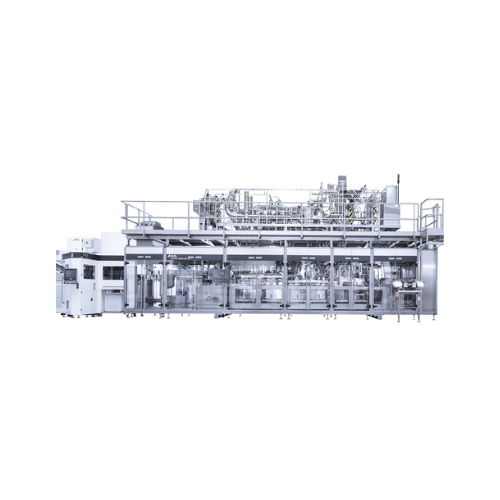

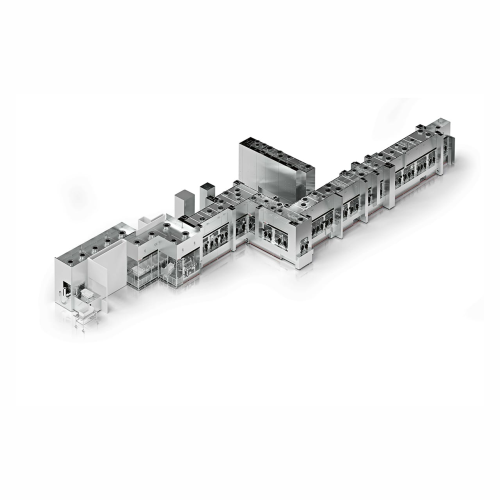

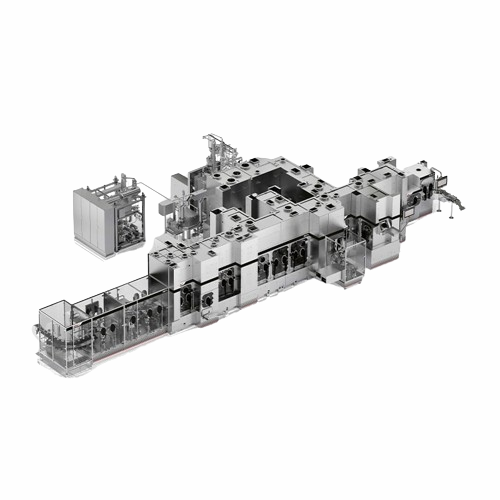

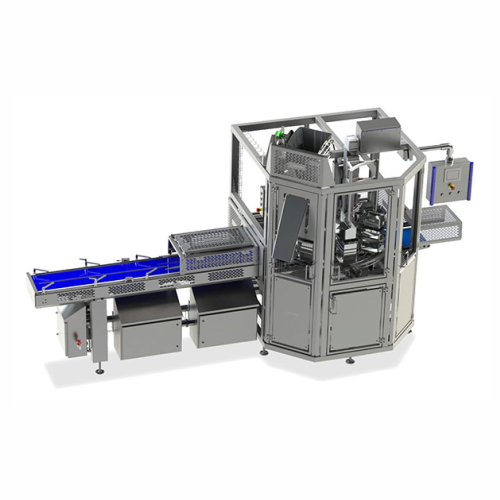

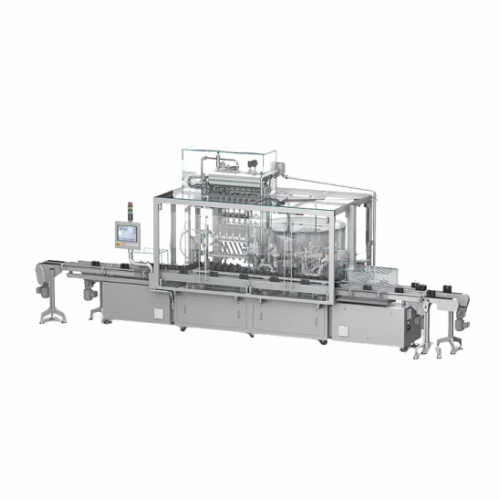

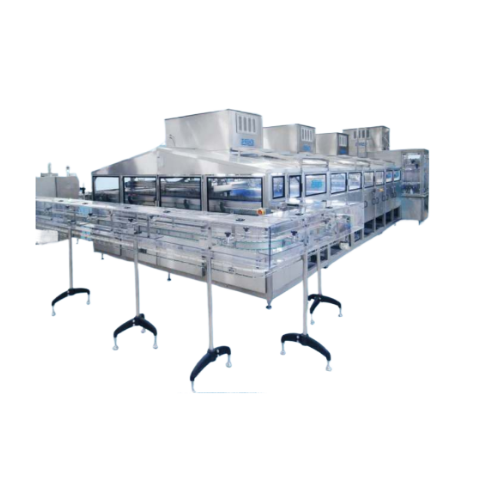

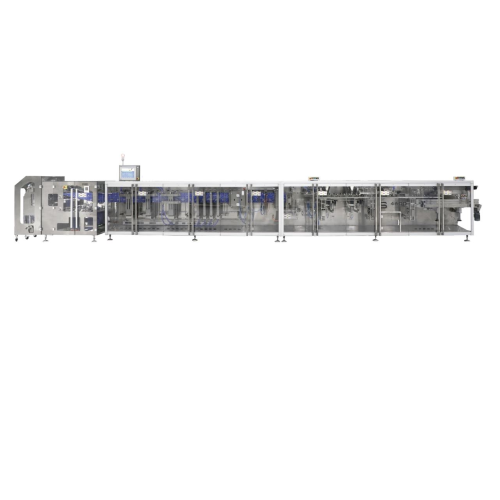

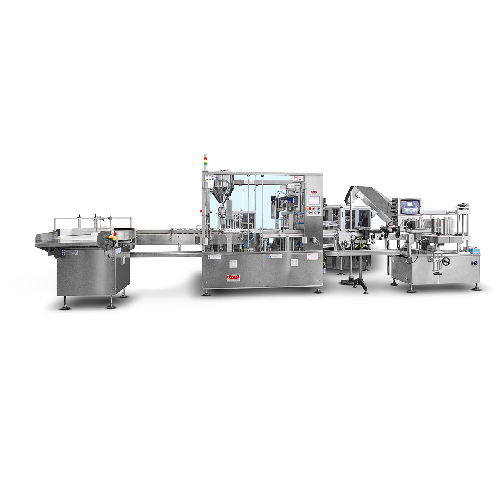

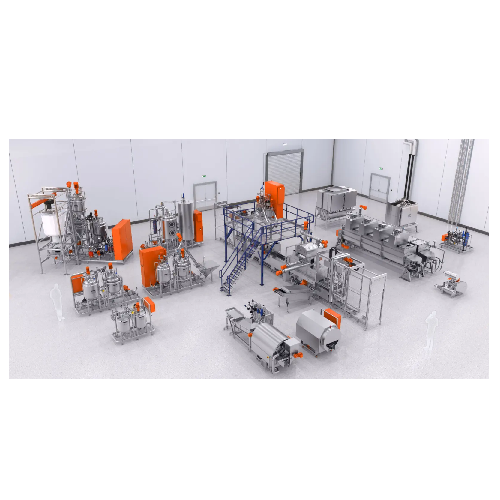

Filling lines

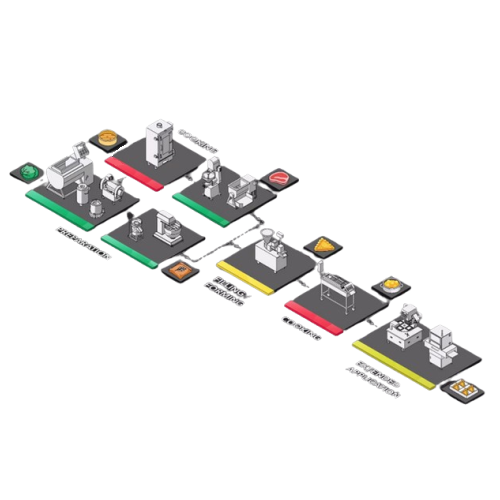

Find innovative filling equipment and connect directly with world-leading technology suppliers

Filling lines are used extensively in all industries, such as food, pharmaceutical, chemical, and cosmetics, to accurately package different products into a container suitable for that product. Although the filling process is at the very end of the production line, it is no less important than the earlier steps. Last but not least, the idiom that dates back to 1382 when John Wyclif wrote the firste the laste, and the laste the firste, indicates just that the last things on a list are just as valuable as the previous ones. In this case, this idiom fits perfectly.

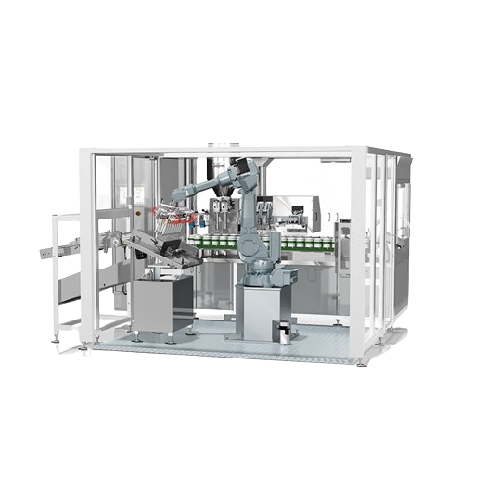

Innovative filling solutions

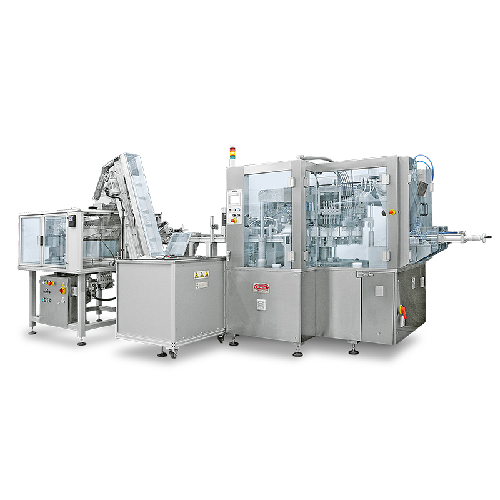

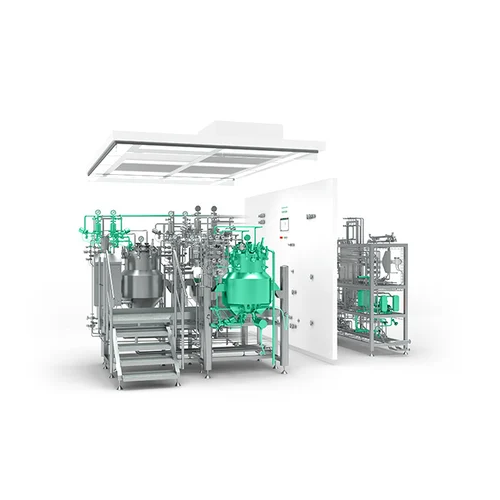

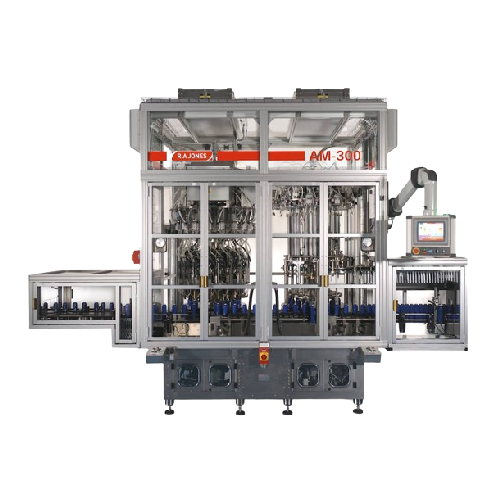

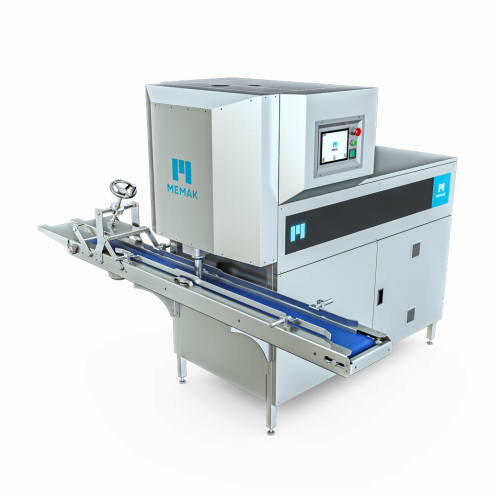

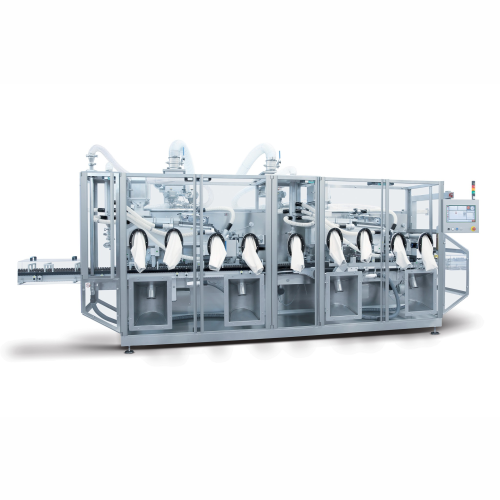

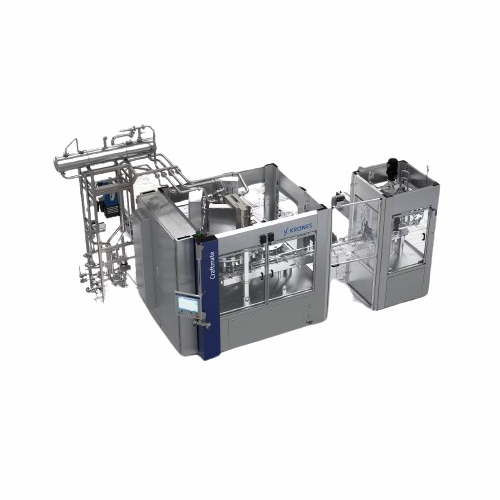

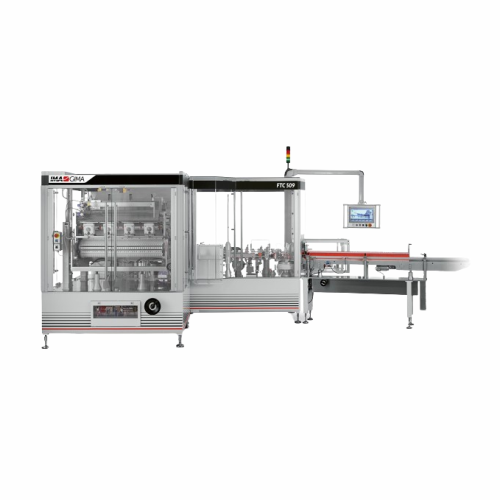

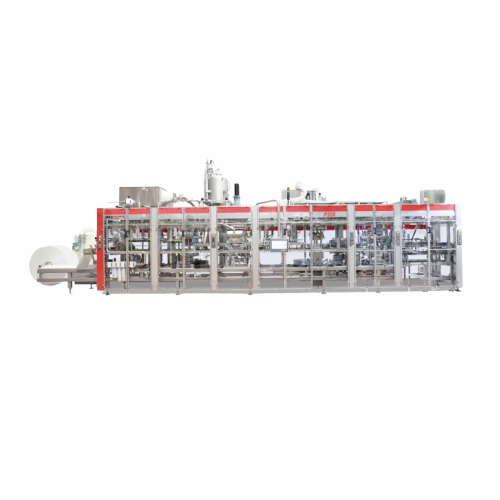

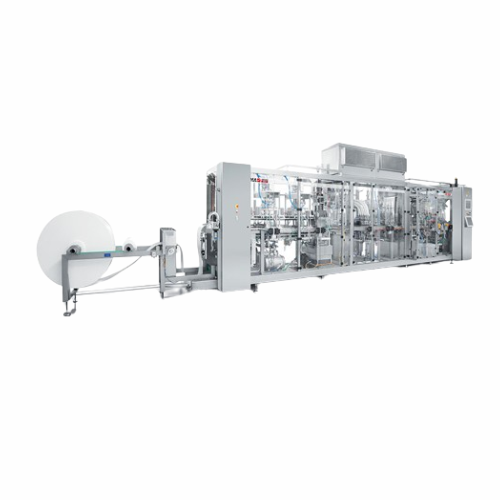

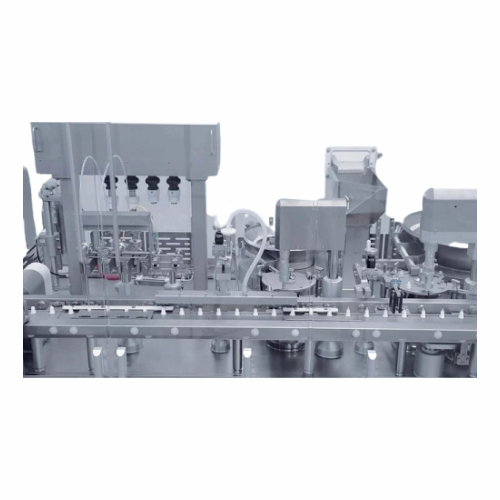

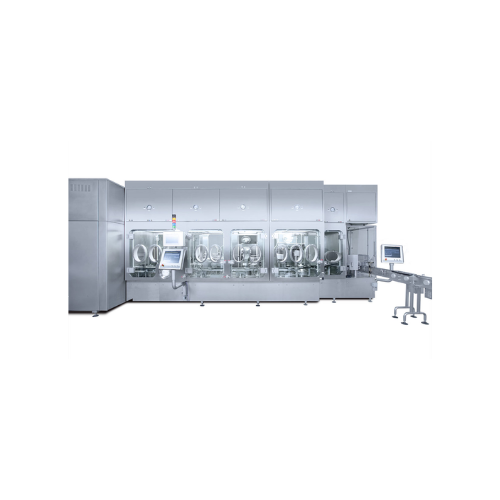

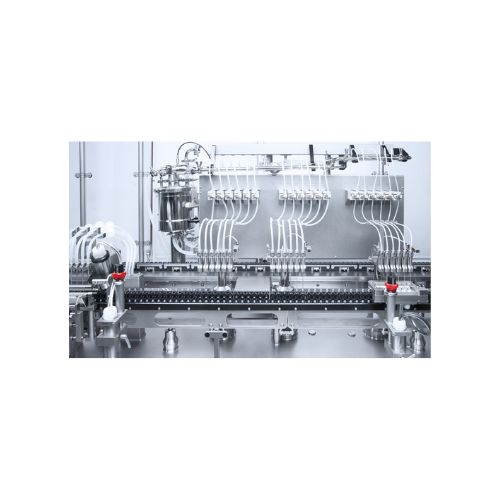

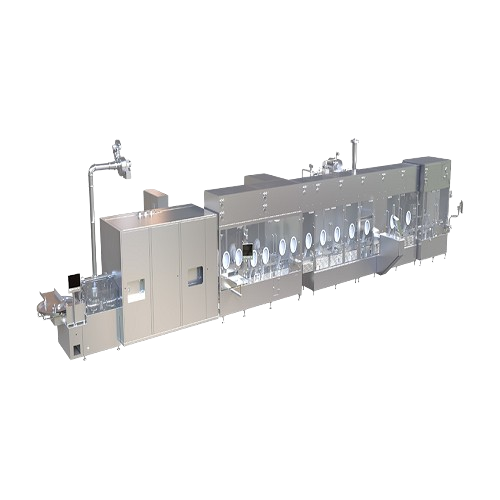

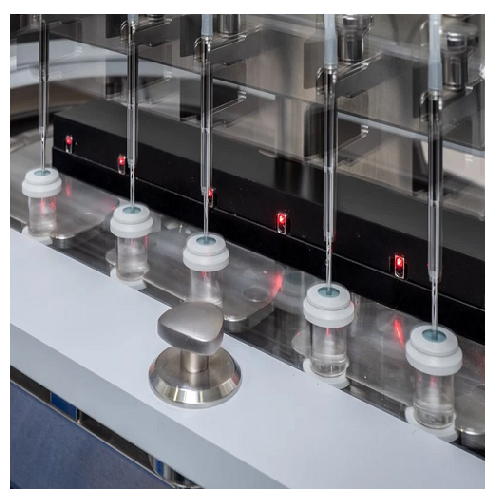

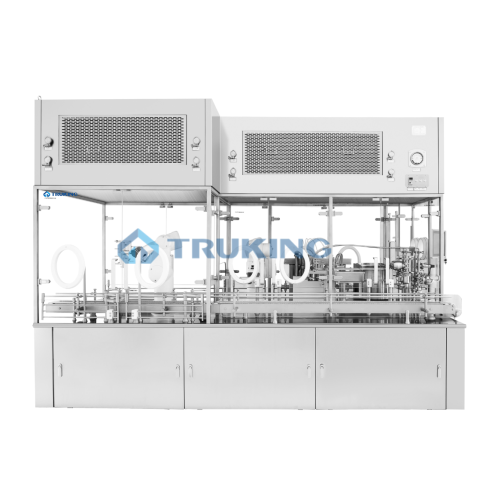

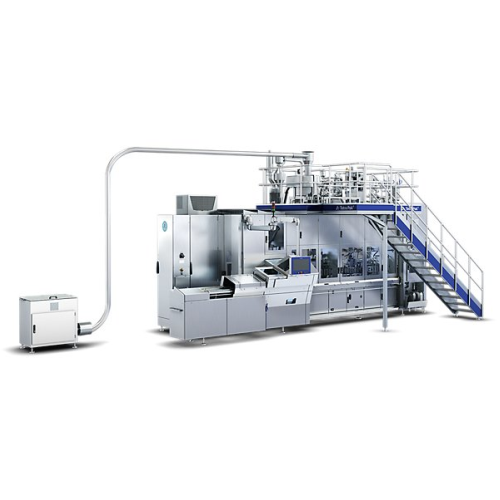

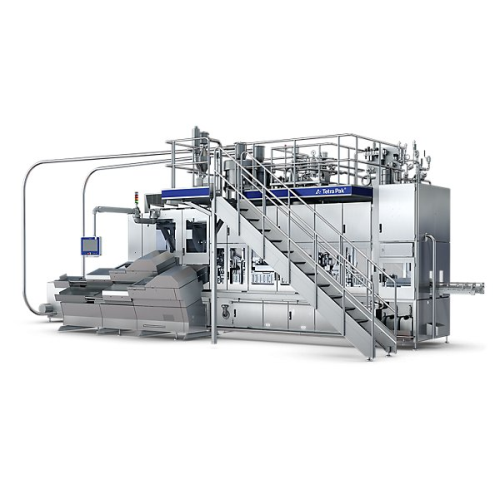

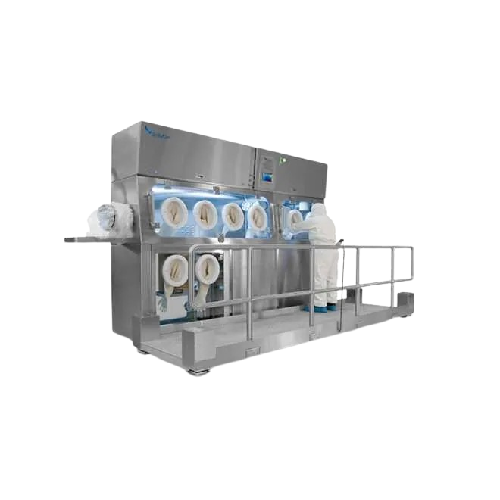

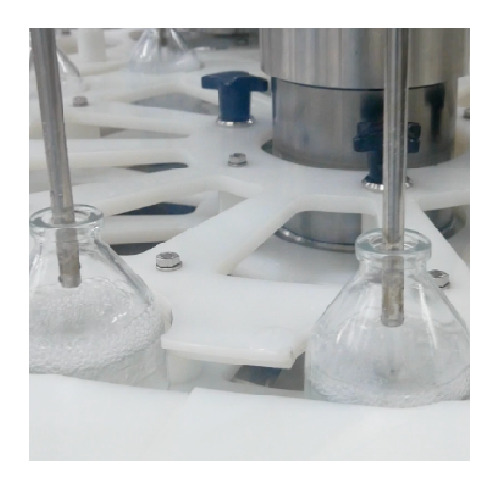

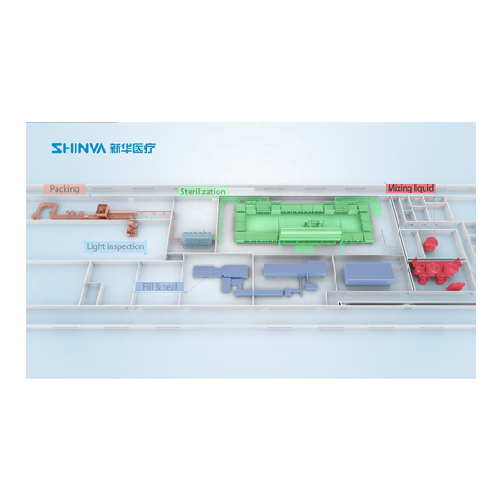

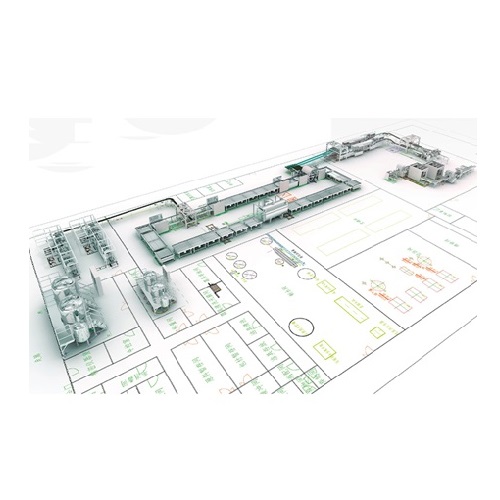

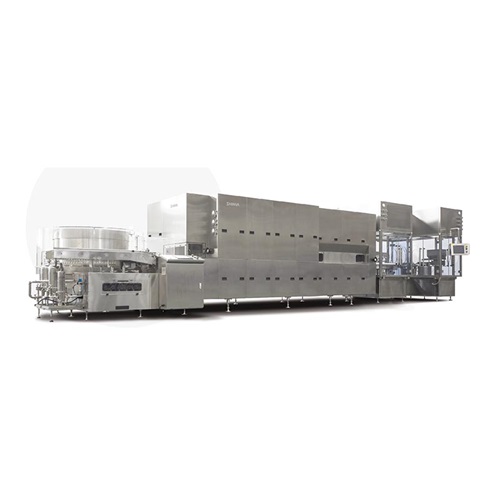

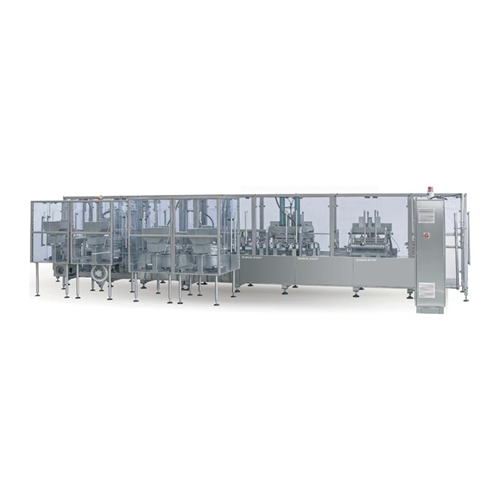

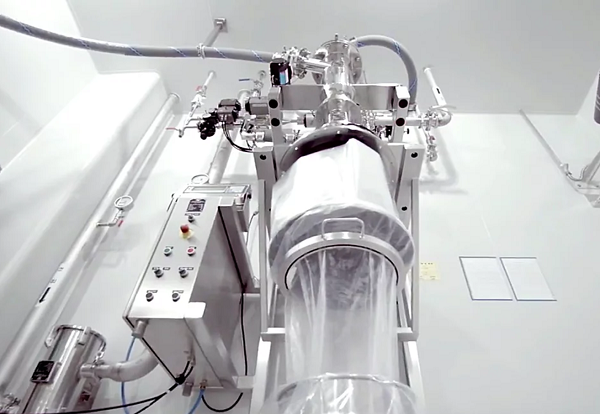

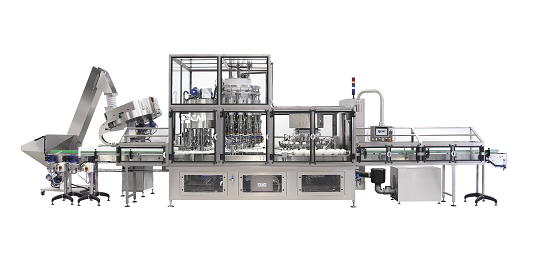

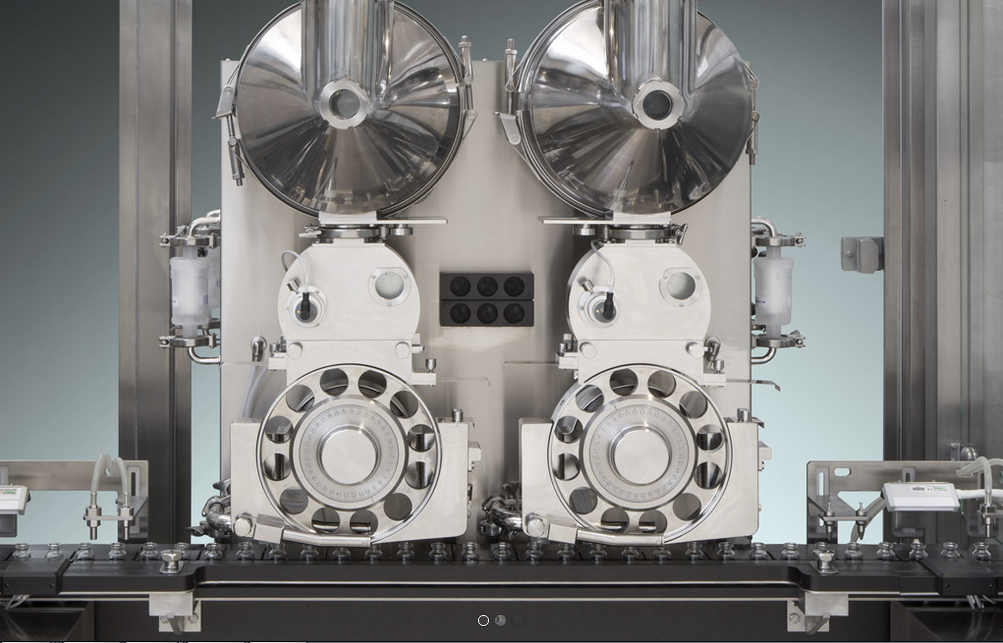

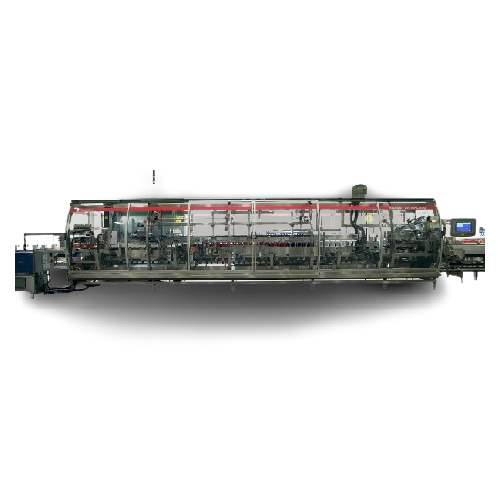

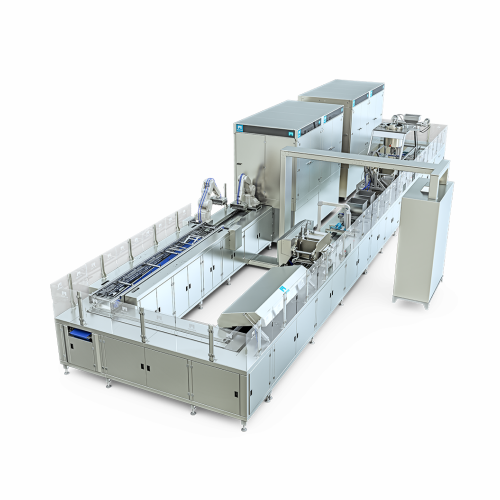

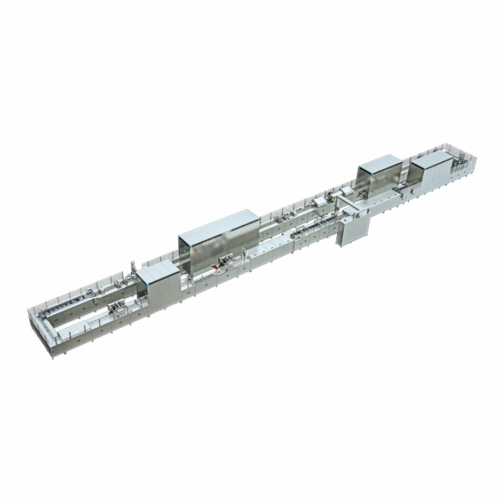

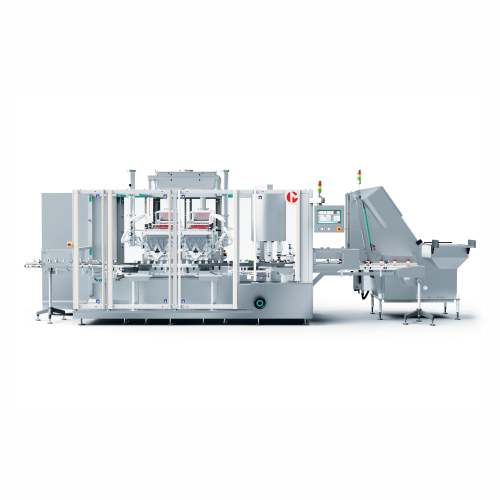

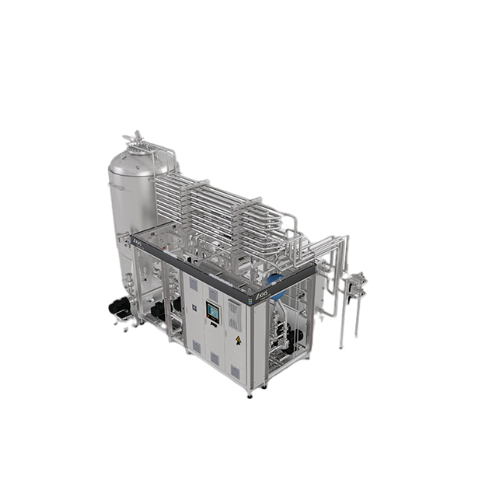

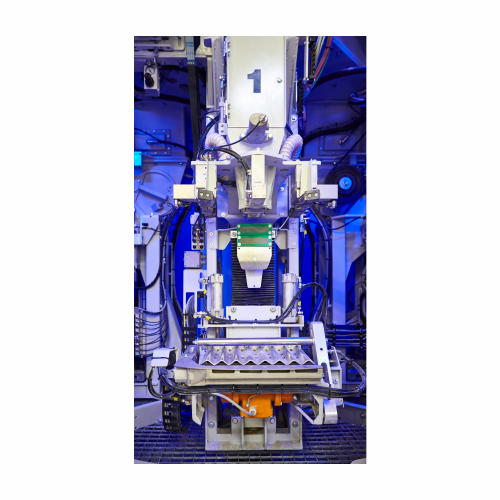

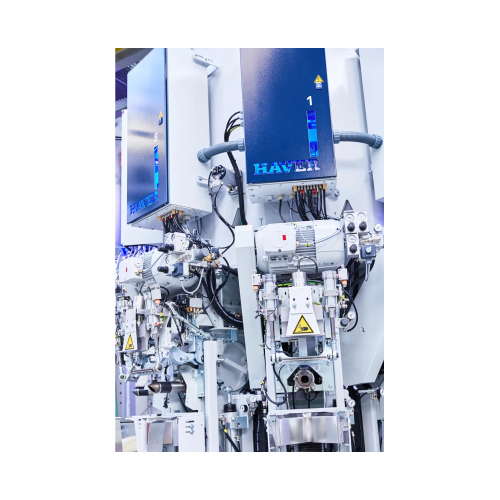

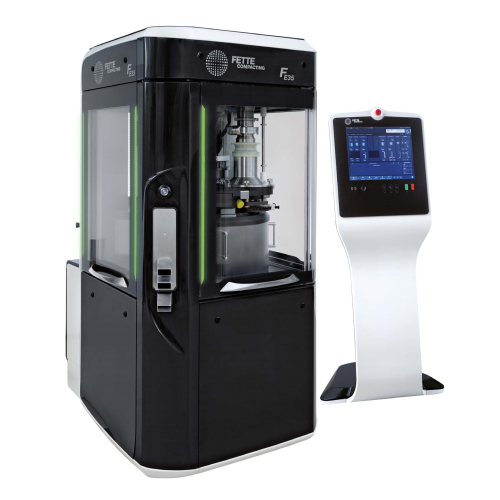

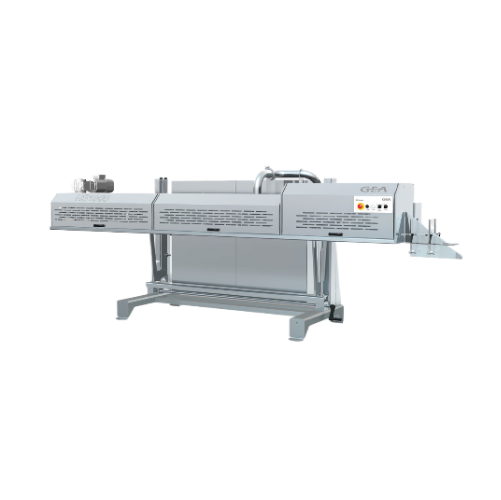

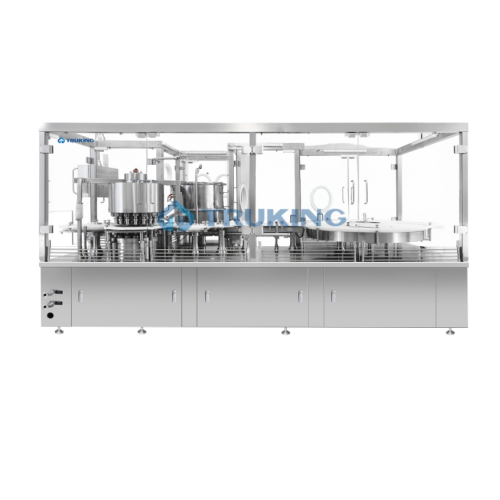

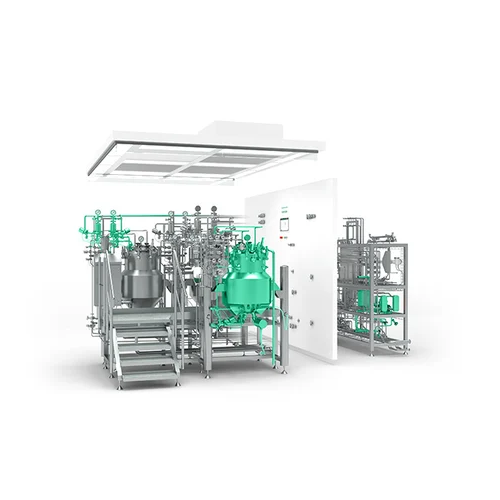

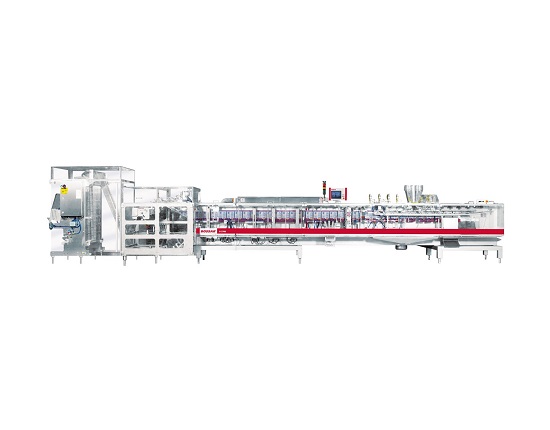

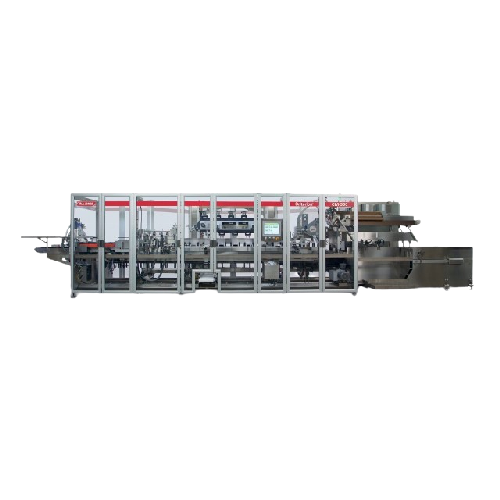

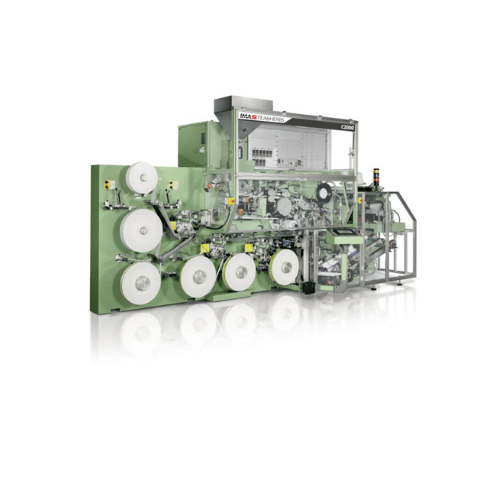

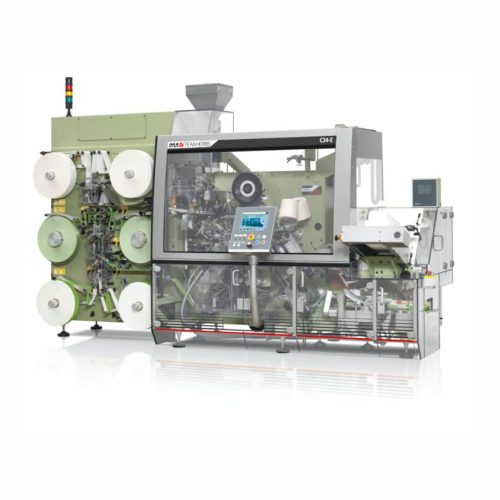

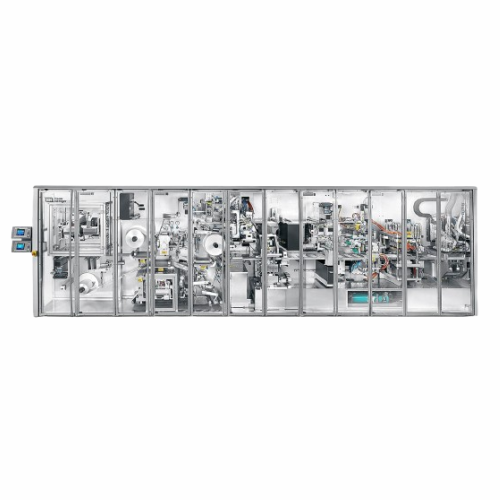

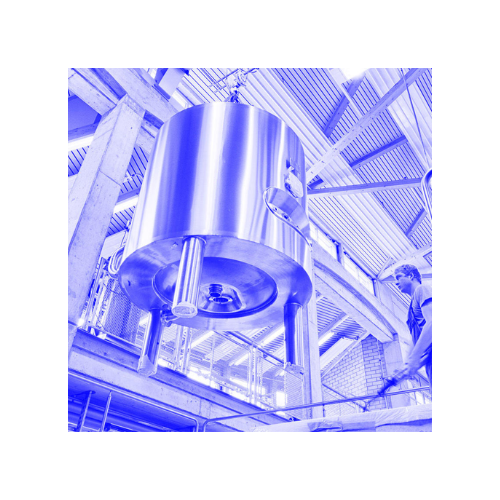

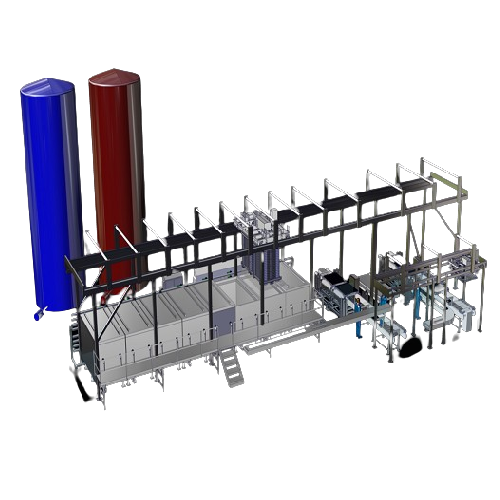

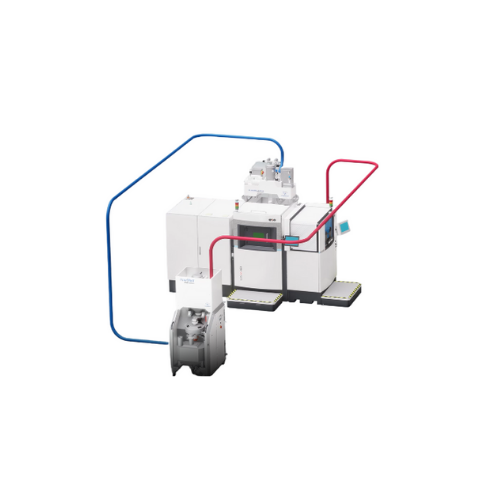

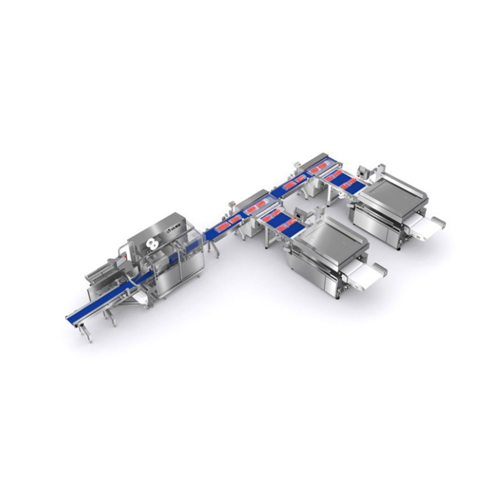

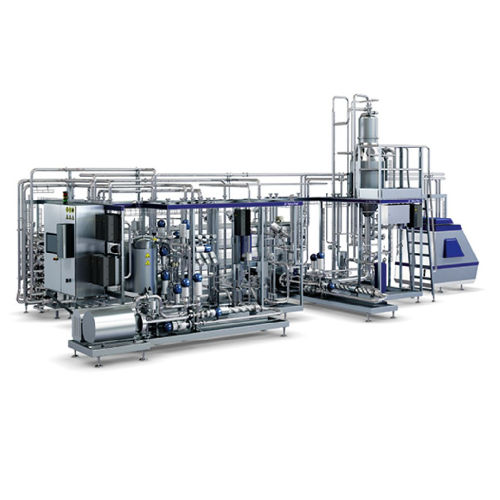

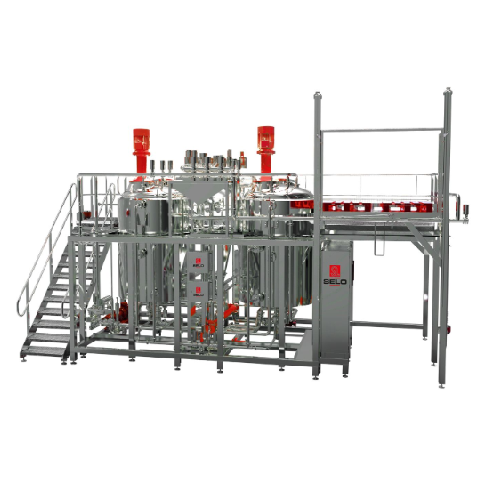

Aseptic filling line for biopharmaceuticals

Streamline your aseptic filling process with precision dosing and minimal spac...

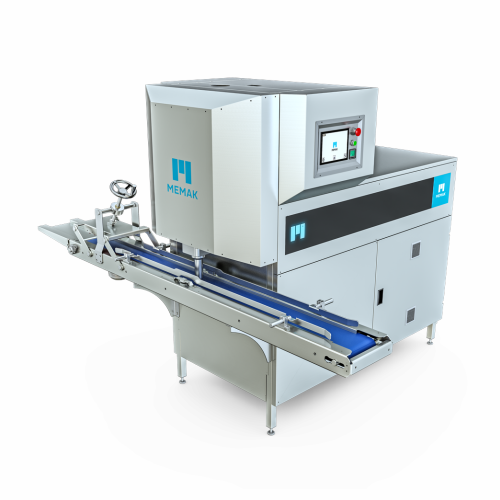

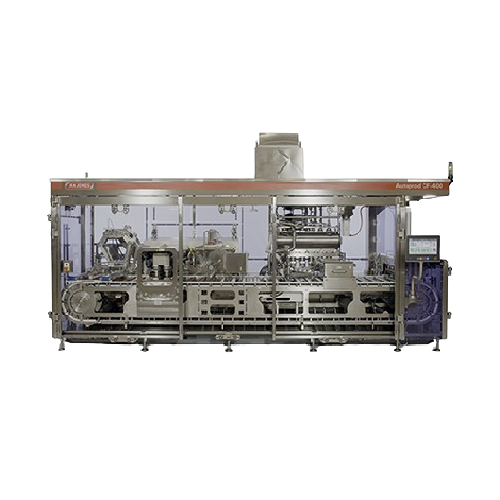

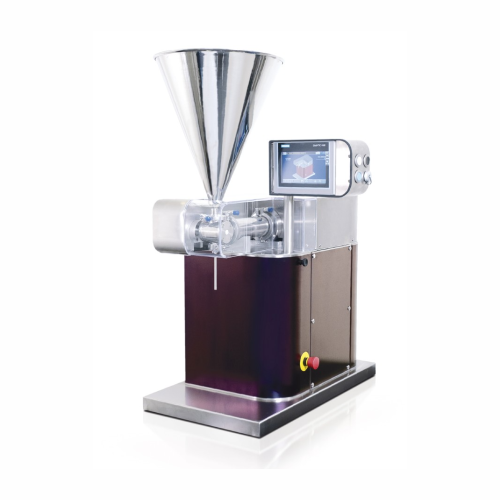

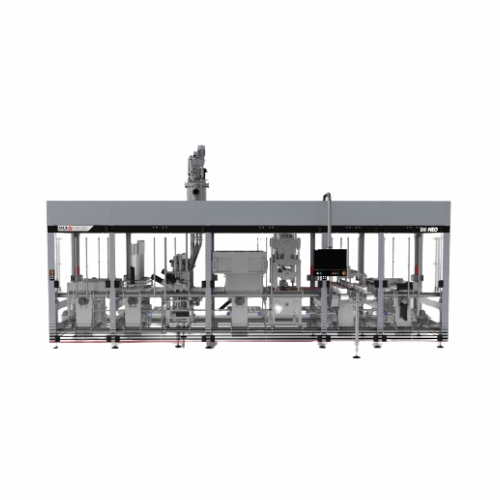

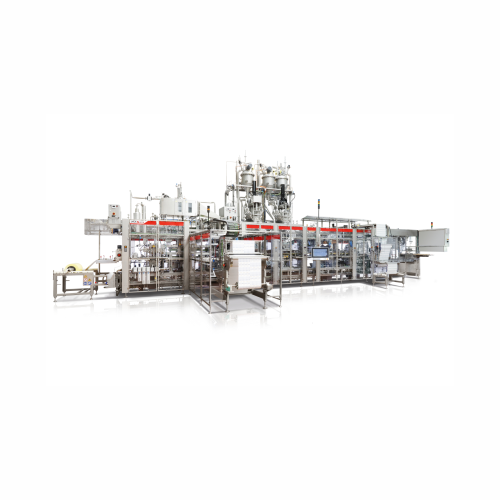

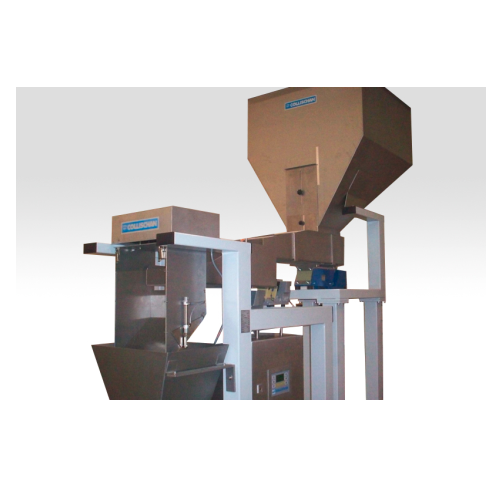

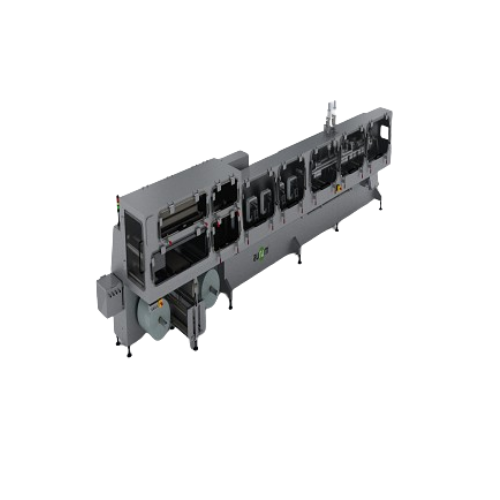

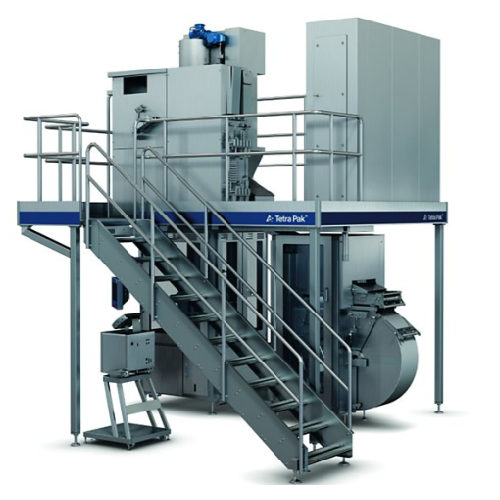

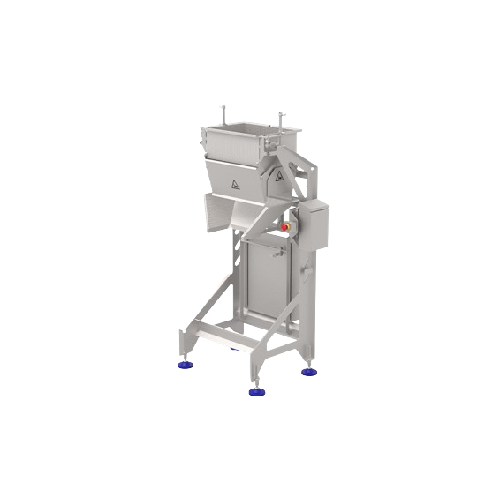

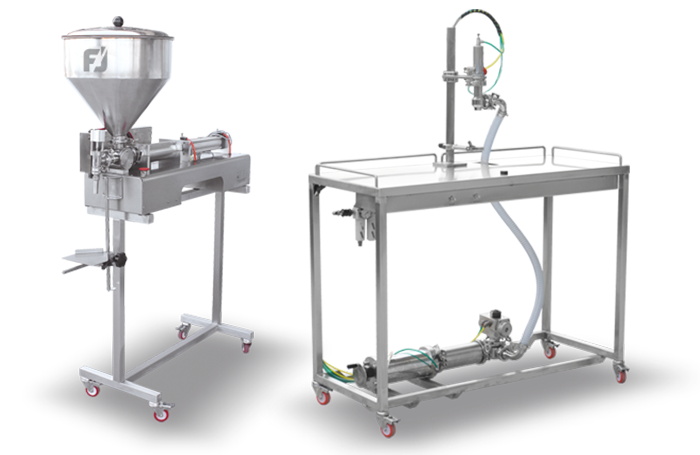

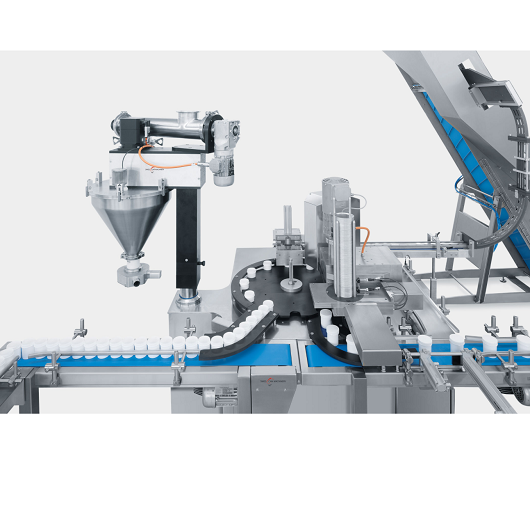

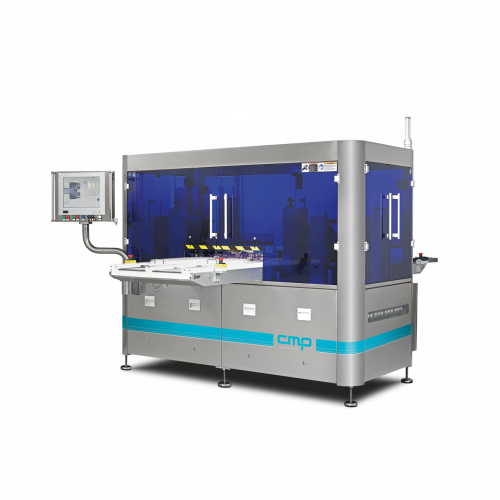

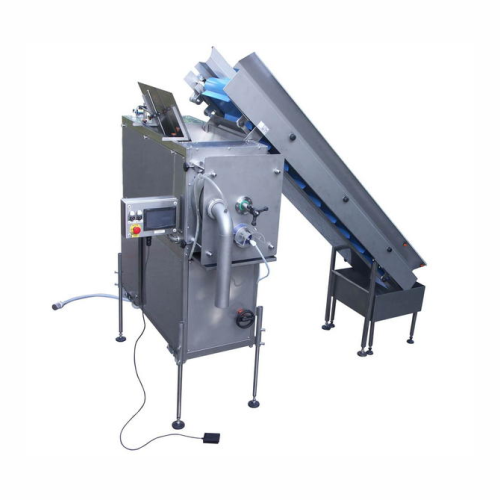

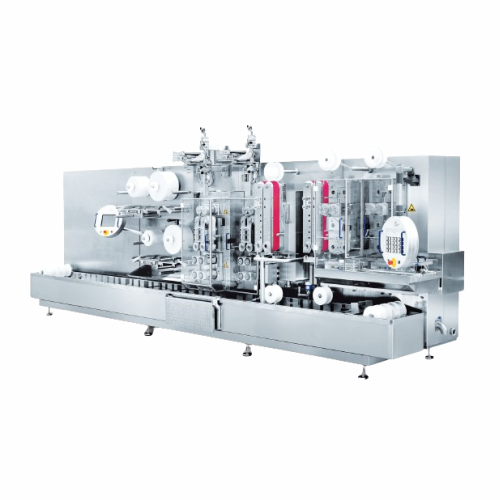

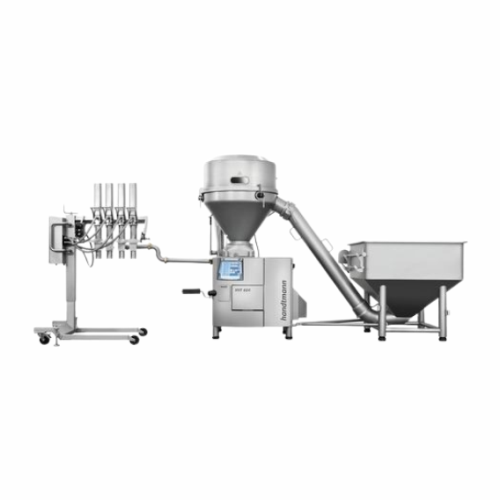

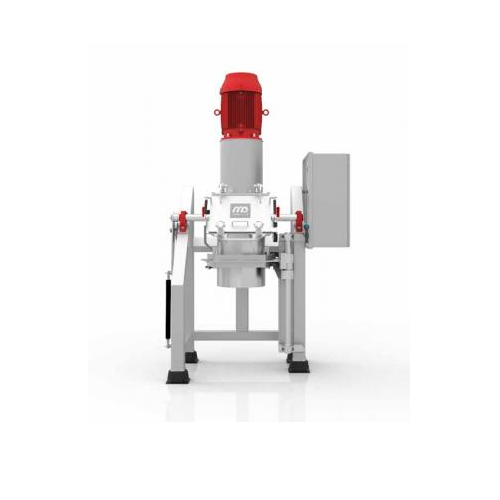

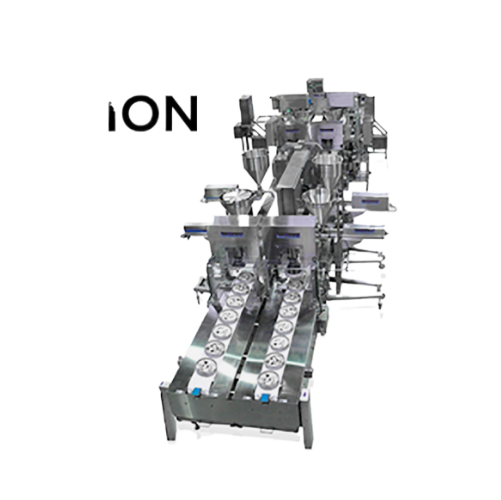

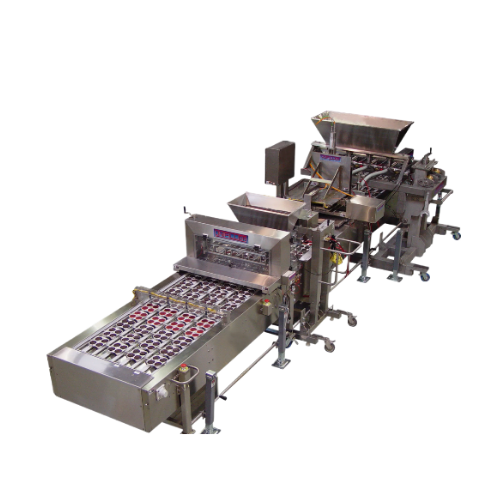

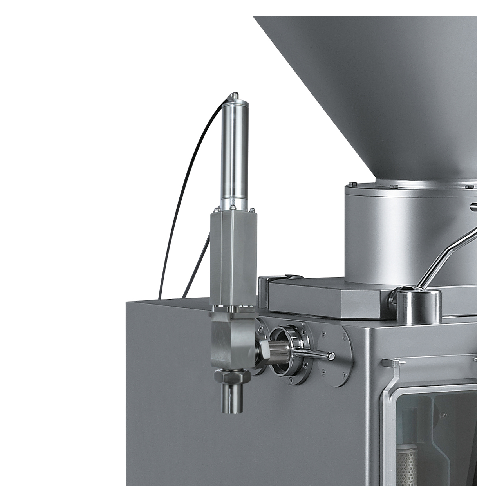

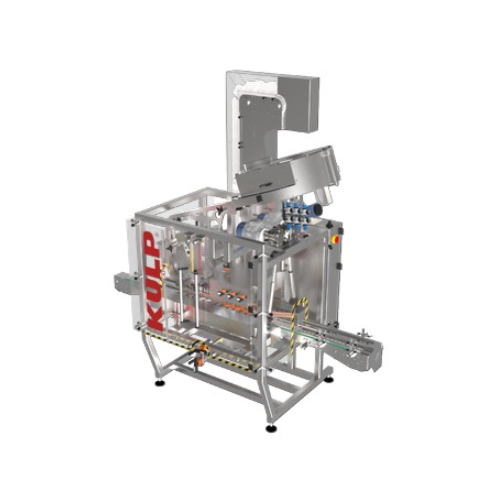

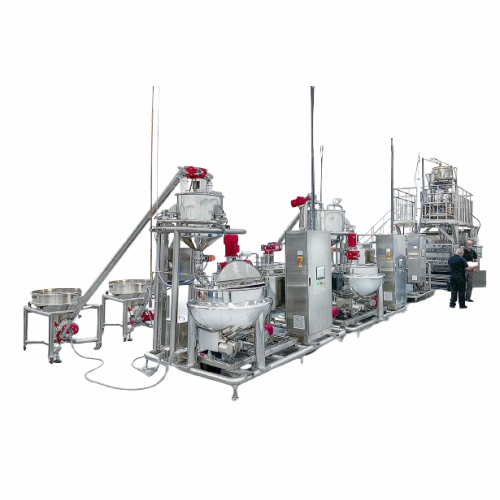

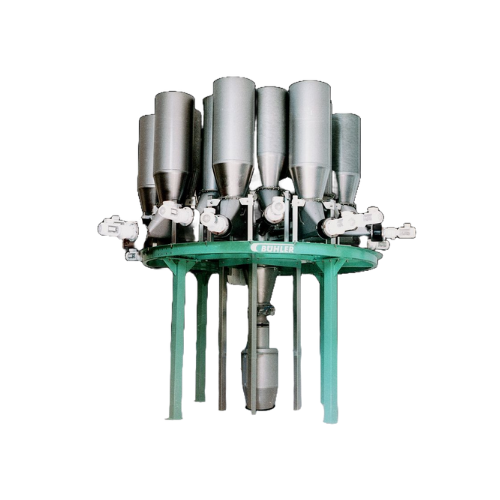

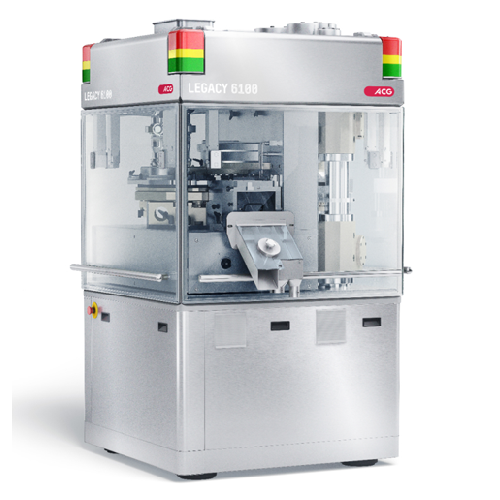

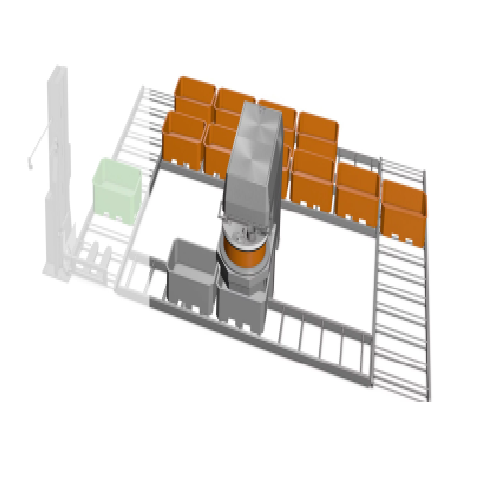

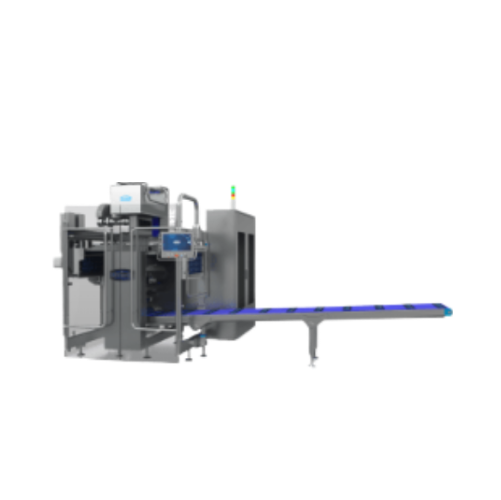

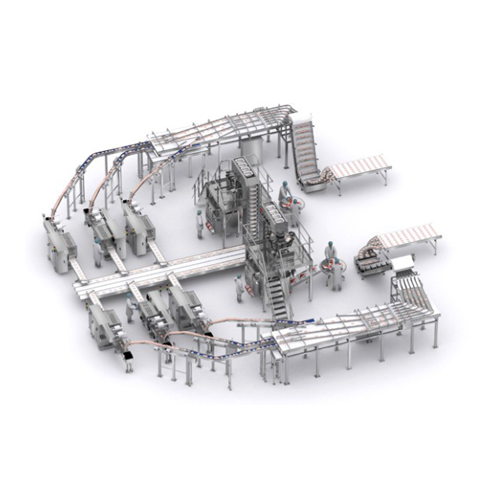

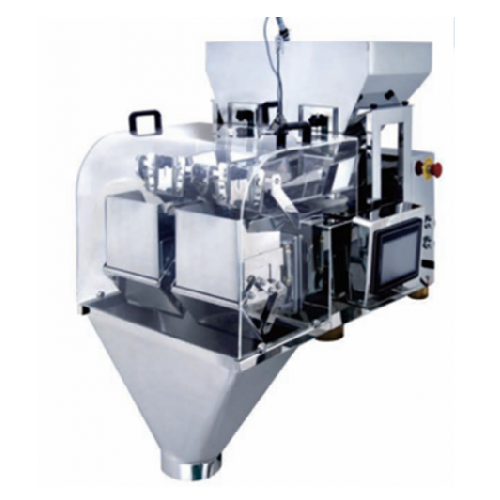

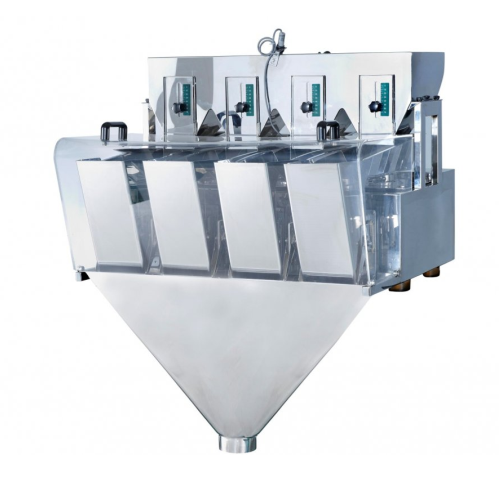

Accurate powder filling solution

When precision is paramount, this solution offers exceptional accuracy, filling powders up ...

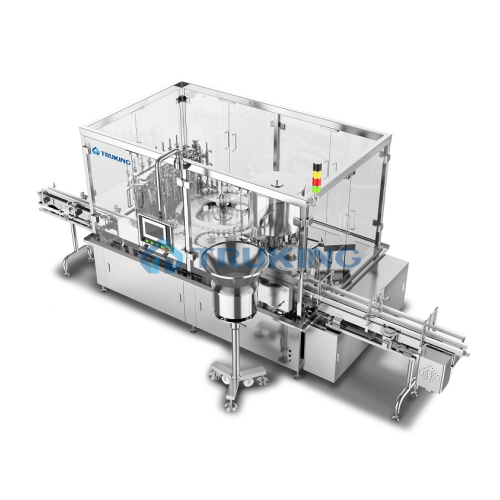

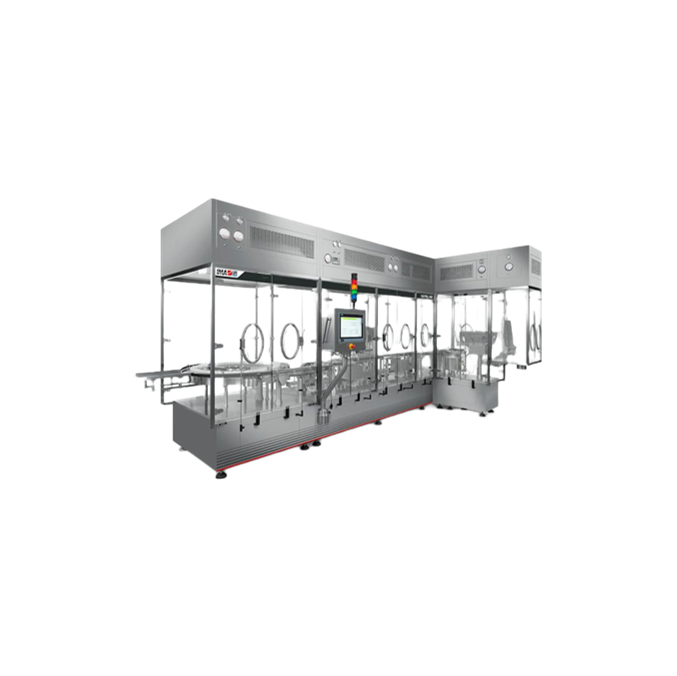

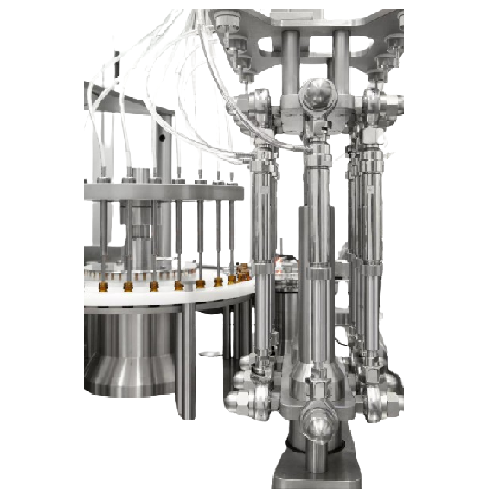

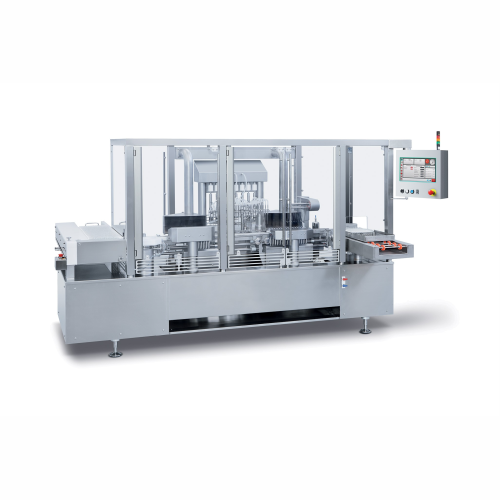

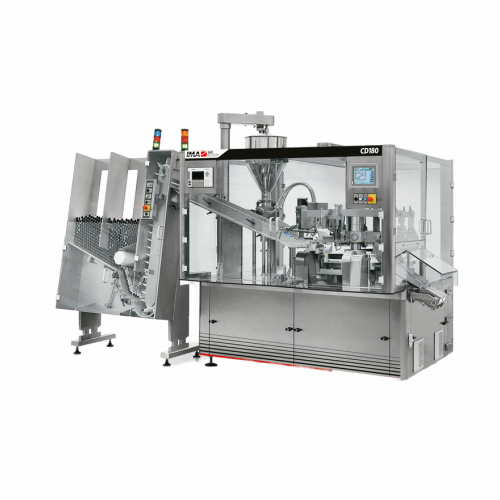

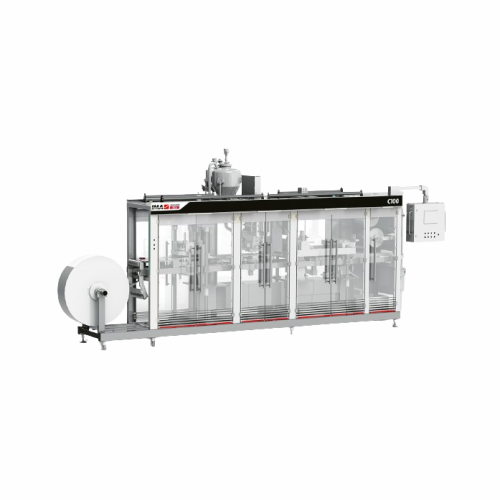

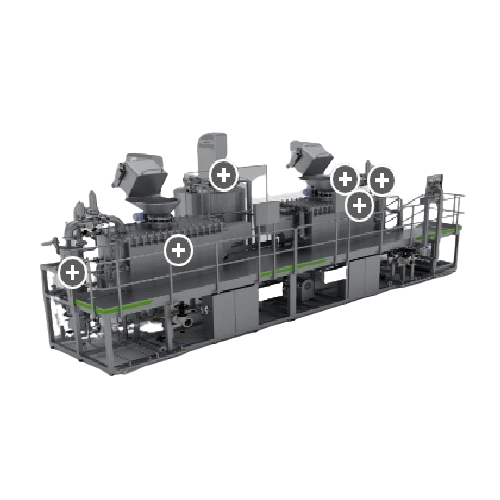

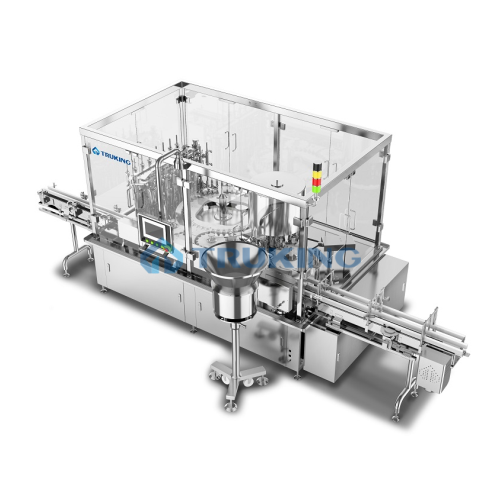

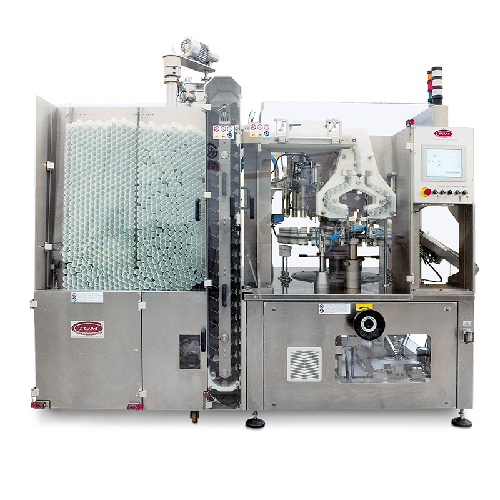

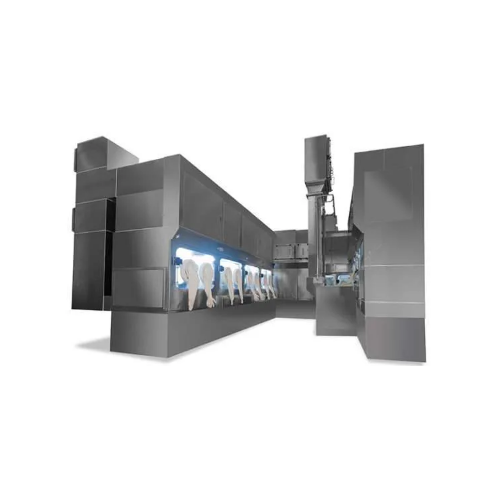

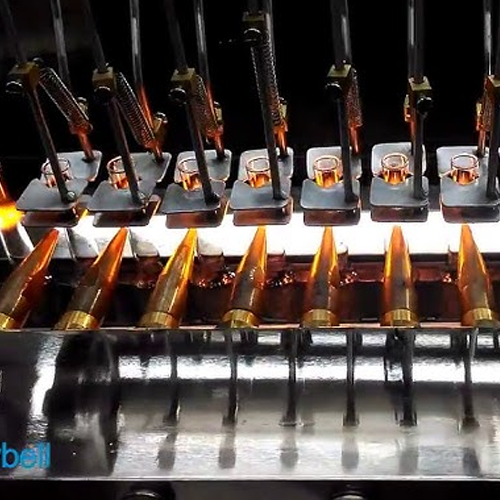

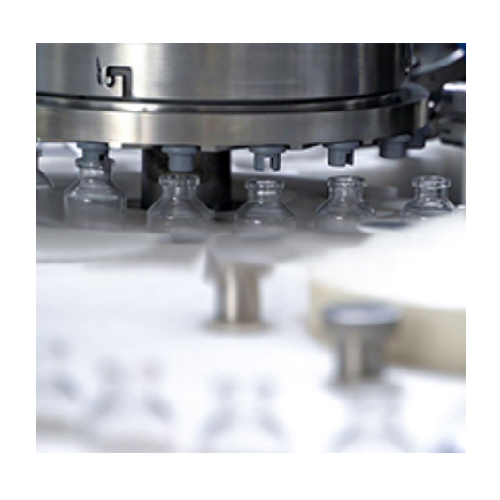

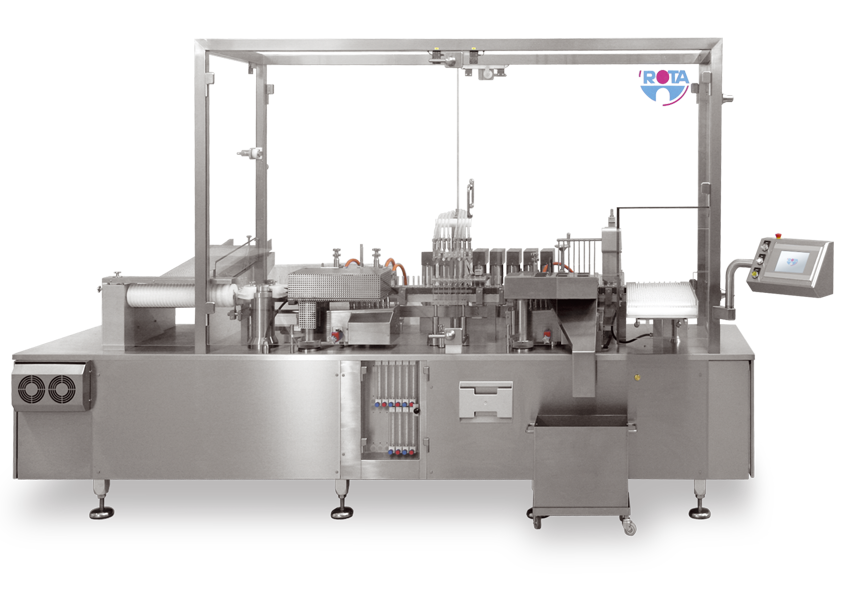

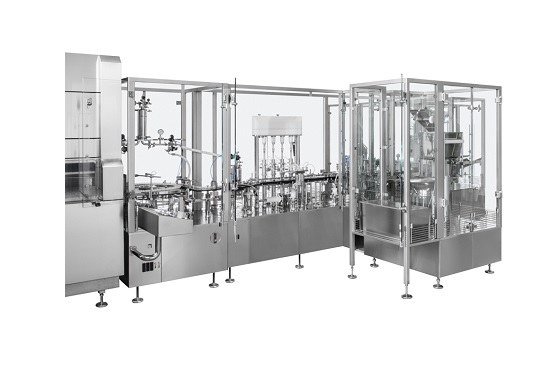

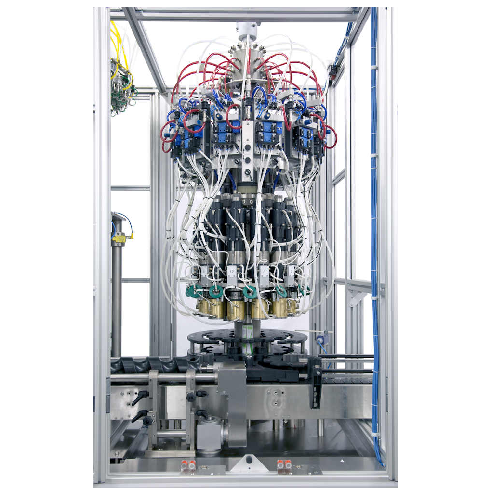

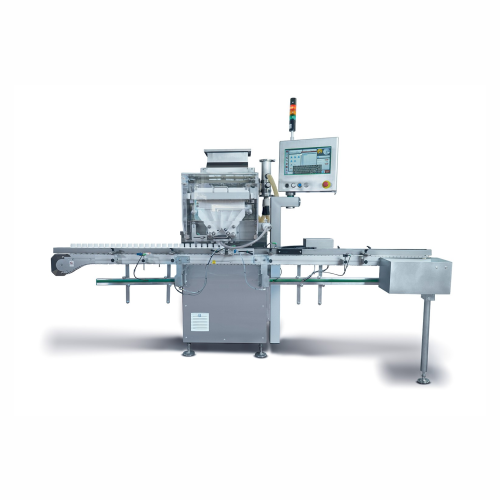

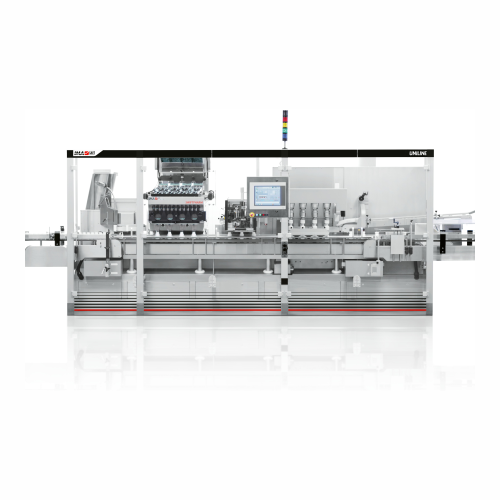

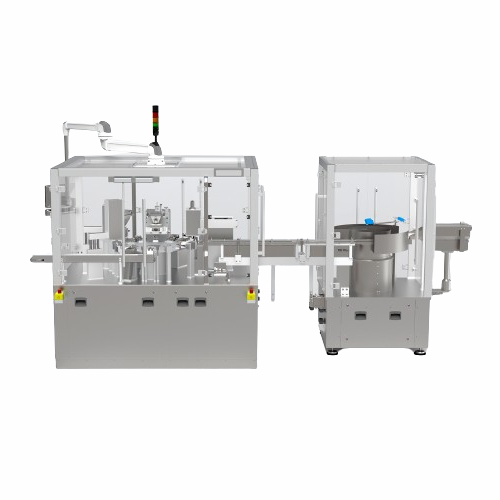

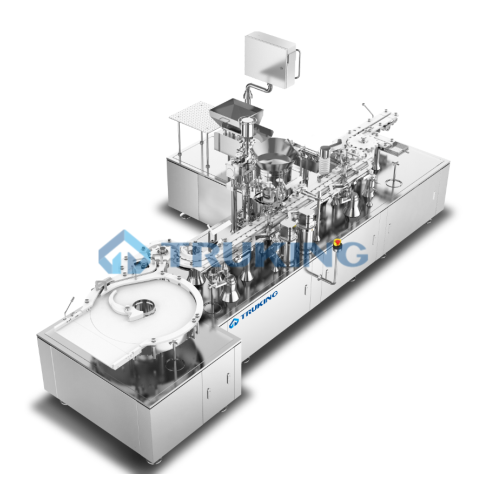

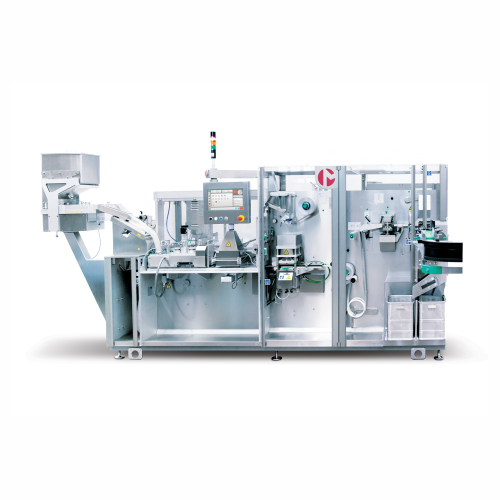

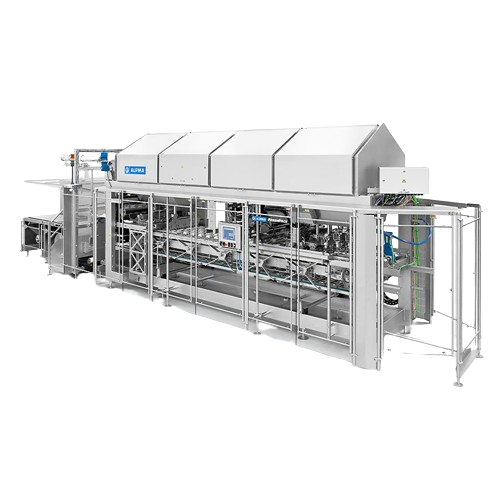

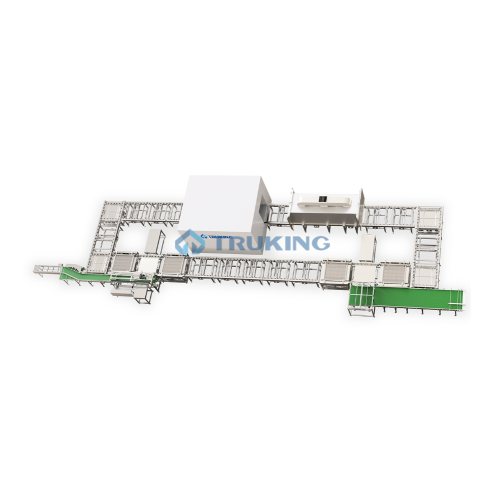

Ampoule filling machine

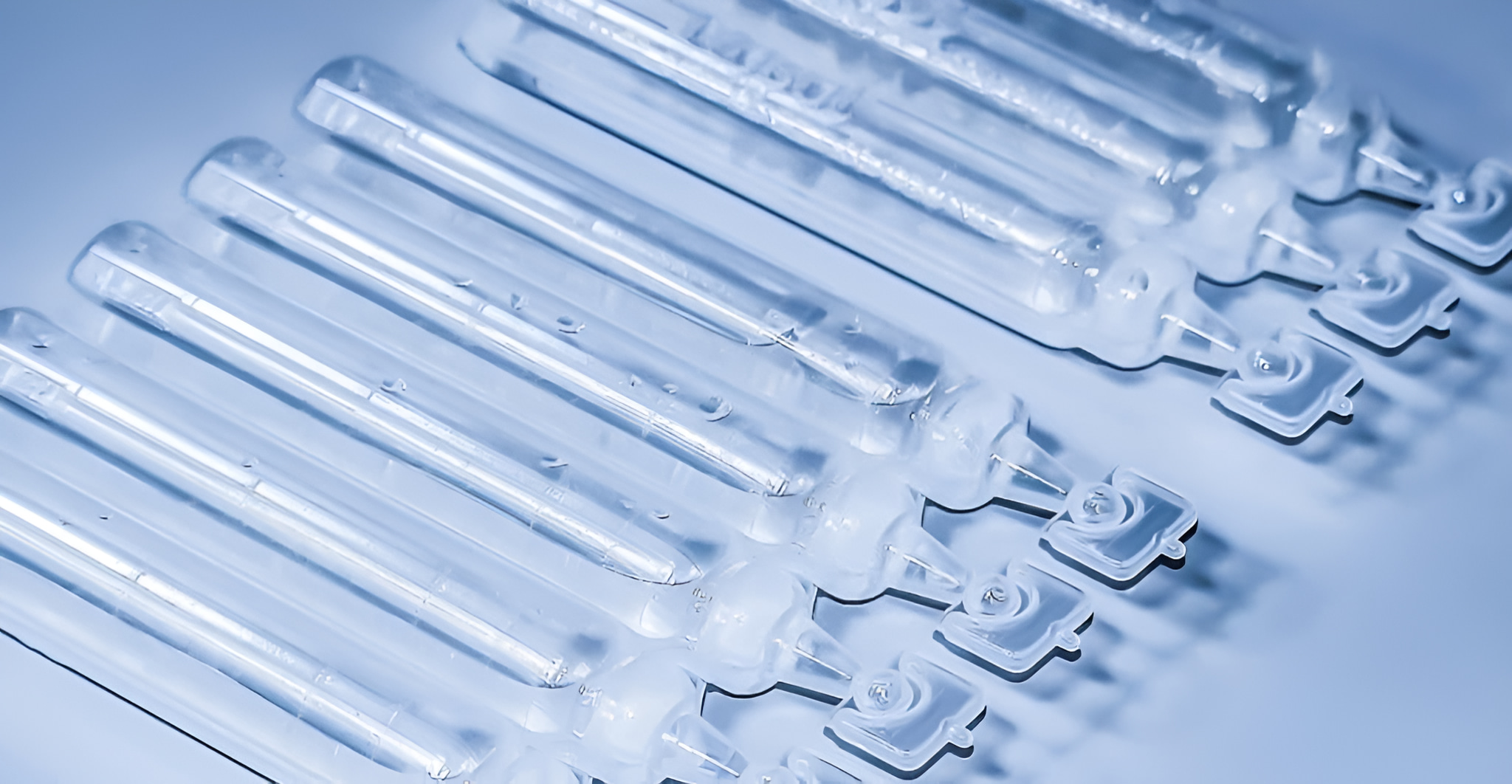

Filling ampoules or vials with parenteral fluids are an essential matter for which you need to consid...

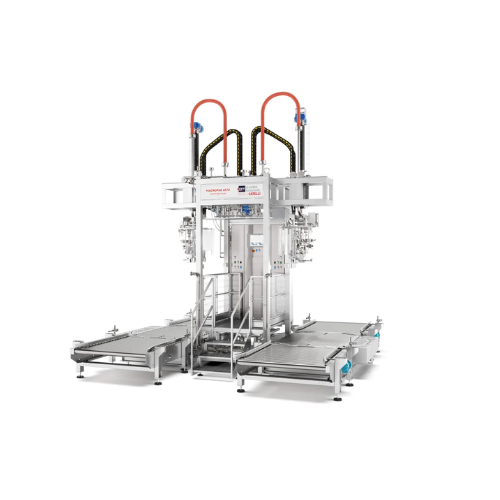

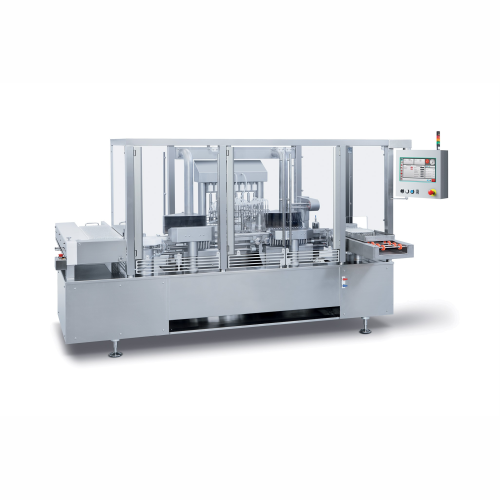

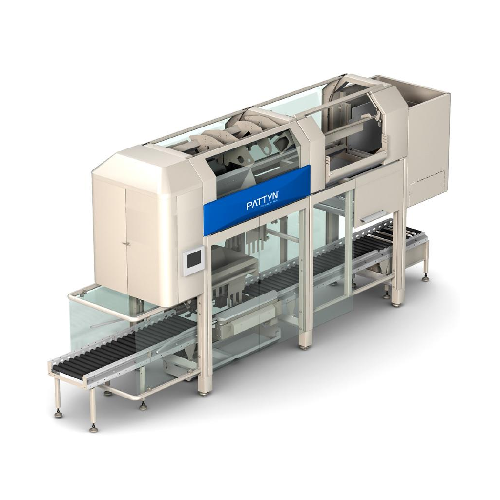

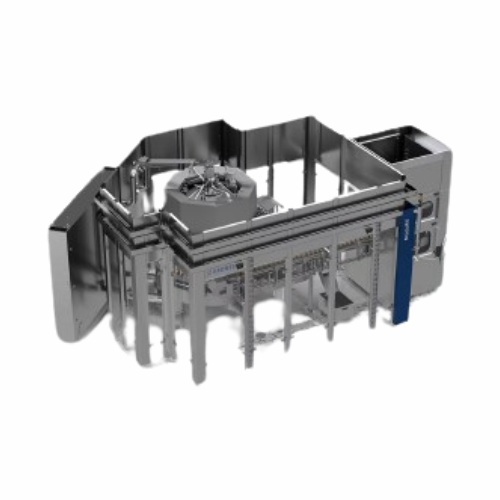

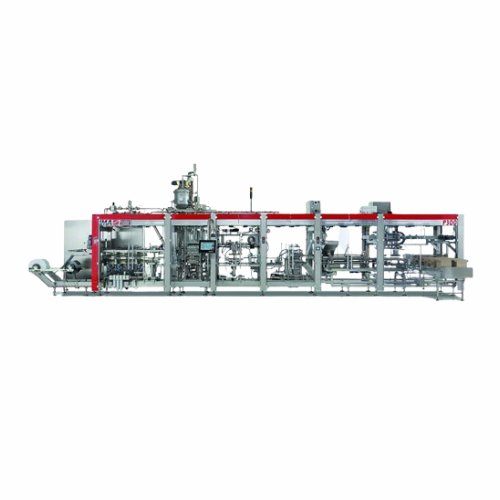

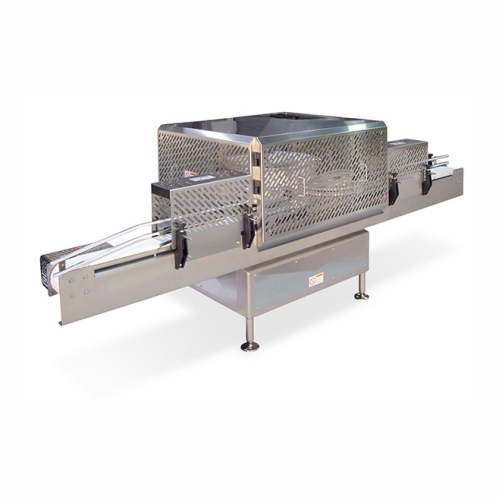

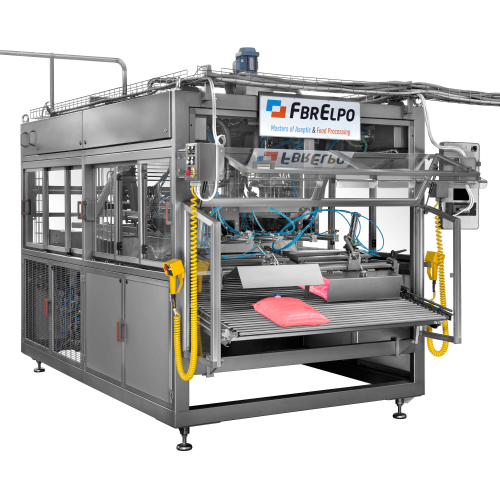

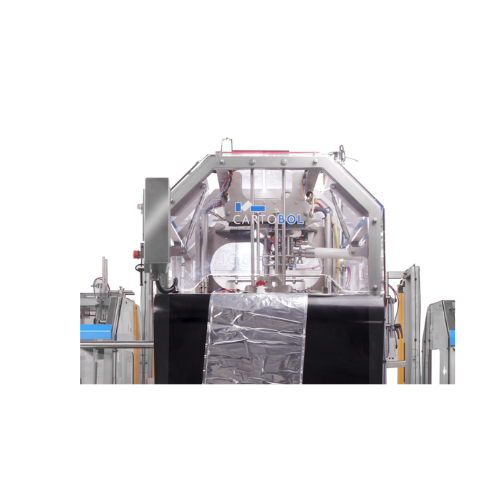

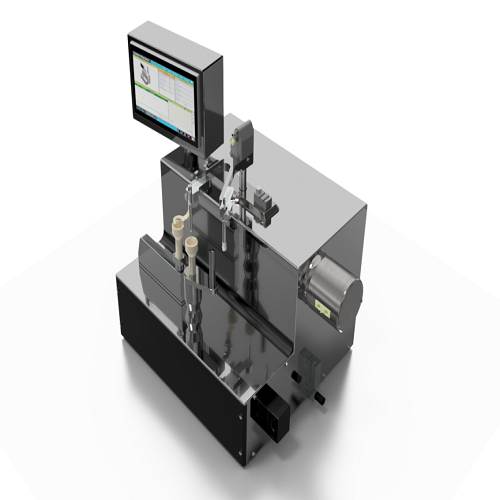

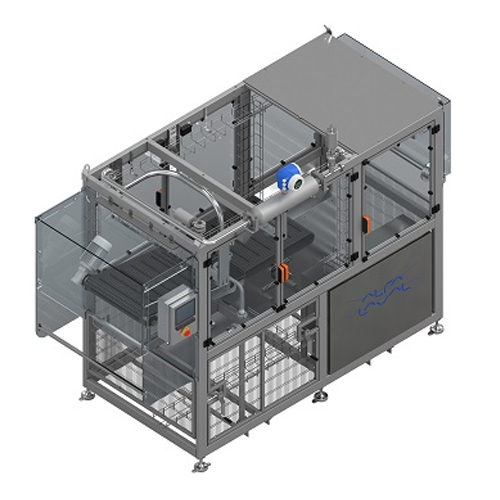

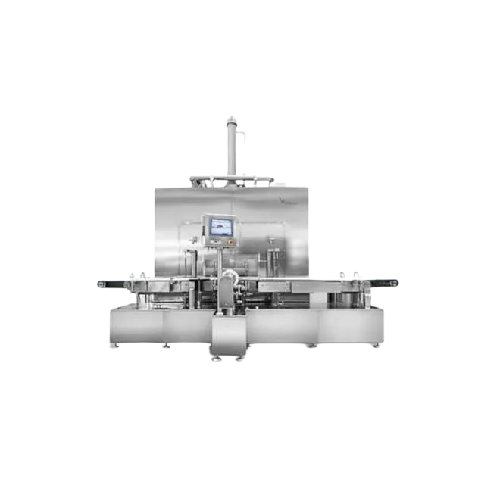

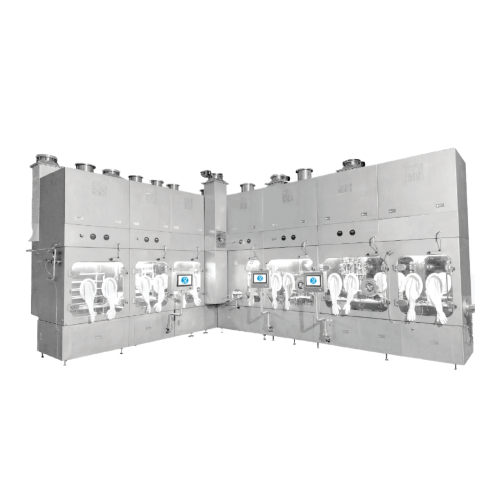

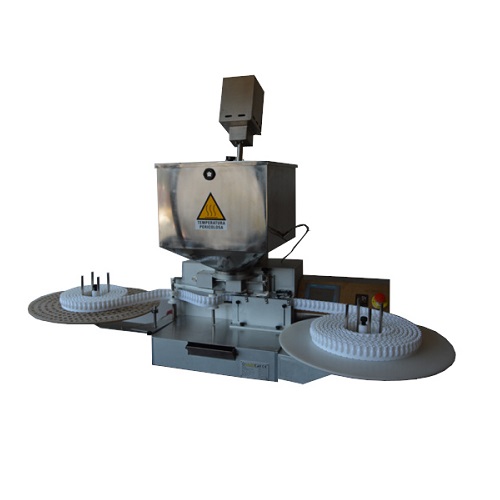

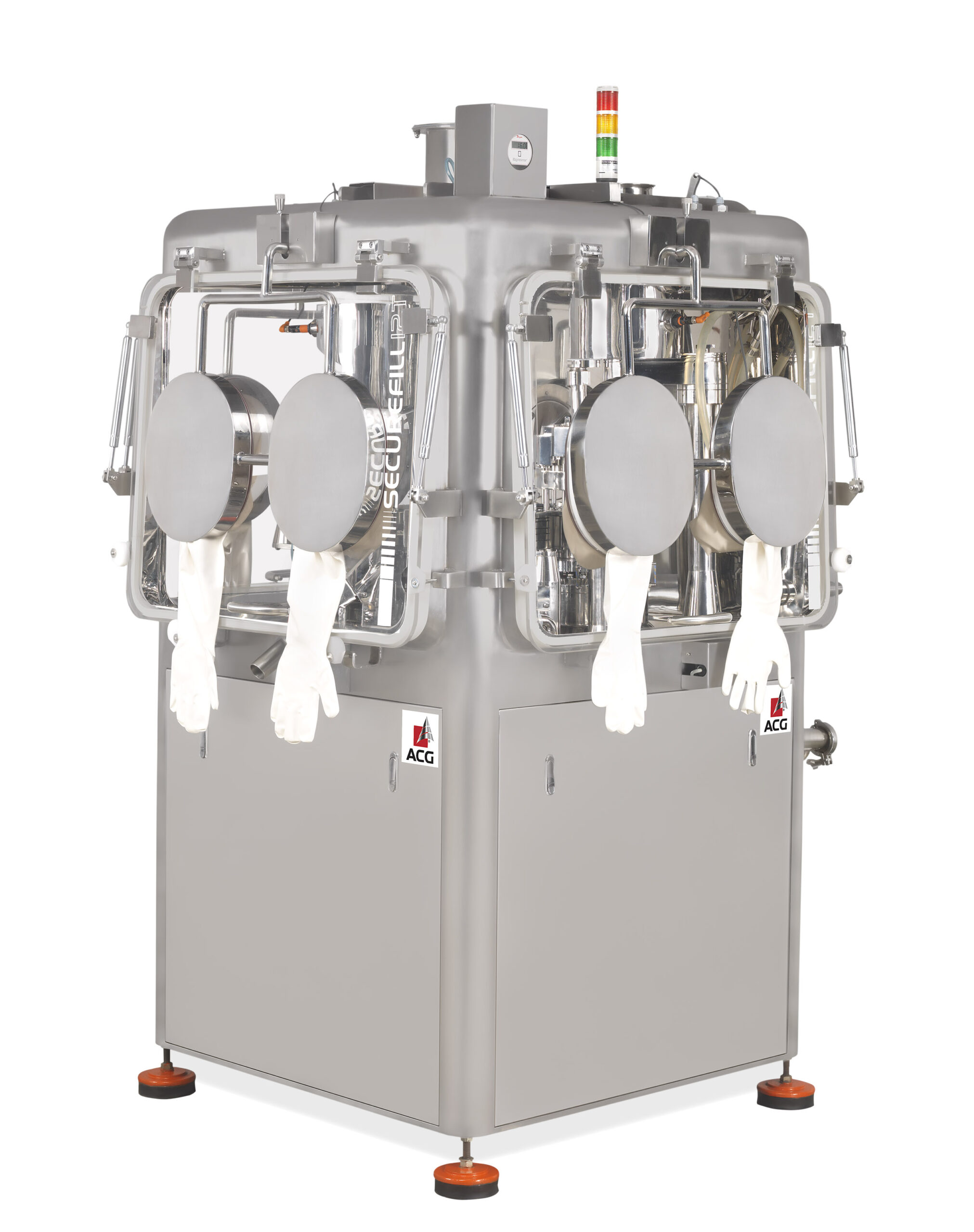

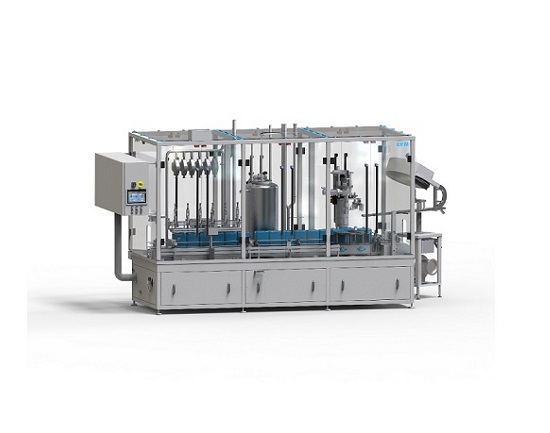

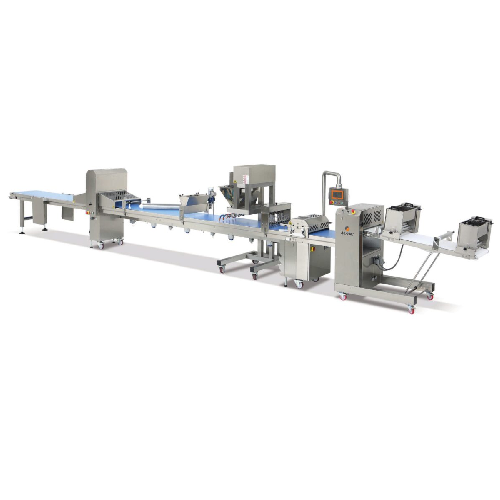

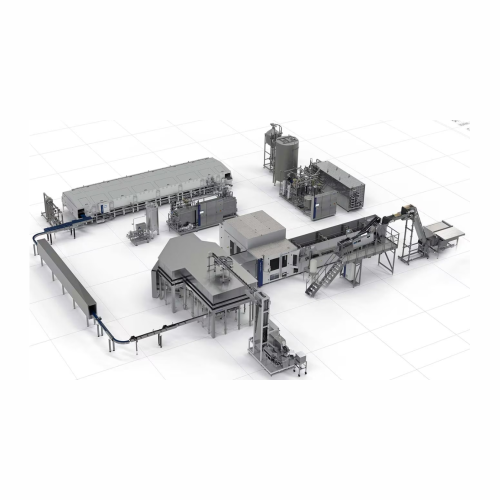

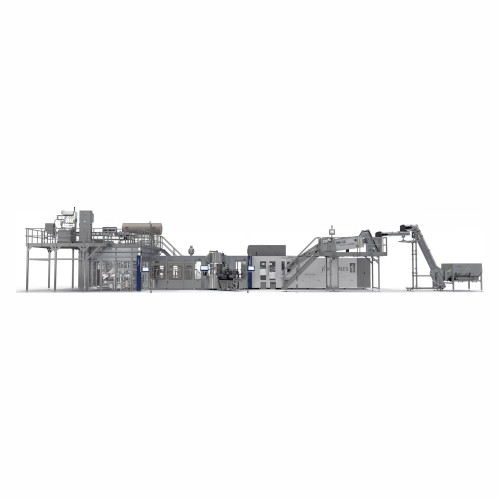

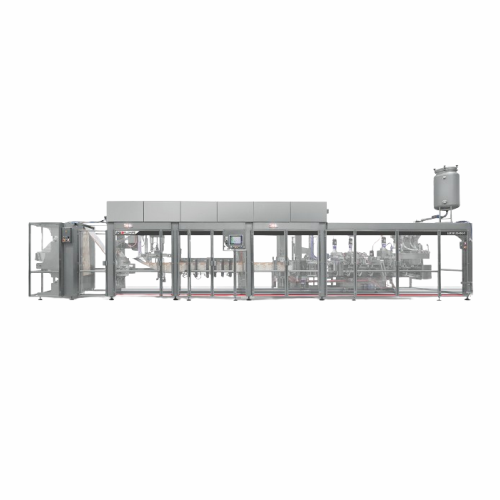

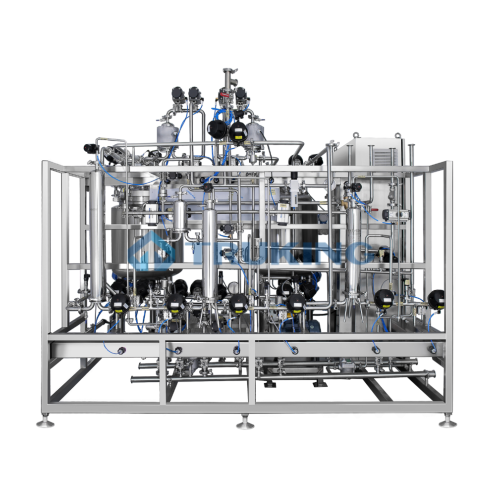

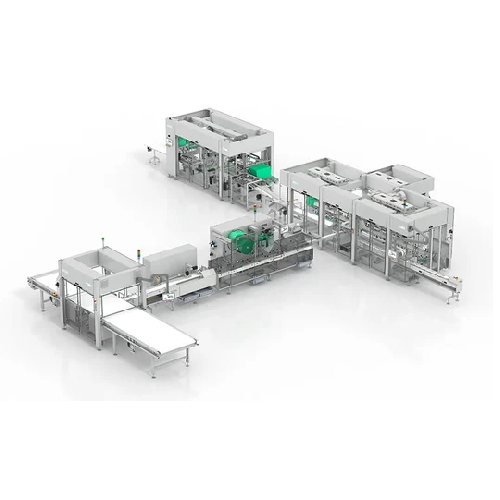

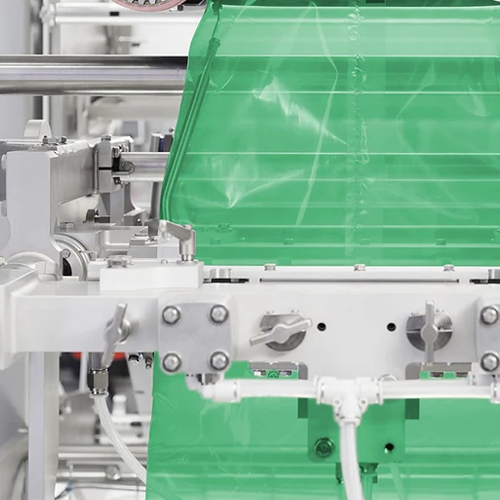

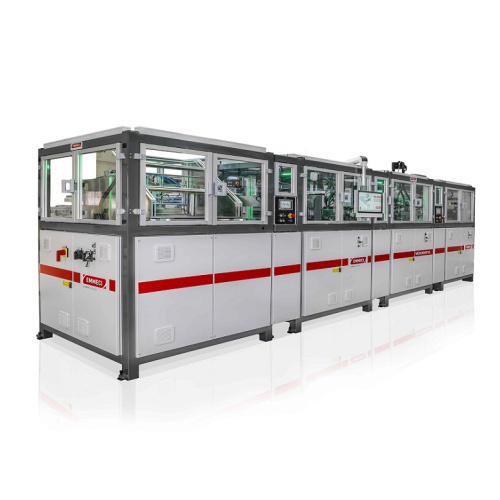

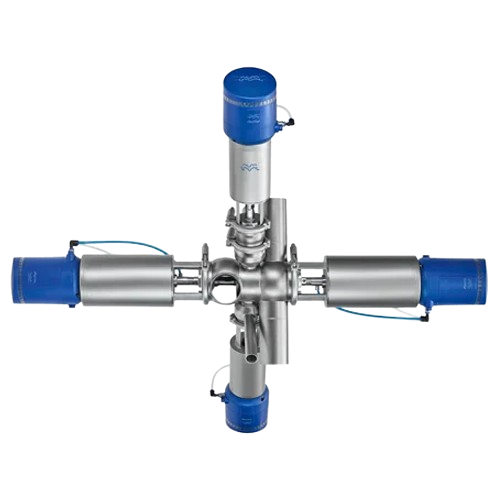

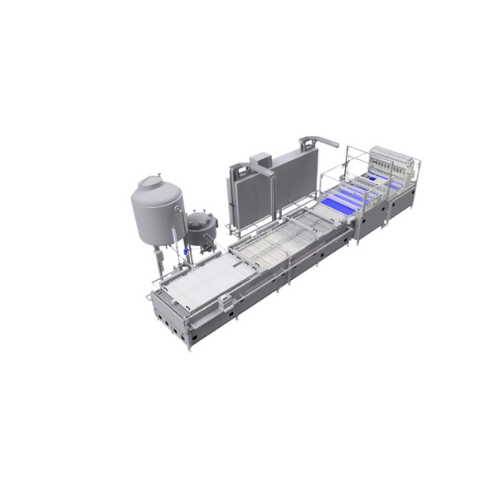

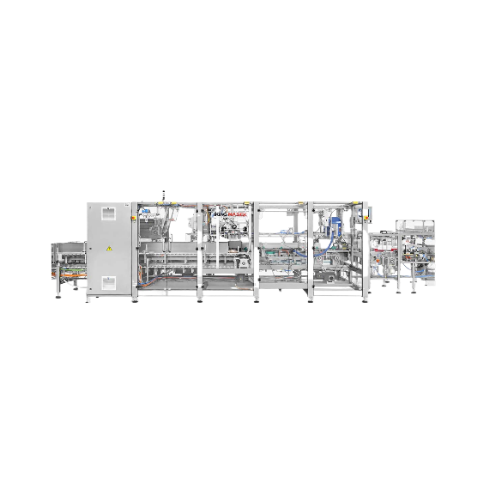

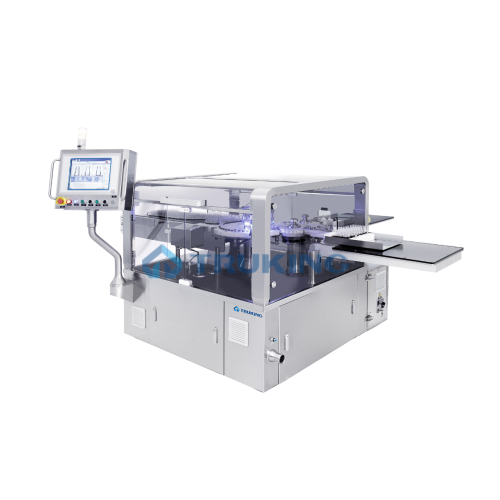

Aseptic filling system for bag-in-box packaging

Efficiently fill a range of liquid products into pre-sterilized bags while...

Based on product characteristics such as viscosity or its physical state – liquid or powder – and the technology they use, filling equipment can be categorized as rotary fillers, volumetric fillers, aseptic fillers, piston filling machines, net weight fillers, free-flowing or non-free-flowing and vibratory weigh filling machines.

Okay, that’s a long list, but no worries. Let’s try to take our time to understand the differences between them and which filling machine works best with which product.

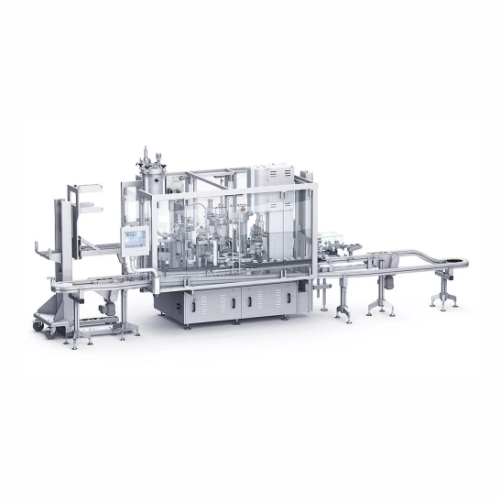

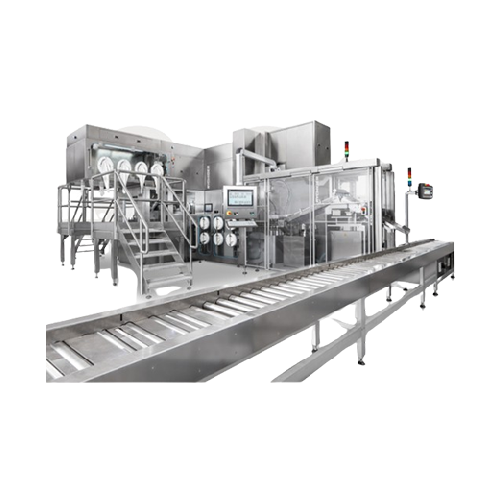

Liquid filling – Choose your liquid fillers depending on the product viscosity

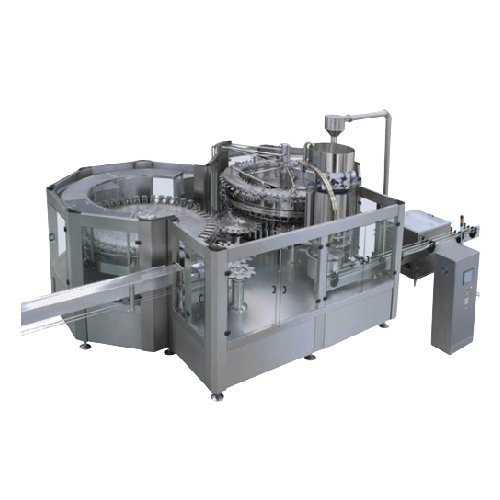

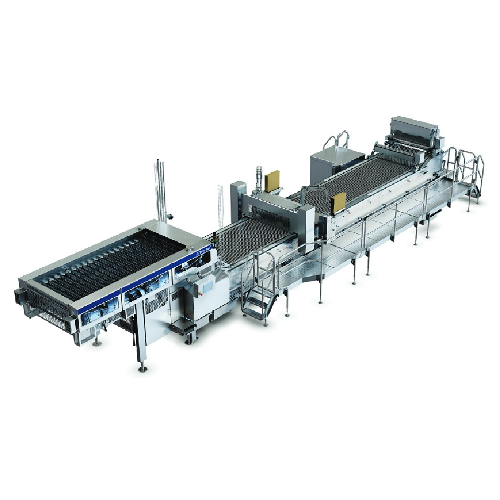

Liquid filling machines, also known as flow filling machines, are used extensively in the beverage industry for products such as mineral water, fruit juice, alcoholic beverages, and soft drinks. On the other hand, volumetric fillers, divided into gravity, pump, and piston fillers, are more suitable for packaging viscous substances. The significant difference between the two is that volumetric machines fill containers with the same product volume regardless of container size. In contrast, liquid fillers always fill containers to the same level, irrespective of volume.

What should you pay attention to when bottling your liquid product?

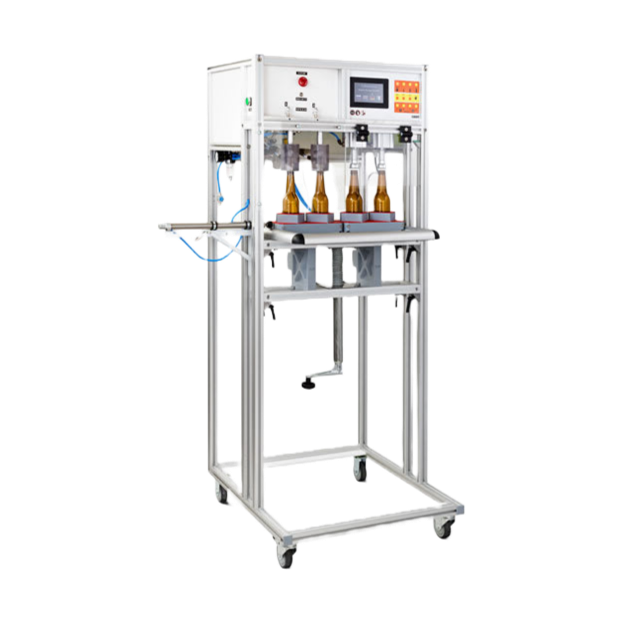

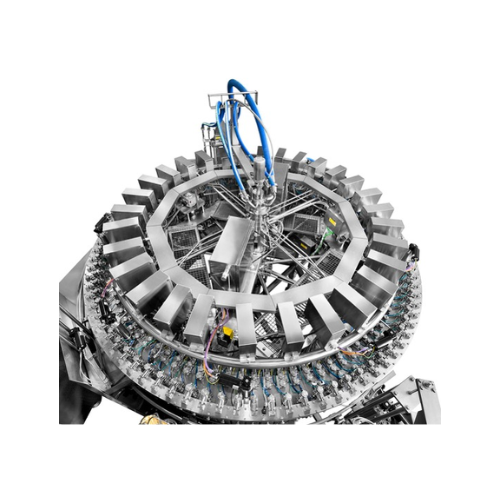

Whether tea, soft drinks, wine, or beer, the first thing that jumps out at you when choosing a drink is always its container. How your favorite beverages are bottled will depend on the beverage formulation and the nature of the liquid itself. During the bottling process, you need to transfer your product to the previously inspected bottle before capping it. Depending on your production scale and operation, you can adopt in-line or rotary fillers.

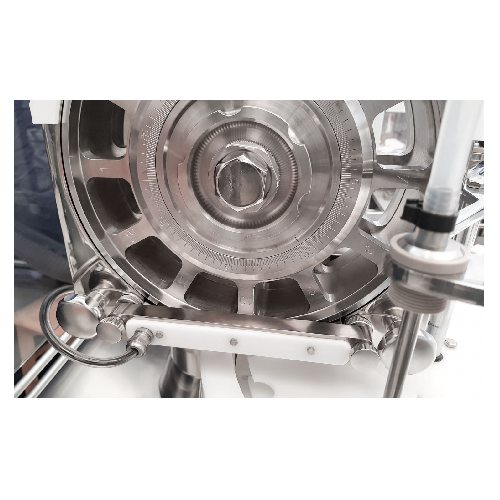

Inline liquid filling machines fill containers with both low- and high-viscosity substances. Rotary liquid filling machines are more complete consisting of several circular stations, each performing a different function, such as filling, sealing, and capping.

Bottling systems are also used in the beverage industry and food for different sauces such as ketchup, mayonnaise, or chili sauce.

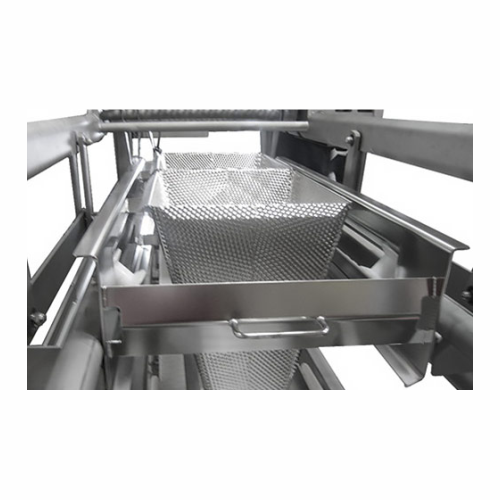

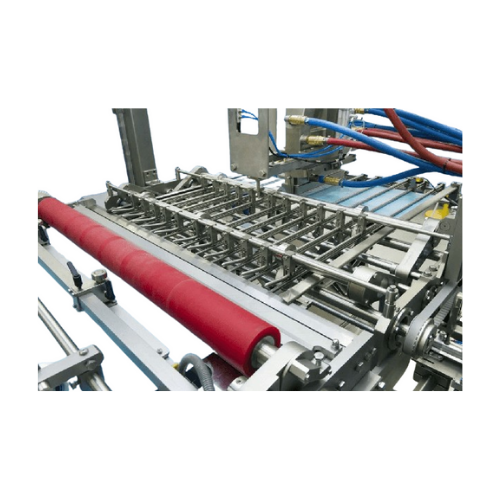

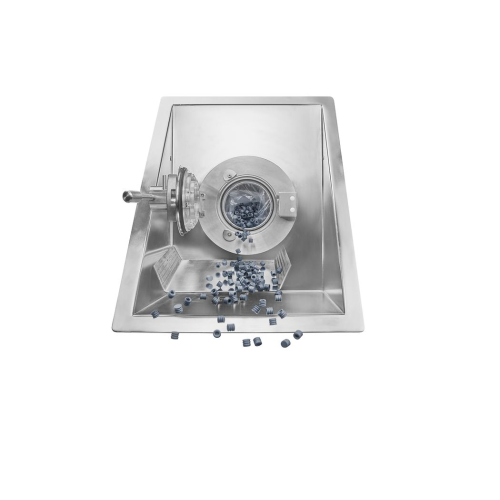

Powder filling – Powder characteristics to consider

It would be too easy if the powder always had the same characteristics, wouldn’t it?

When packaging powdered products such as pharmaceutical powder, protein powder, or milk powder, you need to consider the physical properties of the powder itself. A powder product can be considered free-flowing, non-free flowing, and semi-free flowing. For example, products like granulated sugar are defined as free flowing because their particles are not cohesive. Instead, powdered milk is a non-free flowing powder because it can be easily compressed and retain its shape after adding pressure. Instant coffee can be categorized as semi-free flowing powder.

Auger filling machines belong to the volumetric fillers and are pretty popular in the industry. They don’t weigh the powder, unlike the net weight filling machine, which is the only piece of powder filling equipment to weigh the powder before dispensing it into the container.

The auger filling machine is suitable for powders such as flour but can handle free-flowing powders and some non-free flowing powders. The vacuum powder filling machines are used for powders that do not require any further breakdown or agglomeration because they work without using an auger or agitator. These types of filling machines are not suitable for granules.

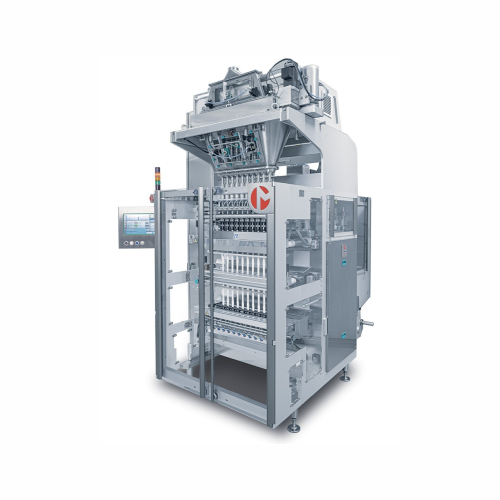

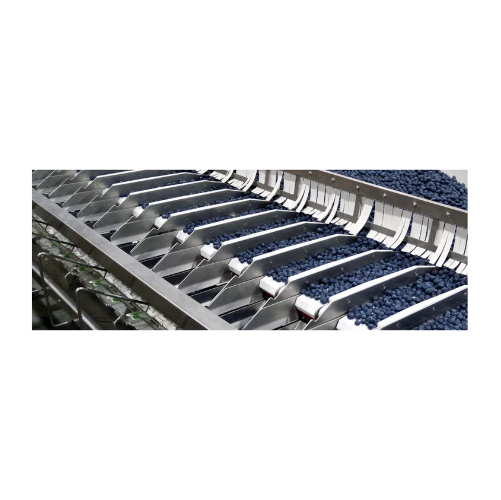

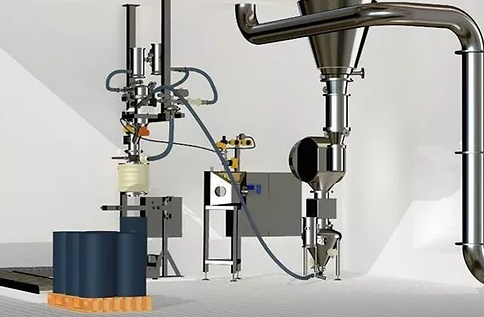

Bagging – not only for powders

Bagging is a packaging process that automatically inserts a measured amount of a product into a bag or a pouch. Powdered products such as coffee, cocoa powder, or baking powder undergo the bagging process. The choice of bagging equipment is critical since food products like coffee are pretty sensitive to air exposure.

Of course, the bag size varies depending on the product size and the production step. For example, semi-finished products such as nuts, seeds, or spices will be packed in flexible bulk containers for transportation and storage. Flexible intermediate bulk containers are used primarily in the chemical industry for fertilizers, dyes, or pigments.

Filling systems in the Pharma and Food industries

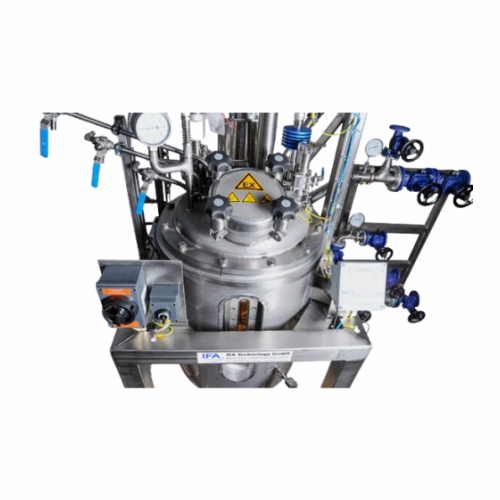

When it comes to pharmaceutical or food products, filling lines may require special precautions because these products are made specifically for human consumption and for being ingested. That’s why you will hear a lot about aseptic and sterile filling, especially in these two industries.

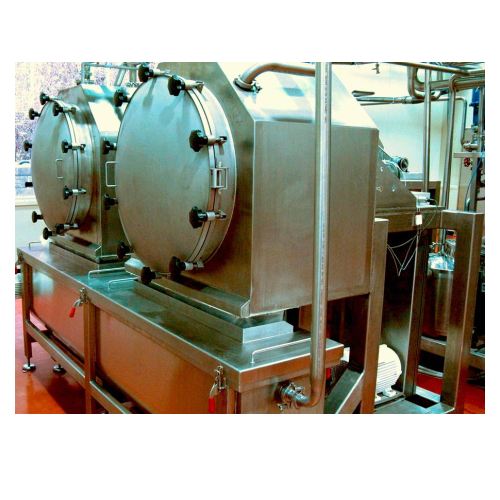

Aseptic vs. sterile – Is there any difference?

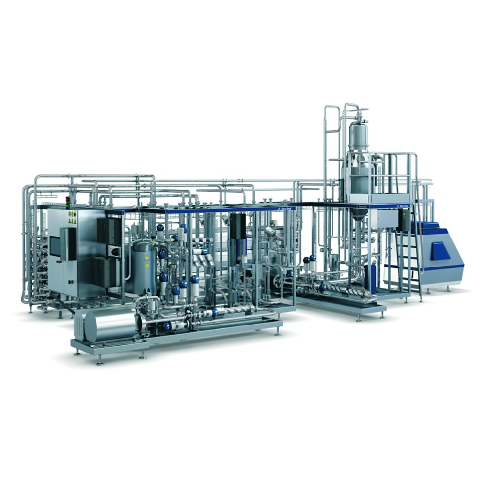

There has always been some confusion around these two terms. Both indicate techniques to create a sterile finished product, thus free of living microorganisms and as safe as possible. But although the two terms go hand in hand, they are different. After filling and sealing the container using sterile filling solutions, the product is subjected to a sterilization process using heat, radiation, or filtration. The product is sterilized in its final packaging.

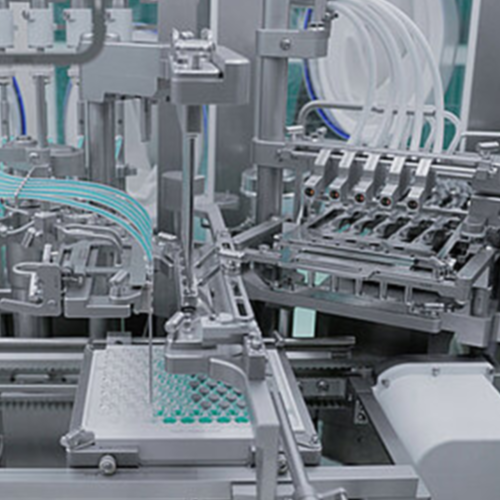

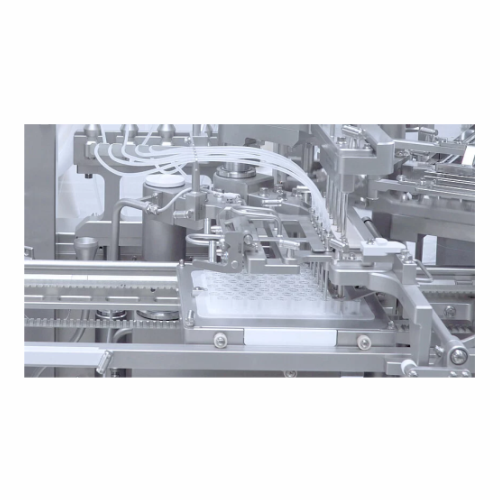

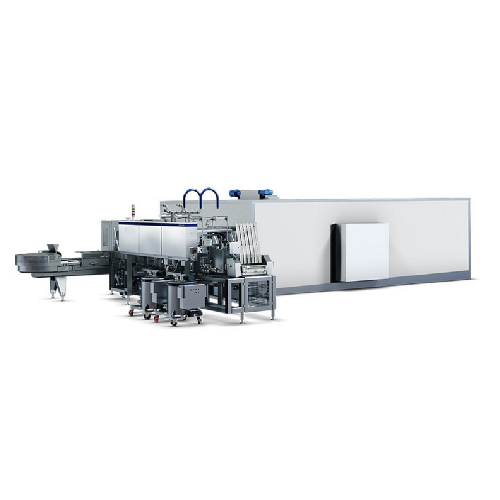

Aseptic processing is reserved for products that cannot withstand heat exposure from the terminal sterilization process. It is a technique where the product, the container, and the container closure are first sterilized separately and then brought together. This method is meant to maintain the sterility of a product assembled from different sterile components. Since the product is not sterilized in its final container, it is essential that the filling and sealing take place in a highly controlled environment (aseptic filling).

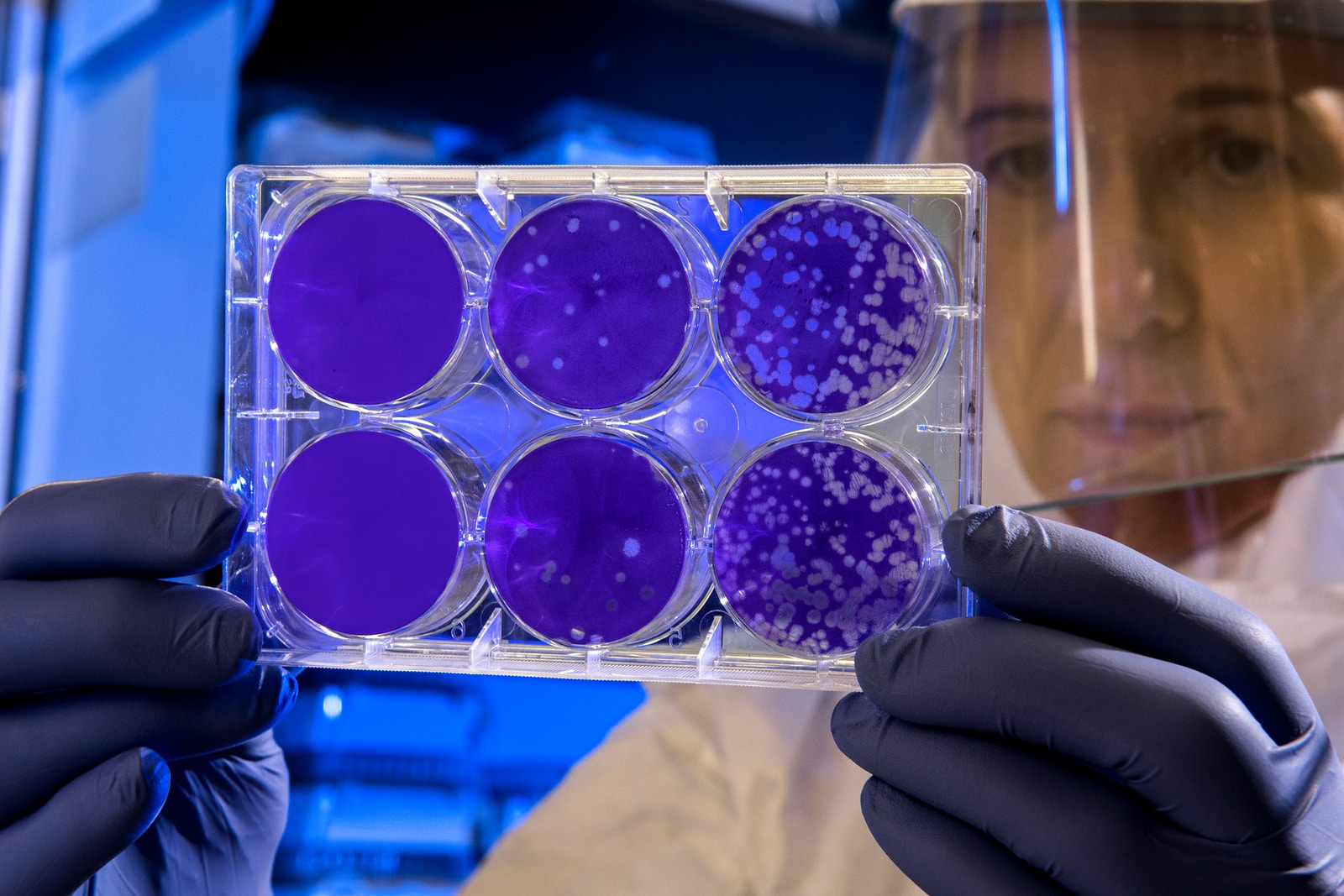

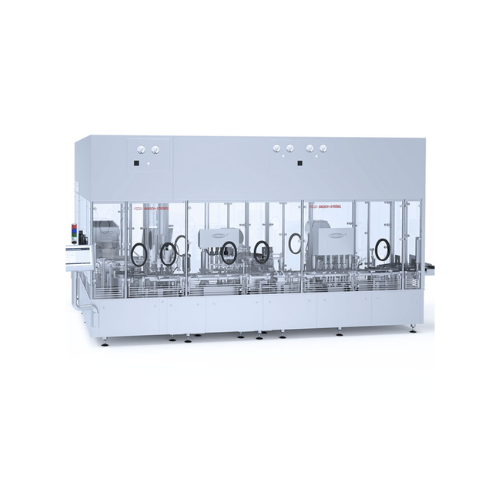

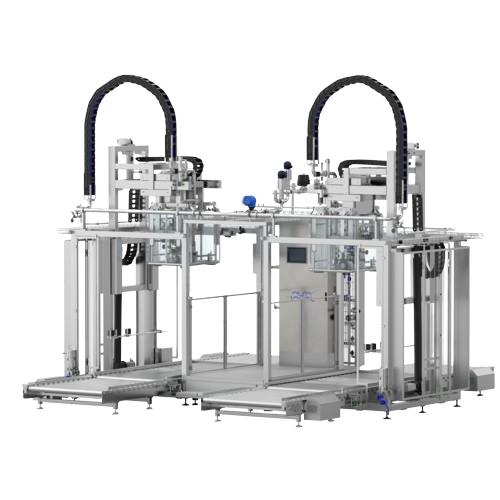

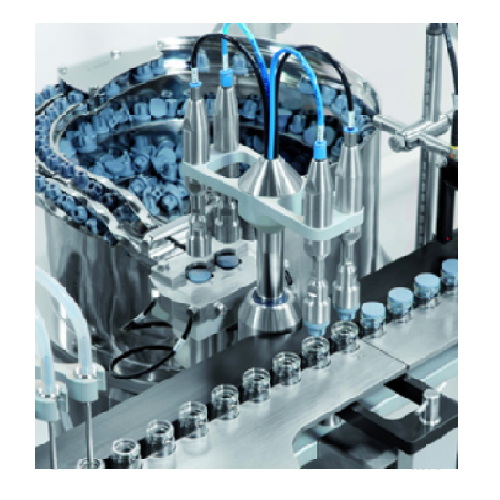

Pharmaceutical filling for ensuring product safety and sterility

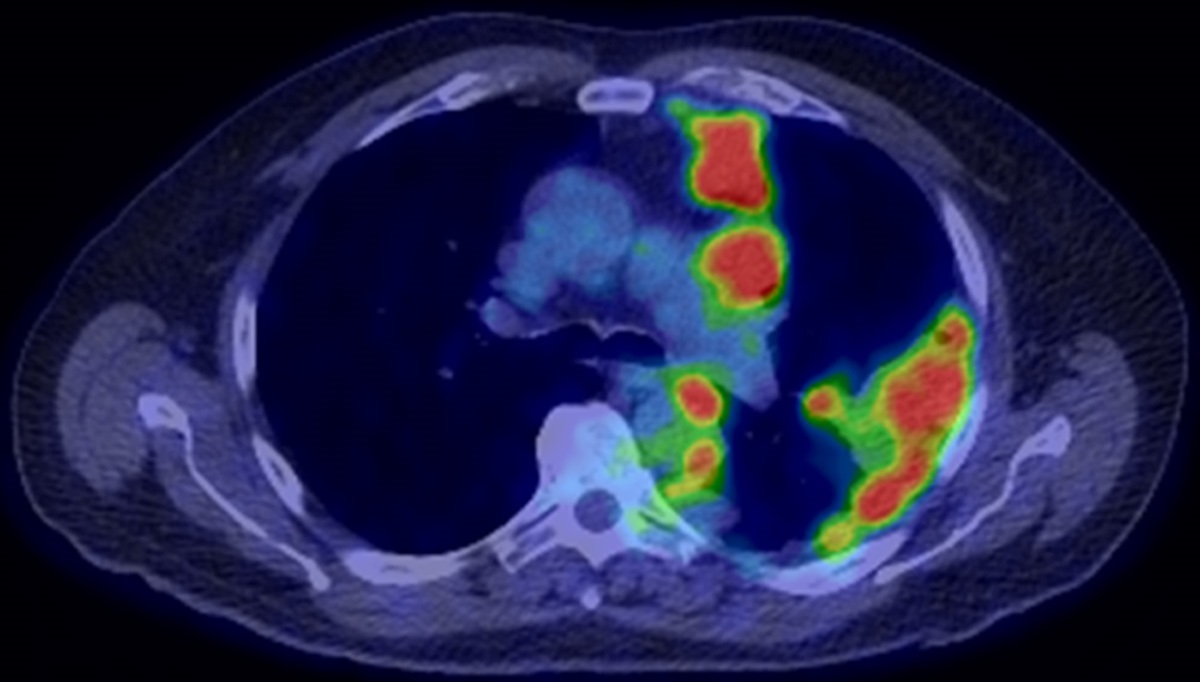

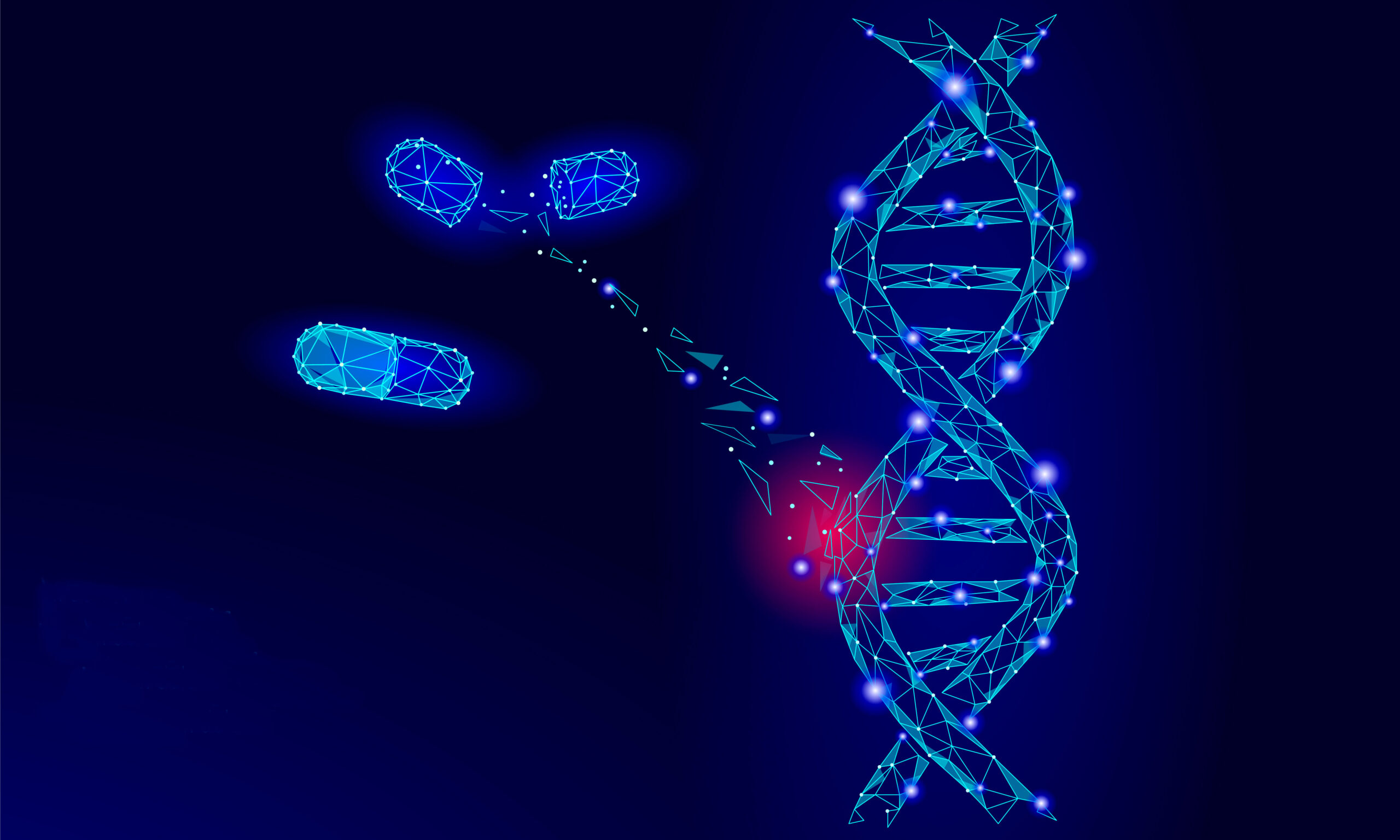

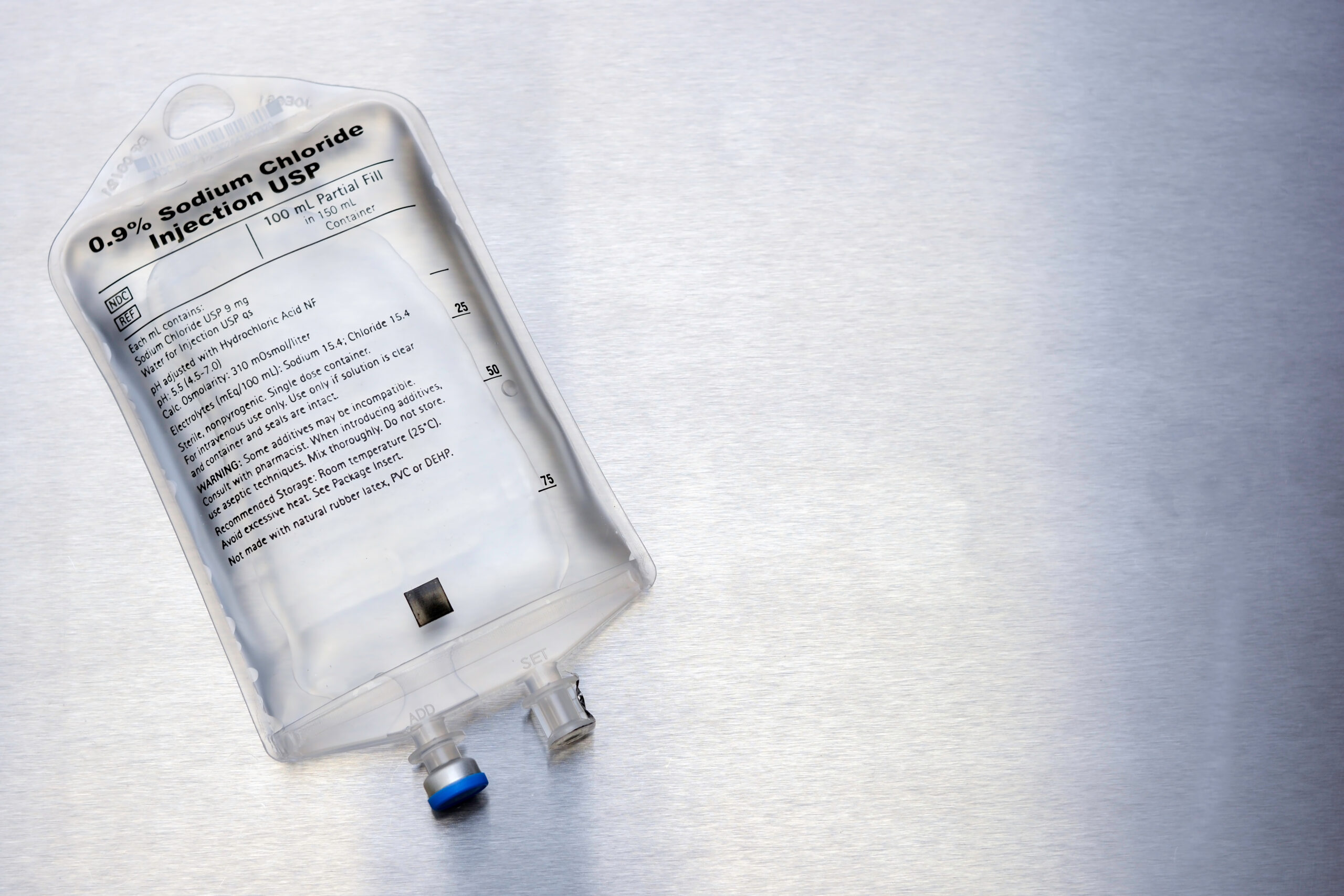

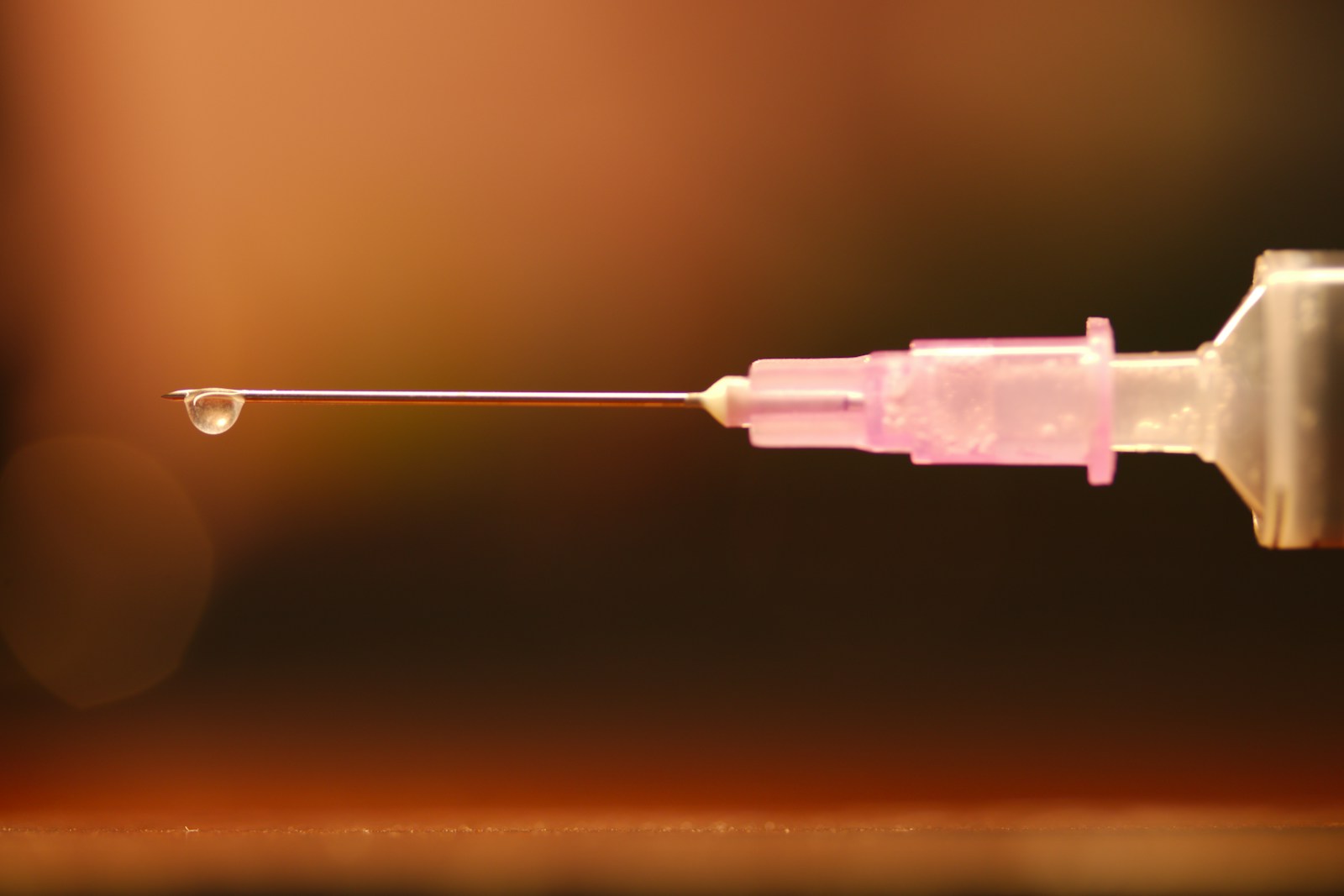

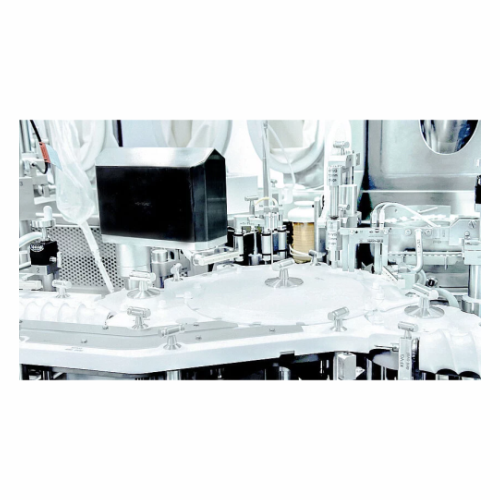

Vaccines or antibiotics are just two examples of drugs that cannot withstand heat sterilization, so they must be made through aseptic processing. When it comes to pharmaceutical filling, to ensure product safety and quality, aseptic fillers are widely used for filling and sealing drug containers such as vials, ampoules, and syringes. Aseptic filling is also used for parenterals since the entire process must be done in an aseptic environment to avoid contamination. The aseptic filling is very challenging since ensuring sterility is not easy, and failure can have dramatic consequences for the patients.

Aseptic filling in the food industry

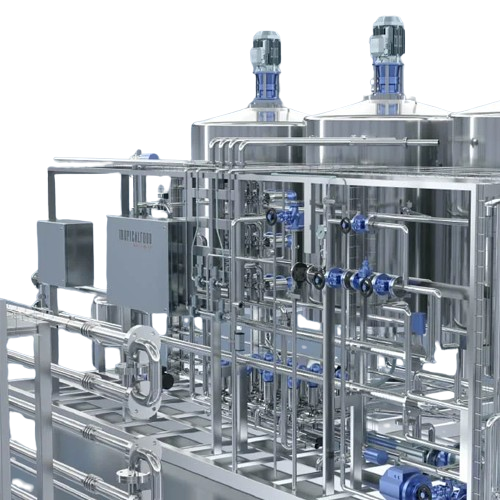

Aseptic filling is a food preservation method that ensures shelf-stable products, extending the food product shelf file and optimizing product quality. The important factors in the aseptic filling process are obtaining and maintaining sterile environment conditions for the filling and sealing process. It is used when producing dairy products, fruit juices, or sauces.

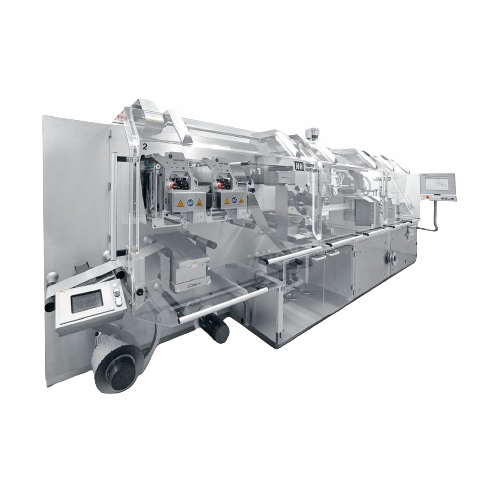

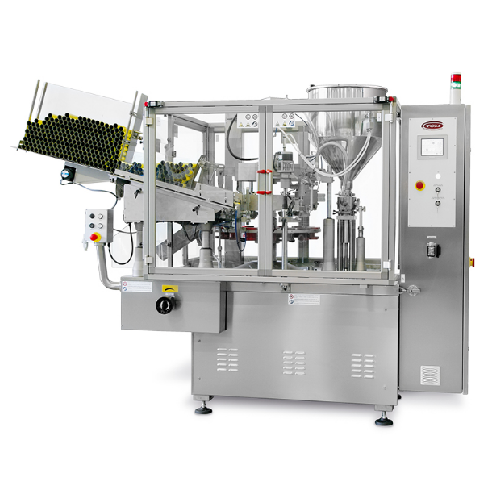

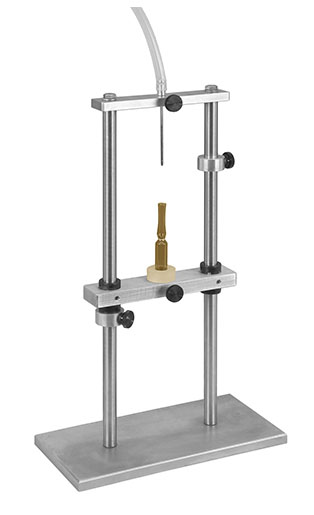

Tube filling equipment for viscous liquids or pastes

The packaging of choice is usually a tube made of plastic or metal when producers have to pack viscous liquid or pastes. In the food industry, tube filling equipment is used for packaging food pastes, while in the cosmetic industry for products such as toothpaste, ointments, gels, and creams.

Tube fillers consist of a pump injecting the product into the tube. The machine then crimps the end of the tube to seal it before packing the products into boxes for shipping.

What are you making?

Acetic acid

Acetone

Acrylic coatings

Acrylic emulsions

Acrylic paint

Acrylic sealants

Active pharmaceutical ingredients (API)

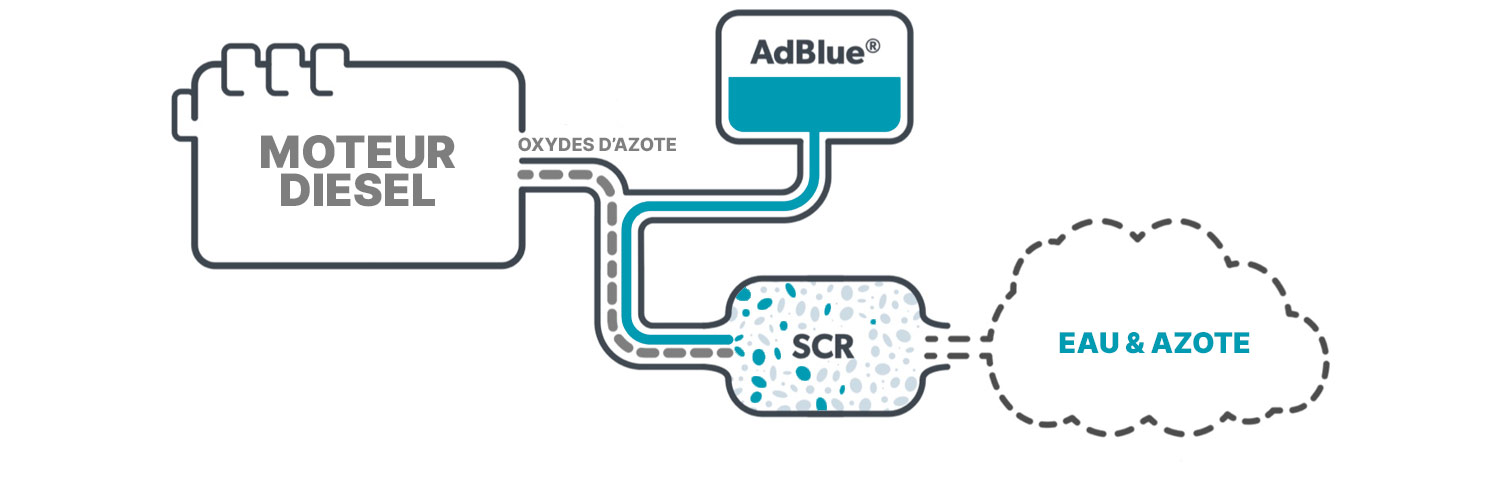

Adblue

Aerosol cans

Aerosols

Aioli

Ale beer

Alfredo sauce

All-purpose flour

Almond butter

Almond flour

Almond milk

Almond milk powder

Aloe vera gel

Alternative medicine

Aluminum beverage cans

Amber ale

Amoxicillin capsules

Ampoules

Analgesic tablets

Anhydrous pastes

Animal health products

Antacid tablets

Anti-aging cream

Anti-dandruff shampoo

Antibacterial ointment

Antibiotics

Antihistamine tablets

Antiseptic solutions

Api suspensions

Apple chips

Apple compote

Apple pies

Aromatherapy oils

Artist colors

Asthma inhalers

Automotive batteries

Ayran

Baby Food

Baby wipes

Bagels

Bakery fillings

Baking powder

Ball donuts

Bao

Barbecue sauce

Batter

Bavarois

Bb cream

Beauty products

Bechamel sauce

Beef gravy

Beef stew

Beer

Beer bottles

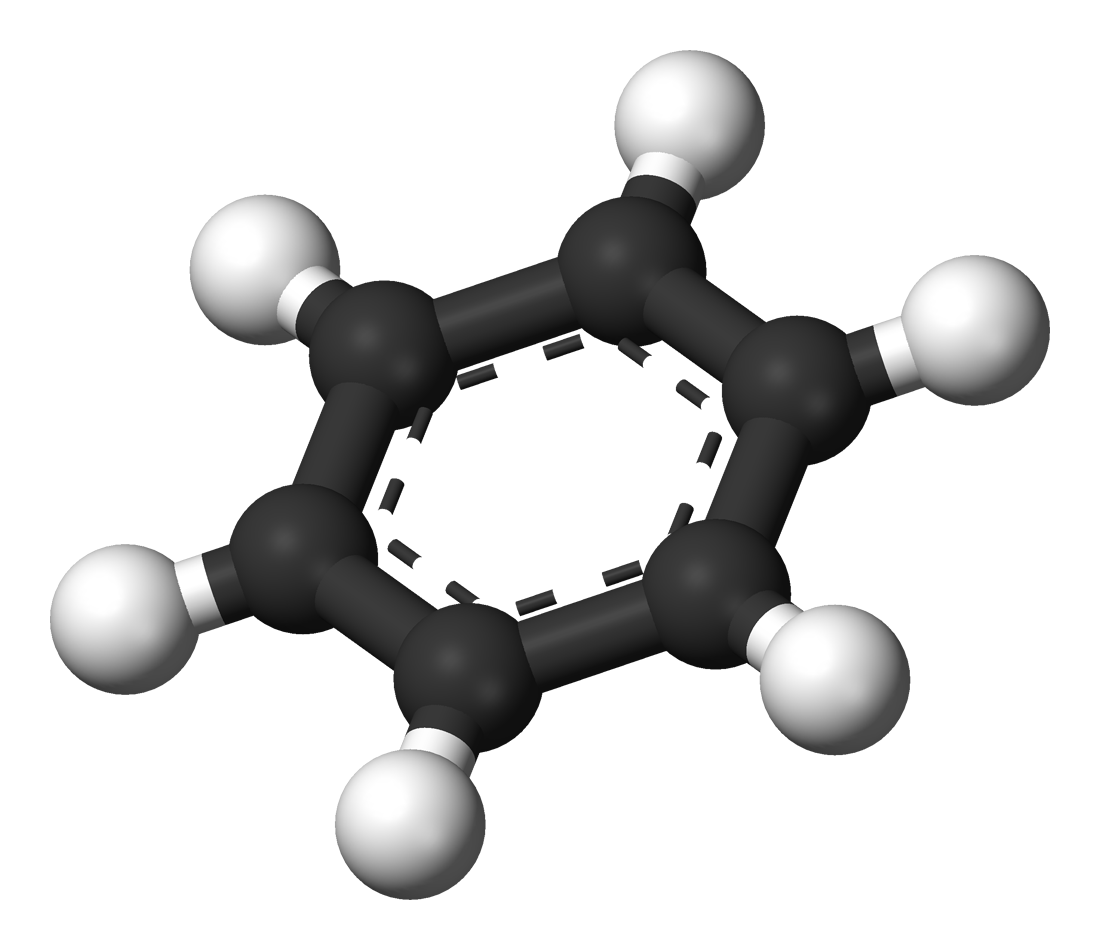

Benzene

Bfs products

Biocides

Biodiesel

Biologics

Blueberry jam

Blueberry muffins

Body care

Body lotion

Body wash

Boiled sausage

Bolognese sauce

Botanical medicine

Bottled drinks

Bottles

Bouillon cubes

Bran

Brandy

Bread mix

Bread spreads

Brie cheese

Brines

Brown sugar

Buffer solutions

Bulk chemicals

Burrata

Buttercream

Cake

Calcium supplements

Candied fruits

Candy bars

Canned beans

Canned beverages

Canned cat food

Canned corn

Canned dog food

Canned fish

Canned fruits

Canned peaches

Canned soft drinks

Canned soup

Canned tomatoes

Cans

Caplets

Carbonated beverages

Carbonated soft drinks (csd)

Carrot juice

Carrot puree

Cartons

Cartridges

Cashew milk

Cat food

Cbd distillate

Cement

Center-filled lollipops

Chamomile oil

Chamomile tea bags

Champagne

Cheese Blocks

Cheese sauce

Cheese spreads

Cheesecake

Chemical additives

Chemical emulsions

Chemotherapy drugs

Chili powder

Chili sauce

Chocolate chip muffins

Chocolate croissants

Chocolate ganache

Chocolate milk

Chocolate molds

Chocolate mousse

Chocolate truffles

Chutneys

Cigarettes

Cigars

Cinnamon rolls

Citrus Fruit

Cleaning agents

Cleaning wipes

Club sandwiches

Coenzyme q10 capsules

Coffee capsules

Cola soft drink

Cold brew coffee

Concrete admixtures

Condensed milk

Condiments

Conditioner

Confectionery fillings

Construction chemicals

Consumer electronics

Cooked sausages

Cooking cream

Corn Chips

Corned beef

Cosmetic creams

Cosmetic emulsions

Cosmetic foundation

Cosmetic lotions

Cosmetic powders

Cosmetic serums

Cottage cheese

Cough syrup

Covid-19 test kits

Covid-19 vaccines

Crackers

Cream cheese

Cream crackers

Cream fillings

Cream puffs

Creams

Croissants

Crop protection agents

Cupcakes

Curd

Curd cheese

Custard

Cytotoxic drugs

Danish pastries

Dental

Deoderant

Deodorants

Desserts

Detergent bottles

Detergent pods

Detergent powder

Detergent tablets

Diagnostic kits

Diagnostic reagents

Diagnostics

Dietary supplements

Digital printing inks

Dijon mustard

Dips

Dishwashing liquid

Dishwashing powder

Disinfectant wipes

Disinfectants

Dna extraction kits

Dressings

Drinks

Drug formulations

Dry pet food

Dry powder inhalants (dpi)

Dulce de leche

Eardrops

Echinacea extract

Eclairs

Egg rolls

Elderberry extract

Electrolyte drinks

Electrolyte solutions

Emulsion paints

Emulsions

Engine oils

Epoxy adhesives

Epoxy coatings

Epoxy resin

Er tablets

Erythropoietin

Esl milk

Essential oil blends

Eucalyptus oil

Evaporated milk

Eye care products

Eyedrops

Fabric softener

Face cream

Facial moisturizers

Fermented dairy products

Feta cheese

Filled croissants

Fillings

Film-coated tablets

Fish oil capsules

Fish oil supplements

Flavoured milk

Flower extract

Fluoride toothpaste

Fluorodeoxyglucose (fdg)

Foam

Food powders

Food supplements

Food-to-go

Formulated dairy products

Foundation cream

Frankfurters

Freeze dried berries

Freeze-dried pharmaceuticals

Freeze-dried plasma

Frosting

Fruit compote

Fruit jam

Fruit jellies

Fruit juice

Fruit juice concentrate

Fruit leather

Fruit nectars

Fruit pies

Fruit preserves

Fruit puree

Fruit syrups

Fruit yogurt

Functional drinks

Fungicides

Garlic paste

Gas

Gasoline

Gel capsules

Gel nail polish

Gelatin capsules

Gelatin desserts

Gels

Gene therapy

Gin

Ginger ale

Ginger paste

Ginkgo extract

Ginseng extract

Glass cleaner

Gloss varnish

Glue

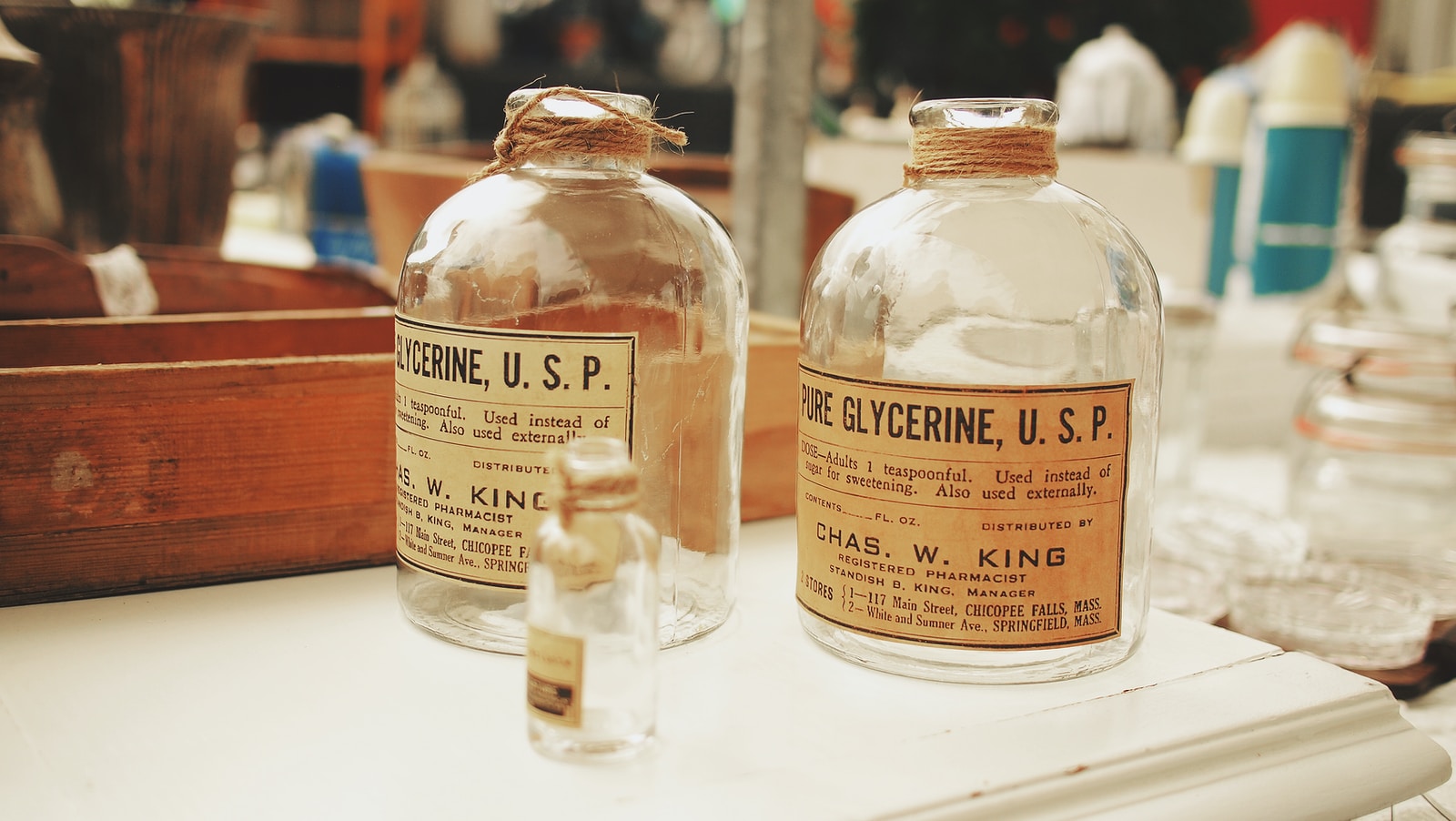

Glycerine

Glyphosate herbicides

Gmp radiopharmacy

Grape Juice

Grapefruit juice

Grease

Greek yoghurt

Hair care products

Hair conditioner

Hair dye kits

Hair gel

Halloumi

Halva

Hand cream

Hand sanitizer

Hand soap

Hard gelatin capsules

Hazelnut spread

Hazelnuts

Hepatitis b vaccines

Herbal Extracts

Herbicides

Herbs

Home care products

Honey

Hormone therapies

Hot dogs

Hot melt adhesives

Hot melt glue sticks

Hot sauce

Household detergents

HPMC capsules

Hummus

Hyaluronic acid

Hyaluronic acid serums

Hydraulic oil

Hydrochloric acid

Hydrocortisone cream

Hydrogen peroxide

Hygiene products

Hygroscopic products

Ibuprofen

Ice cream bars

Ice cream cakes

Ice cream cones

Ice cream cups

Ice cream sandwiches

Ice cream tubs

Iced coffee

Icing

Immediate-release tablets

Infant formula

Infant nutrition

Influenza vaccines

Infusions

Inhalers

Injectable biologics

Ink

Inkjet printer cartridges

Insecticides

Instant drink powders

Insulin

Insulin injections

Insulin pens

Intravenous solutions

Iodine-131

Iron supplements

Isotonic drinks

Italian dressing

Jam

Jars

Jellies

Juice cartons

Kefir

Ketchup

Large volume parenterals

Lasagna

Latex

Laundry detergent

Lavender oil

Layered cakes

Lead-acid batteries

Lemon curd

Lemon juice

Lemonade

Lip balm

Lip gloss

Lipstick

Liquid detergents

Liquid foods

Liquid Formulations

Liquid nutritional supplements

Liquid soap

Liquid supplements

Lotions

Lubricants

Luncheon meat

Lutetium-177

Macaroni and cheese

Macarons

Mango chutney

Mango juice

Mango pulp

Mango sorbet

Maple syrup

Margarine

Margerine

Margherita pizza

Marinades

Marinara sauce

Marmalade

Mascara

Mascarpone

Mayonnaise

Medical devices

Medicine

Methanol

Milkshakes

Mineral oils

Mineral water

Minestrone soup

Mochi

Moisturizers

Monoclonal antibodies

Monomers

Mortadella

Mosquito repellent

Motor oil

Mousses

Mouthwash

Mozzarella

Mrna vaccines

Muffins

Multivitamin supplements

Mustard

Nail polish

Nano suspensions

Nanoemulsions

Nasal spray

Natural paints

Next generation biologics

Nitrogen

Non-alcoholic beer

Non-carbonated beverages

Non-dairy creamer

Nut oil

Nut paste

Nut butter

Nutritional drinks

Nutritional formula

Nutritional shakes

Oat milk

Ointment

Oleochemicals

Olives

Omega-3 capsules

Oncology drugs

Ophthalmics

Oral care

Oral liquid formulations

Oral vaccines

Orange juice

Orange marmalade

Orphan drugs

Paint cans

Paint

Parenteral drugs

Parenterals

Passion fruit juice

Pasta sauce

Pastes

Pasteurized juice

Pasteurized milk

Pastries

Pastry cream

Pcr reagents

Peanut butter

Peanuts

Personalized medicine

Pesticide

Pharmaceutical capsules

Pharmaceutical cartridges

Pharmaceutical creams

Pharmaceutical emulsions

Pharmaceutical granules

Pharmaceutical ointments

Pharmaceutical packaging

Pharmaceutical powders

Pharmaceutical suspensions

Pharmaceutical syrups

Pharmaceutical vials

Pickled vegetables

Pickles

Pie

Pineapples

Plant-based beverages

Plant-based yogurt

Plastic containers

Plastic packaging

Plasticizers

Polishing agents

Polypropylene containers

Pomegranate juice

Popcorn

Pouches

Powder for suspensions (PFS)

Powdered drink mixes

Powdered sugar

Pralines

Pre-dough

Pre-filled Syringes

Preserves

Pretzels

Printer ink

Probiotic drinks

Probiotic supplements

Probiotic yogurt

Probiotics

Protein-based drugs

Protein therapeutics

Pudding

Puree

Purified water

Quiche lorraine

Quiches

Ranch dressing

Ravioli

Reagents

Refrigerants

Rehydration solutions

Resin

Rice pudding

Ricotta

Rigid containers

Road marking paints

Rodenticides

Root beer

Rose oil

Rye bread

Sachets

Salad dressing

Salami

Saline solutions

Salsa

Salted butter

Samosas

Sand

Sandwich cookies

Sandwiches

Sausages

Scones

Sea buckthorn oil

Sealants

Semi-solids

Semolina

Serums

Shampoo

Sheet cakes

Ship paints

Shower gel

Shumai

Silicone

Single-use bags

Skin care

Slurry

Small volume parenterals

Snack packaging

Soap

Soda

Soft Candy

Solvents

Sorbet

Soup cans

Sour cream

Soy milk

Soy yogurt

Sparkling water

Sparkling wine

Spice pastes

Sponge cake

Sport drinks

Sports nutrition

Spring rolls

Stick ice-cream

Structural adhesives

Sublingual spray

Sun care

Supplements

Suspensions

Swiss rolls

Syringes

Tahini

Tapenades

Tartar sauce

Tarts

Tea bags

Tea sachets

Tempeh

Test kits

Thc gummies

Therapeutic proteins

Thermoformed packs

Thinners

Tin bread

Tinctures

Tins

Tissue boxes

Toffees

Toluene

Tomato concentrate

Tomato juice

Tomato paste

Tomato sauce

Tomato soup

Tomatoes

Toner

Tonic water

Toothpaste

Topical creams

Toppings

Torrone

Tortellini

Tortilla Chips

Transdermal patches

Trays

Truffle cream

Tubes

Uht milk

Uv-curable inks

Vaccine vials

Vaccines

Vegan sausage

Vegan sausages

Vegetable chips

Vegetable powder

Vegetable Puree

Vegetarian sausages

Veterinary

Veterinary antibiotics

Veterinary vaccines

Vials

Vinaigrette dressing

Vinegar

Viral vector vaccines

Vitamin C

Vitamin c supplements

Vitamin-enriched beverages

Vitamin premixes

Vitamin water

Vitamins

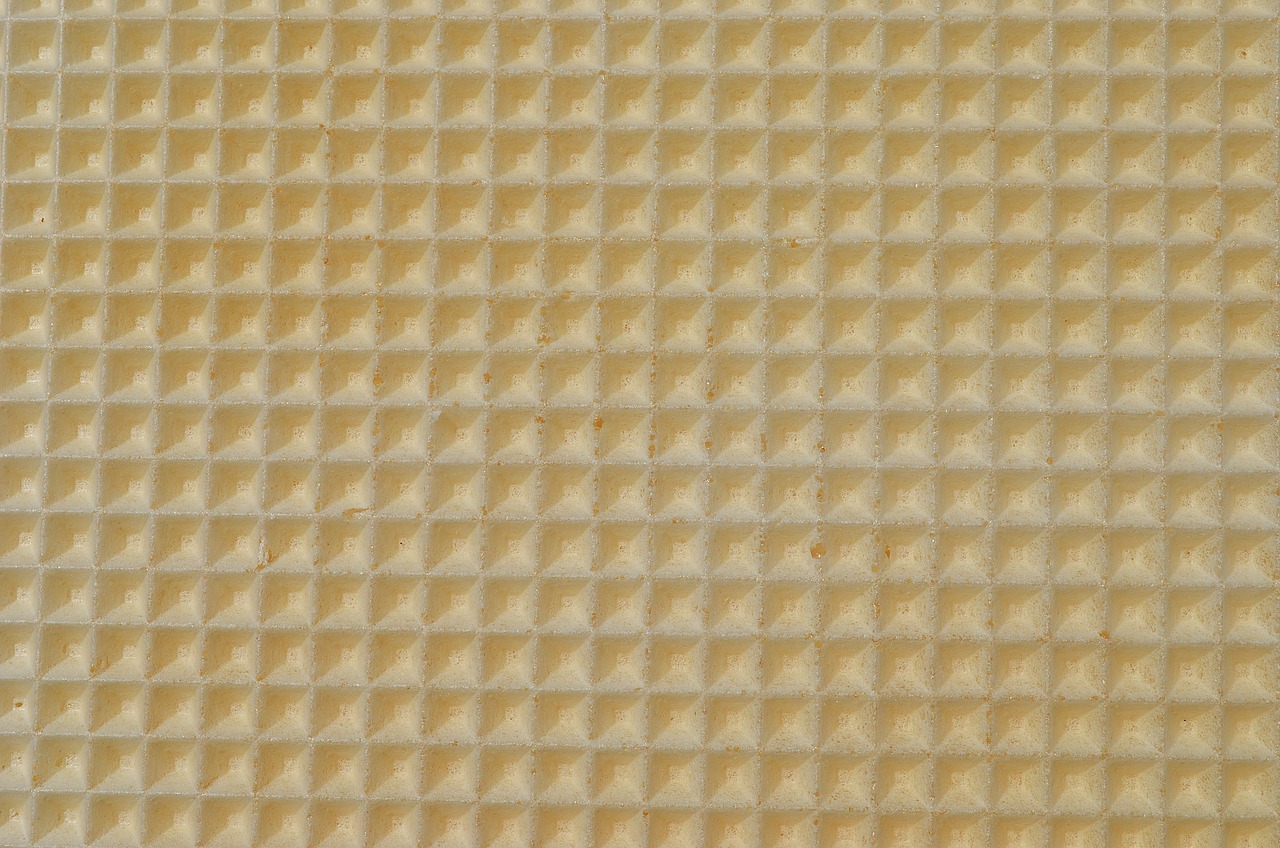

Wafer biscuits

Wafer rolls

Wafer sticks

Wafers

Wall paint

Water-based paints

Water for injection

Water-ice lolly

Water-ice push-up

Waterproof mascara

Wet pet food

Whey

Whey protein

Whipped butter

Whipped cream

Whisky

Whitening toothpaste

Wine bottles

Wraps

Yogurt cups

Yogurt parfaits

Yogurt tubs

Aseptic filling equipment

Aseptic processing systems

Auger filling machines

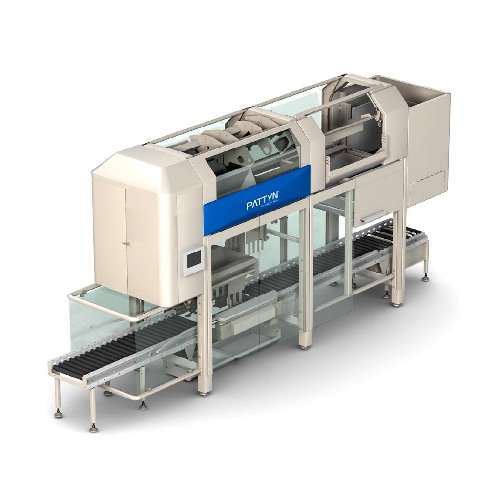

Automatic packaging systems

Bag filling machines

Bag inserters

Bag-in-box fillers

Bagging machines

Beverage filling machines

Bfs systems

Blister packaging machines

Blow Molding Systems

Bottle filling equipment

Bottle filling machines

Bottling lines

Box filling machines

Bulk bag fillers

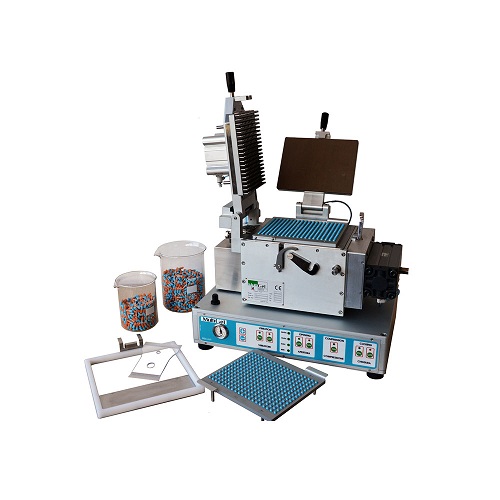

Capsule fillers

Capsule filling machines

Capsule sealing machines

Cartridge filling machines

Corrosive filling machines

Cup filling machines

Diagnostic reagent filling systems

Doypack packaging machines

Fibc fillers

Fill level inspection systems

Filling stations

Filling systems for tins and jars

Flow meter filling machines

Form fill seal machines

Form fill sealing equipment

Gravimetric filling machines

High-speed packaging machines

Horizontal flat pouching machines

Horizontal form fill seal machines

Intermittent motion cartoners

Isobaric filling machines

Large volume oral liquid filling systems

Liquid fillers

Lvp filling lines

Mono-dose strips filling machines

Piston fillers

Plastic bottle bfs machines

Pneumatic filling machines

Pouch filling machines

Powder auger fillers

Precision filling scales

Rotary fillers

Sachet filling machines

Sterile Filling Solutions

Stick pack machines

Svp filling lines

Syringe filling machines

Tablet counter filling machines

Timed fill filling machines

Tube filling equipment

Vacuum bottling machines

Vacuum fillers

Vacuum stuffers

Vertical form fill seal machines

Vial filling lines

Volumetric fillers

Weigh fillers

Which filling technology do you need?

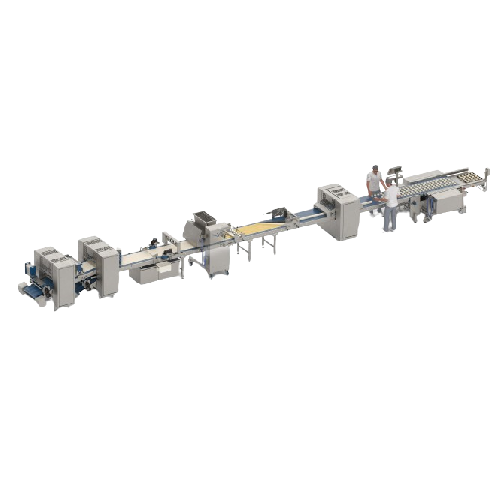

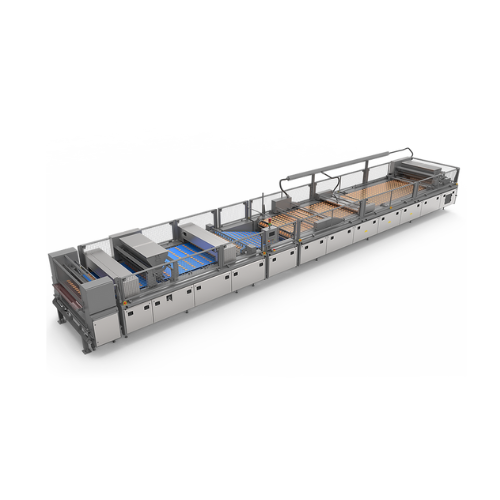

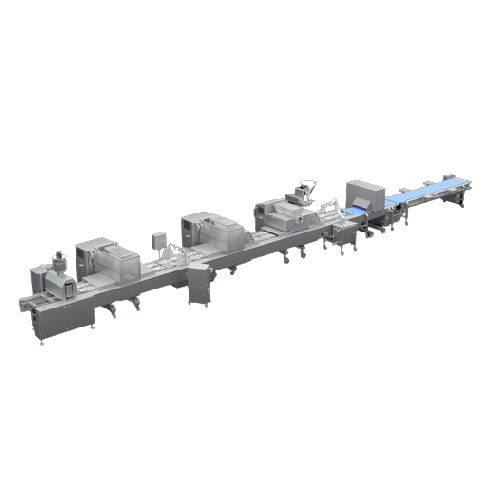

Baguette cutting and sauce filling system

Optimize your bakery production with an innovative system that seamlessly cuts a...

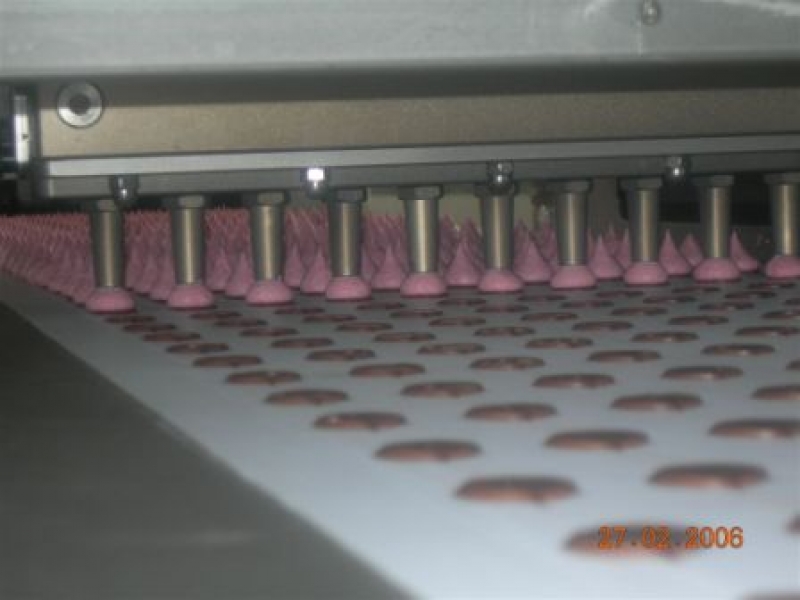

Lobe depositors and extruders for filled and decorated cookies

Optimize your bakery production with precision depositing...

Volumetric piston depositors for cake and pie fillings

Achieve precise depositing and gentle handling of varied doughs an...

Cakes and pastry fill injector

Achieve precise and efficient filling of a variety of bakery products, minimizing waste and d...

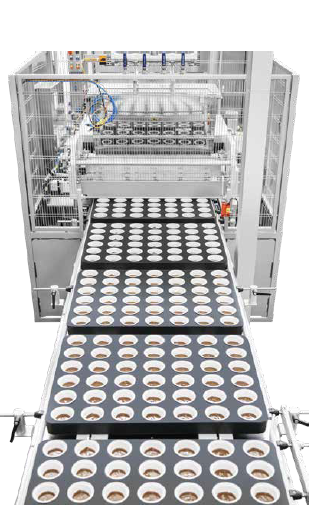

Cup filling and sealing system for dairy products

Optimize your production line with versatile cup filling and sealing ca...

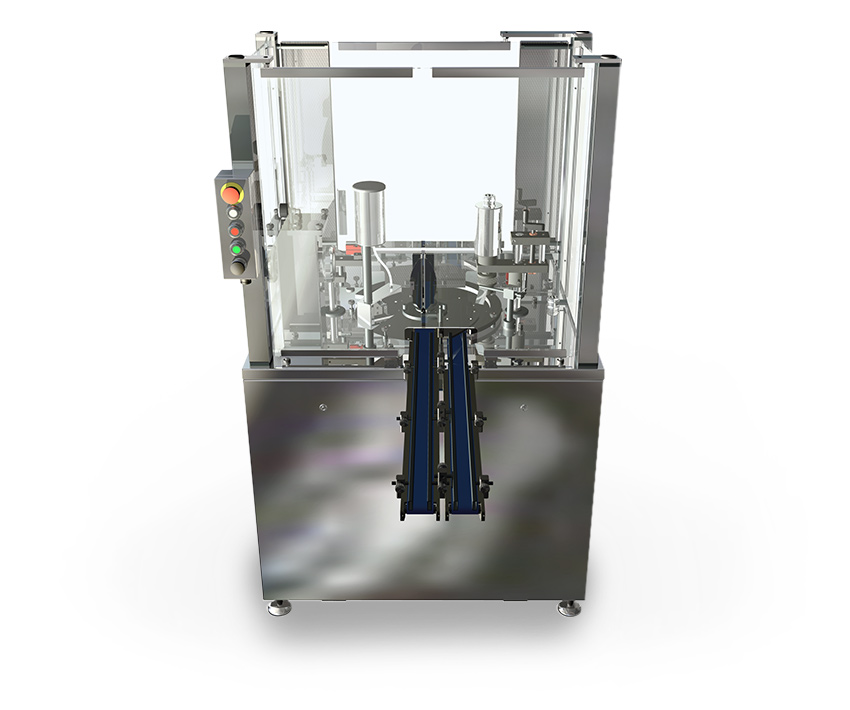

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

High-speed aerosol filling system for personal care products

Streamline your aerosol production with a multi-functional ...

Rotary continuous aerosol product filler

Achieve precise aerosol filling with high-speed efficiency, designed for operation...

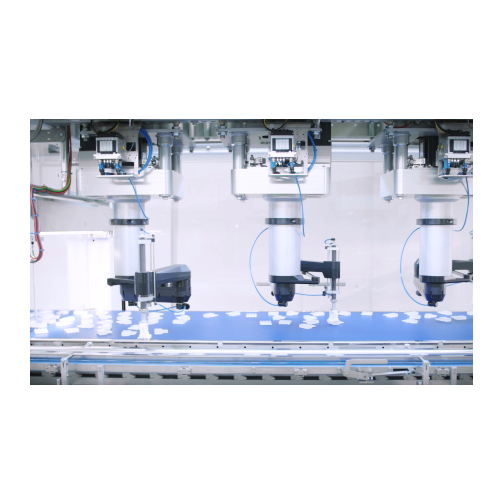

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

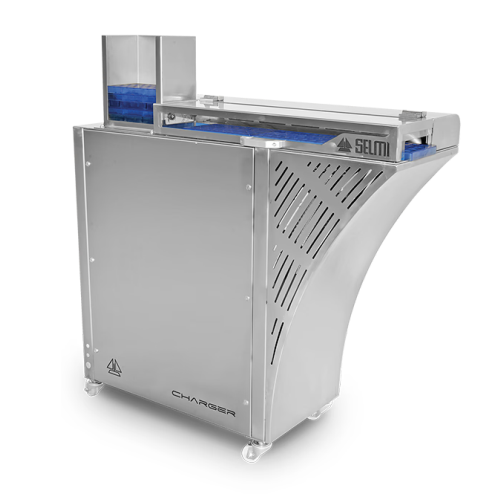

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

Buttercream filling applicator for chocolates

Enhance your confectionery process with precision dosing and moulding to cre...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

Filling system for chocolates and pralines

Efficiently dose, mold, and fill chocolates to create a variety of enticing con...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

Depositors for bakery fillings

Achieve precise and high-speed depositing of bakery and pastry fillings to optimize your prod...

Linear belt vibratory weigh filler for solid chocolate

Optimize your chocolate production by minimizing product giveaway ...

Linear vibratory weigh filler for fragile food products

Achieve precise and gentle filling of fragile food products with ...

Bulk box filler for bakery and pastry products

Efficiently pack fragile bakery and pastry products with gentle handling an...

High-speed baguette case filling station

Effortlessly organize and pack bakery products into cases at high speed, ensuring ...

Vertical fill and seal bagging machine for bakery products

Streamline your bakery product packaging with this versatile ...

Coffee bean and ground coffee filling system

Efficiently fill tins and jars with coffee beans or ground coffee while ensur...

Filling system for ground coffee in tins

Achieve precise weight control and enhanced throughput with a high-speed filling s...

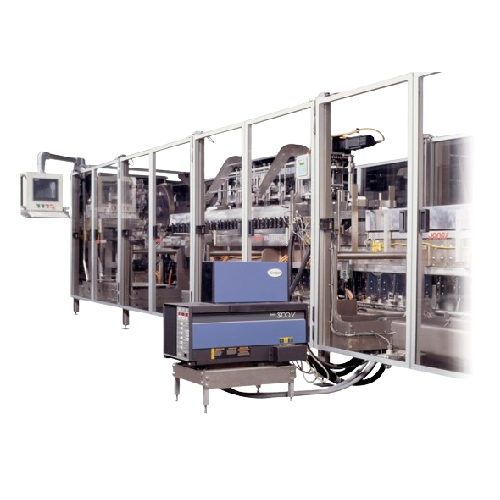

Capsule filling system with in-line weight control

Experience precise capsule filling with high-speed accuracy, designed ...

High throughput capsule filling system

Achieve precise, high-speed capsule filling with versatility, ensuring product integ...

High-speed capsule filling system

Maximize production efficiency with high-speed capsule filling designed for precise dosin...

Capsule filling system for high volume production

Maximize your capsule production efficiency with a system designed to s...

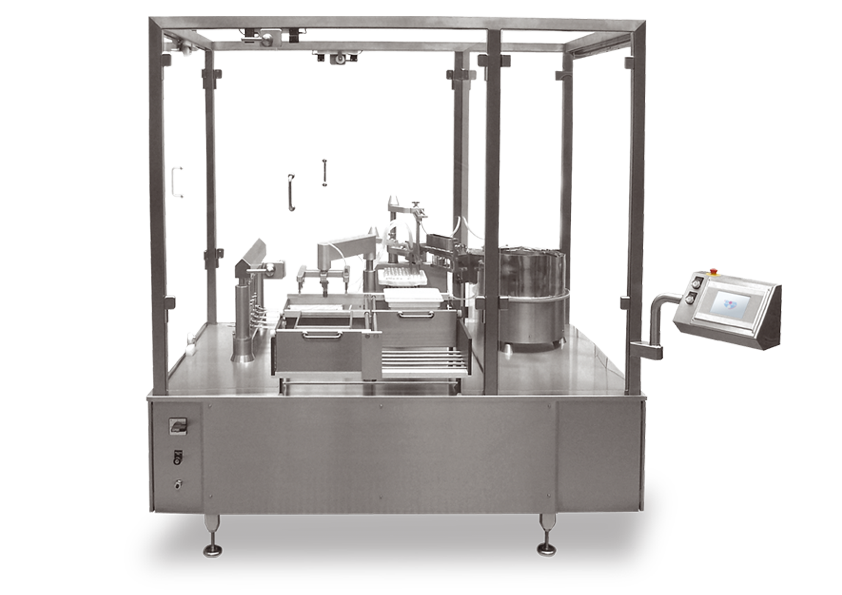

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Carbonation and filling system for Pet and glass bottles

Optimize your beverage production with precise carbonation, fill...

Rotary weight filler for edible oil

Optimize your liquid product filling with precise weight control, ensuring high accurac...

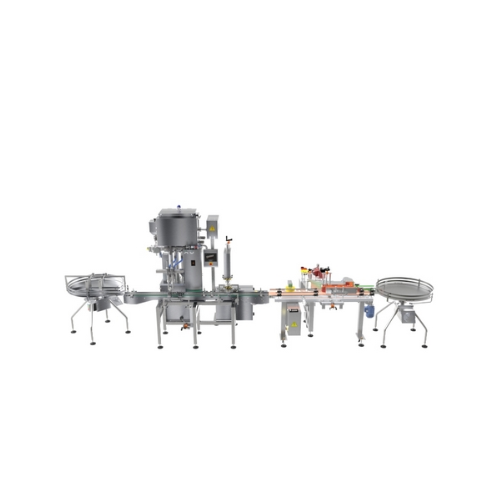

Filling and capping solution for oral liquid products

Achieve precise, high-speed filling and capping of oral liquids wit...

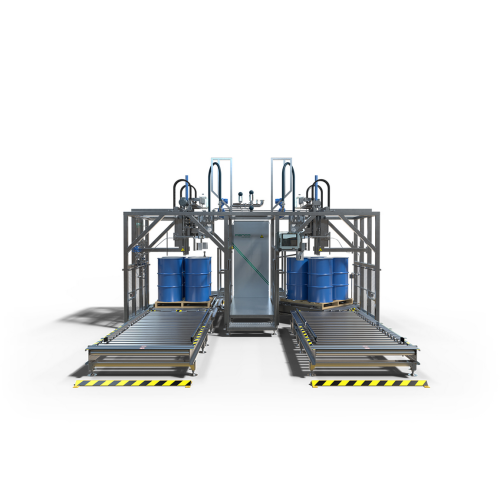

In-line weight filler for drums and kegs

Achieve precise and efficient weight-based filling for large liquid containers, en...

Rotary weight filler for Pet and Hdpe bottles

Enhance your production line with precise weight-based filling, ensuring rap...

Gravimetric filling and capping system for chlorine solutions

Optimize your filling and capping processes for chlorinate...

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

Tube filling solution for plastic and laminate tubes

Ensure precise tube filling and sealing with quick changeovers, enha...

Tube filling solution for plastic, laminate, and aluminum tubes

Optimize your production line with a versatile tube fill...

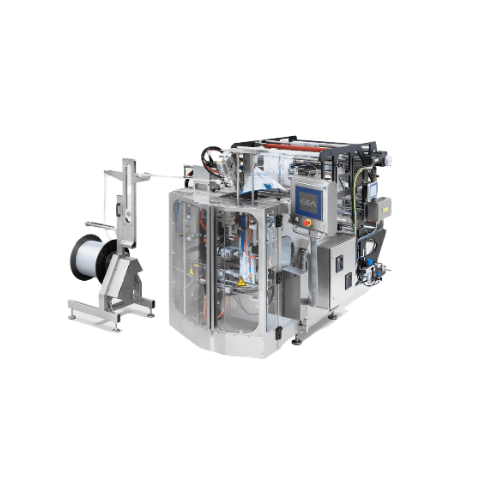

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

Oil and fat filling system for industrial use

Optimize your production line with this precise filling solution, designed t...

Accurate powder filling solution

When precision is paramount, this solution offers exceptional accuracy, filling powders up ...

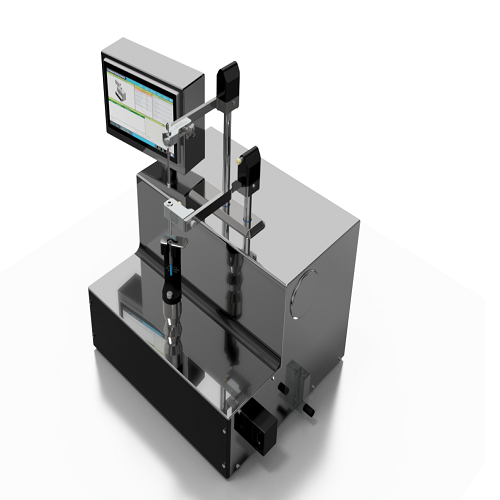

Automated liquid handler for high precision plate filling

Streamline your laboratory workflow with an intuitive system d...

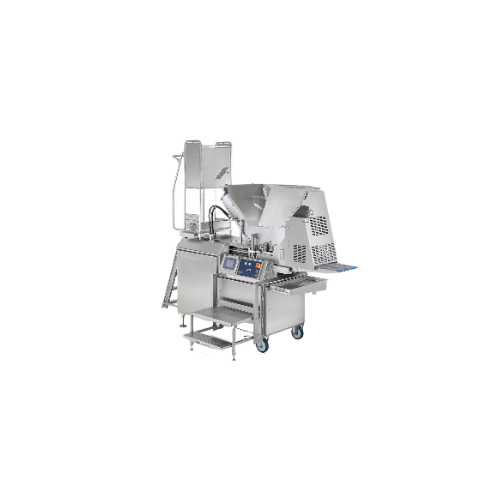

Upright stainless steel hydraulic sausage fillers

Streamline your sausage production with precise portioning and minimal ...

Co-extruder for filled sweet and savoury products

Effortlessly create a variety of filled sweet and savoury products, fro...

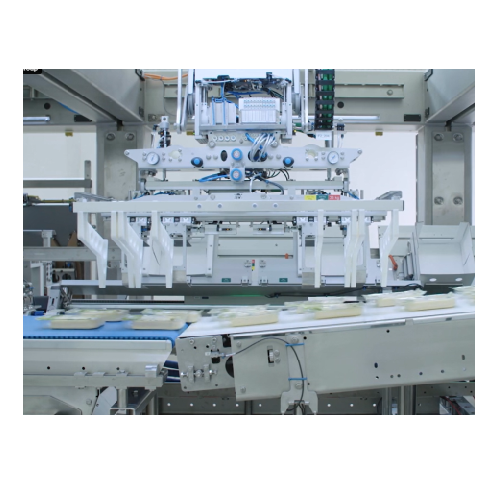

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Cup filling system for jars and buckets

Optimize your confectionery and bakery filling processes with this high-speed cup f...

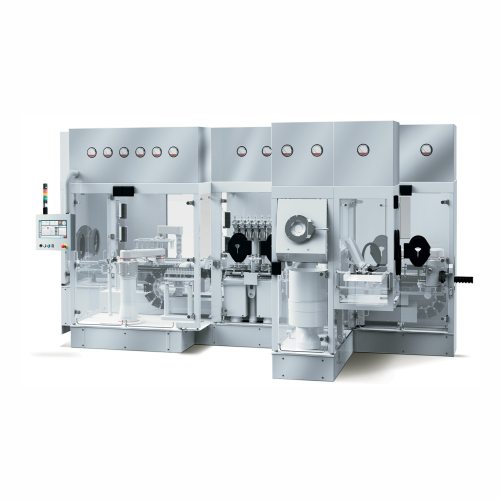

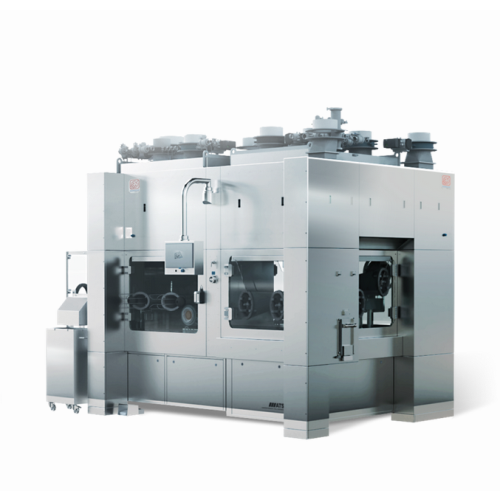

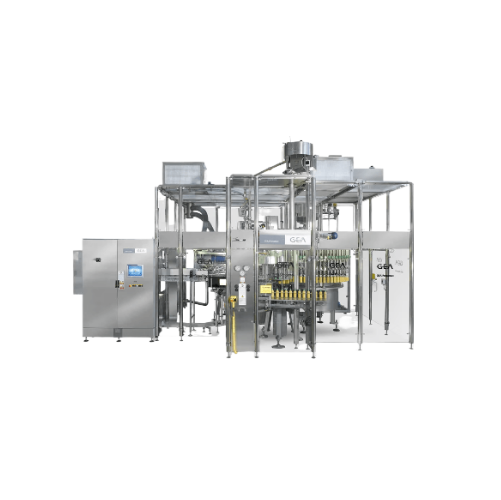

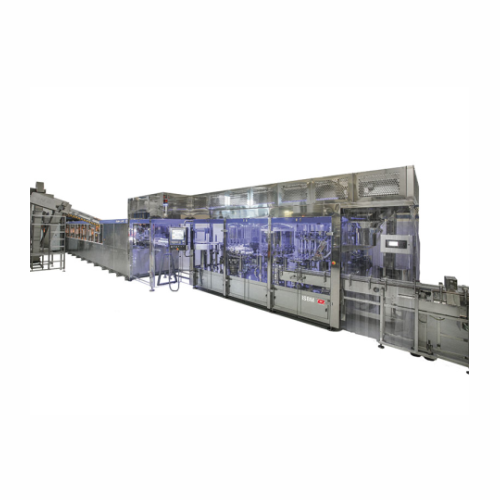

Aseptic filling system for biopharmaceutical products

This system ensures sterility in high-volume aseptic filling operat...

Lab-scale liquid and cream filling system

Streamline your lab production with precise filling of liquids, creams, and past...

Laboratory filling system for liquid and creamy products

Optimize your laboratory processes by precisely handling liquid,...

Mobile melting tank for hot filling lipstick

Optimize your cosmetics production with precise melting and hot filling techn...

Lipstick filling solution for high output production

Achieve precision and efficiency in lipstick production with advance...

Cosmetic pencil filling system

Streamline your cosmetic production with high-speed filling and precise molding capabilities,...

Vial filling and stoppering for aseptic liquid or lyo products

Ensure optimal aseptic conditions in your production line...

Rotary vial filling and stoppering

Ensure precise liquid formulations and lyophilized product consistency with a high-speed...

Mascara and lip gloss filling and capping system

Optimize your cosmetic production line with a high-speed system designed ...

Automatic rotary jar filling and capping system

Optimize your personal care product line by efficiently filling and cappin...

Stickpack filling and closing system for pharmaceutical powders

Achieve precise dosing and secure packaging for pharmace...

Aseptic ampoule filling and sealing solution

Ensure precise dosing and secure sealing of sterile liquid pharmaceuticals in...

Bottle filler and capper

Achieve precise liquid filling and secure capping with high-speed, intermittent motion, ensuring con...

High-speed vial filling and capping system

Ensure precise vial filling and secure capping with this high-speed rotary solu...

Filling and capping solution for bottles

Optimize your bottling efficiency with a robust solution designed to streamline fi...

Aseptic vials filling and capping

Ensure precise vial capping and sealing for liquid pharmaceuticals with advanced aseptic ...

Stickpack filling and closing system

Optimize your stickpack production with precise dosing, uniform sealing, and seamless ...

Sachet filling and closing system

Optimize your production line with a versatile solution designed to fill, seal, and count...

Rigid tube filling and capping system for tablets

Streamline your tablet production with an efficient solution that preci...

Electronic counting and filling system for vials

Efficiently streamline the packaging of solid dosage forms with a cutting...

Filling and stoppering system for nested syringes

Ensure aseptic precision in syringe and vial preparation with a high-sp...

Nested syringe filling and stoppering line

Streamline your aseptic filling process with advanced machinery that handles ne...

Aseptic filling and capping for vials and syringes

Ensure sterility and precision in vial and syringe filling with advanc...

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

Automatic sachet filling and sealing system for liquids and creams

Optimize your cosmetic and personal care production ...

Volumetric filling system for cosmetic products

Streamline your production line with precise volumetric control, ensuring ...

Volumetric filler for liquid and viscous products

Achieve precise and adaptable filling for a wide variety of liquid and ...

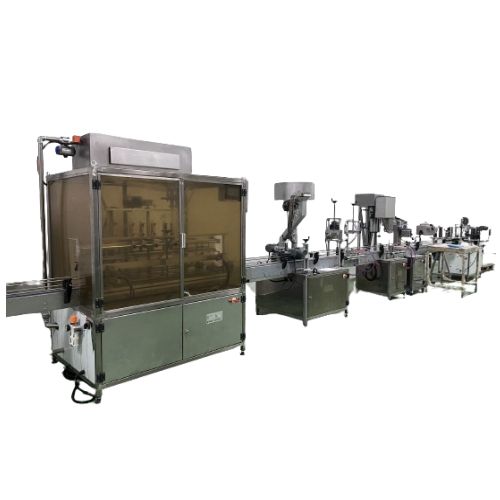

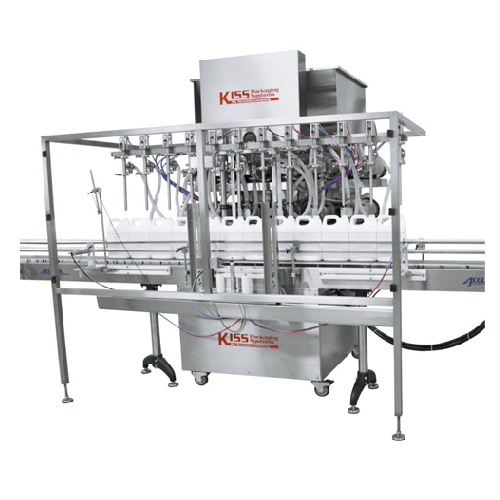

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

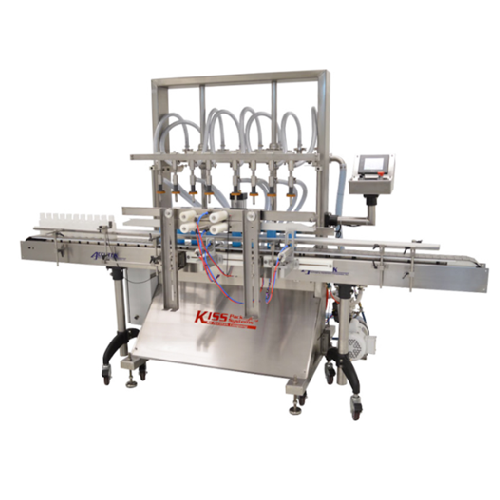

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Paste filling system for high viscosity products

Efficiently fill high viscosity products with precision and speed, reduci...

Two-component filling machines for food and beverage packaging

Streamline your filling process with precise two-componen...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

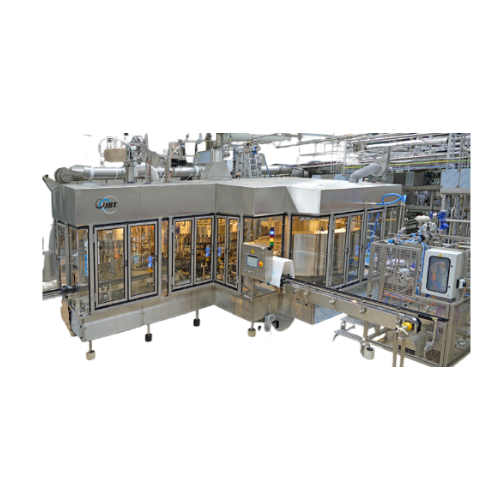

Ultrahygienic block for aseptic filling

When handling sensitive beverages, ensuring microbiological safety and quick produc...

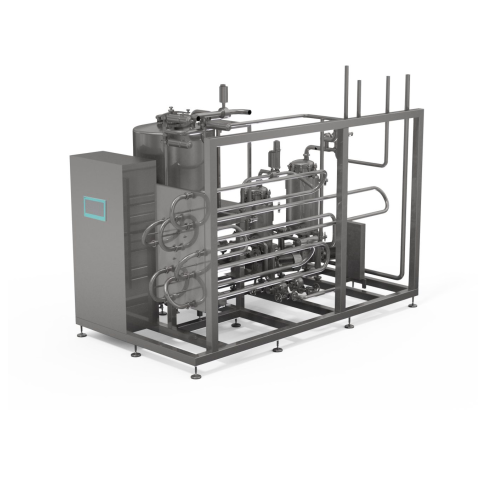

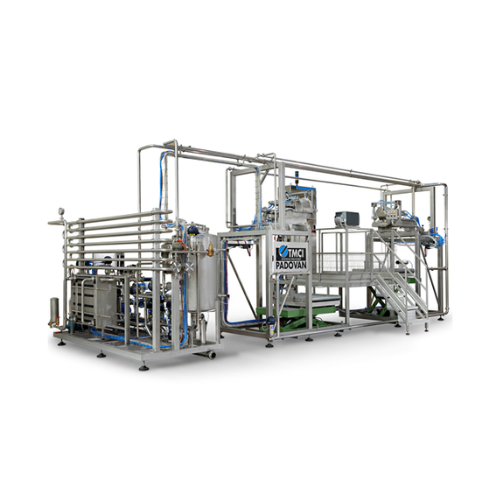

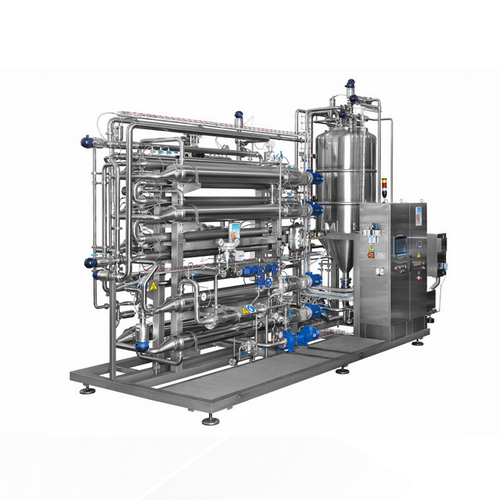

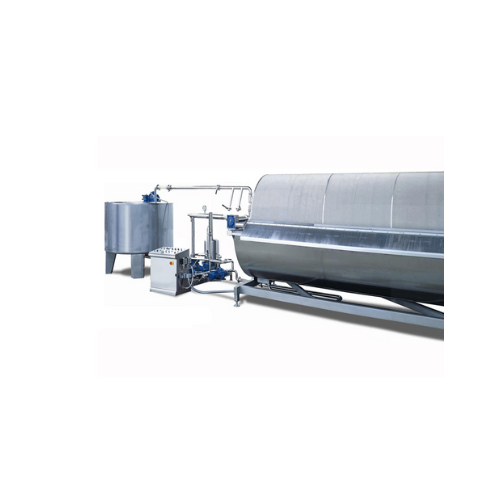

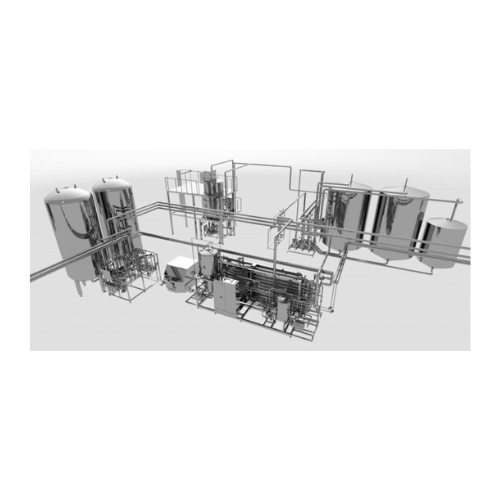

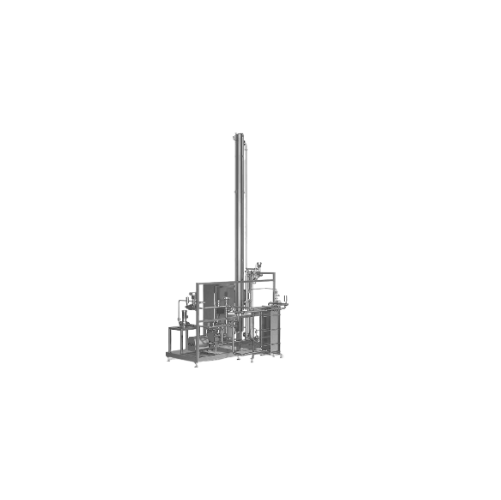

Uht system for aseptic filling of beverages

Ensure microbiological safety and retain natural flavors in your liquid produc...

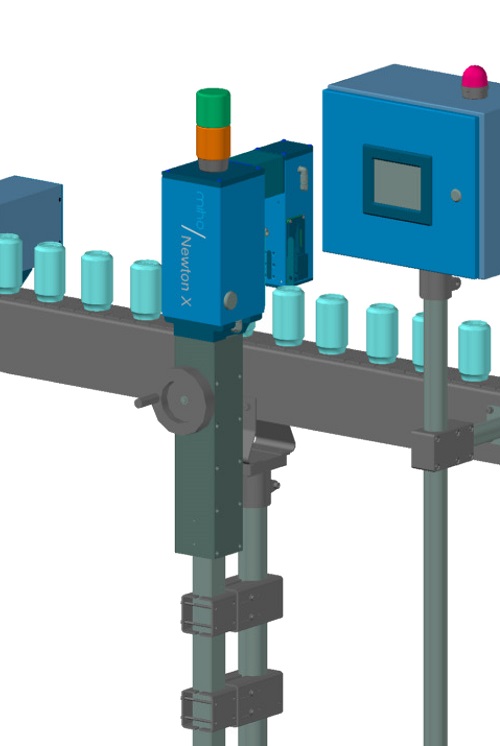

Inspection systems for fillers and cappers

Ensure precise fill levels and secure cap placements with advanced inspection s...

Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines ...

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

Low output can filler for craft beer

For beverage producers looking to efficiently fill cans with precision, this versatile...

Filler-seamer block for cans

For high-speed beverage production, this solution integrates filling, seaming, and cleaning in ...

Vertical form, fill and seal packaging system for small bags

Maximize efficiency with small bag portioning for food and ...

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

Juice bottle and bag-in-box filling systems

Streamline your juice production with versatile filling solutions that accommo...

2-way diverter for tablet and capsule filling

Ensure precision in tablet and capsule filling with seamless batch switching...

Sanitary bulk bag filling system

Streamline your powder handling process with a system designed to improve stability and acc...

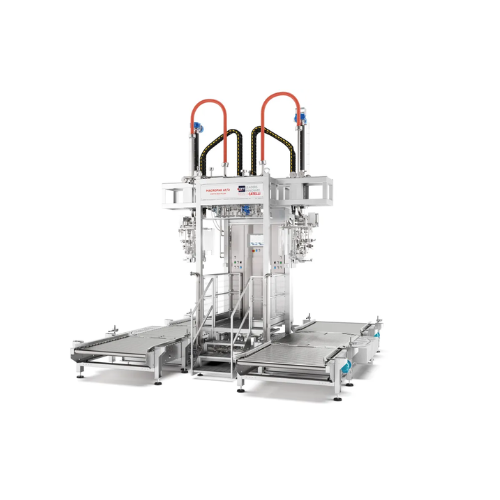

Bulk bag filler with integrated palletizing system

Optimize your powder packaging with a seamless system that fills and a...

Wine and sparking wine filling system

Achieve precise filling and minimal oxygen pickup for high-value beverages with a rel...

Energy-efficient hot filling system for beverages

Optimize your beverage filling processes with a system that ensures pre...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

Glass bottle filler for beer and soft drinks

Optimize your beverage production with a high-speed filling solution that red...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

Bottle filler for beer and soft drinks in glass bottles

Achieve precision in bottling with reduced CO2 emissions and low ...

Hot-fill dosing system for soups and sauces

Efficiently dose hot soups, sauces, and porridges while ensuring workplace saf...

Hot-fill dosing system for soups and sauces

Ensure precise and efficient dosing of hot and cold liquid foods with integrat...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

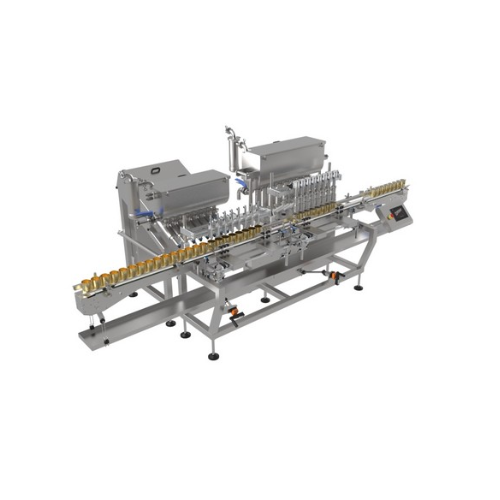

Ampoule filling and sealing system

Designed for high-speed sterile liquid filling and sealing, this system ensures precise ...

Sterile bag filling and closing system

Ensure precision and sterility in multi-chamber bag filling for liquid and powder ph...

Powder filling and stoppering for antibiotic production

Tackle antibiotic resistance with precision powder filling and st...

Capsule filler for pharmaceutical applications

Need precise capsule filling for pharmaceuticals and nutraceuticals? This s...

Table-top capsule filler for micro-dosing

Achieve precise micro-dosing for pharmaceutical powders and pellets with a user-...

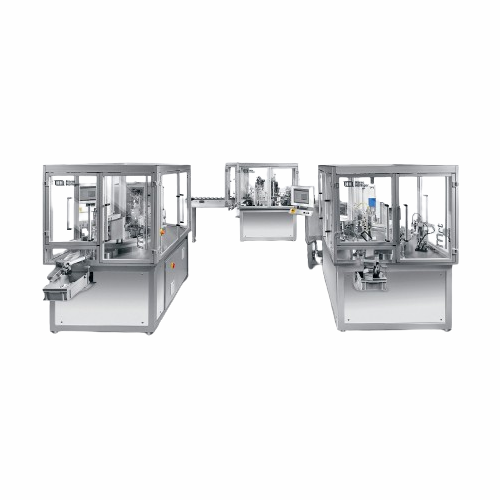

Syringe assembly for pre-filled glass syringes

In the precise world of pre-filled syringe production, ensuring seamless as...

Rotary filling and closing system for pharmaceutical bottles

Optimize your large-batch liquid production with a high-spe...

High-speed fill-finish system for ready-to-use components

Enhance aseptic fill-finish operations with a high-speed solut...

Isolation solutions for aseptic fill-finish lines

Achieve maximum product sterility with advanced isolation solutions, mi...

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Aseptic filling and stoppering solution for vials

Ensure precise aseptic filling and stoppering of vials with enhanced fl...

Automatic tubefiller for pharmaceutical tubes

Streamline your tube packaging process with this versatile solution, optimiz...

Capsule filler for multi-product dosing

Achieve precision and flexibility in capsule filling with a system designed for hig...

Positive displacement gear pump liquid filler

Optimize your liquid filling operations with precision gear pump technology,...

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Stick pack forming, filling, and sealing solution

Enhance packaging efficiency with a high-speed solution designed for pr...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Filling and wrapping system for pasty products

Achieve precise dosing and flexible wrapping of diverse pasty products, ens...

Filling and sealing pre-formed cups solution

Ensure ultra-clean and aseptic processing for pre-formed cups with a fully en...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Form fill and seal solution for liquid and pasty products

Enhance your production efficiency with high-speed forming, fi...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

High-speed pouch filling and sealing system for food and dairy

Achieve precise spouted pouch filling with minimal waste ...

Forming, filling and sealing solution for cups

Maximize production efficiency and flexibility with a high-output machine d...

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

Filling and sealing system for yoghurts and desserts

Efficiently fill and seal a variety of dairy and dessert products wh...

Rotary filling and sealing system for pasty products

Efficiently streamline your cup and tub packaging process with a ver...

Tub filling and sealing for pasty products

Experience high-speed, precision tub filling and sealing designed for pasty pro...

Cup forming, filling, and sealing solution

Optimize your cup production with a compact solution designed for precise formi...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

Capsule filling and sealing system for coffee production

Achieve precise coffee capsule production with a machine that se...

Capsule filling and sealing system for coffee

Optimize your capsule production with a system designed to enhance precision...

Capsule filling and sealing for lab purposes

Streamline your lab-scale coffee capsule production with a compact solution d...

Capsule filling and sealing system for coffee products

Optimizing the precision of coffee and tea capsule production, thi...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Conveyor control system for beverage filling lines

Optimize your production line’s efficiency by seamlessly managin...

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

Automatic salad filler for preformed trays

Streamline your salad packaging process with this high-speed solution, ensuring...

Product transfer shuttle for filling applications

Efficiently manage product flow with precise, customizable filling solu...

Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tra...

Valve bag filling system for cement and chemicals

Optimize your material handling with precision filling and sealing, ens...

Pharmaceutical powder bag filling system

Ensure precision in pharmaceutical formulations with a system that fills high-spee...

Liquid filling system for medical and pharmaceutical products

Enhance your production capabilities with high-speed liqui...

Sterile filling and sealing platform for infusion bags

Achieve reliable aseptic filling and sealing with a versatile plat...

Sterile filling system for Iv bags

Ensure precise and sterile filling of IV and infusion bags with flexible, semiautomatic ...

Commercial blister filling solution for dry powder

Efficiently fill and seal blister packs with precision, ensuring consi...

Commercial capsule filling for small scale production

Efficiently fill and dose capsules with precision, ensuring flawles...

High-containment capsule dosing and filling system

Achieve precise dosing and optimal containment for pharmaceutical prod...

Capsule filling system for powder, pellets, and tablets

Optimize capsule production with rapid dosing changes, minimizing...

Containment capsule filling system for lab and small batch production

Designed to ensure maximum safety in pharmaceutic...

Versatile capsule filler for pharmaceuticals

Effortlessly switch between powder, pellet, and liquid dosing with this adapt...

Disc filler for dry powder inhalers

Optimize your dry powder inhaler production with precision micro-dosing for diverse pow...

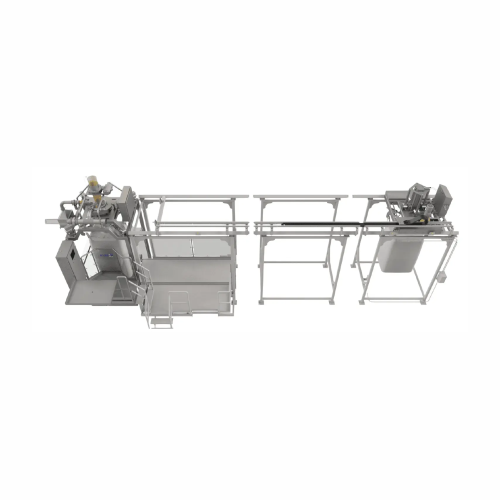

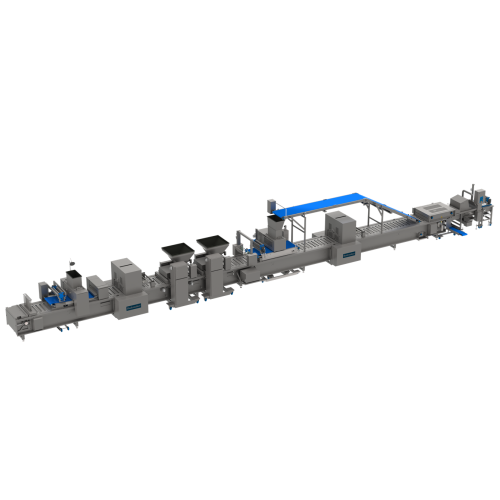

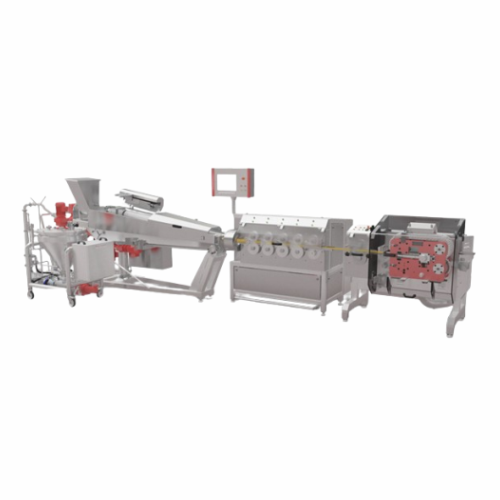

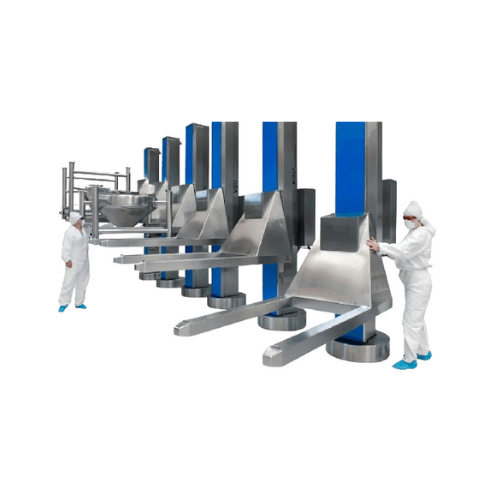

Sausage filling line for natural, collagen, and peel-off casings

Streamline your sausage production with rapid casing ch...

Automatic sausage filling and hanging system

Streamline sausage production with precise portioning and seamless integratio...

Sausage filling line for adjustable portions

Achieve precision in high-speed sausage production with rapid casing changes ...

Automated sausage filling and portioning line

Boost your production efficiency with a versatile solution that seamlessly h...

Automated sausage filling and portioning system

Streamline your sausage production with precision filling and versatile po...

Automatic sausage filling and separating system

Achieve precise portioning with exact weights and lengths for sausages, st...

Sausage filling and portioning line

Streamline your sausage production with versatile equipment designed to seamlessly inte...

Compact vacuum filler for small to industrial scale food processors

Achieve precise portioning and high-speed productio...

Vacuum filler for medium-scale sausage production

Achieve precise portion control and optimal hygiene with a versatile fi...

High-pressure vacuum filler for industrial sausage production

Effortlessly tackle high-pressure demands in sausage produ...

Vacuum filler for sausage and ham production

Achieve precision in filling and portioning pasty and fluid products with a s...

Industrial sausage and ham vacuum filler

Achieve unmatched precision in filling and portioning with high-capacity vacuum te...

High-precision depositing system for fluid and viscous fillings

Achieve precise and efficient dosing for diverse food pr...

Filling flow divider for food and pet food applications

Optimize your production line with precision filling flow divider...

High vacuum filler for dry sausage products

Achieve pore-free, compact dry sausage products with superior evacuation perfo...

High vacuum filler for large-calibre sausages

Achieve pore-free, high-quality products with optimal portioning accuracy an...

High vacuum filler for ham and ground material

Achieve unrivaled product quality and precision with high vacuum technology...

High vacuum filler for cooked ham with whole muscle pieces

Ensure precision and quality in cooked ham production with hi...

Vacuum filler for small and medium-scale meat producers

Achieve precise portioning with high-speed filling and grinding c...

Integrated vial filling system for aseptic and toxic pharmaceuticals

Minimize product loss and ensure high sterility in...

Filling and sealing system for creams and lotions

Achieve precise, high-speed filling and secure sealing of cosmetic cont...

Automatic perfume filling line for cosmetic production

Ensure efficient and precise filling of perfume bottles and liquid...

Aseptic filling solutions for Rtu vials, cartridges, and syringes

Optimize your aseptic filling processes with a system...

Nasal spray and eye drop filling solutions

Enhance the precision and flexibility of your liquid filling operations with ou...

Vial and syringe filling system for pharmaceuticals

Ensure aseptic precision in liquid formulation filling with a modular...

Aseptic syringe filling solution for Rtu containers

Streamline your pharmaceutical liquid filling operations with precise...

Benchtop filling solutions for small batch liquid medicine

Streamline your small batch liquid medicine production with p...

Gloveless robotic filling cell for aseptic pharmaceutical processing

Eliminate human intervention in aseptic filling wi...

Vial filling for pharmaceuticals

Streamline your aseptic processing with vial filling machines that ensure sterile, precise,...

Filling system for consumer healthcare products

For small to medium productions needing versatile filling and sealing, thi...

Filling solution for consumer healthcare products

Navigate complex liquid product formulations with a versatile filling s...

Mascara and lip gloss filling system for cosmetics

Optimize your cosmetic product filling operations with precision, hand...

Automated in-line ice cream filling system

Enhance your ice cream production with precision filling, offering high-speed c...

Industrial manipulator for sterile and nonsterile filling

Maintain the integrity of high-value pharmaceuticals with a hi...

Sterile and nonsterile vial filling system for injectables

Achieve precision and safety in filling and stoppering with a...

Sterile and nonsterile filling for injectable solutions

Efficiently fill and stopper injectable solutions in both sterile...

Filling solution for non-injectable pharmaceutical products

Streamline your pharmaceutical production with a versatile s...

Vial filling system for sterile and nonsterile pharmaceuticals

Enhance precision in injectable drug preparation with a s...

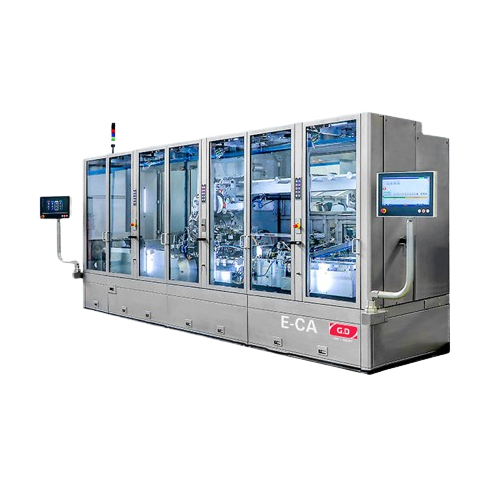

Cartridge assembler and filler for next generation tobacco products

Boost your production line’s efficiency with ...

Vacuum filling system for automated food production

Eliminate manual handling with an advanced system that automates the ...

Piston stuffer casing holder for versatile filling applications

Optimize your filling operations with a solution designe...

Continuous vacuum stuffer for efficient filling and portioning

Streamline your delicatessen and sausage production with ...

High-capacity piston stuffer for industrial filling and portioning

Streamline your production with high-speed, fully el...

Linker filling tube for sausages

Optimize meat product consistency and reduce waste with precision filling and portioning de...

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

Aseptic filler for bag-in-box packaging

Achieve unparalleled product safety and quality in liquid packaging with our advanc...

Aseptic filler for large bags

Ensure safe and sterile packaging of liquid and slurry products in large formats with this ase...

Aseptic filling system for bag-in-box packaging

Efficiently fill a range of liquid products into pre-sterilized bags while...

Aseptic filler for liquid and particulate products

Achieve precise, sterile filling of both liquid and chunky products wi...

Aseptic treatment and filling for concentrates and purees

Optimize your processing line with a compact solution that com...

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Ultra hygienic filler for non-aseptic products

Optimize your production with high-speed filling and sealing of liquid prod...

Aseptic bag-in-box filler for juices and purees

Enhance your filling operations with a high-speed aseptic solution designe...

Aseptic filler for liquids and semi-concentrates

Ensure maximum sterility and precision when filling liquids, concentrates...

Aseptic filling isolator for vial / Pfs / cartridge

Ensure sterile and contamination-free filling of vials, pre-filled sy...

Industrial liquid filler for small to medium volume operations

Ensure accuracy and efficiency in liquid formulation with...

Precision ointment filling and dosing system

Achieve precise filling of liquid formulations with a versatile system capabl...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

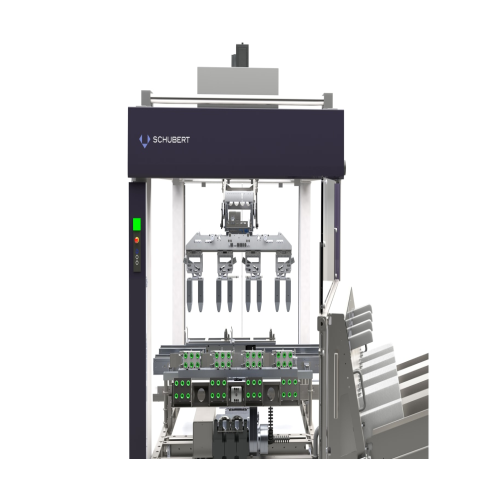

Automatic lidding-up and filling-up for luxury boxes

Enhance your luxury packaging lines with reliable precision, as this...

High-care big bag filling system for hygienic environments

Ensure precise hygienic filling of Big Bags in high-care envi...

Calibratable big bag filling station for dust-free operations

Ensure precise, dust-free filling of bulk bags with ergono...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

Bag-in-box filling system for packaging efficiency

Streamline your packaging process by integrating filling and boxing in...

Electronic filling system for non-carbonated beverages

Optimize your bottling process with precision filling technology t...

Gravity filling systems for still beverages

Ensure precise and clean filling for still beverages with gravity systems that...

Hot beverage gravity filling system

Ensure precise hot filling of beverages with gravity-fed accuracy, handling liquid temp...

Isobaric filling solution for carbonated drinks

Achieve precision filling for carbonated and still beverages with advanced...

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

In-motion pharmaceutical bottle filler

Achieve up to 400 bottles per minute with this modular bottle filling solution, desi...

In-motion bottle filling system for pharmaceuticals

Boost your production efficiency with our high-speed bottle filling s...

Tipping and filling line for bulk Api powder production

Ensure precise and aseptic handling of pharmaceutical powders wit...

Semi-automatic filling system for cell and gene therapy

Optimize your cell and gene therapy processes with a modular fill...

Custom automation for drug-device filling and assembly

Efficiently integrate precise filling and assembly for biopharmace...

High-throughput aseptic isolator for syringes and vials filling

Streamline your aseptic filling process with a high-spee...

High quality sterile filling system

Experience unparalleled precision in aseptic filling with this advanced system, designe...

Dry powder filling isolator for cgmp production

Achieve precise powder dosage and secure containment for hazardous materia...

Sterile robotic filling for ready-to-use vials and syringes

Achieve precise and contamination-free filling for biopharma...

Aseptic filling line for 131i sodium Iodide

Ensure compliant production of iodine-131 radiopharmaceutical vials with preci...

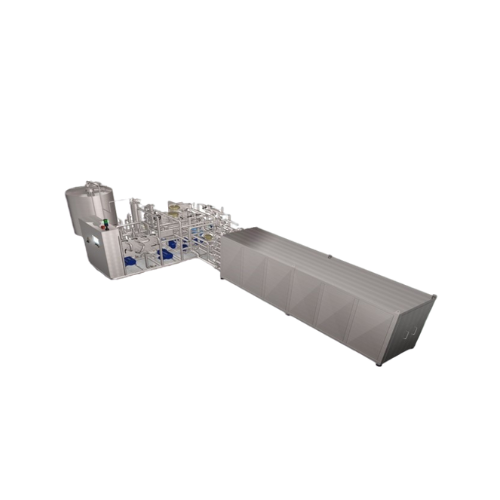

Automatic aseptic filling line for Iv bags

Ensure aseptic integrity and high-speed processing of IV bags with a filling li...

Compact aseptic vial filling system

Optimize your aseptic liquid filling with a compact system designed for seamless integr...

Rotary filling system for Rtu vials in pharma production

Optimize your sterile liquid and powder handling with a versatil...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Bin and carton filling system for cut tobacco

Efficiently manage your tobacco product flow with a high-speed filling syste...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Tube filling solution for health and beauty applications

Achieve consistent quality and efficiency in tube filling operat...

Tube filling solution for health and beauty products

Achieve rapid production with precision in tube filling for personal...

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Linear filling machines for ice cream production

Enhance your ice cream production with modular filling machines designed ...

Rotary filling solutions for ice cream cups and cones

Optimize your ice cream production with customizable rotary filling...

Automatic filling system for continuous bags

Ensure precision in liquid and gas handling with this high-speed system, desi...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

200l buffer tank for bag-in-box fillers

Ensure precise filling and consistent flow control with this stainless steel buffer...

Bag-in-box fully automatic filling line

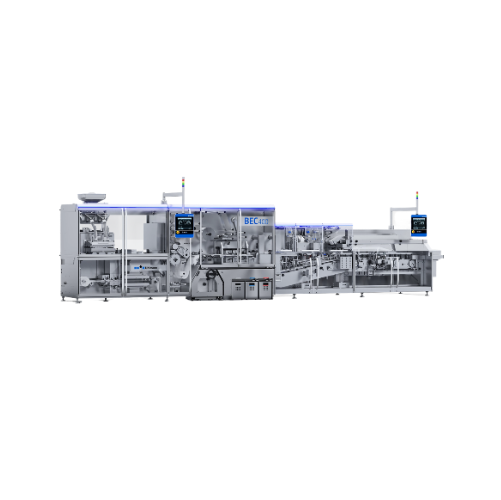

Streamline your liquid packaging operations with a modular system designed to enhan...

Buffer tank for bag-in-box filling

Optimize your liquid packaging with precise flow control and pressurization, ensuring st...

Manual bag-in-box filling solution

Streamline your liquid packaging with a compact, easy-to-operate filling system that sim...

Manual pneumatic filler for bag-in-box

Experience seamless filling for liquid formulations with this pneumatic solution, en...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

Bag-in-box filler with dual heads and automatic features

Boost your liquid production efficiency with a dual-head filling...

High speed continuous motion liquid filling and capping system

Achieve high-speed, precision filling and capping for liq...

Continuous motion liquid filling and capping monobloc

Optimize high-speed liquid filling with seamless transitions from f...

Volumetric filling and capping system for pharmaceuticals

Optimize your liquid filling and capping operations with a ver...

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

Vacuum filler for glass jars and cans

Ensure precise filling and equal headspace for your products with this vacuum filler,...

Vibratory rotary filler for accurate filling in food packaging

Achieve precise and efficient filling of diverse solid pr...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

Dosing unit for semi-automatic filling and packaging extension

Streamline your filling operations with this dosing unit,...

Aseptic filling system for fruit juices and nectars

Effortlessly integrate aseptic filling into your beverage production ...

No-oxygen wine filler

Ensure product integrity with advanced no-oxygen filling systems, designed to preserve delicate flavors...

No-oxygen filler for wine bottling

Enhance liquid bottling with seamless integration that minimizes oxygen exposure, ensuri...

High-capacity no-oxygen wine filler

Ensure optimal flavor retention and prevent oxidation in your bottling process with adv...

Inspection system for filled glass bottles

Ensure high-quality beverage bottling by detecting bottle faults, contaminants,...

Combisys filling and closing system for pharmaceutical containers

Ensure precise filling and closing of pharmaceutical ...

Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with preci...

Filling and closing solution for nested containers

Streamline your vial, cartridge, and syringe production with precise d...

Filling and closing system for nested containers

Optimize liquid formulation packaging with a high-speed system designed f...

Filling and closing solution for vials and stable bottles

Optimize vial and bottle processing with a seamless solution d...

Filling and closing system for cartridges

Enhance your cartridge production with precise filling and closing technology de...

Aseptic filling and closing for flexible Iv bags

Streamline your production line with high-speed aseptic filling and seali...

Semi-automatic filling and closing system for flexible bags

Ensure sterile and precise IV bag filling and closing with a...

Automated filling and closing system for vials and bottles

Optimize your vial and bottle filling line with precise liqui...

Nested vial and syringe filling and closing system

Achieve precise aseptic filling and closing for clinical products with...

Filling and closing system for vials, syringes, and cartridges

Optimize your aseptic fill-finish operations with a versa...

Vial and cartridge filling and closing system

Optimize your aseptic fill-finish process with high-speed, continuous operat...

Filling and closing system for ampoules

Ensure precision and efficiency in your aseptic fill-finish operations with a compa...

Ampoule filling and closing system

Optimize your production line with a high-speed system designed for seamless filling and...

Filling and closing solution for vials and syringes

Achieve precise aseptic fill-finish of liquid formulations in vials a...

Automatic tube filling and closing system

Enhance production efficiency with a high-speed tube filling and closing system ...

Semi-automatic tube filling and closing system

Achieve precise filling and secure closing for diverse tube types, optimizi...

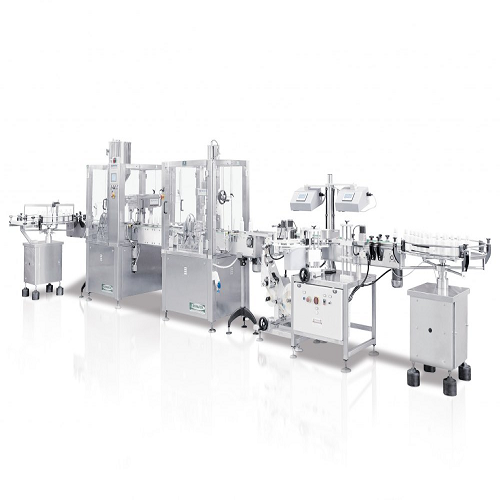

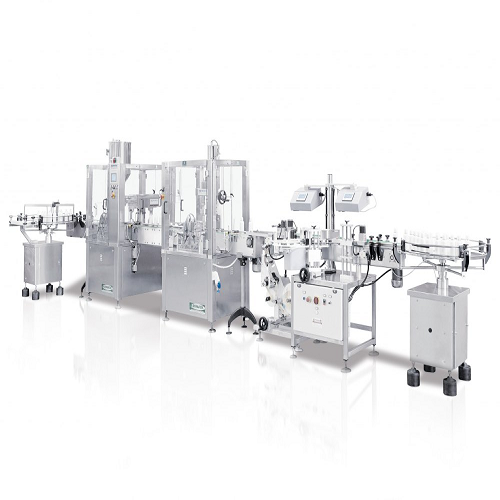

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrat...

Filling, capping, labeling line for hair color products

Streamline your hair color production with an integrated line tha...

Linear filling and capping for stable bottles

Enhance your production efficiency with a solution designed for precise liqu...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Automatic tube filling and closing system

Enhance your packaging efficiency with a high-speed tube filling and closing sol...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Automatic bottles and jars filling and capping line

Streamline your liquid product packaging with this high-speed solutio...

Sterile filling line for liquid and powder

Achieve seamless integration of filling, sterilization, and packaging with this...

Ultra-clean vertical bag filler for viscous and particle-containing products

Streamline your viscous product packaging...

Aseptic filler for bag in drum or box

Enhance product shelf life and maintain quality without preservatives by employing as...

Aseptic linear doypack filler

Ensure extended shelf life and preserve quality in liquid food products with this high-speed a...

Linear filler for preformed containers

Streamline your packaging process with a compact solution that ensures precise filli...

Rotary filler for preformed containers

Ensure microbiological safety and extended shelf life for your liquid products with ...

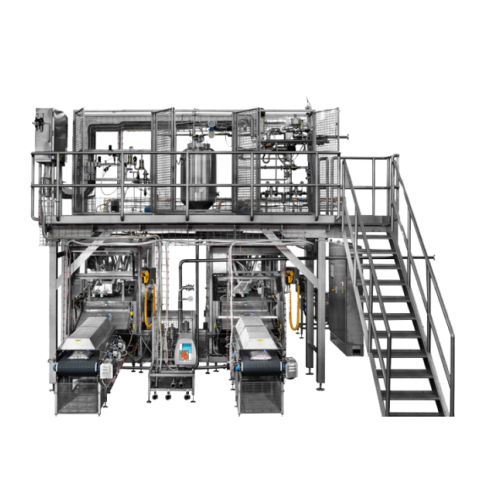

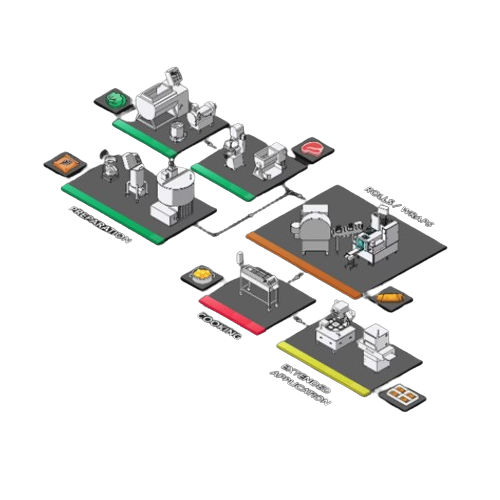

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Robotic filler for aseptic pharmaceutical packaging

Effortlessly manage complex aseptic filling tasks with a system desig...

Tabletop vial and syringe filling system

Ensure precise dosing and maintain sterility in small batch production with a comp...

Automated aseptic filling and closing system for vials and syringes

Optimize small-batch production with precision fill...

Aseptic small batch filling and closing system

Optimize your small-batch aseptic processing with this versatile system, de...

Aseptic vial filling system for gene therapy products

Elevate the sterility of your fill-and-finish process with a high-s...

Aseptic filling line for biopharmaceuticals

Streamline your aseptic filling process with precision dosing and minimal spac...

Aseptic filling station for small batch processes

Streamline small batch manufacturing with a tabletop filling station th...

Aseptic filling isolator for small cgmp batches

Guarantee aseptic integrity for small-scale batches with this isolator, of...

Aseptic filling line for biopharmaceutical products

Achieve precision and sterility in high-speed liquid filling operatio...

Aseptic filling solution for small cgmp batches

Ensure sterile and efficient filling of small-volume parenterals while mai...

Aseptic small / medium batch filling and closing system

Ensure sterility in drug production by seamlessly integrating a v...

Co2/o2 beverage filling device

Ensure precise beverage analysis by maintaining carbonation integrity with a system that tran...

Fill level inspection system for beverage bottling

Ensure compliance and optimize quality control with a system that accu...

Multipurpose filling and forming solutions for dumplings

Enhance your food production with versatile equipment that trans...

Pillow bag horizontal form-fill-seal solution

Optimize production efficiency with seamless integration of continuous, high...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Linear big bottle water filling solution

Streamline your large-format water bottling process with integrated washing, filli...

Small bottle linear type beverage filling production line

Optimize your bottling efficiency with a high-speed solution d...

Glass bottle carbonated soft drink washer, filler, and capper

Streamline your bottling process with this machine that se...

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Automatic edible oil filling & capping solution

Streamline your liquid packaging operations with precise, high-speed filli...

High-capacity carbonated drink filling system

Optimizing your carbonated beverage production, this high-speed filling syst...

Automatic mineral water filling system

Optimize your bottling line with a machine designed for high-speed washing, filling,...

Large bottle water filling system

Streamline your bottled water production with an integrated solution that efficiently was...

Automatic mineral water filling system

Enhance your bottling line with an advanced solution that seamlessly integrates wash...

Carbonated drink filling solution for Pet bottles

Optimize your carbonated beverage production with an all-in-one filling...

5 gallon water filling system

Streamline your bottling process with this integrated system, expertly combining rinsing, fill...

8000bph fruit juice filling system

Optimize your beverage production line with a high-speed fruit juice filling system, des...

Volumetric filler for bags and rigid containers

Optimize precision filling of powders and granules with a versatile soluti...

Miniature auger filler for precise powder filling

Achieve precision filling with a compact, bench-top auger solution desi...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Special purpose auger filling systems for diverse industries

For manufacturers handling precise dosing, our advanced aug...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

In-line filling system for various container sizes

Streamline your production with versatile in-line filling solutions th...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Industrial auger sack filler for large bags

Designed to efficiently fill large bags and sacks, this advanced filling machi...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Flexible bag-in-box filler for liquid and viscous products

Optimized for flexibility and efficiency, this bag-in-box fil...

Bag-in-box filling solution for non-aseptic products

Maximize your production line’s efficiency with a high-speed f...

Thousand-litre aseptic filler

Ensure the aseptic filling of bulk liquid and viscous food products, reducing contamination ri...

Capsule filling solution for small to medium batch sizes

Achieve precise and efficient capsule filling up to 3,400 units ...

Capsule filling system for pharmaceutical production

Efficiently fill and lock capsules of various sizes with exceptional...

Automated bottle and jar filling solution

Streamline your production and minimize waste with a versatile filling solution,...

Bag and pouch filling solution for liquid products

Efficiently package diverse liquid products with precision and speed, ...

Filler and capper for bottles and jars

Optimize your production with a compact filling and capping solution that delivers f...

Tube filler & sealer for metal and plastic tubes

Streamline your production line by efficiently filling and sealing metal ...

Efficient tube filler and sealer

Optimize your production line with a semi-automatic tube filling and sealing solution, desi...

Compact filler and closer for vial processing

Efficiently streamline your vial filling and closing processes with a compac...

Tube filling and sealing for metal and plastic tubes

Achieve precise tube filling and sealing with high speed and efficie...

Automatic flowmeter filler for liquid packaging

Streamline your liquid production with precise filling capabilities, reduc...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Semi-automatic flowmeter boom filler for large volume containers

Effortlessly handle large volume liquid filling with pr...

Rotary filler capper for personal care products

Ensure consistent filling and capping of liquid products with high-speed p...

Liquid capsule filling for r&d and pilot-scale production

Optimize liquid capsule production with a compact machine that...

Liquid filling system for hard capsules

Easily fill two-piece hard capsules with liquids, pastes, and suspensions with prec...

Containment capsule filler for highly potent drugs

Achieve complete operator safety while encapsulating potent pharmaceut...

Containment capsule filling system for highly potent drugs

Ensure operator safety while filling capsules with high-poten...

High-speed capsule filler for large batch production

Achieve higher yields and reduce powder waste with a capsule filling...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Capsule band sealer for liquid-filled hard capsules

Seamlessly seal liquid-filled hard capsules to enhance product integr...

Auto-indexing filler for aqueous solutions and light oils

Streamline your bottling process with this six-head filler, pe...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Rotary overflow filler for non-carbonated liquids

Achieve precise fill levels effortlessly with a high-speed rotary overf...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Rotary volumetric filling solution for viscous products

Achieve precision in volumetric filling with a machine designed f...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Automatic pressure overflow filler for low to medium viscosity liquids

Ensure consistent fill levels for low to medium ...

Semi-automatic timed flow filler for aqueous solutions

Handle diverse liquid filling needs with precision, from thin oils...

Semi-automatic overflow liquid filler

Optimize your production line with a reliable filling solution for low to medium visc...

Form, fill, and seal system for single-use pouches

Achieve precise portion control and secure sealing with an integrated ...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Filling and weighing station for chocolate production

Ensure precise and efficient chocolate mass depositing with a stati...

In-line vacuum powder filler

Optimize your production line with precise, contamination-free filling for nutritional powders,...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

Rotary level filler for low to high viscosity liquid products

Ensure precise fill levels and enhance production efficien...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Automatic tuna can filler

Streamline your high-speed canning operations with precision-engineered fillers that maintain opti...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Vacuum filler for low viscous products

Achieve precise vacuum filling for liquid and granule products while effectively eli...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

Aseptic filler for fluids, concentrates, and particulates

Optimize your fluid and concentrate filling process with a hig...

Aseptic filler for juices and beverages