Industrial water tube steam boilers

Optimize energy efficiency and reduce fossil fuel reliance with high-performance steam production, delivering precise temperature control and versatile fuel adaptability for industrial applications demanding consistent, reliable steam supply.

Produces and Supplies Sustainable High-Temperature Steam

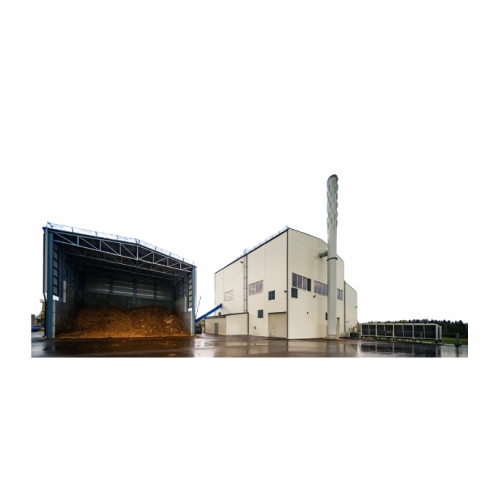

HoSt Group specializes in engineered-to-order steam boiler plants that are key to sustainable energy solutions for various industries. What sets these boilers apart is their use of biomass and refuse-derived fuel (RDF) to produce high-temperature steam efficiently and sustainably. The water tube design is capable of handling a range of fuels with varying moisture contents and challenging compositions, including high chlorine or sulfur content.

Applications for these boilers span industrial steam networks, chemical clusters, and numerous manufacturing processes—from distillation in the food and beverage sectors to temperature control in automotive and textile industries. They are integral for producing chemical solvents, packaged foods, and synthetic fibers, among other end products.

Each plant delivers high throughput with water tube boilers ranging from 8 to 25 MW, seamlessly integrating into existing systems. Energy efficiency is enhanced with advanced combustion control and low flue gas outlet temperatures, leading to reduced energy consumption. Automation is high, with remote monitoring capabilities ensuring minimal downtime and easy operation.

These steam boilers meet stringent environmental standards, offer the option for carbon capture technology, and come with customizable features to suit specific operational needs. They boast a robust design optimized for long-term performance with minimal maintenance requirements, making them a reliable choice for facilities prioritizing efficiency and sustainability.

Benefits

- Maximizes steam production efficiency with versatile fuel usage, reducing reliance on fossil fuels.

- Lowers operational costs through high thermal efficiency and advanced combustion control.

- Enhances environmental compliance with carbon capture and low-emission technologies.

- Minimizes maintenance with automated operation and robust design, ensuring long-term reliability.

- Supports diverse industrial applications, from chemical processing to food production, with adaptable integration.

- Applications

- Food, Paper industry, Distillation processes, Chemical clusters, Sterilization processes, Temperature control in greenhouses, Drying processes, Packaging industry, Automotive industries, Industrial steam networks, Textile industry, Factory processes, Beverage industry

- End products

- Bottled beverages, Automotive parts, Textile fabrics, Spirits, Chemical solvents, Pulp, Packaged foods, Cultivated fruits and vegetables, Synthetic fibers, Cardboard, Dairy products, Pharmaceuticals

- Steps before

- Fuel preparation, Fuel handling, Combustion setup

- Steps after

- Steam distribution, Heat recovery, Carbon capture

- Input ingredients

- biomass, RDF, SRF, wood chips, wood shreds, waste wood grade A, waste wood grade B/C, bark, shavings, sawdust, rejects, recycled paper waste, paper sludge, solid biomass, waste

- Output ingredients

- steam, hot water, bio-CO2, electricity

- Market info

- HoSt is known for designing and manufacturing biogas plants, biomass energy systems, and waste-to-energy technologies. They have a strong reputation for sustainable energy solutions and innovation in renewable energy sectors.

- Steam Temperature

- Up to 480°C

- Pressure

- Up to 90 bar for water tube steam boilers

- Capacity

- 8-25MW for biomass, 10-20MW for RDF, 8-15MW for wood fired fire tube steam boilers

- Boiler Efficiency

- 88-93% depending on calorific value

- Fuel Versatility

- Biomass and RDF/waste

- Fuel Size Compatibility

- Up to 35 cm

- Moisture Content Tolerance

- 10% to 60%

- Automation

- High level of automation with advanced combustion control

- Carbon Capture Technology

- Easily integrable

- Flue Gas Outlet Temperature

- Low temperature for enhanced efficiency

- Annual Availability

- >96% availability, anticipating a 25-year lifetime

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP / Manual

- Fuel versatility

- Biomass / RDF

- Heat recovery

- Integrated

- High plant availability

- >96%

- Corrosive resistance (e.g. acids)

- High

- Fuel versatility

- Biomass, RDF, Wood Chips, Waste Wood, etc.

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Industries Served

- Textile, Food, Beverage, Wood-processing, etc.

- Fuel Types

- Wood chips, RDF, SRF, etc.

- Boiler type

- Water tube / Fire tube

- Heat output capacity

- 8–25 MW

- Steam pressure

- 6–90 bar

- Steam temperature

- Up to 480°C

- Fuel versatility

- Biomass / RDF / Waste