Dairy Production Equipment

Find innovative dairy equipment and connect directly with world-leading technology suppliers

Milk can be consumed as a stand-alone product (whole, low-fat or skim) or can be the starting point for food industry products such as cheese, butter, yogurt, condensed milk, and ice cream. In order to process milk and other dairy products, you need specialized dairy production equipment which then encapsulates different processes such as pasteurization, homogenization, and fermentation.

Top picks for dairy processing

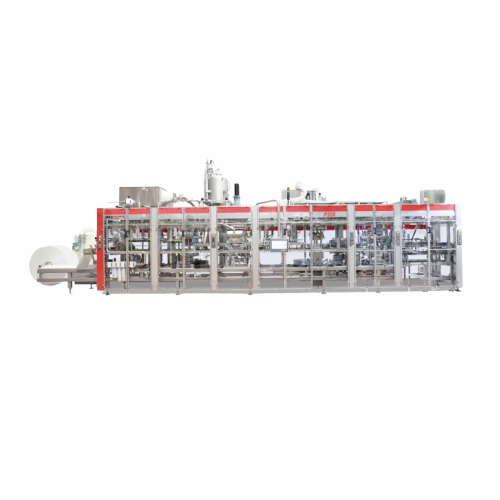

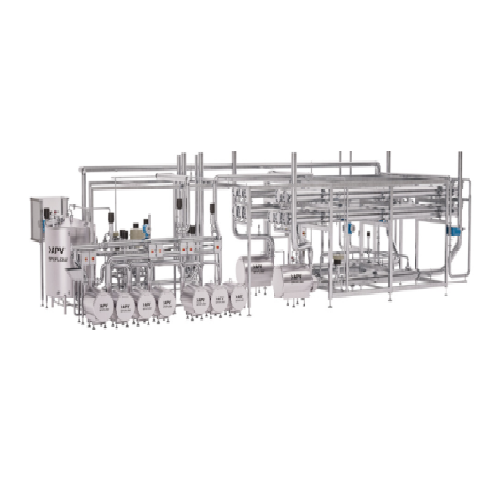

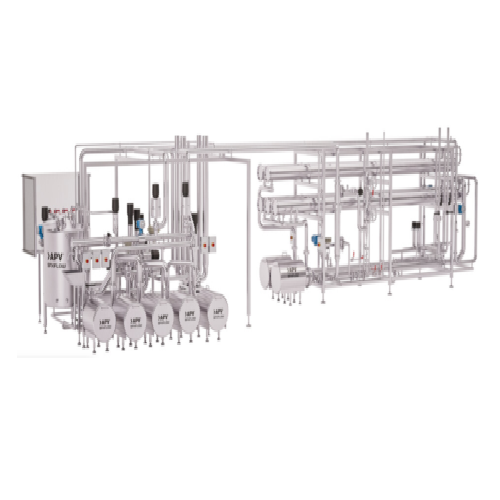

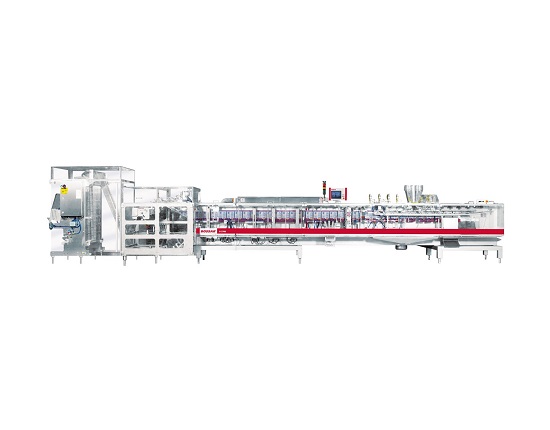

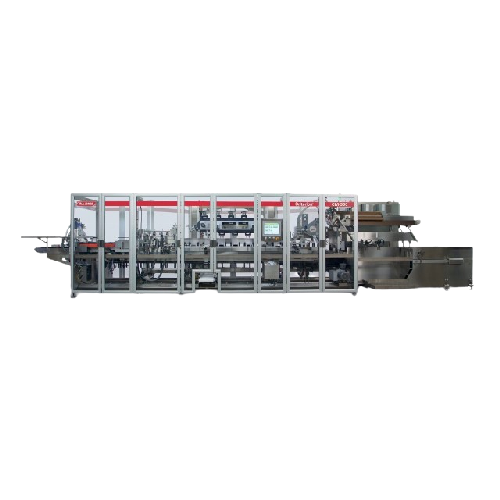

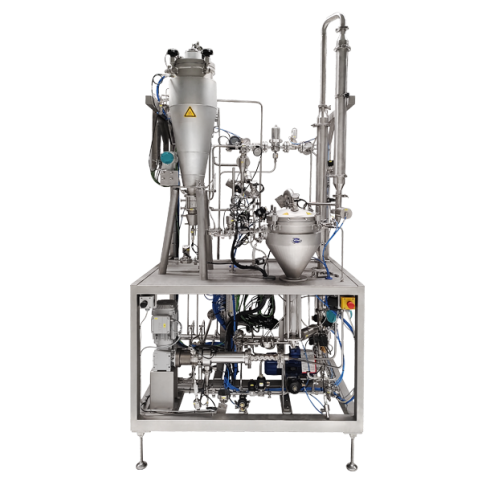

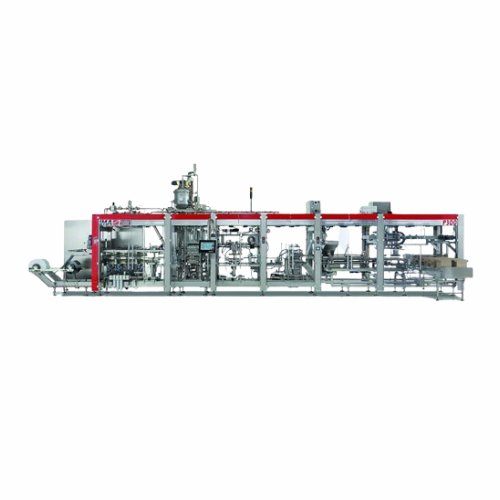

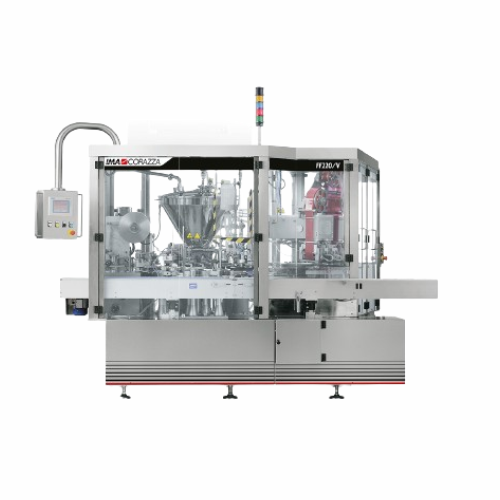

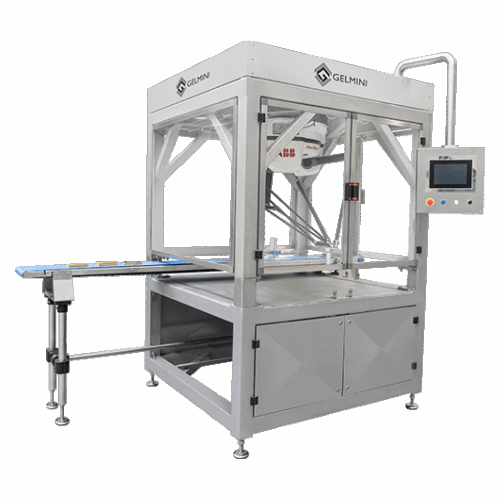

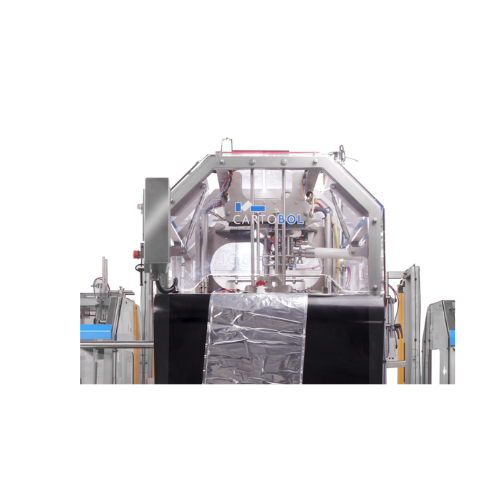

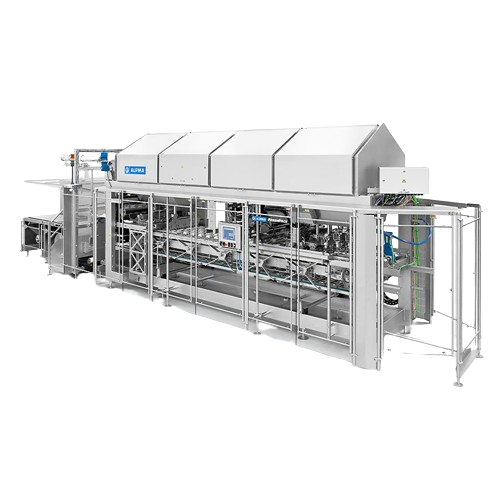

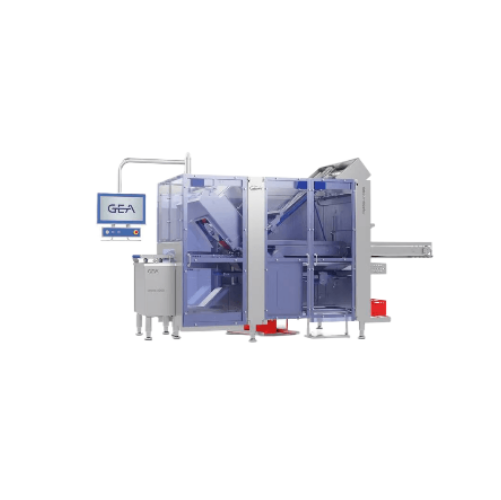

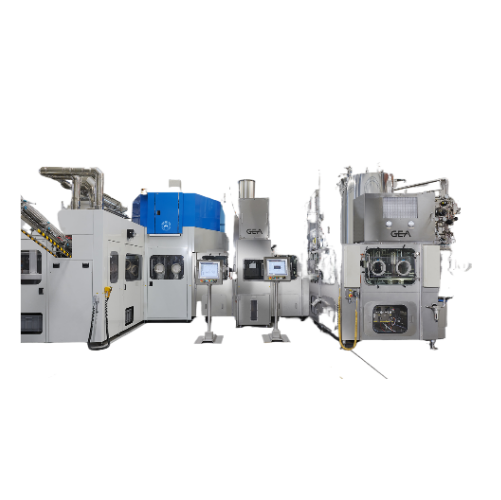

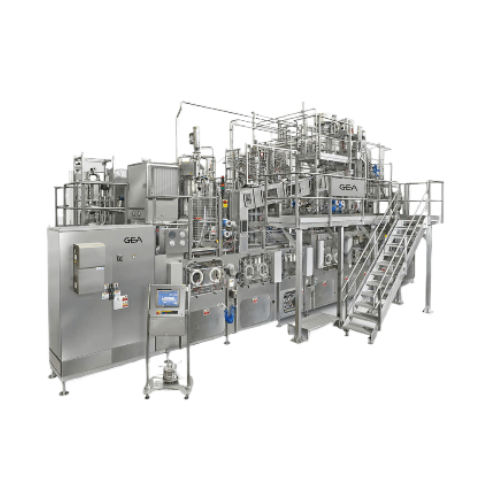

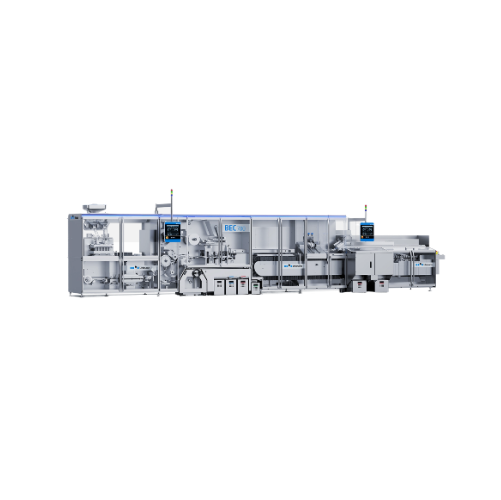

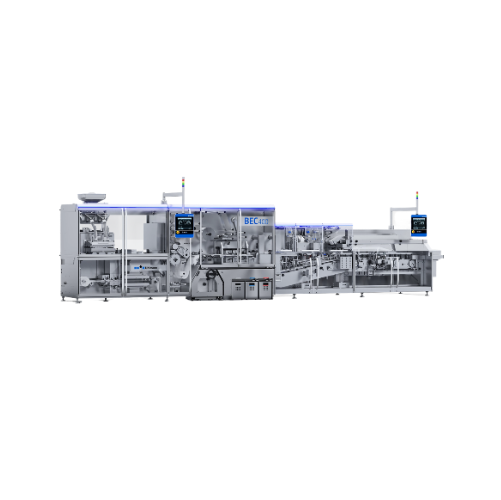

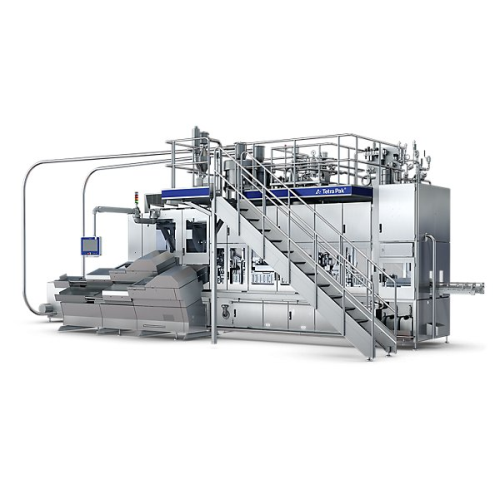

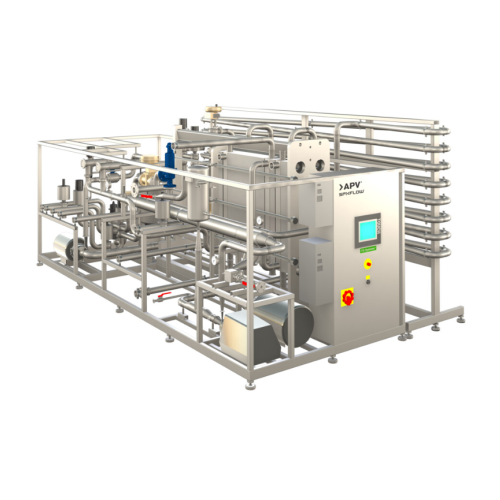

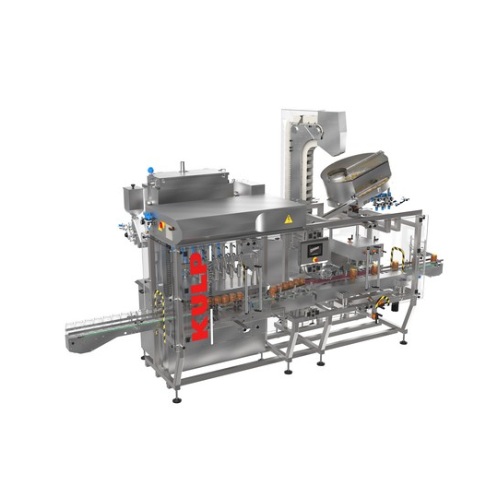

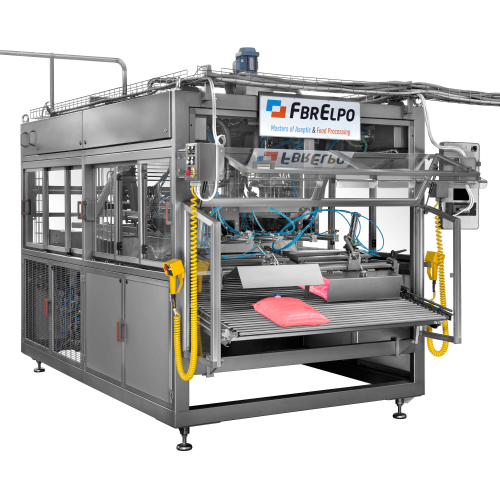

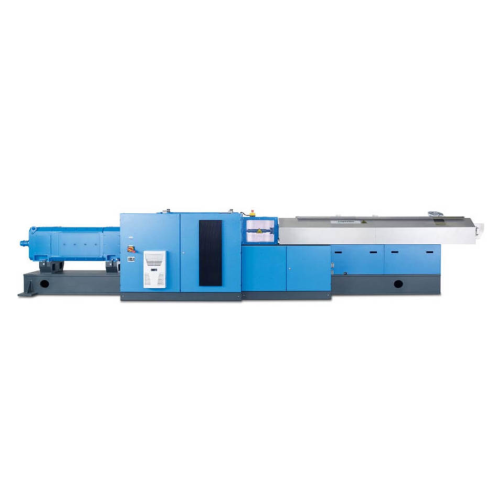

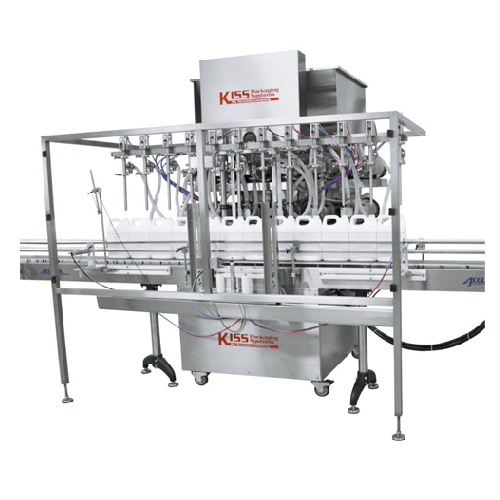

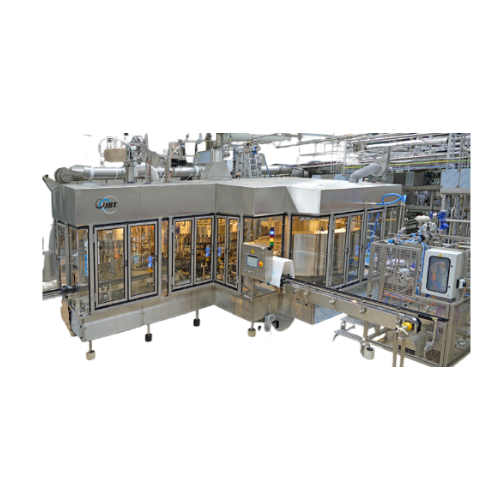

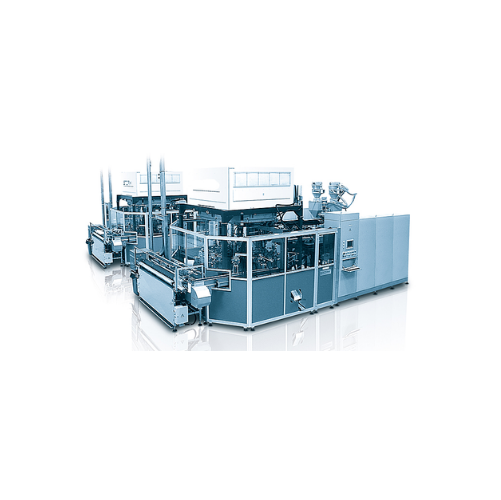

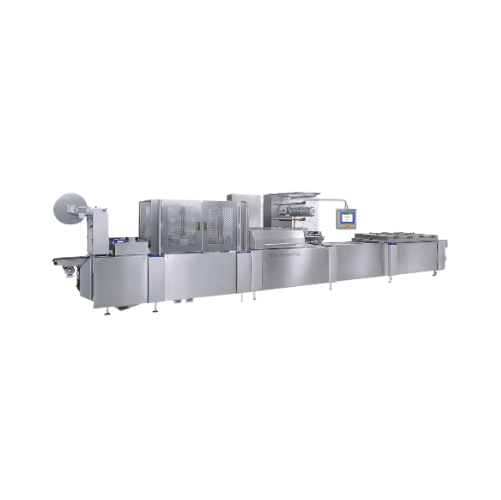

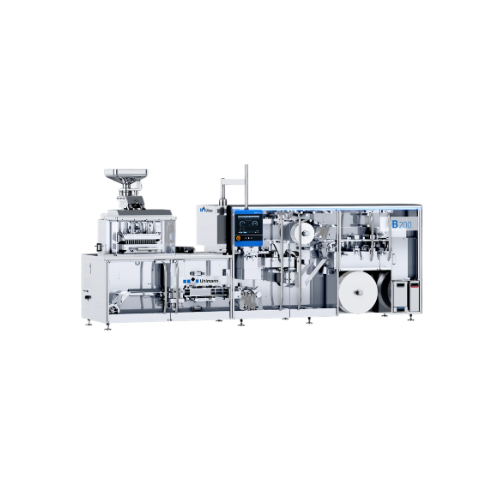

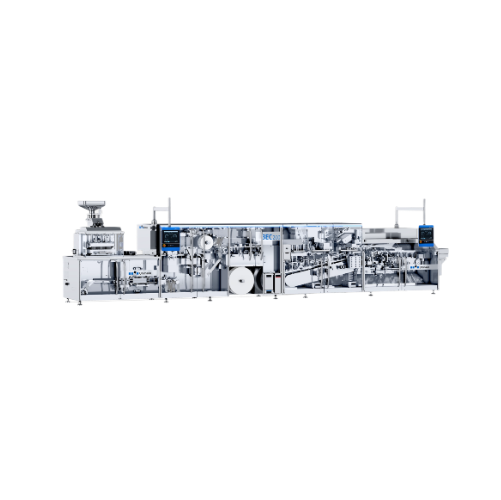

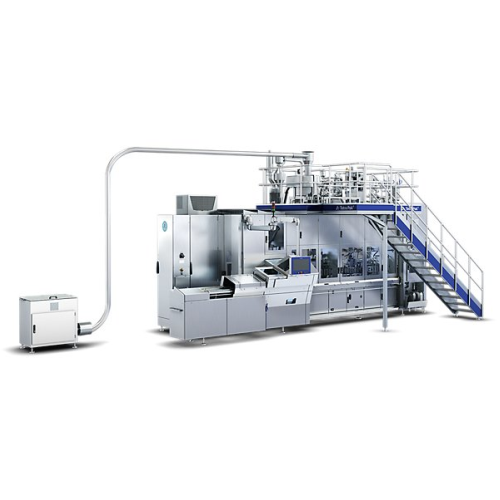

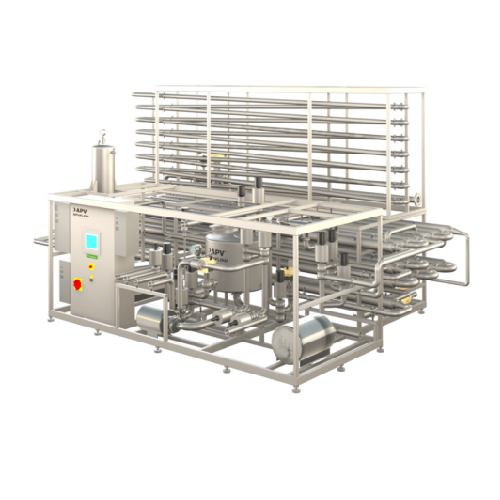

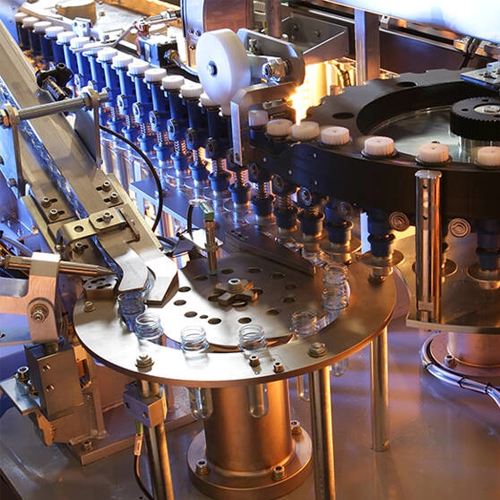

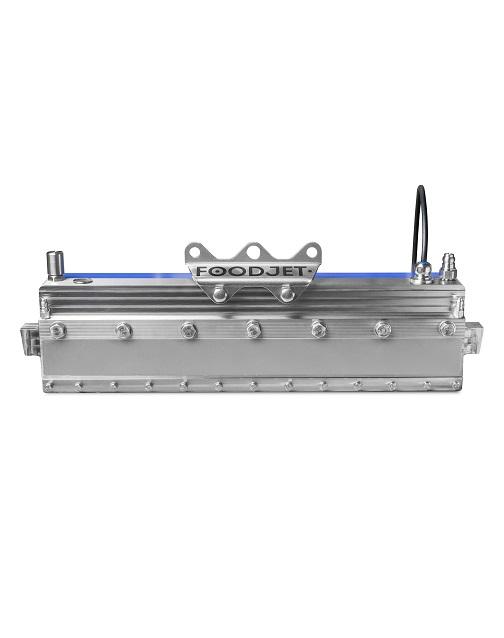

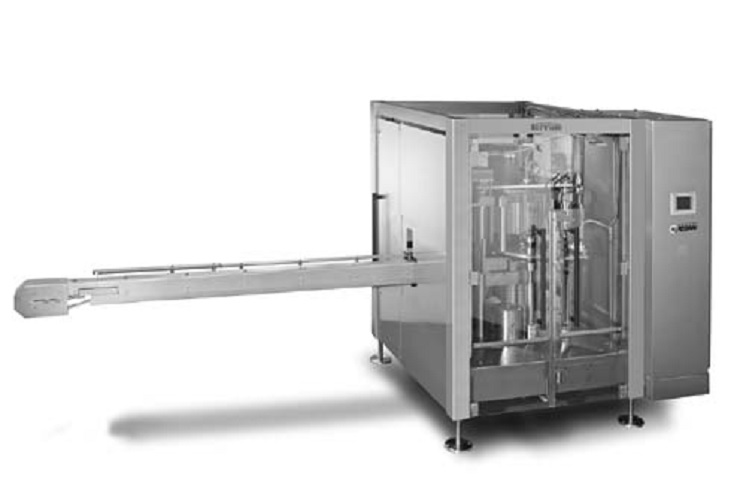

Aseptic filling technology for dairy products

Ensure product integrity and extend shelf life with a high-speed aseptic fil...

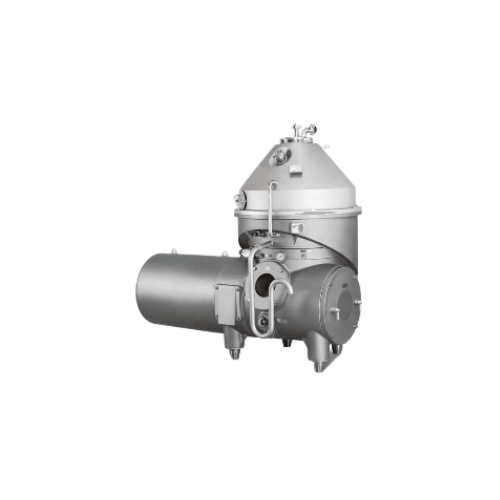

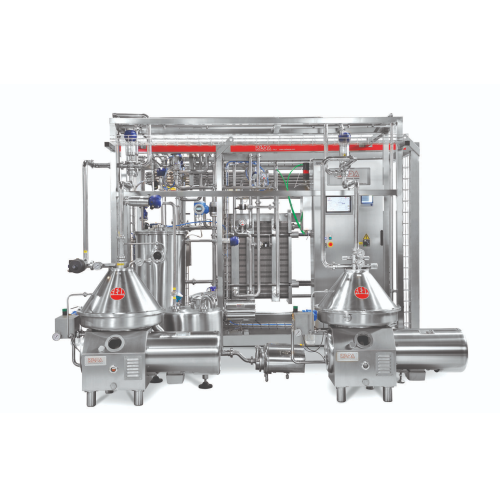

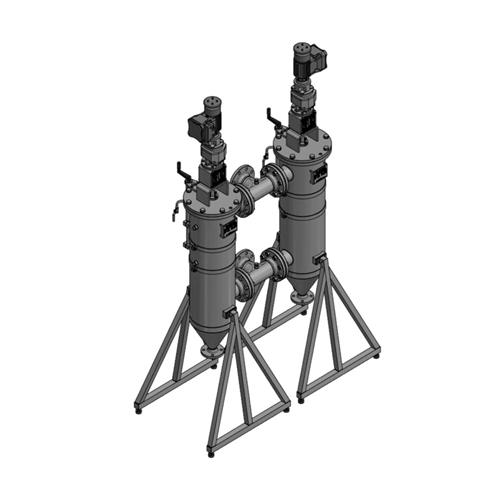

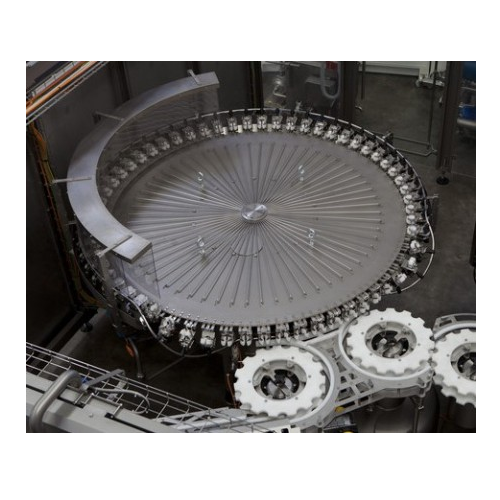

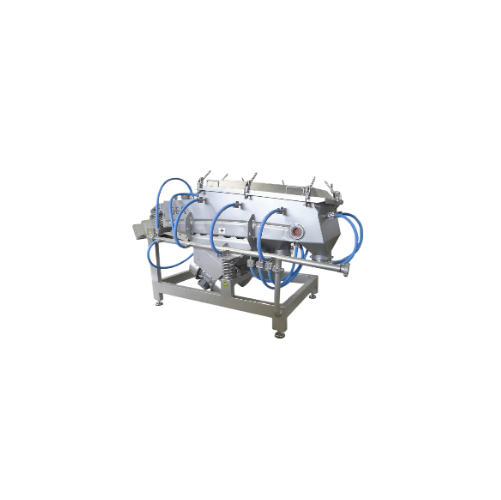

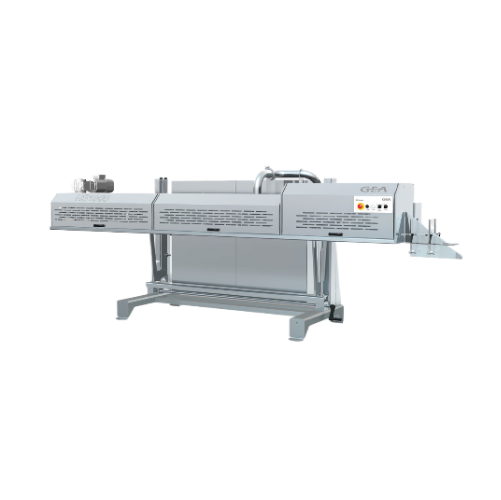

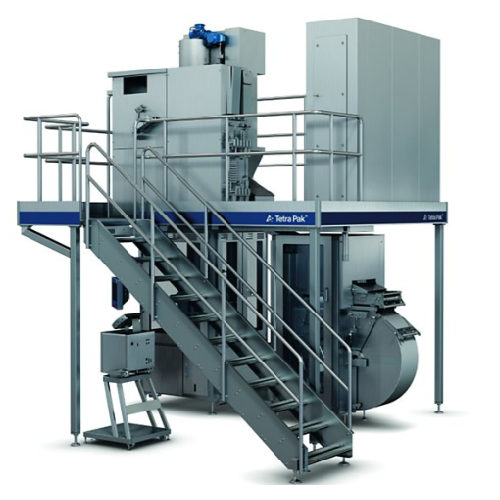

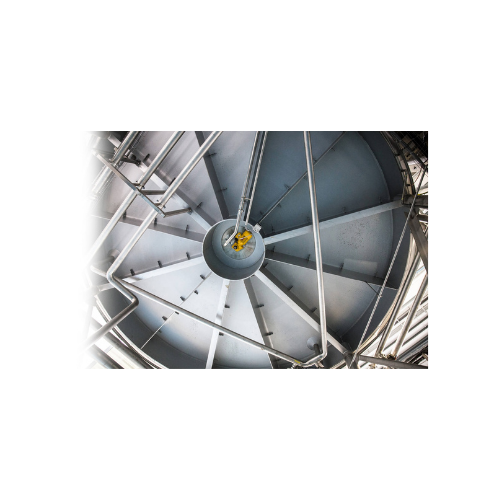

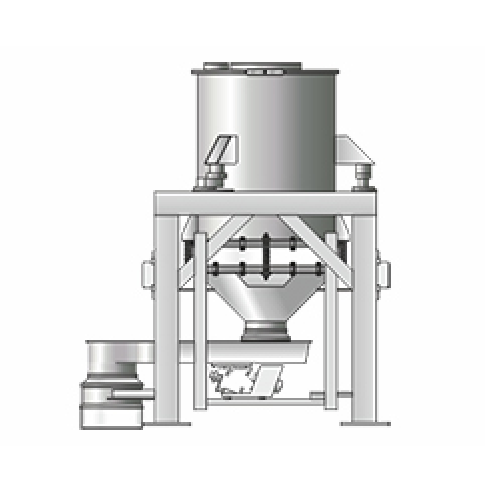

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

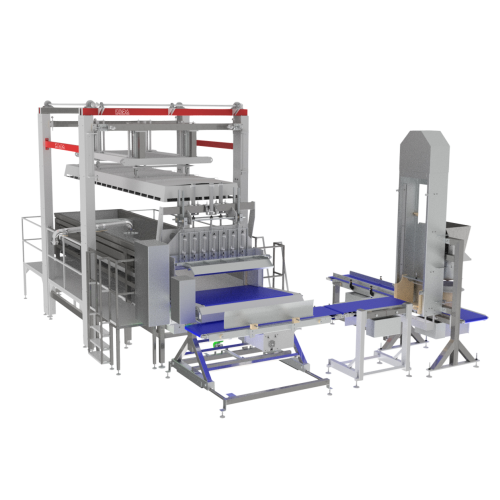

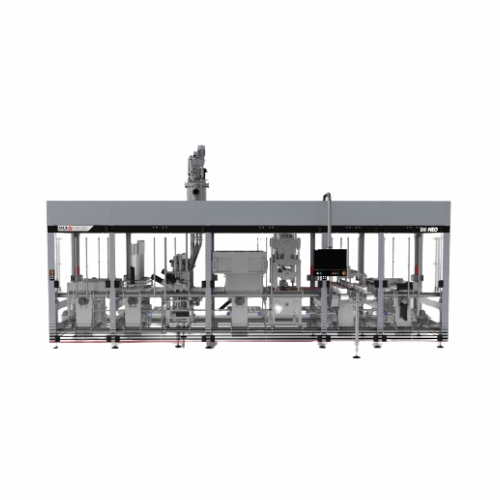

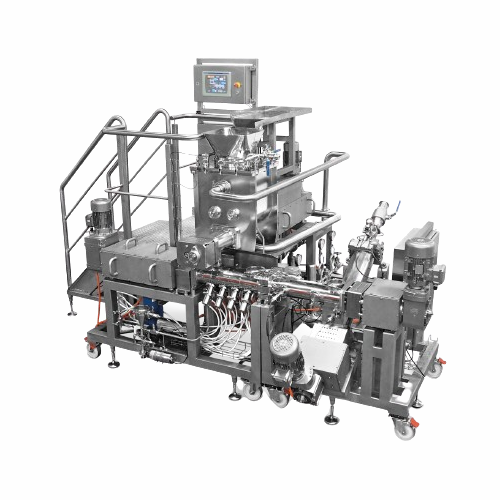

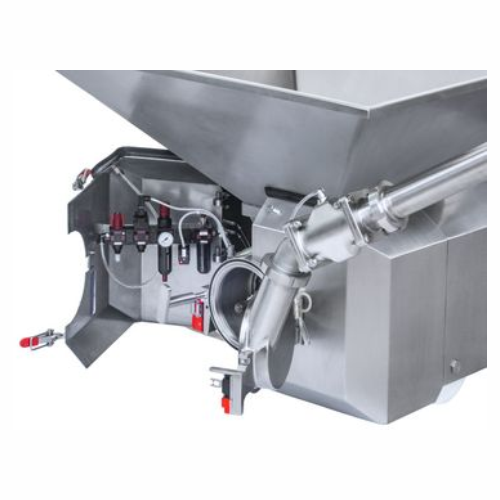

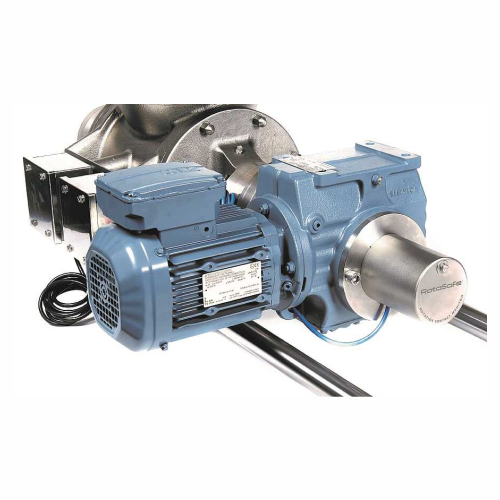

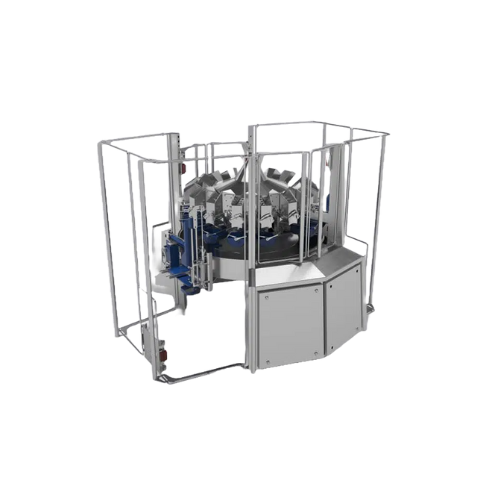

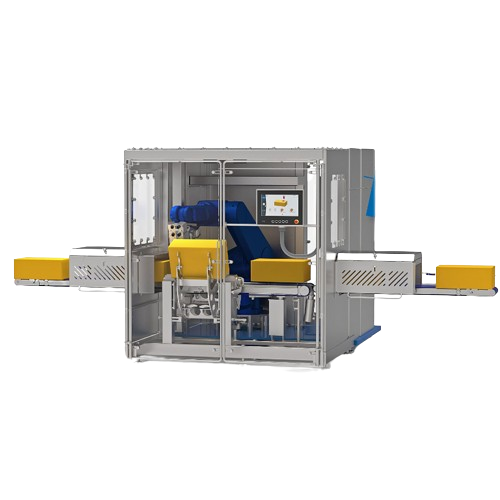

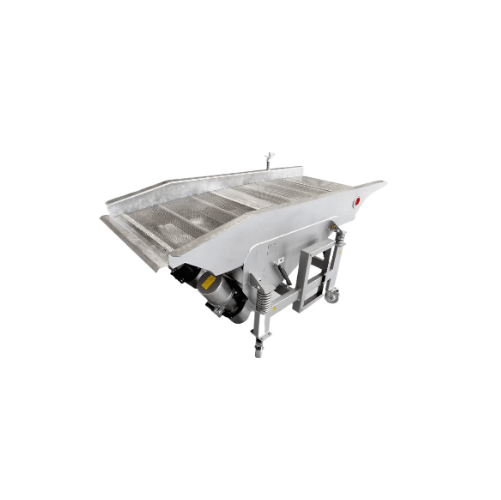

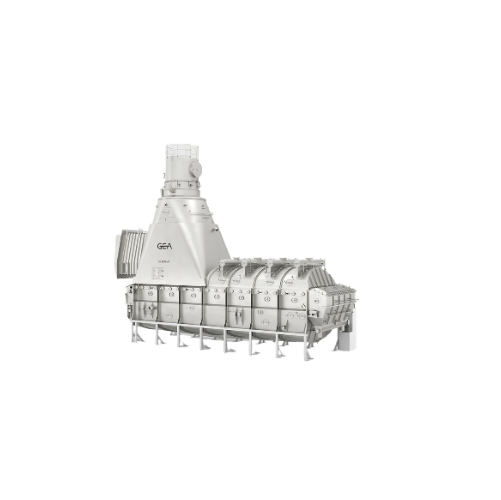

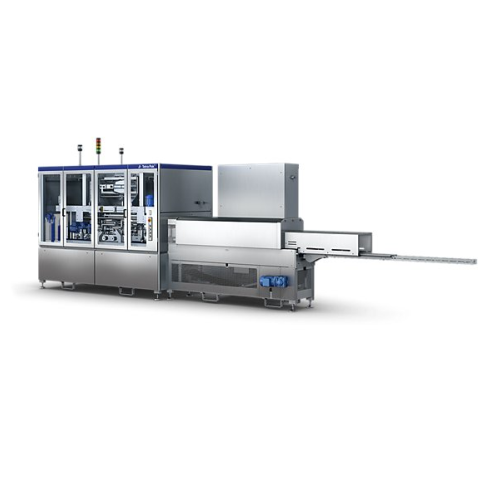

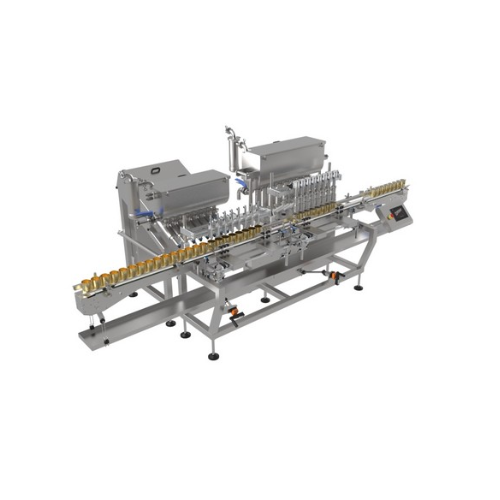

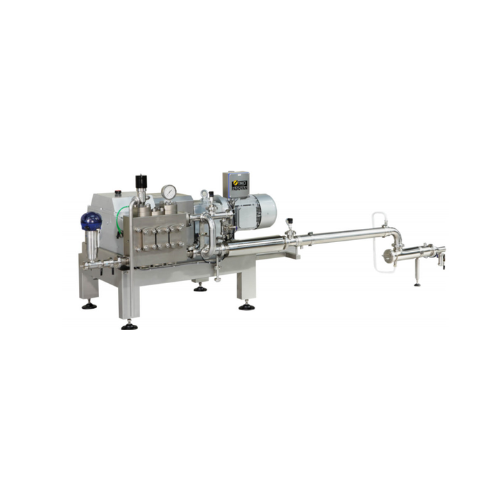

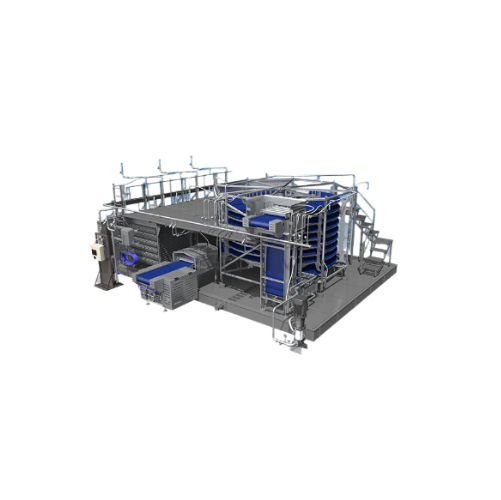

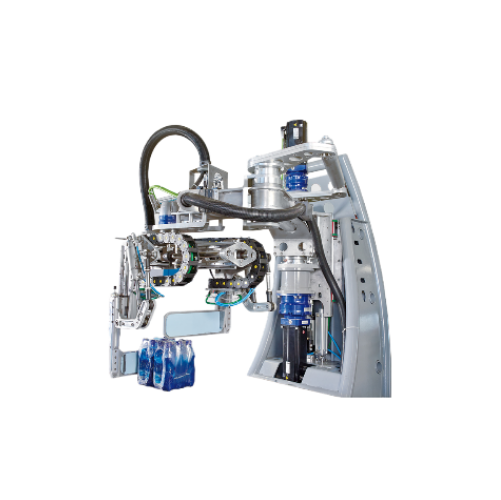

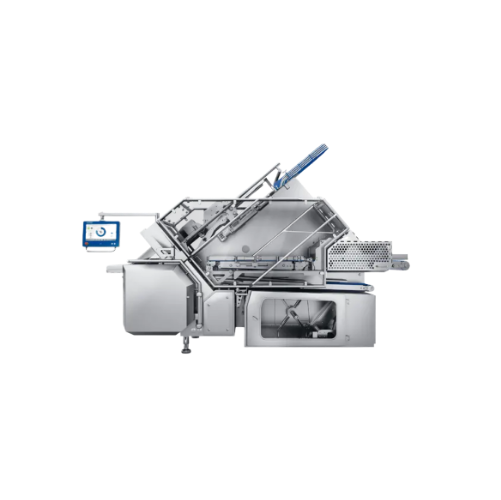

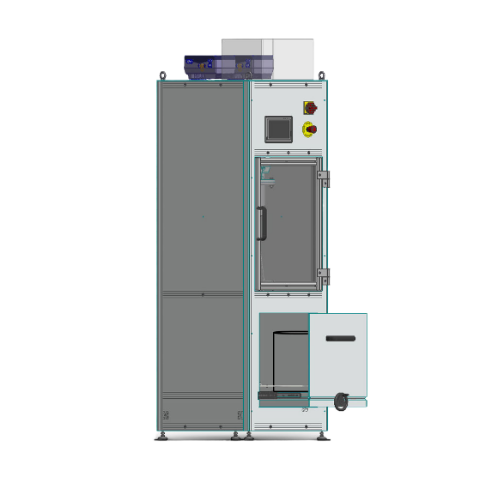

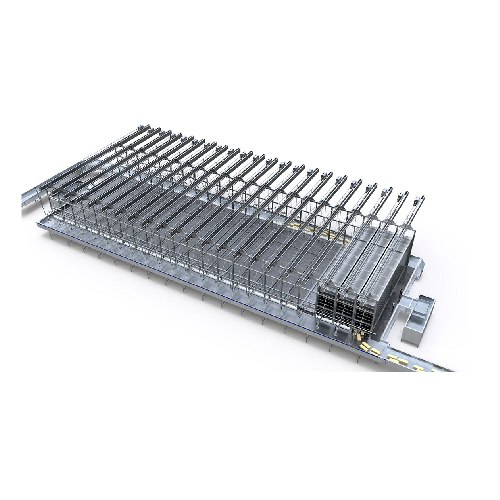

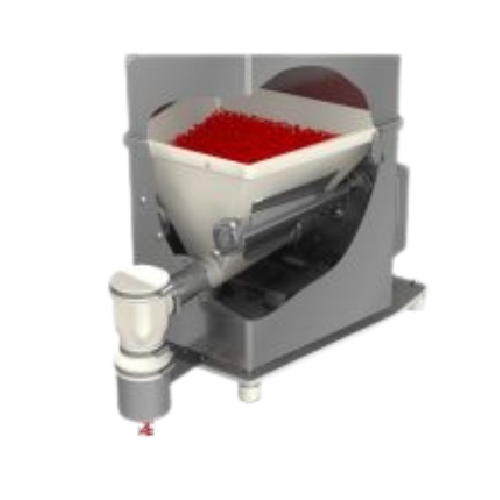

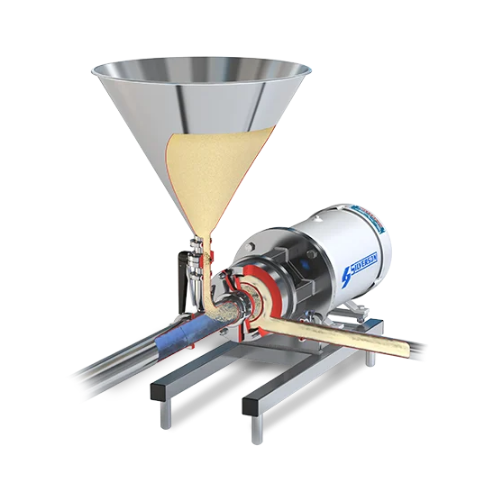

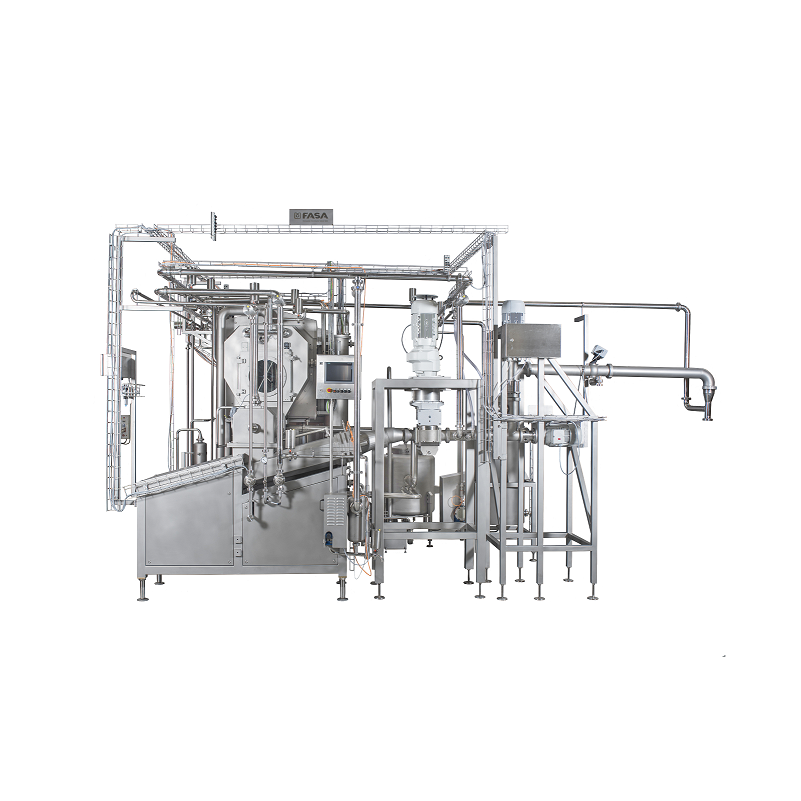

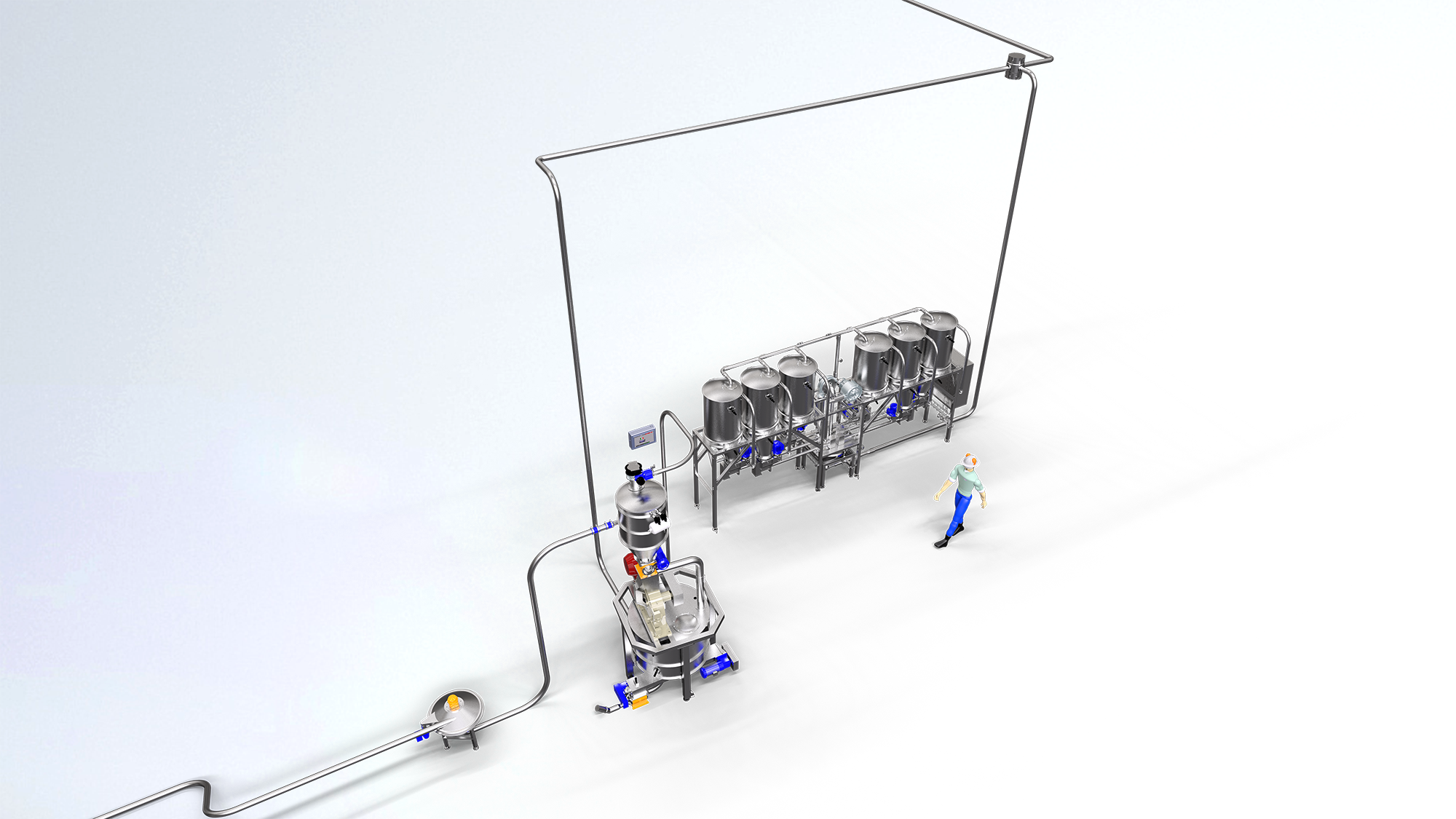

Automated milk dosing system for dairy production

Ensure precise milk allocation for diverse cheese types with this robus...

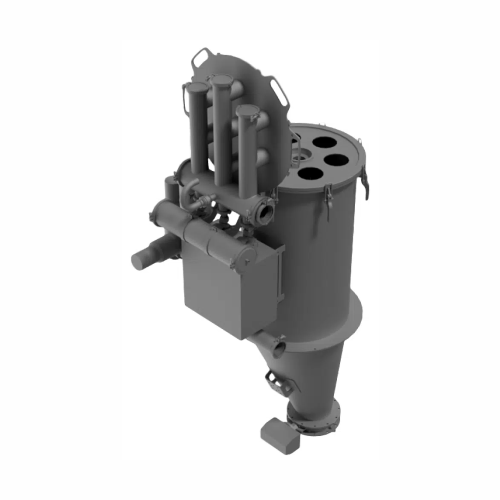

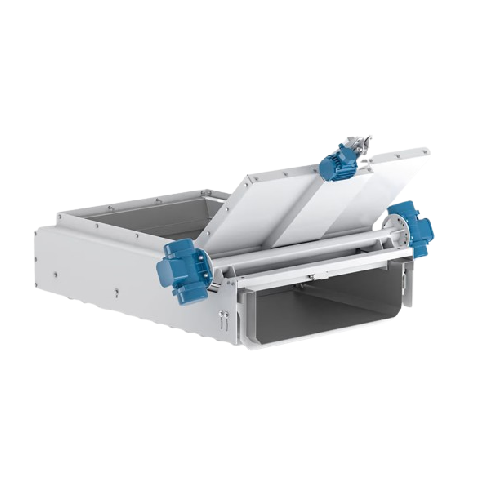

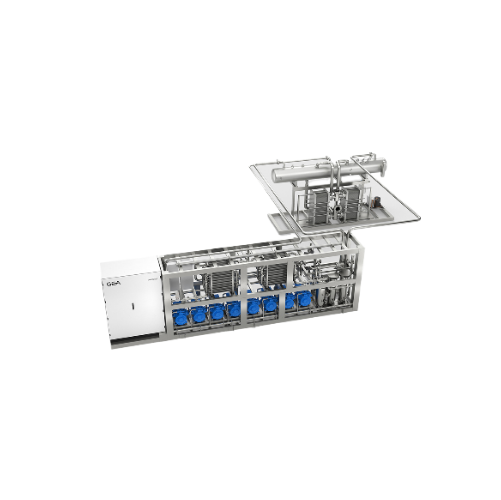

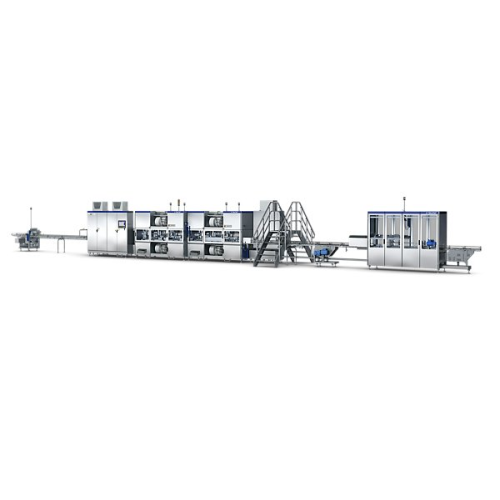

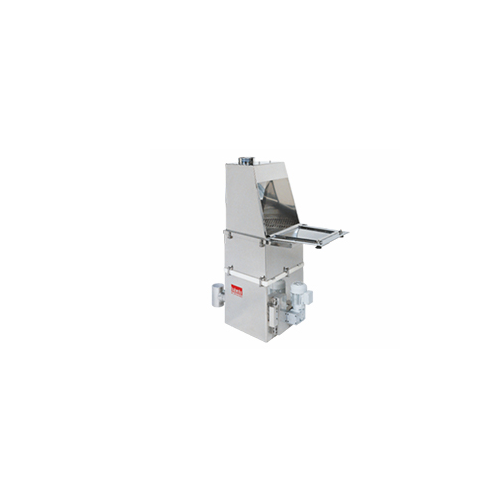

Bacteria removal separator for dairy products

Ensure top-quality dairy and plant-based products with reliable bacteria rem...

What are you making?

Ayran

Buttermilk

Yogurt powder

Yoghurt

Whipped butter

Vegan ice cream

Stick ice-cream

Soy yogurt

Sour cream

Sorbet

Skyr

Salted butter

Quark

Pudding

Rice pudding

Probiotic yogurt

Panna cotta

Margarine

Non-dairy creamer

Mozzarella sticks

Mousses

Lactose

Kefir

Greek yoghurt

Infant formula

Ice cream tubs

Ice cream cups

Ice cream bars

Fruit yogurt

Frozen yogurt

Frozen desserts

Formulated dairy products

Flavoured milk

Fermented dairy products

Dairy powder

Coffee creamer

Whey

Mozzarella

Margerine

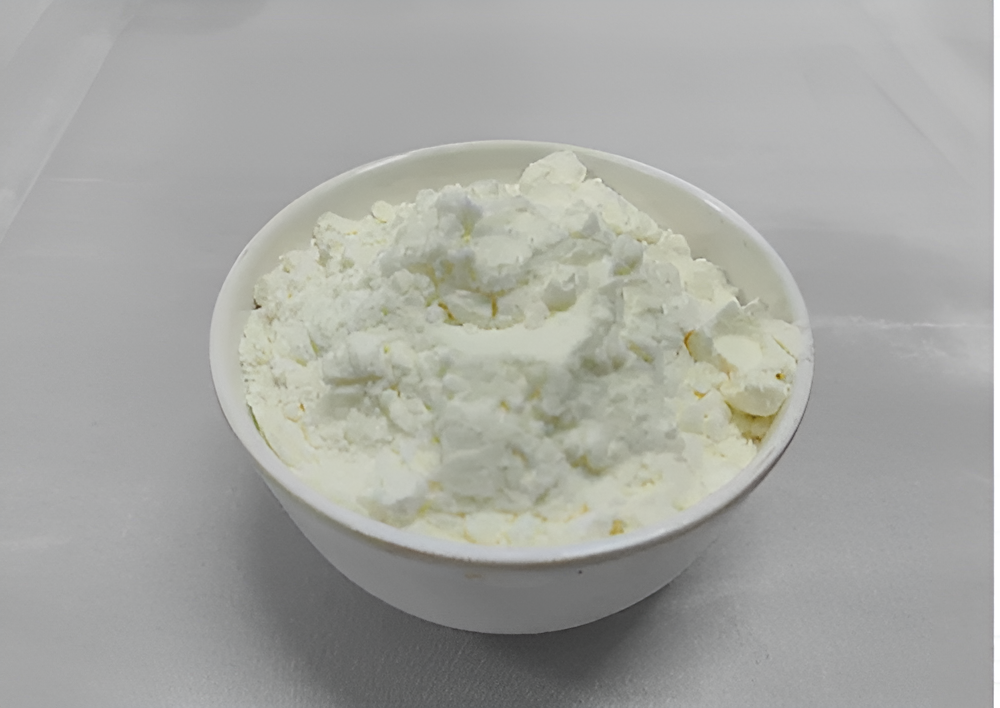

Curd

Whipped cream

Halloumi

Plant-based cheese

Whey protein

Ice cream

Grated cheese

Condensed milk

Cheese spread

Butter

Yogurt

Milk powder

Tell us about your production challenge

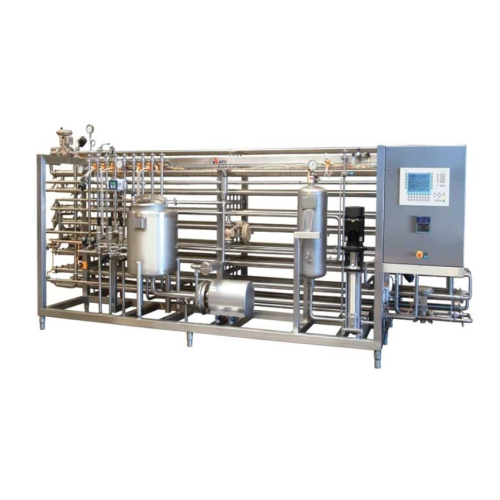

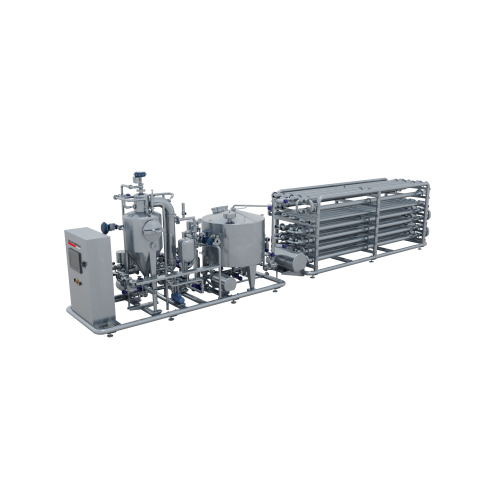

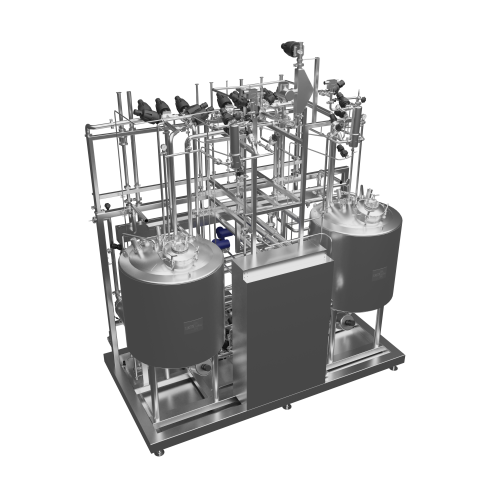

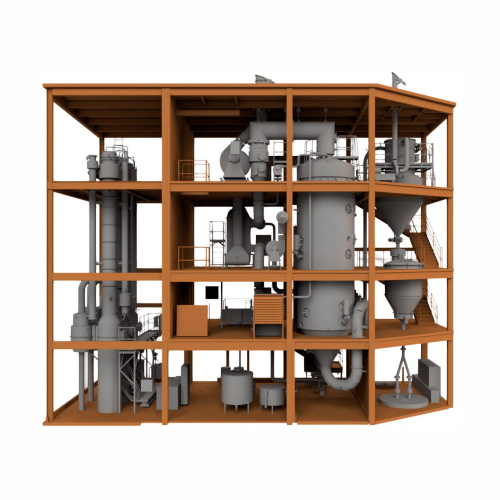

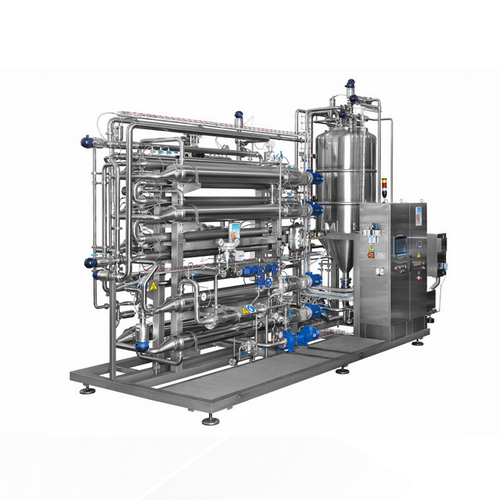

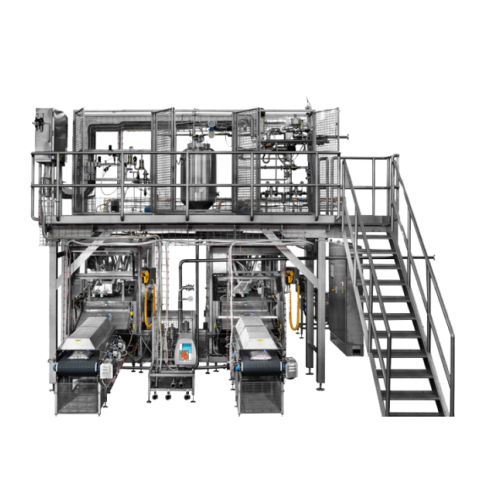

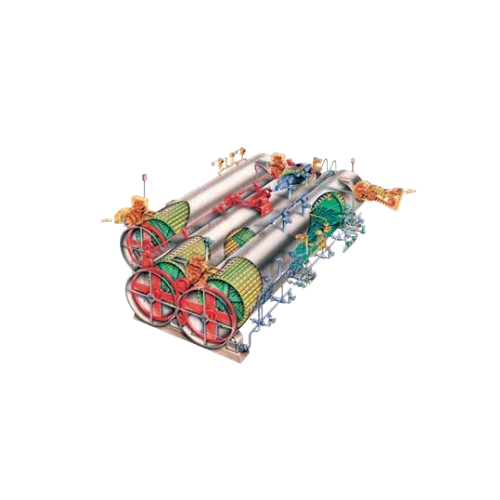

Equipment for making dairy products – How milk is processed

Dairy processing equipment covers multiple automated sub-processes to ensure the milk products quality is at its highest. Since milk is the main ingredient of dairy products, the standard process first requires a pasteurization process. A pasteurizer unit helps to remove harmful bacteria from the milk and extend its shelf life through heating using heat exchangers. From then on, pasteurized milk undergoes different processes depending on the desired output. Usually, the milk goes through a homogenizer after pasteurizing. This improves the milk’s texture before it goes to a fermentation vat where the good bacteria (also known as “starter culture”) is added. When the fermented milk reaches a desired level of acidity, it is cooled down to end the fermentation process.

Regulations relating to dairy products

Standards to produce dairy products vary according to countries and regions. For products such as yogurt, there are classifications based on the content of milk fat or protein. For cheese, there are standards about how much moisture or milk fat it must contain, or in case it is made from unpasteurized milk, there is a required aging time. Processes also have regulations. For example in the United States, during the pasteurization process, every particle of milk must be heated to 143 °F (61.7 °C) for 30 minutes (holding method) or to 160 °F (71.1 °C) for 15 seconds (flash method).

Hybrids as an alternative dairy product

Nowadays, plant-based dairy products are booming in the market – in fact, plant-based milk is a product that even non-vegans can’t do without. This is why people have more and more interest in adding more greens to their diet, having a healthier lifestyle, or a lactose-free diet – in fact, lactose intolerance affects 5-17% of Europeans and about 44% of North Americans. However, since not everyone is totally ready to give up the original flavors of milk, many companies are turning to hybrid dairy products that can offer both of the best worlds. Hybrids are a combination of plant-based proteins and traditional dairy products – for instance, almond milk and cow’s milk. With hybrids, people can still enjoy the original flavor of milk with less sugar, lower fats, fewer calories, and high sources of dietary fiber.

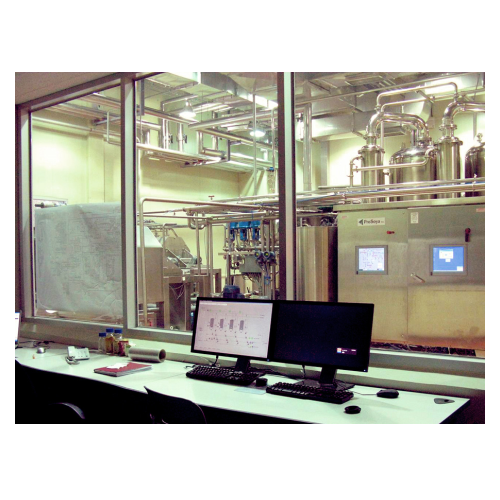

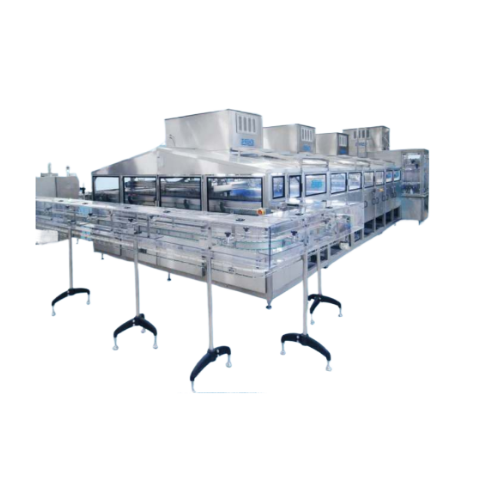

Aseptic filling as a production requirement for dairy products

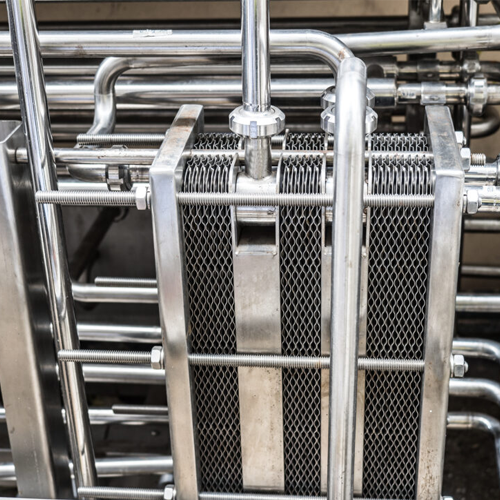

Aseptic filling is a necessary process in the dairy industry that requires a sterile environment for operation. Because of it, equipment, containers, and packaging material are sterilized using steam, heat, and other treatments. This ensures that the product is free from contaminants and safe for consumption. Furthermore, the processing equipment needs to be stainless steel and should incorporate some sort of CIP cleaning system. CIP stands for “Clean In Place” which essentially means that the cleaning systems has been integrated into the machinery or equipment. The reason for this is to save time due to manufacturers not having to dismantle the machinery in order to clean them.

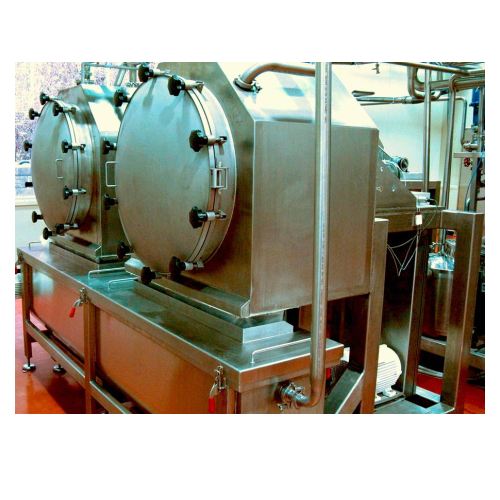

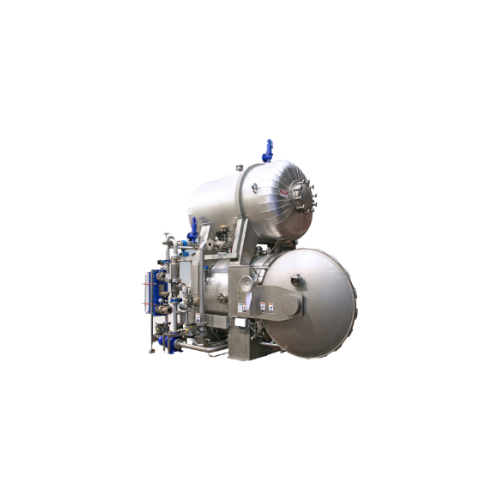

How sterilizers achieve a long shelf life for dairy products

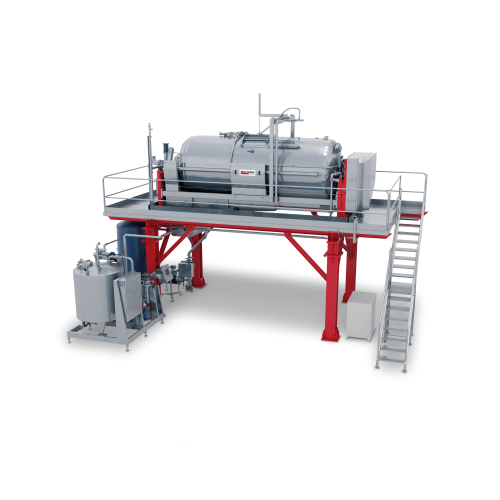

One of the most common yet important processes in the production of dairy foods and products is sterilization. This food processing step ensures a clean final product and helps achieve a long shelf life. The products are heated for a certain amount of time and then cooled in preparation for packing. An autoclave is used as equipment to perform such tasks.

In conclusion, specialized dairy equipment is necessary to process milk and create products such as cheese, butter, and yogurt. The pasteurization, homogenization, and fermentation processes require specific equipment. and adhere to different regulations based on country and region. Aseptic filling and sterilization play a crucial role in making safe and clean dairy products with a longer shelf life. Moreover, hybrids of plant-based proteins and traditional dairy products are becoming more popular among consumers. Whether it’s for a dairy farm or cheese making, it’s important to use the right equipment to produce high-quality dairy products that meet regulatory requirements.

Which dairy technology do you need?

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

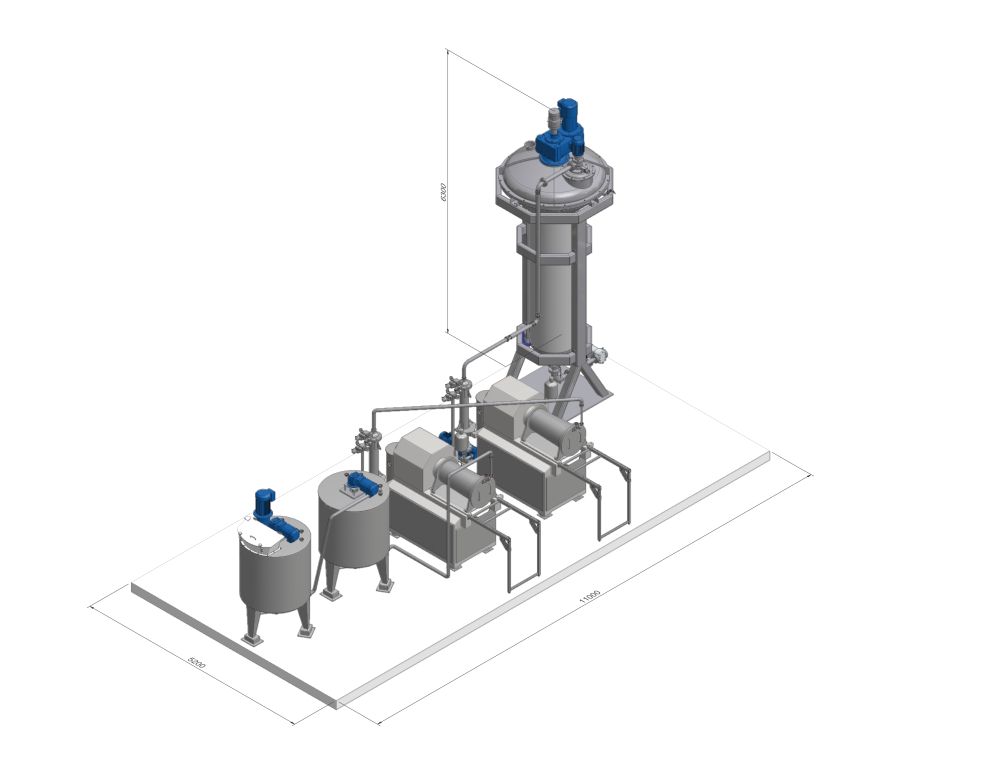

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

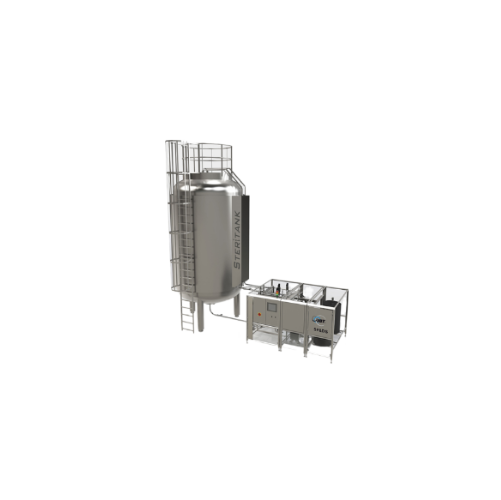

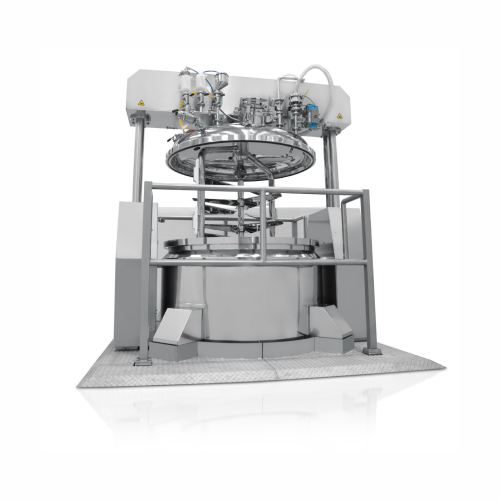

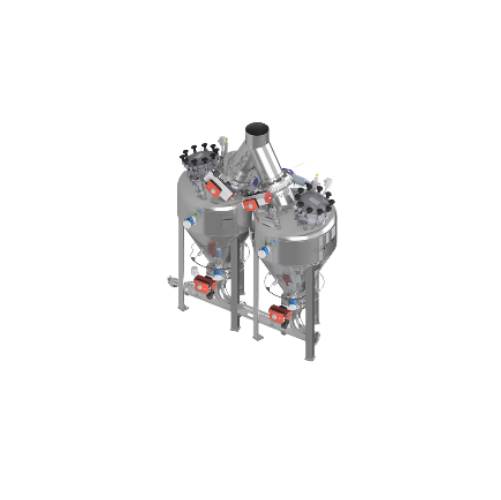

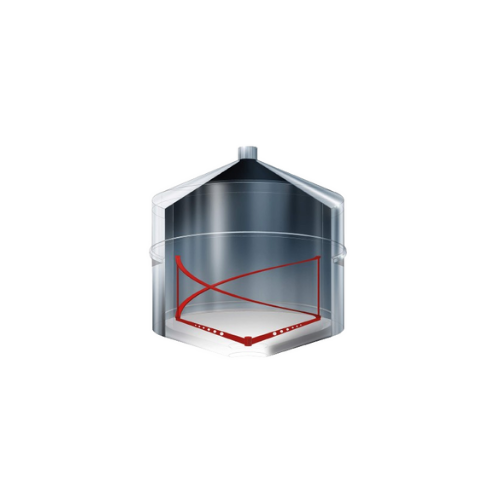

Fermentation tank for yoghurt and fermented dairy products

Optimize your dairy and plant-based drink production with eff...

Bacteria removal separator for dairy products

Ensure top-quality dairy and plant-based products with reliable bacteria rem...

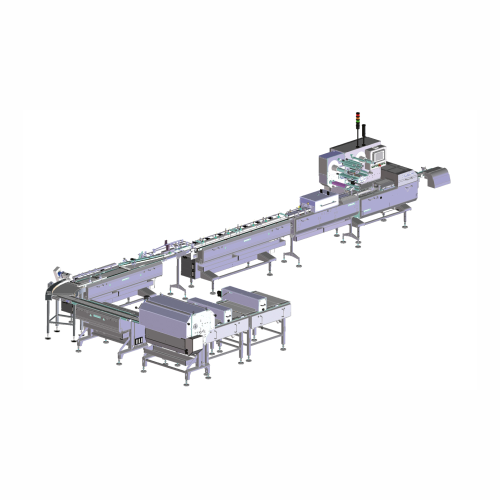

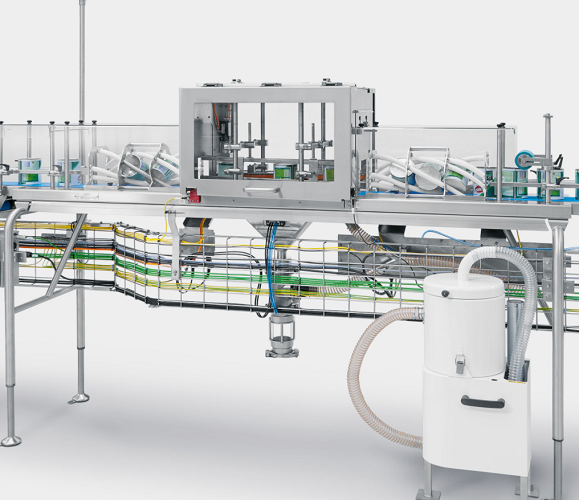

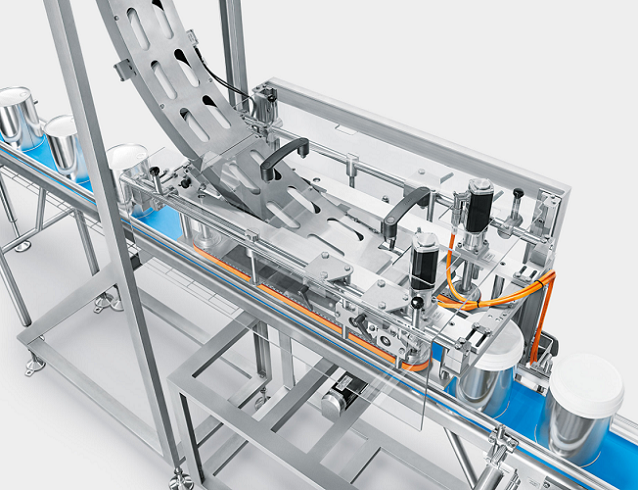

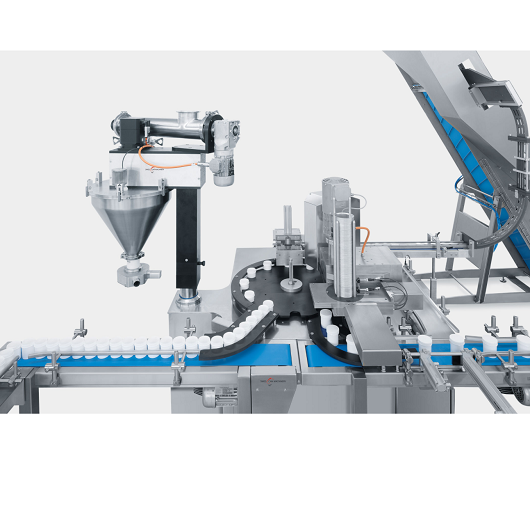

Cup filling and sealing system for dairy products

Optimize your production line with versatile cup filling and sealing ca...

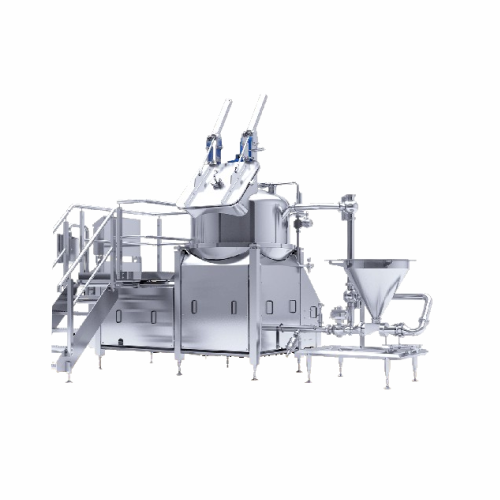

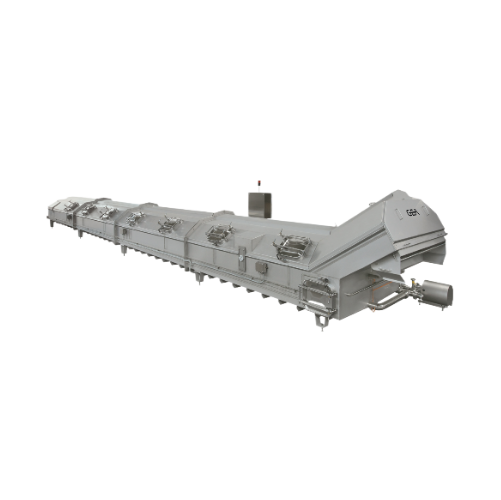

Steam cooking system for dairy production

Ensure precise temperature regulation and efficient moisture control in cheese a...

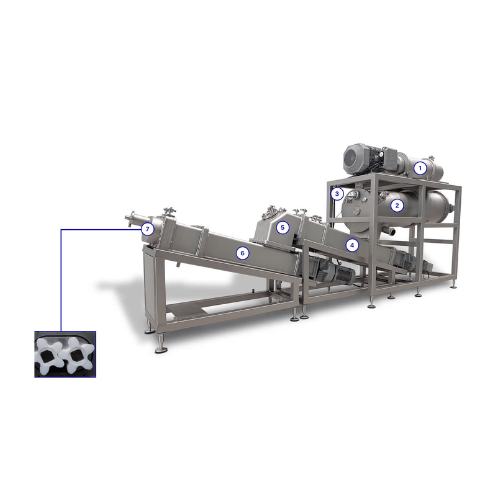

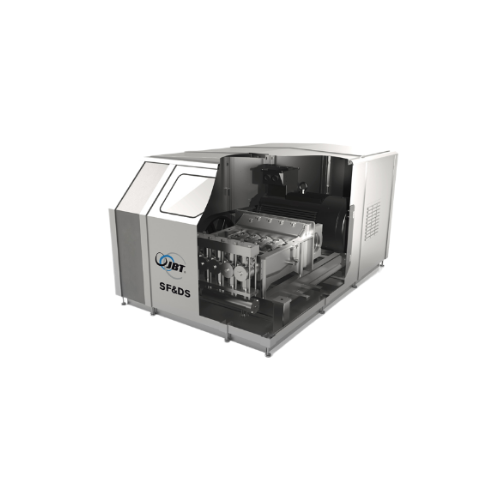

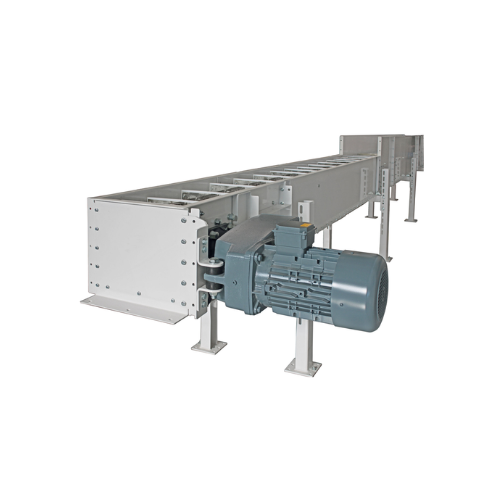

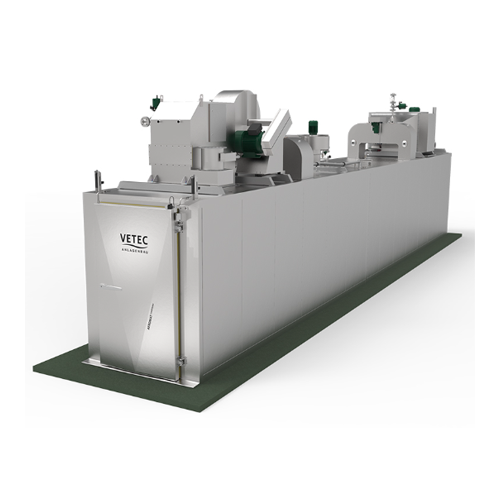

Dynamic brine salting system for dairy production

Streamline your cheese salting process with a system designed to handle...

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

Ice storage tanks for dairy industry

Ensure optimal temperature control and efficiency in cheese production with robust ice...

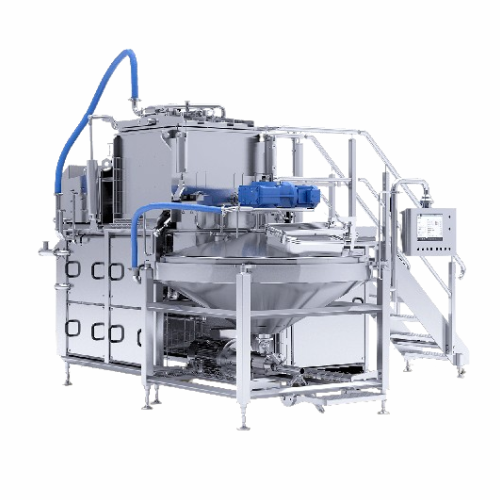

Automated milk dosing system for dairy production

Ensure precise milk allocation for diverse cheese types with this robus...

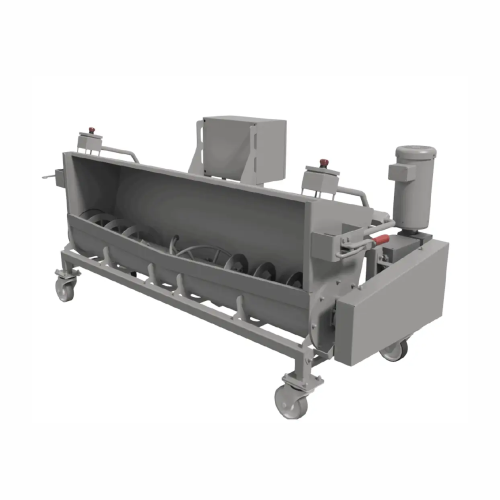

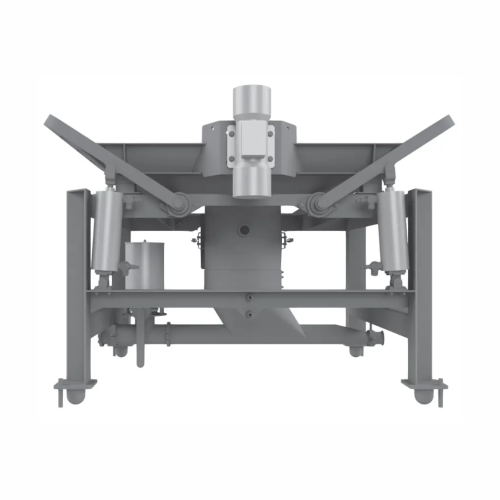

Ricotta smoothing mixer for dairy production

Achieve consistently smooth and perfectly blended ricotta with advanced mixin...

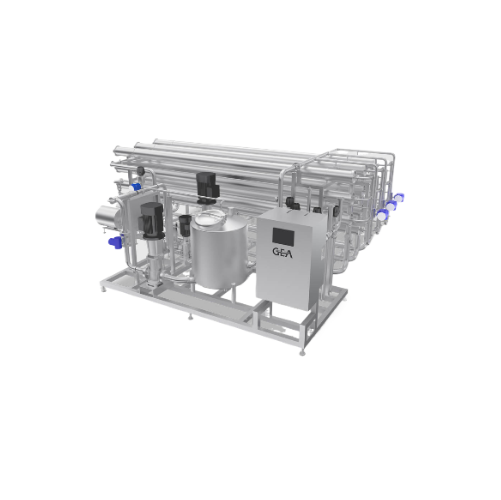

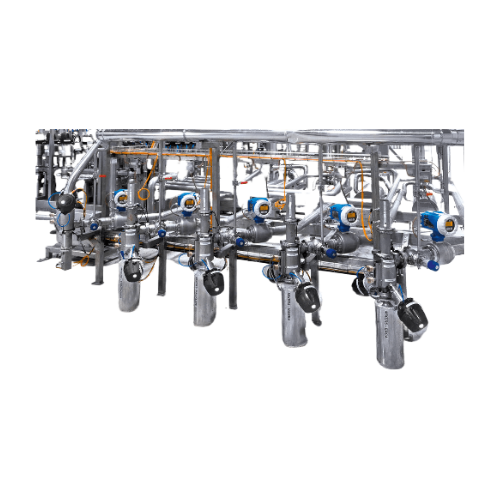

Cip systems for dairy production

Ensure consistent hygiene and sanitation levels in your production line with efficient, aut...

Centrifugal separators for dairy product processing

Ensure optimal dairy product quality with a centrifugal separation so...

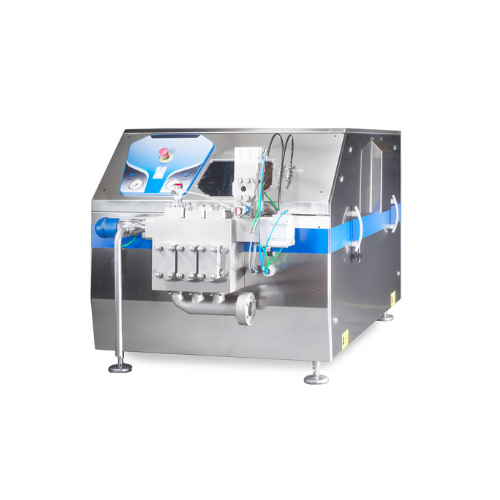

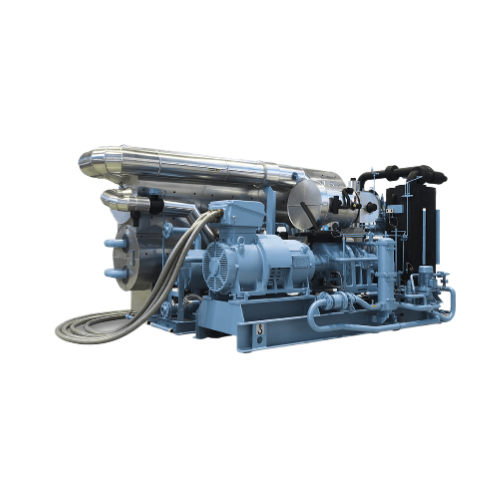

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

Milk pasteurizers for dairy sector

Ensure optimal safety and quality of your dairy products with advanced pasteurization te...

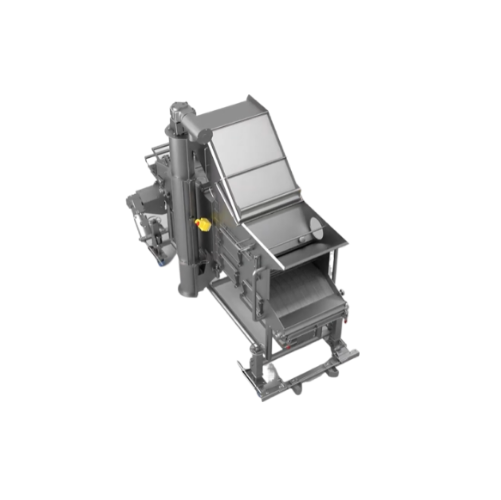

Milk receiving and storage units for dairy operations

Streamline your dairy processing with equipment designed to efficie...

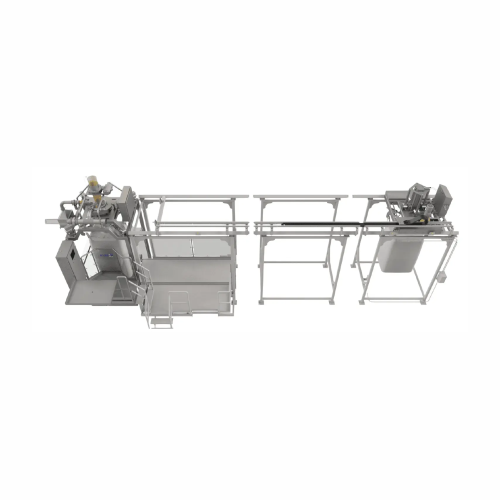

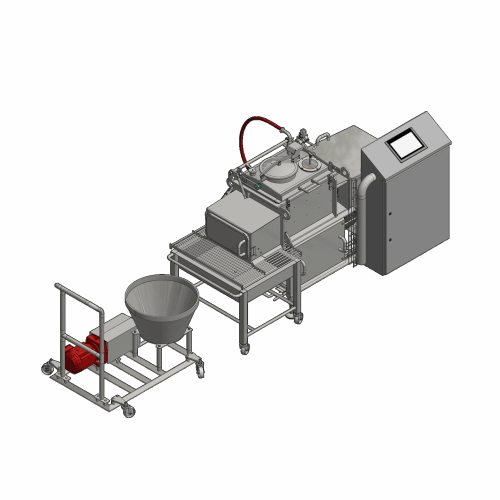

Mini dairy system for small-scale cheese production

Optimize your dairy production with a compact system designed for tra...

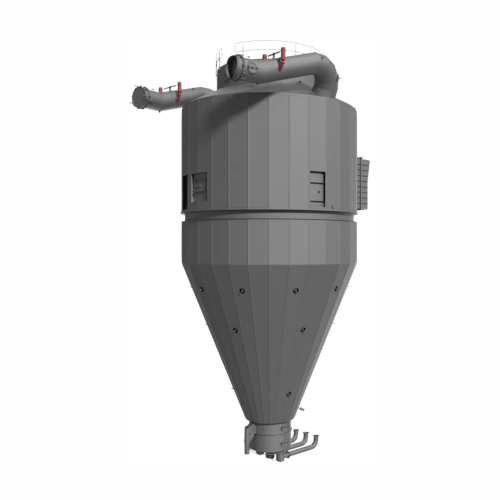

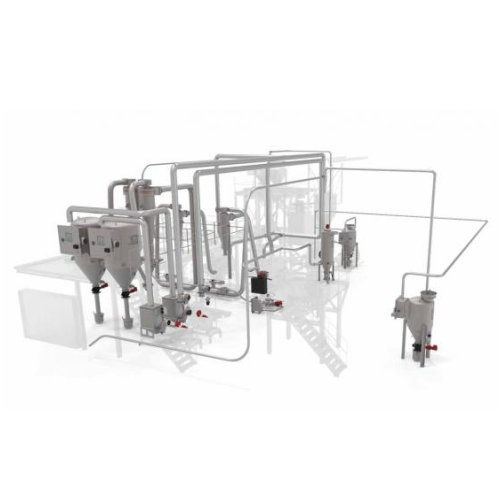

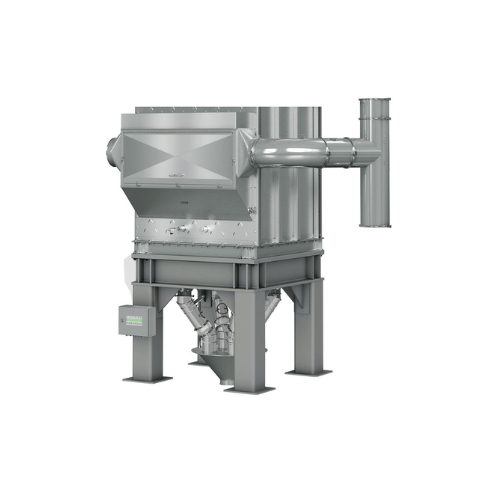

Air filtration system for dairy and food powder processing

Optimize powder processing with advanced air filtration, ensu...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

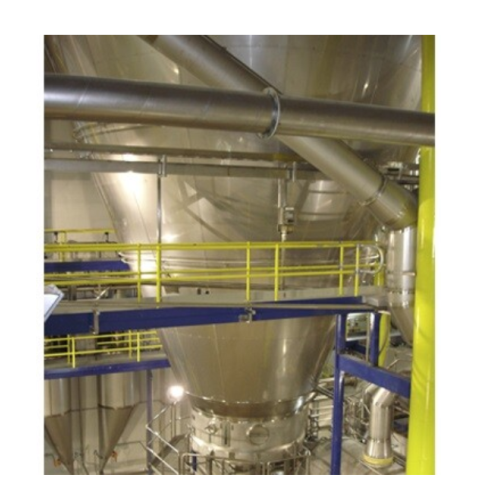

Storage silos and hoppers for food and dairy industries

Ensure optimal powder storage with solutions that enhance space e...

Powder unloading systems for food and dairy applications

Streamline your powder handling with customizable unloading syst...

Food product smoothing system for dairy and purees

Achieve unparalleled texture and fineness in viscous food products wit...

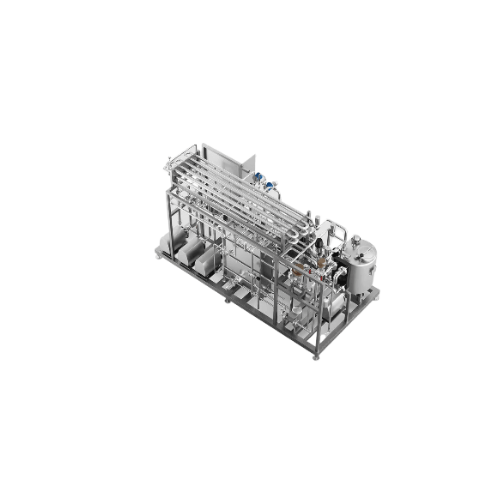

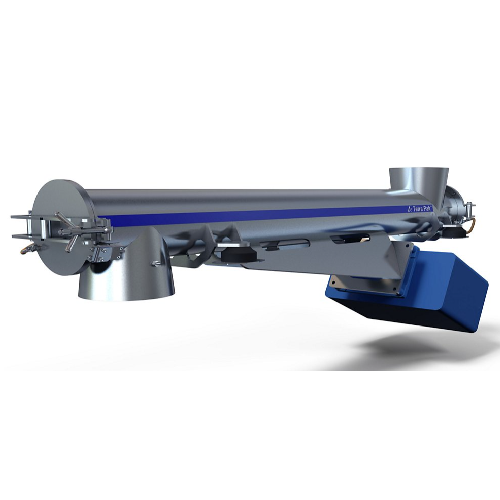

Tubular pasteurizer for wine, grape juice, and dairy

Ensure product integrity by efficiently inactivating microorganisms ...

Cip system for wine, grape juice, oil, and dairy

Ensure optimal hygiene and operational efficiency in processing lines wit...

Evaporators for grape juice and dairy products

Optimize the concentration of grape juice and dairy products with precision...

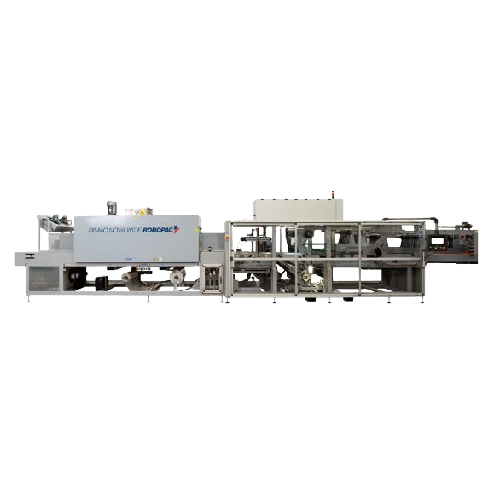

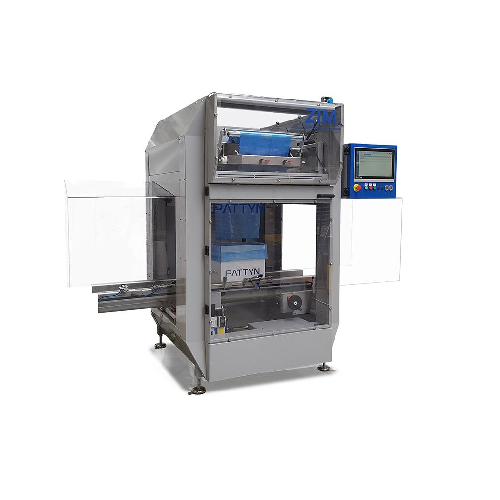

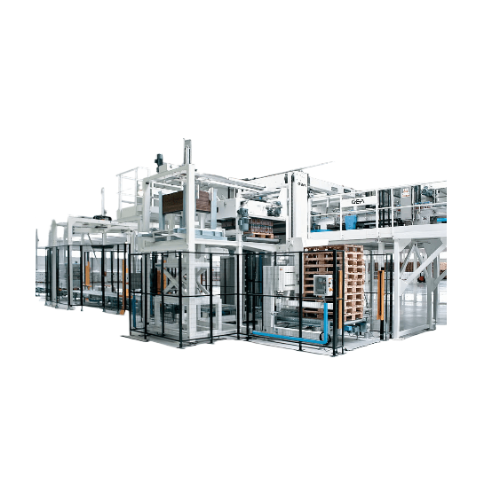

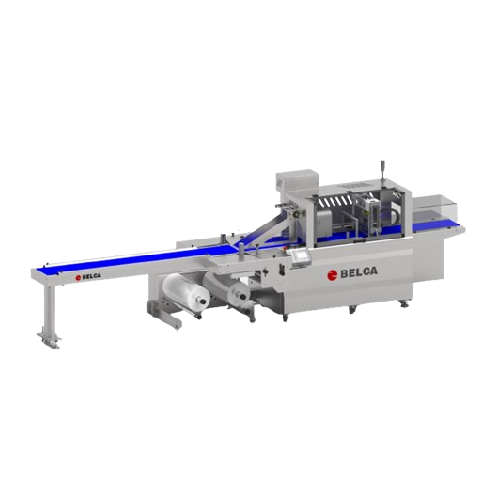

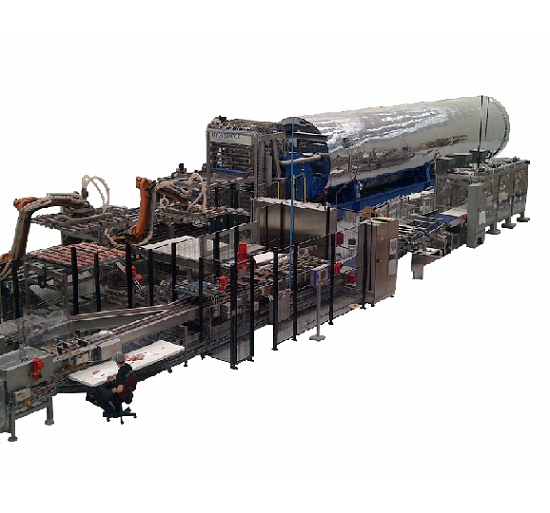

Medium-speed automatic shrink wrapping systems for food and dairy

Optimize your packaging line with this flexible shrin...

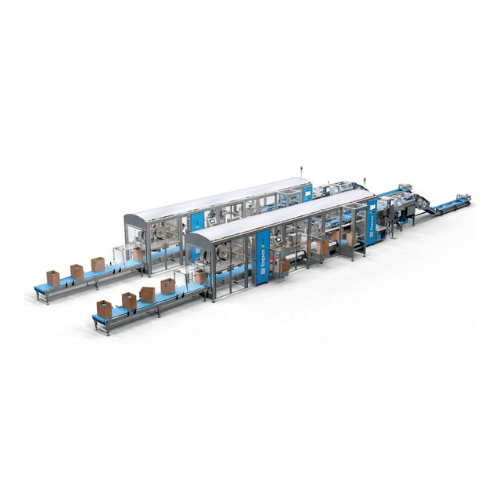

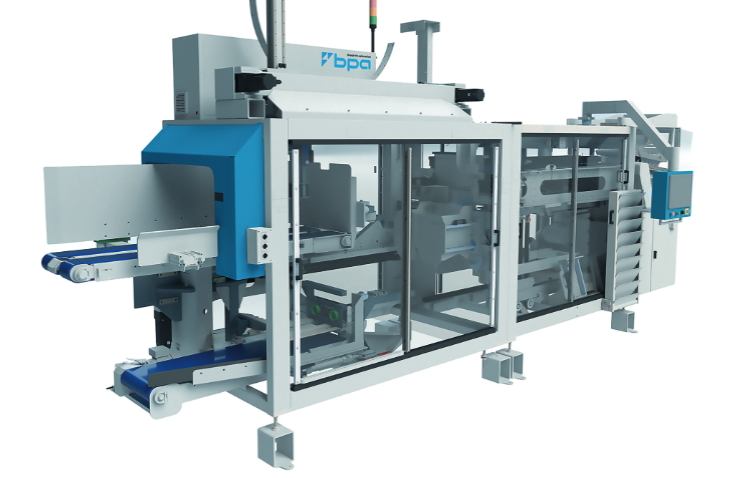

Medium-speed wrap around case packer for food and dairy industries

Optimize your end-of-line efficiency with a reliable...

Shrink wrapping solution for high capacity beverage and dairy bundles

This modular shrink wrapping and tray forming sol...

Homogenizer for dairy products

Achieve precise texture and quality in dairy products with this versatile homogenizer, design...

Stainless steel tanks for dairy processing

Optimize your dairy processing with customizable stainless steel solutions for ...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixin...

Industrial mixer for baby food and dairy production

Optimize your production line efficiency with a versatile mixing solu...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

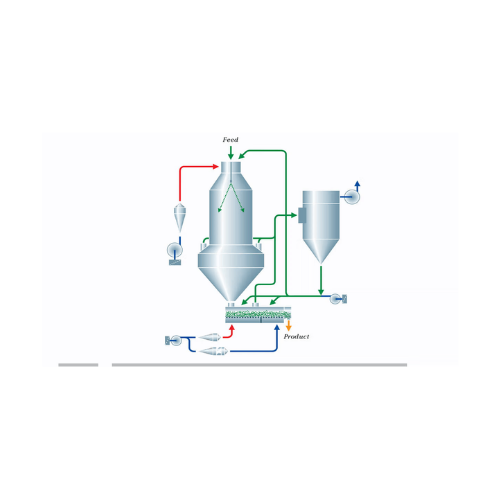

Permeate drying system for dairy applications

Optimize your dairy production with efficient permeate drying, delivering hi...

Protein drying system for dairy products

Optimize your dairy production with a customizable drying system designed for effi...

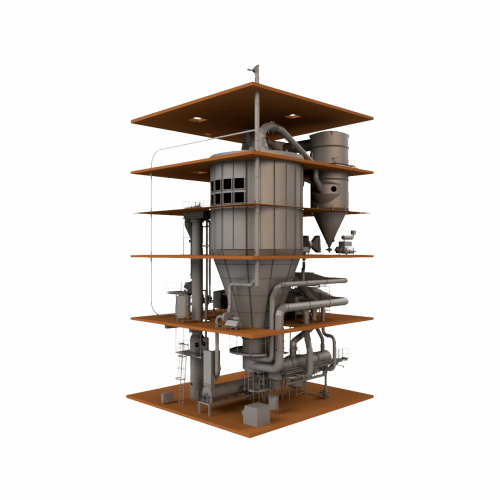

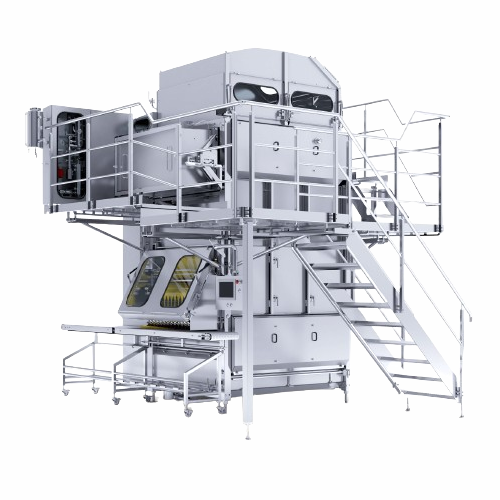

Tall form bustle dryer for dairy and food products

Experience efficient drying and precise moisture control with this inn...

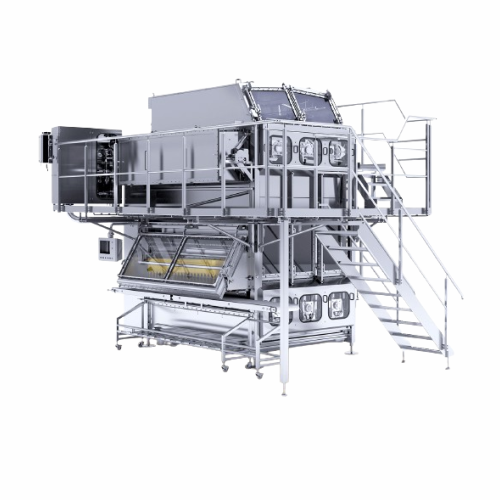

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy an...

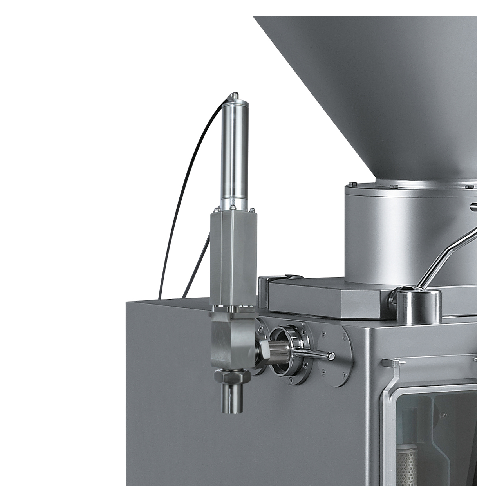

Curd unloader for dairy production

Streamline your cheese production with efficient curd unloading and transfer, ensuring s...

Cheese blockformer for dairy industry

Achieve consistent cheese block quality and seamless curd fusion through precision en...

High-concentration dairy evaporator

Achieve high solids concentrations with enhanced efficiency by integrating this evapora...

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

Cip cleaning system for dairy industries

Ensure hygienic operation with this system, designed to maintain optimal cleanline...

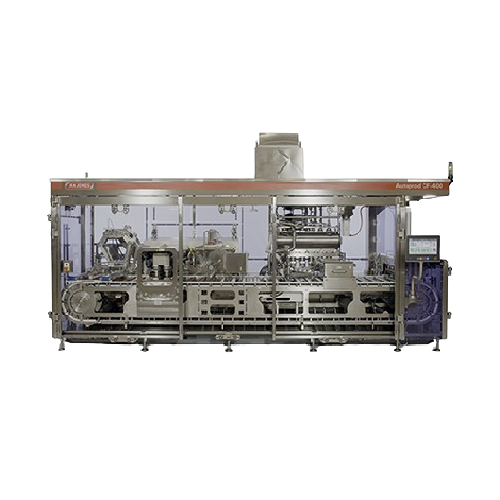

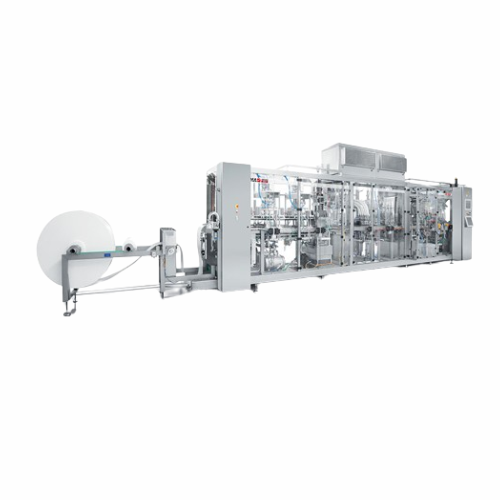

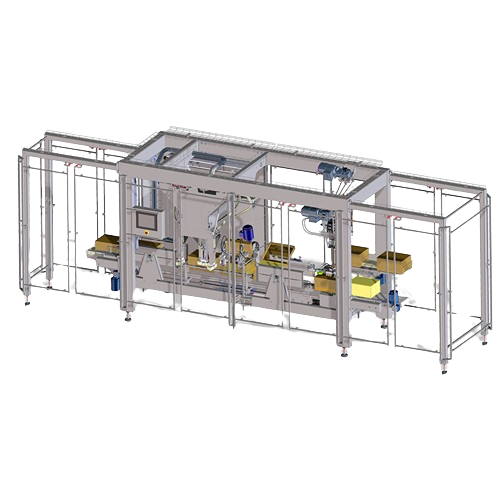

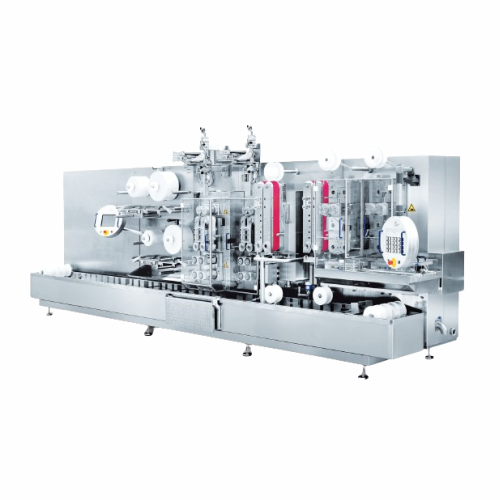

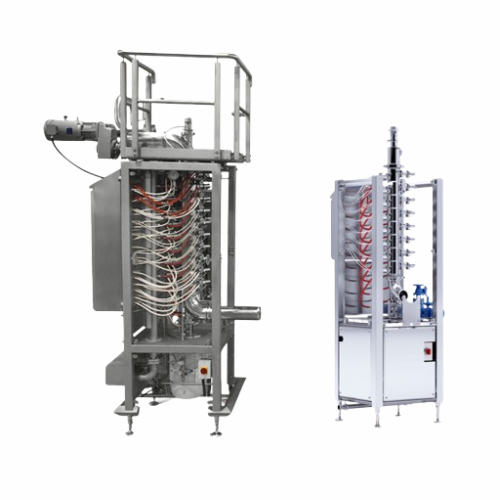

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

High-speed pouch filling and sealing system for food and dairy

Achieve precise spouted pouch filling with minimal waste ...

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

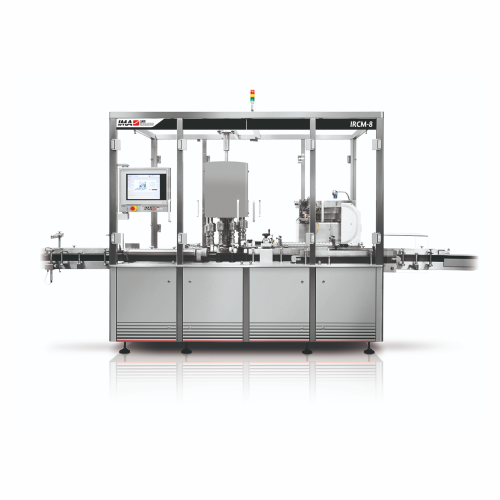

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

High-pressure homogenizers for dairy and juice processing

Ensure superior texture and stability in your liquid formulati...

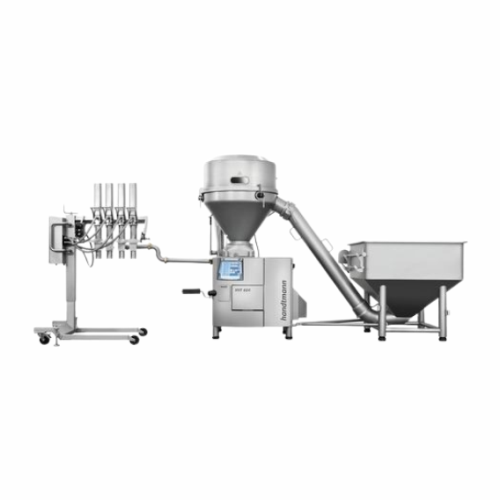

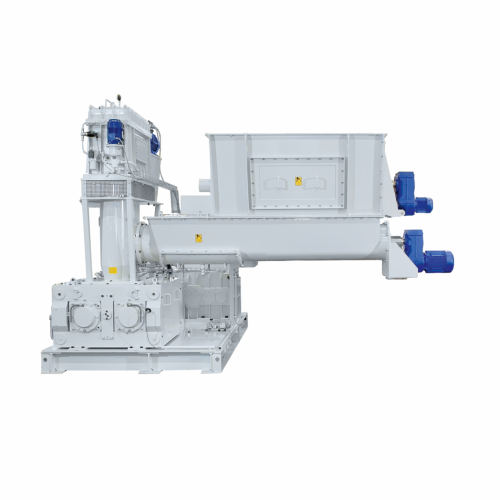

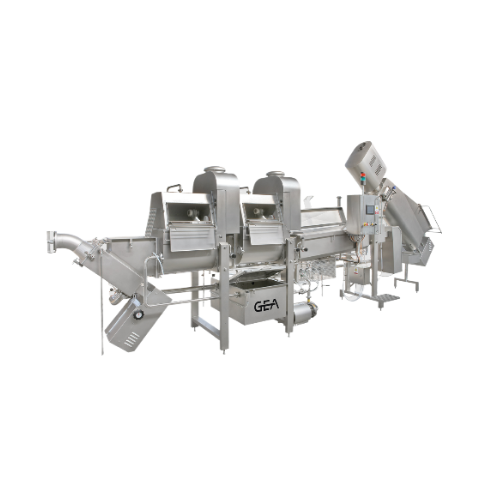

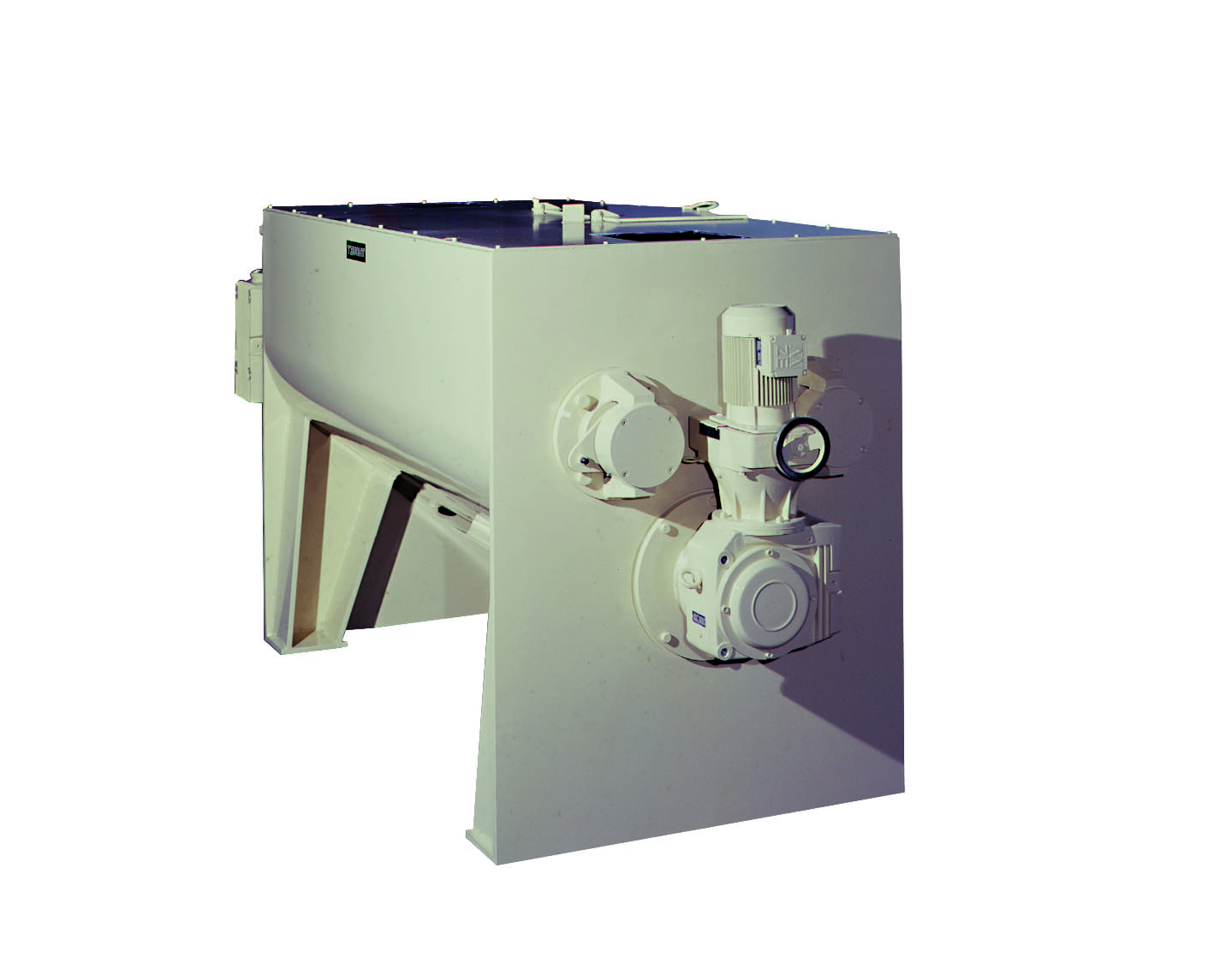

Flexible mixing system for meat and dairy products

This versatile mixing system delivers precise control over temperature...

Industrial pasteurizer for dairy and beverage processing

Enhance product quality and safety with efficient heat treatment...

Pasteurizer for dairy concentrates

Ensure optimal flavor and texture in dairy products with precise pasteurization that pro...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

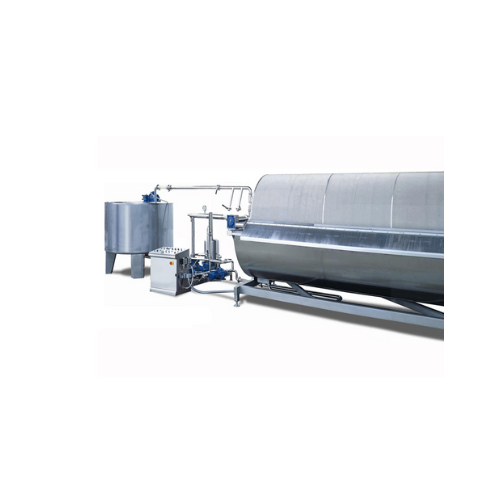

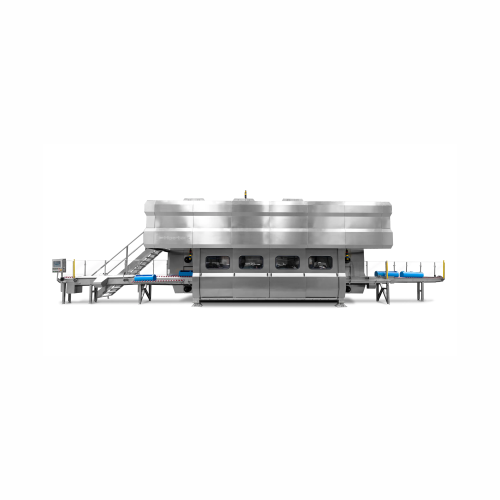

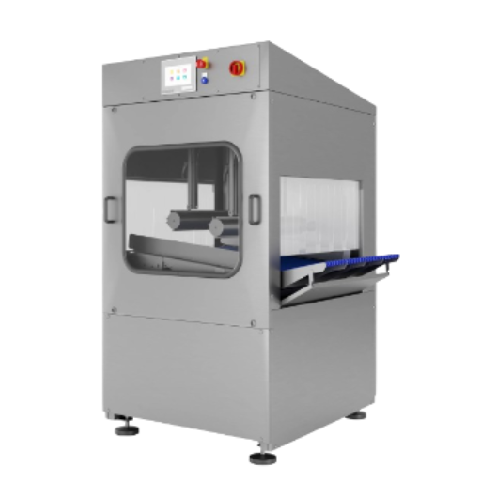

Automatic cheese washing system for dairy industry

Ensure your cheese production maintains optimal hygiene and efficiency...

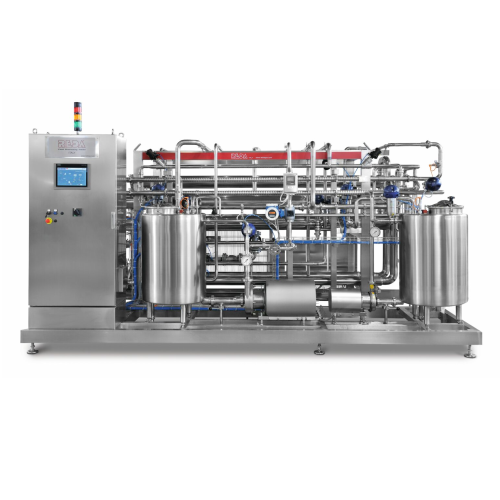

High-temperature short-time pasteurization system for dairy products

Optimize your dairy and ice cream production with ...

Industrial pasteurizer for juice, dairy, and vegetable purees

Ensure product safety and extend shelf life with this comp...

Storage tank for dairy products and juices

Designed for optimal preservation and hygiene, these storage tanks prevent sedi...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Cip cleaning systems for dairy processing plants

Optimize cheese production with precise curd handling and exceptional sti...

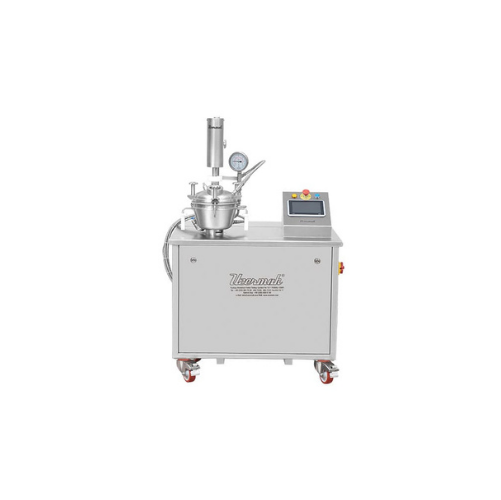

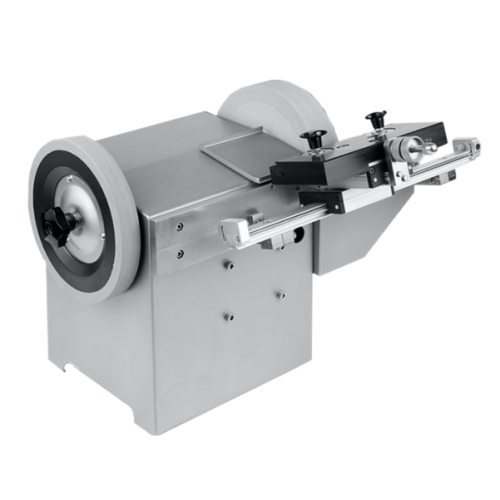

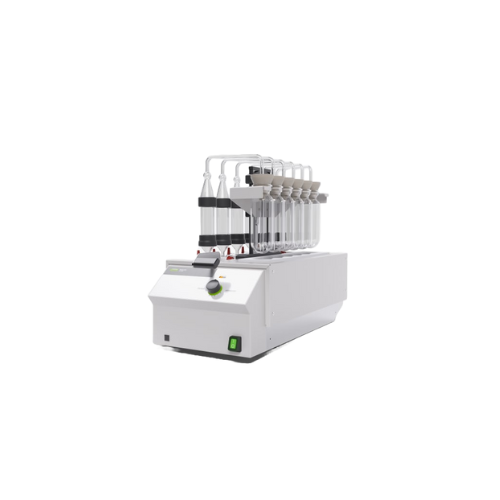

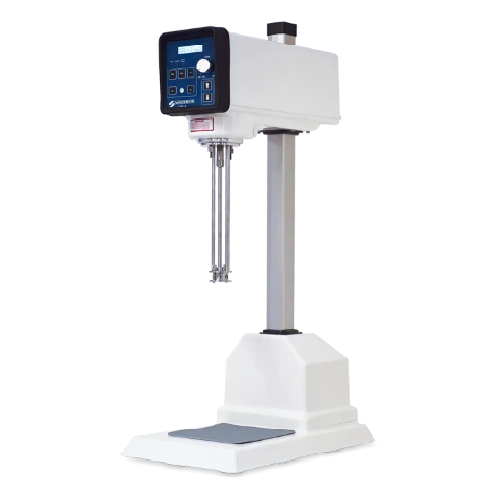

Laboratory homogenizer for dairy and biotech applications

Ensure precise particle size reduction and consistent texture ...

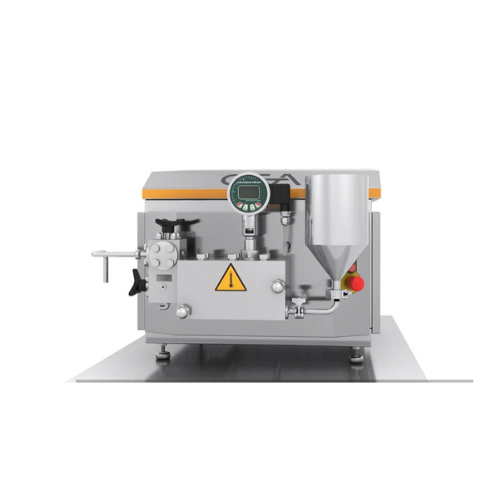

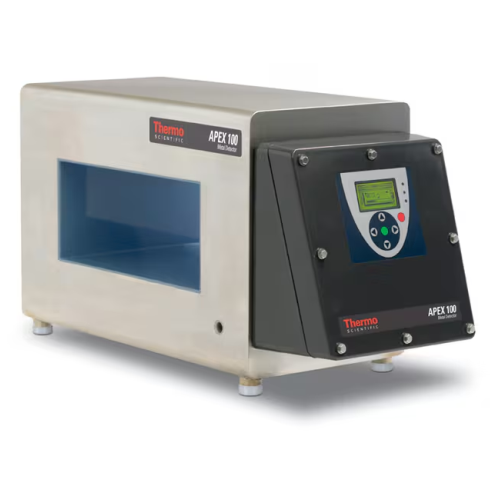

Co2 monitoring for dairy product contamination

Ensure product safety by rapidly detecting microbial contamination in dairy...

Cube cutter for dairy products

Achieve precise and consistent cheese and dairy snack cubes effortlessly with high-speed, con...

Milk clarifier for dairy industry

Enhance your dairy production with efficient milk and whey clarification, ensuring produc...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

Heat exchanger for dairy and beverage applications

Optimize your liquid product thermal processing by directly regenerati...

Coil heat exchanger for dairy and beverage processing

Quickly sterilize and retain product quality with this coil heat ex...

Uht sterilizer for dairy and high-viscosity products

Optimize your production of dairy alternatives and fruit-based drink...

Dual heating coil for dairy and beverage processing

Achieve precise temperature control for your liquid products with a s...

Deaerator for juices and dairy processing

Ensure the quality and shelf-life of liquid foods by effectively removing entrap...

High temperature short time (HTST) dairy pasteurization system

Ensure precise pasteurization with advanced heat transfer...

Aseptic filler for packaged dairy and beverages

Ensure product sterility and extend shelf life efficiently with high-speed...

Powder sampling solution for dairy and food processors

Ensure precise quality control with a versatile sampling system de...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

Continuous in-line blender for dairy applications

Achieve precise and homogeneous blending of sensitive dairy mixtures di...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

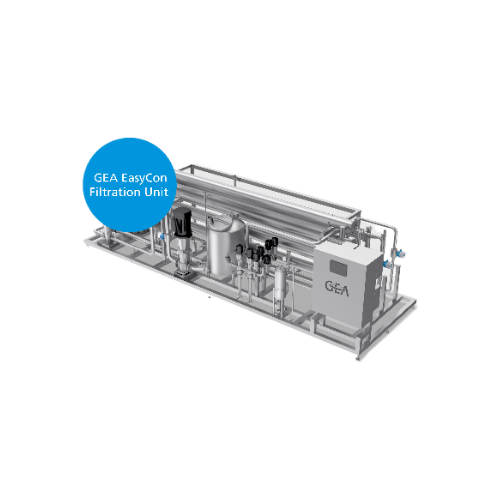

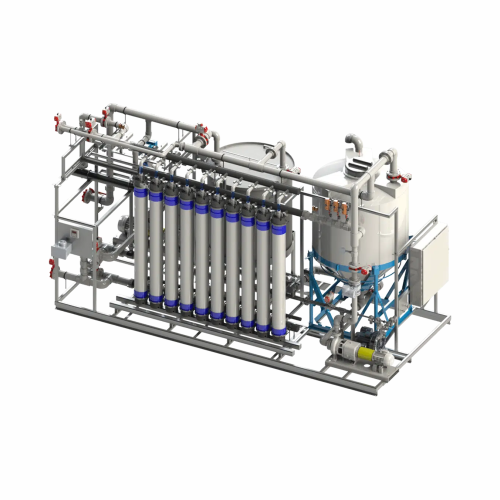

Membrane filtration unit for dairy applications

Achieve precise concentration of dairy products with advanced membrane fil...

Pasteurizer system for dairy applications

Achieve optimal pasteurization with precise temperature control and energy-effic...

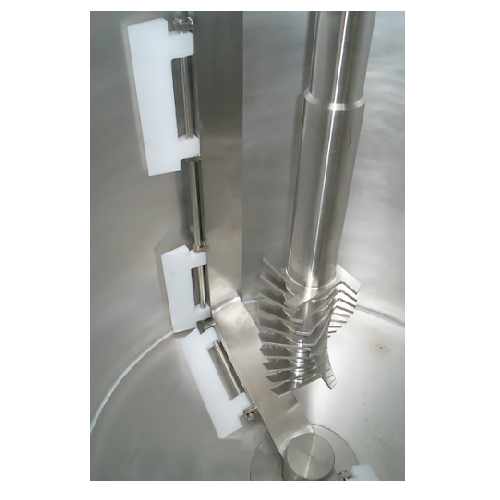

Industrial curd cutters for dairy processing

Optimize your cheese production with curd cutters designed for precision cutt...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

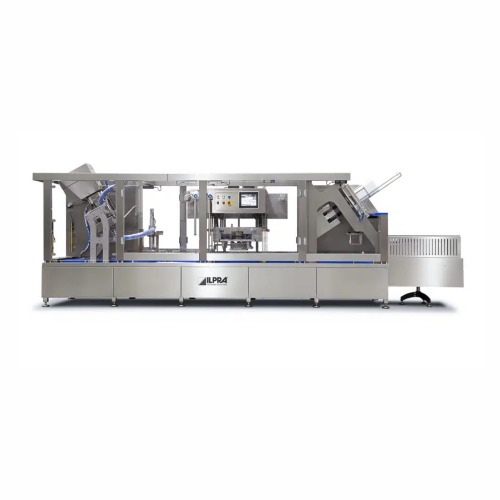

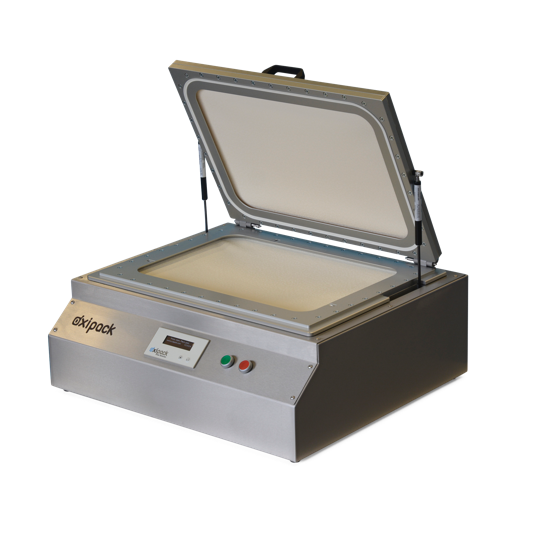

Thermoforming packaging for meat and dairy products

Streamline your packaging process with advanced thermoforming technol...

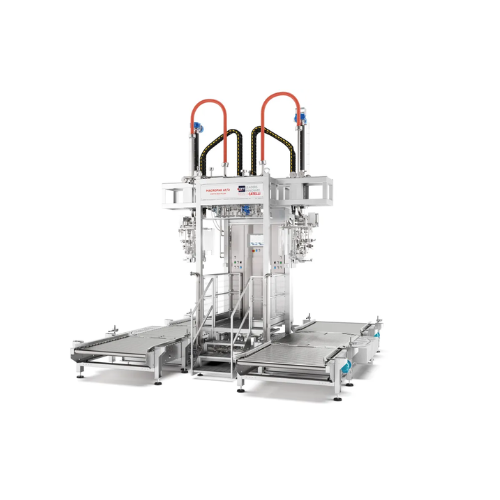

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Dairy evaporator for nutritional formula

Enhance your dairy processing by optimizing energy efficiency and product quality ...

Dairy waste reduction with evaporator product recovery

Transform dairy processing by efficiently recovering valuable low ...

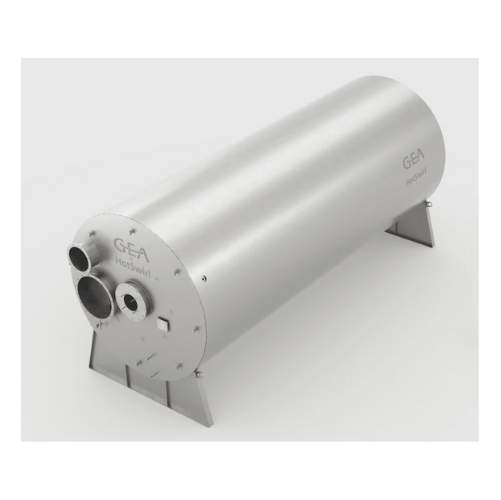

Concentrate heater for dairy spray dryers

Achieve precise temperature control in dairy powder production with a concentrat...

Lecithin adding system for dairy powders

Enhance your spray drying process by seamlessly integrating lecithin to improve so...

Spray dryer for nutritional and dairy powders

Achieve precise particle size and optimal drying of nutritional and dairy po...

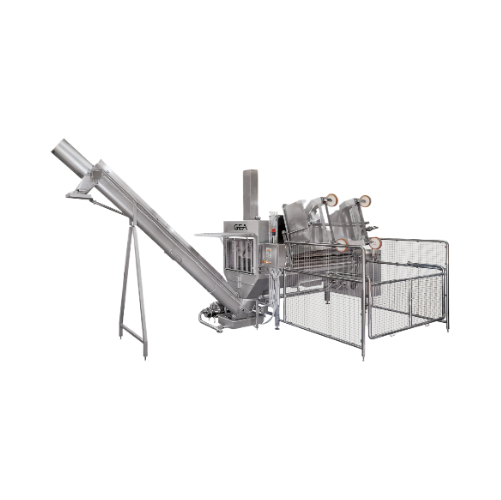

Automated fines return system for food and dairy spray dryers

Enhance your spray drying process by eliminating manual in...

Bag filter for food and dairy spray dryers

Achieve cost-efficient and reliable dedusting for your spray drying processes w...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

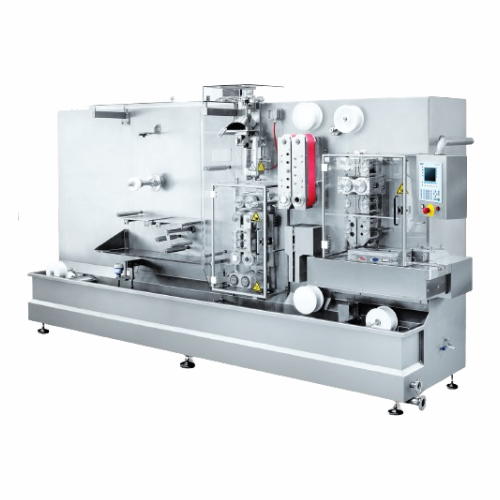

Horizontal stand-up pouching for beverages, dairy, and pet care

Optimize your liquid product packaging with rapid, high-...

Milk reception unit for dairy processing

Ensure precise measurement and streamlined handling of raw milk with an engineered...

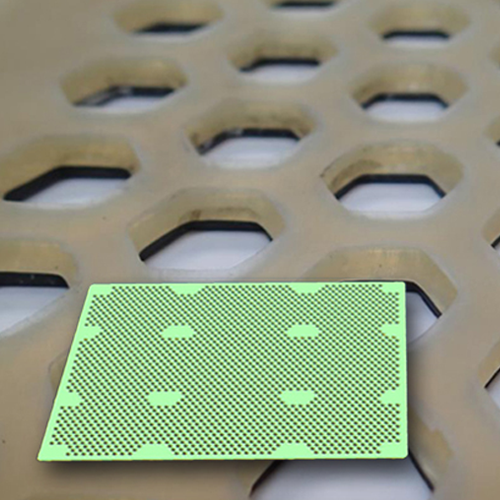

Perforated vat for dairy curd processing

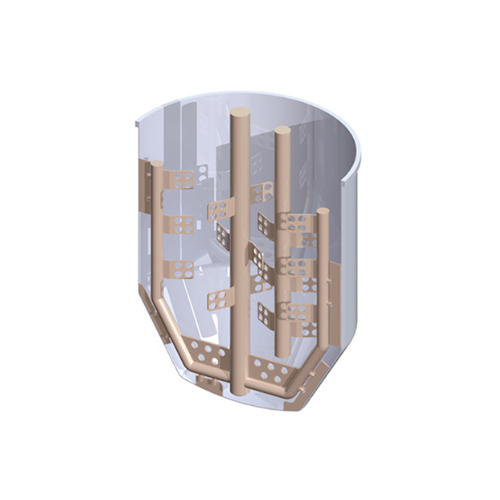

Optimize your curd and cheese production with precision draining and separation, e...

Curd cooking tank for dairy production

Optimize your dairy production with precise temperature control and efficient proces...

Curd cooking vat for dairy production

Optimize dairy production with a curd cooking vat that ensures precise cooking, mixin...

Fermentation vat for dairy products

Optimize your cheese production with a specialized fermentation vat that enhances curd ...

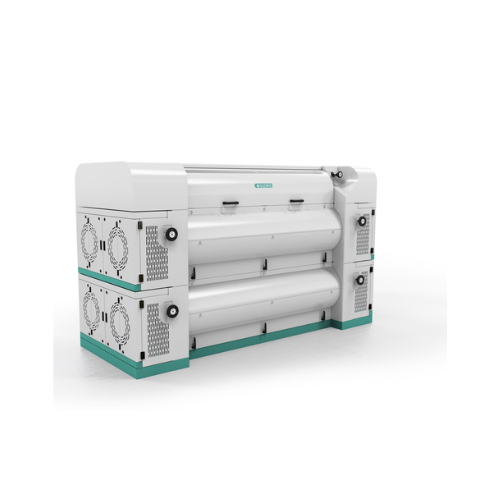

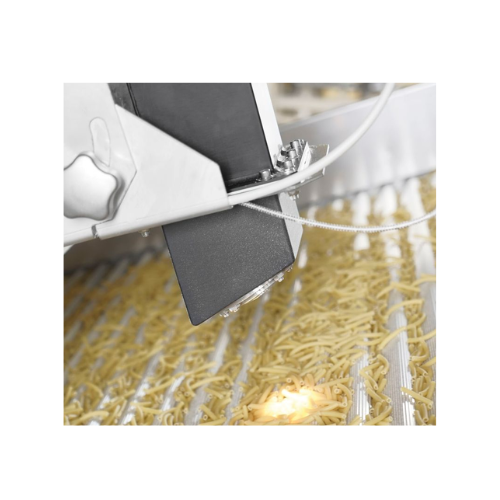

Industrial cheese shredder for dairy processing

Optimize your cheese and potato processing with this advanced shredding so...

Milk vending machines for dairy farmers

Streamline your dairy production with an efficient vending solution, providing farm...

Aseptic filler for fruit juice and dairy products

Ensure sterile, high-speed filling of liquids and creams with precision...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

Indirect Uht treatment for dairy products

Ensure your beverages achieve extended shelf life with consistent quality using ...

Efficient dairy product separator

Achieve precise fat separation and enhance product quality while reducing energy consumpt...

Versatile spray dryer for dairy and plant-based powders

Achieve precise moisture control and optimal powder functionality...

Pasteurizer for dairy products

Enhance food safety and minimize operational costs with a cutting-edge pasteurizer designed f...

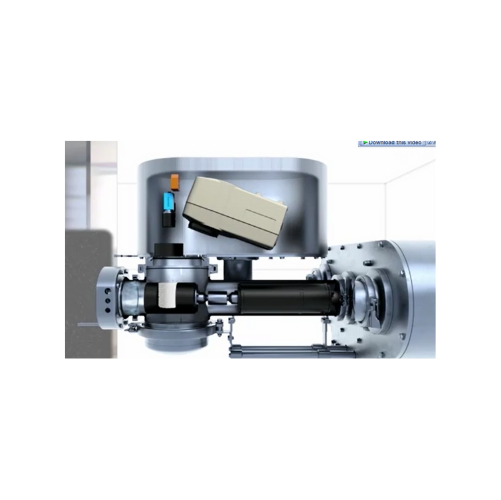

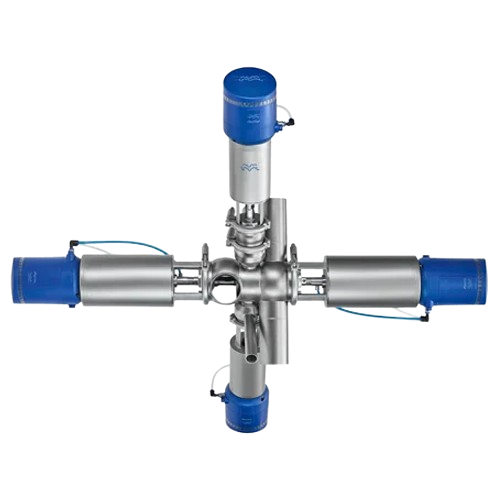

Polynode technology for enhanced dairy separation

Achieve higher separation efficiency and capacity with innovative disc ...

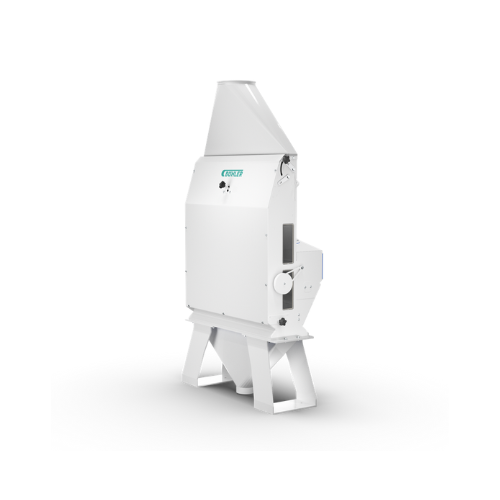

Spore and bacteria removal unit for dairy products

Ensure superior quality by precisely removing spores and bacteria from...

Industrial clarifier for dairy and plant-based products

Optimize your production line with cutting-edge clarification tec...

High shear mixer for dairy and beverage applications

When creating complex formulations like sauces or dairy spreads, ach...

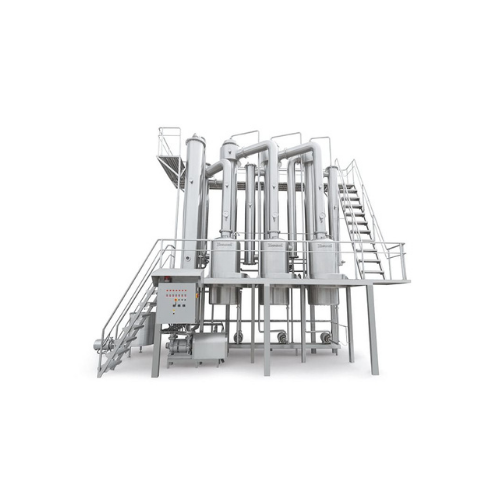

Continuous evaporator for dairy products

Enhance your production efficiency with a fully automatic evaporator designed to m...

Evaporator for dairy products

Need efficient moisture removal in diverse dairy and food applications? This falling film evap...

Fermentation tank for yogurt and fermented dairy products

Ensure perfect fermentation conditions for producing high-qual...

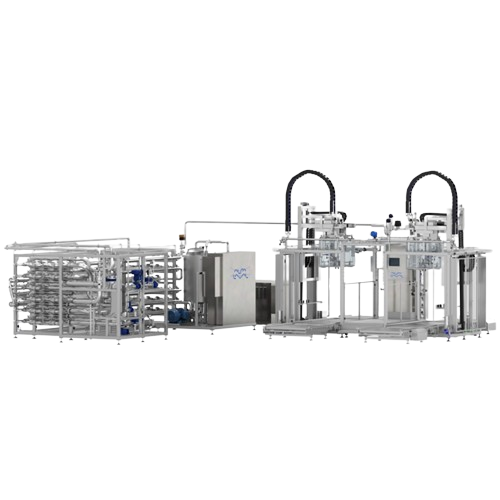

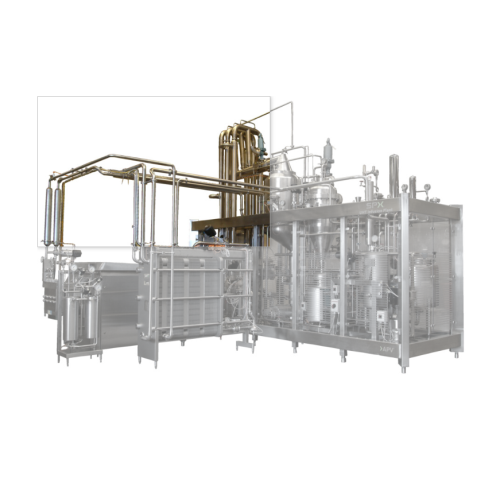

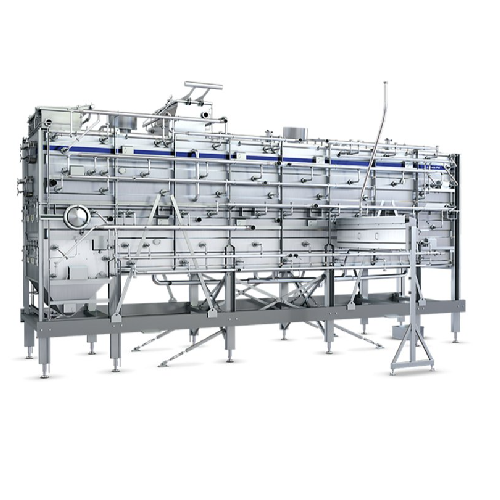

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

In-line blender for dairy products

Streamline your dairy and beverage production with precision ingredient control and redu...

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Uht processing unit for dairy products

Optimize your liquid food production with continuous, high-capacity UHT treatment th...

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high tem...

Dairy pasteurization system for milk, yoghurt, and cream

Ensure reliable dairy processing with an advanced pasteurization...

Spore removal unit for dairy processing

Optimize your dairy production by efficiently removing spores and bacteria, ensurin...

Clarifiers for dairy and plant-based beverages

Ensure optimal product purity and versatility by efficiently removing impur...

Energy-efficient dairy product separator

Achieve up to 40% energy savings in your dairy and beverage processing operations ...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

Dairy pasteurizer

Ensure product safety and quality while reducing energy consumption and operational costs with this advance...

Mid-range capacity homogenizer for dairy and beverage

For operations demanding consistent product quality and high uptime...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Low-energy evaporation system for dairy products

Enhance product quality and lower energy costs with a cutting-edge evapor...

Evaporation system for dairy products

Optimize product quality with continuous evaporation, ensuring efficient moisture rem...

In-line blender for dairy product formulation

Achieve seamless blending and standardization of complex dairy and liquid pr...

Fermentation tank for dairy products

Achieve optimal fermentation conditions for high-quality yoghurt and fermented dairy p...

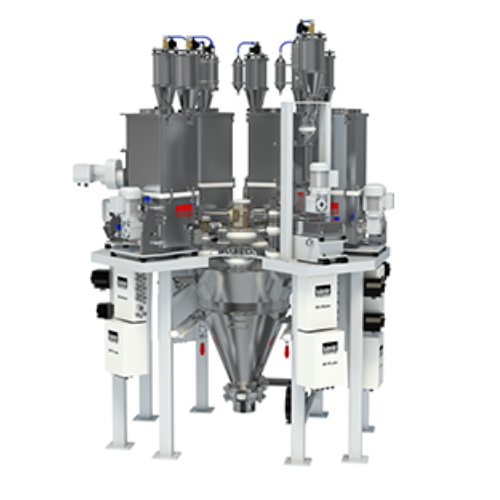

Automated ingredient weigher for dairy production

Optimize your batching process with precise ingredient weight managemen...

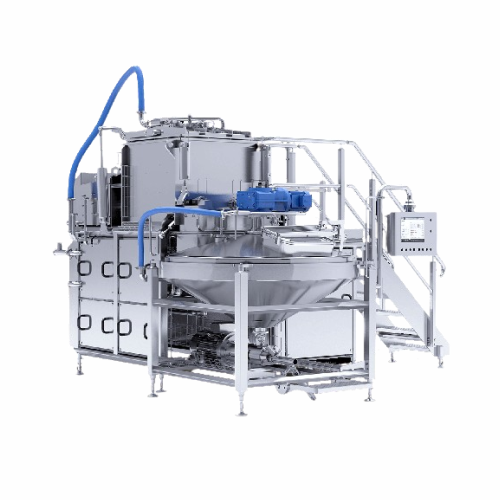

Batch mixing pre-mixers for dairy production

For dairy producers seeking uniform texture and consistency, these batch mixi...

Buffer tanks for dairy processing

Optimize your dairy production with versatile buffer tanks, essential for balancing flow ...

Cleaning in place system for dairy processing plants

Streamline cleaning efficiency and ensure product quality in your da...

Continuous aerator for dairy products

Enhance the texture and flavor of dairy delights with precise gas infusion, transform...

Direct drive centrifuges for dairy and beverage processing

Optimize energy efficiency in high-speed liquid separation wi...

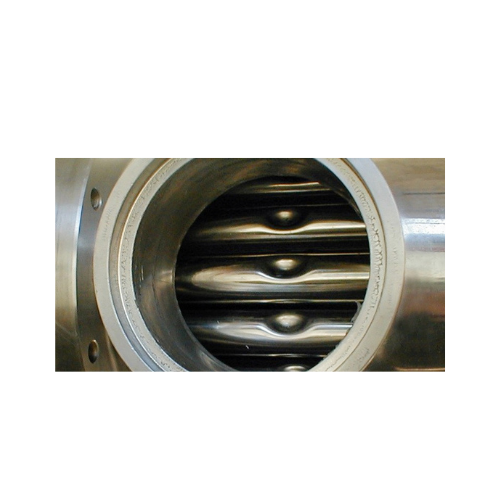

Tubular Uht processing for dairy products

Experience efficient high-pressure thermal processing with tubular UHT technolog...

Ultrafiltration for dairy and plant-based protein concentration

Optimize your production capacity and increase yield wit...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

High pressure homogenizers for dairy and pharmaceutical applications

Optimize your production line with high-pressure h...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

Industrial high pressure homogenizer for dairy and pharmaceutical

Achieve consistent texture and stability in products ...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Reverse osmosis system for dairy and plant-based processing

Enhance your production line with high-pressure reverse osmo...

Uht system for milk and dairy products

Ensure superior product quality and extended shelf-life by utilizing rapid heat trea...

Tubular ultra high temperature processing system for dairy products

Optimize your dairy processing with precise thermal...

Microfiltration system for dairy and plant-based applications

Enhance your production capacity and reduce waste with adv...

Nanofiltration system for dairy and plant-based applications

Enhance your production capacity with nanofiltration, ensur...

Combi ultra high temperature (uht) processing plant for dairy and beverages

Achieve precise heat treatment for diverse...

Infusion Uht plant for dairy products

Achieve precise thermal treatment with minimal product alteration, enhancing quality ...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Versatile food processing solution for dairy and meat products

Optimize your production line with a machine that seamles...

Milk pre-cooling systems for dairy farms

Optimize dairy production with advanced milk pre-cooling systems that significantl...

Instant milk cooling systems for dairy farms

Optimize your dairy operations by instantly cooling milk with systems designe...

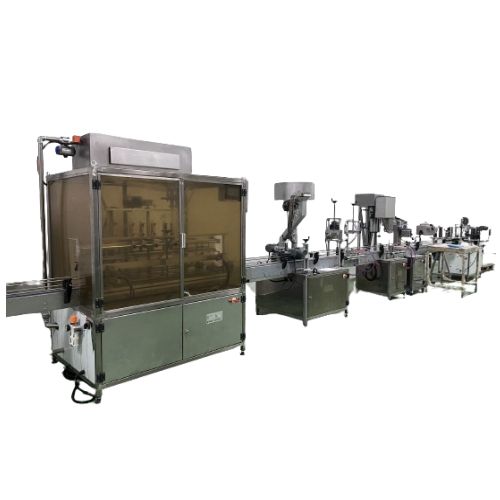

Aseptic filling technology for dairy products

Ensure product integrity and extend shelf life with a high-speed aseptic fil...

Dairy product filling solutions

Optimize your dairy production with advanced filling systems designed to enhance product saf...

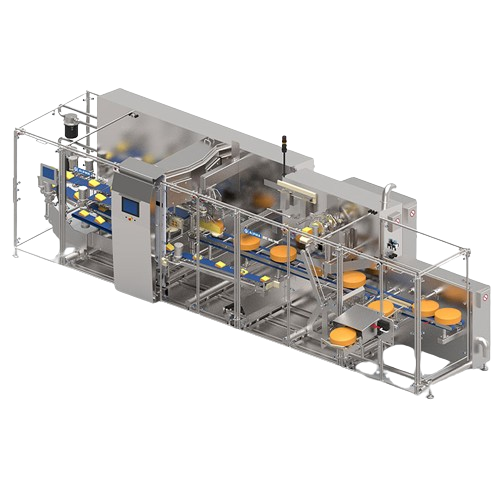

Yoghurt and dairy desserts filling solution

Maximize efficiency in filling and sealing multi-product dairy desserts and be...

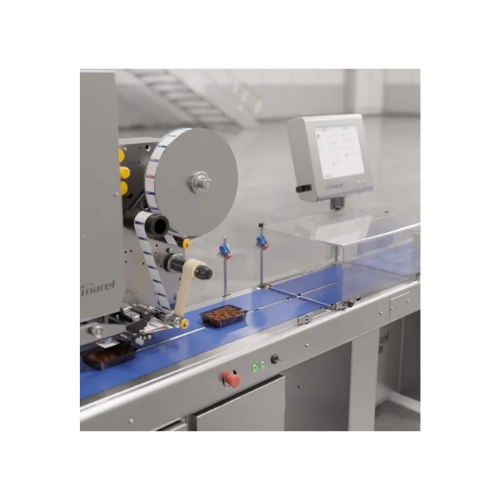

Dairy Equipment Crack Inspection

Dairy producers rely on equipment like spray dryers, silos, and different tanks for the sto...

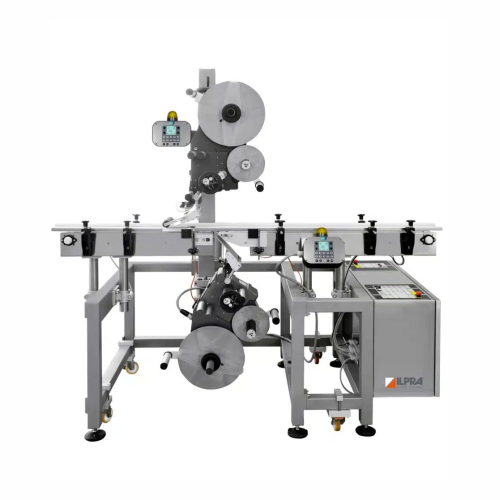

Dairy Packaging Machine

The use of sachets and pouches for powdered or shredded dairy products is an increasingly popular for...

Separator for double cream fresh cheese

Optimize your dairy production with a high-performance centrifugal separator, desig...

Milk and whey skimming centrifuge

Enhance your dairy processing with advanced centrifuge technology, optimizing milk and wh...

Clarifiers for milk, whey, and calcium phosphate

Efficiently separate non-milk solids and impurities from milk, whey, and ...

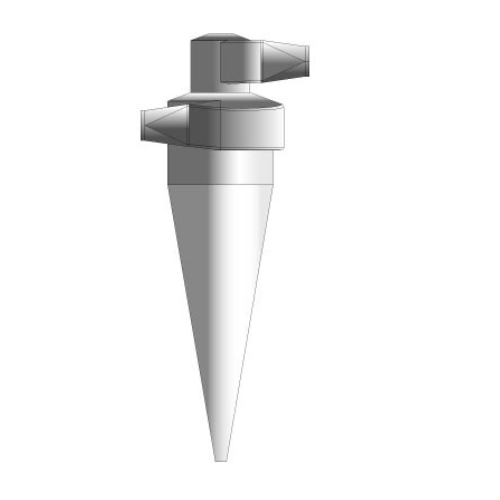

Nozzle separators for strained yoghurt production

Maximize yield and ensure consistency in your dairy production by integ...

Nozzle separators for starch recovery

Optimize your starch recovery process with our nozzle separators—designed to deliver ...

Continuous butter maker for industrial butter production

Streamline your butter production with a system designed for sea...

Continuous butter production system

Efficiently transform cream into versatile butter products, ensuring consistent quality...

Bacteria removal separators for milk and whey

Optimize your dairy production by effectively removing bacteria and spores f...

Clarifier for beverages

Enhance beverage clarity and purity with high-performance centrifugal separation, expertly designed t...

Pilot-scale bioreactor for cell cultivation and fermentation

Scale up your cell cultivation and fermentation processes s...

Cold block piping solution for breweries

Achieve optimal beverage quality and reduce production costs with this advanced pi...

Inline powder analysis system

Ensure optimal powder quality with real-time measurement of moisture, density, and contaminant...

Dual camera system for spray dryer monitoring

Enhance safety and operational efficiency in your drying process by combinin...

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reduc...

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Milk standardization system

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Membrane filtration for whey concentration

Enhance your liquid processing with advanced membrane filtration designed to im...

Cheese forming units for hard and semi-hard cheeses

Optimize your cheese production process with advanced moulding and pr...

Low temperature evaporator for heat-sensitive food products

Efficiently concentrate sensitive liquid products while pres...

Brine purification system for reducing bacteria and molds

Ensure pristine brine quality by continuously removing bacteri...

Clarifier for milk and whey

Optimize dairy and beverage production by efficiently removing fine curd residuals, ensuring hig...

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Pulsed electric field system for food preservation

Enhance your production line with technology that extends shelf life a...

Soya milk production system

Efficiently transform soybeans into high-quality, non-beany soy milk with advanced processing te...

Soya protein isolate production line

Ensure the highest protein purity with this comprehensive production line designed to ...

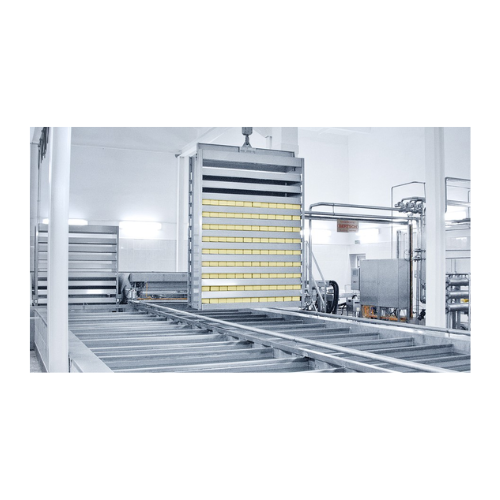

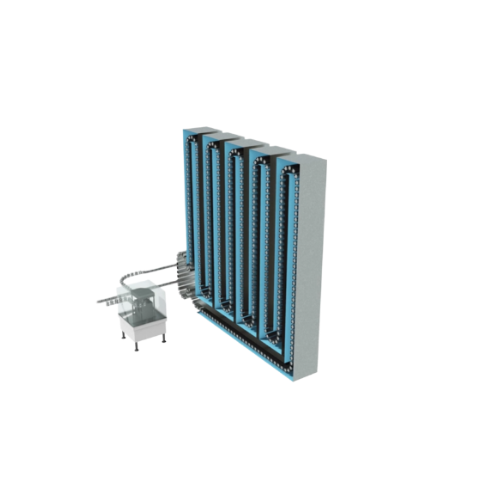

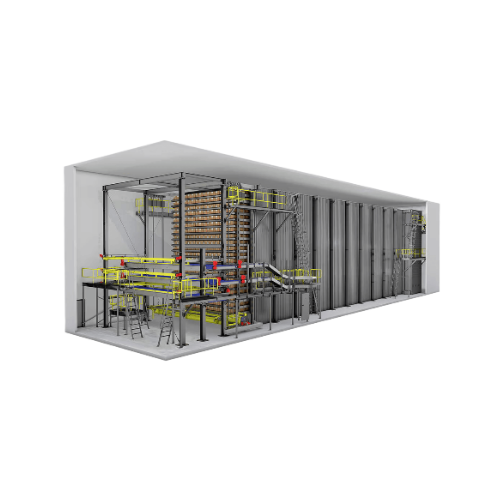

Mechanized systems for hard cheese molding rooms

Optimize your cheese production with advanced systems designed to streaml...

Refrigerated fermentation tank with cold water jacket

Enhance the precision of your cheese production with advanced therm...

Cheese brine immersion salting system

Ensure consistent flavor and quality in cheese production by immersing blocks and whe...

Ultrafiltration system for brine regeneration

Optimize your cheese and brine processes with a versatile ultrafiltration sy...

Whey concentration system with reverse osmosis

Optimize your cheese and dairy production with our reverse osmosis concentr...

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

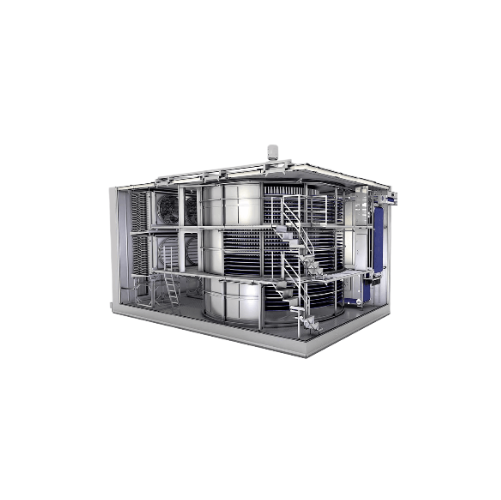

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Condensing unit for ice storage tanks

Enhance the longevity and quality of your dairy and cold storage products with a robu...

Industrial cold storage solutions

Ensure precise temperature control and optimal storage conditions for a diverse range of ...

Milk cream separation system for cheese production

Enhance your cheese production efficiency by seamlessly integrating a ...

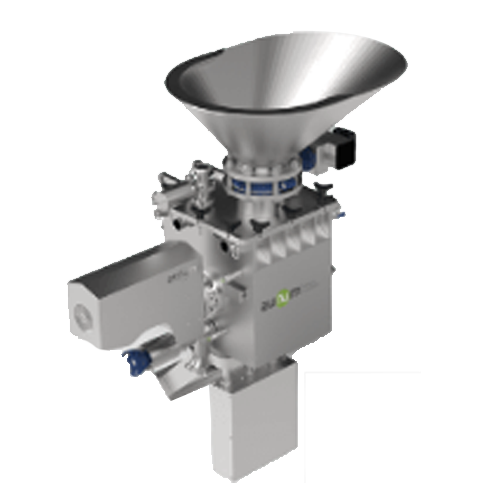

Precise starter culture dosage system for dairies

Ensure precise integration of starter cultures into your cheese product...

Stainless steel milk storage tanks

Optimize dairy operations with versatile tanks designed for precise storage and temperat...

Milk production system for drinking milk

Ensure seamless integration in your dairy production line with this customizable m...

Dynamic salting system for cheese production

Ensure even and efficient salting for soft and semi-hard cheeses with a dynam...

Mechanical ricotta drainage tunnels

Efficiently manage the draining, drying, and cooling of ricotta and curd with our advan...

Ricotta cheese flocculation tank

Optimize your ricotta production with an efficient flocculation tank designed to maximize y...

Multipurpose coagulation vats for cheese production

Streamline your cheese production process with multipurpose coagulati...

Curd drainers and portioners for cheese production

Enhance your cheese production with precise curd draining and portioni...

Stacked block mold tipping solution

Efficiently manage block molds with this tipping solution designed to streamline cheese...

Deodorizing units for milk pasteurization

When handling dairy products, controlling odors during pasteurization is crucial...

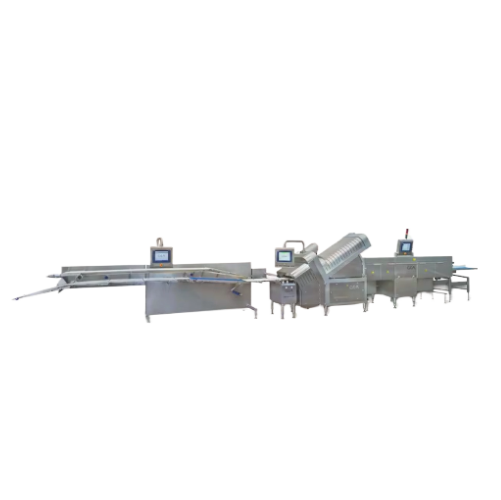

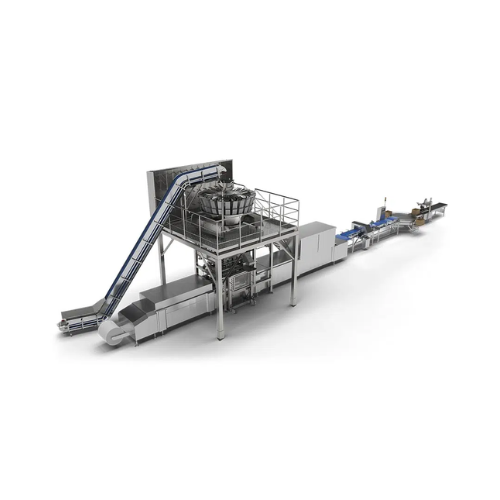

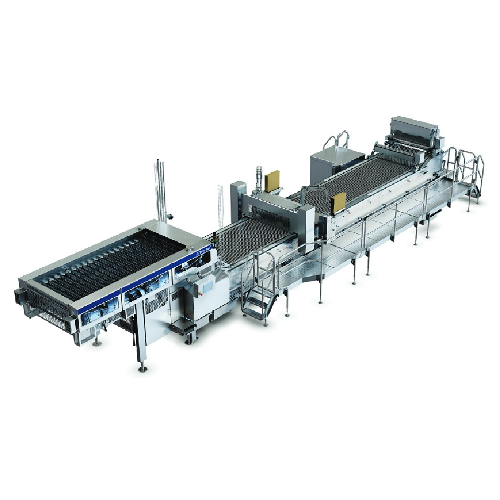

Industrial yogurt production line

Streamline your yogurt production with precise process control to ensure consistent quali...

Pasteurization solutions for liquids with solid pieces

Ensure the integrity of fruit inclusions in beverages and dairy wi...

Food processing blower systems

Optimize your production line with precise air handling and moisture control to ensure qualit...

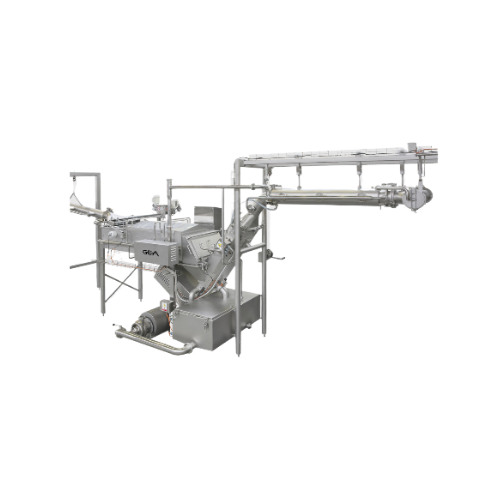

Mechanical conveyors for powder transport

Optimize your powder and granule handling with precise, customizable conveying s...

Magnetic separators for metal contaminant removal in powder processing

Ensure product purity and safety by effectively ...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

Flexible connector system for bulk powder processing

Eliminate leaks and enhance hygiene in your powder processing line w...

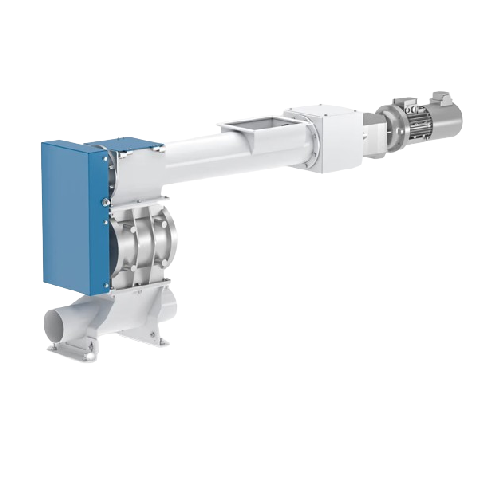

Rotary lobe pump for curds transfer in cheese production

Ensure gentle handling of delicate curds with rotary lobe pumps ...

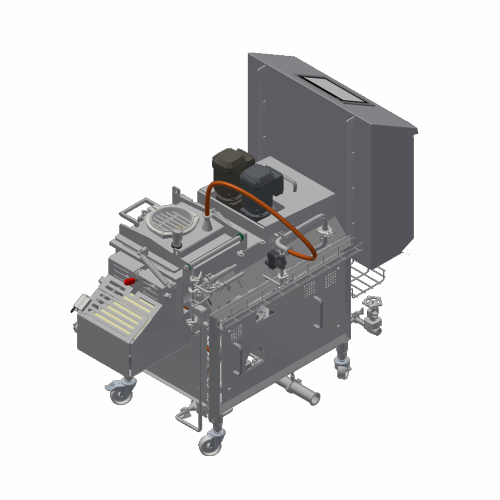

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

Compact cleaning in place units for food industry

Optimize your production line with a compact system designed for effici...

Cleaning-in-place for multiple equipment in food industry

Ensure precise hygiene and traceability with a system designed...

Cleaning and sterilization in place for hygienic control

Ensure maximum hygiene and sterility in your production line wit...

Laboratory homogenizer for viscous products

Achieve ultra-fine textures and improved consistency in pasty and semi-pasty p...

Bottom valve for cheese vats

Enhance your cheese production efficiency with a flush-mounted bottom valve, designed for optim...

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Cip cleaning systems for food and beverage industry

Optimize your cleaning operations with seamless Clean-in-Place and St...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

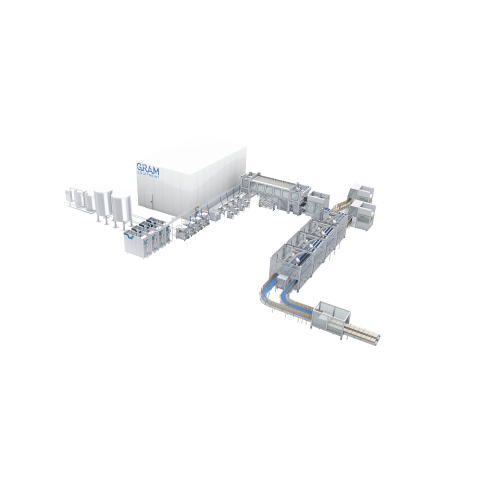

Turnkey food and beverage processing solutions

Optimize your production line with integrated processing systems designed t...

Close proximity cleaning-in-place solution for industrial hygiene

Enhance plant hygiene with a close proximity cleaning...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Clean-in-place system for industrial cleaning needs

Optimize your production efficiency with a system that seamlessly int...

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

Aseptic storage tanks for high efficiency applications

Ensure consistent aseptic storage and efficient handling of variou...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Pig systems for product recovery in food and beverage industry

Maximize yield and minimize waste with advanced PIG syste...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

Automatic bag inserter for various containers

Optimize your packaging process with a high-speed bag inserter that perfectl...

Nanofiltration and reverse osmosis for wine processing

Streamline your beverage production by effectively concentrating l...

Plate flash pasteurizer for wine

Ensure optimal microbial inactivation while maintaining product quality with high-efficienc...

High solids crossflow filter for wine filtration

Optimize filtration efficiency while minimizing operational costs with th...

Vertical leaves pressure filter for wine and viscous liquids

Ensure optimal clarity and consistency in your liquid produ...

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Hygienic buffer tanks for process optimization

Enhance your production flow with hygienic buffer tanks that ensure consist...

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Pilot system for high-viscosity product processing

Efficiently handle high-viscosity or large particle products with this...

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

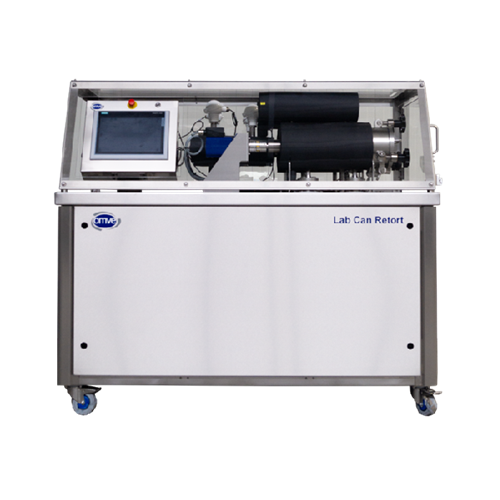

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Cleaning in place unit for lab and pilot equipment

Streamline your lab and pilot-scale cleaning processes with a mobile, ...

Fully automated cleaning in place unit for food processing plants

Enhance food safety and streamline operations with a ...

Continuous ice cream freezer for r&d

Achieve precise control of ice cream texture and consistency with a system that seamle...

Continuous deaeration solution for laboratory and pilot systems

Achieve superior product stability and minimize foaming ...

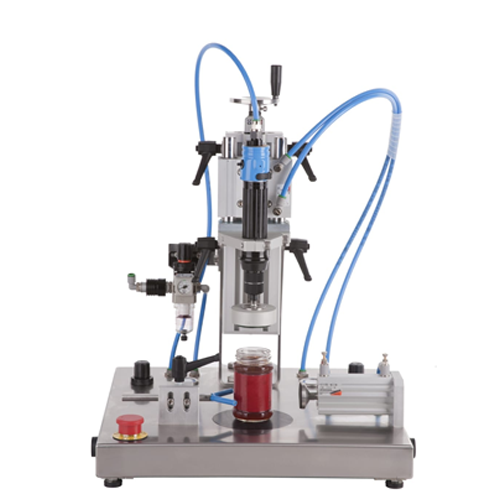

Crown cork sealer for liquid food packaging

Ensure reliable sealing for bottled beverages and dairy with a compact, table-...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Sterile carbonation system for beverages

Achieve precise carbonation for both common and specialty beverages with this vers...

High-speed shrink wrapping for beverage packaging

Optimize end-line packaging with a high-speed solution designed to hand...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Pressurized fermenter for lab-scale fermentation

Achieve precise and controlled fermentation with this advanced pressurize...

Cleaning-in-place (cip) systems for hygienic processing

Elevate hygiene standards in your liquid processing line with an ...

Fermenting tanks for beer production

Optimize your beverage production with advanced fermenting tanks designed to enhance t...

Atmospheric fermenter for lab and pilot scale projects

Streamline your fermentation process with precise control over tem...

Condensed milk preparation system

Enhance the quality of your dairy-based products with a system designed for efficient mix...

Ibc cleaning equipment for hygienic powder handling

Optimize cleaning efficiency and maintain hygiene standards with a ve...

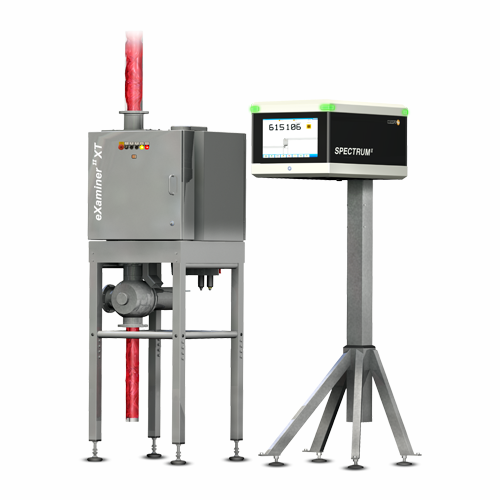

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

High-care food processing combination system with metal detection

Optimize your high-care food environment with a robus...

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

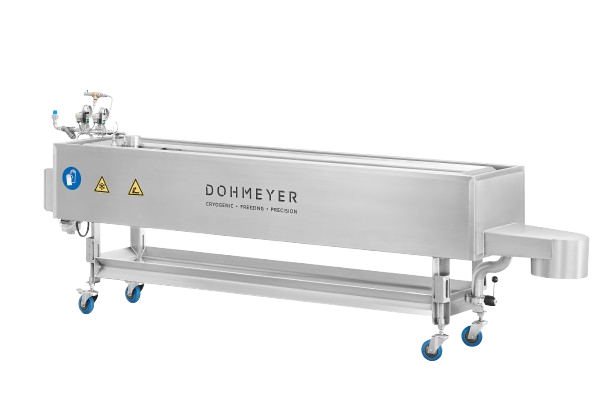

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Cryogenic chilling for meat mixing and blending

Ensure precise temperature control during mixing and blending to prevent b...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Inline mixer for uniform powder blends

Achieve uniform powder blends in minutes with this high shear inline mixer, designed...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Process mixer for food production

Optimize your production line with a versatile and adaptable process mixer that offers se...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Cooling system for vegetables and meat

Optimize cooling efficiency with dual counterrotating agitators and expansive surfac...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Cylindrical buffer tank for processing lightly liquid products

Optimize production continuity with this cylindrical buff...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Ultra high temperature treatment for small-scale production

Achieve extended shelf life and uniform product quality with...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

Uht system for aseptic filling of beverages

Ensure microbiological safety and retain natural flavors in your liquid produc...

Uht system for milk products

Achieve optimal product safety and quality for dairy and plant-based beverages with precise UHT...

Sterile tank system for aseptic processing

Optimize your production with aseptic tank systems that ensure sterile storage ...

Dense phase vacuum conveying for fragile powders

Efficiently convey fragile powders without compromising their integrity, ...

Hollow fiber membranes for clarification in food and beverage industry

Optimize filtration and separation processes wit...

25kg automatic dry powder packaging system

Optimize your packaging line efficiency with precise, high-speed handling for 2...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

Sanitary bulk bag filling system

Streamline your powder handling process with a system designed to improve stability and acc...

Bulk bag filler with integrated palletizing system

Optimize your powder packaging with a seamless system that fills and a...

Sanitary bulk bag unloader for powdered products

Efficiently manage powder discharge with enhanced dust control and stream...

Dense phase pressure conveying system for fragile powders

Ensure gentle handling and long-distance transport of fragile ...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Advanced hollow fiber membrane for wastewater treatment

Tackle high solid challenges in water treatment with robust ultra...

Mbr module for wastewater treatment

Optimize your wastewater management with efficient membrane bioreactors, designed to en...

Lactose drying system for high-quality edible powder

Achieve precise and cost-effective lactose transformation into high-...

Milk drying system

Optimize your dairy production by efficiently transforming liquid inputs into high-quality, dry powders, e...

Sweetened condensed milk production system

Achieve precise concentration and crystallization for sweetened condensed milk,...

Timing belt drying system for whey and permeate powders

Ensure high-quality production of free-flowing and non-caking whe...

Compact drying solution for regular skim and Wpc powders

Streamline your drying process with a compact solution that effi...

Cheese belt for continuous production

Enhance your cheese production with a fully enclosed, adjustable belt system designed...

Curd coagulation detection system

Ensure precise coagulation timing with a system that monitors curd firmness, enhancing yi...

Cottage cheese vat for efficient curds production

Maximize cheese yield while minimizing curd damage with this advanced v...

Curd table for cheese production

Streamline cheese production with effective curd separation, precise salt mixing, and relia...

Lactose crystallizing evaporator

Optimize lactose yield and crystal size control in continuous processing, enhancing product...

Milk product evaporator for high solids concentration

Efficiently concentrate milk products to high solids, optimizing pr...

Cheese vat for consistent curd size and low whey fats

Improve your cheese production with equipment designed for uniform ...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Big bag unloading station for solids handling

Optimize bulk solid ingredient handling with this station, designed to strea...

Micro ingredients loading station for solid additives

Optimize precision dosing and ensure smooth transfer of powdered in...

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Industrial sheet filter for liquid filtration

Optimize your liquid product purity with precise filtration, maintaining int...

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuri...

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

Blender for high viscosity products

When handling thick mixtures that challenge conventional systems, this specialized blen...

Automated Cip system for small facilities

Ensure impeccable hygiene with a mobile cleaning system designed to efficiently ...

Manual Cip system for food processing hygiene

Designed for small-scale hygiene needs, this mobile clean-in-place system en...

Entry-level flow wrapping machine for small and medium products

Optimize your packaging line with a high-speed flow wrap...

Tray packing for square and rectangular cheese portions

Optimize your cheese packaging line with high-speed tray forming ...

Cartoning system for triangular cheese portions

Streamline your cheese packaging process with precision-oriented cartoning...

Semi-automatic tray packing for soup cubes

Effortlessly package soup cubes into organized, stratified layers, optimizing y...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrappin...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Cheese portioning dosing and wrapping solution

Effortlessly streamline cheese portioning with high-speed dosing and wrappi...

High speed cheese dosing and wrapping solution

Achieve precise dosing and efficient wrapping of cheese portions with versa...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Stand-up pouch making system

Efficiently transform pre-printed reels into customizable stand-up pouches with precise unwindi...

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

Filling and wrapping system for pasty products

Achieve precise dosing and flexible wrapping of diverse pasty products, ens...

High-speed dosing and wrapping for butter and margarine

Achieve precision in butter and margarine packaging with a high-s...

Filling and sealing pre-formed cups solution

Ensure ultra-clean and aseptic processing for pre-formed cups with a fully en...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Form fill and seal solution for liquid and pasty products

Enhance your production efficiency with high-speed forming, fi...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

Butter portion dosing and wrapping system

Efficiently manage butter portion packaging with a compact system designed for p...

Forming, filling and sealing solution for cups

Maximize production efficiency and flexibility with a high-output machine d...

Flow wrapping system for hygienic food packaging

Enhance your packaging line with a modular flow wrapping solution that en...

Filling and sealing system for yoghurts and desserts

Efficiently fill and seal a variety of dairy and dessert products wh...

Rotary filling and sealing system for pasty products

Efficiently streamline your cup and tub packaging process with a ver...

Tub filling and sealing for pasty products

Experience high-speed, precision tub filling and sealing designed for pasty pro...

Cartoning solutions for processed cheese products

Optimize your cheese production line with a cartoning solution that ens...

Flow wrapper for processed meat and cheese

Optimize wrapping efficiency and hygiene in your meat and cheese packaging line...

Top loading case packer for loose or bundled bottles

Effortlessly handle and pack both standard and uniquely shaped bottl...

Cartoning solution for cheese portions

Optimize your cheese packaging with a flexible cartoning solution designed to accomm...

Wrap-around cartoning solution for butter and yeast

Optimize your packaging line with a high-speed cartoning system that ...

Wrap-around cartoner for processed cheese portions

Streamline your cheese packaging with high-speed wrap-around cartoning...

Cup forming, filling, and sealing solution

Optimize your cup production with a compact solution designed for precise formi...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

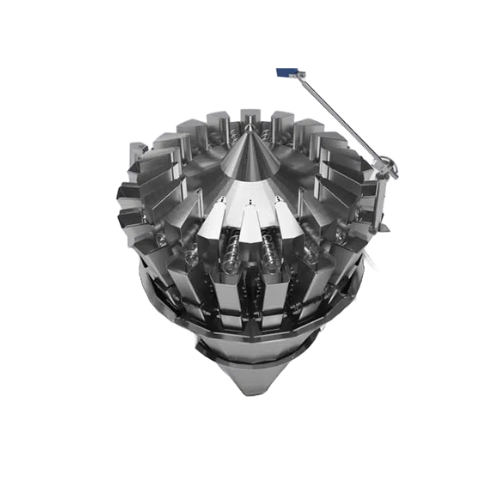

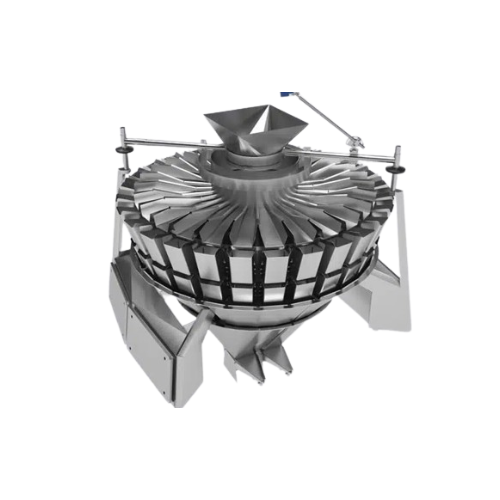

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Entry-level in-line traysealer for ready-to-eat meals

Streamline your ready meal packaging with a compact traysealer that...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

R&d scale steam cooker for small batch processing

Optimize your R&D with a steam cooker that replicates large-scale ...

Mozzarella cooker stretcher for continuous production

Experience continuous mozzarella production with steam injection te...

Pilot unit for processed cheese slices

Perfect for R&D and small-scale production, this adaptable unit offers high fle...

Processed cheese slice production system

Reduce recontamination risks in cheese production with a system designed for high-...

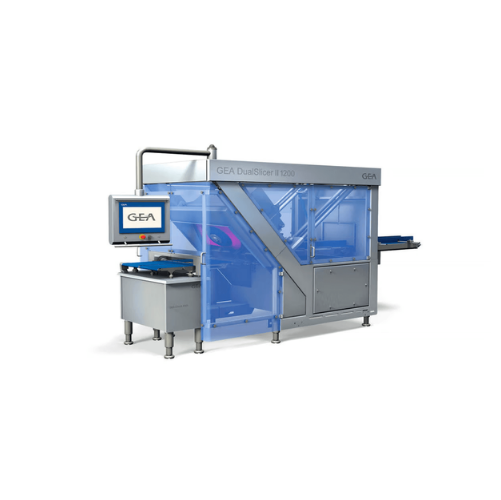

Cheese forming and slicing system

Optimize your cheese production with high-speed, precision forming and slicing, ensuring ...

Individually wrapped processed cheese slice production line

Efficiently produce consistent, individually-wrapped cheese ...

Separating packed cheese products from packaging

Efficiently separate individual cheese portions from packaging, reducing ...

Cheese packaging system for mixed cheese types

Optimize your cheese production line by seamlessly integrating a system des...

Processed cheese slice forming system

Effortlessly produce high-quality Slice-on-Slice cheese slices, cubes, shreds, and st...

Multifunctional batch processing system for processed cheese

Enhance your production line with a sophisticated batch pro...

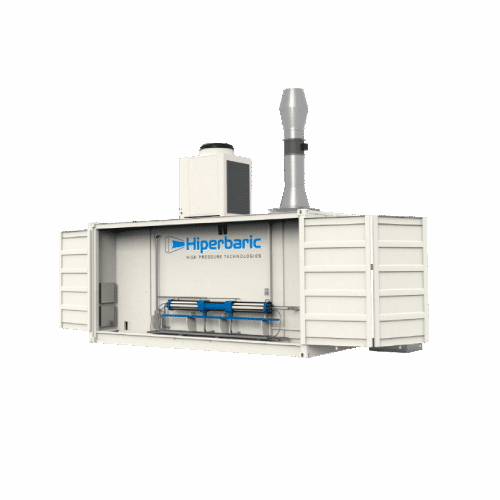

Hpp system for small-scale food production

Enhance food safety and prolong shelf life with this compact high pressure proc...

Cheese grinder for fine cheese grinding

Achieve optimal protein emulsification and minimize waste with this high-capacity g...

Beer production filtration system

Enhance your beverage production with cutting-edge filtration systems designed to maintai...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...

Fruit and vegetable juice filtration

Ensure superior clarity and purity in your juice production with advanced filtration s...

Self-cleaning automatic filters for industrial liquids

Ensure reliable filtration of high-contamination liquids while min...

Stainless cartridge filters for industrial applications

Achieve precise fine filtration and maximize efficiency in liquid...

Automatic sausage filling and hanging system

Streamline sausage production with precise portioning and seamless integratio...

Automated sausage filling and portioning line

Boost your production efficiency with a versatile solution that seamlessly h...

Industrial grinder for ultra-fine grinding and homogenizing

Enhance your production line with versatile grinding technol...

High-capacity industrial grinder for frozen and fresh raw materials

Effortlessly grind both deep-frozen blocks and fres...

Industrial mixer for food and pet food production

Achieve precise and efficient mixing of viscous to highly viscous produ...

Sausage filling and portioning line

Streamline your sausage production with versatile equipment designed to seamlessly inte...

Vacuum filler for medium-scale sausage production

Achieve precise portion control and optimal hygiene with a versatile fi...

Vacuum filler for sausage and ham production

Achieve precision in filling and portioning pasty and fluid products with a s...

Industrial sausage and ham vacuum filler

Achieve unmatched precision in filling and portioning with high-capacity vacuum te...

Multi-lane forming system for 3d food product shapes

Achieve precise weight accuracy and high-speed production of diverse...

Forming system for multi-lane production of shaped foods

Streamline your production of uniform shaped foods with a multi-...

Industrial forming and cutting system for diverse products

Maximize product versatility with a system that effortlessly ...

High-precision depositing system for fluid and viscous fillings

Achieve precise and efficient dosing for diverse food pr...

Depositing system for multi-lane dosing with vertical traversing

Achieve precision dosing and flexible portioning with t...

Cutting valve for chunky food portioning

Achieve precise portioning of chunky products, reducing waste and increasing effic...

Automatic multi-lane dosing system for fluid to pasty products

Streamline your production with precise multi-lane dosing...

High vacuum filler for dry sausage products

Achieve pore-free, compact dry sausage products with superior evacuation perfo...

High vacuum filler for large-calibre sausages

Achieve pore-free, high-quality products with optimal portioning accuracy an...

High vacuum filler for ham and ground material

Achieve unrivaled product quality and precision with high vacuum technology...

Vacuum filler for small and medium-scale meat producers

Achieve precise portioning with high-speed filling and grinding c...

Tying solution for sausage products in natural and collagen casings

Efficiently portion and tie sausage products to per...

Open milk cooler with 2,000 liters capacity

Ensure optimal milk quality and temperature with this open milk cooler, design...

Vertical milk cooler for large-scale farms

Optimize your milk preservation with this space-efficient vertical cooler, desi...

Semi-automatic cheese portioning solution

Enhance your cheese processing capabilities with a versatile portioning solution...

Automatic foil unpacking system for cheese

Streamline your cheese production with cutting-edge technology designed to repl...

Double cheese shredder for soft, semi-hard and hard cheeses

Optimize your cheese production with a robust shredding solu...

Mixing drum for shredded cheese

Optimize your dairy production line with this innovative mixing drum designed to effortlessl...

Cheese shredding line for large volume production

Achieve seamless cheese processing with a fully integrated shredding li...

Square and rectangular cheese cutter for bars and halves

Perfect for cheese processors needing precision, this machine ef...

Automatic cheese slicer feeder

Optimize your cheese processing line with a fully automatic solution designed to streamline s...

Fully automatic slicer feeder for cheese bars

Enhance your cheese processing efficiency with high-speed slicing and sortin...

Automatic slicer feeder for large cheeses

Streamline your cheese processing with a system designed to seamlessly transform...

Cheese portion cutter

With ultrasonic precision, this semi-automatic cutter transforms cheese blocks into uniform portions an...

Cheese portion cutting solution

Achieve precise weight-based portions for cheese products, enhancing product consistency and...

Cheese shape cutter for animal, letter, and custom designs

Transform cheese slabs into creative shapes with precision, e...

Cheese snack cutter for various shapes and sizes

Streamline your cheese production with precision cutting for a variety of...

Automatic cheese derinding system for rectangular cheeses

For cheese processors seeking effortless precision, this machi...

Automated in-line ice cream filling system

Enhance your ice cream production with precision filling, offering high-speed c...

Continuous ice cream freezer

Enhance the consistency and texture of frozen desserts with this self-contained solution, strea...

Cheese shredding solution for soft, semi-hard, and hard cheeses

Maximize cheese processing efficiency with precise shred...

Automatic solution for unpacking foil-ripened cheese

Streamline your cheese processing with this fully automated solution...

Automated cheese unpacking and cutting line

Streamline your cheese production process with a fully automated system capabl...

Juice storage tank with hygienic and cooling options

Ensure optimal freshness and stability of juices and beverages with ...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

High-speed ice cream extrusion line

Achieve precise shapes and textures in your frozen treats with advanced extrusion solut...

Extruded ice cream with large inclusions

Streamline your ice cream production with an innovative extrusion solution, allowi...

High-precision volumetric feeder for bulk materials

Achieve precise bulk material flow with a solution that ensures consi...

Contact detection system for rotary valves

Prevent product contamination and equipment damage with instant contact detecti...

Quick-clean hygienic rotary valves

Ensure seamless cleaning and minimal downtime in your production line with rotary valves...

Cheese portion thermoforming system for automation

Optimize your cheese production with precision portioning and efficien...

Cheese cutting machine for various cheese types

Optimize your cheese and meat processing line with high-speed, precise cut...

Wedge aligning robot for hard cheese

Streamline your cheese processing with precision and efficiency; this solution expertl...

Plate sterilizer for low fiber content liquids and juices

Efficiently sterilize and prepare low-consistency liquids with...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Aseptic filler for bag-in-box packaging

Achieve unparalleled product safety and quality in liquid packaging with our advanc...

Aseptic filling system for bag-in-box packaging

Efficiently fill a range of liquid products into pre-sterilized bags while...

Aseptic treatment and filling for concentrates and purees

Optimize your processing line with a compact solution that com...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

Aseptic filler for liquids and semi-concentrates

Ensure maximum sterility and precision when filling liquids, concentrates...

Cheese dicer for precision cuts

Streamline your cheese processing with unparalleled precision and versatility, ensuring clea...

High-capacity cheese dicer with sanitary design

For high-volume cheese producers, achieving consistent cube cuts without p...

High-capacity shredder for cheese processing

Achieve impeccable cut accuracy and consistent shred dimensions for high-volu...

Cheese shredder for high-volume applications

Streamline your cheese processing with a high-capacity shredder designed to d...

Full block cheese shredder

Maximize your production line’s efficiency with a versatile shredder that seamlessly proces...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Modular pulsed electric field system for food processing

Enhance your food processing efficiency with a modular system th...

Fruit processing system for jams and marmalades

Optimize your fruit-based product manufacturing with equipment designed fo...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Calibratable big bag filling station for dust-free operations

Ensure precise, dust-free filling of bulk bags with ergono...

Drum and container emptying system

Ensure safety and efficiency when handling and emptying drums or containers, whether dea...

Lactose pneumatic conveying solution

Eliminate frequent production halts due to lactose buildup with our conveying solution...

Bag-in-box filling system for packaging efficiency

Streamline your packaging process by integrating filling and boxing in...

Fully automatic continuous flow wine press

For winemakers seeking to optimize operations, this advanced pneumatic pressing...

Temperature control systems for winemaking

Achieve precise temperature regulation in fermentation and storage processes wi...

Gravity filling systems for still beverages

Ensure precise and clean filling for still beverages with gravity systems that...

Rotary container rinser

Ensure your bottles are thoroughly clean and sterile before filling, enhancing product safety and she...

Continuous sugar dissolving system for beverage production

Effortlessly transform granulated sugar into a consistent, hi...

Solution blenders for chunk-containing beverages

Maintain the integrity and consistency of chunk-filled beverages without ...

Stabilizer dissolution system for beverage industry

Efficiently dissolve and homogenize stabilizers like pectin or CMC in...

Press-on capping system for bottles

Ensure precise and secure closure of various bottle types with our versatile press-on c...

Automated Cip systems for beverage and food industry

Ensure high hygiene standards in your production line with advanced ...

Medium-low density food cooker

Streamline your cooking process for medium-low density foods with precision-controlled mixing...

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Vacuum high shear mixer for medium to high viscosity products

Achieve flawless blending and air-free consistency in visc...

Single station modified atmosphere packaging system

Ensure the extended shelf life of sensitive foods with precise gas fl...

High-capacity manual mixer for industrial applications

Optimize your mixing process with a highly efficient, manually ope...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Dense-phase powder conveying system

Optimize your powder processing with a system designed to handle abrasive and fragile m...

Low temperature freeze dryer for high sugar or acid content products

Perfect for producing freeze-dried goods from food...

Single-station Map packaging system for bulk products

For food packaging facilities that need reliable sealing through co...

Inclined screw loader for food processing

Optimize your food processing line with an inclined screw loader, designed for e...

Pallet lift for food processing handling

Enhance your food processing efficiency with a robust pallet lift designed for sea...

Pilot plant system for margarine and bakery fats production

Streamline your development and testing of diverse spreads a...

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Precision size grader for tomatoes and round fruits

Ensure precise grading and sorting of tomatoes and round fruits to op...

Sterilizers and pasteurizers for industrial food processing

Optimize thermal processing for viscous foods and beverages ...

Energy efficient tomato evaporator

Achieve up to 98% steam savings in your evaporation process while ensuring minimal CO2 e...

Piston pump continuous ice cream freezer

Optimize your ice cream production with a continuous freezing solution that seamle...

Industrial ice cream continuous freezer

Ensure precise temperature control and product consistency in ice cream manufacturi...

Batch mix preparation system for ice cream

Optimize your ice cream production with an efficient system designed for precis...

200l buffer tank for bag-in-box fillers

Ensure precise filling and consistent flow control with this stainless steel buffer...

Bag-in-box fully automatic filling line

Streamline your liquid packaging operations with a modular system designed to enhan...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

Vacuum filler for glass jars and cans

Ensure precise filling and equal headspace for your products with this vacuum filler,...

High-speed weighing system for large batch sizes

Maximize yield and minimize waste with a high-speed batching solution des...

Multihead weigher for sticky products

Efficiently tackle the challenge of weighing extremely sticky products like mixed sal...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

Weighing optimization with sensorfeed