Aquafeed

Find innovative production technology for making aquafeed and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Which aquafeed technology do you need?

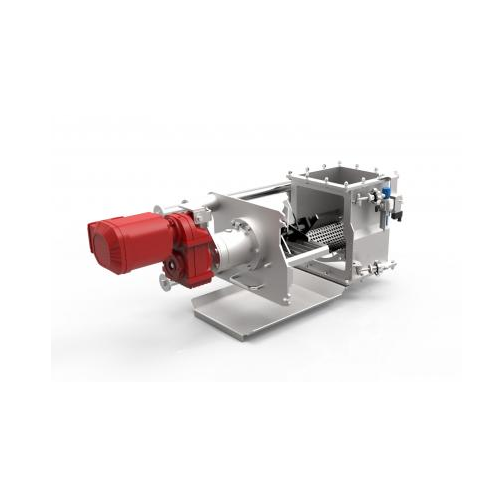

Screw press for insect protein extraction

Address the rising protein demand with our screw press, designed to efficiently ...

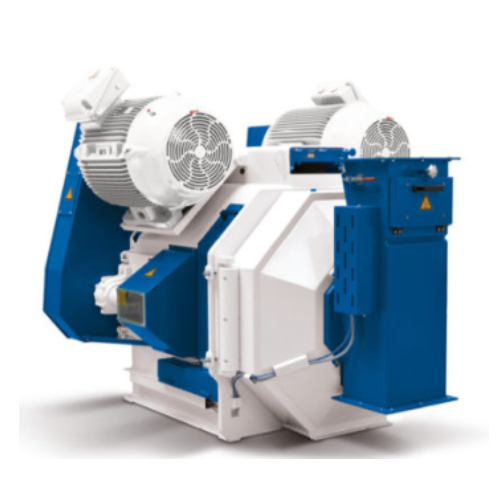

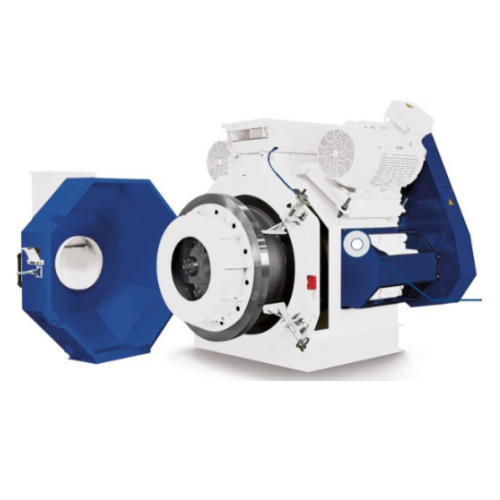

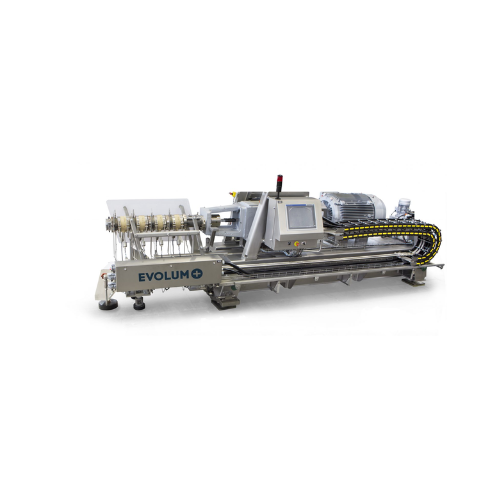

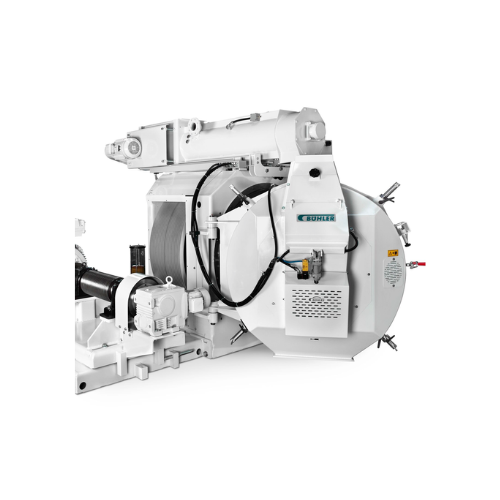

Pellet mill for high efficiency animal feed production

Achieve stable, vibration-free pellet production with enhanced ene...

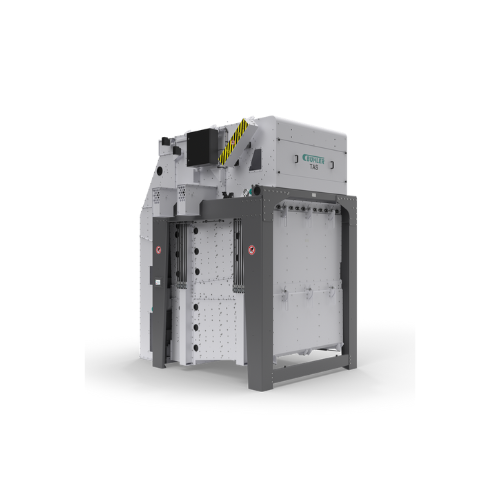

Pellet mill for animal feed production

Optimize your feed production with a robust pellet mill designed to enhance the dura...

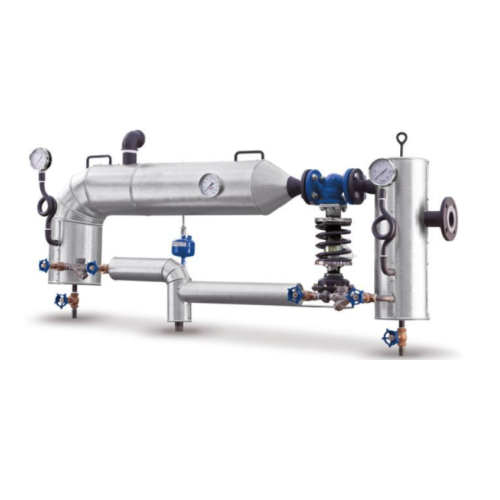

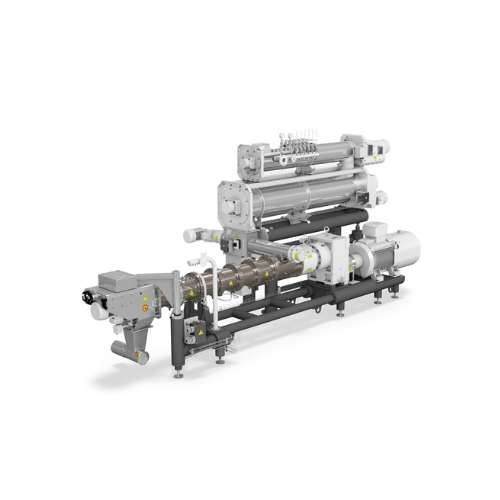

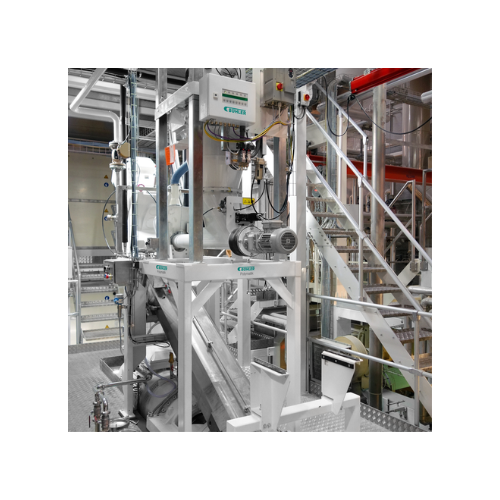

Steam injection systems for animal feed production

Enhance product quality in animal feed production with steam injection...

Cryloc rotary screens for grain processing

Efficiently sort and separate fine particles with high precision to enhance pro...

Industrial vibrating sieves for pellets and fine particles

Optimize feed quality and material flow in your production li...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

Cylindrical storage silos for long-term raw material storage

Efficiently store bulk raw materials for extended periods w...

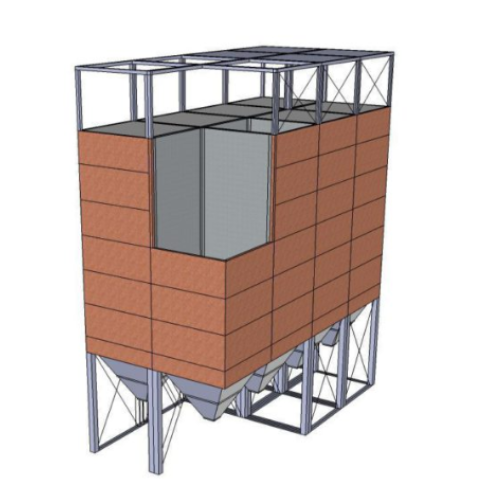

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

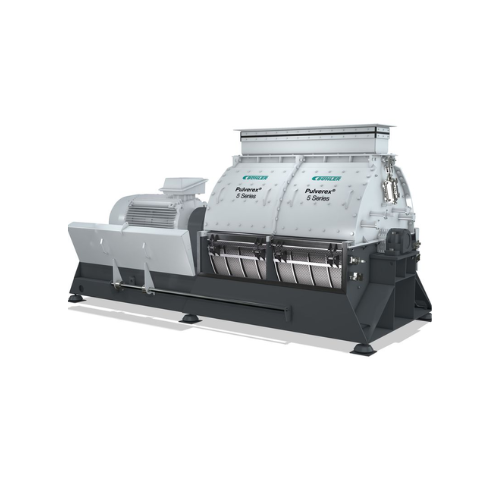

Hammer mills for high-efficiency grinding in feed production

Optimize your feed production with high-efficiency grinding...

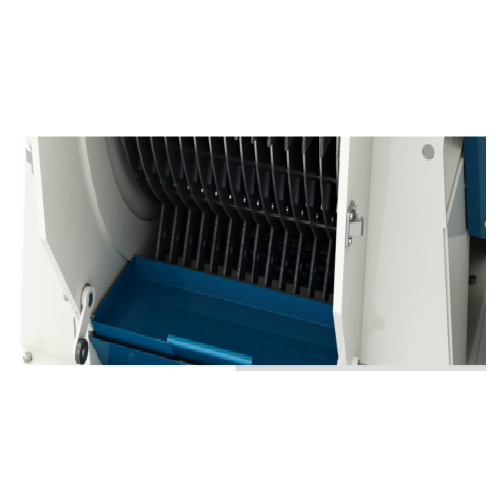

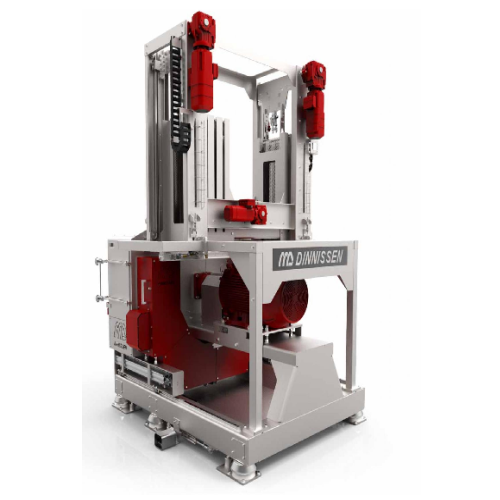

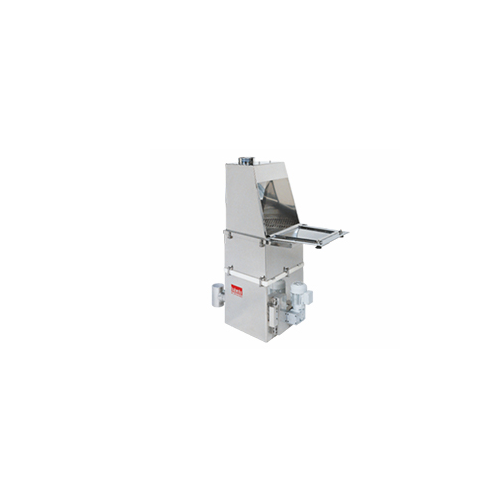

Quick hammer exchange system for hammer mills

Streamline hammer replacement in your milling process with a system designed...

Roll feeders for consistent hammer mill supply

Ensure precise and controlled feedstock delivery to your hammer mill, effec...

Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and c...

High efficiency roller mill for grain and oilseeds

Optimize your crushing and grinding processes with a versatile roller ...

Continuous mixers for feed mill applications

Optimize your liquid incorporation process with continuous mixers that ensure...

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

Horizontal ribbon mixers for animal feed production

Experience precise and efficient mixing with low energy consumption f...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

Inline and continuous weighers for accurate product flow management

Maintain precision and efficiency in your productio...

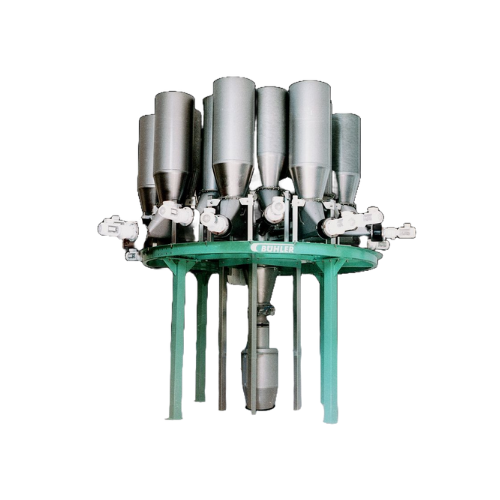

High accuracy micro dosing system

When handling diverse ingredients, precise dosing is crucial to ensuring consistent produ...

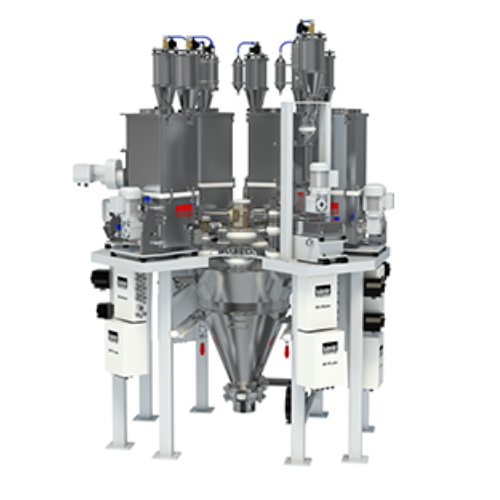

Micro-ingredient dosing system for animal feed production

Optimize your feed formulation accuracy with precision dosing,...

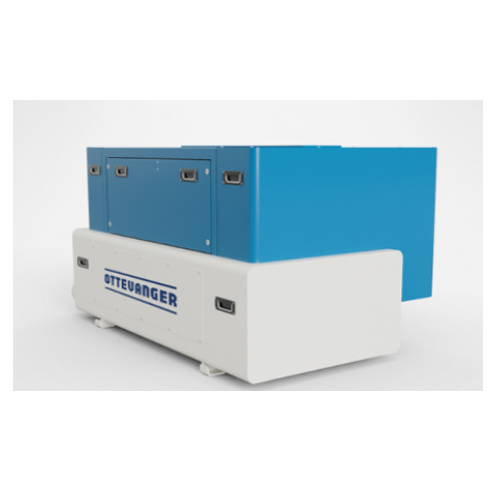

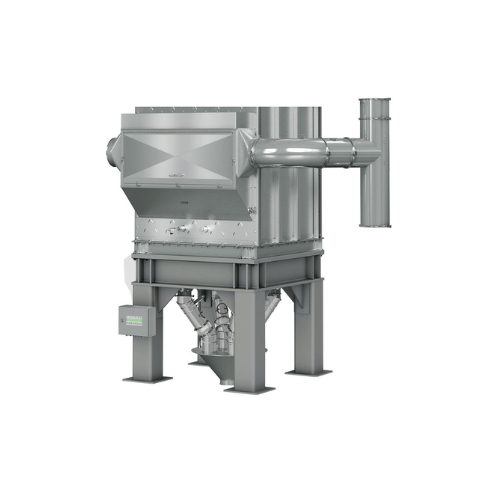

Counterflow pellet coolers

Optimize temperature control and enhance product integrity in your feed production line with prec...

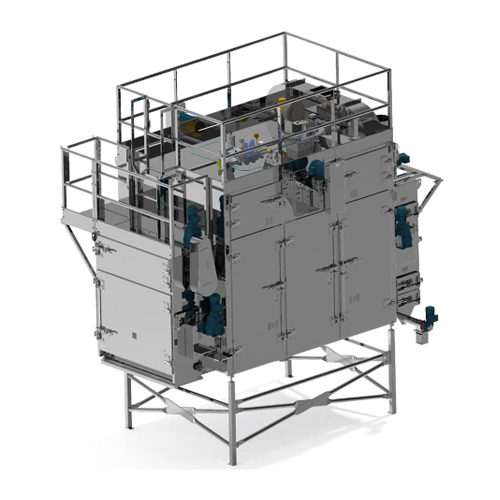

Counterflow dryer for pet food and fish feed

Optimize moisture control and enhance feed quality with efficient drying, cru...

Industrial control panel construction

Streamline your production line with advanced panel building solutions that enhance a...

Process automation for feed mills

Optimize your feed production line by seamlessly integrating advanced process automation ...

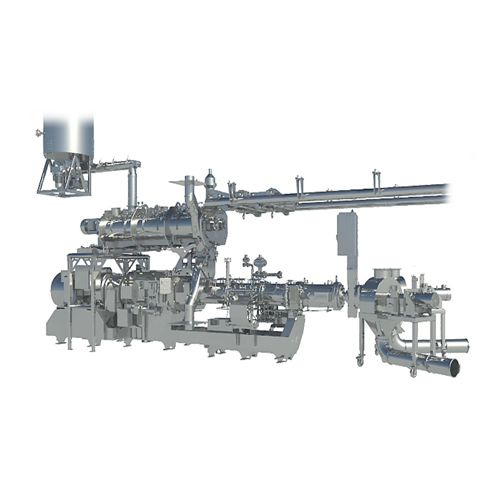

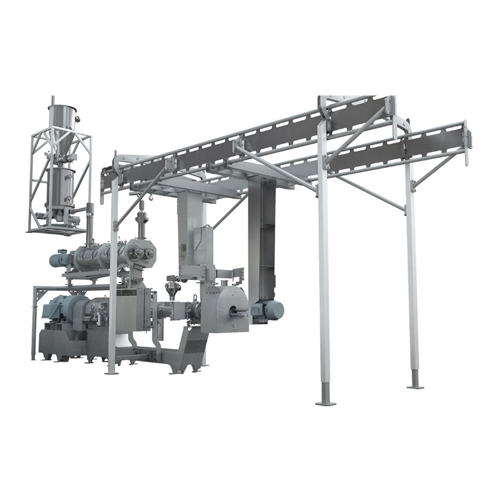

Extruders for animal feed production

Optimize nutritional value and ensure efficient processing of animal and aqua feeds wi...

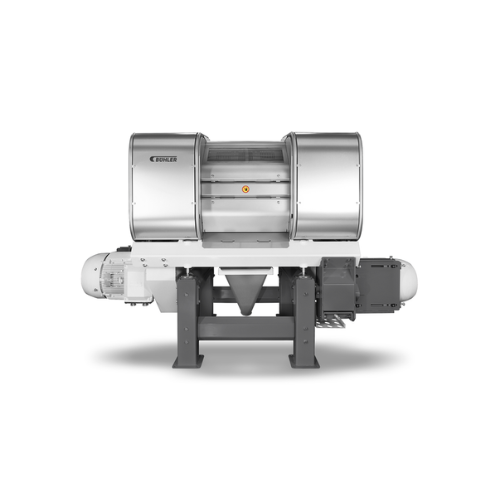

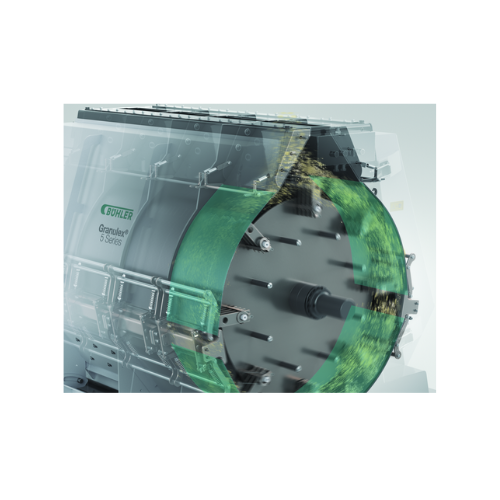

Industrial hammer mill for granulate grinding

Optimize the grinding process in feed production with a high-efficiency solu...

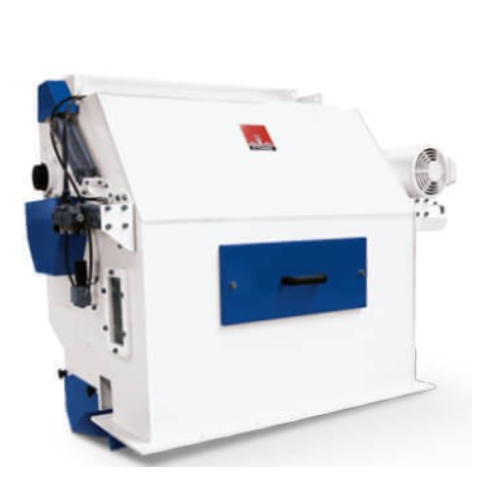

Hammer mill for efficient particle size reduction in feed mills

Optimize your feed milling operations with this hammer m...

Feed expander for improved pellet mill output

Enhance your feed quality and production efficiency with a robust expander d...

Hot start conditioner for feed and food processing

Enhance your production process with a high-efficiency thermal heating...

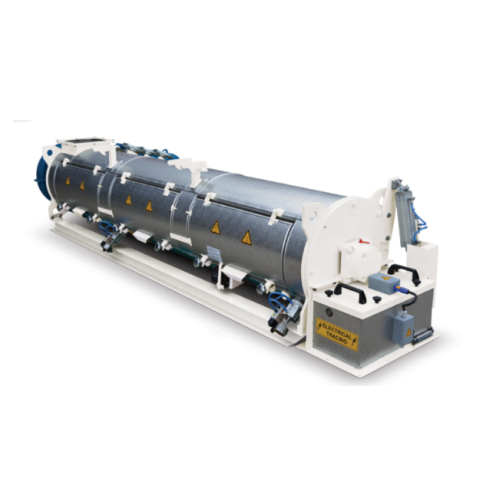

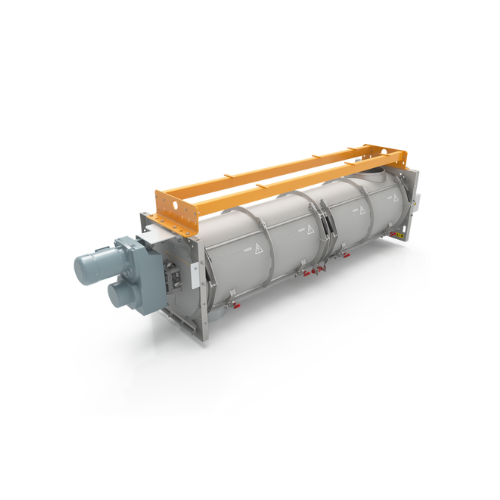

Retention time barrel for feed pelleting

Enhance your feed processing efficiency with a specialized retention time barrel, ...

Bucket elevators for bulk material handling

Efficiently transport and discharge granular and powdered materials with preci...

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

Efficient powder and granulate flight conveyors

Elevate your production efficiency with our cutting-edge flight conveyors,...

Rotary dischargers for powders and granules

Prevent production halts with this solution designed for efficient discharge o...

Screw conveyors for grain processing and feed mills

Optimize your production line with versatile screw conveyors, designe...

Feed pellet crumbler

Achieve precise size reduction of feed pellets with high efficiency and minimal fines, optimizing your p...

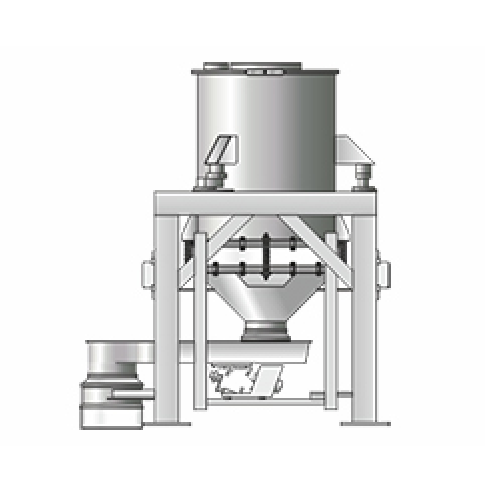

Batch weighers for large-volume powder and granulate weighing

Ensure precise ingredient dosing and streamline your produ...

Industrial pre-cleaners for raw material safeguarding

Effectively eliminate foreign objects from your raw materials with ...

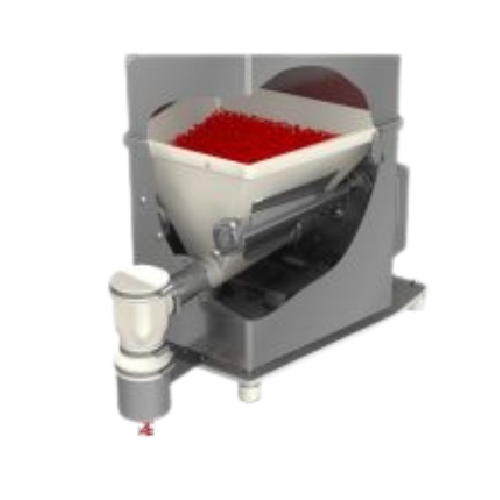

Continuous coater for pellet and extrudate liquid addition

Efficiently enhance your feed products by uniformly adding li...

Vacuum coaters for high liquid addition in feed production

Enhance your feed production with precision liquid coating, s...

Feed mill compactor for improved pellet quality

Optimize your feed production with a compactor designed to enhance pellet ...

Single conditioner for feed mills

Achieve homogeneous mixing and enhanced hygiene in feed production with adjustable paddle...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Industrial shredder for diverse material reduction

Achieve precise and efficient material resizing for diverse applicatio...

Industrial vibrating sifters for granular material separation

Achieve precise particle separation and ensure product pur...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Continuous mixer for industrial powders and liquids

Achieve precise and efficient mixing of solids and liquids with minim...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

R&d mixer for small batch experimentation

Perfect your mixing techniques swiftly with precision-controlled small batch exp...

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

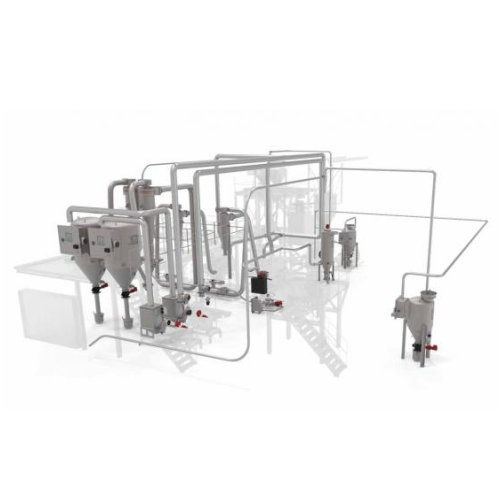

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

Product handling system for big bags and containers

Optimize your production line with a comprehensive system for transpo...

Rotary drum sifter for pellets and chunks

Achieve precise particle separation and minimize product loss with a rotary drum...

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Hammer mill with automatic screen exchange

Optimize your milling operations with a high-speed solution that ensures seamle...

Industrial hammer mill for grinding and sifting

Ensure precise particle size reduction and consistent product quality with...

Fast screen exchange grinding solution for medium-hard products

Maximize your milling efficiency with a solution that al...

High-care big bag filling system for hygienic environments

Ensure precise hygienic filling of Big Bags in high-care envi...

Mechanical horizontal conveyor for powders and granulates

Efficiently handle and transport your delicate powders and gra...

Vertical transport for bulk goods

Efficiently move bulk goods vertically with minimal energy usage, ensuring seamless integ...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial mixer for moisture conditioning

Ensure precise moisture levels and homogeneous mixtures for complex extrusion p...

Big bag conditioning system for compact materials

Struggling with clumped materials during unloading? This system expertl...

Calibratable big bag filling station for dust-free operations

Ensure precise, dust-free filling of bulk bags with ergono...

Industrial breaker for reducing large lumps and agglomerates

Efficiently break down challenging materials with a robust ...

Centrifugal mill for fine grinding in industrial processes

Achieve exceptional fineness without overheating your materia...

Industrial centrifugal sifter for solid particulate materials

Quickly and accurately sift a wide range of powders and gr...

Bag emptying system for bulk material handling

Streamline your material processing operations with a versatile solution de...

Hygienic industrial grinder for food and pharma applications

Achieve optimal hygiene and efficiency in your grinding pro...

Drum and container emptying system

Ensure safety and efficiency when handling and emptying drums or containers, whether dea...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

Bag-in-box filling system for packaging efficiency

Streamline your packaging process by integrating filling and boxing in...

Oilseed flaking mill

Enhance flake consistency and output efficiency with advanced roll technology designed to optimize your ...

Industrial moisture and temperature control conditioner

Optimizing moisture absorption and temperature management, this c...

Centric pelletizer for direct extrusion

Effortlessly transform materials into uniform granules with our high-speed pelletiz...

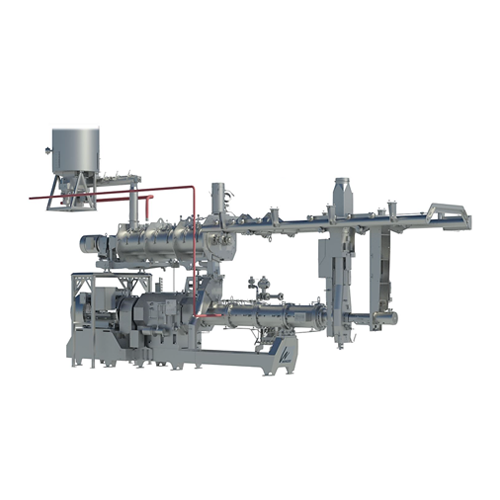

High-performance twin-screw extruder for food production

Enhance your production line efficiency and product quality with...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Vertical hammer mill for feed and grain processing

Optimize your milling operations and improve energy efficiency with th...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Automatic rice whitening solution

Need consistent rice whiteness and bran removal without manual intervention? This high-sp...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

Pellet mill for biomass and sunflower hulls

Achieve high-speed, continuous production of durable pellets from varied mater...

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

Commercial pasta press for diverse ingredients

Optimize your pasta production with a flexible solution capable of handling...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Retentioner for animal feed safety enhancement

Enhance your feed production line with a retention system designed for unif...

Horizontal hammer mill for grain processing

Optimize your grinding processes with our horizontal hammer mill, designed to ...

Industrial hammer mill for size reduction in food and feed processing

Achieve precise grinding and milling for diverse ...

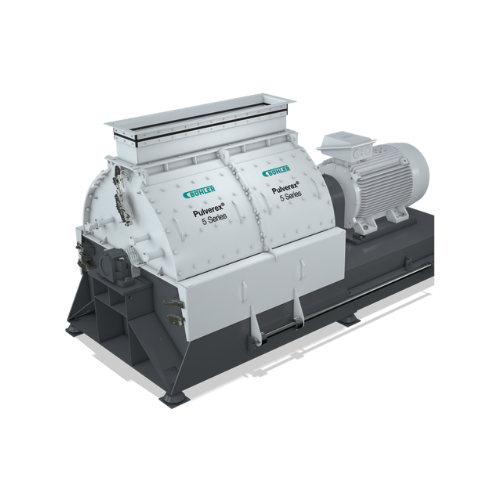

High-efficiency pulverizer for ultra-fine applications

Optimize your production of animal and aqua feed with this high-sp...

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Fully automatic bagging station for granular products

Streamline your packaging line with a high-speed solution designed ...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Flaking mill for oilseeds

Achieve consistent, high-throughput flake production with precise thickness control, ideal for enh...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

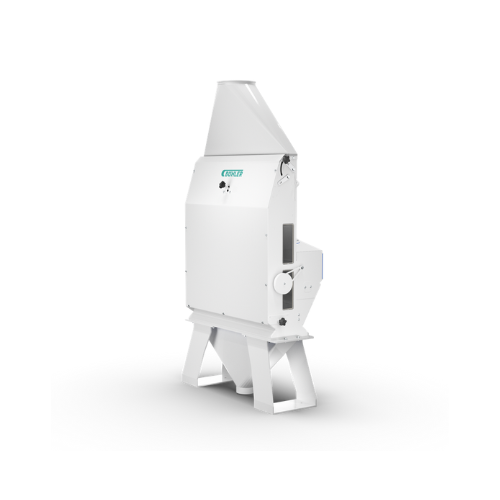

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

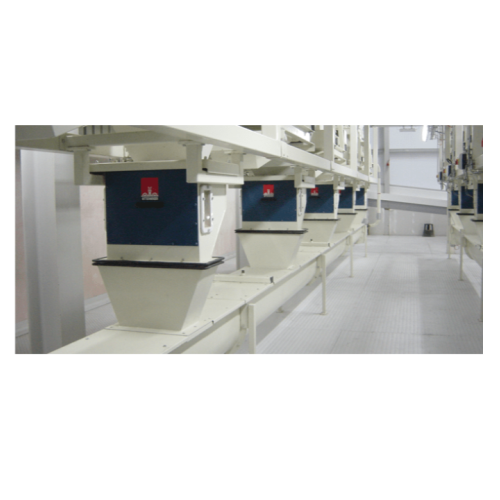

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Cracking mill for oilseeds and feed processing

Maximize your production efficiency with advanced cracking and milling solu...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Hammer mill for size reduction in food and feed processing

Efficiently tackle size reduction challenges with a versatile...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

Hammer mill for animal feed grinding

Achieve precise granulation with high throughput and energy efficiency, while reducing...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Micro-dosing system for animal feed additives

Achieve precise and consistent feed formulation with high-precision micro-do...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

High capacity horizontal dryers and coolers for industrial applications

Achieve consistent moisture levels and uniformi...

Light duty oven for snacks and light density foods

Maximize efficiency with precision-controlled drying and heating of sn...

Extruder for aquatic feed production

Efficiently produce a wide range of aquatic and pet feed with precise control over pel...

Conical twin screw extruder for pet food and aquatic feed

Precision-engineered for high-speed extrusion and drying proce...

High-sme extruder for structured meat analogs

Enhance production versatility with precise extrusion control, accommodating...

Single screw extruder for pet food and aquatic feed

Maximize production capacity and optimize product quality with advanc...

Extruder for high-volume pet food production

Maximize production efficiency with an advanced extrusion system designed for...

Coating and enrobing system for pet foods and treats

Achieve precise coating and flavoring of various food and feed produ...

Convection roaster for pet food and delicate food products

Achieve optimal texture and moisture control in delicate food...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pellet oil coating unit for feed production

Enhance feed pellet nutrition and quality with precise oil, enzyme, and methio...

Industrial smoking chamber for smoked meat and fish products

Achieve consistent smoky flavors and enhanced textures in y...

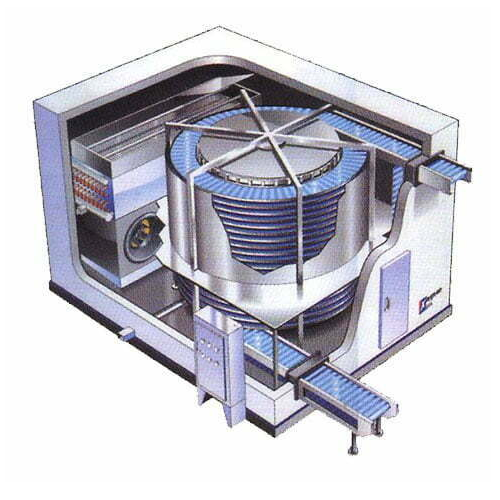

Industrial spiral freezer for quick-frozen food

Optimize your freezing process with a compact spiral design that minimizes...

Commercial patty making machine

Optimize your patty production with a machine designed to meet diverse culinary demands, off...

Horizontal contact plate seafood freezer

Achieve rapid, efficient freezing with the Horizontal Contact Plate Seafood Freeze...

Bubble type fruit and vegetable washer

Ensure your produce is impeccably clean and damage-free with our bubble-type washing...

Automatic fish cutting solution for diverse processing needs

Optimize your fish processing with precision cutting techno...

Industrial food drying oven

Achieve efficient dehydration and heat curing with precision control, ensuring uniform drying ac...

Fruit and vegetable drying equipment

Achieve optimal moisture control for your fruits, vegetables, and herbs with versatile...

Bin activator for reliable bulk solids discharge

Ensure reliable flow and prevent compaction in your production line with ...

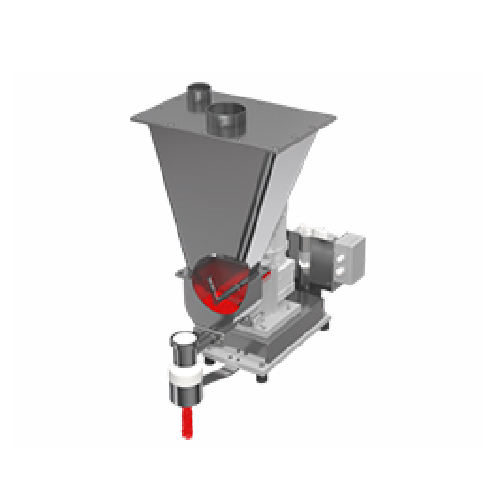

Volumetric feeder for flowable ingredients

Ensure consistent and precise dosing of diverse materials in your production li...

Volumetric feeder for consistent ingredient flow

Achieve precise and consistent ingredient dosing in your production line ...

Single screw feeder with stirring agitator for powders and pellets

Ensure consistent mass flow and precise dosing with ...

Twin screw feeder with stirring agitator for poor flowing powders

Optimize your processing line with a highly adaptable...

Loss-in-weight feeder for flowable ingredients

Achieve precise ingredient delivery with this feeder, designed to handle a ...

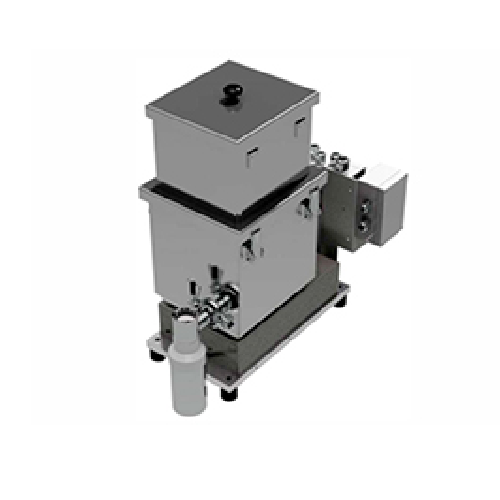

Laboratory loss-in-weight feeder for powders or pellets

Achieve precise dosing for lab-scale trials with this versatile f...

Loss-in-weight feeder for liquids

Achieve precise and continuous liquid dosing with high accuracy, adapting seamlessly to y...

Loss-in-weight feeder for non-hygroscopic ingredients

Ensure precision in your dosing and weighing processes with this ad...

Single screw loss-in-weight feeder for powders and pellets

Ensure precise dosing and mixing in continuous automated oper...

Twin screw volumetric feeder for poor flowing powders

Struggling with poor flowing or floodable powders? This twin screw ...

Vibrating tray loss-in-weight feeder for grained ingredients

Achieve precise and continuous dosing of free-flowing solid...

Weigh-belt feeder for industrial processes

Efficiently manage material flow and precision with a dependable weigh-belt fee...

Dust filter for loss-in-weight feeder refill

Optimize your feeder operations by effectively filtering displaced air and mi...

Bigbag discharge station

Efficiently manage bulk material unloading with this solution, which facilitates seamless dischargin...

Hopper scale for precision batching

Achieve high batch accuracy with a central weighing hopper engineered for seamless inte...

Batch ingredient dosing system for high-accuracy weight control

Achieve precise weight measurement for multi-ingredient ...

Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consiste...

Double screw batch feeder for poorly flowing powders

Effectively manage challenging powders with precise batch dosing and...

Feeder controller for gravimetric feeders

Optimize your dosing precision and monitoring accuracy with a versatile feeder c...

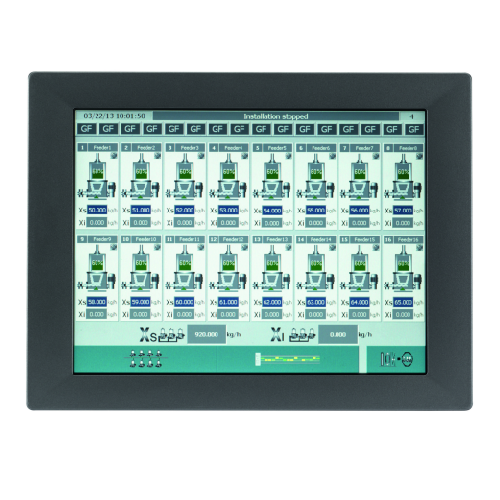

Gravimetric feeder operator interface

Efficiently manage up to 16 gravimetric feeders with a user-friendly interface, enabl...

Single feeder operator interface for gravimetric feeders

Enhance precision in your dosing operations with an intuitive to...

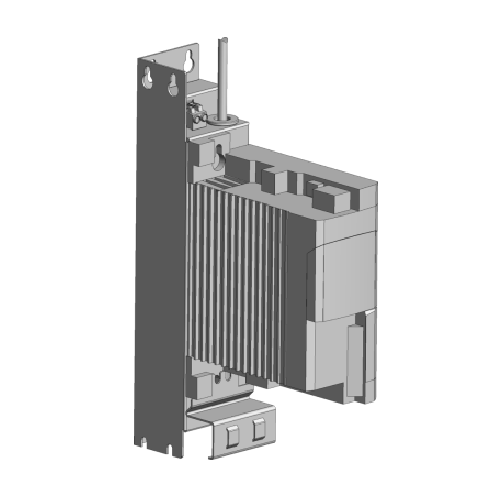

Speed controller for feeders

Ensure precise material flow by integrating this speed controller, ideal for managing both volu...

Loss-in-weight feeder for long and uneven fibers

Optimize feeding precision for challenging materials like long and uneven...

Loss-in-weight feeder for flowable particles

Ensure precise ingredient delivery with a feeder designed for high accuracy a...

Batch feeder for bulk solids processing

Achieve precise batch dosing with this advanced feeder, designed to handle a variet...

Precision batch feeder for flowable ingredients

Achieve precise ingredient control with a batch feeder designed for versat...

Microbatch dosing for precision ingredient measurement

Achieve precise ingredient dosing with our MicroBatch system, desi...