Making Wet Pet Food

Find innovative production technology for making wet pet food and connect directly with world-leading specialists

In 1922, the first canned wet pet food made of horse meat hit the US market. Due to the product’s popularity, farmers started breeding horses to supply the demand for wet pet food. Nowadays, wet pet food is no longer made of horse meat, but of chicken, fish, beef and pork and also vegetables, grains and added vitamins and minerals. Wet pet food processing involves different steps such as weighing, grinding, mixing, packaging, and sterilization.

Stories about wet pet food

Select your wet pet food process

Tell us about your production challenge

Wet pet food processing – How is it made?

Whether it’s in cans, trays or pouches, wet pet food is made with animal meat byproducts such as liver, lungs and kidneys which are not used for human consumption. The wet pet food production line consists of several parts: various grinders, deboning machines, gravy mixers, product transfer equipment, packaging and sterilization equipment.

The raw material, whether meat, vegetables or fish can be fresh or frozen. When working with frozen products it is to avoid contamination. The meat by-products are deboned and ground with industrial grinders. Only then are the vegetables mixed with the meat to prevent them from breaking down in the grinders. Dry ingredients like grains, minerals and vitamins provide the animals with the proper nutrients, based on their age and size. For example, pea fiber, flaxseed, and glucosamine hydrochloride are added to wet pet food for senior dogs to help digestion and improve joint function.

Wet pet food packaging and sterilization: the crucial steps

After combining all the ingredients, wet pet food is transferred into its packaging- cans, trays and pouches. Sealing the packaging of wet pet food is absolutely crucial, because an airtight seal, along with proper sterilization, guarantees the product has a stable shelf life. Sterilization destroys any harmful microorganisms and wet pet food has to be sterilized at a temperature of 121.1°C.

Retort sterilization occurs after the product is packaged into its plastic pouches or cans and then heated up to ensure complete sterilization of both the food and the packaging. With regard to consumers, food pouches are becoming more popular than cans for wet pet food. Food pouches are re-sealable and cost-effective, making dosing a meal easier for the consumer.

Additives in wet pet food

Additives are often added in wet pet food to add nutrition, safety, color, taste, and viscosity to the finished product. Coloring agents such as food dyes or mineral-based colors and flavors such as extracts from fish can improve the appearance and the palatability of wet pet food. Emulsifiers keep fat in the food and water from separating, while thickeners improve the viscosity of the food.

Carrageenan is the most widely used gelling agent in wet pet food manufacturing. It is often used in combination with other thickeners like cassia gum, guar gum or locust bean gum. As for the regulations, both the FDA and the EU find carrageenan safe for both human and animal consumption if the intake is below 75 mg/kg and when used in the amount necessary as an emulsifier, stabilizer, or thickener in foods.

Wet pet food international standards and regulations

Wet pet food processing is strictly regulated around the world. No need to say that pet food must be safe to eat and must be produced under sanitary conditions. In the EU for instance, the meat used for wet pet food has to pass veterinary inspections and be fit for human consumption as well.

In the US, the FDA states that pet food must not contain toxins like arsenic, lead and mercury. Moreover, if you are producing canned wet pet food, you must comply with the FDA’s regulations on low-acid preparation standards: products with pH higher than 4.6 are classified as low-acid. Regarding labeling, the FDA states that the label must include product name, manufacturer’s name and address, the list of ingredients, feeding direction, net quantity statement just to name a few.

Processing steps involved in wet pet food making

Which wet pet food technology do you need?

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

Laboratory nutsche filter dryer for solid-liquid separation

Optimize your lab processes with a versatile benchtop filter...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

Efficient pouch cooling solution

Designed to cut cooling times in half, this solution efficiently reduces the bacterial dang...

Rotary drum blancher for industrial food processing

Optimize your food processing line with a robust solution that ensure...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

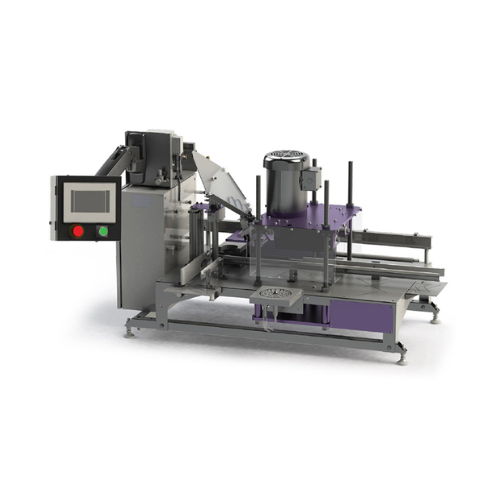

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Twin ribbon blender for processed cheese and meat products

Achieve seamless blending and consistent feeding for large-sc...

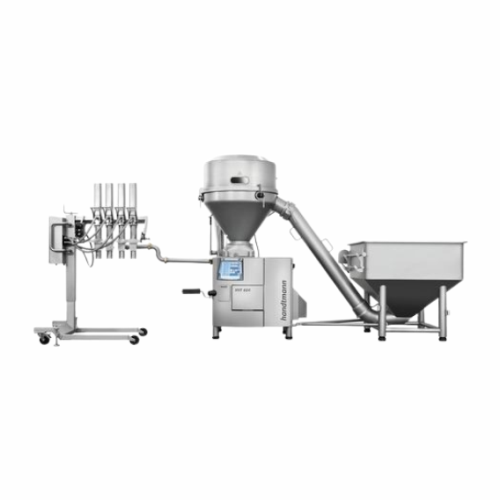

Automated sausage filling and portioning line

Boost your production efficiency with a versatile solution that seamlessly h...

Industrial mixer for food and pet food production

Achieve precise and efficient mixing of viscous to highly viscous produ...

Vacuum filler for medium-scale sausage production

Achieve precise portion control and optimal hygiene with a versatile fi...

Cutting valve for chunky food portioning

Achieve precise portioning of chunky products, reducing waste and increasing effic...

Vacuum filler for small and medium-scale meat producers

Achieve precise portioning with high-speed filling and grinding c...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

High-capacity manual mixer for industrial applications

Optimize your mixing process with a highly efficient, manually ope...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Laboratory twin screw extruder for small batch processing

Efficiently develop formulations and conduct precise research ...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

Horizontal case packing and tray loading

Enhance your packaging line efficiency with a highly adaptive system that seamless...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

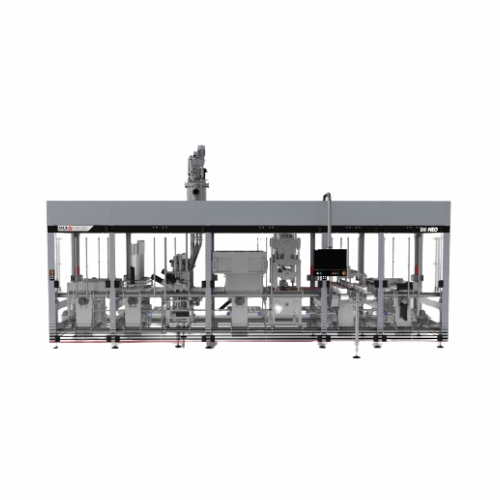

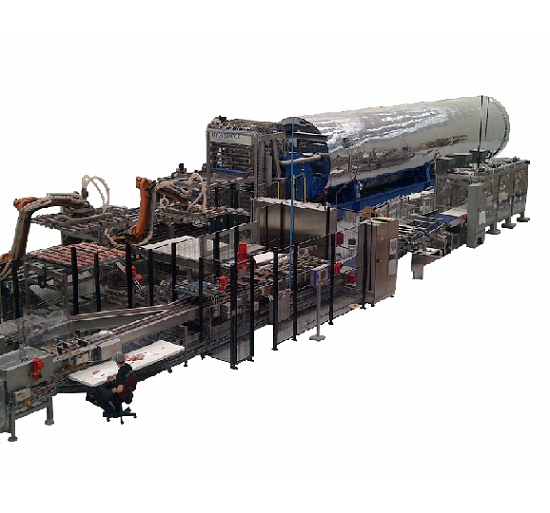

Wet pet food processing system

Optimize your wet pet food production with a system that integrates steaming, cooling, mixing...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Tuna vacuum pre-cooker cooler

Optimize your tuna and seafood processing with precise thawing, cooking, and cooling under vac...

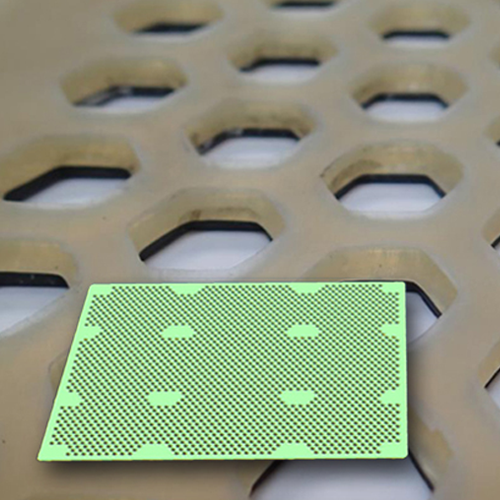

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Expandable high pressure processing system

Optimize your production line with an expandable high-pressure processing syste...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

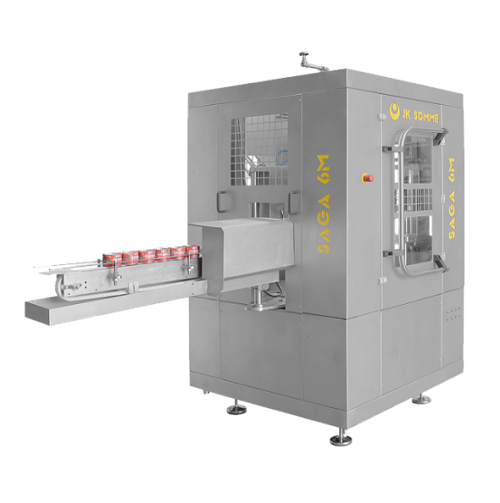

Seamers for round food containers

Ensure airtight sealing for food products with high-speed seamers designed for precision ...

Coating and enrobing system for pet foods and treats

Achieve precise coating and flavoring of various food and feed produ...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Container filling system for pasty and chunky products

Achieve precise, drip-free filling of diverse pasty and chunky pro...

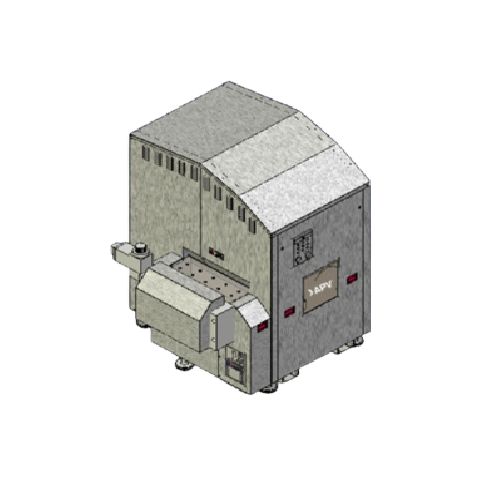

Grinding and separating solution for meat processing

Optimize your meat and plant-based production lines by integrating a...

Linking, hanging, and cutting system for sausage production

Streamline your sausage production process with precision-en...

Sausage linking and portioning solution

Optimize your sausage production with precise linking, hanging, and cutting technol...

Dough portioner for baked goods applications

Achieve precise and gentle portioning with advanced dough portioning technolo...

Vacuum filling machines for cooked ham & sausages

Achieve precise portioning and enhanced product quality with this advan...

Single piston depositors for bakery and food production

Optimize your depositing and filling processes with versatile equ...

Industrial food portioning system

Optimize your production flow with precision portioning equipment designed to handle a di...

Food grade transfer pump for semi-solid products

Streamline your production with a high-speed transfer pump designed for s...

Dual or triple lane food depositor

Enhance your production efficiency with a depositor that seamlessly handles a variety of...

Large portion depositor for food production

Achieve precision and efficiency in depositing large portions with versatile s...

Bakery and food grade conveyor systems

Optimize your bakery and food production with versatile conveyors designed for seaml...

Compact food depositor for direct container use

Streamline your depositing process with a versatile solution that handles ...

Compact food transfer pump

Effortlessly maintain your production flow with a compact transfer pump designed to handle a wide...

Bakery transfer pump for smooth and chunky products

Ensure consistent product quality with this transfer pump that gently...

Aseptic rotary cup filling and closing solution

Maximize your production capacity with this cutting-edge aseptic solution,...

Medium torque top entering mixer for high fluid forces

Equip your production line with a robust mixer that transforms cha...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Hygienic tanks for various processing needs

Achieve optimal processing and storage with customizable hygienic tanks, desig...

Automated mayonnaise and dressing production line

Ensure the consistent quality of your mayonnaise, dressings, and sauces...

Feeding system for filter cake and wet pet food

Achieve seamless material handling and agitation for solid shortening and ...

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...

Precision filler for convenience and pet food

Achieve unparalleled precision and efficiency in filling solids, powders, li...

Frontal discharge mixer for meat processing

Enhance your mixing process with an efficient solution that seamlessly combine...

Industrial grinder for fresh meat and food products

Optimize your fresh food processing with a versatile grinding solutio...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Machine for packing canned pet food

Most packaging applications require different types of packaging machines, some need wr...

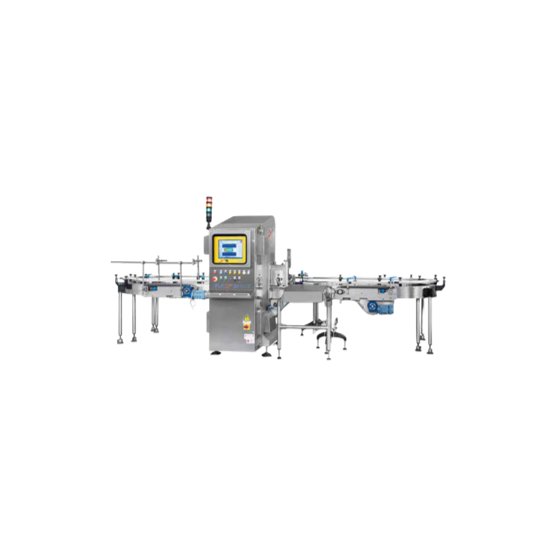

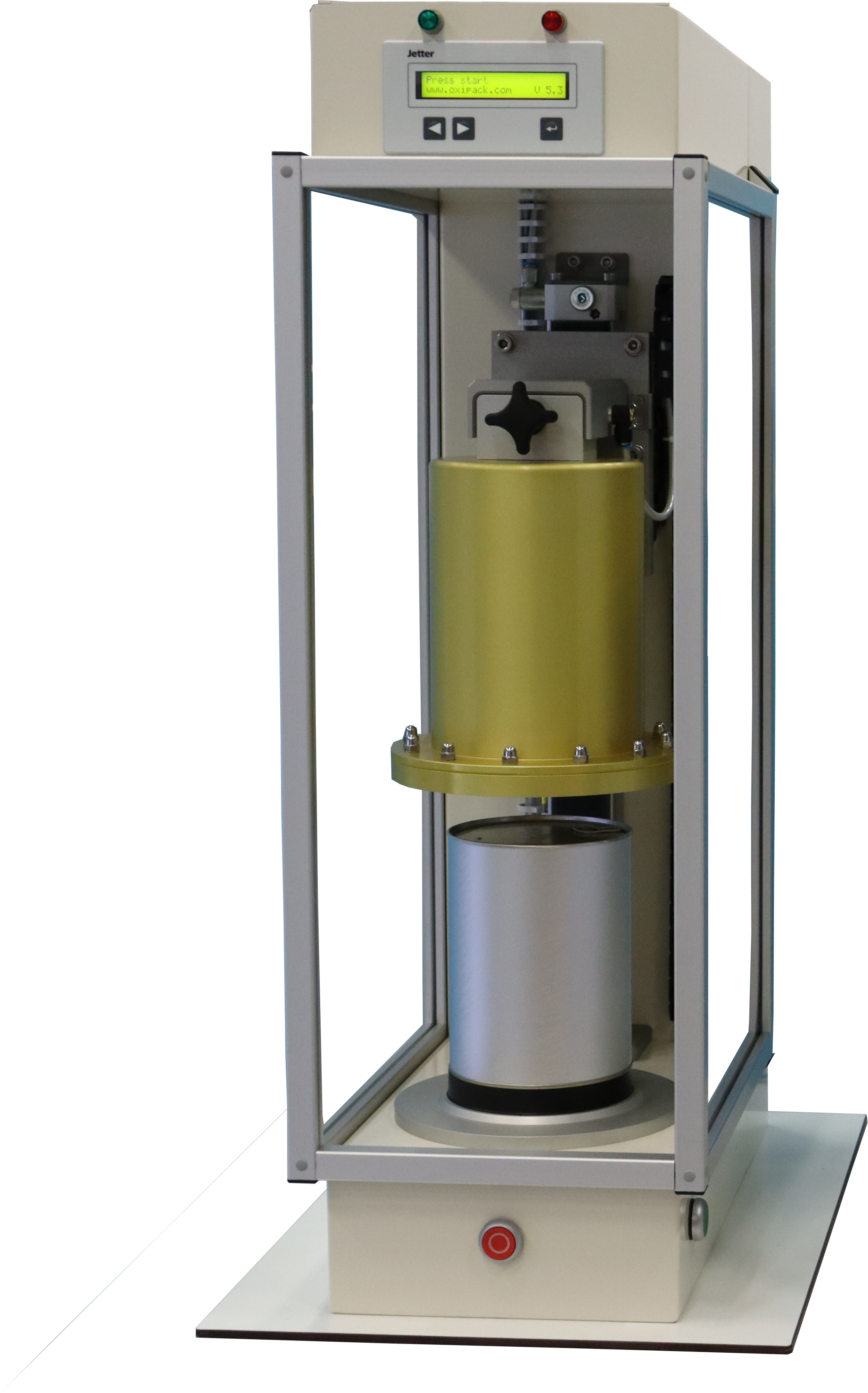

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

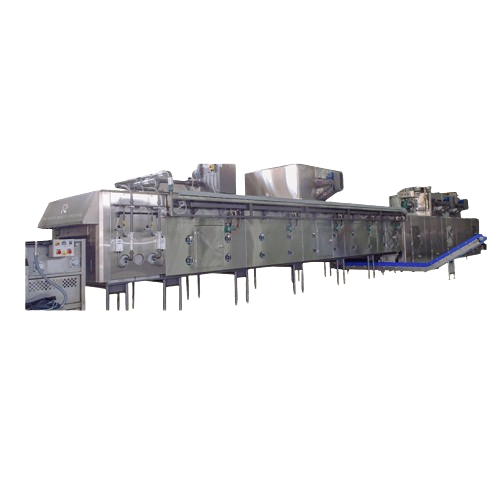

Continuous sterilizer for pet food

Sterilization is a critical operation in the manufacturing of wet pet foods. An importan...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Flexible pasteurizer for packaged food

Autoclaves for sterilising and cooking food products are a mainstay of many producti...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Autoclave for doypack pouches

The self-standing Doypack and other similar pouch products are a very popular method of packag...

Autoclave for canned food

Sealing and cooking products in cans, pouches or other containers is a very popular method of pres...

Steam sterilizer for food pouches

Aluminium-lined pouches and plastic containers are becoming the preferred packaging choic...