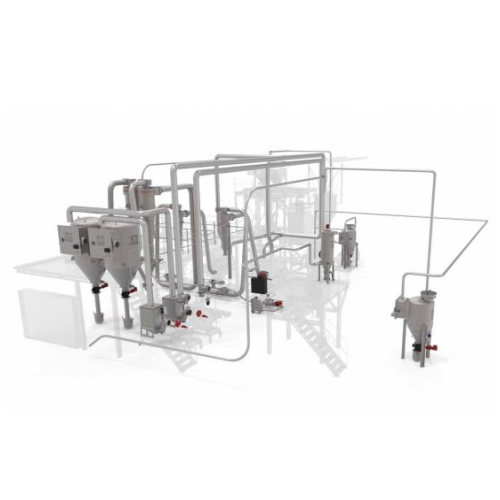

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and granulates with precision pneumatic conveying, ensuring efficient handling and minimal product damage across extensive production lines.

Transports and Dispenses Bulk Materials

Dinnissen’s Pneumatic Conveying System offers a versatile solution for efficiently transporting bulk materials across various industries such as food, pharma, and chemicals. This system utilizes both dilute-phase and dense-phase transport methods, enabling flexible adjustments based on the materials involved, like milk powder and mineral granules. Offering throughput capacities of up to 50 tons per hour and conveyance lengths up to 700 meters, this system is ideal for operations requiring continuous, high-speed, and automated processes. It integrates seamlessly with existing production lines, using either air or inert gases like nitrogen to ensure explosion and oxidation-free environments. The system’s hygienic design supports dust-free transport, reducing product damage while maintaining high cleanliness standards. Available with features like high-pressure locks or transmitting barrel transport, it meets strict compliance standards with optional material choices and certifications suited for sensitive applications. Maintenance is simplified with options for automatic cleaning systems and ultra-dustproof sealing, ensuring reliability and efficiency in various applications.

Benefits

- Ensures dust-free and hygienic transport, minimizing contamination risks.

- Reduces product damage with controlled conveying speeds and phases.

- Adapts to versatile material types and conditions with customizable transport methods.

- Saves energy and operational costs through efficient air/gas usage.

- Integrates seamlessly into existing production lines, enhancing process efficiency.

- Applications

- Food, Chemicals, Feed, Pet food, Pharma, Minerals, Aquafeed, Dairy

- End products

- Cocoa powder, Pet food kibbles, Chemical powders, Sugar, Granulated animal feed, Mineral granules, Milk powder, Fish pellets, Chalk, Sand, Pharmaceutical powders

- Steps before

- Intake, Mixing, Weighing, Grinding

- Steps after

- Screening, Filling, Packaging, Sampling

- Input ingredients

- powders, grains, granulates, bulk goods, abrasive materials, greasy raw materials, milk powder, sugar, sand, chalk, milk, cocoa

- Output ingredients

- hygienic transport, dust-free transport, suction transport, overpressure transport, dilute-phase transport, dense-phase transport, high transport speeds, minimal product damage, explosion-free transport, oxidation-free transport

- Market info

- Dinnissen is renowned for its expertise in process technology, specializing in innovative solutions for powder handling, mixing, and bulk materials processing for various industries, including food, feed, and chemicals, with a reputation for quality and custom engineered solutions.

- Conveyance length

- up to 700 meters

- Capacity

- up to 50 tons per hour

- Gas velocity with dilute-phase conveying

- 4-15 m/s

- Gas velocity with dense-phase transport

- 20-30 m/s

- Air pressure for slow-flow transport

- 0.2 to 0.5 bar

- Transport medium

- Air or gas

- Transport method

- Suction / Overpressure

- Phase type

- Dilute-phase / Dense-phase

- Transport speed

- 4-30 m/s

- Transport capacity

- Up to 50 tons per hour

- Conveyance length

- Up to 700 meters

- Cleaning method

- Automatic / CIP

- Medium reliance

- Air / Gas

- System type

- Closed-loop / Open-loop

- Automation level

- PLC-controlled

- Product handling

- Dust-free environment

- Hygiene level

- High precision and hygiene

- Energy consumption

- Low

- Cleanability

- Easy to clean, hygienic

- Corrosive resistance (e.g. acids)

- Corrosion-resistant materials

- Density/particle size

- Powders, grains, granulates

- Conveyance length

- up to 700 meters

- Capacity

- up to 50 tons per hour

- Gas Choice

- Air / Inert Gas (e.g., Nitrogen)

- Phase of Transport

- Dilute-phase / Dense-phase

- Transport Pressure Type

- Negative Pressure / Positive Pressure

- System Design

- Custom Tailored to Product

- Integration with Current Systems

- Yes, suitable for integration

- Cleaning Method

- Automatic Cleaning / Ultra-dustproof

- Load vs. Conveyance Air Ratio

- Optimal for low-speed transport

- Transport Medium Generation

- Medium Pressure Blower / Compressor

- Transport Speed

- Adjustable Speeds

- Control Panel Type

- Available on request

- Explosion-proof Design

- Closed-loop with Inert Gas

- Slow-flow Transport Option

- Available for special requirements

- Gas Recovery System

- Innovative system minimizes gas costs