Mixing Equipment

Find innovative mixing equipment and connect directly with world-leading technology suppliers

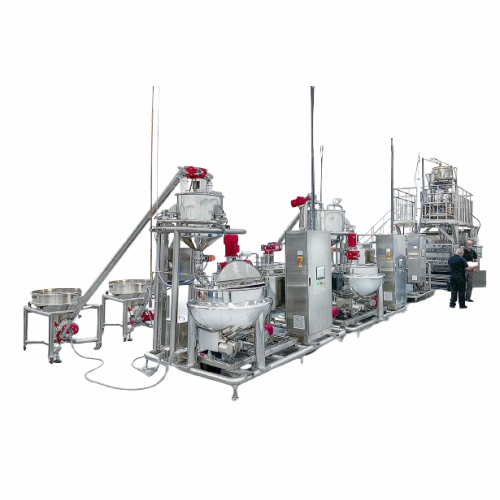

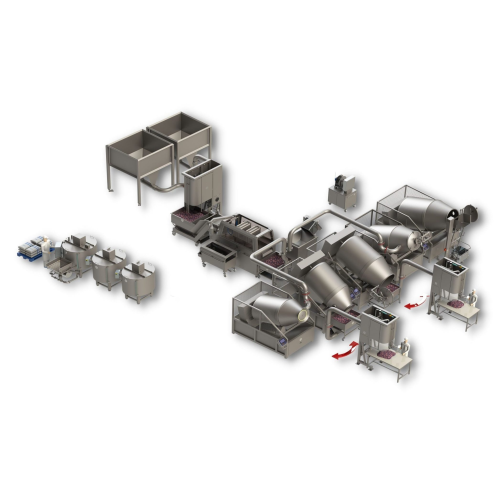

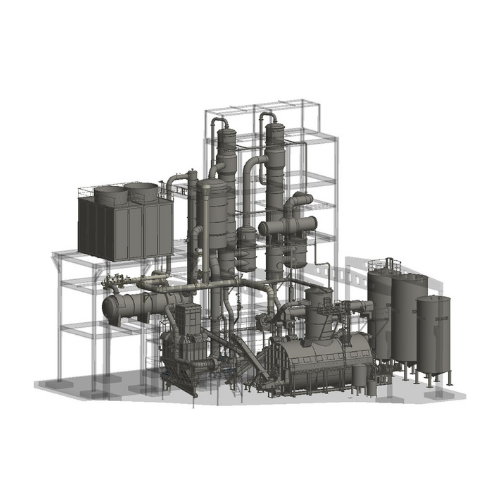

Industrial mixing equipment is used to combine two or more solid, liquid or gaseous segregated ingredients into a homogenous single product. The choice of mixing technology depends largely on the physical state of the ingredients and the desired final product. But the sensitivity of the ingredients, the process temperature, and pressure requirements are also critical factors. All these parameters result in a wide range of industrial mixers.

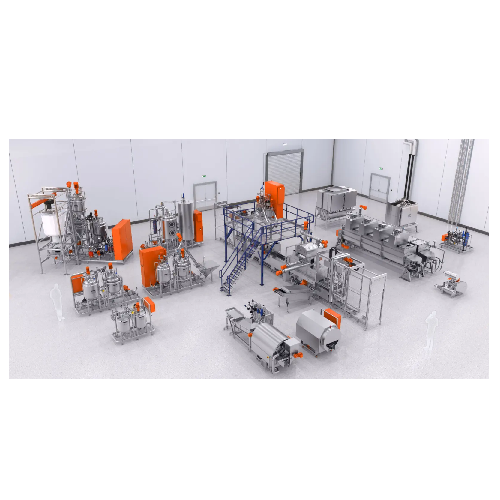

Innovative mixing solutions

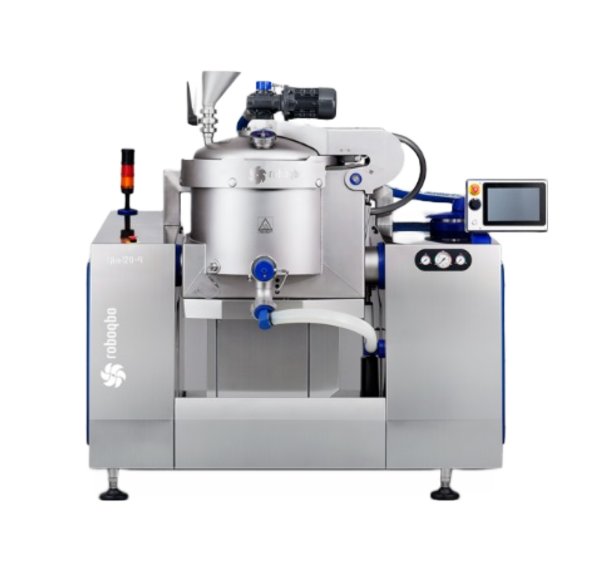

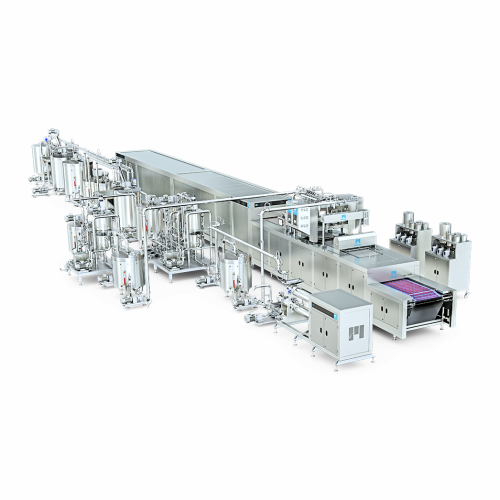

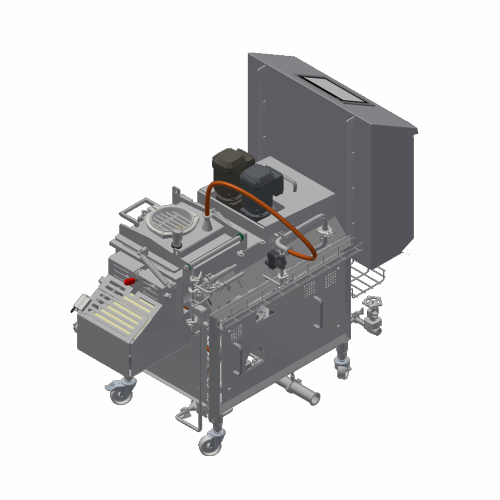

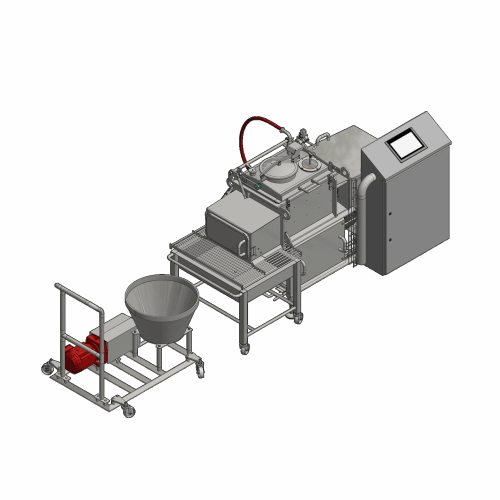

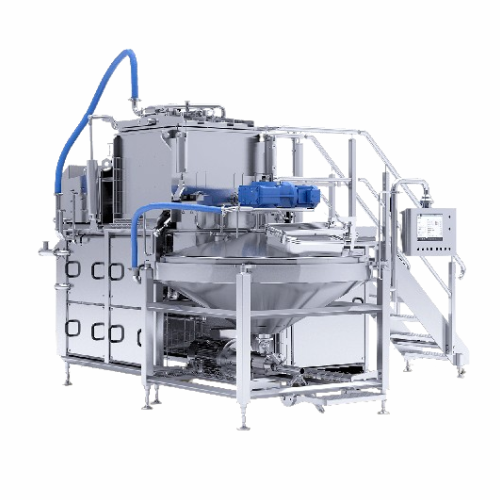

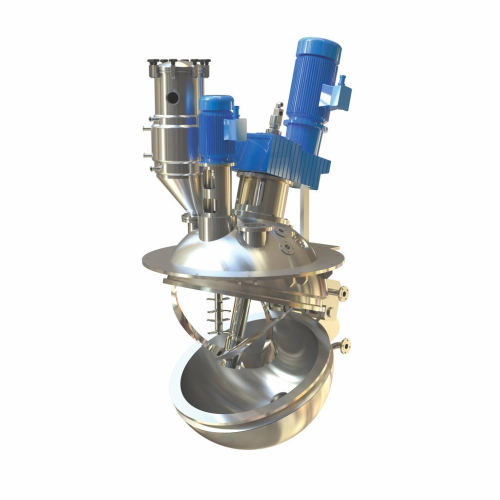

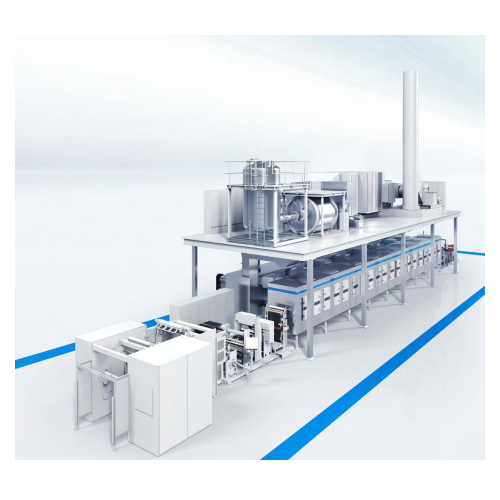

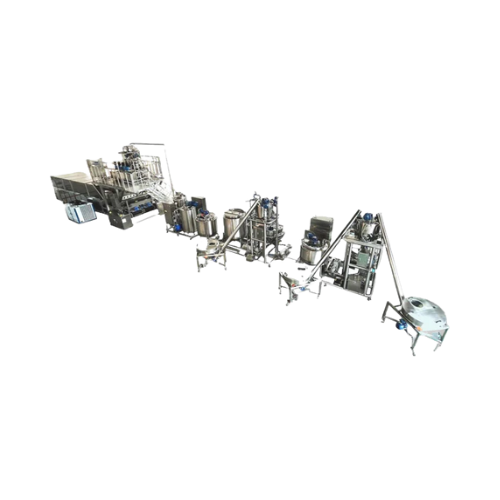

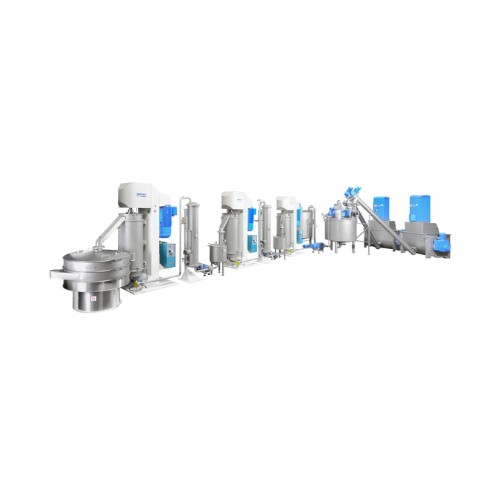

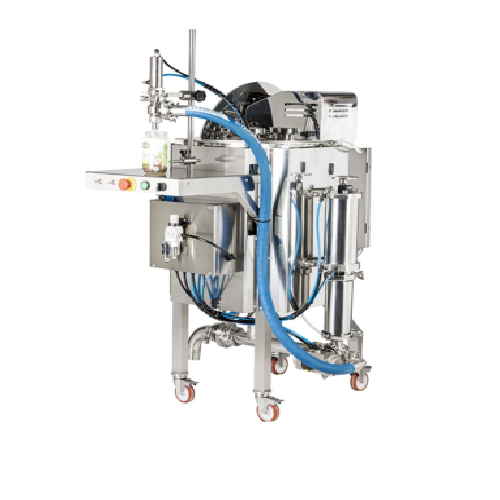

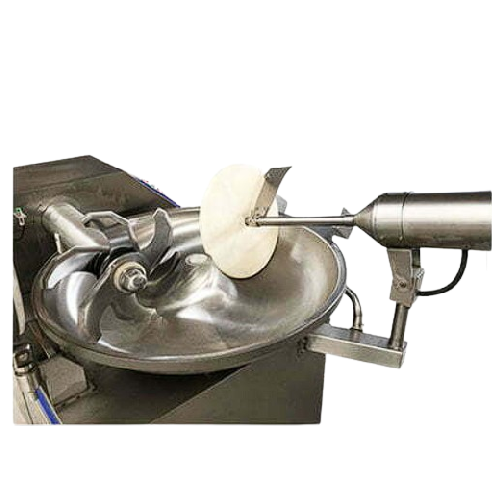

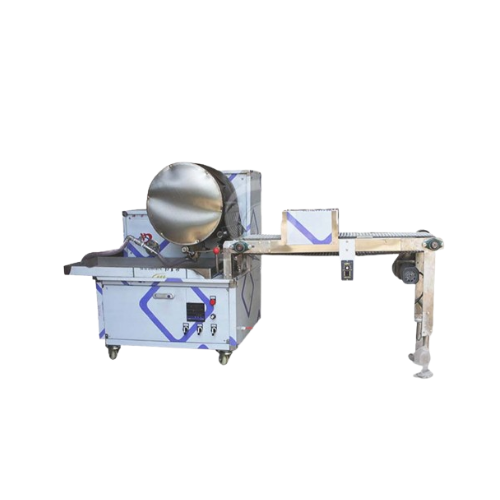

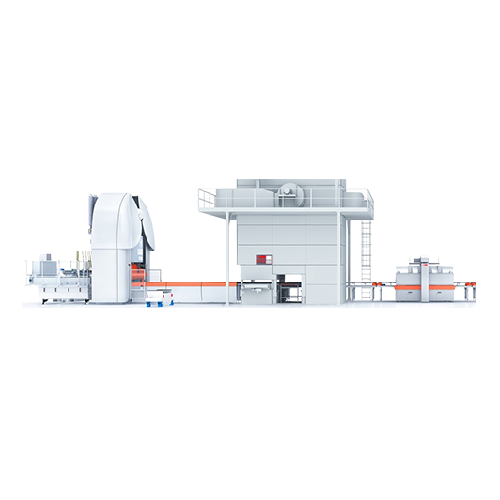

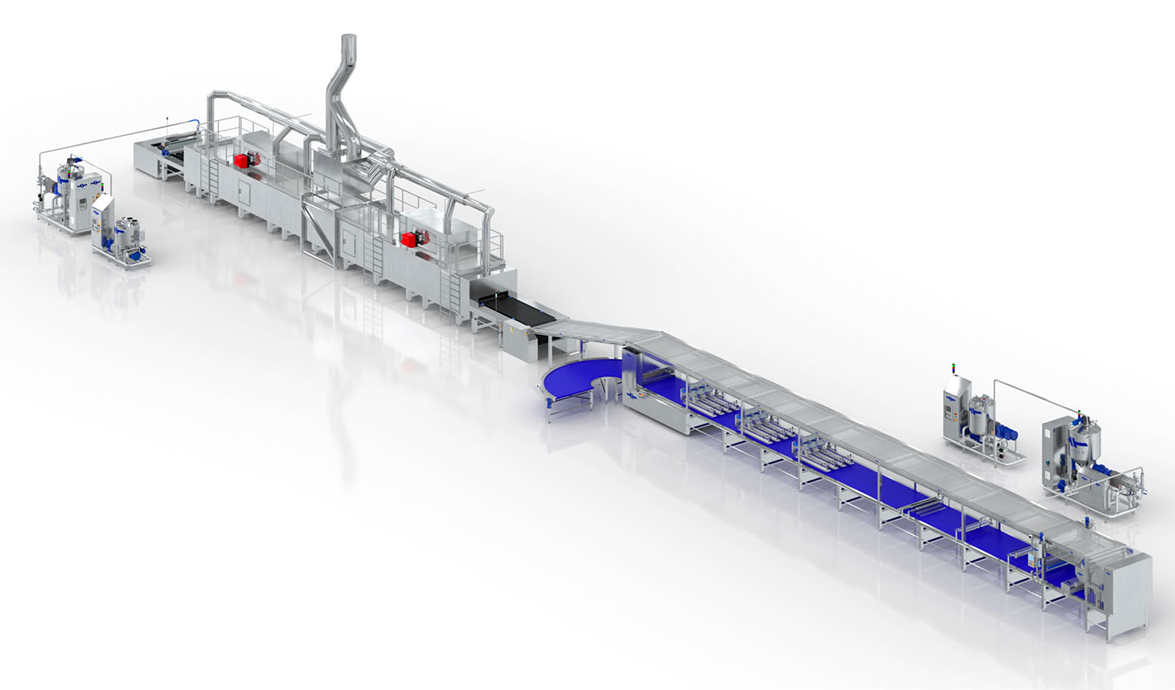

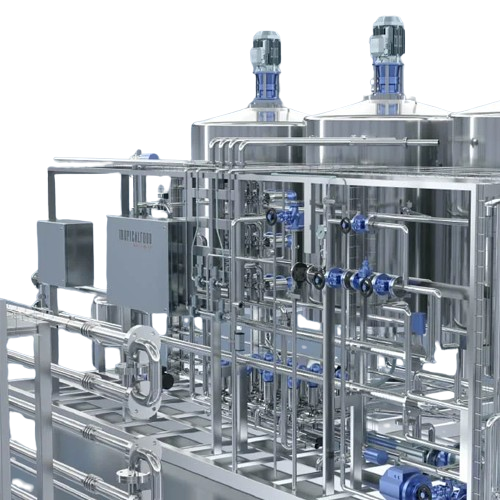

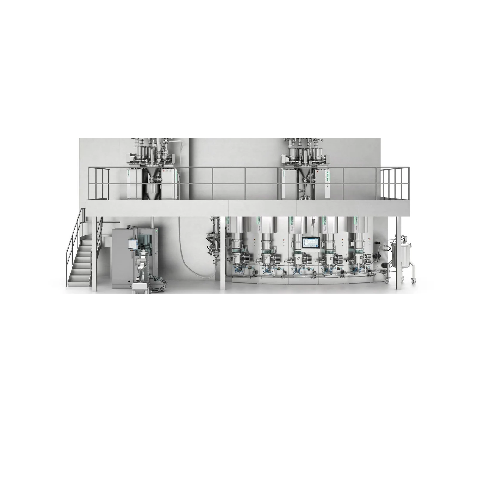

Complete cutting, mixing, emulsifying and heating system

From laboratory scale to large volume food or cosmetic productio...

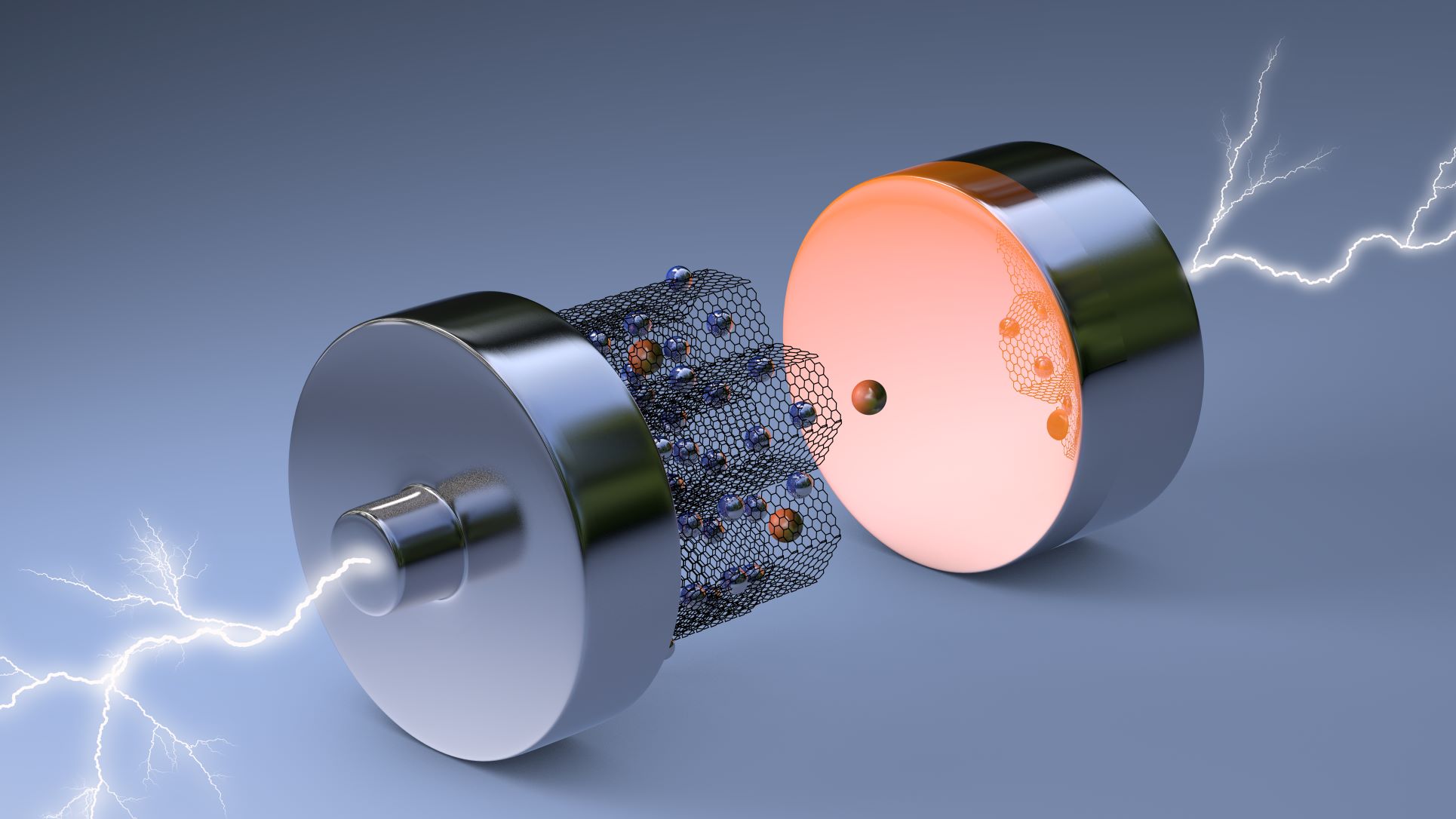

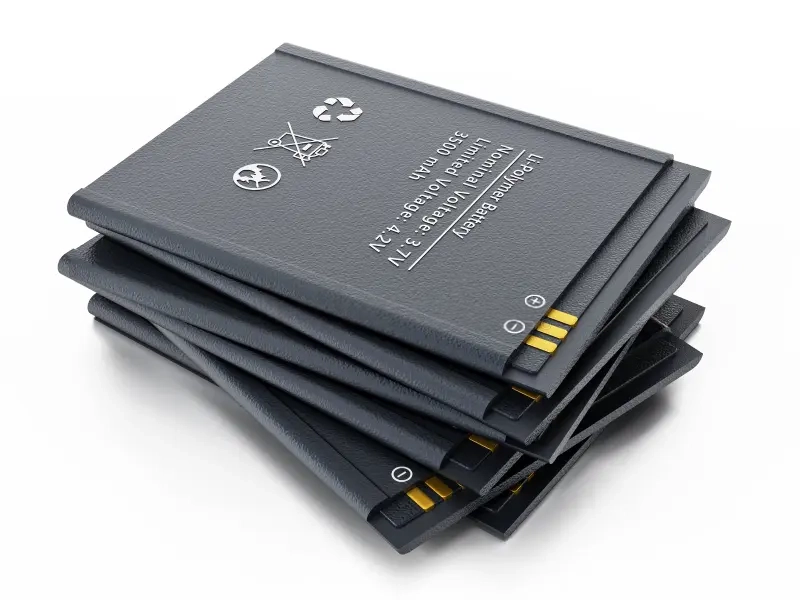

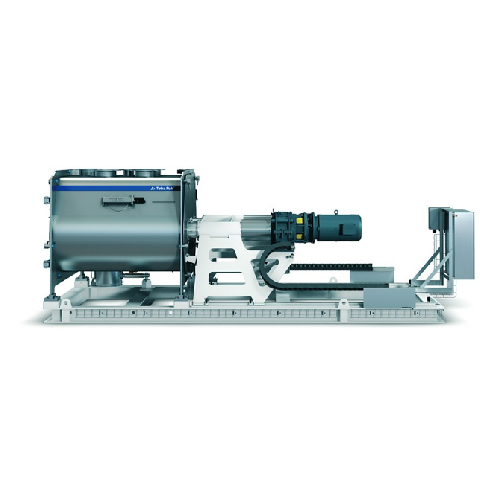

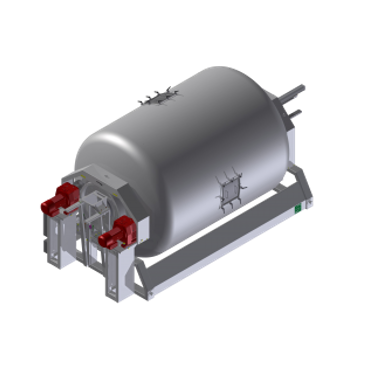

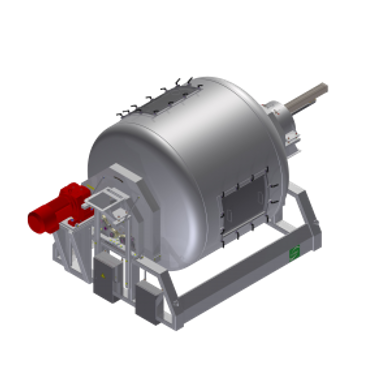

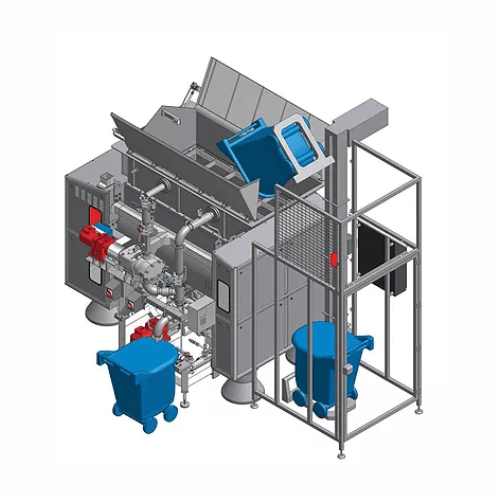

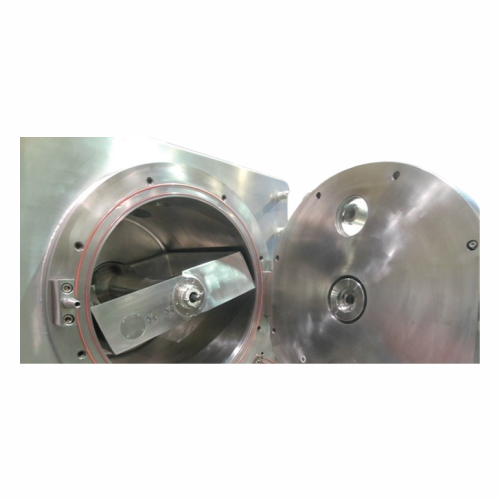

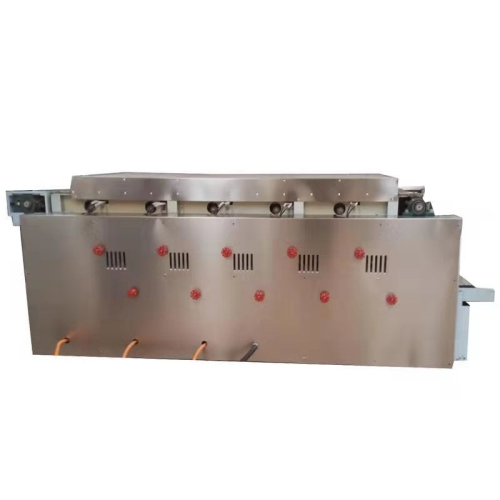

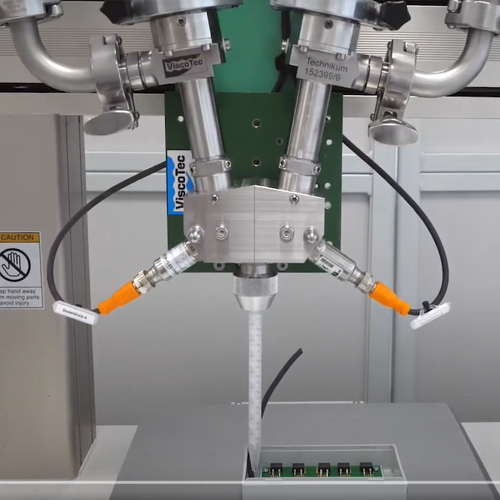

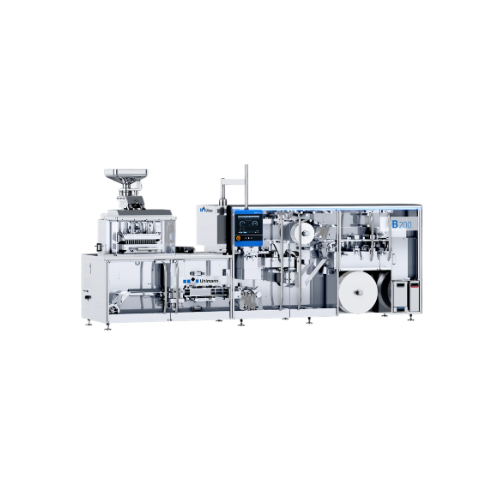

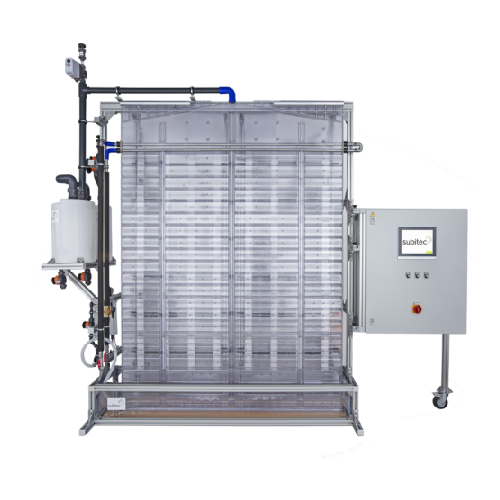

Inline solid-liquid mixer for battery production

In battery production, a critical phase entails mixing solids with liquid...

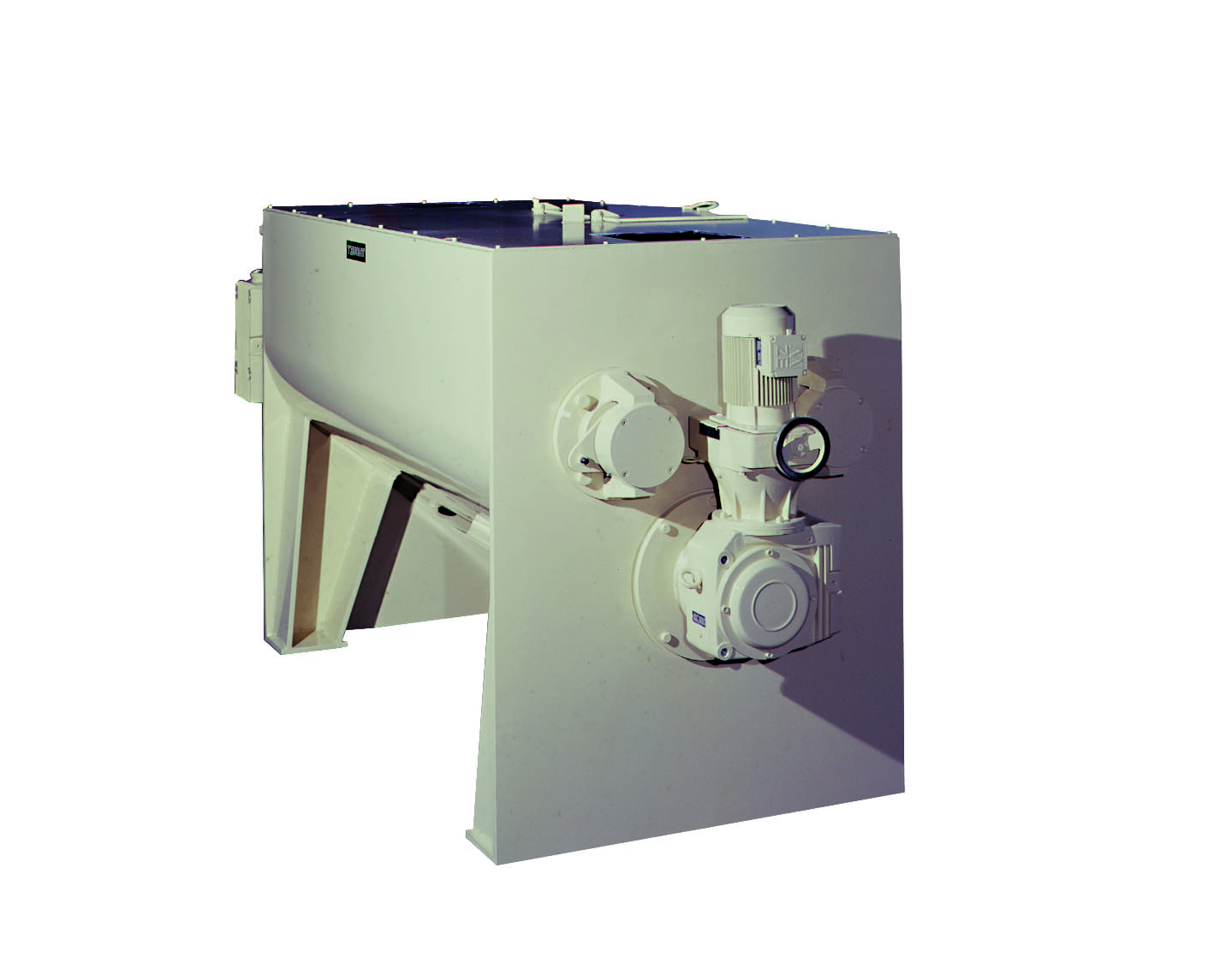

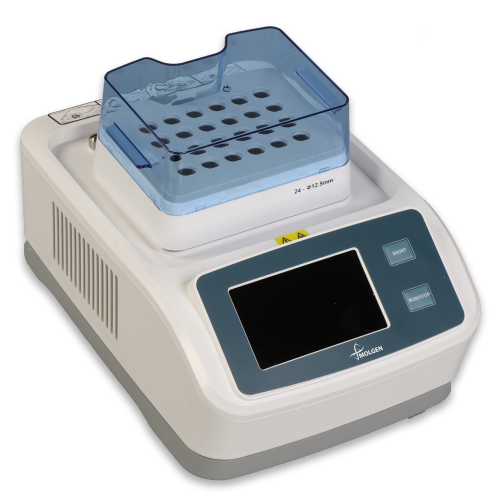

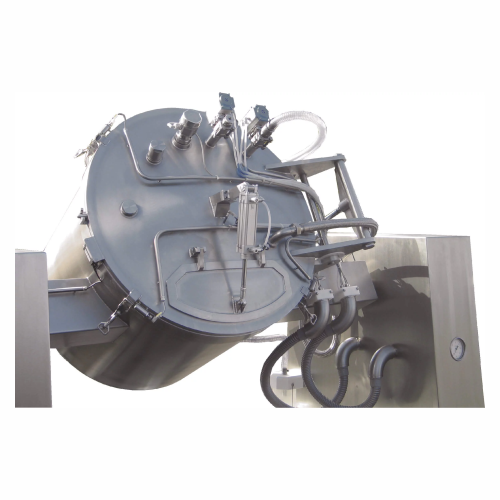

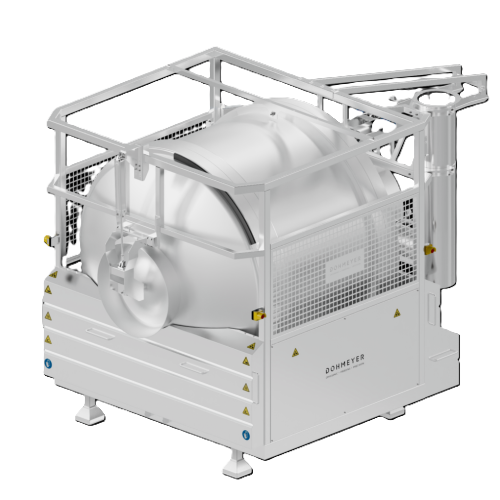

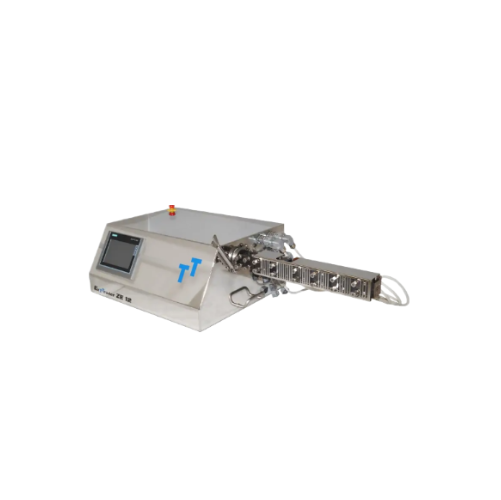

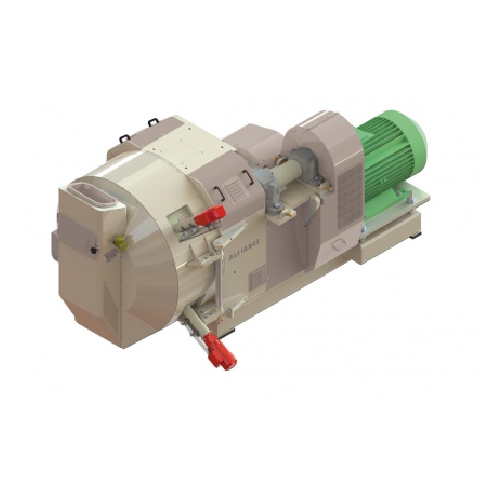

3D powder mixer for active pharmaceutical ingredients

Proper mixing and homogenization are essential to achieve a reliabl...

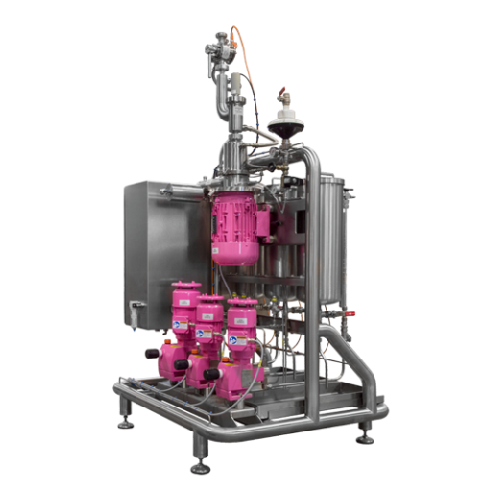

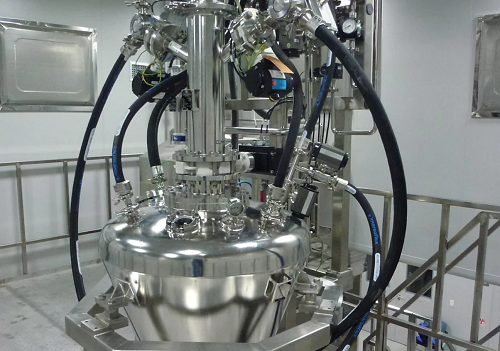

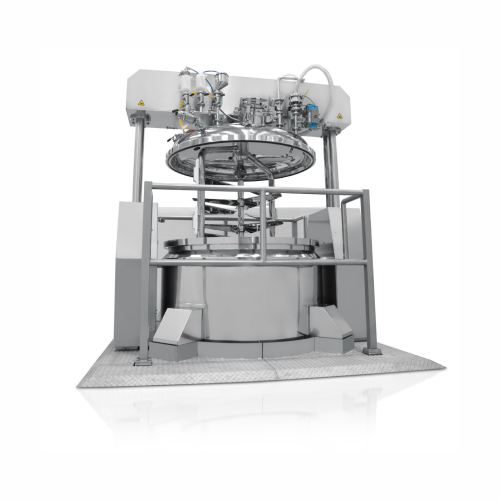

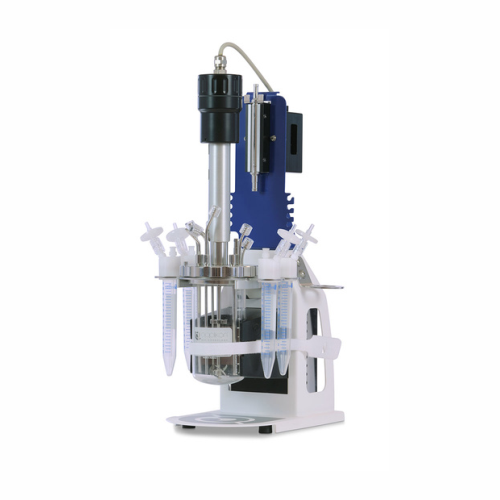

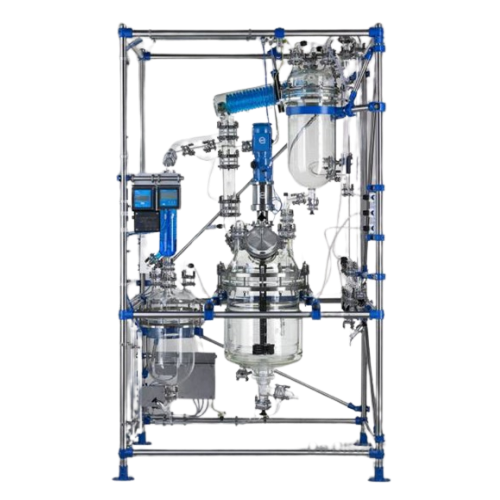

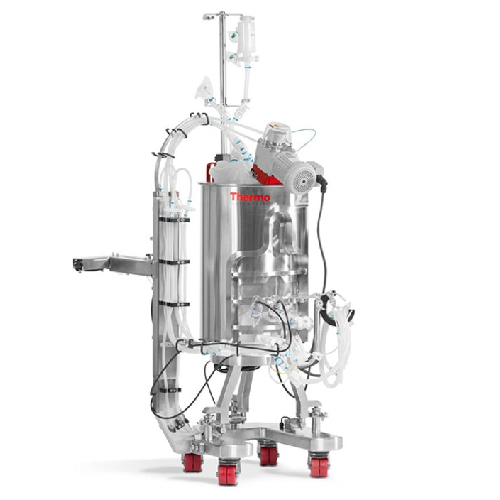

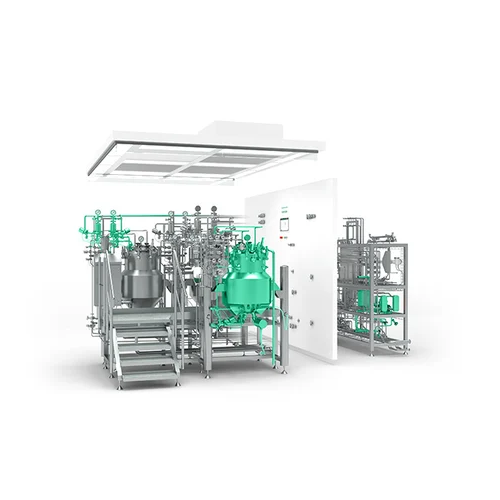

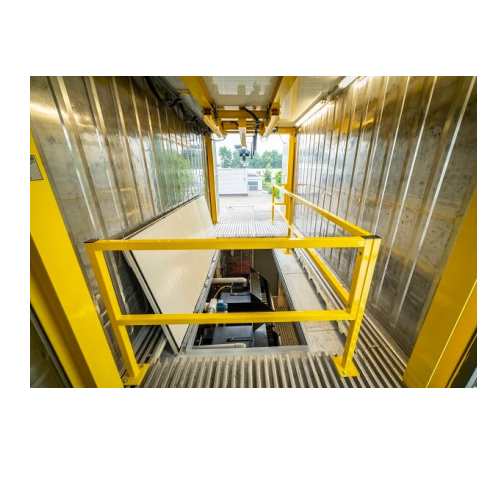

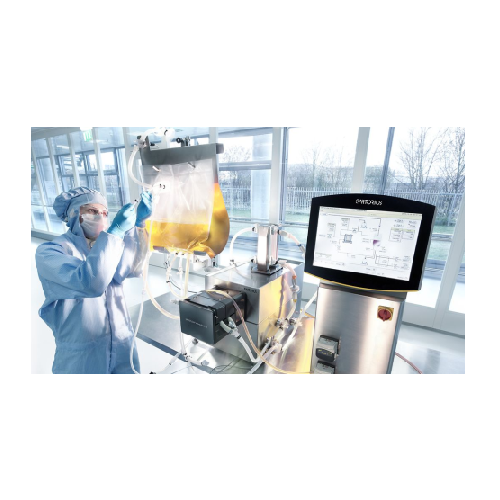

Aseptic magnetic mixer for hygienic production

Experience seamless mixing to the last drop with advanced levitating impell...

Select the mixing technology that can handle the format of your material

Mixing technology is ubiquitous across industries. From food manufacturing to feed and pharmaceutical, mixer machines are crucial equipment in the transformation processes. The overarching types of industrial mixers are designed according to the material format.

There is mixing technology for powders, liquids, gases, and everything in between – solids/liquids, mash, and other solids.

Adapt the attributes of the mixing technology to the ingredients and manufacturing industry

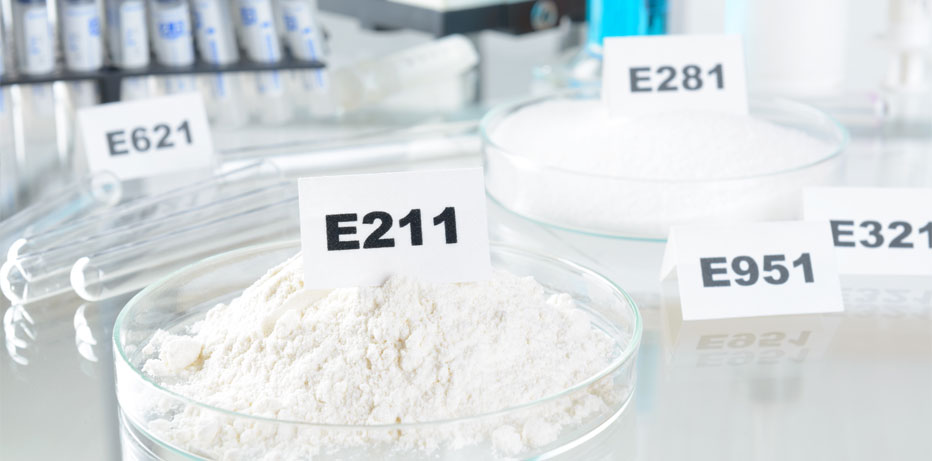

Besides the material form, industrial mixers must be tailored to the industries. For example, pharmaceutical mixing technology is made from hygienic steels.

However, there are multiple mixing techniques used in the same industry. So, the suitable industrial mixer depends on the process step, the characteristics of the ingredients, and the final product. The attributes of mixing machines, like speed, temperature, and time control, contribute to a specific result.

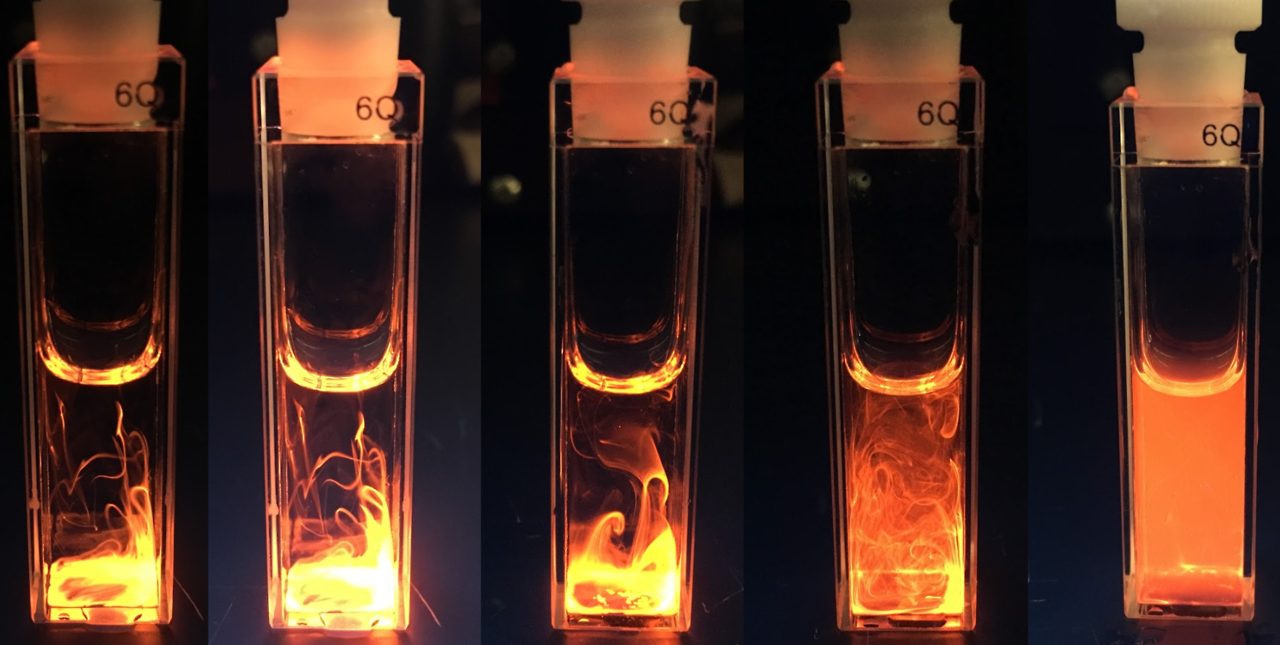

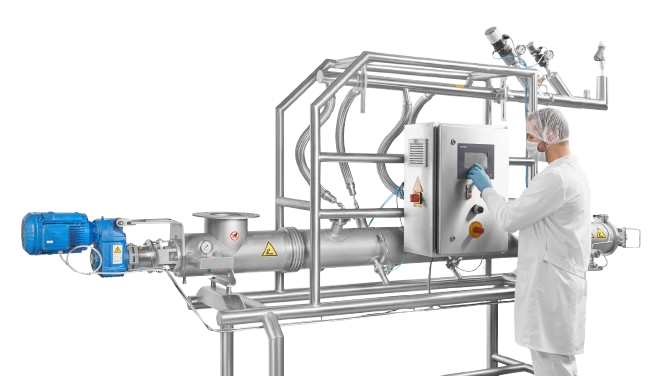

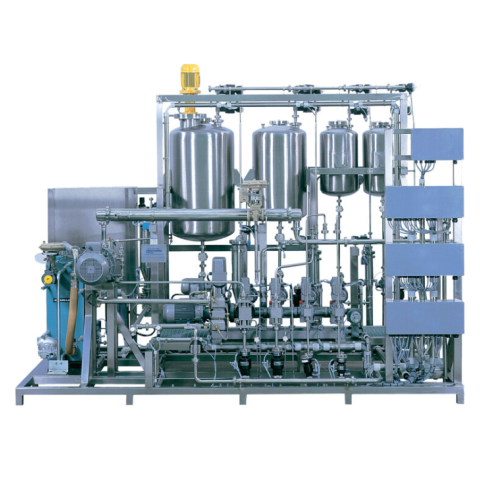

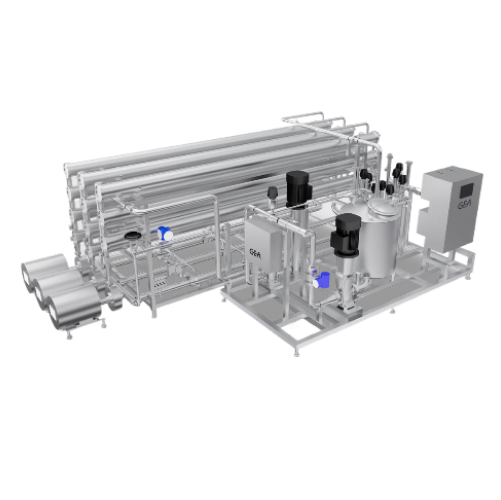

Apply high-pressure homogenizers to process liquids into high-quality pharmaceuticals and nanomaterials

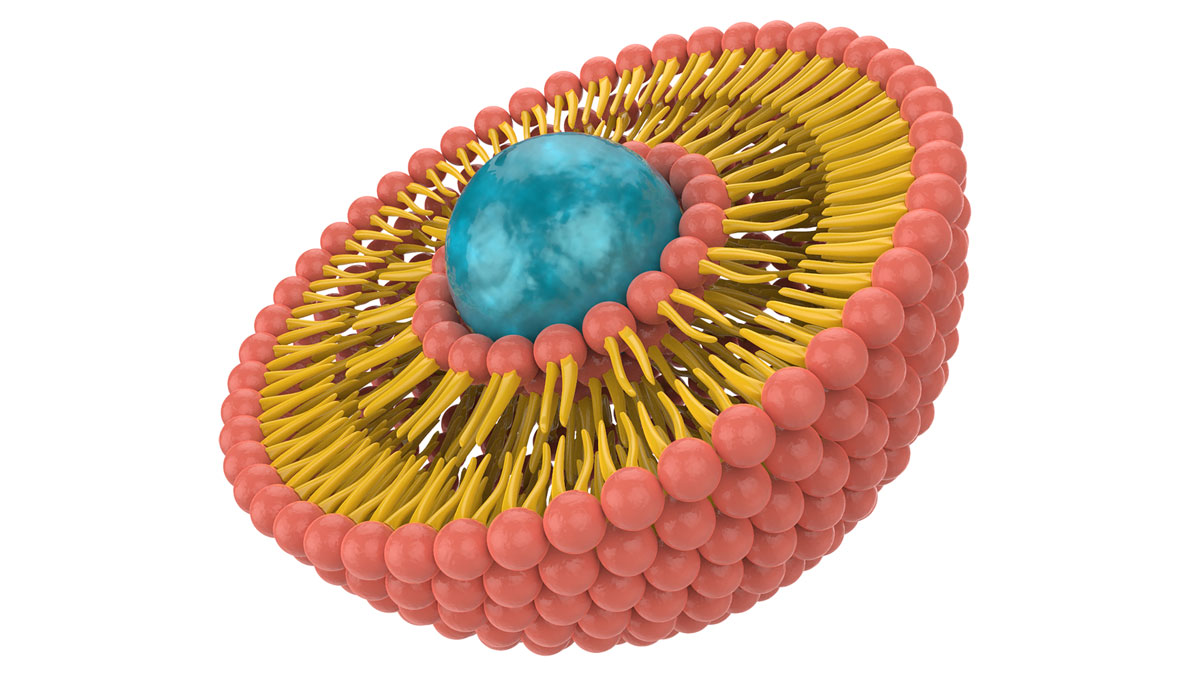

A high-pressure homogenizer is used for mixing and emulsifying liquids. The liquid flows through a narrow orifice, creating turbulence, shear forces, and cavitation by applying pressures over 20,000 psi. This mixing technology is widely used in pharmaceuticals and nutraceuticals to produce nanomaterials like green-based biomolecules.

Ensure that the liquid ingredients don’t have a high content of solid matter. This could clog the orifices and damage or reduce the machine’s life. Additionally, clean the homogenizer thoroughly after every use to prevent cross-contamination from products.

Combine immiscible materials with emulsifying equipment

A particular class of mixing technology mixes immiscible ingredients such as water and oil by emulsification. Industrial emulsifiers are used across many industries to make products from sauces and creams to lubricants and disinfectants.

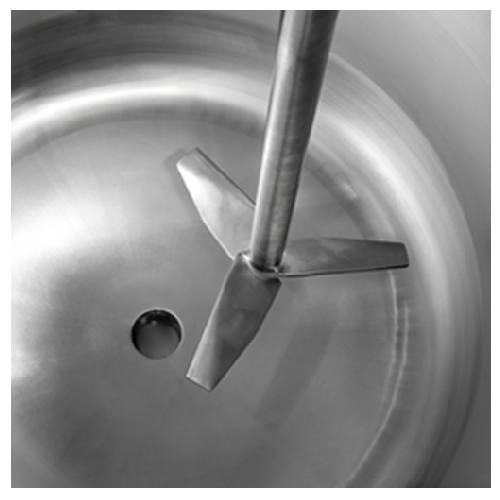

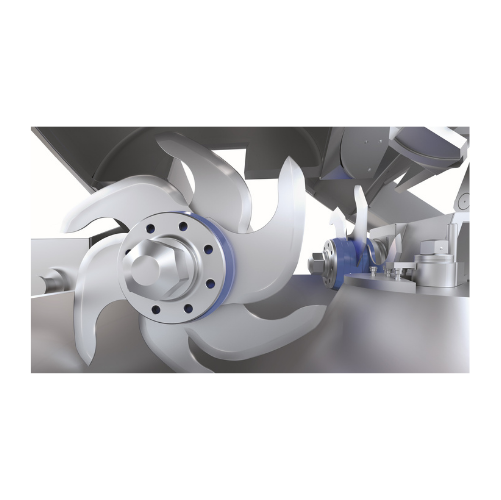

Emulsifying devices with high-speed rotors and impellers combine shearing and expanding forces to generate the turbulences needed to mix the liquids and combine them in a emulsion state.

Alternative mixing equipment to achieve emulsification

Although there are special emulsification machines, mixing technology like high-pressure homogenizers, agitators, and high-shear mixers can produce a similar result with immiscible ingredients.

There is a wide range of emulsification equipment available. Machines operate in continuous or batch processes and from lab to industrial scale. The common principle is that they cause mixing by subjecting ingredients to very high speeds.

Blend food ingredients with specialized mixing equipment

Mixing equipment for food varies depending if the ingredients are solids, liquids, or a mix of both. Another important consideration is whether the food mass is wet or dry.

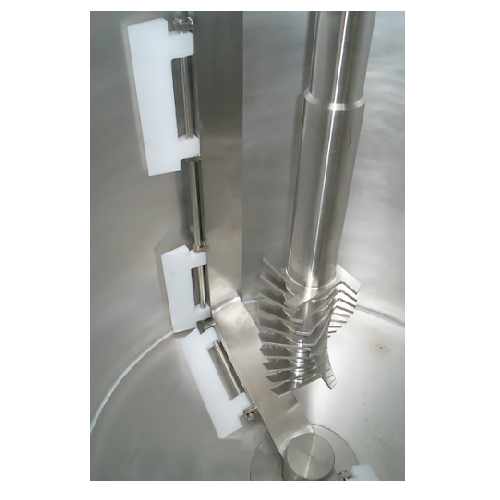

Vertical and horizontal mixers can handle most types of materials. The main difference in the mixing method is that vertical mixers allow ingredients to scatter by gravity. Horizontal mixers, in contrast, drive the parts from one end to the other using ribbons or paddles. Most mixers, however, are engineered for a specific product type. Kneaders, for example, are designed for dough mixing, while blending systems are for mixing dry powders like fruit extracts or spices.

Feed mixing solutions can be used for dry and wet ingredients

Ingredients for feed products are processed dry (powders) or wet (feed mashes). But apart from the consistency and moisture content, mixing technology needs to consider other factors.

The main three parameters are the sensitivity of the ingredients, the process temperature, and the pressure requirements. Mixing technology is designed to handle each of these differently, and the more complex the final product is, the more specific the mixer needs to be.

What are you making?

Automotive tires

3d lollipops

Acetone

Acrylic coatings

Acrylic emulsions

Acrylic paint

Acrylic sealants

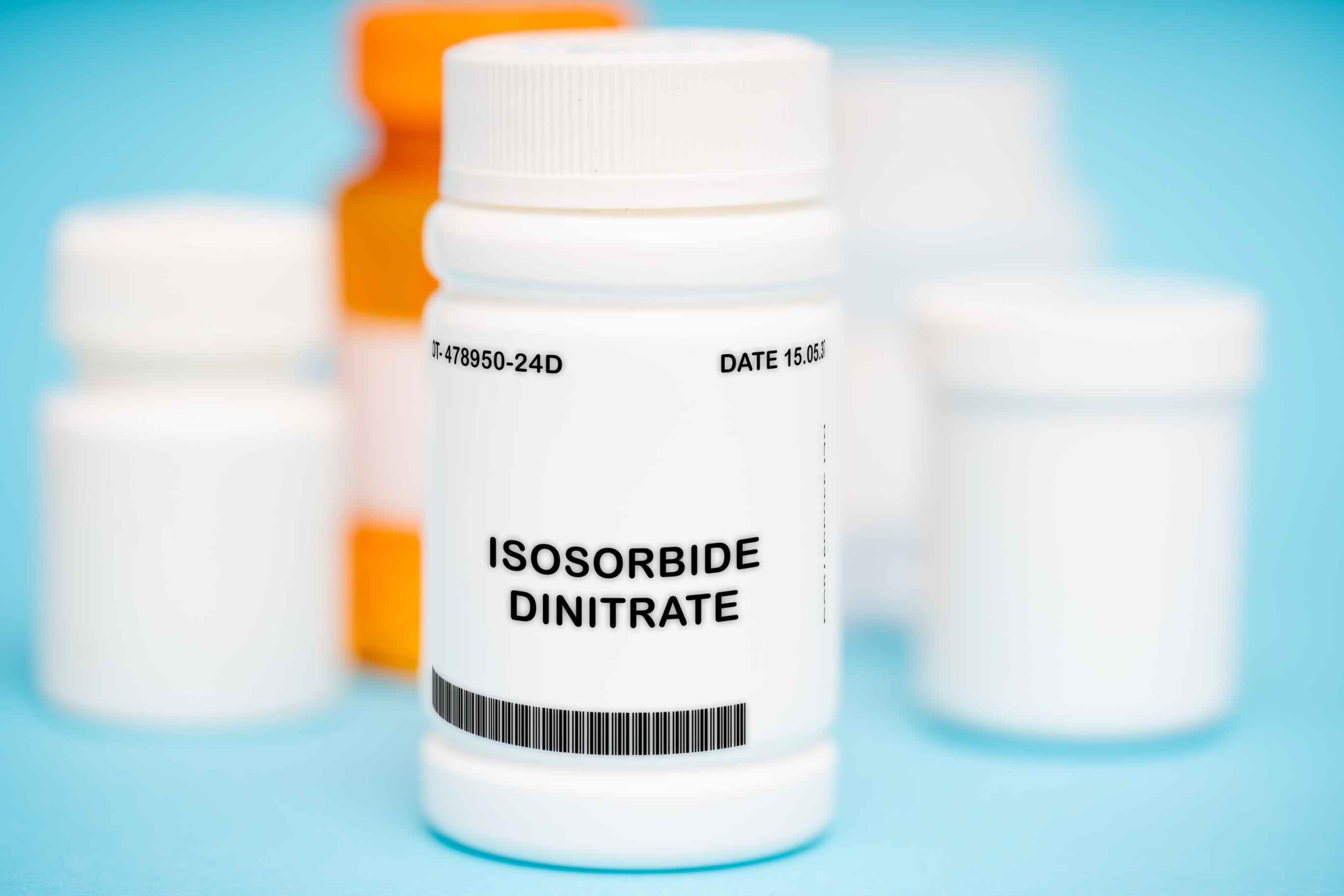

Active pharmaceutical ingredients (API)

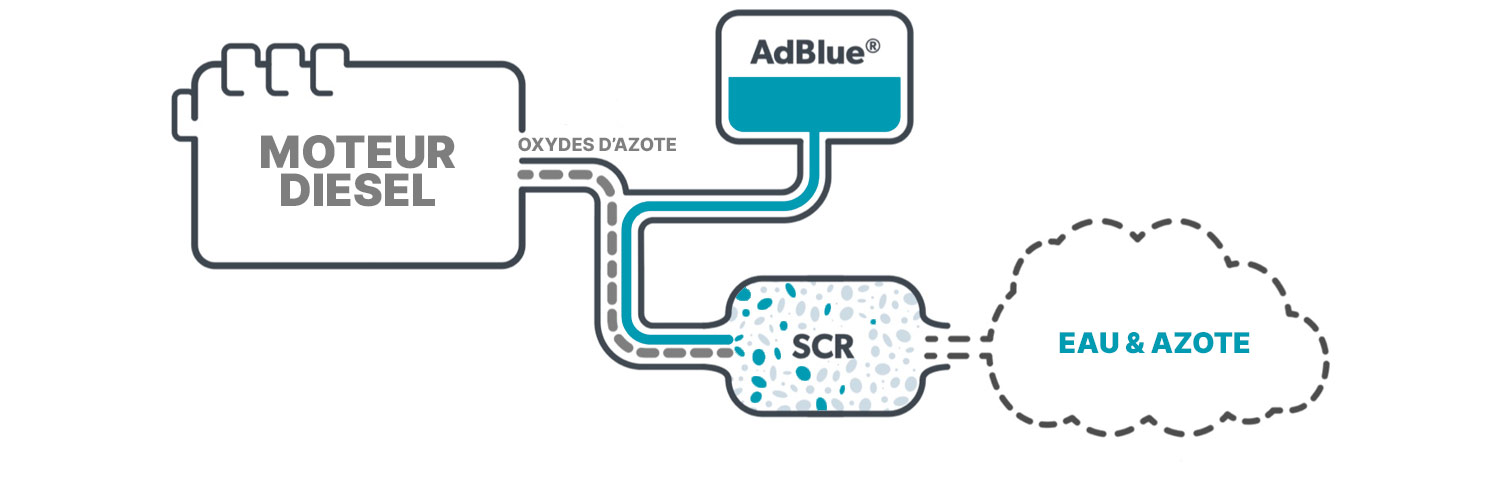

Adblue

Advanced ceramics

Aerated chocolate

Aerosols

Aerospace coatings

Agglomerates

Agrochemicals

Aioli

Alfredo sauce

All-purpose flour

Alloys

Almond butter

Aluminium oxide

Anhydrous pastes

Animal feed

Animal feed additives

Animal health products

Anode and cathode materials

Anti-corrosion coatings

Anti-dandruff shampoo

Anti-friction coatings

Antibiotic powders

Antibiotic tablets

Antihistamine tablets

Antioxidant supplements

Antiseptic solutions

Api suspensions

Apple chips

Apple compote

Apple concentrate

Apple juice

Apple pies

Apricot puree

Aquafeed

Aromas

Aromatherapy oils

Artificial sweeteners

Artisan bread

Artist colors

Aspartame

Asphalt

Aspirin

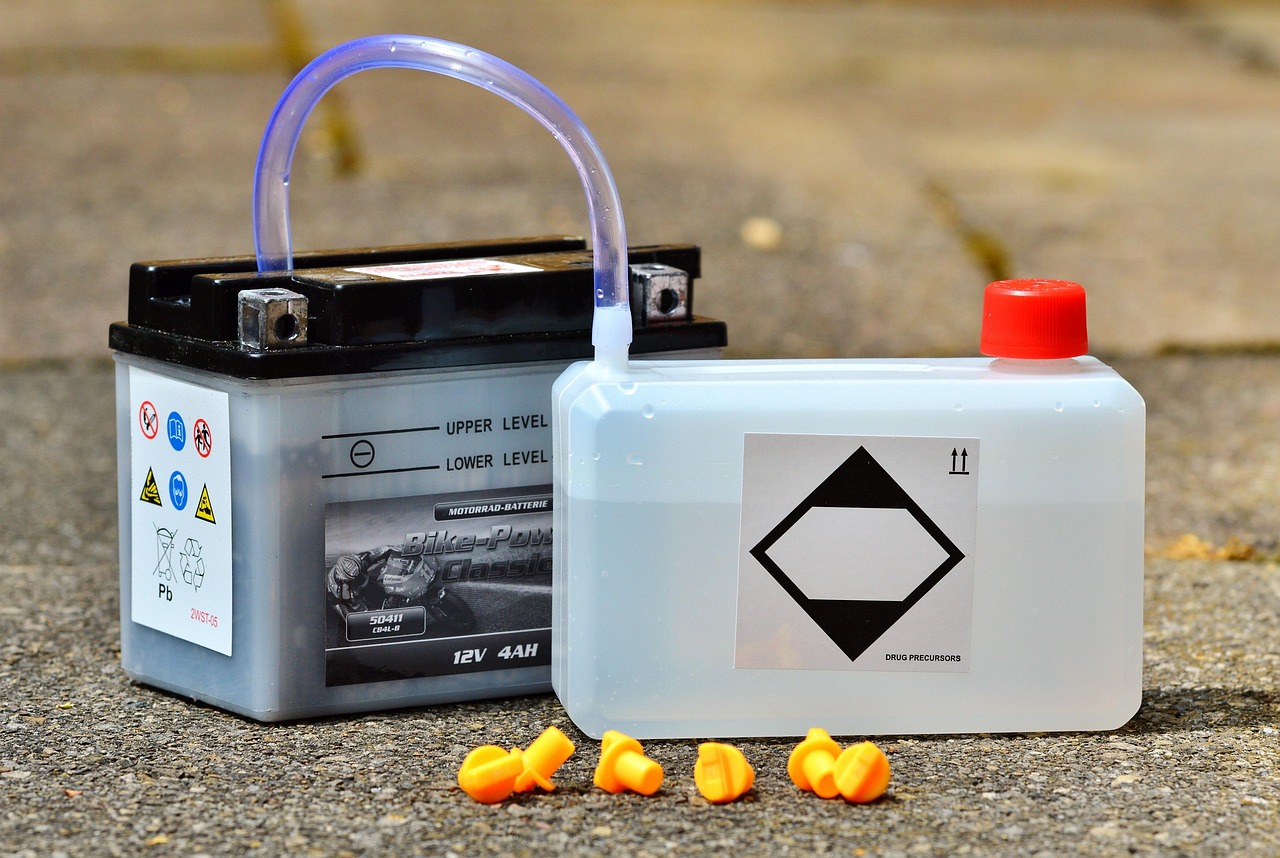

Automotive batteries

Automotive catalysts

Automotive paints

Ayran

Baby Food

Baby wipes

Bagels

Baked goods

Baker's yeast

Bakery fillings

Bakery ingredients

Bakery mixes

Baking powder

Baking soda

Ball donuts

Banana chips

Banana puree

Bananas

Bao

Barbecue sauce

Batter

Battered fish fillets

Battered nuts

Battered onion rings

Battery electrodes

Bavarois

Bb cream

Beauty products

Bechamel sauce

Beef gravy

Beef jerky

Beef patties

Beetroot juice

Bentonite clay

Benzene

Beverage concentrates

Beverage ingredients

Bioplastics

Bioactive compounds

Biochemistry

Biocides

Biodegradable plastics

Biodegradable polymers

Bioenergy

Bioethanol

Biofuel

Biogas digestate

Biomass briquettes

Biomass pellets

Biopolymers

Biscotti

Biscuits

Blueberry jam

Blueberry muffins

Bocconcini

Body care

Body lotion

Body wash

Bolognese sauce

Chocolate bonbons

Botanical extracts

Botanical medicine

Bouillon cubes

Bran flakes

Brandy

Bratwurst

Bread

Bread loaves

Bread mix

Bread spreads

Breaded products

Breadings

Breadsticks

Breakfast cereals

Brick

Brines

Brioche

Briquettes

Brittles

Broth

Broths

Brown sugar

Brownies

Bubble gum

Buffer solutions

Building materials

Bulk chemicals

Burrata

Butter

Butter biscuits

Buttercream

Buttermilk

Cabernet sauvignon

Caesar salad dressing

Cake

Cake mixes

Calcium phosphate

Candy coatings

Cannabis candy

Cannabis edibles

Canned cat food

Canned dog food

Canned soft drinks

Canned soup

Canned tuna

Caplets

Car tires

Caramel

Carbon black

Carbon materials

Carbon nanotubes

Carbonated beverages

Carbonated soft drinks (csd)

Carrot puree

Cashew milk

Casting compounds

Catalyst powders

Catalysts

Cathode materials

Cattle feed

CBD gummies

Celery juice

Cell and tissue culture

Cell culture

Cell culture media

Cement

Cement additives

Cement blocks

Ceramic glazes

Ceramic pigments

Ceramic powders

Ceramic tiles

Cereal bars

Cereal grains

Cereals

Chalk

Chapati

Cheese crackers

Cheese puffs

Cheese sauce

Cheese shreds

Cheese slices

Cheese spread

Cheese spreads

Cheese sticks

Cheese wheels

Cheesecake

Chemical additives

Chemical catalysts

Chemical compounds

Chemical emulsions

Chemical granules

Chemical intermediates

Chemical powders

Chemical solvents

Chemical suspensions

Chemistry

Chemotherapy drugs

Chestnut puree

Chewable tablets

Chewing gum

Chewing gum sticks

Chicken feed

Chicken manure

Chicken mince

Chicken nuggets

Chicken tenders

Chili powder

Chili sauce

Chocolate bars

Chocolate coatings

Chocolate fillings

Chocolate milk

Chocolate mousse

Chocolate spread

Chocolate spreads

Cider

Cleaning agents

Cleaning wipes

Coated nuts

Coated seeds

Coated tablets

Cocoa powder

Coleslaw

Color masterbatches

Colorants

Concrete

Concrete additives

Concrete admixtures

Concrete mixtures

Condensed milk

Condiments

Conditioner

Conductive additives

Conductive coatings

Conductive inks

Confectionery coatings

Confectionery fillings

Construction chemicals

Consumer electronics

Convenience foods

Cookie dough

Cookies

Cooking cream

Copper sulfate

Corn puffs

Corn tortillas

Cosmetic creams

Cosmetic emulsions

Cosmetic foundation

Cosmetic lotions

Cosmetic powders

Cosmetic serums

Cottage cheese

Cottonseed meal

Cough syrup

Couscous

Crab cakes

Crackers

Cream cheese

Cream crackers

Cream fillings

Cream puffs

Creams

Crispbread

Crispies

Croissants

Crop protection agents

Croutons

Culture media

Cupcakes

Curd

Curd cheese

Cured meats

Curry paste

Curry powder

Custard

Dark chocolate

Dental

Deoderant

Deodorants

Desserts

Detergent pods

Detergent powder

Detergent tablets

Dextrose

Diagnostic reagents

Dietary supplements

Digestive biscuits

Digital printing inks

Dijon mustard

Dips

Dishwasher tablets

Dishwashing liquid

Dishwashing powder

Dispersion paints

Dog biscuits

Dog food

Dog treats

Donuts

Dough

Dragees

Dressings

Dried distillers grains (DDGS)

Dried sausage

Drinks

Drug formulations

Dry pet food

Dry powder inhalants (dpi)

Dry powders

Drymix building materials

Drywall

Dumplings

Dyes

Eardrops

Echinacea extract

Eclairs

Effervescent granules

Effervescent tablets

Egg noodles

Egg rolls

Eggs

Elastomers

Elderberry extract

Electrolyte drinks

Electrolyte solutions

Electronic materials

Emulsifiers

Emulsion paints

Emulsions

Energy bars

Engine oils

Engineering plastics

Enteric Coated Tablets

Enzyme catalysts

Epoxy adhesives

Epoxy coatings

Epoxy resin

Er tablets

Eucalyptus oil

Excipients

Extended-release tablets

Extrudates

Extruded aquafeed

Extruded cereal

Extruded snacks

Eyedrops

Eyeshadow

Fabric softener

Fabricated chips

Face cream

Face powder

Facial moisturizers

Fat-based compounds

Feed additives

Feed concentrates

Feed premixes

Fertilizer pellets

Fettuccine

Filled croissants

Fillings

Film-coated tablets

Filter coffee

Firebricks

Fish feed

Fish fingers

Fishmeal powder

Flakes

Flame retardants

Flatbread

Flavor enhancers

Flavor extracts

Flavored mineral water

Flavoring agents

Flavors

Flavoured milk

Floating pellets

Flower extract

Fluoride toothpaste

Foam

Foam kisses

Focaccia

Fodder

Fondant

Fondant icing

Food additives

Food colorants

Food flavorings

Food ingredients

Food powders

Food preservatives

Food supplements

Formulated dairy products

Foundation cream

Fragrance compounds

Fragrance oils

Fragrances

Frosting

Frozen beef patties

Frozen croissants

Frozen desserts

Frozen dough

Frozen yogurt

Fruit bars

Fruit chews

Fruit jam

Fruit jellies

Fruit juice

Fruit pastes

Fruit pies

Fruit powder

Fruit preserves

Fruit punch

Fruit puree

Fruit salad

Fruit syrups

Fruit yogurt

Fudge

Functional drinks

Functional foods

Fungicides

Fusilli pasta

Ganache

Garlic

Gel nail polish

Gelatin desserts

Gels

Gingerbread biscuits

Ginkgo extract

Ginseng extract

Glass

Glass cleaner

Gloss varnish

Glue

Gluten-free bread

Gluten-free flour

Glycerin suppositories

Glyphosate herbicides

Granola

Granola bars

Grape Juice

Graphite anodes

Gravy

Green beans

Ground coffee

Guacamole

Gummy Bears

Gypsum board

Hair conditioner

Hair gel

Halloumi

Halva

Hamburger buns

Hand cream

Hand sanitizer

Hand soap

Hard Candy

Hard gelatin capsules

Hard lemonade

Hard seltzer

Hash Browns

Hazelnut spread

Herbal Extracts

Herbal medicines

Herbal supplements

Herbal tinctures

Herbicides

Herbs

High-fructose corn syrup

High potent drugs

Hollandaise sauce

Home care products

Homeopathy

Honey

Hormonal injections

Hormone therapies

Hormones

Hot melt adhesives

Hot melt glue sticks

Hot sauce

Household detergents

Hummus

Hyaluronic acid

Hyaluronic acid serums

Hydraulic oil

Hydrocolloids

Hydrocortisone cream

Hygiene products

Ibuprofen

Ice cream

Ice cream bars

Ice cream cakes

Ice cream cones

Ice cream cups

Ice cream sandwiches

Ice cream tubs

Iced coffee

Icing

Immediate-release tablets

Infant formula

Infant nutrition

Infusions

Inhalers

Ink

Inorganic chemicals

Insecticides

Instant coffee

Instant drink powders

Instant soup

Intermediates

Intravenous solutions

Iron oxide pigments

Iron supplements

Isotonic drinks

Italian dressing

Jam

Japanese peanuts

Jellies

Jelly

Jelly beans

Juice cartons

Kaiser rolls

Kebap

Kefir

Ketchup

Kettle chips

Kibble

Kielbasa

Kimchi

Kombucha

Lacquers

Lactic acid

Lactose

Lactose-free milk

Laminated dough

Large volume parenterals

Lasagna

Laser printer toner

Laundry detergent

Lavender oil

Layered cakes

Lecithin

Lemon curd

Lemonade

Lentil chips

Licorice

Linguine

Lip balm

Lip gloss

Liposomes

Lipstick

Liqueurs

Liquid detergents

Liquid egg products

Liquid foods

Liquid Formulations

Liquid nutritional supplements

Liquid soap

Soup liquids

Liquid supplements

Liquid sweeteners

Lithium-ion battery anodes

Lithium-ion battery cathodes

Livestock feed

Loaves of bread

Lollipops

Longmoulded rolls

Lotions

Lubricants

Luncheon meat

Macaroni

Macaroni and cheese

Macarons

Malt extract

Malt rings

Maltodextrin

Mango chutney

Mango juice

Mango pulp

Mango sorbet

Margarine

Margherita pizza

Marinades

Marinara sauce

Marmalade

Marshmallows

Marzipan

Masa

Mascara

Mascarpone

Mash

Masterbatches

Mayonnaise

Meat alternatives

Meat analogs

Meat and bone meal

Meatballs

Meatloaf

Medical gummies

Medicine

Metal powder

Micro-tablets

Microtablets

Milk chocolate

Milk powder

Minced meat

Mineral slurries

Mineral supplements

Mixed nuts

Mixed salad bags

Mixed vegetable packs

Mochi

Moped tires

Mortadella

Mortar mix

Mosquito repellent

Mousses

Mouthwash

Mozzarella

Muesli

Muesli bars

Muffins

Multi-layer tablets

Multigrain bread

Multivitamin supplements

Mustard

Naan bread

Nacho chips

Nail polish

Nanoemulsions

Nasal spray

Natural food colorants

Natural paints

Nectar

Nitrogen fertilizer

Non-carbonated beverages

Noodles

Nougat

Nuggets

Nut bars

Nut brittle

Nut butter

Nutritional drinks

Nutritional formula

Nutritional shakes

Oat milk

Oatmeal cookies

Ointment

Olive paste

Olives

Ophthalmics

Oral liquid formulations

Orange marmalade

Paint

Pancakes

Panettone

Panna cotta

Paratha

Parenterals

Pasta sheets

Pastes

Pastries

Pastry cream

Patties

Pcr reagents

Peanut butter

Pectin jellies

Pellet fuel

Pellet snacks

Pelleted feed

Penne pasta

Pepperoni

Perfume

Pesto

Pet care

Pharmaceutical creams

Pharmaceutical emulsions

Pharmaceutical granules

Pharmaceutical ointments

Pharmaceutical suspensions

Pharmaceutical syrups

Phosphorus fertilizer

Pie

Pita bread

Frozen pizza

Pizza

Pizza dough

Plant-based cheese

Plant-based meat

Plant-based protein

Plaster

Plaster of paris

Plasterboard

Plastic intermediates

Plastic resins

Plasticizers

Polenta

Polyester resin

Polyethylene

Polyethylene film

Polyethylene granules

Polyethylene pellets

Polyethylene powder

Polymer dispersions

Polymer emulsions

Polymer granules

Polymer pellets

Polymer powders

Polymer resins

Polymers

Polyolefins

Polypropylene

Polypropylene granules

Polypropylene pellets

Polystyrene beads

Polyurethane adhesives

Polyurethane coatings

Polyurethane foam

Polyurethane varnish

Popcorn

Porcelain

Portland cement

Potash

Potato co-products

Potato croquettes

Potato starch

Poultry feed

Pound cake

Powder coating

Powder detergent

Powder dissolving

Powder for suspensions (PFS)

Pralines

Pre-cooked meals

Pre-dough

Pre-filled Syringes

Pre-packaged meals

Pre-packaged salads

Precast concrete

Pretzels

Primers

Pringles

Printer ink

Probiotic cultures

Probiotics

Protective coatings

Protein bars

Protein powder

Protein supplements

Pudding

Puff pastry

Quiche lorraine

Raisin rolls

Ramen noodles

Ranch dressing

Raw pet food

Ready meals

Reagents

Recombined milk

Red velvet cakes

Refill tablets

Refrigerants

Regenerative medicine

Rehydration solutions

Resin

Rice cakes

Rice crackers

Rice Crispies

Rice flour

Rice milk

Rice noodles

Rice pudding

Ricotta

Rituximab

Road marking paints

Rodenticides

Root beer

Rose oil

Rte cereals

Rubber

Rubber tires

Rye

Rye bread

Sachets

Salad dressing

Salads

Saline solutions

Salsa

Salted butter

Saltine crackers

Samosas

Sand

Sandwich cookies

Sandwiches

Sauerkraut

Saurkraut

Sausages

Savoury snacks

Scamorza

Schnitzels

Scones

Sea buckthorn oil

Sealants

Seasonings

Seaweed

Seed coatings

Semi-solids

Semolina

Serums

Sesame oil

Shampoo

Sheet cakes

Ship paints

Shortbread

Shower gel

Shredded cheese

Shrimp crackers

Shrimp feed

Shumai

Silica

Silica gel

Silicone

Sinking pellets

Skin care

Slit rolls

Slow sinking pellets

Slurry

Small molecule drugs

Small volume parenterals

Snack bars

Soap

Soap bars

Soda

Soft bread

Soft Candy

Soft caramels

Soft drinks

Softgel capsules

Solids

Solvents

Sorbet

Sorbitol

Sour cream

Sourdough bread

Soy protein powder

Soy yogurt

Spaghetti

Sparkling water

Specialty chemicals

Spelt bread

Spice blends

Spice pastes

Split peas

Sponge cake

Sport drinks

Sports nutrition

Spring rolls

Starch

Starch derivatives

Stews

Stick ice-cream

Stock cubes

Strawberries

Structural adhesives

Sublingual spray

Sugar

Sugar-coated sweets

Sugar-free gummies

Sugar solutions

Sugar substitutes

Sugar syrup

Sun care

Sunscreen

Supplements

Suppositories

Surface coating

Sushi rice

Suspensions

Sustained-release capsules

Sustained-release tablets

Sweeteners

Swiss rolls

Synthetic pigments

Synthetic rubber

Tablet coatings

Taco shells

Tagliatelle

Tangerine juice

Tapenades

Tapioca pearls

Tartar sauce

Tarts

Tea

Tea extracts

Tea tree oil

Technetium-99m radiopharmaceuticals

Technical ceramic

Tempeh

Terpenes

Test kits

Textile dyes

Textile fibers

Textured Vegetable Protein

Thc distillate

Thc gummies

Thc oil

Thermoplastics

Thickening agents

Thinners

Tinctures

Tire treads

Titanium dioxide

Toffees

Tofu burgers

Tomato juice

Tomato sauce

Tomato soup

Tomatoes

Toner

Tonic water

Toothpaste

Topical creams

Toppings

Torrone

Tortellini

Tortillas

Tostadas

Traditional chinese medicine

Trail mix

Treats

Truffle balls

Truffle cream

Truffles

Udon noodles

Uncoated tablets

Uv-curable inks

Vaccine adjuvants

Vaccines

Vanilla extract

Varnishes

Vegan burgers

Vegan cheese

Vegan ice cream

Vegan mayonnaise

Vegan meatballs

Vegan nuggets

Vegan sausage

Vegan sausages

Vegetable broth

Vegetable concentrates

Vegetable juice

Vegetable patties

Vegetable Puree

Vegetable soup

Vegetarian sausages

Veggie chips

Vermicelli

Veterinary

Veterinary antibiotics

Veterinary tablets

Veterinary vaccines

Vinaigrette dressing

Vinegar

Virgin olive oil

Vitamin C

Vitamin c supplements

Vitamin d supplements

Vitamin d3 supplements

Vitamin e supplements

Vitamin-enriched beverages

Vitamin gummies

Vitamin premixes

Vitamin water

Vitamins

Wafer biscuits

Wafer cups

Wafer rolls

Wafer sheets

Wafer sticks

Wafers

Waffles

Wall paint

Water-based paints

Water-ice lolly

Water-ice push-up

Waterproof mascara

Wax emulsions

Wet pet food

Wheat

Whey

Whey protein

Whey protein powder

Whipped butter

Whipped cream

White chocolate

Whitening toothpaste

Whole grain products

Wipes

Wood coatings

Wood varnish

Wort

Wraps

Xanthan gum

Yeast extract

Yogurt

Yogurt cultures

Yogurt parfaits

Zeolite catalysts

Zinc concentrate

Beating machines

Bin blenders

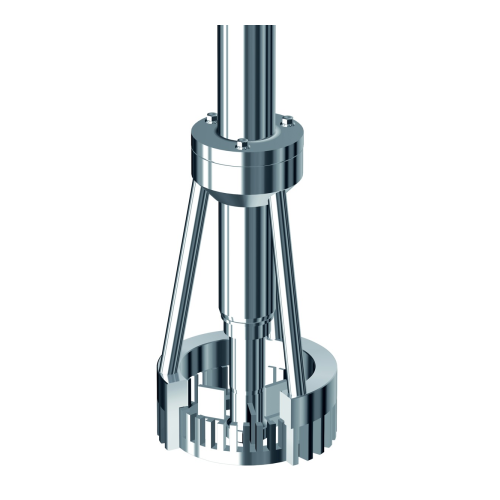

Bottom entry mixers

Colloid mills

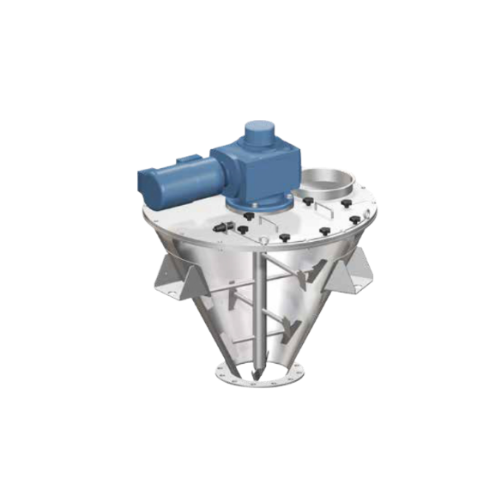

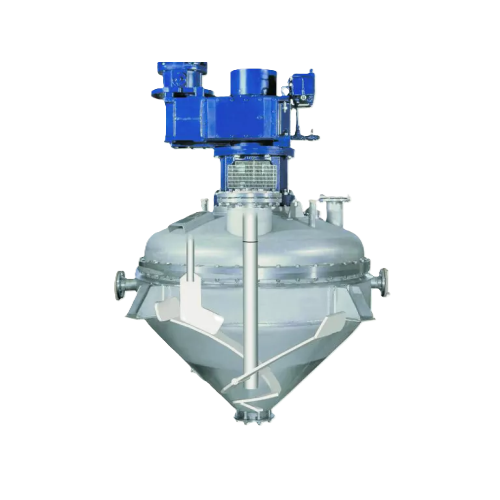

Conical powder mixers

Conical screw mixers

Cooling mixers

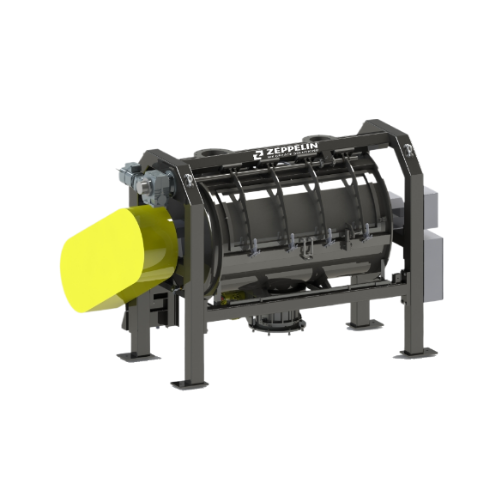

Double shaft mixers

Double shaft paddle mixers

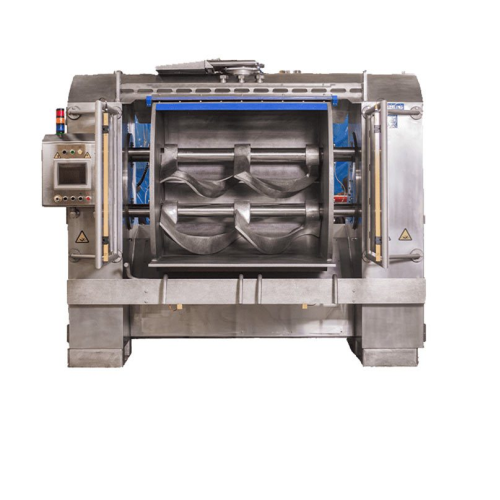

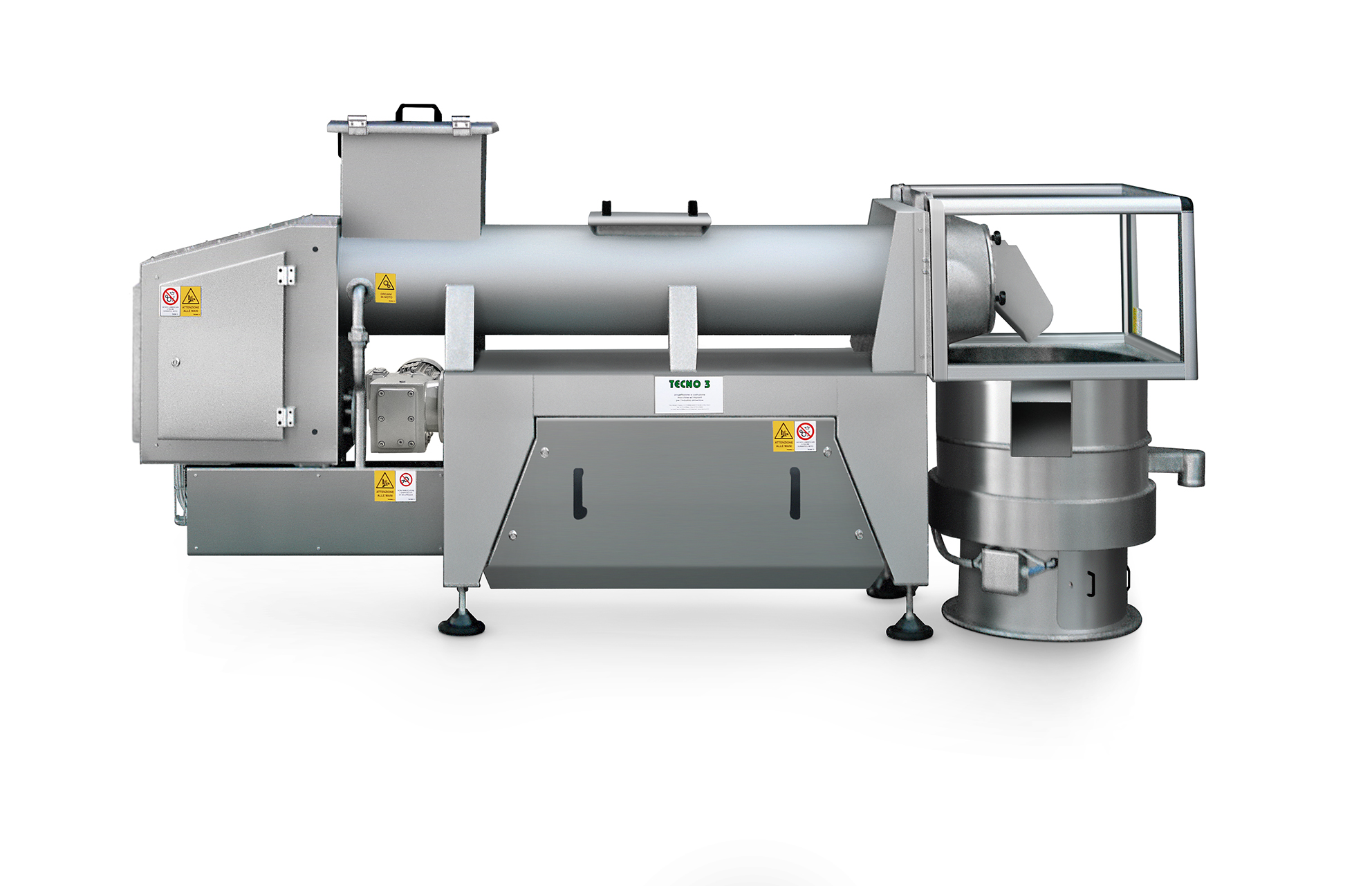

Double sigma arm mixers

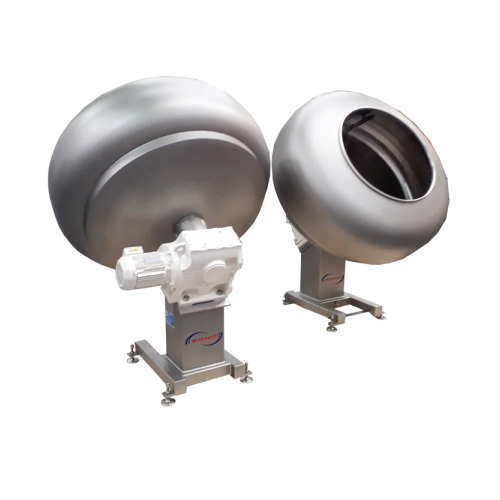

Drum roasters

Explosion-proof dissolvers

Flashmix powder/liquid mixers

Food Processors

Formulation vessels

High intensity mixers

High pressure homogenizers

High shear mixers

High viscosity mixers

High-shear mixers

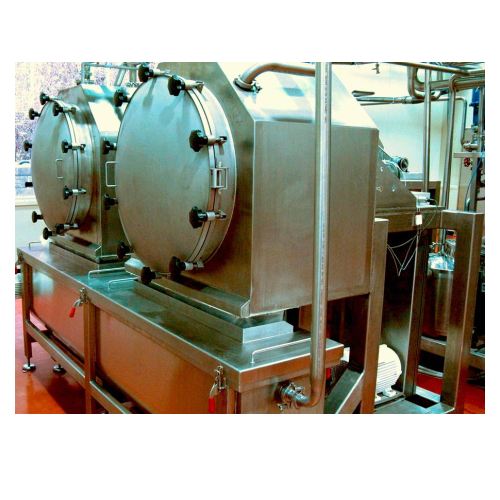

Industrial vacuum mixers

Ingredient dissolvers

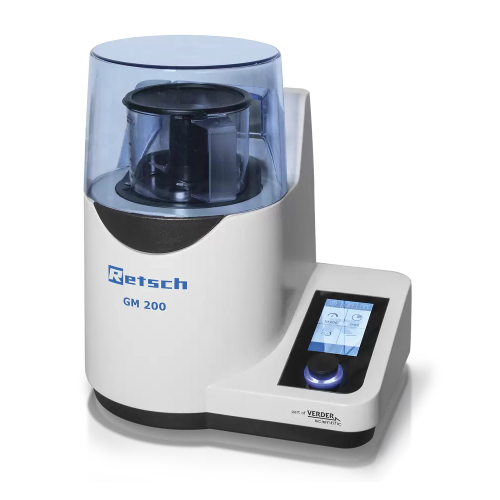

Laboratory homogenizers

Laboratory mixers

Magnetic mixers

Mixer grinders

Mixing kettles

Mixing vessels

Paddle mixers

Planetary mixers

Ploughshare mixers

Plow mixers

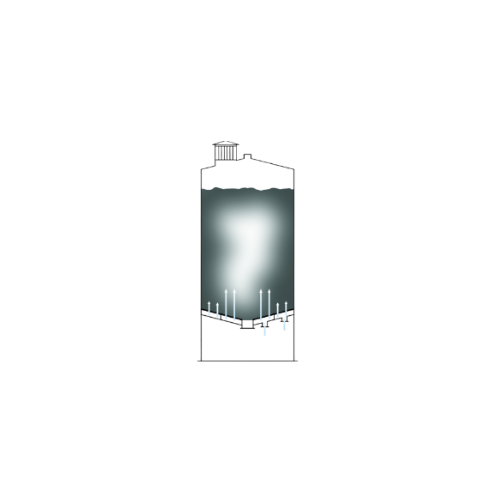

Radial jet mixers

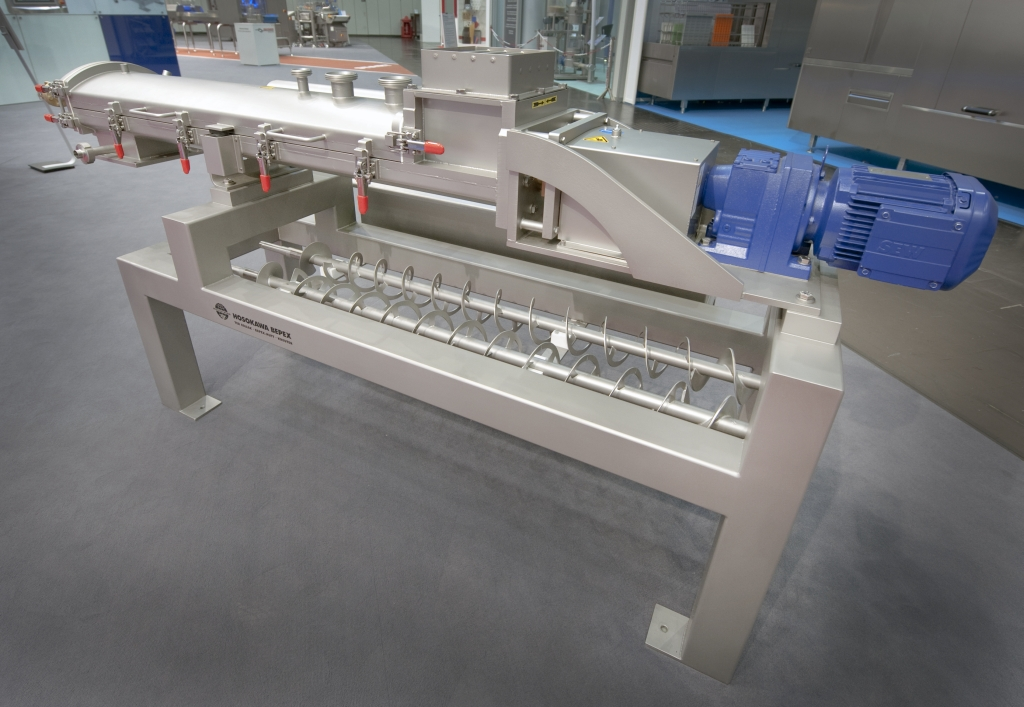

Ribbon blenders

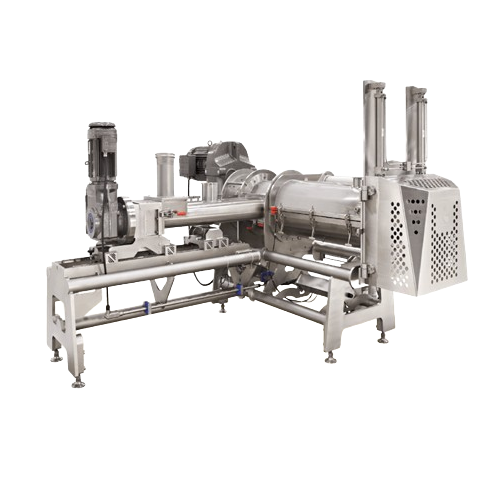

Rotary drum mixers

Sanitary mixers

Single sigma arm mixers

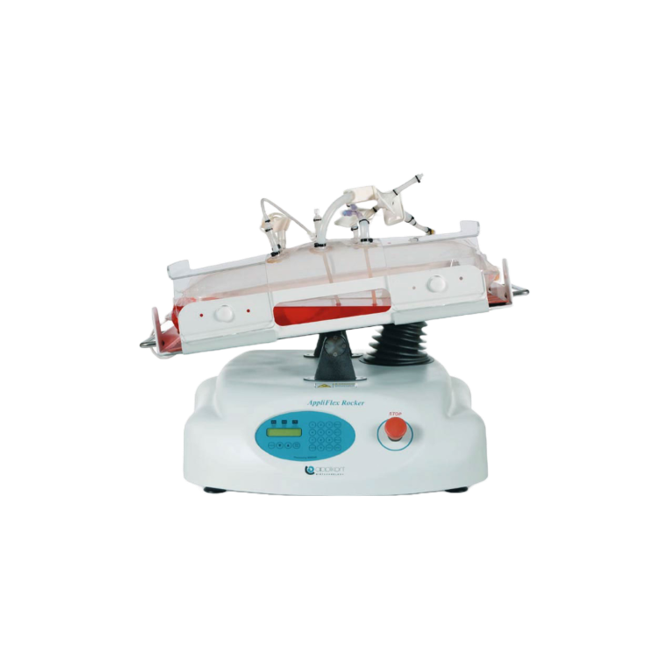

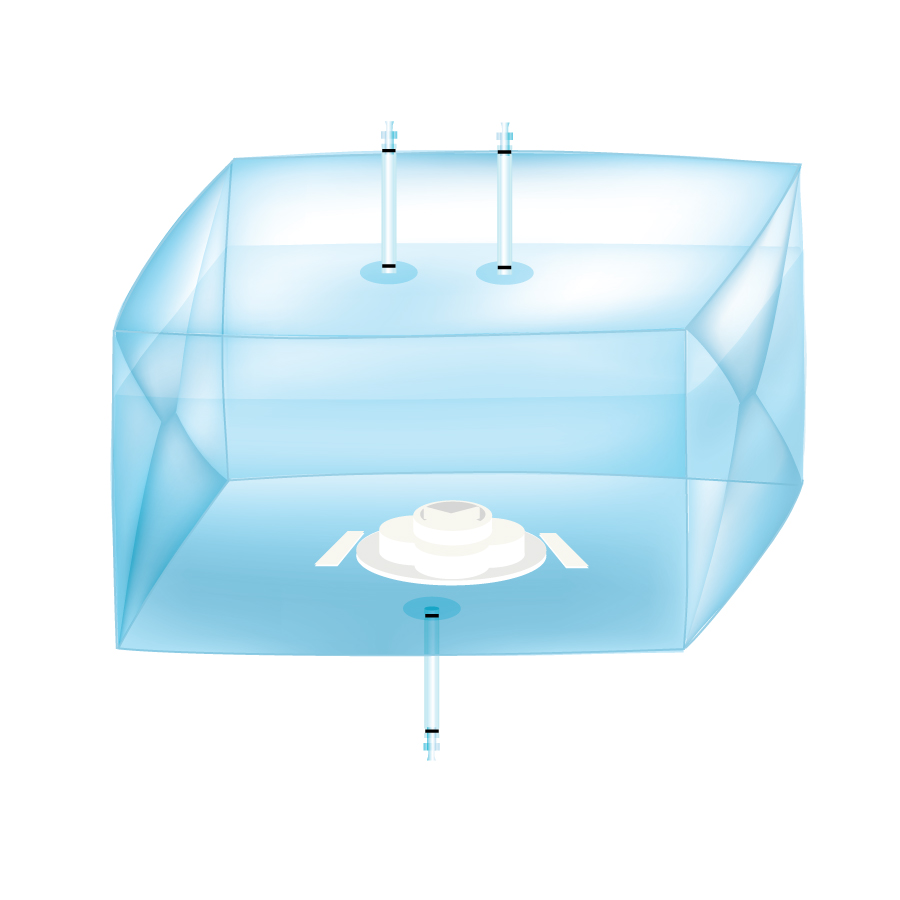

Single use systems

Single-shaft mixers

Single-use mixers

Slurry mixers

Spiral mixers

Top entry mixers

Triple roller bar mixers

Turbulent mixers

Ultramix mixers

Vacuum dispersion systems

Vacuum dissolvers

Vacuum evaporators

Vacuum mixers

Vertical mixers

Which mixing technology do you need?

Mixer-Settler for Solvent Extraction and Purification

For solvent extraction processes requiring longer residence times, ...

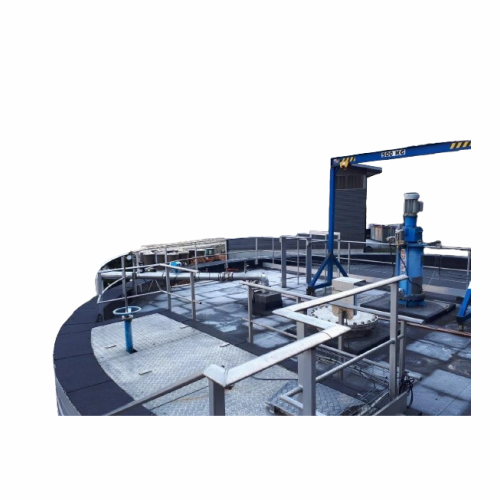

Liquid jet mixer for homogeneous tank mixing

Achieve efficient and consistent mixing in large storage tanks with this adva...

Mixing system for beer mix beverages

Enhance your beverage offerings with precise mixing and dosing systems designed to pro...

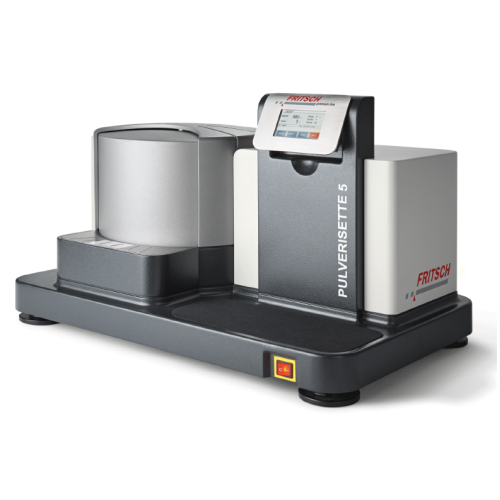

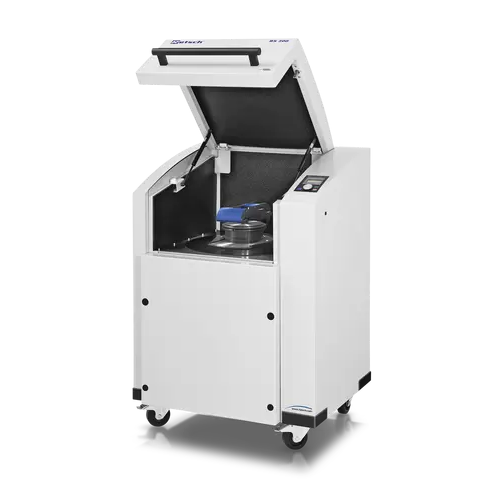

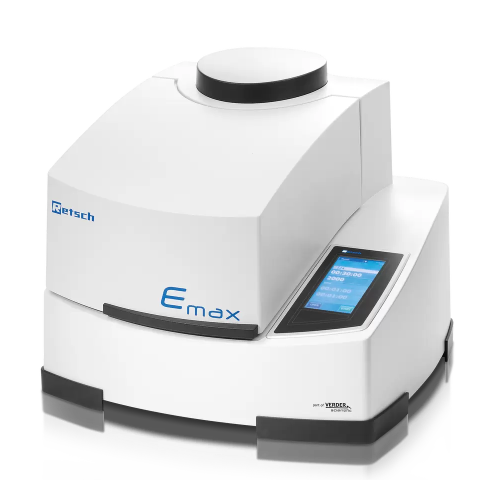

Laboratory mixer mill for small volume grinding

Designed for rapid homogenization and size reduction, this versatile mixer...

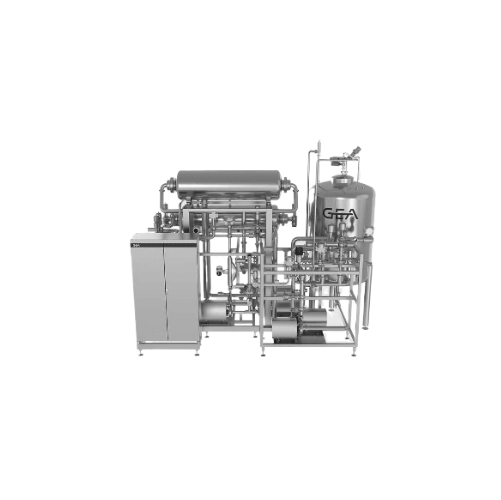

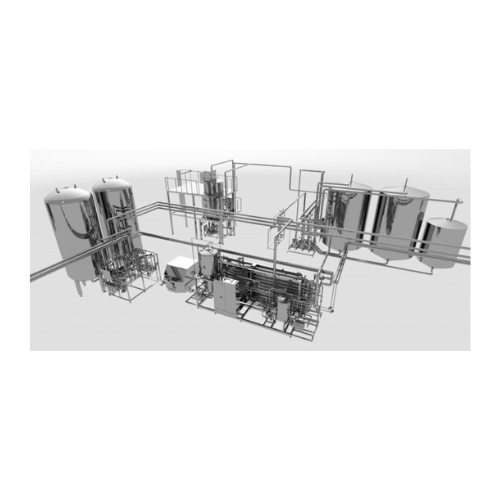

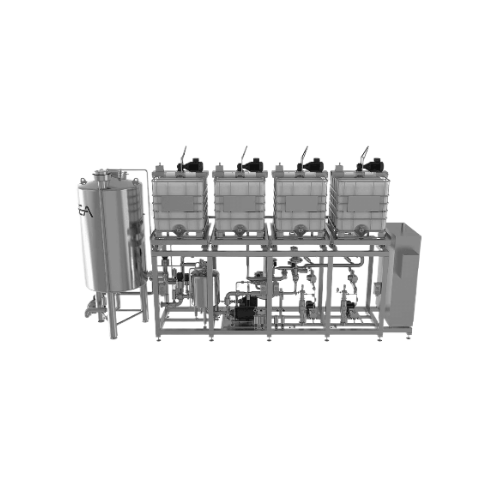

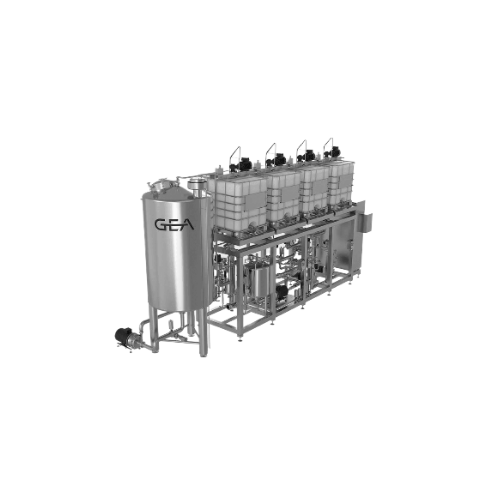

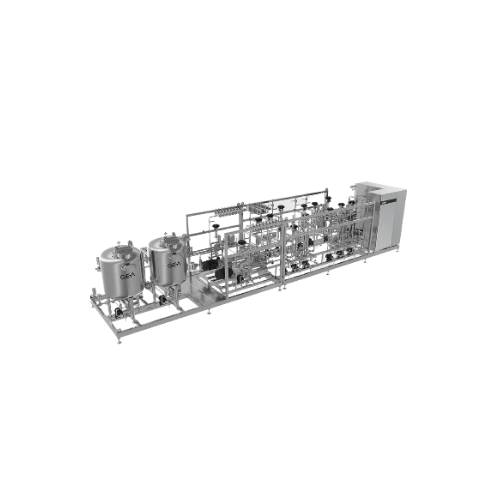

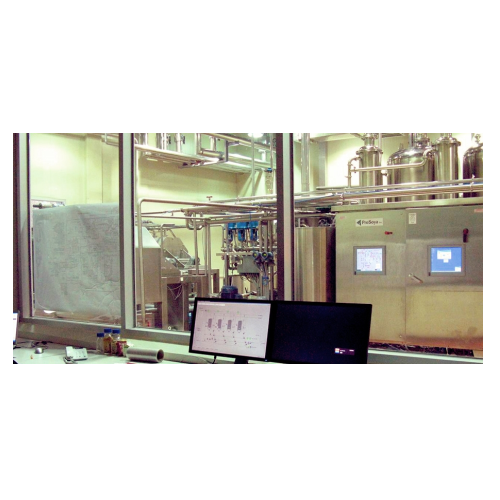

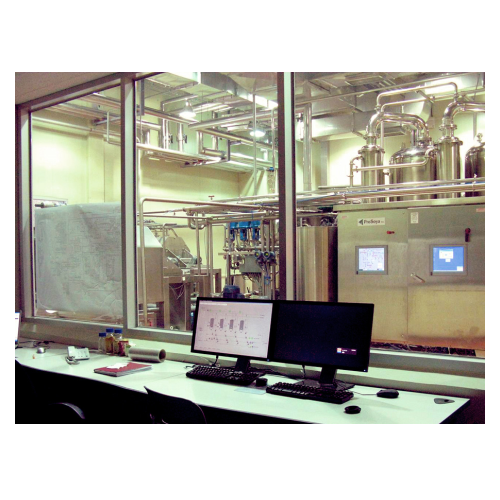

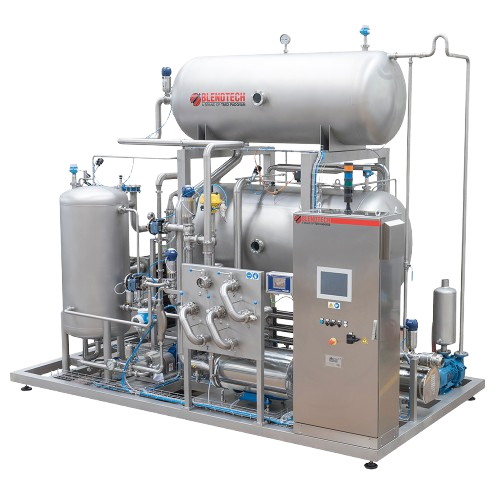

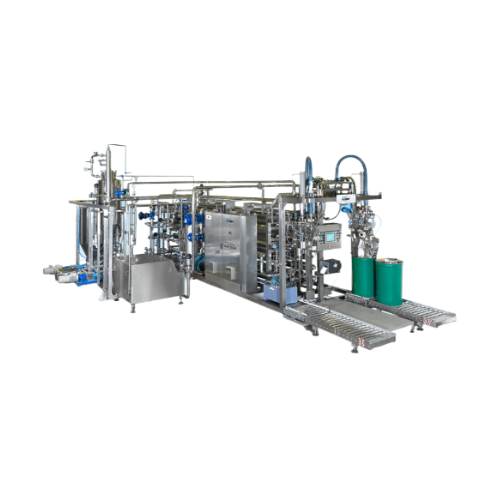

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

Vertical spindle mixer for dough processing

Optimize your dough consistency and quality with this vertical spindle mixer, ...

Continuous mixer for cookie and snack dough

Achieve uniform and consistent mixing of cookie and snack dough with seamless ...

Industrial mixer for various dough types

Efficiently mix a wide range of doughs with precise temperature control to achieve...

Continuous mixer for cookie dough

Achieve consistent dough quality and streamline your production with a continuous mixing ...

Continuous mixer for wheat-based products

Achieve consistent dough quality with minimal variation using a continuous mixer...

Industrial direct drive mixer for dough preparation

Optimize your production line with a robust mixer designed for seamle...

Multistage mixer for emulsions and dispersions

Enhance your production with a versatile multistage mixer that ensures opti...

Multistage mixers for emulsions and dispersions

Experience efficient emulsification and dispersion processes with this ver...

Ricotta smoothing mixer for dairy production

Achieve consistently smooth and perfectly blended ricotta with advanced mixin...

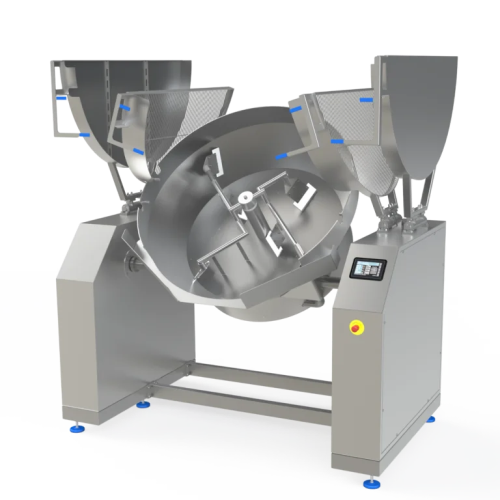

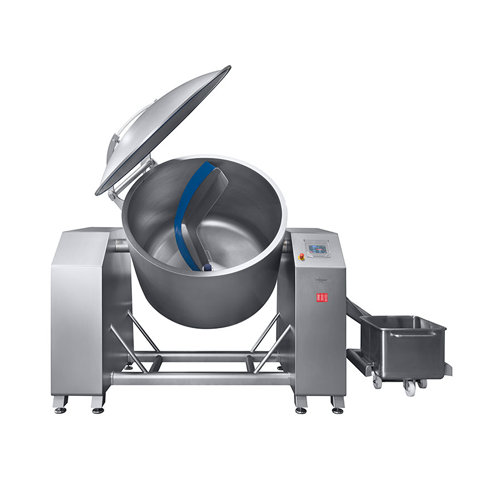

Melting and mixing kettles for chocolate production

Achieve consistent melting and mixing of chocolates, butter, and jams...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

Chocolate melting and mixing kettle for small-scale production

Streamline your confectionery production with a compact k...

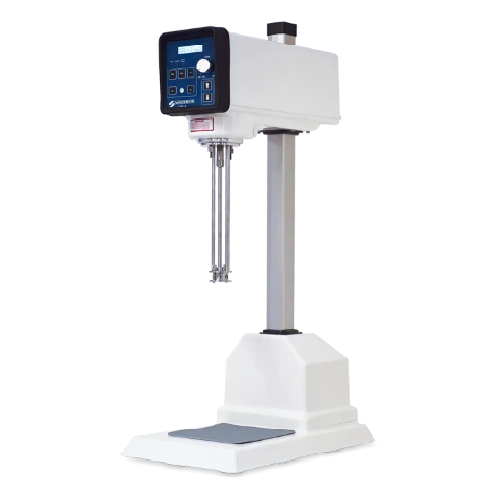

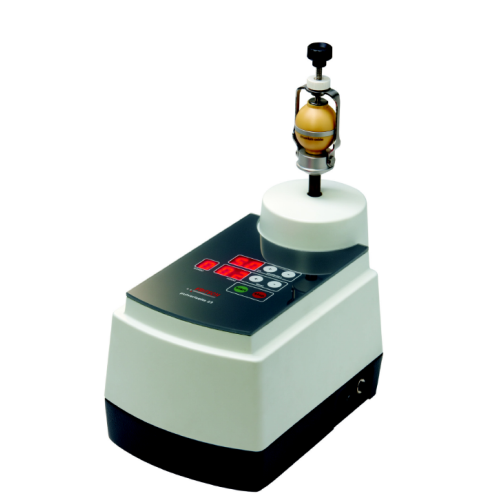

Analog stirring controller for precise lab mixing

Enhance control over your laboratory stirring processes with precise ma...

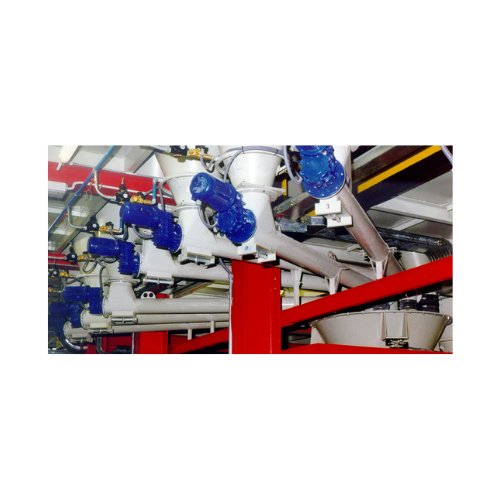

Industrial agitation and mixing solutions

Enhance your production line efficiency with engineered agitation and mixing sys...

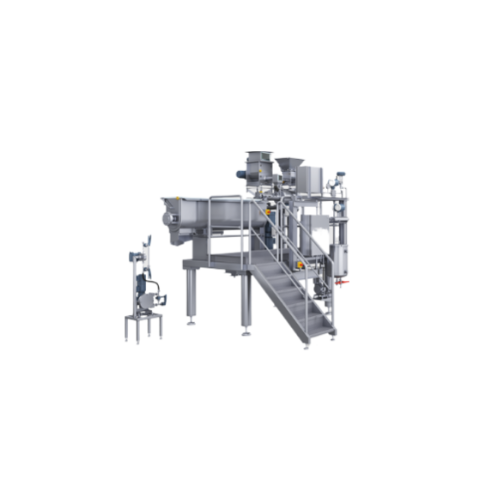

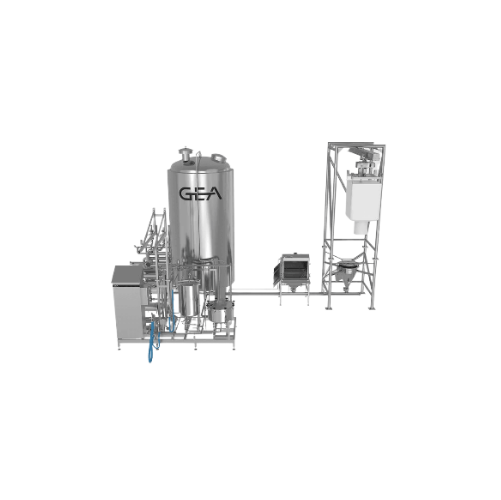

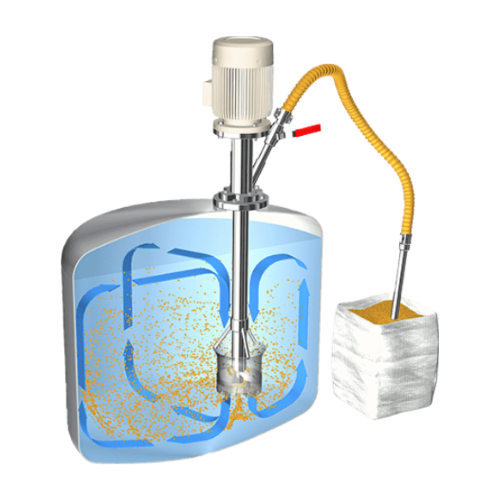

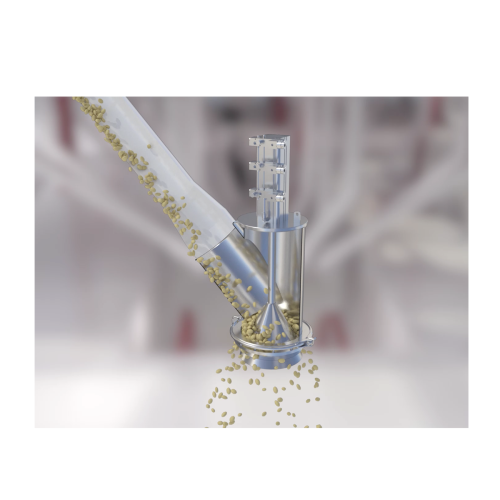

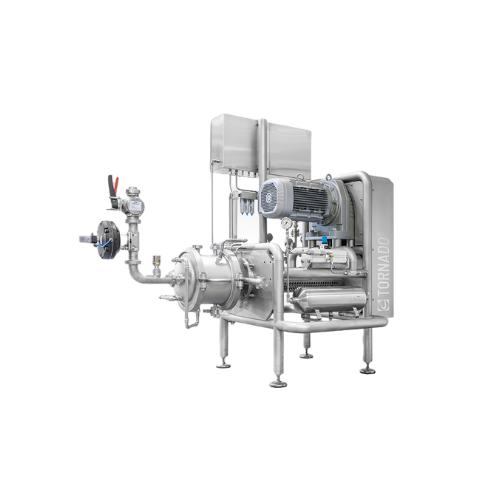

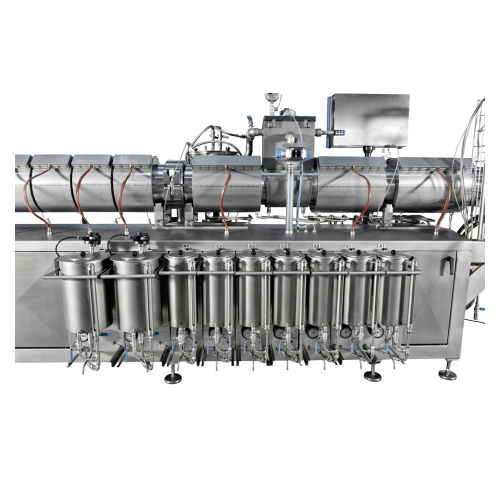

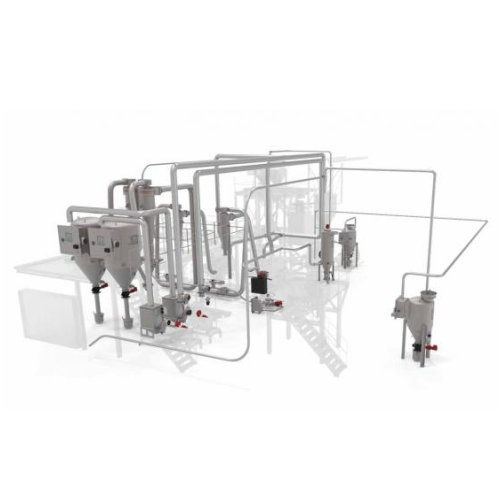

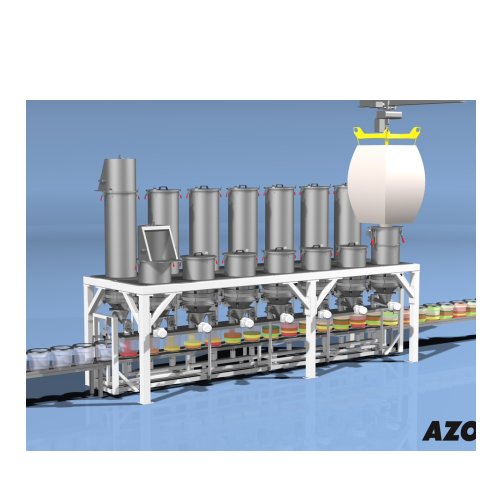

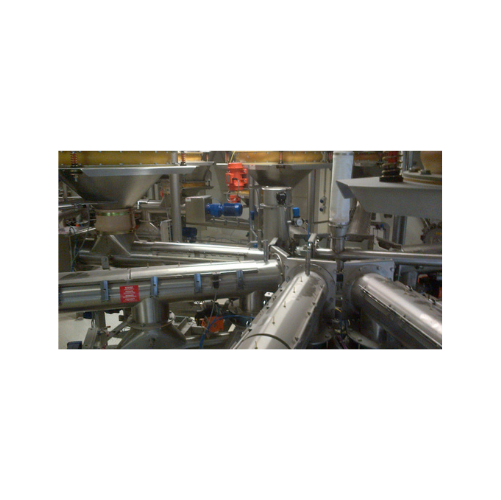

Powder and liquid mixing system for food and life sciences

Achieve rapid and homogeneous dissolution of large quantities...

Industrial premixing system for batch and inline processing

Streamline your production with advanced premixing systems d...

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Slurry mixer for cake batters and premix ingredients

Efficiently mix cake batters and premix ingredients with precision, ...

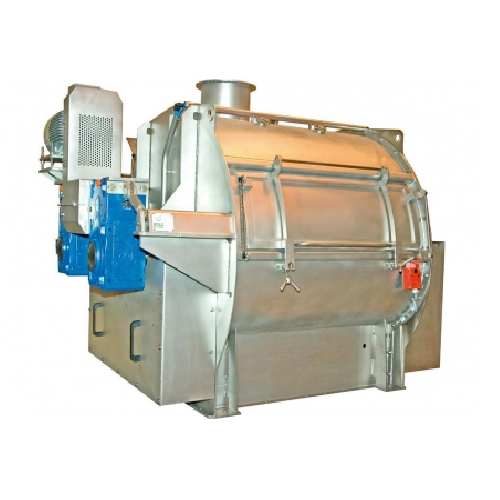

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

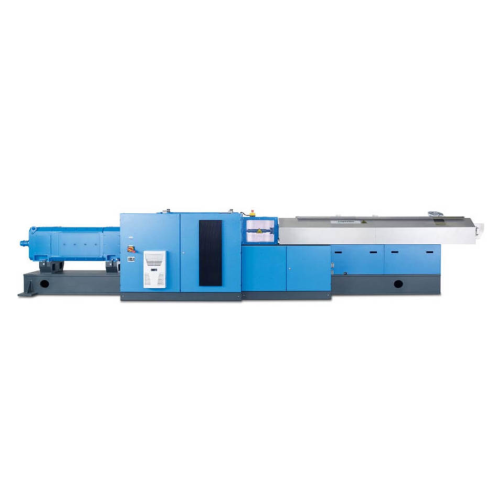

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Continuous mixer for batters and cremes

Achieve consistent texture and uniform cell structure in your cake batters and crèm...

Premix system for alcoholic beverage preparation

Enhance your beverage production with precision mixing and carbonation, e...

Wine carbonator with static mixer

Achieve precise CO2 saturation with a sintered stainless steel static mixer, mimicking a ...

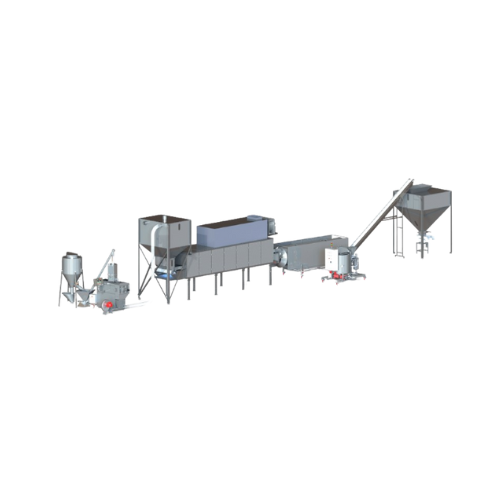

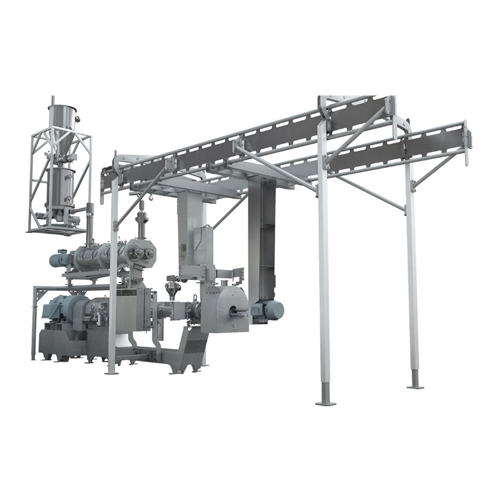

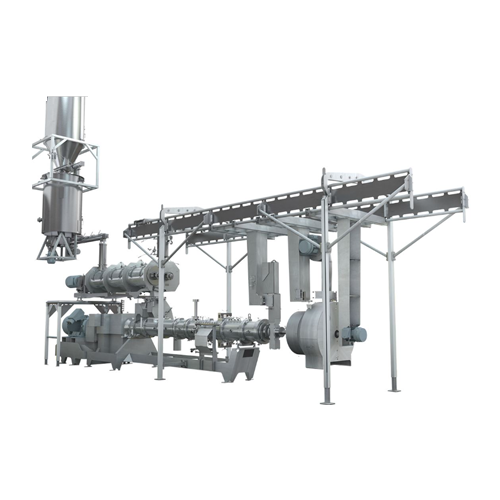

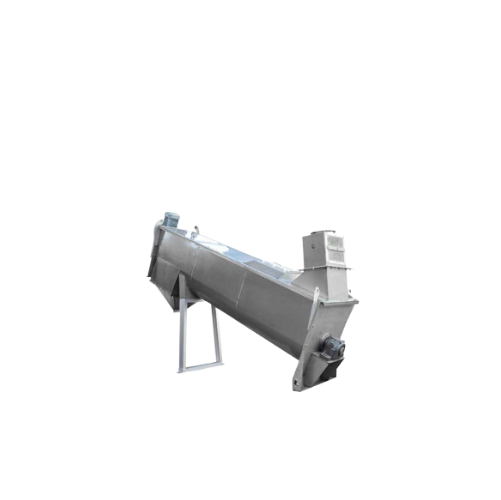

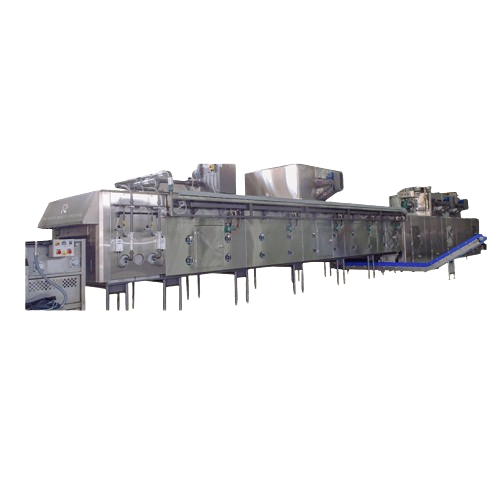

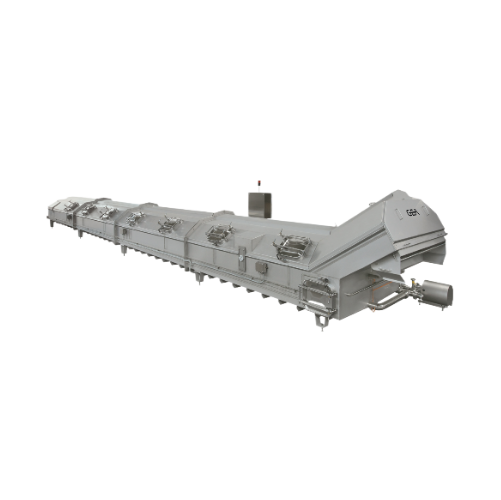

Continuous mixers for feed mill applications

Optimize your liquid incorporation process with continuous mixers that ensure...

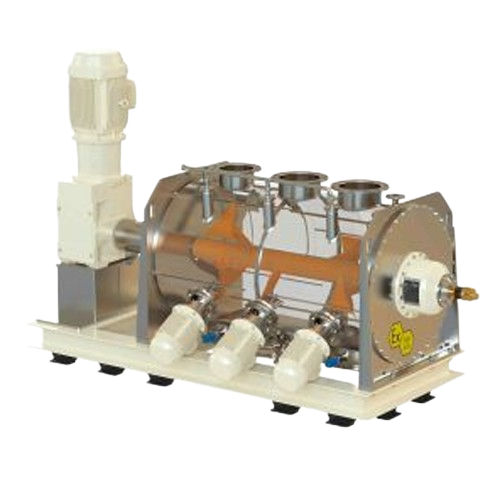

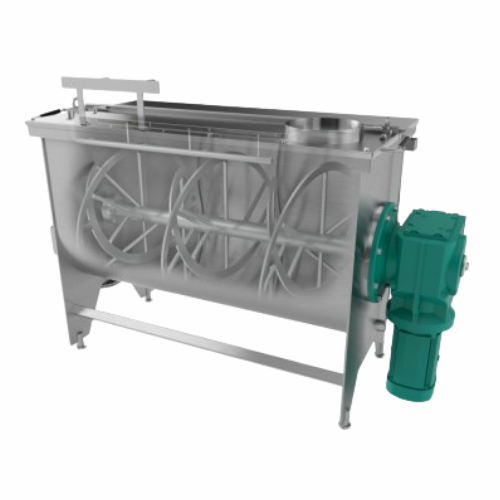

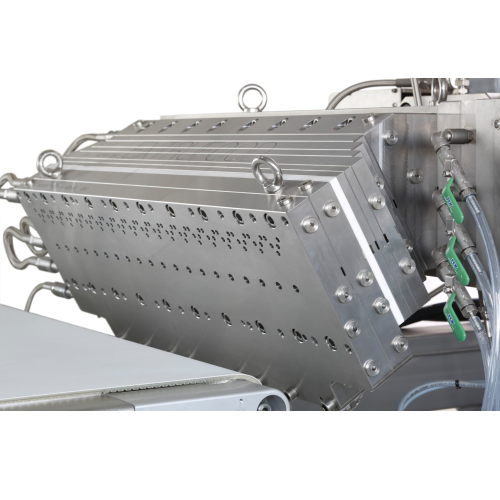

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

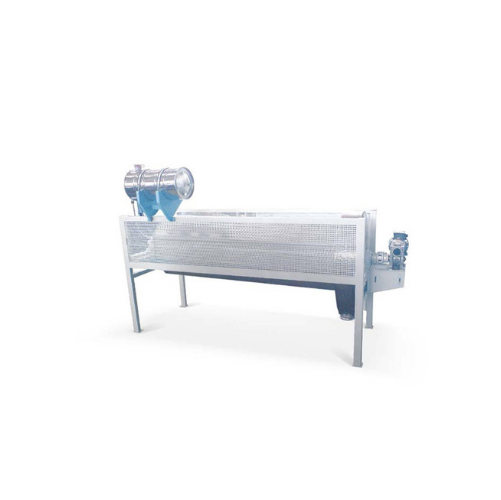

Horizontal ribbon mixers for animal feed production

Experience precise and efficient mixing with low energy consumption f...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

Vertical mixers for animal feed industry

Efficiently combine a variety of powdered and raw materials with precision, ensuri...

Compact orbital vortex mixer for lab use

Streamline your lab’s mixing needs with a compact, space-saving device, idea...

Industrial meat mincer with mixing system capacity

Optimize your meat processing workflow with a versatile mincer that se...

Pneumatic and electric lift for industrial mixing tanks

Enhance operational efficiency and safety with versatile lifts fo...

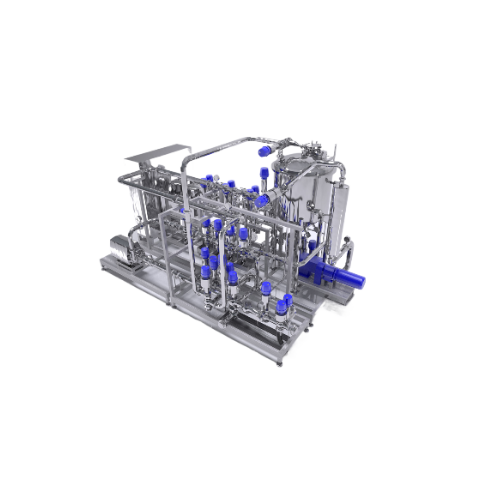

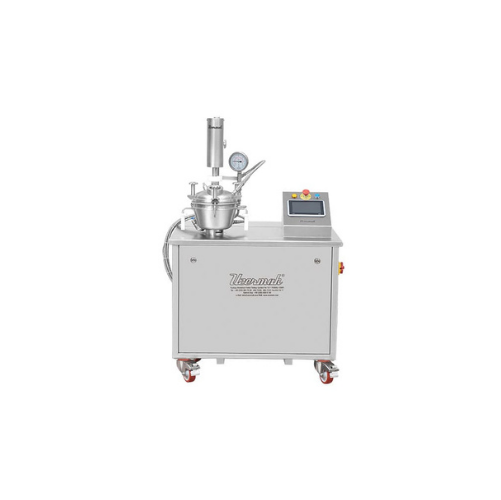

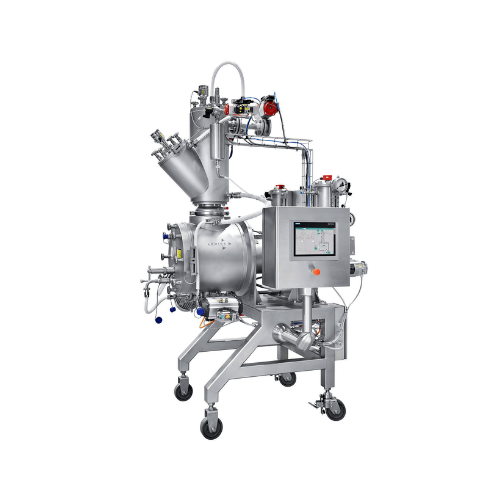

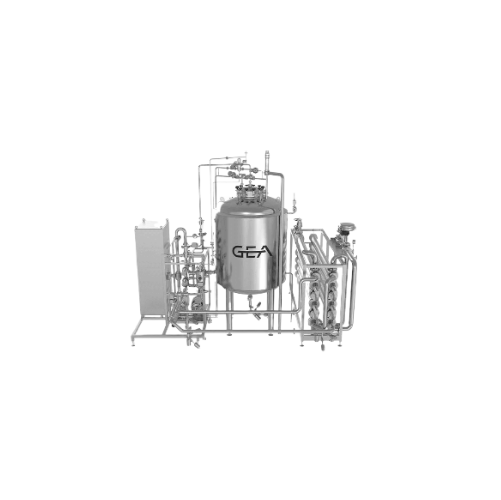

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Dished end for optimized mixing in small-volume vessels

When space constraints challenge vessel design, this solution eli...

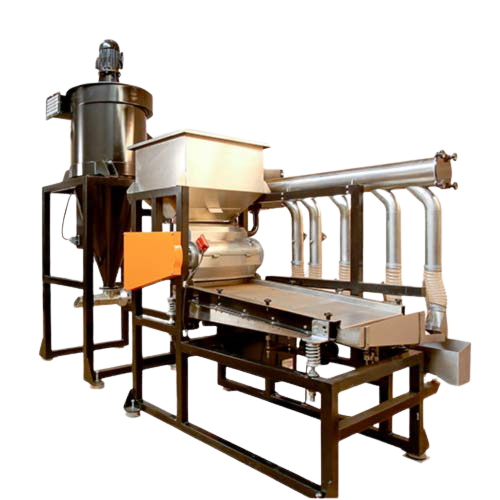

High power mixing solution for powder applications

Achieve rapid, uniform mixing of challenging powders and non-shear sen...

High shear mixer for emulsification

Achieve precise emulsification and dispersions with magnetic high shear technology, ens...

Single-use mixing solutions for downstream processes

Designed for safe and efficient one-time use, this mixing solution e...

Low shear mixer for shear-sensitive applications

Optimize shear-sensitive mixing with precision control, enhancing product...

Versatile magnetic mixer for pharmaceutical and biotechnology applications

Optimize your biopharmaceutical mixing proc...

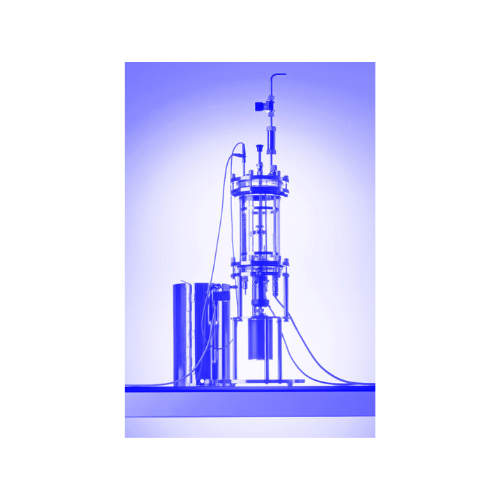

Bioreactor mixer for gentle mixing applications

When handling sensitive biomaterials, ensuring optimal mixing while mainta...

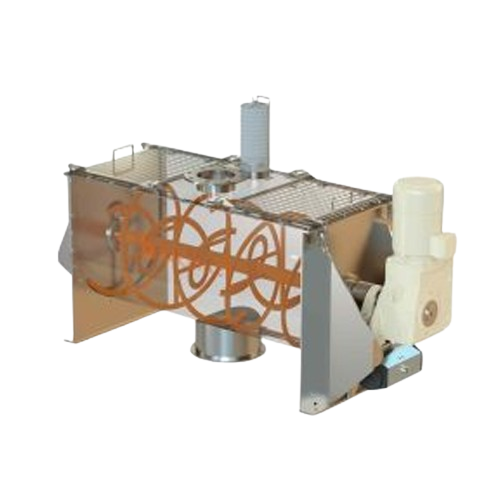

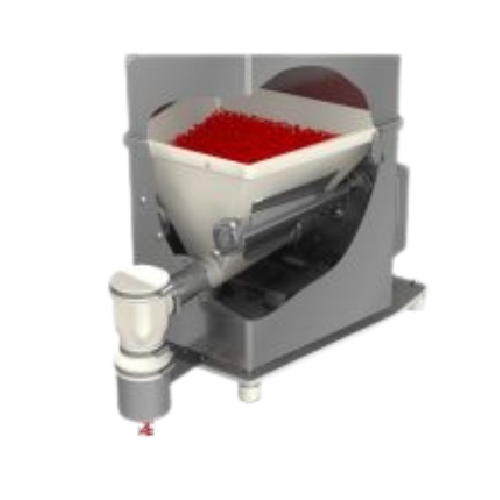

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

High viscosity material mixer for bakery and chocolate

Efficiently mix and knead high-viscosity materials for premium cho...

Removable bowl system mixer for dough preparation

Optimize your bakery production with this advanced mixer featuring a re...

Fixed bowl spiral mixer for dough preparation

Ideal for perfecting dough consistency, this spiral mixer offers two-speed o...

Ibc blender for industrial powder mixing

Streamline your powder mixing with rapid batch changeovers and reduced cleaning do...

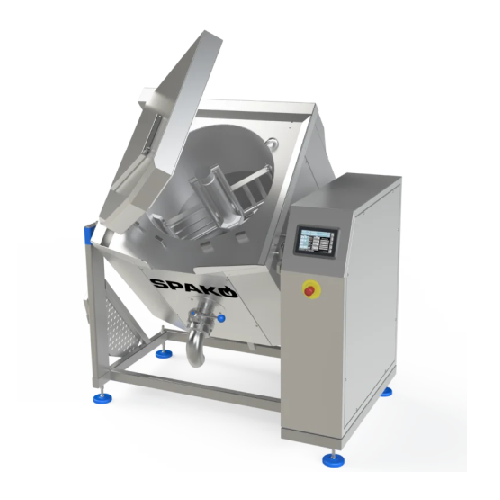

Industrial double shaft mixer for food processing

Ensure precise mixing in industrial food production with this double sh...

Industrial double shaft mixer for homogeneous blending

Achieve quick, gentle, and homogeneous mixing for diverse food mat...

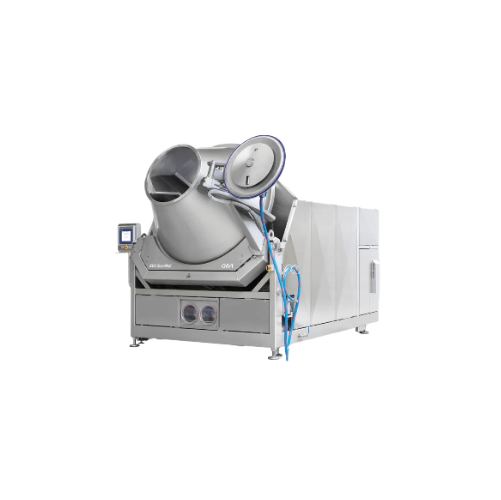

Vacuum mixer for fresh and frozen ground meat

Achieve precise homogeneity with this vacuum mixer, designed to handle high-...

Industrial mixer-grinder for food processing

Streamline your processing line with a robust mixer-grinder that combines eff...

Semi-automatic batter mixer for prepared food production

Achieve consistent, high-quality batter for a variety of conveni...

Automatic mixer grinder for industrial meat processing

Efficiently mix and grind meat and frozen material to produce unif...

Industrial automatic mixer grinder for meat processing

Effortlessly process and mix large quantities of meat and frozen m...

Industrial meat mixing solution

Streamline your meat processing operations with a high-capacity mixer designed for effortles...

Industrial meat ginder and mixer

Streamline your large-scale meat production with a machine that seamlessly mixes, grinds, a...

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Ploughshare mixer for batch operation

Achieve superior mixing quality with a system designed for rapid batch operations. Ex...

Continuous ploughshare mixer for diverse industrial applications

Enhance mixing efficiency and achieve precise particle ...

High-speed mixer for continuous high throughputs

Achieve exceptional homogeneity in mixing liquid and pasty components int...

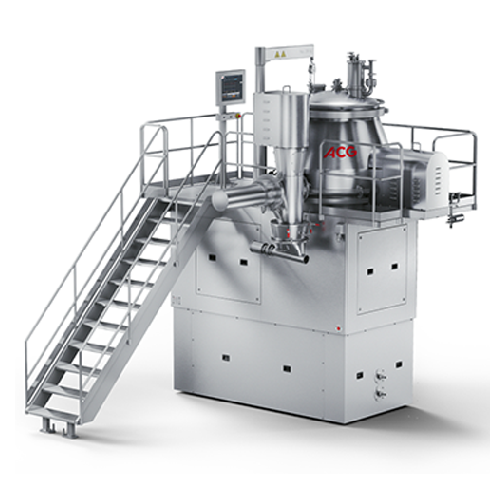

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

Laboratory mixer granulator

Achieve high-quality mixtures in R&D and small-batch production with versatile laboratory m...

Batch mixer for powdery, granular, and fibrous materials

Achieve precise consistency and high batch reproducibility in yo...

Cryogenic cooling system for meat mixing

Efficiently manage heat during meat mixing to enhance product quality and ensure s...

Cryogenic chilling for meat mixing and blending

Ensure precise temperature control during mixing and blending to prevent b...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Inline mixer for uniform powder blends

Achieve uniform powder blends in minutes with this high shear inline mixer, designed...

Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixin...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

Process mixer for food production

Optimize your production line with a versatile and adaptable process mixer that offers se...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Industrial mixer for baby food and dairy production

Optimize your production line efficiency with a versatile mixing solu...

Food mixing and blending system

Enhance your production line with a versatile system designed for gentle processing needs, o...

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

Industrial mixer for vegetable, powder, rice, noodle blending

Effortlessly achieve consistent blends with this 100-liter...

Commercial food drum mixer for sauerkraut and salads

Streamline your batch production with this versatile commercial food...

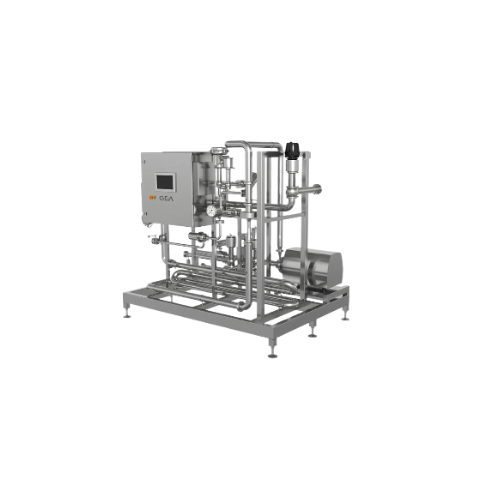

Mixer for carbonated and non-alcoholic drink production

Efficiently mix and carbonate a variety of beverages while optimi...

Industrial salad and delicatessen mixer

Achieve consistent and gentle mixing for diverse food applications with a solution ...

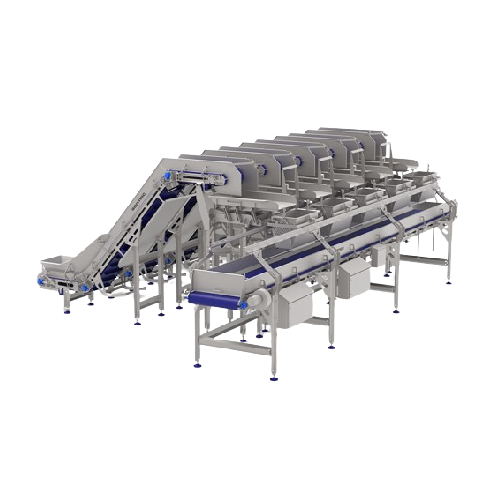

Automatic weighing belt system for mixed products

Achieve precise control and seamless integration of product flows with ...

Laboratory mixer for intensive sample preparation

For precise and efficient preparation of both liquid and dry formulatio...

Laboratory mixer for homogenizing and mixing samples

Achieve precise sample preparation and efficient mixing with this ve...

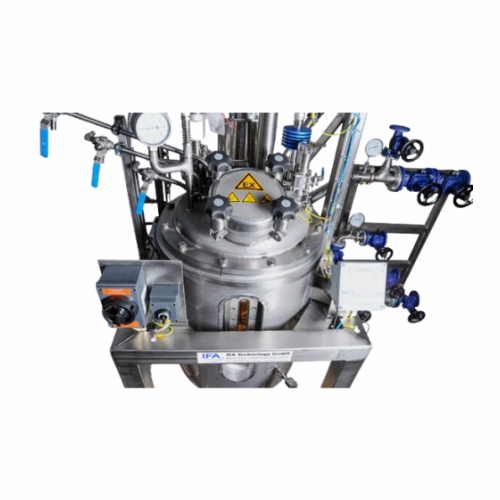

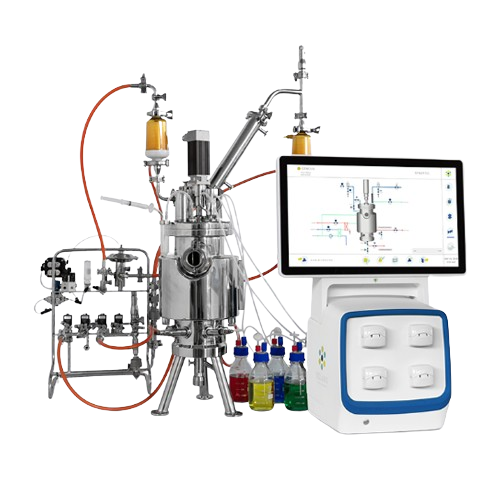

Laboratory dispersion reactor for 2l mixing and reaction processes

Streamline your laboratory processes with a versatil...

Scalable laboratory reactor for mixing and dispersing

Optimize laboratory-scale production with a versatile reactor desig...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

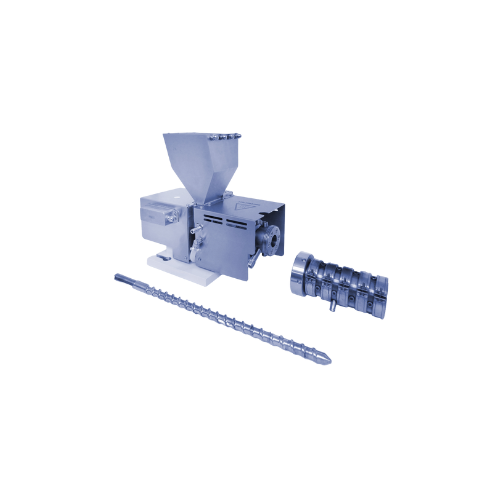

Mixer grinders for meat processing

Optimize your meat processing with our mixer grinders, designed for seamless blending an...

Industrial mixer grinder for fresh and frozen meat processing

Efficiently process diverse meat products for fresh and fr...

High shear plough mixer for powders, granules, and pastes

Achieve rapid and efficient blending with high shear mixers de...

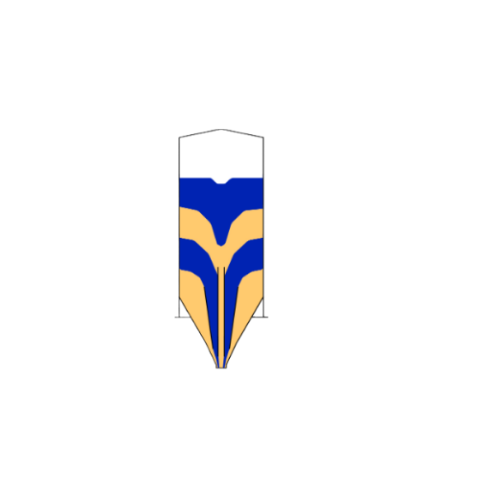

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Counter-rotating blender for cosmetic and pharmaceutical mixing

Achieve precise mixing and homogenizing of complex formu...

Hydroalcoholic gel mixing system

Ensure seamless production of hydroalcoholic gels with an advanced mixing system designed f...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

Powder blender for liquid mixing applications

Optimize your process with a compact blender designed to efficiently dissolv...

Standard batch mixer for salt and citric acid mixing

Achieve perfectly homogeneous blends of salts, sugars, and challengi...

Brine and syrup mixing system

Achieve precise mixing of brines, syrups, and challenging additives with advanced automation, ...

Powder liquid mixer for pectins and starches

Struggling with clumpy, undissolved granules in your mixtures? This innovativ...

Tank bottom mixer for high viscosity applications

Achieve seamless emulsification and homogenization of high-viscosity pr...

High shear vertical mixer for dispersion and emulsification

Achieve seamless emulsification and homogenization in divers...

Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid ty...

Wine tank agitator for homogeneous mixing

Achieve precise mixing and uniform temperature distribution in your wine product...

Powder mixing system for beverage industry

Enhance your beverage production with an advanced powder mixing system that ens...

High shear mixer granulator for pharmaceutical applications

Achieve optimal granulation with precise shear control, enha...

Bin tumbler for efficient mixing

Achieve precise blending and homogenizing of powders and granules with dual-inclination des...

High impact mixer for powders and liquids

Achieve highly homogeneous mixtures with precision. This high impact mixer excel...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Continuous mixing for fine and cohesive powders

Achieve unparalleled mixing precision for cohesive powders while reducing ...

Mixer/extruder for viscous pastes and plastic masses

Achieve seamless mixing, kneading, and extrusion of viscous material...

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate produc...

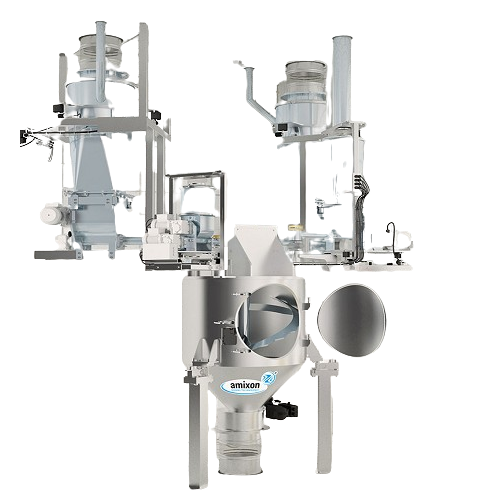

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Super high shear mixer for nano to micron powders

Achieve high-precision mixing and surface treatment of nano to micron-s...

Lab mixer for powder formulations

Achieve precise particle mixing and coating with this stand-alone high-shear lab mixer, d...

Lab mixer for high-accuracy powder and paste mixing

Achieve precise mixing of powders and pastes with a gentle convective...

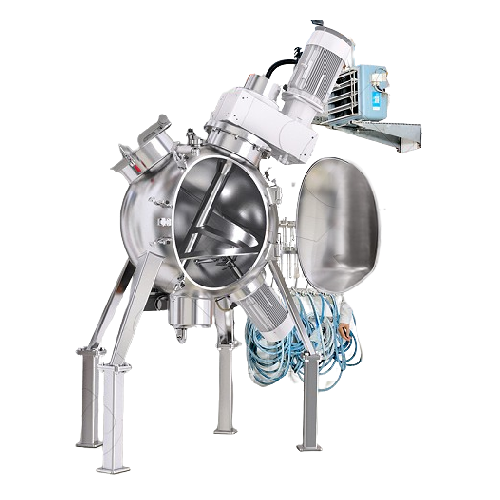

Conical paddle mixer for accurate powder blending

Achieve precise blending of fragile powders and liquids with a versatil...

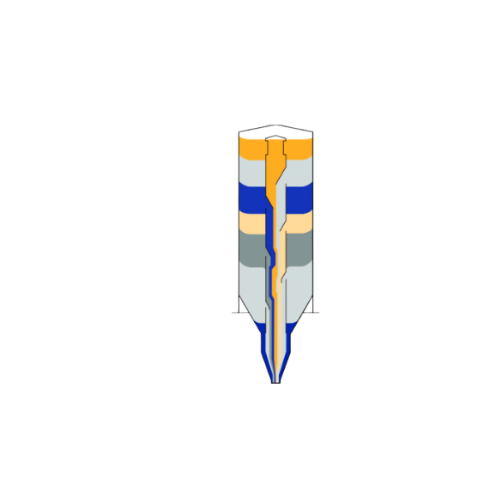

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Industrial liquid mixers for continuous slurry movement

Ensure uniform slurry consistency with precision-engineered liqui...

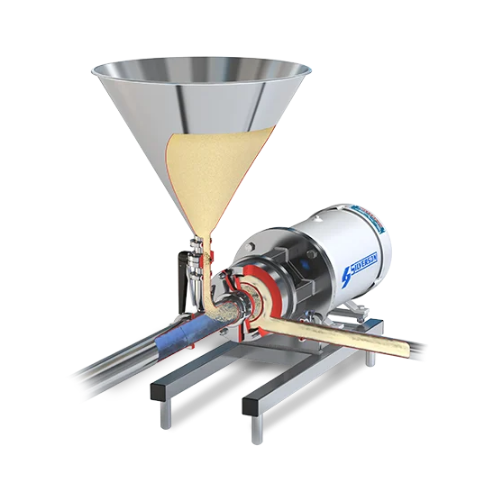

Powder feeder for consistent mixing in pan coating processes

Ensure precise dosing and mixing of pharmaceutical powders ...

Drum mixer for dispersions & agitations

Achieve seamless fluid formulation and agitation with a compact, high-speed drum mi...

Dual shaft mixer for high viscosity products

Achieve uniform dispersions in high-viscosity processes with a dual-shaft mix...

Triple shaft mixer for high viscosity products

Achieve uniform mixing and dispersion for high-viscosity materials with tri...

Horizontal paste mixer for high-viscosity materials

Efficiently transform high-viscosity and challenging materials into u...

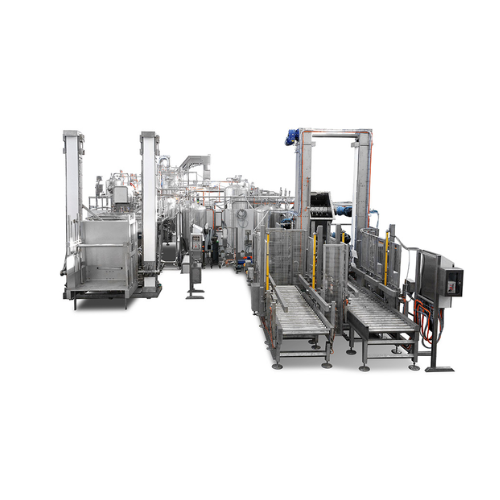

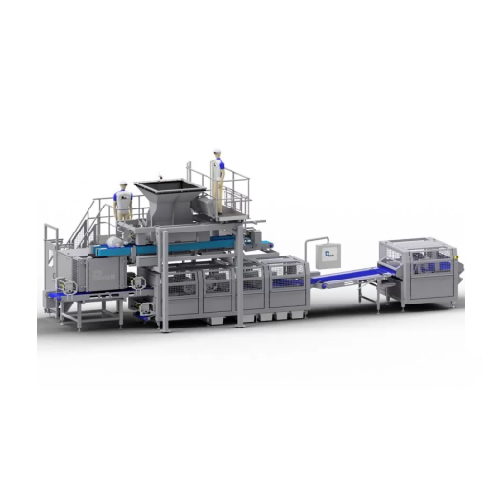

Cheese packaging system for mixed cheese types

Optimize your cheese production line by seamlessly integrating a system des...

Homogeneous brine mixer for meat processing

Achieve rapid and uniform brine solutions with precise integration into your p...

Vacuum tumbler for mixing, blending, and marinating

Optimize marination and mixing processes with precision-controlled va...

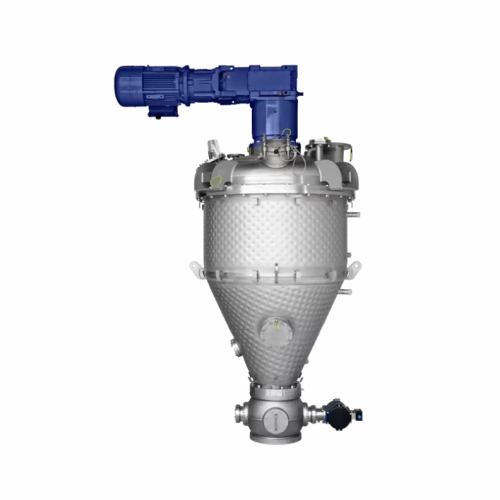

Conical screw mixer for pharmaceutical and chemical industries

Optimize mixing precision and efficiency with a conical s...

Cylindro conical mixer for batch mixing

Maximize mixing efficiency in compact spaces with this versatile solution, ideal fo...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

Cream preparation plant for homogeneous mixing

Optimize your snack production with precise mixing technology, ensuring con...

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

Seasoning mixing system for extruded snacks

Achieve consistent flavor profiles in your extruded snacks with this high-spee...

Industrial agitator for large-scale mixing applications

Enhance operational efficiency with high-capacity mixing solution...

Coaxial mixer for high viscosity liquids

Achieve seamless blending of high-viscosity materials with a coaxial mixer designe...

Sealless top-entry industrial mixer

Engineered for diverse industrial applications, this sealless top-entry mixer offers su...

Side entry mixer for industrial fluid mixing

Optimize your fluid mixing processes with high-speed side entry mixers, desig...

Universal industrial agitator for various fluid mixing needs

Optimize your production with an industrial agitator design...

Flexible mixing system for meat and dairy products

This versatile mixing system delivers precise control over temperature...

Ibc tumbler for uniform batch mixing

Achieve consistent and homogenous mixing of powders, granules, and solid products with...

Industrial mixer for food and pet food production

Achieve precise and efficient mixing of viscous to highly viscous produ...

Double shaft batch mixer for chocolate production

Optimize your chocolate and confectionery production with precise mixin...

Dosing unit for automated mixing in of ingredients

Achieve precise ingredient integration for confectionery and nutraceut...

Mixing drum for shredded cheese

Optimize your dairy production line with this innovative mixing drum designed to effortlessl...

Additive mixing and dosing system for potato flakes

Achieve precise flavor and texture in potato flakes with this system,...

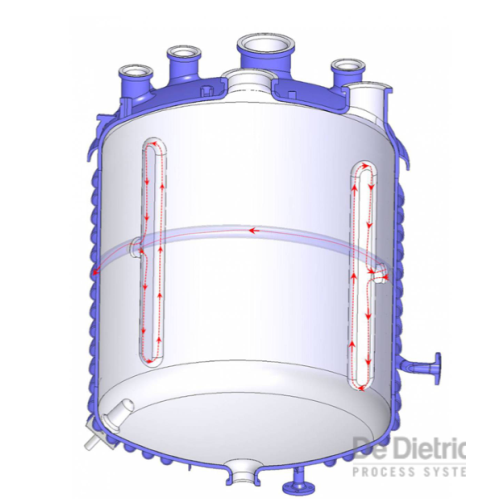

Glass-lined mixing systems for pharmaceutical industry

Achieve consistent mixing and thorough agitation for complex formu...

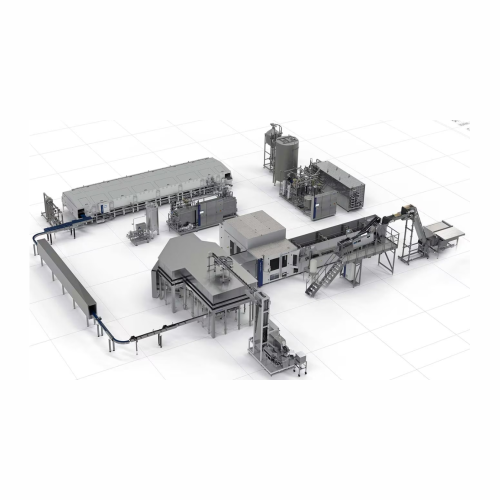

Industrial mixing and processing plant for demanding products

Enhance your production line with precise mixing and proce...

Industrial food mixer for sensitive product mixing

Enhance your production line with precise mixing capabilities, ensurin...

Laboratory mixing plant for small scale food production

Achieve precise control over small batch food processing with a v...

Small batch free fall mixer for food industry applications

Efficiently handle diverse ingredient integration for plant-b...

High-speed mixer for granulating and mixing powders

Achieve consistent granulation and mixing with precise temperature co...

Mixer for blending coffee beans

Achieve precise and consistent coffee blends with a versatile mixer designed for smooth inte...

Single shaft batch mixer for chemical and pharmaceutical applications

Optimize mixing efficiency with rapid batch proce...

Continuous inline mixing for late product differentiation

Achieve seamless product differentiation with compact inline m...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Continuous mixer for homogeneous blending

Achieve consistent product quality with precise mixing and blending, ideal for a...

Laboratory mixer for r&d and small batch production

Achieve superior mixing precision for R&D and pilot production w...

Continuous powder mixer for industrial applications

Achieve precise and efficient integration of powders, granules, and l...

Eurobin tumbler/mixer for meat processing

Efficiently handle tumbling, mixing, and marinating with minimal product damage,...

High shear granulation mixing system

Optimize your powder granulation process with a system designed for precise control ov...

Industrial brine mixers for meat and poultry processing

Optimize your production line with brine mixers that ensure homog...

High shear mixer granulator for efficient wet granulation

Achieve consistent and precise granule formation with high she...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Planetary mixer for industrial pastry production

Achieve precise dough consistency and enhance baked goods quality with th...

Planetary mixer with double tool for pastry dough

Optimize your pastry production with precise mixing capabilities that e...

Automatic mixing and bowl handling system

Enhance your mixing operations with a fully automatic system that streamlines do...

Double jacketed mixer for dough cooling

Achieve consistent dough quality and superior gluten development with precise tempe...

Spiral mixers with bottom discharge system

Ensure consistent dough quality while optimizing space and efficiency with a mi...

Industrial spiral mixer with bottom discharge system

Enhance dough quality and streamline operations with a dual-tool mix...

Spiral mixer with removable bowl for bakery production

Achieve consistent dough quality with advanced bowl locking and mo...

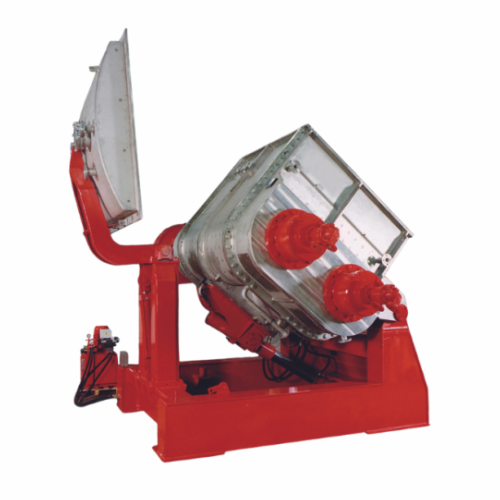

Tumbling cube mixer for homogeneous blending

Achieve uniform blending with precision using a cube mixer that enhances mixi...

Double cone mixer for free flowing powders and granules

Achieve uniform blending of powders and granules with precision, ...

Drum hoop mixer for uniform three-dimensional mixing

Achieve consistent, homogenous mixing of powders and granules with a...

Laboratory high speed mixer for powders and granules

Achieve homogenous blending of powders and granules efficiently with...

Planetary stirrer for creams and ointments mixing

Achieve homogeneous mixing of creams, ointments, and pastes efficiently...

V-mixer for solid bulk material blending

Achieve precise and uniform mixing of sensitive powders with gentle treatment, ide...

All-purpose mixer and processor for laboratory and small scale production

Optimize your small-scale production with a ...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Laboratory mixer and dryer for solids

Enhance your laboratory capabilities with precision mixing and drying for small batch...

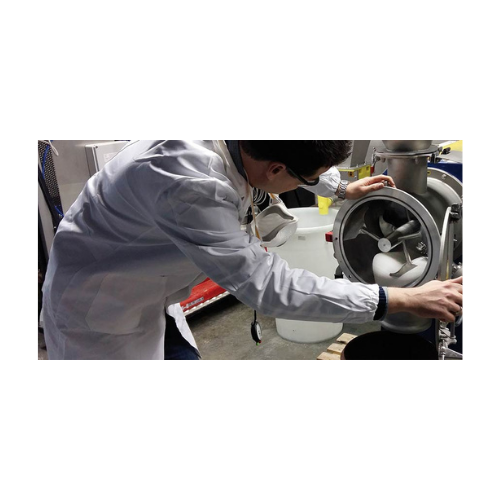

High-shear mixer granulator for pharmaceutical production start-up

Effortlessly achieve optimal granule consistency and...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Pharmaceutical high-shear mixer granulator

Enhance your production efficiency with a high-shear mixer granulator, designed...

Versatile entry-level mixer granulator

Solve complex mixing and granulating challenges with this compact solution, offering...

High-capacity universal mixer for industrial applications

Optimize your batch processing with a versatile high-speed mix...

Premium stainless steel spiral mixer for doughs

Perfect for bakeries aiming to deliver consistent artisan breads, this spi...

Industrial wendel mixer for dough production

Optimize your dough and bar production with reduced kneading times and increa...

Hygienic design dough mixer

Achieve superior dough consistency and safety with our hygienic design mixer, ideal for reducing...

Premium industrial mixer for dough production

Enhance dough production efficiency with a mixer that reduces kneading times...

Laboratory unit for mixing, granulating, and vacuum drying

Achieve precise mixing, granulating, and drying in laboratory...

Continuous mixer for industrial powders and liquids

Achieve precise and efficient mixing of solids and liquids with minim...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

R&d mixer for small batch experimentation

Perfect your mixing techniques swiftly with precision-controlled small batch exp...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial mixer for moisture conditioning

Ensure precise moisture levels and homogeneous mixtures for complex extrusion p...

Compact spiral mixer for small-scale dough production

For kitchens and bakeries needing precise control, this compact spi...

Powder blender for efficient mixing and discharge

Achieve precise mixing and efficient discharge with advanced powder ble...

Glass-lined reactor for enhanced mixing performance

Optimize your chemical processes with a reactor that enhances mixing ...

Liquid/liquid extraction mixer-settler plant

Optimize your extraction processes with a highly efficient mixer-settler syst...

Cooker for nougat and hard mixtures

Optimize the production of high-density mixtures like nougat and meat sauces with this ...

Planetary cooker for medium-high density mixtures

Achieve smooth, consistent textures with a planetary cooker designed fo...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

Lab-scale high-shear mixer for recipe development

Optimize your recipe development process with precise mixing, homogeniz...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Vacuum high shear mixer for medium to high viscosity products

Achieve flawless blending and air-free consistency in visc...

High-capacity manual mixer for industrial applications

Optimize your mixing process with a highly efficient, manually ope...

Industrial food mixer for high-volume processing

Achieve consistent mixing and precise blending of diverse food ingredient...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Overlapping paddle mixer for precise food processing

For precise and thorough mixing in food processing, this solution en...

Bulk material mixer for high-speed homogenization

Achieve fast and gentle homogenization of bulk materials with a high-sp...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Laboratory high shear mixer for wet mixing and granulation

Optimize your mixing, granulation, and drying processes with ...

Mini laboratory mixer for tabletops

Optimize your lab’s mixing precision with this compact tabletop bin mixer, design...

Wheeled laboratory mixer for powder and granule mixing

Achieve uniform mixing of small powder and granule batches with pr...

Premix system for carbonated beverages

Ensure precise carbonation and blending for your beverage lineup with this advanced ...

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Batch weighing system for precise raw ingredient mixing

Optimize your confectionery production with a precise batch weigh...

High shear mixer system for hydrocolloids

Streamline your confectionery production with a high-shear mixer designed for pr...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

Batch mix preparation system for ice cream

Optimize your ice cream production with an efficient system designed for precis...

Double sigma kneader for viscous product mixing

Optimize the mixing and kneading of high-viscosity products with our doubl...

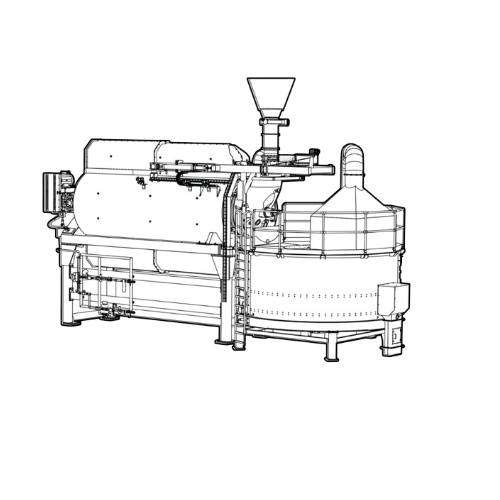

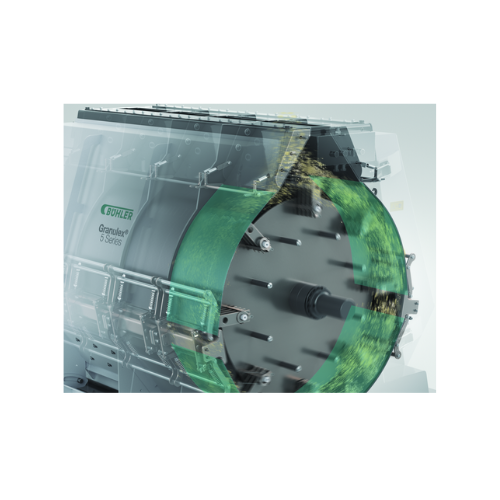

Chocolate processing unit for mixing, grinding, and conching

Optimize chocolate production with precise mixing, grinding...

Chocolate processing unit for mixing and grinding

Achieve precise mixing and conching efficiency for premium chocolate an...

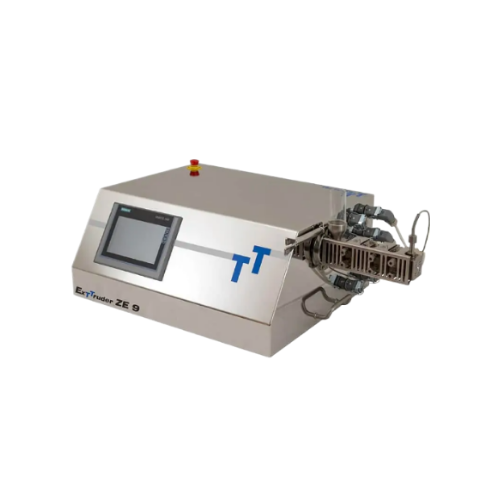

Lab scale mixer, extruder & spheronizer for r&d formulation

Optimize and streamline your research and development proces...

Bench-top mixer and spheronizer for formulation development

Accelerate R&D success by seamlessly integrating mixing...

Small batch mixer granulator blender

Effortlessly manage small batch mixing, blending, and granulation with a compact solut...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Compact batter mixing system

For food producers aiming to ensure consistent batter quality, this modular system streamlines ...

High-speed mixer for dough production

Achieve consistent dough quality and streamline your production process with this ver...

Turbo cream mixer for fat cream production

Achieve consistent and homogeneous cream fillings quickly with this advanced hi...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

Commercial juice mixing station

Streamline your beverage production with precise mixing and dosing, ensuring consistently hi...

Planetary mixer for homogeneous material mixing

Achieve precise and consistent mixing of diverse materials from powders to...

Gluten-free flour mixing solution

Ensure consistent dough quality and precise analysis in gluten-free production with a rob...

Measuring mixer for small grain samples

Optimize the precision of your formulation processes with a solution designed for p...

Measuring mixer for flour and dough analysis

Optimize your dough consistency and quality with precise mixing and kneading ...

Measuring mixer for flour farinograph tests

Achieve precise dough consistency with ease—this mixer ensures reliable testin...

Horizontal mixer for creams

Achieve optimal and uniform mixing of creams, pasty products, and powders with advanced horizont...

Vertical mixer for creams and desserts

Achieve uniform mixing and precise temperature control for diverse creamy and liquid...

Turbo mixer for homogeneous solutions in food and pharmaceutical industries

Effortlessly achieve uniform suspensions a...

Premix system for soft drinks production

Efficiently produce both carbonated and non-carbonated beverages by integrating th...

Mixer-pasteurizer-carbonator for soft drinks and juices

Optimize your beverage production with a versatile system that se...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Laboratory vacuum mixer reactor for liquids and semi-solids

Achieve precise emulsification and mixing for high-viscosity...

Vacuum mixer for liquid and cream processing

When dealing with high-viscosity liquids and creams, achieving uniform consis...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Feeding, dosing, weighing and mixing system for granulate

Achieve precise granulate mixing and rapid color changes with ...

Water mixing and dosing unit for dough production

Achieve precise dough temperature control effortlessly, ensuring consis...

Vacuum homogenizer for high-quality mixing and emulsification

Achieve optimal consistency and enhanced product stability...

High viscosity product mixer

Struggling with mixing high viscosity products like creams and gels? This co-axial mixer enhanc...

Industrial dough mixer for high capacity food production

Enhance dough consistency and texture with a high-speed industri...

Automatic seasoning mixer for food production

Effortlessly blend diverse ingredients with precision in your production lin...

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Precision powder mixer for baby formula

Achieve consistent texture and rapid homogenization for sensitive powder blends lik...

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mix...

Vertical single-shaft mixer for dry, moist, and viscous materials

In industries requiring precise and thorough mixing o...

Vertical twin-shaft mixer for dry, moist, and viscous materials

Achieve consistent mixing and blending of diverse materi...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Container mixer for dry and moist materials

Achieve exceptional mixing quality with variable filling levels, ensuring cons...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Large batch gyraton® mixer for homogenizing moist and poorly flowing materials

Optimize your production line with this...

Open frame mixer for industrial dough mixing

Streamline your bakery’s mixing process with precision control and enha...

Automatic carbonated beverage mixing system

Optimize your beverage production by ensuring precise carbonation and mixing w...

Mobile mixing system for beverages in breweries

Optimize blending and carbonation processes with a mobile solution that st...

Hybrid powder mixer for powder-liquid blending

Achieve consistent powder-liquid blends with reduced processing times and e...

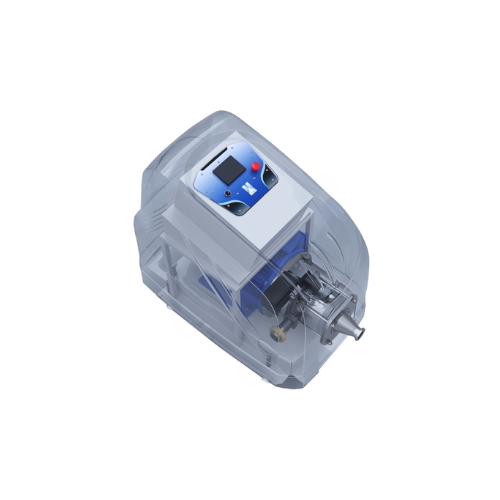

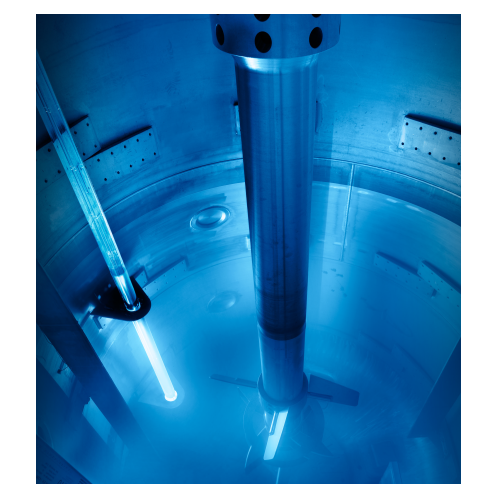

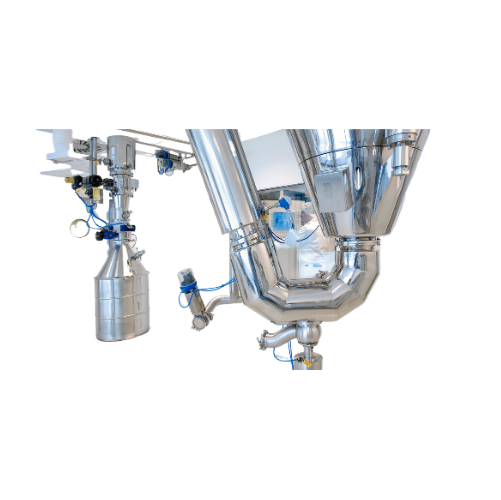

Aseptic magnetic mixer for hygienic production

Experience seamless mixing to the last drop with advanced levitating impell...

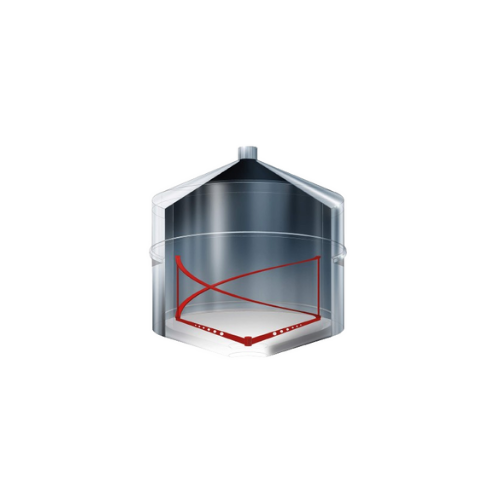

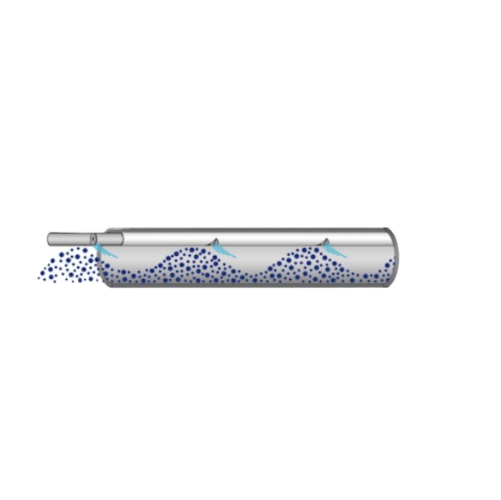

Rotary jet mixer for efficient liquid, gas, and powder mixing

Achieve seamless integration and efficiency in liquid, gas...

Bin blender for pharmaceutical powder mixing

Achieve uniform mixing and homogenization of dry powders directly in storage ...

Mobile bin blender for mixing and homogenizing dry powders

Ensure thorough powder uniformity and eliminate cross-contami...

Drum blender for homogeneous powder mixing

Achieve precise powder homogenization directly in storage drums, minimizing han...

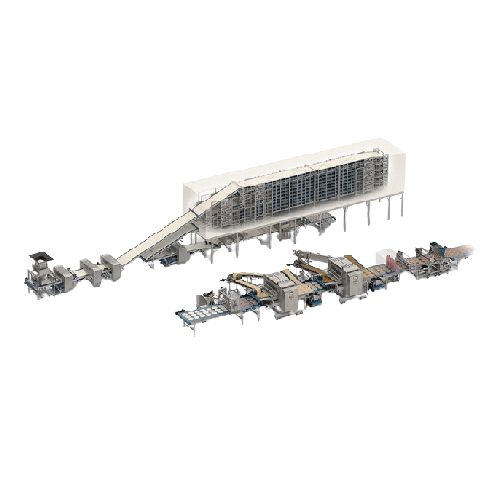

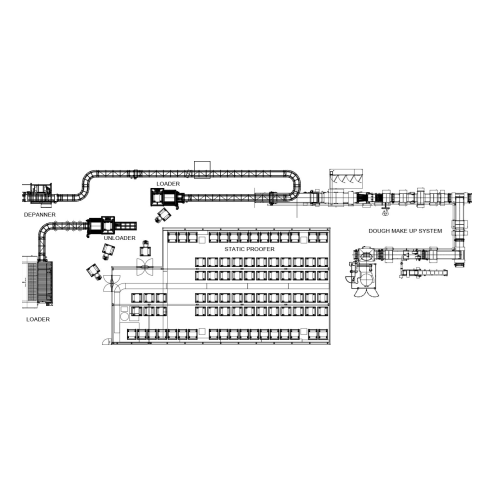

Industrial dough mixing system for bakeries

Enhance your bakery’s efficiency with a system that ensures precise doug...

Benchtop mixer for lab-scale product development

Easily scale up your formulations with precise and repeatable lab-scale m...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

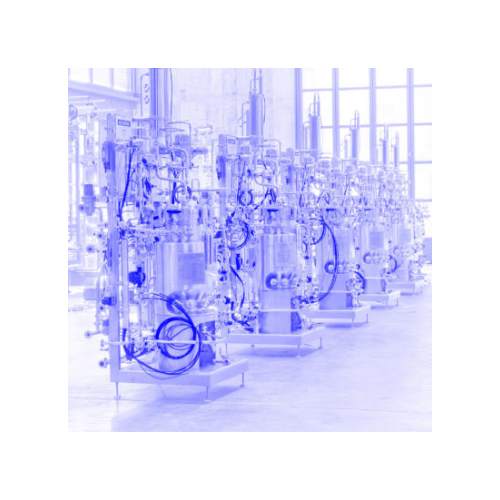

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

Dual asymmetric centrifugal mixer for epoxy and slurry mixing

Achieve precise mixing and consistency in your formulation...

Planetary ball mill for powder material mixing and alloying

Achieve precise control in particle size reduction and homog...

High-shear mixer granulator for pharma and nutraceuticals

Optimize your batch and high-speed production with a powerful ...

High-shear mixer granulator for small batches

Achieving consistent particle size and mix uniformity in pharmaceutical and ...

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear...

High-shear mixer for small batch granulation

Enhance your production efficiency with a high-shear mixer designed for preci...

Auxiliary feeder mixer for chocolate production

Optimize ingredient incorporation seamlessly with a versatile system that ...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Beverage deaeration, carbonation and mixing system

Streamline your beverage production process with an efficient solution...

Mixing tank for soups, sauces, and dressings

Streamline your soup and sauce production with advanced mixing technology des...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Powder induction system for efficient liquid powder mixing

Achieve precise and dust-free powder incorporation into liqui...

Double-shaft paddle mixer for homogeneous raw masses

Optimize your mixing efficiency with a dual-shaft system designed fo...

Automatic chemical mixing system for postharvest treatment

Achieve precise chemical dosing and mixing for postharvest tr...

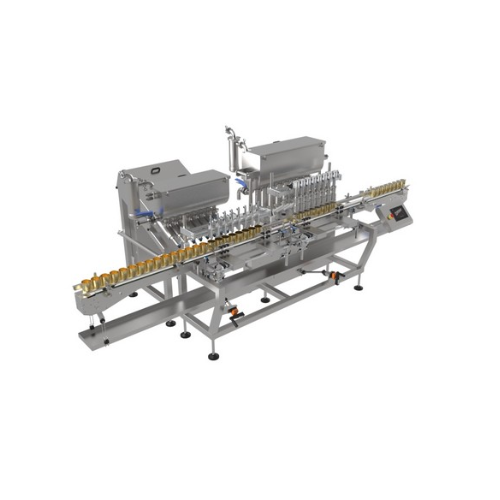

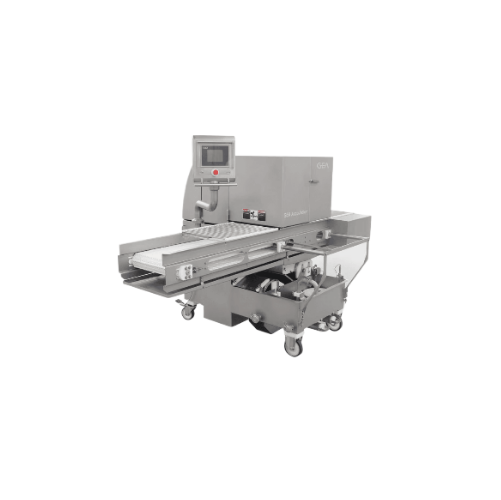

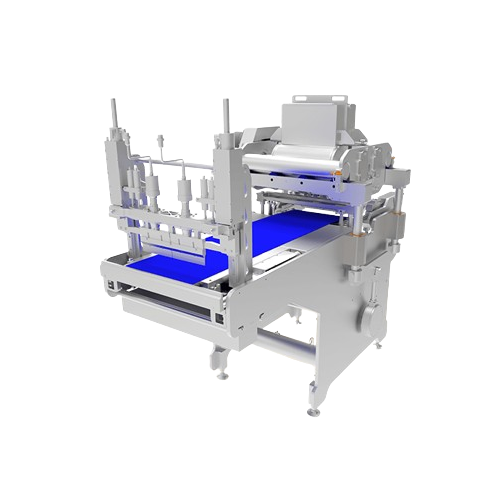

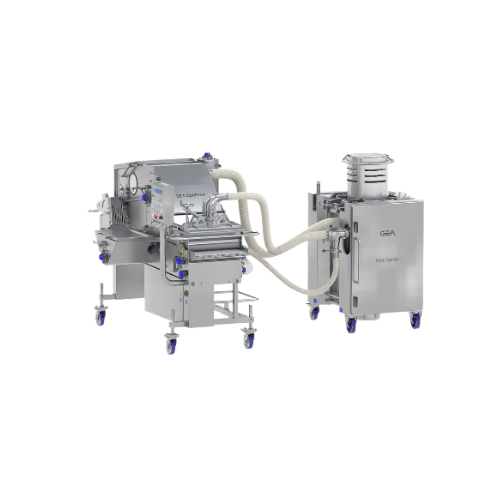

Automatic batter mixer for coating applications

Achieve consistent batter viscosity for precise coating in high-demand foo...

Automatic tempura batter mixer for poultry and seafood

Enhance the consistency and quality of your tempura coatings while...

Batter mixer for small to medium food production lines

Achieve precise, consistent batter mixing with our semi-automated ...

Industrial batter mixer for food preparation

Achieve consistent batter quality with precise control over viscosity and tem...

Industrial brine mix and chill system

Streamline your production with a versatile system that seamlessly blends and chills ...

Advanced brine mixing system for poultry processing

Ensure your brine solutions are consistently mixed and chilled with p...

Homogenizing mixer for product distribution

Optimize the flow of your production with a high-speed distributor mixer, ensu...

Powder and granulate premixer

Achieve consistent, homogenous blends of powders and granulates with our advanced premixing te...

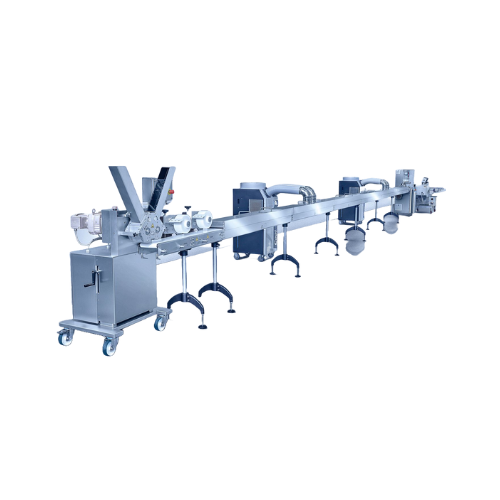

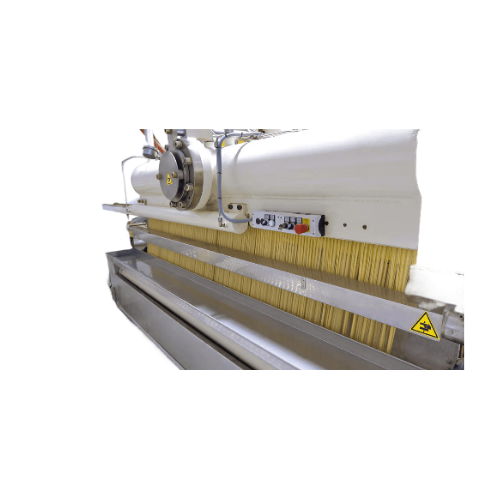

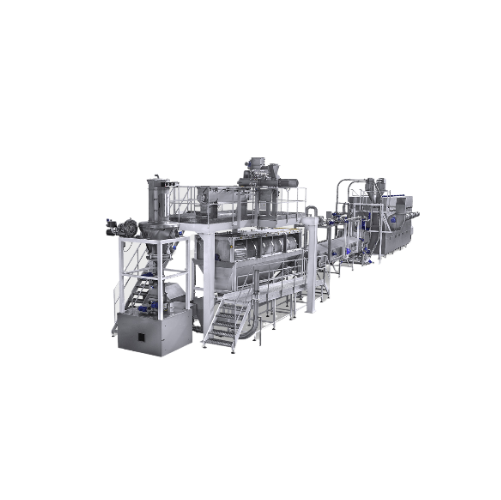

Mixer kneader sheeter for fresh pasta processing

Streamline your pasta and dough production with a single machine that eff...

Batch standing mixer for dough preparation

Enhance your mixing precision with a batch standing mixer that optimizes paddle...

Dough distribution system for multiple mixing points

Ensure precise dough allocation across multiple production stages wi...

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing ...

Modular batch mixing system for beverages

Streamline your beverage production with a flexible solution that manages comple...

Tailor made mixing systems for personal and home care products

Achieve precise mixing for liquid formulations with conti...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear mixer for low viscosity products

Achieve precise mixing and dispersion for diverse liquid applications with a h...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Industrial defrosting and mixing for frozen raw materials

Reduce frozen material tempering time from hours to minutes, e...

Intermeshing mixing and grinding for ground meat products

Achieve consistent mixing and grinding with a single, versatil...

Twin-shaft mixer for food preparation

Achieve optimal protein extraction and ingredient distribution with this twin-shaft m...

Twin-shaft mixer for meat mix preparation

Achieve consistent texture and flavor in your meat and plant-based products with...

Brine mixing equipment for food processing

Achieve homogeneous brines and marinades effortlessly with our state-of-the-art...

Mixer and carbonator for soft drinks

Achieve precision in continuous mixing and carbonation, ensuring perfect beverage cons...

Carbonating system for beer and beer mix beverages

Achieve precise carbonation and consistent original wort control for y...

Automated tempura batter mixer

Achieve consistent tempura batter quality with automated mixing control that ensures precise ...

Screw belt mixer for dry materials

Achieve uniform mixing of bulk dry materials with variable speed control, ensuring preci...

Shear stream mixer for dough and batter preparation

Efficiently mix and homogenize dry ingredients with liquids, preservi...

High-speed paddle mixer for food industry blends

Achieve rapid, high-energy blending of varied particulate materials with ...

Pneumatic mixer for fluidizable bulk materials

Achieve uniform and gentle mixing of powdered ingredients with minimal effo...

Vertical cooler mixer for industrial cooling mixing

Enhance your production line with efficient temperature control and r...

Liquid additive dosing system for industrial mixers

Achieve unparalleled precision in liquid ingredient integration with ...

High precision mixer for metallic powder paints

Achieve unparalleled precision and uniformity in producing high-gloss and ...

Laboratory mixer for complex mixing tasks

Optimize your laboratory processes with a versatile mixer designed for accurate ...

Horizontal cooling mixer for industrial applications

Efficient cooling in your production line enhances material quality ...

Horizontal homogenizing mixer for all-purpose applications

Achieve uniformity and consistency in your products with a ve...

Horizontal cooling mixer

Ensure consistent batch temperatures and reduce production costs with this robust cooling mixer, des...

Universal mixer for diverse industrial mixing needs

Achieve precise homogenization and optimal emptying with a versatile ...

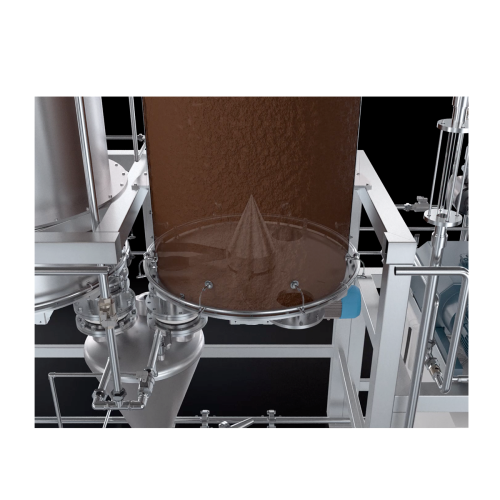

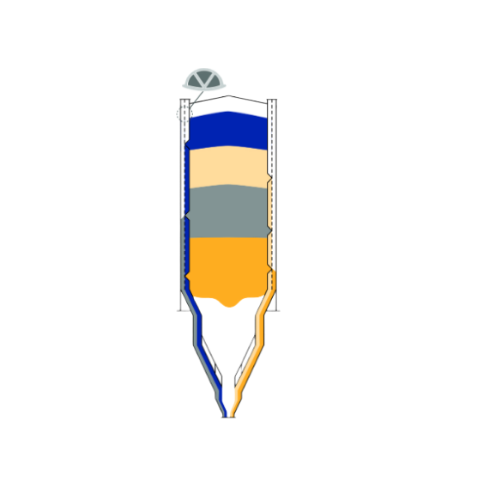

Fluidizing bed blending silo for powder mixing

Optimize your batch mixing process with a fluidizing bed blending silo, des...

High intensity industrial mixer

Achieve rapid homogenization and outstanding dispersion with this versatile mixer, designed ...

Industrial jetstream mixer for homogeneous mixing

Achieve consistent product quality with precise micro and macro mixing ...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

High-performance dispersing and mixing solutions

Enhance your mixing and dispersing processes with advanced fluid stream t...

Multipurpose mixing equipment for chemical and pharmaceutical production

Achieve unparalleled flexibility with modular,...

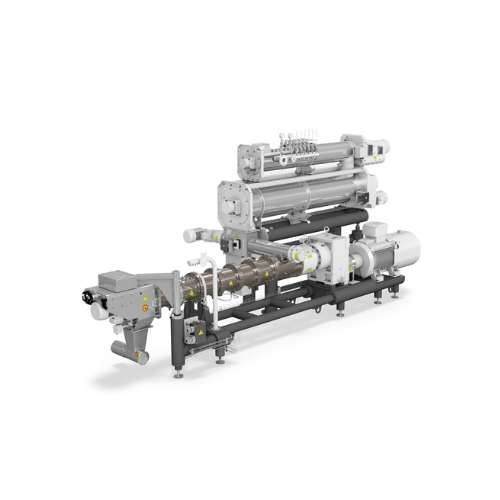

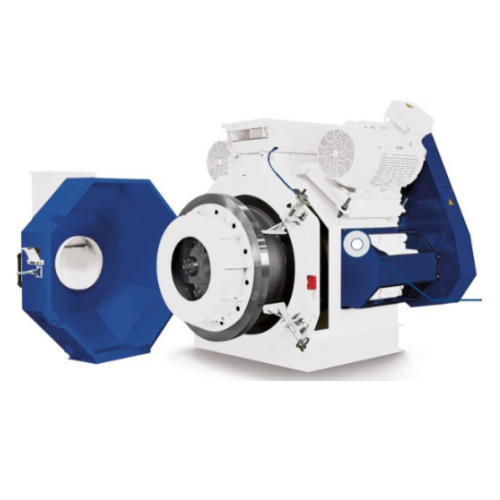

Inline disperser for lithium-ion electrode slurry mixing

Achieve highly efficient dispersion and homogeneity for battery ...

High performance spiral mixer for dough preparation

Achieve consistent dough quality with ease by integrating a high-perf...

Helix mixer for soft wheat and rye doughs

Effortlessly enhance dough volume and tension with minimal energy input using th...

Automatic dough mixing system for high-quality doughs

Transform your dough production with a system designed for rapid, c...

Mixing system for long dough resting times

Achieve consistent dough quality with extended resting times, optimizing water ...

Linear mixing system for high-capacity dough production

Achieve perfect dough consistency with precise mixing, rapid cycl...

Industrial spiral mixer for dough production

Achieve precise control in dough consistency and quality with this spiral mix...

Industrial spiral mixer for dough processing

Achieve optimal dough consistency and quality effortlessly with a cutting-edg...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

High-speed mixer for homogenous mixing of powders and pastes

Achieve rapid and precise mixing with high-speed dispersion...

Industrial rapid turbulent mixer for homogeneous mixing

Achieve unparalleled homogeneity with rapid turbulent mixing, ess...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Twin shaft mixers for fragile and high throughput applications

Maximize mixing efficiency and protect delicate materials...

Horizontal shaft mixer for free-flowing materials

Achieve consistent mixing of diverse free-flowing materials with a reli...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Laboratory mixers for product development and research

Optimize your R&D efforts with advanced mixing solutions desi...

Industrial blenders for powder and granule mixing

Optimize your production line with advanced mixing solutions designed f...

Pv mixing vessels for industrial hire

Optimize your production mix with vessels that ensure precise blending, heating, and ...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Mixing and dispersing solution for ultra high-viscous products

Efficiently process ultra high-viscous and thixotropic ma...

Triple shaft mixer for high-viscosity products

Achieve precision mixing and dispersing of high-viscosity products with a p...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

Batch-control system for dosing, mixing, and weighing processes

Enhance your process control by automating dosing, mixin...

Batch-type single shaft mixer for efficient discharging

Optimize your material mixing and discharging processes with a sy...