Making Cosmetic Creams

Find innovative production technology for making cosmetic creams and connect directly with world-leading specialists

Did you know that in the 30s, cosmetic creams that contained radioactive material were booming on the market because they promised to reduce wrinkles? Thank God that's no longer the case. To make a cosmetic cream today, you need to create a stable mixture of oil and water and add an emulsifier to join these otherwise immiscible substances.

Stories about cosmetic creams

Tell us about your production challenge

Let’s dive into the cosmetic cream manufacturing equipment

Producing cosmetic creams involves two major stages. The first is the independent mixture of water and oil-soluble ingredients, while the second involves the combination of the two in a homogenizer for a uniform emulsion. The first stage typically utilizes elevated temperatures to facilitate even dispersion of constituents.

The combination phase permits the addition of more heat-sensitive elements, such as essential oils, and requires a slower, more delicate homogenizing system to finesse the desired consistency and potency. Selecting effective cosmetic cream manufacturing equipment requires an understanding of the properties of your ingredients to optimize the time required from start to finish.

Employing emulsifiers for effortlessly incorporating elements

Emulsifiers are an essential inclusion in your body lotion formula. The beauty of emulsifiers is that the molecules contain an aspect for binding to both polar substances, like water, and nonpolar substances, like oil. As a result, oil in water suspensions will see tiny droplets of oil bound by emulsifiers and dispersed into water. This formulation leaves minimal residue when applied to the skin. Water in oil suspensions will naturally see the opposite.

These heavier creams are excellent for people with dryer skin needing greater skin barrier protection to maintain good moisturization. The oil will usually carry most of the active ingredients, and you can regulate the viscosity or thickness of the cream by the amount of water included. Preservatives are essential in preventing degradation, as microbes are keen to grow in any well-hydrated environment.

The incredible variety of cosmetic creams and their constituents

Cosmetic creams may differ in their constituents according to their desired effect and time of application. Day creams, for example, tend to be lighter and less prone to clogging up pores in the presence of pollutants. On the other hand, nights creams can be heavier in the absence of environmental irritants and provide an extended window to buffer and rejuvenate the skin. Care must be taken to consider the biochemical requirements of active ingredients to ensure optimal bioavailability.

Blocking blue light, an aging accelerator?

With the majority of industry moving indoors, and a growing understanding of the dangers of UV rays, people are ever more careful to protect themselves from the harsher habits of sunlight. Even so, another contender has taken its place as the most prevalent threat. Phones and laptops have become as ubiquitous as the air we breathe, and the blue light they produce may provoke undesirable consequences in those frequently exposed to it. Research has shown that blue light may lead to the loss of cell mass and even cell death, so modern cosmetic creams have begun to offer protection against such undesirable consequences. Blue light cosmetics typically invoke antioxidants and ingredients that preferentially block such wavelengths of light, so formulas including them must invariably take care to ensure they lose no potency during incorporation.

Processing steps involved in cosmetic creams making

Which cosmetic creams technology do you need?

Perforated disc mill for pre-comminution and mashing

Achieve precise granulating and mashing of diverse materials with th...

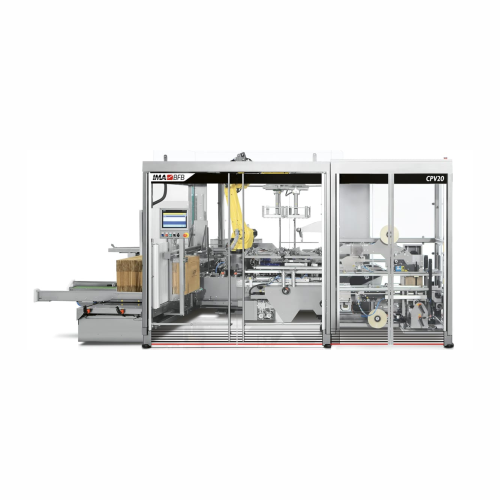

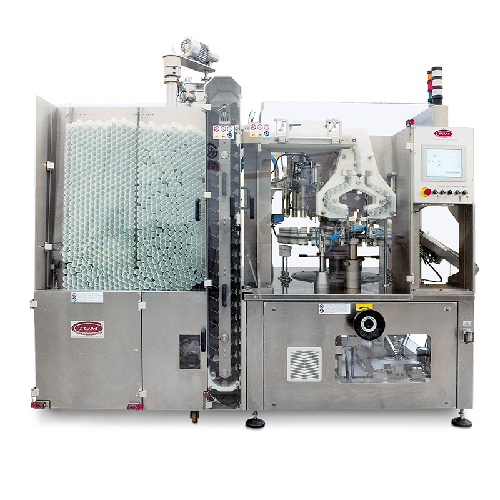

Hig Speed Tube Cartoner

Achieve seamless integration into your high-speed packaging line with a cartoning solution that ensur...

Gas pycnometer for precise density determination

Achieve accurate and reliable density measurements for a diverse range of...

Industrial melter for cosmetic product processing

Streamline your production with this versatile melter, designed to effi...

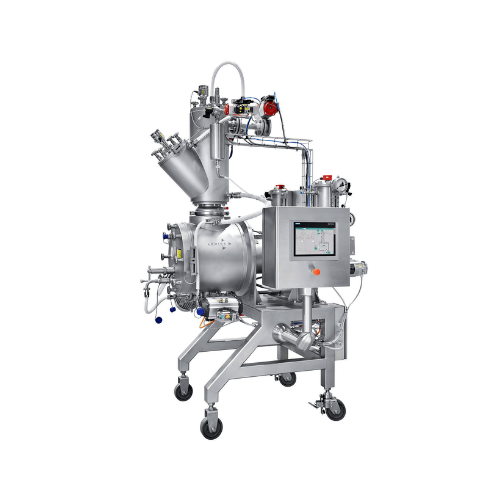

Vacuum turboemulsifier for medium-scale production

Achieve precise emulsification and consistent quality in liquid and cr...

Cosmetic pencil filling system

Streamline your cosmetic production with high-speed filling and precise molding capabilities,...

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

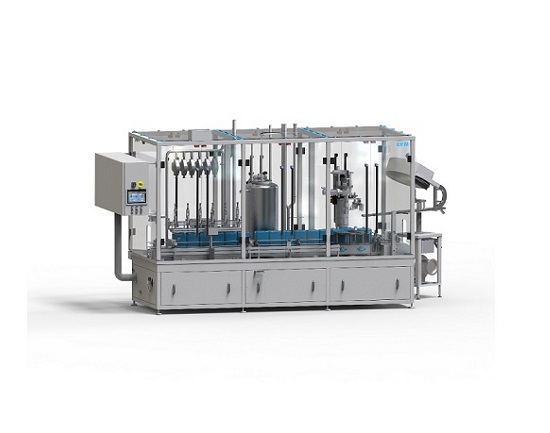

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

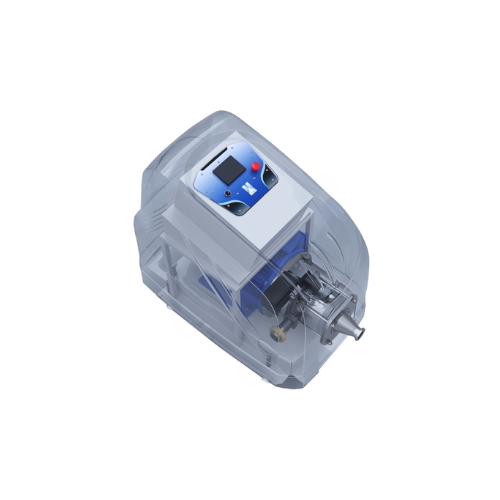

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Highly scalable reactors for chemical synthesis

Optimize your production line with versatile reactors designed for seamles...

Laboratory mixer for homogenizing and mixing samples

Achieve precise sample preparation and efficient mixing with this ve...

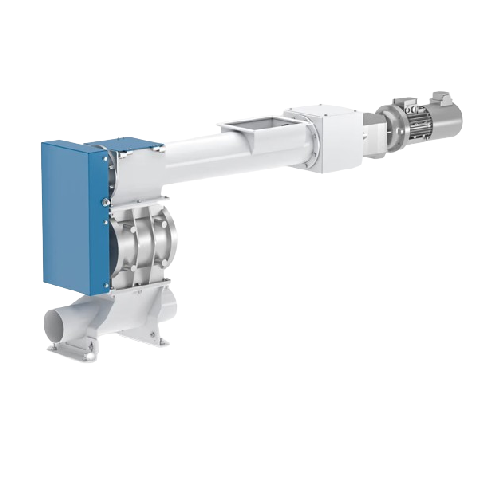

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Counter-rotating blender for cosmetic and pharmaceutical mixing

Achieve precise mixing and homogenizing of complex formu...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

Counter-rotating agitator for high viscosity products

Achieve seamless heat transfer and precise mixing with a counter-ro...

Top-loading case packer for pharmaceutical and cosmetic products

Ensure precision and flexibility in packaging with this...

Cone mill for particle size reduction

For precise particle size reduction, the cone mill offers flexible screening options ...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Overwrapping system for cosmetic and toiletry items

Ensure precise overwrapping of cosmetic and toiletry items with advan...

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Drum mixer for dispersions & agitations

Achieve seamless fluid formulation and agitation with a compact, high-speed drum mi...

Immersion mill with sweep blade for high-viscosity products

Optimize your production line with this immersion mill desig...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Mascara and lip gloss filling system for cosmetics

Optimize your cosmetic product filling operations with precision, hand...

Laboratory mortar grinder for wet and dry grinding

Ensure precise blending of fine powders, pastes, and creams with contr...

Intermittent side-load cartoner for pouches or stick packs

Optimize your packaging process with an intelligent side-load...

Vacuum processing units for lab scale applications

Optimize the development and scaling of cosmetic and pharmaceutical pr...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Pharmaceutical high-shear mixer granulator

Enhance your production efficiency with a high-shear mixer granulator, designed...

High-capacity universal mixer for industrial applications

Optimize your batch processing with a versatile high-speed mix...

Containment solutions for pharmaceutical production

Enhance operator safety and product integrity with advanced containme...

Single-pot processor for wet granulation and vacuum drying

Achieve efficient mixing, granulation, and swift vacuum dryin...

Laboratory unit for mixing, granulating, and vacuum drying

Achieve precise mixing, granulating, and drying in laboratory...

Interchangeable tool stainless steel kneader

Streamline your batch processing with this flexible mixing technology that of...

Tube filling solution for health and beauty applications

Achieve consistent quality and efficiency in tube filling operat...

Tube filling solution for health and beauty products

Achieve rapid production with precision in tube filling for personal...

Cosmetic jar filling solution

Reduce product contamination and ensure precise filling with an intermittent jar filling solut...

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

Full-volume bead mill for wet grinding applications

Achieve superior dispersion and particle size consistency with advanc...

Vertical mixer for creams and desserts

Achieve uniform mixing and precise temperature control for diverse creamy and liquid...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Colloidal mill for industrial homogenization

Achieve consistent emulsification, size reduction, and uniform particle distr...

Horizontal vacuum paddle dryer for thermosensitive products

For high-viscosity products like active pharmaceuticals or p...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Automatic tube filling and closing system

Enhance production efficiency with a high-speed tube filling and closing system ...

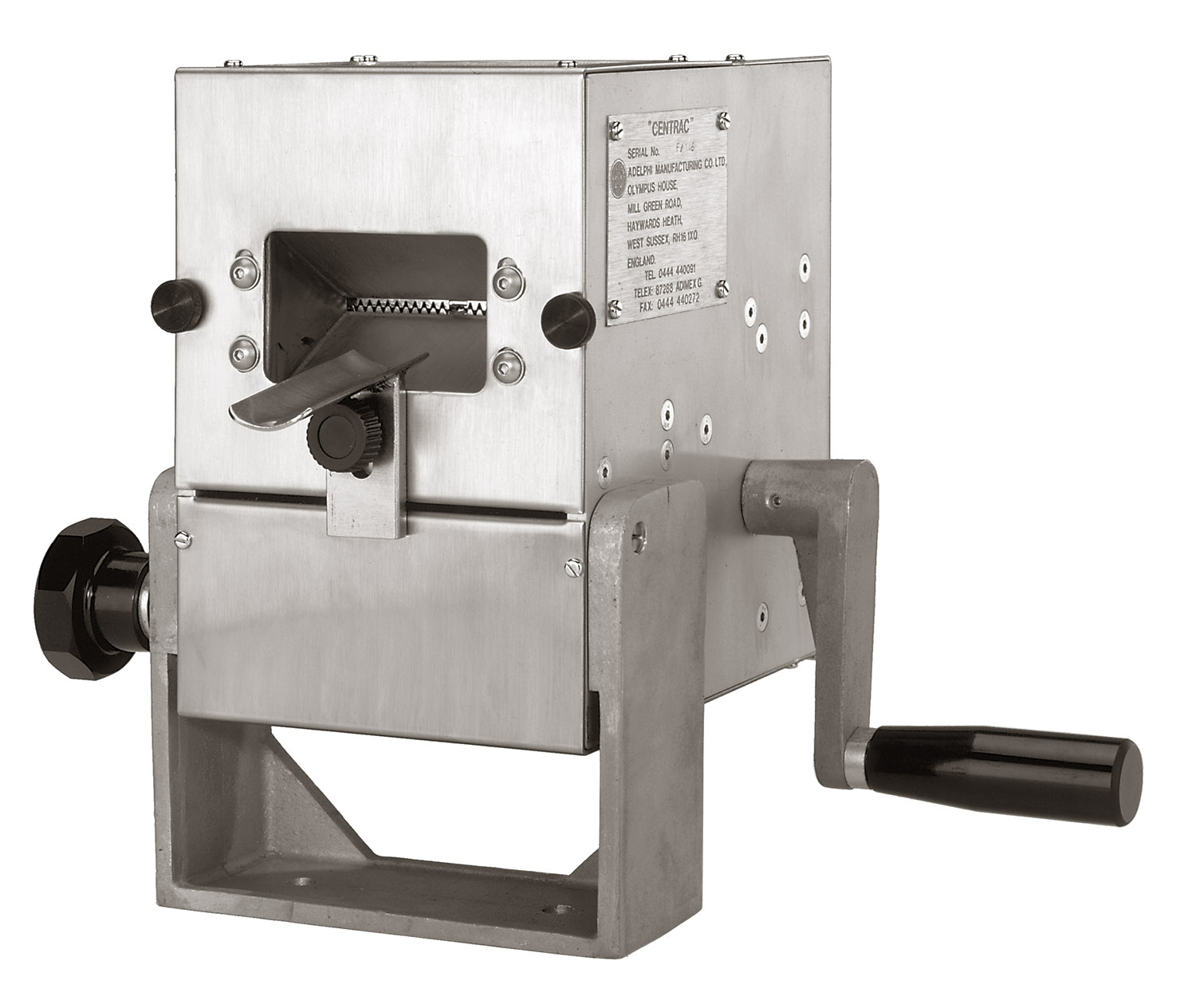

Manual sealing machine for aluminum tubes

Ideal for laboratories and small-scale production, this compact manual sealing m...

Manual tube sealer for plastic and laminated tubes

Secure precise and reliable seals on plastic and laminated tubes with ...

Melter for vacuum turboemulsifiers

Achieve optimal mixing, dispersion, and temperature control with precision-engineered me...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Industrial water chiller for homogenizers and filling machines

Optimize your production line with customizable water chi...

In-line checkweighing and printing system for cartons

Ensure precision and efficiency in your packaging line with a compa...

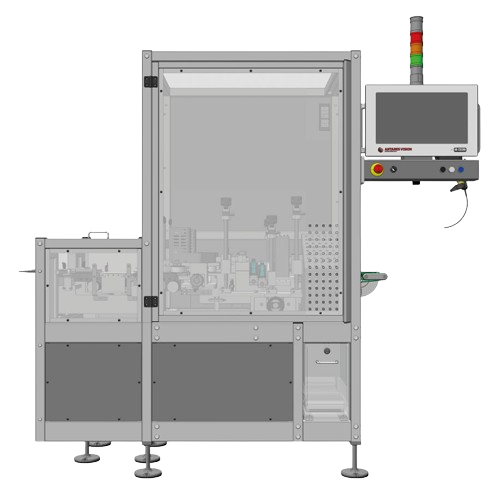

X ray inspection for unstable cosmetic products

Ensure product integrity by detecting contaminants in unstable packaging w...

Non-contact accumulator for packaging lines

Experience seamless integration and reduced product interference with this inn...

Semi automatic Pet bottle blow molding for 5l bottles

Maximize production efficiency by precisely forming PET containers ...

Automatic servo Pet bottle blower

Elevate your production capabilities with a PET bottle blowing machine designed for high-...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

Bag and pouch filling solution for liquid products

Efficiently package diverse liquid products with precision and speed, ...

Tube filler & sealer for metal and plastic tubes

Streamline your production line by efficiently filling and sealing metal ...

Efficient tube filler and sealer

Optimize your production line with a semi-automatic tube filling and sealing solution, desi...

Tube filling and sealing for metal and plastic tubes

Achieve precise tube filling and sealing with high speed and efficie...

Automatic flowmeter filler for liquid packaging

Streamline your liquid production with precise filling capabilities, reduc...

Drum decanting unit for high viscosity liquids

Efficiently decant high viscosity liquids like solvent-based paints and ess...

Semi-automatic flowmeter boom filler for large volume containers

Effortlessly handle large volume liquid filling with pr...

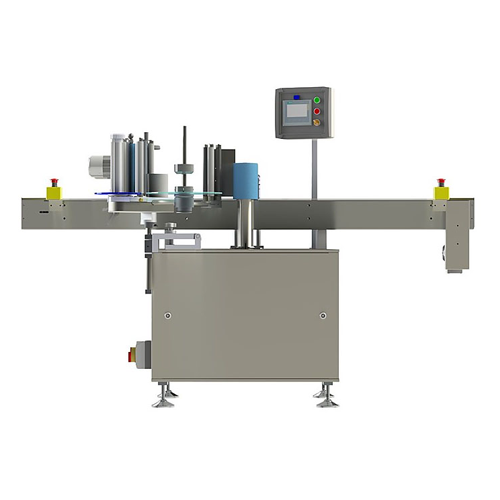

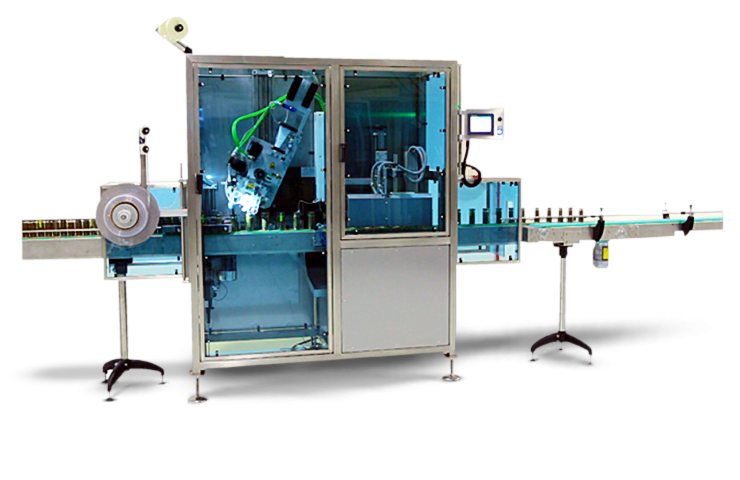

Compact wraparound labelling system for bottles

Streamline your packaging process with a fast and reliable wraparound labe...

High precision three-roller wraparound labeller

Achieve precise label placement on round containers effortlessly with a th...

Front and back labelling for small production lines

Streamline your labelling process with precise front and back applica...

Dual asymmetric centrifugal mixer for epoxy and slurry mixing

Achieve precise mixing and consistency in your formulation...

Ultrasonic tube sealer for plastic tubes

Seal plastic tubes with precision and speed using our ultrasonic technology, ensur...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Customizable sanitary conveyor systems

Efficiently transport and handle diverse products with a sanitary conveyor system de...

Retorquer for tamper-evident bottle caps

Ensure seal integrity and maintain tamper-evidence in high-speed production lines ...

Continuous raw material distribution screw doser

Optimize your material flow with a screw doser designed for precise and c...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

Laboratory homogenizer for scaling nisox-valve benefits

Achieve reliable scaling from lab to production with this precise...

High-efficiency ammonia chiller package for industrial applications

Optimize your cooling and refrigeration processes w...

Inline disperser for lithium-ion electrode slurry mixing

Achieve highly efficient dispersion and homogeneity for battery ...

X-ray inspection system for wet environments

Ensure unparalleled product inspection under extreme cleaning conditions with...

Batch coding system for product verification

Optimize your production line with an integrated system that accurately marks...

Laboratory disperser for high-viscosity products

Optimize your laboratory processes with precise mixing and dispersing of ...

High-performance mill for paint and varnish industry

Achieve superior fine dispersing and grinding efficiency for liquid ...

Batch-control system for dosing, mixing, and weighing processes

Enhance your process control by automating dosing, mixin...

Advanced dissolver for high-viscosity products

Handle ultra-high viscosity mixing challenges effortlessly with this advanc...

Shaftless spiral conveyor for waste water treatment

Efficiently handle challenging materials like de-watered sludge and s...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

Horizontal flat pouching for top-cap pouches

For manufacturers aiming to streamline pouching operations, this high-speed h...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Horizontal bead mill for industrial production

Ensure ultra-fine particle size reduction in high-demand processes with thi...

Atex horizontal bead mill

Ensure precision and safety in explosive environments with a robust solution that finely grinds an...

Laboratory and pilot plant horizontal bead mill

Achieve precision milling with minimal product waste, ensuring consistent ...

Pressure monitoring solution for dosing processes

Optimize your production line by ensuring precise pressure monitoring, ...

1-component industrial dispenser for precision dosing

Achieve unparalleled precision in microdispensing across diverse ap...

High-volume dispensing for single-component fluids and pastes

Enhance your production line with a pump that delivers lar...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Industrial food portioning system

Optimize your production flow with precision portioning equipment designed to handle a di...

Servo multi depositor for food portioning

Achieve precise portion control and high-speed depositing with versatility acros...

Stuffing feeding device for extruders

Efficiently feed cohesive or lightweight powders into extruders to enhance product qu...

Automatic mono-dose strip filling system

Optimize your liquid product packaging with a multi-functional system designed for...

Automatic tube filler for multi-color coextruded products

Achieve precise dual- or tri-color product designs with except...

Automatic tube filling for coextruded products

Maximize efficiency in high-volume production with precision co-extruding c...

Automatic tube filling solution for high-volume production

Effortlessly streamline your production with this high-speed ...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Manual monoblock for filling and capping spouted pouches

For those handling liquid or semi-dense products, this manual mo...

Freeze dryer for small batch scale-up in biotech and pharma

Optimize freeze-drying processes for small batches or high-v...

Colloid mill for particle size reduction and emulsification

Achieve precise particle size reduction and stable emulsions...

High-shear mixer for emulsions, dispersions, and foams

Achieve precise emulsions and dispersions effortlessly with high-s...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Industrial high pressure homogenizer for dairy and pharmaceutical

Achieve consistent texture and stability in products ...

Industrial batch mixer agitators

Achieve precise and efficient mixing of diverse materials with industrial batch mixer agita...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Manual plastic tube sealing equipment

Working in labs or with small batch production lines where you have to seal plastic o...

Semi-automatic filler

When you are a small or a medium-sized manufacturer the manual filling processes might often lead to in...

R&D bottle washer

When you pack your products in bottles, vials, syringes, and test tubes you need to wash them before fillin...

Manual metal tube sealing equipment

For small-batch productions where you utilize metal tubes as containers for your produc...

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

Up to four head automatic filling machine

When your consumer demand is increasing you will need new and more effective pac...

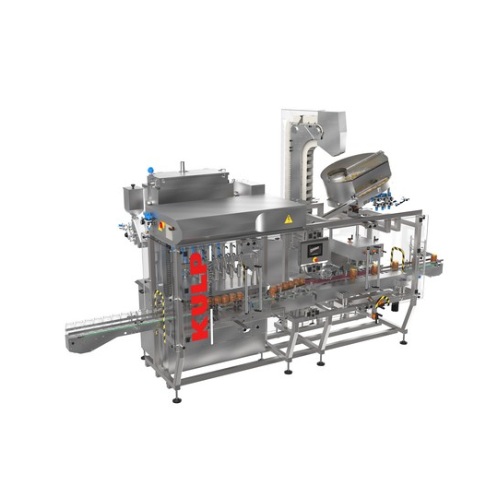

Emulsifier for cosmetic creams

The process of making cream and lotion involves mixing of water phase and oil phase to create...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Pilot ultrasonic extractor

In the herbal medicine industry, an ultrasonic extractor is a valid alternative to conventional e...

Batch vacuum mixer for emulsion-based products

The production of creams or ointments can be either be a water in oil (w/o)...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Pharmaceutical formulation and mixing tanks

Preparation lines for formulating pharmaceuticals include fixed and mobile tan...

Filling machine for creams

Liquid cosmetics have particular requirements when it comes to filling and capping containers. Mo...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

Homogenizer for creams

Homogenization (or pharmaceutical micronization) is the process of reducing particle sizes, and is a v...

Vacuum mixer for suspensions

The production of high quality pharmaceuticals often requires mixing of suspensions and similar...

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

Compact monoblock filler

Filling and capping bottles and pots for food, chemical and cosmetics industries using separate mach...

Single head capper

For the stand-alone capping of bottles of up to 30 litre capacity for smaller-scale production you need a ...

Tube unloader and feeder

The pharmaceutical and cosmetic industries utilise high speed tube fillers on large-scale production...

Tube feeding unit for high volume and high speed tube filler

High performance tube-filling machines are used for large s...

Loading cassette for a tube filler

High performance tube-filling machines are used in the pharmaceutical and cosmetic indus...

Tube feeder for a small scale production tube filler

Low speed tube-filling machines are used for small scale production ...

High speed automatic tube filler

For high-volume lines filling pharmaceutical, cosmetic or food products into tube container...

Medium speed tube filler and sealer

For scale-up filling of tube packaging for pharmaceuticals, cosmetics and food products...

Medium and high speed range automatic tube filler

When scaling up production of pharmaceutical, food or cosmetic products...

Low speed tube filler

Increasing numbers of products in the pharmaceutical, cosmetic and food industries are delivered in fle...

A two-component filling application tube filler

A wide variety of pharmaceutical, cosmetic and food products require tube-...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Multi-head capper

For the stand-alone capping of bottles of up to 2.5litre capacity you need a robust and flexible machine wi...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

Compact shrink sleeve applicator

Adding tamper prevention to product packaging can be expensive and difficult to set up. Thi...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Dispersing machine for emulsions and suspensions

Equipment operating under the rotor/stator principal is often employed wh...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Dispersing machine for very fine emulsions and suspensions

For continuous high performance mixing of solid and liquid ra...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

Continuous homogenizing system

Certain mixing tasks present unique challenges and manufacturers need equipment that is speci...

High accuracy homogenizing system

When extremely high accuracy is required in your recipe or formulation traditional mixing...

Horizontal kneader

For high viscosity products, better results and reduced process times can be achieved with kneading type r...

Vertical kneader

Production of highly viscous products with high solid content often benefits from kneading processes rather t...

Continuous kneader

Effective mixing of highly viscous products with extremely high solids content can be difficult and the re...

Batch dispersing machine

Equipment operating under the rotor/stator principal is often employed when more traditional methods...

Batch dispersing machine for abrasive products

For mixing and dispersing tasks that cannot be completed by conventional st...

Batch dispersing machine for bottom entry into vessels

When your process requires high performance mixing or dispersion b...

Cost-effective homogenizing and emulsifying system

Manufacturers of cosmetic products need mixing equipment that is capab...

Dust-free continuous homogenizing system

Producers in a wide variety of industries benefit from equipment that can continuo...

Dilution system for two or more liquids in one pass

Onsite dilution of liquid process ingredients has historically been a...

Pilot dispersing machine for testing and scale-up

Innovators in process development need laboratory equipment that helps ...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

Jet flow agitator for high-viscosity media

Processes including homogenization, dispersing, suspension, emulsification and ...

Agitator for medium viscosity media

Mixing fluids of medium viscosity for many production processes requires an agitator wi...

Agitator for low viscosity media

Reliably agitating fluids in open or pressure-less vessels in a laboratory or small scale p...