Let's make spirits

Find innovative spirits equipment and connect directly with world-leading technology suppliers

Spirits are an expression of their combined surroundings. Everything that goes into producing a liquor bottle leaves a unique mark on the final product. So, liquor making machines are a particular equipment category in the food and beverage industry. Every detail in their design can be tasted in the spirit’s flavor, texture, or aroma. Next time you allow yourself to a tipple, raise a glass to technology.

Top picks for producing spirits

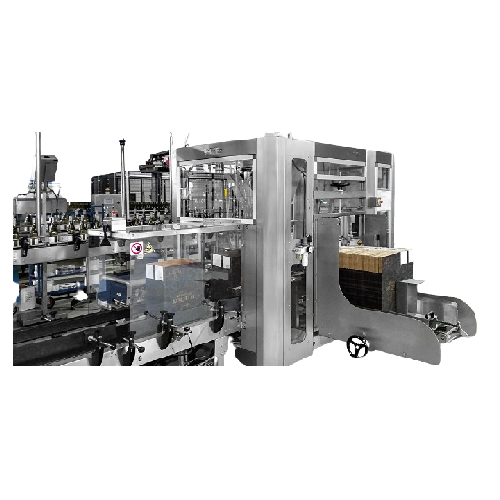

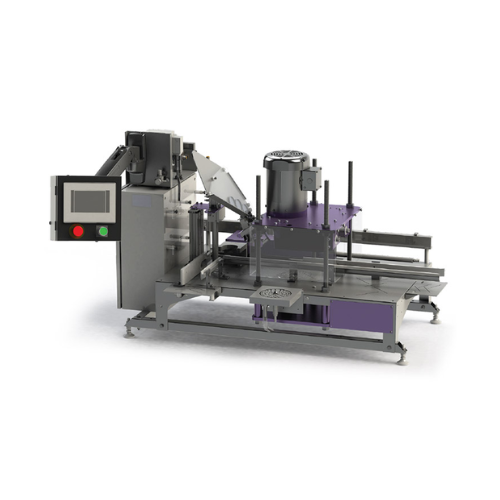

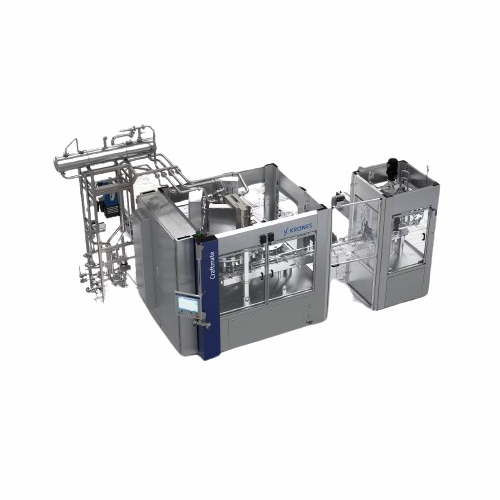

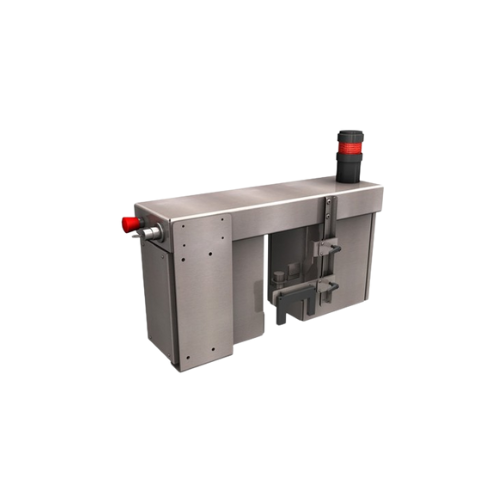

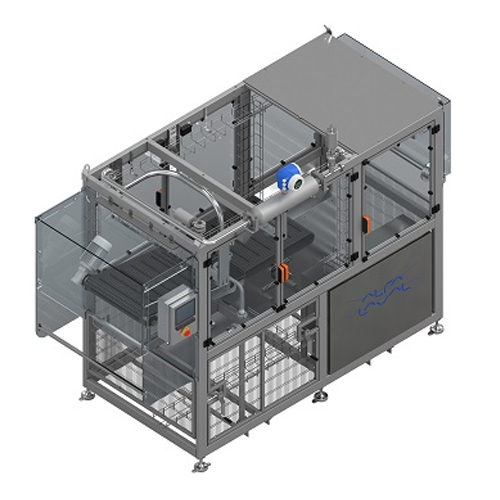

Bottle Cartoning Machine for Spirits

Cognac, brandy, whiskey and other luxurious spirits often come in uniquely branded pac...

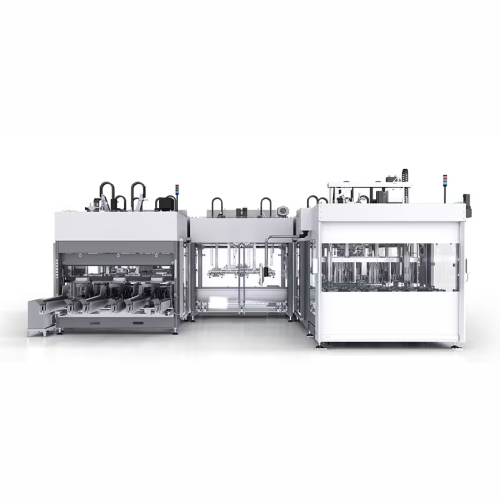

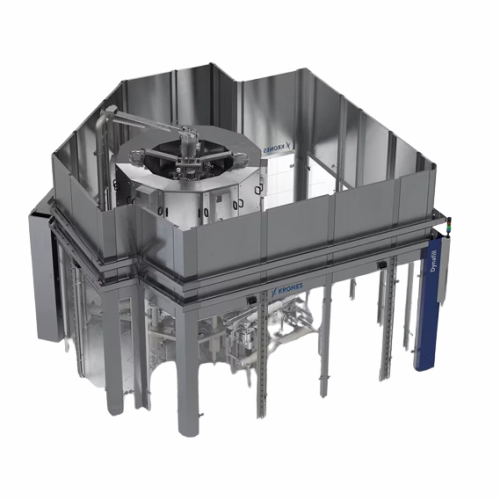

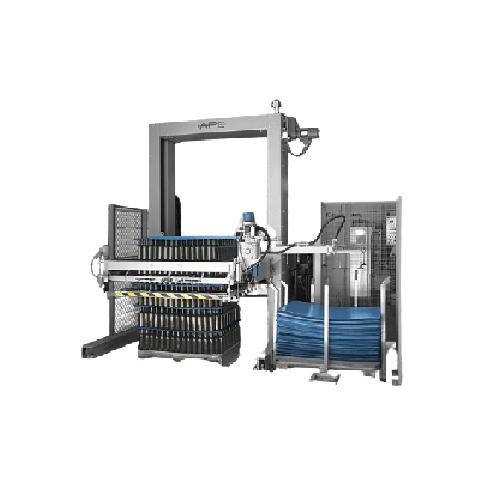

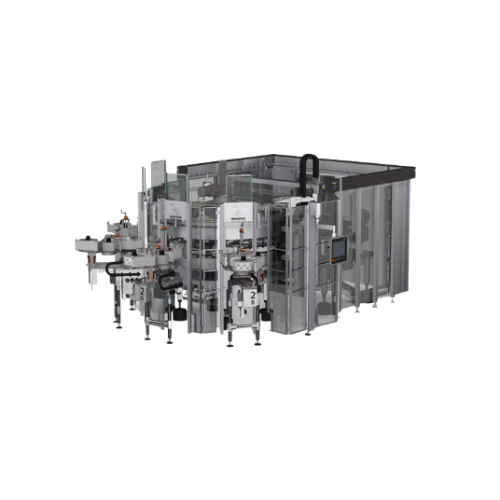

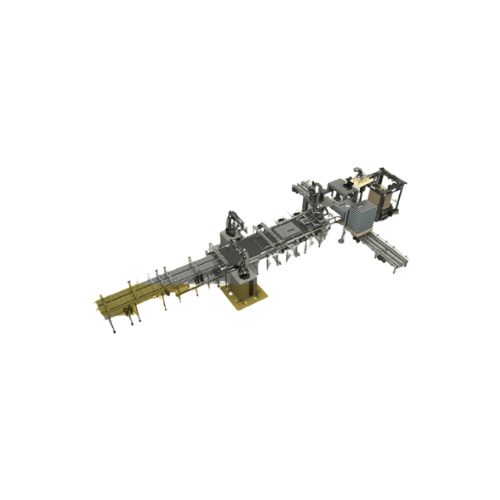

Automatic palletizer for bottle packaging lines

Streamline your bottling line with advanced palletizing solutions engineer...

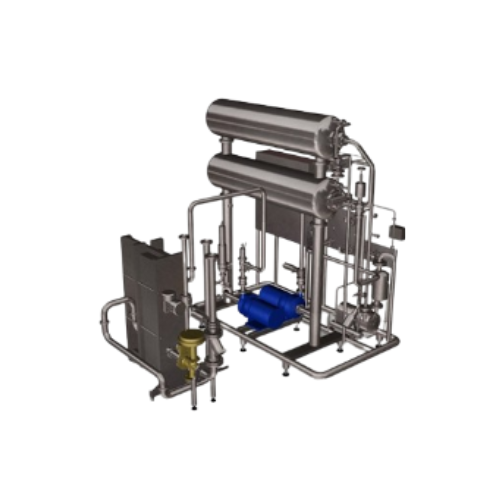

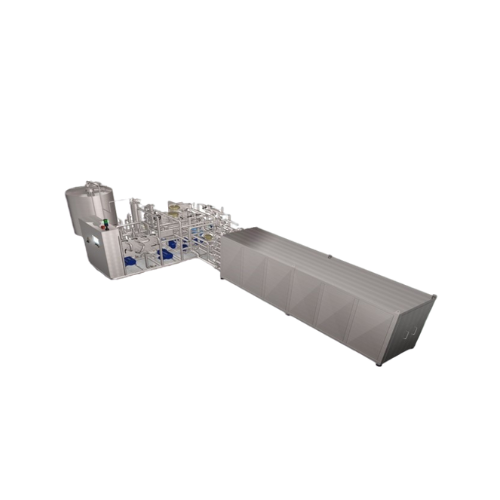

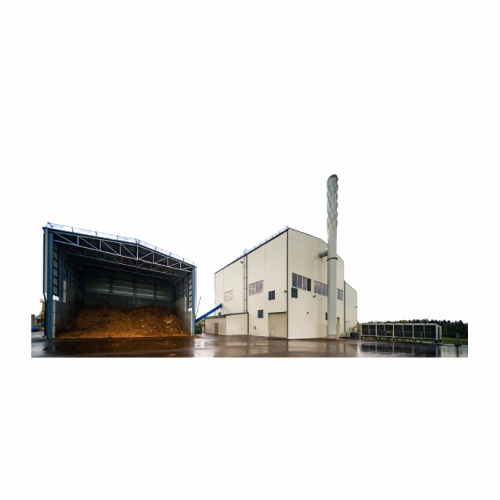

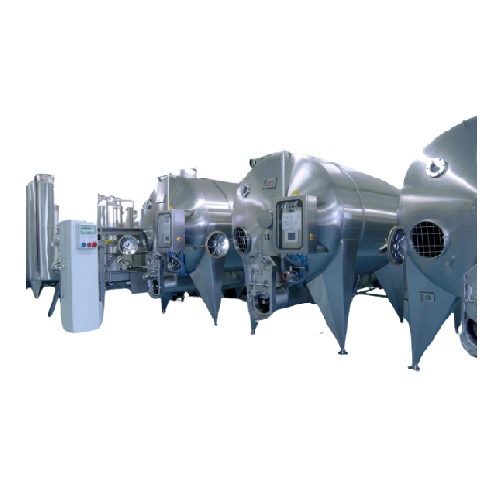

Drying systems for alcohol production

Enhance your spirits production with precise moisture control and nutrient retention,...

What are you making?

Tell us about your production challenge

Crush the grains into a coarse meal

Most spirits are made from cereals such as barley and rye. The high starch content in these ingredients presents a risk of gelatinization. So integral part of the preparation process involves hydrolysis to break down the starches.

To facilitate the hydrolyzation, remove the husks in a de-awner or hulling machine and grind the grains into a coarse meal with a crusher.

Form the ingredients into a mash to release the sugars

Starch is a polysaccharide composed of a series of glucose units. These are the sugars that react to produce alcohol.

Mix the crushed grains with water to transform starches into simple sugars and create a ‘mash’. Temperature-controlled mashing systems infuse the grains with hot water to separate proteins and make the malts easier to ferment.

Fermentation equipment provides yeast with the best conditions to consume sugars

The conversion of sugars into alcohol is a natural phenomenon triggered by yeast. The bacteria multiply as they consume the sugars, leaving ethanol and carbon dioxide as a by-product.

But yeast needs safe conditions to grow. Industrial fermentation technology ensures a closed environment away from oxygen and thermal control to maintain the temperature. Fermentation produces the base liquor that is turned into spirit.

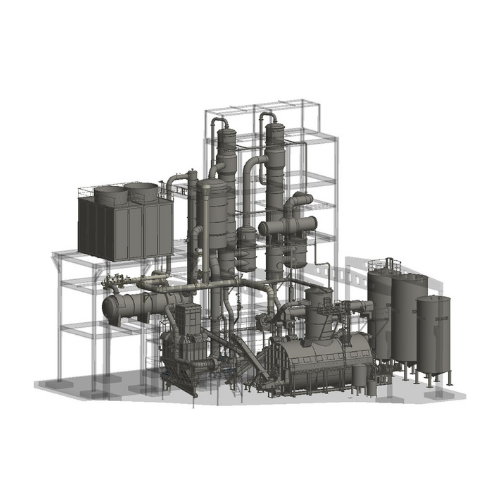

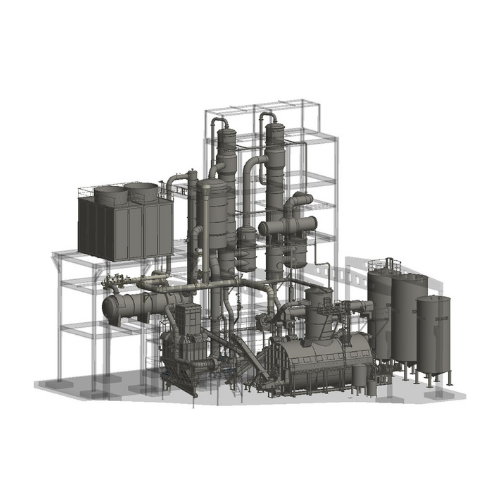

Distill the alcohol from congeners and impurities

The leap from raw alcohol to spirit takes place with distillation. Base liquor such as wine and beer contains other ingredients like grain particles and water. The process of distillation purifies alcohols from these congeners.

Distillation technology heats the liquid, but since ethanol has a lower boiling point, it vaporizes and escapes the mixture. The special liquor making machines capture these vapors and condense them into raw spirits.

Allow time for maturation after the journey through liquor making machines

Distillation is the final step in making spirits, but some liquor categories require aging. Indeed, some producers choose to age distilled alcohols that do not strictly need it, like vodka or gin.

On the other hand, certain spirits like whisky, rum, and brandy must observe a specific aging regime to classify as such. The maturation period develops aromas, bouquets, and colors as the distilled liquors interact with the cask.

Apply the solera maturation technique for rum

Some rum distillers do not age their spirits, producing a fresher product with a grassy aroma. If you age rum, alternative techniques exist to develop complex flavors.

The traditional single-barrel method lets the liquor sit in an oak cask for at least a year. More recently. Producers have been experimenting with the solera technique, originally used for sherry, stacking the barrels in a pyramid. The finished liquor is drawn from the base, adding a new spirit to the top.

Cognac must be aged in French oak

Like whisky and rum, brandy is aged in charred oak casks. In Cognac, France, brandy maturation is regulated by state laws.

Very Special Cognac (VS) must age for two years, and Very Superior Old Pale (VSOP) for at least four years. Producers must wait six years for their brandy to reach the Extra Old Cognac (XO) category. Of course, casks must be made from French oak.

Whisky extracts the characteristics of casks during the aging phase

Whisky starts as a harsh, transparent spirit. But aging in oak barrels mellows it down and develops its golden colors. Scotch whiskies must be aged for at least three years, whereas American bourbon requires two.

There are more variables than maturation time. Barrels from American oak produce softer tones, while French oak develops spicy notes. Whisky is aged in toasted sherry casks, while bourbon is kept in charred barrels. The burnt layer filters out impurities from the spirits.

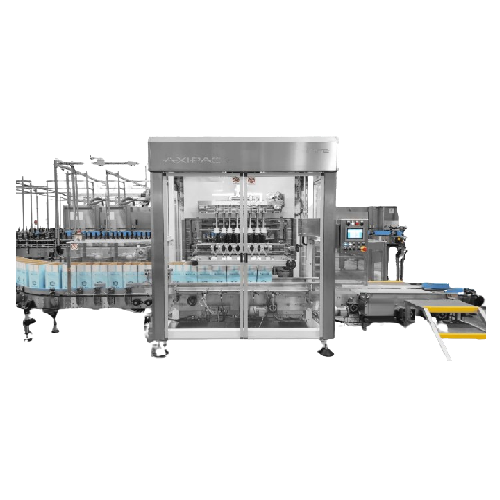

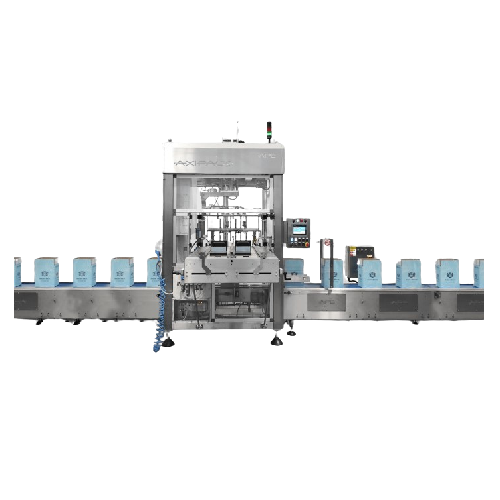

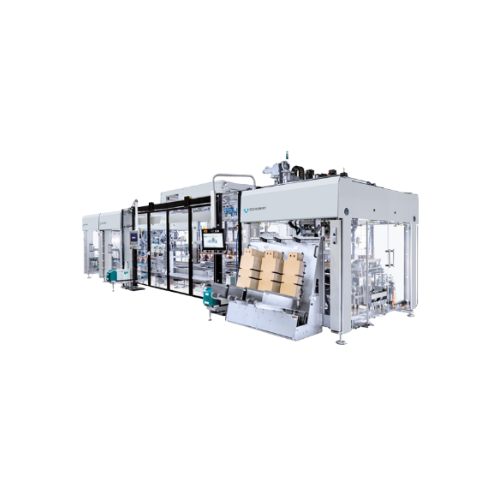

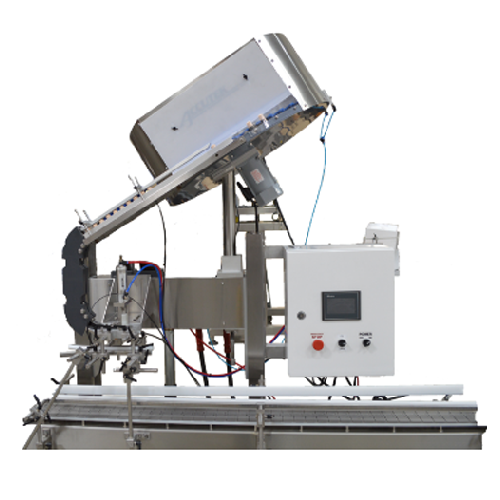

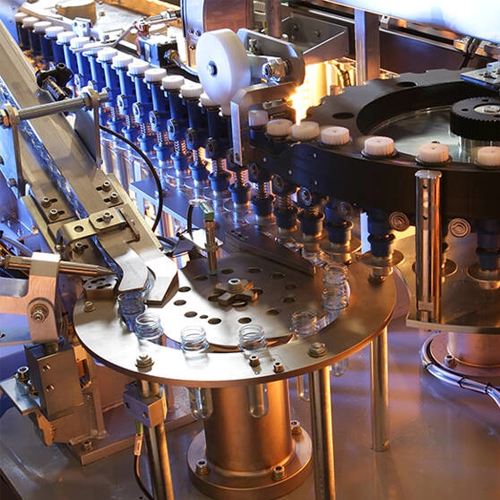

Packaging machines for liquor bottles are top-loading systems

After a long rest in barrels, the spirits are ready for their final journey before they reach the consumers. The liquor is pumped into a filling machine, pouring the correct dose into bottles. Some recipes add a blending stage before filling, combining different spirits.

Regarding packaging, liquor cartoning is typically performed by a top-loading machine, dropping the bottles into boxes from above.

Which spirits technology do you need?

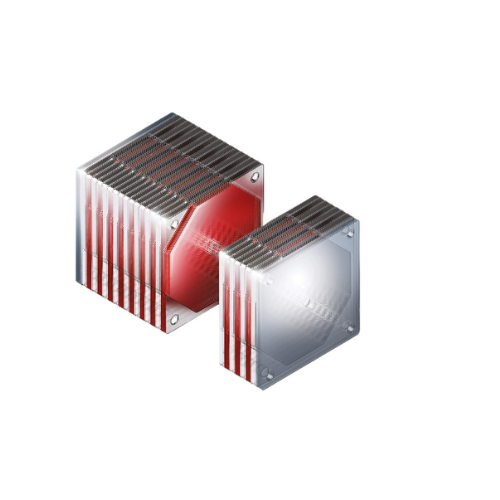

Industrial cooling unit for beverages and spirits

Ensure optimal chilling and condensation for beverages and spirits with...

Continuous distillation columns for spirits production

Optimize your spirits production with advanced distillation column...

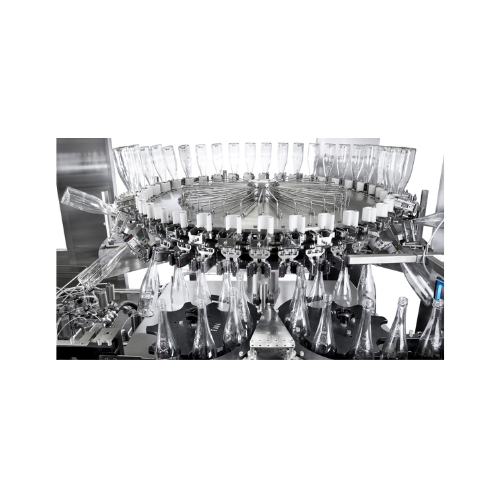

Level bottle filler for wine and spirits

Achieve consistent fill levels with precision sensor technology, ideal for ensurin...

Volumetric bottle filler for distilled spirits

Ensure precise volume control and compliance with regulatory standards in y...

Volumetric bottle filler for high proof spirits

Ensure precise and consistent bottle filling for high-proof spirits with t...

Bottle Cartoning Machine for Spirits

Cognac, brandy, whiskey and other luxurious spirits often come in uniquely branded pac...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

Nanofiltration and reverse osmosis for wine processing

Streamline your beverage production by effectively concentrating l...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Automated case erector for Rsc cartonboard

Streamline your packaging line with an innovative solution that efficiently for...

Automatic case erector for Rsc-american cartonboard

Streamline your packaging process with precise and efficient setup by...

Automatic case erector for cartonboard with hot-melt glue binding

Streamline your packaging line with efficient case er...

Unpacker for return bottles

Effortlessly manage return bottle operations with high-speed unpacking solutions that ensure pre...

Automated carton forming for bottles

Optimize your bottling line with an integrated carton forming solution that combines s...

Automated bottle packaging solution for breweries

Streamline your packaging process with a compact unit that combines bas...

Flexible depalletizers for bottling lines

Streamline your packaging operations with a compact depalletizing solution desig...

Automated case erector for high-speed packaging lines

Streamline your packaging line with this solution that forms and se...

Bottle repacking system for return cartons

Optimize your bottle repacking efficiency with a system designed specifically f...

Automated packaging line for bottling industry

Streamline your packaging operations with a fully automated solution design...

Automated case erector for american cases

Streamline your packaging line by efficiently erecting American-style cases with...

Automatic bag-in-box packaging system

Optimize your liquid packaging with a precise and seamless workflow, ensuring efficie...

Advanced case erector for Rsc/american cartonboard

Optimize your packaging line with precise case erection and glue seali...

Robotic crating and decrating solution for returnable glass bottles

Streamline your bottling line by efficiently handli...

Crate washer for beverage manufacturers

Ensure thorough cleaning of beverage crates with an advanced washing system featuri...

Flexible packaging line for beverage production

Streamline your beverage production with a flexible system capable of hand...

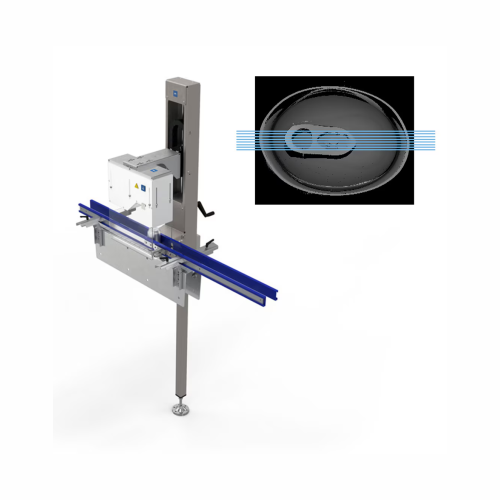

Leakage detection for beverage cans

Ensure each canned beverage leaves your facility ready to impress, with precise leak de...

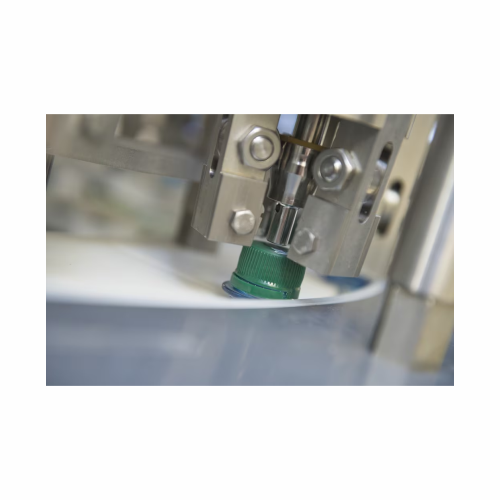

Decapper for removing screw caps

Efficiently unscrew caps from various bottle types without damaging the threads, even under...

Bottle inspection system for foreign particles detection

Ensure your beverage products remain uncontaminated with high-pr...

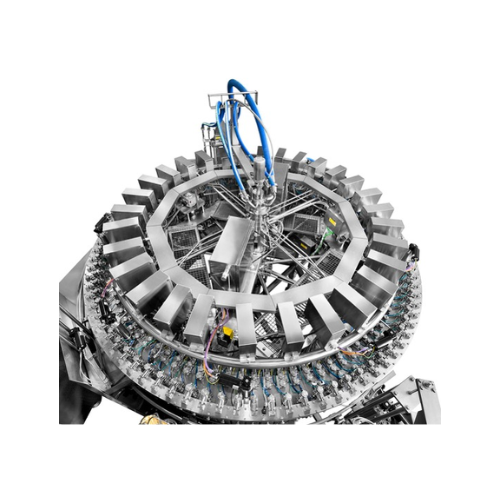

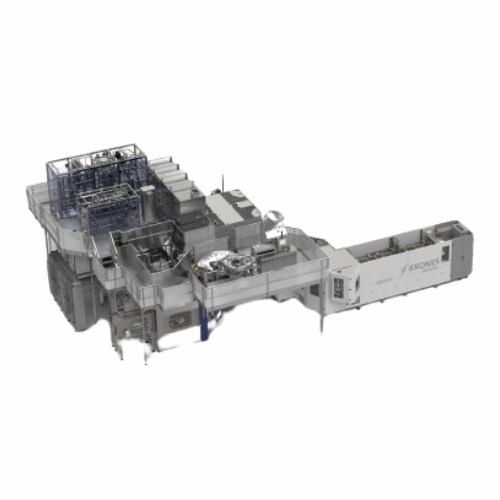

Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines ...

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

Wine and sparking wine filling system

Achieve precise filling and minimal oxygen pickup for high-value beverages with a rel...

Closure inspection system for crown corks and metal caps

Ensure product integrity with high-speed 360° closure inspection...

In-line additive dosing systems for beverages

Ensure precision and safety in beverage production by integrating in-line do...

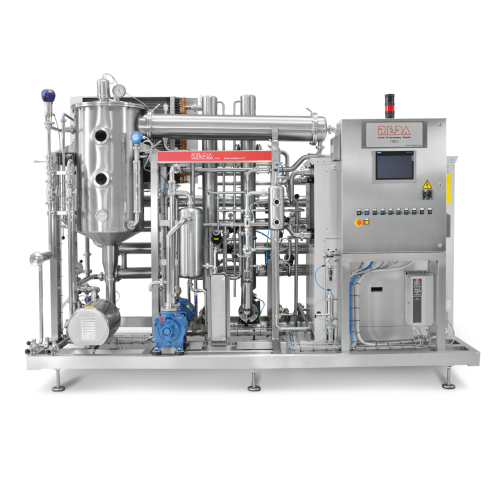

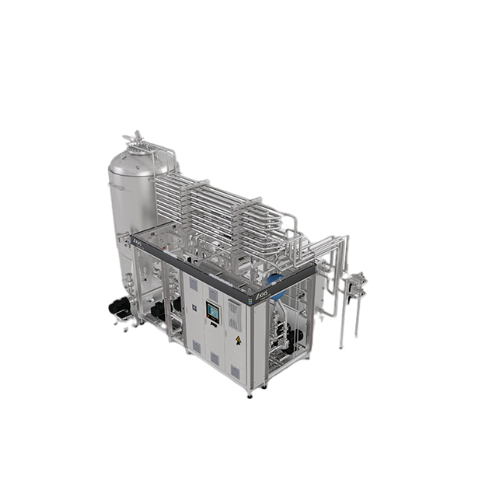

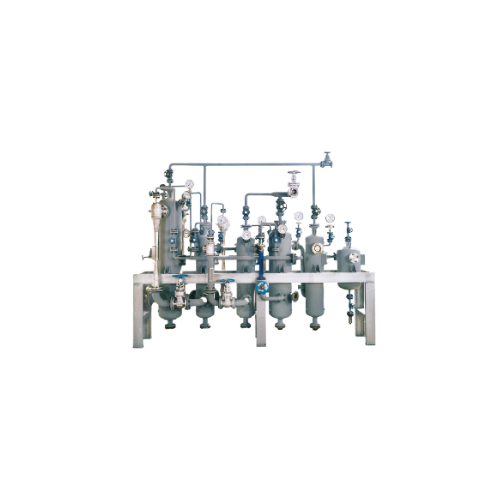

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

Thermal treatment units for wine processing

Optimize your wine and spirits production with precise temperature control, en...

Complete bottling lines for beverage industries

Optimize your bottling process with high-speed, precision-engineered lines...

Mohno pumps for efficient grape marc transfer

Ensure gentle handling and uninterrupted flow of grape marc with low-vibrati...

Electronic filling system for non-carbonated beverages

Optimize your bottling process with precision filling technology t...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

Compact combined labelling solution for bottling lines

Optimize your bottling line with a versatile, compact labelling so...

Combined wet glue and self-adhesive labeling system

Achieve seamless labeling with combined wet glue and self-adhesive te...

Self-adhesive labeling system for bottles

Streamline your bottling operations with high-precision labeling that enhances p...

Storage tanks for wine preservation

Ensure optimal preservation of beverages with robust storage solutions featuring precis...

Continuous grape pomace dealcoholizer

Streamline your spirit production with efficient dealcoholization and rectification o...

Advanced must, juice, and wine turbocooler

Optimize your beverage production with precise temperature control, ensuring co...

Thermostabilizer for beer and wine sterilization

Ensure biological stability in beverages by efficiently inactivating yeas...

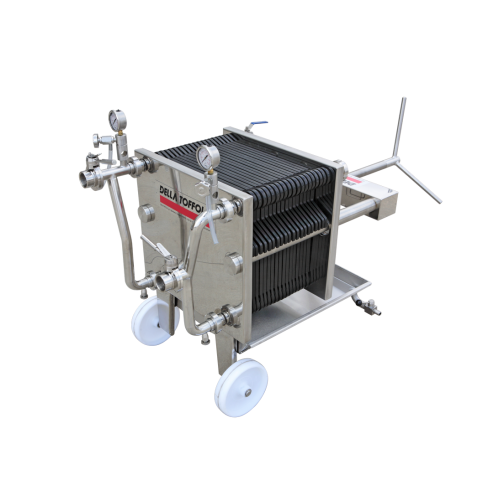

Pre-coat filter with horizontal discs for wine

Ensure optimal clarity in your beverage processes with a solution designed ...

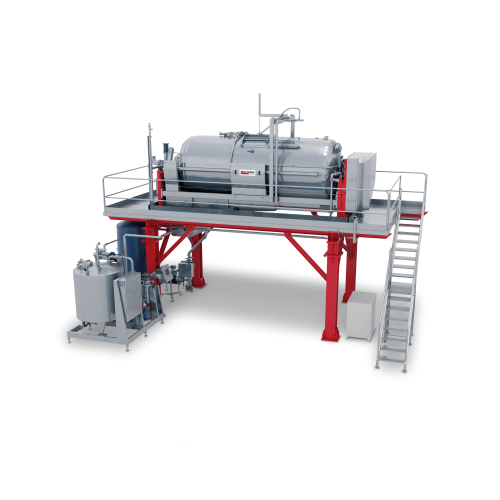

Batch still for high-quality distillates

Optimize your distillation process with precise temperature control and efficient ...

Self-cleaning pre-coat filter for wine filtration

Solve complex filtration challenges effectively with this advanced self...

Automated beverage canning line

Optimize your beverage packaging with a high-speed canning line that seamlessly integrates f...

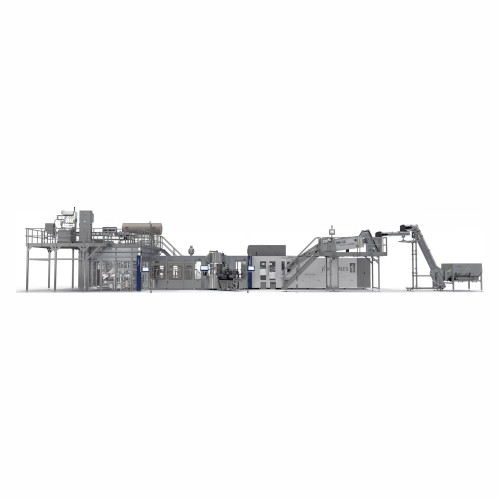

Turnkey distilling system for grain to spirit production

Streamline your distillation process with this adaptable system,...

No-oxygen wine filler

Ensure product integrity with advanced no-oxygen filling systems, designed to preserve delicate flavors...

No-oxygen filler for wine bottling

Enhance liquid bottling with seamless integration that minimizes oxygen exposure, ensuri...

Industrial bottle rinsing systems

Ensure pristine bottle hygiene and maintain high production standards with advanced rinsi...

Automatic packaging line for bag-in-box

Streamline your bag-in-box production with a seamless solution that ensures precisi...

Automatic case erector for cartonboard packaging

Streamline your packaging process with precision engineering that simplif...

Automatic case erector for cartonboard packaging

Streamline your packaging process and enhance operational efficiency with...

Packaged beverage analyzer for alcohol and Co2

Ensure precise beverage analysis with a streamlined solution that integrate...

Automatic case erector for american cases

Streamline your packaging line with high-speed case erecting, reducing labor cos...

Thread neck inspection for beverage bottles

Ensure bottle closure integrity by detecting subtle thread defects, such as cr...

Reverse osmosis dealcoholization technology

Elevate your beverage production capabilities with advanced dealcoholization t...

Cold-glue labeller for cylindrical or shaped containers

Achieve seamless high-speed labeling of glass, plastic, and metal...

Drying systems for alcohol production

Enhance your spirits production with precise moisture control and nutrient retention,...

Wine dealcoholization system for low-alcohol wines

Struggling to meet market demands for low-alcohol wines? Achieve preci...

2-stage rotary vane vacuum pump for distillation processes

Achieve precise control and efficiency in distillation and fr...

Centrifugal pumps for food & beverage and biopharmaceutical applications

Optimize your liquid transfer processes with p...

Aseptic sampling devices for biopharmaceutical applications

Secure aseptic sampling ensures your high-value biopharmaceu...

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

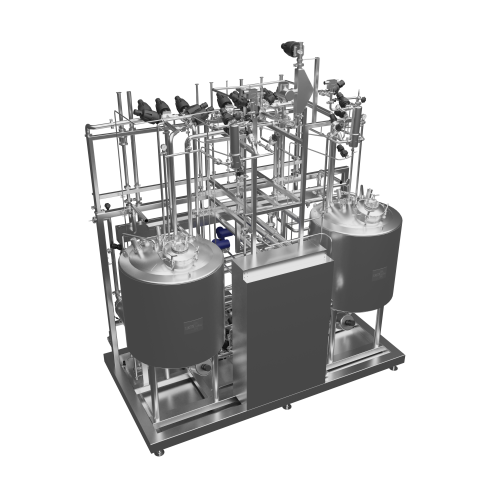

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Industrial agitation and mixing solutions

Enhance your production line efficiency with engineered agitation and mixing sys...

Cleaning and sterilization in place for hygienic control

Ensure maximum hygiene and sterility in your production line wit...

Close proximity cleaning-in-place solution for industrial hygiene

Enhance plant hygiene with a close proximity cleaning...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Industrial cooling vessel for ready meal components

Enhance your production with precise cooling and gentle handling of t...

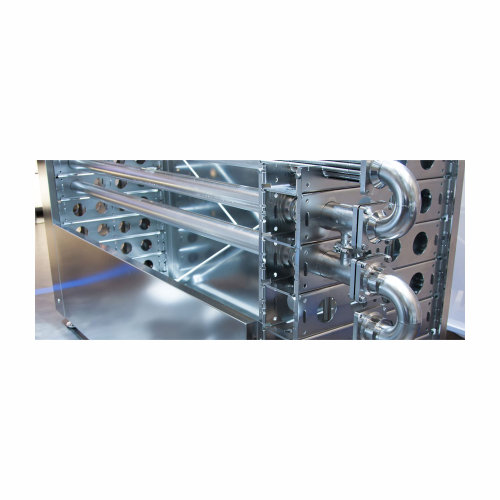

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Ped tested filtration system for sparkling wines

Ensure consistent carbonation and clarity in your sparkling beverages wit...

Premix system for alcoholic beverage preparation

Enhance your beverage production with precision mixing and carbonation, e...

Tunnel pasteurizer for wine

Optimize your wine production with a high-efficiency tunnel pasteurizer, designed to enhance pro...

Fermentation temperature control for wine production

Ensure precise fermentation with advanced temperature control, cruci...

Crossflow filter for wine and grape juice

Efficiently streamline your beverage filtration process with a versatile crossfl...

Horizontal plates d.e. filter for wine and vinegar

Optimize filtration and purification across liquids with precision, en...

Vertical leaves pressure filter for wine and viscous liquids

Ensure optimal clarity and consistency in your liquid produ...

Ion exchange system for wine and grape juice stabilization

Enhance wine and grape juice quality by achieving consistent ...

Wine carbonator with static mixer

Achieve precise CO2 saturation with a sintered stainless steel static mixer, mimicking a ...

Automated carton former for Rsc american boxes

Streamline your packaging line with high-speed carton forming that combines...

Depalletisers for high-capacity bottle handling

Streamline your bottling line with a versatile depalletising system design...

Automatic palletizer for bottle packaging lines

Streamline your bottling line with advanced palletizing solutions engineer...

Monoblock capsuling solution for bottles

Streamline your bottling process with this high-speed capsuling machine, deliverin...

Heavy-duty palletizing robot for production lines

Effortlessly streamline your production with this robust palletizing ro...

Inspection system for returnable glass containers

Ensure the safety and quality of your beverage containers with a precis...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

High-performance stretch blow moulding and labelling system

Maximize space and efficiency with this compact system that ...

Container sweep-off depalletiser

Enhance your beverage production line efficiency with a high-performance depalletising solu...

Juice product deaerator

Ensure high-quality filling without foam formation through efficient deaeration, perfect for manufact...

Palletizing grouping system for non-returnable packs

For beverage and packaging lines, precise and rapid palletizing of n...

Syrup room for customized beverage ingredient preparation

Achieve unparalleled flexibility in beverage production with a...

Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchan...

Stretch blow moulder for Pet containers

Optimize energy efficiency and production versatility with this stretch blow moulde...

Compact fill level and cap inspection system

Ensure flawless beverage quality by integrating a compact system for precise ...

Empty bottle inspector with deep learning

Ensure that every beverage container in your production line is pristine with cu...

Can inspection unit for quality control

Ensure the integrity of your beverage cans with precise defect detection and qualit...

Caustic residue detection for bottle washing

Ensure product purity by detecting and eliminating residual caustic in return...

Inspection systems for fillers and cappers

Ensure precise fill levels and secure cap placements with advanced inspection s...

Cip system for cleaning bottling lines and processing sections

Ensure a sterile production environment by integrating a ...

Sterile tank system for aseptic processing

Optimize your production with aseptic tank systems that ensure sterile storage ...

Aseptic bottle sterilisation system for Pet containers

Ensure aseptic integrity and high-speed efficiency in beverage pro...

Automated product change-over system

Maximize your production line efficiency by reducing downtime during product changeove...

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

Blow-moulder and labeller integration for Pet bottles

Streamline and enhance your PET bottle production with seamless blo...

Low output can filler for craft beer

For beverage producers looking to efficiently fill cans with precision, this versatile...

Hollow fiber membranes for clarification in food and beverage industry

Optimize filtration and separation processes wit...

Flexible labeling system for returnable and non-returnable containers

Achieve precise labeling and enhanced alignment w...

Self-adhesive labeling for glass and Pet bottles and beverage cans

Maximize your production efficiency with a labeling ...

Flexible packaging system for beverage containers

Streamline your packaging process with a modular system that adapts sea...

Enclosed film packaging solution

Eliminate the need for corrugated trays and minimize packaging waste with a robust solution...

Bright beer tank cellar for beer storage

Enhance your beverage production efficiency with a fully automated solution that m...

Water deaerator for beverage production

Enhance the quality and extend the shelf life of your beverages with our cutting-ed...

Filter system for beverage stabilization and clarification

Ensure your beverages are crystal clear and stable with a ver...

Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures pre...

Blending system for fine adjustment of original gravity in beer

Ensure precise control over your beer’s original gravity...

Continuous flash pasteurizer for beverage shelf life extension

Maximize beverage shelf life with precise microbial and e...

Blending system for deaeration and carbonation of beverages

Achieve precise blending, efficient deaeration, and accurate...

Stretch blow molding with integrated coating for Pet bottles

Enhance product longevity and quality by integrating stretc...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

Carbonating solution for precise Co2 content in beverages

Enhance your beverage production with seamless CO2 integration...

Compact cleaning system in container format

Optimize your production lines with a space-saving cleaning system capable of ...

Cip cleaning system for food and beverage production lines

Ensure microbiological safety and maintain quality standards ...

Dosing and blending system for beverage production

Enhance your beverage production with a flexible system capable of pre...

Multifunctional filter system for beverages and gases

Achieve precise filtration across multiple beverage and gas mediums...

High-performance palletizer for cans, Pet, and glass containers

Elevate your palletizing efficiency with cutting-edge ro...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Robotic layer grouping system for container distribution

Streamline your packaging line with precise, high-speed containe...

360° palletizing and depalletizing robot

Optimize your packaging flow with a robot offering seamless 360° operation for pre...

180° palletizing robot for automated palletizing and depalletizing

Optimize your production line with a versatile solut...

Flexible tunnel pasteurizer for beverage sterilization

Maximize product safety and flexibility in your production line wi...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

Gentle container conveyor for bottles and cans

Achieve seamless container flow with minimal noise and enhanced precision, ...

Multifunctional packing system for beverage containers

Maximize your facility’s packing efficiency with a versatile...

Packer and unpacker for returnable and non-returnable containers

Streamline your packaging line with a versatile machine...

Depalletizer with accurate level compensation

Optimize your high-speed assembly line with a depalletizer designed for prec...

High-speed beverage industry palletizer

Optimize your palletizing process with a flexible, high-speed solution that adapts ...

Industrial code verification system for product packaging

Ensure flawless packaging integrity with high-speed code verif...

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by...

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Pallet inspection system

Ensure the stability and integrity of diverse pallets with a high-speed inspection system that minim...

Container rejection system for high-speed operations

Ensure product safety by swiftly removing defective containers at hi...

Bottle filler for beer and soft drinks in glass bottles

Achieve precision in bottling with reduced CO2 emissions and low ...

Pvpp beer stabilization system for breweries

Reduce beer hazing and extend shelf life with this advanced stabilization sys...

Wine tank agitator for homogeneous mixing

Achieve precise mixing and uniform temperature distribution in your wine product...

Oxygen and carbon dioxide monitoring and elimination system

Achieve precise control over dissolved gases with a system t...

Piping discharge system for product separation in transfer lines

Optimize your beverage production by preventing product...

Micro-filtration system for beverage industry

Achieve microbiological stability at cold temperatures with our micro-filtra...

Powder mixing system for beverage industry

Enhance your beverage production with an advanced powder mixing system that ens...

Wine recovery system for bottling processes

Streamline bottling operations by recovering and re-dosing valuable wine, redu...

Co2 dosing system for effervescent beverage bottling

For beverage manufacturers requiring precise carbonation, this solut...

Industrial water tube steam boilers

Optimize energy efficiency and reduce fossil fuel reliance with high-performance steam ...

Semi-modular labeller for precise beverage bottle labelling

Achieve millimeter-precision bottle labelling with seamless ...

X-ray assisted empty bottle inspection

Enhance your production line with advanced X-ray and optical technology to ensure pr...

Full container check system for beverage industry

Streamline your quality assurance process with advanced detection techn...

Empty bottle inspection for beverages

Ensure high quality control and prevent contamination in beverage production lines wi...

Grape harvest cooling tunnel

Ensure optimal grape quality for winemaking by precisely controlling temperature with a mobile ...

Juice storage tank with hygienic and cooling options

Ensure optimal freshness and stability of juices and beverages with ...

Fermentation monitor for alcohol production

Optimize anaerobic yeast fermentations with precise monitoring of carbon conve...

Plate and sheet filter for beer

Enhance your beer’s clarity with a plate and sheet filter designed for sterilization a...

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Presses compensated with inert gas for winemaking

Ensure the protection of delicate wine flavors during pressing by utili...

Fully automatic continuous flow wine press

For winemakers seeking to optimize operations, this advanced pneumatic pressing...

Industrial crossflow filters with ceramic membranes

Achieve precise filtration with robust ceramic membranes, ideal for h...

Reverse osmosis system for wine production

Enhance wine quality and versatility with advanced reverse osmosis systems that...

Continuous flotation units for wine clarification

Optimize your wine and juice production with our advanced flotation uni...

Sheet filters for wine and beer filtration

Enhance your filtration process with reliable sheet filters designed for high-q...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

Self-adhesive labelling system for bottles

Enhance your bottling line with a versatile labelling system that supports medi...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

Automatic cross-flow filter for wine

Experience enhanced filtration efficiency with reduced waste, as this cross-flow filte...

Plate filter for beverage sterilization

Achieve absolute clarity and sterilization of your beverages with a versatile plate...

Rotary vacuum filter for wine filtration

Enhance your wine production with efficient filtration of grape must and wine lees...

Continuous tartar stabilization for small wine batches

Achieve continuous tartar stabilization in wine with precise cryst...

Grist mill for brewing and distilling

Achieve optimal grain processing with reduced energy consumption and increased brewho...

Turnkey brewing systems

Streamline your brewing and distilling operations with a comprehensive system that integrates grain h...

High-capacity no-oxygen wine filler

Ensure optimal flavor retention and prevent oxidation in your bottling process with adv...

Industrial capping systems for bottling lines

Optimize your bottling process with versatile capping solutions designed for...

Inspection system for filled glass bottles

Ensure high-quality beverage bottling by detecting bottle faults, contaminants,...

Co2/o2 beverage filling device

Ensure precise beverage analysis by maintaining carbonation integrity with a system that tran...

Packaged beverage analyzer for beer, wine, and cider

Ensure precision in beverage quality control with rapid, direct samp...

Depalletising solutions for bottles and containers

Optimize your production line with advanced depalletising solutions th...

Full label inspection system for not-oriented containers

Ensure precise label application and integrity on any container ...

Cap inspection and fill level inspection system for beverage containers

Ensure precise cap application and fill level m...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Bag-in-box filling solution for non-aseptic products

Maximize your production line’s efficiency with a high-speed f...

Bottle corking system for high-volume production lines

Streamline your bottling line with precise and reliable cork inser...

Multi-stage steam jet vacuum pumps for industrial applications

Achieve precise vacuum conditions for evaporation, distil...

Compressor package for freezing and heat pump applications

Optimize your heating and cooling systems with high-efficienc...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

Reverse osmosis beer dealcoholization technology

Achieve precise alcohol removal from beer while preserving flavor integri...

Internal wort boiler for precision boiling in brewing

Achieve consistent wort quality with precision boiling, designed to...

Fermentation and storage solutions for breweries

Enhance your brewing process with robust fermentation and storage tanks d...

Membrane mash filter for brewing

Optimize your brewing process with advanced membrane filtration, ensuring maximum yield and...

Lauter tun for enhanced lautering efficiency and yields

Achieve faster lautering and higher yields with optimized spargin...

Counter pressure filler for carbonated beverages

Ensure optimal carbonation and minimal oxygen exposure during bottling, e...

Counter pressure can filler for carbonated beverages

Achieve precise carbonation levels and minimal oxygen exposure in ca...

Counter pressure bottle filler for carbonated beverages

Maintain carbonation levels while filling bottles efficiently, en...

Counter pressure bottle filling system for carbonated beverages

Enhance your bottling efficiency with a versatile counte...

Frontal filtration system for wine clarification

Ensure your wine retains its unique flavors and aromas with an energy-eff...

Leak testing system for aerosol cans

Ensure the integrity of your aerosol and metal packaging with a high-speed leak testin...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Horizontal stand-up pouching for beverages, dairy, and pet care

Optimize your liquid product packaging with rapid, high-...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Bottle and jar rinsing system

Achieve optimal internal sanitization and cleanliness for bottles and jars with a versatile ri...

Self-adhesive label applicator for cylindrical and shaped bottles

Simplify label application on varied bottle shapes wi...

Bench-top labeling system for cylindrical and shaped containers

Effortlessly label diverse bottle shapes and sizes with ...

Combined air water rinser for bottles and jars

Optimize your bottling process with an integrated solution for rinsing and ...

Vacuum bottling equipment for wineries and breweries

Optimize your bottling process with a vacuum solution that fills up ...

Vacuum filler for wine and oils

Optimize your beverage bottling process with a compact vacuum filler designed for precise le...

Pomegranate peeling and seed separating system

Streamline your pomegranate juice and wine production with a system that ef...

Horizontal fermentation tanks for winemaking

Achieve optimal fermentation with minimal liquid lees through advanced cap ma...

Vertical fermentation tanks for winemaking

Achieve optimal fermentation with vertical tanks designed for gentle must movem...

Integrated linear blowing and filling system for Pet containers

Streamline your PET container production with integrated...

Cip sanitizing unit for food and beverage production

Ensure meticulous hygiene with a compact unit designed for seamless ...

Cartoning solutions for beverage and food industries

Optimize your packaging line with a versatile range of cartoning sys...

Single-stage plastic container production system

Eliminate multiple steps and minimize production costs with an integrated...

Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system en...

Heat exchangers for wine processing

Ensure precise temperature control and efficient cooling for your wine-making process w...

Cylindrical insulated tanks for wine production

Optimize fermentation and storage stages with precision temperature contro...

White and rosé wine-making Se elliptical tank

Optimize your wine production with an elliptical tank designed for perfect a...

Truncated wine fermentation tank

Achieve optimal temperature control and efficient maceration for red wine production with a...

Aseptic tank for liquid food storage

Store and maintain the sterility of low and high acid liquid foods while ensuring prod...

Continuous sugar dissolver for high brix solutions

Optimize your beverage production with a system that dissolves sugar u...

Pasteurization solution for food liquids

Extend the shelf-life of your liquid products while maintaining their quality with...

Custom syrup preparation systems

Optimize your beverage production with precision-engineered syrup preparation systems desig...

Uht sterilization solution for liquid food products

Enhance your liquid food processing with reliable UHT sterilization, ...

Industrial solutions for beverage mixing and carbonation

Optimize your beverage production with precise mixing and carbon...