Plant-Based Milk Equipment

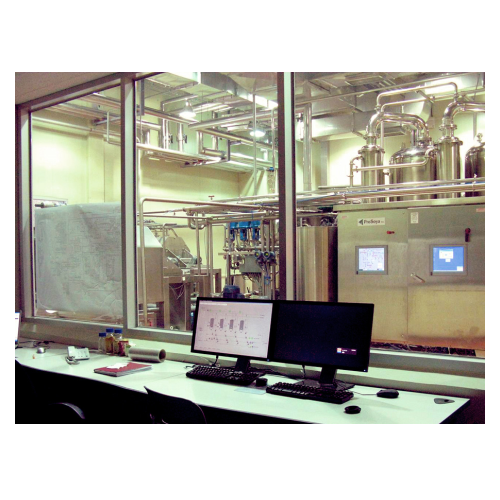

Find innovative plant-based milk equipment and connect directly with world-leading technology suppliers

With the right processing machines, almonds, cashews, pine nuts, hemp, coconut, oat and soy can be processed into healthy plant-based milk. To produce it, grind the raw materials, screen, soak and mix them till you obtain a milky white liquid.

Top picks for plant based milk production

Clarifiers for dairy and plant-based beverages

Ensure optimal product purity and versatility by efficiently removing impur...

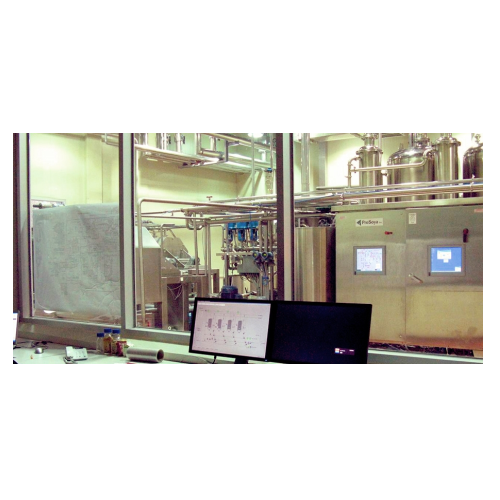

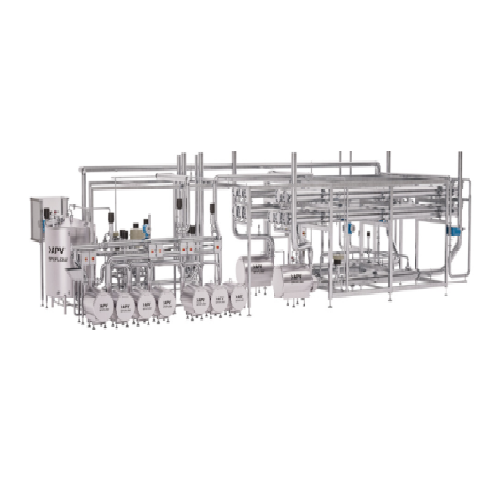

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

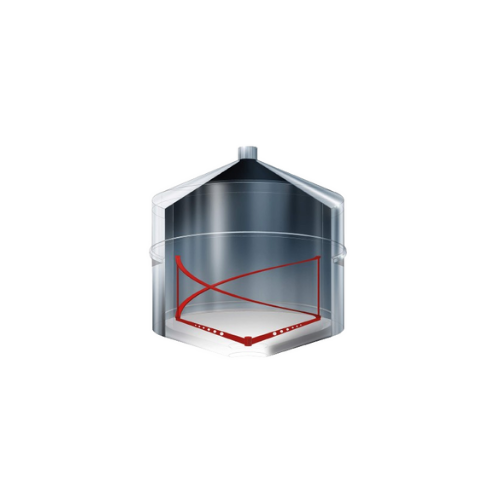

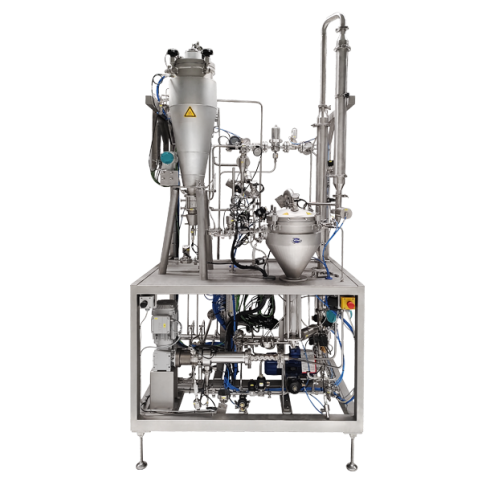

Hydrolysation tank for plant-based beverages

Optimize your plant-based beverage production with a hydrolysation tank that ...

Tell us about your production challenge

Using alternative milk processing machines

Plant-based milk is nutritional as well as being rich in both flavour and texture. The search for healthy dairy free milk is increasing in the US and other countries, as it is lower in calories and saturated fat than cow milk. Plant based milk in US is expected to reach $21.52 billion in 2024, and it is growing at an annual growth rate of 10.18%.

You can create pure dairy-free milk, or you could blend it with dairy products such as cow milk. If you want it pure, grind the nuts, starch or legumes and water in a colloid mill, then filter the milk with a mesh sieve. Lastly, use a sterilizer to remove bacteria from the milk and fill it into bottles. For the blended version, mix cow milk with the nuts before grinding.

Emulsifiers like sunflower lecithin help the milk to stay well dispersed, giving the milk a consistent texture. A peeling machine helps you to separate the nut kernels from the skin, while a milk maker crushes the nut to extract the milk. This apples to all different types of nuts such as almonds, cashews, pine nuts and hazelnuts.

The importance of sterilizing plant-based milk

Sterilization is essential in plant milk production because it kills the microorganisms that are present in the milk. So when you package the product, it can stay for up to 6 months on the shelves.

There are some precautionary actions you need to take to sterilize the plant-based milk. If your product is made from nuts, you first need to ensure that you are not using rancid or contaminated nuts. Always use fresh nuts. To keep the nuts fresh for up to 3 months, store them in airtight containers.

Secondly, you need to ensure that the nuts are washed with filtered water before grinding. Next, sterilize the milk by heating it in sealed containers continuously at 115° C for at least 15 minutes.

Effect of plant-based milk production on the environment

In the last 5 years, the production and sales of almond milk have grown 250% to more than $894.6 million. This means that these types of milk have become a popular choice for both vegans and those that want to reduce carb intake. Milk alternatives from plants, such as soy milk, are nutritious, low in calories and don’t raise blood sugar. Commercial production is contributing a lot of people choose a healthier lifestyle.

The only downside of plant-based milk production is that it is taking a toll on the environment. It takes 16 gallons of water just to produce 16 almonds, making almonds a water-intensive crop. Micro irrigation is now used as an alternative to reduce the amount of water used for almond production. Additionally, the pesticides used for the commercial production of almonds contaminates the limited water sources and toxifies drinking water for people in farming communities.

Which plant-based milk technology do you need?

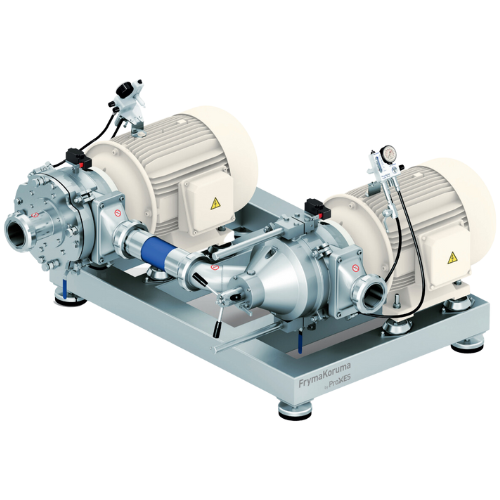

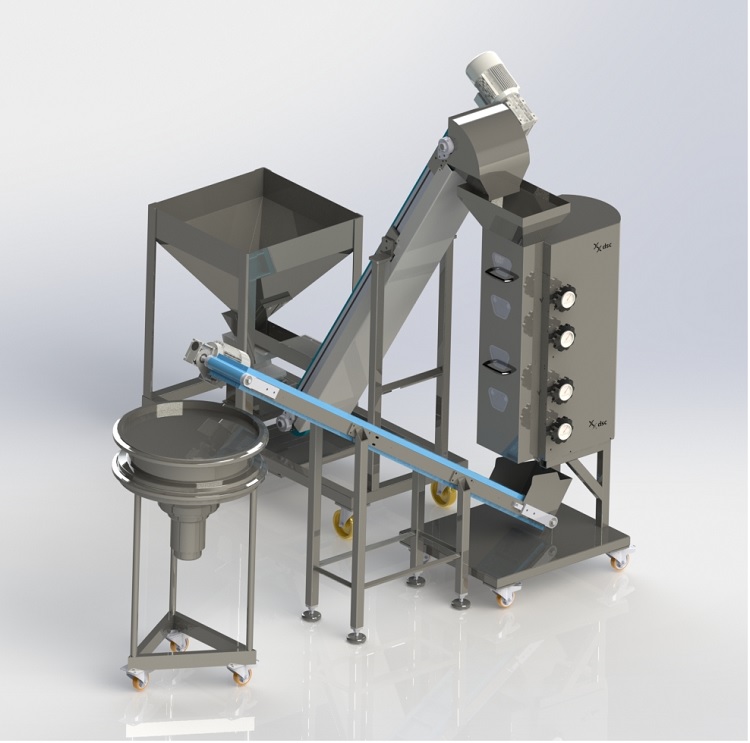

Energy efficient grinder for plant-based milk

Buying pre-processed materials, such as flour, and handling and dispersing t...

Bacteria removal separator for dairy products

Ensure top-quality dairy and plant-based products with reliable bacteria rem...

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

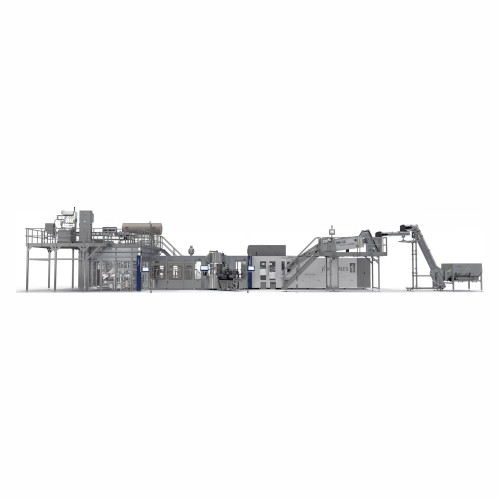

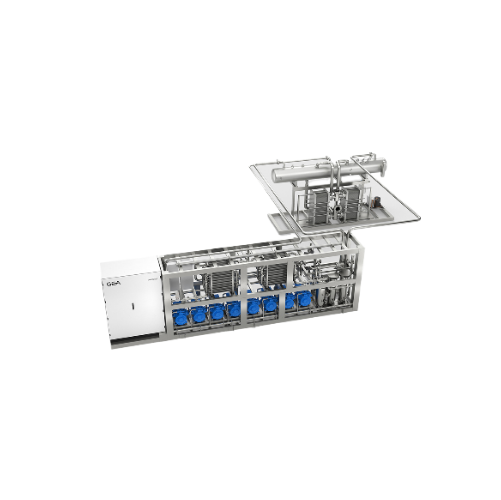

Oat milk processing plant

Transform whole oats into creamy, nutritious oat milk with precision, leveraging advanced continuo...

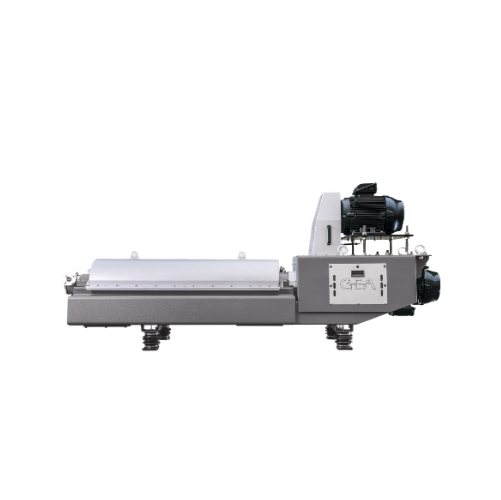

High-performance decanter centrifuge for dewatering

Achieve efficient and reliable dewatering by integrating a decanter c...

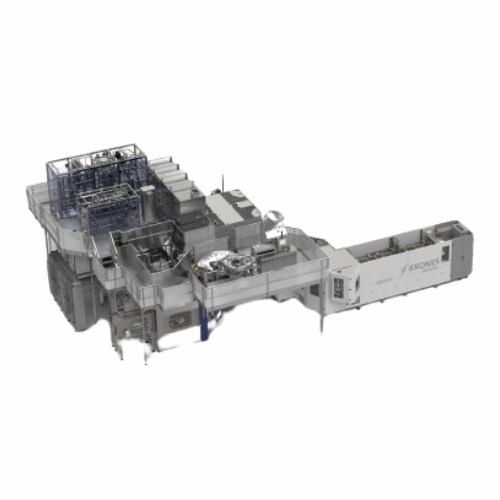

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

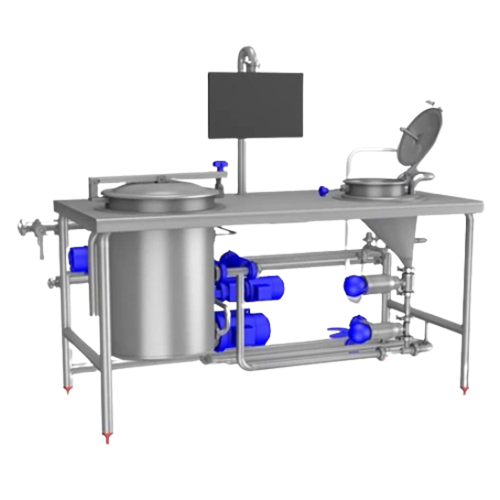

Bench-top blending vessel for small batch preparation

For small-batch liquid products, achieve precise mixing, heating, a...

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

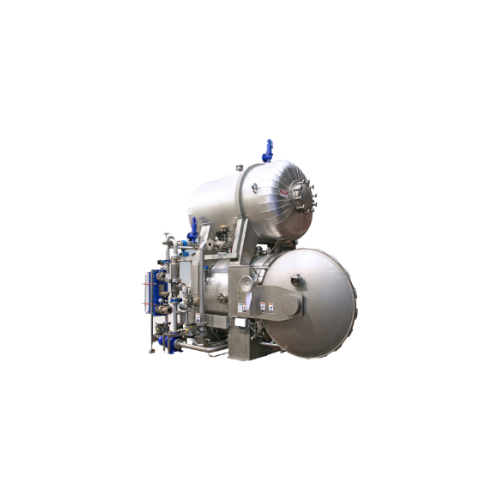

Small-scale in-container spray pasteurizer for laboratory use

Optimize your R&D processes with precise control over...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

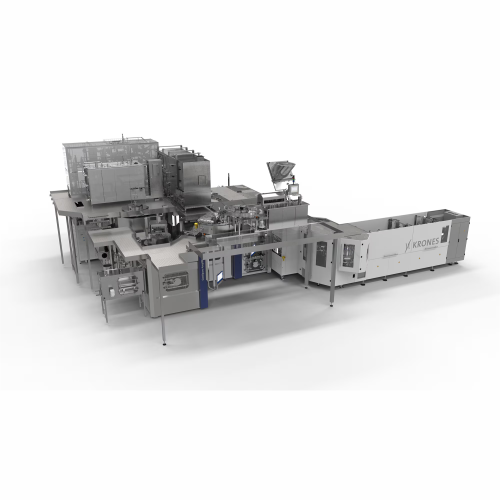

High-performance stretch blow moulding and labelling system

Maximize space and efficiency with this compact system that ...

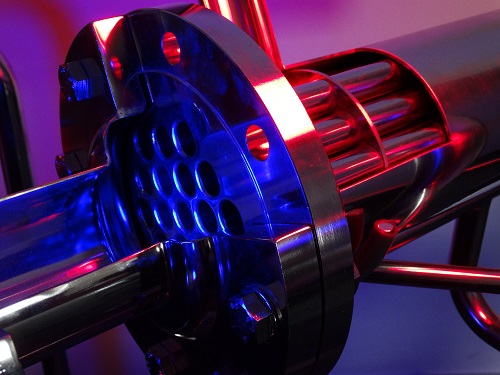

Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchan...

Stretch blow moulder for Pet containers

Optimize energy efficiency and production versatility with this stretch blow moulde...

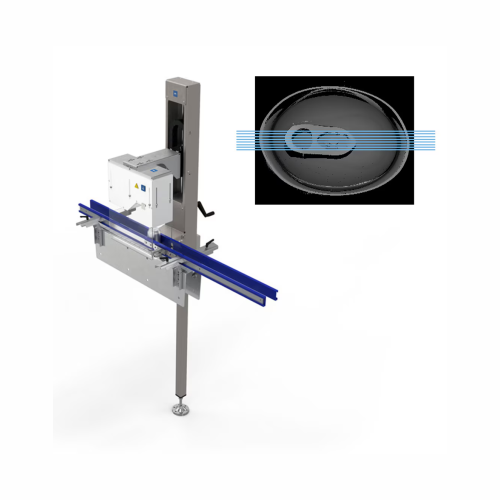

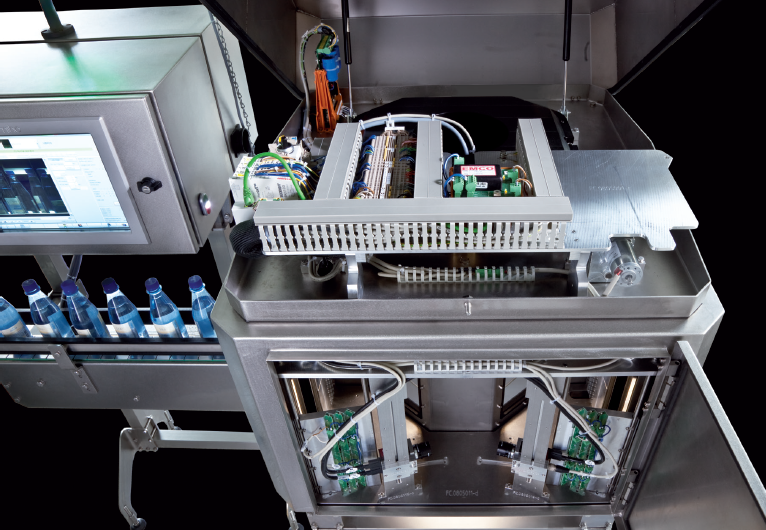

Can inspection unit for quality control

Ensure the integrity of your beverage cans with precise defect detection and qualit...

Cip system for cleaning bottling lines and processing sections

Ensure a sterile production environment by integrating a ...

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

Clean-in-place systems for biotechnology and pharma

Ensure seamless transitions between production batches with efficient...

Multipurpose membrane filtration system for pilot testing

Optimize your pilot-scale processes with a versatile filtratio...

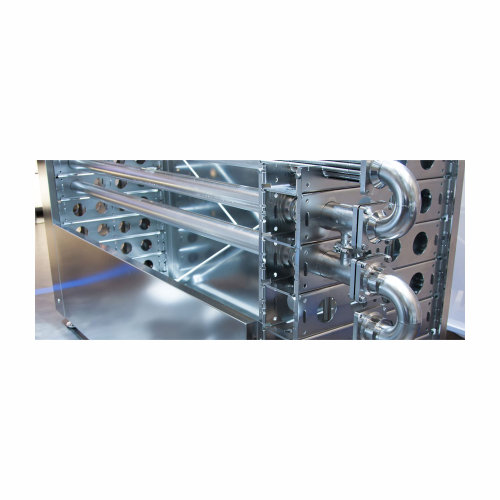

Tubular heat exchanger for thermal treatment of viscous products

Optimize efficiency in heating, cooling, and pasteuriza...

Hot fill gravity filler for beverages

Achieve precise hot filling with versatile gravity filling technology that maintains ...

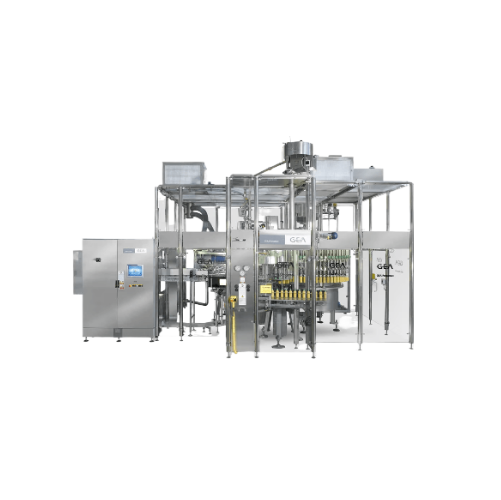

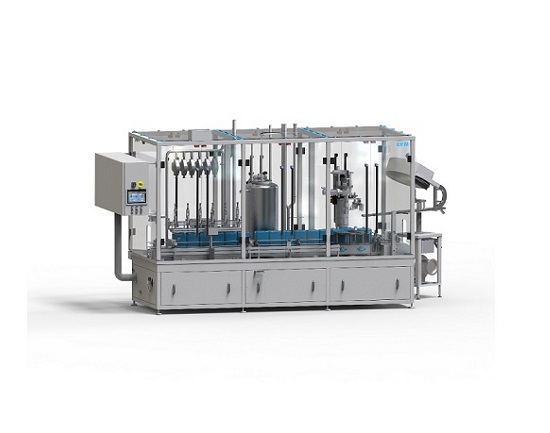

Cold chain filling system for sensitive beverages

Ensure extended shelf-life for liquid dairy and sensitive beverages wit...

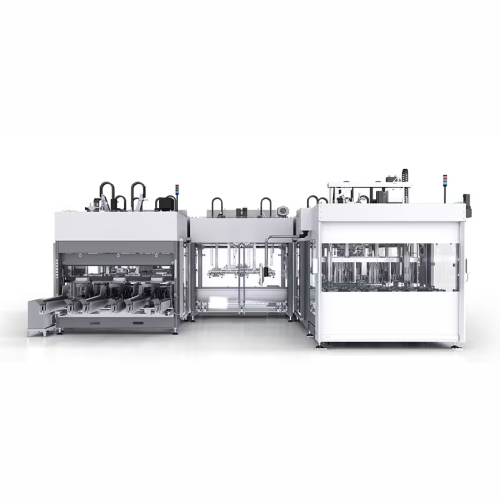

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Large-volume stainless steel brewery tanks

Optimize your fermentation and storage operations with precision-crafted tanks,...

Efficient mash agitator for breweries

Enhance your mashing process with an agitator designed to optimize heat transfer and ...

High performance industrial pasteurizers

Enhance your liquid processing with fully autonomous pasteurizers that ensure opti...

High-speed blender for commercial use

Designed for high-performance blending tasks, this solution integrates vacuum technol...

High-speed liquid mixing solution

Optimize your beverage mixing operations with a system that ensures even ingredient distr...

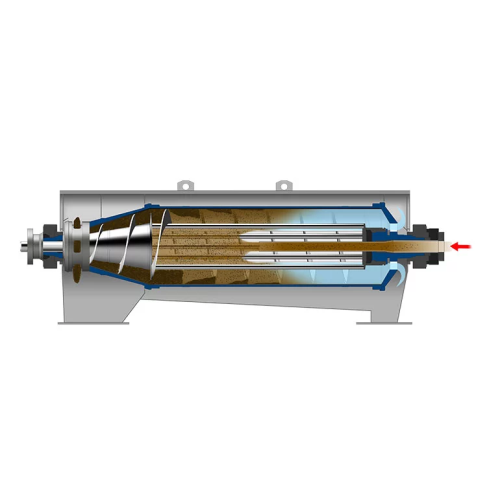

Double decanter for plant-based beverages

Optimize your plant-based beverage production by achieving high protein yield an...

Industrial grinder for plant-based beverages production

Achieve optimal particle size for seamless integration with your ...

Continuous soya extraction unit

Enhance your plant-based beverage production with a unit that maximizes protein yield and re...

Continuous carbonator for beverage production

Optimize your beverage production with seamless continuous carbonation, ensu...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Double decanter for plant-based beverage extraction

Maximize protein yield and enhance extraction efficiency in your plan...

Industrial grinder for plant-based beverages

Ensure optimal particle size for hydrolysis in plant-based beverage productio...

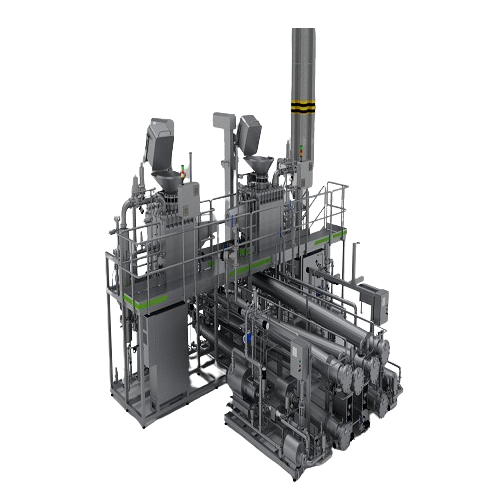

Continuous soya protein extraction system

Optimize plant-based milk yield and reduce waste with a versatile extraction sys...

Evaporation system for dairy products

Optimize product quality with continuous evaporation, ensuring efficient moisture rem...

Tubular ultra high temperature processing system for dairy products

Optimize your dairy processing with precise thermal...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Small scale continuous evaporator

Ideal for lab and small-scale production, this evaporator offers precise control for redu...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

Skid mounted process plant

Simplify your production setup with skid-mounted process plants, designed for quick installation ...

Nozzle separators for starch recovery

Optimize your starch recovery process with our nozzle separators—designed to deliver ...

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

Low temperature evaporator for heat-sensitive food products

Efficiently concentrate sensitive liquid products while pres...

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Soya milk production system

Efficiently transform soybeans into high-quality, non-beany soy milk with advanced processing te...

Soya protein isolate production line

Ensure the highest protein purity with this comprehensive production line designed to ...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Batch processing systems for industrial applications

Optimize batch production with versatile systems that enhance energy...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

Fs closing devices for industrial packaging solutions

Streamline your packaging process with versatile closing devices, d...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

Ultrahygienic block for aseptic filling

When handling sensitive beverages, ensuring microbiological safety and quick produc...

Juice product deaerator

Ensure high-quality filling without foam formation through efficient deaeration, perfect for manufact...

Palletizing grouping system for non-returnable packs

For beverage and packaging lines, precise and rapid palletizing of n...

Syrup room for customized beverage ingredient preparation

Achieve unparalleled flexibility in beverage production with a...

Crate washer for beverage manufacturers

Ensure thorough cleaning of beverage crates with an advanced washing system featuri...

Flexible packaging line for beverage production

Streamline your beverage production with a flexible system capable of hand...

Caustic residue detection for bottle washing

Ensure product purity by detecting and eliminating residual caustic in return...

Leakage detection for beverage cans

Ensure each canned beverage leaves your facility ready to impress, with precise leak de...

Bottle inspection system for foreign particles detection

Ensure your beverage products remain uncontaminated with high-pr...

Sterile tank system for aseptic processing

Optimize your production with aseptic tank systems that ensure sterile storage ...

Aseptic bottle sterilisation system for Pet containers

Ensure aseptic integrity and high-speed efficiency in beverage pro...

Automated product change-over system

Maximize your production line efficiency by reducing downtime during product changeove...

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

Blow-moulder and labeller integration for Pet bottles

Streamline and enhance your PET bottle production with seamless blo...

Blending system for deaeration and carbonation of beverages

Achieve precise blending, efficient deaeration, and accurate...

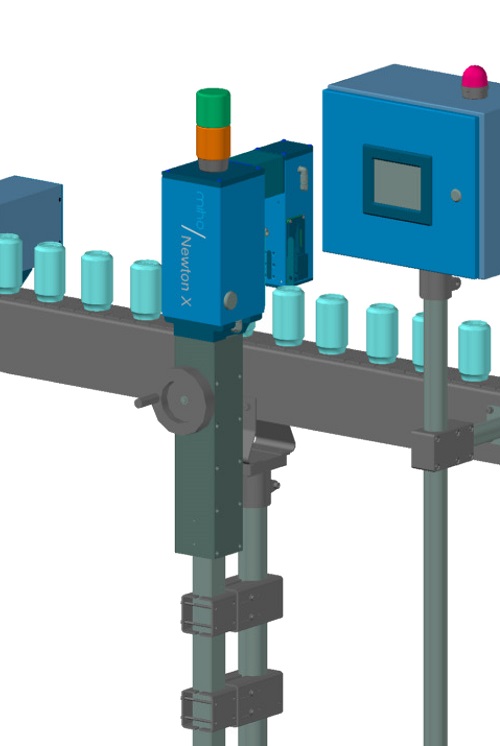

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

Automatic leakage detection for Pet bottles

Ensure the integrity of bottled beverages by detecting even the smallest leaks...

Decanter centrifuge for soft sediment separation

For operations dealing with soft, easy-flowing sediments, ensuring effici...

2-phase separator for clarifying liquids

Efficiently refine and clarify liquids while minimizing waste. This 2-phase separa...

3-phase liquid separation solution

Achieve precise separation of liquids and solids to enhance product quality and streamli...

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

Advanced sludge dewatering for sewage treatment plants

Optimize sludge dewatering with a centrifuge that enhances separat...

High-performance decanter centrifuge for industrial separation

Optimize your production with a centrifuge solution that ...

Industrial nozzle separator for high solids concentration

Optimize your production with high-performance nozzle separato...

Pharmaceutical reactor for efficient cleanability

Optimize your production with this reactor, designed for efficient mixi...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

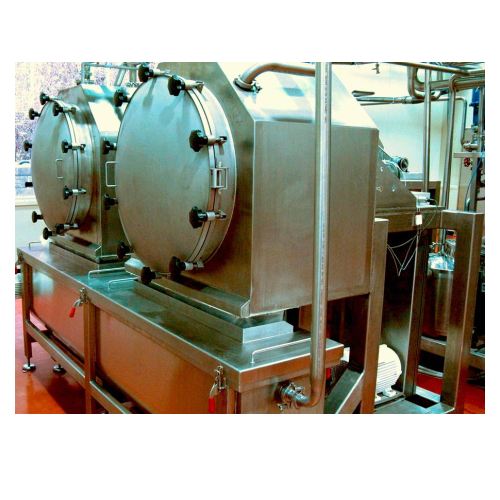

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Depositing line for cake production with paper cup denester

Optimize your cake production by seamlessly depositing marbl...

Aseptic cooking line for plant-based products

Enhance your production efficiency and product quality with an advanced doub...

Combi x-ray and checkweigher for vertical products

Ensure precise weight control and contamination detection for vertical...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Rising film evaporator for concentration of viscous liquids

Effortlessly concentrate low-to-medium fouling and highly vi...

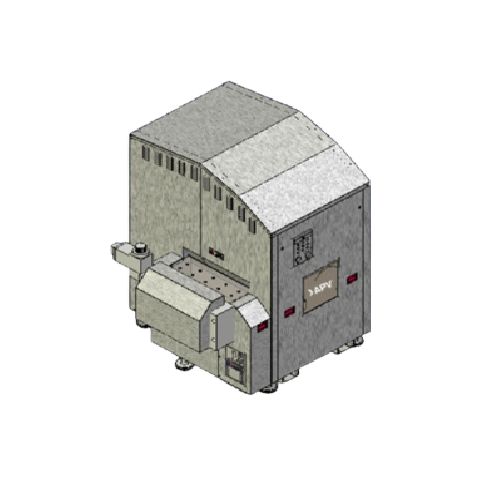

Sterilization pilot systems for small batch heat treatment

Optimize product safety and quality in small batch production...

Water remineralization system for mineral and flavored water production

Achieve precision in mineral content with a sys...

Industrial bagging system for high-speed processing

Optimize your packaging line with this engineered-to-order bagging sy...

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

Gentle can handling ejector for rotary cooker

Achieve seamless can transfer and sterilization with reduced damage during h...

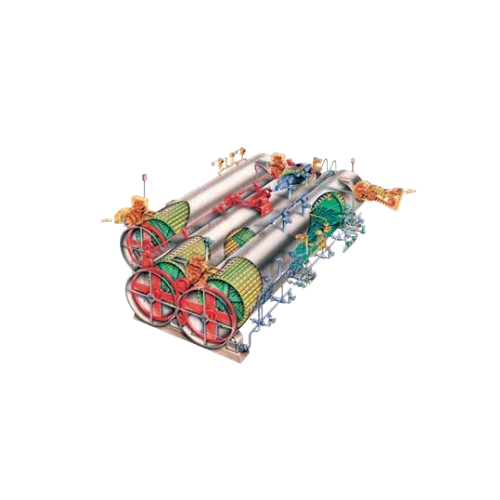

Rotary pressure sterilizer for canned food products

Streamline your canning operations with continuous high-speed sterili...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

Battering machine for food coating applications

Enhance your food products with uniform and efficient batter application, ...

Uht plant for aseptic product treatment

Ensure optimal product quality and production safety with versatile UHT solutions f...

Laboratory homogenizers for nanoparticles and emulsions

Tackle the challenge of achieving consistent nano-scale dispersio...

Laboratory homogenizer for scaling nisox-valve benefits

Achieve reliable scaling from lab to production with this precise...

Esl beverage filling system

Ensure extended shelf life and maintain beverage quality with sterile filling and decontaminatio...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Aseptic filling system for sensitive beverages

Optimize your beverage production with an aseptic filling system that ensur...

Heat pump solution for spray dryers

Enhance your spray drying efficiency and sustainability with an innovative heat pump sy...

High-yield fermentation system for raw material processing

Achieve precise control in fermentation with advanced systems...

Industrial chiller with high part-load efficiency

Optimize your cooling processes with a versatile chiller designed for p...

Clarifying decanter for food ingredient processing

Optimize your protein recovery and ensure high-quality separation with...

Internal wort boiler for precision boiling in brewing

Achieve consistent wort quality with precision boiling, designed to...

Membrane mash filter for brewing

Optimize your brewing process with advanced membrane filtration, ensuring maximum yield and...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

High-capacity industrial dicer for vegetables and fruits

Streamline your food processing line with a high-capacity soluti...

Industrial homogenizers for liquid processing

Achieve consistent product quality and energy efficiency in liquid processin...

High-speed vacuum blender for commercial use

Achieve optimal blending with cutting-edge vacuum technology, ensuring vibran...

Industrial-scale bioreactors for large-scale biomanufacturing

When producing at large volumes, efficient and reliable bi...

Manual bag tipping unit for powder handling

Ensure a contamination-free environment with a compact manual bag tipping unit...

Direct Uht treatment for liquid foods

Optimize aseptic production with advanced UHT technology to preserve nutritional valu...

Milk skimming separator

Achieve superior separation efficiency and reduced energy consumption in dairy processing with seamle...

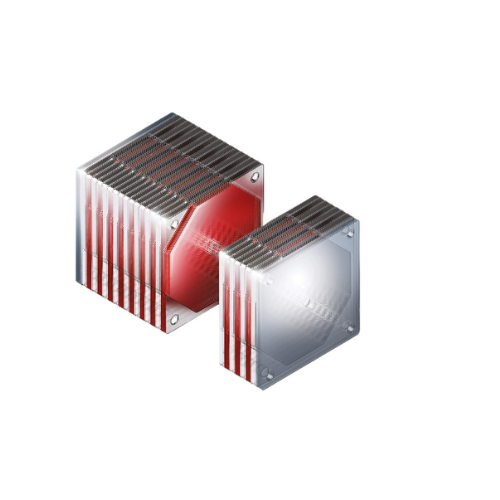

Polynode technology for enhanced dairy separation

Achieve higher separation efficiency and capacity with innovative disc ...

Industrial clarifier for dairy and plant-based products

Optimize your production line with cutting-edge clarification tec...

Ingredient dissolver for small batch processing

Optimize your mixing processes with a versatile dissolver designed for eff...

Beverage preparation system for large-scale production

Ideal for producers looking to scale up, this versatile system eff...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Hydrolysation tank for plant-based beverage production

Ensure optimal hydrolysis conditions for plant-based beverages wit...

Thermal deactivation unit for plant-based base creation

Efficiently deactivate enzymes in plant-based beverages with prec...

High-precision decanter for plant-based beverages

Enhance your plant-based beverage production with a decanter engineered...

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

Uht processing unit for dairy products

Optimize your liquid food production with continuous, high-capacity UHT treatment th...

Clarifiers for dairy and plant-based beverages

Ensure optimal product purity and versatility by efficiently removing impur...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

Dairy pasteurizer

Ensure product safety and quality while reducing energy consumption and operational costs with this advance...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

Hydrolysation tank for plant-based beverages

Optimize your plant-based beverage production with a hydrolysation tank that ...

Thermal deactivation unit for plant-based beverages

Enhance your plant-based beverage production by effectively reducing ...

Low-energy evaporation system for dairy products

Enhance product quality and lower energy costs with a cutting-edge evapor...

Plant-based beverage extraction system

Maximize yield and product quality in plant-based and dairy beverages with high-effi...

Aseptic tank for intermediate storage

Ensure safe and sterile storage for liquid and slurry products, minimizing product lo...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

Ibc rack for storing and discharging ingredients

Optimize ingredient management with efficient storage and discharge of bu...

Ingredient reception tank for liquid storage and processing

Ensure efficient storage and processing of liquid ingredient...

Filling system for gable top cartons chilled products

Achieve precise filling and reliable sealing for chilled beverages ...

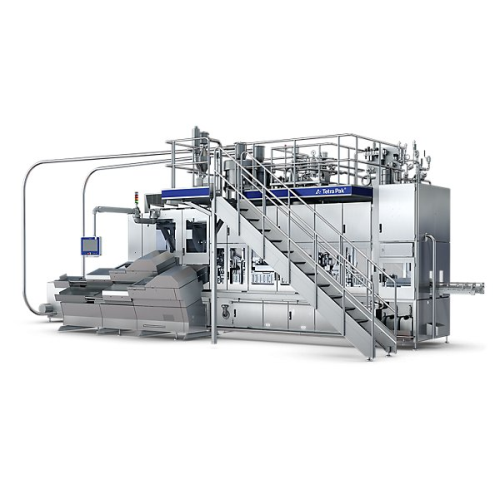

Filling solution for tetra brik® packages

Optimize your filling and packaging process with a system that seamlessly switch...

Filling solution for various container types

This versatile filling solution optimizes liquid packaging by accommodating a...

Medium torque mixer for chemical processing

Achieve optimal mixing efficiency and process consistency in demanding applica...

Line blender for continuous flow mixing

Achieve instantaneous mixing with minimal space and maintenance using a continuous ...

Medium torque top entering mixer for chemical processing

Achieve consistent mixing results with a versatile, high-torque ...

High torque top entering mixer

Ensure consistent high-torque mixing for various industrial applications with this robust top...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

High pressure homogenizers for dairy and pharmaceutical applications

Optimize your production line with high-pressure h...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Reverse osmosis system for dairy and plant-based processing

Enhance your production line with high-pressure reverse osmo...

Soymilk processing plant

Enhance your plant-based production with our tailored soymilk processing plants, designed to efficie...

Microfiltration system for dairy and plant-based applications

Enhance your production capacity and reduce waste with adv...

Milk pasteurizer system

Ensure your dairy and plant-based beverages achieve optimal safety and quality with precise temperatu...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Isobaric filler for glass and Pet bottles

Achieve precise liquid filling with enhanced operational flexibility and hygiene...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

Chilled water milk can cooler for small farms

Ensure milk quality and safety with rapid cooling from 35°C to 8°C in under ...

Lab-scale filtration system for micro- and ultrafiltration

Simplify complex microfiltration and ultrafiltration tasks wi...

Benchtop membrane filtration for process development

Eliminate fouling and achieve precise separation with a benchtop fil...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Homogenization and emulsifying system for fine foods

Texture and consistency are critical to foods with delicate composit...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Beer pasteurizer

Contamination and cross-infection by microorganisms is a major risk in the production of foods and beverages....

Craft Beer Pasteurizer

Pasteurization of craft beers in breweries is very important to ensure the maintenance of taste and ex...

Sugar dissolving system for beverages

In the beverage industry, production of sweet drinks requires the addition of sugar s...

Pasteurizer machine for sensitive beverages

When you want to expand your beverage production line, following a new global ...

Water treatment for beverage preparation

Water is one of the main ingredients in producing juices and other beverages. If i...

Continuous sterilizer for milk beverages

An important goal of heat processing in the manufacturing of milk beverages is to ...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Flash pasteurizer for beer

The food and beverage industry are faced with constant challenges. Contamination and cross infect...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

Metal detector for bottles

For metal contamination detection in finished products that are bottled, traditional solutions re...

Air knife dryer for bottles

When filling glass bottles during beverage production, the cleaning and filling processes often ...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products acro...

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Vibrating sieve for liquid solid separation

Many industrial processes require the efficient separation of solids from a sl...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...

Empty bottle height sorting system

An empty bottle sorting system that uses the light barrier technology. It detects bottle...