Detergent Manufacturing Equipment

Find innovative detergents equipment and connect directly with world-leading technology suppliers

Detergents are cleaning agents that help remove dirt and grease from porous and non-porous surfaces. Industrial production of detergents began after World War I. Still, it was after the 1950s and 1960s that the detergent industry grew exponentially due in part to the development of new detergent manufacturing equipment.

Innovative technologies for producing detergents

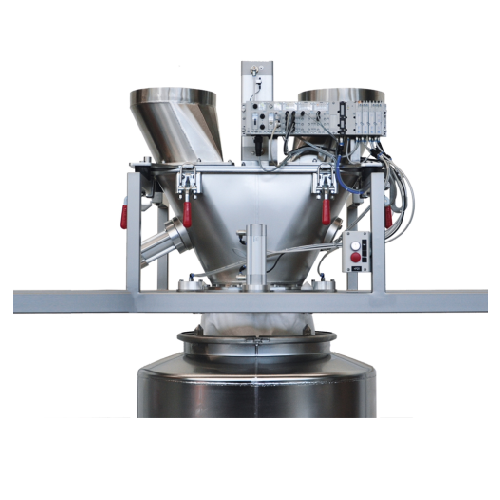

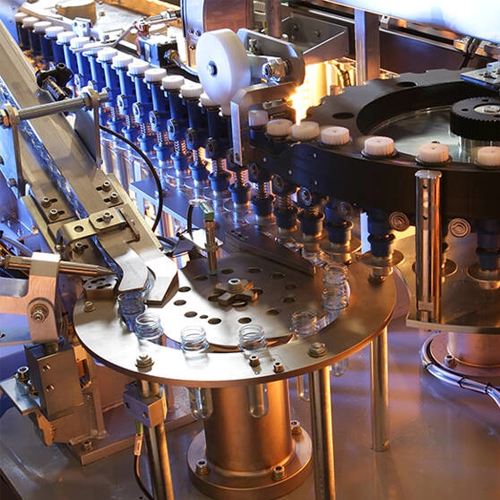

Liquid detergent filling machine

Filling of liquid detergents requires specialised equipment because of the foaming nature o...

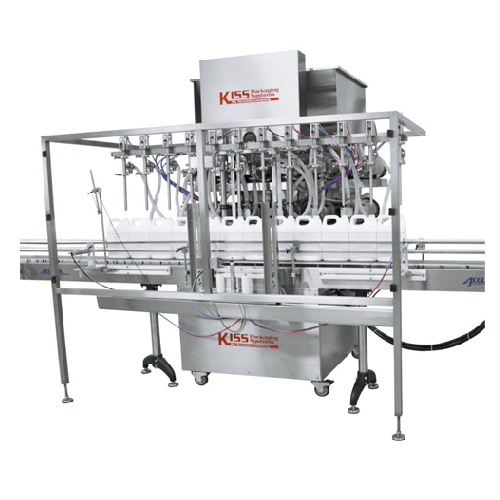

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Hand sanitizer capping machine

Bottled products such as hand sanitizers, shampoos, and liquid detergents, have different cap...

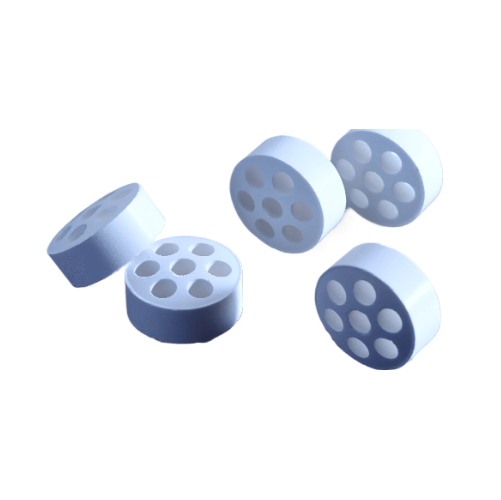

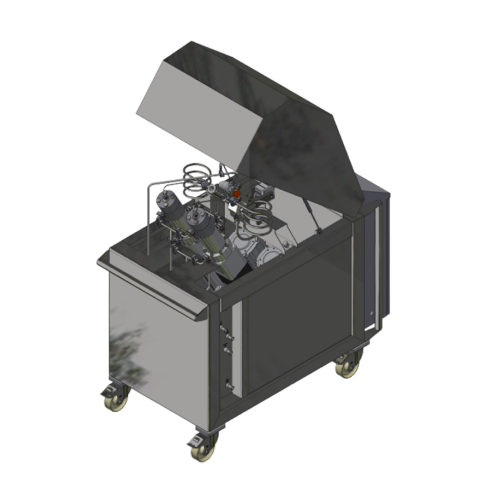

Three-layer dishwasher tablet press

Dishwasher detergent tablets come either in a single layer or multi-layer form. Multi-l...

Select your detergents process

Tell us about your production challenge

Dirty substances are generally related to hydrophobic fatty materials insoluble in water. However, detergents are amphiphilic, meaning they contain both non-polar hydrophobic (water-hating) and polar hydrophilic (water-loving) ends. This dual nature allows the detergent to grab the oily-greasy dirt stains and wash them away.

As surfactants or a mixture of surfactants, detergents have the ability to decrease the surface tension of water. This function facilitates the formation of dispersions, emulsions, and suspensions.

The most common detergent is soap, a sodium salt of fatty acids. To increase solubility, modern detergents contain alkyl-benzene sulfonates. In fact, these compounds (polar sulfonate group) are more soluble in hard water than soap (polar carboxylate group). Polar sulfonate is less likely to bind to calcium and other ions of the hard water than polar carboxylate.

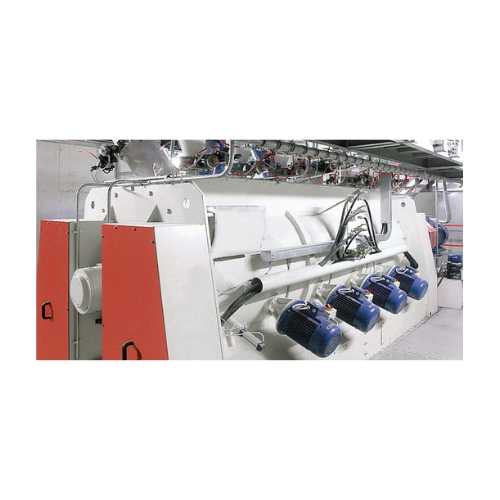

Detergent manufacturing process

Detergent manufacturing involves mixing the raw materials in large tanks; the manufacturing process can be batch as well as continuous. Raw materials are selected based on the form and properties of the desired end product. It is essential to mix all ingredients thoroughly in a mixer machine to ensure that the chemicals are evenly distributed in the detergent.

Fillers, surfactants, disinfectant agents, and chemical agents are used as ingredients in detergent making. To give color, powdered pigments can be added. In hand soap production, for example, adding a preservative is critical to prevent the proliferation of bacteria if the soap is exposed to a substandard environment.

Liquid detergent, powder detergent, or laundry detergent?

Historically, when people referred to detergent, they usually indicated laundry detergent. It was only after the 20th century, due to the development of detergent making equipment, that the word detergent acquired a broader meaning with its liquid and powder form.

Laundry detergent

Wash, dry, fold, repeat. This is the daily formula for doing laundry. Helping us in this daily task is detergent which has a slightly different formula.

Producers can use three methods when making laundry detergent: dry mixing, agglomeration, or spray drying. The spry drying technique is the most used because it produces a lightweight, well-hydrated product that doesn’t cake. Pay attention to the pH range when producing the washing powder; the pH has to be 9-10.5. to ensure it is compatible with human skin and can clean effectively.

Powder vs. liquid detergent

The ingredients that make up powder detergents are builders, surfactants, and enzymes. This detergent is mainly used as a laundry detergent and is a more affordable choice because containing no water is lighter than liquid detergent, meaning that it has lower transportation costs. Powder detergent can be made by the agglomeration method and can be easily recognized by its granule-like appearance; however, the spry drying method is widely used in the detergent industry because it simplifies the process and improves the profit margin by turning a slurry into a dried powder in a single step.

Liquid detergents are nothing more than powders mixed with water and chemical solutions called solubilizers, making detergents dissolvable in water.

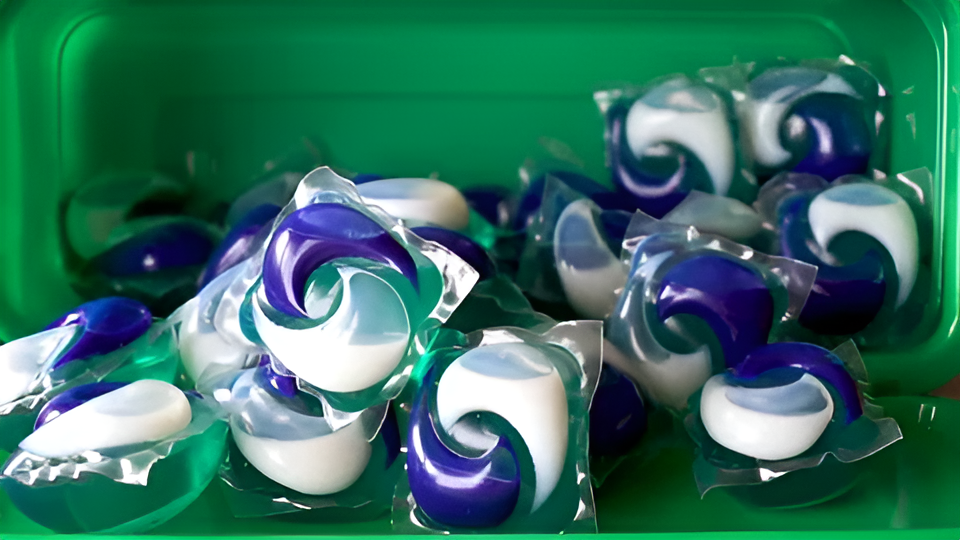

…And what about dishwasher tablets?

Dishwasher tablets are essential to make your dishes shine. The dishwasher tablet production always starts by obtaining granular detergent additives from a spray-dried slurry – Did we already mention that the spray-drying method is everywhere in the detergent making process?

After combining the granules with builders, water, surfactant, bleaching agent, dye, and fragrance, producers transfer it to a hydraulic or rotary press for the tableting process.

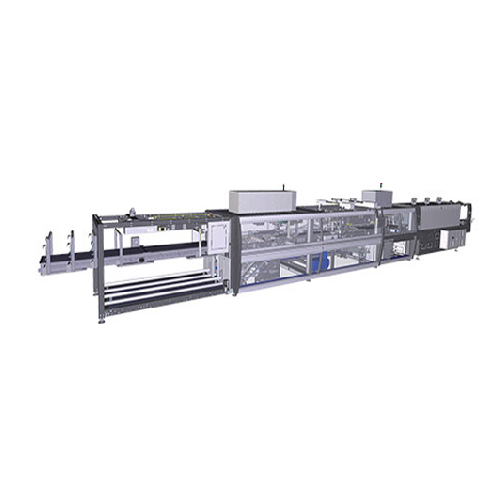

Packing your detergent products

When it comes to detergents, the packaging process depends on whether the detergent comes in liquid or powder form. For liquid detergents, a filling system pumps the liquid product into plastic bottles where a weighing device controls the correct filling level. After filling, a capping machine seals the bottles. For powder detergent, the packaging process begins by creating the bag or the pouch from a flat carton or laminated film. Then the selected container will be filled with powder detergent and sealed.

Detergent making videos

Detergent filling machine

Detergent capping machine

Which detergents technology do you need?

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Liquid detergent filling machine

Filling of liquid detergents requires specialised equipment because of the foaming nature o...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Laboratory vacuum cold trap for extract purification

Optimize your vacuum purging and drying applications with this advan...

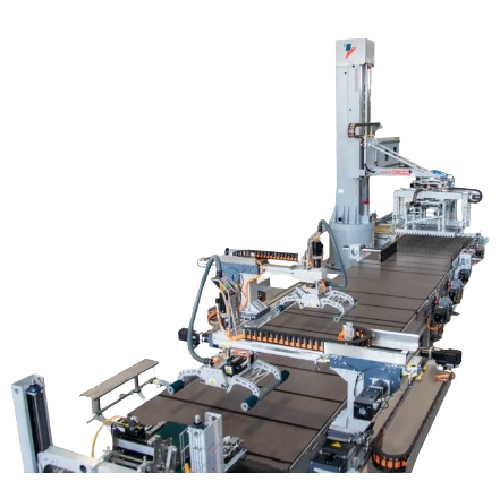

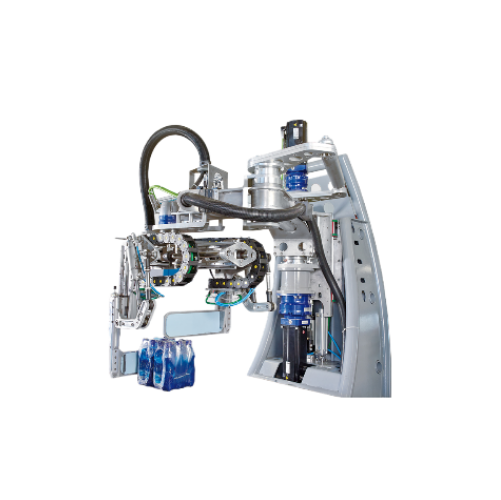

Hybrid palletizer for bagged products

Optimize your palletizing process with high-speed robotic solutions designed to secur...

Automated bag folding for packaging

Streamline your packaging operations with a high-speed solution that seamlessly integra...

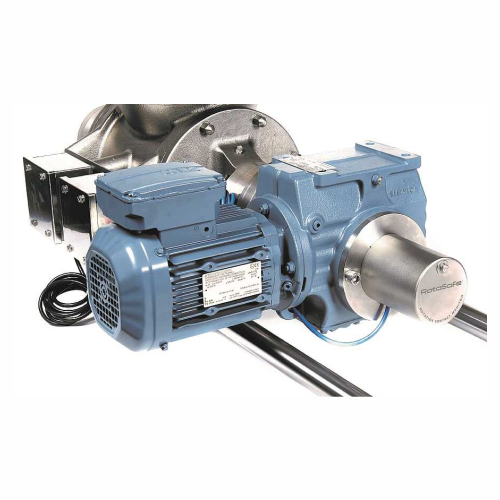

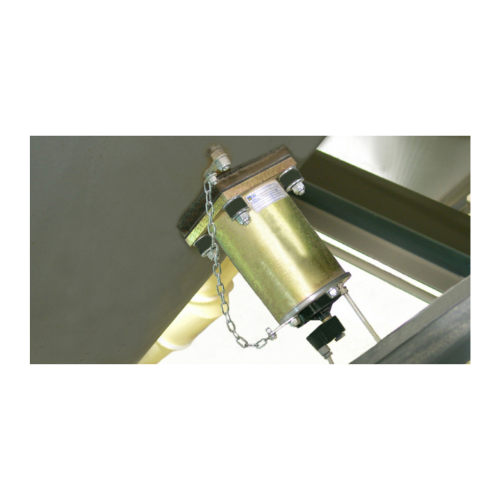

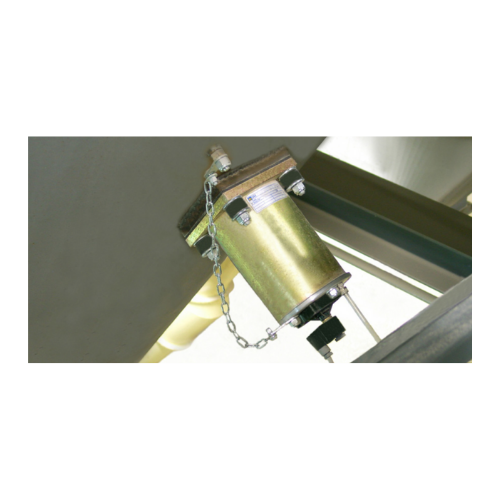

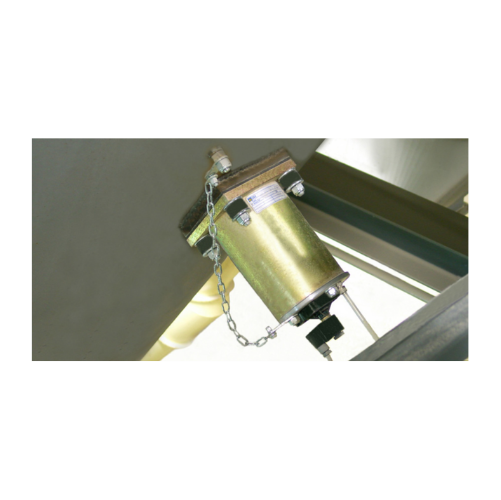

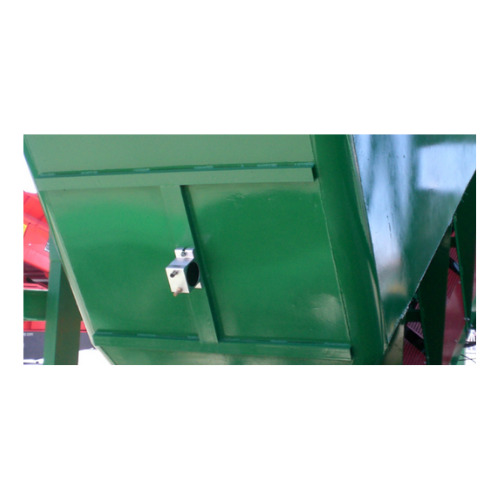

Mounting configurations for industrial agitators

Optimize your mixing processes with versatile agitators designed for effi...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

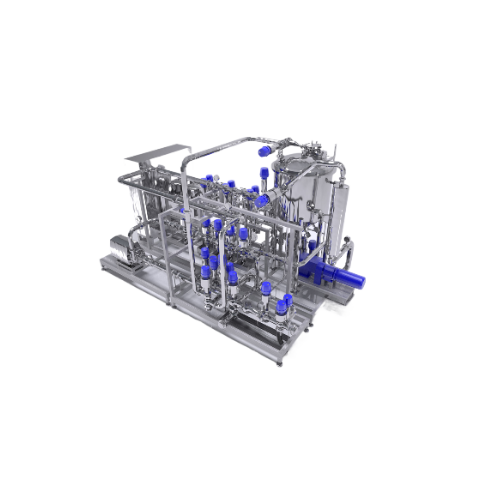

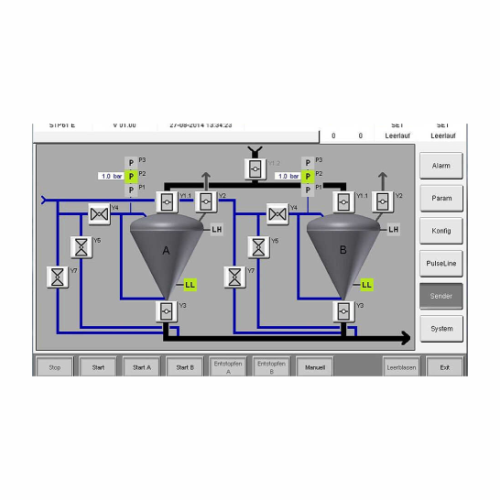

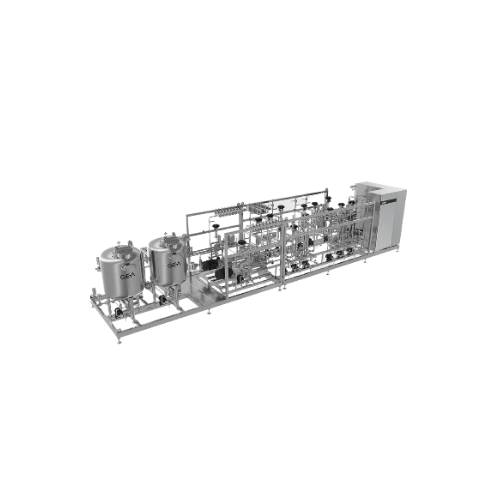

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

High-speed drift-dwell motion doypack forming system

Optimize your liquid packaging efficiency with a dual-motion system ...

Positive displacement gear pump liquid filler

Optimize your liquid filling operations with precision gear pump technology,...

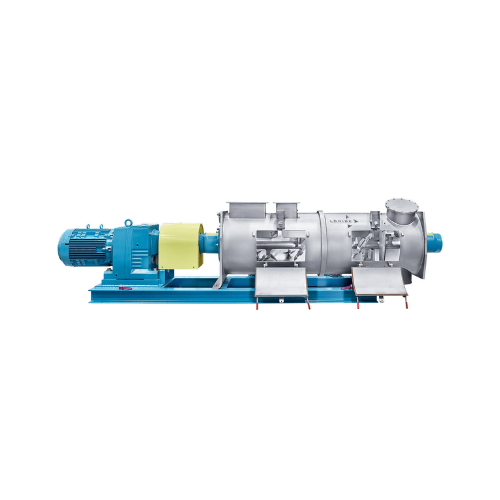

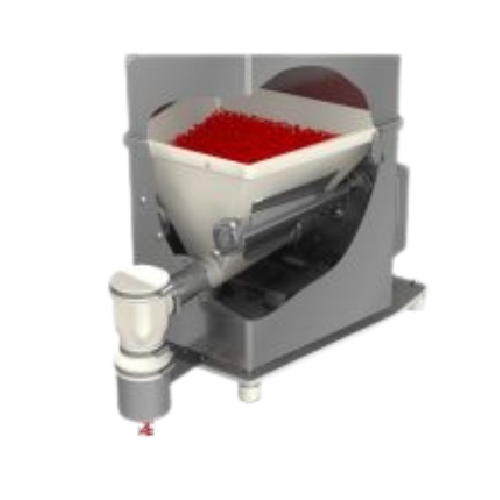

High impact mixer for powders and liquids

Achieve highly homogeneous mixtures with precision. This high impact mixer excel...

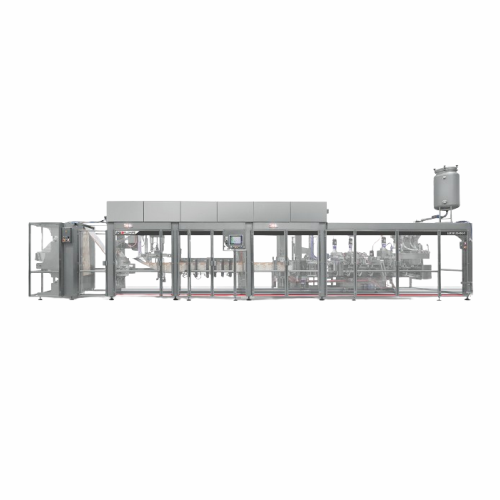

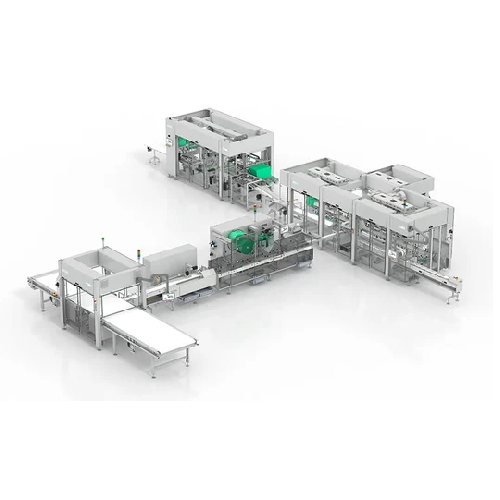

Production system for multi-chamber portion packs

Efficiently produce multi-chamber portion packs with high precision for...

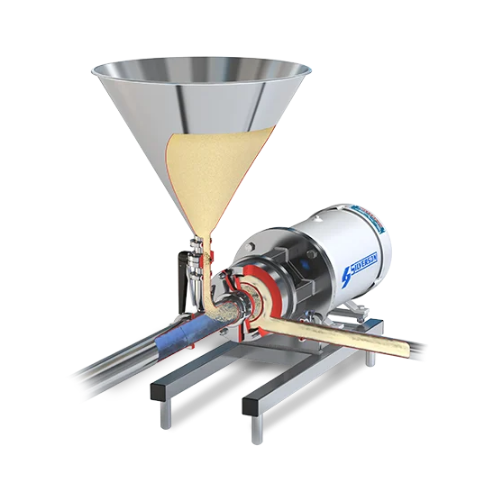

High-precision volumetric feeder for bulk materials

Achieve precise bulk material flow with a solution that ensures consi...

Mini batch blender for pharmaceutical solids

Achieve precise mixing homogeneity with the mini batch blender, perfect for l...

Quick-clean hygienic rotary valves

Ensure seamless cleaning and minimal downtime in your production line with rotary valves...

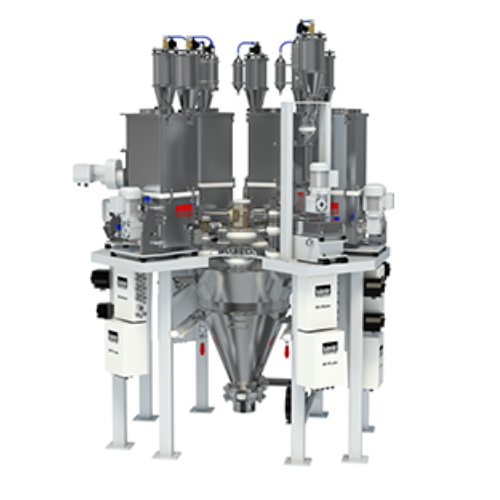

High-precision gravimetric feeders for industrial bulk solids

Achieve unparalleled accuracy in your production line with...

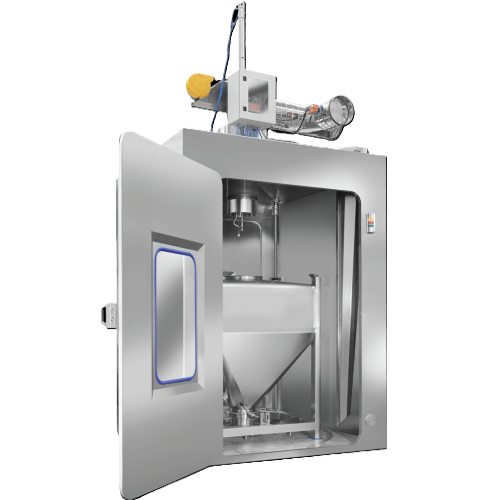

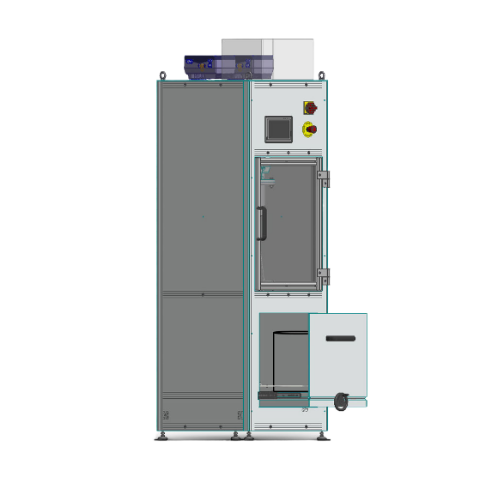

Internal and external bin washing cabinet

Streamline your sanitation process with automated bin cleaning that ensures thor...

Multiformat high-speed labelling for self-adhesive labels

Achieve precision labelling on diverse container formats with ...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

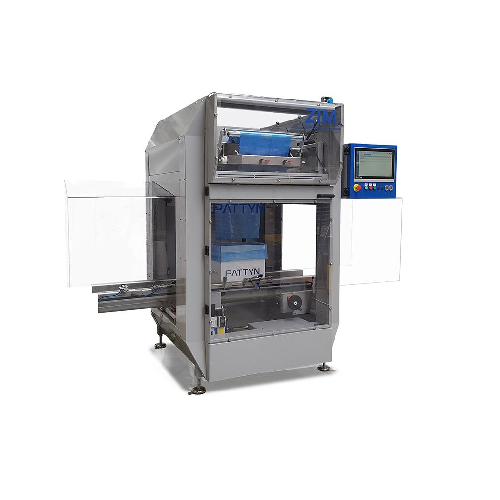

Automatic bag-in-box carton closer

Streamline your packaging line with a high-speed carton closer, designed to efficiently ...

High speed continuous motion liquid filling and capping system

Achieve high-speed, precision filling and capping for liq...

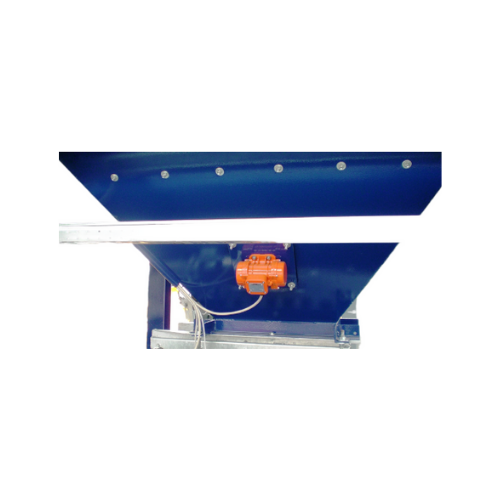

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Automatic edible oil filling & capping solution

Streamline your liquid packaging operations with precise, high-speed filli...

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

Automated Cip station for brewery cleaning

Ensure thorough hygiene and product integrity in your brewing process with a ve...

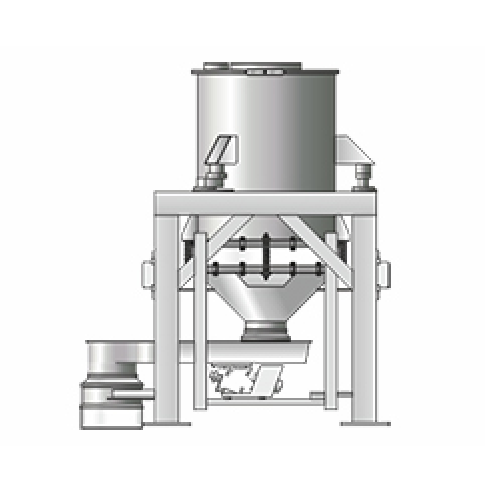

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

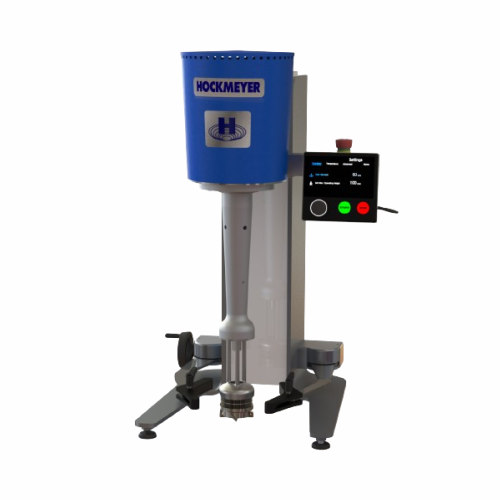

Benchtop mixer for lab-scale product development

Easily scale up your formulations with precise and repeatable lab-scale m...

Automatic flowmeter filler for liquid packaging

Streamline your liquid production with precise filling capabilities, reduc...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

Rotary tablet press for abrasive powders

Achieve precise tablet sizing and bilayer production, even with abrasive powders, ...

Rotary tablet press for large volume industrial tablets

Optimize your high-volume tablet production with a fully automati...

Big bag emptying station for bulk product handling

Streamline your bulk material handling with a station designed to effi...

Tailor made mixing systems for personal and home care products

Achieve precise mixing for liquid formulations with conti...

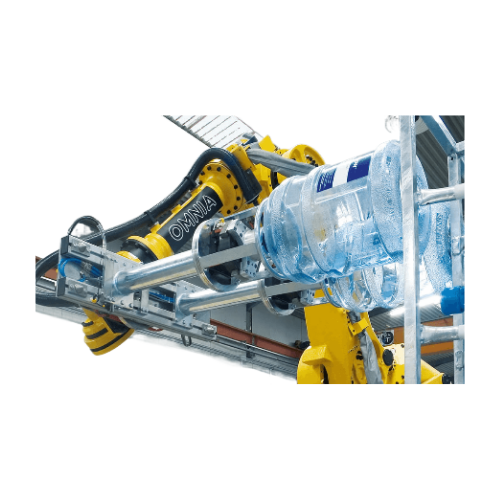

Robotic palletizer for food and beverage industries

Enhance your production line’s efficiency with a flexible robot...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Static fluid bed dryer for powder and granular materials

Achieve optimal moisture control in powder and granular products...

Cip for pharmaceutical process plants

Streamline your cleaning processes with integrated CIP systems to ensure precise and ...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

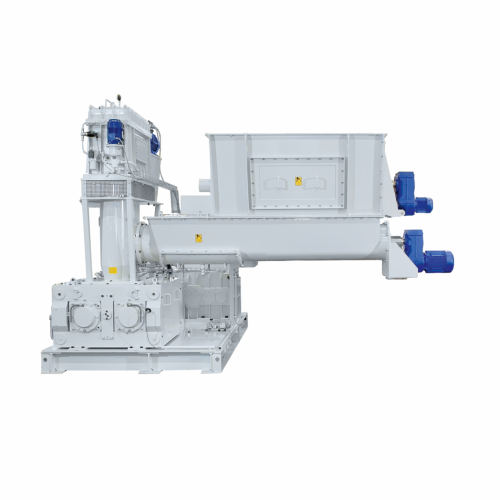

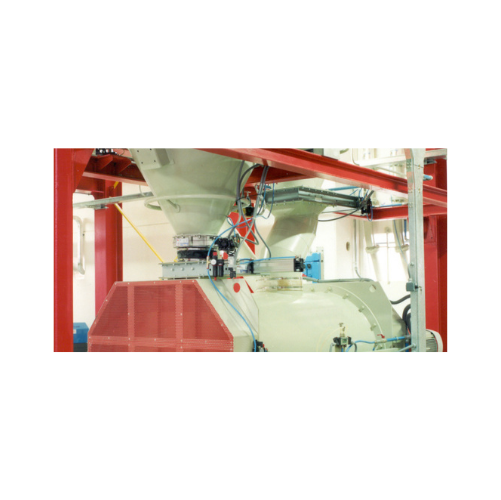

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Membrane pressure relief valve for silo protection

Ensure immediate pressure stabilization in your bulk storage silos wit...

High flow rate Fibc discharger

Optimize your bulk material handling with a system designed for efficient and dust-free FIBC ...

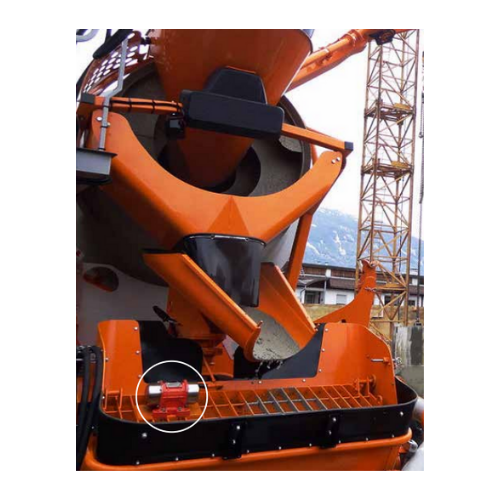

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

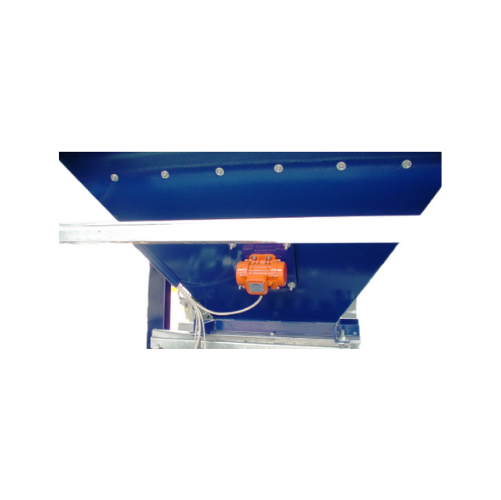

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Horizontal flat pouching for top-cap pouches

For manufacturers aiming to streamline pouching operations, this high-speed h...

Accurate pharmaceutical dispenser for high-viscosity fluids

Achieve precise liquid dosing with ease, designed to handle ...

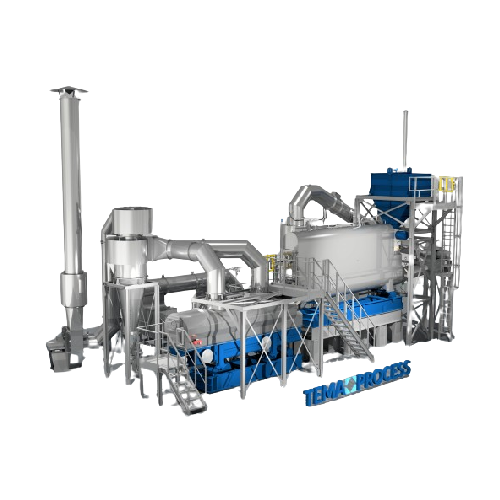

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

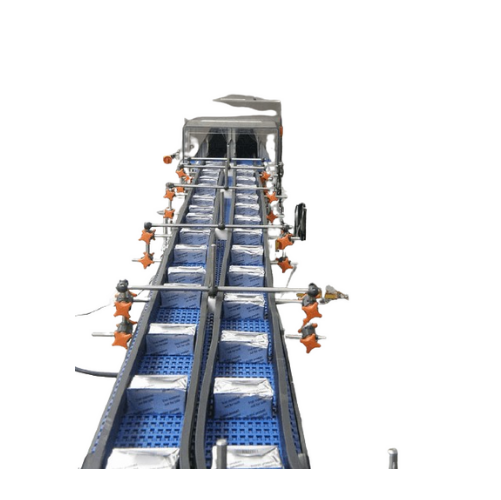

Industrial conveyor system for food and pharma applications

Optimize your production workflow with a versatile conveyor ...

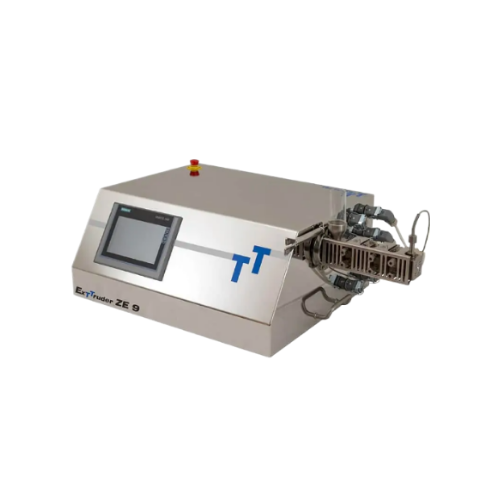

Table-top mini extruder for precision material processing

Achieve precise control over complex formulations with this fl...

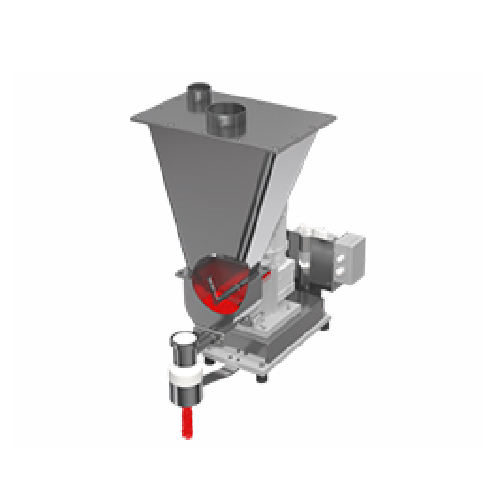

Volumetric twin-screw feeder for poorly flowing powders

For manufacturers dealing with powders that clump or cake, this f...

Twin screw feeder for poorly flowing powders

Optimize your process with precision feeding for powders that easily clump or...

Quick change feeding devices for industrial applications

Experience seamless product transitions with quick-change feedin...

Powder auger filler for precise weighing and depositing

Ensure accurate and efficient powder filling with this innovative...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Wet granulation cleaning system

Ensure optimal cleaning and purification within your production line with a system designed ...

Twin screw feeder with stirring agitator for poor flowing powders

Optimize your processing line with a highly adaptable...

Vibrating tray loss-in-weight feeder for grained ingredients

Achieve precise and continuous dosing of free-flowing solid...

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

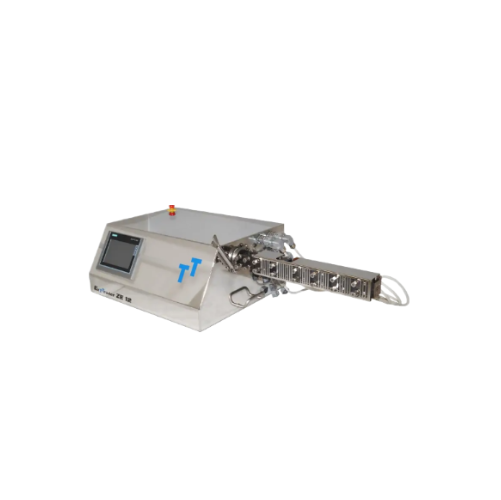

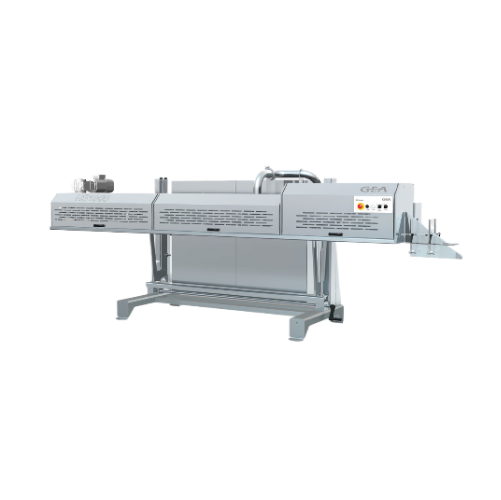

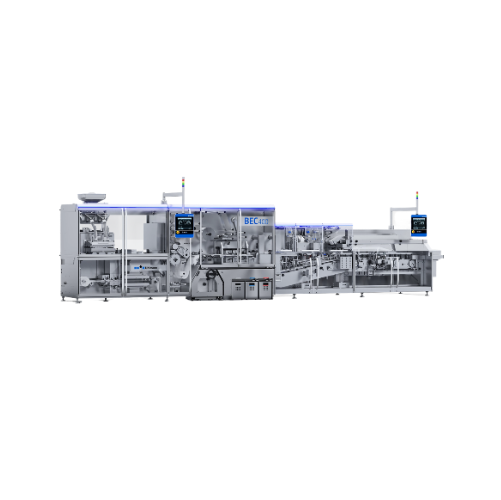

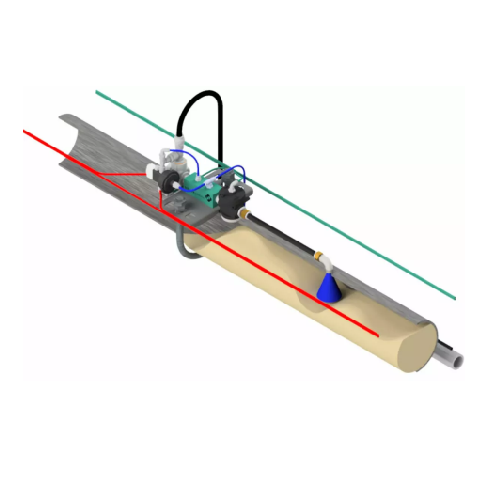

Fully automated dishwasher tablet press

The process of making dishwasher tablets that have more than one layer is very deli...

Hand sanitizer capping machine

Bottled products such as hand sanitizers, shampoos, and liquid detergents, have different cap...

Three-layer dishwasher tablet press

Dishwasher detergent tablets come either in a single layer or multi-layer form. Multi-l...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Separator for oil refining

Optimize your oil refining processes with a centrifugal separator that enhances purity by efficie...

Clarifier for industrial fluids

Optimize fluid purity and extend equipment lifespan by efficiently separating contaminants f...

Drum mills for fine grinding of large volumes

Achieve consistent and precise pulverization of large sample volumes with dr...

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

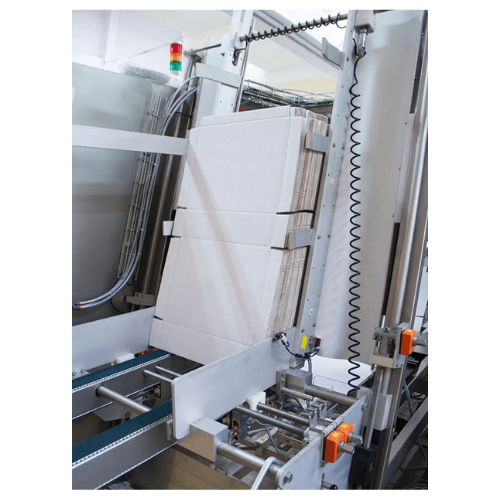

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Automatic bag inserter for boxes and crates

Optimize your packaging line with a compact solution that seamlessly inserts p...

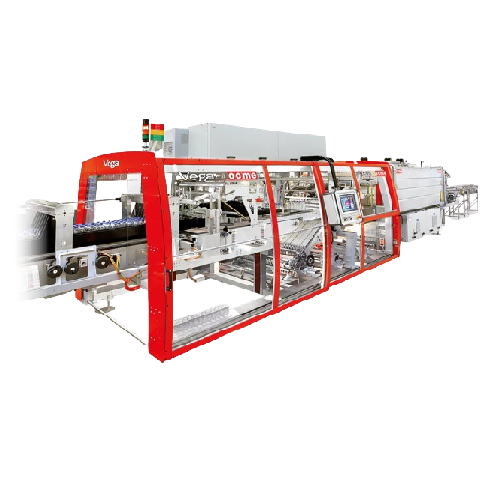

Shrink wrap packer for beverage and food industries

Optimize your production line efficiency with a versatile packer capa...

Robotic palletizer for row gripping

Optimize your palletizing efficiency with a robotic system designed for fast, continuou...

Single-column palletizer for medium to high production

Optimize your production line efficiency with a versatile single-c...

Particle size and shape analyzer

Achieve precise particle size and shape analysis from 0.8 μm to 8 mm with exceptional speed...

Pneumatic and electric lift for industrial mixing tanks

Enhance operational efficiency and safety with versatile lifts fo...

Cleaning-in-place (cip) systems for hygienic processing

Elevate hygiene standards in your liquid processing line with an ...

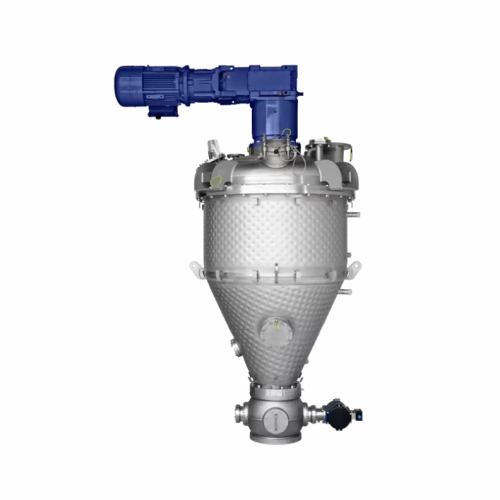

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Single-use mixing solutions for downstream processes

Designed for safe and efficient one-time use, this mixing solution e...

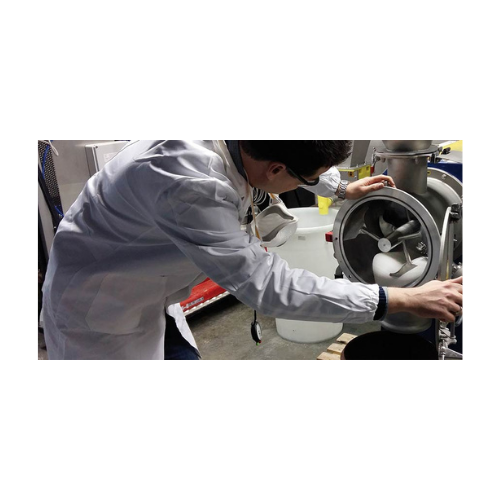

Versatile magnetic mixer for pharmaceutical and biotechnology applications

Optimize your biopharmaceutical mixing proc...

Flexible powder recipe formulation system

Streamline your batch production with efficient, dust-tight formulation and blen...

Ploughshare mixer for batch operation

Achieve superior mixing quality with a system designed for rapid batch operations. Ex...

Continuous ploughshare mixer for diverse industrial applications

Enhance mixing efficiency and achieve precise particle ...

Volumetric filler for liquid and viscous products

Achieve precise and adaptable filling for a wide variety of liquid and ...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

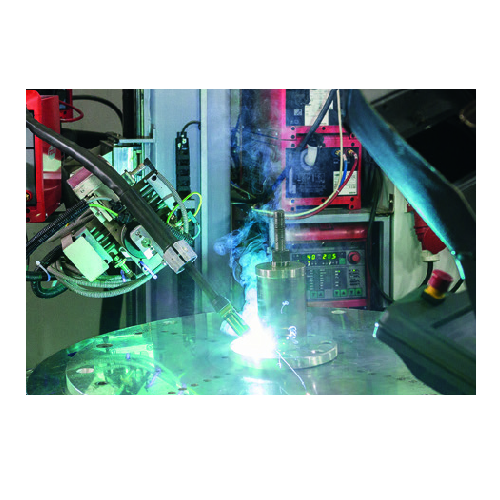

Spot welding robot for confined spaces

Optimize spot welding efficiency in tight manufacturing spaces with a compact robot ...

High pressure homogenizer for pharma applications

Achieve precise particle size reduction and stability in liquid formula...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

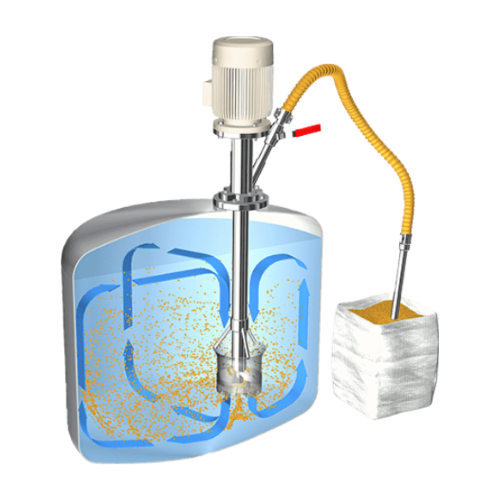

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

High-speed beverage industry palletizer

Optimize your palletizing process with a flexible, high-speed solution that adapts ...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Intermittent motion cartoner for pharma packaging

Streamline your packaging line with versatile cartoning solutions that ...

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

Bin tumbler for efficient mixing

Achieve precise blending and homogenizing of powders and granules with dual-inclination des...

Continuous mixing for fine and cohesive powders

Achieve unparalleled mixing precision for cohesive powders while reducing ...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Laboratory vacuum dryer for heat-sensitive materials

Optimize moisture control in heat-sensitive materials with precise a...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Conical paddle vacuum dryer for powders and granules

Achieve efficient drying of sensitive materials with this versatile ...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Classifier mill for ultrafine grinding

Achieve precise particle size distribution and contamination-free processing with th...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Lab-scale disperser and immersion mill

Achieve precise dispersing and milling with rapid changeover capabilities, ideal for...

Laboratory vacuum milling for fine particle size reduction

Streamline your lab and pilot processes with high-speed vacuu...

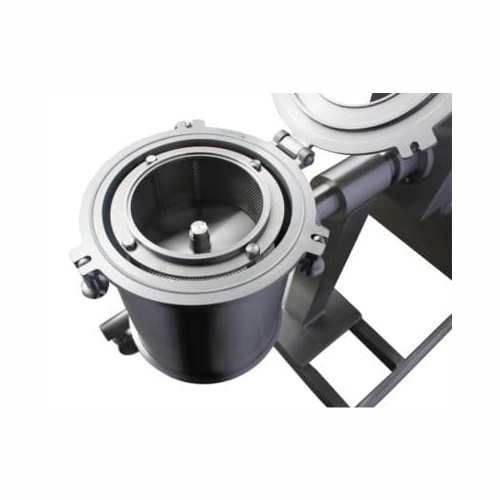

Self-cleaning filter for industrial and hygienic applications

Ensure continuous operation and minimal waste in your liqu...

Pre-breaker for initial material size reduction

Efficiently prepare your bulk materials for further processing by swiftly ...

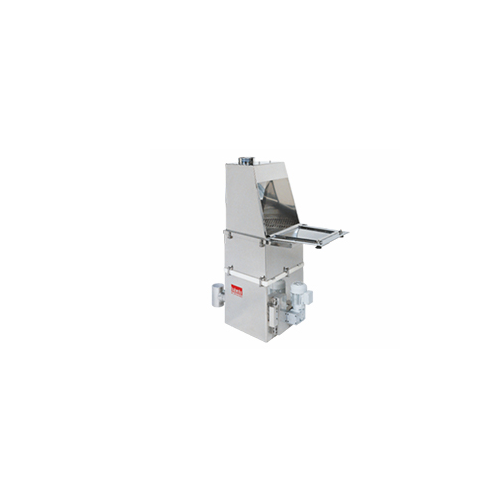

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Centrifugal powder sifter for particle separation

Achieve consistent material quality with efficient powder sifting and d...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Industrial drum tumblers for uniform batch processing

Achieve precise mix uniformity in your batches with drum tumblers, ...

Fluid bed granulation system for food and chemical industries

Achieve efficient granulation and drying of liquids with c...

Vacuum pneumatic conveying for infant nutrition

Ensure efficient handling of delicate powders with a versatile vacuum pneu...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

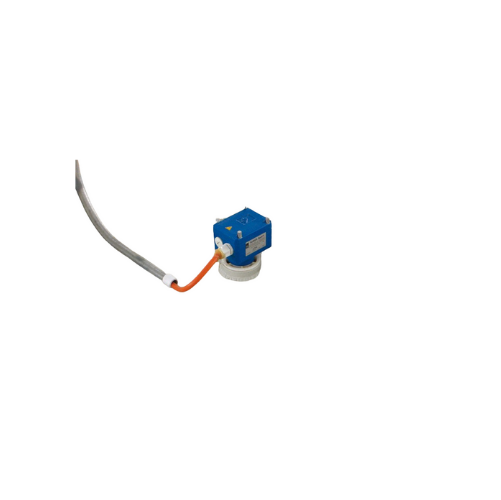

Contact detection system for rotary valves

Prevent product contamination and equipment damage with instant contact detecti...

Sack tipping station for dust-free bulk material handling

Efficiently manage bulk materials while minimizing dust exposu...

Single shaft batch mixer for chemical and pharmaceutical applications

Optimize mixing efficiency with rapid batch proce...

Hygienic flexible sleeves for tri-clamp connections

Ensure seamless, contamination-free transitions between processing st...

Continuous inline mixing for late product differentiation

Achieve seamless product differentiation with compact inline m...

Conveying controller for dense phase conveying

Streamline your dense phase conveying operations with precise control and m...

Dense phase pneumatic conveying system for powder transfer

Ensure gentle and efficient material transport with minimal m...

Pneumatic dilute phase conveying system for powders and bulk materials

Optimize your production line’s efficiency...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Universal controller for feeders in powder handling applications

Simplify and enhance your powder handling with precise ...

Deagglomerator for consistent particle size reduction

Struggling with inconsistent particle sizes or unwanted lumps in yo...

Continuous mixer for homogeneous blending

Achieve consistent product quality with precise mixing and blending, ideal for a...

Laboratory mixer for r&d and small batch production

Achieve superior mixing precision for R&D and pilot production w...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

Centrifugal sifter for bulk solids and powders

Achieve precise particle separation and enhance product quality with a solu...

Continuous powder mixer for industrial applications

Achieve precise and efficient integration of powders, granules, and l...

Heavy duty blowing seals for abrasive products

For operations dealing with abrasive materials under high pressure, these r...

Laboratory spray dryer for sub-gram powder samples

Achieve precise control in developing fine chemical and pharmaceutical...

Fluid bed system for granulation and coating

Optimize your production with a multi-purpose fluid bed system designed for e...

Filter washing cabinet for industrial cartridge filters

Achieve hygienic standards with precision washing and drying of i...

Centrifugal sifter for particle size classification

Achieve precise particle size control with high output efficiency, en...

Fluid bed processor for granulation and coating

Fluid bed processors offer efficient granulation and coating, streamlining...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Thermogravimetric analyzer for moisture, ash, and volatiles analysis

Streamline your laboratory analysis with this solu...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

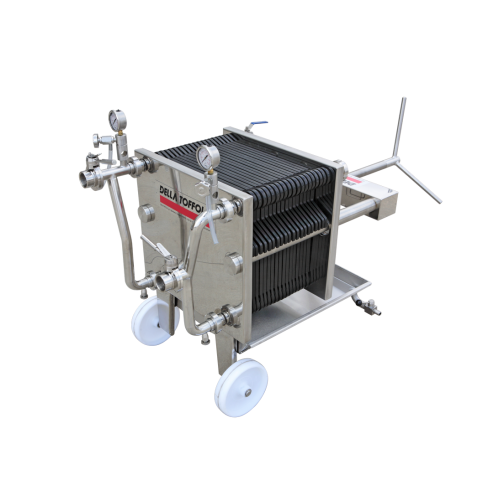

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Sheet filters for wine and beer filtration

Enhance your filtration process with reliable sheet filters designed for high-q...

Big bag emptying station for powder handling

Ensure safe and efficient powder discharge with precision containment, adapta...

Industrial cooker for food processing

Enhance your production line with versatile cooking solutions designed for precise te...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

Bag-in-box carton erector

Experience seamless carton erection with advanced servomotor technology, enhancing both efficiency...

Laboratory oven for accurate thermal processing

Achieve precise thermal control for sensitive formulations, ensuring consi...

High-speed horizontal case packer for shipping cases

For high-demand production lines, this modular case packer streamlin...

High-speed continuous motion horizontal cartoner

Achieve seamless high-speed cartoning with precision cartoner systems des...

Industrial fume scrubber for safety compliance

Enhance workplace safety by efficiently neutralizing hazardous fumes and va...

Industrial tanks for diverse applications

Efficiently manage your liquid production processes with customizable storage, m...

Mobile Cip plant for pipe and tank cleaning

Optimize your cleaning processes with this mobile CIP plant, designed for effi...

Planetary mixer for homogeneous material mixing

Achieve precise and consistent mixing of diverse materials from powders to...

Vacuum deaerator for elimination of gases

Optimize your product quality by eliminating occlusive gases with this advanced ...

Shell and tube heat exchangers

Efficiently manage heat transfer in your production line with custom-engineered shell and tub...

Dry cleaning container & hopper station

Effectively manage cleaning of rotation-symmetrical containers with minimal downtim...

Dust-tight docking for dosing units to bulk solids containers

Ensure seamless, dust-free transfer and dosing of bulk sol...

Precise dosing system for bulk materials

Ensure precise bulk material dosing with minimal dust, seamlessly switching betwee...

Big bag connection system for dust-free docking

Achieve dust-free docking and seamless discharging of bulk solids with an ...

Automated bulk material handling system

Ensure precise batch tracking and efficient handling of challenging bulk materials ...

Contamination-free docking system for bulk solids

Achieve contamination-free transfer of bulk powders and granules while ...

Cip clean-in-place system for undervacuum homogenizers

Ensure seamless sanitation for your undervacuum homogenizers with ...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

Gmp steam sterilizer for pharmaceutical applications

Ensure consistent sterilization and contamination control across you...

Screen scroll centrifuge for flexible dewatering

Ensure maximum uptime and consistent dewatering performance amidst variab...

Volumetric filler for bags and rigid containers

Optimize precision filling of powders and granules with a versatile soluti...

Ultrafiltration and microfiltration test unit

Streamline your filtration and membrane testing with a flexible, scalable un...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Lifting column for drums and bins

Optimize your powder handling operations with a versatile lifting solution designed for p...

Mobile bin blender for mixing and homogenizing dry powders

Ensure thorough powder uniformity and eliminate cross-contami...

Vacuum conveyor for powder and granule transfer

Ensure efficient and contamination-free transfer of powders and granules w...

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Filler and capper for bottles and jars

Optimize your production with a compact filling and capping solution that delivers f...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Drum decanting unit for high viscosity liquids

Efficiently decant high viscosity liquids like solvent-based paints and ess...

Semi-automatic flowmeter boom filler for large volume containers

Effortlessly handle large volume liquid filling with pr...

Automatic positive displacement filler for various liquids

Achieve precision and versatility in liquid filling operation...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

High-speed bottle orientator

Efficiently streamline your bottling process by ensuring containers are swiftly and accurately ...

Bottomless conveyor for 90° bottle transfer and coding

Efficiently connect disparate production systems in your bottling ...

R&d vessels for research and development centers

Optimize your R&D operations with versatile vessels designed to hand...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Heavy-duty tablet press for single & double-layer tablets

Maximize your tablet production with a high-speed solution cap...

Industrial rotary press for single-layer tablet production

Optimize your tablet production with precision-engineered rot...

Self-priming side channel pump for high gas content media

When handling media with high gas content, achieving efficient...

Single-stage centrifugal pump for heavy-duty applications

Optimize fluid handling with a high-efficiency centrifugal pum...

Fibc emptying stations for powder processing

Streamline your bulk powder handling with single-operator FIBC emptying stati...

Rotary tube selector valve for powder conveying

Streamline your pneumatic transport system with a robust solution that div...

Vibrating feeder for food and pharmaceutical industries

Optimize your production line with precision dosing and gentle ma...

Continuous in-line blender for home and personal care products

Achieve precision and flexibility in blending liquid mult...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Inline real-time fluid quality monitoring system

Optimize fluid quality control with continuous, inline measurements that ...

Layer preparation system for high-speed palletizing

Optimize your palletizing process with a system that ensures precise ...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Forced circulation evaporator for highly viscous liquids

Optimize energy efficiency and minimize fouling in your evaporat...

R&d spray drying solution for small batch production

Efficiently convert liquid solutions into precise, uniform powders f...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

Pure steam generator for industrial applications

Ensure the highest levels of steam purity and precise pressure control fo...

Rotary piston fillers for pumpable products

Optimize high-speed production lines with precision filling for diverse liquid...

Bright beer tanks for breweries

Enhance your beverage production with precise carbonation and conditioning, ensuring excepti...

Traditionally welded silos for constrained installation sites

Ideal for facilities with limited space, these traditional...

Autonomous process control for petrochemical and food industries

Streamline your production with autonomous control syst...

Advanced degassing and temperature control solution for process silos

Optimize your production line with precise contro...

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

Compact serialisation solution for cartons

Optimize your packaging line with a versatile serialisation solution designed t...

High-speed checkweigher for dynamic weighing

Achieve precision and consistency in high-speed production environments with ...

Checkweigher and metal detector for heavy loads

Streamline your inspection process by combining precision weighing with co...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Batch-type single shaft mixer for industrial mixing

Achieve precise and uniform mixing with high-speed, single-shaft mixe...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Industrial slide valve for heavy-duty applications

When managing gravity material flow in abrasive environments, achievin...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Double dump valves for high temperature granules

Ensure precise material flow and withstand extreme temperatures with thes...

Stainless steel tubular screw conveyor for bulk solids handling

Ensure precise material handling with stainless steel tu...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Lump breaking feeder valve for bulk material processing

Tackle bulk material flow challenges with a feeder valve engineer...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Vertical conveyor for fine aggregates and minerals

Optimize the handling of abrasive materials with a vertical conveying ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Trough screw conveyors for powdery and granular materials

Optimize your material handling process with a flexible screw ...

Stand-up pouch filling and sealing system

For packaging lines that demand quick, efficient, and flexible pouching, this hi...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Powder locks for safe bulk material handling

Ensure containment and prevent contamination while processing sensitive bulk ...

Powder handling vacuum conveyor system

Streamline your material transfer with a versatile vacuum conveyor system that ensur...

Integrated conveying and weighing system for bulk materials

Achieve precise material management with a solution that sea...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Lump breaker for breaking agglomerates and lumps

Effortlessly break down challenging agglomerates and clumps to ensure smo...

Dosing pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with flexibility in dosing volu...

Dosing and filling pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with compact, hygi...

Pressure monitoring solution for dosing processes

Optimize your production line by ensuring precise pressure monitoring, ...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Adjustable integral stand mixer for transport containers

Achieve optimal mixing and stirring in diverse transport contain...

Tank agitator for low-level installation

Efficiently optimize your mixing processes with a bottom-entry tank agitator, desi...

Homogenizer for low to medium viscosity media

Achieve uniform mixing and prevent air entrapment in low to medium viscosity...

Semi-automatic stands blender for facade paints

Optimize your paint production with a versatile stirring system designed f...

Industrial mixer for product-critical processes

When dealing with high-hygiene requirements and complex mixing tasks acros...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Compact dust extractors for cleanroom applications

Ensure safe and efficient dust extraction in cleanroom environments wi...

In-line mixer for liquid-liquid and solid-liquid processes

Optimize your mixing operations with an efficient solution th...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Single piston food filler

Achieve precise portioning and consistent product flow with a versatile solution perfect for handl...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Automated wrap-around packaging system

Streamline your packaging process with a system that efficiently groups, folds, and ...

Mini extruder for small batch processing

Ideal for precise control in experimental formulations, this mini extruder streaml...

Volumetric twin screw feeder for powder and micro-granules

Optimize your production flow by ensuring consistent and prec...

High-precision feeding system with load cell and weighing electronics

Achieve unparalleled accuracy in dispensing powde...

Twin screw feeder for bulk material handling

Optimize your bulk material processing with a solution designed for precise f...

Precise volumetric or gravimetric powder feeder

For precise feeding of challenging powders prone to clumping and bridging,...

Volumetric flat-bottom twin-screw feeder for powders

When handling powders prone to clumping, a reliable feeder ensures u...

Volumetric single-screw feeders for free-flowing products

Achieve precise and continuous feeding of free-flowing powders...

Gravimetric single-screw feeder for free-flowing products

Optimize your dosing precision for powders and granulates with...

Granulator for processing strands into granulate

Optimize granule production with precise control over pellet size and ext...

Hot cutter for processing extrudate into pellets

Efficiently transform extrudates into precise pellet sizes, enhancing you...

Gravimetric auger filler for powder weighing

Achieve precise powder filling with this gravimetric auger solution, ensuring...

Roller compactors for dry granulation

Optimize your powder processing with advanced roller compaction, ensuring consistent ...

Automatic liquid filling solutions for various containers

Ensure precise liquid packaging for diverse container types, e...

Pneumatic syringe dosing system

Streamline your liquid dosing process with precision and efficiency, ensuring each applicati...

Vibrating fluid bed dryer for bulk materials

Ensure efficient moisture removal and thermal processing with this fluid bed ...

Low profile flow-thru separator for wet or dry scalping

Efficiently handle high-capacity separation with a compact design...

High-capacity industrial sifter for chemical and food processing

Achieve unparalleled screening precision and efficiency...

Round vibratory separation equipment - bag dump screener system

Enhance your material handling and safety by efficiently...

Round vibratory separation for various industrial applications

Ensure accurate material separation with a robust solutio...

Vibratory finishing and deburring technology

Achieve precise surface finishing and deburring with advanced vibratory motio...

Sub-micron particle size reduction grinding mill

Achieve precise particle size reduction effortlessly with advanced vibrat...

Medium steam sterilizer for laboratory applications

Ensure consistent and reliable sterilization of heat- and moisture-st...

Multiple-effect water still for pharmaceutical applications

Optimize your pharmaceutical water production with a system ...

Industrial blender for uniform mixing

Optimize your process with precise mixing and consistent blending, ensuring uniformit...

Medium torque mixer for chemical processing

Achieve optimal mixing efficiency and process consistency in demanding applica...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

Medium torque top entering mixer for industrial applications

Optimize your mixing and blending operations with precise t...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

Clean in place (cip) system for industrial cleaning

Ensure optimal hygiene and production efficiency with a system that s...

Bigbag discharge station with dust-free docking system

Streamline your production line with an efficient solution for man...

Bin activator for reliable bulk solids discharge

Ensure reliable flow and prevent compaction in your production line with ...

Volumetric feeder for flowable ingredients

Ensure consistent and precise dosing of diverse materials in your production li...

Volumetric feeder for consistent ingredient flow

Achieve precise and consistent ingredient dosing in your production line ...

Single screw feeder with stirring agitator for powders and pellets

Ensure consistent mass flow and precise dosing with ...

Loss-in-weight feeder for flowable ingredients

Achieve precise ingredient delivery with this feeder, designed to handle a ...

Laboratory loss-in-weight feeder for powders or pellets

Achieve precise dosing for lab-scale trials with this versatile f...

Loss-in-weight feeder for liquids

Achieve precise and continuous liquid dosing with high accuracy, adapting seamlessly to y...

Loss-in-weight feeder for non-hygroscopic ingredients

Ensure precision in your dosing and weighing processes with this ad...

Single screw loss-in-weight feeder for powders and pellets

Ensure precise dosing and mixing in continuous automated oper...

Twin screw volumetric feeder for poor flowing powders

Struggling with poor flowing or floodable powders? This twin screw ...

Weigh-belt feeder for industrial processes

Efficiently manage material flow and precision with a dependable weigh-belt fee...

Dust filter for loss-in-weight feeder refill

Optimize your feeder operations by effectively filtering displaced air and mi...

Bigbag discharge station

Efficiently manage bulk material unloading with this solution, which facilitates seamless dischargin...

Hopper scale for precision batching

Achieve high batch accuracy with a central weighing hopper engineered for seamless inte...

Batch ingredient dosing system for high-accuracy weight control

Achieve precise weight measurement for multi-ingredient ...

Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consiste...

Double screw batch feeder for poorly flowing powders

Effectively manage challenging powders with precise batch dosing and...

Feeder controller for gravimetric feeders

Optimize your dosing precision and monitoring accuracy with a versatile feeder c...

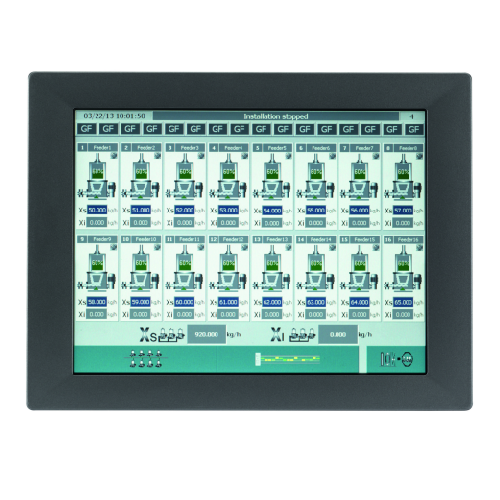

Gravimetric feeder operator interface

Efficiently manage up to 16 gravimetric feeders with a user-friendly interface, enabl...

Single feeder operator interface for gravimetric feeders

Enhance precision in your dosing operations with an intuitive to...

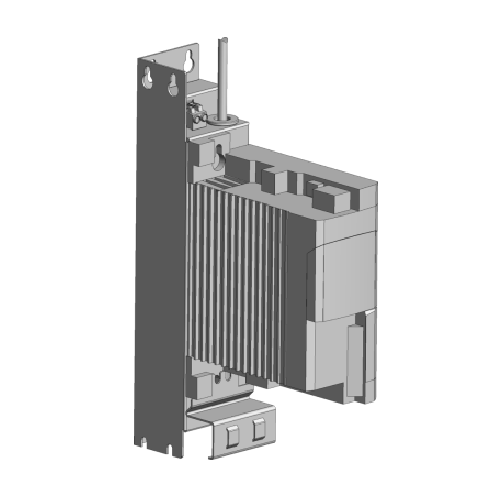

Speed controller for feeders

Ensure precise material flow by integrating this speed controller, ideal for managing both volu...

Loss-in-weight feeder for long and uneven fibers

Optimize feeding precision for challenging materials like long and uneven...

Loss-in-weight feeder for flowable particles

Ensure precise ingredient delivery with a feeder designed for high accuracy a...

Batch feeder for bulk solids processing

Achieve precise batch dosing with this advanced feeder, designed to handle a variet...

Precision batch feeder for flowable ingredients

Achieve precise ingredient control with a batch feeder designed for versat...

Microbatch dosing for precision ingredient measurement

Achieve precise ingredient dosing with our MicroBatch system, desi...

Hyper-clean electronic volumetric filler for Pet bottles

Enhance your liquid filling operations with precision and hygien...

Combined packers with in-line infeed for plastic and glass containers

Streamline your packaging process with a versatil...

Cip sanitizing unit for food and beverage production

Ensure meticulous hygiene with a compact unit designed for seamless ...

Single-stage plastic container production system

Eliminate multiple steps and minimize production costs with an integrated...

Injection stretch-blow molding system for Pet containers

For manufacturers aiming to produce versatile, high-quality PET ...

Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system en...

High shear powder mixing solution

Achieve agglomerate-free, homogeneous mixing of powders and liquids with high shear effic...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

High shear inline mixer for continuous processing

Effortlessly streamline your mixing process with this solution capable ...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

Pilot scale batch mixer for small scale production

Achieve precise control and consistency in small-scale production with...

High shear batch mixer for industrial mixing

Optimize your production cycle with this high shear batch mixer, designed to ...

Bottom entry mixers for high viscosity products

Optimize your production line with mixers designed to handle both high and...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Versatile rotary filler-capper for liquid products

Optimize your liquid product production with a versatile solution that...

Injected density stabilizer for pneumatic conveying

Optimize your dense phase pneumatic conveying with a stabilizer desig...

Infrared moisture analyzer for lab and production use

Achieve precise and reliable moisture analysis with minimal time an...

High-accuracy moisture analyzer for lab weighing

Achieve precise and reproducible moisture content determination for diver...

Explosion proof weighing cells for hazardous environments

Designed for hazardous environments, these weighing cells ensu...

Cartoner for pharmaceutical products

Effortlessly streamline your packaging line with compact cartoning capabilities, ensur...

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Eccentric press for refill tablets

Hundreds of different refill tablets, of various shapes or sizes, are on the market toda...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

Automatic bottle capping machine

Traditional bottle capping systems are inflexible, limiting the scope of your packaging and...

Air knife drying system for containers

In food or beverage production where a product is filled into jars, there is often r...

Semi-automatic trigger capping machine

Trigger spray bottle are the ideal capping solution for many chemical and household ...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Air rinsing system for containers

Traditional water rinsing solutions for containers used in the food and pharmaceutical se...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...