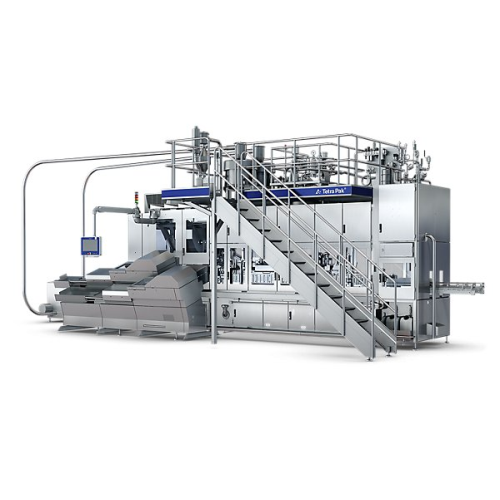

Filling system for gable top cartons chilled products

Achieve precise filling and reliable sealing for chilled beverages and dairy products with enhanced hygiene, optimizing production efficiency and ensuring product safety with advanced disinfection and emission control technology.

Fills, Seals, and Disinfects Liquid Products

The Tetra Pak TR/28 is a high-speed filling and sealing machine engineered for the food and beverage industry, specializing in liquid products such as dairy, juices, and plant-based drinks. What sets the TR/28 apart is its integrated cleaning system and cutting-edge emission control, securing best-in-class hygiene and operator safety.

This machine supports operations with continuous, automated processes and precise fill accuracy that minimizes waste. Designed for seamless integration into your packaging line, the TR/28 features PLC controls, ensuring reliable performance with minimal downtime.

Capable of handling a diverse range of applications, from milk and yogurt to protein shakes and probiotic drinks, the TR/28 also boasts a dedicated cap and carton disinfection system, maintaining product quality over extended shelf life. Constructed with stainless steel top sealers and temperature-controlled heaters, the machine forms robust and leak-proof seals, essential for maintaining the integrity of the packaged product.

Energy efficiency is key, as the TR/28 consumes less energy through its optimized design, while still offering a customizable platform with engineering support to meet the specific needs of dairy producers, beverage manufacturers, and food packaging companies.

Benefits

- Ensures product safety with advanced cap and carton disinfection, extending shelf life.

- Increases production efficiency with precise fill accuracy, reducing waste and maintaining consistent quality.

- Enhances operator safety through emission control systems that clean the air and eliminate the need for additional exhaust setups.

- Lowers operational costs with automated cleaning systems that consume fewer resources.

- Offers flexibility in packaging a wide range of liquid products, supporting business adaptability and growth.

- Applications

- Food, Nectar, Still drinks, Cheese, Plant-based products, Powder, Ice cream, Juice, Chilled products, Dairy

- End products

- Fresh cream, Protein shakes, Probiotic drinks, Still water, Flavored milk, Whey protein powder, Cheese slices, Orange juice, Almond milk, Ready-to-drink tea, Yogurt, Fresh salsa, Milk, Apple nectar, Soy milk, Coconut water, Lactose-free milk, Plant-based smoothies, Cold brew coffee, Ice cream tubs

- Steps before

- Pre-processing, Blending, Homogenization, Pasteurization

- Steps after

- Capping, Sealing, Labeling, Palletizing, Distribution

- Input ingredients

- chilled products, cap disinfection spray, carton disinfection spray, hydrogen peroxide, peracetic acid

- Output ingredients

- Tetra Rex® gable top cartons, safe food packaging, sealed cartons, chilled dairy products, juice, nectar and still drinks

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Filling accuracy

- ± 1 gr

- Automation

- PLC-controlled

- Capacity

- Up to 500 packages/hour increase

- Cleaning method

- Automated cleaning system

- Chemical used

- Peracetic acid / Hydrogen peroxide (H₂O₂)

- Emission control

- Below 0.5 ppm

- Package Types

- Tetra Rex® Base, Tetra Rex® Arch, Tetra Rex® High

- Sealing type

- Mechanically driven top sealers

- Temperature control

- Temperature-controlled heaters and mandrel tops

- Disinfection method

- Cap and carton disinfection spray

- Cooling system

- Long cooling period

- Automation level

- High (PLC / SCADA)

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- CIP 121°C

- Cleaning method

- CIP

- Emissions control

- Patented emission control system

- Operator safety

- Complies with new directives

- Air incorporation control

- Yes

- Production output increase

- Up to 500 p/h

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- 100 ml - 1000 ml

- Container material compatibility

- Sustainable packaging

- Container type

- Gable top cartons

- Product diversity

- Chilled products

- Machine footprint

- Compact

- Control panel type

- Operator panel with status bar

- Discharge method

- Sealed gable top cartons