Cocoa Powder Manufacturing Equipment

Find innovative production technology for making cocoa powder and connect directly with world-leading specialists

Cocoa minus its fats makes cocoa powder. Deriving this culinary element follows a careful process of roasting and winnowing cocoa beans before the nibs are ground, generating a liquor. The butter that results from melting fats is removed to leave the ingredient that defines recipes from brownies to a Frostbite cocktail.

Technology picks for cocoa powder

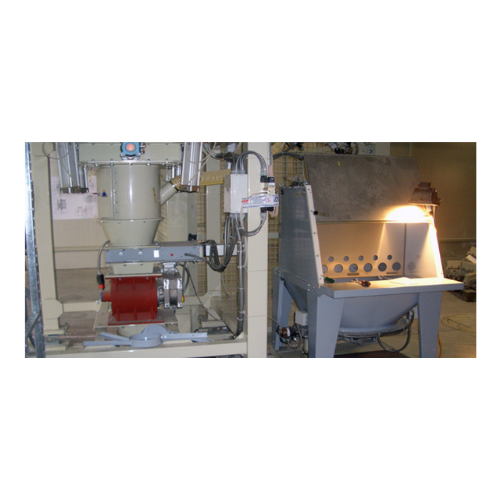

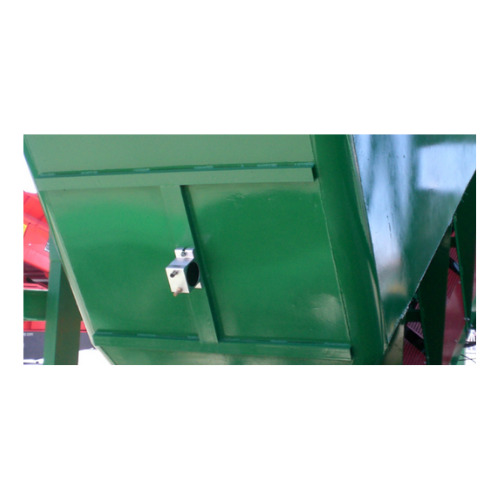

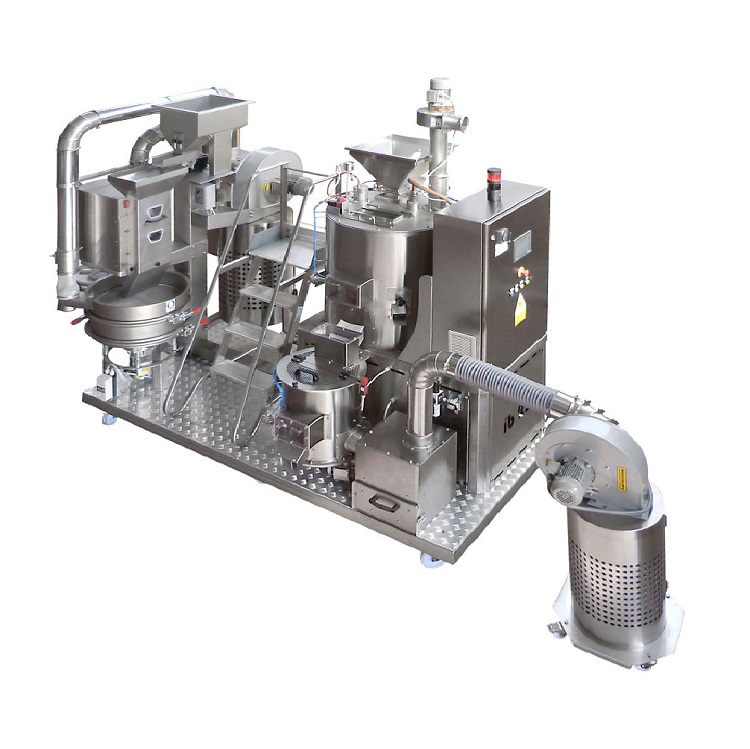

Cocoa powder processing line

Cocoa beans are first fermented, dried, roasted, and separated from their skins to obtain a coc...

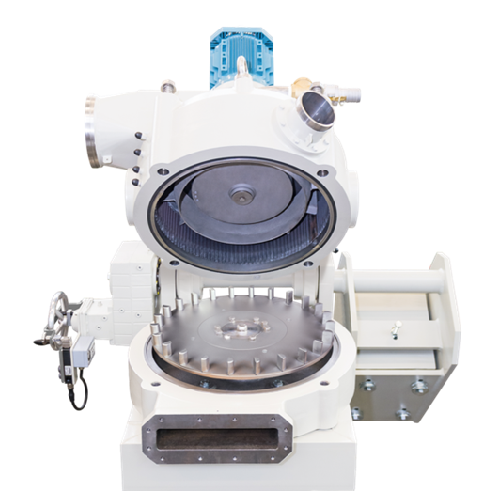

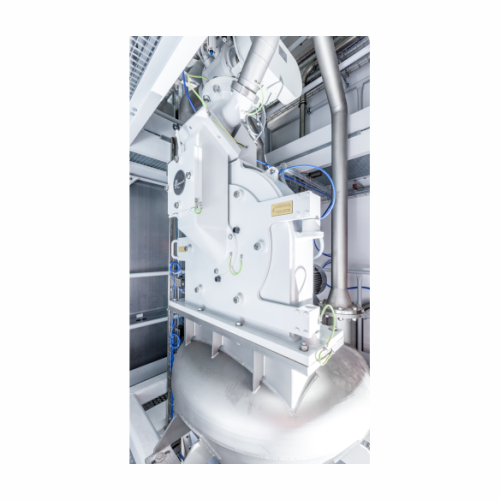

Alkalizing system for cocoa powder coloring

Achieve precise cocoa powder coloration and enhanced flavor development with a...

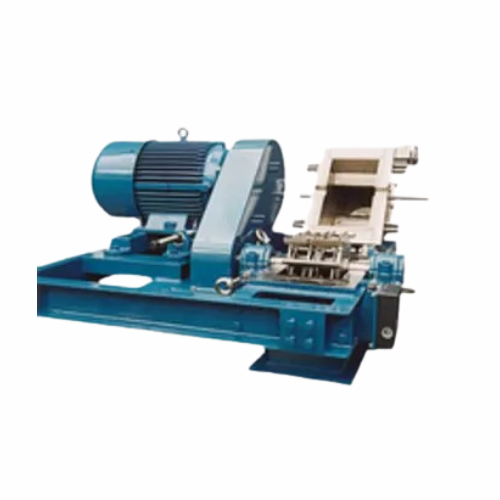

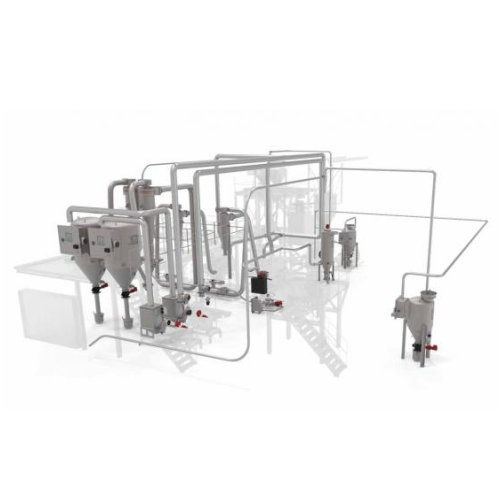

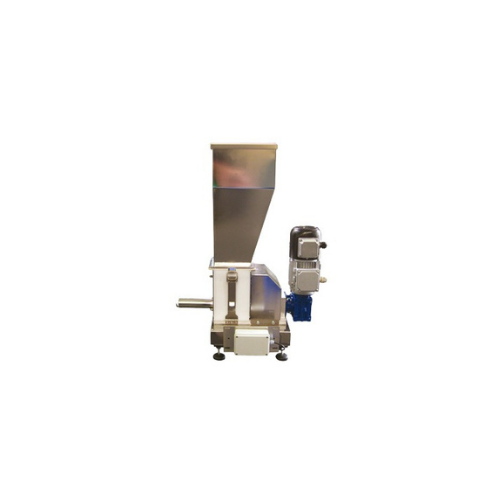

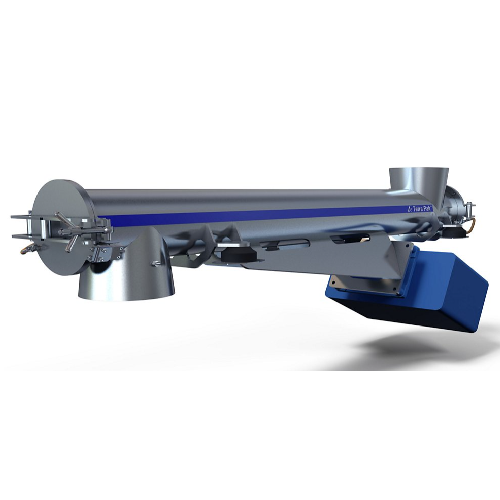

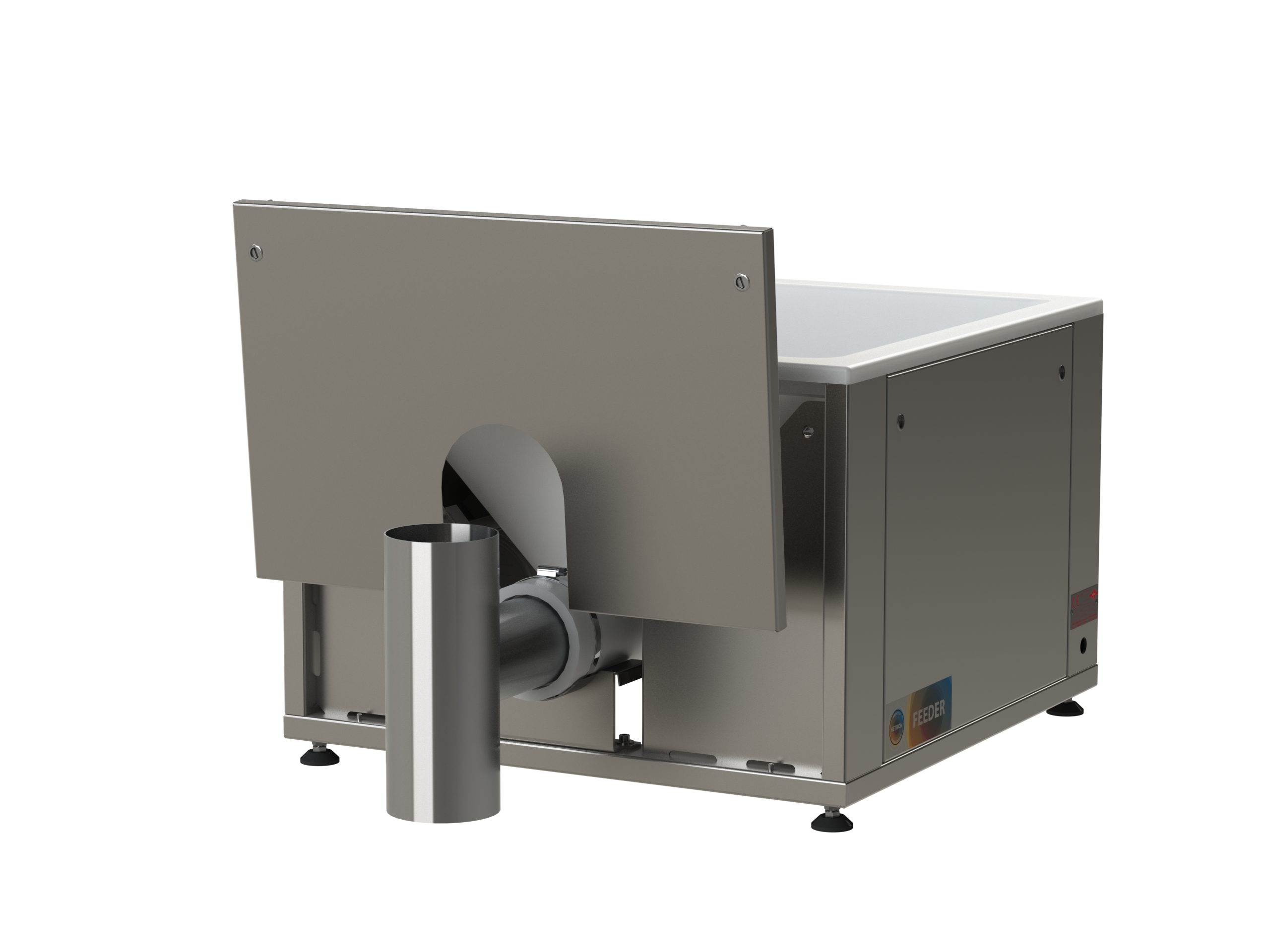

Systems for transporting cocoa powders and ingredients

Efficiently transport and dose your cocoa powders and semiliquid i...

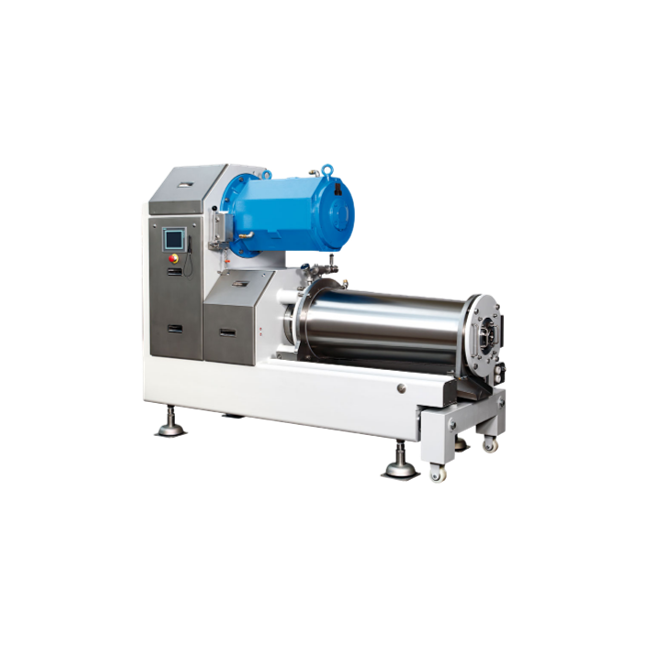

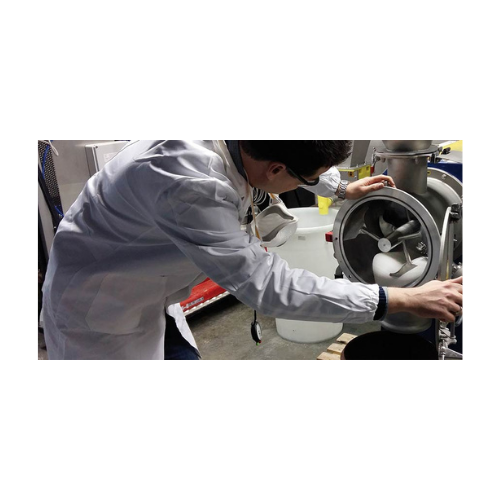

Ball mill refiner for fine cocoa grinding

Achieve high-precision grinding and refining of chocolates and cocoa with minima...

Select your cocoa powder process

Tell us about your production challenge

How natural cocoa powder is made

In order to process cocoa, the beans need to go through the process of roasting. For this, specialized stainless steel roasting machines are used, similar to those used in roasting almonds and peanuts.

Cocoa beans contain around 54% oils that are separated from the cocoa liquor that forms as the nibs are finely processed by the grinder. The remaining paste is then placed in a cocoa press and subjected to high pressure, hardening it into a “cocoa cake”. The compact block is subsequently passed through a series of crushers and grinding machines until it reaches the right granularity and is ready for the packaging machine.

Natural cocoa powder has a reddish-brown color and reaches a pH level between 5.3 and 5.8, producing a slightly acidic taste that intensifies the flavors of foods it eventually combines with. Not to be confused with cocoa butter which are both derived from the same bean but are processed differently.

Add alkali for the Dutch cocoa process

An alternative method, known as the Dutch process, immerses the cocoa in an alkali solution to neutralize its pH, blunting its acidity level. Using moisture reduction technology, the liquid parts are decreased to 5%, turning the mixture back into a powder but with a darker brown color. The Dutch process allows the cocoa powder to dissolve more quickly in recipes, making it an easier ingredient to work with than natural cocoa powder.

Different acidity levels for different recipes

The Dutch variation has a milder flavor compared with the natural type and does not activate a leavening agent like baking soda, so it is a perfect match for baked products that include baking powder such as fudgy cookies or chocolate marshmallows. The more intense chocolaty flavor of cocoa powder processed in the Dutch style also makes it an ideal option in industry in the preparation of hot cocoa, ice creams or puddings.

On the other hand, the acidity in the natural cocoa powder reacts with leaveners to produce carbon dioxide in batters. Traditional recipes for baked items like chocolate breads, cakes, or cupcakes typically have a carbon soda base, making natural cocoa powder the better ingredient.

Gentle drying and packing to guarantee your cocoa powder quality

The fine grains of cocoa powder are particularly sensitive to temperature fluctuations and the final drying process requires specialized processing equipment to extract any residual moisture content.

Cocoa powder is then checked for any unwanted particles that may have entered the production cycle. Using purposely-designed screening and separating technology, manufacturers can inspect the final product before packing.

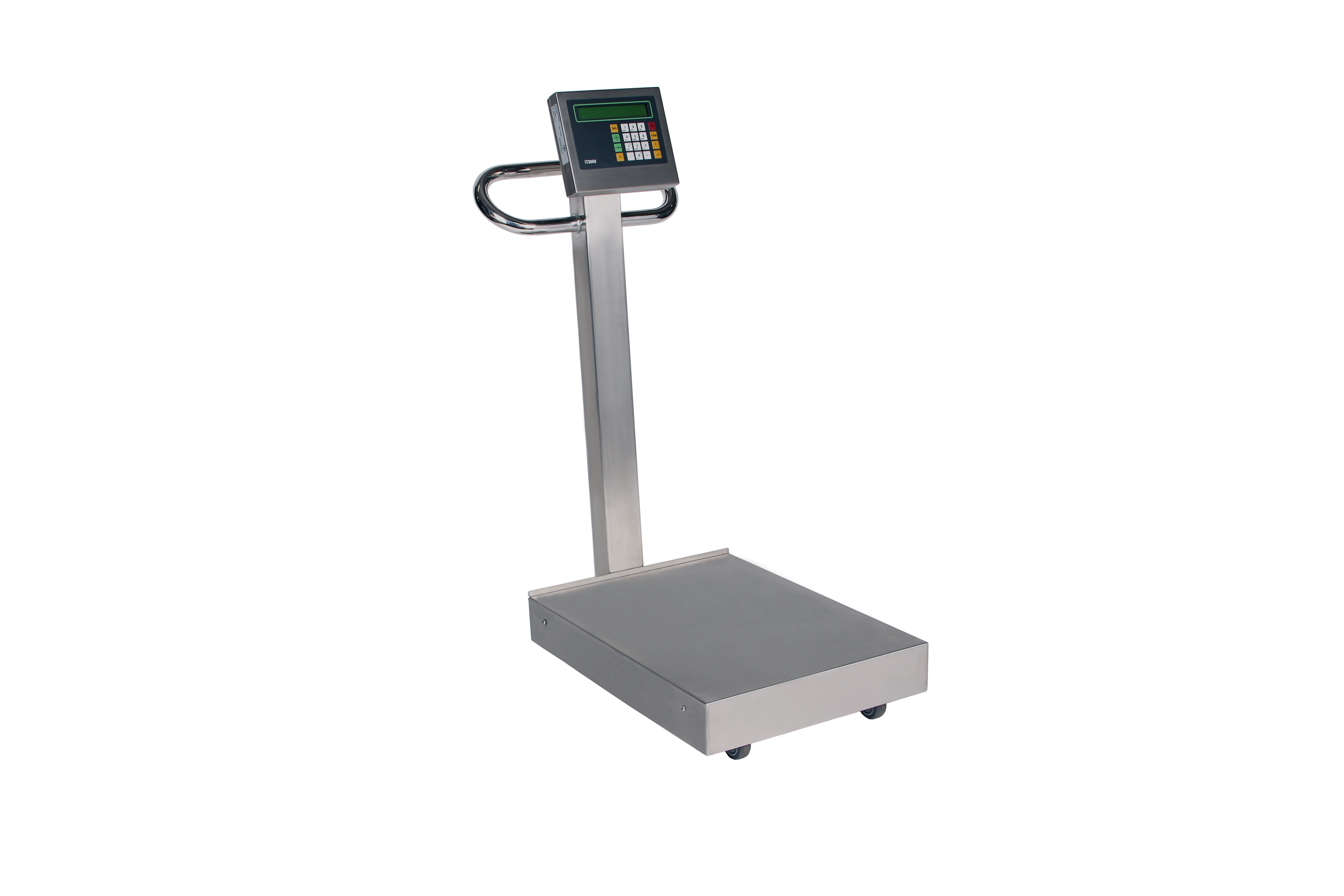

Finally, the powder is packaged into sachets, sacks, boxes or other storage solutions according to the needs of the end users. The main formats require different packaging systems using precise dosing scales and safe sealing machines, making sure cocoa powder arrives in the best condition to enrich the delectable creations that people love to share.

Processing steps involved in cocoa powder making

Which cocoa powder technology do you need?

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

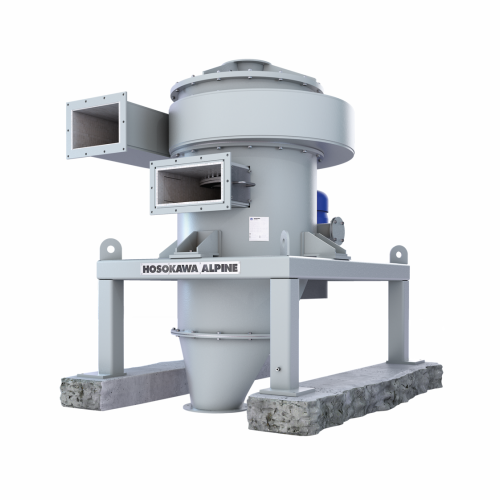

Impact classifier mill for fine grinding of brittle materials

Achieve precise particle size distribution with advanced g...

Unloader for conical bottom silos

Eliminate product flow challenges effortlessly with this hydraulic-driven unloader, ensur...

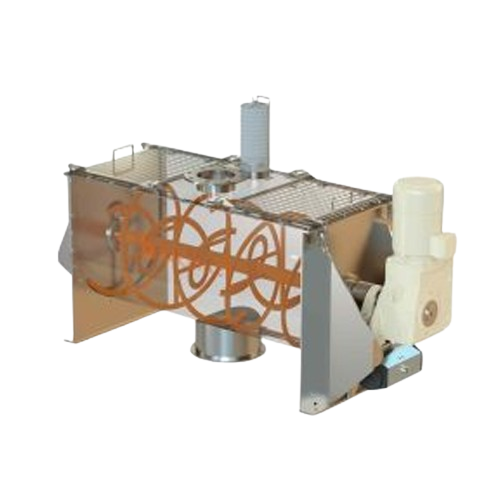

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

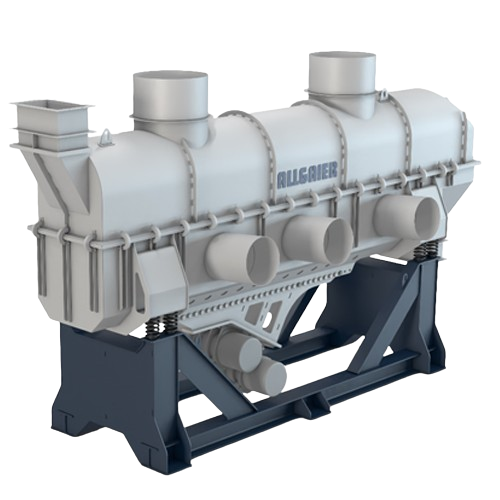

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Vacuum dryers for powders and bulk solids

Achieve precise drying and mixing of sensitive materials with advanced vacuum te...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

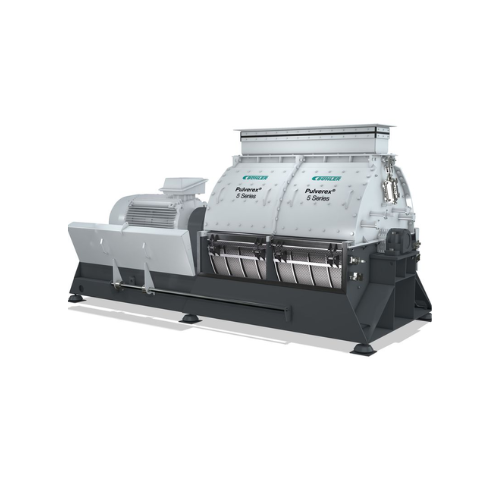

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

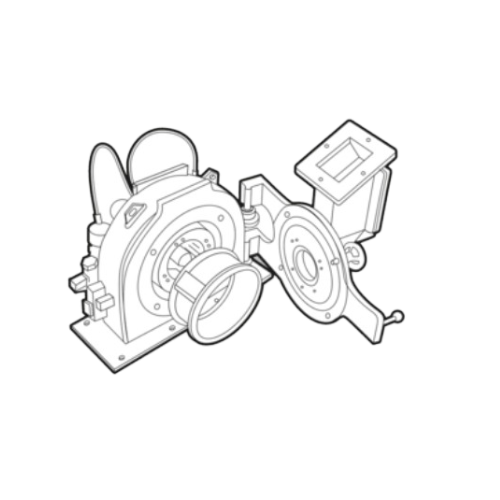

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

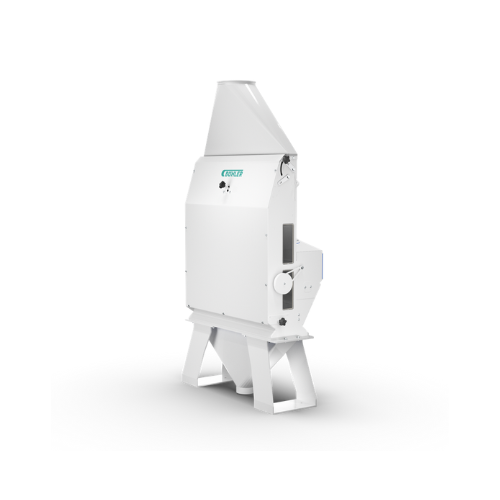

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Classifier mill for ultra-fine grinding and precise particle size control

Achieve consistent ultra-fine particle distr...

Air classifier for classifying industrial minerals

Achieve precise particle separation with advanced air classifiers, par...

Air classifier for fine to medium-fine separation

Reduce energy consumption and wear while achieving high precision in th...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

Rotary crushing valve for lump breaking

When handling bulk solids, effective pre-breaking and sizing are crucial to ensure ...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

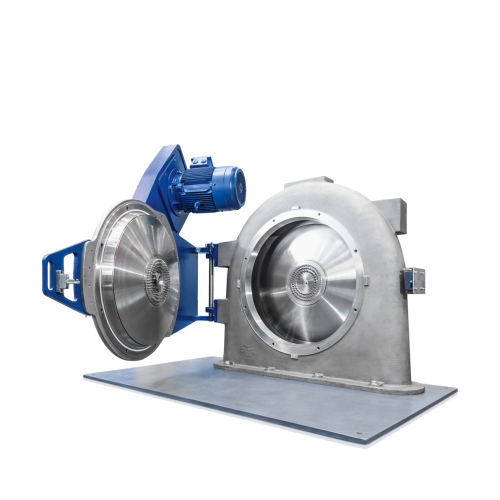

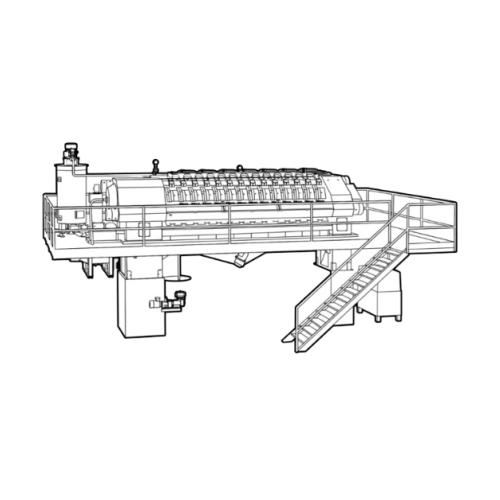

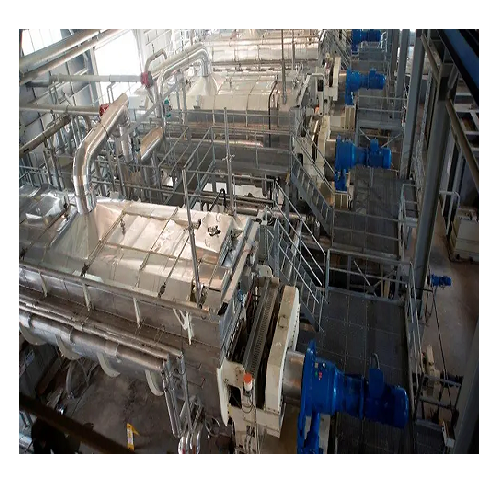

Cocoa pressing plant for high-capacity cocoa liquor processing

Optimize your cocoa processing by converting cocoa liquor...

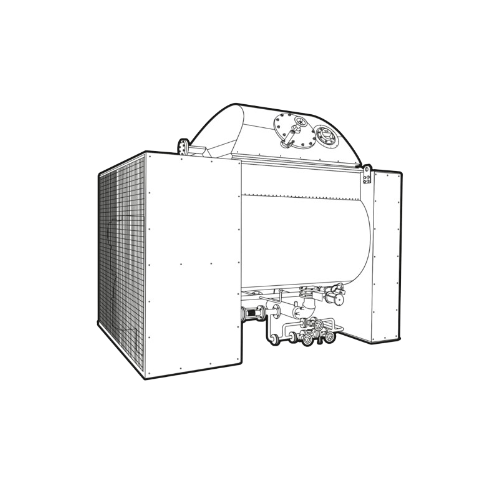

Cocoa sterilizing and alkalizing plant

Optimize cocoa product quality with a system engineered for precise sterilizing, alk...

Batch conche for chocolate making

Achieve optimal texture and flavor development in your chocolate with precise control ove...

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

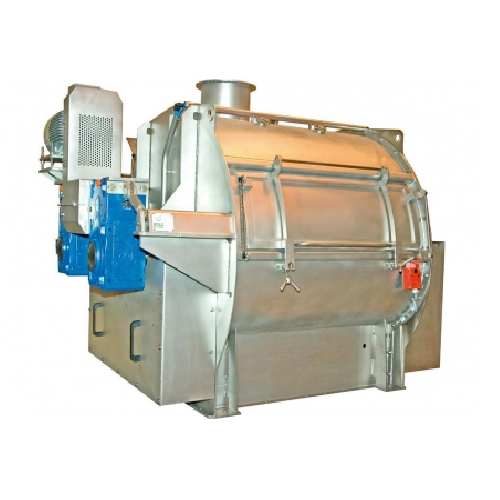

Double shaft batch mixer for chocolate production

Optimize your chocolate and confectionery production with precise mixin...

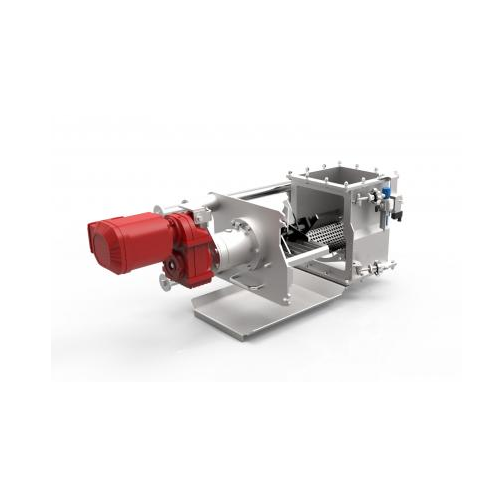

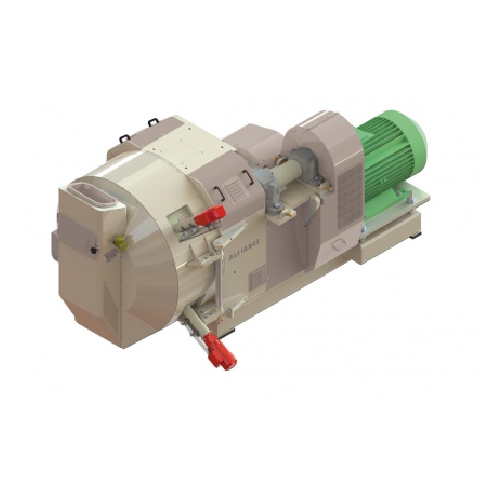

Pre-refiner for chocolate processing

Optimize pre-refining in chocolate and cocoa production with precise fineness control,...

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Industrial breaker for reducing large lumps and agglomerates

Efficiently break down challenging materials with a robust ...

Industrial centrifugal sifter for solid particulate materials

Quickly and accurately sift a wide range of powders and gr...

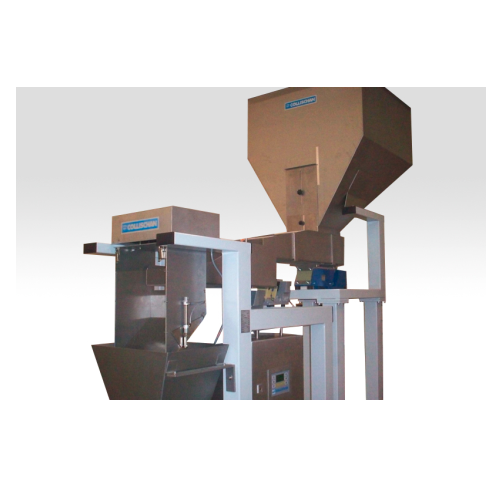

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

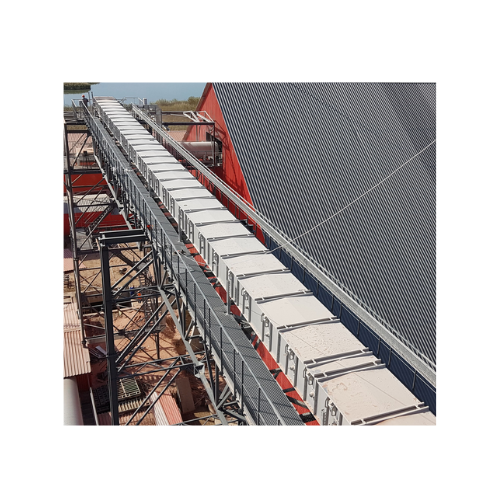

Enclosed belt conveyor for grain handling

Optimize your material transportation and ensure dust-free operations with this ...

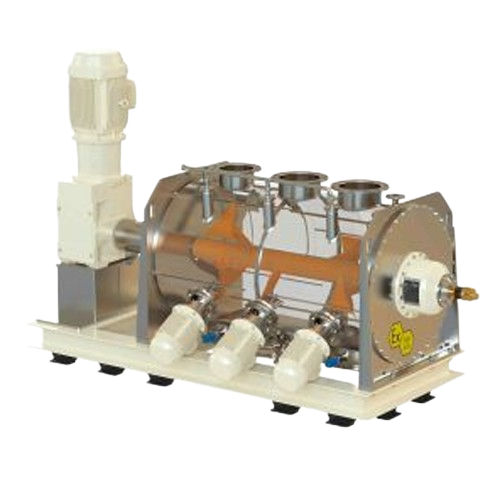

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Alkalizing system for cocoa powder coloring

Achieve precise cocoa powder coloration and enhanced flavor development with a...

Infrared pre-treatment system for cocoa beans

Unlock maximum yield and preserve flavor in cocoa processing with this innov...

Infrared pre-treatment for cocoa beans

Achieve optimal cocoa nib separation and consistent moisture control while preventin...

Cocoa nibs and malt roaster

Achieve precise roasting, sterilization, and taste control of cocoa and malt with adaptable heat...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Small plansifter for grain milling

Optimize your grain milling with a compact plansifter designed for high-speed, precise s...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Systems for transporting cocoa powders and ingredients

Efficiently transport and dose your cocoa powders and semiliquid i...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Horizontal vacuum paddle dryer for thermosensitive products

For high-viscosity products like active pharmaceuticals or p...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Dust-free big bag connection system for bulk solids

Eliminate dust and ensure reliable discharge with this vacuum docking...

Mill sifter for precise bulk density and particle size distribution

Achieve precise particle size and uniform bulk dens...

Paddle dryer for industrial sludge

Achieve consistent drying and pasteurization of complex materials with this advanced pad...

Fluidized bed dryer for industrial materials

Enhance product quality and energy efficiency with fluidized bed dryers, opti...

Filling and weighing station for chocolate production

Ensure precise and efficient chocolate mass depositing with a stati...

Self-cleaning silo filter

Ensure purity and compliance by trapping dust effectively during silo loading, while maintaining c...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Auger powder sampler for industrial quality control

Ensure precise quality control by integrating an auger powder sampler...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

Automatic bag slitting and emptying for powders

Streamline your powder-processing operations by seamlessly integrating bag...

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

Automated powder bag filling system

Streamline your powder packaging operations with a fully integrated system that automat...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

Powder separation cyclone for food and chemical industries

Optimize your powder production with advanced cyclone technol...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

Industrial powder fillers for various containers

Optimize your packaging line with high-speed powder fillers that handle d...

Pneumatic mixer for fluidizable bulk materials

Achieve uniform and gentle mixing of powdered ingredients with minimal effo...

Rotary feeder for powdered bulk materials

Achieve precise control in feeding and discharging powdered materials with a rot...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

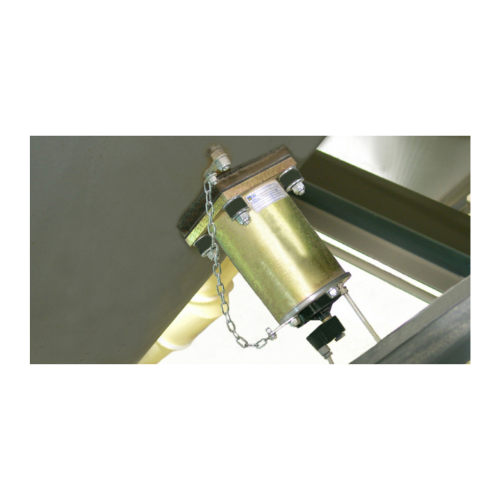

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

High flow rate Fibc discharger

Optimize your bulk material handling with a system designed for efficient and dust-free FIBC ...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Air cannons for resolving bulk material flow issues

Solve bridging and rat-holing issues in bulk material storage with po...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Loss-in-weight screw feeder for precise powder dosing

Achieve high precision in continuous dosing with this advanced scre...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Vibratory outlet hopper for bulk solids discharge

Reduce material handling challenges with highly efficient vibration tec...

Big-bag unloading station for bulk materials

Facilitate seamless integration into your production line with efficient bulk...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Manual bag tipping unit for powder handling

Ensure a contamination-free environment with a compact manual bag tipping unit...

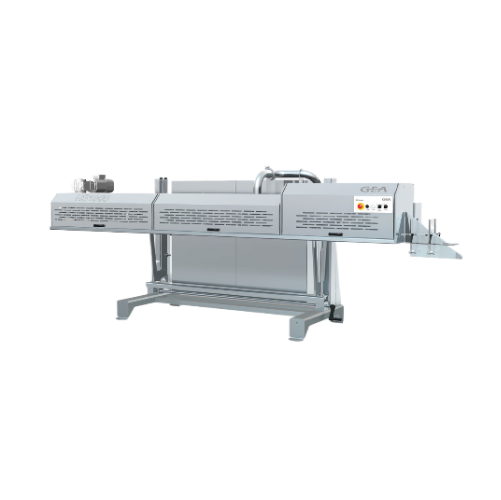

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this...

Cocoa bean processing line from cocoa pod to cocoa nibs

Streamline your cocoa production process by transforming raw coco...

High-capacity industrial sifter for chemical and food processing

Achieve unparalleled screening precision and efficiency...

Thermal conditioning for improved meal flow and starch digestibility

Ensure optimal meal flow and starch digestibility ...

Twin shaft paddle mixer for bulk materials

Achieve precise blend consistency with a twin shaft paddle mixer designed to ha...

Continuous mixer for accurate ingredient blending

Achieve precise mixing in continuous production with optimal control ov...

High-capacity pre-cleaner drum for grain silo storage

Optimize your pre-cleaning process with a high-capacity drum that e...

High-capacity sleeve filters for silo dedusting

Optimize your production with filtration systems that ensure efficient dus...

Pellet mill conditioner for optimal granulation

Enhance pellet quality and efficiency by seamlessly integrating steam mixi...

Pellet mill for powdery animal feed products

Maximize plant efficiency and product quality with a versatile pelleting solu...

Agricultural cleaner-separator for grain processing

Optimize your grain processing with a versatile cleaner-separator eng...

Efficient grinding and drying mill

Transform your production line with a versatile mill that simultaneously grinds, dries, ...

Sanitary modular bulk silos for efficient storage

Maximize your storage capacity and streamline assembly with a modular s...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

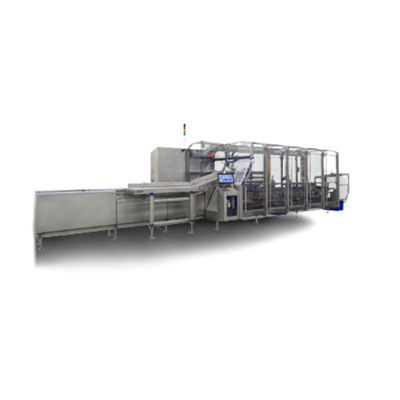

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Hygienic mobile scale

Having a reliable and accurate weighing and measuring solution is absolutely essential, especially in t...

Fast gravimetric powder microdosing 50 - 200 g

Micro-dosing powders of high-value food or chemical products can be challen...

Metal detector for granulated products

Free-fall applications, such us flour, sugar, spices and other granulated or powdere...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

Multifrequency sieve for separation of difficult particles

Separating particles in difficult-to-process materials for pr...

Screener and separator of dry powder

Many industries require the effective screening and separating of a range of dry powde...

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Packaging machine for preformed paper bags from 500 g to 5 kg.

Paper bag filling and closing for larger quantities of ma...

Horizontal form, fill and seal machine for bags up to 10kg

Bagging small quantities of solids or liquids, whether in pap...