Powder Manufacturing Equipment

Find innovative powder equipment and connect directly with world-leading technology suppliers

The building blocks of matter have driven the imagination of philosophers, scientists, and artists for millennia. But, for manufacturers, these elements have a more concrete existence as powders. Powder processing technology conditions these primary materials to create a vast range of products, from chemicals and foods to pharmaceuticals and ceramics.

Top picks in powder process equipment

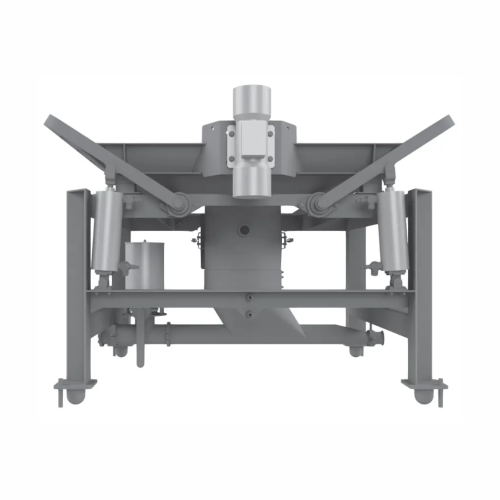

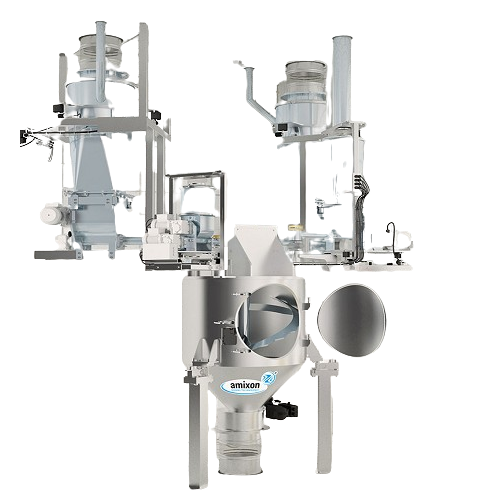

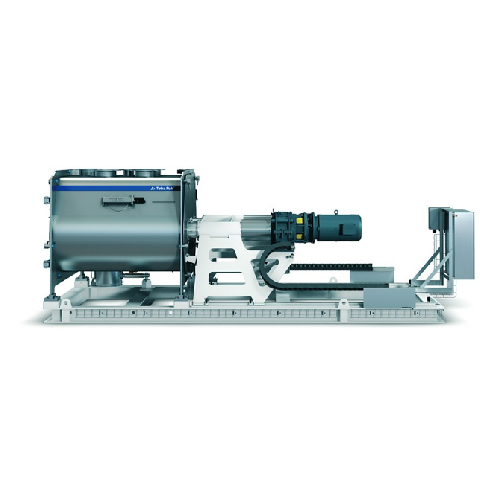

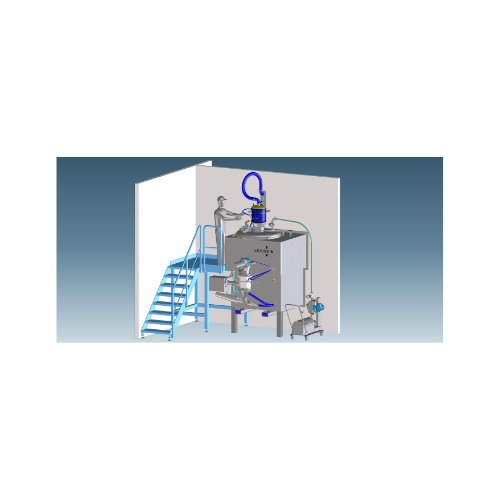

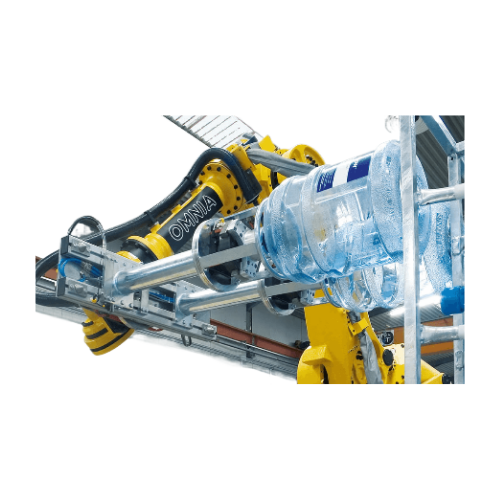

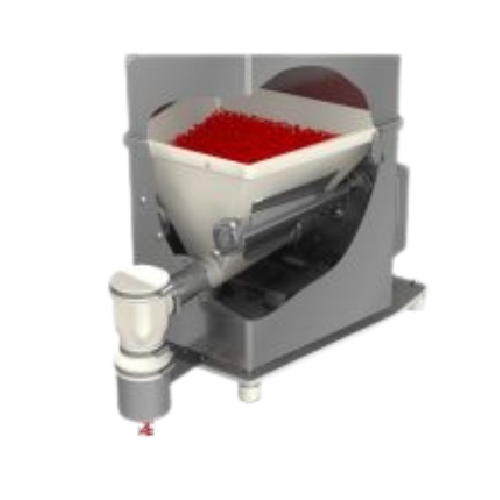

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate produc...

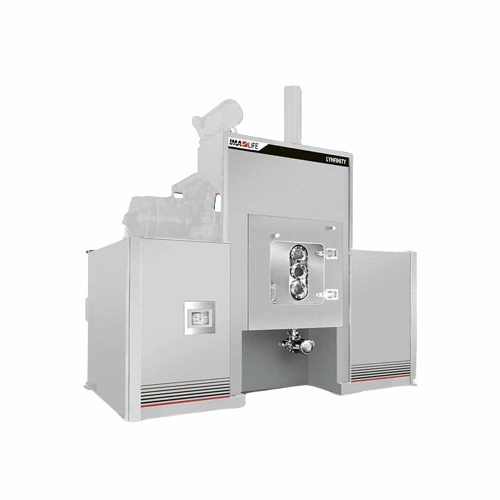

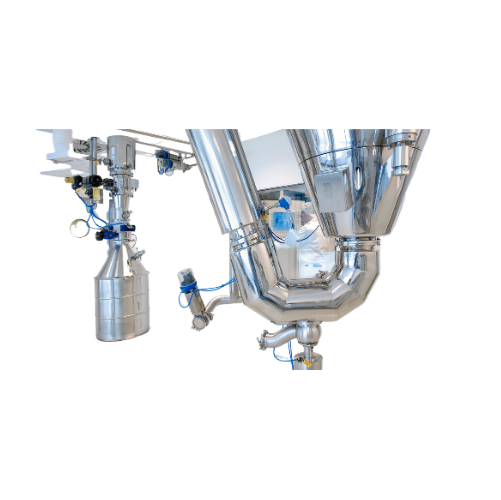

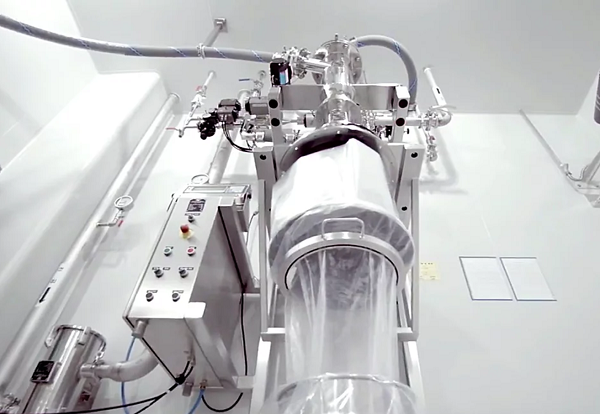

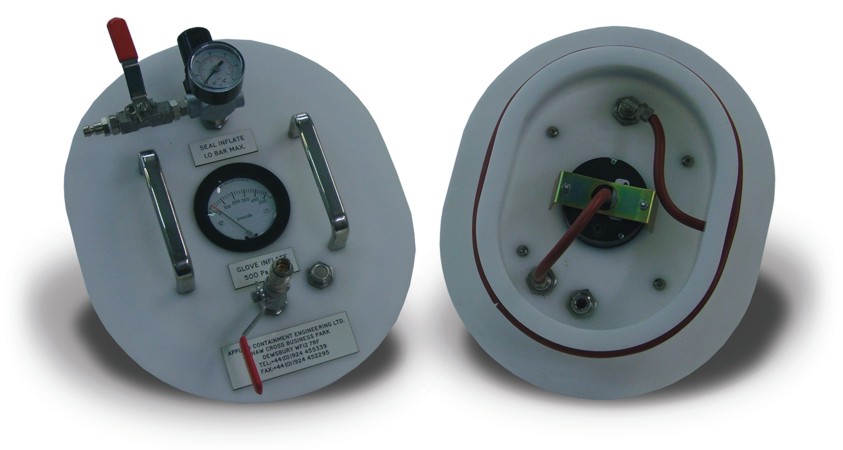

Atex compliant isolator for dispensing powder procedures

Ensure safe weighing and transfer of explosive and pharmaceutica...

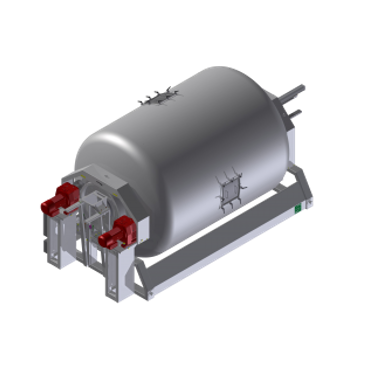

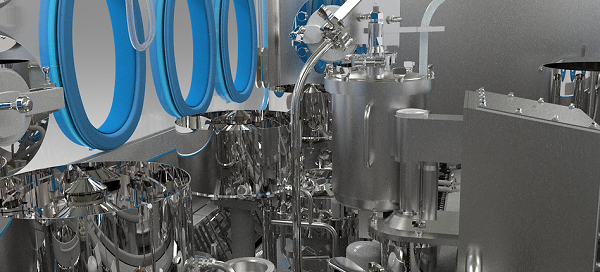

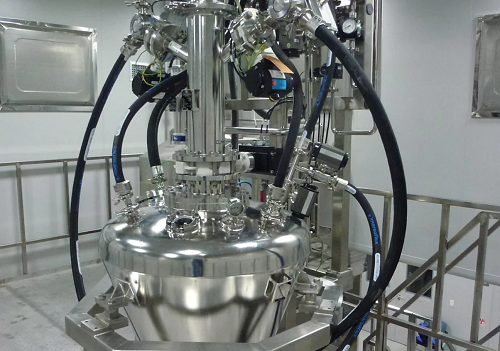

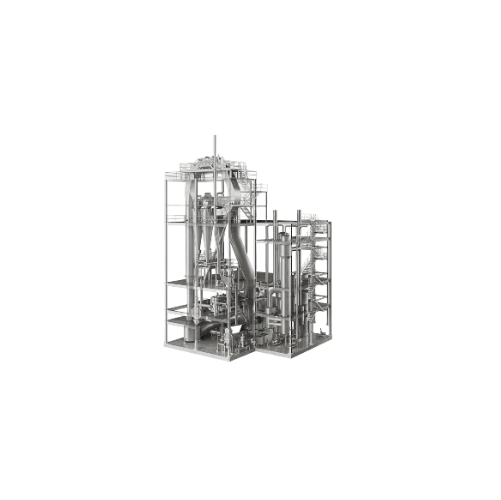

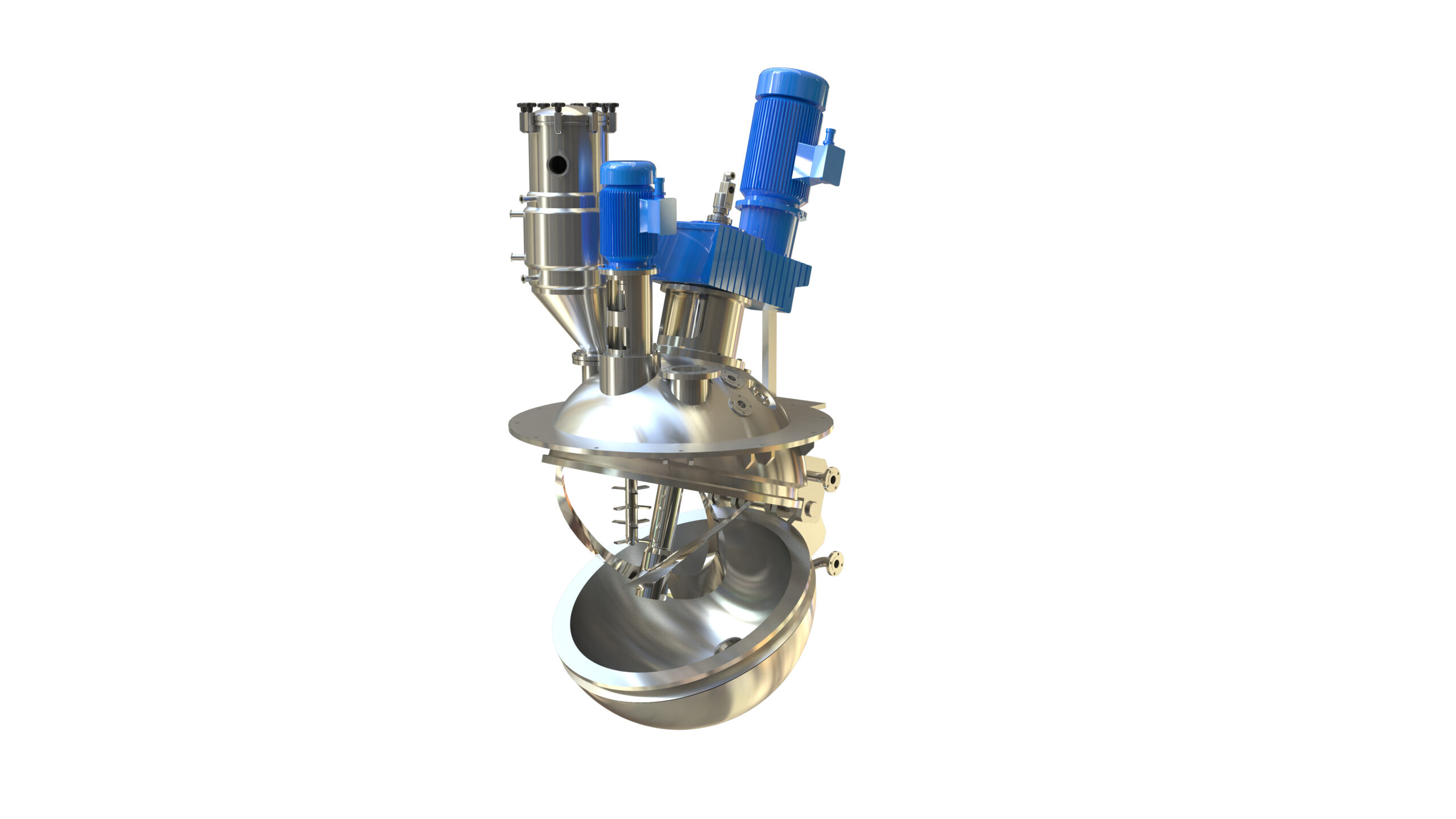

Powder synthesis reactors for nanometer and micrometer particles

Achieve precise particle control and enhance material p...

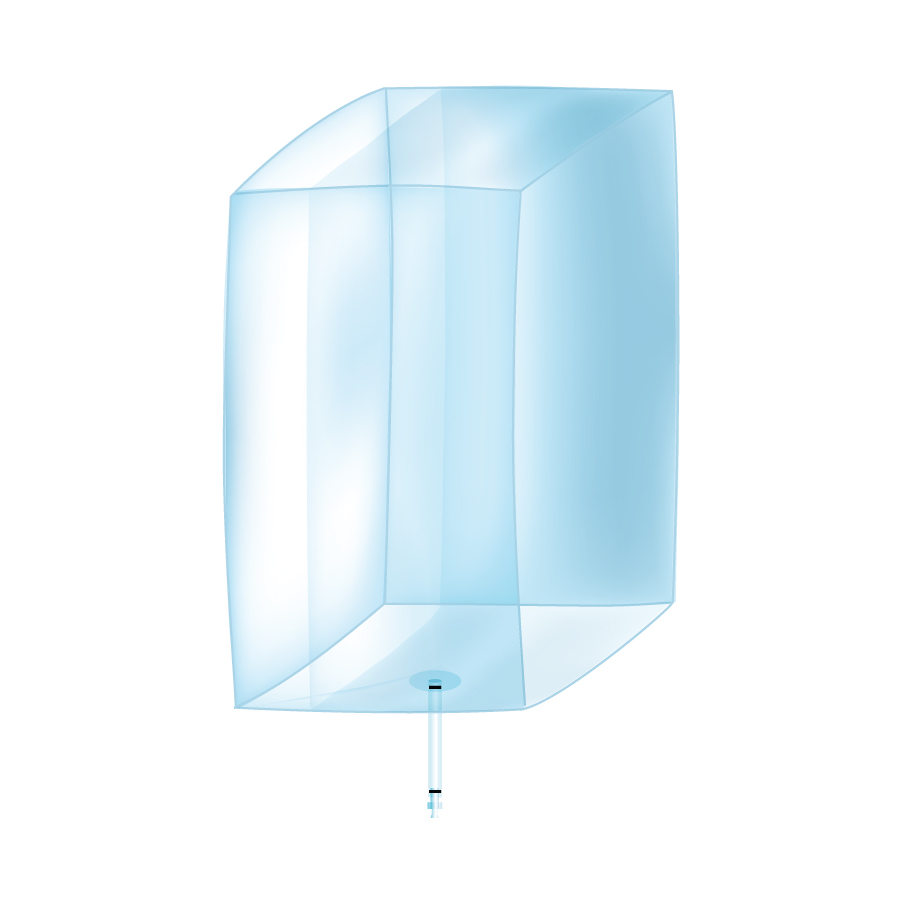

API powders storage bottle

Users who prefer rigid storage over single-use pharma charge bags, require lightweight solutions ...

Stories about powder

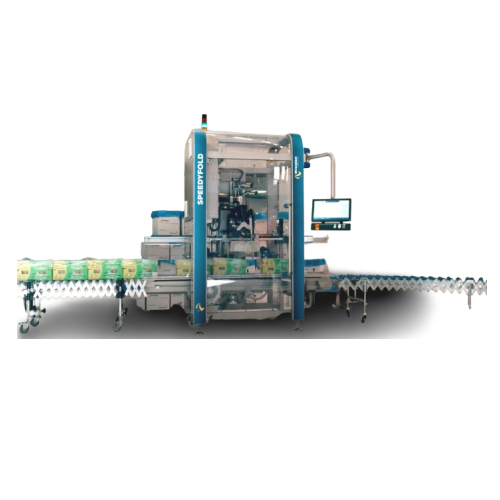

Keeping up with the trends: cartoning sustainable materials and utilizing AI all at once

Powder and liquid, a delicate equilibrium in paint production

Wet milling: The revolution in the API production

From flavorless to fabulous: unlocking the full potential of reaction flavors for tasty plant-based food

Preserve your milk powder during transportation. Big Bags: “Challenge accepted!”

Closing the containment loop in HPAPI manufacturing

#Changemaker: Chickpea protein for your plant-based food product!

Clean up your label, drying fruit extracts without using carriers

#Changemaker: FIBC with brains

Unpacking the world of stick pack cartoning

#Changemaker: white chlorella as your next protein source!

What are you making?

Talc powder

Soy flour

Solids

Powder dissolving

Polymer powders

Polyethylene powder

Lentil flour

Hygroscopic products

Free-flowing powders

Food powders

Dry powders

Chemical powders

Spirulina powder

Chlorella powder

Vegetable powder

Gypsum

Gelatin powder

Metal powder

Powder detergent

Face powder

Eyeshadow

Protein powder

Active pharmaceutical ingredients (API)

Curry powder

Chili powder

Fruit powder

Instant soup

Milk powder

Instant coffee

Ground coffee

Flour

Baking powder

Tell us about your production challenge

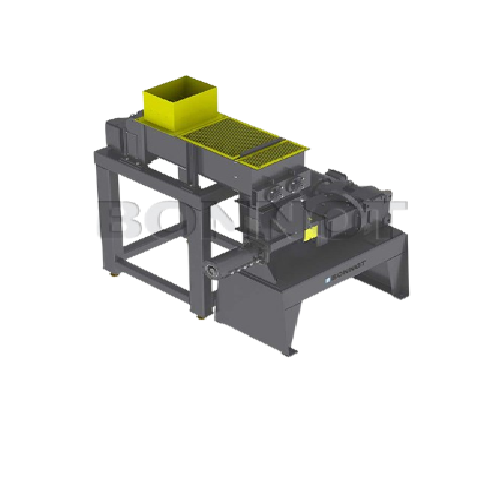

Crush primary materials to free valuable grains from impurities

The first step to pulverizing a solid is through a crusher. The raw material is downsized to flakes, chips, or granules by crushing technology. Some bulk types, such as plastics or resins, are broken down into filaments.

Crushing breaks the grains away from gangue materials, particularly in the case of ore. Undesired compounds such as common silicate and carbonates are removed using separation technology like magnetic separators for metals and froth flotation for hydrophobics.

Use anti-clogging powder process equipment to ensure flowability

One of the main attributes of powders is flowability. Dry materials with a similar particle structure flow more easily than powders of different shapes. However, size is also an important variable in industrial powder handling.

Flowability decreases with the particle size as powders display greater cohesion and internal friction the smaller they become. To prevent ratholes or bridging and facilitate flow, advanced manufacturing equipment applies anti-clogging systems. These powder processing systems and techniques are designed to move fine to ultra-fine bulk in specialized powder applications from pharmaceuticals to food to cosmetics.

Avoid unwanted agglomeration by coating powders in anti-adherent components

Manufacturing technology often subjects powders to thermal stresses that could degrade their processability. High pressure friction and heat lead to surface diffusion, bonding particles together.

To prevent such undesired agglomeration, coat the powder particles in an anti-adherent substance like magnesium stearate. The water-insoluble compound is sprayed onto the material in a mixing drum to create a film around the particles.

Heat mineral and metal fine powders to overcome resistance to compaction

Mineral and metal powders present unique challenges in terms of processing, particularly when they are comminuted to finer materials. Particles become harder as their surface area increases, making them more challenging to densify.

Ductile metals like aluminum and copper retain plastic deformation properties down to particle sizes of 50-100 nanometers. But beyond that, powders need to be subjected to high temperatures to be effectively compacted.

Reduce powders to their nanostructures to maximize their properties

Particles of nanometric scale bond together to form nanopowders. As the ratio between surface area and volume increases, the characteristics of the atoms become more pronounced.

For instance, nanocrystalline materials such as titanium alloys nickel exhibit enhanced hardness and plasticity. Advancements in powder processing technology allow engineering at the nanoparticle level, opening opportunities for new lightweight materials with solid structural stability.

Develop nanopowders either by bonding particles or downsizing granules

There are two ways to approach the production of nanopowders: large-to-small or small-to-large. When working with large materials like metals or minerals, the powders are generated by attrition. The techniques here are primarily mechanical, using dry milling equipment like jet mills or roll mills.

If you work with molecules such as sodium, the process goes from small to large by bonding molecules together to form the particle. This involves electromagnetic techniques like electrospinning and electrodepositing.

Which powder technology do you need?

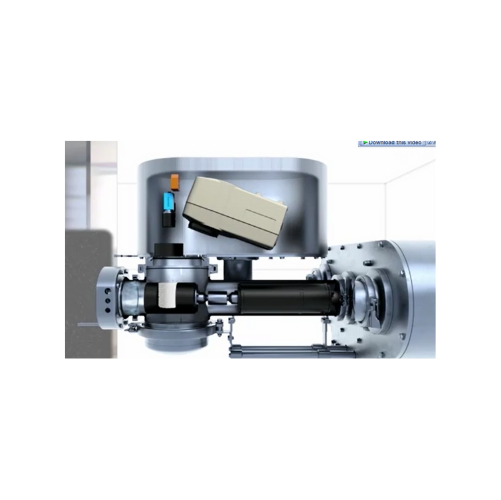

Inline powder analysis system

Ensure optimal powder quality with real-time measurement of moisture, density, and contaminant...

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

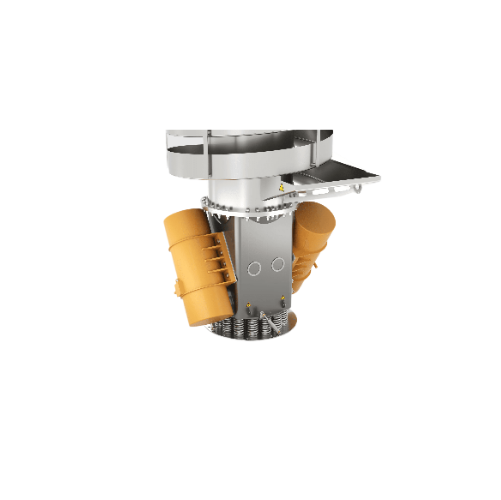

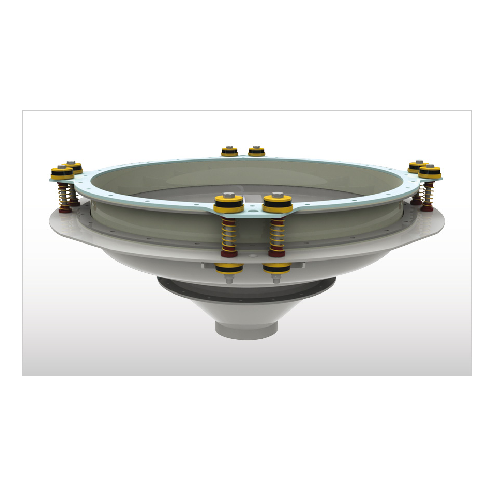

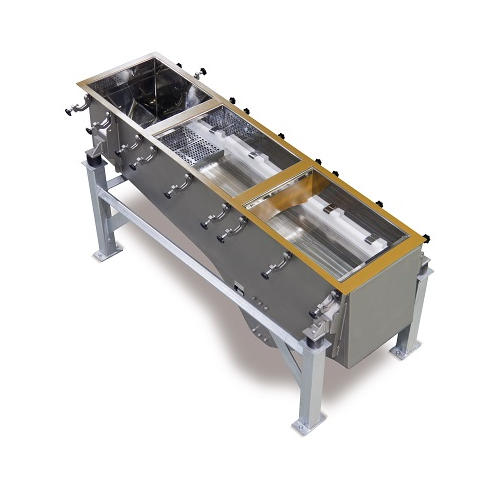

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Conical mill for high-capacity powder milling

Optimize your powder milling process with efficient conical milling systems ...

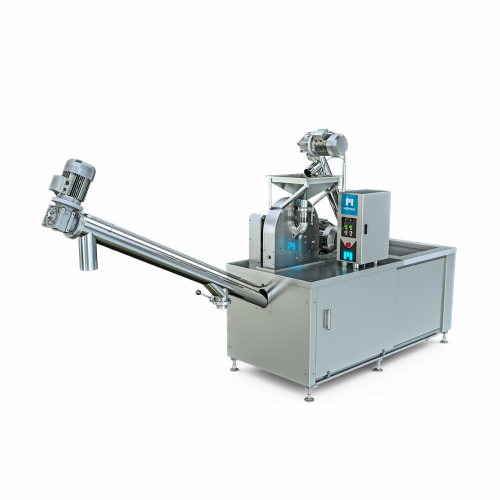

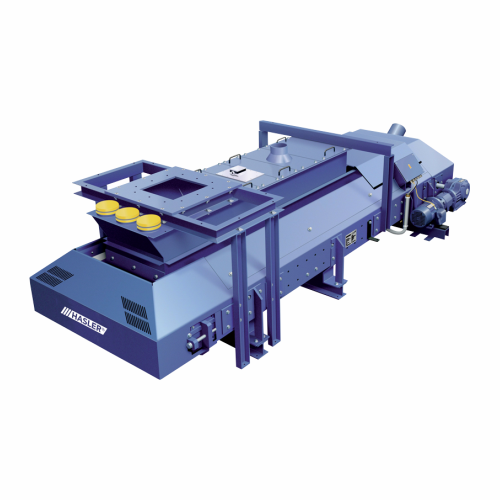

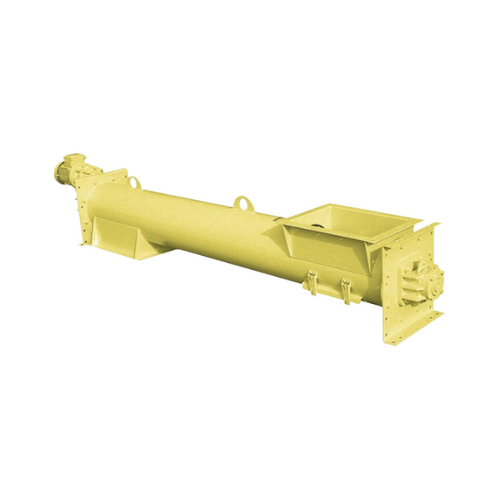

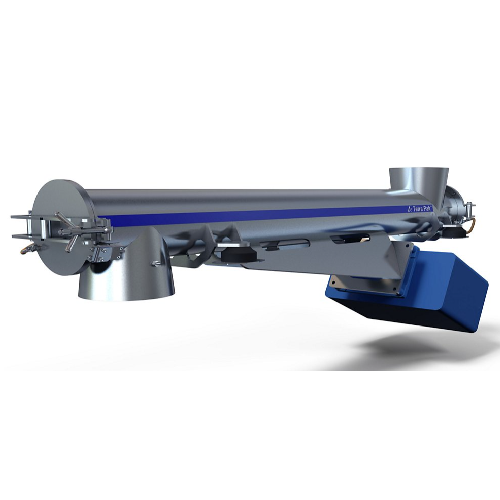

Mechanical conveyors for powder transport

Optimize your powder and granule handling with precise, customizable conveying s...

Magnetic separators for metal contaminant removal in powder processing

Ensure product purity and safety by effectively ...

Air filtration system for dairy and food powder processing

Optimize powder processing with advanced air filtration, ensu...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

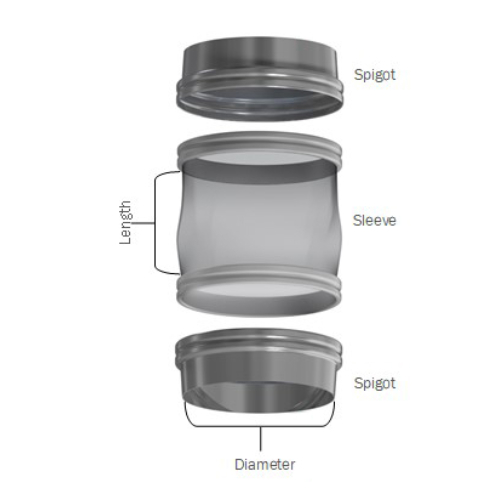

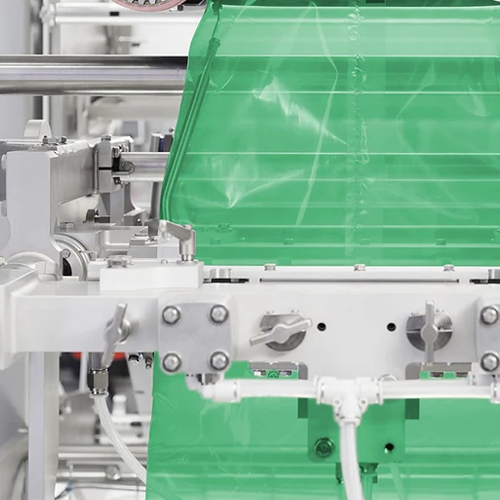

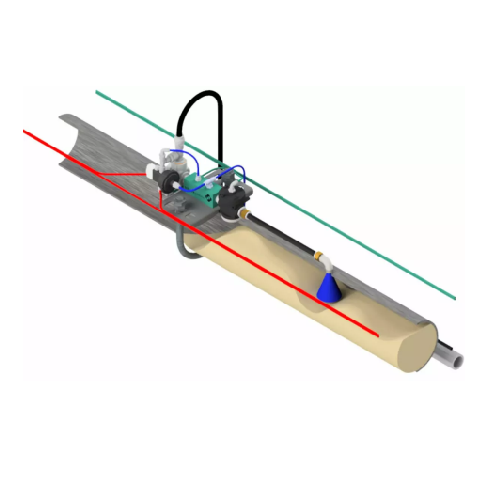

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

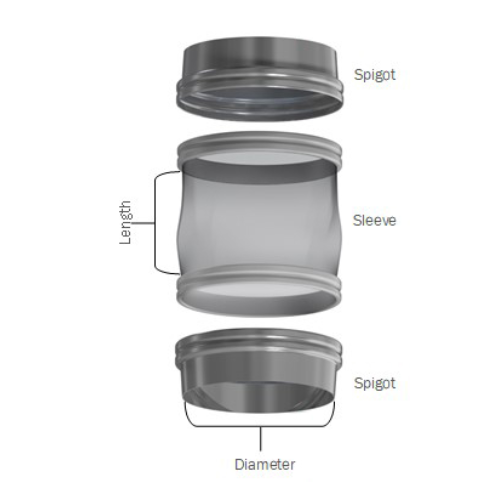

Flexible connector system for bulk powder processing

Eliminate leaks and enhance hygiene in your powder processing line w...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

Efficient powder and granulate flight conveyors

Elevate your production efficiency with our cutting-edge flight conveyors,...

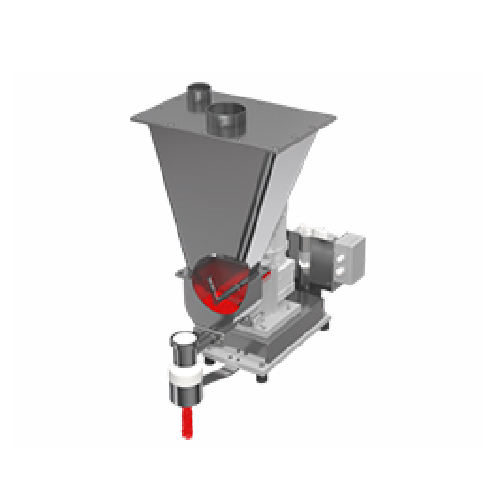

Rotary dischargers for powders and granules

Prevent production halts with this solution designed for efficient discharge o...

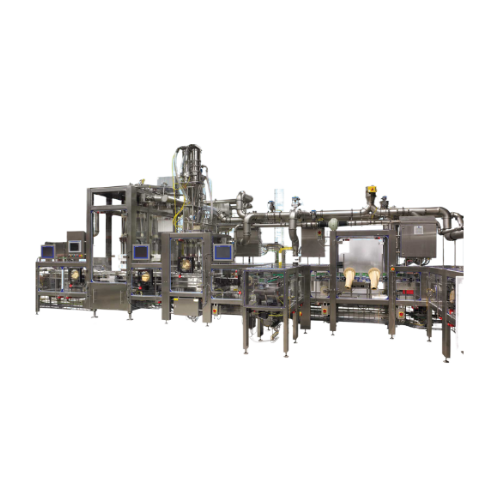

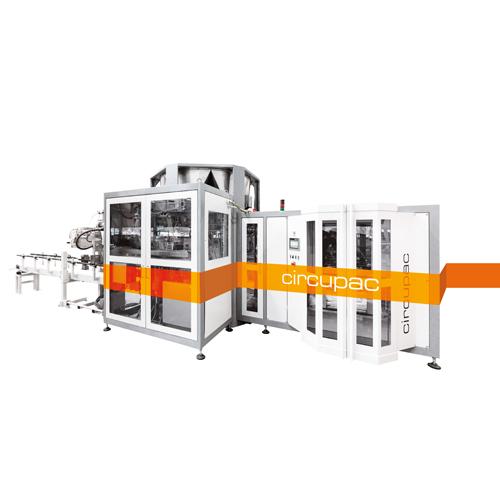

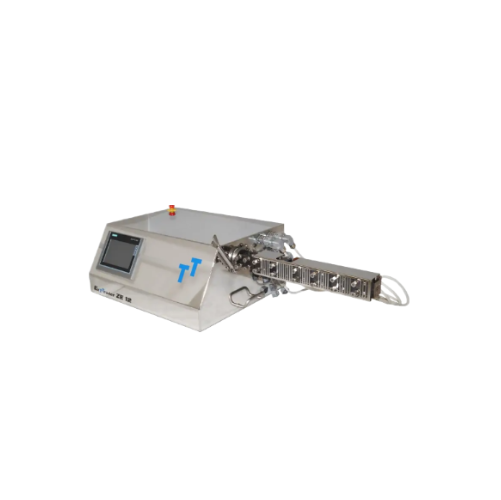

Continuous motion micro dosing system for nutraceutical powders

Streamline your powder processing with a high-speed, con...

Accurate powder filling solution

When precision is paramount, this solution offers exceptional accuracy, filling powders up ...

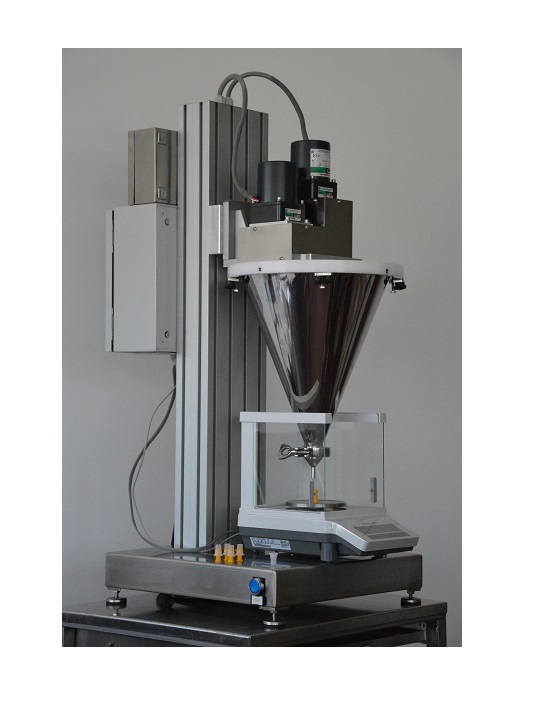

Lab powder dispenser for precision measurements

Effortlessly streamline your lab’s powder dispensing tasks with a ve...

High power mixing solution for powder applications

Achieve rapid, uniform mixing of challenging powders and non-shear sen...

Industrial sugar powder mill

Achieve precise sugar granulation with a high-speed mill designed for continuous production, en...

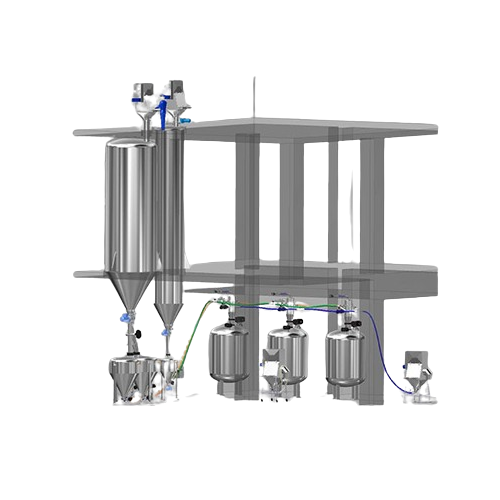

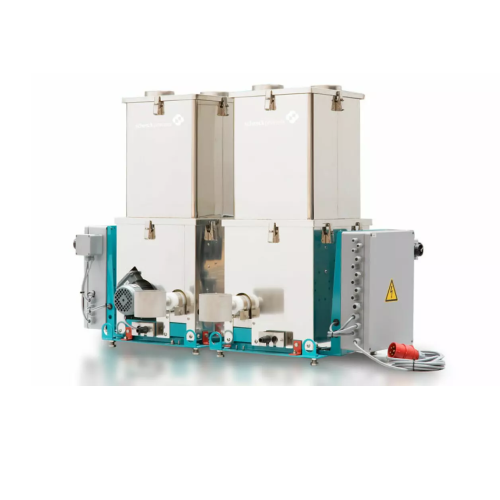

Flexible powder recipe formulation system

Streamline your batch production with efficient, dust-tight formulation and blen...

Ibc blender for industrial powder mixing

Streamline your powder mixing with rapid batch changeovers and reduced cleaning do...

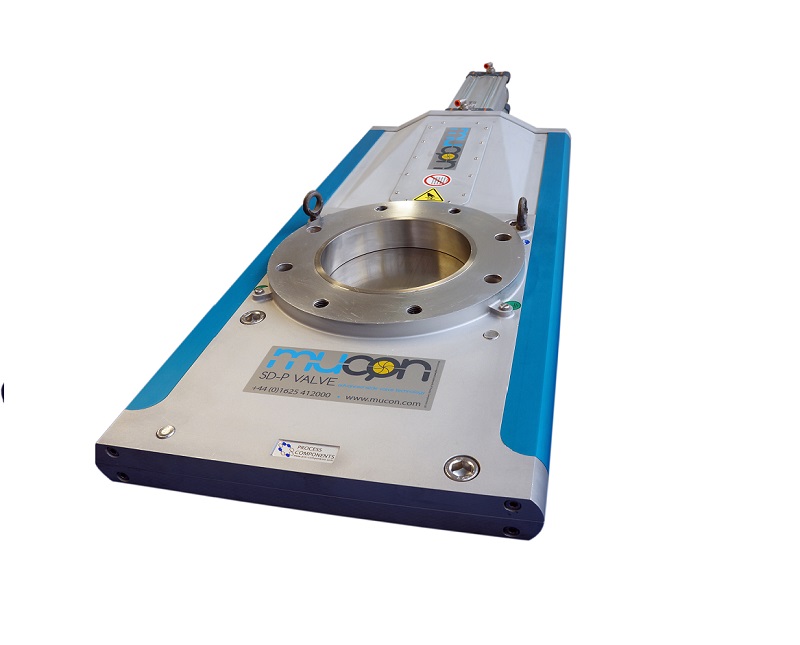

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

Powder handling system for industrial applications

Overcome powder flow issues and enhance production efficiency with adv...

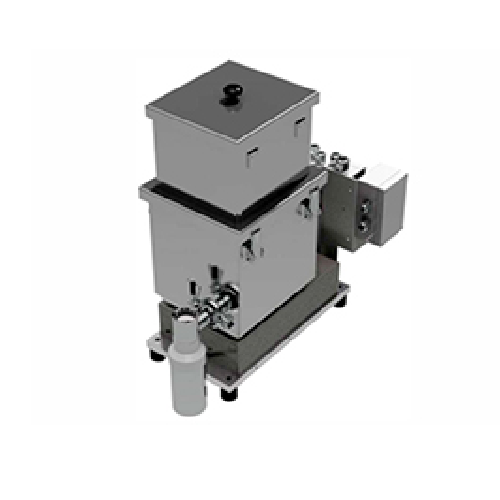

Small powder recipe formulation system

Streamline the formulation of diverse powder recipes with seamless integration into ...

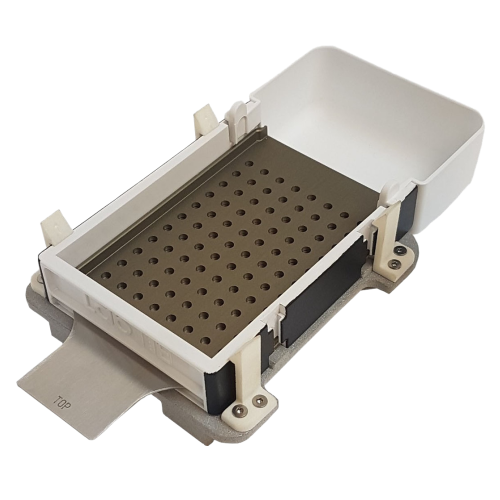

Pharmaceutical powder and granule metal detection system

Ensure the integrity of your pharmaceutical and nutraceutical pr...

Powder handling systems for battery production

Optimize your battery production with a versatile powder handling system th...

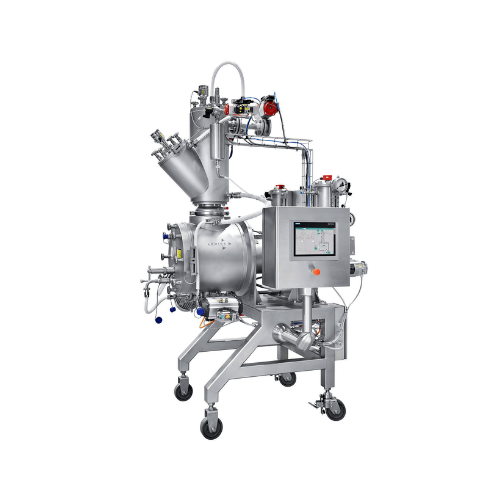

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

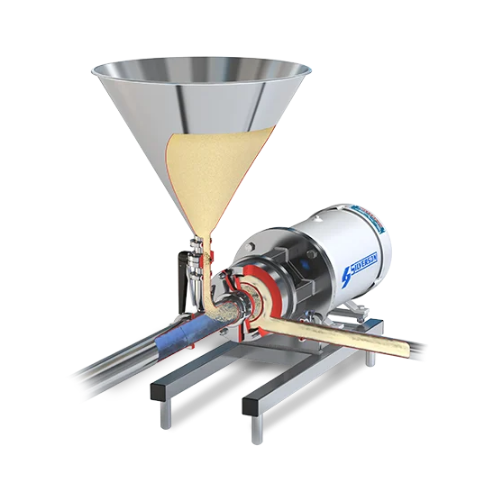

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

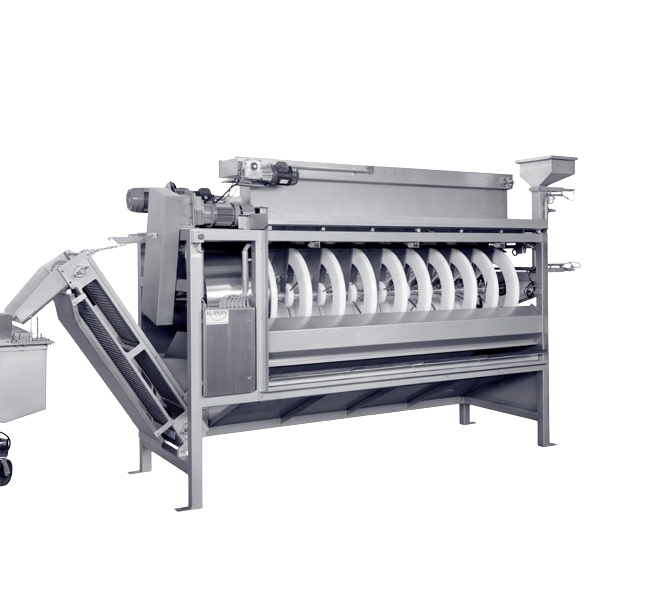

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

Industrial mixer for vegetable, powder, rice, noodle blending

Effortlessly achieve consistent blends with this 100-liter...

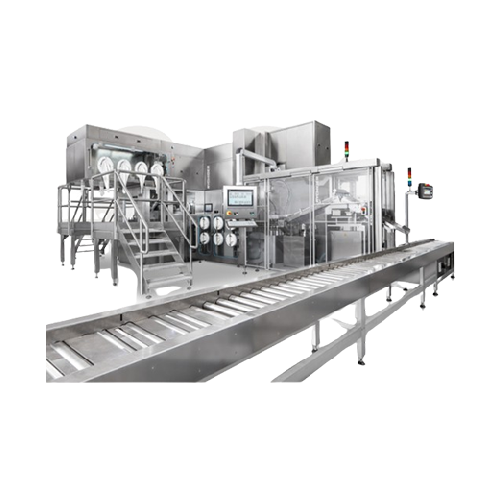

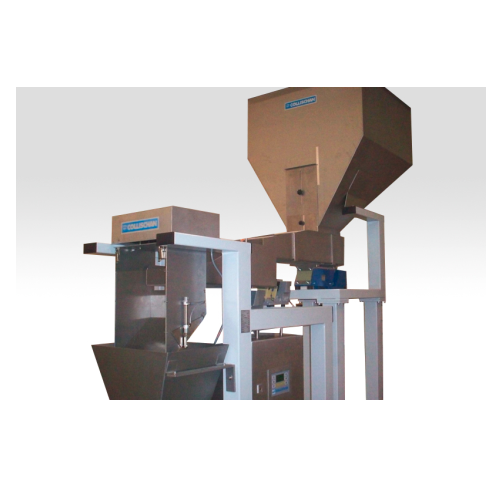

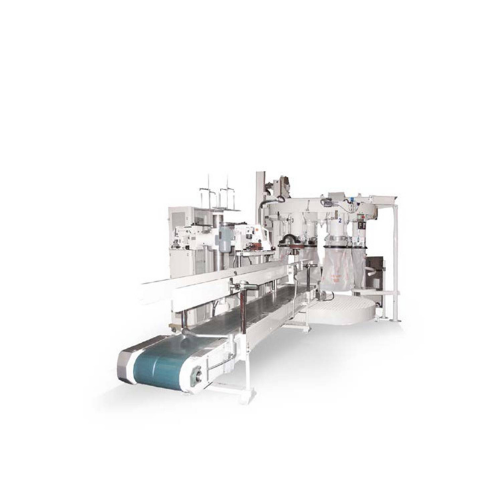

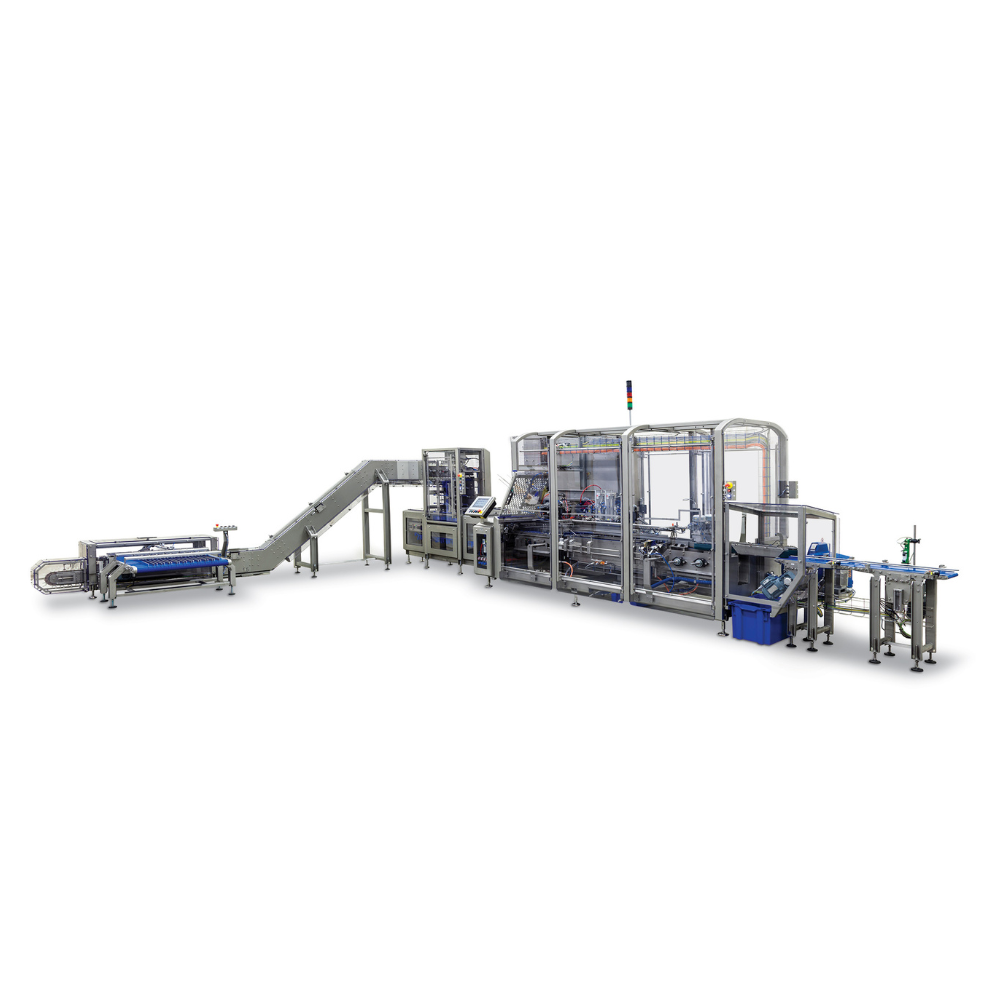

25kg automatic dry powder packaging system

Optimize your packaging line efficiency with precise, high-speed handling for 2...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

Sanitary bulk bag unloader for powdered products

Efficiently manage powder discharge with enhanced dust control and stream...

Dense phase pressure conveying system for fragile powders

Ensure gentle handling and long-distance transport of fragile ...

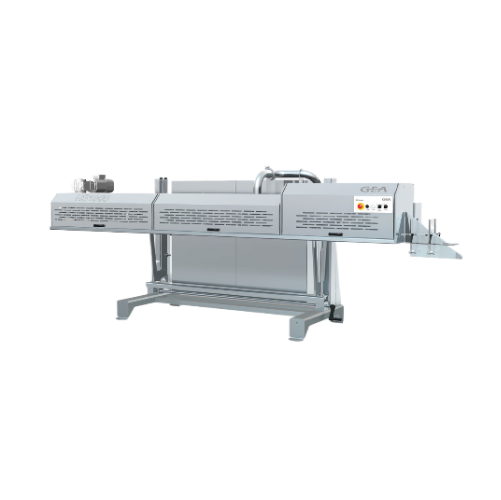

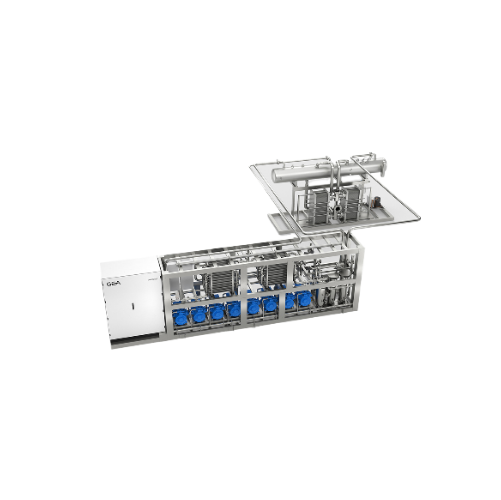

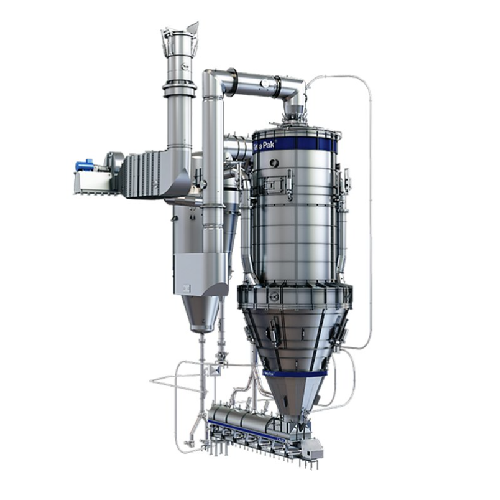

Lactose drying system for high-quality edible powder

Achieve precise and cost-effective lactose transformation into high-...

Compact drying solution for regular skim and Wpc powders

Streamline your drying process with a compact solution that effi...

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

High shear plough mixer for powders, granules, and pastes

Achieve rapid and efficient blending with high shear mixers de...

Homogenous blending solution for powders and granules

Achieve precise, homogenous blending of challenging materials like ...

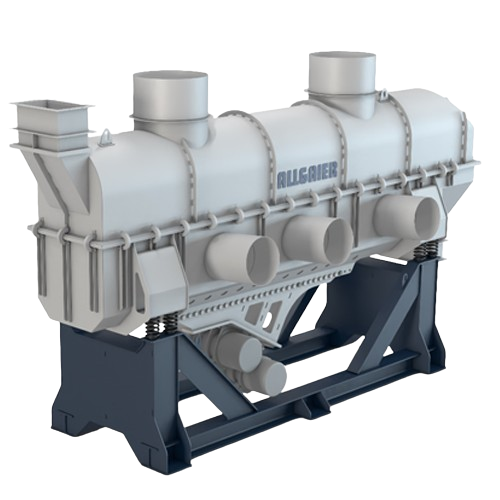

Tumbler screener for multi-deck screening in powders and granules

Achieve precise separation and de-dusting of powders ...

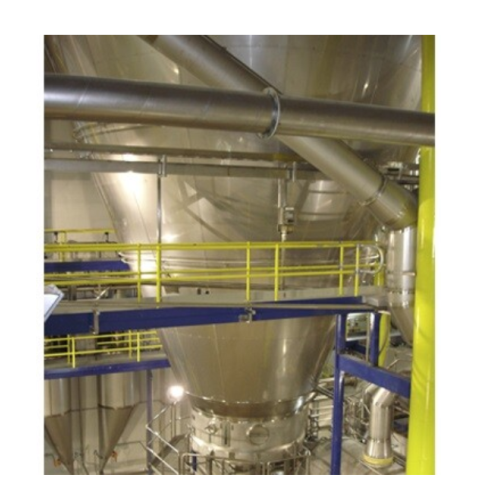

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

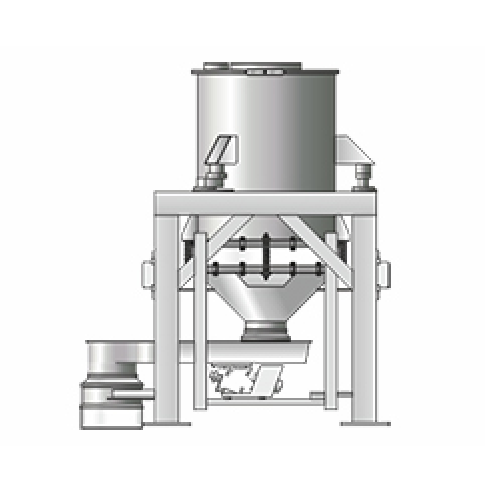

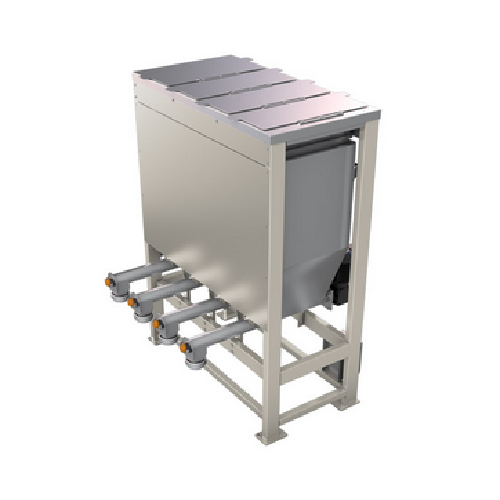

Buffer tanks for powdered or granulated solids storage

Enhance your production line with buffer tanks designed for precis...

Hydrocolloid powder dispersion unit

Achieve seamless dispersion of hydrocolloid powders in liquids, eliminating common issu...

Powder liquid blender for food processing

Achieve seamless integration of solids into liquids with precision-engineered bl...

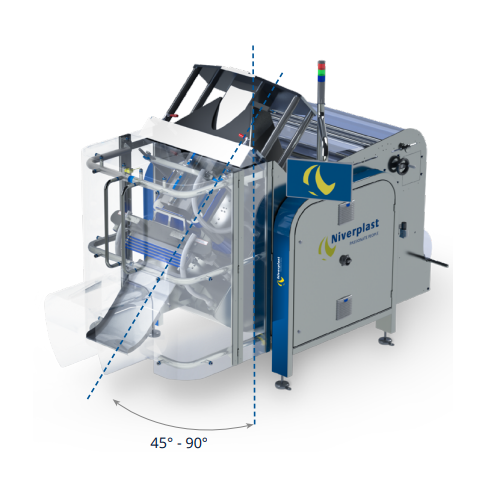

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

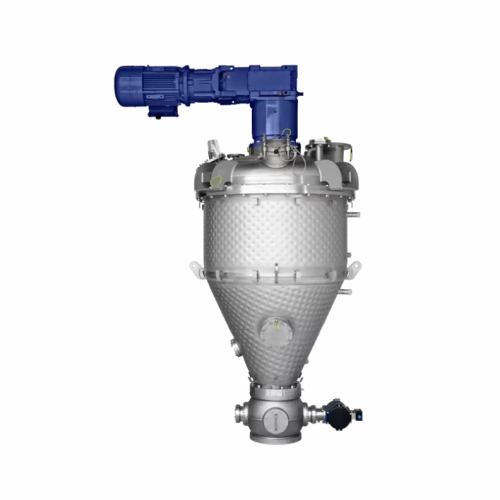

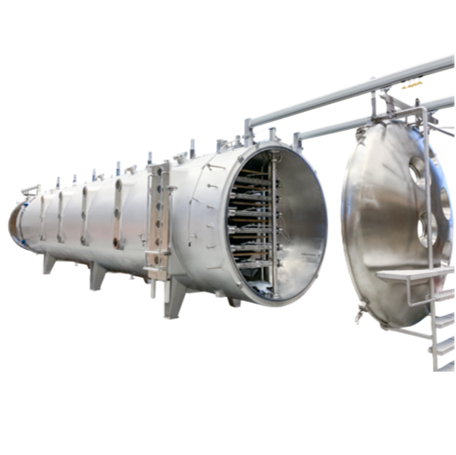

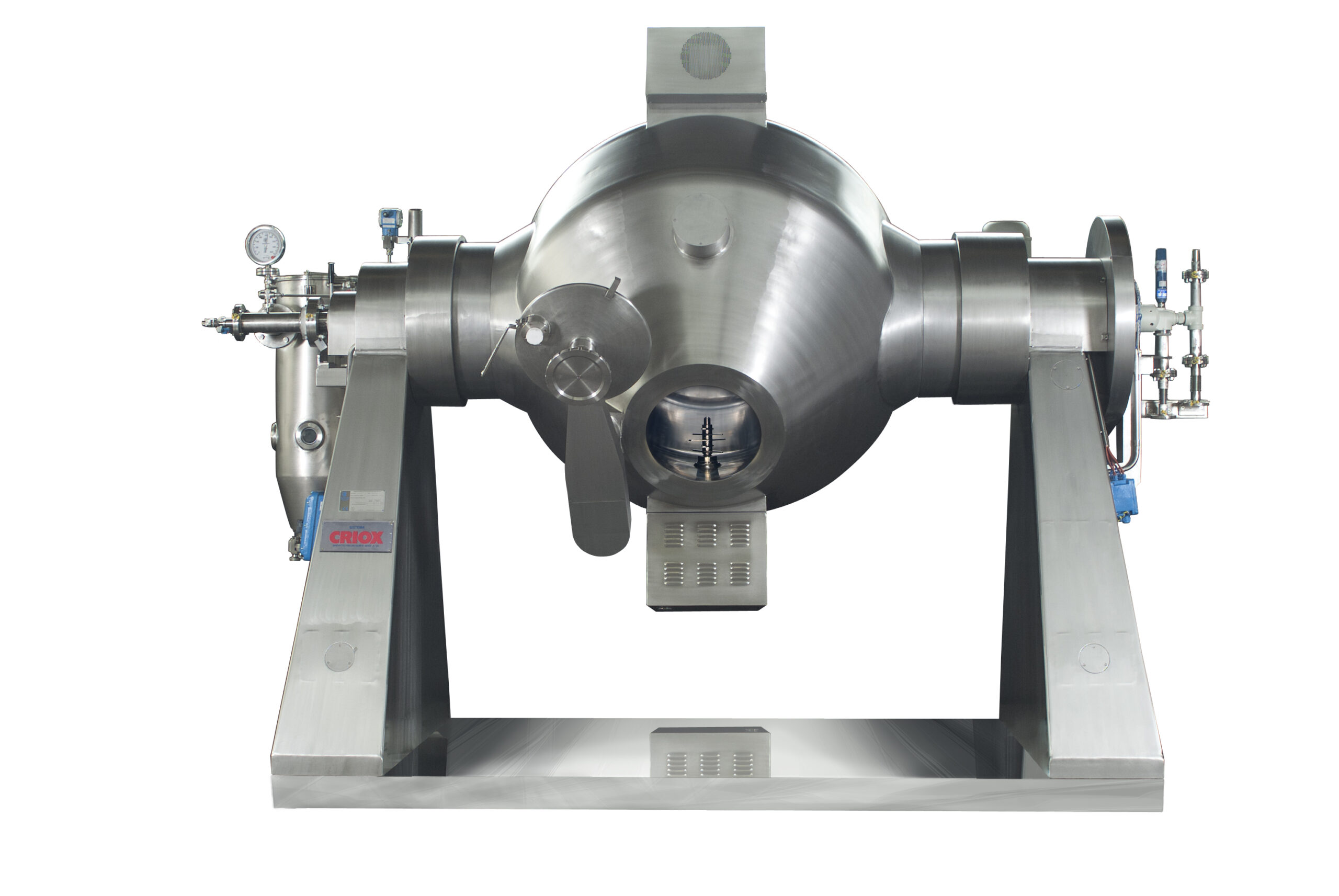

Vacuum dryers for powders and bulk solids

Achieve precise drying and mixing of sensitive materials with advanced vacuum te...

High impact mixer for powders and liquids

Achieve highly homogeneous mixtures with precision. This high impact mixer excel...

Continuous mixing for fine and cohesive powders

Achieve unparalleled mixing precision for cohesive powders while reducing ...

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Super high shear mixer for nano to micron powders

Achieve high-precision mixing and surface treatment of nano to micron-s...

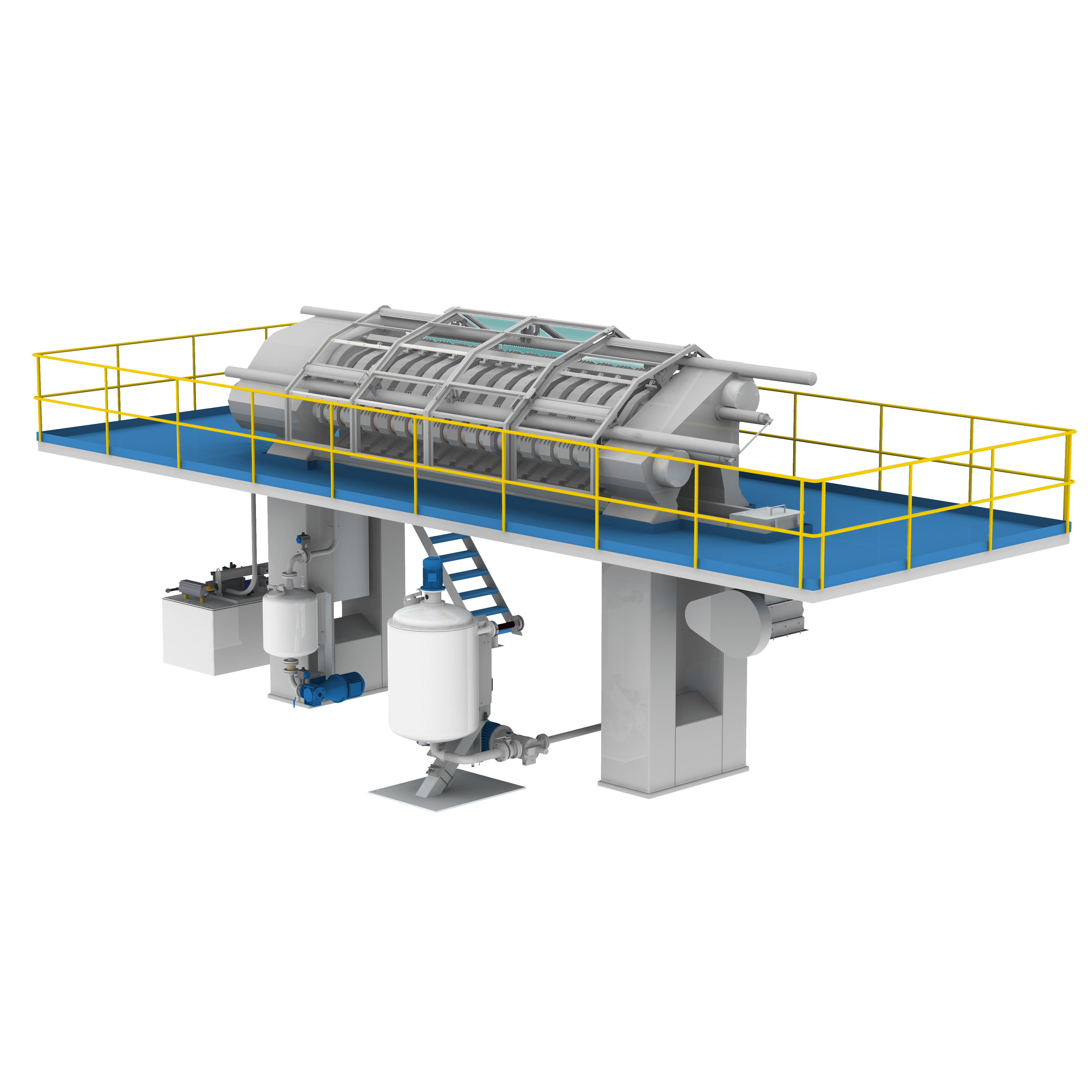

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab mixer for powder formulations

Achieve precise particle mixing and coating with this stand-alone high-shear lab mixer, d...

Lab mixer for high-accuracy powder and paste mixing

Achieve precise mixing of powders and pastes with a gentle convective...

Conical paddle mixer for accurate powder blending

Achieve precise blending of fragile powders and liquids with a versatil...

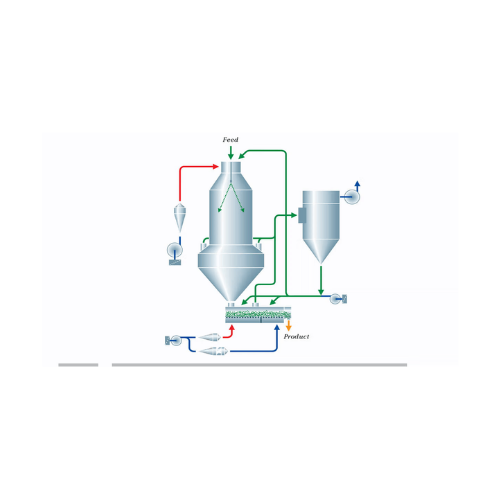

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Conical paddle vacuum dryer for powders and granules

Achieve efficient drying of sensitive materials with this versatile ...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

Ultra-fine powder grinding with jet mills

Achieve unparalleled fineness and purity in powder production with cutting-edge ...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

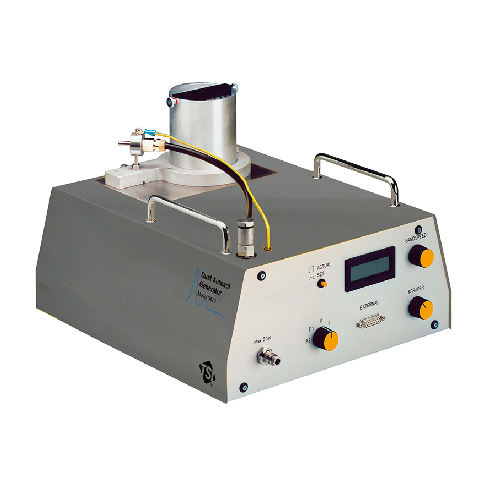

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

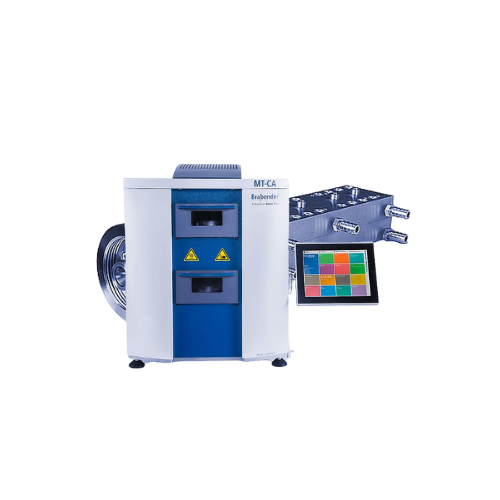

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

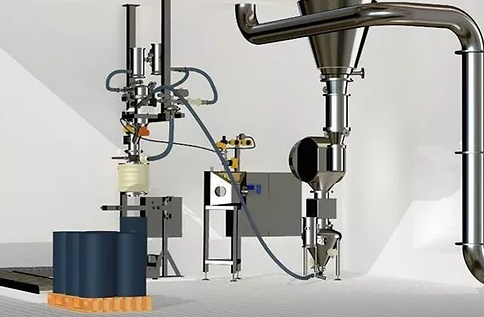

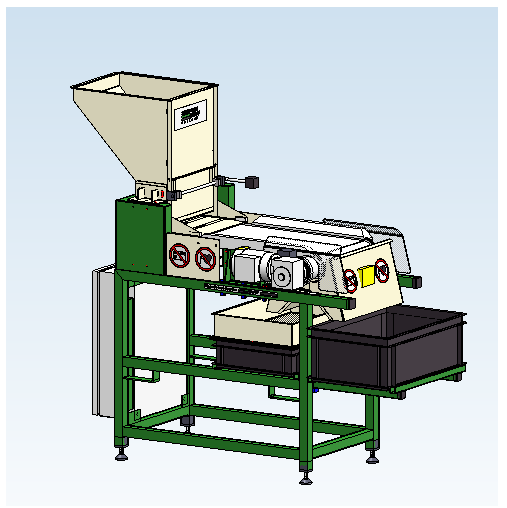

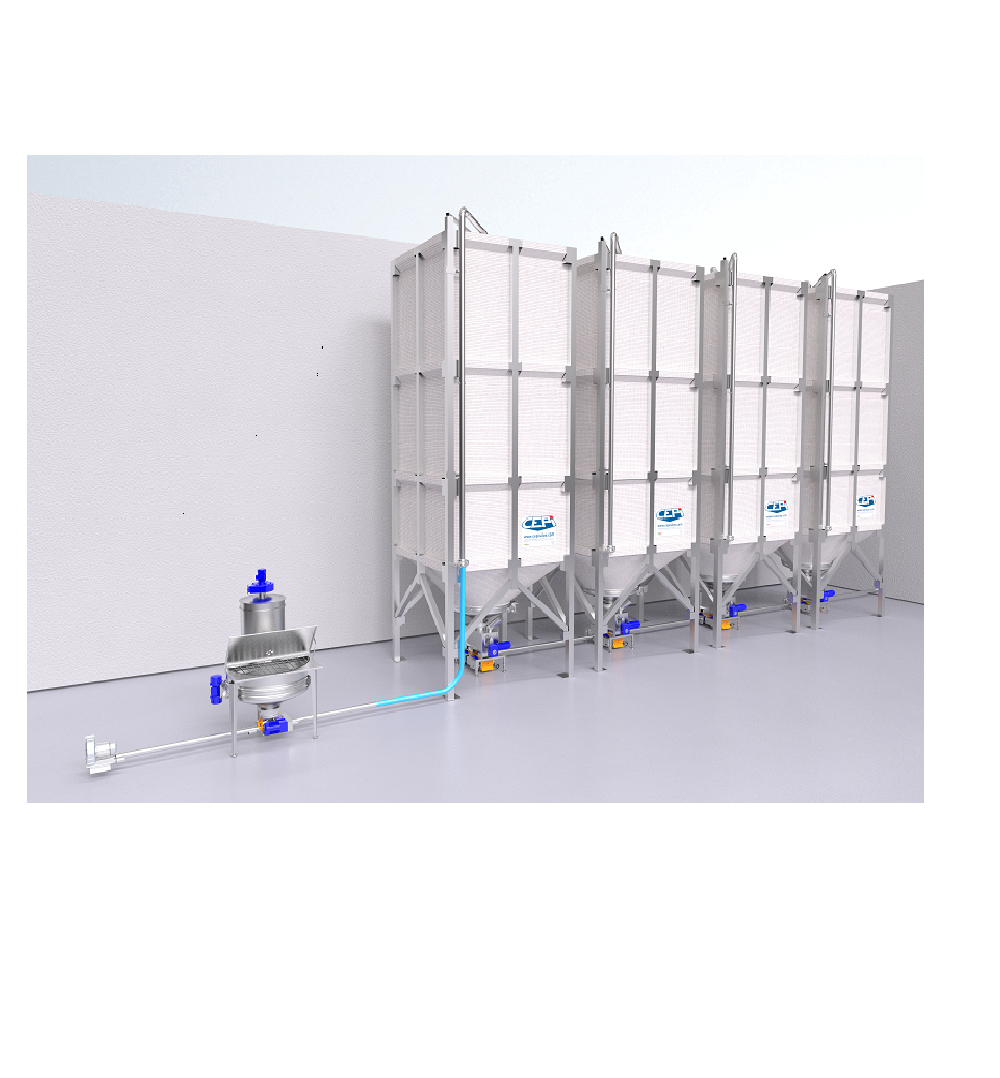

Powder dosing system for big-bags

Efficiently dose and fill various powdered materials directly from big-bags into your pro...

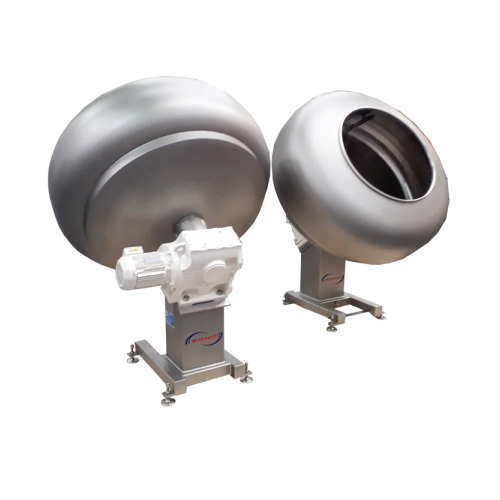

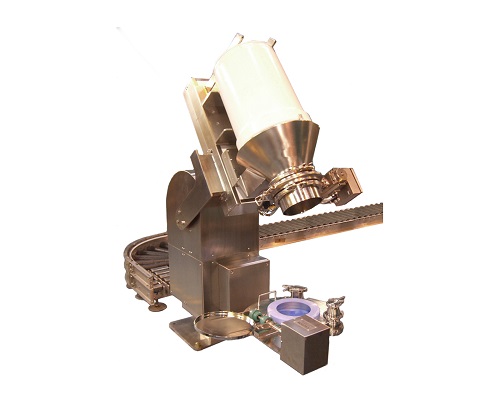

Powder feeder for consistent mixing in pan coating processes

Ensure precise dosing and mixing of pharmaceutical powders ...

Powder belt feeder for accurate powder metering

Achieve precise powder metering with a specialized feeder that maintains d...

Double-stage rotary weigh feeder for precise powder dosing

Ensure consistent dosing and precise weighing of challenging ...

Powder dosing for lab and galenics

Ideal for precise dosing needs, this compact lab device streamlines powder filling proce...

Semi-automatic powder dosing system

Achieve precise micro-dosing for pharmaceutical powders with a flexible system ideal fo...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

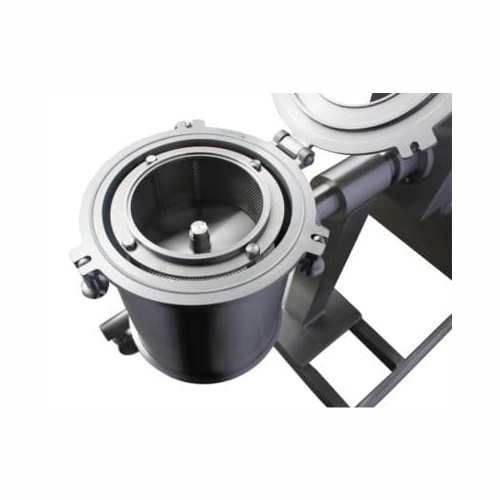

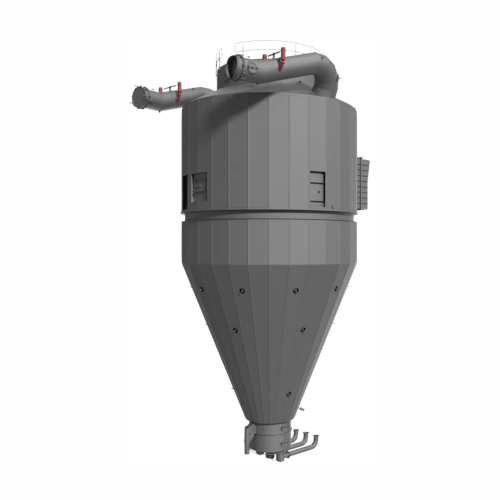

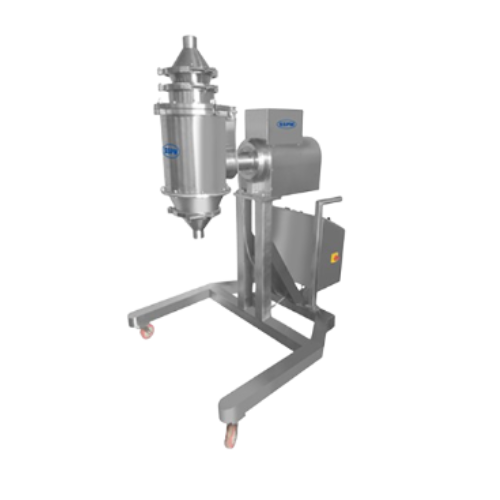

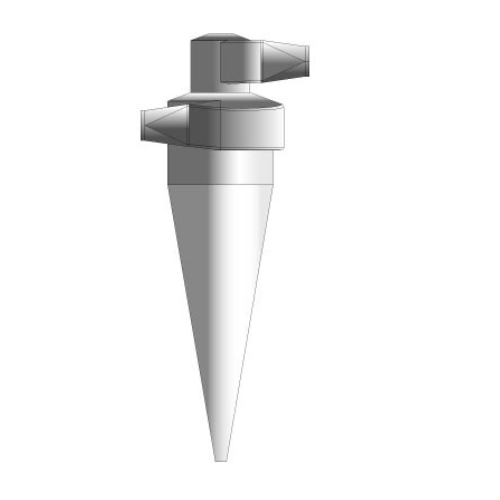

Waste powder recovery cyclone for pharmaceutical processes

Efficiently recover up to 99.9% of waste powder from oral sol...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

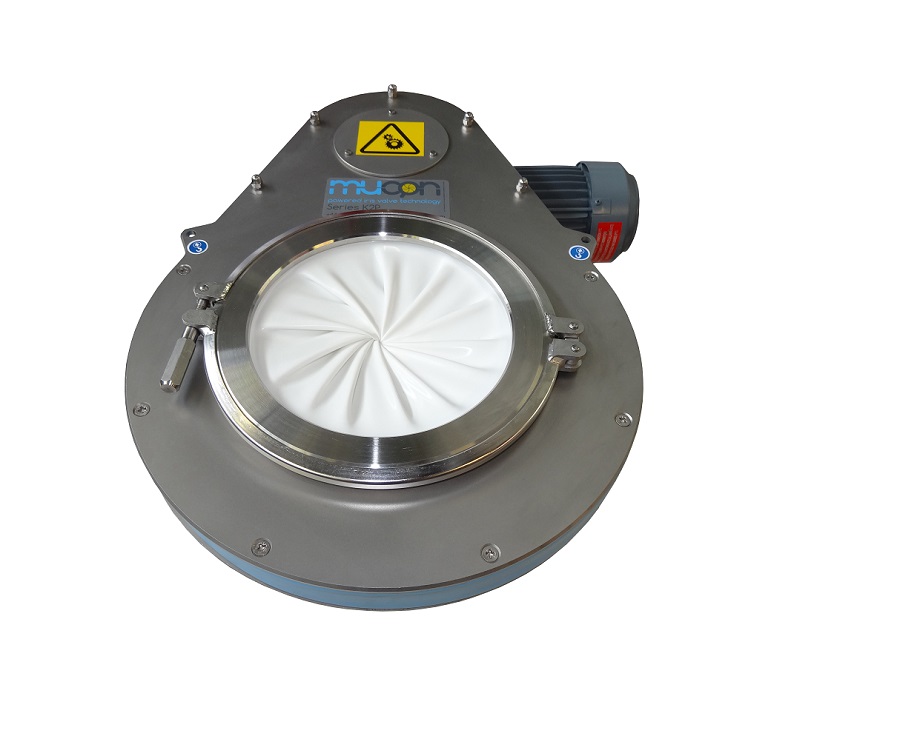

Split butterfly valve for sterile powder transfer

Ensure safe and sterile transfer of powders with unparalleled containme...

Stainless steel drums for powder storage

For high-value powder storage, these stainless steel drums offer reliable containm...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

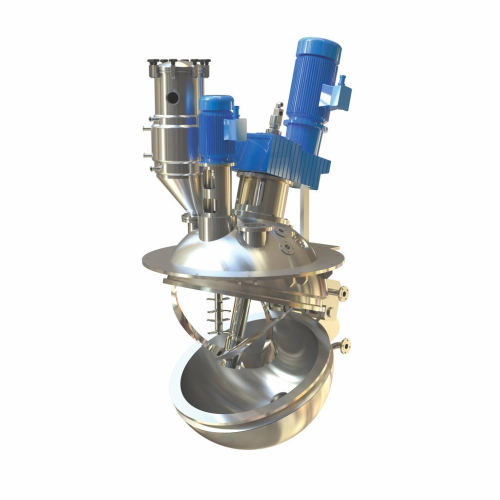

Powder synthesis reactors for nanometer and micrometer particles

Achieve precise particle control and enhance material p...

High-speed mixer for granulating and mixing powders

Achieve consistent granulation and mixing with precise temperature co...

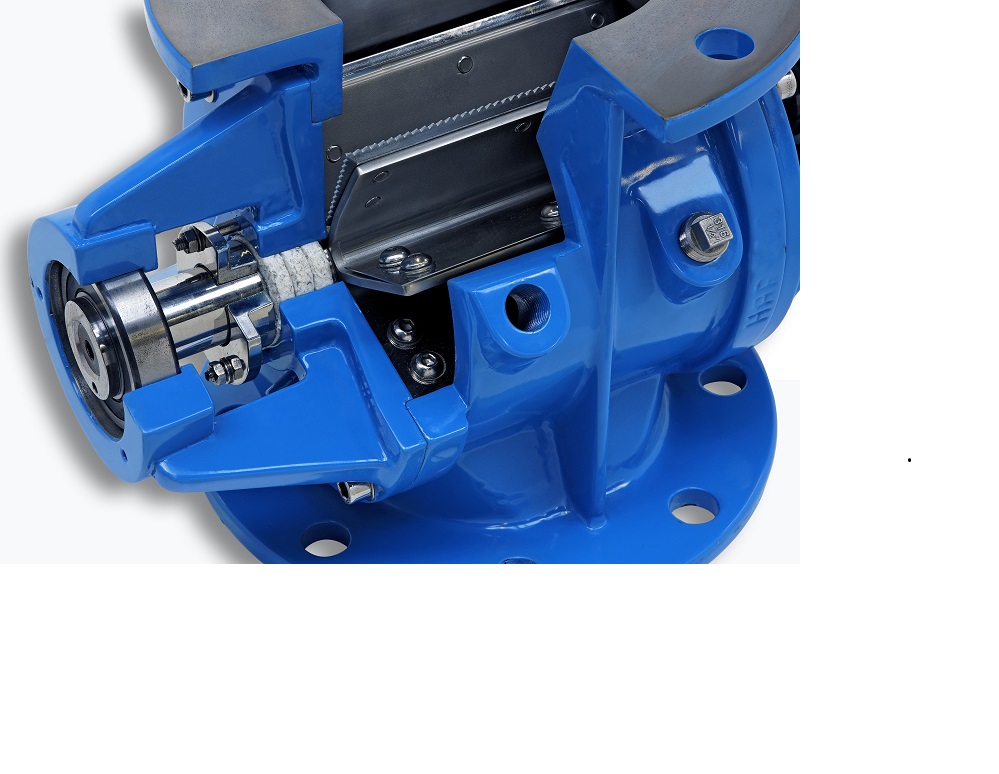

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Dense phase pneumatic conveying system for powder transfer

Ensure gentle and efficient material transport with minimal m...

Pneumatic dilute phase conveying system for powders and bulk materials

Optimize your production line’s efficiency...

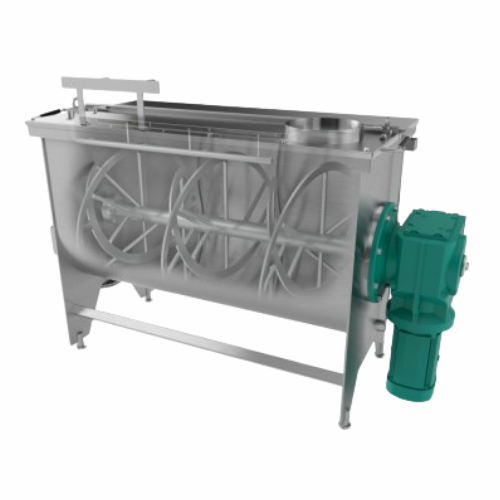

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Universal controller for feeders in powder handling applications

Simplify and enhance your powder handling with precise ...

Wurster coating system for fine powders and pellets

Achieve precision coating for multiparticulate cores and mini-tablets...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

High shear granulator for wet granulation of powders

Achieve consistent granule density and size with a high shear granul...

Laboratory spray dryer for sub-gram powder samples

Achieve precise control in developing fine chemical and pharmaceutical...

Dry granulation system for powder compaction

Achieve consistent sheet hardness and increased density in powdered materials...

Pilot blender for small batch powder blending

Optimize your R&D processes with this versatile mobile blender, ideal f...

Conical screen mills for powder calibrating

Achieve precise particle size distribution for your powders and granules with ...

Pharmaceutical powders and granules dry blending

Achieve uniform blending of diverse powder and granule formulations with ...

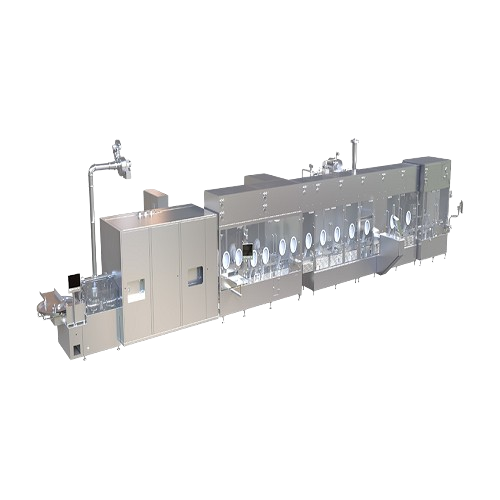

Sterility test isolator for injectables and sterile powders

Ensure sterility and compliance for injectables and biopharm...

Vacuum transfer system for powders and granules

Effortlessly transfer and manage powders and granules with seamless integr...

Pharmaceutical powder blender

Ensure uniform mixing of pharmaceutical powders and granules with advanced blenders designed f...

Double cone mixer for free flowing powders and granules

Achieve uniform blending of powders and granules with precision, ...

Tapped density tester for pharmaceutical and chemical powders

Ensure precise density measurements for pharmaceuticals an...

Continuous mixer for industrial powders and liquids

Achieve precise and efficient mixing of solids and liquids with minim...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

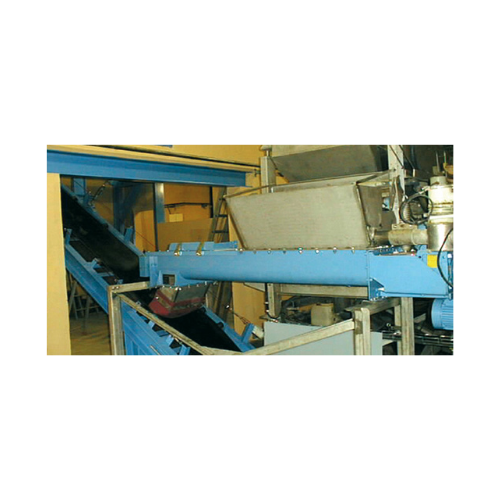

Mechanical horizontal conveyor for powders and granulates

Efficiently handle and transport your delicate powders and gra...

Powder blender for efficient mixing and discharge

Achieve precise mixing and efficient discharge with advanced powder ble...

Big bag emptying station for powder handling

Ensure safe and efficient powder discharge with precision containment, adapta...

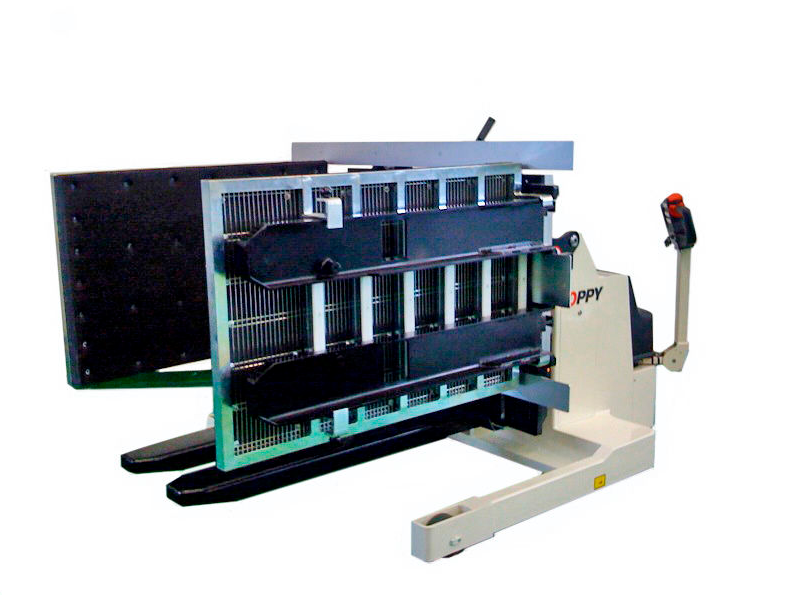

Mobile powder transfer system for pharmaceuticals and chemicals

Efficiently transfer and charge powders into various ves...

Benchtop laboratory powder blender

Perfect for R&D labs needing precise, small-batch powder blending and mixing, this ...

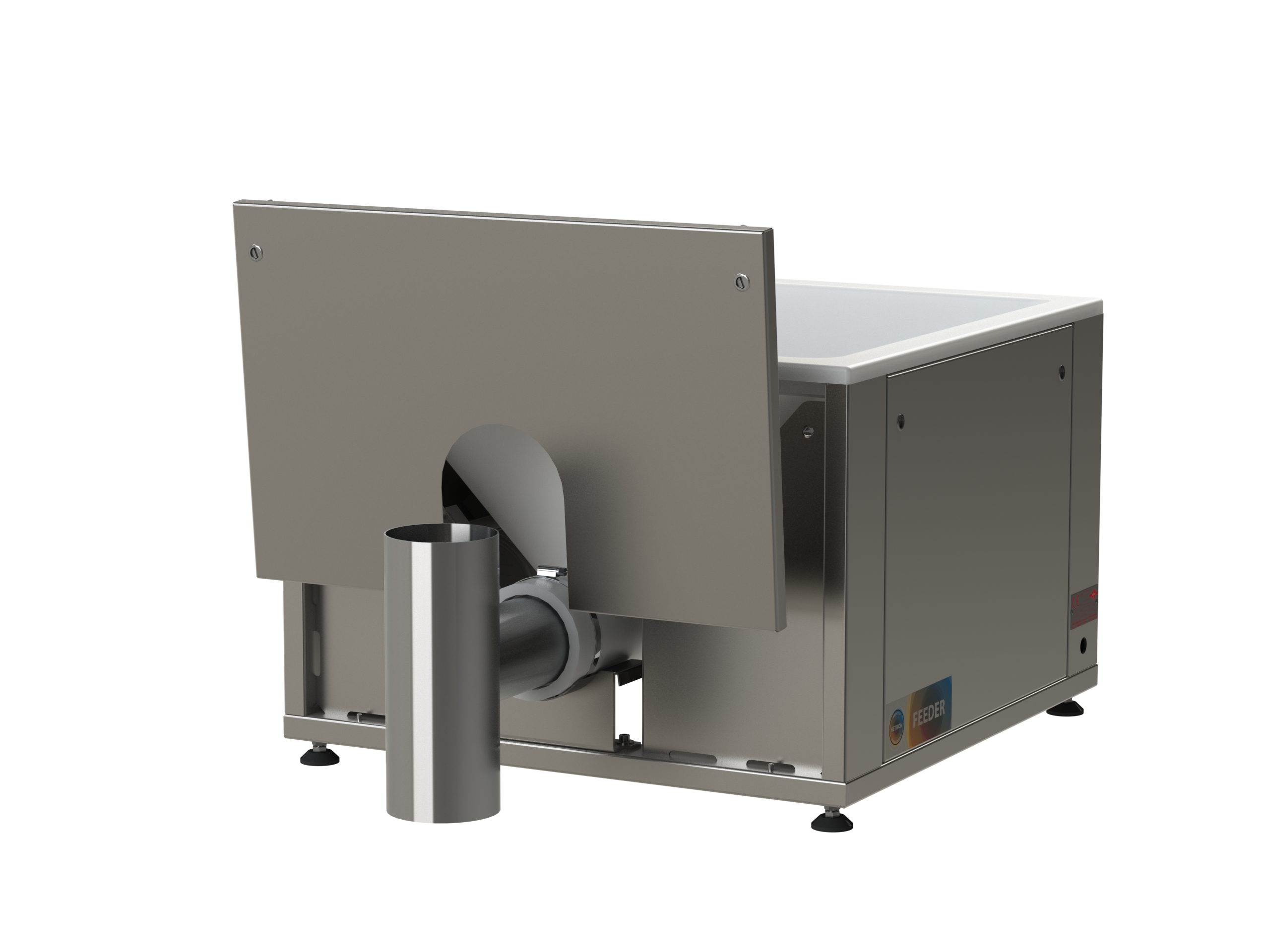

Powder handling drum dock station

Ensure safe and efficient powder transfers with high containment levels, minimizing opera...

Powder conditioning station for high containment applications

Ensure safe and precise handling of hazardous powders with...

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

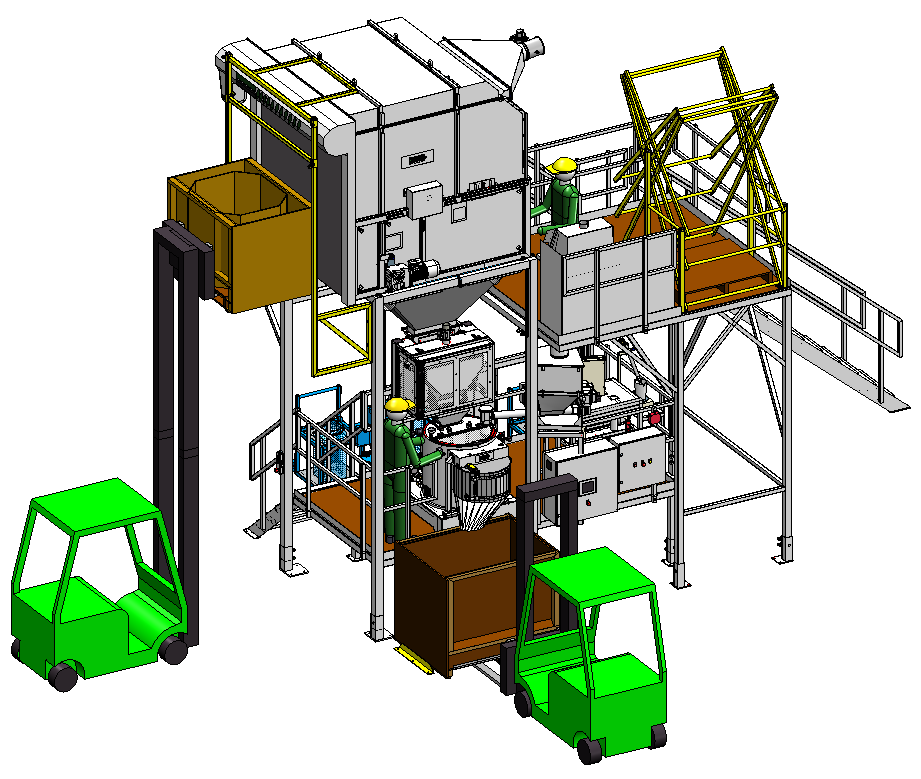

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Dense-phase powder conveying system

Optimize your powder processing with a system designed to handle abrasive and fragile m...

Milling flash dryer for fine powder processing

Achieve precise moisture control and prevent agglomeration in your processi...

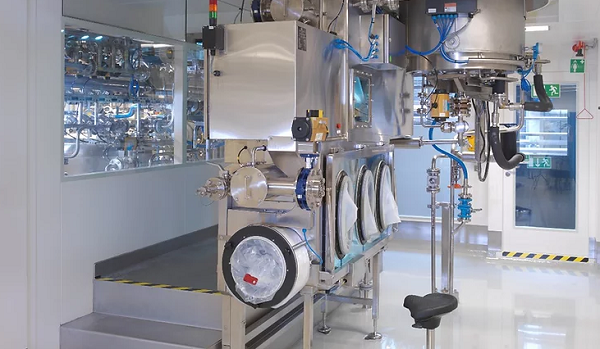

Production isolator for powder preparation and weighing

Ensure precise weighing and safe handling of pharmaceutical powde...

Atex compliant isolator for dispensing powder procedures

Ensure safe weighing and transfer of explosive and pharmaceutica...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

Vibratory collar for powder flow assistance

Struggling with sticky or poorly flowing powders during discharge? This vibrat...

Powder addition system for oils and fats

Efficiently integrate powdered additives into your liquid processes with our hygie...

High containment powder transfer valve

Ensure high containment for potent powders in your production line, reducing contami...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

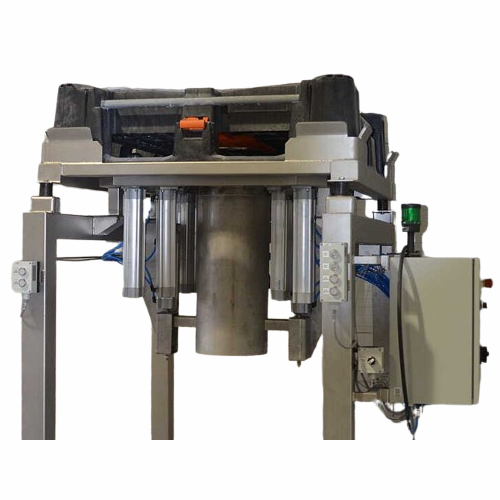

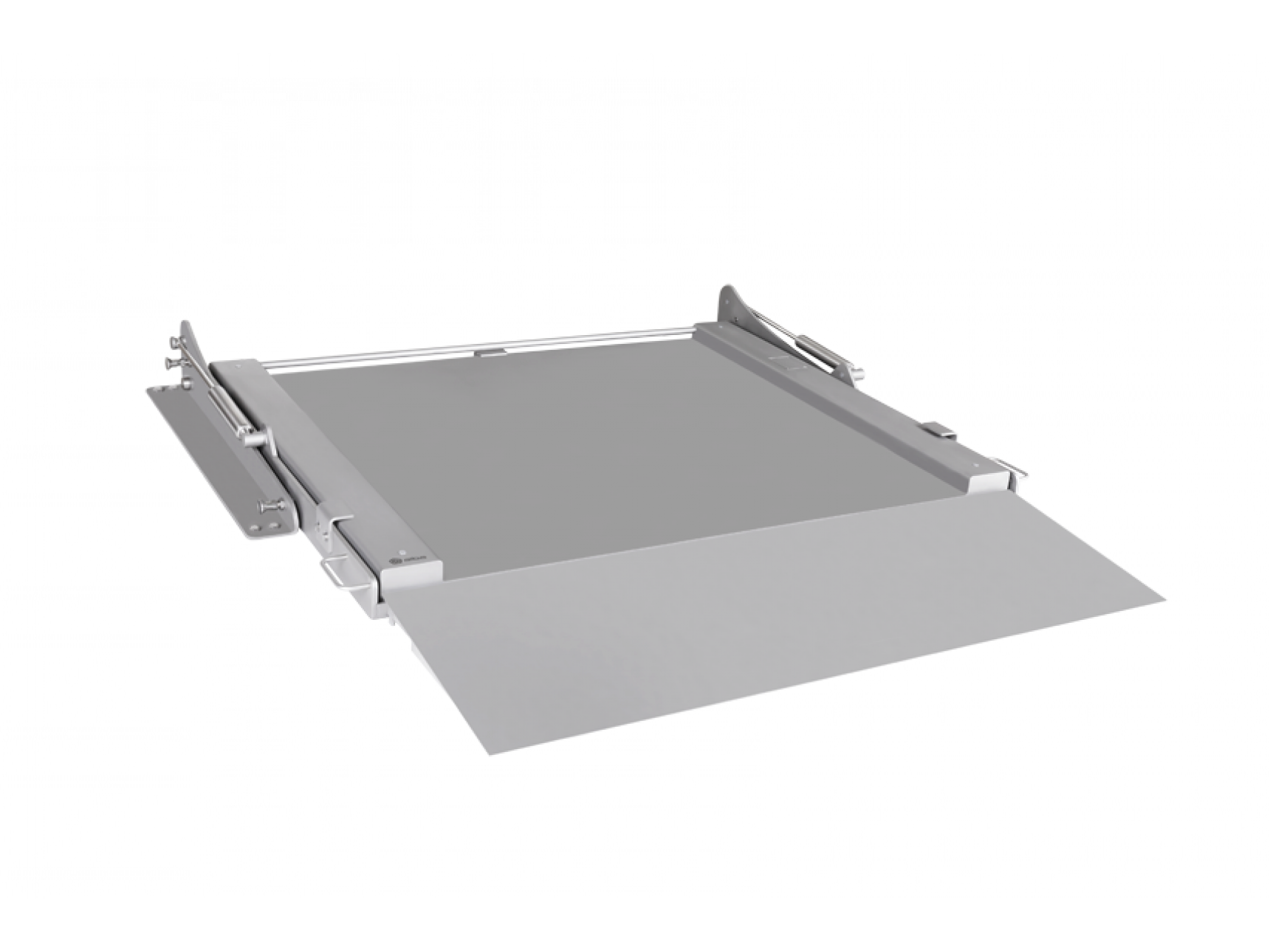

Automatic docking system for bulk powder handling

Optimize docking precision and ensure seamless alignment in bulk powder...

Single use valves for powder transfer

Efficiently transfer powder ingredients with a single-use containment solution, ensur...

Single use powder handling bags for pharmaceutical ingredients

Achieve contamination-free powder transfers with ease, ma...

Bulk powder transfer safety device

Ensure stable and secure docking by minimizing equipment damage during powder transfer p...

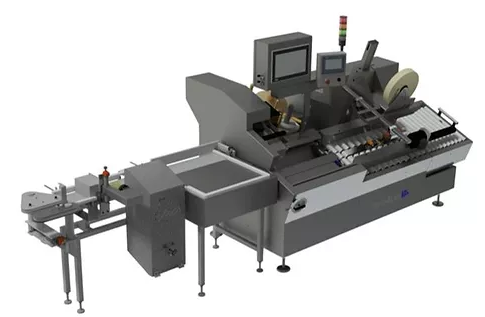

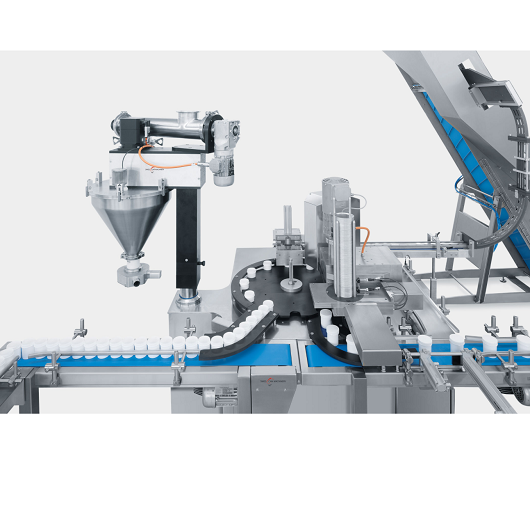

Continuous motion powder dosing system

Ensure precise dosing of pharmaceutical and nutritional powders with this continuous...

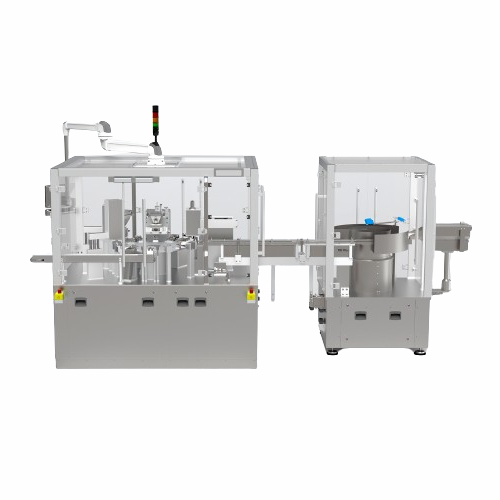

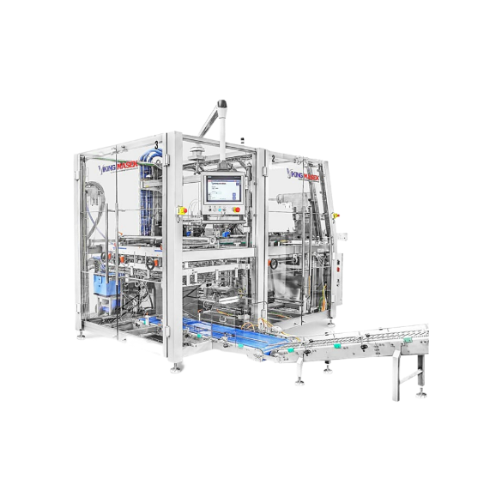

Intermittent motion powder dosing and capping system

Ensure precise powder dosing and secure capping in one seamless step...

Industrial sieving solution for powders and granulates

Ensure top sanitation and food safety in your production line with...

Systems for transporting cocoa powders and ingredients

Efficiently transport and dose your cocoa powders and semiliquid i...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Advanced powder dosing system for continuous production

Achieve precise powder integration into your liquid processes, en...

Accurate dosing for powder products

Ensure precise dosing and consistent flow of bulk powders in your production line to en...

Automatic powder vacuum conveying system for infusion production

Enhance your production line with our vacuum conveying ...

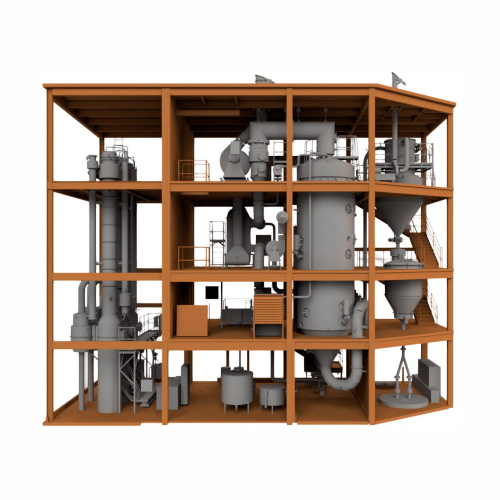

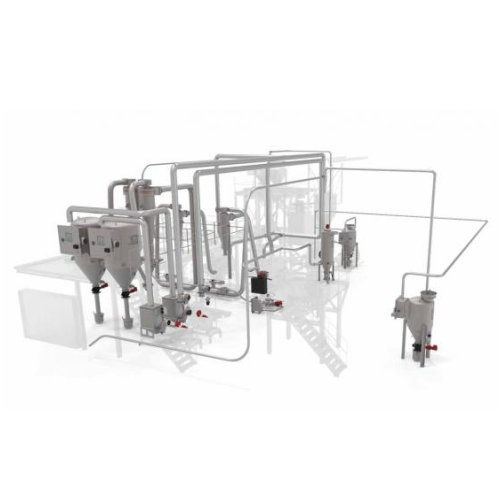

Fine chemical powder system

Optimize your powder processing with a solution tailored to handle complex feeding, conveying, a...

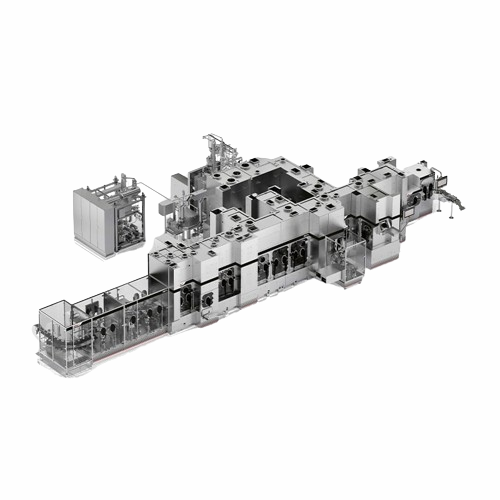

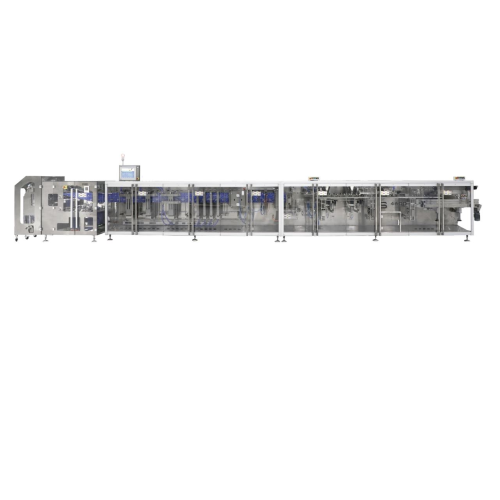

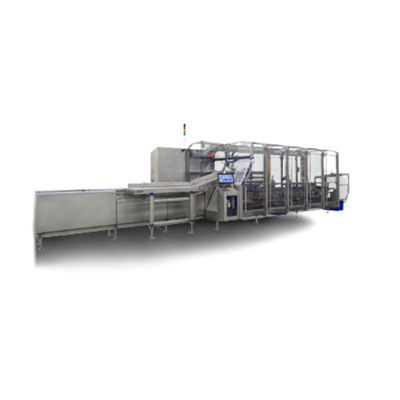

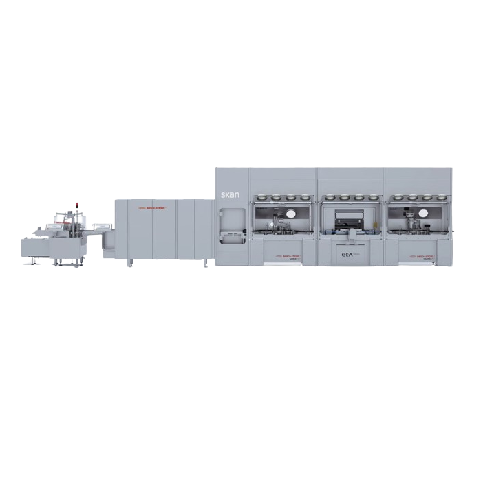

Sterile filling line for liquid and powder

Achieve seamless integration of filling, sterilization, and packaging with this...

Powder ingredient vibro separator and filter

Effortlessly achieve uniform powder consistency and enhance flow efficiency b...

Continuous granulator for powdery goods

Achieve uniform particle size and structure with a continuous granulation process t...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Miniature auger filler for precise powder filling

Achieve precision filling with a compact, bench-top auger solution desi...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Bin blender for pharmaceutical powder mixing

Achieve uniform mixing and homogenization of dry powders directly in storage ...

Mobile bin blender for mixing and homogenizing dry powders

Ensure thorough powder uniformity and eliminate cross-contami...

Drum blender for homogeneous powder mixing

Achieve precise powder homogenization directly in storage drums, minimizing han...

Vacuum conveyor for powder and granule transfer

Ensure efficient and contamination-free transfer of powders and granules w...

Conveyor for acidic and corrosive powders

Effectively handle corrosive and aggressive powders in chemical processes with t...

Ped-compliant vacuum conveyor for powder transfer

Achieve safe and efficient powder transfer in pressure environments wit...

Powder hopper loaders for free-flowing materials

Efficiently transport free-flowing powders, including PVC and polyethylen...

Planetary ball mill for powder material mixing and alloying

Achieve precise control in particle size reduction and homog...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

In-line gassing system for powder processing

Optimize shelf life and quality of your powdered products by effectively redu...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

Continuous dosing and blending for pharmaceutical powders

Optimize your pharmaceutical production with precise dosing an...

Containment valves for pharmaceutical powder transfer

Ensure safe transfer of highly potent pharmaceuticals with this mod...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

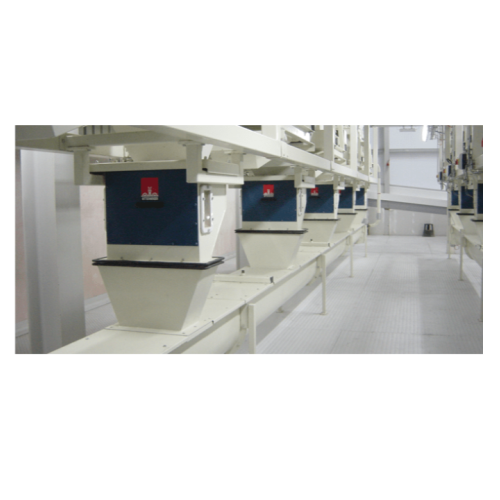

Micro-ingredients doser for precise powder additives

Maintain precision and hygiene in your production line with a specia...

Powder and granulate premixer

Achieve consistent, homogenous blends of powders and granulates with our advanced premixing te...

Industrial vibrating sieve for powder and lump separation

Ensure precise separation of powders and lumps with this oscil...

Dense phase vacuum conveying system for powder handling

Effortlessly transport delicate powders and fragile granules with...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Lean phase vacuum conveying system for powder handling

Efficiently transport and separate powders and granules with preci...

25kg bag tipping station for powder discharge

Efficiently discharge and sieve 25kg bags of powder while minimizing dust em...

Fibc emptying stations for powder processing

Streamline your bulk powder handling with single-operator FIBC emptying stati...

Rotary tube selector valve for powder conveying

Streamline your pneumatic transport system with a robust solution that div...

Auger powder sampler for industrial quality control

Ensure precise quality control by integrating an auger powder sampler...

Vibrating conveyor for powder and granule handling

Effortlessly convey and process fragile products with precision, minim...

Powder sampling solution for dairy and food processors

Ensure precise quality control with a versatile sampling system de...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

Automatic bag slitting and emptying for powders

Streamline your powder-processing operations by seamlessly integrating bag...

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Bag, box, and drum container handling solutions for powder products

Optimize the flow and integrity of your powder pack...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

Hygienic powder filling system for low throughput

Ideal for compact production facilities, this filling system efficientl...

Automated powder bag filling system

Streamline your powder packaging operations with a fully integrated system that automat...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

Lecithin adding system for dairy powders

Enhance your spray drying process by seamlessly integrating lecithin to improve so...

Spray dryer for nutritional and dairy powders

Achieve precise particle size and optimal drying of nutritional and dairy po...

Spray drying solution for uniform powder production

Achieve seamless transformation of liquid feeds into uniform, free-fl...

Lab-scale spray dryer for small volume powder samples

When developing new formulations, achieving consistent powder quali...

Fluid bed drying system for wet powder chemicals

Achieve efficient large-scale drying and cooling of wet powder chemicals ...

Static fluid bed dryer for powder and granular materials

Achieve optimal moisture control in powder and granular products...

Vibrating fluid bed for final stage powder drying

Enhance powder processing precision with a vibrating fluid bed that ens...

Vacuum hopper loader for automatic feeding of powders and pellets

Optimize your material handling with seamless automat...

Industrial rotary feeder for powder and agglomerates

Achieve seamless integration in your production line with a robust s...

Sampler for powdered and granular bulk materials

Ensure precise sampling of powdered and granular materials under varied o...

High-pressure rotary feeder for continuous powder handling

Optimize your production line with reliable powder handling, ...

Rotary feeder for powdered bulk materials

Achieve precise control in feeding and discharging powdered materials with a rot...

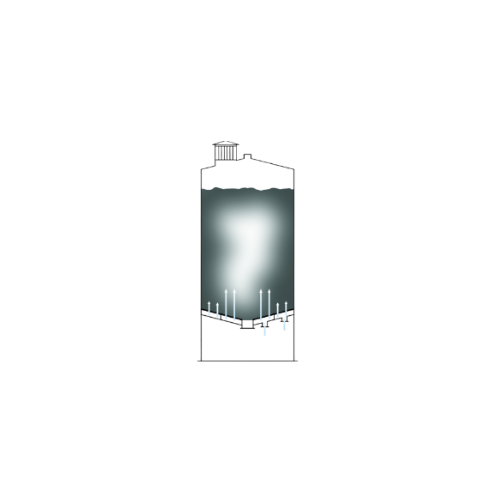

Fluidizing bed blending silo for powder mixing

Optimize your batch mixing process with a fluidizing bed blending silo, des...

High-pressure rotary feeder for powder and agglomerates

Optimize your production line with a high-torque solution that ef...

Laboratory disperser for powder induction and wetting

Optimize your pilot and laboratory processes with a high-speed disp...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

A-type rotary feeder for powder and pelleted bulk materials

Ensure precise feeding and discharging of powdered and pelle...

High-speed mixer for homogenous mixing of powders and pastes

Achieve rapid and precise mixing with high-speed dispersion...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Butterfly valves for dry powder and granule flow interception

Ensure precise control over material flow in your processi...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Tubular screw conveyor for powdery and granular materials

Optimize your material handling processes with a versatile sol...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Combined hammer blaster for powder handling

Address powder flow issues with ease by preventing bridging and ratholing, ens...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

High efficiency micro-batch feeder for powdery or granular materials

Achieve precise volumetric feeding and metering of...

Aeration pads for powdery material flow in silos

Ensure consistent material flow in your silos and bins with a reliable ae...

Continuous level measurement system for powdery or granular materials

Ensure precise inventory management and enhanced ...

Bin level indicators for powder and granular material

Ensure precise inventory management and prevent overflows in your p...

Tubular trough screw conveyors for gentle powder and granular material handling

Achieve precise powder and granular ma...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Powder handling vacuum conveyor system

Streamline your material transfer with a versatile vacuum conveyor system that ensur...

Vibratory feeder for dosing powders and bulks

Ensure precise feeding of powders and bulk materials with a system that inte...

Industrial vacuum pumps for efficient powder conveyance

Harness the power of efficient vacuum generation to streamline th...

Automatic metal powder filling system for 3d printers

Ensure seamless operation of your 3D printing process with a system...

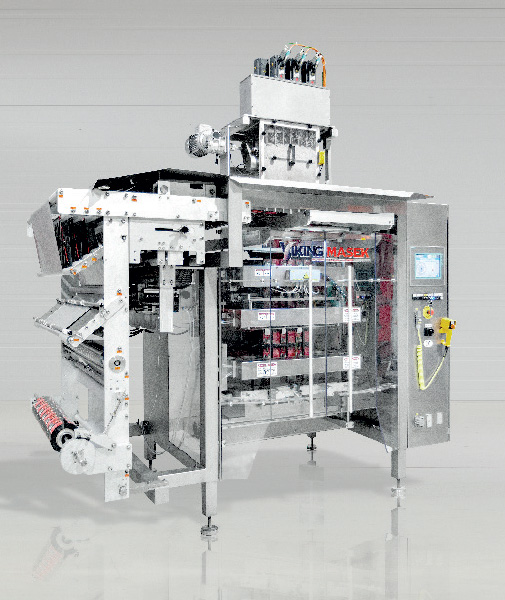

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Pneumatic diverting valve for powder and granule transfer

Efficiently redirect bulk materials from one point to another ...

Bucket elevator for grain and powder products

Efficiently transport bulk materials like grain and powder vertically with p...

Flat-bottom twin-screw feeder for precise powder feeding

Achieve precise control in powder dispensing with this flat-bott...

Volumetric twin screw feeder for powder and micro-granules

Optimize your production flow by ensuring consistent and prec...

Volumetric twin-screw feeder for poorly flowing powders

For manufacturers dealing with powders that clump or cake, this f...

Twin screw feeder for poorly flowing powders

Optimize your process with precision feeding for powders that easily clump or...

Small-scale twin-screw feeder for powder handling

Perfect for precision in lab environments, this small-scale feeder effi...

Precise volumetric or gravimetric powder feeder

For precise feeding of challenging powders prone to clumping and bridging,...

Gravimetric twin screw feeders for pharma powders

Optimize feeding for challenging materials with dust and water-resistan...

Twin-screw feeder for powders and micro-granules

Ideal for handling poorly flowing powders and granules, this advanced twi...

Volumetric flat-bottom twin-screw feeder for powders

When handling powders prone to clumping, a reliable feeder ensures u...

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Volumetric auger filler for precise powder weighing

Optimize your production line with a high-speed volumetric auger fill...

Volumetric auger for powder weighing and depositing

Ensure precise powder weighing and depositing for consistent product ...

Sachet powder filling machine

Optimize your packaging line with this efficient solution for precise powder filling, ensuring...

Gravimetric auger filler for powder weighing

Achieve precise powder filling with this gravimetric auger solution, ensuring...

Powder auger filler for precise weighing and depositing

Ensure accurate and efficient powder filling with this innovative...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

Big bag discharger for powder handling

Effortlessly discharge large bags of powdered ingredients with a modular, safe syste...

Manual bag tipping unit for powder handling

Ensure a contamination-free environment with a compact manual bag tipping unit...

Spray dryer for heat-sensitive powders

Ensure high-quality drying of heat-sensitive powders, producing non-caking and non-h...

Air jet cleaning system for powder production

Eliminate water and chemical use while maximizing production efficiency with...

Lump breaker for dry powders and granulates

Optimize the consistency of your production line by efficiently breaking up lu...

Centrifugal sifter for food and pharmaceutical powders

Ensure consistent particle size and remove contaminants in high-sp...

Industrial powder mixer for food production

Enhance your production line with a high-speed batch mixer designed for precis...

Conical homogenizer for powder and granulated products

Achieve seamless homogenization of diverse powders and granulated ...

Big bag filler for granulated or powder components

Ensure precise and dust-free filling of large bags with a unit designe...

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this...

Pneumatic conveyor for fragile powders

Handle your delicate powders with care, ensuring minimal breakdown while achieving h...

Spray dryer for nutritional powders

Ensure precise moisture control and enhance powder quality in nutritional products with...

Continuous spray dryer for permeate powder

Efficiently transform liquid whey and milk into high-quality, non-caking, and n...

Continuous fluid bed dryer for powder and granules

Enhance your production line with precise moisture control and energy ...

Ginger powder processing line

Optimize your spice production with comprehensive ginger powder processing, transforming fresh...

Ultrasonic round vibratory separator for fine powders

Efficiently prevent screen blinding during powder separation proces...

Material handling system for granules and powders

Optimize your production with seamless material handling specifically d...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Spray bed dryer for agglomerated powder production

Efficiently transform liquid feedstock into consistent, dust-free powd...

Spray dryers for producing free-flowing dustless powders

Achieve consistent product quality with customizable spray dryer...

Single screw feeder with stirring agitator for powders and pellets

Ensure consistent mass flow and precise dosing with ...

Industrial fluid bed dryers for powder processing

Enhance moisture control and uniformity in powder products with dynamic...

Laboratory loss-in-weight feeder for powders or pellets

Achieve precise dosing for lab-scale trials with this versatile f...

Double screw batch feeder for poorly flowing powders

Effectively manage challenging powders with precise batch dosing and...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Powder flow tester for pharmaceutical powder flowability

Quickly assess powder flow characteristics to ensure consistent ...

High shear powder mixing solution

Achieve agglomerate-free, homogeneous mixing of powders and liquids with high shear effic...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

Pneumatic conveying system for dry bulk powders

Ensure seamless and contamination-free transfer of pharmaceutical powders ...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Coriolis mass flow meter for powdered materials

Achieve precise continuous feeding and control of bulk solids like cement ...

Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried...

Gentle mixing solution for gelatin powder

The fragile nature of gelatin makes it a challenging material to blend homogeneo...

Accurate multiple dosing system for powders

Dosing multiple powders in a batch process is time inefficient, especially whe...

High-speed powder dosing system

Balancing speed and accuracy in powder dosing is crucial to fulfilling production viability....

Powder micro-dosing system

Pharmaceutical powders in metered doses demand maximum filling precision. This is particularly ch...

Aseptic filling machine for liquids and powders

Aseptic filling of containers such as vials, syringes, bottles, and cartri...

Pharmaceutical powder mixer

Large batches of powders with different characteristics are commonly mixed in pharmaceutical ind...

Powder dosing system

Dosing of powder products must be done in a continuously controlled manner to provide a precise amount o...

Powder transfer system

Loading powder from a container source to vessels, tanks, or mixers that are under pressure may be haz...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Fast gravimetric powder microdosing 50 - 200 g

Micro-dosing powders of high-value food or chemical products can be challen...

Gravimetric powder microdosing 2 - 100 g

Powders and granules are commonly dosed for the manufacturing of pharmaceuticals, ...

Gravimetric powder microdosing 0.400 - 2 g

If you need to process high value food, pharmaceuticals or chemicals, there is ...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

Single-use powder handling bag

Containers for handling pharmaceutical and biopharmaceutical powders may be disposable, to av...

API powders storage bottle

Users who prefer rigid storage over single-use pharma charge bags, require lightweight solutions ...

Metal detector for pharmaceutical powders

Powdered and granulated pharmaceuticals require careful screening against metal ...

Blending tank for cosmetic powders

The production of high-quality cosmetics powders requires perfect mixing and dispersal o...

Manual cosmetic powder press

The design, manufacture and testing of new cosmetic powder products require a small-scale press...

Drop tester for compacted powders

A key requirement for cosmetic compressed powder products is that they maintain their com...

Vibrating screen for cosmetic powders

Dense or viscous compounds can be difficult to prepare for use in cosmetic products. ...

Cosmetic powder pressing machine

For the medium and large-scale production of compressed powder cosmetics, a fully-automatic...

Powder pressing mould

Traditional powder pressing moulds are based on plain shapes or basic designs. In order to differentiat...

R&D V-type powder blender

Many pharmaceutical processes rely on the complete blending and homogenizing of different powdered...

Semi-automatic powder dosing machine

Powders or granules are common dose types used in many pharmaceutical and nutraceutica...

Compact powder pressing machine

Pressed powder products are extremely popular in cosmetics, but their production has challen...

Powder transfer vessel

Intermediate bulk storage of pharmaceutical product requires specialist containers. For increased effi...

Screener and separator of dry powder

Many industries require the effective screening and separating of a range of dry powde...

Cocoa powder processing line

Cocoa beans are first fermented, dried, roasted, and separated from their skins to obtain a coc...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Bellows for pharmaceutical powders

Thermal and mechanical changes can lead to stresses in industrial piping systems. These ...

Microdosing machine for sterile powders

Fill sterile pharmaceutical powders into vials under aseptic conditions with a spee...

Flexible contained powder charging solution

Filling of transportation bags and discharging them into mix tanks or reactor ...

Open-mouth baggers for free flowing powders

For bagging free flowing materials into open mouth bags, this system is ideal....

Dosing machine for nonfree-flowing powders

Fill poorly flowing powders, dry syrups and similar substances into various gla...

Flexible contained handling of powder transfer bags

Filling of transportation bags and discharging them into mix tanks or...

Flexible contained powder discharge into FIBC’s

Flexible intermediate bulk containers known as FIBC’s are commonly used in...

Flexible contained powder discharge into drums

Powdered products are handled every day in the pharmaceutical and bioproces...

Drum mills for fine grinding of large volumes

Achieve consistent and precise pulverization of large sample volumes with dr...

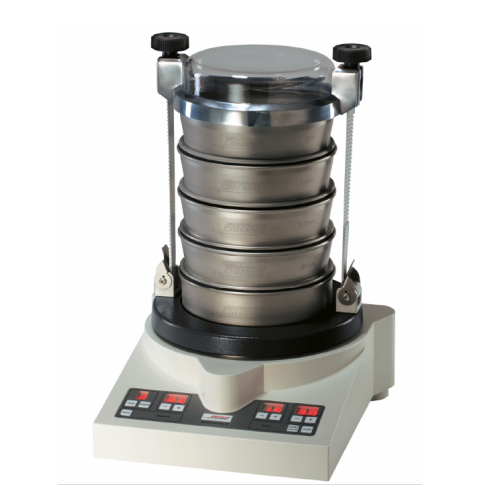

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Rotating sample divider for large bulk materials

Achieve precise, dust-free division and volume reduction of bulk material...

Sample divider for on-site reduction of bulk materials

Ensure consistent sample analysis with precise on-site material di...

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

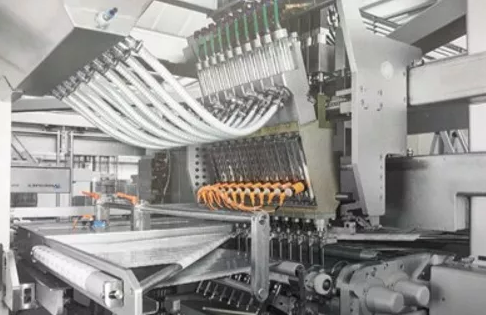

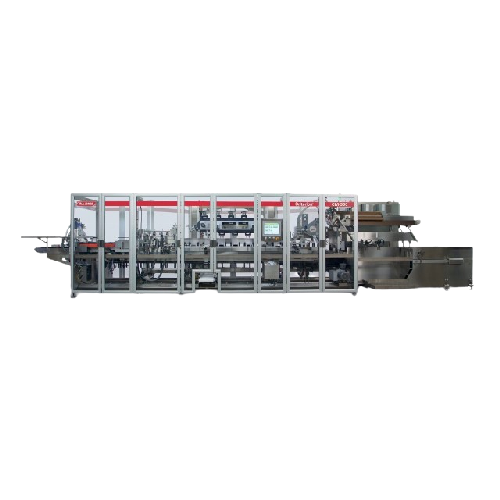

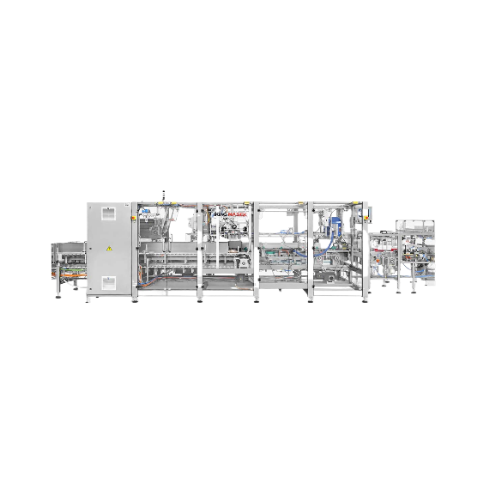

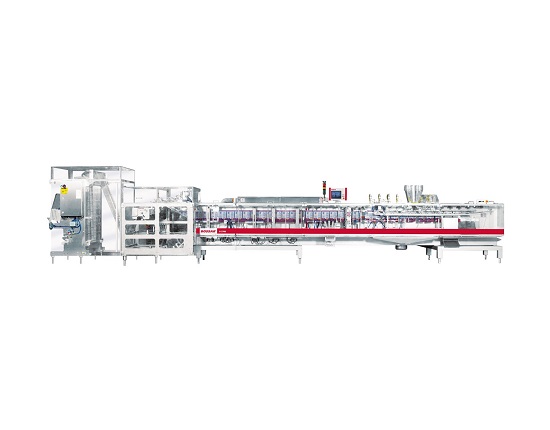

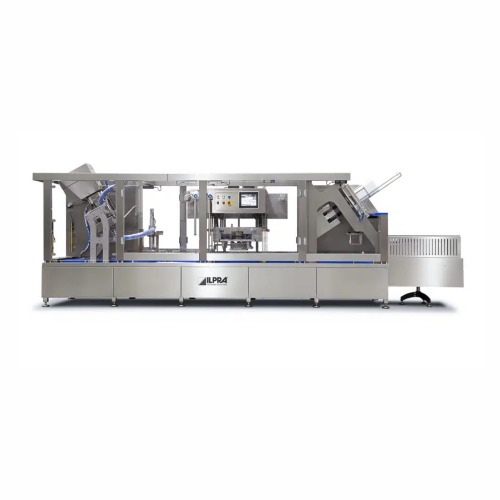

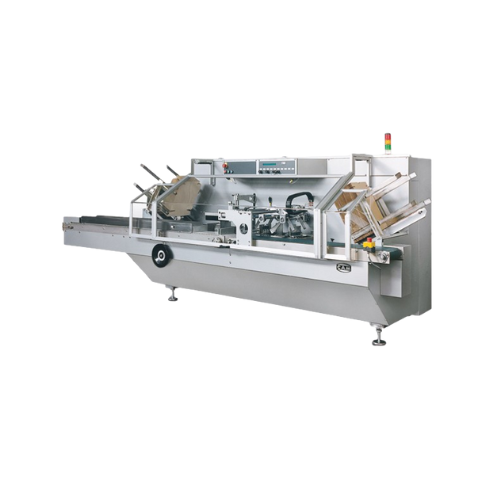

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Deagglomeration and delumping system

Ensure product integrity and streamline operations by effectively breaking down agglom...

Soya milk production system

Efficiently transform soybeans into high-quality, non-beany soy milk with advanced processing te...

Uv monitoring system for small volume dissolution studies

Efficiently monitor small-volume dissolution processes in real...

Automated bagmaker inserter for crystallizing products

Enhance your hygienic packaging efficiency by seamlessly integrati...

Industrial bag tie-wrapping solution

Ensure your bulk packaging is reliably sealed with a tamper-evident tie-wrap, allowing...

Bag inserter for drums

Effortlessly streamline your packaging process by automatically inserting custom-made bags into drums,...

Inline and continuous weighers for accurate product flow management

Maintain precision and efficiency in your productio...

Bucket elevators for bulk material handling

Efficiently transport and discharge granular and powdered materials with preci...

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

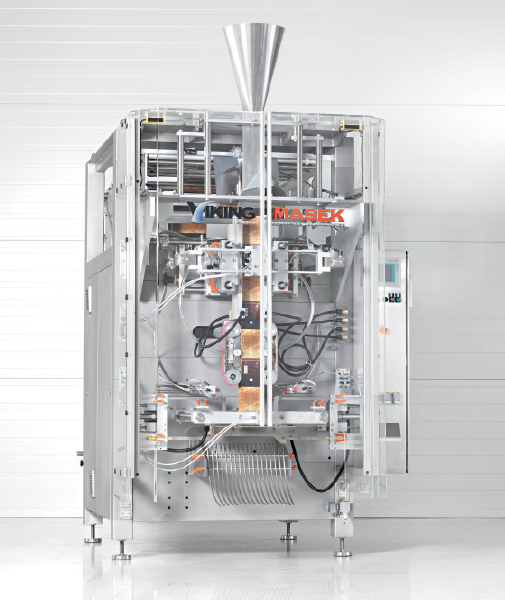

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

High-speed bag placing system for e-commerce fulfillment centers

Optimize your packaging line with a high-speed system t...

Automatic bag sealing system for packaging operations

Optimize your packaging efficiency with this high-speed sealing sys...

Manual bag placing solution for various materials

Increase your efficiency in manual bag placing with an ergonomic soluti...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

Unloader for conical bottom silos

Eliminate product flow challenges effortlessly with this hydraulic-driven unloader, ensur...

Laser diffraction particle size analyzer

Achieve precise particle size analysis with laser diffraction technology, ensuring...

Gas pycnometer for precise density determination

Achieve accurate and reliable density measurements for a diverse range of...

Inspection system for glass containers

Ensure precise inspection of liquid, freeze-dried, and powdered products in glass co...

Stickpack filling and closing system

Optimize your stickpack production with precise dosing, uniform sealing, and seamless ...

Sachet filling and closing system

Optimize your production line with a versatile solution designed to fill, seal, and count...

Ploughshare mixer for batch operation

Achieve superior mixing quality with a system designed for rapid batch operations. Ex...

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

Automated headspace inspection for parenteral containers

Ensure the integrity and quality of pharmaceuticals by inspectin...

Commercial food drum mixer for sauerkraut and salads

Streamline your batch production with this versatile commercial food...

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

Milk drying system

Optimize your dairy production by efficiently transforming liquid inputs into high-quality, dry powders, e...

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy an...

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Bag dump station for handling solid foodstuffs

Efficiently manage manual dosing of solid foodstuffs and powders with this ...

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

Vertical intermittent motion stick packaging

Experience seamless packing for diverse products, from powders to dense paste...

Fluid bed and coating system for small batch processing

Streamline your R&D process with a modular system that ensur...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Isolation solutions for aseptic fill-finish lines

Achieve maximum product sterility with advanced isolation solutions, mi...

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

Continuous aseptic spray-freeze-drying system

Achieve higher sterility and improved product uniformity with a continuous a...

Lifting column for drums and containers

Streamline your production with lifting columns designed for precise handling, blen...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

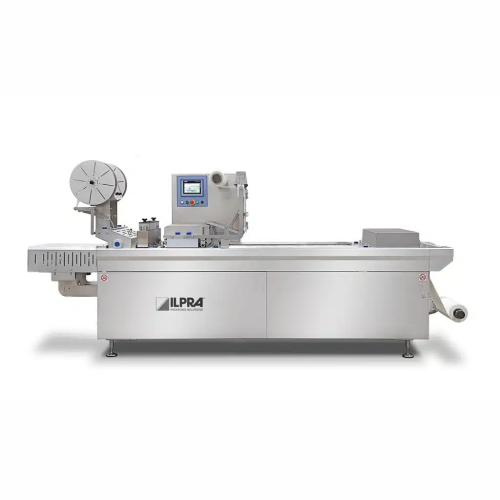

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

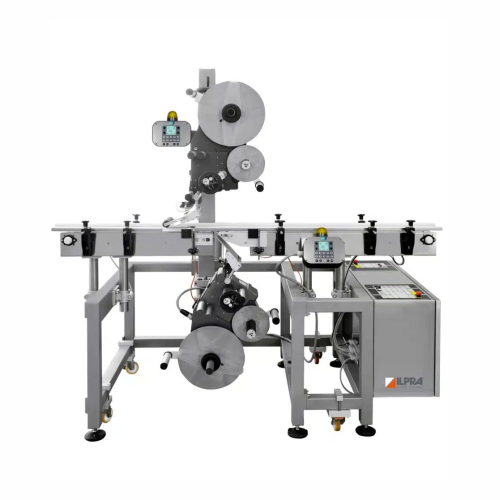

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

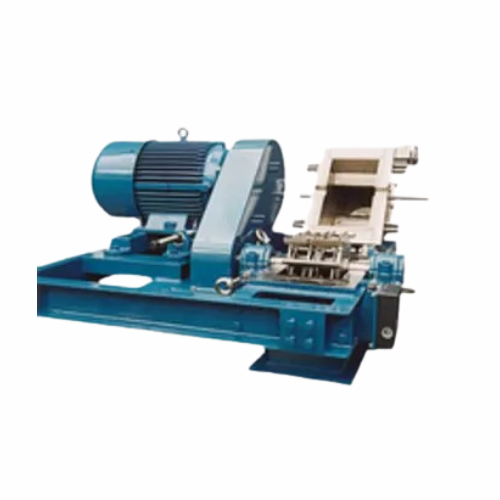

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Vacuum drying solution for filter cake or viscous materials

When faced with the challenge of drying filter cake or trans...

Cylindro conical mixer for batch mixing

Maximize mixing efficiency in compact spaces with this versatile solution, ideal fo...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

Pharmaceutical metal detectors

Ensure product purity by detecting and eliminating metal contaminants in pharmaceuticals, enh...

Integrated packaging system for cement and building materials

Streamline your packing operations with a fully enclosed s...

Integrated packaging system for valve and Ffs bags

Streamline your packaging operations with a versatile system designed ...

High-precision belt feeder for granular materials

Achieve precise material dosing and consistent flow in your continuous ...

Production system for multi-chamber portion packs

Efficiently produce multi-chamber portion packs with high precision for...

Lab machine for producing portion packs

Efficiently form, fill, seal, and punch portion packs in laboratory settings with c...

Ultra-hygienic vacuum conveyor for pharmaceutical industry

Optimize powder transfer with ultra-hygienic vacuum conveying...

Vacuum conveyor for hygienic material transfer

For operations demanding swift, dust-free material handling, this solution ...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Pre-breaker for initial material size reduction

Efficiently prepare your bulk materials for further processing by swiftly ...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Stainless steel intermediate bulk containers for pharmaceutical use

Ensure safe, efficient transport and handling of po...

Conical mill for particle size reduction

Achieve precise particle size control and reduce thermal stress on materials with ...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Industrial container lifting system

Optimize your production line with a versatile lifting solution designed to safely hand...

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Spherical vacuum dryer for Apis and fine chemicals

Achieve precise moisture control and efficient drying for APIs and fin...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Big bag pallet unloader for bulk products

Efficient and reliable solution for unloading and transporting powders and bulk ...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

Bin aeration system for silo and hopper material flow

Optimize the flow of your stored powders and granules with an effic...

Vibratory sieve shaker for precise particle size distribution

Achieve precise particle size distribution with advanced v...

Commercial scale spray dryer for pharmaceutical materials

Optimize the drying of pharmaceutical and industrial materials...

Mini High shear granulator for wet granulation

Optimize your powder granulation with precision and flexibility, ensuring c...

Benchtop spray dryer for drug discovery

Optimize your formulation development with a compact spray dryer that streamlines t...

Fluid bed granulator for industrial granulation

Optimize your production efficiency with versatile fluid bed granulation, ...

Roll compactor system for dry granulation

Achieve consistent tablet hardness and increased powder density with a versatile...

Centrifugal sifter for particle size classification

Achieve precise particle size control with high output efficiency, en...

Laboratory scale fluid bed system for granulation and coating

For precise formulation and optimization, this fluid bed s...

Development fluid bed system for feasibility studies

Explore precise granulation and coating capabilities for small batch...

Closed loop granulator for pharmaceutical production

Streamline your production with a fully automated closed-loop system...

Screw heat exchanger for efficient thermal processing

Optimize your heating and cooling processes with this robust double...

Tumbling cube mixer for homogeneous blending

Achieve uniform blending with precision using a cube mixer that enhances mixi...

Drum hoop mixer for uniform three-dimensional mixing

Achieve consistent, homogenous mixing of powders and granules with a...

V-mixer for solid bulk material blending

Achieve precise and uniform mixing of sensitive powders with gentle treatment, ide...

Double roll crusher for laboratory applications

Optimize material processing with a double roll crusher designed for preci...

Lab-scale ball mill for crystalline material grinding

Effortlessly grind and mix crystalline materials into fine powders ...

Conical mill for particle size reduction and homogenization

Achieve precise particle size reduction and homogenization w...

Fluid bed processor for granulating, drying, and coating in pilot scale

When scaling from laboratory to production, rel...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Product handling system for big bags and containers

Optimize your production line with a comprehensive system for transpo...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial mixer for moisture conditioning

Ensure precise moisture levels and homogeneous mixtures for complex extrusion p...

Bag emptying system for bulk material handling

Streamline your material processing operations with a versatile solution de...

Lactose pneumatic conveying solution

Eliminate frequent production halts due to lactose buildup with our conveying solution...

Industrial roto-flash dryer for chemical applications

Achieve uniform moisture and particle size in demanding drying proc...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Laboratory fluid bed dryer for pharmaceutical granulation

Optimize your lab-scale drying and granulation processes with ...

Mini laboratory mixer for tabletops

Optimize your lab’s mixing precision with this compact tabletop bin mixer, design...

Industrial smart flow meter

Ensure precise metering and smooth handling of bulk materials with a device that eliminates movi...

Twin screw feeders for difficult bulk materials

For manufacturers handling sticky or fine powders, twin screw feeders ensu...

Industrial vacuum blower for continuous pressure conveying

Optimize your production line with reliable vacuum conveying,...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

Bottle cleaning station for controlled environments

Ensure high-level decontamination of passive units and containers wit...

Stickpack wrapper for lollipops

Enhance your confectionery line’s efficiency by wrapping up to 480 lollipops per minut...

Small batch mixer granulator blender

Effortlessly manage small batch mixing, blending, and granulation with a compact solut...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

Small plansifter for grain milling

Optimize your grain milling with a compact plansifter designed for high-speed, precise s...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Moisture analyzer for flour and tobacco

Optimize your moisture measurement process with precision and speed, ensuring quali...

Planetary mixer for homogeneous material mixing

Achieve precise and consistent mixing of diverse materials from powders to...

Horizontal mixer for creams

Achieve optimal and uniform mixing of creams, pasty products, and powders with advanced horizont...

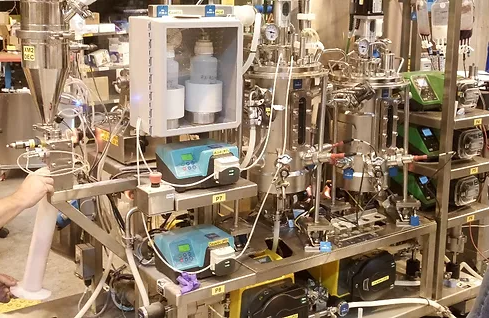

Media and buffer preparation solution for bioprocessing

Achieve seamless media and buffer preparation with precise dosing...

Lifting column for industrial packing drum handling

Efficiently handle heavy drums and containers with precision—streamli...

Big bag discharge station for bulk material handling

Ensure low-dust and efficient discharge of bulk materials with a sys...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Precise weighing solutions for small batch production

Streamline handling of diverse ingredient blends with precise dosin...

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Bag feeding hopper for bulk solids

Optimize your material handling with a robust feeding hopper that seamlessly integrates ...

Dust-tight docking for dosing units to bulk solids containers

Ensure seamless, dust-free transfer and dosing of bulk sol...

Cost-effective dosing container for minor ingredients automation

Optimize your production by streamlining ingredient han...

Dust-free big bag connection system for bulk solids

Eliminate dust and ensure reliable discharge with this vacuum docking...

Automated bulk material handling system

Ensure precise batch tracking and efficient handling of challenging bulk materials ...

Integrated raw & auxiliary material pre-treatment system

Experience dust-free processing with an integrated system design...

Automatic seasoning mixer for food production

Effortlessly blend diverse ingredients with precision in your production lin...

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Vertical single-shaft mixer for dry, moist, and viscous materials

In industries requiring precise and thorough mixing o...

Vertical twin-shaft mixer for dry, moist, and viscous materials

Achieve consistent mixing and blending of diverse materi...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Container mixer for dry and moist materials

Achieve exceptional mixing quality with variable filling levels, ensuring cons...

Indirect drying drums for solvent-based products

Optimize energy use and safety with our indirect drying drums, ideal for ...

Dryer for pigments and hydroxides

Achieve precision drying of complex suspensions and pastes into uniform powders, optimizi...

Volumetric filler for bags and rigid containers

Optimize precision filling of powders and granules with a versatile soluti...

Special purpose auger filling systems for diverse industries

For manufacturers handling precise dosing, our advanced aug...

Tumbler screening for fine and ultra-fine sieving

For operations demanding precise particle separation, this solution off...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

In-line filling system for various container sizes

Streamline your production with versatile in-line filling solutions th...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Industrial auger sack filler for large bags

Designed to efficiently fill large bags and sacks, this advanced filling machi...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Industrial roller compaction for chemical applications

Enhance material flow and density with advanced roller compaction ...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Lifting column for drums and bins

Optimize your powder handling operations with a versatile lifting solution designed for p...

Mobile lifting column for drum handling

Streamline your powder and drum handling operations with this versatile mobile lift...

Vacuum transfer system with integrated cleaning

Ensure sterile powder handling and contamination-free production with vacu...

Hygroscopic material lump breaker

Ensure seamless processing by breaking down compacted or hygroscopic powders efficiently,...

Compressed air loaders for material conveying

Efficiently convey diverse materials with minimal operator intervention, usi...

Digital doser system for plastics additive feeding

Achieve precise additive dosing for plastics, ensuring consistent qual...

High-precision analytical balance for laboratory use

Achieve precise measurements and ensure reliability in your laborato...

High-speed capsule filler for large batch production

Achieve higher yields and reduce powder waste with a capsule filling...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

Automatic granular product weighing system

Effortlessly achieve precise fills for dry granular products and powders while ...

Desiccant inserter for pharmaceutical containers

Prevent product degradation by efficiently inserting desiccants into cont...

Form, fill, and seal system for single-use pouches

Achieve precise portion control and secure sealing with an integrated ...

Granulated sugar storage and conveyance solutions

Optimize your sugar processing with versatile solutions for storage, pr...

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

Vacuum gassing seamer for infant formula packaging

Ensure low residual oxygen levels in your powdered products with a spe...

High-speed container reject system

Ensure product integrity by swiftly rejecting non-compliant containers at speeds up to 3...

Cyclone filter for pneumatic conveying systems

Efficiently separate and filter airborne dust in pneumatic conveying lines,...

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

Sifter for pet food, fish feed, and animal feed

Achieve precise particle separation and enhance feed quality with this vib...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Big bag loading station for bulk product handling

Efficiently manage big bag handling with a system that combines hoistin...

Bulk storage silos for food products

Ensure optimal powder storage and handling with versatile silos designed for efficient...

Circular distribution feeder for fragile product handling

Achieve precise dosing and reduced product damage with a versa...

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

Vibrating feeder for food and pharmaceutical industries

Optimize your production line with precision dosing and gentle ma...

Intermediate bulk container (ibc) blending for pharmaceutical manufacturing

Streamline your pharmaceutical blending pr...

Continuous granulation and drying system for pharma production

Achieve precise control over granule quality with a conti...

Pharmaceutical bottom-drive high shear granulator

Achieve optimal granule uniformity and precise control over moisture le...

Robotic palletizer for food and beverage industries

Enhance your production line’s efficiency with a flexible robot...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Heat pump solution for spray dryers

Enhance your spray drying efficiency and sustainability with an innovative heat pump sy...

Pharmaceutical spray dryer

Unlock the potential of spray drying to enhance bioavailability, achieve controlled release, and ...

Automated fines return system for food and dairy spray dryers

Enhance your spray drying process by eliminating manual in...

Feed-type ring dryer for industrial drying processes

Optimize your production with a versatile drying solution designed f...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Industrial ring dryer for efficient particle processing

Control particle size and drying efficiency with precise recircul...

Conventional spray drying for chemical industry