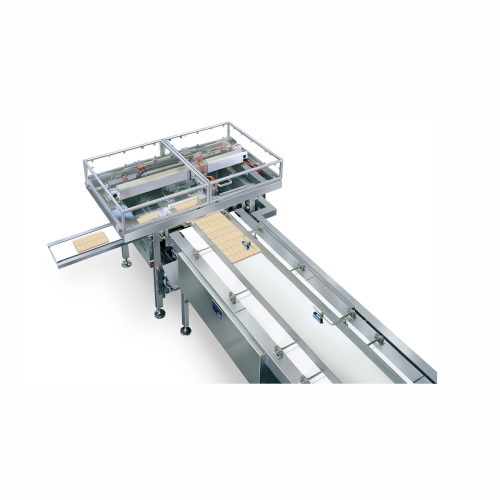

Wafer row discharge device for feeding packing machines

Efficiently automate wafer row feeding to improve packaging throughput and precision with this versatile discharge device, ensuring seamless separation and orderly distribution to packing machines, maximizing your production line efficiency.

Feeds and Distributes Wafers for Packing

The Wafer Discharge Device WEP from Hebenstreit GmbH is engineered to streamline the feeding and distribution of wafers and snacks to packing machines. Its fully automatic system gently separates and discharges up to 45 rows of product per minute, maintaining integrity and quality during the transition. Specially designed for food processing and confectionery manufacturers, it ensures precise handling of various end products, including flat and coated wafers, curls, and cereals.

This device integrates seamlessly into existing production lines with its high-speed operations and is adaptable to handle diverse snack forms. The equipment’s PLC-controlled automation enhances efficiency, reducing manual intervention and minimizing potential downtime. Crafted with durable materials suitable for food-grade applications, it supports a hygienic and contamination-free production environment. Hebenstreit offers customizable configurations to meet specific production requirements, supported by a responsive engineering team.

Benefits

- Enhances production efficiency by feeding up to 45 wafer rows per minute.

- Maintains product integrity through gentle handling during discharge.

- Reduces labor costs with seamless integration into automated packing lines.

- Customizable to accommodate various snack and wafer shapes and sizes.

- Supports continuous operation, minimizing downtime in high-demand environments.

- Applications

- Wafers, Snacks, Pet food, Extruded products, Breakfast cereals, Savoury snacks

- End products

- Spirals, Curls, Coated hollow wafers, Rings, Filled snacks, Coated wafers, Moulded wafers, Flat wafers, Microcrispies, Malt rings, Pork rind snacks, Hollow wafers, Balls, Whole grain curls, Sticks, Flakes, Crispies

- Steps before

- Batter Preparation, Baking, Sheet Cooling, Conditioning, Spreading, Stacking, Sandwich Cooling, Cutting

- Steps after

- Packing

- Input ingredients

- cut wafer rows

- Output ingredients

- packed wafers, single or double wafer rows, wafer discharge

- Market info

- Hebenstreit is known for specializing in the manufacture of industrial equipment for wafer production, offering advanced technology and customization for the food industry, with a reputation for high-quality and reliable machinery.

- Discharge Speed

- Up to 45 discharges per minute

- Output Speed

- Up to 40 discharges per minute

- Automation

- Fully automatic

- Feeding Capability

- Single or double rows

- Directional Feeding

- Left or Right, or both

- Product Handling

- Kind to the product

- Working Mechanism

- Fully automatic feeding

- Automation Level

- Fully automatic

- Discharge Method

- Single or double rows

- Changeover Time

- Seamless switching between single and double rows

- Discharge Rate

- Up to 45 discharges per minute

- Gentle Handling

- Product kind discharge

- Separation Method

- Clean separation of wafer rows

- Direction Configuration

- Left, right, or both

- Cleanability

- Easy to clean surfaces

- Corrosive resistance (e.g. acids)

- Stainless steel

- Density/particle size

- Applicable for various densities of wafers

- Abrasiveness of Wafers

- Low

- Discharge Method

- Fully automatic feeding

- Product Handling

- Gentle separation of wafer rows

- Discharge Versions

- Single or double rows, left or right or both

- Discharge direction

- Left, Right, Left, Right

- Discharge configuration

- Single or double wafer rows