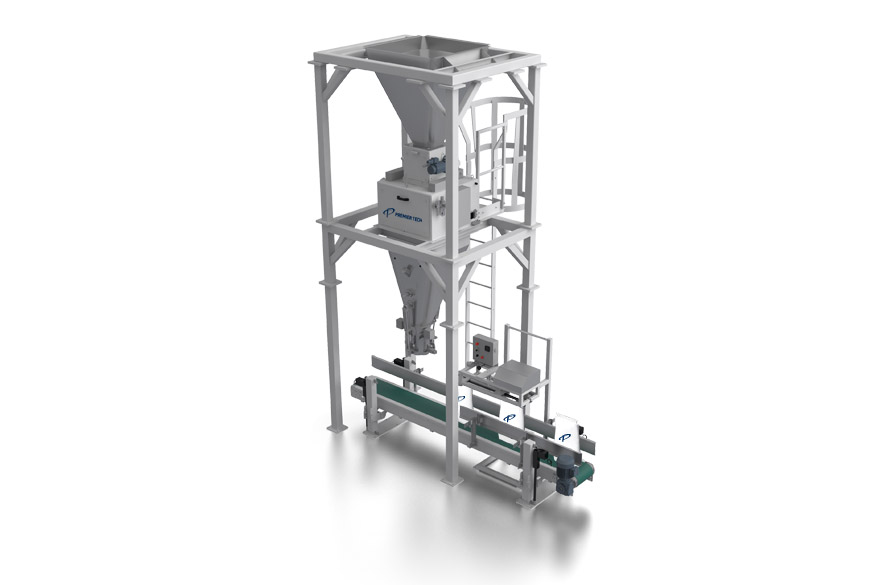

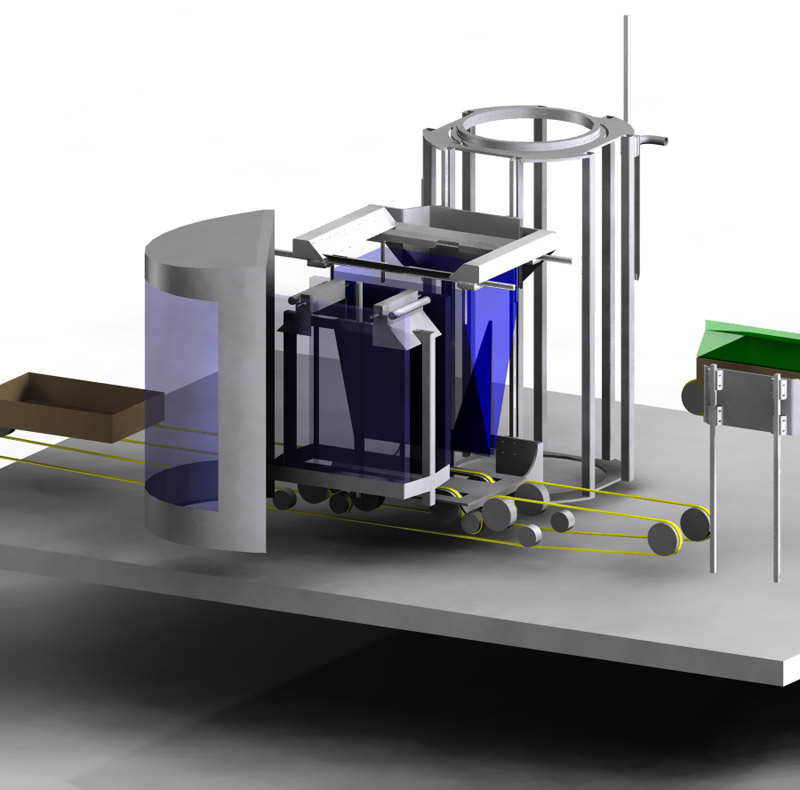

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Industrial freeze dryer for large scale food processing

Optimize moisture removal for high-quality food preservation and ...

Food counting system for hygienic applications

For food processors needing precise quantity control, this counting system ...

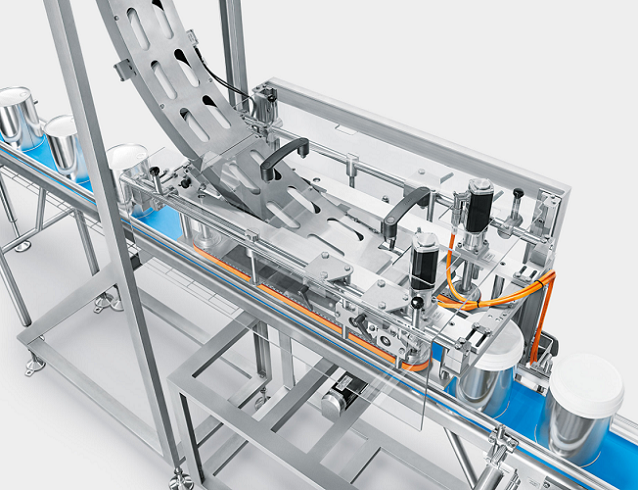

Product counting system for confectionery and food products

Achieve 100% counting accuracy and seamless integration in y...

Frozen meat grinder for industrial food processing

Efficiently process frozen meat into uniform, high-quality products wi...

Industrial food mixer for high-volume processing

Achieve consistent mixing and precise blending of diverse food ingredient...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Transfer hopper with stainless Pd pump for food processing

Eliminate spillage and maintain continuous flow with a positi...

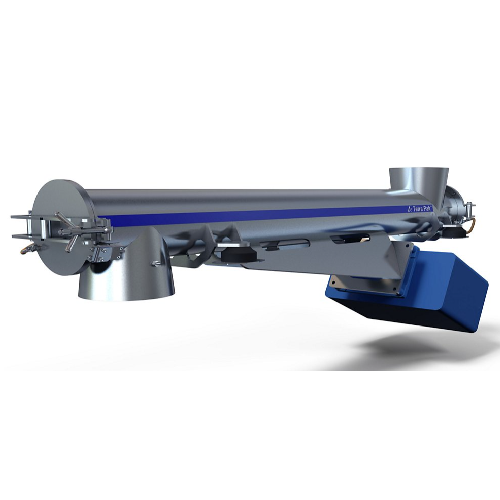

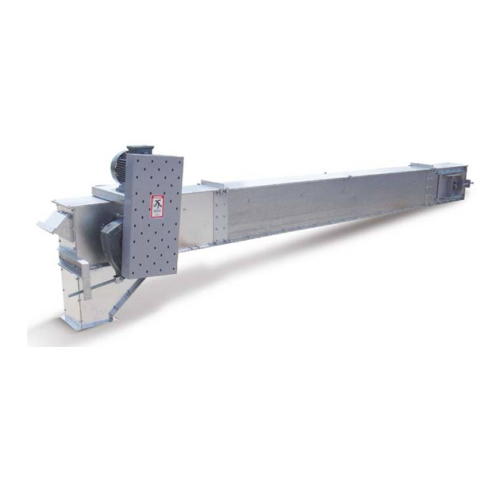

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Inclined screw loader for food processing

Optimize your food processing line with an inclined screw loader, designed for e...

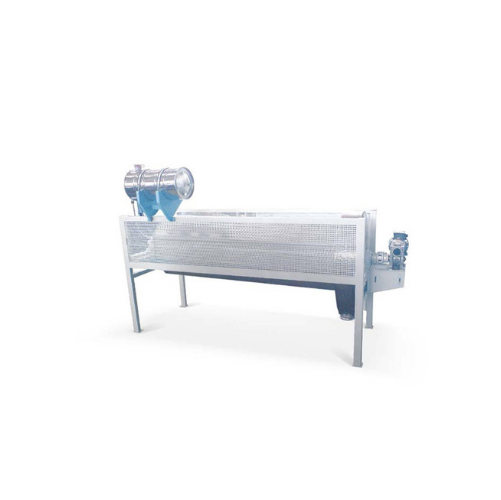

Overlapping paddle mixer for precise food processing

For precise and thorough mixing in food processing, this solution en...

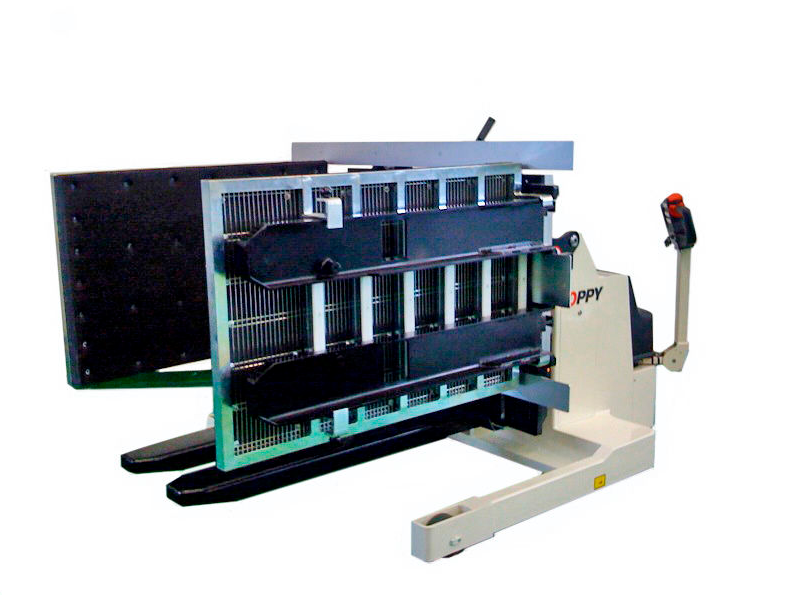

Pallet lift for food processing handling

Enhance your food processing efficiency with a robust pallet lift designed for sea...

Gravity-fed emulsion system for meat and pet food processing

Achieve optimal particle size reduction and seamless integr...

Compact food emulsion and reduction system

Achieve precise control over product texture and temperature with a compact sol...

Sanitary bulk solids receiver for food and pharma

Ensure precise control over bulk solid transfer with a system designed ...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

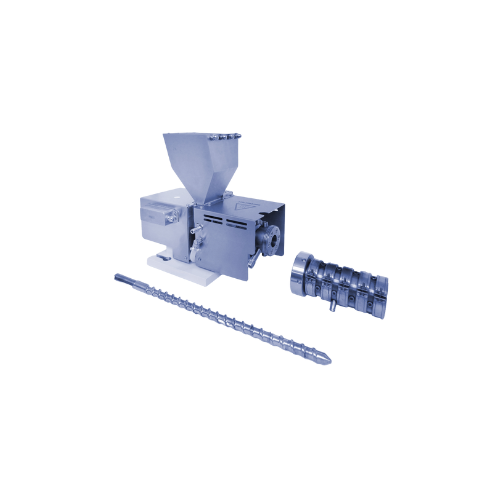

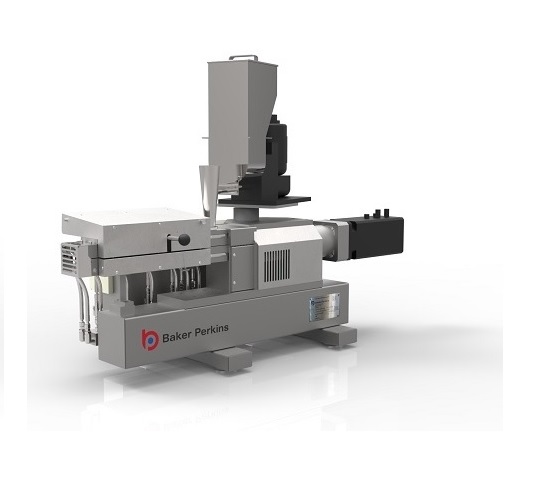

High-performance twin-screw extruder for food production

Enhance your production line efficiency and product quality with...

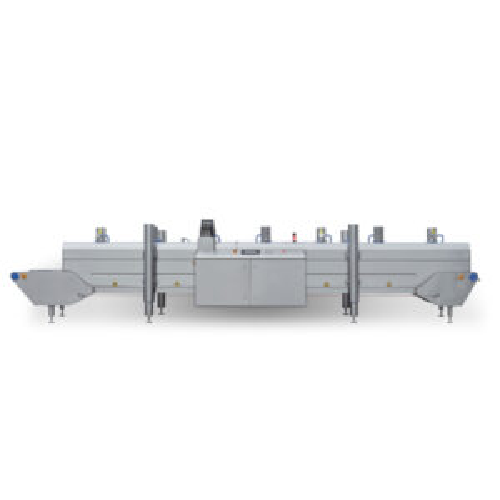

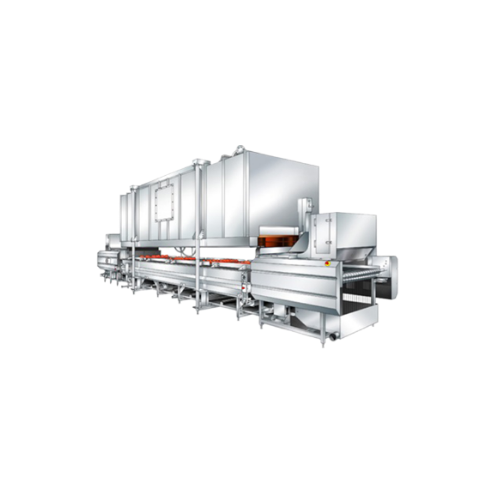

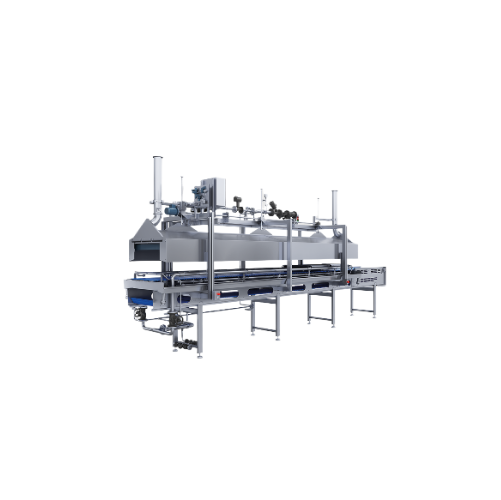

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Industrial cooking kettles for food processing

Optimize your production with versatile cooking kettles designed to handle ...

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Sterilizers and pasteurizers for industrial food processing

Optimize thermal processing for viscous foods and beverages ...

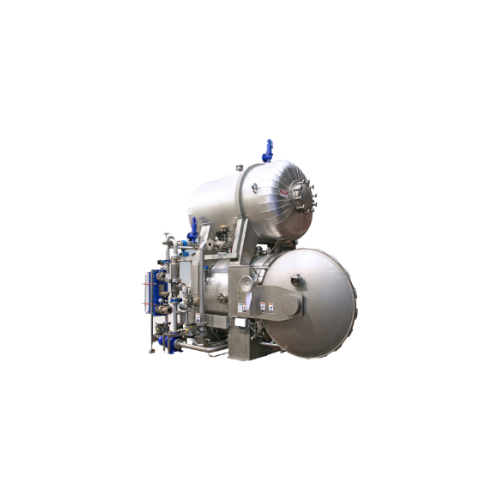

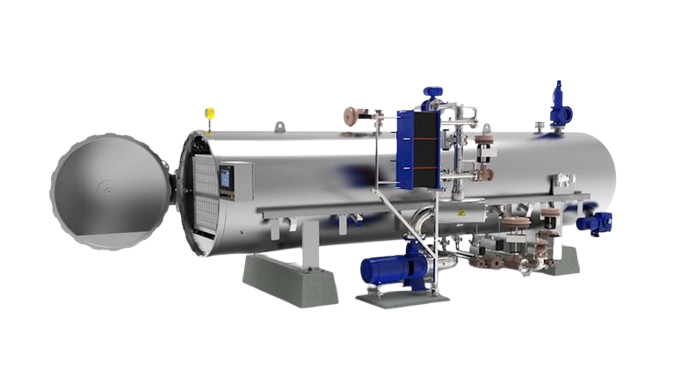

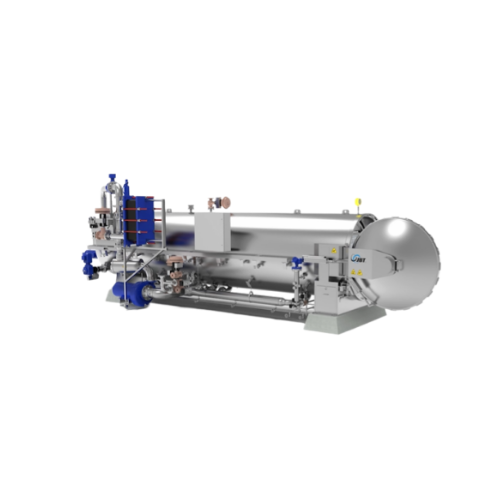

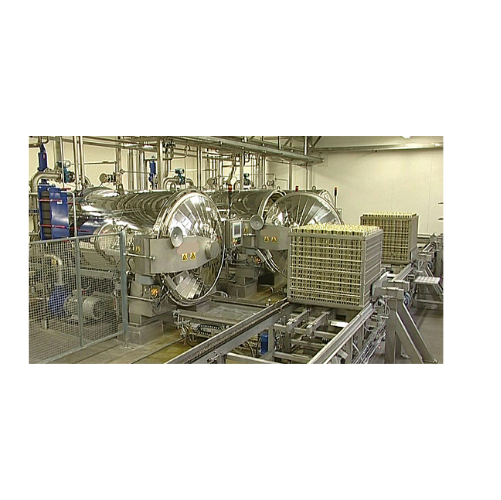

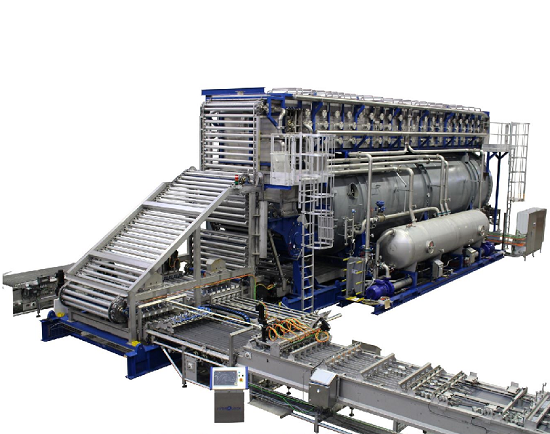

Batch retorts for food sterilization and pasteurization

Achieve optimal sterilization and pasteurization of packaged food...

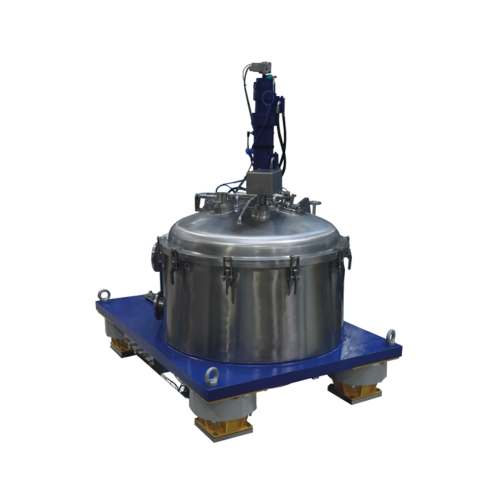

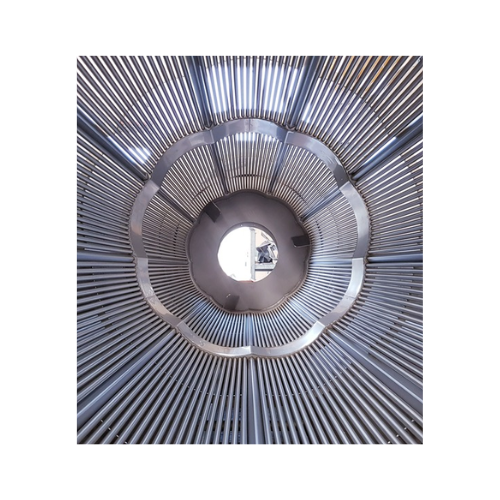

Centrifugal separator for food processing

Optimize your production line with high-speed disc stack centrifuges, designed t...

Industrial exhaust air treatment for food processing

Effectively eliminate volatile organic compounds and odors while max...

Food and confectionery twin-screw extruder

Enhance your confectionery production with a versatile twin-screw extruder desi...

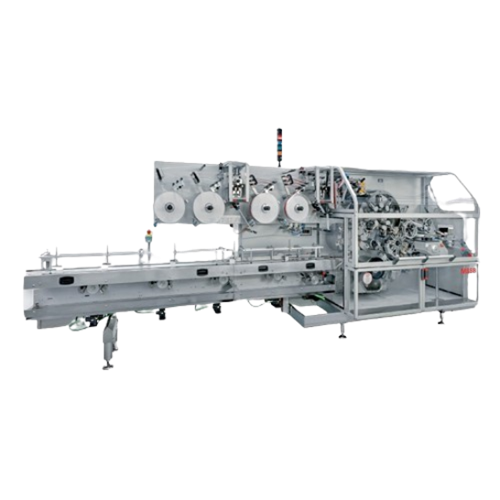

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

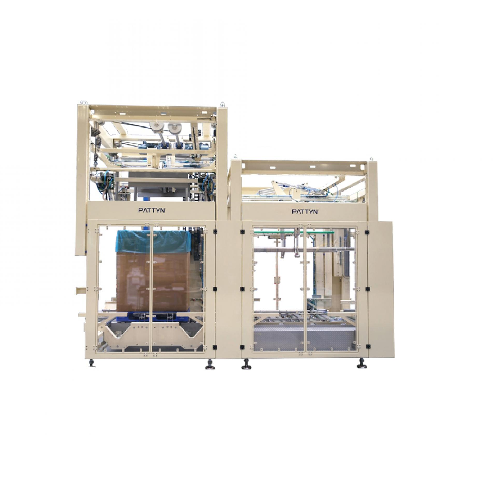

Horizontal case-packer for medium-sized shipping cases in pharma and food

Streamline your packaging line with a versat...

Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly fo...

Intermittent motion overwrapper for cosmetic and food products

Achieve flawless packaging with precision wrapping and se...

Vacuum waste handling system for food processing

Optimize waste management with a vacuum system that enhances hygiene, red...

Seafood cooker for brown crabs

Optimize your crab processing line with a high-speed seafood cooker designed for precision he...

Vibratory rotary filler for accurate filling in food packaging

Achieve precise and efficient filling of diverse solid pr...

Industrial weighing and batching system for meat, poultry and seafood

Optimize your production line with a high-precisi...

Belt thawing unit for seafood and meat

Efficiently thaw block-frozen products with a continuous submersion belt system, ens...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Industrial hammer mill for size reduction in food and feed processing

Achieve precise grinding and milling for diverse ...

Hammer mill for size reduction in food and feed processing

Efficiently tackle size reduction challenges with a versatile...

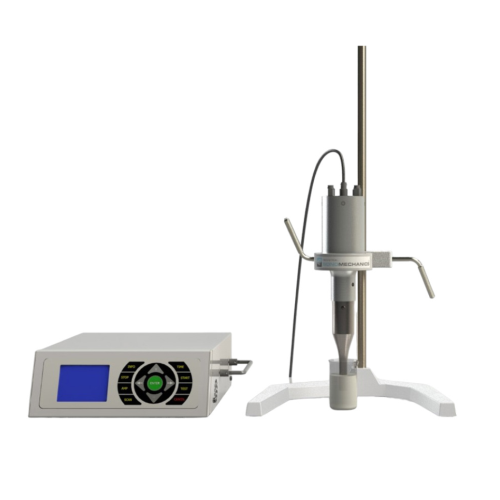

Homogenizer for food and feed analysis

Achieve precise homogenization and particle size distribution with this high-speed b...

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products...

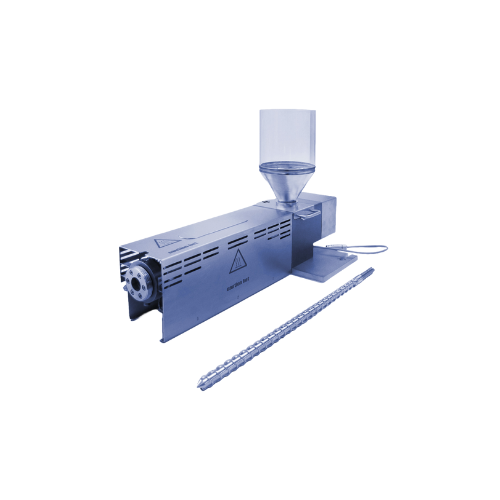

Stand-alone extruder for polymer and food processing

Optimize your extrusion process with a versatile and efficient machi...

Pasta die head for food industry extrusion

Achieve precise pasta shapes with enhanced cooling efficiency, ensuring consist...

Turbo mixer for homogeneous solutions in food and pharmaceutical industries

Effortlessly achieve uniform suspensions a...

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Multi feeding system for baby food and purees

Streamline your puree production with a versatile feeding system that expert...

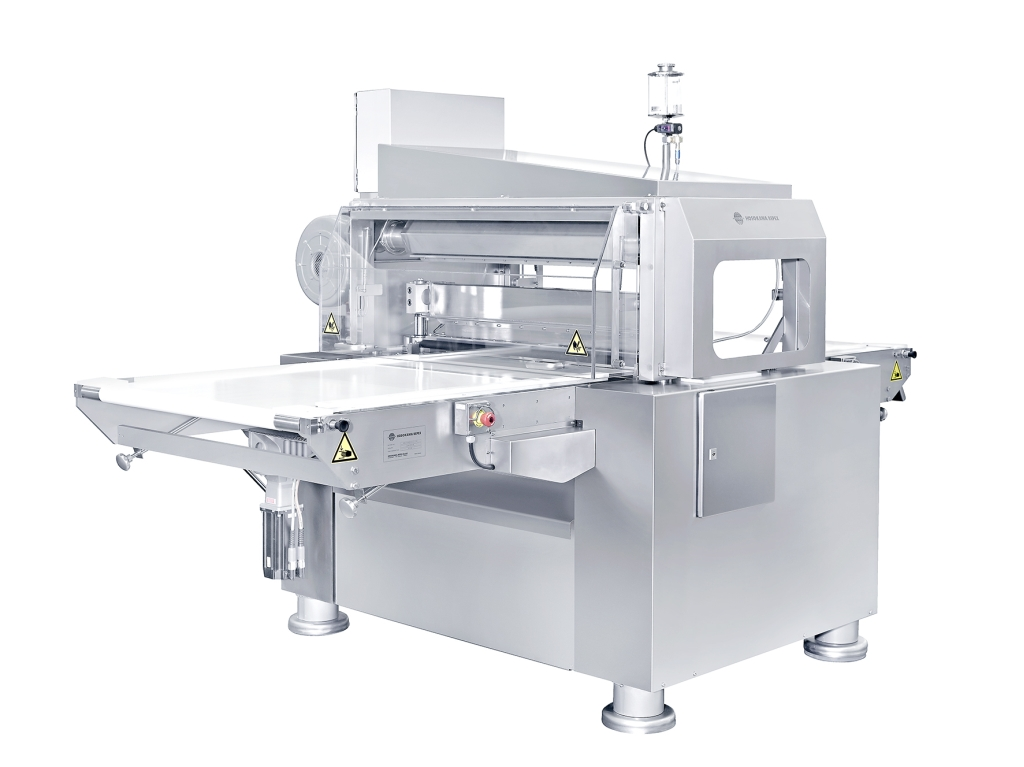

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Drizzler for precise food decoration

Transform ordinary dishes into visually stunning creations with a precise drizzling sy...

Sterilization for food and pharmaceutical processing lines

Ensure your liquid product’s sterility before productio...

Aseptic cooking line for industrial food processing

Achieve seamless aseptic cooking and filling for diverse food product...

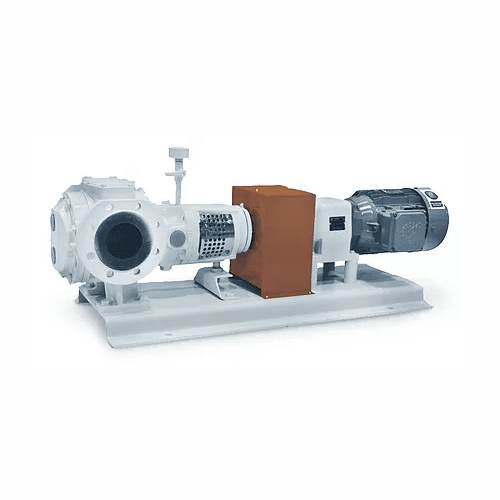

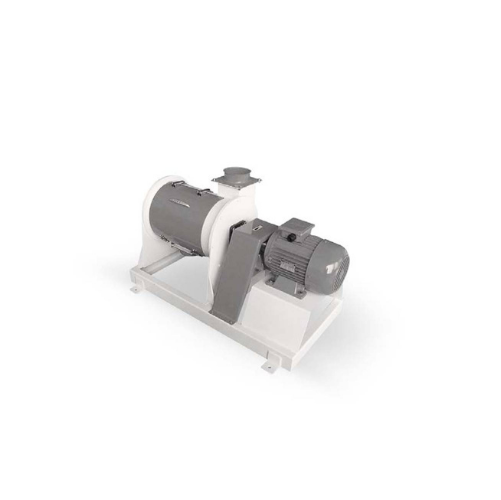

Industrial shear pump for high-viscosity food applications

Optimize your high-viscosity food processing with a shear pum...

Small batch cooking and blanching system for food industry

Optimize your food production line with a versatile cooking a...

Industrial tumbler for precise food massaging

Achieve consistent marination and coating with precise massaging and mixing,...

Automated quality control for food packaging

Ensure seamless quality control with real-time inspections, serialization, an...

Empty bottle inspection system for food industry

Detect subtle defects in empty bottles before filling to ensure product s...

Automatic batter breading system for deep-fried foods

Effortlessly achieve even coating of various foods with waterfall-t...

Food x-ray inspection system for contaminant detection

Ensure the purity and safety of your food products with advanced x...

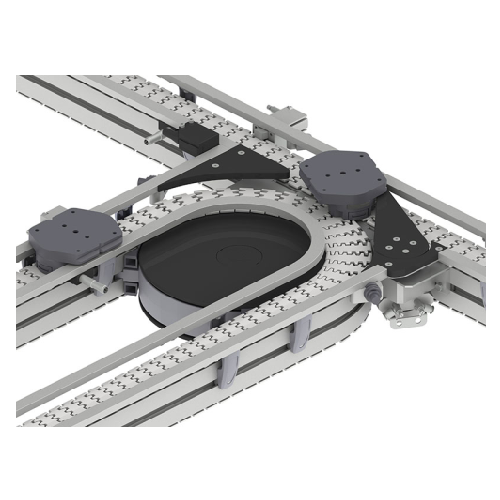

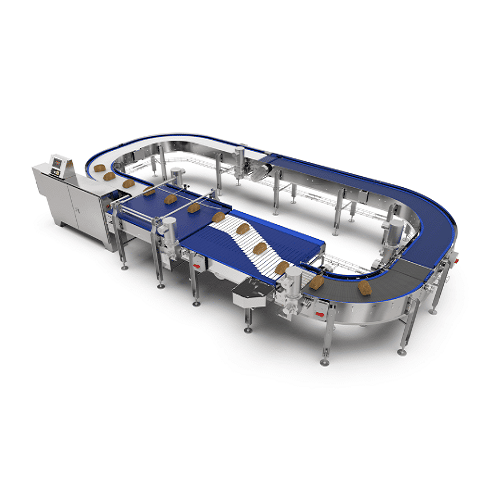

Automatic rounding conveyor for food production

Effortlessly transform diverse food products into uniform spherical shapes...

Continuous-type sealing solution for food packaging

Enhance your food production line with efficient sealing technology, ...

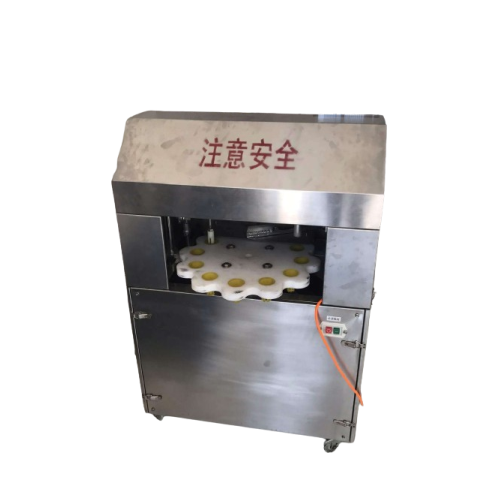

Automatic table-type encrusting and forming machine for diverse ethnic foods

Optimize your food production with a comp...

Industrial stir fryer for food production

Maximize cooking efficiency with a multi-function stir fryer that excels in cont...

Automatic crumb breading machine for food production

Perfect for creating evenly breaded products like tempura shrimp and...

Industrial dough mixer for high capacity food production

Enhance dough consistency and texture with a high-speed industri...

Industrial conveyor fryer for high-volume food production

Optimize frying operations with precision temperature control,...

Automatic seasoning mixer for food production

Effortlessly blend diverse ingredients with precision in your production lin...

Stir fryer for industrial food production

Streamline your culinary operations with this innovative stir fryer, designed to...

Multipurpose vegetable cutting solution for food production

Efficiently handle diverse pre-processing tasks with a solut...

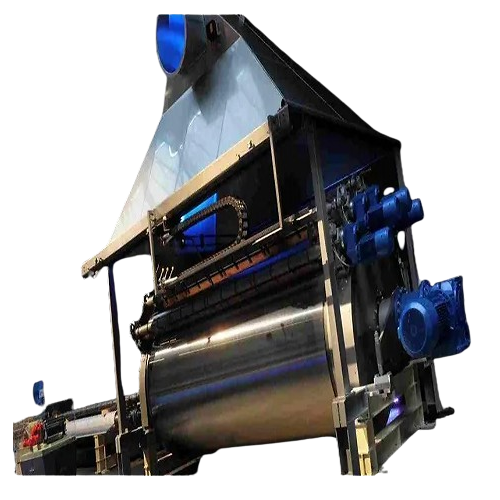

Contact drum dryer for industrial food and chemical processing

Optimize your drying process with a contact drum dryer th...

Decanter centrifuge for food industry separation

Achieve precise separation and ensure optimum product quality with our ad...

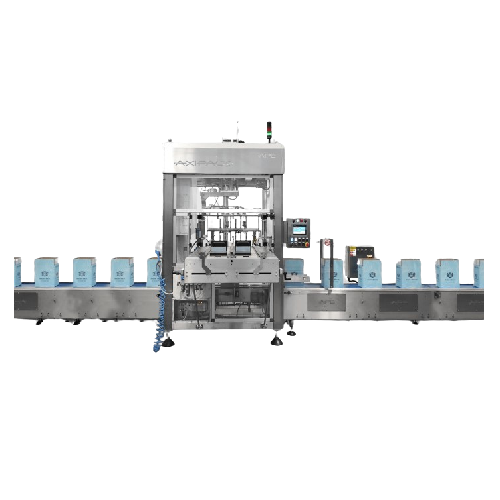

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

Automatic top sealing for frozen food packaging

Streamline your food packaging operations with a top sealing machine desig...

Centrifuge separator for food and beverage clarification

Ensure high efficiency and minimal product loss in your producti...

Gas steamer for food production

Achieve rapid and uniform steaming across diverse food applications with a robust solution t...

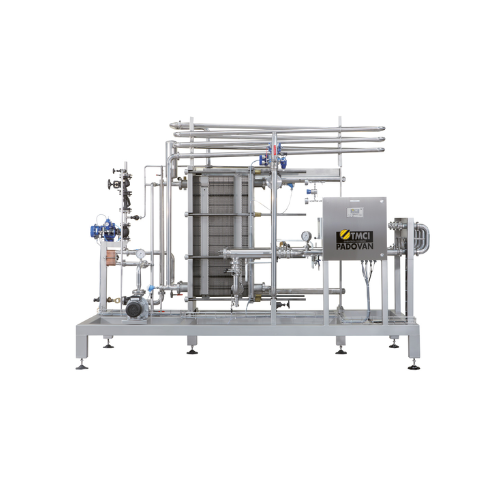

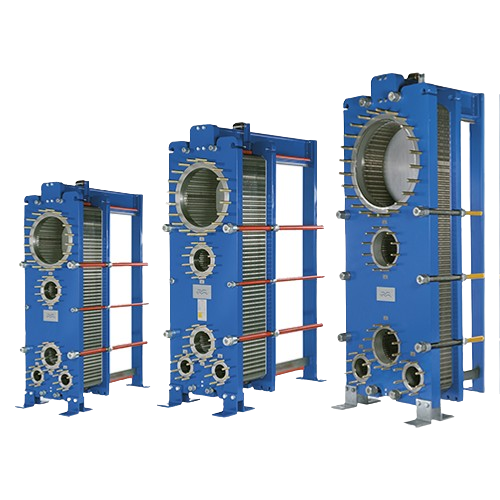

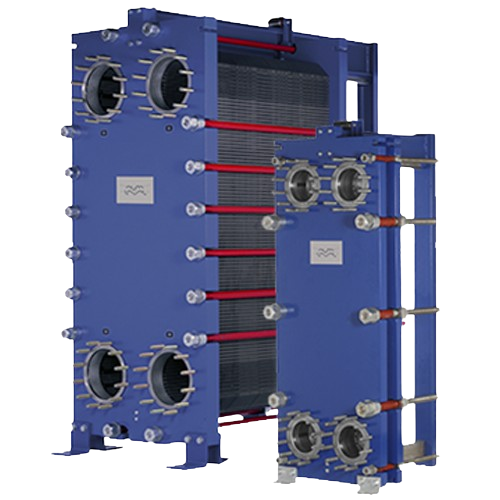

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Aseptic tank module for liquid food storage

Ensure safe storage of sterilized liquid foods with a customizable tank module...

Foodec decanter centrifuge for food processing

Achieve high yields and clear liquid separation in your food processing lin...

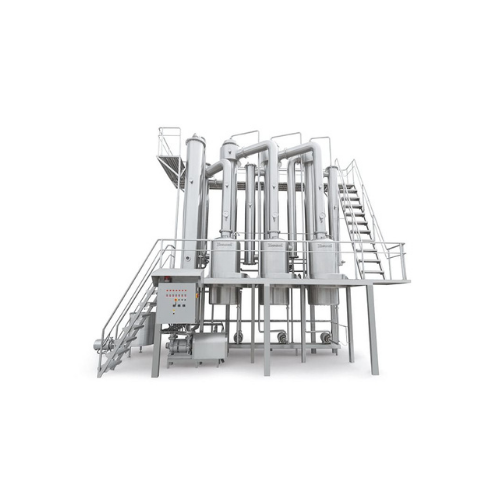

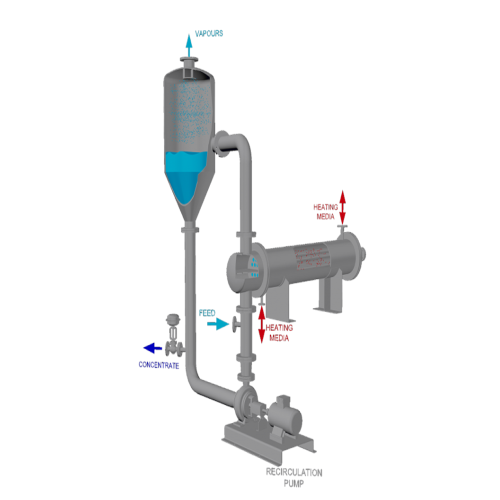

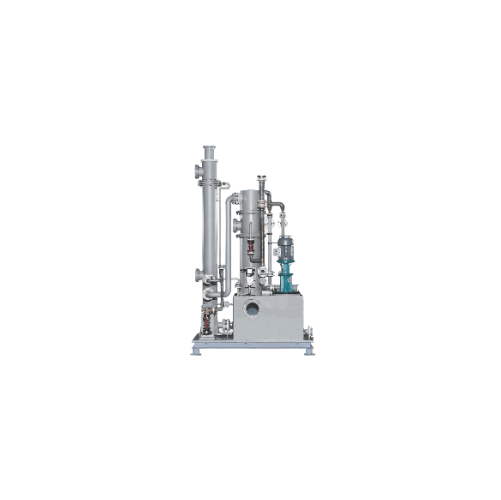

Climbing film plate evaporator for food industry

Efficiently concentrate heat-sensitive liquids while minimizing product e...

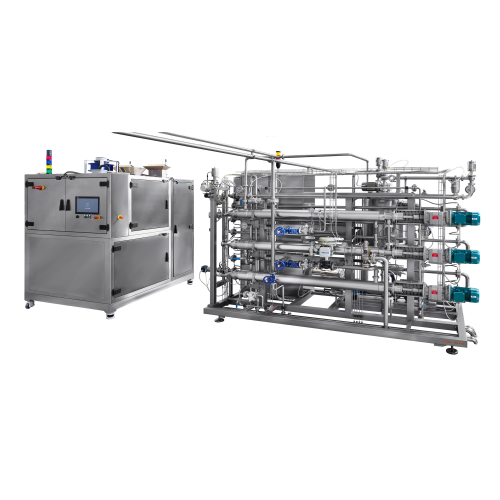

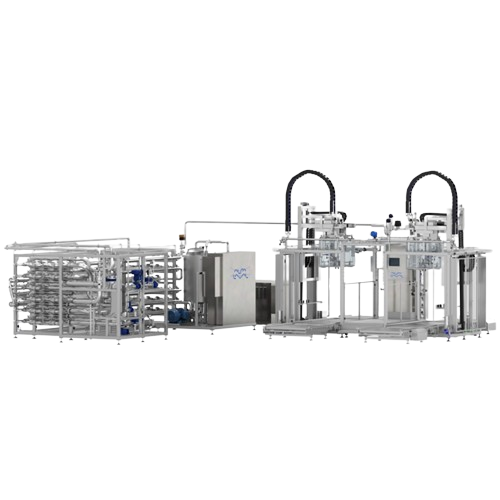

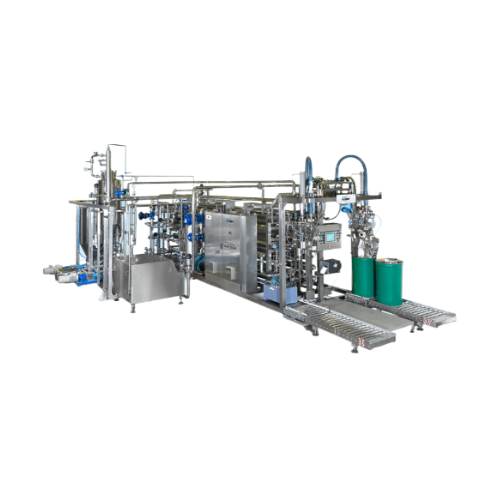

Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product...

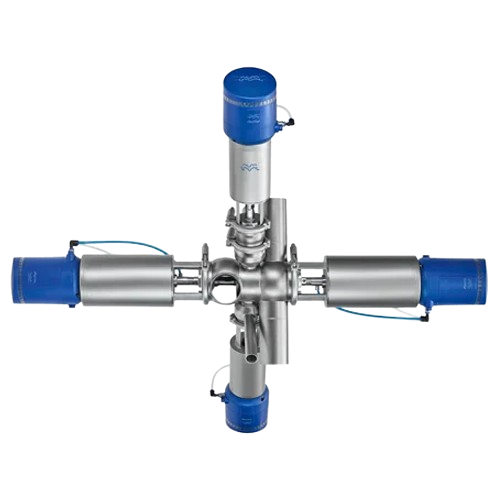

Air-operated single-seat valves for food and beverage industries

Achieve precise flow control and elimination of downtim...

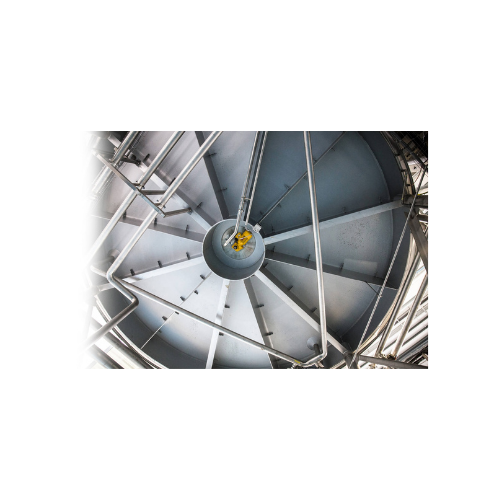

Rotary jet head tank cleaning system for food and beverage industry

Reduce your tank cleaning costs by up to 70% with a...

Sanitary static blender for food and beverage

Optimize your mixing process with low shear, energy-efficient blending desig...

High speed horizontal flow wrapper for food products

Achieve precise, high-speed packaging for snacks with this versatile...

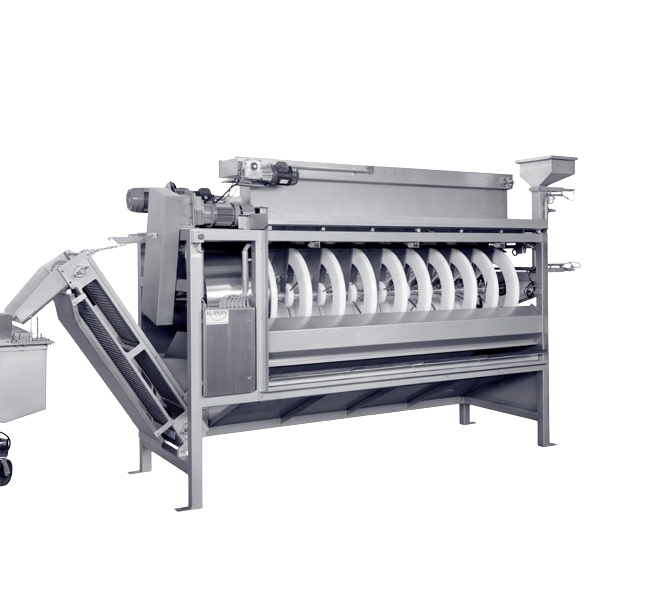

Split peanut blancher for snack food processing

Efficiently transform roasted or dried peanuts into perfectly blanched pro...

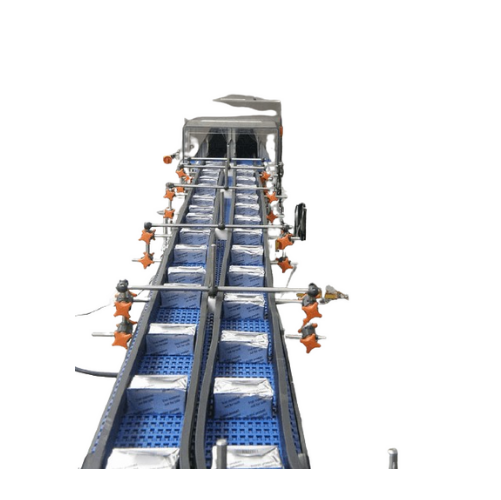

Conveyors for material handling in food processing

Streamline your snack production line with conveyors designed to effic...

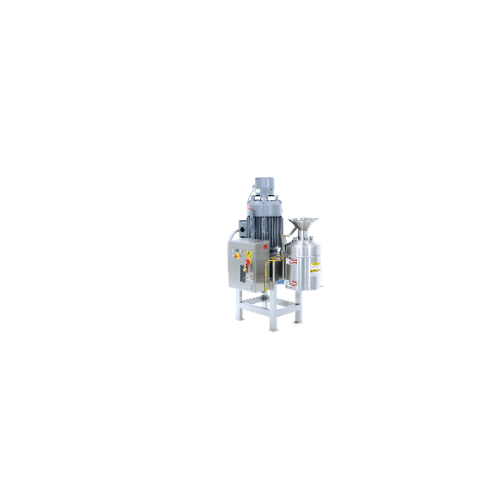

Nut butter mill for snack food processing

Efficiently transform various nuts into smooth, spreadable butters with precisio...

Food forming solution for poultry and plant-based products

Optimize your production line with high-pressure forming that...

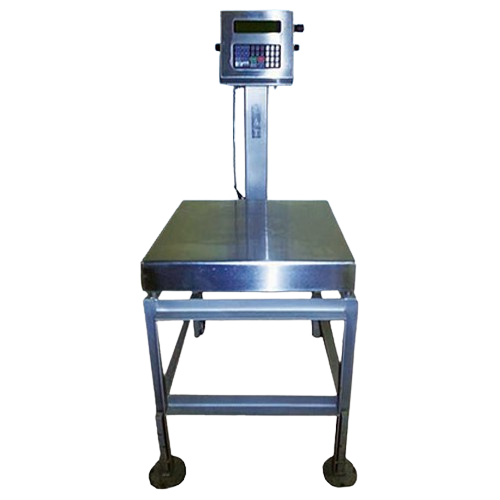

Compact digital bench weighing scale for food processing

Ensure precise portioning with this compact and durable digital ...

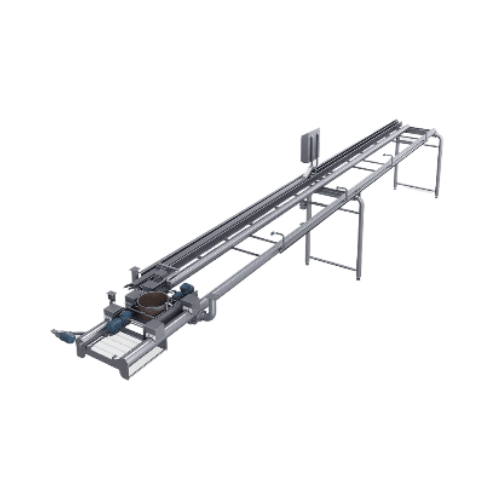

Flat belt product transfer conveyor for food processing

Efficiently streamline your production line with a hygienically d...

Automatic tray sealer for high-speed food packaging

Optimize your production line with a high-capacity tray sealing solut...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

High-speed tray sealer for food

Enhance your packaging line’s efficiency with a high-speed, in-line tray sealer design...

High-capacity tray sealer for poultry, meat & seafood

Optimize your high-speed packaging line with this large-capacity tr...

Automatic inline tray sealer for food packaging

Streamline your packaging process with high-speed, reliable tray sealing t...

Tenderizer for poultry, meat, and seafood

Achieve consistent meat tenderness and improved marinade absorption with a high-...

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

Electric bin tipper system for food processing

Achieve consistent product flow and minimize manual handling with this adva...

Weighing conveyor for consistent product flow in food processing

Ensure uniform product distribution and precise weight ...

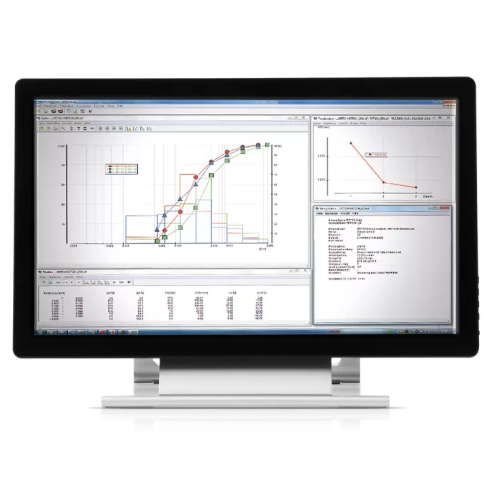

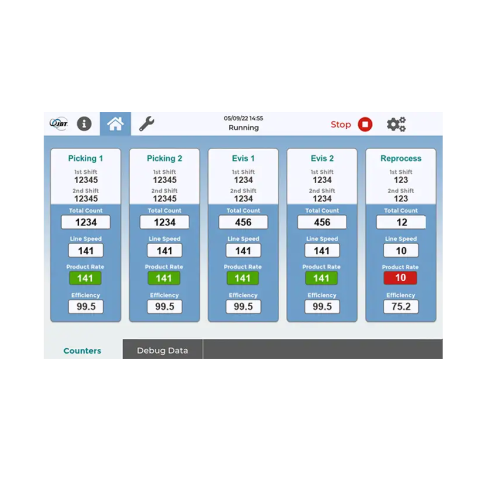

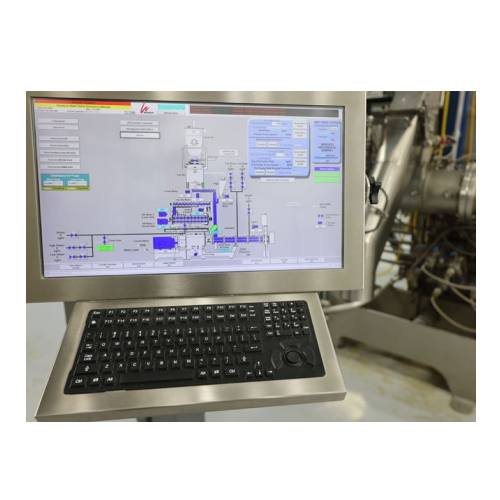

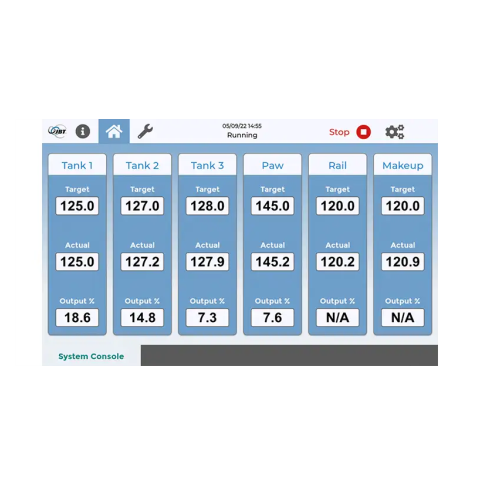

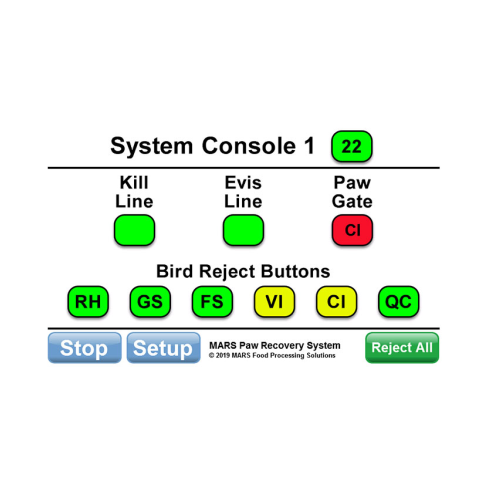

Real-time process monitoring for poultry, meat, and seafood

Ensure full control and validation of your processing with a...

Advanced control system for food processing lines

Streamline your production with a web-enabled interface that allows sea...

Ohmic heat exchanger for high viscosity foods

Optimize the thermal processing of heat-sensitive foods with precise ohmic h...

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous ...

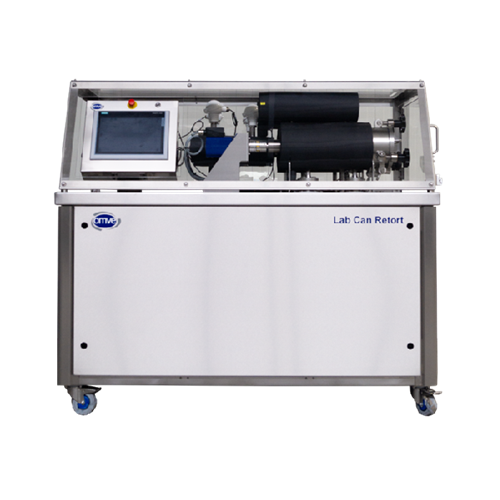

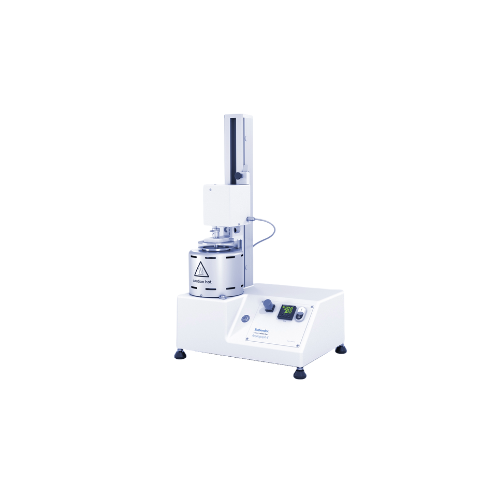

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing syst...

Rotary atmospheric sterilizer for high acid canned foods

Optimize your canning process with uniform heat penetration and ...

Rotary pressure sterilizer for canned food products

Streamline your canning operations with continuous high-speed sterili...

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their ...

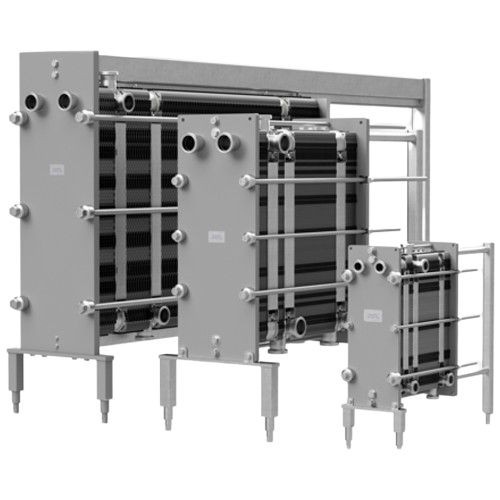

Heat exchanger for liquid and semi-liquid foods

Optimize your heating and cooling processes with superior heat transfer ef...

Low energy suction system for food processing retorts

Optimize your sterilization process with innovative suction technol...

Steam water spray retort for shelf-stable food processing

Ensure uniform heat distribution and precision control in ster...

Agitating batch retort for food sterilization

Ensure superior heat distribution and precise control in your sterilization ...

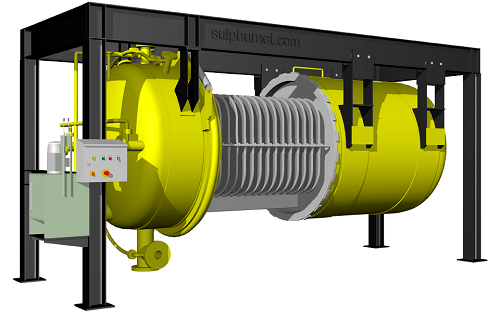

Industrial retort for food sterilization

Achieve uniform sterilization and cooling in your batch production processes while...

High velocity impingement oven for food processing

Optimize your cooking operations with a high velocity impingement oven...

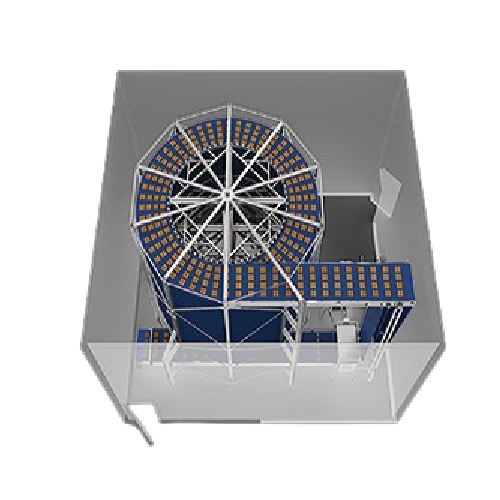

Spiral pasteurization system for packaged foods

Enhance product durability and quality with a compact spiral pasteurizatio...

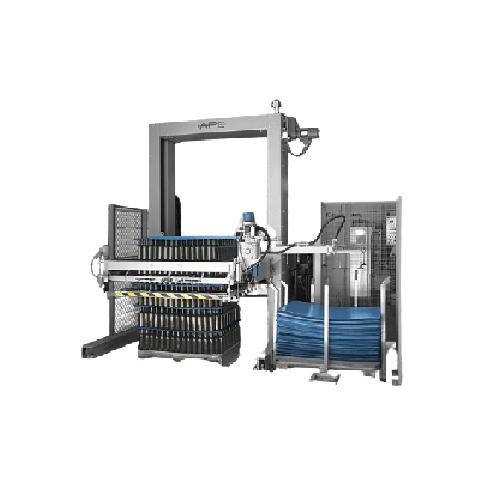

Automated batch retort system for food sterilization

Optimize your sterilization process with seamless transportation fro...

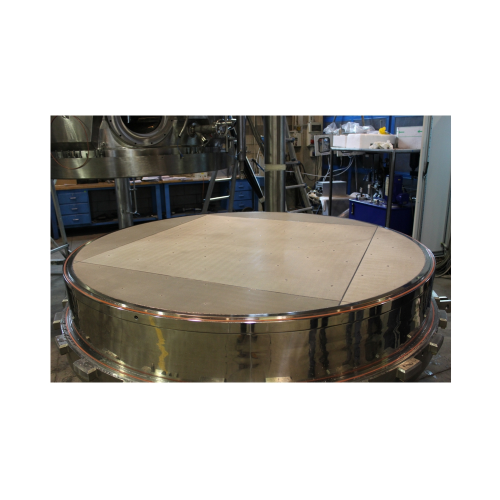

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

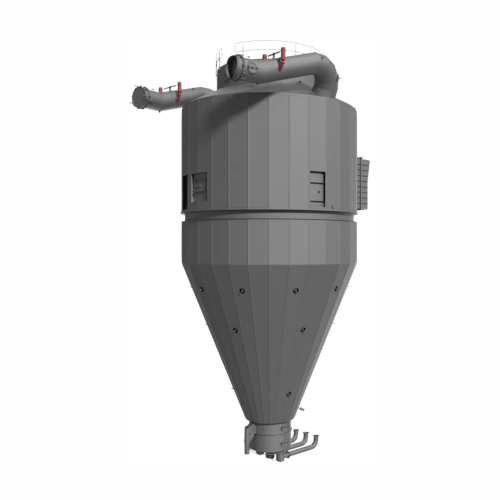

Industrial dust collection system for food processing

Effectively capture and separate airborne dust particles from conti...

Linear convection oven for food processing

Achieve precise cooking and browning of diverse food products simultaneously wh...

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

Compact massager for poultry, meat & seafood

Optimize your marination and curing processes with this compact massager, str...

High-pressure processor for seafood processing

Transform shellfish processing with advanced high-pressure technology that ...

Industrial injector for poultry, meat and seafood

Enhance your protein processing with precise injection and tenderizing ...

Laboratory fryer for food product development and small runs

Ideal for perfecting culinary creations, this fryer facilit...

Direct heated immersion fryer for convenience food processing

Achieve superior temperature control and minimize oil cons...

Force flow hot oil filter for food processing

Upgrade your frying oil filtration with a system that removes particulates d...

Conveyorized thermal fluid immersion fryer for coated food products

Optimize frying processes with precise heat control...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

High pressure processing for diverse food products

Maximize production versatility and ensure product safety with a high-...

Industrial fryer for meatballs and vegetarian food

Enhance your production with a versatile industrial fryer that offers ...

Compact spiral freezer for food processing

Enhance your production efficiency and hygiene standards with a compact, self-s...

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, o...

Spiral freezer for frozen food production

Optimize your product’s shelf life and quality with advanced freezing tech...

Industrial spiral freezer for high-volume food processing

Optimize your production line with a modular spiral freezer th...

Spiral freezer for high-volume food products

Achieve rapid, sanitary freezing with this spiral system, designed to handle ...

Structure supported spiral freezer for food products

Optimize your high-speed production with a versatile spiral freezer ...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Efficient industrial re-chiller for poultry and seafood cooling

Enhance your production line’s efficiency by maint...

Portioning system for poultry, meat, and seafood

Achieve precise cuts and maximize yield with high-speed waterjet technolo...

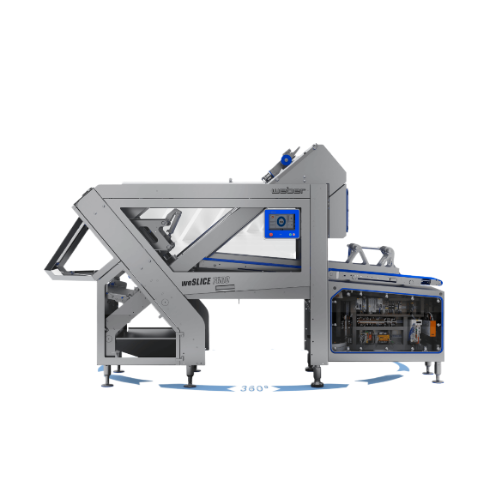

Adaptive slicer for poultry, meat & seafood

Optimize your slicing and portioning with precision control, leveraging real-t...

Inspection system for portioning precision in food processing

Enhance your production line with an advanced inspection s...

Tempura batter applicator for poultry, meat & seafood

Achieve uniform and complete tempura coating with the total immersi...

Automatic tempura batter mixer for poultry and seafood

Enhance the consistency and quality of your tempura coatings while...

Batter applicator for poultry, meat, and seafood

Achieve precise batter application with adjustable submerger controls, en...

Batter mixer for small to medium food production lines

Achieve precise, consistent batter mixing with our semi-automated ...

Breading applicator for poultry, meat & seafood products

Improve your production line with versatile breading and predust...

Electric breading applicator for high-volume food production

Enhance coating precision and ensure dust containment with ...

Breading line for poultry and seafood products

Elevate your production with high-speed breading lines designed for uniform...

Viscous coating applicator for poultry, meat & seafood

Effortlessly apply even viscous coatings like tempura or marinades...

Industrial dust extraction system for food processing

Ensure a dust-free environment in food production with a high-effic...

Preduster for fine-grain coating in food processing

Ensure your products receive a perfect, consistent fine-grain coating...

Breading applicator for poultry, meat & seafood

Ideal for optimizing your coating line, this applicator efficiently handle...

Rotary drum breader for irregular-shaped food coating

Enhance your food products with precise, customizable coating using...

Battering machine for food coating applications

Enhance your food products with uniform and efficient batter application, ...

Industrial batter mixer for food preparation

Achieve consistent batter quality with precise control over viscosity and tem...

Automatic double clipper for sausage and food packaging

Streamline your packaging process with precision clipping technol...

Brine preparation system for poultry, meat & seafood

Optimize your brine production for consistent flavor and texture wit...

Seafood brine preparation system

Optimize your meat and seafood production with this versatile brine preparation system, ens...

Brine preparation system for poultry, meat, and seafood

Achieve consistent marination with precise ingredient dissolution...

Dry condensing vacuum system for food industry

Optimize energy consumption and wastewater disposal in your production line...

Industrial slicer for natural shaped food products

Achieve superior slicing precision and efficiency with high-speed tech...

3a certified product recovery system for food and pharmaceuticals

Optimize your production line with a system designed ...

Overlapping loader for sliced food products

Achieve precise overlapping in high-speed slicing operations, ensuring consist...

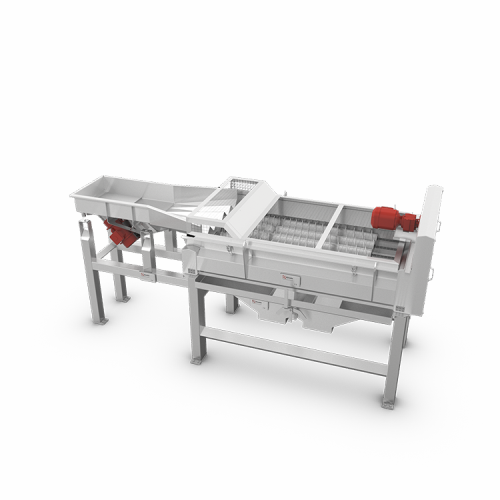

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Sifter for pet food, fish feed, and animal feed

Achieve precise particle separation and enhance feed quality with this vib...

Silo unloading belt for food industry

Ensure seamless flow and precise control when unloading silos with this automated bel...

Bulk storage silos for food products

Ensure optimal powder storage and handling with versatile silos designed for efficient...

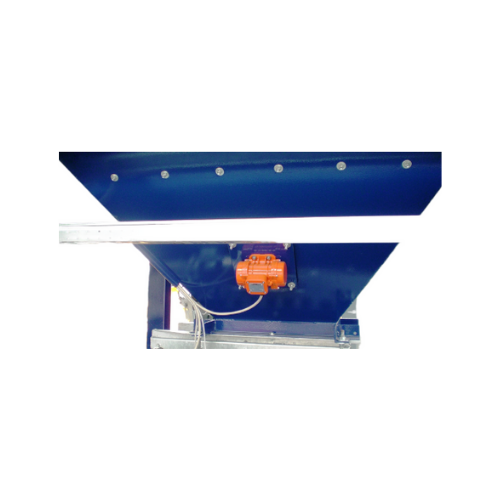

Vibrating feeder for food and pharmaceutical industries

Optimize your production line with precision dosing and gentle ma...

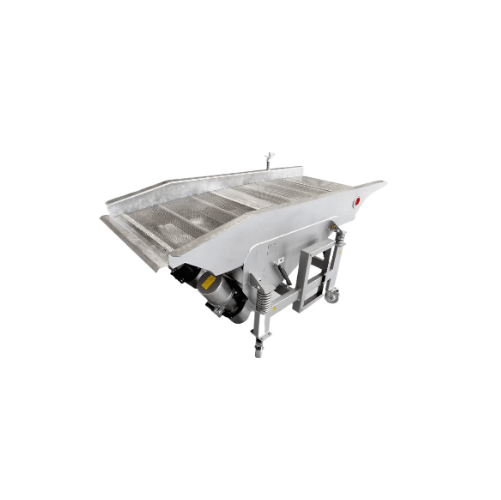

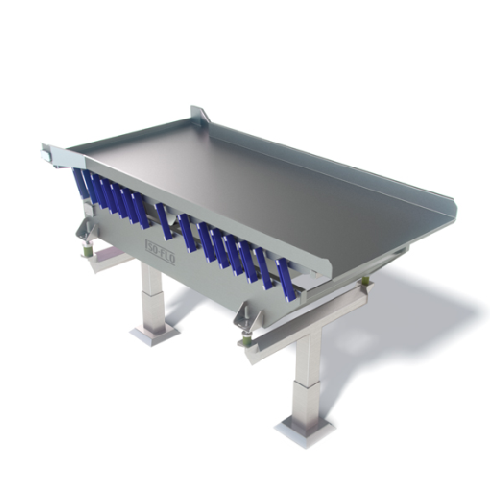

Vibration table for food, feed, and chemical industries

Optimize your production line with a versatile vibration table de...

Powder sampling solution for dairy and food processors

Ensure precise quality control with a versatile sampling system de...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

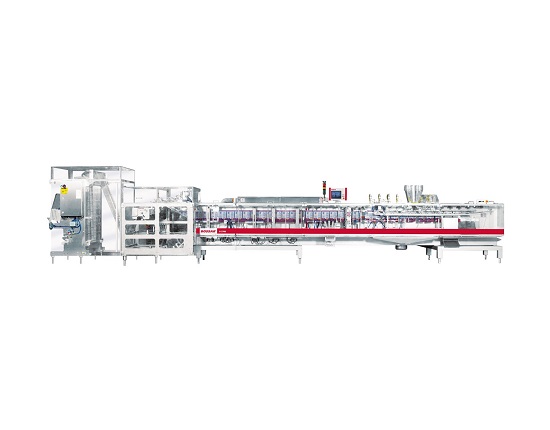

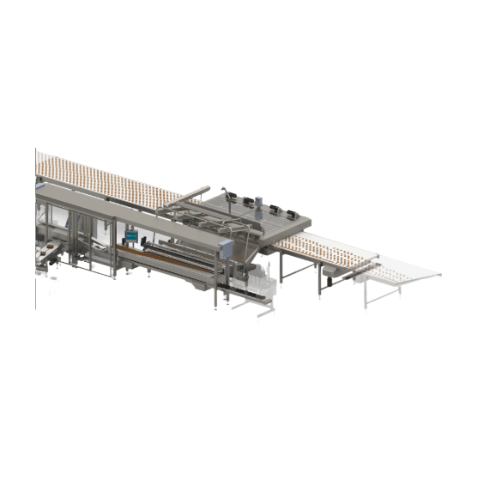

Vertical packaging system for short-cut pasta and dry granular food

Streamline your packaging operations with a high-sp...

Packaging system for short-cut pasta and dry granular food

Streamline your packaging process with a versatile system des...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Industrial predryer for humidity reduction in food processing

Ensure optimal shelf life and prevent product sticking wit...

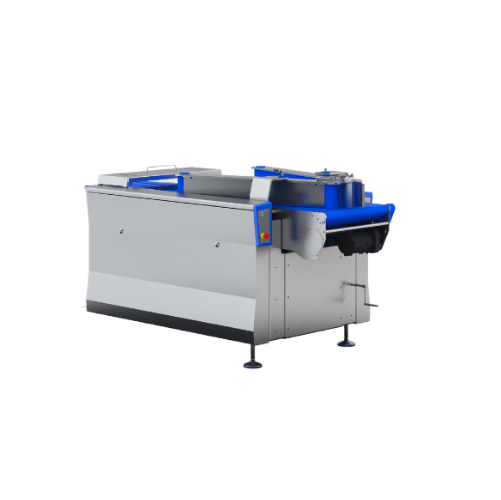

Industrial water cooling system for food products

Efficiently cool and convey food products with a system designed for un...

Industrial food grinder for meat and vegetables

Enhance your grinding process with a robust solution designed to efficient...

Twin-shaft mixer for food preparation

Achieve optimal protein extraction and ingredient distribution with this twin-shaft m...

Brine chiller for meat and seafood injection

Achieve consistent brine injection by stabilizing temperature fluctuations, e...

Massaging and tumbling system for meat and seafood

Enhance your meat and seafood processing with a versatile system offer...

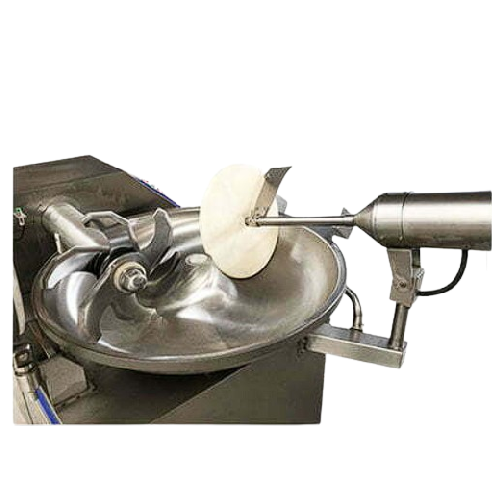

Bowl cutter and emulsifier for food processing

For food processors looking to achieve precise cutting, mixing, and emulsif...

Vacuum-sealed bowl cutter for food processing

Enhance your food production with a vacuum-sealed bowl cutter that optimizes...

Brine mixing equipment for food processing

Achieve homogeneous brines and marinades effortlessly with our state-of-the-art...

Tempura coating system for food processing

Achieve consistent and efficient tempura coating with a versatile system that s...

Industrial food coating solution

Achieve precise and customizable coatings with advanced equipment designed to enhance produ...

Versatile plate forming system for food products

Optimize your food production line with a system that forms everything fr...

Industrial fryer for pork, poultry, and seafood

Enhance your production line with a fryer that ensures consistent, high-qu...

Industrial food processing fryer

Ensure consistent frying quality and enhanced sediment removal for high-volume food product...

Frying oil management system for food producers

Achieve consistent product quality and minimize frying costs with this sys...

Industrial fryer for deep and flash fried foods

Boost your production capacity and product quality with a fryer designed f...

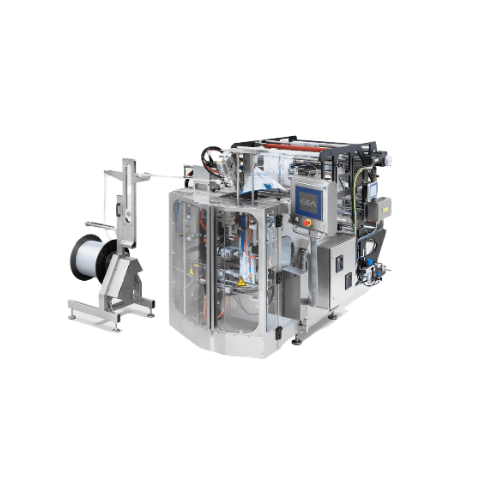

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

Customized spiral freezer solution for food industry

Designed to enhance your freezing efficiency, our spiral solution ha...

Dust-free flour applicator for food coating

Eliminate dust from your coating process with precise flour application, ensur...

Flexible battering system for food production

Optimize your coated product output with a flexible battering solution that ...

Industrial batter applicator for food coating

Enhance your coating process efficiency and precision with a state-of-the-ar...

Robotic palletizer for food and beverage industries

Enhance your production line’s efficiency with a flexible robot...

3-in-1 food package inspection system

Ensure your packaged food products meet safety and regulatory standards with a system...

Entry-level thermoforming packaging system for food products

Streamline your packaging process with a versatile thermofo...

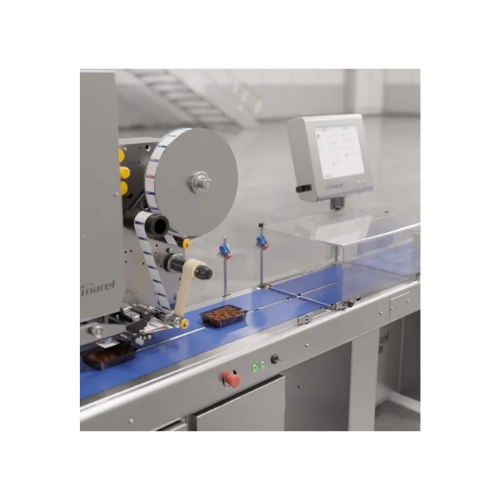

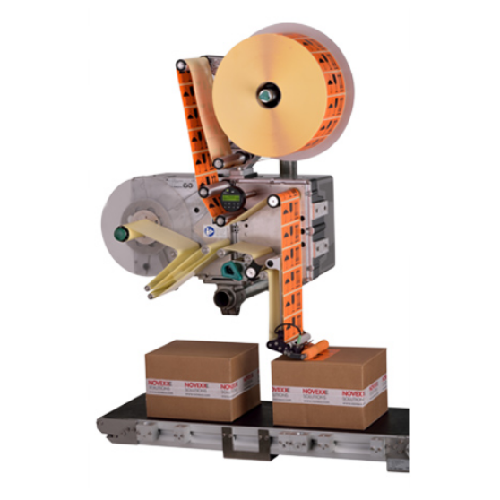

High-speed cross-web labeling for food packaging

Streamline your packaging process with a high-speed labeling system desig...

Thermoforming packaging for food products

Enhance your packaging operations with advanced thermoforming technology, perfec...

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

Single-screw cooking extruder for high-value food products

Transform raw materials into diverse, high-value products wit...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

Freeze concentration system for liquid food products

Achieve precise concentration while preserving volatile components a...

Freeze concentration system for liquid food concentrates

Achieve superior concentration of liquid food products while pre...

Powder separation cyclone for food and chemical industries

Optimize your powder production with advanced cyclone technol...

Automated fines return system for food and dairy spray dryers

Enhance your spray drying process by eliminating manual in...

Bag filter for food and dairy spray dryers

Achieve cost-efficient and reliable dedusting for your spray drying processes w...

Spray cooler for food and chemical industry applications

Achieve precise particle size control and encapsulation for melt...

Industrial freeze drying system for high-volume food products

Achieve precise moisture removal and preserve product qual...

Liquid nitrogen freezer for sensitive food and fermentation ingredients

Achieve rapid, uniform freezing of sensitive fo...

Batch freeze drying system for food and beverage preservation

Achieve precise and efficient preservation of your food an...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

Sterilization of concentrated food products using direct steam

Achieve rapid and efficient sterilization with direct ste...

Clarifying decanter for food ingredient processing

Optimize your protein recovery and ensure high-quality separation with...

Cip cleaning system for food industry facilities

Ensure optimal hygiene in juice production lines with an advanced CIP cle...

Food freeze dryer for bulk materials

Achieve efficient and uniform drying of fruits, herbs, and other materials with advanc...

Rotary vacuum fillers for liquid and semi-liquid food products

Achieve precise filling of a wide range of liquid and sem...

Handpack fillers for diverse food products

Streamline your canned food production by efficiently filling a wide range of c...

Solid product feeding systems for food industry

Ensure consistent product flow and maximize filling efficiency in your pro...

Integrated filling and capping system for food and soft drinks

Streamline your bottling operations with an integrated sy...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Automatic can seamers for food and beverage industry

Ensure airtight sealing of canned goods with precision seamers desig...

Seamers for round food containers

Ensure airtight sealing for food products with high-speed seamers designed for precision ...

Complete filling and closing line for food containers

Optimize your production line with a versatile solution that ensure...