Leakage detection for beverage cans

Ensure each canned beverage leaves your facility ready to impress, with precise leak detection measuring internal pressure without contact.

Detects Leaks in Beverage Cans

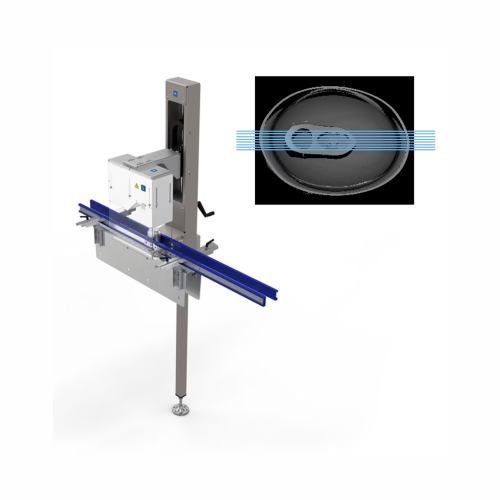

The Checkmat SLD from Krones is a sophisticated leakage detection system designed for the beverage industry. What sets this equipment apart is its contact-free operation using a 3D laser scanning process to accurately detect leaks in beverage cans. By projecting a fanned-out laser beam onto each can and capturing the lid’s bulge profile, it reliably assesses internal pressure without halting your production line. This method ensures continuous, high-speed operation without wear-related downtime and eliminates the need for physical contact, thus maintaining the cans’ integrity. Ideal for dynamic food and beverage environments, the Checkmat SLD is beneficial for applications involving soda, juice, spirits, milk, and water. With a focus on efficiency and integration, it requires a corresponding layout drawing of the filling line, with pressure usually stabilizing around 30 minutes post-filling. This unit streamlines quality assurance, ensuring only perfectly sealed cans proceed down the line, effectively reducing waste and safeguarding product quality.

Benefits

- Increases production efficiency by detecting leaks without stopping the line.

- Minimizes product waste with precise, contact-free pressure evaluation.

- Maintains product integrity with non-invasive 3D laser scanning.

- Ensures high-speed operation without wear-related downtime.

- Supports diverse beverage canning applications, enhancing versatility.

- Applications

- Water, Milk and milk-based drinks, Beverage cans, Spirits, Plant-based milk alternatives, Juice, Soft drinks

- End products

- Sparkling water cans, Soda cans, Canned evaporated milk, Canned almond milk, Beer cans, Mixed spirit cocktails in cans, Orange juice cans

- Steps before

- Filling

- Steps after

- Packing, Conveying, Labelling

- Input ingredients

- beverage cans

- Output ingredients

- leakproof beverage cans, rejected cans

- Market info

- Krones is renowned for its expertise in manufacturing beverage and liquid food processing and packaging equipment, offering comprehensive solutions that include filling, packaging technology, and processing systems, and is reputed for innovation and quality in the industry.

- Leakage Detection Type

- Seam Leakage Detection (SLD)

- Detection Method

- Contact-free with 3D scanner and camera

- Automation

- Camera-analyzed laser-generated 3D profile

- Speed Restrictions

- No speed restrictions

- Internal Pressure Evaluation

- Based on lid bulge

- Working mechanism

- Contact-free with 3D scanner and camera

- Integrated steps

- Leakage detection through internal pressure measurement

- Automation level

- Automatic

- Batch vs. continuous operation

- Continuous

- Changeover time

- No changeover required

- Energy efficiency

- Efficient due to contact-free process

- Cleaning method

- Not applicable (contact-free)

- Speed restrictions

- No speed restrictions

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Metal cans

- Lid bulge measurement

- Determines internal pressure

- Contact-free scanning

- 3D scanner and camera

- Scanner type

- Fanned-out laser beam

- Construction

- Non-contact method, no wear

- Machine layout requirement

- Needs corresponding layout drawing

- Contact-free operation

- Yes

- Integration with filling line layout

- Required