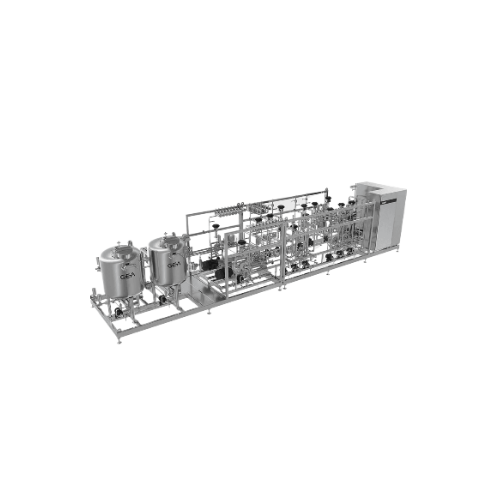

Continuous in-line blender for home and personal care products

Achieve precision and flexibility in blending liquid multi-component products while reducing footprint and maintenance costs with advanced continuous in-line mixing technology.

Blends and Mixes Liquid Components Efficiently

The GEA DICON® Continuous In-Line Blenders offer unparalleled efficiency for home and personal care, chemical, and biofuel applications. Utilizing precise dosing and metering technology, these systems excel at consistently blending multi-component liquid products directly in the pipeline, optimizing space and reducing operational costs. Their design eliminates the need for traditional mixing tanks, leveraging high-precision flow meters for accurate mixing, with minimal product residue. Capable of handling both low and high capacities, these blenders facilitate seamless integration into your production line, supported by a wide measuring and control range. Designed with flexible production demands in mind, they ensure economic operation and exact process reproducibility. Available with robust material options, they suit various chemical environments and ensure long-term reliability.

Benefits

- Enhances production efficiency by eliminating the need for separate mixing tanks, saving space and costs.

- Ensures precise product consistency with high-accuracy dosing and metering.

- Adapts to varying production demands with a wide capacity range.

- Minimizes waste with low residual product quantities remaining in the system.

- Increases production flexibility, allowing for fast adaptation to new formulations and process changes.

- Applications

- Liquid fertilizers, Biofuels, Anti-freezing agents, Oral care products, Urea, Skin care products, Health care products, Cleaning agents, Laundry detergents, Liquid soaps

- End products

- Hand soap, Biodiesel, Ethylene glycol antifreeze, Npk liquid fertilizer, Dishwashing liquid, Toothpaste, Antiseptic solutions, Mouthwash, Diesel exhaust fluid, Fabric softener, Moisturizing cream

- Steps before

- Dosing preparation, Ingredient feeding, Deaeration

- Steps after

- Product QA testing, Packing, Distribution

- Input ingredients

- cleaning agents, laundry detergents, liquid soaps, oral care products, skin care products, health care products, liquid fertilizers, biofuels, anti-freezing agents, urea

- Output ingredients

- mixed cleaning agents, mixed laundry detergents, mixed liquid soaps, mixed oral care products, mixed skin care products, mixed health care products, mixed liquid fertilizers, mixed biofuels, mixed anti-freezing agents, mixed urea

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Mixing accuracy

- High mixing precision

- Capacity

- Very low to very high capacities

- Automation

- PLC-controlled

- Batch vs. continuous

- Inline Continuous

- Space requirement

- Mixing in the pipeline (low space required)

- Flow meter precision

- Precise flow meters

- Mixing in the pipeline

- Yes

- No costs for mixing tanks

- Investment, CIP, maintenance savings

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP

- Automation level

- High (via precise flow meters)

- Flexibility

- High

- Liquid compatibility

- Cleaning agents, laundry detergents, liquid soaps

- Compatibility with chemicals

- Liquid fertilizers, biofuels, anti-freezing agents, urea

- Pipeline space requirement

- Low

- Main pipeline feed

- Yes

- Dosing sections

- Feeding pumps and deaerating vessels

- Metering technology

- Precise flow meters

- Mixing capacity

- Very low to very high capacities

- Control system integration

- PLC/SCADA integration

- Footprint

- Compact, pipeline-based design

- Dosing sections

- Includes feeding pumps and deaerating vessels

- Metering precision

- High mixing precision