Cream Manufacturing Equipment

Find innovative cream equipment and connect directly with world-leading technology suppliers

The topical route is a convenient route for the self-administration of drugs. But turning a pharmaceutical formulation into an easy-to-use cream involves specialized cream manufacturing equipment. Topical dosage forms are essentially an emulsion of oil and water. But the ratios can be changed to process it into lotions, ointments, and gels.

New solutions for processing creams

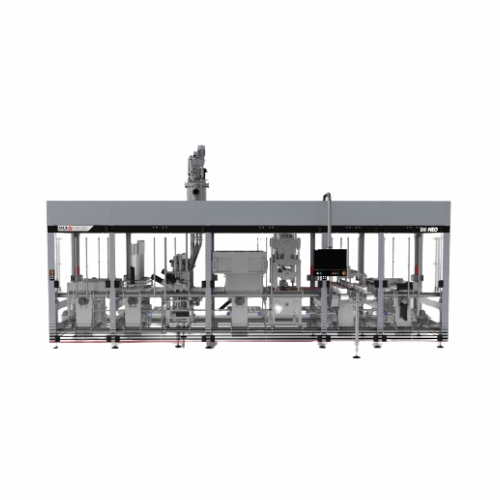

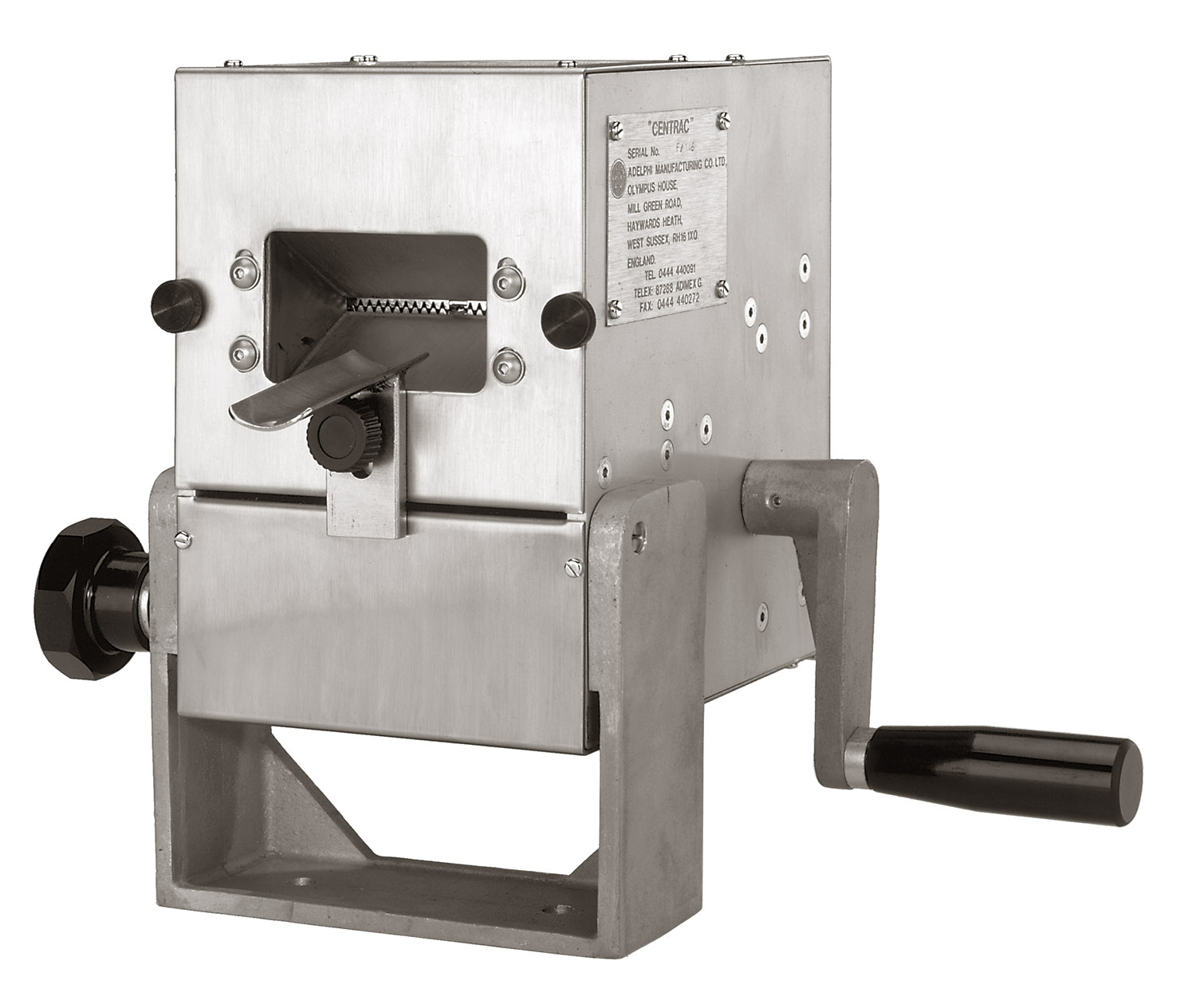

Benchtop mill for ointments

Pharmaceutical and cosmetic creams, ointments, gels and pastes can deliver a wide range of activ...

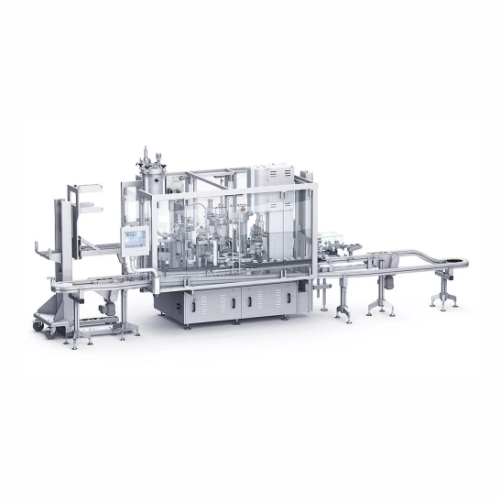

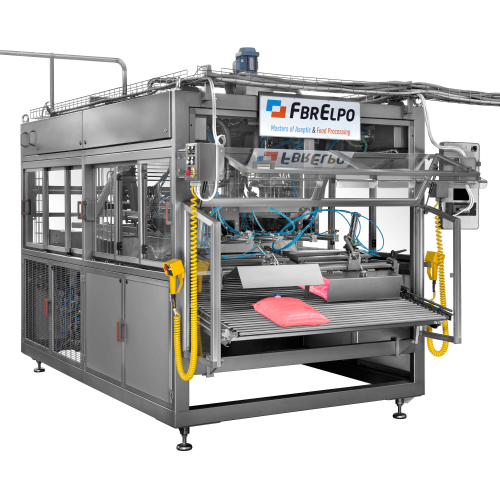

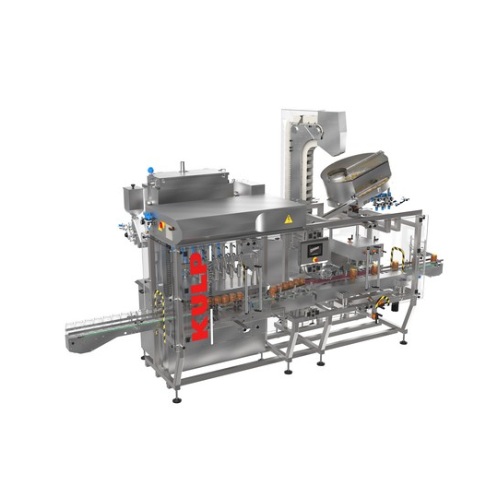

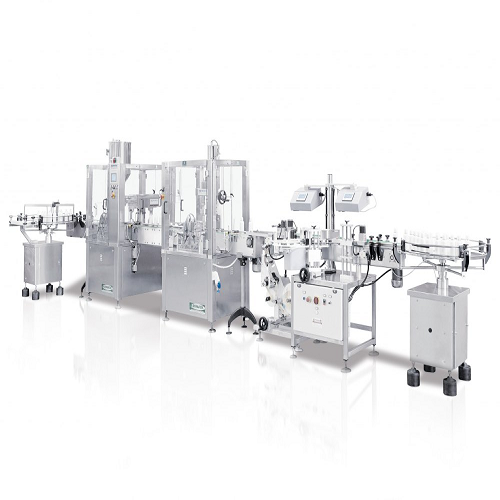

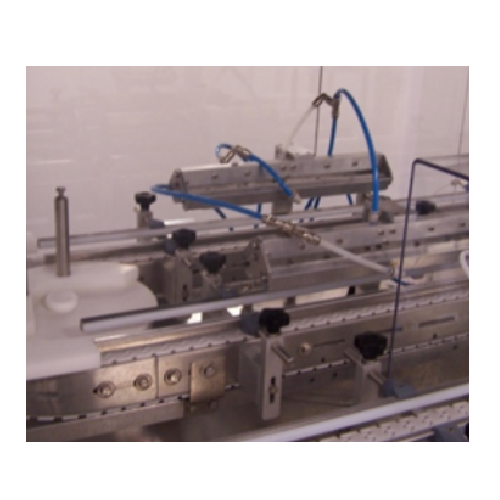

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

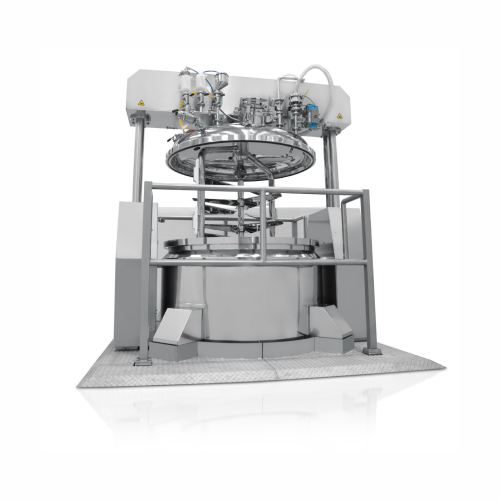

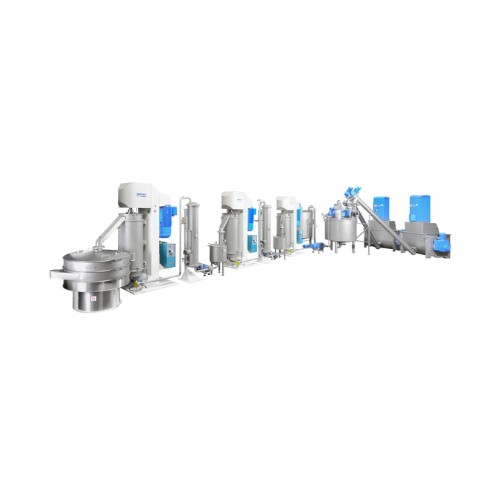

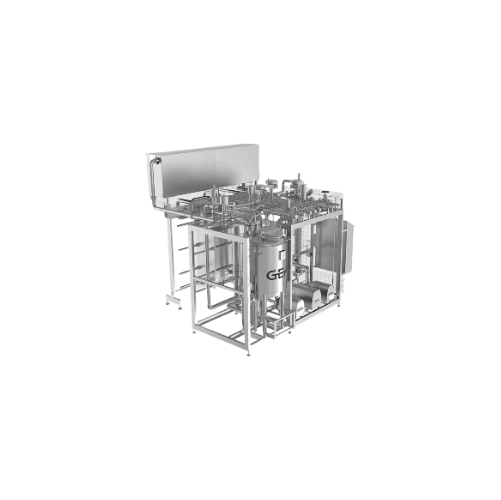

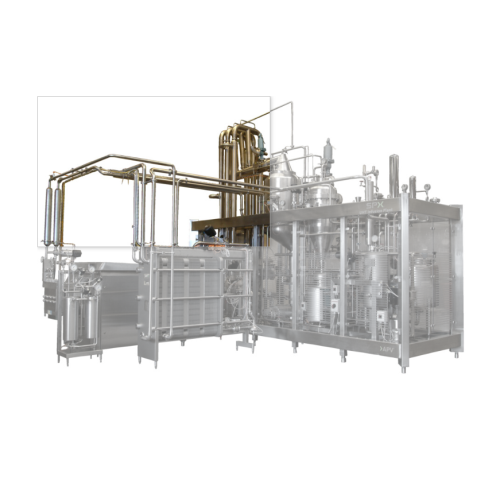

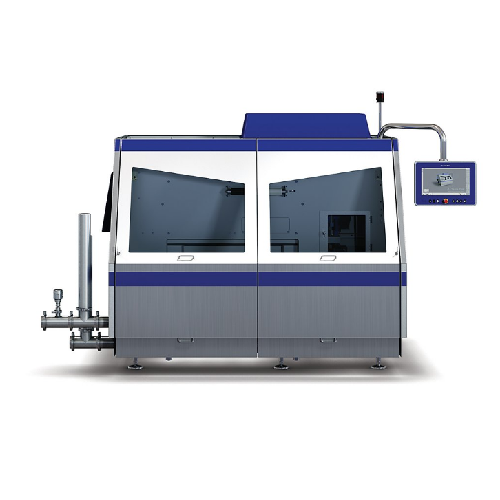

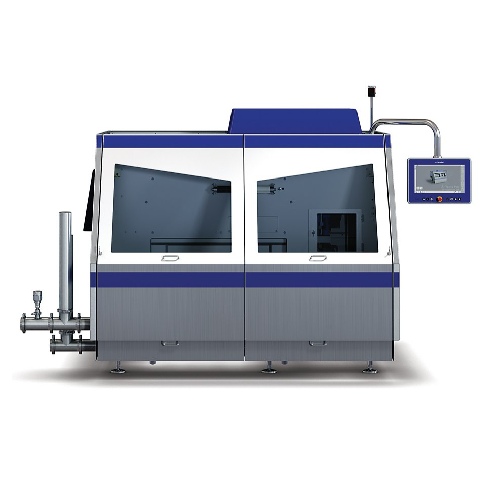

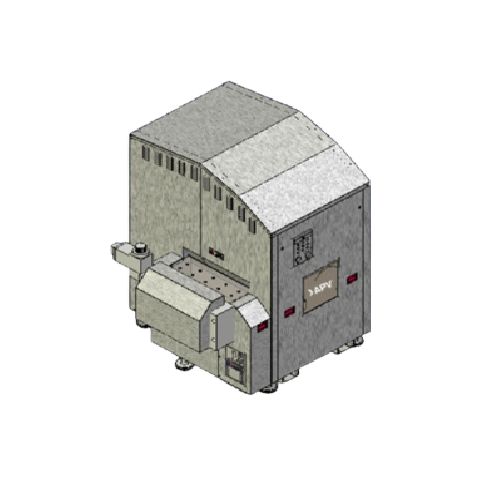

Batch vacuum mixer for emulsion-based products

The production of creams or ointments can be either be a water in oil (w/o)...

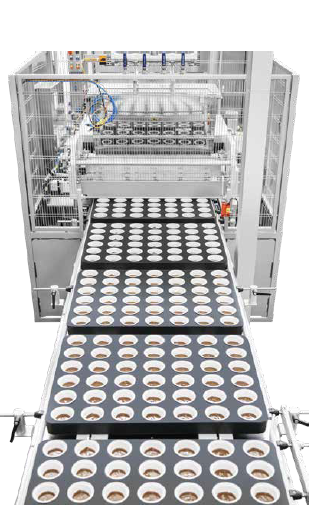

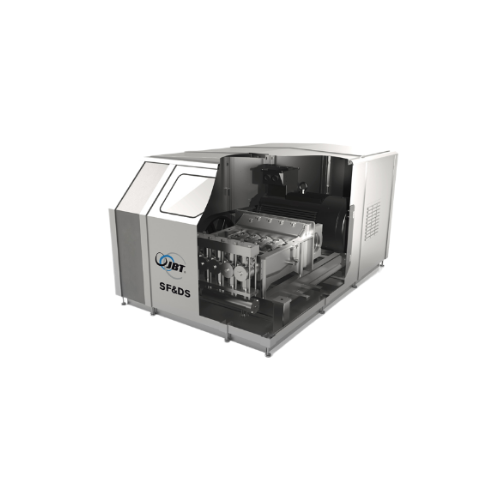

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

Select your cream process

Tell us about your production challenge

Raise the API content to 99%

Pharmaceutical creams are mostly used to treat skin issues such as rashes, stings, or fungal infections. Unlike cosmetic creams, medicated creams penetrate the epidermis and target cells in the lower layers of the skin.

Pharmaceutical creams must contain 99% pure active ingredients. However, APIs are applied in lower concentrations than in other formulations like tablets.

Mix the water and oil phases to produce a stable emulsion

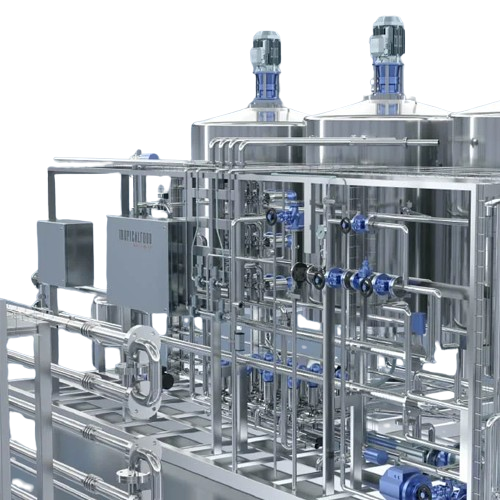

The preparation of oil and water phases involves different cream manufacturing equipment. Oils are extracted and purified from biological materials using extraction technology. Water is filtered from contaminants and distilled.

The two come together in specialized mixing systems that suspend the liquids into an emulsion. A finer droplet renders a more stable emulsion and a smoother cream consistency.

Disperse the drugs and additives in the liquids before emulsification

The oil phase can be either a mineral oil or a silicone, enriched with emollients and lubricants. If the additives are in wax form, heating equipment is used to melt them into the oil base.

Excipients such as binders, thickeners, and stabilizers help the two phases to emulsify. But these agents are dispersed into the water phase. Active ingredients are dispersed into both phases depending on their reactive properties.

Use high-shear mixing equipment to prevent lumps

Not all mixing technologies are suitable for manufacturing pharmaceutical creams. The mechanism needs to incorporate the drugs (typically in powder form) into the emulsion droplets. Failing to combine the materials homogeneously causes agglomerate in the formulation down the line.

High-shear mixers disperse the API and excipients uniformly in the oil and water phases. Similarly, the high rate of agitation lowers the interfacial tension between the phases, producing a more stable emulsion.

Add viscosity modifiers to retain a consistent texture in creams

Excipients are used to facilitate drug delivery. But, at the same time, molecules can coalesce into a microstructure forming large crystals.

Lubricants keep the fluidity of the formulation. But changing temperatures alter their behavior, and creams may feel greasy in warmer environments. Viscosity modifiers reduce the change of stickiness in lubricants to keep a consistent structure.

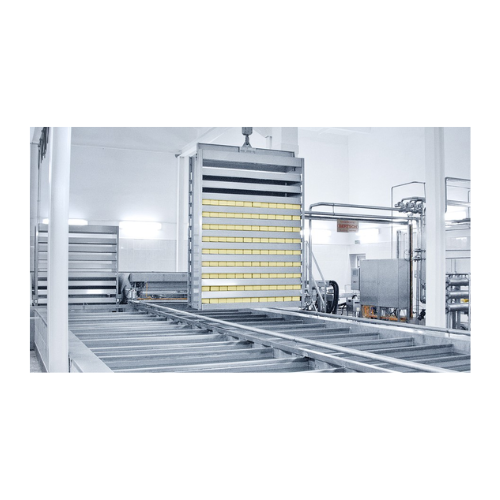

How to pack your creams and ointments

When filling topical formulations it is essential to get the amount of product in various consistencies per container just right and to be able to accommodate various container shapes and sizes. There are many factors that influence the decision for choosing a container to fill in topical dosage forms. Some of these factors are materials and visual appearance while others are specific to the usage of the product filled. The most common containers for filling creams are tubes and glass or plastic jars.

Tubes have narrow openings that protect the creams against contamination and preserve the product’s shelf life. Tubes are mostly made from low or high-density polyethylene and aluminum. They have various top shapes that can be applied. For example, triangular toppers allow to push out as much product as needed with precision. Push tops are also common for creams that need controlled amounts produced with each pump. Tubes can be of different diameters ranging from 16mm to 50mm and the capacity ranging from 5ml to 240ml. A filling machine, therefore, becomes a critical piece of equipment for any cream manufacturing plant.

Which cream technology do you need?

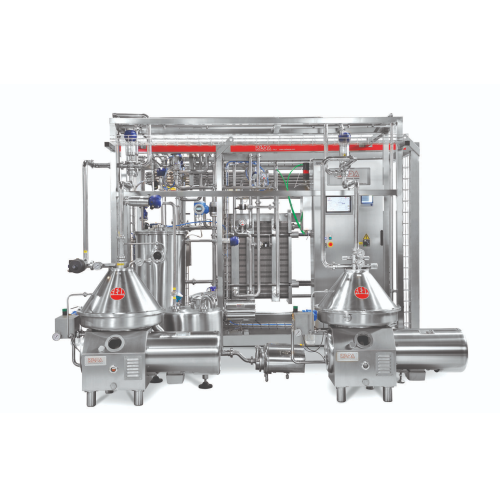

Separator for double cream fresh cheese

Optimize your dairy production with a high-performance centrifugal separator, desig...

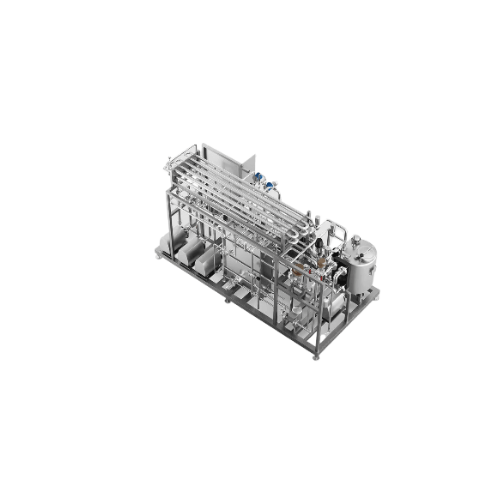

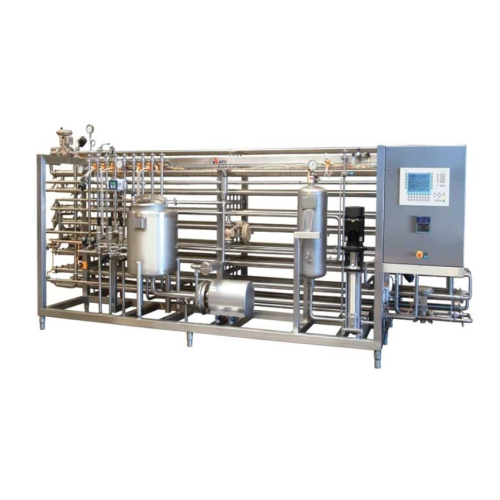

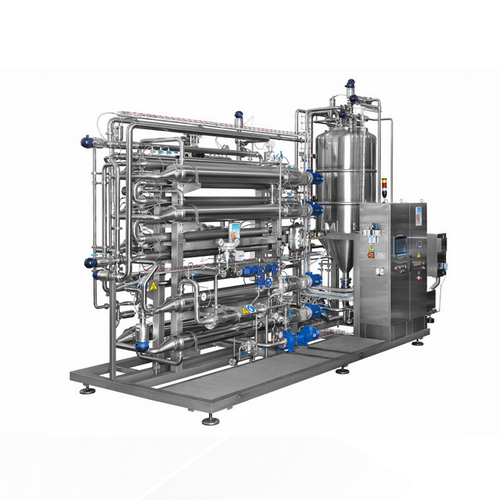

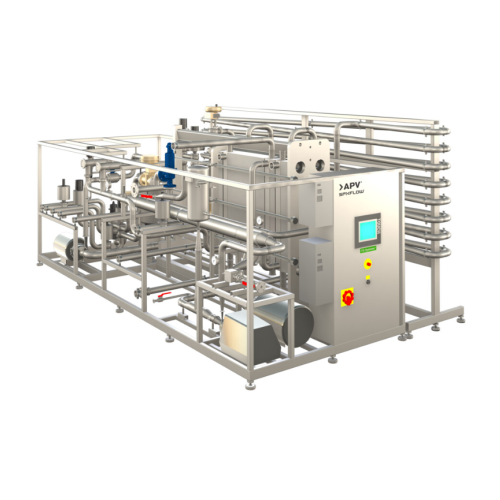

Milk pasteurizer for whey and cream

Ensure optimal product safety and quality with advanced heat exchange technology, reduc...

Milk cream separation system for cheese production

Enhance your cheese production efficiency by seamlessly integrating a ...

Cream delivery solution for sandwiching lines

Achieve precise cream delivery with enhanced control and efficiency, optimiz...

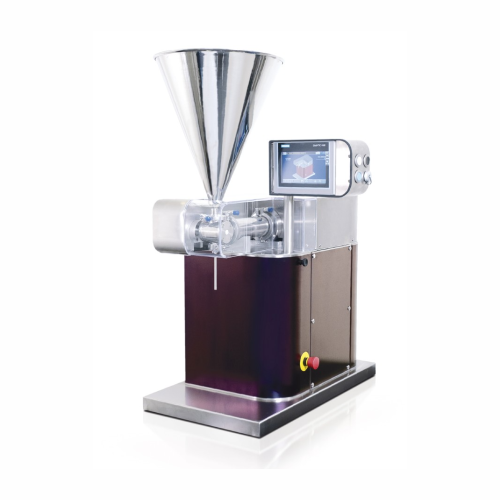

Industrial cream doser for pastry applications

Efficiently dose and fill a variety of bakery and confectionery mixtures wi...

Professional dosing system for creams and sauces

Streamline your production with precise dosing of creams and sauces, tail...

Lab-scale liquid and cream filling system

Streamline your lab production with precise filling of liquids, creams, and past...

Laboratory filling system for liquid and creamy products

Optimize your laboratory processes by precisely handling liquid,...

Vacuum turboemulsifier for liquid and creamy products

Achieve precise emulsification and mixing of liquid and creamy form...

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboe...

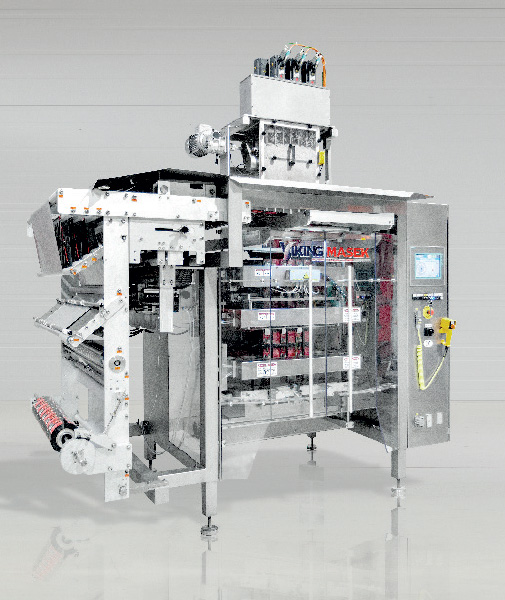

Automatic sachet filling and sealing system for liquids and creams

Optimize your cosmetic and personal care production ...

Wafer cutting system for cream-filled wafers

Achieve precise cuts on filled and coated wafer products with high-speed effi...

Contact spreading machine for cream application on wafer sheets

Ensure precise cream application with our specialized co...

Cream preparation plant for wafer production

Achieve consistent cream texture and optimal weight for perfect wafer product...

Wafer sheet cream application system

Achieve precision in cream application with high-capacity, continuous film spreading, ...

Cream preparation plant for homogeneous mixing

Optimize your snack production with precise mixing technology, ensuring con...

Intermediate cream container for snack production

Ensure consistent cream texture before extrusion with a solution design...

Filling and sealing system for creams and lotions

Achieve precise, high-speed filling and secure sealing of cosmetic cont...

Planetary stirrer for creams and ointments mixing

Achieve homogeneous mixing of creams, ointments, and pastes efficiently...

Planetary stirrer for creamy and foamy masses

Achieve consistent texture and optimal air incorporation in your products wi...

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

Turbo cream mixer for fat cream production

Achieve consistent and homogeneous cream fillings quickly with this advanced hi...

Cooling tunnel for cream-filled wafer blocks

Ensure your wafer products maintain optimal texture and integrity with a stat...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

Horizontal mixer for creams

Achieve optimal and uniform mixing of creams, pasty products, and powders with advanced horizont...

Vertical mixer for creams and desserts

Achieve uniform mixing and precise temperature control for diverse creamy and liquid...

Industrial cream whipping machine

Elevate your production with a whipping machine that amplifies cream volume by up to 50%,...

Vacuum mixer for liquid and cream processing

When dealing with high-viscosity liquids and creams, achieving uniform consis...

Vacuum homogenizer for creams and ointments

Streamline your production with cutting-edge vacuum homogenization, perfect fo...

Undervacuum homogenizer for cosmetic and pharmaceutical creams

Optimizing the production of creams and lotions, this und...

Auto bakery tray depositor for creams and batters

Efficiently deposit precise quantities of creams and batters with high-...

Creamy filling dosing system

Effortlessly dose creamy fillings into your production line with precision, ensuring chunk size...

Standardization unit for cream fat or milk fat

Optimize your milk standardization process to achieve precise cream and fat...

Compact milk pasteurizer for milk, cream, and whey

Ensure consistent product quality with precise pasteurization and skim...

Processing vessel for liquid, sauce, or cream products

Efficiently mix and integrate liquid, cream, or slurry products wi...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

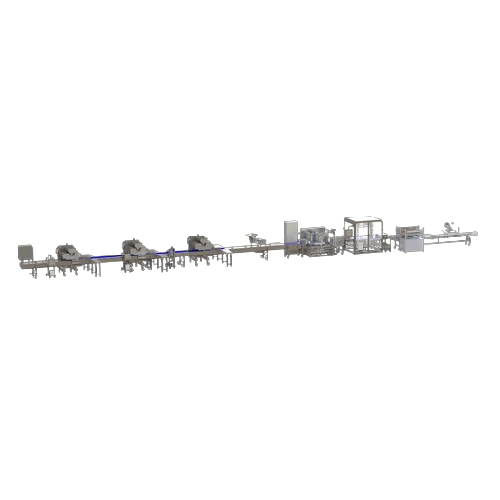

Coconut processing line for green coconut water and cream

Enhance your coconut processing with a fully automatic line th...

Dairy pasteurization system for milk, yoghurt, and cream

Ensure reliable dairy processing with an advanced pasteurization...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

Chocolate and spreadable cream dispenser

Effortlessly enhance your confection creations with a dispenser that precisely mel...

Refiner for spreadable cream and chocolate

Achieve optimal texture and consistency for your spreadable creams and chocolat...

Foil wrapping machine for cream cheese

When producing cream cheese and selling them in foil wrapped bricks you need a relia...

Emulsifier for cosmetic creams

The process of making cream and lotion involves mixing of water phase and oil phase to create...

Cream filling machine for bakery industry

Cream and other fillings in bakery products must be injected in the right volume...

Mixing system for batter and cream

When making a cake, the proper mixing of liquid batter is critical to ensuring it looks ...

Cake batter and cream depositing machine

Whether you’re making muffins or cupcakes, you need just the right amount of...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

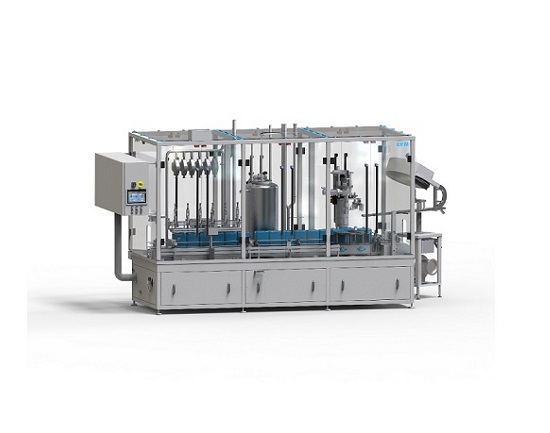

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

High shear lab mixer for creams

Lab-scale mixers are vital in the design or small-batch production of a range of pharmaceuti...

Strand forming machine for creamy mixtures

Turn your ingredients mixture into strands and slabs for further processing int...

Filling machine for creams

Liquid cosmetics have particular requirements when it comes to filling and capping containers. Mo...

Homogenizer for creams

Homogenization (or pharmaceutical micronization) is the process of reducing particle sizes, and is a v...

Piston filler for creams into moulds

The perfect cream filler, which the main feature is its accuracy and that can contain ...

Flexible mixing system for whipped cream and pastries

Delicacies such as meringue, ganache, and marzipan undergo various ...

Cakes and pastry fill injector

Achieve precise and efficient filling of a variety of bakery products, minimizing waste and d...

Uht sterilization for drinkable milk

Ensure long shelf-life and food safety without compromising the natural qualities of y...

Pasteurizer for extended shelf-life (esl) milk

Extend the shelf life of milk while maintaining its taste and nutritional i...

Milk collection system for bulk tankers

Optimize milk transfer and storage with a reliable system that reduces discharge ti...

Milk skimming separators for dairy applications

Enhance dairy production with high-efficiency skimming separators that opt...

Milk standardization system

Achieve precise milk and cream fat standardization with this advanced inline system, optimizing ...

Pasteurizer for fresh milk

Ensure your dairy and beverage lines achieve optimal product safety and quality by leveraging adv...

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

Vacuum deaeration with aroma recovery for juices

Eliminate oxygen from liquid foods to prevent oxidation while retaining v...

Juice clarification system

Ensure consistent beverage clarity with advanced separation technologies, enhancing production ef...

Aseptic tank for sterile liquid food storage

Ensure sterility and maximize shelf life for liquid foods by utilizing an ase...

Uht sterilization for milk

Enhance your production line with advanced UHT sterilization, ensuring extended shelf-life and un...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Stainless steel milk storage tanks

Optimize dairy operations with versatile tanks designed for precise storage and temperat...

Centrifugal separators for dairy product processing

Ensure optimal dairy product quality with a centrifugal separation so...

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

Milk pasteurizers for dairy sector

Ensure optimal safety and quality of your dairy products with advanced pasteurization te...

Milk receiving and storage units for dairy operations

Streamline your dairy processing with equipment designed to efficie...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Crystallizer for small-scale aeration and crystallization processes

Streamline your production with a versatile crystal...

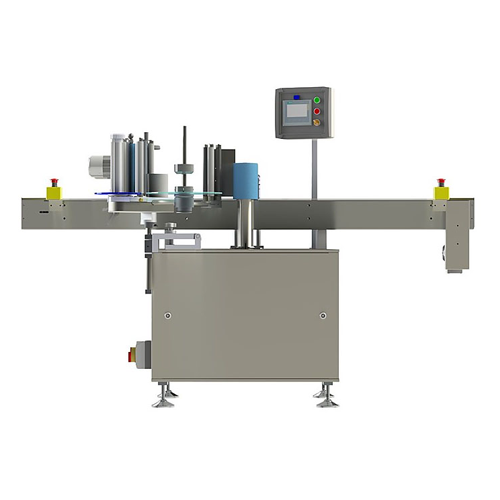

Rotary labeling solution for bottles and containers

Optimize your labeling process with high-speed precision, handling va...

Homogenizer for dairy products

Achieve precise texture and quality in dairy products with this versatile homogenizer, design...

Vacuum turboemulsifier for medium-scale production

Achieve precise emulsification and consistent quality in liquid and cr...

Vacuum turboemulsifier for small-scale production

Optimize your product development with versatile vacuum turboemulsifier...

Automatic rotary jar filling and capping system

Optimize your personal care product line by efficiently filling and cappin...

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

Counter-rotating agitator for high viscosity products

Achieve seamless heat transfer and precise mixing with a counter-ro...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Tub filling and sealing for pasty products

Experience high-speed, precision tub filling and sealing designed for pasty pro...

Cartoning solution for cheese portions

Optimize your cheese packaging with a flexible cartoning solution designed to accomm...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

Dual shaft mixer for high viscosity products

Achieve uniform dispersions in high-viscosity processes with a dual-shaft mix...

Triple shaft mixer for high viscosity products

Achieve uniform mixing and dispersion for high-viscosity materials with tri...

Stainless steel cooking kettle for food, pharma, and cosmetics

Efficiently streamline your production with versatile sta...

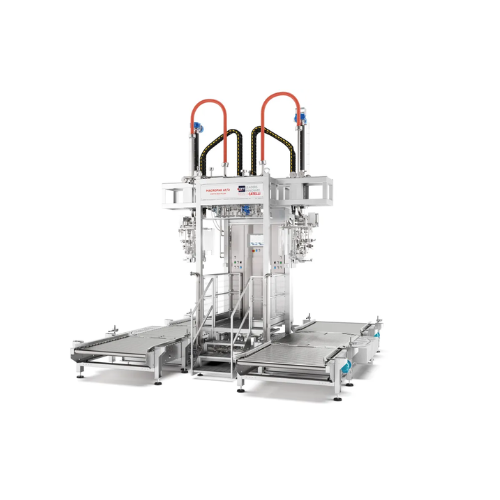

Aseptic filling system for bag-in-box packaging

Efficiently fill a range of liquid products into pre-sterilized bags while...

Aseptic filler for liquid and particulate products

Achieve precise, sterile filling of both liquid and chunky products wi...

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Planetary mixer with double tool for pastry dough

Optimize your pastry production with precise mixing capabilities that e...

Vacuum processing units for lab scale applications

Optimize the development and scaling of cosmetic and pharmaceutical pr...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Pasteurizer for dairy concentrates

Ensure optimal flavor and texture in dairy products with precise pasteurization that pro...

Medium-low density food cooker

Streamline your cooking process for medium-low density foods with precision-controlled mixing...

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

Drying solution for cosmetic slurries

Streamline the drying process of cosmetic slurries with precision control to achieve ...

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

Fully automatic chocolate processing line

Accelerate your chocolate and confectionery production with this high-speed syst...

Laboratory batch chocolate processing unit

Achieve precision in developing chocolate recipes with a compact 3-in-1 unit th...

Chocolate processing unit for mixing, grinding, and conching

Optimize chocolate production with precise mixing, grinding...

Ball mill refiner for fine cocoa grinding

Achieve high-precision grinding and refining of chocolates and cocoa with minima...

Chocolate processing production line

Efficiently streamline your chocolate and compound production with a fully automatic s...

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Vacuum deaerator for elimination of gases

Optimize your product quality by eliminating occlusive gases with this advanced ...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Semi-automatic tube filling and closing system

Achieve precise filling and secure closing for diverse tube types, optimizi...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Manual sealing machine for aluminum tubes

Ideal for laboratories and small-scale production, this compact manual sealing m...

Melter for vacuum turboemulsifiers

Achieve optimal mixing, dispersion, and temperature control with precision-engineered me...

High viscosity product mixer

Struggling with mixing high viscosity products like creams and gels? This co-axial mixer enhanc...

Alternate movement bottle filling and capping system

Enhance your production line with a versatile filling and capping so...

Linear filler for preformed containers

Streamline your packaging process with a compact solution that ensures precise filli...

Milk clarifier for dairy industry

Enhance your dairy production with efficient milk and whey clarification, ensuring produc...

Benchtop screw capper for diverse bottle sizes

Ensure precision and efficiency in your capping process with this adaptable...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Rotary volumetric filling solution for viscous products

Achieve precision in volumetric filling with a machine designed f...

Semi-automatic piston injector for bakery products

Enhance your bakery production with precise delivery of a wide range o...

Retorquer for tamper-evident bottle caps

Ensure seal integrity and maintain tamper-evidence in high-speed production lines ...

Industrial homogenizer for Uht sterilization systems

Achieve smoother product consistency with high-pressure homogenizati...

Lobe pump for soft fillings

Efficiently dose and feed soft fillings for food products with precision, ensuring smooth integr...

Pasteurizer system for dairy applications

Achieve optimal pasteurization with precise temperature control and energy-effic...

Small-scale milk pasteurizer with skimming centrifuge

Quickly integrate a versatile pasteurization system into your produ...

Uht plant for aseptic product treatment

Ensure optimal product quality and production safety with versatile UHT solutions f...

Product spreader for cooling conveyor

Optimize the cooling process of cream-filled products by gently spreading sandwiches ...

Planetary mixers for baking and food industries

Achieve precise mixing and consistency across a range of products with adv...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

Energy-saving cooling tumbler for industrial kitchens

Optimize food quality and texture with a versatile cooling tumbler ...

Stainless steel milk storage tank

Optimize your dairy production with robust stainless steel milk storage that ensures hygi...

Uht system for processed cheese

Ensure the extended shelf life and freshness of various cheese products with precise ultra-h...

Centrifugal separators for liquid/liquid/solid separation

Achieve efficient separation and clarification for diverse app...

Industrial homogenizers for liquid processing

Achieve consistent product quality and energy efficiency in liquid processin...

High speed pneumatic depositor for bakery applications

When depositing batters, creams, and sauces, achieving consistent ...

Food transfer and dosing pumps for bakeries

Enhance efficiency in food processing with pumps designed for precise transfer...

Layered food production line

Effortlessly streamline your production of layered foods with versatile technology that pumps, ...

Parfait production line equipment

Optimize your dessert production with advanced depositing technology, perfect for creatin...

Pneumatic depositor for bakery batters and fillings

Perfect for high-speed bakeries aiming to enhance efficiency, this se...

Portable table top bakery depositor

Optimize your baked goods production with precise portioning and rapid depositing, all ...

Pneumatic Rp depositor for bakery and food plants

Optimize your production line with a high-speed depositor designed to d...

Tabletop food depositor for portion control

Streamline your food production with precise portion control, reducing waste a...

Commercial food mixers for versatile culinary applications

Streamline your food production with mixers and kneaders desi...

Milk skimming separator

Achieve superior separation efficiency and reduced energy consumption in dairy processing with seamle...

Efficient dairy product separator

Achieve precise fat separation and enhance product quality while reducing energy consumpt...

Automatic milk standardization unit

Achieve precise control over milk’s fat, protein, and solids content, reducing cr...

Pasteurizer for dairy products

Enhance food safety and minimize operational costs with a cutting-edge pasteurizer designed f...

Industrial homogenizer for liquid food applications

Achieve unparalleled product consistency and quality with high-speed ...

Direct Uht processing system for dairy and plant-based beverages

Achieve ultra-high temperature treatment with minimal i...

Automated milk standardization unit

Achieve precise in-line standardization of milk components, ensuring optimal quality an...

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high tem...

Efficient milk skimming separator

Optimize your dairy processing with our high-efficiency separator, designed to ensure sup...

Dairy pasteurizer

Ensure product safety and quality while reducing energy consumption and operational costs with this advance...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Buffer tanks for dairy processing

Optimize your dairy production with versatile buffer tanks, essential for balancing flow ...

Continuous aerator for dairy products

Enhance the texture and flavor of dairy delights with precise gas infusion, transform...

Dry and liquid ingredient batch mixer for bakery applications

Achieve homogeneous mixing with precise heat control and e...

Industrial peanut butter production line

Enhance your production line with this comprehensive peanut butter processing solu...

Direct drive centrifuges for dairy and beverage processing

Optimize energy efficiency in high-speed liquid separation wi...

Tubular Uht processing for dairy products

Experience efficient high-pressure thermal processing with tubular UHT technolog...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

High pressure homogenizers for dairy and pharmaceutical applications

Optimize your production line with high-pressure h...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

Uht system for milk and dairy products

Ensure superior product quality and extended shelf-life by utilizing rapid heat trea...

Ultra high temperature infusion plant for milk processing

Achieve extended shelf life and superior taste in dairy produc...

Ultra high temperature (uht) direct heating for infusion Esl plant

Achieve extended shelf life and superior flavor with...

Hygienic tanks for various processing needs

Achieve optimal processing and storage with customizable hygienic tanks, desig...

Infusion Uht plant for dairy products

Achieve precise thermal treatment with minimal product alteration, enhancing quality ...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Scraped surface heat exchanger for high viscosity products

When dealing with complex formulations, achieve efficient hea...

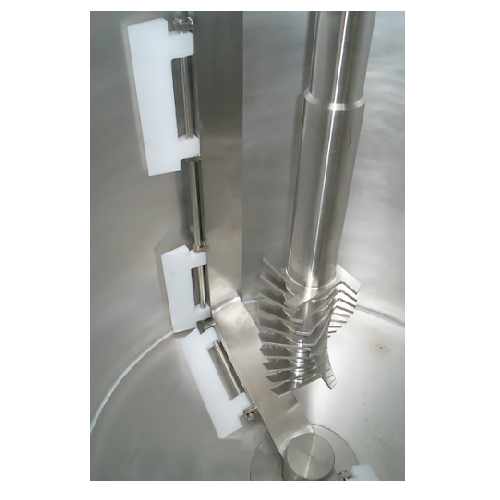

Crystallization and pin-working equipment for food processing

Optimize your food product quality with precise crystalliz...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Pilot ultrasonic extractor

In the herbal medicine industry, an ultrasonic extractor is a valid alternative to conventional e...

Batch vacuum mixer for emulsion-based products

The production of creams or ointments can be either be a water in oil (w/o)...

Pharmaceutical formulation and mixing tanks

Preparation lines for formulating pharmaceuticals include fixed and mobile tan...

Benchtop mill for ointments

Pharmaceutical and cosmetic creams, ointments, gels and pastes can deliver a wide range of activ...

Ice coating machine

Make consistent use of this high-quality, finish coat with your covered product. This is a coating machin...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Complete cutting, mixing, emulsifying and heating system

From laboratory scale to large volume food or cosmetic productio...

Clarifier for beverages

Enhance beverage clarity and purity with high-performance centrifugal separation, expertly designed t...

Cold block piping solution for breweries

Achieve optimal beverage quality and reduce production costs with this advanced pi...

Layer cake production system

Effortlessly streamline your bakery production with a system designed for precise layering and ...

Volumetric piston depositors for cake and pie fillings

Achieve precise depositing and gentle handling of varied doughs an...

Low temperature evaporator for heat-sensitive food products

Efficiently concentrate sensitive liquid products while pres...

Clarifier for milk and whey

Optimize dairy and beverage production by efficiently removing fine curd residuals, ensuring hig...

Curd making equipment for cheese production

Optimize your cheese production with versatile curd making equipment, designed...

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Cip systems for dairy production

Ensure consistent hygiene and sanitation levels in your production line with efficient, aut...

Deodorizing units for milk pasteurization

When handling dairy products, controlling odors during pasteurization is crucial...

Industrial premixing system for batch and inline processing

Streamline your production with advanced premixing systems d...

High solids crossflow filter for wine filtration

Optimize filtration efficiency while minimizing operational costs with th...

Fermenting tanks for beer production

Optimize your beverage production with advanced fermenting tanks designed to enhance t...

Stainless steel tanks for dairy processing

Optimize your dairy processing with customizable stainless steel solutions for ...

Lipstick moulding system

Achieve precision and efficiency in your cosmetic production line with advanced moulding and dosing ...

Lipstick packaging fit tester

Ensure precise packaging fit for lipsticks, improving product quality and decreasing return ra...

Laboratory demoulding unit for lipstick samples

Streamline your laboratory’s lipstick sampling process with a versat...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Horizontal element kieselgur filters

Enhance your production with a filtration system that ensures effective separation of ...

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

Centrifugal separators for dairy products

Enhance your liquid food product quality with centrifugal separators designed fo...

Cip cleaning system for dairy industries

Ensure hygienic operation with this system, designed to maintain optimal cleanline...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

High speed cheese dosing and wrapping solution

Achieve precise dosing and efficient wrapping of cheese portions with versa...

Filling and sealing pre-formed cups solution

Ensure ultra-clean and aseptic processing for pre-formed cups with a fully en...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

Beer production filtration system

Enhance your beverage production with cutting-edge filtration systems designed to maintai...

Open milk cooler with 2,000 liters capacity

Ensure optimal milk quality and temperature with this open milk cooler, design...

Vertical milk cooler for large-scale farms

Optimize your milk preservation with this space-efficient vertical cooler, desi...

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Aseptic filler for bag-in-box packaging

Achieve unparalleled product safety and quality in liquid packaging with our advanc...

Industrial pasteurizer for dairy and beverage processing

Enhance product quality and safety with efficient heat treatment...

Inline system for personal care product production

Optimize your personal care production with precise mixing, heating, a...

Caramel cooking solution

Optimize your confectionery production with precise mixing, dissolving, and heat transfer technologi...

Gravity filling systems for still beverages

Ensure precise and clean filling for still beverages with gravity systems that...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Semi-automatic filler for bag-in-box packaging

Streamline your liquid packaging process with a versatile filler that integ...

Chocolate processing unit for mixing and grinding

Achieve precise mixing and conching efficiency for premium chocolate an...

Automatic chocolate processing line

Transform your production by automating the complete chocolate-making process—from prec...

Ball mill refiner for cocoa liquor and chocolate production

Optimize your cocoa and chocolate refinement with precise gr...

Scraped surface sterilizer for high viscosity liquid products

Optimize your production of high viscosity liquids with a ...

Industrial cheese processing plants

Streamline your cheese production with custom-engineered systems designed to enhance ef...

Cheese processing plant

Transform your dairy processing with comprehensive, tailored systems designed to optimize production ...

Cheese processing plant for hard and semi-hard cheese

Optimize your cheese production with a versatile solution designed ...

Cip cleaning systems for dairy processing plants

Optimize cheese production with precise curd handling and exceptional sti...

Cheese vat for varied cheese types

Ensure consistent high-quality cheese production with a vat that accommodates multiple c...

Cheese vat for diverse cheese production

Optimize your cheese production with a versatile cheese vat designed for precision...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Full production line with depositing and ultrasonic cutting

Streamline your baked goods and dessert production with this...

Linear filling and capping for stable bottles

Enhance your production efficiency with a solution designed for precise liqu...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

Rotary filler for preformed containers

Ensure microbiological safety and extended shelf life for your liquid products with ...

Label inspection for vertical products

Ensure label quality and accuracy with advanced inspection technology designed for p...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Aseptic tank module for liquid food storage

Ensure safe storage of sterilized liquid foods with a customizable tank module...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

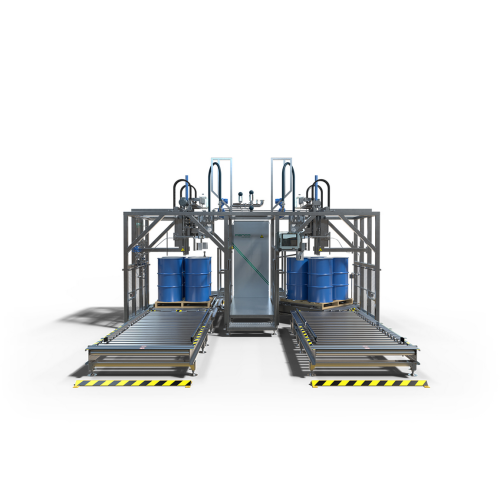

Drum decanting unit for high viscosity liquids

Efficiently decant high viscosity liquids like solvent-based paints and ess...

High precision three-roller wraparound labeller

Achieve precise label placement on round containers effortlessly with a th...

Industrial melt tanks for butter and chocolate

Reduce manual labor and elevate safety in your production line with a melt ...

Rotary pressure sterilizer for canned food products

Streamline your canning operations with continuous high-speed sterili...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Hygienic centrifugal pump for beverage applications

Ensure gentle handling and efficient transfer of sensitive liquids wi...

Sustainable packaged compressor system

Enhance your production with a scalable compressor system designed for high efficien...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Very high pressure homogenizer compression block

Experience reliable performance at extreme pressures with a compression b...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

Aseptic filling system for bag-in-box containers

Ensure sterility and precision in filling aseptic liquid products, with s...

Aseptic liquid dosing system

Ensure precise, sterile dosing of aseptic liquid products, enhancing product integrity and exte...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Solid-wall bowl separators for milk & whey

Achieve precise skimming and standardizing of milk and whey with this advanced ...

Rotary piston fillers for pumpable products

Optimize high-speed production lines with precision filling for diverse liquid...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Milk reception unit for dairy processing

Ensure precise measurement and streamlined handling of raw milk with an engineered...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Turnkey stainless steel tanks

Optimize your liquid processing with versatile stainless steel tanks designed for efficient st...

Industrial chiller systems for processing cooling

Optimize your production line with advanced chiller systems designed to...

Industrial depositor for automated recipe management

Effortlessly streamline your production with precise depositing cont...

Multi piston depositors for bakery production

For bakeries seeking precision in depositing and filling, these multi piston...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

Rotary cup filling and closing system

Maximize production efficiency with a system that offers precision filling and secure...

Forming, filling, and sealing system for liquid food products

Achieve precise portion control and versatile packaging wi...

Indirect Uht treatment for dairy products

Ensure your beverages achieve extended shelf life with consistent quality using ...

Direct Uht processing for heat-sensitive liquid products

Achieve optimal taste and nutritional value in liquid foods thro...

Spore and bacteria removal unit for dairy products

Ensure superior quality by precisely removing spores and bacteria from...

Industrial clarifier for dairy and plant-based products

Optimize your production line with cutting-edge clarification tec...

High shear mixer for dairy and beverage applications

When creating complex formulations like sauces or dairy spreads, ach...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Evaporator for dairy products

Need efficient moisture removal in diverse dairy and food applications? This falling film evap...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

Uht processing unit for dairy products

Optimize your liquid food production with continuous, high-capacity UHT treatment th...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Ingredient dissolver for small batches

Efficiently dissolve water-soluble powders and concentrates up to 200 cP with precis...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

Storage tank for food liquid storage

Ensure seamless liquid product handling with precision-engineered storage tanks design...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Semi-automatic capping solution for small to medium operations

Streamline and personalize your capping processes with ve...

Cleaning in place system for dairy processing plants

Streamline cleaning efficiency and ensure product quality in your da...

Milk pasteurizer system

Ensure your dairy and plant-based beverages achieve optimal safety and quality with precise temperatu...

Pilot plant homogenizer for immiscible liquids

Streamline your R&D with precise homogenization, allowing you to test ...

Multipurpose ultra high temperature (uht) pilot plants

Optimize liquid food production with a versatile pilot unit design...

Plate juice pasteurizer system

Ensure optimal pasteurization with precise temperature control and high heat recovery, reduci...

Combi ultra high temperature (uht) processing plant for dairy and beverages

Achieve precise heat treatment for diverse...

Sanitary gasketed plate heat exchangers for clean applications

Ensure product purity and maintain hygienic standards wit...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Clean in place (cip) system for industrial cleaning

Ensure optimal hygiene and production efficiency with a system that s...

Centrifugal atomizer for precise spray drying

Achieve precise control over particle size and moisture content with centrif...

Process tanks for mixing, cooking, and cooling applications

Efficiently tackle viscous product challenges with advanced ...

External washing and drying system for sealed vials

Ensure contamination-free packaging of liquid vials with this precise...

Milk pre-cooling systems for dairy farms

Optimize dairy production with advanced milk pre-cooling systems that significantl...

Instant milk cooling systems for dairy farms

Optimize your dairy operations by instantly cooling milk with systems designe...

Remote monitoring app for milk coolers

Ensure milk quality and streamline operations with a remote monitoring app that prov...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Manual metal tube sealing equipment

For small-batch productions where you utilize metal tubes as containers for your produc...

R&D bottle washer

When you pack your products in bottles, vials, syringes, and test tubes you need to wash them before fillin...

Up to four head automatic filling machine

When your consumer demand is increasing you will need new and more effective pac...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

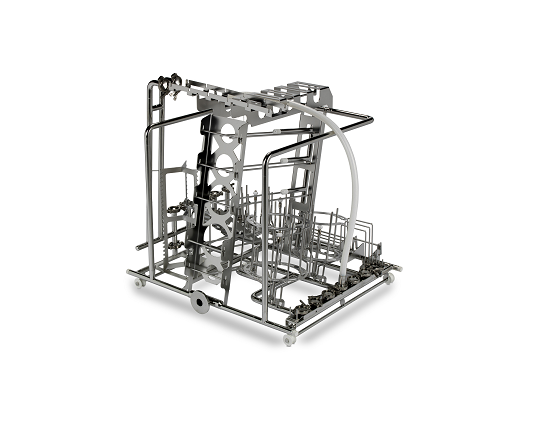

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a wa...

Bulk chamber washer

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

Compact monoblock filler

Filling and capping bottles and pots for food, chemical and cosmetics industries using separate mach...

Single head capper

For the stand-alone capping of bottles of up to 30 litre capacity for smaller-scale production you need a ...

Tube unloader and feeder

The pharmaceutical and cosmetic industries utilise high speed tube fillers on large-scale production...

Tube feeding unit for high volume and high speed tube filler

High performance tube-filling machines are used for large s...

Loading cassette for a tube filler

High performance tube-filling machines are used in the pharmaceutical and cosmetic indus...

Tube feeder for a small scale production tube filler

Low speed tube-filling machines are used for small scale production ...

High speed automatic tube filler

For high-volume lines filling pharmaceutical, cosmetic or food products into tube container...

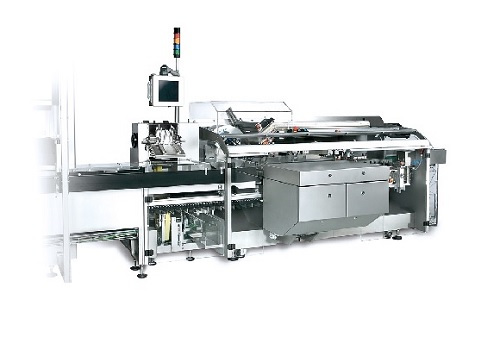

High-capacity horizontal cartoner for pharma and cosmetics appliances

Cartoners take carton blanks which are formed and...

Automatic cartoner for applications in pharma and cosmetics

For high capacity production of cosmetics and pharmaceutical...

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed ...

Horizontal cartoner for pharma and cosmetics

Most pharmaceutical and cosmetics products are packed in cardboard cartons fo...

High capacity cartoner for pharmaceutical applications

Many pharmaceutical products are packed in protective and decorati...

Vertical cartoner for pharmaceutical applications

Many pharmaceutical and cosmetic products are sold in protective and de...

Medium speed tube filler and sealer

For scale-up filling of tube packaging for pharmaceuticals, cosmetics and food products...

Medium and high speed range automatic tube filler

When scaling up production of pharmaceutical, food or cosmetic products...

Low speed tube filler

Increasing numbers of products in the pharmaceutical, cosmetic and food industries are delivered in fle...

A two-component filling application tube filler

A wide variety of pharmaceutical, cosmetic and food products require tube-...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Multi-head capper

For the stand-alone capping of bottles of up to 2.5litre capacity you need a robust and flexible machine wi...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Dispersing machine for emulsions and suspensions

Equipment operating under the rotor/stator principal is often employed wh...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Dispersing machine for very fine emulsions and suspensions

For continuous high performance mixing of solid and liquid ra...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

High accuracy homogenizing system

When extremely high accuracy is required in your recipe or formulation traditional mixing...

Horizontal kneader

For high viscosity products, better results and reduced process times can be achieved with kneading type r...

Vertical kneader

Production of highly viscous products with high solid content often benefits from kneading processes rather t...

Continuous kneader

Effective mixing of highly viscous products with extremely high solids content can be difficult and the re...

Batch dispersing machine

Equipment operating under the rotor/stator principal is often employed when more traditional methods...

Batch dispersing machine for abrasive products

For mixing and dispersing tasks that cannot be completed by conventional st...

Batch dispersing machine for bottom entry into vessels

When your process requires high performance mixing or dispersion b...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

Agitator for low viscosity media

Reliably agitating fluids in open or pressure-less vessels in a laboratory or small scale p...

Small batch filter press for oil seeds

Getting a high-quality oil filtration can be a challenging task, with a filtration ...

Cold oil press for seeds

With a cold oil press, you can optimize the process of extracting oil from a wide variety of oil see...