Pet Food Processing Equipment

Find innovative pet food equipment and connect directly with world-leading technology suppliers

Pet food is a specialty food mostly based on formulated ingredients for various nutritional and dietary requirements. Pet food formulas are becoming more diverse and complex, considering the special health conditions and needs of young and aging pets that live in cities. The production of pet food is similar to processing food in general when it comes to fresh feedstock and flesh products.

Innovative pet food equipment

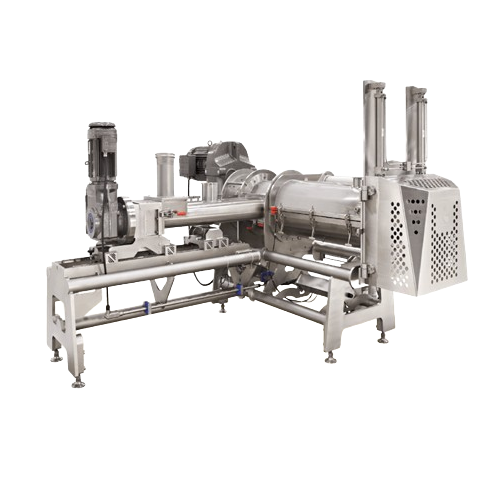

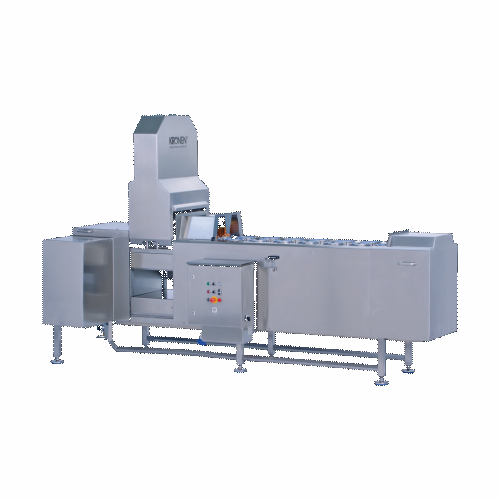

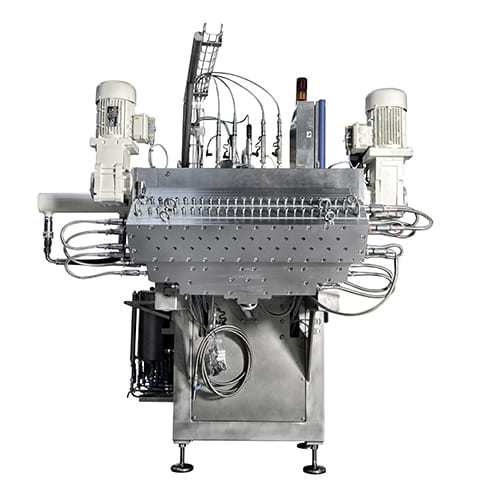

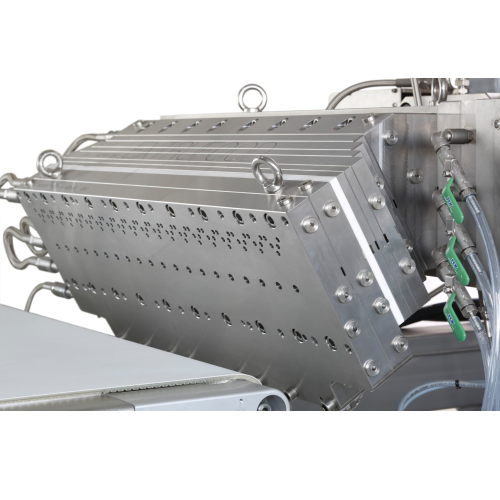

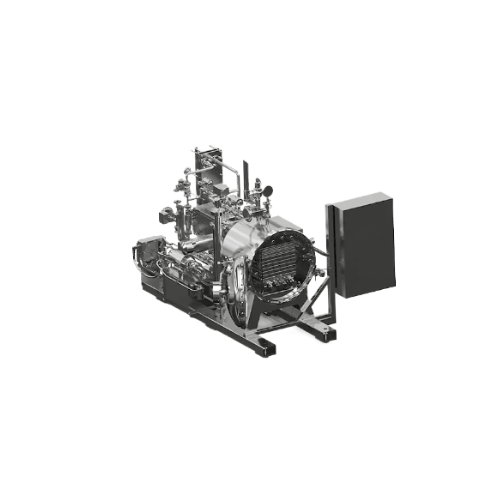

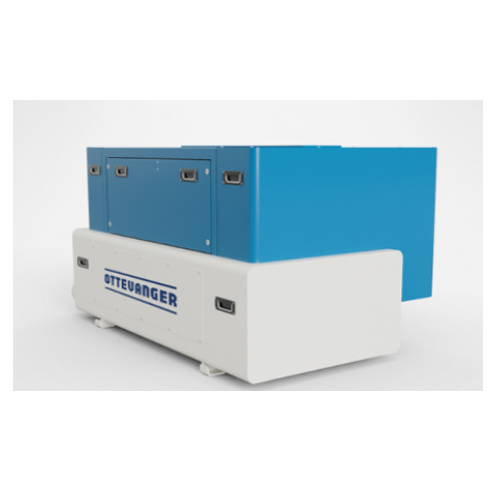

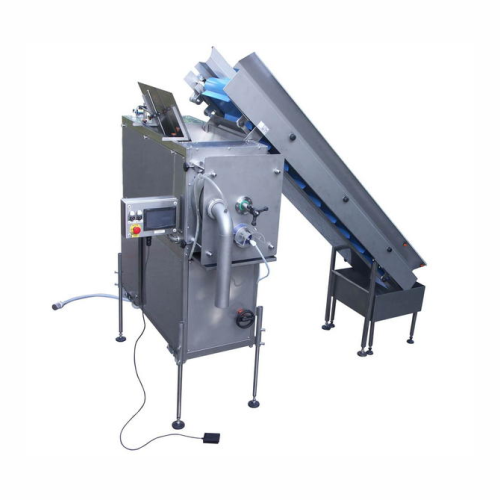

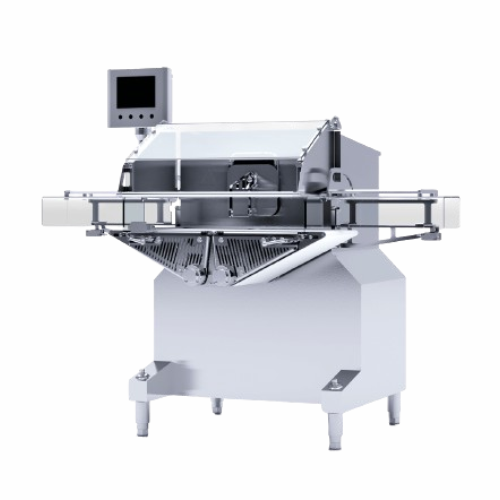

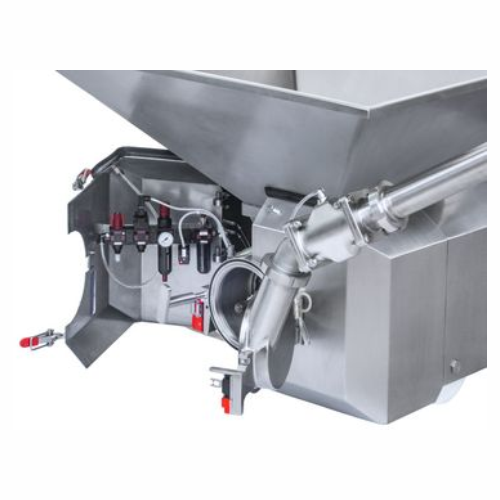

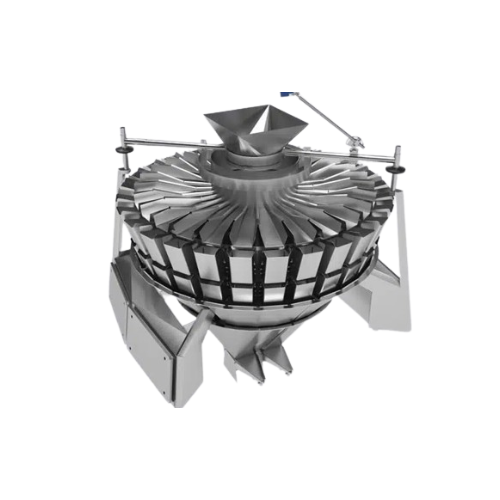

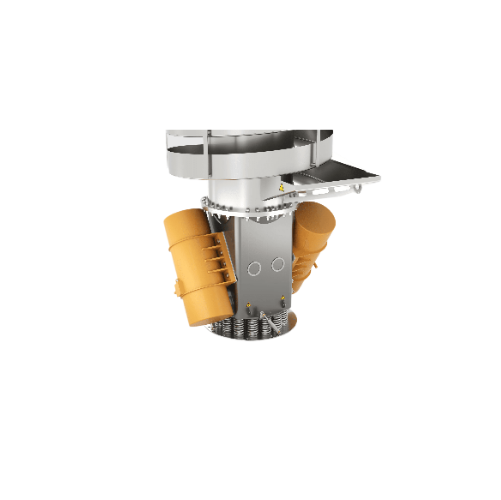

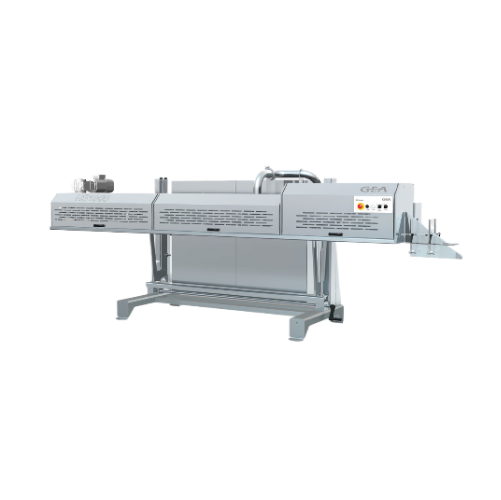

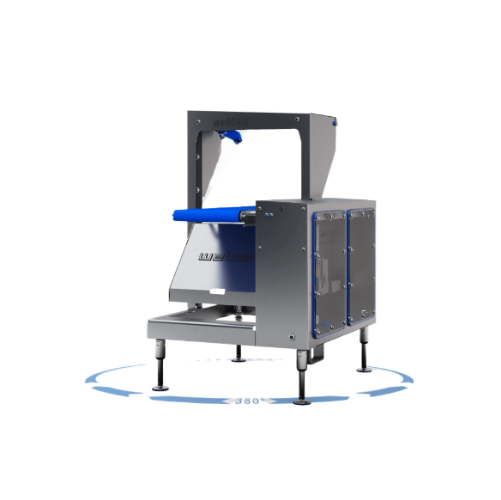

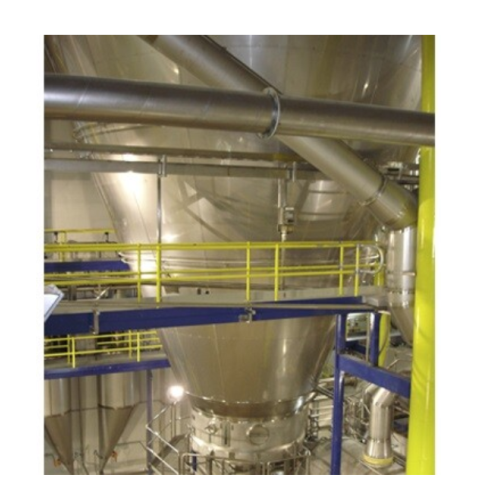

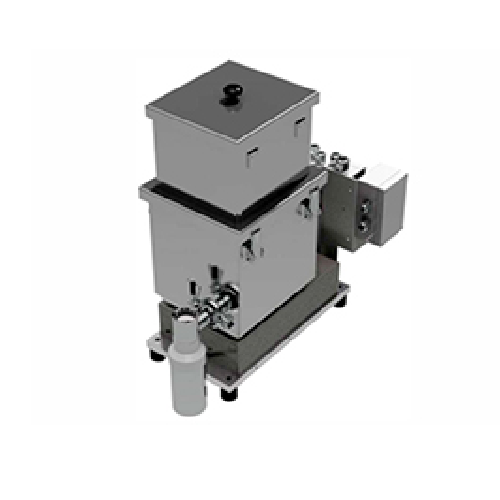

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

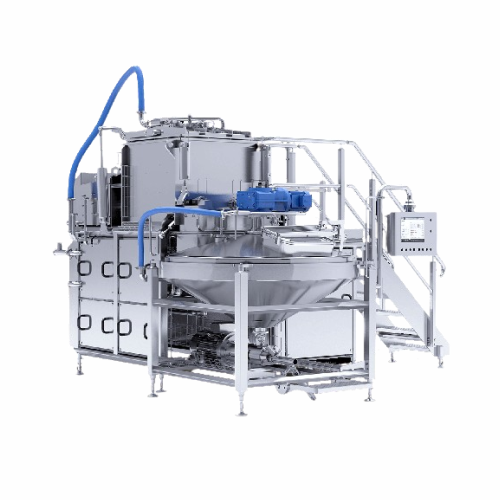

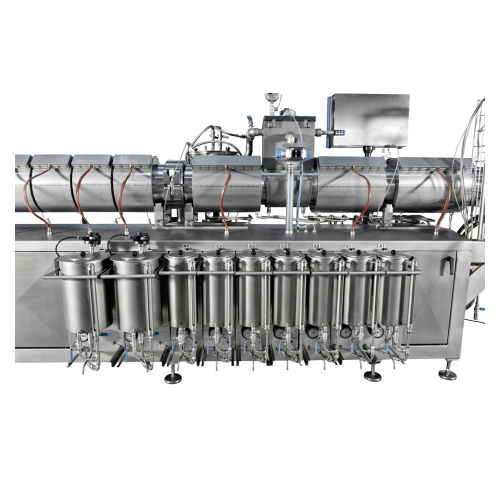

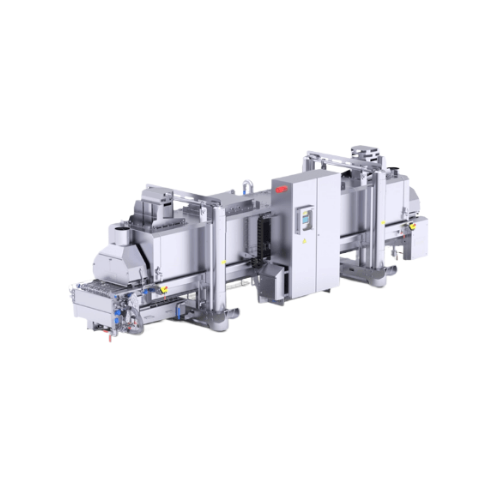

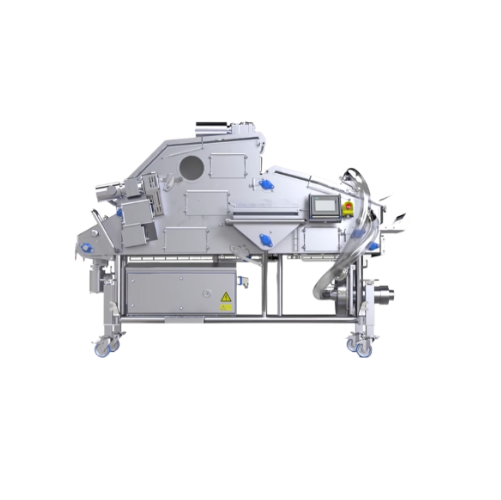

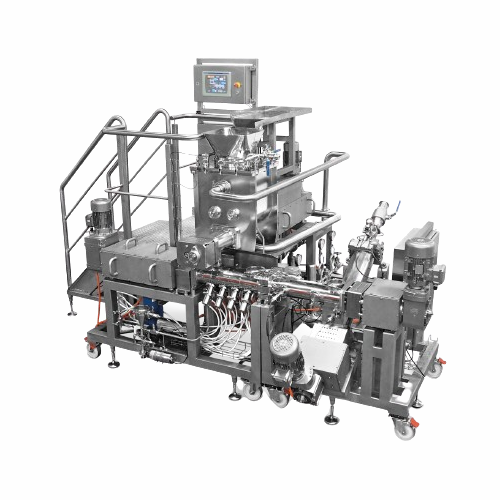

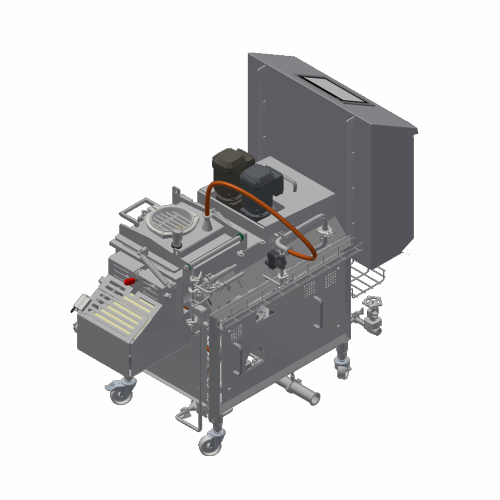

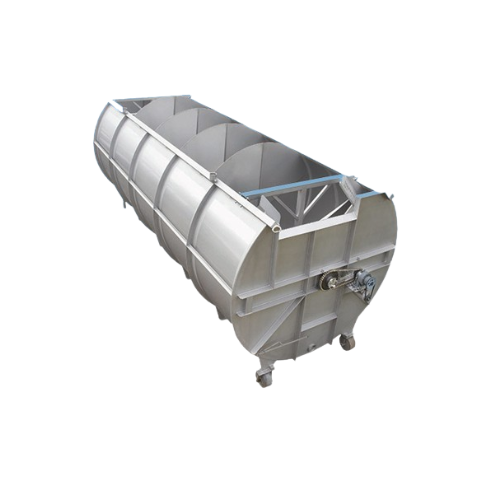

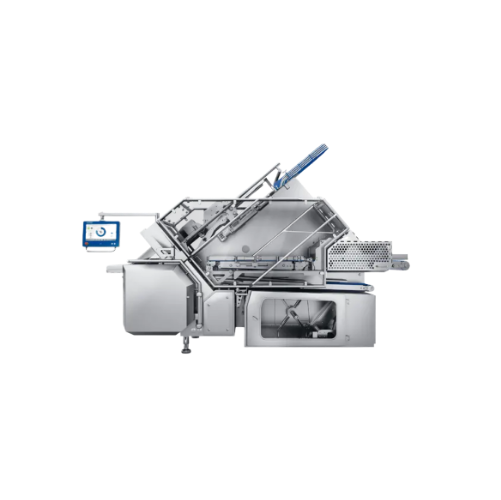

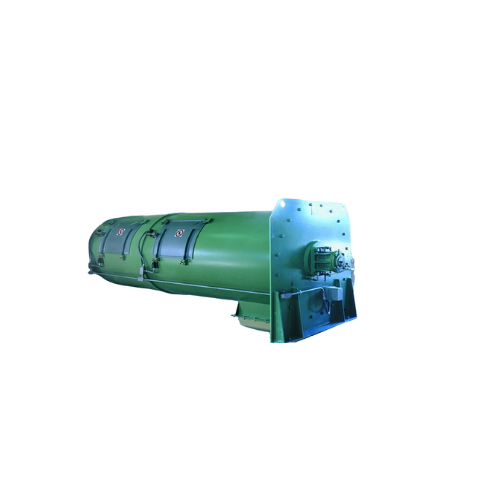

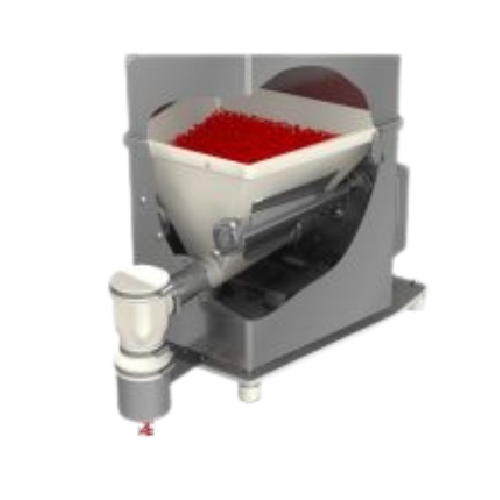

Batch cooker and mixer for food and pet food production

Streamline your cooking and mixing processes with a versatile bat...

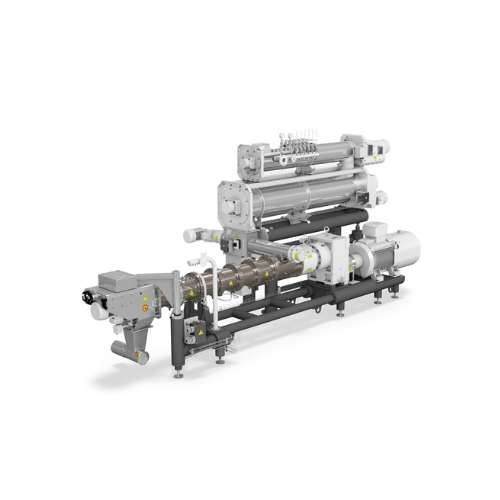

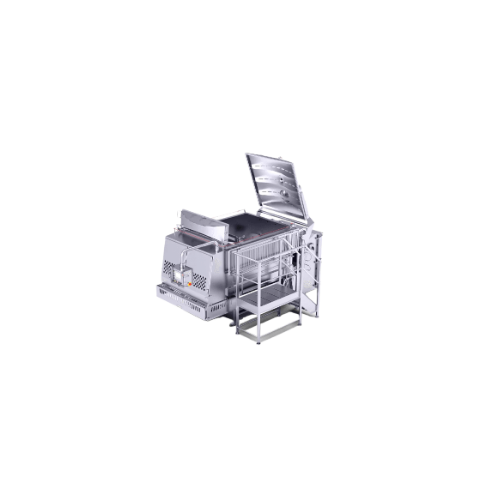

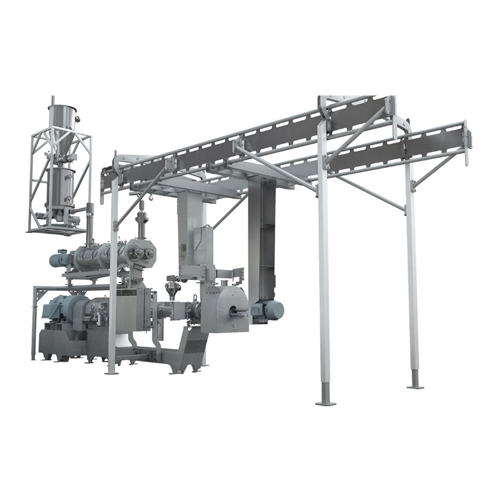

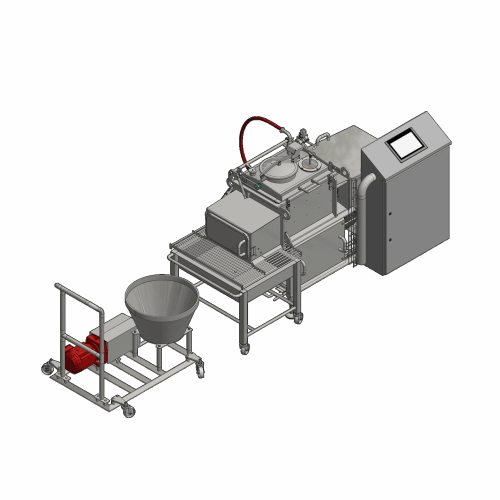

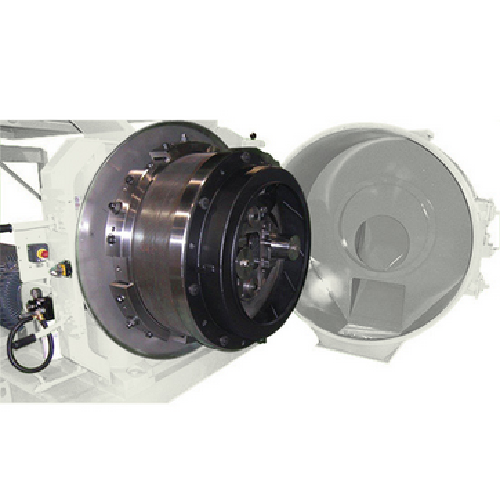

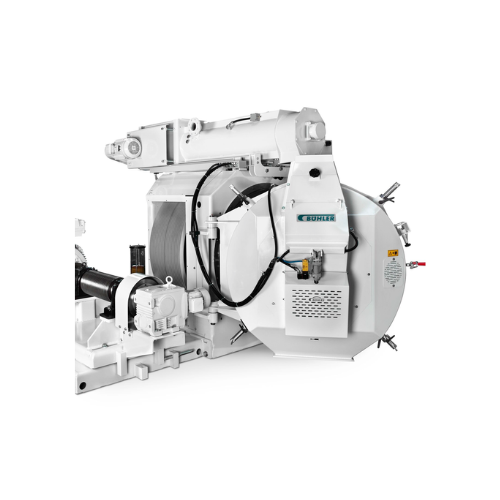

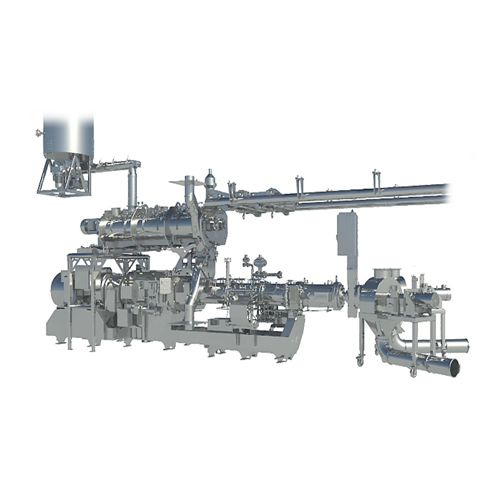

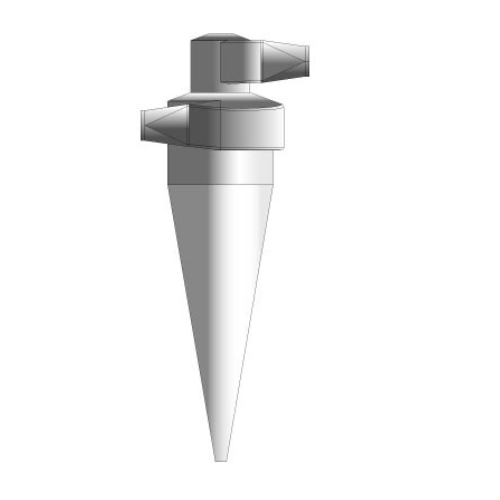

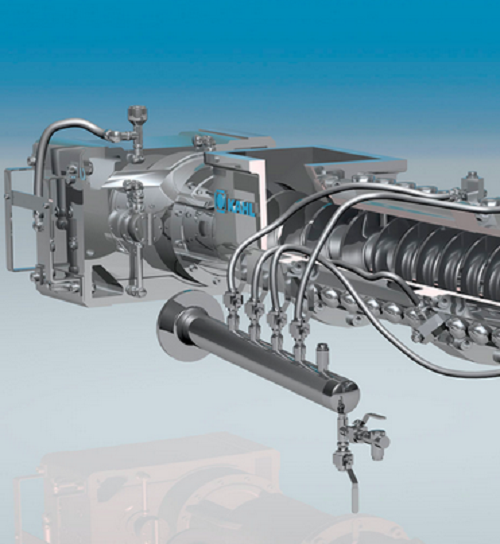

Conical twin screw extruder for pet food and aquatic feed

Precision-engineered for high-speed extrusion and drying proce...

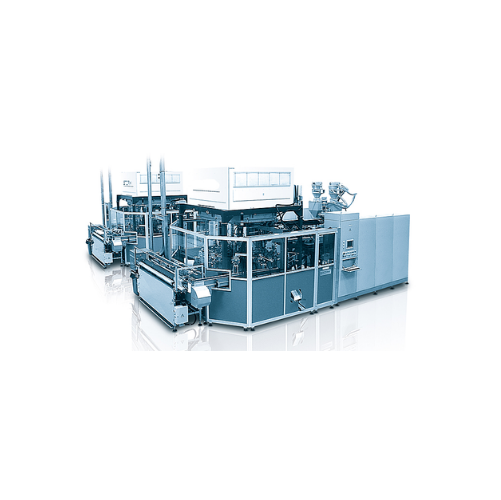

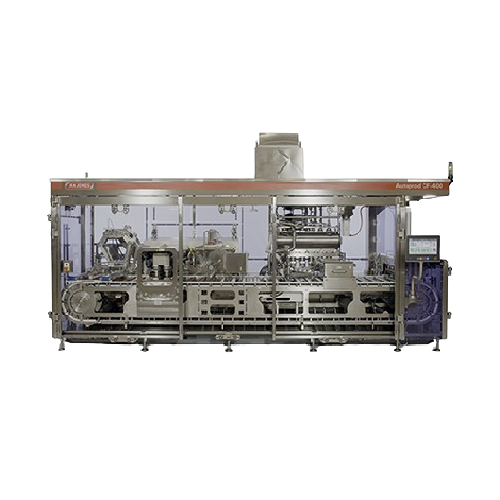

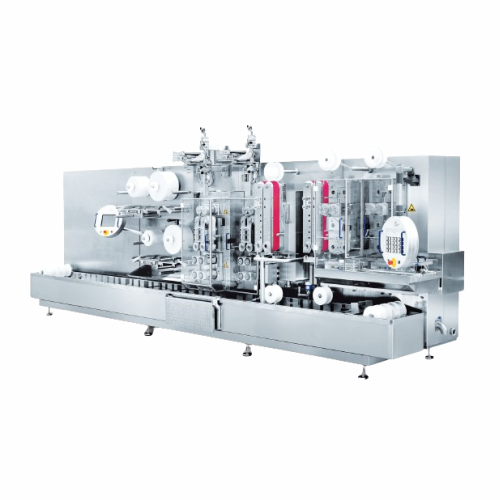

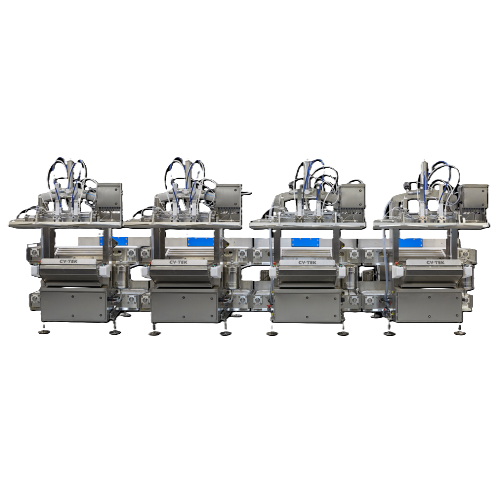

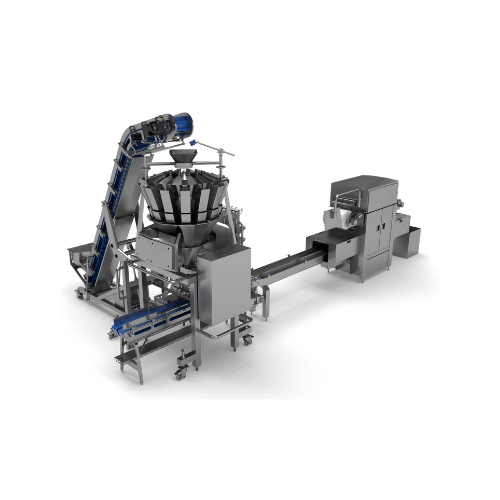

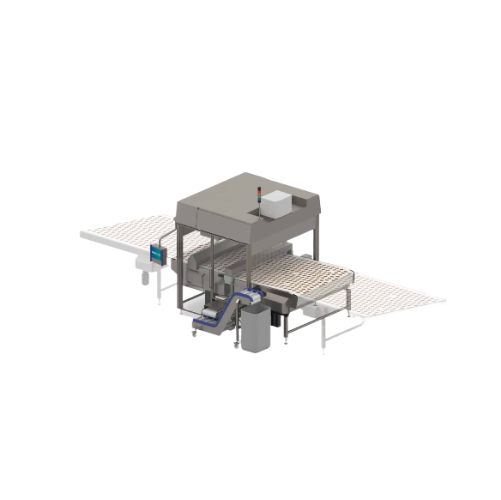

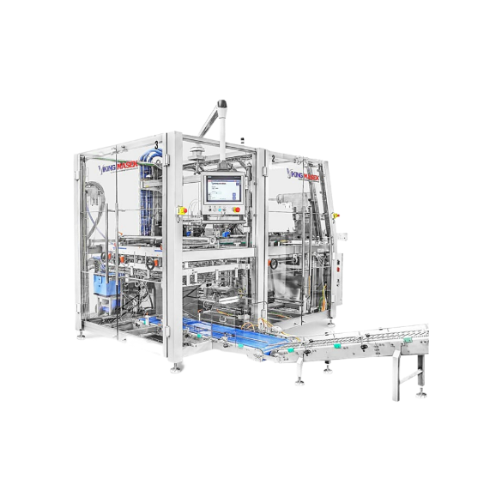

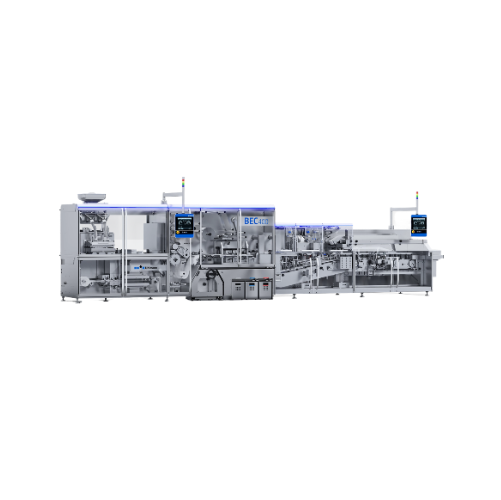

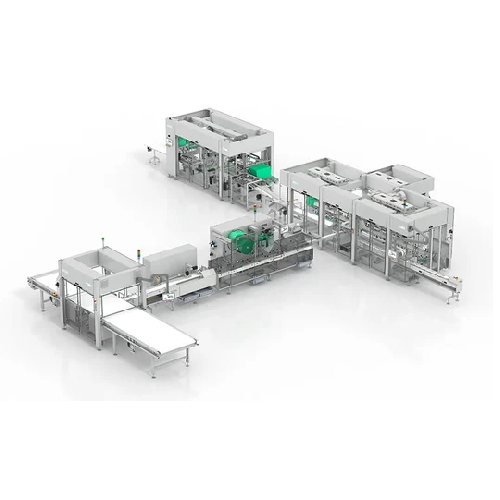

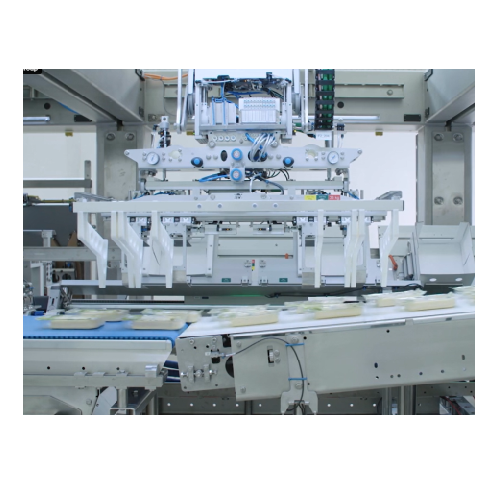

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...

Stories about pet food

Select your pet food process

What are you making?

Tell us about your production challenge

Pet food usually comes in the form of pellets and kibbles that are extruded or baked from dry compound feed. Dry pet foods contain grains and cereals, meat meal and fat, vegetables and proteins and functional ingredients. Wet pet food has similar dry ingredients to dry pet food, but is usually produced in the form of single-serve tin cans or pouches filled with high moisture level. Meat pieces and gravy or jelly are commonly seen in wet pet food mixed with vitamins and minerals.

Pet food making process

Following the increasing demand for nutrition and regulatory compliance, pet food formulation needs to take factors such as fat tissue content, protein quality, the moisture level of raw materials into consideration. Pet foods oftentimes are made from dry ingredients such as feed grain and soybean meal, byproducts of meat and seafood, and liquid ingredients such as water and meat broth. Also, coatings and coloring and flavoring agents are needed in pet food formulas to appeal to different pet groups.

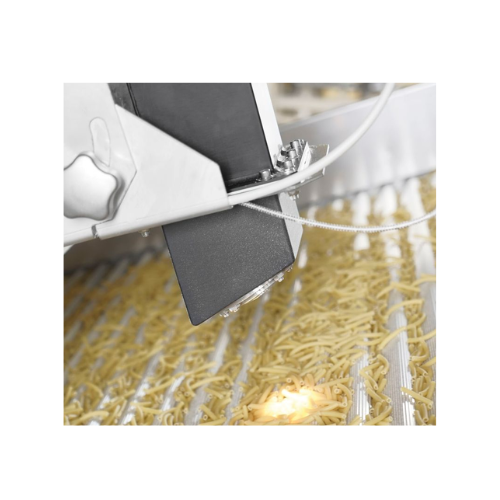

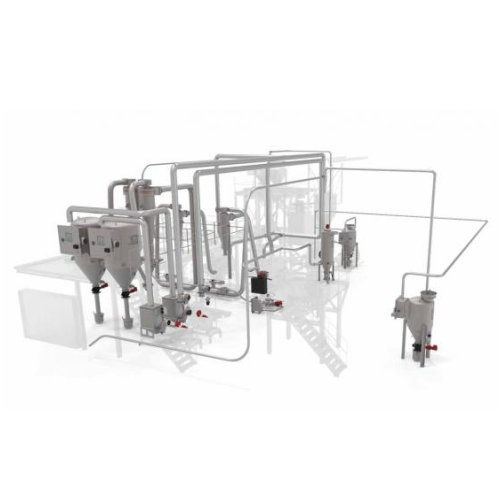

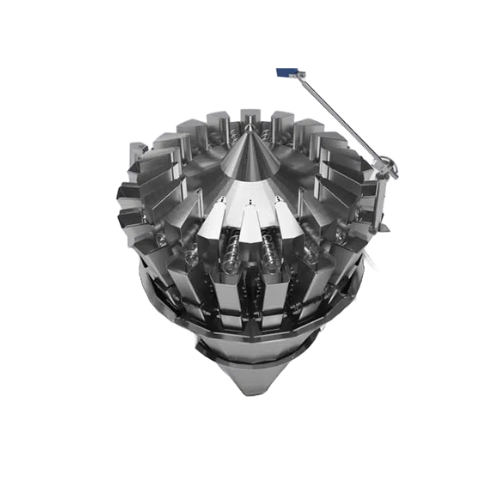

The broad range of available ingredients for pet food production requires precise weighing and dosing in the handling of raw materials. Another crucial step in processing pet food ingredients is grinding and mixing, ensuring the required particle size and consistency of the mixture. Before going into extrusion, the grinded and mixed ingredients need to be (pre-) conditioned. The addition of moisture and fat with pre-heating conditions makes sure that the mixture to be extruded reach the desired nutritional quality, bulk density and consistency. Finally, extruded and pelleted pet foods proceed to the coating and cooling section of the entire production before packaging.

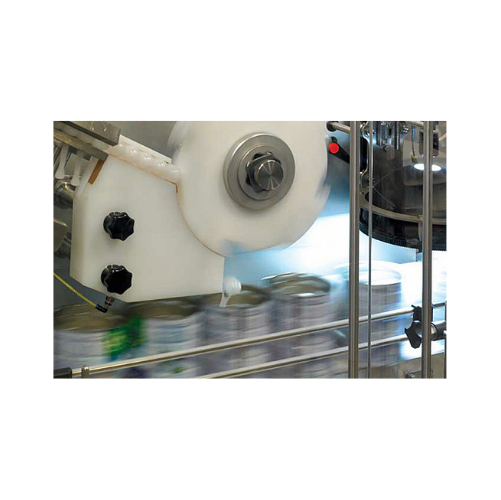

For canned pet food, the production process centers around the handling of meat and flesh products from defrosting and rendering to grinding, cooking and mixing with other ingredients such as vitamins, minerals and preservatives. After packaging and sealing in cans (and labeled), wet pet food needs to go through a crucial step, sterilization.

Extruded or baked pet food?

For producing dry pet foods, there are two main cooking methods: extrusion (the most common) and baking. Nowadays about 95% of pet foods is made by extrusion.

In the extrusion process, a mixture of wet and dry ingredients called dough enters the expander which cooks the doughy mixture at high pressure and high temperature. Then, the dough is forced through the dies that create ribbons of the desired shapes that are cut with a rotary cutter afterwards. Instead, when baked, the dough is cut by rotary moulders into the desired shapes and sizes. Then, the final moulded products are placed into the oven and baked.

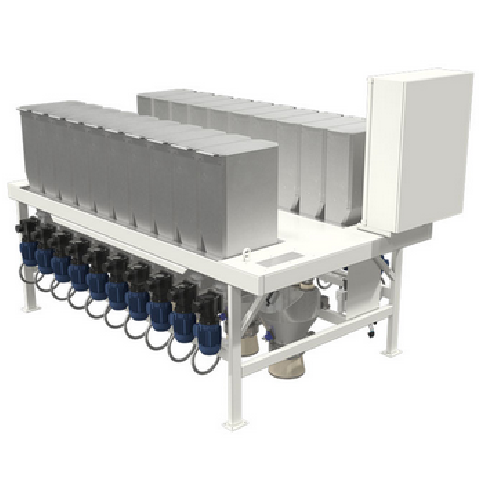

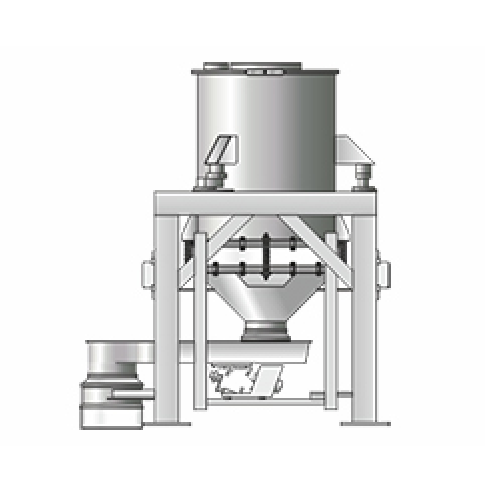

Weighing and dosing of pet food

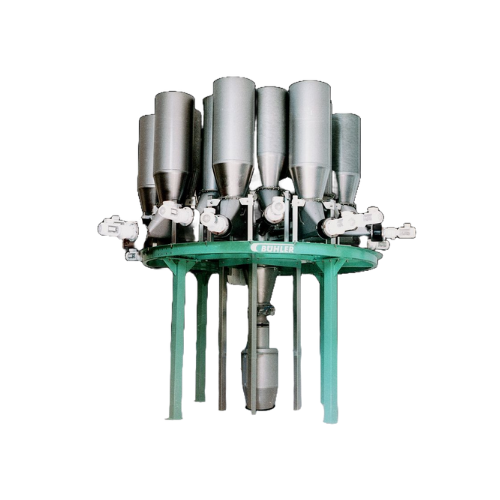

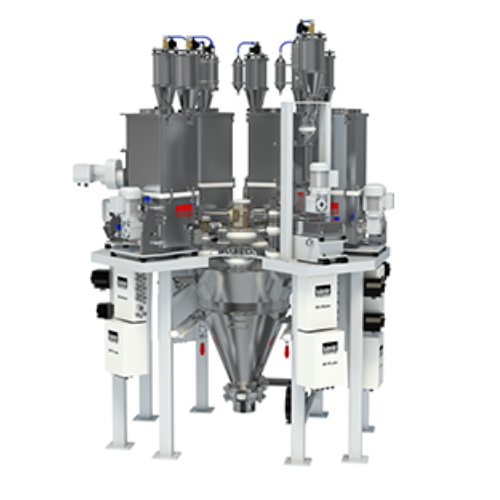

Dosing and weighing process – from the intake of raw material to the distribution of finished product – is the key factor to ensure the balanced mixture of ingredients based on what animal needs.

To provide zero contamination and avoid human error, for example KSE supplies fully automatic dosing and weighing systems, thus eliminating hand dosing. Plus, for a quick and a zero-contamination dosing , KSE supplies a new type of technology called “dosingtainers”, which reduces the number of dosing steps. If bulk ingredients stay for too long in a silo, they can get spoilt. Therefore, using these dosing containers instead of traditional silos saves time because ingredients can also be dosed inside them.

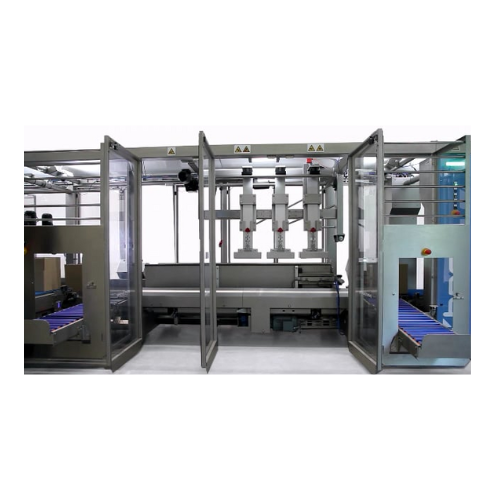

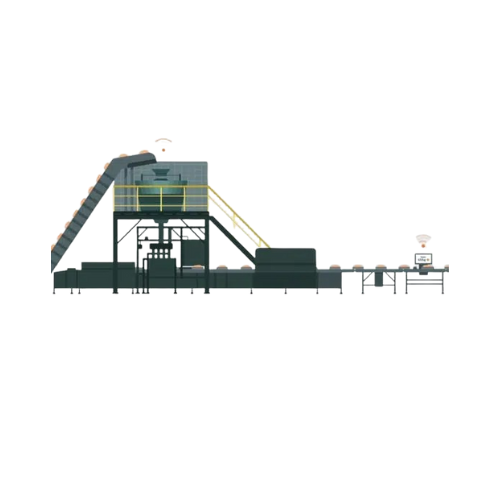

Packaging and sterilization of pet food

The basic difference between wet and dry pet food is the water content, which affects the shelf life of the product – 3-5 years for wet pet food and 10-12 months for dry pet food. The most common forms of dry pet food include kibbles, biscuits and snacks, which after processing are transferred to bags, boxes or pouches to pack the right amount of weight.

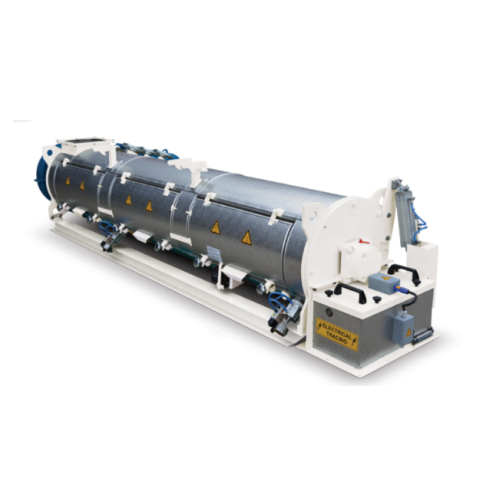

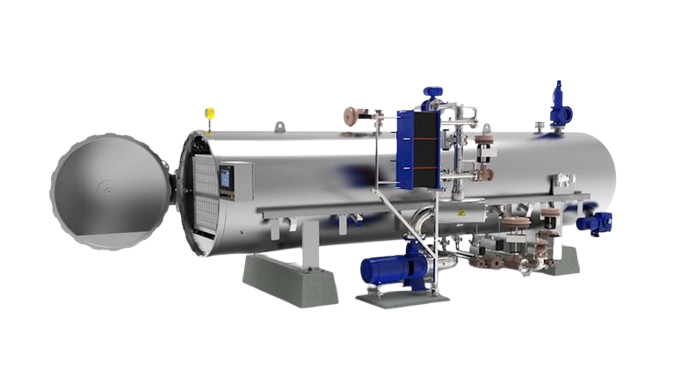

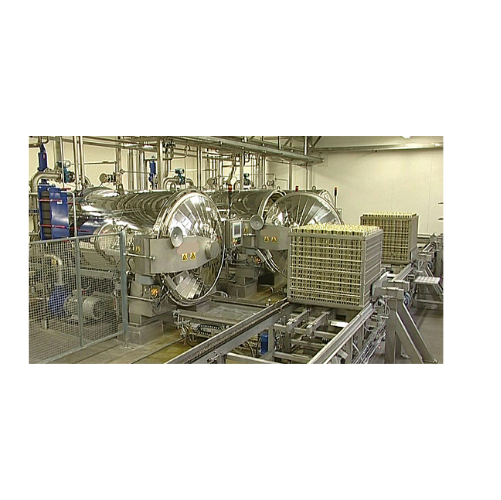

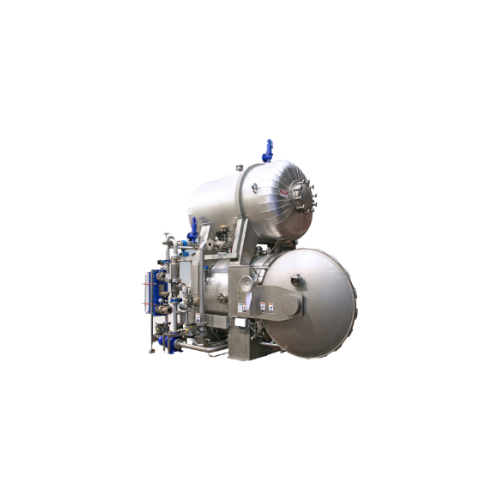

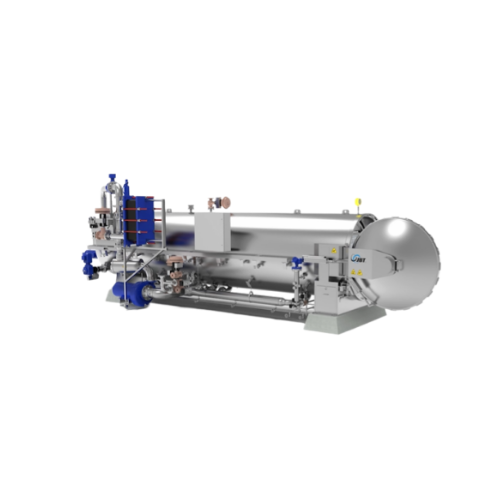

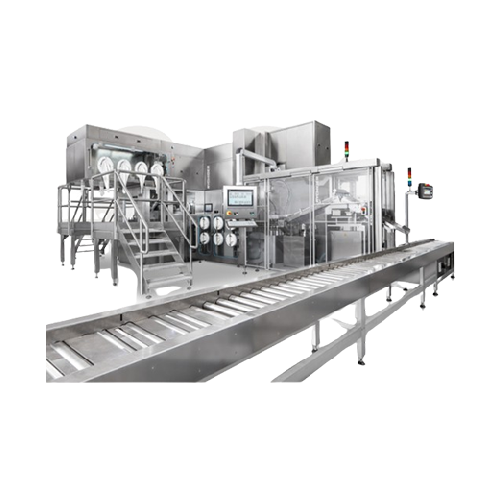

Instead, ingredients in wet pet food are measured and mixed together and put into cans, trays or pouches. The selected container is sealed and cooked at certain temperatures. To guarantee the microbiological safety of the food, sterilization is a critical part of wet pet food manufacturing process. Sterilization takes place in a retort where steam is pumped under high pressure.

Pet food making videos

How pet food is made?

Dry pet food packaging

Which pet food technology do you need?

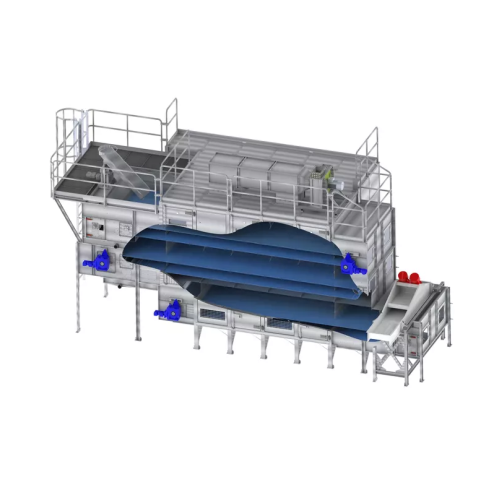

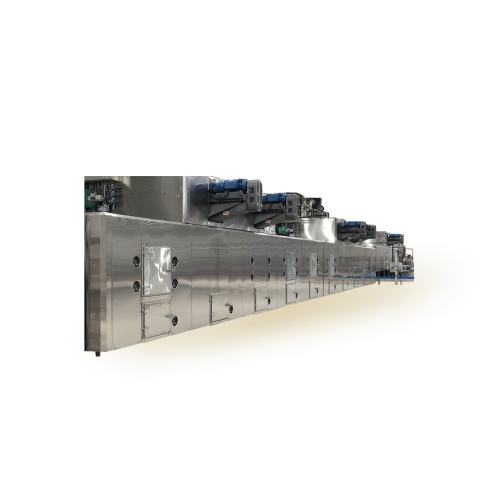

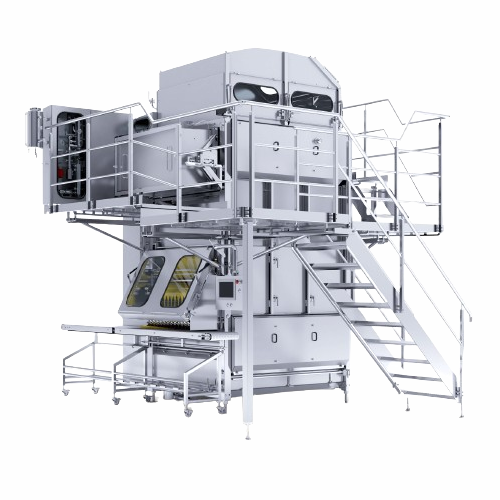

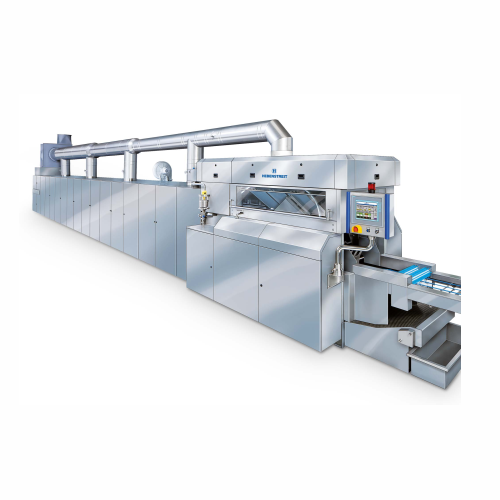

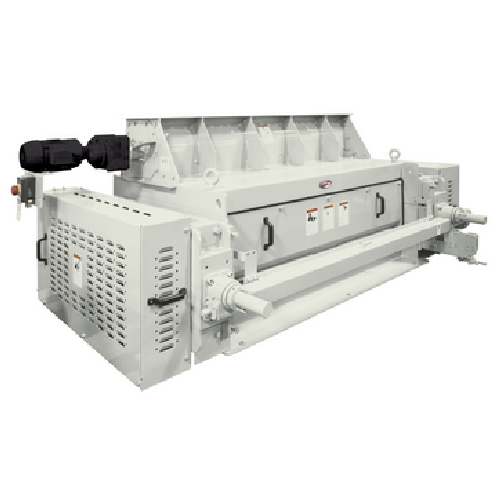

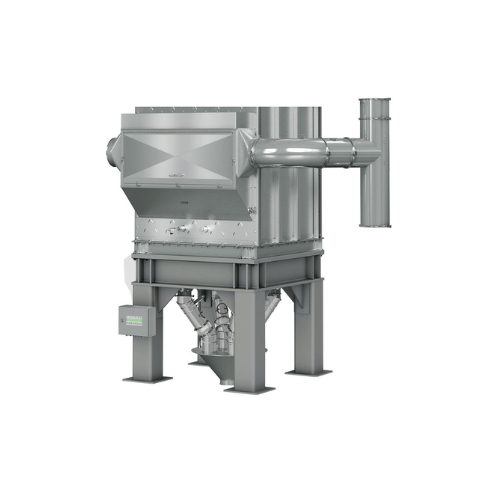

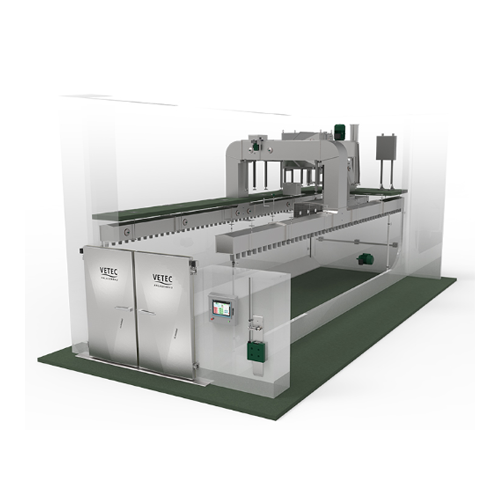

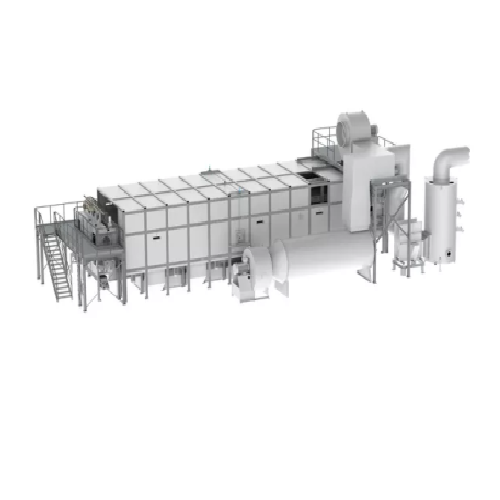

Counterflow dryer for pet food and fish feed

Optimize moisture control and enhance feed quality with efficient drying, cru...

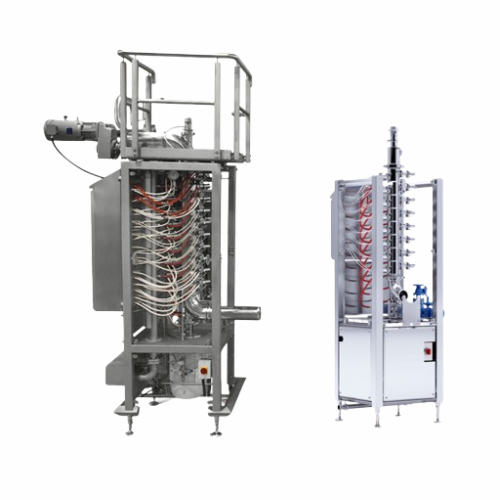

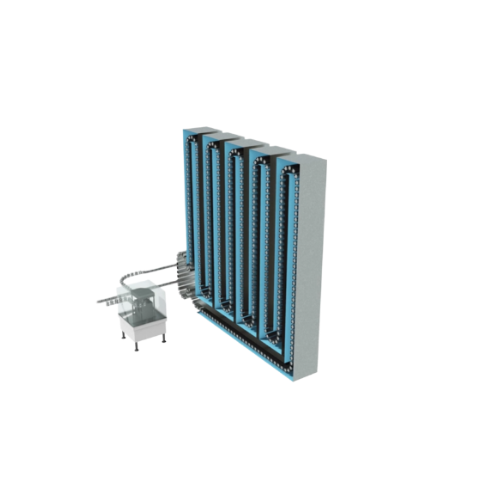

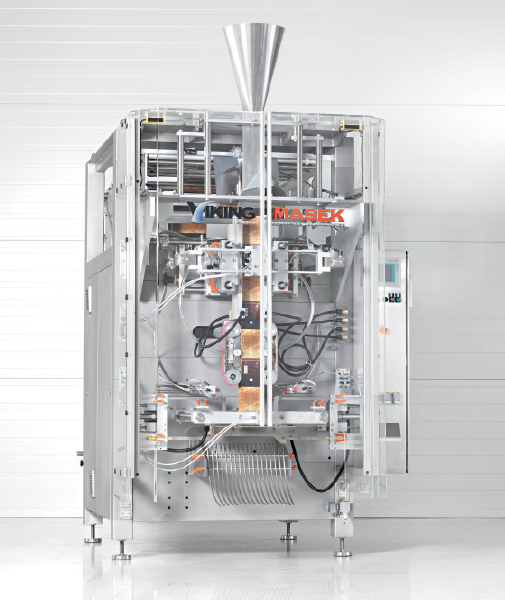

Vertical packaging system for pet food

Streamline your production line with high-speed packaging capabilities, handling var...

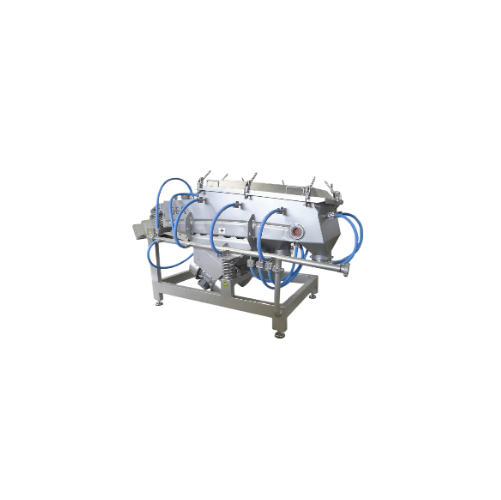

Industrial mixer for food and pet food production

Achieve precise and efficient mixing of viscous to highly viscous produ...

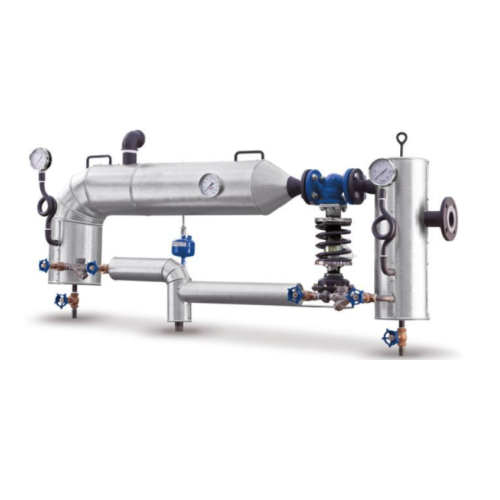

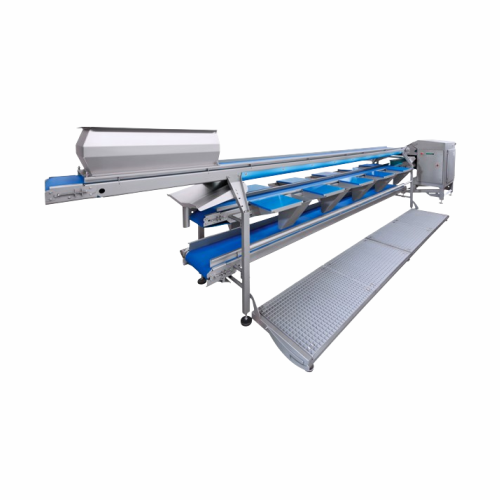

Filling flow divider for food and pet food applications

Optimize your production line with precision filling flow divider...

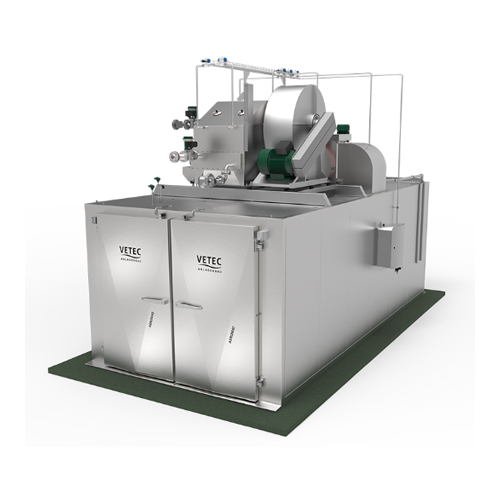

Advanced vacuum coating system for pet food and feed

Achieve uniform saturation in pellets and granules with precise liqu...

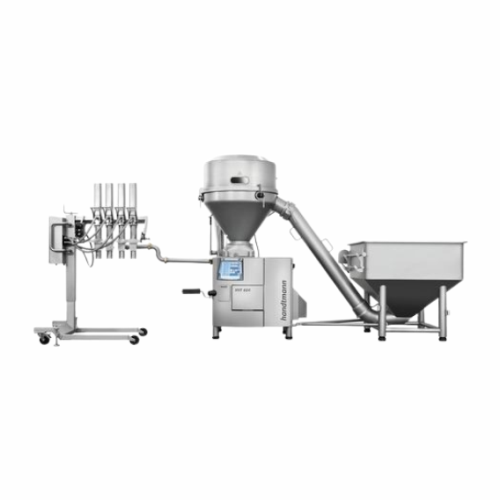

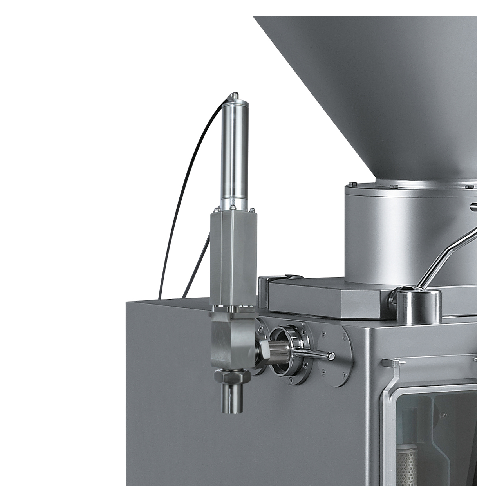

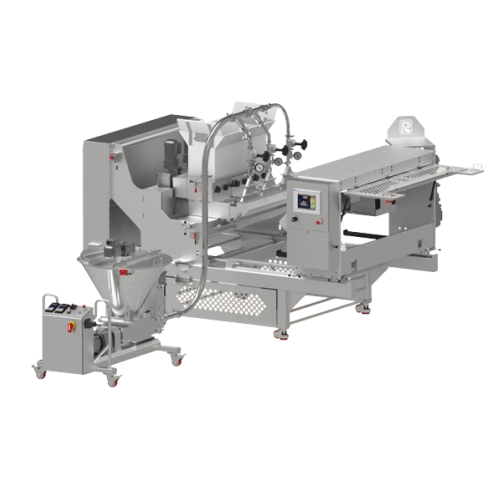

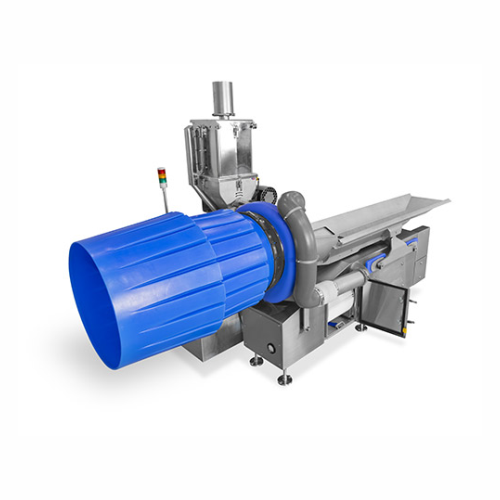

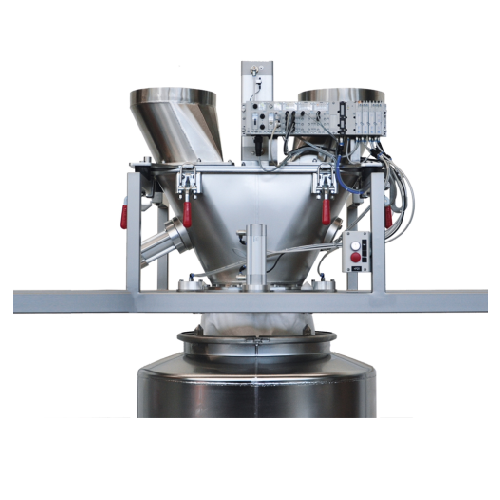

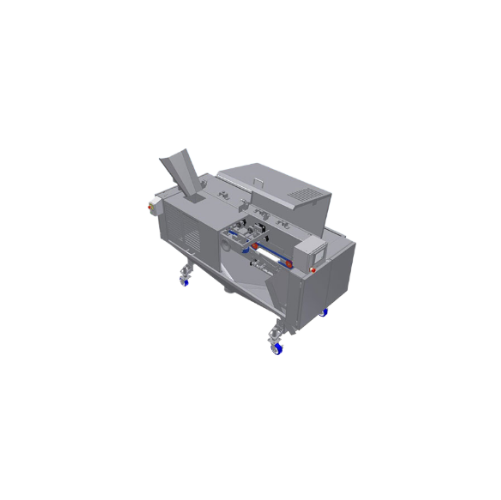

Gravity-fed emulsion system for meat and pet food processing

Achieve optimal particle size reduction and seamless integr...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

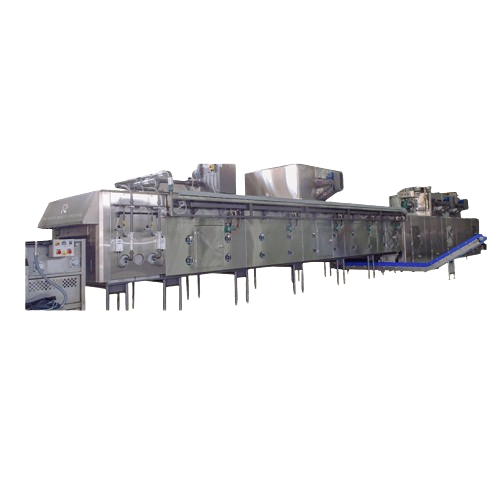

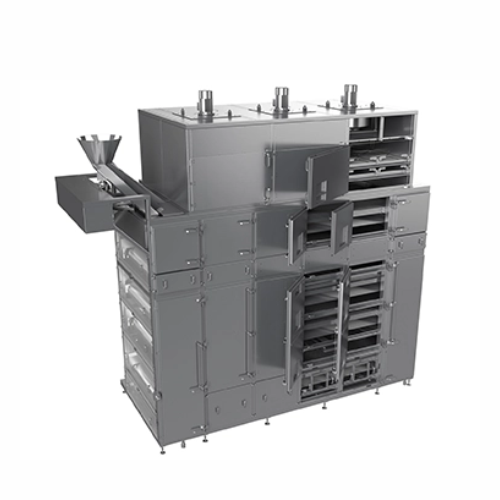

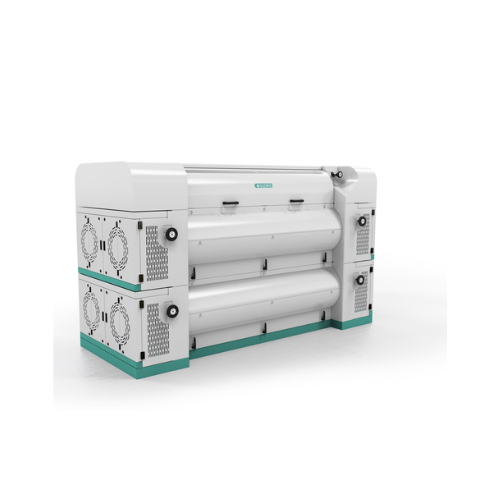

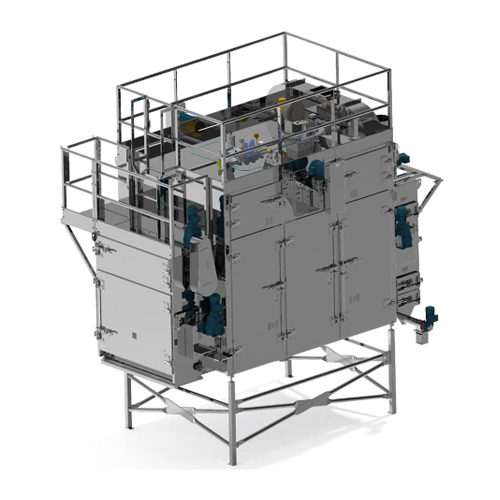

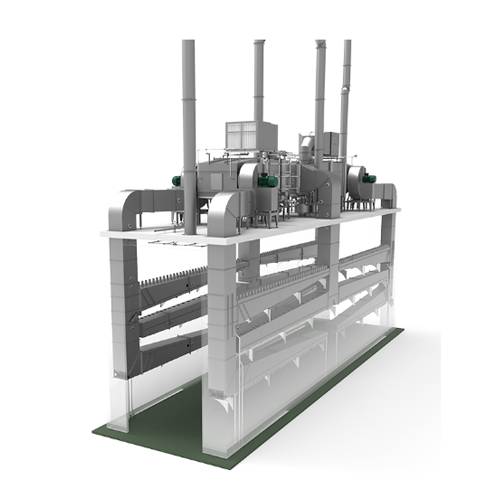

Multi-pass pet food dryer for consistent moisture content

Achieve precise moisture control and enhanced product quality ...

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

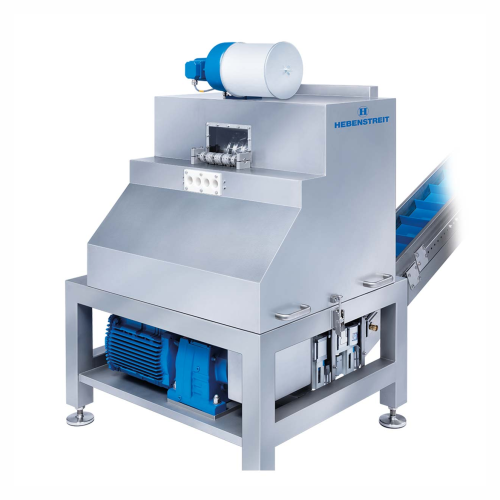

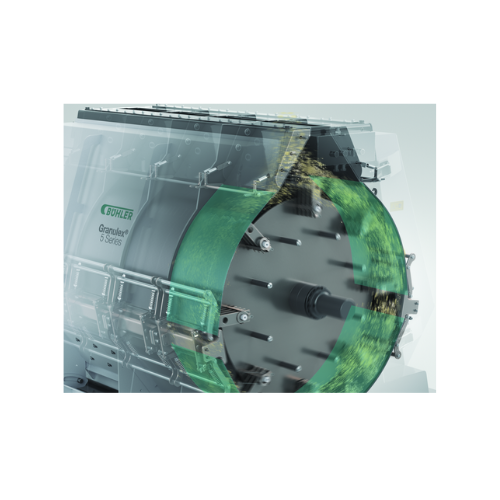

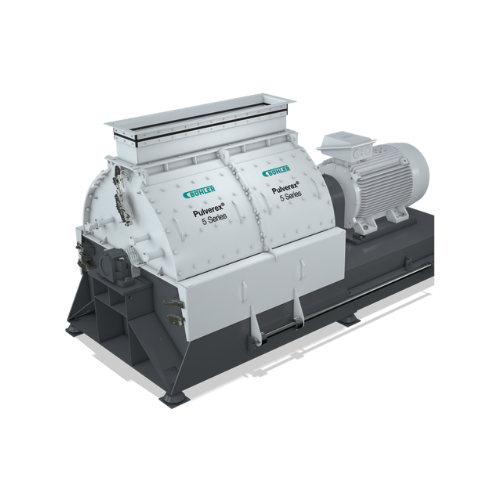

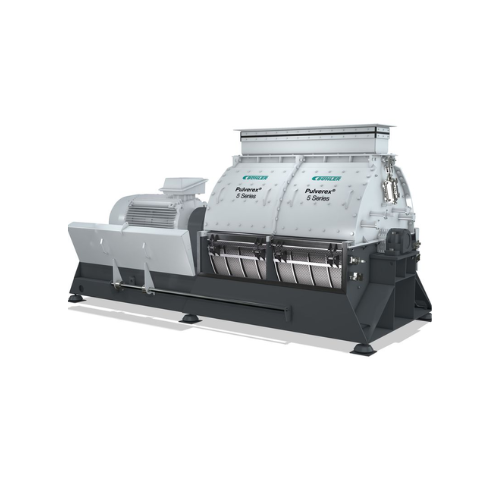

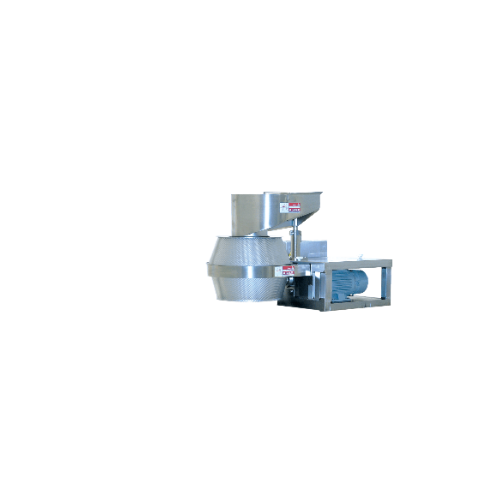

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

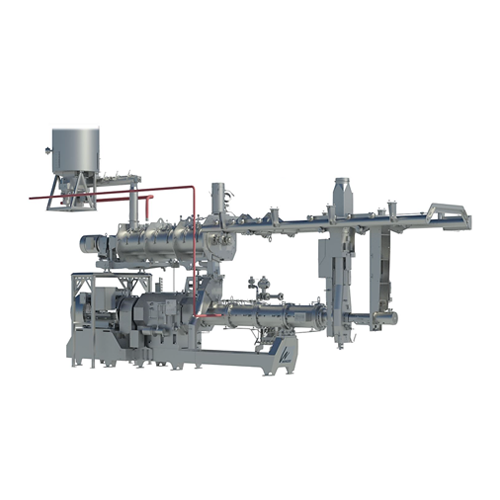

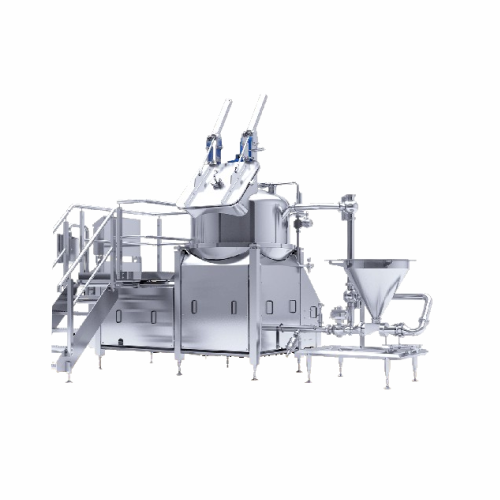

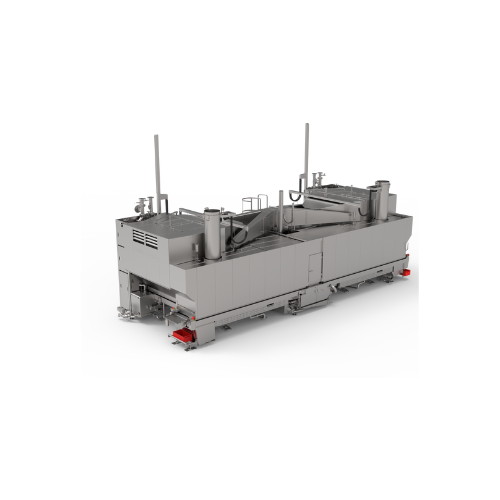

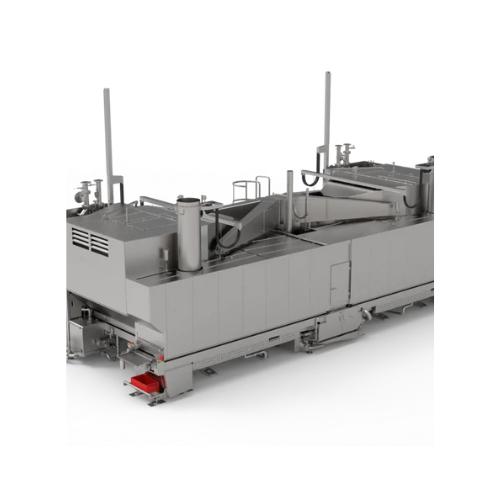

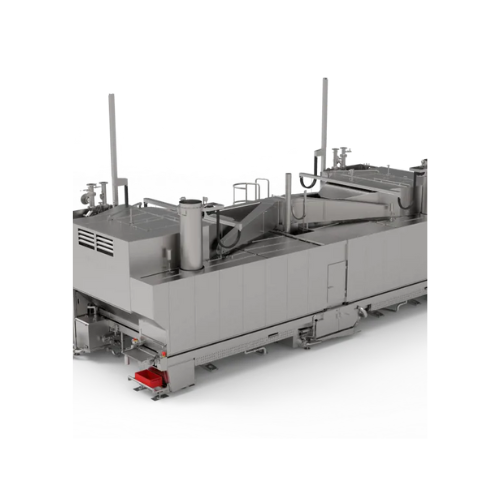

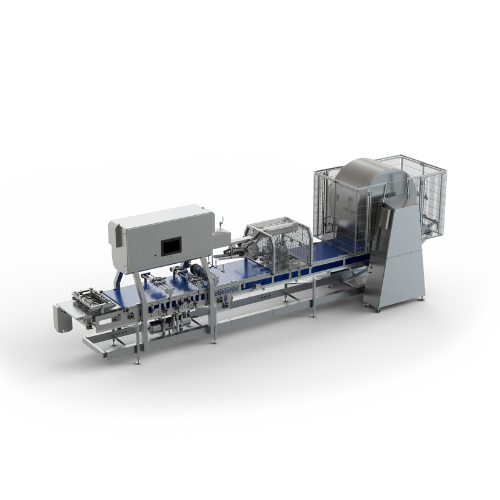

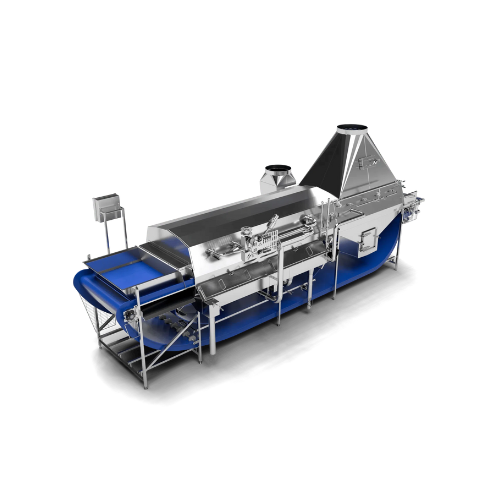

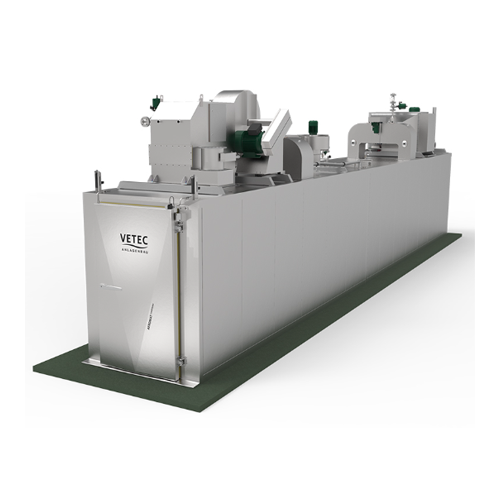

Wet pet food processing system

Optimize your wet pet food production with a system that integrates steaming, cooling, mixing...

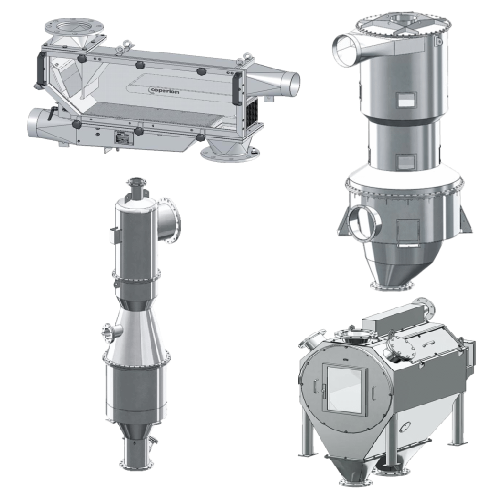

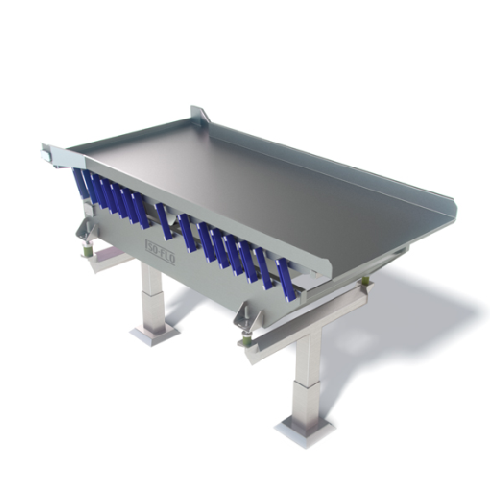

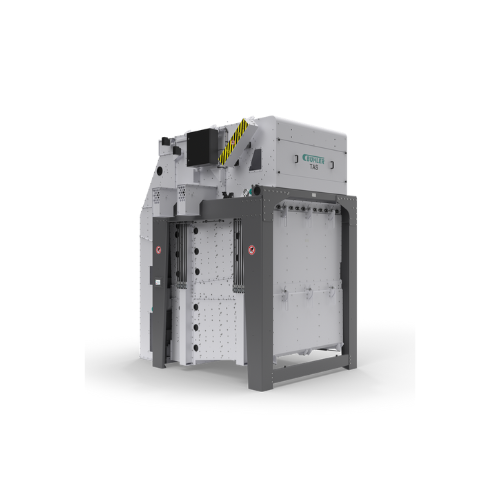

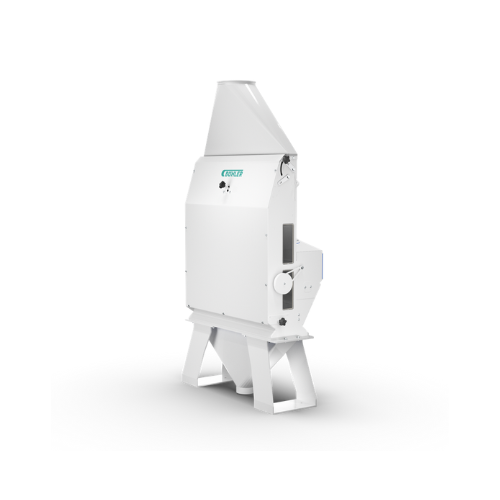

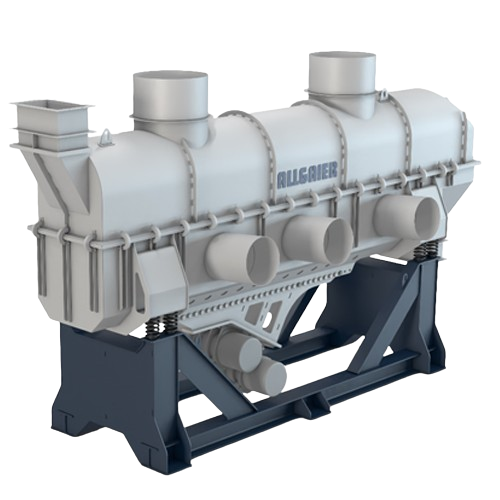

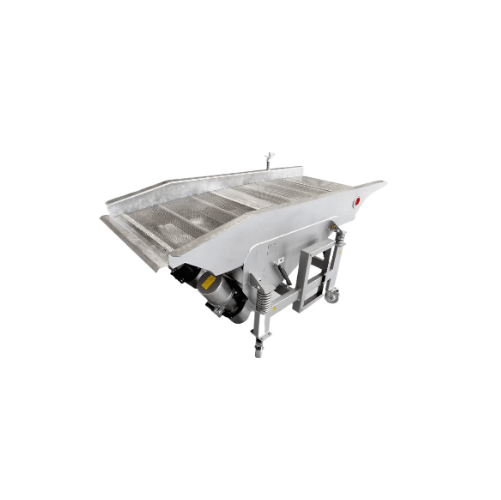

Sifter for pet food, fish feed, and animal feed

Achieve precise particle separation and enhance feed quality with this vib...

Conical twin screw extruder for pet food and aquatic feed

Precision-engineered for high-speed extrusion and drying proce...

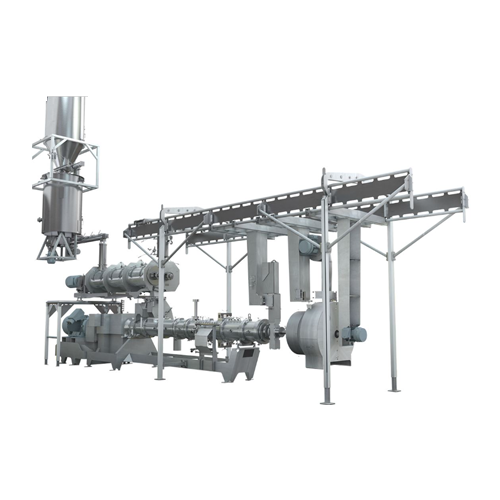

Single screw extruder for pet food and aquatic feed

Maximize production capacity and optimize product quality with advanc...

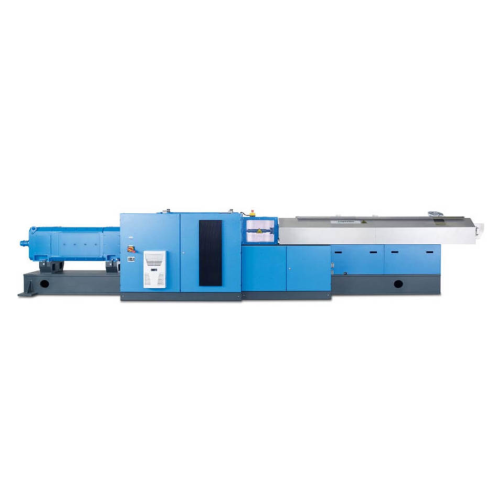

Extruder for high-volume pet food production

Maximize production efficiency with an advanced extrusion system designed for...

Coating and enrobing system for pet foods and treats

Achieve precise coating and flavoring of various food and feed produ...

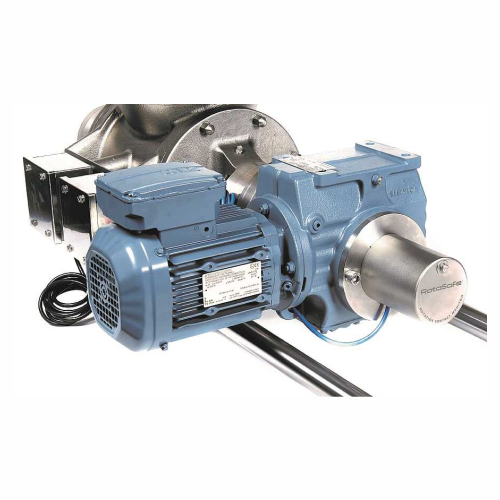

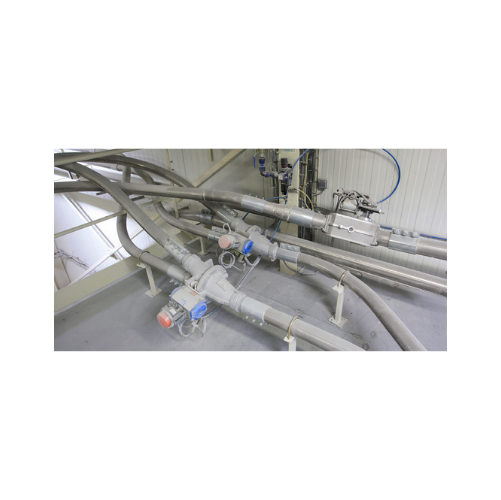

Meat injection system for pet food production

Integrate fresh meat seamlessly into your pet food production line, enhancin...

Convection roaster for pet food and delicate food products

Achieve optimal texture and moisture control in delicate food...

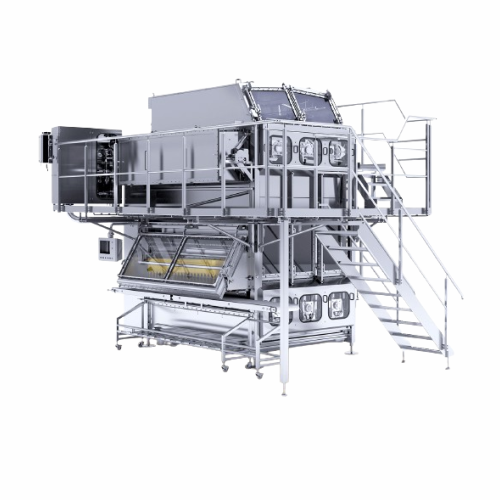

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

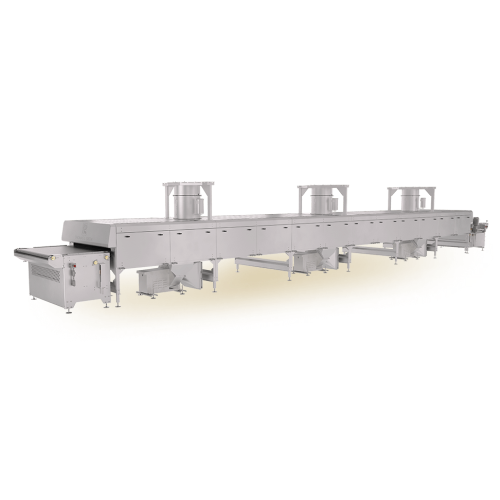

Belt dryer for food and pet food products

Optimize drying processes with customizable belt dryers, engineered to handle ro...

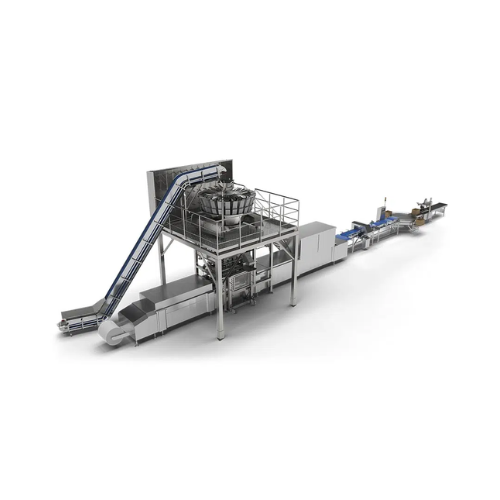

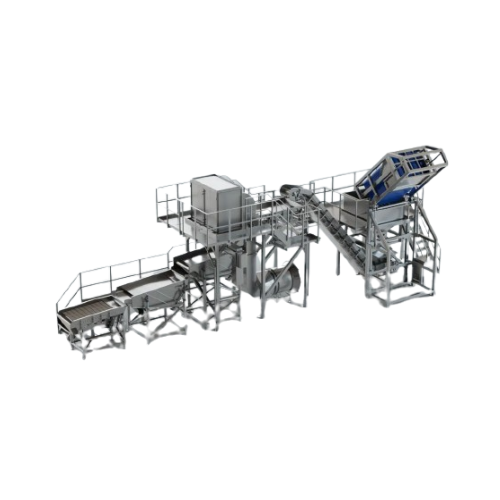

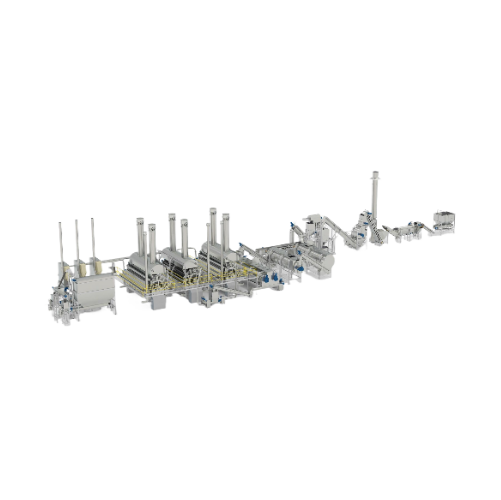

Pet food production line

Enhance your pet food production with a seamless, efficient system that emulsifies, extrudes, and pa...

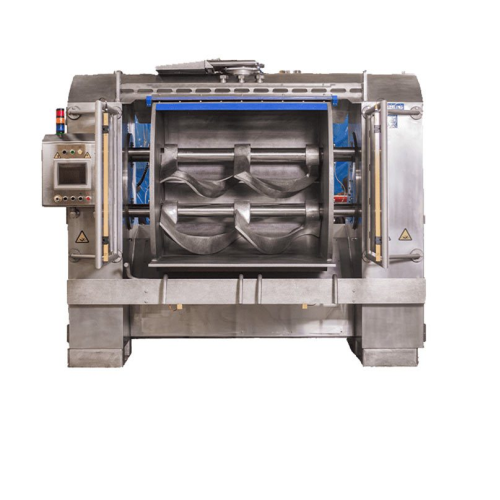

Industrial batch mixers for pet food

Achieve homogenous mixing of complex multi-ingredient formulations with precision and ...

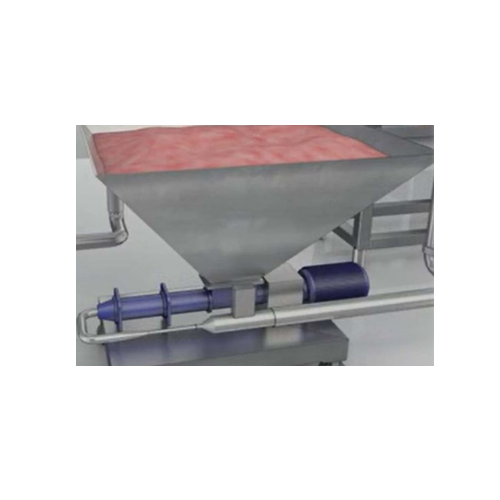

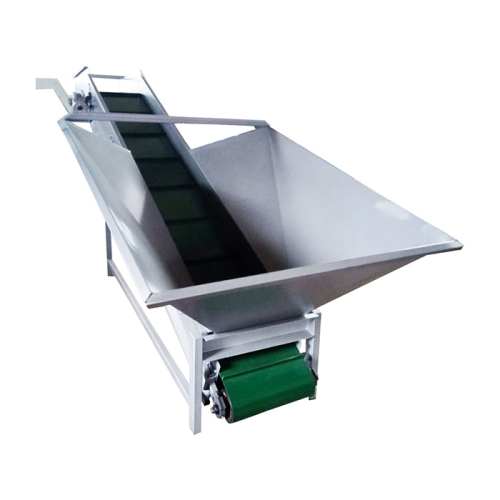

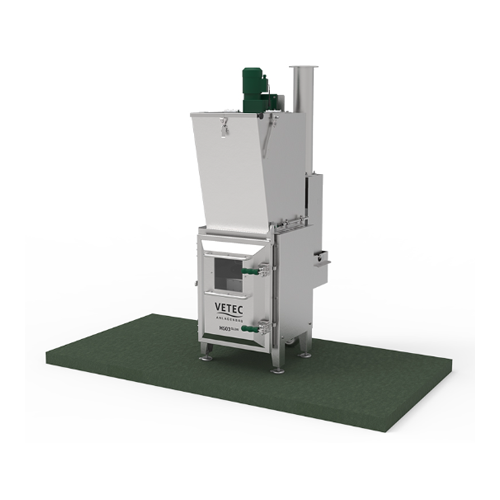

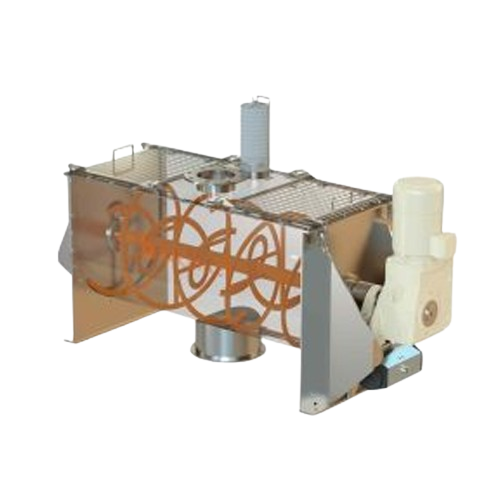

Feeding system for filter cake and wet pet food

Achieve seamless material handling and agitation for solid shortening and ...

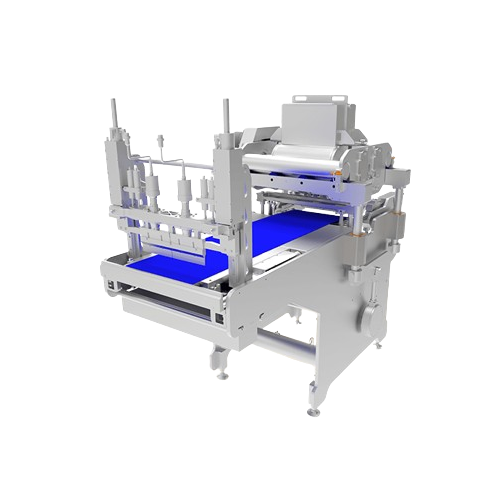

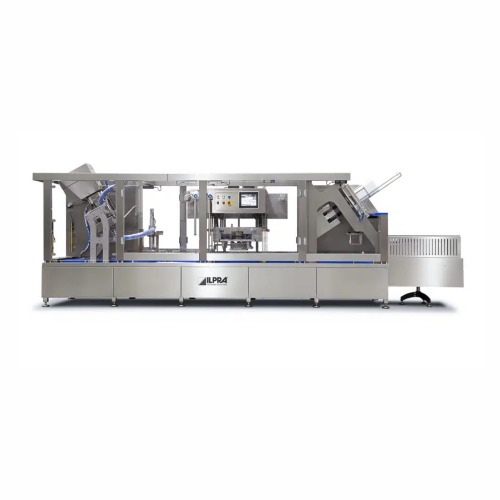

Convenience and pet food filling solution

Optimize your production line with high-speed, hygienic filling of diverse food ...

Precision filler for convenience and pet food

Achieve unparalleled precision and efficiency in filling solids, powders, li...

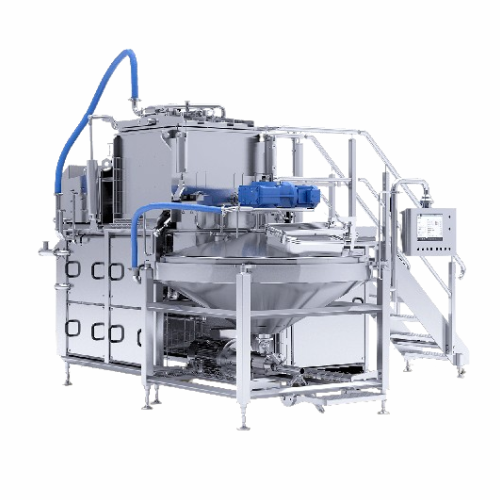

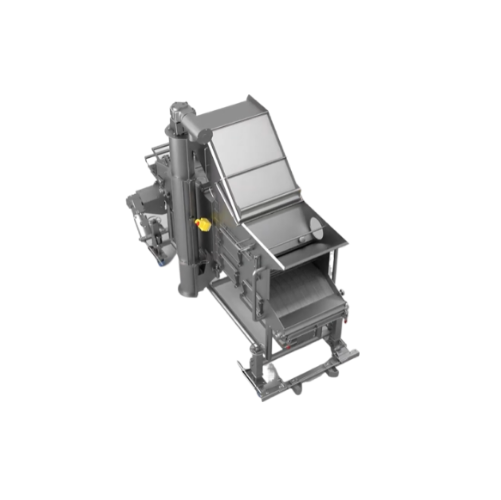

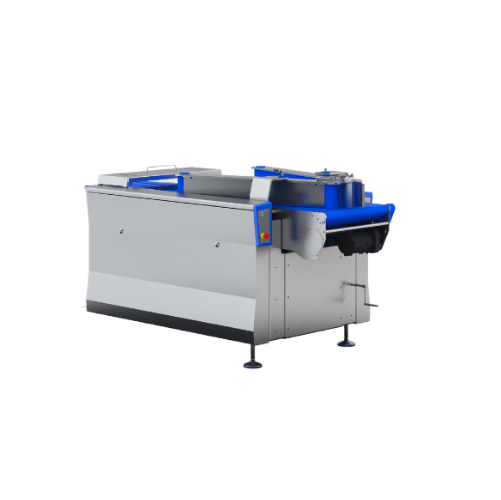

Batch cooker and mixer for food and pet food production

Streamline your cooking and mixing processes with a versatile bat...

Machine for packing canned pet food

Most packaging applications require different types of packaging machines, some need wr...

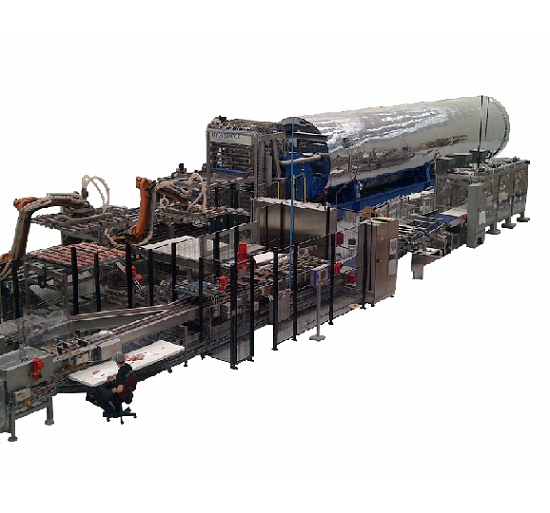

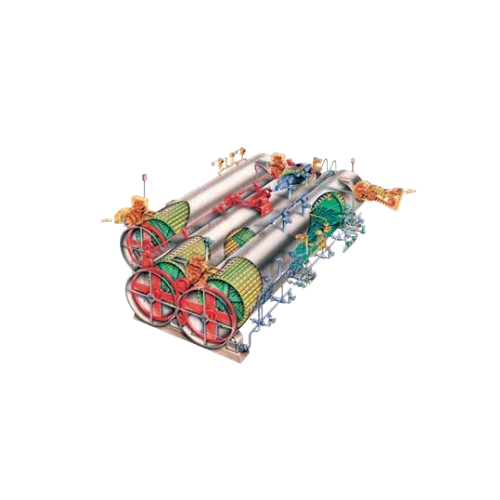

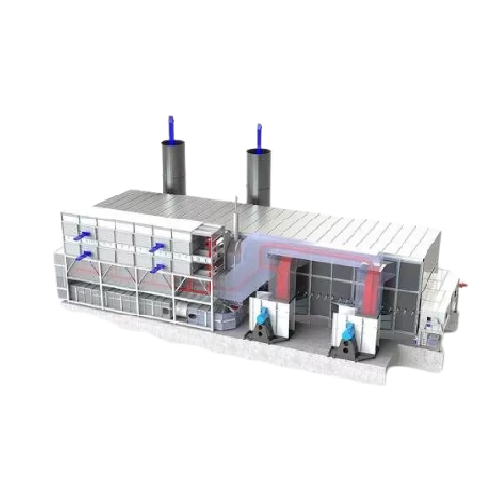

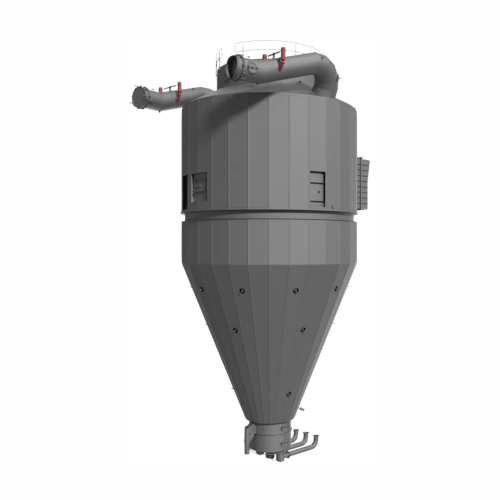

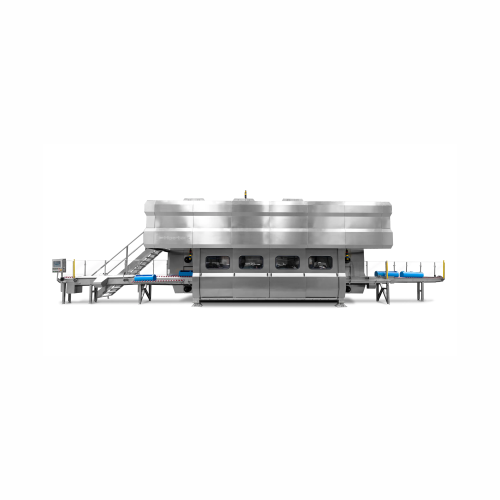

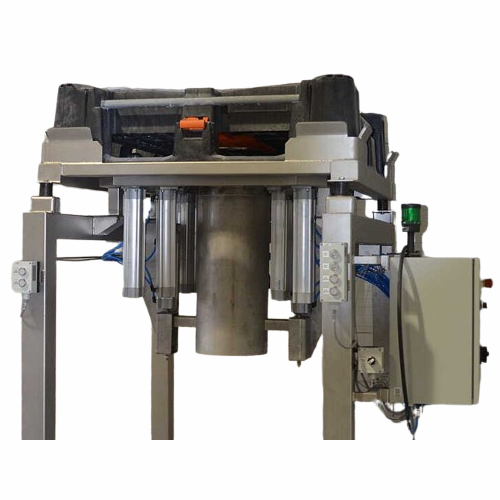

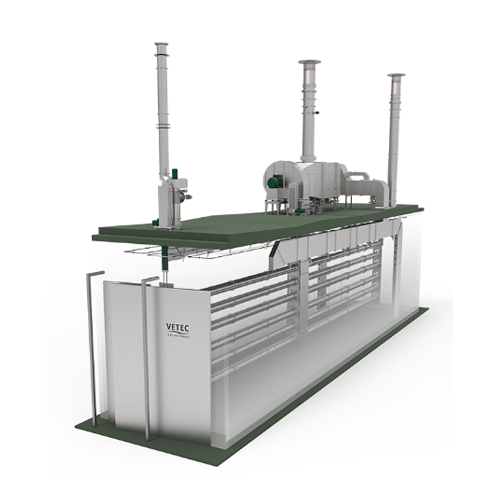

Continuous sterilizer for pet food

Sterilization is a critical operation in the manufacturing of wet pet foods. An importan...

Screw press for insect protein extraction

Address the rising protein demand with our screw press, designed to efficiently ...

High pressure extruder for expanded snacks

Enhance your snack production with precise control over texture and shape throu...

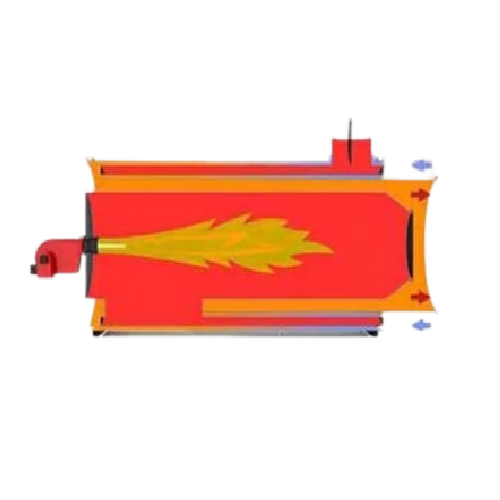

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

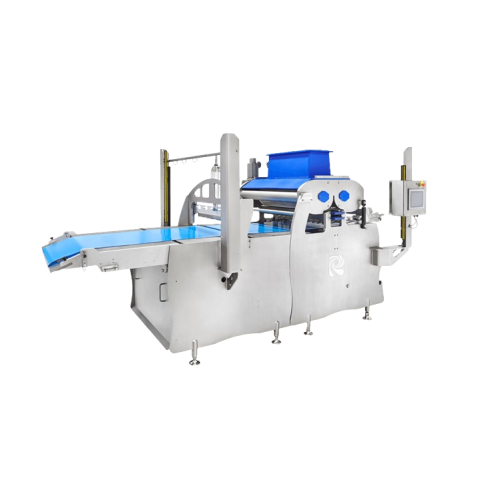

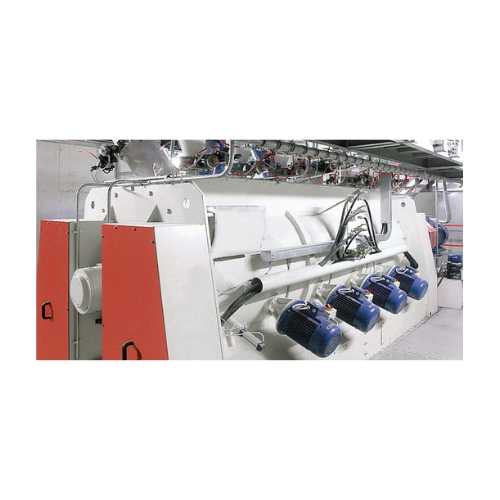

Continuous mixer for wheat-based products

Achieve consistent dough quality with minimal variation using a continuous mixer...

Efficient dough dump station for bakery systems

Streamline your dough handling process with this advanced dumping station,...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

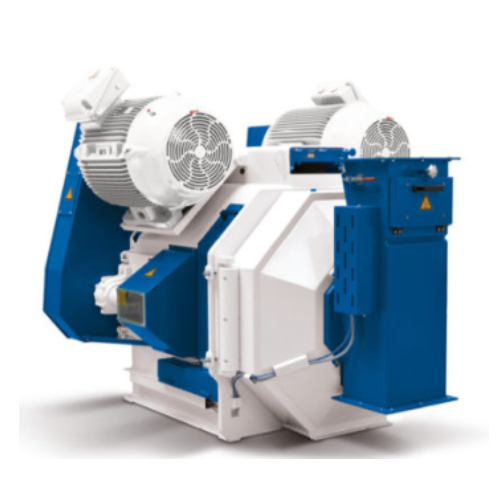

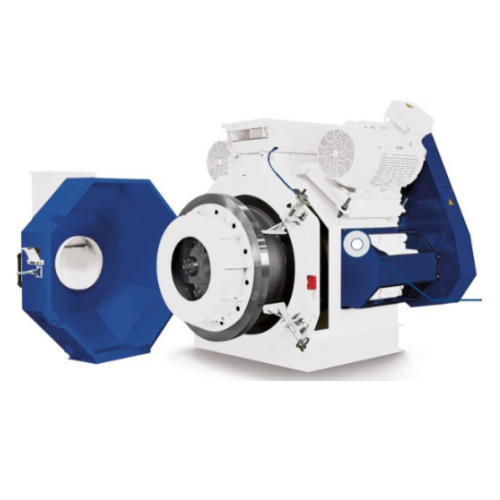

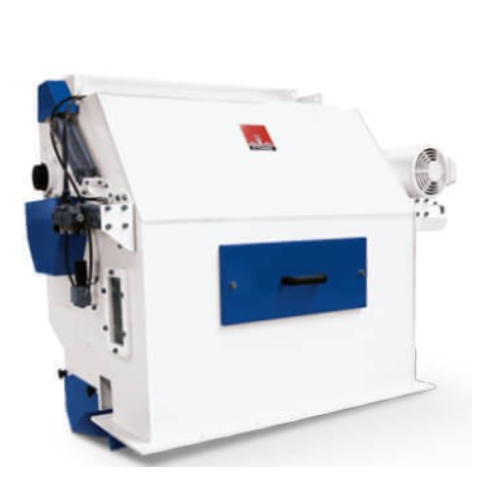

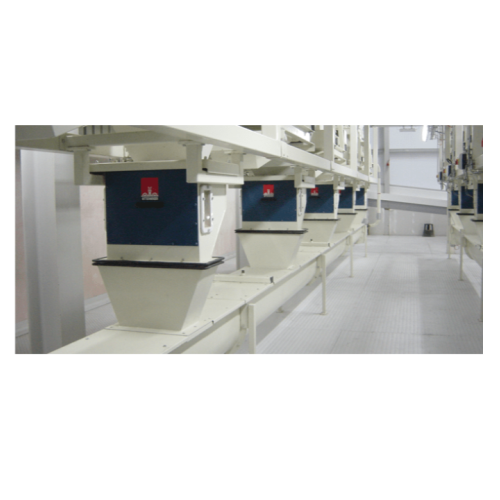

Pellet mill for high efficiency animal feed production

Achieve stable, vibration-free pellet production with enhanced ene...

Pellet mill for animal feed production

Optimize your feed production with a robust pellet mill designed to enhance the dura...

Industrial vibrating sieves for pellets and fine particles

Optimize feed quality and material flow in your production li...

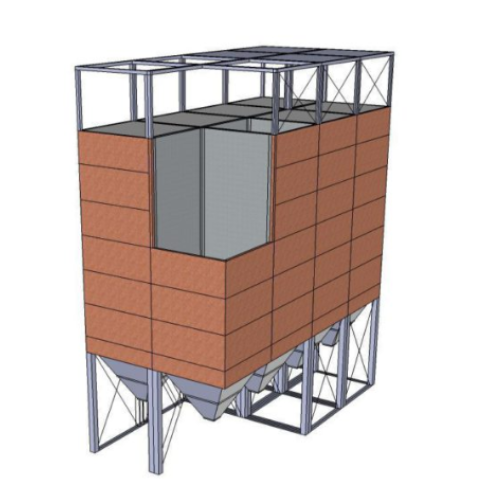

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

Quick hammer exchange system for hammer mills

Streamline hammer replacement in your milling process with a system designed...

Roll feeders for consistent hammer mill supply

Ensure precise and controlled feedstock delivery to your hammer mill, effec...

Continuous mixers for feed mill applications

Optimize your liquid incorporation process with continuous mixers that ensure...

Horizontal ribbon mixers for animal feed production

Experience precise and efficient mixing with low energy consumption f...

Single shaft paddle mixers for dry powders and granulates

Achieve uniform and precise mixing for your batch processing n...

Vertical mixers for animal feed industry

Efficiently combine a variety of powdered and raw materials with precision, ensuri...

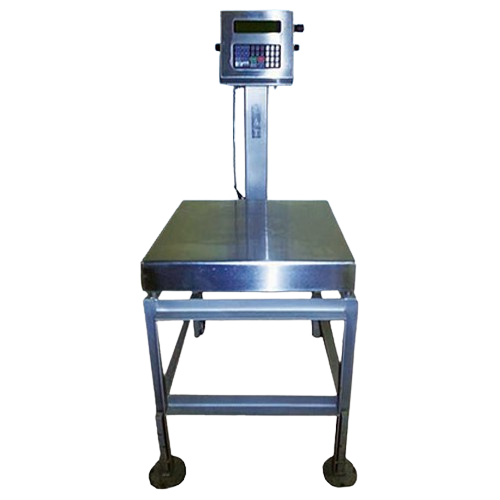

Inline and continuous weighers for accurate product flow management

Maintain precision and efficiency in your productio...

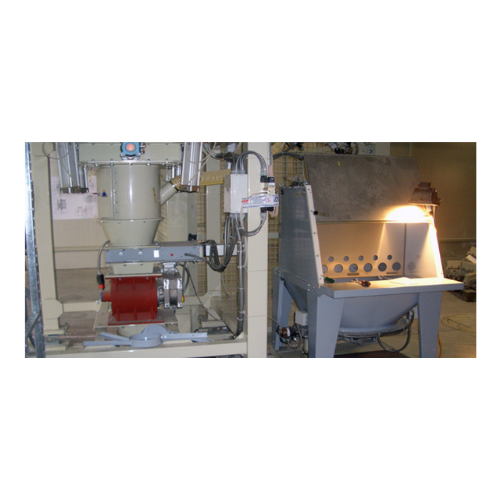

High accuracy micro dosing system

When handling diverse ingredients, precise dosing is crucial to ensuring consistent produ...

Micro-ingredient dosing system for animal feed production

Optimize your feed formulation accuracy with precision dosing,...

Counterflow pellet coolers

Optimize temperature control and enhance product integrity in your feed production line with prec...

Extruders for animal feed production

Optimize nutritional value and ensure efficient processing of animal and aqua feeds wi...

Industrial hammer mill for granulate grinding

Optimize the grinding process in feed production with a high-efficiency solu...

Feed expander for improved pellet mill output

Enhance your feed quality and production efficiency with a robust expander d...

Hot start conditioner for feed and food processing

Enhance your production process with a high-efficiency thermal heating...

Retention time barrel for feed pelleting

Enhance your feed processing efficiency with a specialized retention time barrel, ...

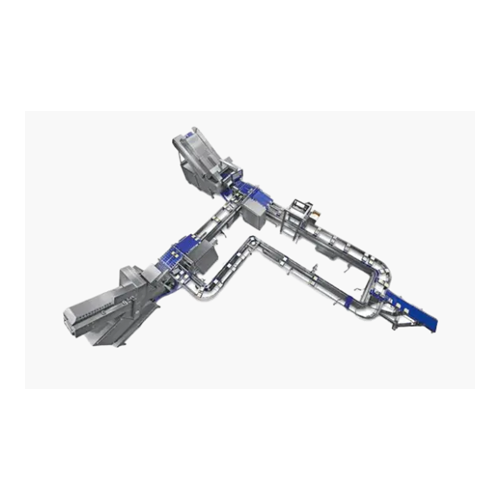

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

Rotary dischargers for powders and granules

Prevent production halts with this solution designed for efficient discharge o...

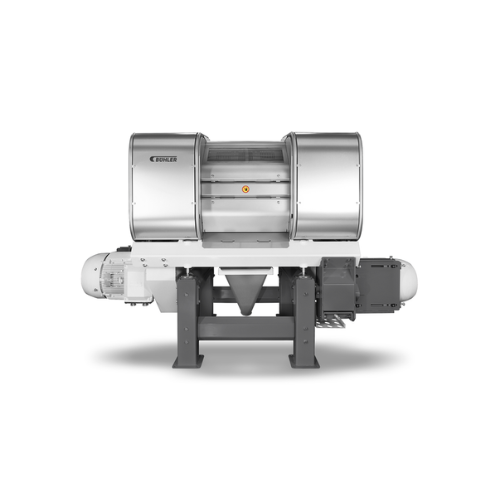

Feed pellet crumbler

Achieve precise size reduction of feed pellets with high efficiency and minimal fines, optimizing your p...

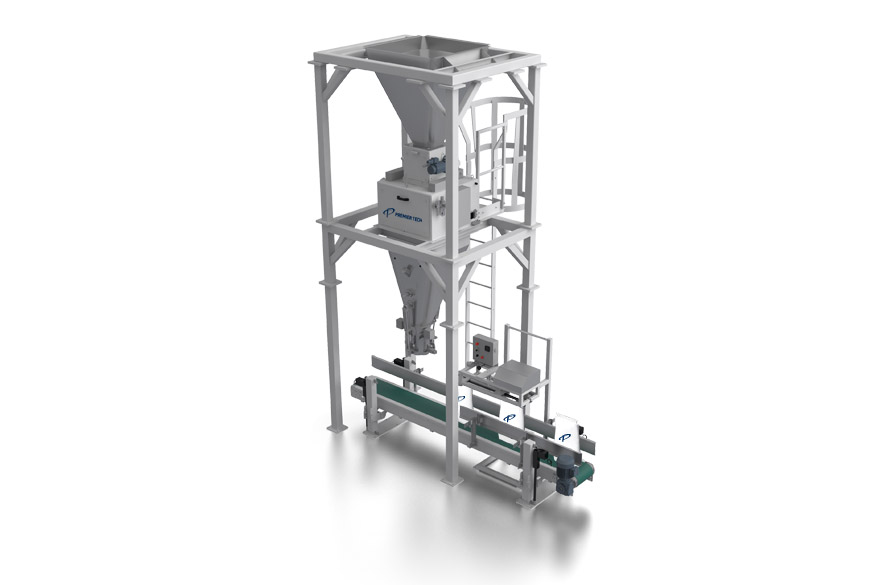

Batch weighers for large-volume powder and granulate weighing

Ensure precise ingredient dosing and streamline your produ...

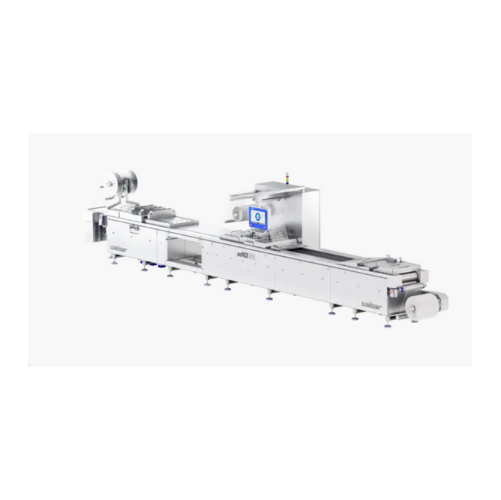

Vacuum packaging system for high-volume operations

Optimize your packaging line with high-speed vacuum sealing for divers...

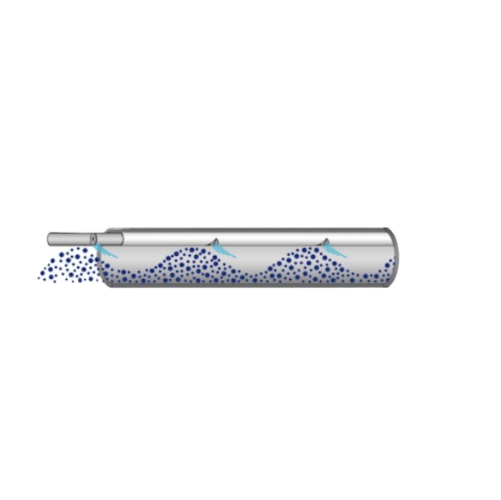

Continuous coater for pellet and extrudate liquid addition

Efficiently enhance your feed products by uniformly adding li...

Vacuum coaters for high liquid addition in feed production

Enhance your feed production with precision liquid coating, s...

Feed mill compactor for improved pellet quality

Optimize your feed production with a compactor designed to enhance pellet ...

Single conditioner for feed mills

Achieve homogeneous mixing and enhanced hygiene in feed production with adjustable paddle...

System for packaging stacked coffee pods in filter paper

Streamline your pod production with precision bagging and sealin...

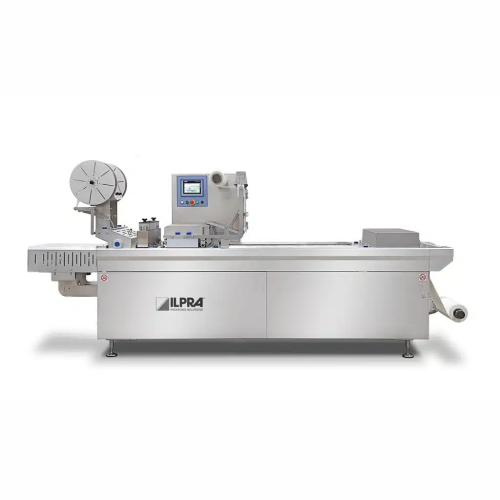

Vacuum packaging system for food products

Optimize your packaging process with high-speed vacuum technology designed to pr...

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

Industrial mixer-grinder for food processing

Streamline your processing line with a robust mixer-grinder that combines eff...

Heavy duty soak tanks for dry bean processing

Optimize your pre-processing with heavy duty soak tanks designed to ensure u...

Intermediate snipper for green bean processing

Optimize your green bean processing with a high-efficiency snipping solutio...

Pouch cooling system for food processing

Experience rapid cooling for your pouched food products, minimizing time in the ba...

Rapid food cooling solution for vegetables and pasta

Efficiently reduce the temperature of particulate foods with rapid p...

Efficient pouch cooling solution

Designed to cut cooling times in half, this solution efficiently reduces the bacterial dang...

High-capacity pouch cooling system

Move pouched foods swiftly through critical temperature zones, ensuring rapid cooling fo...

Lift and dump system for blanchers and cookers

Enhance precision in your food processing line by seamlessly integrating a ...

Rotary drum blancher for vegetables

Streamline your processing line with this rotary drum solution, ensuring precise blanch...

Sanitary cooker and cooler for pasta and rice

Effortlessly tackle the challenges of undercooked or overcooked pasta and ri...

Rice cooking system for low-moisture processing

Achieve fully cooked, low-moisture rice with precise control over absorpti...

Vegetable and fruit peeling and washing

Efficiently wash and peel a wide range of fruits and root vegetables in one seamles...

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-p...

Industrial food dehydrator for fruit and vegetables

Optimize your drying process with a high-temperature food dehydrator ...

Commercial dicing machine for fruit and vegetables

Effortlessly transform your raw vegetables and fruits into uniform dic...

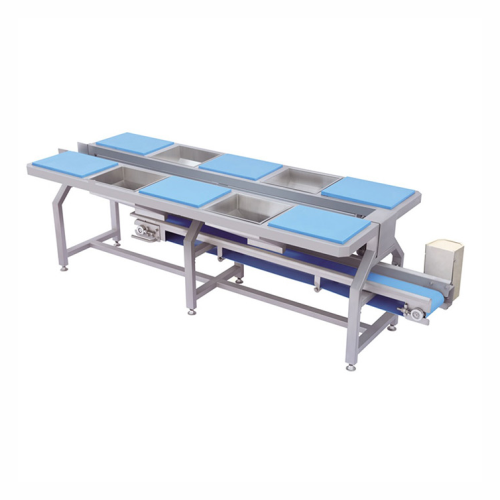

Inspection table for vegetables and fruits

Streamline your quality control with an efficient inspection table designed for...

Industrial salad and delicatessen mixer

Achieve consistent and gentle mixing for diverse food applications with a solution ...

Continuous packaging solution for free-flowing food products

Streamline your production with a high-speed packaging mach...

Pepper coring and dividing system

Effortlessly core and segment bell peppers, slashing labor costs while ensuring consisten...

Cutting solution for large fruits and vegetables

Optimize your food processing operations with a semi-automatic solution d...

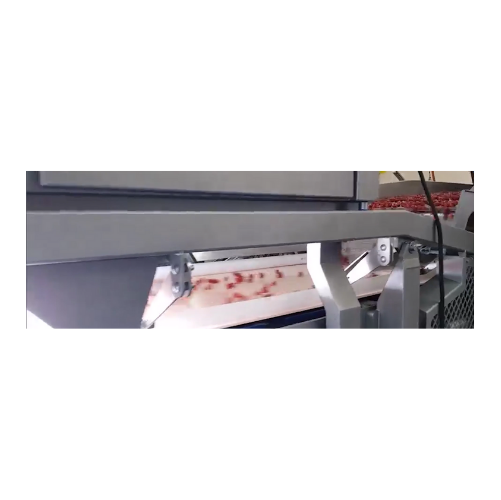

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

Industrial mixer grinder for fresh and frozen meat processing

Efficiently process diverse meat products for fresh and fr...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Packaging solution for small bottles and jars

Effortlessly seal and fill non-stackable containers, ensuring precision for ...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Multifunctional batch cooker for various food products

Optimize your production line with a versatile batch cooker design...

Lump-free emulsifier and steam batch cooker for processed cheese

Achieve consistent, lump-free processed cheese and crea...

Continuous cooker for high-volume food processing

Elevate your production efficiency with a continuous cooker that ensure...

Cooling drum for seasoned extrudates

Ensure consistent texture and quality in your extruded snacks by effectively cooling s...

Cream preparation plant for homogeneous mixing

Optimize your snack production with precise mixing technology, ensuring con...

Seasoning drum for extruded snack products

Achieve consistent seasoning and mixing for extruded snacks with precision and ...

Industrial raw material mixer for complex recipes

Struggling with complex raw material mixtures? This advanced mixing sol...

Conveyor systems for snack production

Streamline your snack production with advanced conveyor systems designed for seamless...

Multi-purpose oven for prepared foods

Ensure consistent cooking precision with this multi-purpose oven, designed to optimiz...

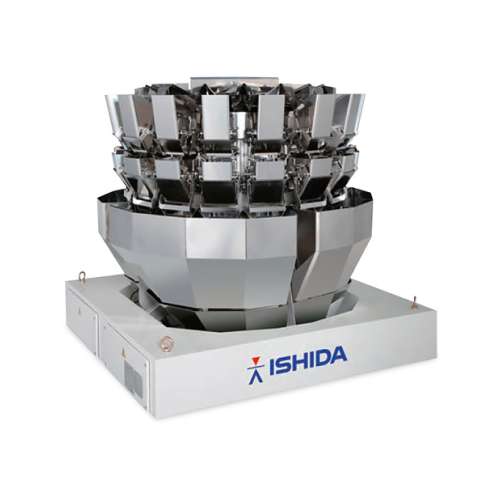

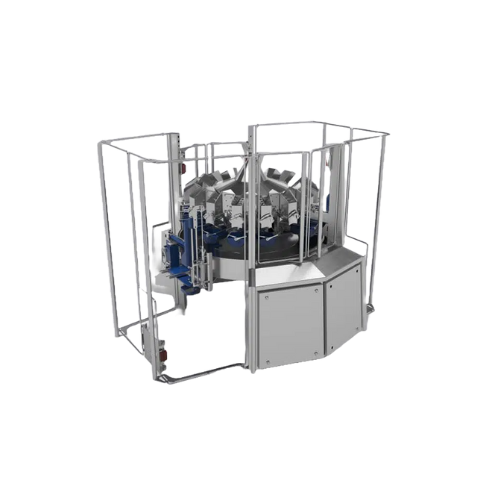

Blending multihead weigher for accurate component mixing

Achieve precise blending in high-speed operations with individua...

Linear weigher for dry or frozen free-flowing products

Optimize precision in high-speed weighing tasks with a compact sol...

Flexible drying system for various industrial applications

Achieve precise moisture control across diverse materials wit...

Drum dryer for animal feed

Achieve efficient and uniform drying for a variety of products, from nuts to medicinal cannabis, ...

Continuous belt dryer for industrial production

For operations requiring precise moisture control, this continuous belt dr...

Automatic sausage filling and hanging system

Streamline sausage production with precise portioning and seamless integratio...

High-performance sausage linking and hanging line

Boost your production efficiency with a high-speed line designed for se...

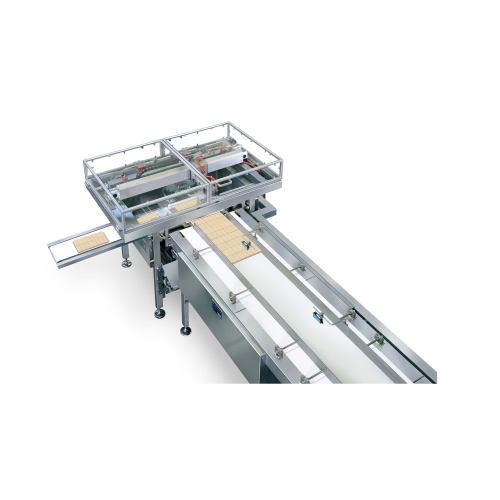

Dough portioning system for bakery operations

Achieve precise dough portioning with minimal waste using our advanced syste...

Inline grinding system for sausage and minced meat production

Streamline your production line by simultaneously grinding...

Minced meat portioning line

Optimize your production line with precise portioning and packaging of minced meat, enhancing ef...

High-capacity industrial grinder for frozen and fresh raw materials

Effortlessly grind both deep-frozen blocks and fres...

Industrial sausage and ham vacuum filler

Achieve unmatched precision in filling and portioning with high-capacity vacuum te...

Industrial forming and cutting system for diverse products

Maximize product versatility with a system that effortlessly ...

High-precision depositing system for fluid and viscous fillings

Achieve precise and efficient dosing for diverse food pr...

Cutting valve for chunky food portioning

Achieve precise portioning of chunky products, reducing waste and increasing effic...

High vacuum filler for dry sausage products

Achieve pore-free, compact dry sausage products with superior evacuation perfo...

High vacuum filler for large-calibre sausages

Achieve pore-free, high-quality products with optimal portioning accuracy an...

High-capacity piston stuffer for industrial filling and portioning

Streamline your production with high-speed, fully el...

Industrial sugar sander for confectionery coating

Enhance product appeal and longevity with a sugar sander designed to un...

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

Extrusion system for color changing confectionery strands

Easily switch colors in confectionery strands mid-production, ...

High precision dosing system for color, flavor, and acid

Achieve precision and reliability in dosing color, flavor, and a...

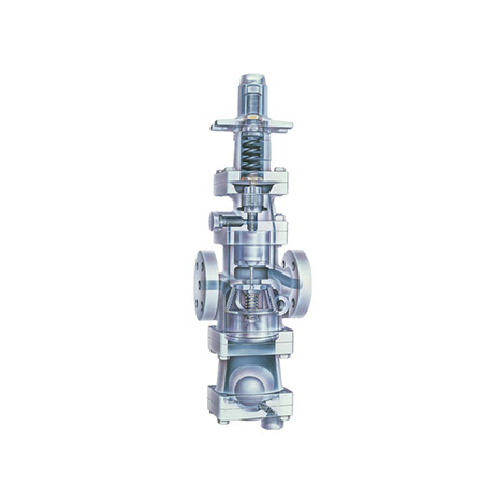

Screen changer for extrusion lines

Prevent clogs and maintain quality with this screen changer, designed to filter out soli...

Slurry preparation for licorice production

Ensure a continuous and homogeneous feed of licorice slurry to your extruder, o...

Industrial shredder for diverse material reduction

Achieve precise and efficient material resizing for diverse applicatio...

Continuous mixer for industrial powders and liquids

Achieve precise and efficient mixing of solids and liquids with minim...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

R&d mixer for small batch experimentation

Perfect your mixing techniques swiftly with precision-controlled small batch exp...

Rotary drum sifter for pellets and chunks

Achieve precise particle separation and minimize product loss with a rotary drum...

Fast screen exchange grinding solution for medium-hard products

Maximize your milling efficiency with a solution that al...

Mechanical horizontal conveyor for powders and granulates

Efficiently handle and transport your delicate powders and gra...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Industrial mixer for moisture conditioning

Ensure precise moisture levels and homogeneous mixtures for complex extrusion p...

Liquid dosing system for powders and granulates

Achieve precise liquid addition with this dosing system, ideal for integra...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

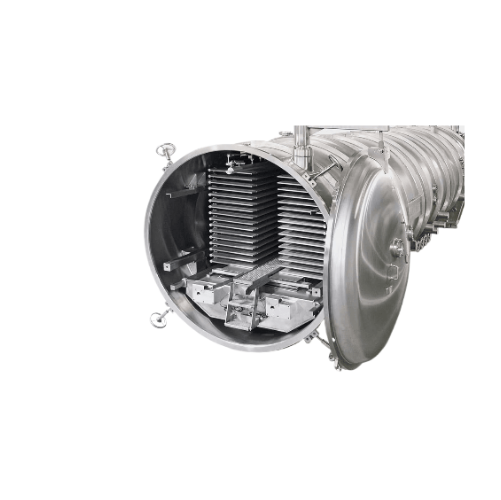

Industrial freeze dryer for large scale food processing

Optimize moisture removal for high-quality food preservation and ...

Accurate weighing system for micro ingredients

Ensure precise micro-ingredient dosing for batch operations with this versa...

High-capacity ring-die pellet mill for animal feed production

Optimize your high-capacity feed production with this pell...

Loss-in-weight scale for micro ingredient batching

Enhance precision in your production line with advanced micro ingredie...

Pellet crumbler for animal feed pelleting

Optimize pellet size reduction with precise control and high efficiency, ensurin...

Oilseed flaking mill

Enhance flake consistency and output efficiency with advanced roll technology designed to optimize your ...

Frozen meat grinder

Streamline your protein processing with a solution designed to efficiently grind frozen meats, ensuring c...

Vacuum mixer/blender for food processing

Achieve precise mixing and blending with air removal for consistent quality across...

Stuffing hopper with stainless positive displacement pump

Enhance your high-volume processing line with a seamless integ...

Transfer hopper with stainless Pd pump for food processing

Eliminate spillage and maintain continuous flow with a positi...

Vertical screw conveyor for ground materials

Optimize floor space in food processing with this vertical solution, ensuring...

Emulsion and reduction system for meat processing

Achieve precise particle consistency and texture control in food proces...

Pellet dedusting elutriators

Achieve superior purity in your production line by effectively removing dust and streamers with...

Aerolock surge hopper for precise bulk material management

Optimize your production with a surge hopper designed to ensu...

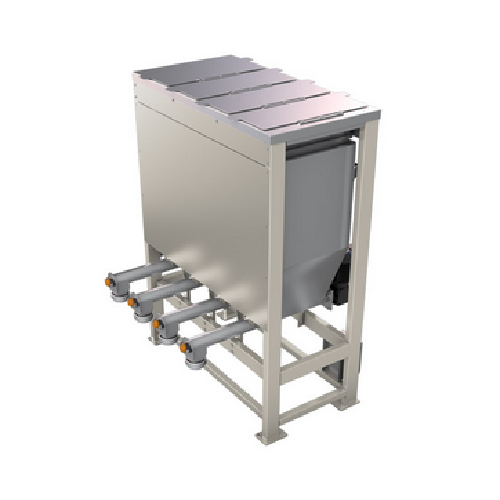

Feed bins for pre-conditioning materials

Optimize your material flow by pre-conditioning bulk solids for efficient vacuum c...

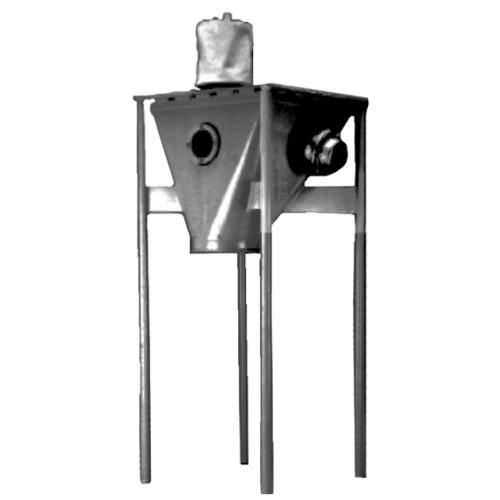

Scale hopper for bulk material processing

Optimize your bulk material handling with precise control in separation, filling...

Laboratory twin screw extruder for small batch processing

Efficiently develop formulations and conduct precise research ...

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Vacuum sequencing blower for industrial conveying systems

For manufacturers handling bulk materials like powders and gra...

Centric pelletizer for direct extrusion

Effortlessly transform materials into uniform granules with our high-speed pelletiz...

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Industrial rice cooker

Enhance rice processing with an engineered solution that ensures precise cooking and cooling, optimizi...

Vacuum filler for glass jars and cans

Ensure precise filling and equal headspace for your products with this vacuum filler,...

Marinating line for meat and poultry

Streamline your marinating process with reduced spillage and cleaning time by incorpor...

Air-cleaning system for fragile berries

Ensure the pristine quality of your delicate berries with a system designed for gen...

Continuous belt thawing unit for frozen seafood

Quickly defrost block-frozen products with minimal water usage, enhancing ...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

High-efficiency pulverizer for ultra-fine applications

Optimize your production of animal and aqua feed with this high-sp...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

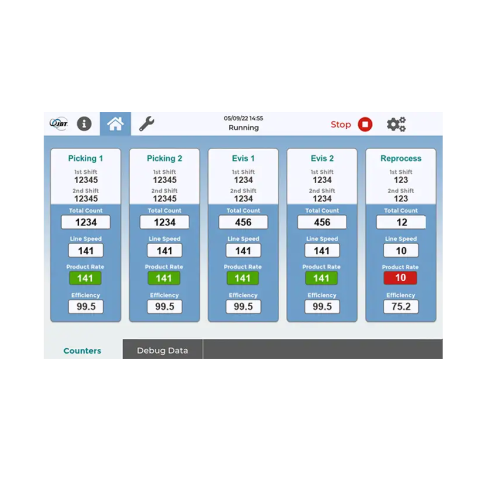

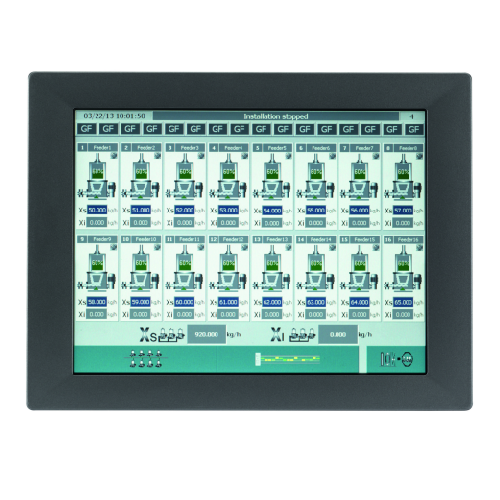

Bagging control system for centralized operations

Streamline your bagging operations with a centralized control system, d...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Hammer mill for animal feed grinding

Achieve precise granulation with high throughput and energy efficiency, while reducing...

Micro-dosing system for animal feed additives

Achieve precise and consistent feed formulation with high-precision micro-do...

Gluten quality testing solution

Ensure optimal flour quality by rapidly assessing gluten properties, allowing you to refine ...

Full Rsc case shaker-compactor-sealer

Streamline your packaging line with a solution that compacts and seals cases to elimi...

Big bag connection system for dust-free docking

Achieve dust-free docking and seamless discharging of bulk solids with an ...

Food forming solution for poultry and plant-based products

Optimize your production line with high-pressure forming that...

Industrial bagging system for high-speed processing

Optimize your packaging line with this engineered-to-order bagging sy...

Semi-automatic tray sealer for ready meals

Achieve optimal freshness with consistent sealing, maximizing shelf life for va...

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

Energy efficient steaming for fresh produce

Achieve exceptional product quality while minimizing energy use by up to 90% w...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Industrial hot water heating system

Optimize your production line’s efficiency with precise water temperature control...

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise s...

Tuna vacuum pre-cooker cooler

Optimize your tuna and seafood processing with precise thawing, cooking, and cooling under vac...

Hydrostatic sterilizer for continuous food processing

Maximize your production line’s efficiency with a continuous ...

Gentle can handling ejector for rotary cooker

Achieve seamless can transfer and sterilization with reduced damage during h...

Steam water spray retort for shelf-stable food processing

Ensure uniform heat distribution and precision control in ster...

Industrial retort for food sterilization

Achieve uniform sterilization and cooling in your batch production processes while...

Automated batch retort system for food sterilization

Optimize your sterilization process with seamless transportation fro...

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Linear convection oven for food processing

Achieve precise cooking and browning of diverse food products simultaneously wh...

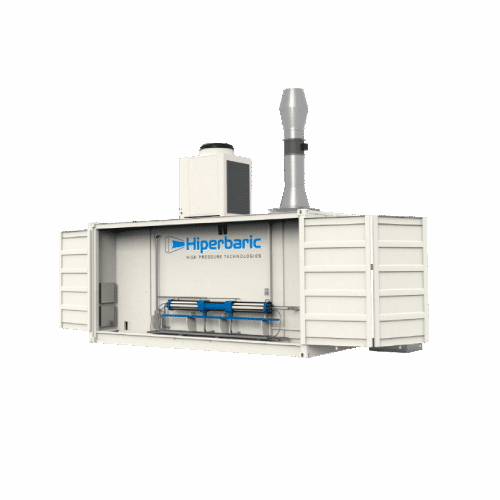

Expandable high pressure processing system

Optimize your production line with an expandable high-pressure processing syste...

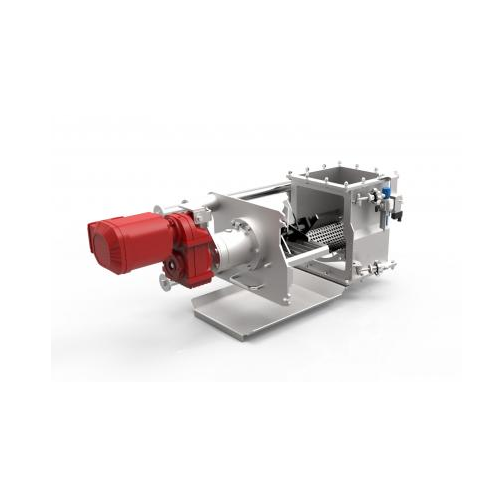

Double-shaft paddle mixer for homogeneous raw masses

Optimize your mixing efficiency with a dual-shaft system designed fo...

High pressure processing for diverse food products

Maximize production versatility and ensure product safety with a high-...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

High capacity volumetric filler for pumpable products

When you need high-speed, precise filling for diverse liquid and sl...

Portioning system for poultry, meat, and seafood

Achieve precise cuts and maximize yield with high-speed waterjet technolo...

Home style drum breader for meat and poultry

Achieve consistent, high-quality breading on diverse food products with this ...

Preduster for fine-grain coating in food processing

Ensure your products receive a perfect, consistent fine-grain coating...

Automatic clipper for pre-tied casings

Streamline your casing process with a solution designed for efficient stuffing and c...

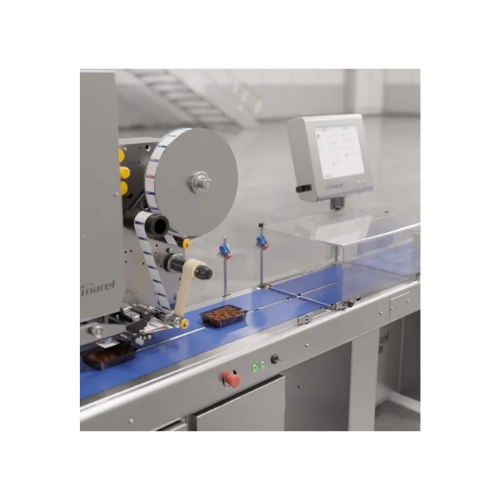

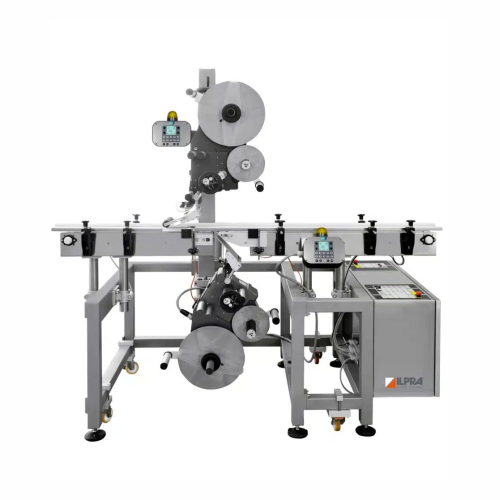

Industrial labeling system for precise product traceability

Enhance your production line with a state-of-the-art system ...

Automatic double clipper for sausage and food packaging

Streamline your packaging process with precision clipping technol...

Extrusion blow molder for custom bottles

Enhance your production line by creating versatile and customized bottles with sea...

High precision multihead weigher for dry pasta

Enhance your production line’s efficiency with precise weighment and ...

Industrial food grinder for meat and vegetables

Enhance your grinding process with a robust solution designed to efficient...

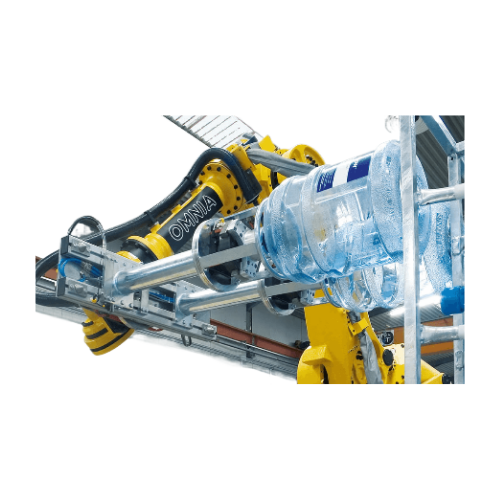

Robotic palletizer for food and beverage industries

Enhance your production line’s efficiency with a flexible robot...

Batch freeze drying system for food and beverage preservation

Achieve precise and efficient preservation of your food an...

Pilot plant freeze dryer for sensitive products

Achieve precise moisture control and nutrient preservation in food and pha...

Automatic can seamers for food and beverage industry

Ensure airtight sealing of canned goods with precision seamers desig...

Seamers for round food containers

Ensure airtight sealing for food products with high-speed seamers designed for precision ...

High capacity horizontal dryers and coolers for industrial applications

Achieve consistent moisture levels and uniformi...

Sanitary dryers for textured vegetable proteins

Optimize drying and sanitation for textured vegetable proteins and pet foo...

High-sme extruder for structured meat analogs

Enhance production versatility with precise extrusion control, accommodating...

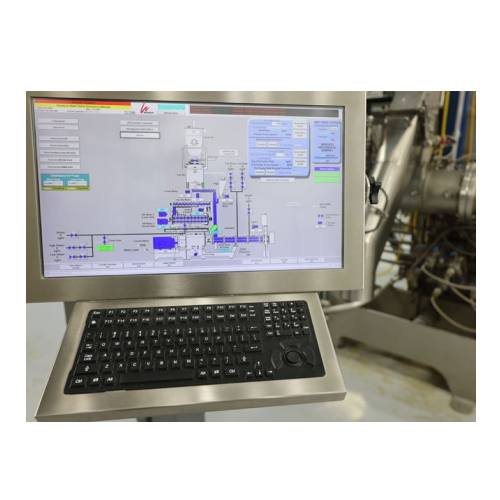

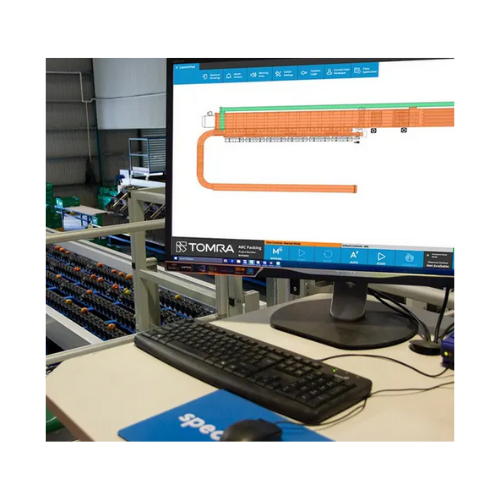

Automated process management system for industrial extrusion

Optimize your production line with precise control and moni...

High intensity preconditioner for textured vegetable proteins

Optimizing your production with precise moisture control a...

Tanker loading bellow for dust-free bulk solids loading

Optimize tanker loading while minimizing dust emissions with this...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Tapered twin shaft screw feeders for bulk solids

Ensure consistent flow and avoid material bridging challenges with a solu...

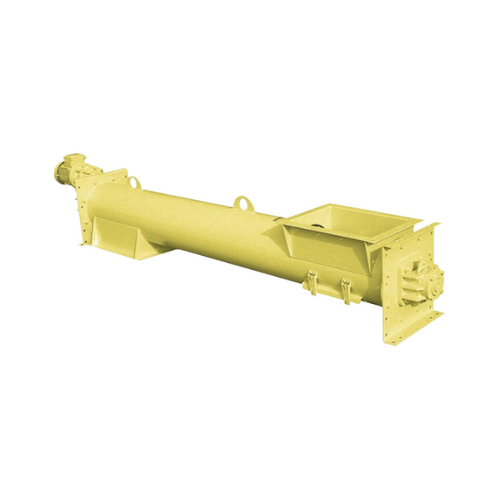

Trough screw conveyors for powdery and granular materials

Optimize your material handling process with a flexible screw ...

Tubular trough screw conveyors for gentle powder and granular material handling

Achieve precise powder and granular ma...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Friction smoke generator for hot smoking and climatic maturing

Optimize your production with a friction smoke generator ...

Closed glow smoke generator for hot smoking installations

Enhance your smoking process with efficient energy use and sea...

Liquid smoke system for meat and seafood processing

Achieve uniform smoking results across diverse products by employing ...

Dual-method cooling system for sausage and meat products

Achieve optimal freshness, flavor, and shelf life for your meat ...

Industrial food cooling system

Achieve precise core temperatures and optimized shelf life with rapid cooling for diverse foo...

Horizontal air flow drying and smoking system for meat products

Achieve superior drying and smoking efficiency with hori...

Air-conditioned storage chambers for post-curing

Ensure consistent product quality with precise humidity control, essentia...

Grinding and separating solution for meat processing

Optimize your meat and plant-based production lines by integrating a...

Linking, hanging, and cutting system for sausage production

Streamline your sausage production process with precision-en...

Vacuum filling machines for cooked ham & sausages

Achieve precise portioning and enhanced product quality with this advan...

High capacity shredder, slicer, and strip cutter

Optimize your production line with advanced cutting versatility, handling...

Industrial cheese shredder

Optimize continuous food processing with a machine that handles high-speed shredding, slicing, cu...

Single piston food filler

Achieve precise portioning and consistent product flow with a versatile solution perfect for handl...

Single piston depositors for bakery and food production

Optimize your depositing and filling processes with versatile equ...

Industrial depositor for automated recipe management

Effortlessly streamline your production with precise depositing cont...

High speed pneumatic depositor for bakery applications

When depositing batters, creams, and sauces, achieving consistent ...

Servo multi food portioner

Achieve precise portion control and high-speed depositing for diverse applications with this adva...

Food spraying and flocking system for bakery applications

Enhance your production line with precision spraying and flock...

Multi piston depositors for bakery production

For bakeries seeking precision in depositing and filling, these multi piston...

Multi piston depositors for high-volume baking production

Optimize your high-speed production line with precision deposi...

Food transfer and dosing pumps for bakeries

Enhance efficiency in food processing with pumps designed for precise transfer...

Food grade transfer pump for semi-solid products

Streamline your production with a high-speed transfer pump designed for s...

Dual or triple lane food depositor

Enhance your production efficiency with a depositor that seamlessly handles a variety of...

Food depositor for large chunk applications

Need precise depositing of chunky food products like stew or salsa? This versa...

Large portion depositor for food production

Achieve precision and efficiency in depositing large portions with versatile s...

Bakery batter depositor for efficient, consistent depositing

Enhance your bakery production with precision depositing fo...

Bakery and food grade conveyor systems

Optimize your bakery and food production with versatile conveyors designed for seaml...

Compact food depositor for direct container use

Streamline your depositing process with a versatile solution that handles ...

High-speed piston depositor for food applications

Achieve precise portioning and rapid depositing of diverse food product...

Industrial food filler for precise depositing over conveyors

Optimize your food production line with a versatile filler ...

Single piston food depositor

Achieve precise portion control for diverse food products, from soups to chunky fillings, with ...

Automated production lines for cakes and cupcakes

Streamline your bakery’s production line with a versatile automat...

Tabletop food depositor for portion control

Streamline your food production with precise portion control, reducing waste a...

Semi-automated depositor with handheld nozzle

Maintain portion precision and reduce ingredient waste with a versatile depo...

Compact food transfer pump

Effortlessly maintain your production flow with a compact transfer pump designed to handle a wide...

Bakery and food grade conveyors

Enhance your bakery and food production with conveyors designed to seamlessly transport and ...

Bakery transfer pump for smooth and chunky products

Ensure consistent product quality with this transfer pump that gently...

Screw conveyor for grain or finished products

Optimize your production line with a space-efficient screw conveyor designed...

Dosing scale for accurate raw material weighing in feed recipes

Ensure precise feed formulation by weighing raw material...

Food dehydrator with Bpa-free plastic trays

Achieve precise dehydration for fruits, vegetables, and snacks with advanced t...

In-line filling and closing system for pre-formed containers

Looking to enhance production efficiency with a solution th...

Aseptic rotary cup filling and closing solution

Maximize your production capacity with this cutting-edge aseptic solution,...

Industrial shrink wrapping solution

Optimize your packaging line with a robust shrink wrapping solution, efficiently accomm...

Professional food dehydrator for fruits and vegetables

Enhance your culinary creations with precise dehydration technolog...

Food sorting system for nuts and dried fruit

Streamline sorting processes by removing visual irregularities, defects, and ...

Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and r...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

High-speed form and seal machine for retortable food packages

Streamline your production with a machine engineered for h...

Compact filling system for retortable carton packages

Simplify your production of ready meals and soups with a space-savi...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Commercial meat bone grinder for whole chicken & fish

Effortlessly transform whole chickens and fish into finely minced p...

Industrial animal bone crushing solution

Efficiently transform hard animal bones into fine granular materials, enhancing nu...

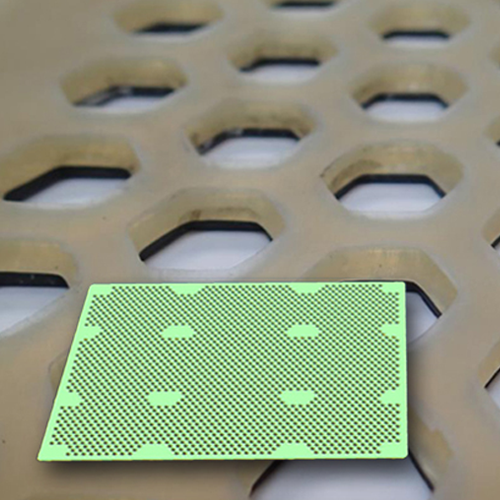

Vacuum coater for petfood and livestock feed

Enhance nutritional value and product quality with precision liquid incorpora...

Laboratory pilot sterilizers for food packaging

Optimize your R&D with precise sterilization and heat treatment capab...

Cascading water autoclave for food sterilization

Streamline your food sterilization process with an energy-efficient autoc...

Low-emission belt dryer for timber industry

Achieve maximum drying efficiency and significant energy savings in your proce...

Mid-size belt-chamber vacuum packaging for smallgoods and seafoods

Optimize your packaging line with efficient mid-spee...

Scraped surface heat exchangers for high viscosity products

Ideal for continuous processing, these heat exchangers effic...

Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consiste...

Speed controller for feeders

Ensure precise material flow by integrating this speed controller, ideal for managing both volu...

Dough chunkers for bakery production

Optimize dough processing by efficiently feeding and dividing dough portions, ensuring...

Dough kibbler for bakery production

Effortlessly transform large batches of dense dough into uniform, manageable pieces wit...

Single sigma arm bakery mixer

Streamline complex mixing tasks with precision using a mixer designed for optimal batch contro...

Grain unloading conveyor for ground level use

Efficiently unload bulk materials at ground level while minimizing dust and ...

Surge hoppers for efficient batch mixing

Streamline your production with surge hoppers engineered to reduce batch cycle tim...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

Industrial high-speed turbo blender

Achieve homogeneous blending with high-speed precision, ideal for creating fine product...

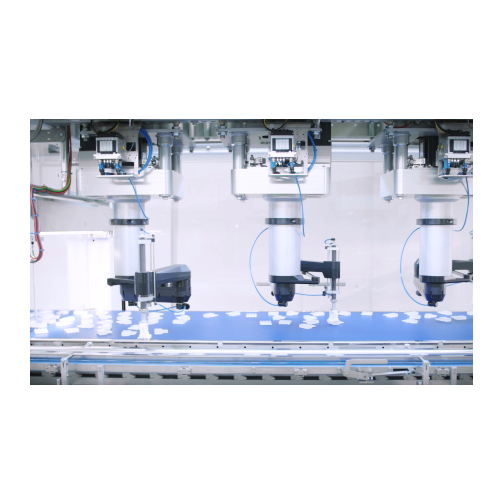

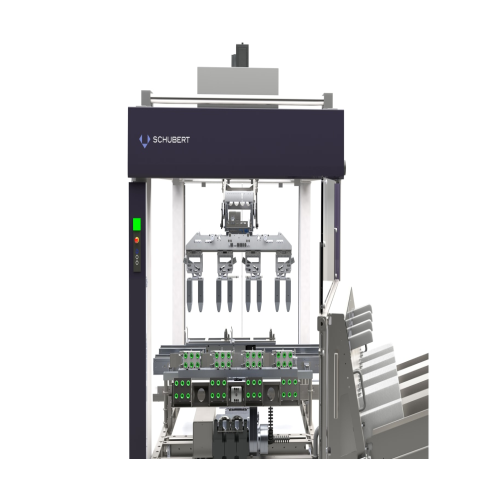

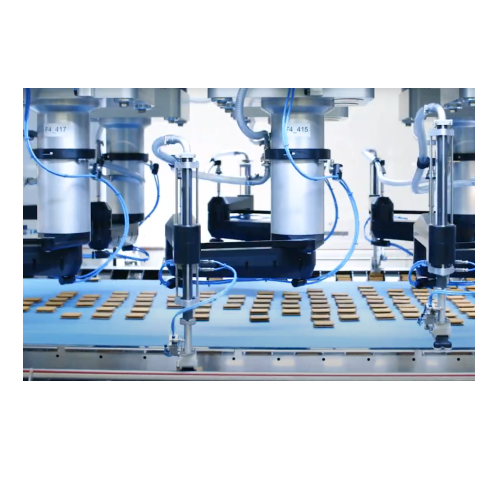

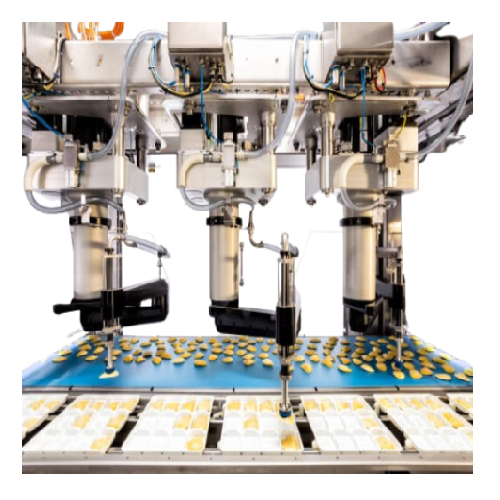

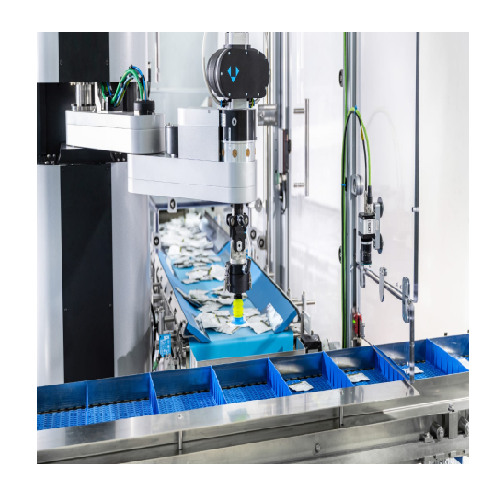

Pick and place robots for efficient product handling

Enhance your production line with high-speed pick and place robots c...

Compact carton packing solution for standardized tasks

Streamline your packaging workflow with a preconfigured solution d...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Modular packaging systems for diverse industries

Effortlessly adapt to market demands with versatile packaging systems, de...

Compact carton blank feeding system

Maximize your production efficiency with a solution designed to streamline carton blank...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Filling system for solids, pastes, and liquids

Eliminate contamination risks while achieving high-speed, precise filling o...

Organized component storage for vacuum fillers

Prevent equipment damage and streamline cleaning operations with a storage ...

Automatic tying system for fresh sausages

Streamline your sausage production process with high-speed tying, ensuring consi...

Double head forming system for burger production

Streamline your burger production with a high-speed forming system that e...

Frontal discharge mixer for meat processing

Enhance your mixing process with an efficient solution that seamlessly combine...

Flaker for frozen meat and food blocks

Efficiently transform solid blocks of frozen foodstuffs into precise cuts and flakes...

High speed portioner for minced meat and burgers

Optimize your production speed and portioning precision with this high-pe...

High performance minced meat portioner

Achieve consistent and precise minced meat portions with advanced grinding and porti...

Vertical dosing valve for accurate food portioning

Ensure precision in portioning liquid and semi-liquid food products wi...

Casing spinner for natural sausage casings

Improve efficiency in your sausage production by seamlessly integrating natural...

Innovative sausage production with vegetable coating

Optimize sausage production with a vegetable-based alginate coating,...

Forming system for meatballs

Achieve precise portioning and consistent shapes for various food balls and dumplings, enhancin...

Industrial heat pump dryer

The drying of extruded products is highly energy-demanding in traditional belt dryers that use ga...

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

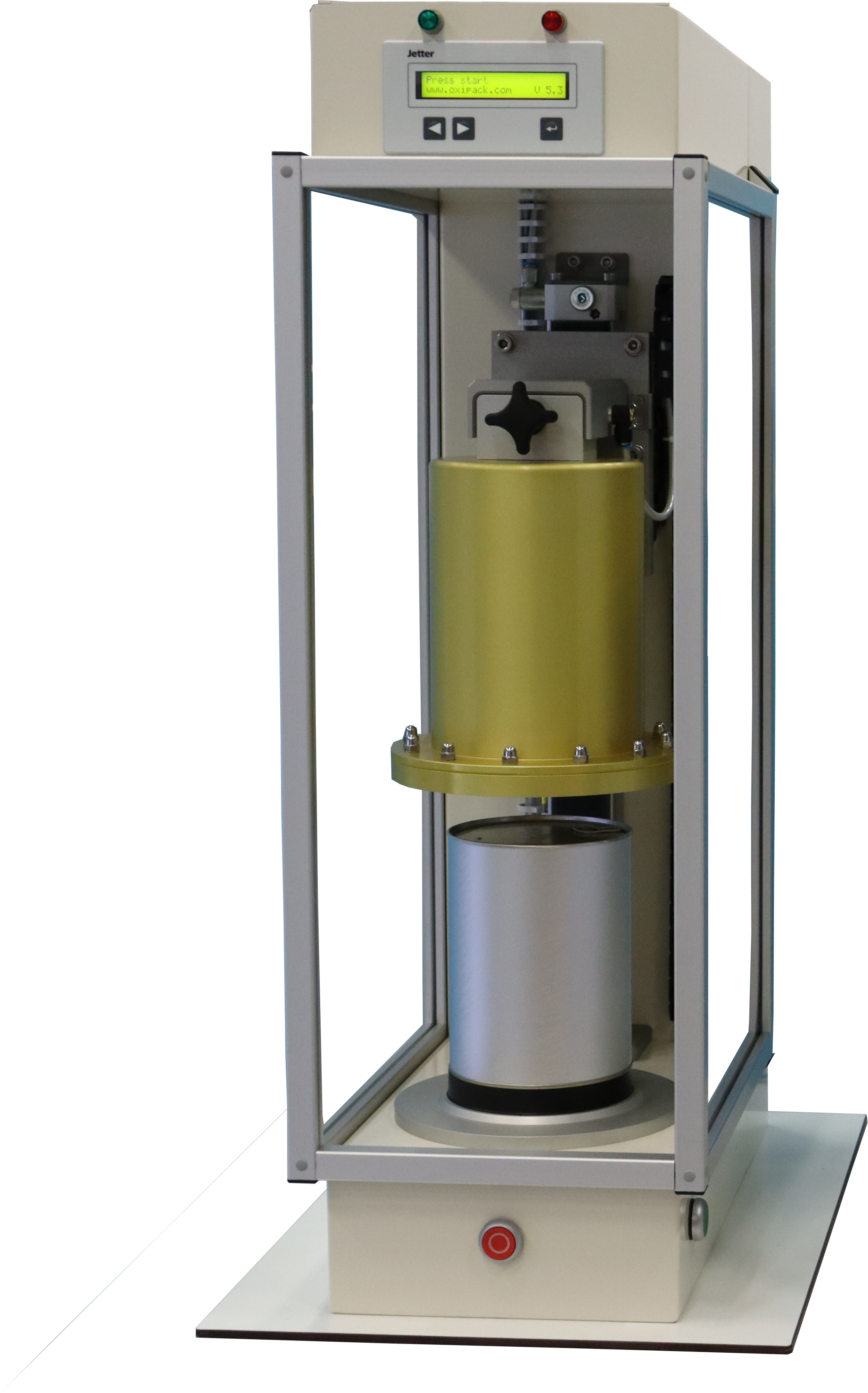

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

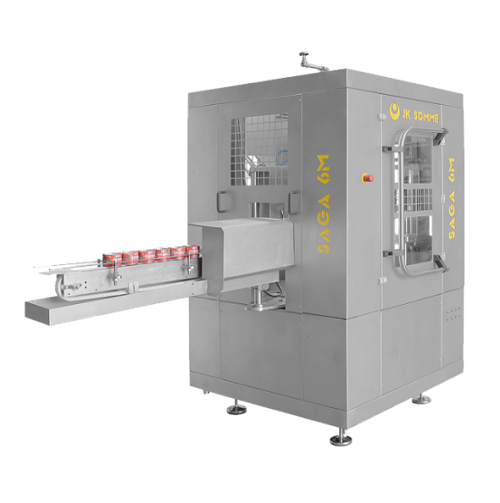

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

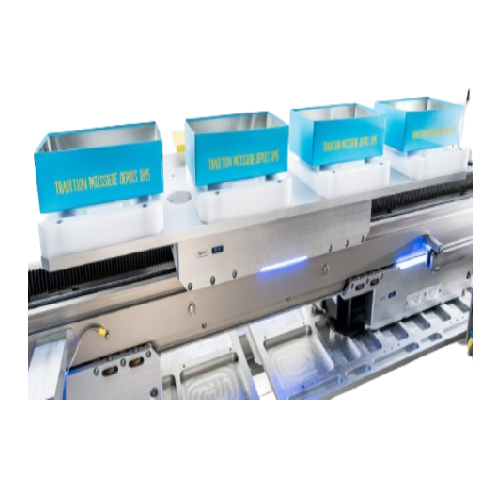

Macro ingredient dosing system

Traditional dosing systems do not have a very long operational life and are hard and expensiv...

Exchangeable silo dosing system

Rarely used bulk ingredients, like grains, agricultural feed or silage, can get spoilt if th...

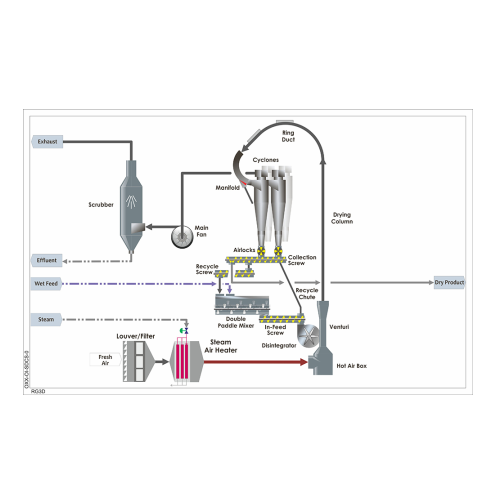

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

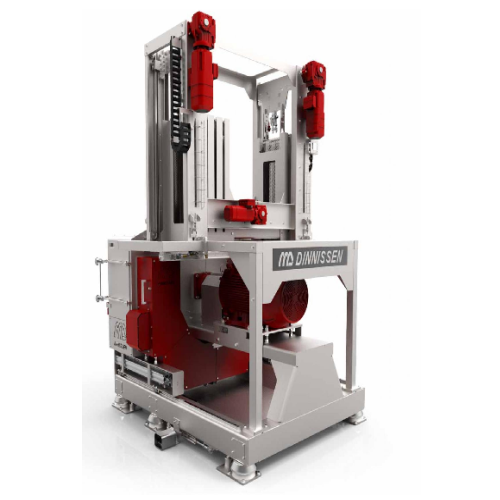

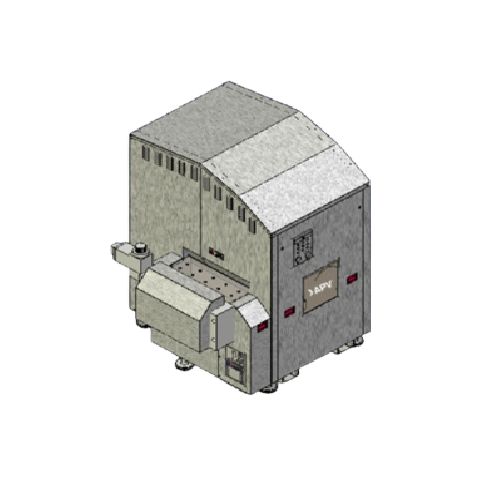

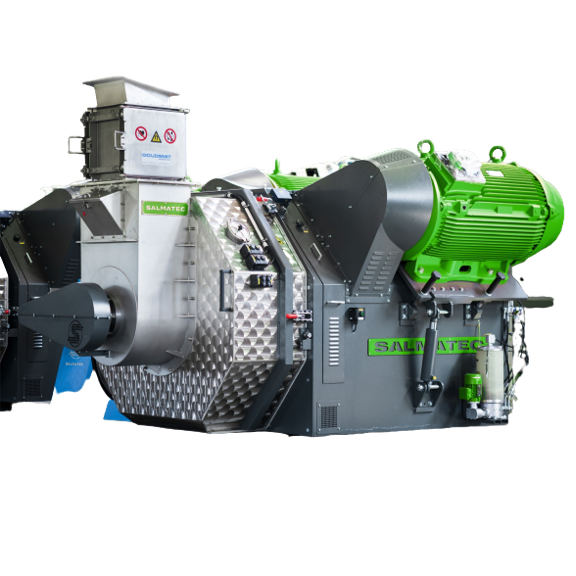

Pelleting press for feed and petfood

The production of agricultural feed and pet food products requires machines and plants...

Cookie dough wirecut machine

Achieve precise control and flexibility in shaping a wide variety of cookies and bars with this...

Continuous mixer for cookie and snack dough

Achieve uniform and consistent mixing of cookie and snack dough with seamless ...

Rotary moulder for high-definition cookie dough shapes

Efficiently shape intricate dough designs with precision, ensuring...

Industrial tumble dryer for moisture control in snack production

Ensure precise moisture reduction and optimal air circu...

Servo in-line dough laminator for industrial bakeries

Optimize your snack production with precise dough sheet cutting, st...

Continuous mixer for cookie dough

Achieve consistent dough quality and streamline your production with a continuous mixing ...

Industrial multi-pass dryer for bakery products

Ensure consistent moisture reduction and quality enhancement in your baker...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

Fried snack extruder for potato rings

Efficiently produce a variety of fried snacks, from potato rings to ethnic noodles, w...

Automated frozen dough production solution

Maximize your frozen dough production with precision control and streamlined ma...

Electric oven zones for snack and cookie baking

Optimize your baking line with electric oven zones designed to eliminate e...

Emithermic zone for baking biscuits and cookies

Enhance your baking efficiency and precision with a flexible heat transfer...

Emithermic Xe zone for baking biscuits and crackers

Achieve precise baking and drying for your bakery products with a sys...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Industrial direct drive mixer for dough preparation

Optimize your production line with a robust mixer designed for seamle...

Automated dough handling system for pretzel production

Streamline your dough processing with a system that precisely port...

Vertically feeding system for cookie dough

Optimize your dough handling with a system that ensures seamless and efficient ...

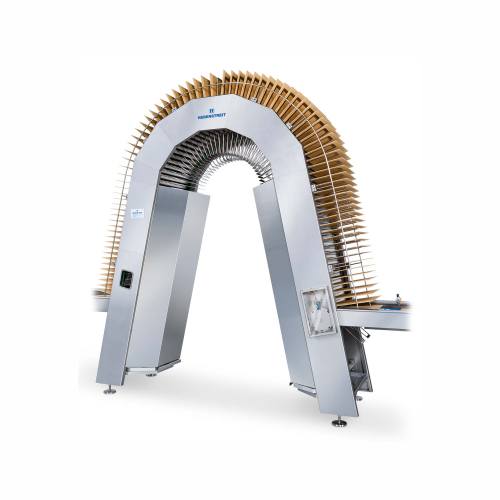

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air t...

Cup filling and sealing system for dairy products

Optimize your production line with versatile cup filling and sealing ca...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous ultra-high temperature processor for processed cheese

Ensure precise thermal treatment and enhanced flavor re...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Steam injection systems for animal feed production

Enhance product quality in animal feed production with steam injection...

Cryloc rotary screens for grain processing

Efficiently sort and separate fine particles with high precision to enhance pro...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

Cylindrical storage silos for long-term raw material storage

Efficiently store bulk raw materials for extended periods w...

Hammer mills for high-efficiency grinding in feed production

Optimize your feed production with high-efficiency grinding...

Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and c...

High efficiency roller mill for grain and oilseeds

Optimize your crushing and grinding processes with a versatile roller ...

Double shaft paddle mixers for industrial powders and granulates

Achieve precise mixing and homogenization of dry powder...

Industrial control panel construction

Streamline your production line with advanced panel building solutions that enhance a...

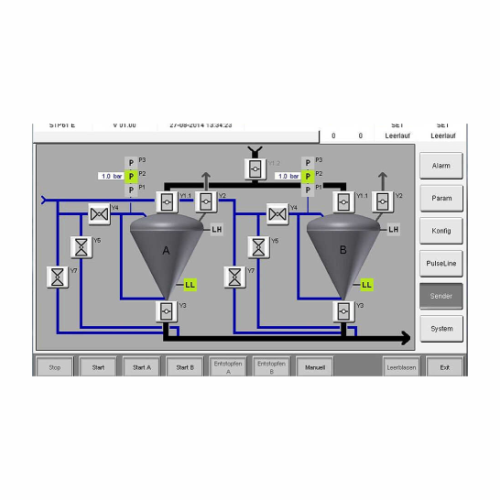

Process automation for feed mills

Optimize your feed production line by seamlessly integrating advanced process automation ...

Hammer mill for efficient particle size reduction in feed mills

Optimize your feed milling operations with this hammer m...

Bucket elevators for bulk material handling

Efficiently transport and discharge granular and powdered materials with preci...

Efficient powder and granulate flight conveyors

Elevate your production efficiency with our cutting-edge flight conveyors,...

Vertical bagging system for four corner seal bags

Optimize your coffee pod and capsule production with a high-speed, cont...

Industrial pre-cleaners for raw material safeguarding

Effectively eliminate foreign objects from your raw materials with ...

Automated capsule packaging system

Streamline your high-speed packaging operations with a system designed for precision fil...

Filter paper pod production system

Streamline your production of single-serve beverages with precise weight control and sea...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Powder packing module for consistent flow

Enhance your production efficiency with streamlined powder packing that ensures ...

Powder handling system for industrial applications

Overcome powder flow issues and enhance production efficiency with adv...

Ibc cleaning equipment for hygienic powder handling

Optimize cleaning efficiency and maintain hygiene standards with a ve...

Inline marinating and coating for meat and poultry

Enhance product quality and consistency with an inline tumbler that si...

High-pressure forming solution for plant-based and meat products

Experience precision forming with versatile application...

Low pressure forming for plant-based products

Achieve precise shape and weight consistency in plant-based products with lo...

Industrial double shaft mixer for food processing

Ensure precise mixing in industrial food production with this double sh...

Industrial double shaft mixer for homogeneous blending

Achieve quick, gentle, and homogeneous mixing for diverse food mat...

Vacuum mixer for fresh and frozen ground meat

Achieve precise homogeneity with this vacuum mixer, designed to handle high-...

Spiral oven for cooking plant-based and conventional products

Achieve perfectly cooked products every time with advanced...

Flake ice producer for food-safe ice

Enhance your production line with hygienic flake ice, optimized for energy efficiency ...

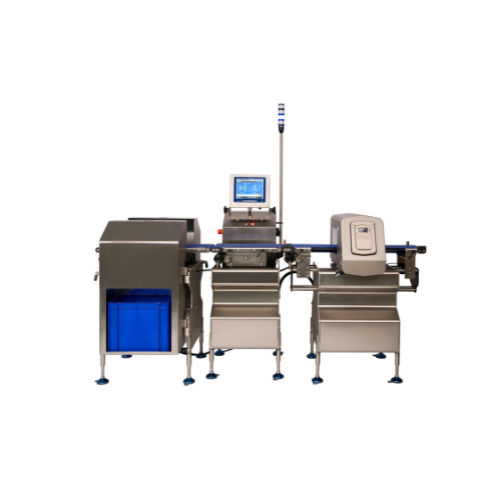

Checkweigher for food processing compliance

Ensure accurate package weights while preventing underweight or overweight pro...

Oven for high-yield cooking of prepared foods

Achieve unparalleled consistency and enhanced yield in food production with ...

Modular industrial oven for high-yield food processing

Need a solution that offers high-yield roasting and precision cook...

Automatic box and crate labeler

Achieve precise, high-speed labeling and weighing for various packaging needs, ensuring cons...

Industrial grinder for fresh and frozen meat

Optimize your production line with high-performance grinding capabilities for...

Compact grader for poultry and meat processing

Streamline your production line with this precise grading solution, designe...

Weigh price labeler for retail food products

Achieve consistent, high-speed labeling and pricing with precision—streamlini...

Industrial fryer for uniformly cooked convenience foods

Ensure perfectly fried textures and flavors with cutting-edge oil...

Pack turner for efficient label presentation

Optimize your packaging line efficiency and accuracy by ensuring precise labe...

Industrial automatic mixer grinder for meat processing

Effortlessly process and mix large quantities of meat and frozen m...

Industrial meat mixing solution

Streamline your meat processing operations with a high-capacity mixer designed for effortles...

High-capacity extrusion grinder for industrial applications

Achieve seamless integration of grinding, mixing, and extrud...

Industrial meat ginder and mixer

Streamline your large-scale meat production with a machine that seamlessly mixes, grinds, a...

Rotary drum pasteurizer for pouches

Efficiently pasteurize delicate pouch contents like meats, vegetables, and grains with ...

Root crop peeler and scrubber

Achieve efficient peeling and scrubbing of root crops while maximizing product recovery, makin...

Sealed drum separator for rendering operations

Efficiently recover liquids and manage odors with a robust solution designe...

Single drum wastewater screen for liquid-solid separation

Optimize your liquid-solid separation process and reduce indus...

Water reuse system for poultry plants

Optimize your water usage and reduce operating costs with an efficient system that re...

Cluster cutter for green bean processing

Efficiently streamline your green bean and vegetable processing with advanced snip...

Green bean snipper for minimizing bruising

Efficiently snip and process green beans with reduced bruising while integratin...

Green bean snipper for snap bean processing

Achieve precision in green bean processing with a specialized snipping solutio...

Unsnipped bean remover for green bean processing

Enhance your green bean processing line by seamlessly removing unsnipped ...

Industrial food cooler for pasta, rice, and vegetables

Rapidly reduce temperatures to halt cooking and preserve quality i...

Blanching solution for pasta and rice

Eliminate clumping and overcooking with a high-capacity continuous system designed fo...

Rotary drum blancher for high volume food processing

Optimize your food production line with a versatile rotary drum blan...

Continuous steam blancher for vegetables

Efficiently reduce water and energy usage while ensuring uniform blanching and coo...

Combination cooker-cooler for pasta production

Streamline your production with a machine that efficiently cooks and cools ...

Rotary drum blancher for industrial food processing

Optimize your food processing line with a robust solution that ensure...

Cryogenic tunnel freezer for continuous food processing

Optimize product quality and retention with advanced cryogenic fr...

Cryogenic freezing systems for food processing

When you need precise and rapid freezing for diverse food products, these a...

Precision weighing tank for liquid and dry ingredient blending

Enhance your production line with precision control over ...

Cryogenic food freezer

Achieve rapid and precise freezing for diverse food products, ensuring optimal texture and moisture re...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Cryogenic chilling for meat mixing and blending

Ensure precise temperature control during mixing and blending to prevent b...

Cryogenic freezer for food industry applications

Efficiently tackle high-speed freezing and chilling challenges with a ver...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixin...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

Process mixer for food production

Optimize your production line with a versatile and adaptable process mixer that offers se...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Blender for high viscous products

Tackle high-viscosity challenges with an advanced blending solution designed for efficien...

Oil cooling tank for fast product cooling

Accelerate your cooling process efficiently with an advanced oil cooling tank fe...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Cooling system for vegetables and meat

Optimize cooling efficiency with dual counterrotating agitators and expansive surfac...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

Emulsifying and blending system for liquid and semi-liquid food products

Efficiently emulsify and blend liquid and semi...

Food mixing and blending system

Enhance your production line with a versatile system designed for gentle processing needs, o...

Powder dissolver for large liquid quantities

Achieve uniform powder blending swiftly with a vacuum-assisted system that pr...

Cylindrical buffer tank for processing lightly liquid products

Optimize production continuity with this cylindrical buff...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

Vegetable and fruit dicer for commercial use

Efficiently transform a variety of produce into precise cubes, slices, or shr...

Automatic dosing and packing system for cabbage and sauerkraut

Streamline your vegetable processing line with a robust, ...

Hydraulic box tipper for pallets

Streamline your material handling with precision and safety by integrating this hydraulic t...

Hydraulic juice press for fruit and vegetables

Streamline your juicing operations with this hydraulic solution, expertly d...

Vibrating sorting table for pre-dewatering

Efficiently streamline your production with a versatile vibrating sorting table...

Vegetable and fruit cutting solution for slices, segments, and sticks

Streamline your pre-processing with a versatile c...

Trimming table for fruit and vegetables

Streamline your pre-processing phase with this trimming table, helping you efficien...

Uvc surface disinfection for food packaging and tools

Achieve fast and effective UVC disinfection of food products and pa...

Industrial washing and sorting for bell peppers

Efficiently sort, trim, and wash your peppers with a single system, ensuri...

Fruit processing and packaging line

Streamline your fruit and vegetable processing with this semi-automatic system designed...

Vegetable and fruit slicer

Achieve uniform, precise slices for your fruits and vegetables with a state-of-the-art cutting so...

Manual melon chunk cutter

Transform your melon processing with a compact tabletop cutter, designed for efficient chunking an...

Flexible packaging solution for large food volumes

For high-volume food packaging, achieving consistent bag sizes and red...

Decontamination system for whole fruits and vegetables

Enhance hygiene and extend shelf life by effectively reducing micr...

Centrifugal drying system for lettuce and vegetables

Enhance your production line’s efficiency with this high-capac...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

Manual vegetable and fruit grid cutter

Effortlessly transform small-sized fruits and vegetables into decorative and functio...

Industrial dipping bath for prolonging shelf life of cut fruits and vegetables

Enhance the shelf life and hygiene of y...

High-capacity cutting solution for fruits and vegetables

Efficiently transform large volumes of food products into cubes,...

Automatic crate weighing system for fresh produce

Streamline your fresh produce processing by precisely weighing and fill...

Industrial belt cutting system for vegetables and fruits

Achieve precise and high-capacity cutting for various food produ...

Cabbage coring solution for high throughput

Streamline your high-volume cabbage processing with a precise and efficient co...

Automated chicory root cutter

Streamline your chicory processing with precise root removal, reducing waste and enhancing yie...

High-performance cube, strip & slice cutting solution

Achieve precision in high-volume food processing with a cutting sol...

Wide body dryer for dairy and food products

Achieve precise moisture control and optimal powder agglomeration for dairy an...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

Industrial transfer conveyor system

Efficiently transport and sort diverse food products with precision, ensuring seamless ...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

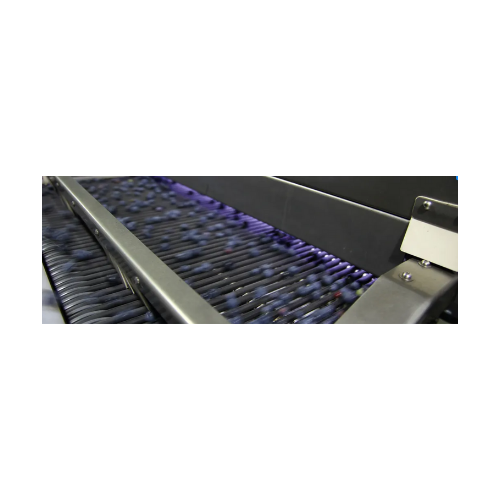

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Vibrating control screeners for high volume screening and sifting

Ensure precise material separation with a solution de...

Heavy duty lump breaker for coarse and pre-grinding

Achieve consistent particle size reduction with this heavy-duty solut...

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

Automatic defect removal for french fries

Maximize yield and enhance quality in potato strip production with precision cut...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Homogenous blending solution for powders and granules

Achieve precise, homogenous blending of challenging materials like ...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Horizontal flow wrapper for medium performance level

Offering high-speed, continuous flow wrapping, this versatile machin...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

Vertical baggers for confectionery packaging

Streamline your packaging operations with high-performance vertical baggers d...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

Automatic vertical casepacker for efficient packaging integration

Streamline your packaging process with a vertical cas...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Traysealer for modified atmosphere packaging - food products

Optimize your packaging line with this semi-automatic trays...

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

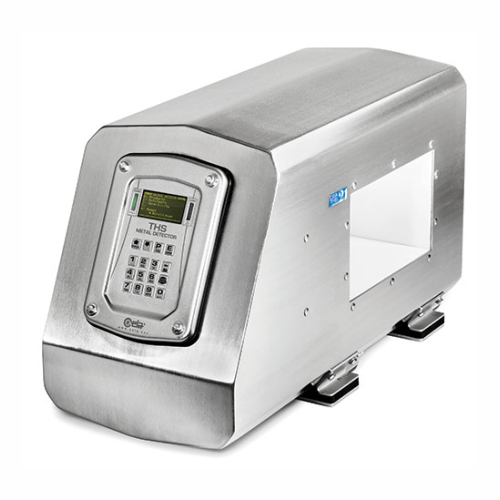

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Entry-level in-line traysealer for ready-to-eat meals

Streamline your ready meal packaging with a compact traysealer that...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

Traysealer for small scale food packaging

Improve your production efficiency with a compact traysealer designed for versat...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

High-speed cheese slice wrapper

Achieve unparalleled efficiency with the high-speed wrapping machine that securely packages ...