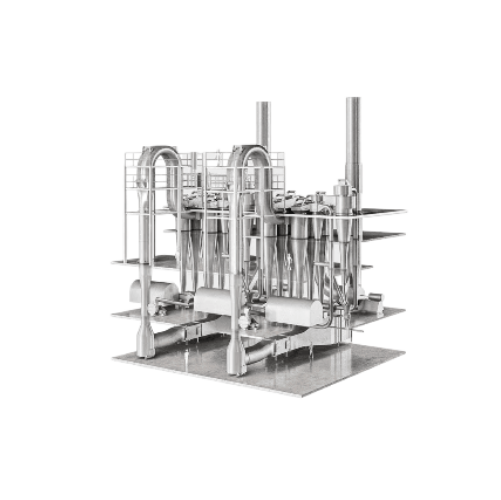

Flash dryer for industrial moisture removal

Optimize your production with rapid moisture removal, efficiently transforming wet feed into dried product with precision control, ensuring quality retention and energy savings across various materials and processes.

Dries and Conveys Moisture-Rich Materials Efficiently

The Flash Dryer from GEA Solid Feed Drying utilizes a high-temperature pneumatic system to swiftly drive off free moisture, ensuring minimal risk of thermal degradation. It caters to industries such as agrifood, chemicals, and pharmaceuticals, supporting products like cornflakes, fertilizer granules, and soy protein isolate. The dryer is designed for continuous, high-speed operations and can process a range of materials including powders, slurries, and pastes. It features partial gas recycle (PGR) for enhanced thermal efficiency and reduced emissions. The system integrates smoothly into production lines, offering flexibility through automation and minimal maintenance with its simple design and few moving parts. Available with options for stainless steel construction, it meets various industry standards for quality and safety.

Benefits

- Ensures optimal product quality with rapid moisture reduction.

- Provides energy savings through partial gas recycle configuration.

- Enhances operational flexibility with integration into various production systems.

- Reduces maintenance requirements with a simple, robust design.

- Supports environmentally compliant operations by meeting current emission standards.

- Applications

- Chemicals, Gels, Organic fertilizers, Slurries, Granules, Animal feeds, Sludges, Viscous products, Soy fibre, Waste products, Agrifood, Pastes, Cakes, Modified starches, Minerals, Flakes, Powders

- End products

- Modified wheat starch, Organic fertilizer pellets, Animal feed pellets, Limestone powder, Gelatin powders, Soy protein isolate, Paint sludge coating, Cornflakes, Liquid detergents, Biopolymers, Pigment dispersions, Granola, Industrial sludge pellets, Fertilizer granules, Muesli base flakes, Ceramic slurries, Ceramic powders, Cellulose ether powders, Cement additives

- Steps before

- Slurry Preparation, Wet Feed Conditioning, Backmixing with Dry Product

- Steps after

- Cooling, Conveying, Cyclone Separation, Bag Filtering, Scrubbing, Exhaust Gas Cleaning, Packing

- Input ingredients

- wet material, wet feed, slurries, pastes, sticky materials, powders, cakes, granules, flakes, gels

- Output ingredients

- dried product, powdered product

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Drying method

- Flash drying

- Product temperature control

- Instant cooling

- Heat source

- Heated air or gas

- Feed type

- Powders, cakes, granules, flakes, pastes, gels, slurries

- Exhaust gas cleaning

- Cyclones, bag filters, scrubbers

- Thermal efficiency

- Recycling of exhaust gases

- Residence time

- Short

- Operational configuration

- Open circuit or partial gas recycle

- Atmospheric conditions

- Inert atmosphere possible

- Cooling system

- Pneumatic cooler with ambient or conditioned air

- Finer control option

- Controlled humidity and temperature

- Working mechanism

- Pneumatic system

- Integrated steps

- Drying, Cooling, Conveying

- Batch vs. continuous operation

- Continuous

- Automation level

- High (SCADA available)

- Energy efficiency

- Recycling of exhaust gases

- Air incorporation control

- Airflow control via system design

- Cleaning method

- Manual / CIP options

- Density/particle size

- Variable, depending on product

- Heat Sensitivity

- Sensitive

- Viscosity

- Varies (low to high)

- Moisture Content before Drying

- Varied

- Compact footprint

- Yes

- Control panel type

- PLC

- Discharge method

- Cyclones / Bag filters

- Control panel type

- PLC / Touchscreen

- Pneumatic cooler options

- Ambient air / Conditioned air

- Gas recycle configuration

- Open circuit / Partial gas recycle (PGR)

- Inert atmosphere operation

- Yes

- Backmixing system

- Available / Optional