Light duty oven for snacks and light density foods

Maximize efficiency with precision-controlled drying and heating of snacks and plant-based foods, ensuring optimal texture and flavor retention while minimizing fines.

Dries and Heats Snack and Protein Products

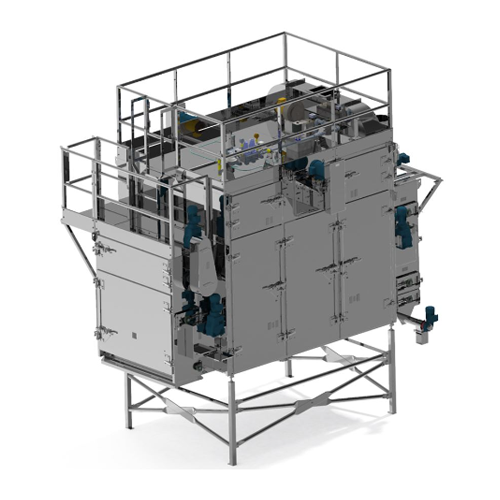

The Series IV Light Duty Oven from Wenger is engineered to deliver precise drying and heating solutions tailored for snack and protein product manufacturers. Utilizing variable-speed fans and conveyors, it provides flexible, modular operation that seamlessly integrates with existing production lines, and supports continuous, automated processes. Capable of handling diverse applications like corn puffs, plant-based burger patties, and aquatic feeds, this oven operates with a maximum temperature of 195°C. It allows for customizable retention times from 3 to 15 minutes across one to three passes. The oven’s design incorporates a continuous fines recovery system, which minimizes cleaning frequency, and is available with gas, steam, or electric heating options for energy-efficient operation. Engineered for ease of maintenance, it features the Wenger Automated Process Management system for complete control and monitoring, ensuring optimal performance and product quality.

Benefits

- Enhances product consistency with controlled drying and heating processes.

- Reduces cleaning time and maintenance efforts thanks to continuous fines recovery.

- Offers scalability with modular capacity expansion options.

- Provides energy efficiency through customizable gas, steam, or electric heating systems.

- Improves process flexibility with adjustable retention times and variable-speed operation.

- Applications

- Rte cereals, Hybrid products, Ingredients, Textured vegetable proteins, Snacks, Pet food, Structured meat analogs, Aquatic feed, Protein crisps, Breadings

- End products

- Pea protein crisps, Trout fry feed, Granola clusters, Soy nuggets, Plant-based burger patties, Chicken-flavored kibble, Soy-milk hybrid drinks, Corn puffs, Whey protein isolate, Panko breadcrumbs

- Steps before

- Emulsification, Mixing, Extrusion, Forming

- Steps after

- Packing, Coating, Cooling, Quality Control

- Input ingredients

- textured vegetable proteins, structured meat analogs, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products

- Output ingredients

- dried textured vegetable proteins, dried structured meat analogs, dry ingredients, dried protein crisps, dried breadings, dried RTE cereals, dried snacks, dried hybrid products

- Market info

- Wenger is known for its expertise in manufacturing extruders and dryers for pet food, aquatic feed, and food processing industries, renowned for reliability, innovation, and custom-engineered solutions worldwide.

- Retention Time

- 3–15 minutes

- Pass Options

- 1-3 pass

- Heating Options

- Gas, steam, electric

- Maximum Temperature

- 195°C

- Speed Control

- Variable speed (VFD)

- Fines Recovery System

- Continuous

- Process Control System

- Wenger Automated Process Management

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Continuous fines recovery system

- Energy efficiency

- Variable speed (VFD) for fans and conveyors

- Heat source options

- Gas, steam, or electric

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product density

- Light

- Product type

- Snacks/Light Density foods

- Machine footprint

- Modular design

- Heating options

- Gas, steam, or electric

- Conveyor type

- Variable speed (VFD)

- Modularity

- 1-3 pass options available

- Insulated enclosure

- Max temperature 195°C

- Capacity scalability

- Flexible, modular design

- Fines recovery system

- Continuous

- Control panel type

- Wenger Automated Process Management

- Heating options

- Gas, Steam, Electric

- Variable Speed Control

- Conveyors, Process Fans, Exhaust Fans

- Modular Design

- 1-3 pass options, additional capacity