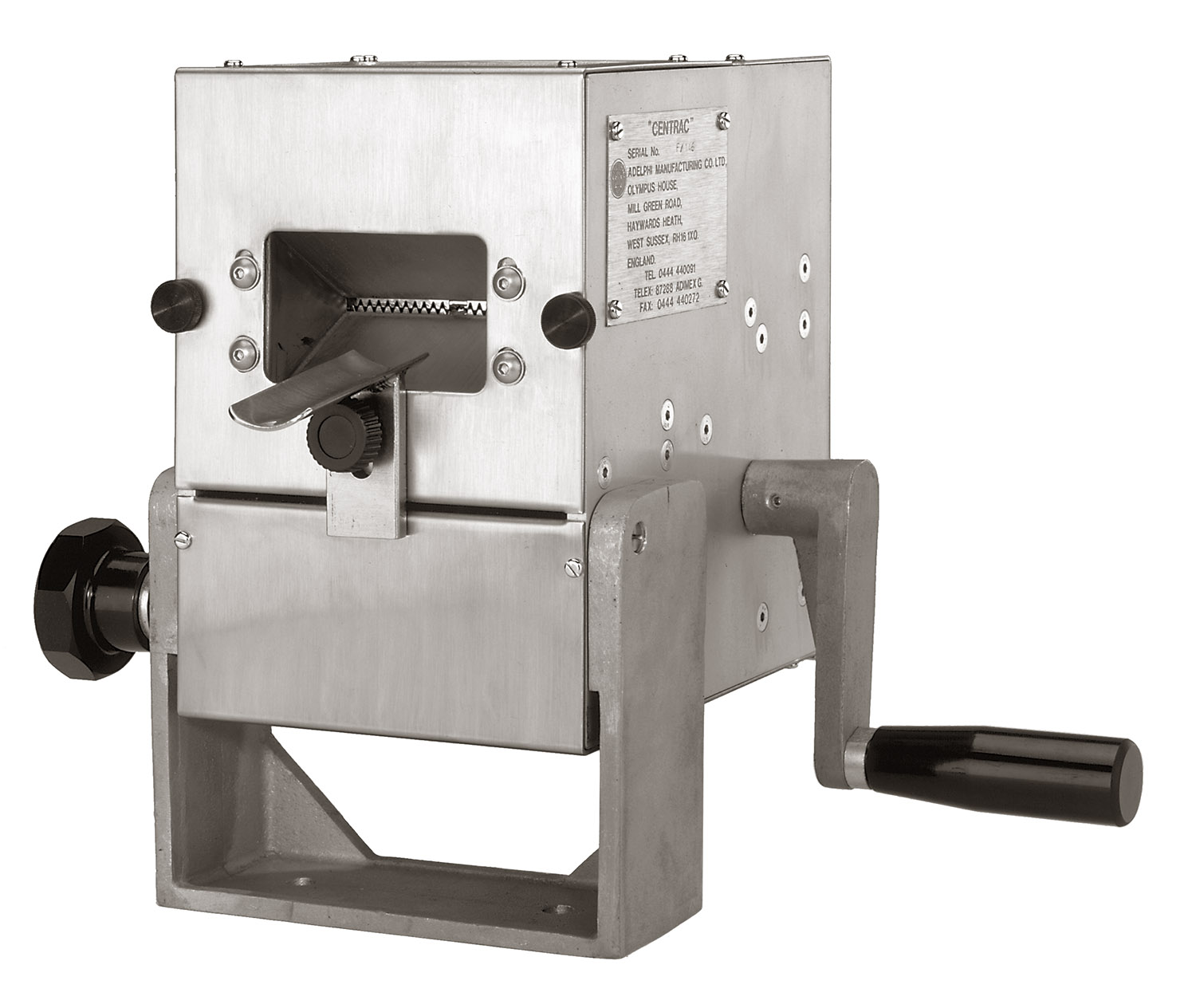

Manual metal tube sealing equipment

For small-batch productions where you utilize metal tubes as containers for your products, the sealing process requires closing the open end of the tube by folding and crimping. You may even require coding marks as part of your standard procedure. Performing these three steps through one piece of equipment can help you reduce costs and save time and space.

Folding, crimping, and coding of metal tubes using a single equipment

The Centrac FCC Tube Closer from Adelphi is a manually operated sealing system for metal tube containers with diameters ranging from 12 to 40mm. The system only requires two handle rotations to close, fold, and crimp the metal tube. It is provided with an adjustable rest to load the tube in the correct position, a gauge plate to regulate the fold depth, and a wing nut to adjust the crimp depth. Coding jaws are supplied with the unit for code marking up to 4 digits or characters. The operation angle can be adjusted up to 90 degrees for greater operator comfort and all working parts are fully guarded for safety. The system has an output of up to 600 tubes per hour.

Benefits

- Simple operation (2 handle rotations to perform closing, folding, and crimping)

- Angle of operation can be adjusted up to 90° for greater operator comfort

- Up to 600 tubes per hour

- Coding jaws are supplied with the equipment