Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and precision, ensuring seamless integration into continuous production lines for processing powders and granules.

Processes and Grinds Complex Materials Efficiently

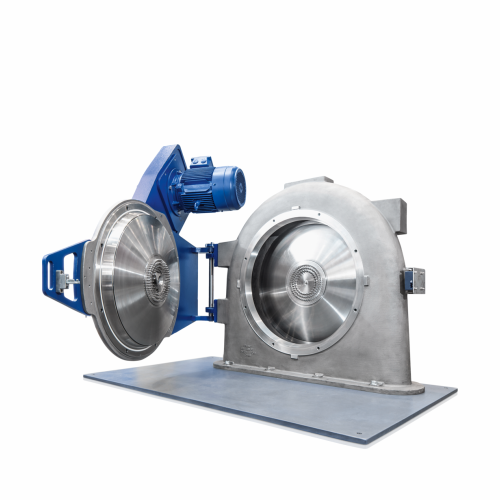

The Contraplex CW II from Hosokawa Alpine is a versatile fine impact mill designed to tackle the challenges of grinding and mixing complex materials, including sticky, heat-sensitive, and greasy substances. This dual-driven pin disc mill operates with counter-rotating discs, achieving relative speeds of up to 240 m/s for exceptional fineness. Ideal for applications across chemicals, pharmaceuticals, and food industries, it handles an array of end-products like lithium-ion battery anodes, spice blends, and synthetic rubber.

With a robust belt drive system, the Contraplex CW II ensures optimal energy efficiency and performance, while the wide-chamber housing prevents material build-up and blockages. The equipment offers easy integration into continuous production lines, supported by PLC controls for automation and seamless operation.

Constructed from mild or stainless steel, the machine is suitable for various processing environments, offering special options for pharma and coating applications. The design facilitates easy cleaning and maintenance, featuring a hinged mill door for swift access. Additionally, it supports customization in disc speeds and rotational direction to meet specific grinding conditions.

Ideal for manufacturers seeking high precision and adaptability, the Contraplex CW II meets rigorous industry standards, with optional configurations available for enhanced performance and specific requirements.

Benefits

- Achieves high fineness levels, enhancing product quality in demanding applications.

- Supports continuous operation, reducing production downtimes and increasing throughput.

- Ensures optimal energy efficiency through its robust drive system, lowering operational costs.

- Flexible design accommodates diverse materials, from sticky to heat-sensitive, offering broad application versatility.

- Simplifies maintenance and reduces cleaning time with easy access for swift product changeovers.

- Applications

- Chemicals, Food, Vitamins, Auxiliaries, Protein, Metals, Pesticides, Spices, Plastics, Minerals, Rubber, Pigments, Carboxymethylcellulose, Recycling, Pharmaceuticals

- End products

- Carbon black, Fish meal supplements, Protein bars, Spice blends, Cocoa powder, Synthetic rubber, Vitamins capsules, Talc powder, Plastic pellets, Carboxymethylcellulose powder, Lithium-ion battery anodes, Recycled polypropylene, Ultramarine pigment, Flavorings, Calcium carbonate powder, Pepper, Pvc powder, Tablets, Lactose powder, Tpu granules

- Steps before

- Emulsification, Drying, Pre-crushing, Intensive mixing with liquid nitrogen

- Steps after

- Sterilization, Packing, Coating, Tablet Pressing

- Input ingredients

- sticky materials, moist products, greasy products, hygroscopic materials, brittles, crystalline materials, minerals powders, calcium carbonate, calcium hydroxide, fillers, stearic acid, silane, vitamins, pharmaceutical auxiliaries, fatty proteins, spices, nutmeg, cloves, pepper, corn starch, lactose, cacao, fish meal, presscake, plastics, TPU, PA, pesticides, hydrotalcite, pigments, ultramarine, carboxymethylcellulose, CMC, rubber

- Output ingredients

- fine powders, high fineness products, homogeneous mixtures, embrittled materials, processed sticky products, processed moist products, pulverized minerals, coated fillers, ground vitamins, processed pharma auxiliaries, ground fatty proteins, pulverized spices, processed lactose, processed cacao, ground fish meal, fine ground plastics, fine ground pesticides, pulverized pigments, fine ground CMC, fine ground rubber

- Market info

- Hosokawa Alpine is known for its expertise in manufacturing advanced process equipment and systems for powder and particle processing technology. It has a strong reputation for innovation, quality engineering, and customer-focused solutions in various industries.

- Speed

- Up to 240 m/s

- Fineness Range

- 10 to 500 µm

- Disc Speed

- Adjustable

- Housing Type

- Wide-chamber

- Disc Diameter

- Available from 250 to 800

- Pressure Relief Design

- Up to 1.4 bar

- Material Construction

- Mild steel or stainless steel

- Cooling Option

- Liquid nitrogen embrittlement

- Drive Type

- Belt drive

- Cleaning Access

- Hinged door

- Energy Efficiency

- Higher than direct drives

- Safety Design

- Safety interlock

- Bearings

- Permanently lubricated, air rinsing

- Feed Material Compatibility

- Sticky, moist, greasy products

- Working mechanism

- Pin mill with two driven pin discs

- Batch vs. inline flow

- Continuous operation

- Cleaning method

- Easy to clean, hinged mill door

- Automation level

- Adjustable pin disc speeds

- Pin disc speed adjustment

- Up to 240 m/s

- Application adaptability

- Suitable for greasy, oily, sticky and hygroscopic materials

- Temperature and vibration monitoring

- Preventative maintenance

- Pin rotation direction

- Adjustable

- Product mixing capability

- Intensive, agglomerate-free mixing

- Safety features

- Safety interlock available

- Continuous operation stability

- Trouble-free

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Yes/No

- Heat sensitivity

- High/Medium/Low

- Moisture content

- 0%-50%

- Viscosity

- Low/Medium/High

- Pharma design

- Optional

- ATEX certification

- Pressure relief design up to 1.4 bar

- Machine footprint

- Varies based on machine size (e.g., 250 - 800 model)

- Hinge mechanism

- Wide-opening mill door

- Discharge method

- Standard or tangential discharge

- Pin Disc Size

- Varies by model

- Adaptable for different applications

- Construction materials

- Cast or welded housing, mild steel or stainless steel

- Pressure rating

- Pressure relief design up to 1.4 bar

- Discharge method

- Standard / Tangential

- Pin disc speed and direction

- Adjustable

- Material

- Mild steel / Stainless steel

- Housing design

- Cast / Welded