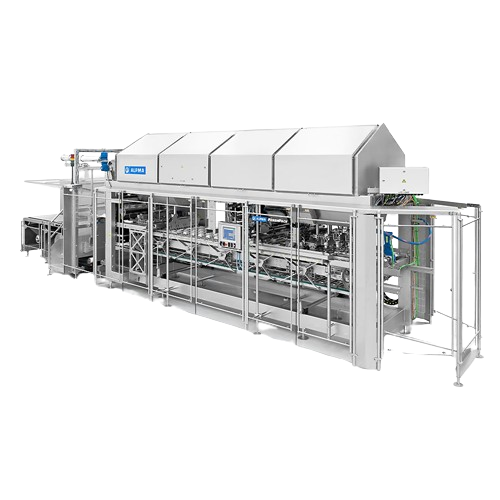

Fully automatic packaging solution for butter and pasty products

Streamline your production line with this versatile packaging solution, ideal for efficiently forming, sealing, and folding butter, cheese, and other pasty products into perfectly sealed foil cups with tamper-proof closures.

Forms, Folds, Seals, and Packs Foil Cups

The FreshPack from ALPMA Alpenland Maschinenbau GmbH is a state-of-the-art packaging machine that uniquely combines folding, forming, and sealing for a variety of food and dairy applications. It stands out for its fully automatic operation, forming foil cups from roll-fed material, and handles products like butter portions, cream cheese, and pâté with precision. Capable of producing up to 250 packages per minute, the FreshPack ensures product integrity with tamper-proof closures and aroma seals, facilitating easy opening for end-users. Its high-speed, continuous operation is ideal for dairy producers and food manufacturers seeking efficient packaging solutions. The equipment integrates seamlessly into existing production lines, featuring advanced PLC control for streamlined operations and minimal energy consumption. Constructed from robust materials, the FreshPack upholds hygiene standards and supports CIP systems, ensuring efficient cleaning and compliance with food safety regulations. Customization options and engineering support are available to tailor the system to specific production requirements.

Benefits

- Enhances operational efficiency by producing up to 250 packages per minute.

- Maintains product freshness with tamper-proof closures and aroma sealing.

- Integrates seamlessly into production lines with advanced PLC controls for monitoring and automation.

- Minimizes energy consumption through optimized motor performance.

- Simplifies maintenance with CIP-compatible design, ensuring compliance with hygiene standards.

- Applications

- Snacks, Pasty products, Cream cheese, Soft cheese, Butter, Mixed fat products

- End products

- Herb-infused cream cheese, Cream cheese portions, Foil-packed butter segments, Pâté, Snack cheese cubes, Butter portions, Margarine, Processed cheese slices, Spreadable cheese

- Steps before

- Mixing, Blending, Homogenization

- Steps after

- Sealing, Folding, Outfeed Conveying, Quality Control

- Input ingredients

- butter, mixed fat, cream cheese, pasty products

- Output ingredients

- foil-wrapped butter, foil-wrapped mixed fat, foil-wrapped cream cheese, foil-wrapped pasty products

- Market info

- ALPMA Alpenland Maschinenbau is known for specializing in manufacturing cutting-edge machinery and processing equipment for the cheese and dairy industry, holding a strong reputation for innovation, quality, and highly engineered-to-order solutions globally.

- Speed

- up to 250 packages/min

- Automation

- Fully automatic

- Sealing

- Tamper-proof closure, aroma seal

- Folding Concept

- Innovative folding concept

- Packaging Material

- Foil from roll

- Product Compatibility

- Soft, pasty-like products

- Output Rate

- Up to 250 packs/min

- Automation level

- Fully Automatic

- Batch vs. continuous operation

- Continuous

- Packing speed

- Up to 250 packs/min

- Folding concept

- Innovative folding

- Sealing method

- All-around seal

- Closure type

- Tamper-proof closure

- Aroma seal

- Yes

- Easy opening

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed method

- From the roll

- Discharge method

- Outfeed conveyor

- Packaging custom size

- Available for different product types (butter, mixed fat, cream cheese)

- Folding concept

- Innovative folding for soft, pasty-like products

- Sealing capability

- All-around sealing with tamper-proof closure

- Automation level

- Fully automatic operation

- Integration with production line

- Compatible with existing conveyor systems

- Control system

- PLC/HMI included

- Aroma seal option

- Easy opening with aroma seal