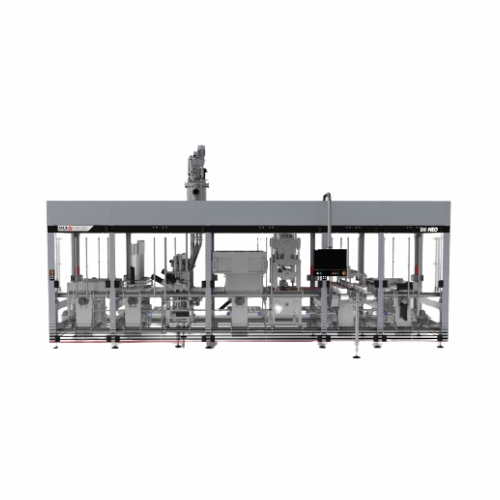

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adaptable format options, catering to a wide variety of liquid and semi-liquid end products.

Fills and Seals Pre-formed Cups Efficiently

The HAMBA BK-NEO from IMA Group is a versatile filling and sealing machine that revolutionizes cup handling. Specializing in high-speed, hygienic processing for dairy and food products, it features a chainless transport system ensuring precise placement of pre-formed cups. This machine excels with automated format changeovers, allowing seamless adaptation to diverse container sizes and production demands without downtime.

Ideal for filling products ranging from plain yogurt to deli salads and creamy soups, its modular design can be tailored to specific operational needs. With a throughput of up to 49,600 cups per hour, the HAMBA BK-NEO maximizes efficiency, enhanced by a recipe control functionality for optimal production rates.

Advanced hygienic filling solutions and an integrated CIP (clean-in-place) program provide effective cleaning during production without reducing output. The equipment is adaptable to various product viscosities and is available in different configurations, ensuring compatibility across multiple industries, including food, dairy, and baby food. Offering comprehensive customization and engineering support, HAMBA BK-NEO is engineered to integrate seamlessly into your existing production line, maintaining the highest standards of quality and efficiency.

Benefits

- Increases production flexibility with automated format changeovers, minimizing setup time.

- Enhances product quality with precise cup positioning, ensuring consistent output.

- Maintains high hygienic standards with CIP functionality, reducing contamination risks.

- Adapts easily to a variety of product viscosities and container sizes, expanding production capabilities.

- Improves operational efficiency by maintaining performance during on-the-fly cleaning processes.

- Applications

- Sauces, Soups, Fruit purees, Salads, Pet food, Jams, Dips, Desserts, Dressings, Sweet spreads, Baby food, Dairy products

- End products

- White cheese (curd), Guacamole dip, Wet cat food, Multi-layer dessert, Plain yoghurt, Deli chicken salad, Creamy tomato soup, Hazelnut spread, Single-layer dessert, Fresh cheese, Strawberry jam, Marinara sauce, Cottage cheese, Apple fruit puree, Potato salad, Organic baby food, Fruited yoghurt, Mayonnaise, Aerated mousse, Ranch dressing

- Steps before

- Preparation of liquid to pasty products, Cup pre-forming, Ingredient mixing, Product homogenization

- Steps after

- Sealing, Lidding, Quality inspection, Storage

- Input ingredients

- liquid products, pasty products, plain yoghurt, fruited yoghurt, fresh cheese, white cheese (curd), cottage cheese, single-layer desserts, multi-layer desserts, aerated mousse products, deli salads, dips, dressings, hot filled sauces, soups, jams, fruit purees, tomato paste, sweet spread, baby food, pet food

- Output ingredients

- pre-formed cups, filled pre-formed cups, sealed cups

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Output (max.)

- 49, 600 cups/h

- Round cup (max. ø)

- 180 mm

- Height (max.)

- 150 mm

- Automation

- Automatic format change over

- Platform type

- Chainless

- Material

- Stainless steel

- Cleaning method

- Washing on the fly

- Operating platform

- Single or double index

- Recipe functionality

- Index speed control

- Available formats

- Two pre-installed formats

- Working Mechanism

- Chainless transport system

- Integrated Steps

- Automatic format change

- CIP Principles

- Washing of trolleys "on the fly"

- Modularity

- Individually adaptable to customer requirements

- Format Flexibility

- Multi-format operation

- Automation Level

- Automated cell plate change

- Recipe functionality

- Control index speed to maximize product output

- Indexing

- Single or double index operating platform

- Cleaning Method

- Cleaning during production

- Cleanability

- Cleaning during production

- Corrosive resistance

- Stainless steel

- Hygienic filling

- Hygienic filling solutions

- Viscosity

- Liquid to pasty

- Container type

- Pre-formed cups

- Container size and shape

- Various sizes and shapes

- Machine footprint

- Not specified

- Frame material

- Stainless steel

- Design

- Open design

- Transport system

- Chainless platform

- Trolley feature

- Automated trolley change

- Cleaning method

- Washing on the fly

- Multi-format capability

- Yes

- Operating platform type

- Single or double index

- Control panel type

- HMI with recipe functionality

- Modular design

- Individually adaptable to customer requirements

- Chainless transport system

- Precise positioning, no chain wear

- Automated cell plate change

- Multi format

- Washing on the fly

- Cleaning during production without reducing machine output

- Available formats

- Two pre-installed formats

- Recipe functionality

- Control index speed to maximize product output