Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing with high efficiency, reducing energy consumption and noise, while maintaining smooth operations across demanding production lines.

Handles Aerated Liquids and Self-Priming Processes

The APV Ws+ Series Self-Priming Centrifugal Pump is engineered to excel in handling aerated liquids, offering energy-efficient operation with reduced noise levels. Utilizing a unique liquid ring formation through its eccentric air screw and fluid recirculation loop, this pump ensures efficient vacuum generation and self-priming performance. Suitable for a wide range of applications, the Ws+ is perfect for food and beverage processors, dairy producers, and chemical facilities, processing products like whey, creams, syrups, and essential oils.

With a throughput capacity of up to 484 GPM and a maximum discharge pressure of 138 psi at 60 Hz, it ensures consistent fluid handling across demanding industrial operations. The Ws+ Series integrates seamlessly into existing lines, featuring interoperability with W+ parts to lower inventory requirements. Constructed from high-grade SS 316L for durability and corrosion resistance, it fulfills stringent hygiene standards, being EHEDG and 3-A certified. Incorporating a built-in Clean-In-Place (CIP) system, it delivers ease of maintenance, enhancing production efficiency while lowering running costs. For added versatility, this pump can be customized to meet specific duty requirements with adjustable impeller sizes, backed by dedicated engineering support.

Benefits

- Reduces energy consumption and noise, enhancing operational efficiency and workplace safety.

- Customizable impeller sizes align with specific duty requirements for optimized performance.

- Supports hygiene-critical applications with EHEDG and 3-A compliance, ensuring product integrity.

- Simplifies inventory management through parts interchangeability with the W+ series.

- Efficiently handles challenging aerated liquids, minimizing processing delays and product waste.

- Applications

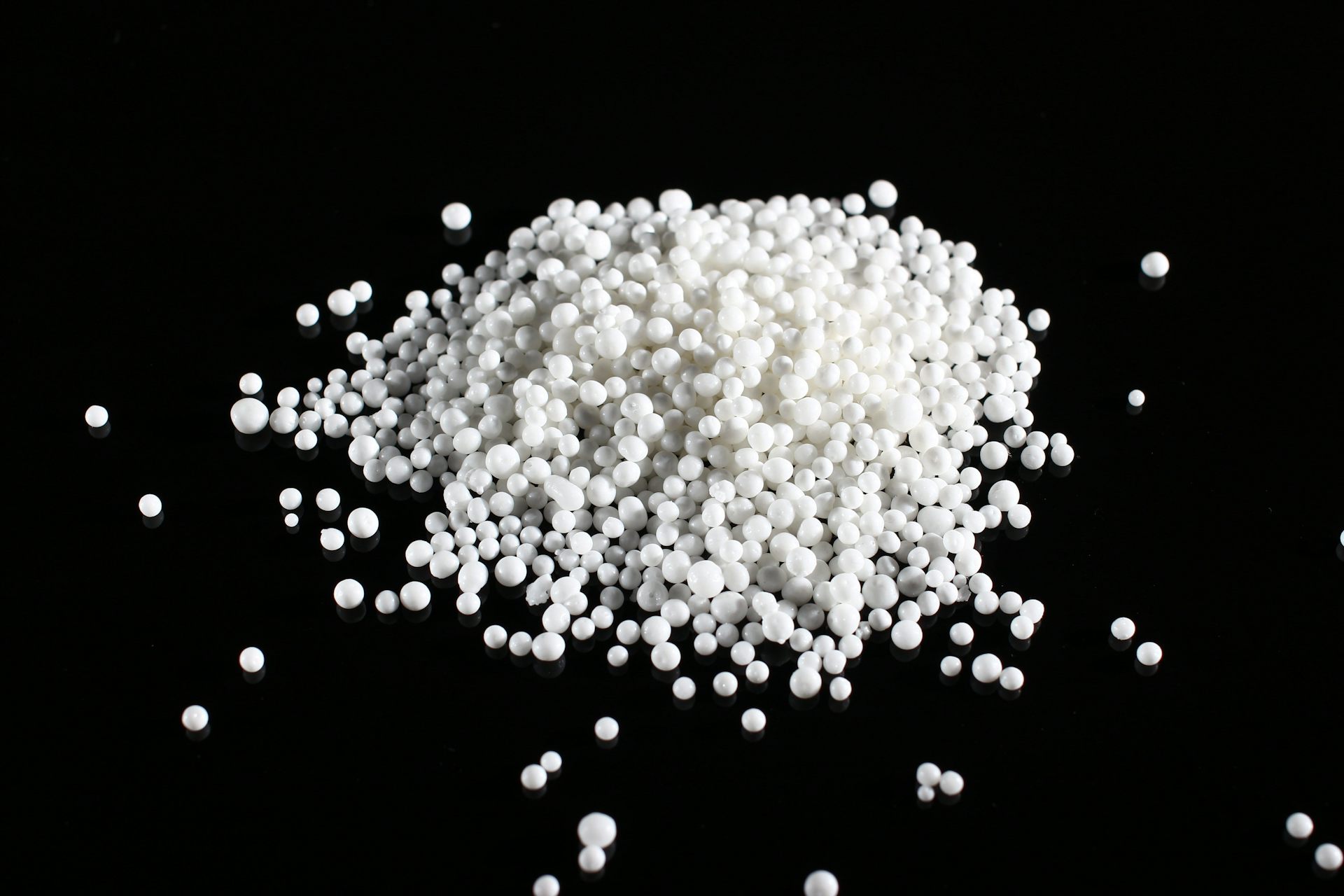

- Cream, Solutions, Batters, Fats, Extracts, Oils, Whey, Sweeteners, Dairy, Dyes, Alcohols, Detergents, Yeast slurry, Slurries, Syrups, Pharmaceutical/cosmetics, Milk, Ammonium nitrate, Chemical/industrial, Potassium chloride, Ro/uf systems, Flavorings, Sweetened condensed, Soap liquors, Sodium acetate, Emulsions, Bakery and confectionery, Propyl alcohol, Essential oils

- End products

- Sweetened condensed milk, Bread, Pastry doughs, Glucose syrup, Vanilla essence, Cheese, Ultra-filtered milk, Molasses, Solvent-based dyes, Laundry detergent, Lavender oil, Soap bars, Fertilizer solutions, Rubbing alcohol, Croissants, Ice cream, Lotions, Yogurt, Food-grade sodium acetate, Olive oil, Vegetable oil, Shampoos, Potassium salt solutions, Herbal extracts, Cosmetic creams, Ethanol, Dishwashing liquid, Maple syrup, Instant yeast solutions, Honey

- Steps before

- Mixing, Heating, Emulsification

- Steps after

- Clean-In-Place, Sterilization, Packaging

- Input ingredients

- entrained air, CIP return, fluids with entrained air and foam, Bakery ingredients, Batters, Fats, Oils, Flavorings, Sweeteners, Yeast Slurry, Syrups, Dairy products, Whey, Cream, Milk, Sweetened Condensed Milk, RO/UF Systems, Pharmaceutical and cosmetic ingredients, Emulsions, Extracts, Slurries, Dyes, Alcohols, Essential Oils, Chemical and industrial materials, Detergents, Soap Liquors, Solutions, Ammonium Nitrate, Propyl Alcohol, Potassium Chloride, Sodium Acetate

- Output ingredients

- processed fluids, aerated products, vacuum in suction pipe

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Maximum Pressure (50 Hz)

- 94 psi (6.5 bar)

- Maximum Flow Capacity (50 Hz)

- 396 GPM (90 m³/hour)

- Maximum Pressure (60 Hz)

- 138 psi (9.5 bar)

- Maximum Flow Capacity (60 Hz)

- 484 GPM (110 m³/hour)

- Efficiency Increase Compared to Liquid Ring Pumps

- 20-90% more efficient

- Noise Level

- Significantly lower than traditional liquid ring pumps

- Pump Sizes

- Ws+ 20/15, Ws+ 30/30, Ws+ 44/50

- Self-priming capability

- With built-in air screw

- Noise level

- Low, due to hydraulic design

- Energy consumption

- Reduced, due to high efficiency impeller

- Operating pressure

- 94 psi (6.5 bar) at 50 Hz, 138 psi (9.5 bar) at 60 Hz

- Flow capacity

- 396 GPM (90 m3/hour) at 50 Hz, 484 GPM (110 m3/hour) at 60 Hz

- CIP (Clean-in-Place) return handling

- Included

- Interchangeability with W+ parts

- Yes, reduces inventory

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine Footprint

- Compact

- Pump Size

- Ws+ 20/15, Ws+ 30/30, Ws+ 44/50

- Inlet Size

- Varies by model

- Outlet Size

- Varies by model

- Frame Size

- 145TC, 182TC, 184TC

- Material

- SS 316L and SS 304

- Noise Level

- Low

- Discharge Method

- Self-Priming

- Dimensions

- Varies by model

- Material

- SS 316L, SS 304

- Shaft Seal

- Carbon/Silicon Carbide, optional Silicon Carbide/Silicon Carbide

- Elastomers

- Standard