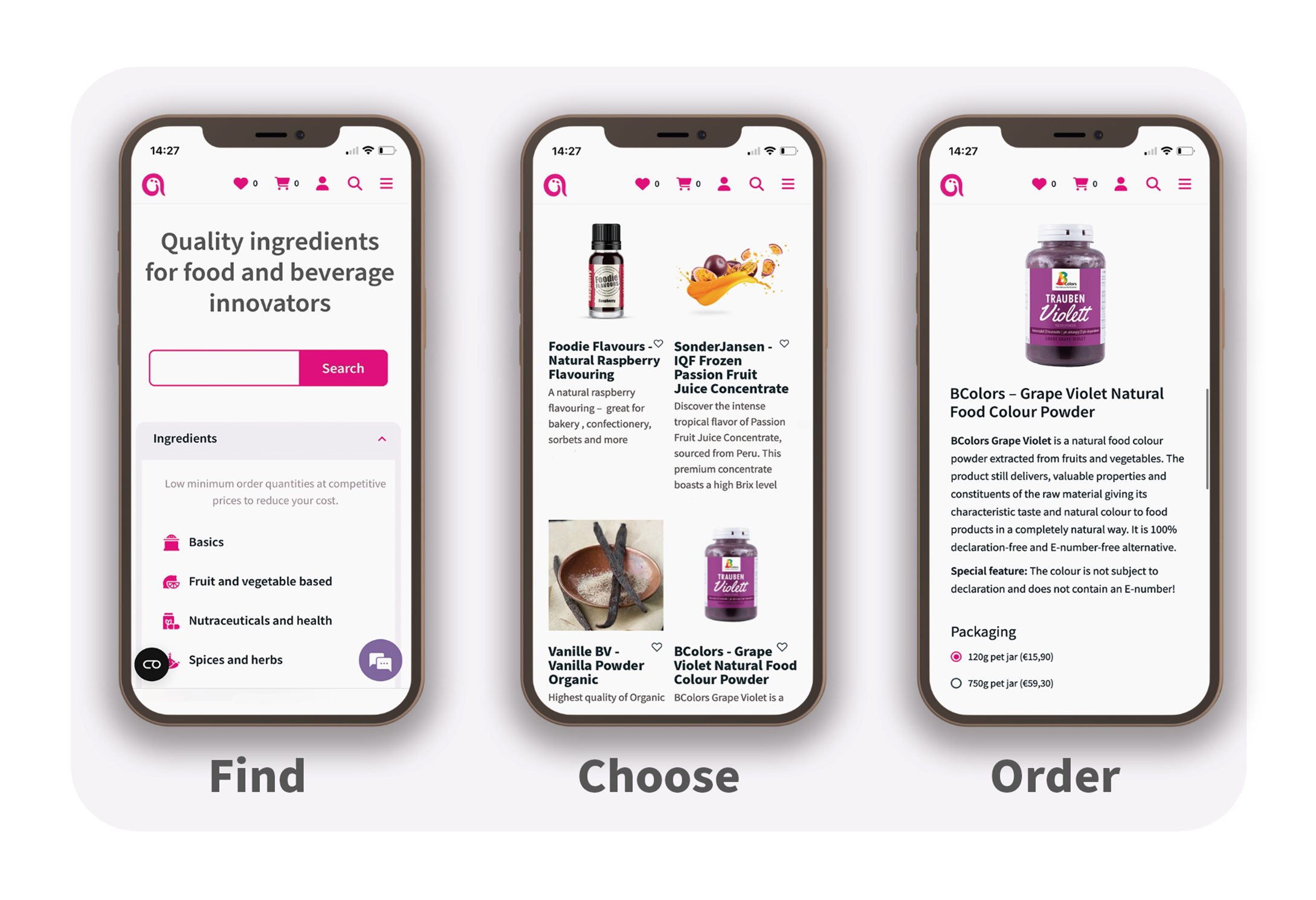

Industrial Bakery Equipment

Find innovative bakery equipment and connect directly with world-leading technology suppliers

Do you have a sweet tooth, or are you more into a warm loaf of bread for a savory lunch? The bakery shop window displays something for everyone, from baguettes over croissants to muffins. Bakery products are a wide range of baked goods prepared from flour or meal derived from grains. These undergo mixing, fermentation, and baking processes with the help of bakery processing equipment such as a series of low- and high-speed mixers, fermentation tanks, and baking chambers.

Top picks for bakery technology

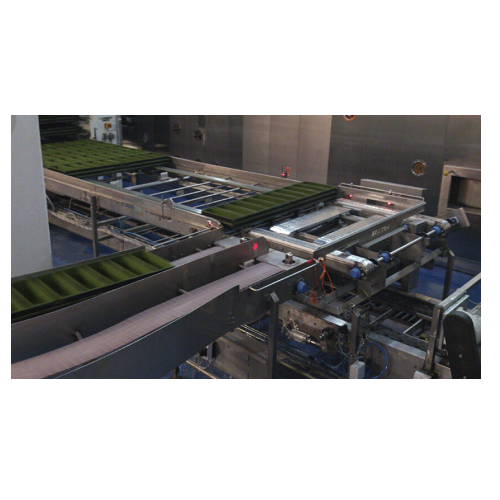

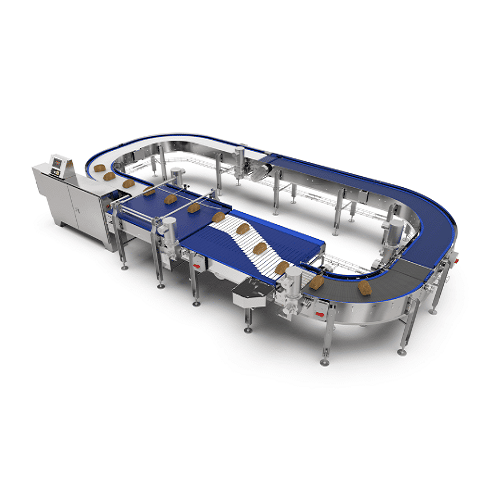

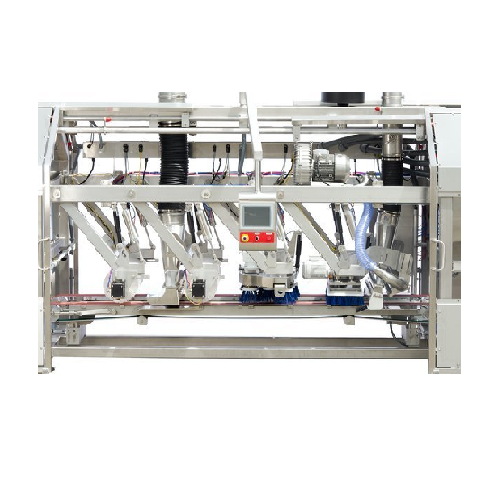

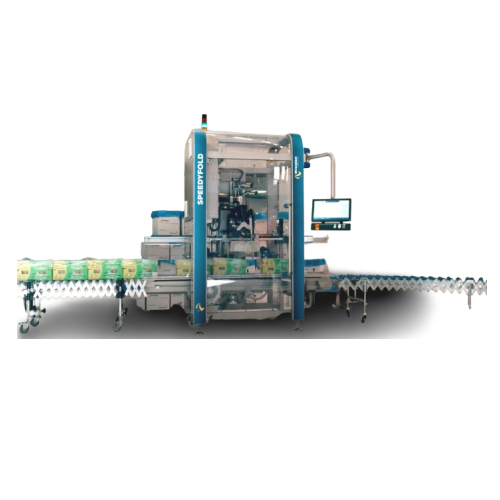

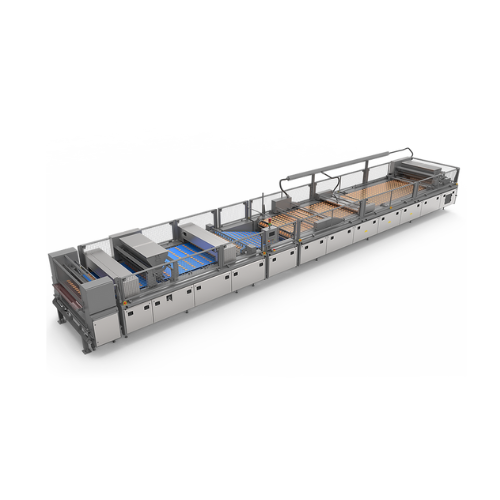

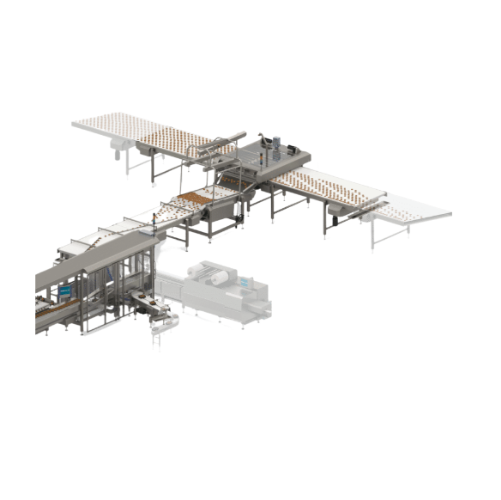

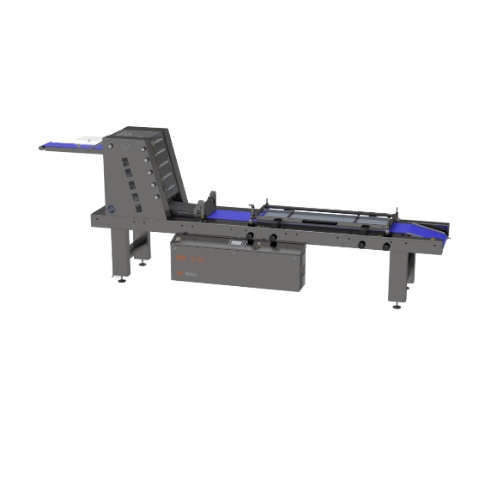

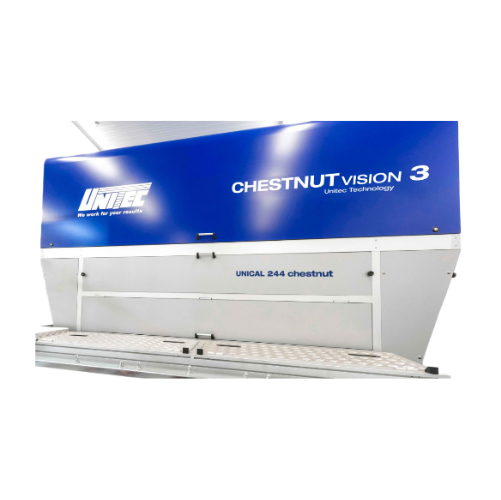

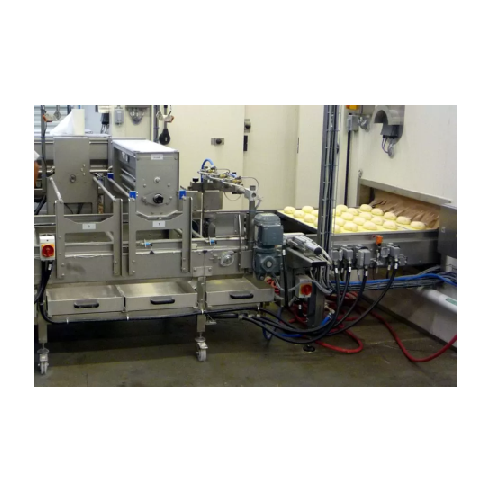

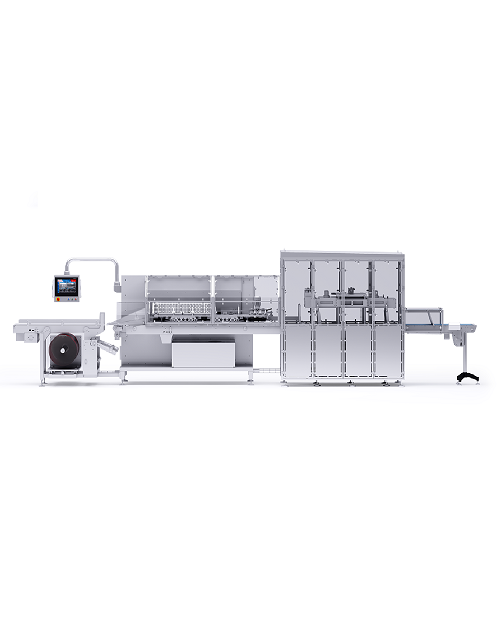

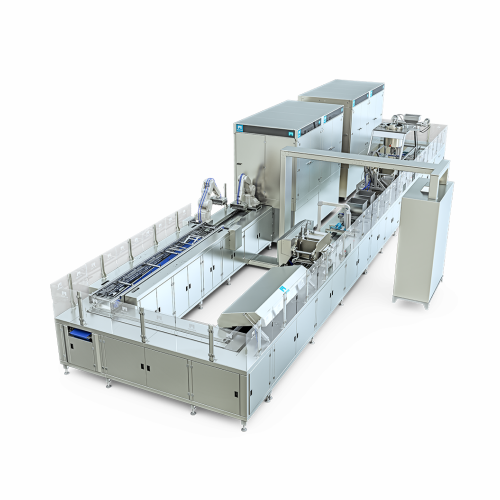

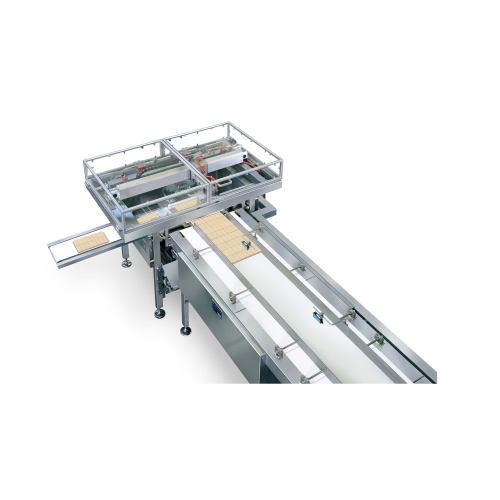

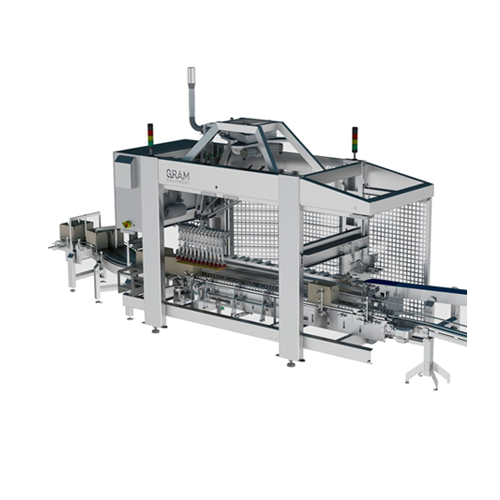

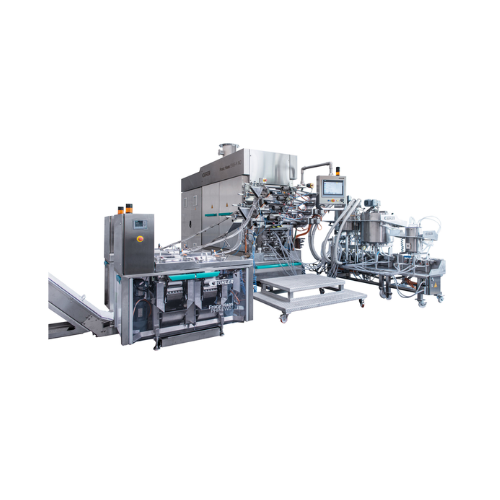

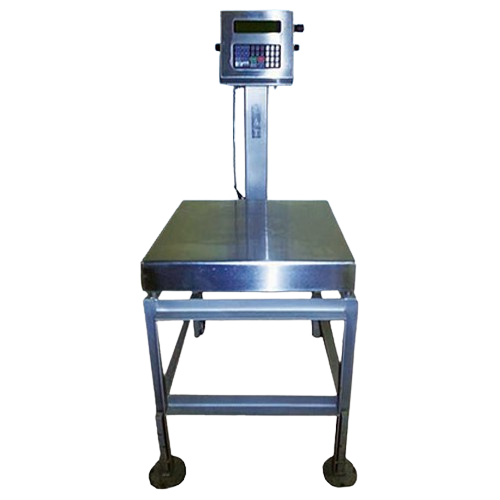

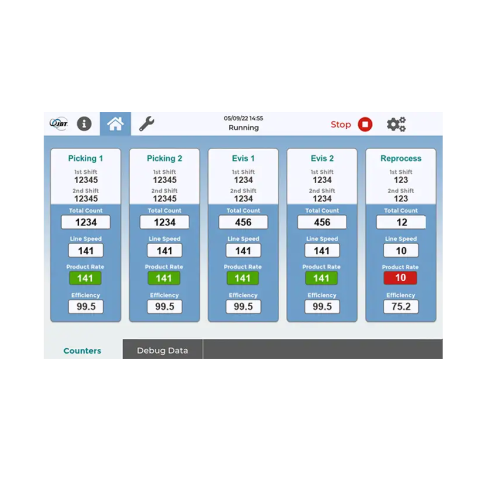

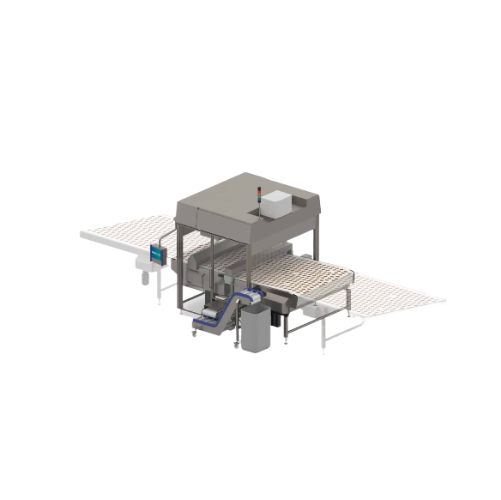

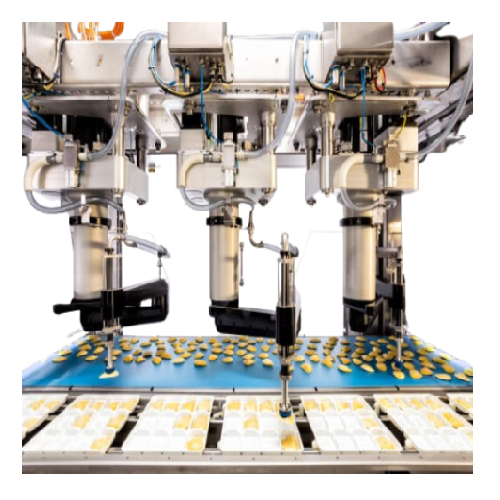

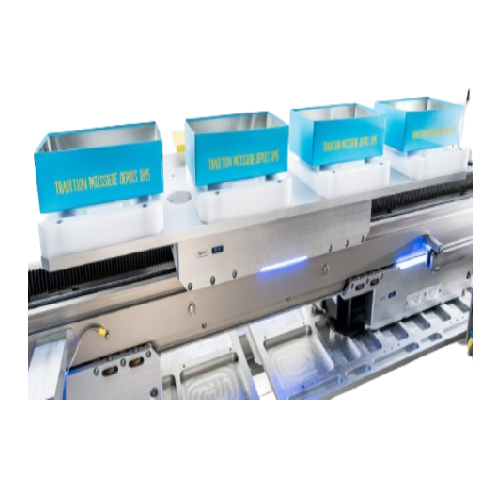

Bakery product quality control and counting system

Optimize your bakery line with precise control and counting of long pr...

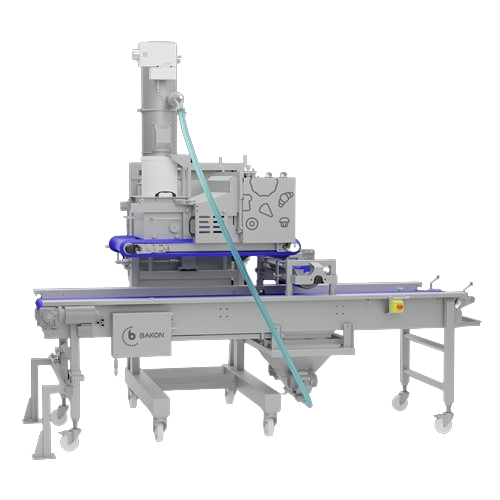

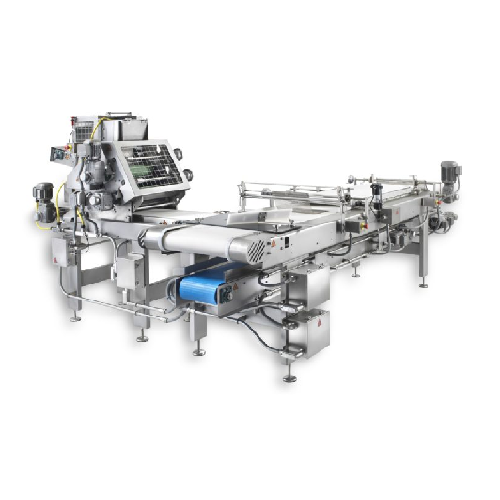

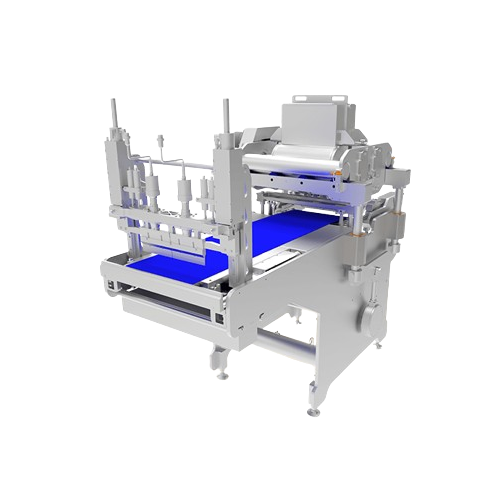

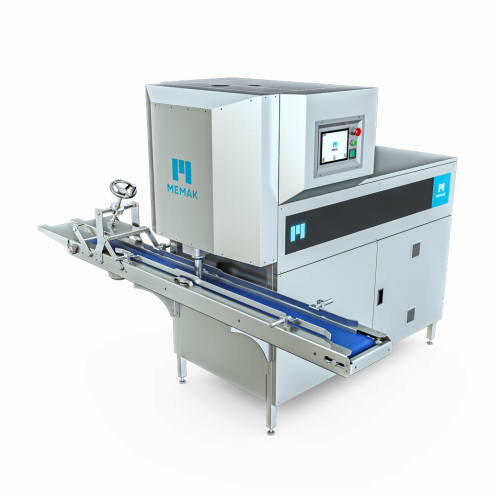

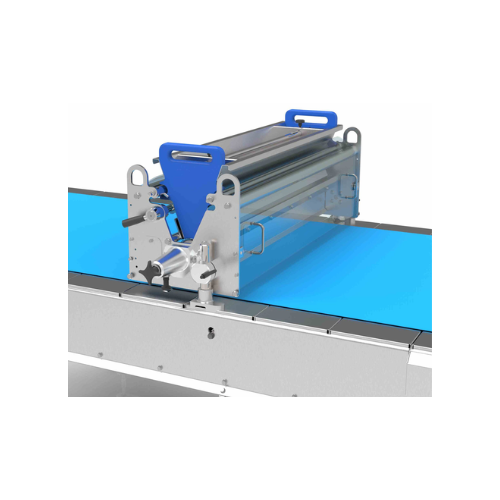

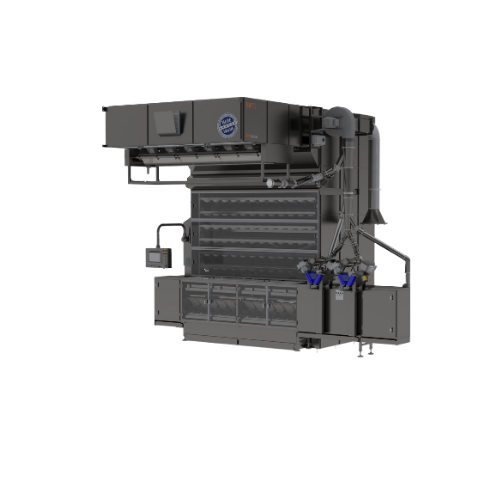

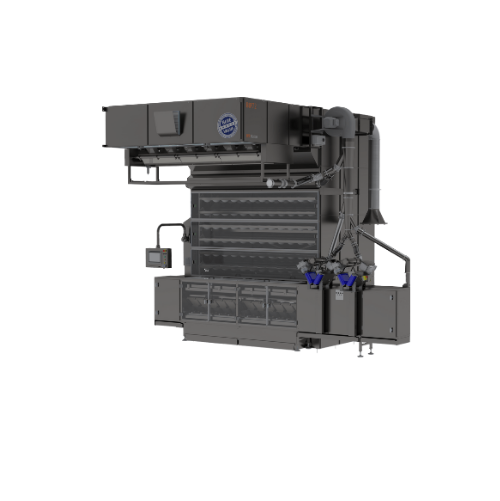

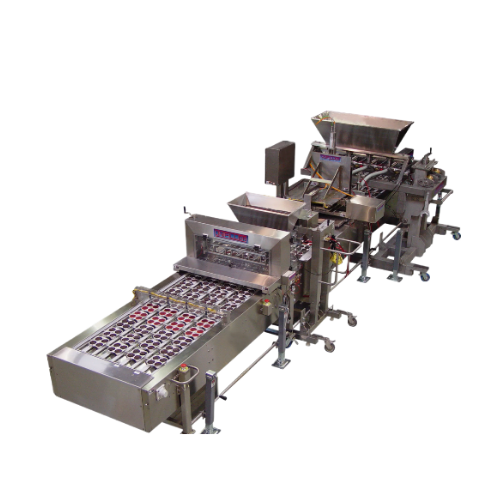

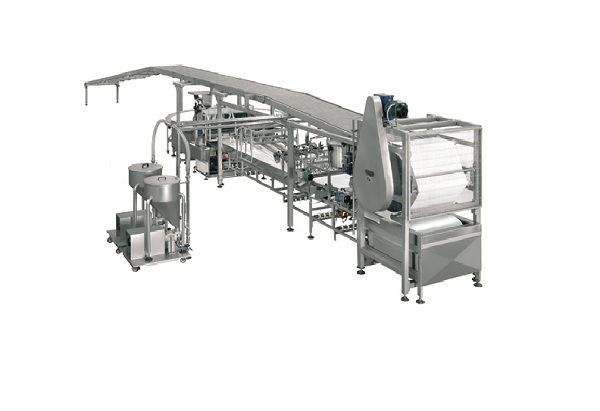

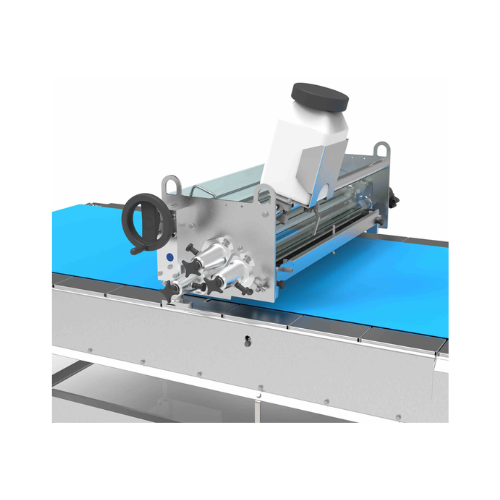

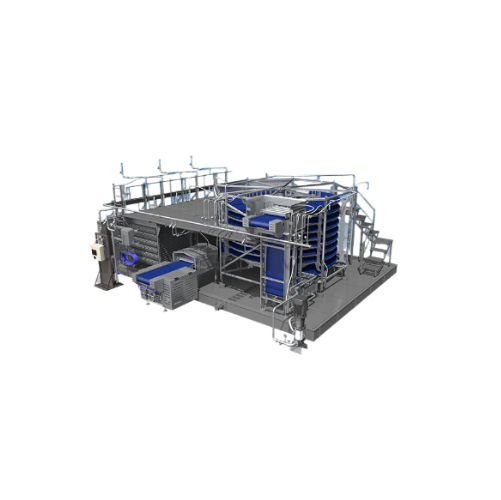

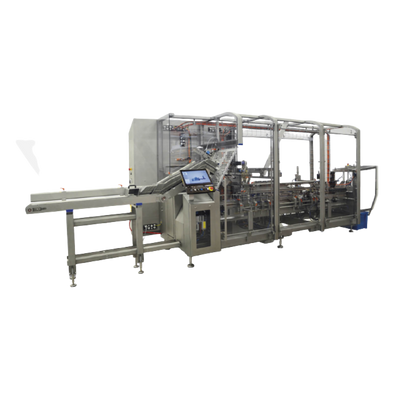

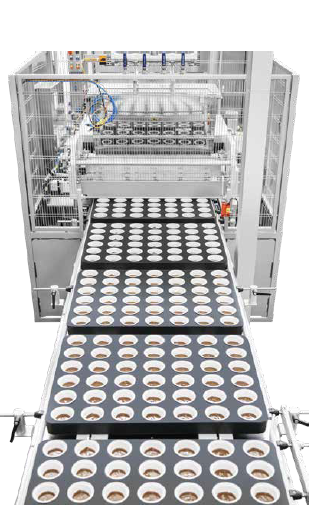

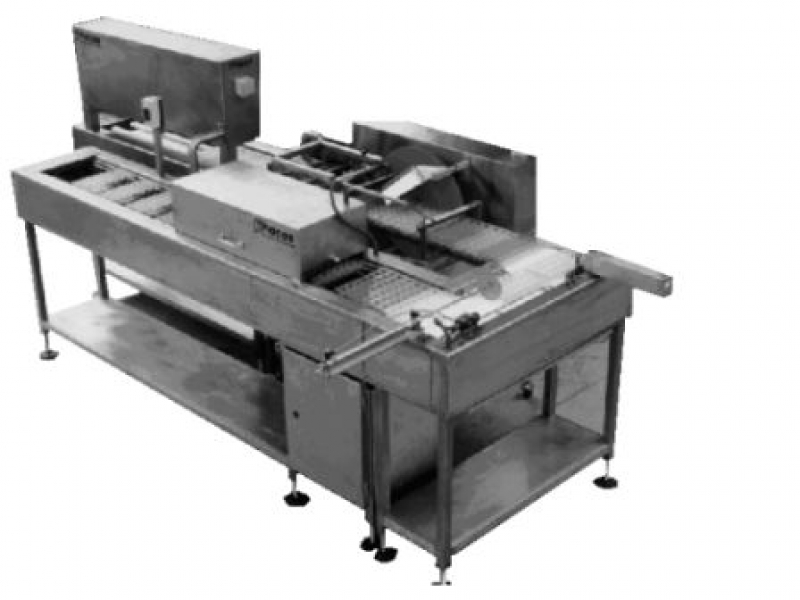

Auto bakery tray depositor for creams and batters

Efficiently deposit precise quantities of creams and batters with high-...

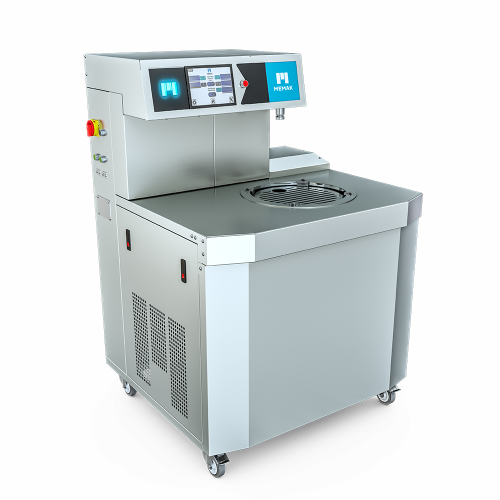

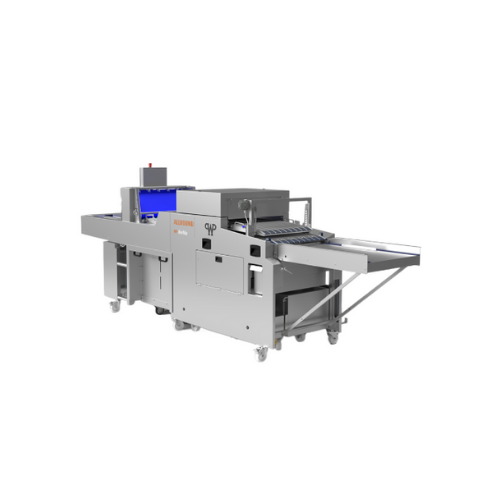

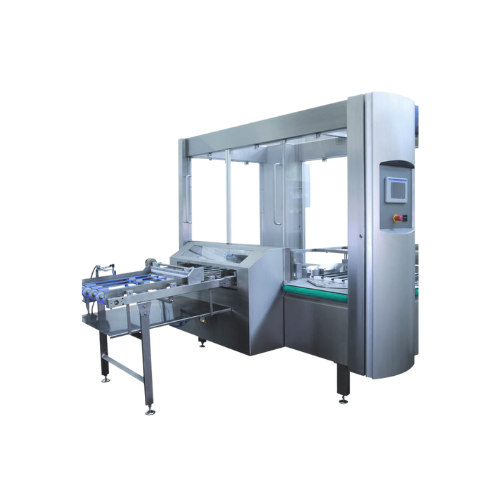

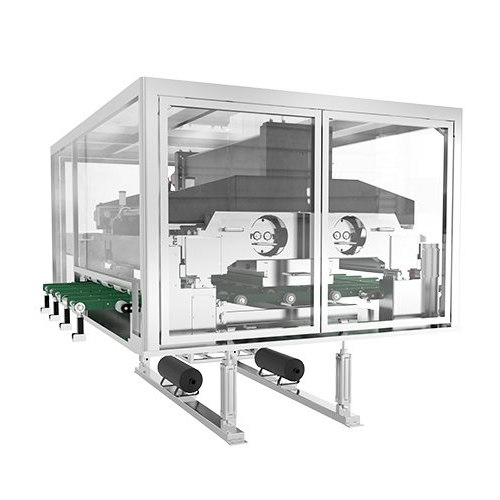

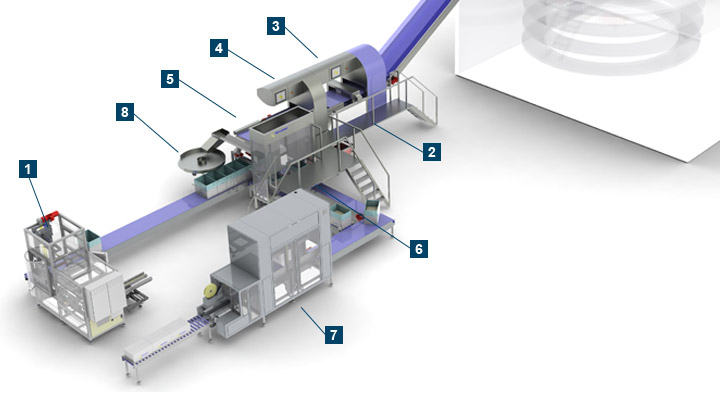

3d vision quality inspection system for bakery products

Streamline your bakery production with high-speed 3D vision inspe...

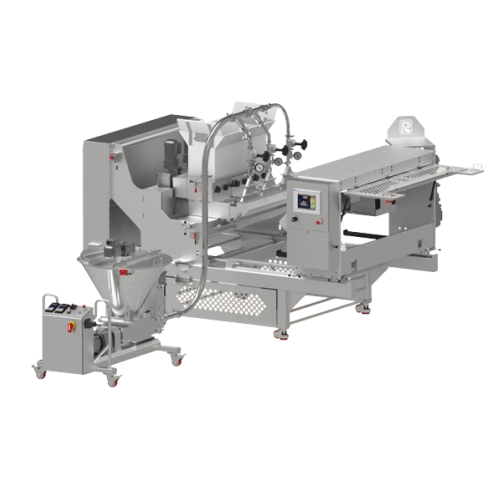

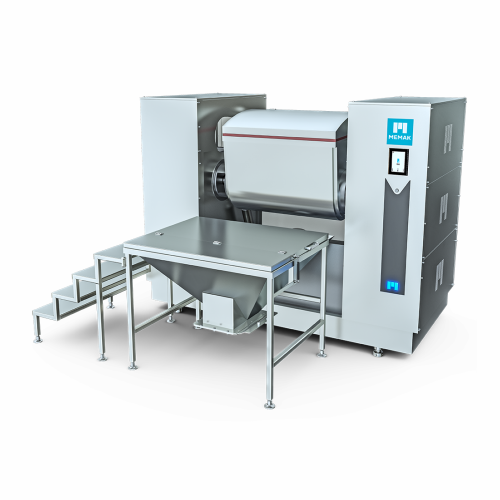

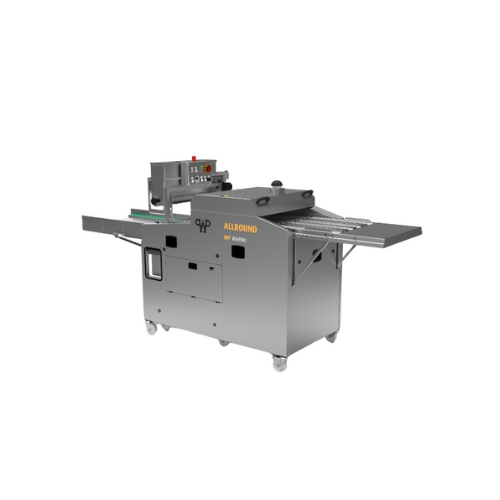

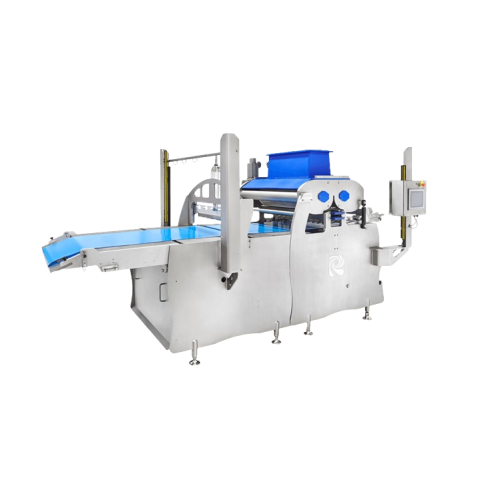

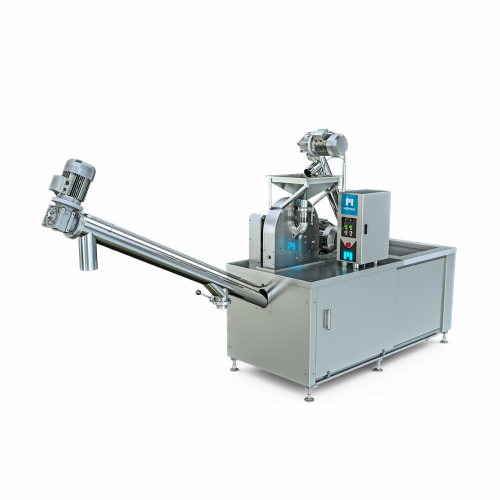

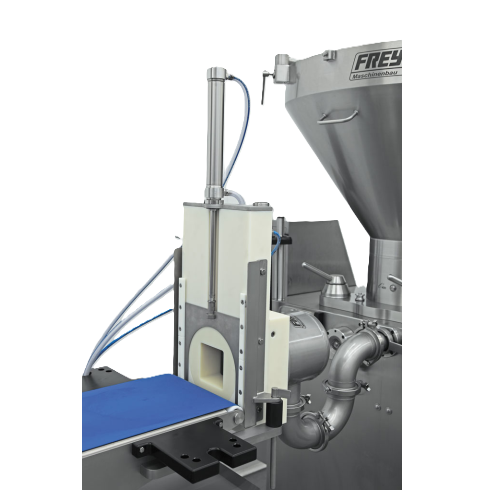

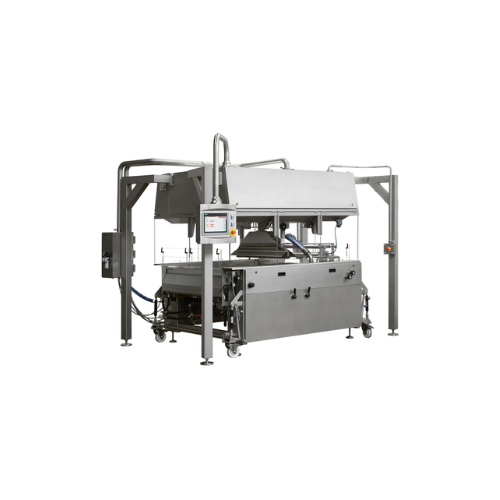

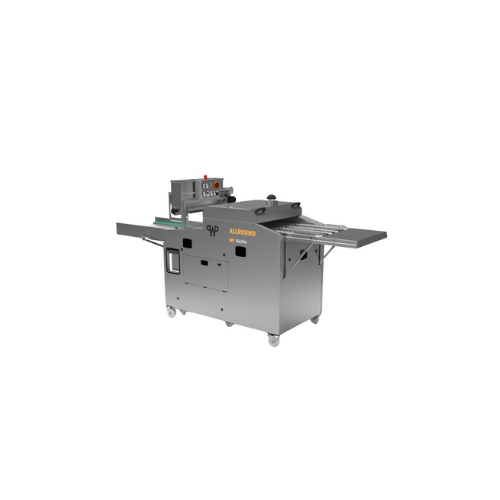

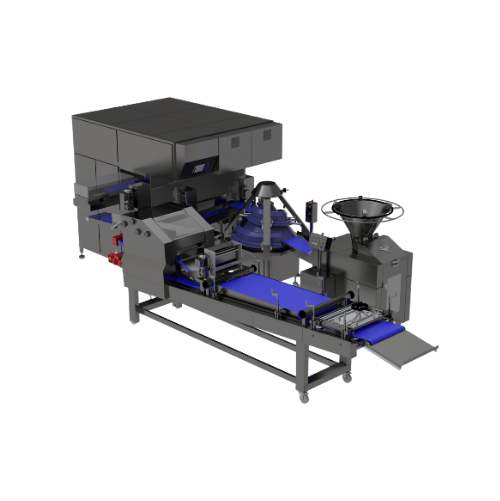

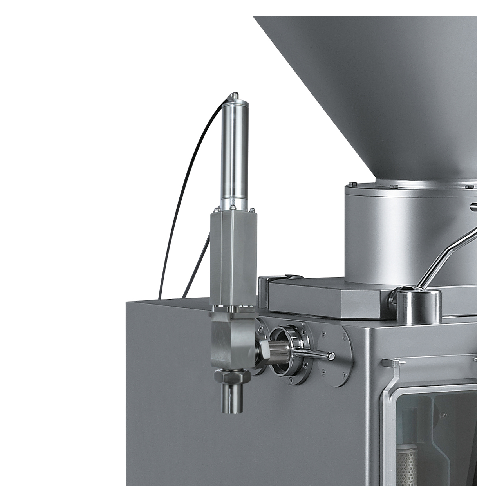

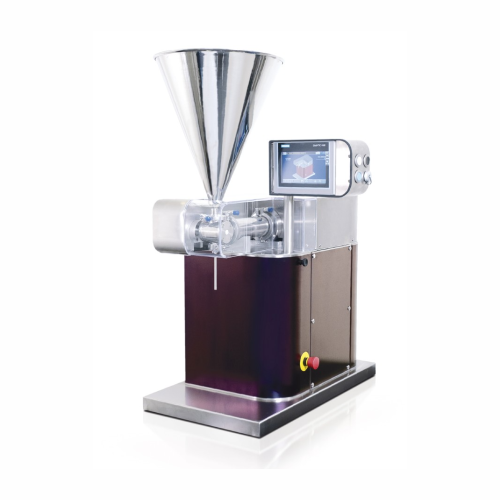

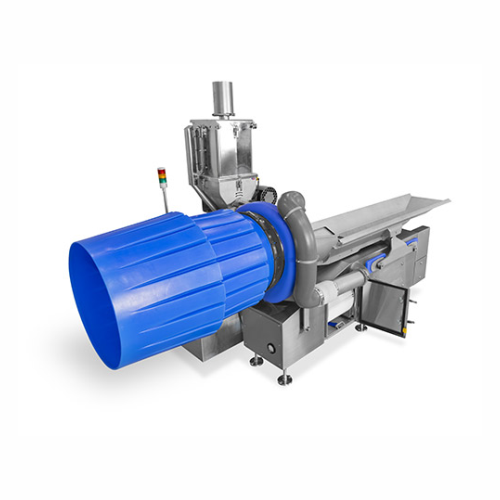

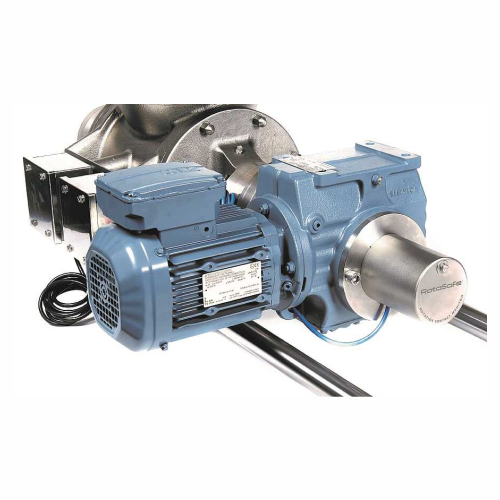

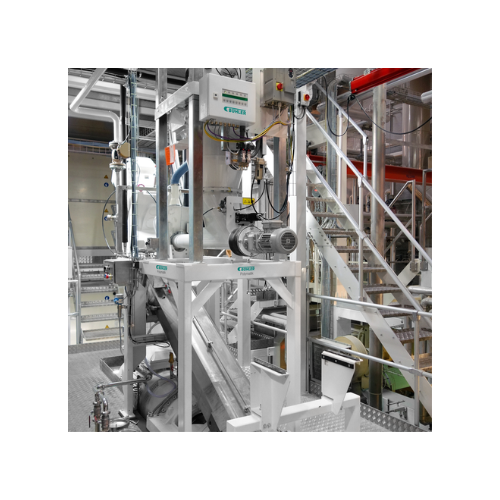

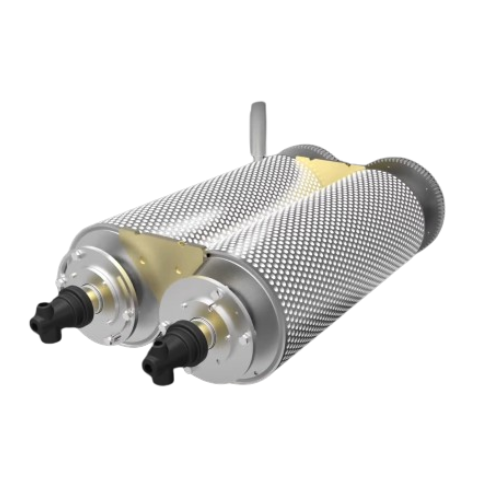

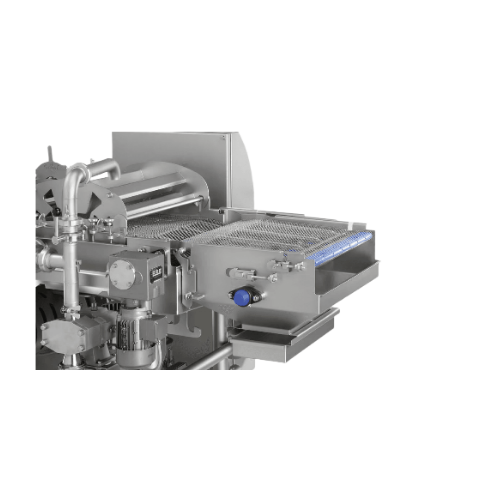

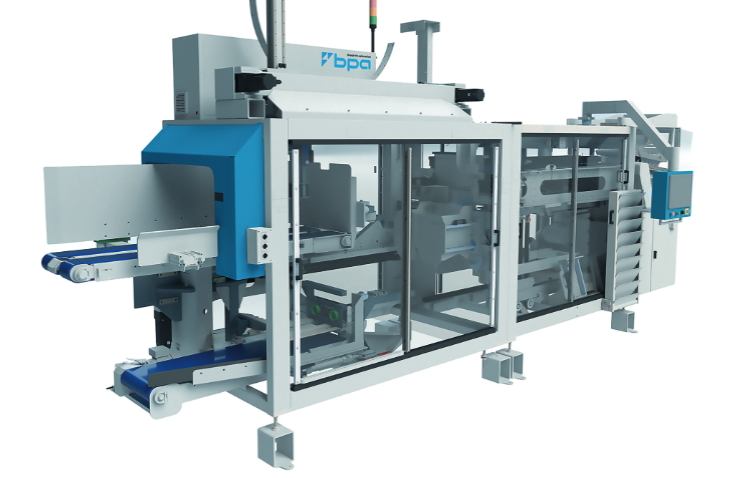

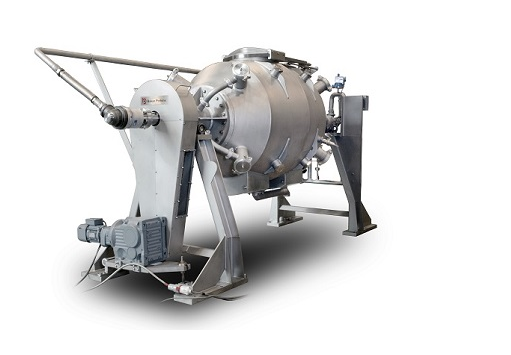

3-roll extruder for heavy dough products

Streamline dough processing for consistent, high-quality confections and baked goo...

Stories about bakery

Order all your food Ingredients easily online at 1-2-Taste

Whipping your cream at lower speeds for faster results

#Changemaker: Moulding trays from spent cocoa shells

Remember when big biscuit producers still used thermoformed plastic trays?

#Changemaker: Chickpea protein for your plant-based food product!

Gluten morgen… Temperature control in your sponge cake production

Perfect cake slices with ultrasonic cutting technology

Chocolate surface filling for cup cakes

Select your bakery process

What are you making?

Masa

Breadings

Bread mix

Buttercream

Bavarois

Bao

Brownies

Bread loaves

Bakery ingredients

Bakery mixes

Breadcrumbs

Breadsticks

Brioche

Bakery fillings

Blueberry muffins

Baker's yeast

Butter biscuits

Baked goods

Apple pies

Artisan bread

Biscotti

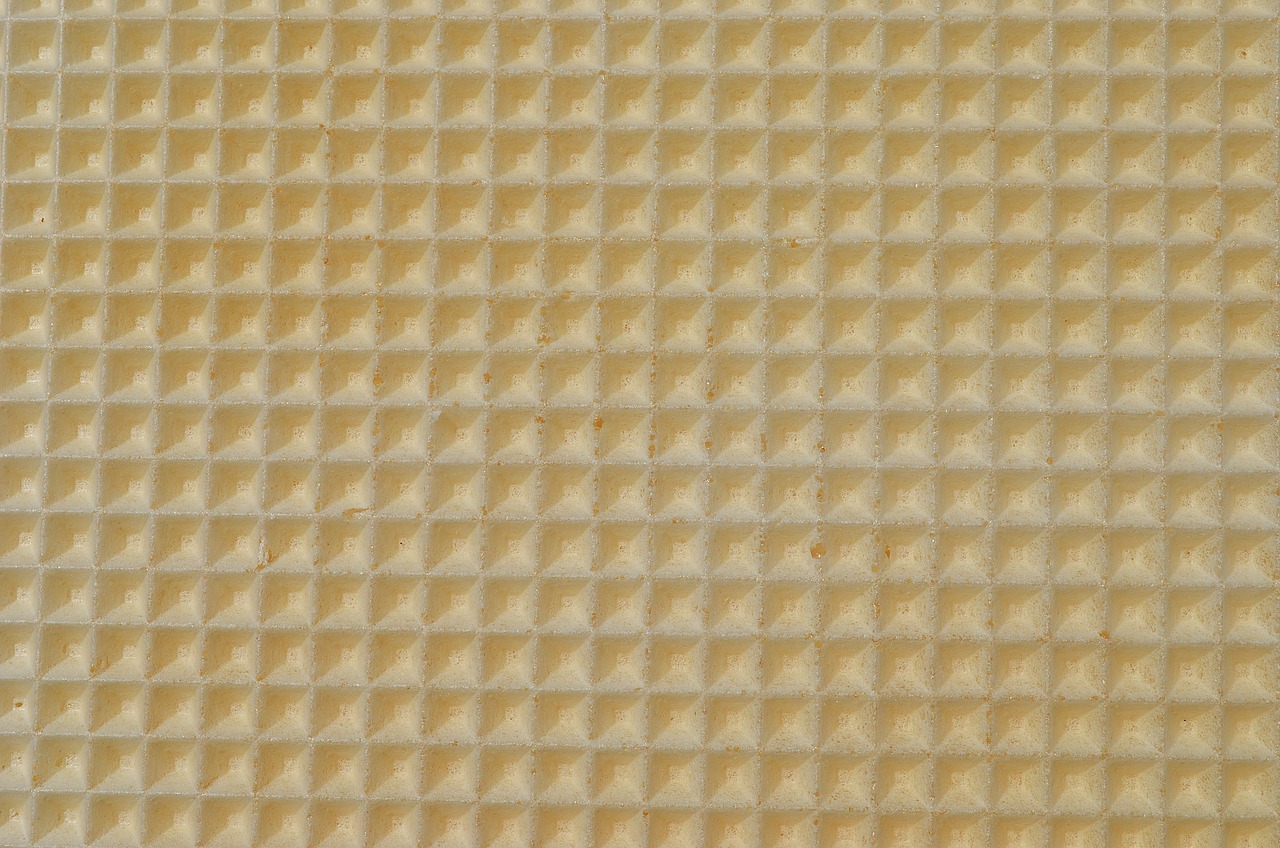

Wafer sheets

Wafer cups

Tostadas

Toast

Tin bread

Tarts

Taco shells

Swiss rolls

Sponge cake

Spelt bread

Sourdough bread

Soft bread

Shortbread

Sheet cakes

Scones

Red velvet cakes

Sachets

Quiches

Quiche lorraine

Rye bread

Puff pastry

Pre-dough

Cake mixes

Pound cake

Pizza dough

Pizza

Pita bread

Pastry fillings

Pastry cream

Paratha

Panettone

Pancakes

Margherita pizza

Oatmeal cookies

Loaves of bread

Naan bread

Multigrain bread

Layered cakes

Laminated dough

Kaiser rolls

Mochi

Gluten-free bread

Icing

Ice cream sandwiches

Ice cream cones

Ice cream cakes

Gingerbread biscuits

Hoagie rolls

Fruit pies

Frozen dough

Frozen croissants

Frosting

Hamburger buns

Fondant icing

Focaccia

Eclairs

Donuts

Filled croissants

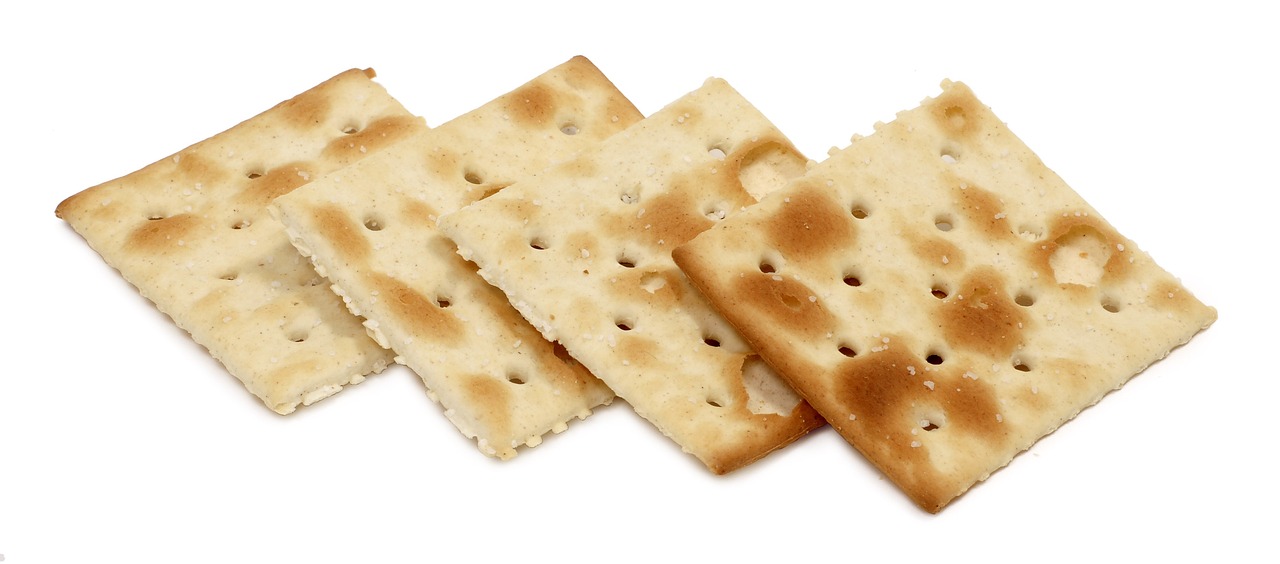

Digestive biscuits

Danish pastries

Custard

Cupcakes

Crispbread

Cream puffs

Cream crackers

Corn tortillas

Cookie dough

Almond flour

All-purpose flour

Cinnamon rolls

Ciabatta

Chocolate croissants

Chocolate chip muffins

Chocolate chip cookies

Bagels

Pie

Flatbread

Waffles

Wafers

Bread Rolls

Pretzels

Pastries

Muffins

Crackers

Buns

Baguettes

Whipped cream

Frozen cakes

Ready meals

Yeast

Fondant

Batter

Flour

Dough

Croutons

Croissants

Cookies

Biscuits

Frozen pizza

Bread

Baking powder

Tell us about your production challenge

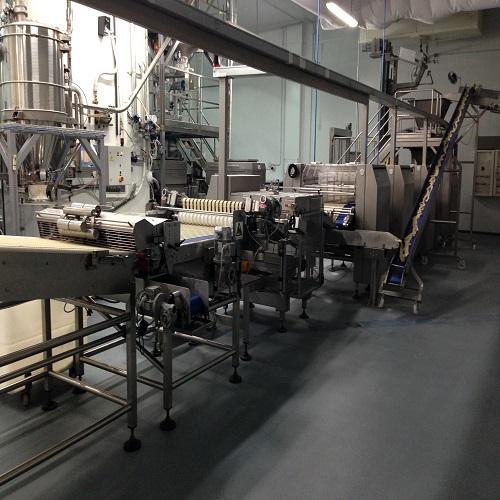

Industrial production and bakery processing equipment

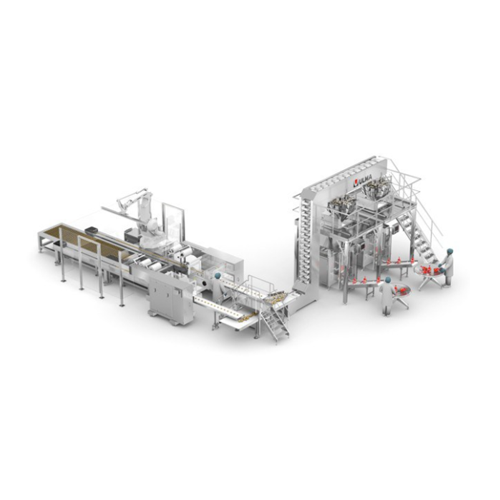

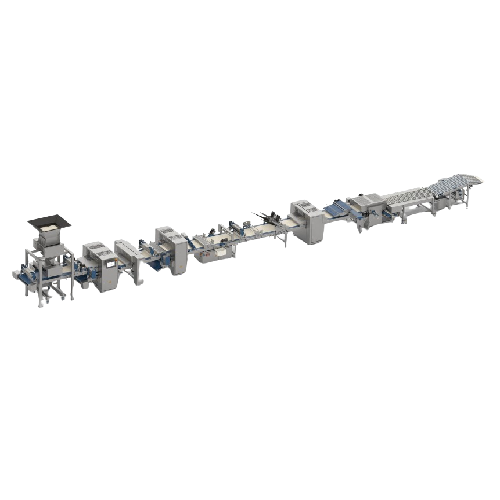

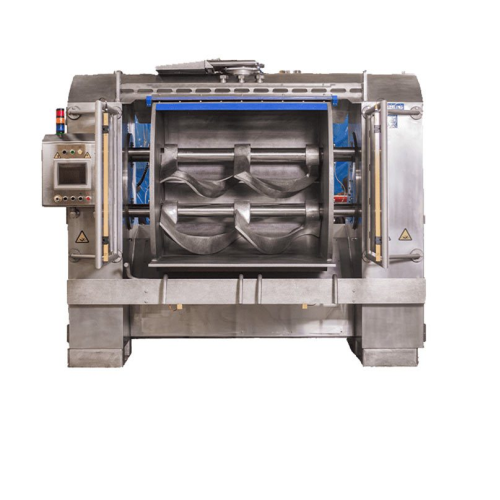

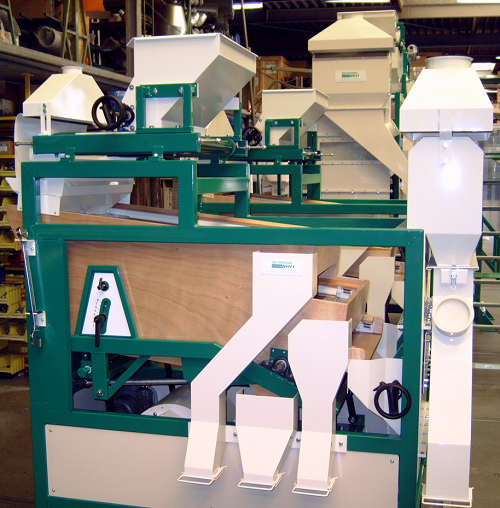

Although bakery products entail a variety of products ranging from bread to sweet goods such as cakes, each product undergoes the same key processes due to the base ingredients being flour, water, and leavening agents such as yeast, baking soda, or baking powder in addition to sugar, salt, oils, etc. The production process starts with mixing the ingredients in bakery processing equipment, including spiral, horizontal, low- or high-speed mixers.

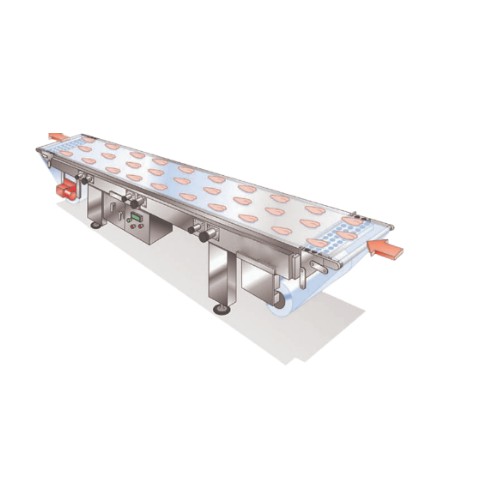

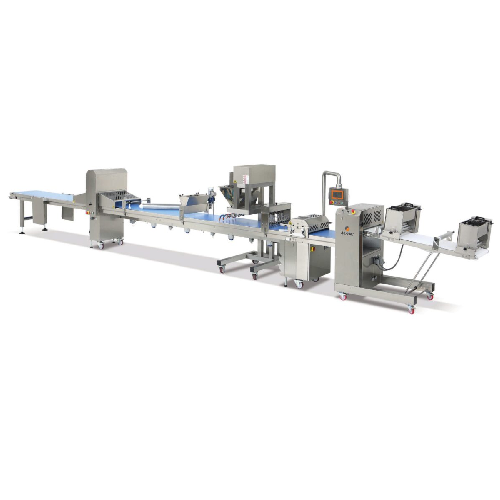

The next step is fermentation which allows yeast to convert sugars and starches into simpler substances and raise the dough. After a few hours of fermentation and proofing, the bulk dough is loaded on a conveyer and cut by dividers into desired sizes, which are later shaped according to the end-product specifications. The final step is baking, which is different for yeast-leavened and chemically-leavened products. While the former goes through three stages of baking which are the expansion of the dough, drying of the surface, and crust browning, for the latter the stages depend based on formulation. The baked good must be cooled, and if required, especially for certain pastries, it can be either decorated or completed with a filling or glazing.

Tradition vs. Modernism in the baking industry

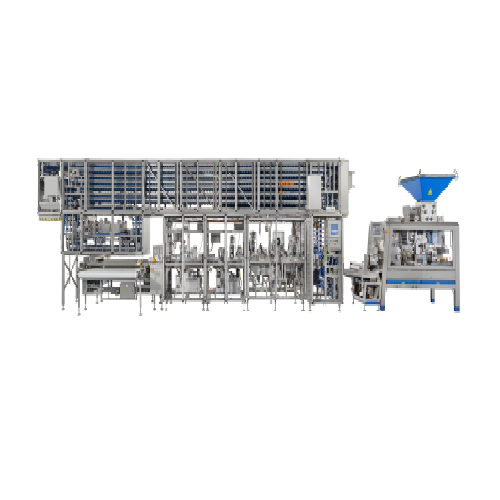

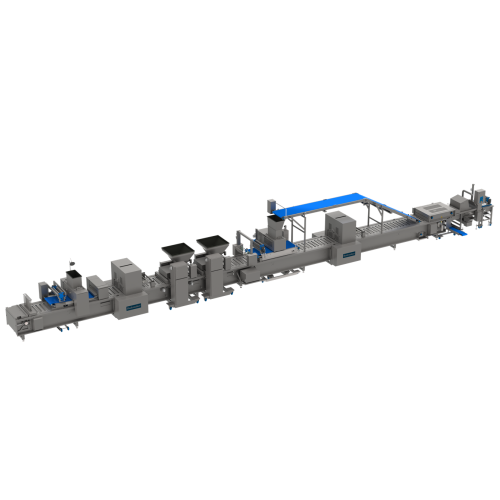

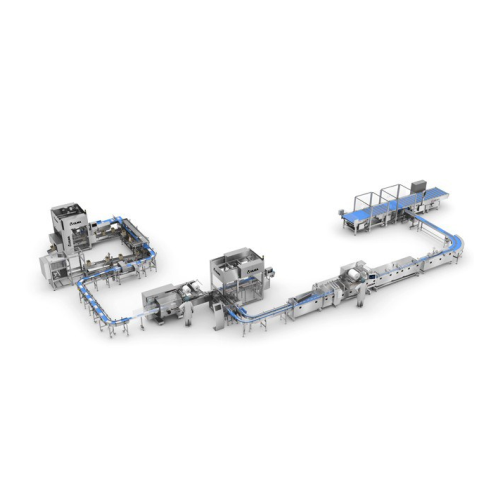

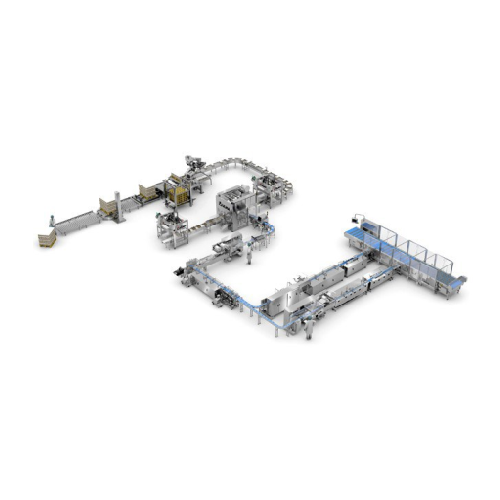

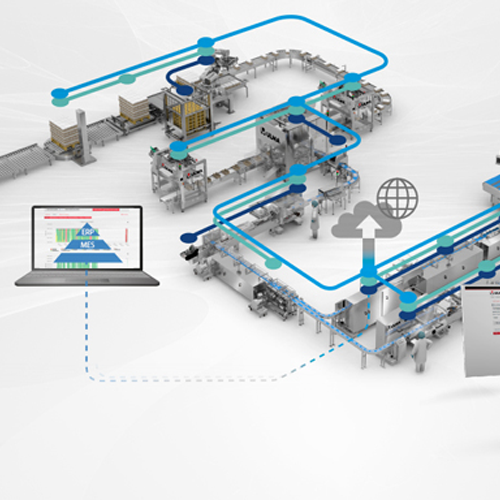

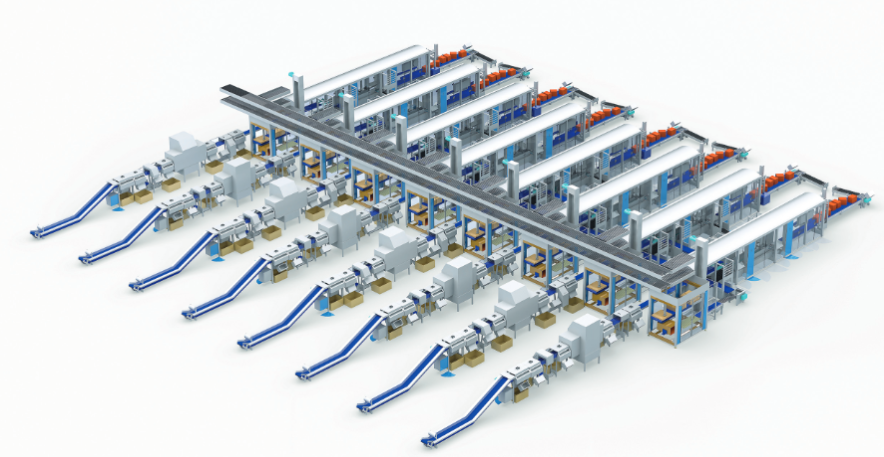

There are two main types of bakeries: small, locally-owned businesses that sell their products to individuals and mass-producing bakeries that sell their products to restaurants, grocery stores, and cafes. While the large- and medium-scale bakeries fully automated their processes, small-scale bakeries have only started doing so. Automated processes reduce the waste of raw materials, speed up the process, and increase reliability, improving the quality of products, all of invaluable importance in the hyper-competitive industry.

Namely, one of the challenges that small bakeries face is the lack of space for all the automated equipment and machinery that replace manual labor. While some small bakeries may use basic mixers and ovens, others may still rely on manual mixing and kneading, which makes their production more labor-intensive. However, small-scale bakeries possess the flexibility to adapt and experiment with recipes, a contrast to the standardized formulas of the mass-producing giants. Moreover, they procure ingredients locally, resulting in products with fewer additives and preservatives.

The staple food: making bread

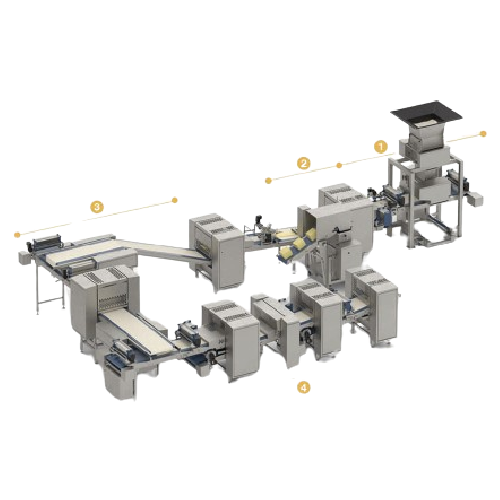

Despite being a fairly simple food made of only a few base ingredients such as flour, water, and yeast, slight differences in the production process result in a large number of bread types. Some of the most popular are white bread, baguettes, ciabatta, or rye bread. However, the basic production processes of mixing, fermentation, and baking are staples.

The objective of mixing is the blending and hydration of dry ingredients, air incorporation, and gluten development which takes up to 15 minutes in mixing equipment. The fermentation process is crucial for developing flavor and texture through yeast growth. The dough is fermented in fermentation tanks at room temperature for several hours.

The proofed dough is then cut, rested, and shaped in the molder with a minimum amount of pressure and stress on the dough to avoid damaging the cell structure. The final step is baking. The duration and temperature depend on the type of bread. The difference between types such as white, wholemeal, and rye bread is in the type of flour used, from white wheat flour over wholemeal to rye meal mixed with wheat flour. Two widely beloved types of white bread, for instance, baguette and ciabatta, are shaped differently. While the baguette is molded and shaped into a cylinder, ciabatta dough is gently sheeted and divided into desired dimensions to preserve the honeycomb-type structure.

Sweet treats from cakes to biscuits

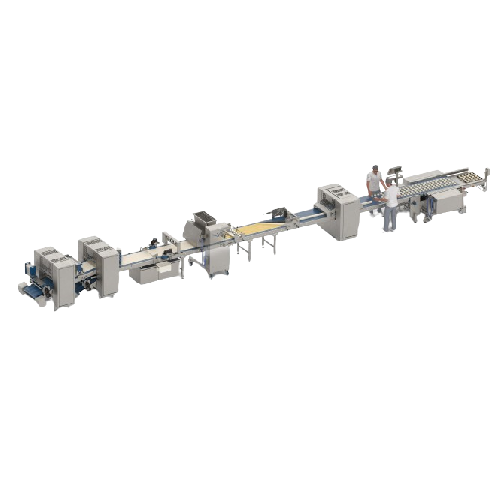

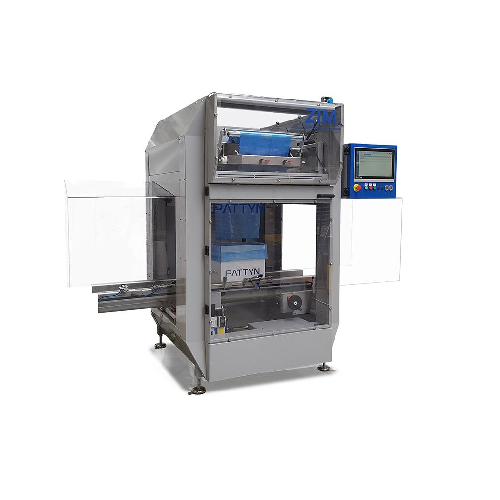

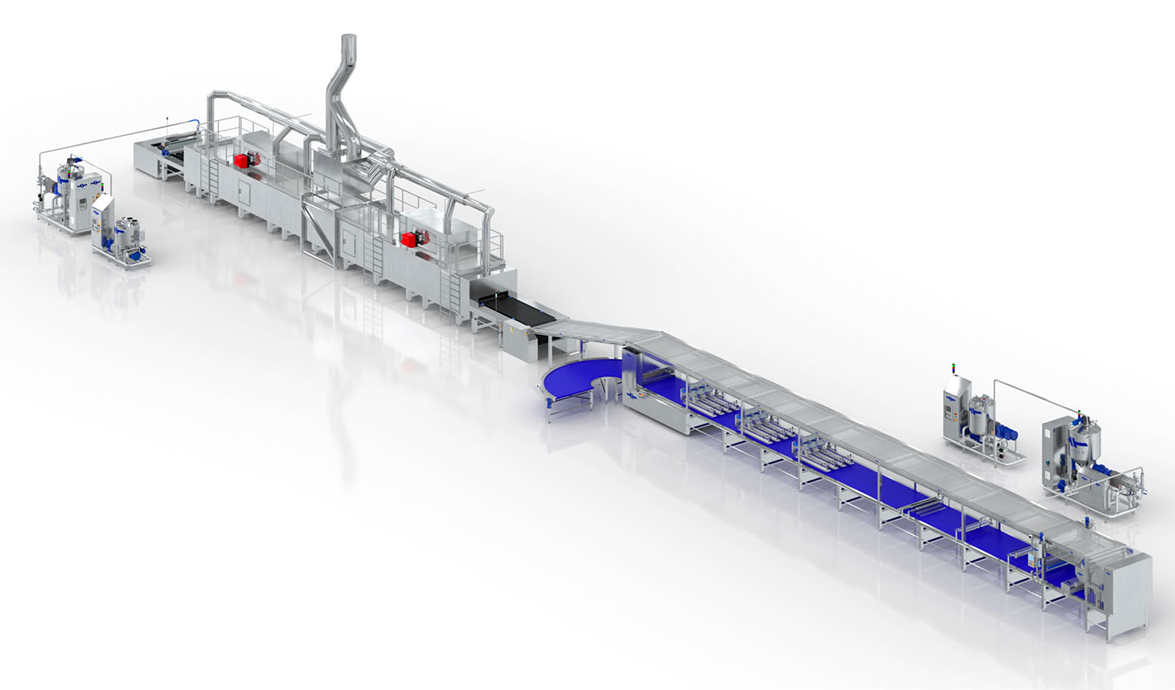

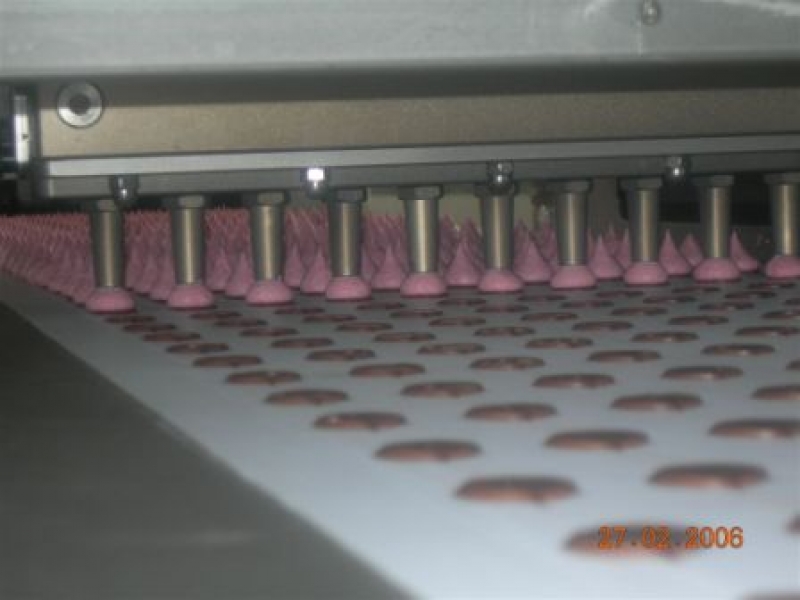

Sweet goods, including cakes, doughnuts, croissants, cookies, and biscuits, are just as important in a bakery’s assortment as bread. Cake production starts with dough or batter production in a vertical batch mixer which is then pressed into pans with a filling machine. The cake is baked in a tunnel oven, cooled, and transported to the packaging machines. For doughnut production, the wet yeast slurry is mixed separately, added to the flour-water mixture, and mixed by a large dough hook.

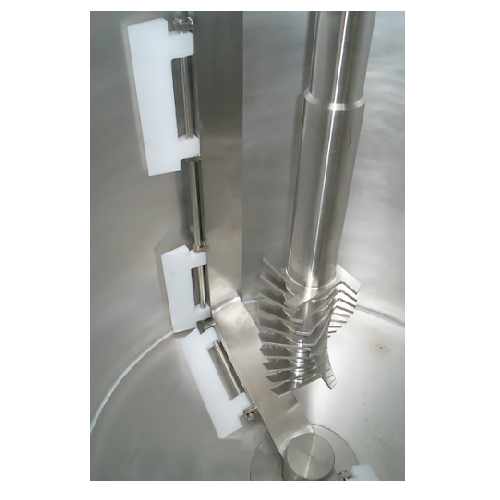

Once mixed well, it simulates the human kneading process to homogenize the ingredients. The rested dough is forced into a hopper and transferred to an extruder to form the doughnut shapes. Unlike other pastries, doughnuts are fried in an open fryer and finally glazed. The main difference in croissants production is that the main ingredient along with flour is butter, which plays a key role in the process of lamination that gives it the signature flaky texture.

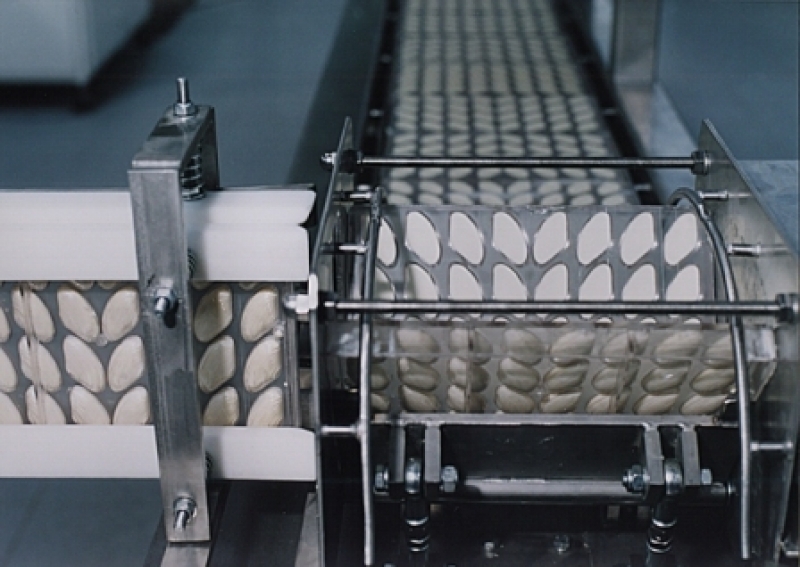

The dough is rested and proofed several times and treated with egg wash before baking at 200°C. The cookies and biscuits-making process starts with dough production, followed by dough feed and molding. While soft biscuit dough contains more fat and is molded in mold cavities of the biscuit line, hard biscuits are sheeted into layers and pressed through rolls. Cookie batter, on the other hand, is extruded via pumps. The shaped dough is transported into baking chambers.

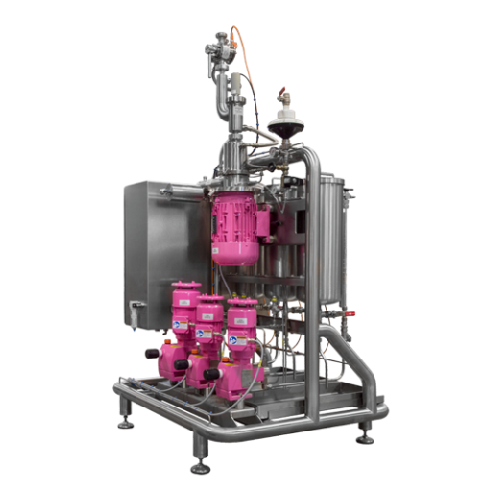

Ful-filling the sweet cravings

In order to satisfy even the most demanding sweet tooth, manufacturers fill their goods with dairy-based cremes such as custards or dulce de leche, chocolate ganache, fruit-based fillings, or nut-based fillings, which are primarily ground nuts similar to spreads. Basic cream fillings consist of superfine sugar, shortening or oil, corn syrup, water, and other minor ingredients and can be either deposited or injected into the product. On the other hand, fruit-based fillings are mainly fruit puree and gelling agents such as alginates. Another popular pastry filling is whipped cream, a rich emulsion of dairy fat and sugar processed in high-power industrial mixers or whipping machines.

Gluten-free and vegan bakery goods

As gluten intolerance is becoming more common, the baking industry is trying to reach the demand by using gluten-free cereals and pseudocereals, as well as milled legumes, seeds, and nuts as an alternative to wheat flour. Gluten is a binding structural protein that provides elasticity and retains moisture. Some of the substitutes used in gluten-free products are xanthan gum, guar gum, or ground seeds like psyllium, flax, and chia.

In order to improve the texture, taste, and shelf-life of gluten-free bakery products, manufacturers utilize sourdough with microbial strains, while the addition of modified starches and protein isolates enhances the quality. The demand for vegan bakery goods is also rising. Although bread is traditionally vegan, pastries require substituting dairy for plant-based milk and margarine, while replacing eggs remains the biggest challenge. Some of the plant-based egg substitutes are applesauce, mashed bananas, soaked flax or chia seeds, etc.

Which bakery technology do you need?

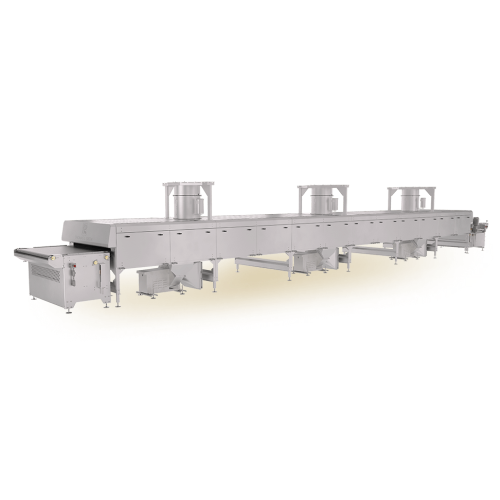

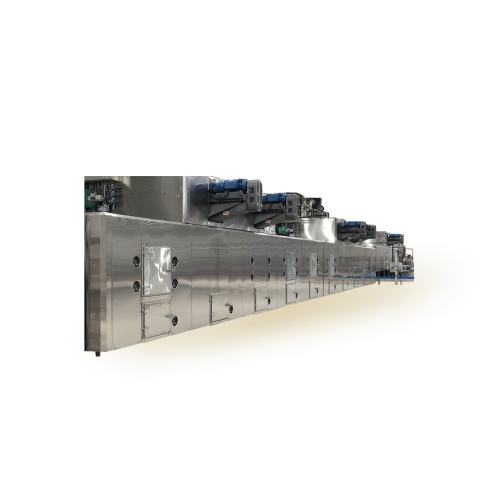

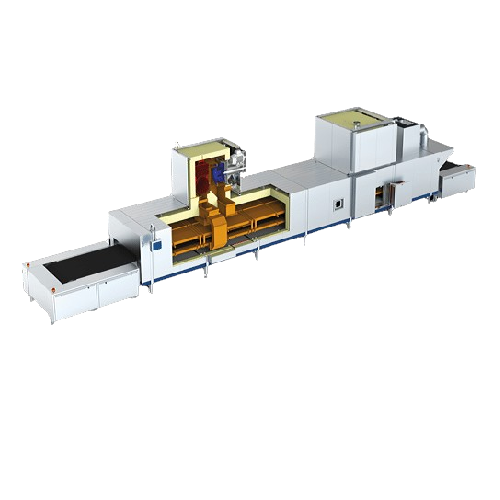

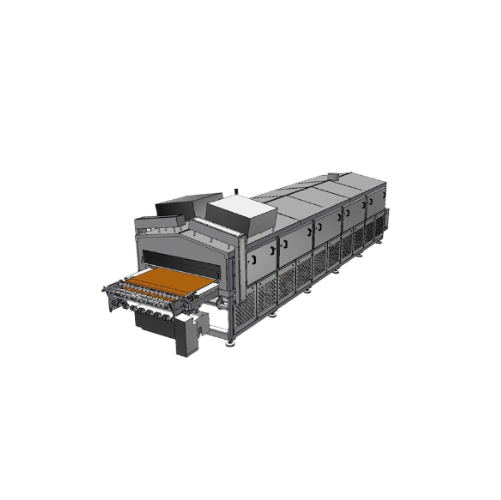

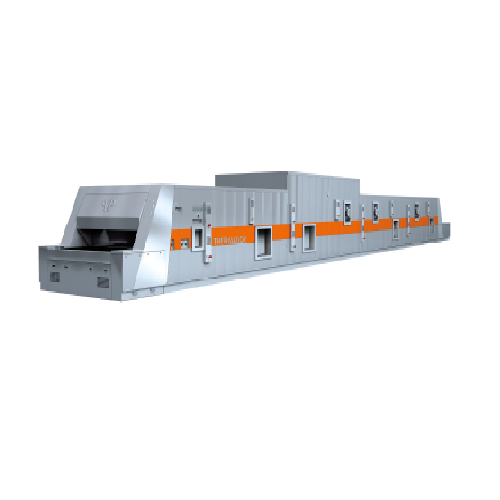

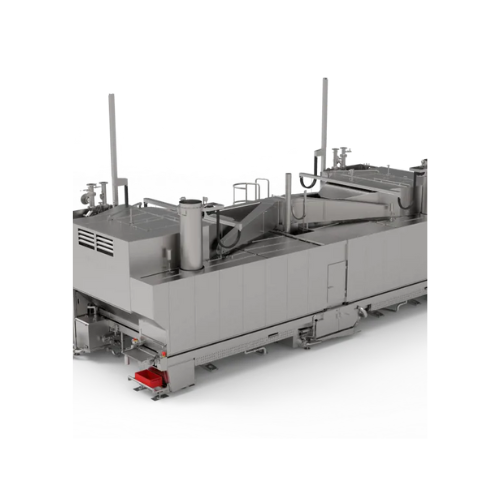

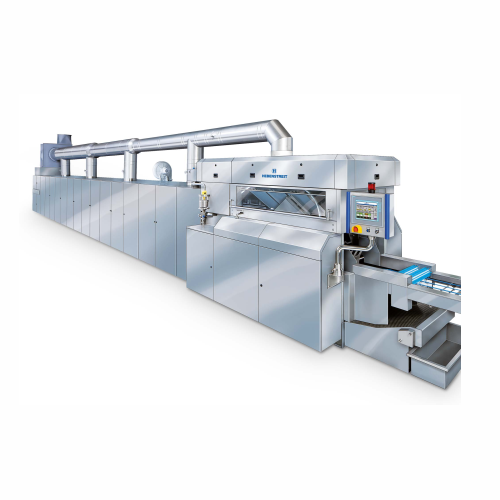

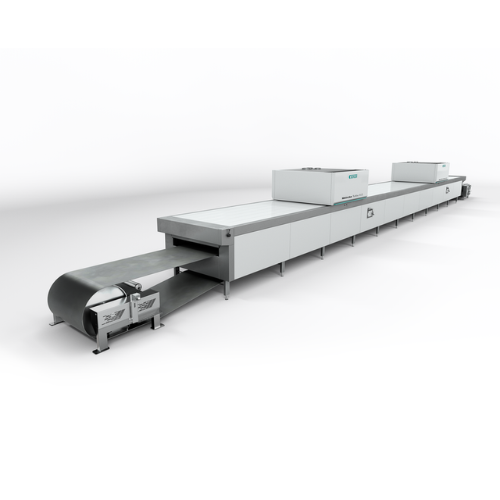

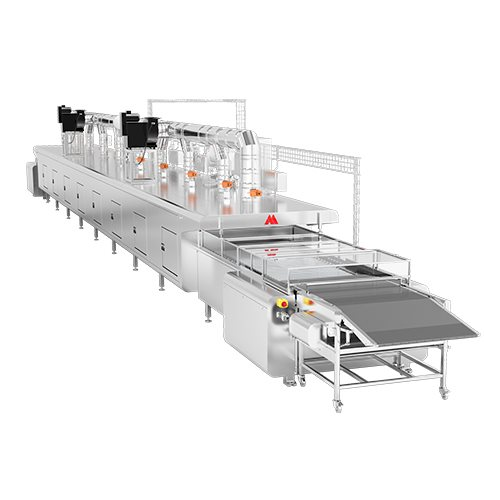

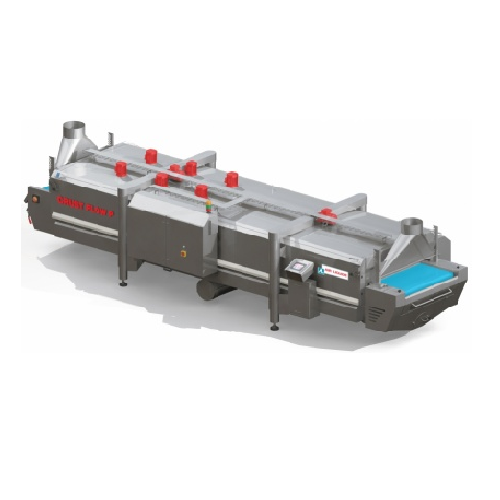

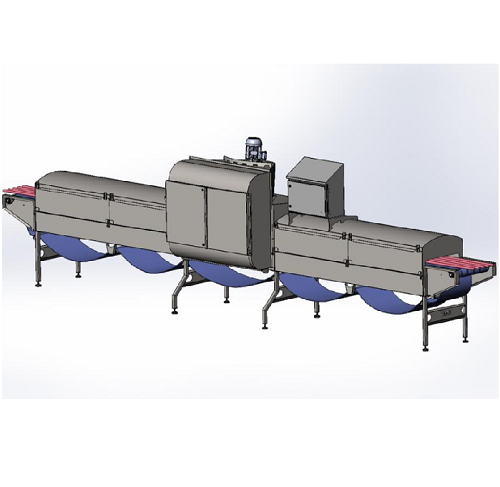

Industrial tunnel ovens for bakery products

Achieve precise control over baking processes with these industrial tunnel ove...

Cup denester for bakery production

Effortlessly enhance efficiency in bakery production lines by streamlining the process o...

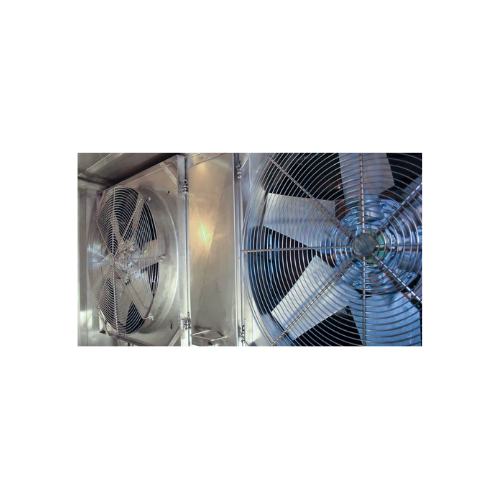

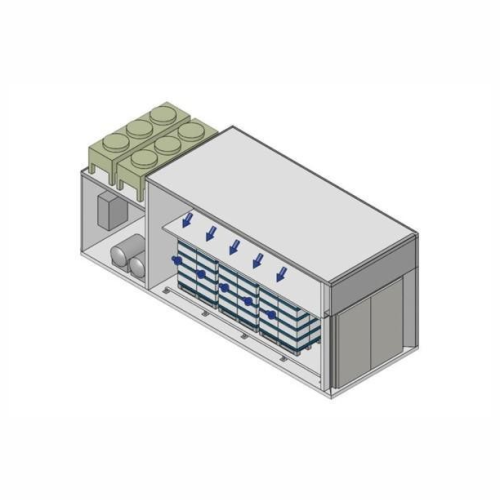

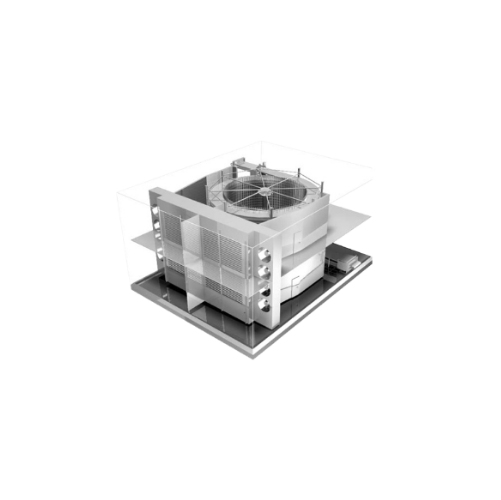

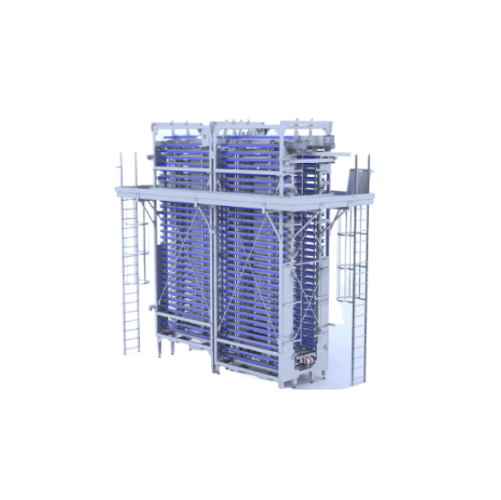

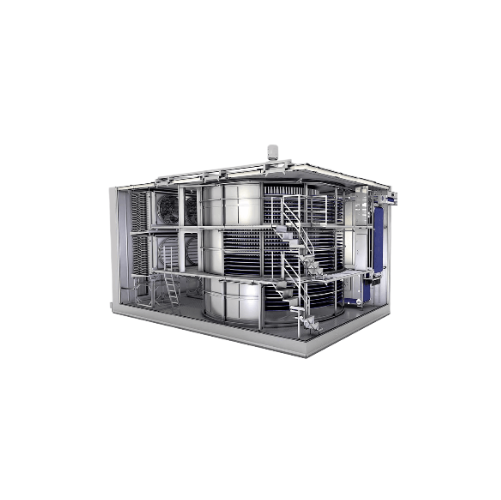

Freezing and cooling systems for bakery products

Enhance your bakery production line with advanced freezing and cooling sy...

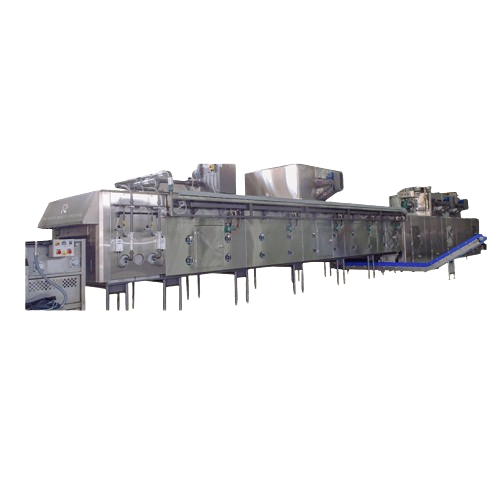

Industrial multi-pass dryer for bakery products

Ensure consistent moisture reduction and quality enhancement in your baker...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

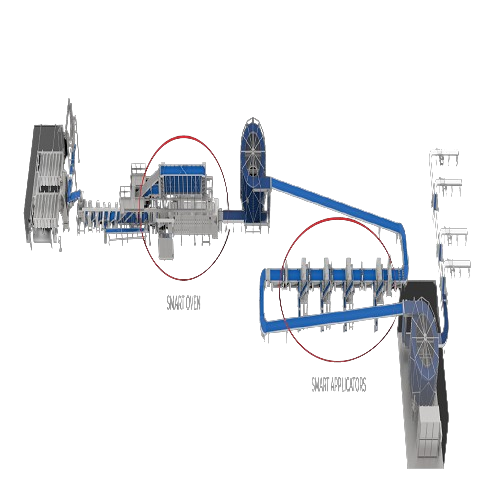

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

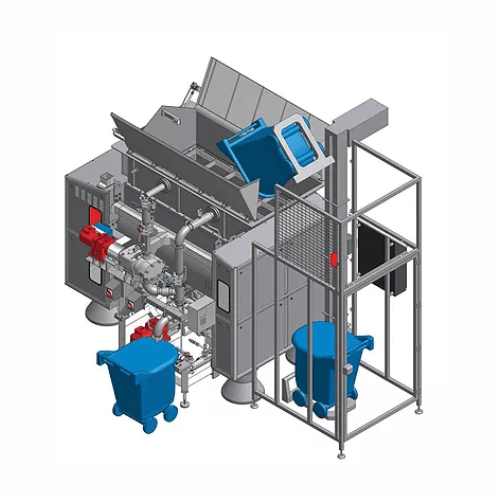

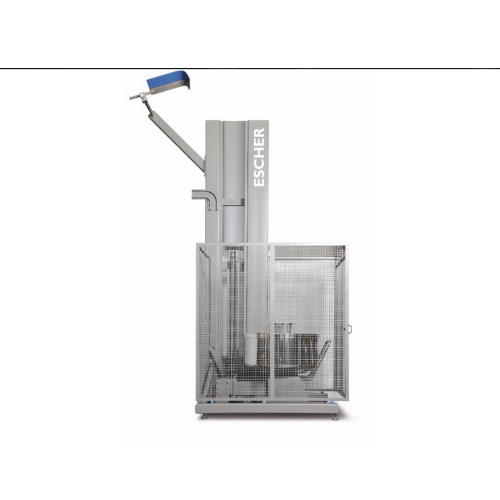

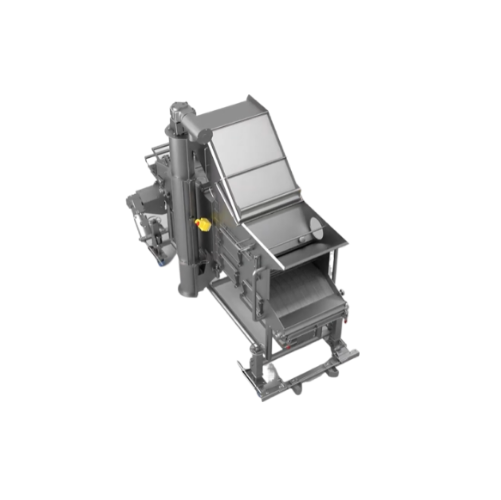

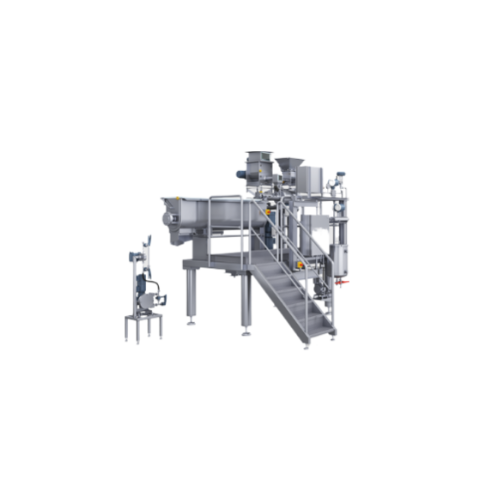

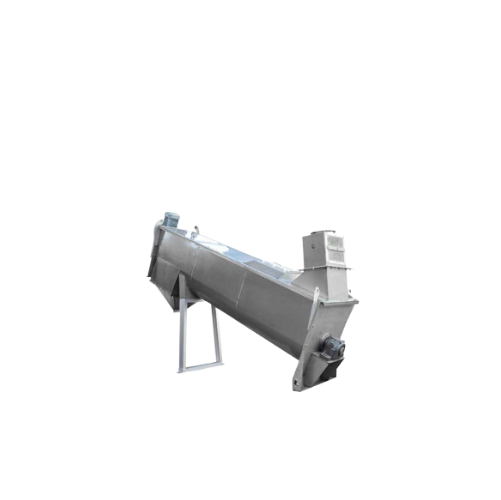

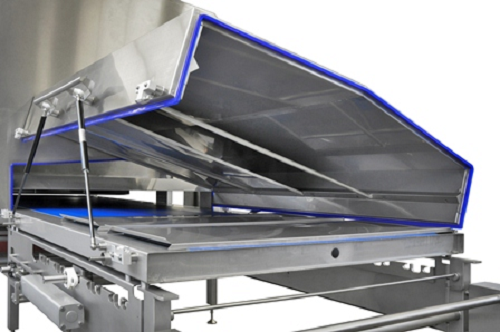

Efficient dough dump station for bakery systems

Streamline your dough handling process with this advanced dumping station,...

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air t...

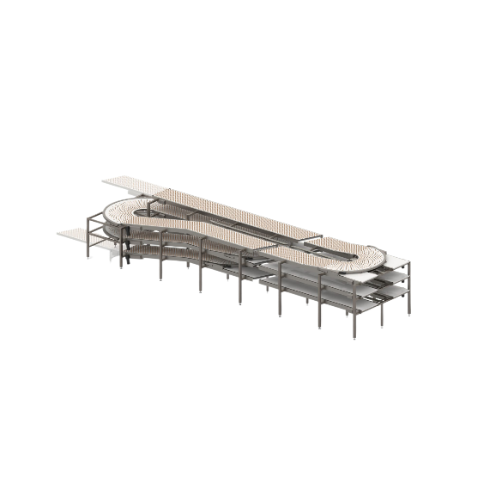

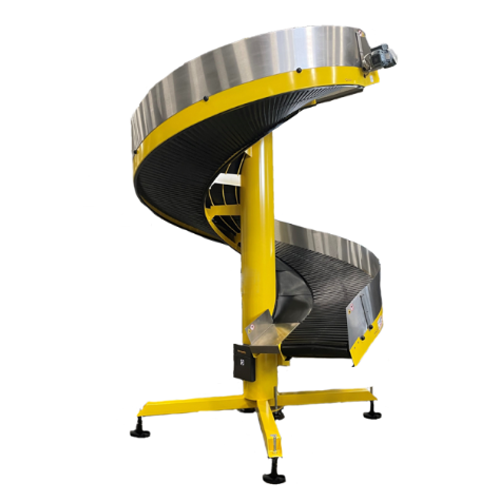

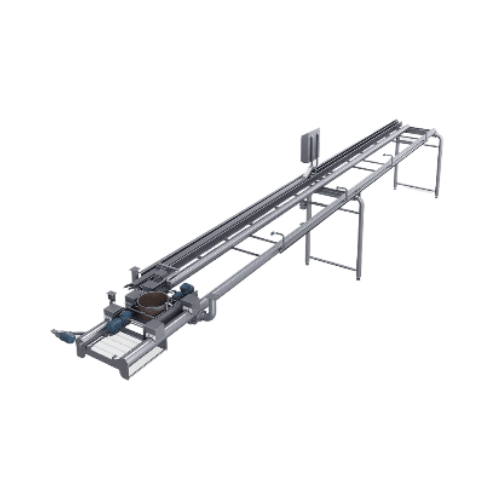

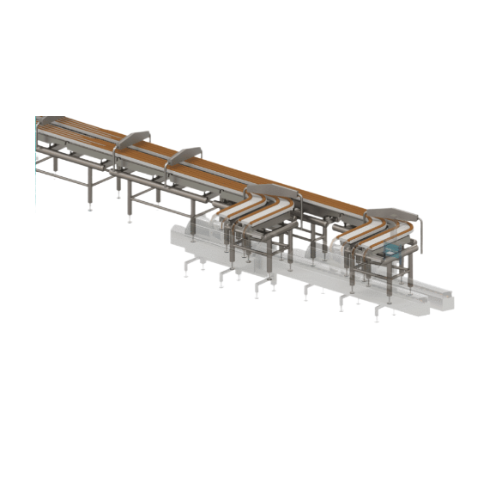

Industrial bakery conveying solutions

Ensure seamless, hygienic transport of bakery goods with precision-engineered conveyi...

Advanced bakery depanning solutions

Streamline your bakery production with cutting-edge depanning technologies designed to ...

Enrobers for bakery goods coating

Ensure complete and uniform coating of baked goods, snacks, and pastries, enhancing produ...

High-speed sandwiching for bakery production

Streamline your production of sandwich biscuits with a machine engineered to ...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Depositors for bakery fillings

Achieve precise and high-speed depositing of bakery and pastry fillings to optimize your prod...

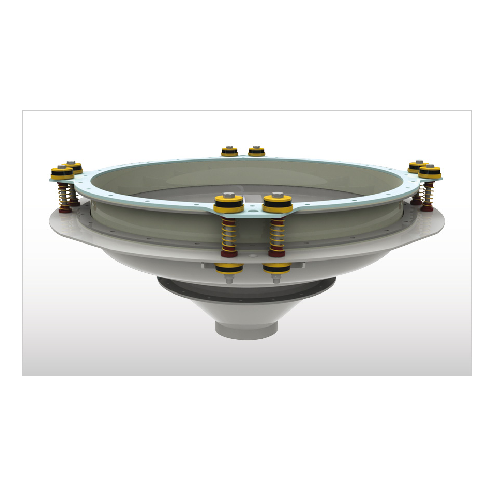

Vibrating counting system for small bakery products

Optimize counting precision and efficiency for your bakery production...

Vision counting system for bakery products

Achieve precise and consistent product counting with this advanced system, desi...

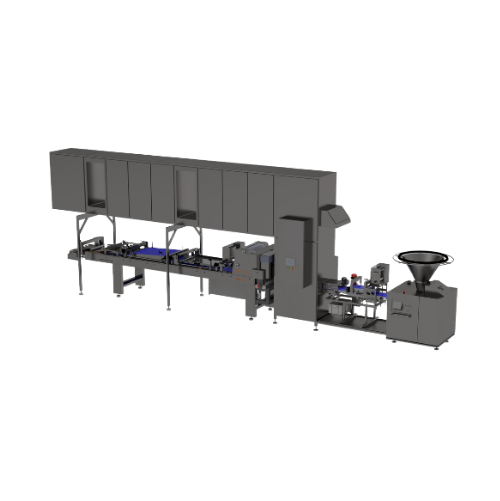

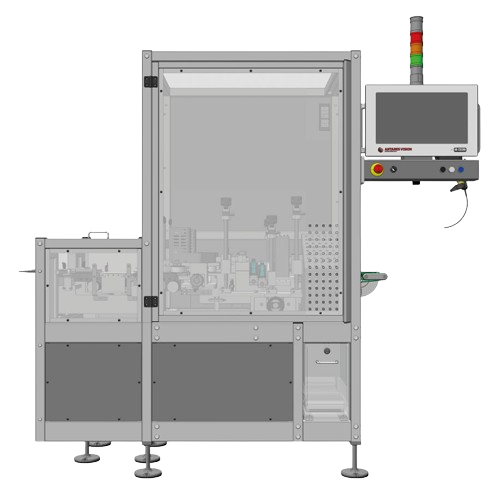

3d vision quality inspection system for bakery products

Streamline your bakery production with high-speed 3D vision inspe...

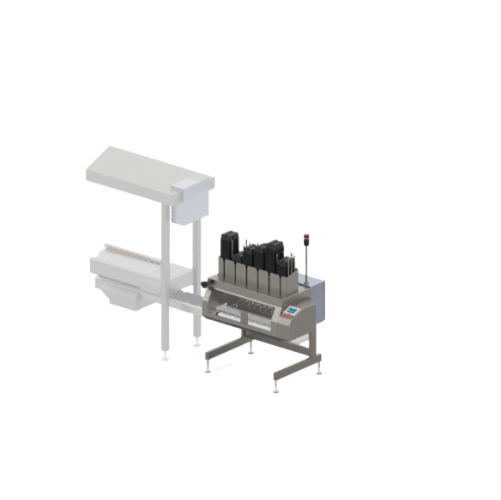

Bakery product quality control and counting system

Optimize your bakery line with precise control and counting of long pr...

Bulk box filler for bakery and pastry products

Efficiently pack fragile bakery and pastry products with gentle handling an...

Industrial bakery bag dropper for boxes or trays

Enhance your bakery line with precision-based bag dropping solutions that...

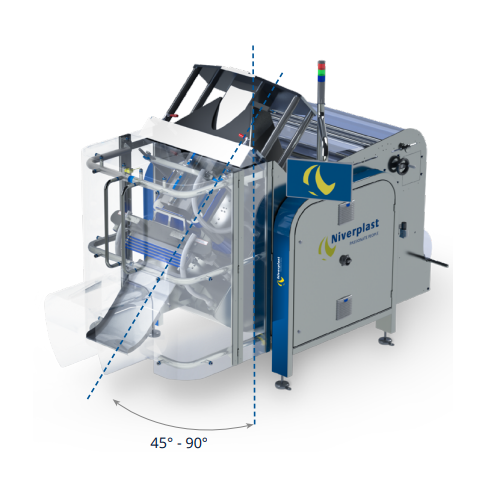

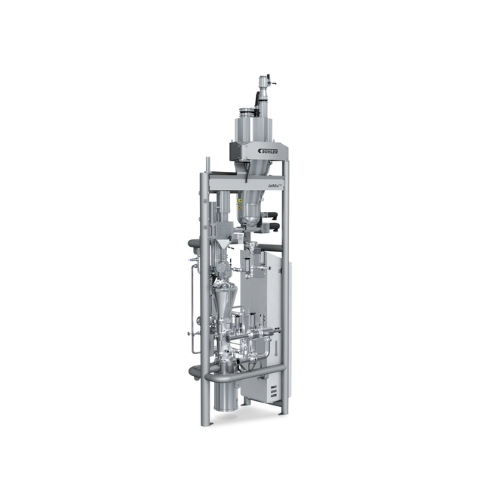

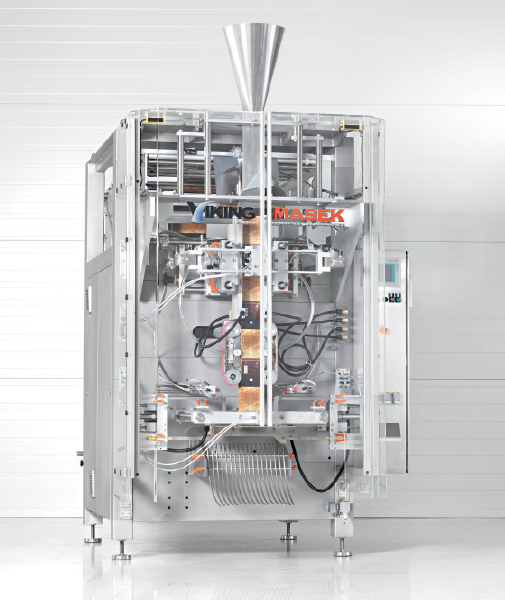

Vertical fill and seal bagging machine for bakery products

Streamline your bakery product packaging with this versatile ...

Touch-free layer packaging for bakery products

Optimize your packaging line with a touch-free solution that ensures hygien...

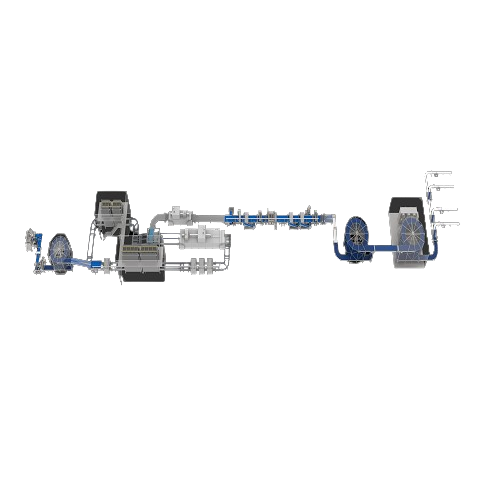

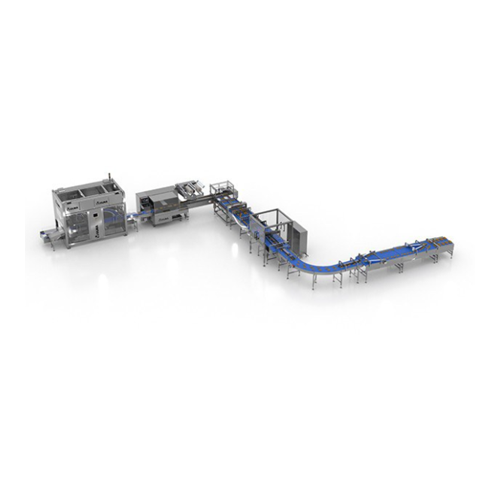

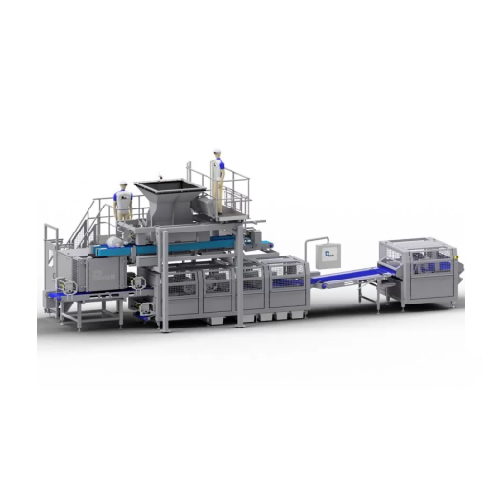

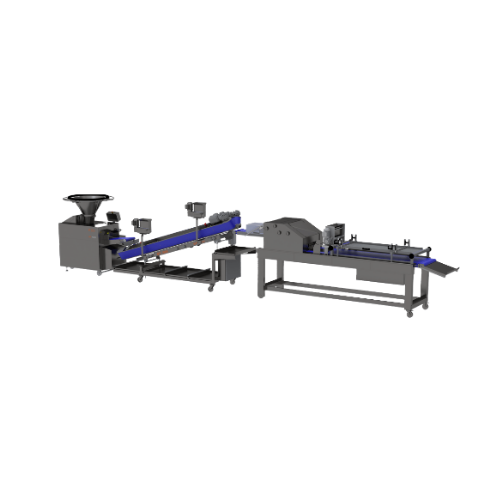

Production line for coiled bakery products

Enhance your bakery’s efficiency with a versatile system designed to crea...

Dual dosing and topping system for bakery products

Enhance your bakery’s production efficiency with advanced dosing...

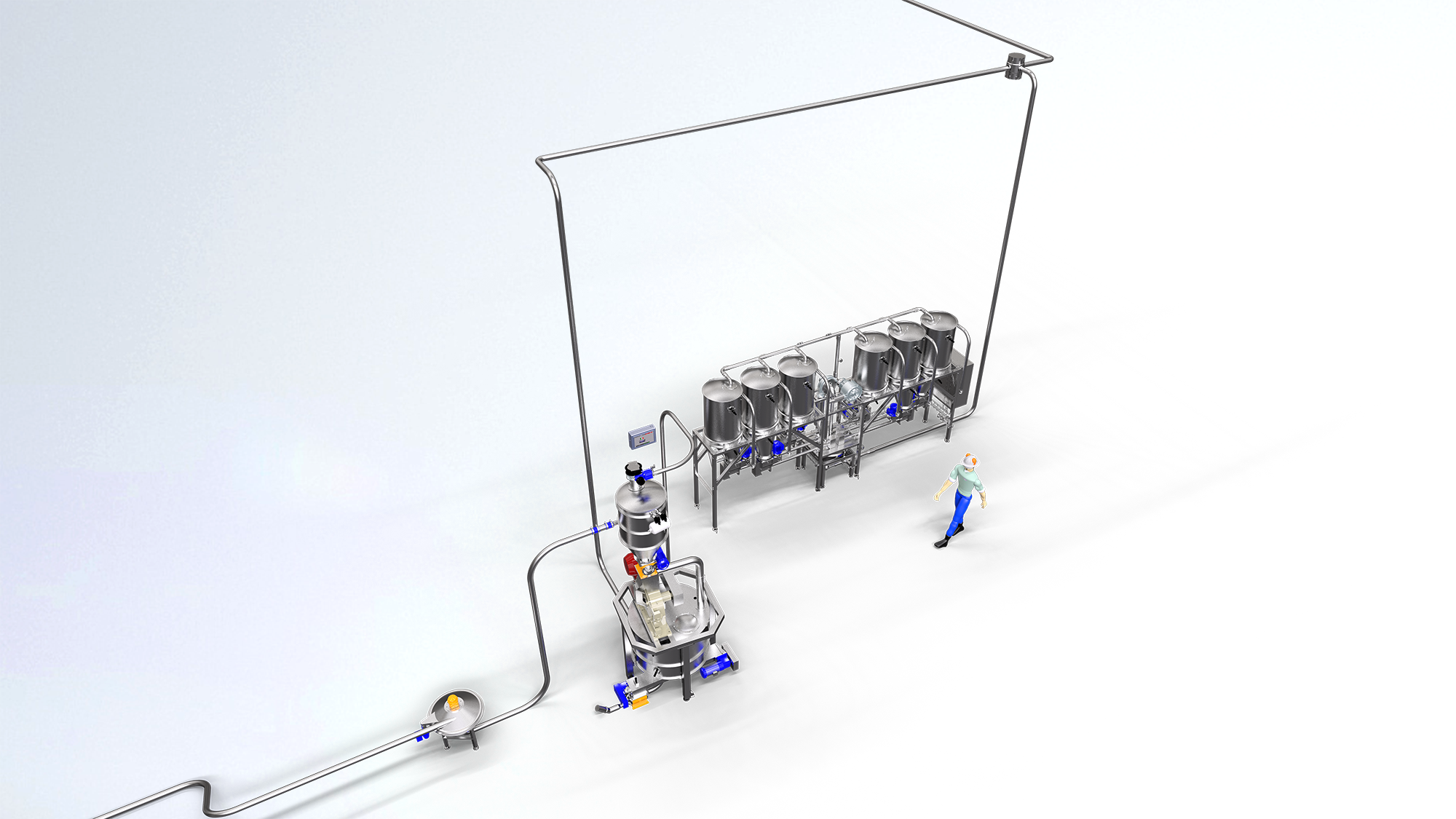

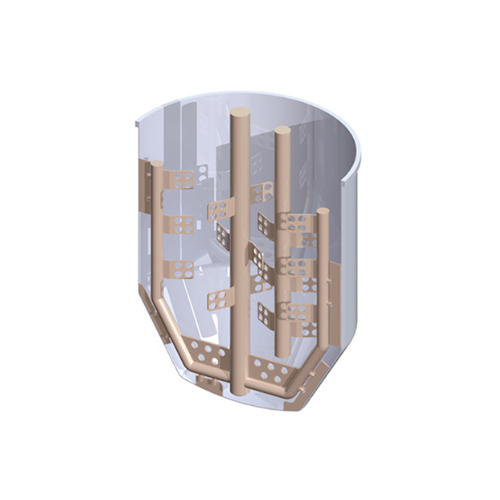

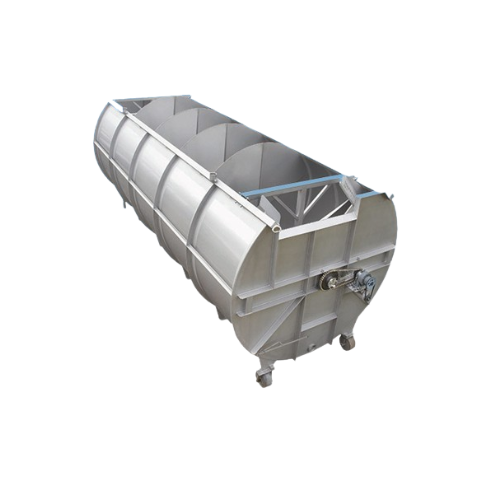

Chocolate and bakery fermentation unit

Achieve consistent quality and flavor in chocolate and bakery products with precisio...

Dough divider for high-efficiency bakery production

Achieve precise dough division and high-speed production efficiency w...

Convection oven for bakery production

Optimize your baking with precise temperature and humidity control, ensuring perfect ...

Industrial fat melting tank for bakery and chocolate production

Efficiently melt solid fats to precise temperatures with...

Laboratory type ball mill for chocolate and bakery applications

Optimize your R&D processes with precise grinding a...

High viscosity material mixer for bakery and chocolate

Efficiently mix and knead high-viscosity materials for premium cho...

Electrical deck oven for bakery applications

For bakery operations seeking precise control, our deck ovens deliver optimal...

Advanced convection oven for bakery applications

Enhance your bakery’s production efficiency and product quality with a ve...

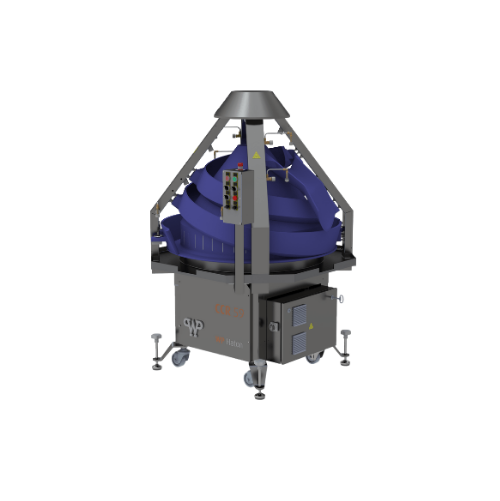

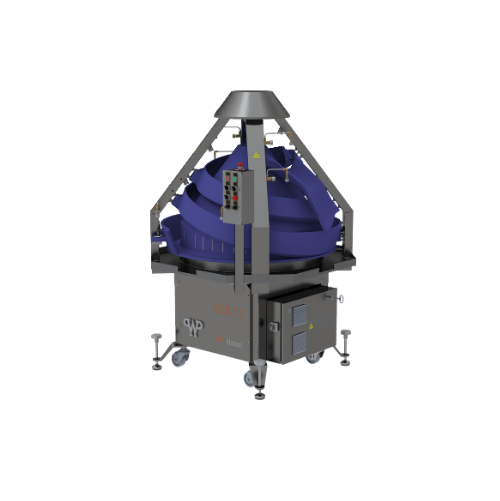

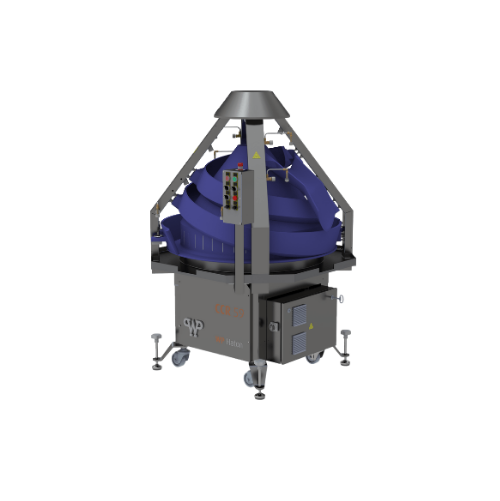

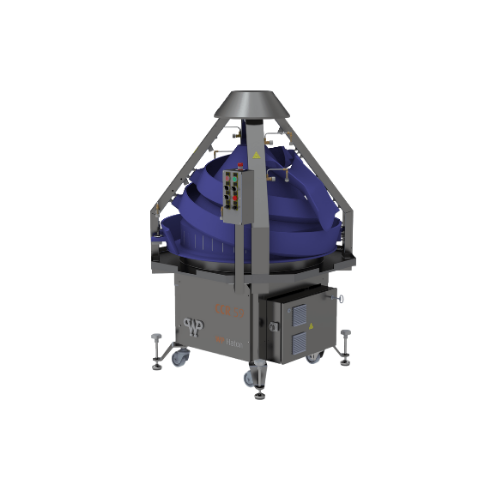

Conical rounder for bakery products

Optimize your dough handling process with efficient shaping solutions, ensuring consist...

Industrial long moulder for bakery production

Enhance your bakery’s efficiency with a high-speed long moulder ideal ...

Dough aligning system for bakery production

Enhance your bakery’s precision and efficiency with a system that ensure...

Industrial bakery oven with proofing cabinet

Optimize your bakery production with an all-in-one solution that seamlessly i...

Dough portioning system for bakery operations

Achieve precise dough portioning with minimal waste using our advanced syste...

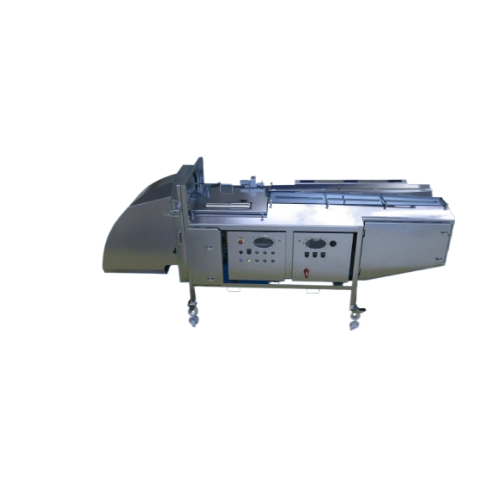

Horizontal partial cut slicer for bakery products

Achieve precision in your bakery with a horizontal partial cut slicer, ...

Spiral mixer with removable bowl for bakery production

Achieve consistent dough quality with advanced bowl locking and mo...

Planetary stirrer for bakery and confectionery

Achieve consistent textures and presentation by effortlessly stirring, beat...

Multi-injection plate for leavened bakery foods

Optimize your bakery production line with precise and customizable filling...

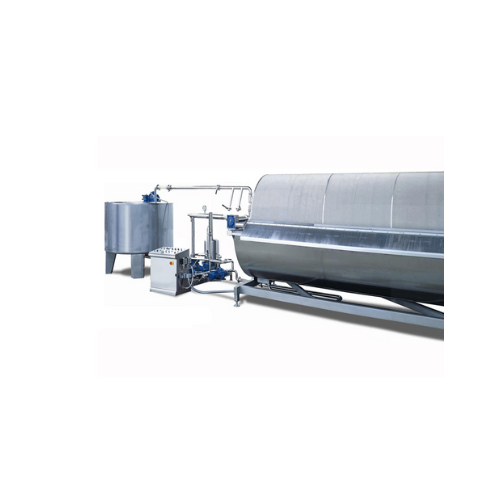

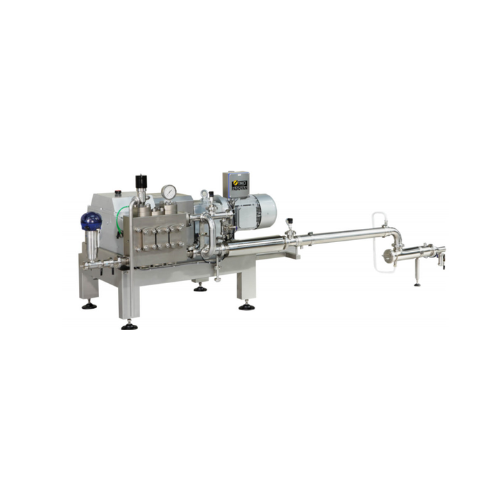

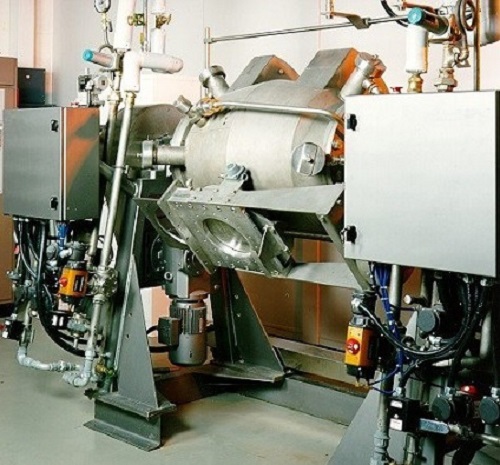

Pilot plant system for margarine and bakery fats production

Streamline your development and testing of diverse spreads a...

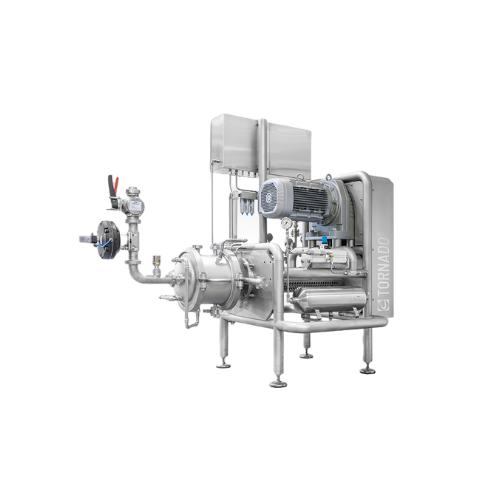

Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed ...

Smart pattern splitter for bakery products

Achieve precise split patterns on various bread types with an innovative water ...

Fruit base processing technology for yoghurt and bakery

Ensure the integrity of fruit preparations while maximizing varie...

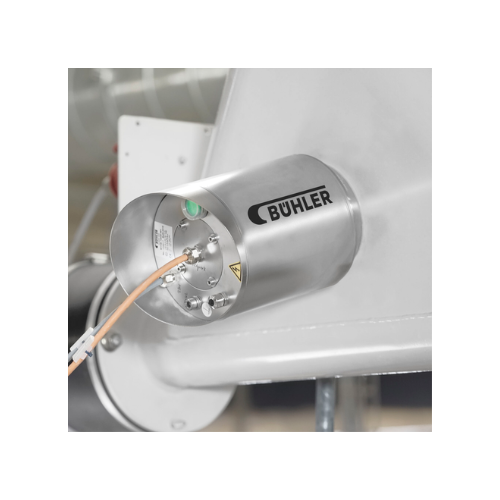

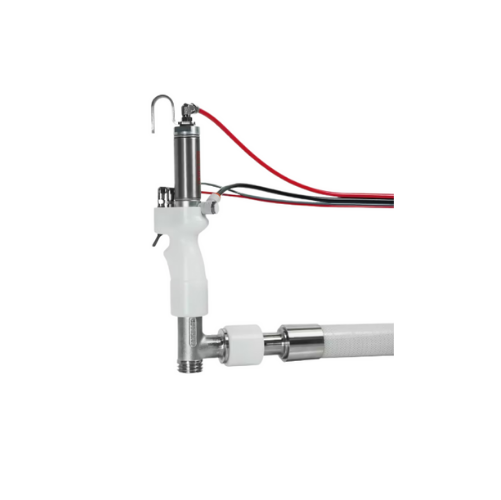

Glaze spraying system for bakery products

Achieve perfect glaze and finish on your bakery products with precision spraying...

Bakery spraying system for accurate liquid application

Achieve precise and consistent liquid application across diverse c...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

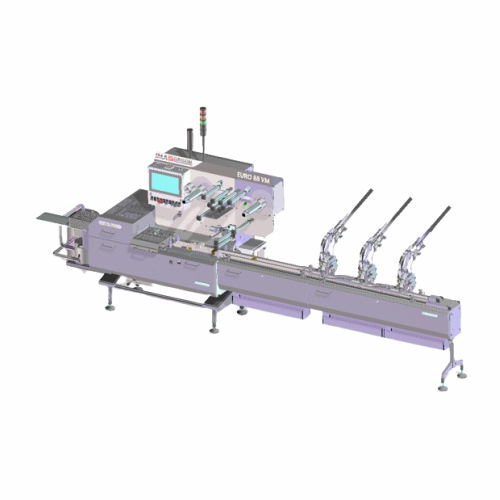

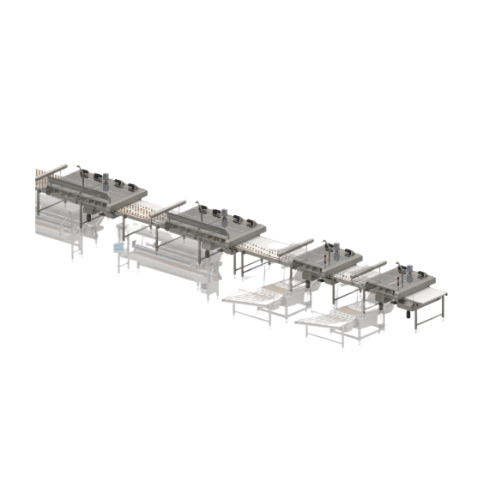

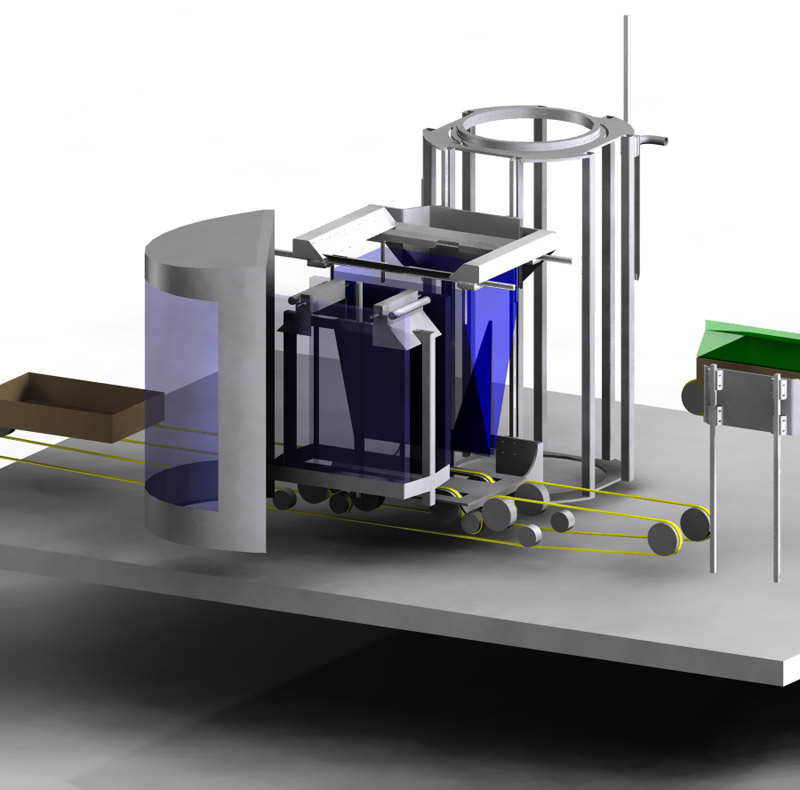

Multifunctional depositing line for bakery production

Optimize your bakery and food production with a modular depositing ...

Ultrasonic cutting line for bakery products

Experience precise slicing and cutting efficiency with our high-capacity ultra...

Chocolate spraying system for bakery decoration

Achieve precision chocolate coatings and intricate dessert decorations eff...

Egg wash disc sprayer for bakery finishing

Achieve precise liquid application with minimal waste using this disc sprayer, ...

Industrial glaze sprayer for high-volume bakery production

Enhance product appeal and extend shelf life with precise gla...

Efficient topping strewer for bakery production lines

Enhance your product’s appeal and streamline topping applicat...

Full production greasing and depositing line for bakery products

Elevate your production process with a greasing and dep...

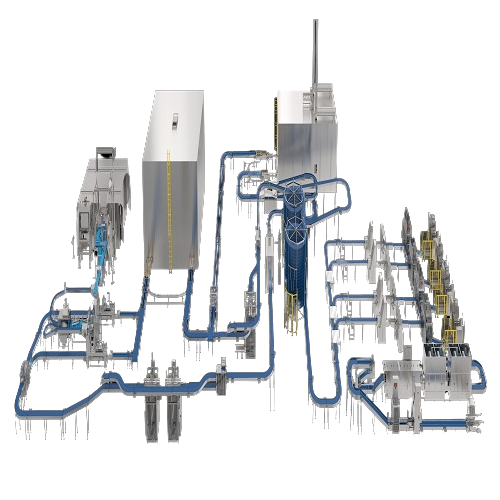

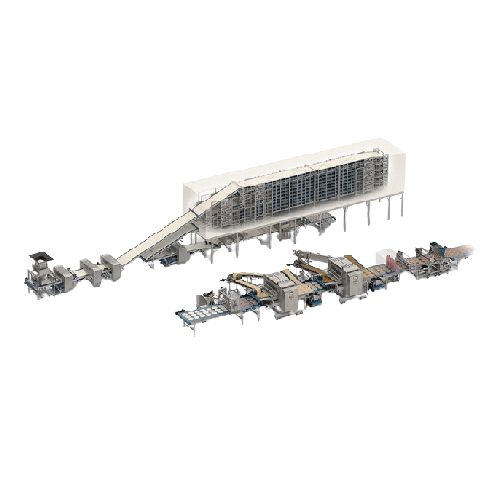

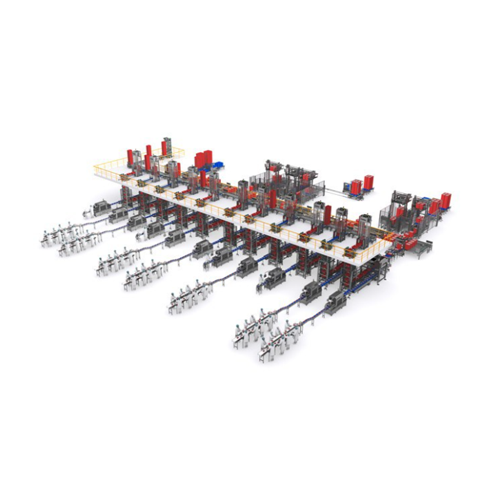

Dough lines for industrial bakery production

Optimize your bakery’s dough production with versatile solutions for pr...

Bakery product conveying solution

Optimize your bakery’s production line by seamlessly transferring diverse products ...

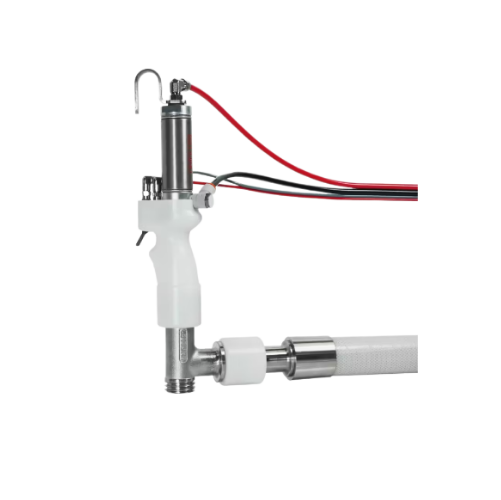

Semi-automatic piston injector for bakery products

Enhance your bakery production with precise delivery of a wide range o...

Servo bakery tray depositor

Enhance production efficiency with precise dough placement, reducing manual labor and ensuring c...

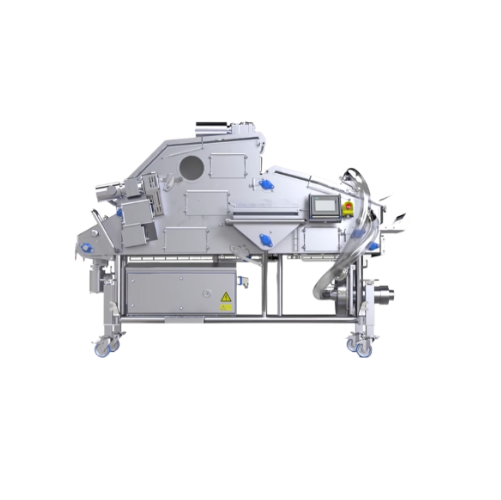

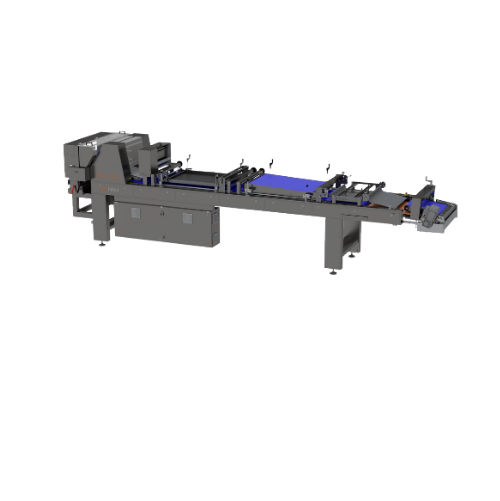

Auto bakery tray depositor for creams and batters

Efficiently deposit precise quantities of creams and batters with high-...

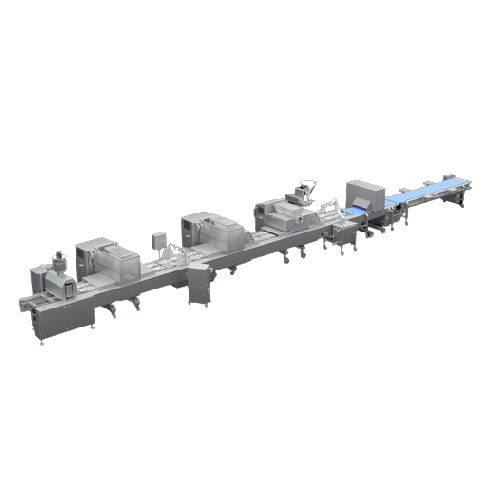

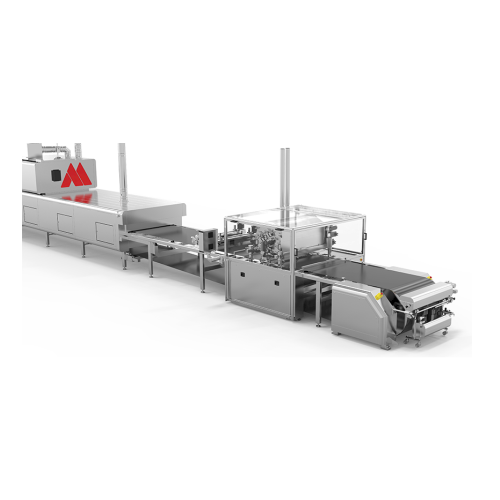

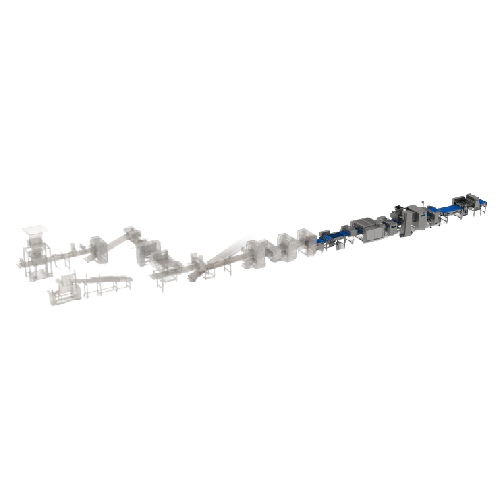

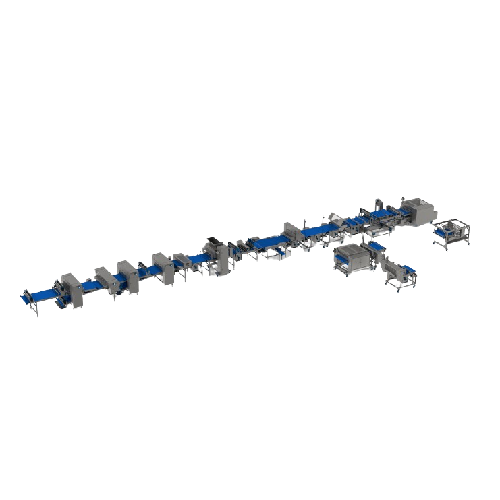

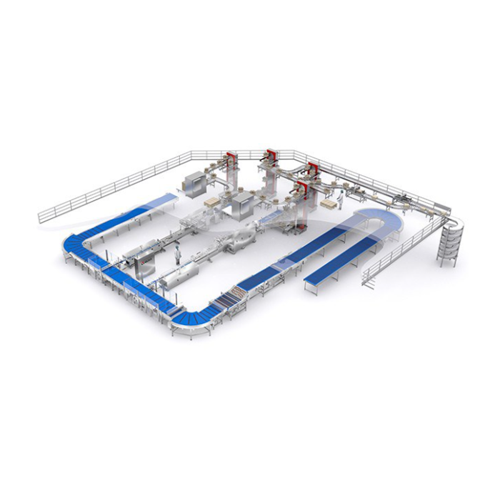

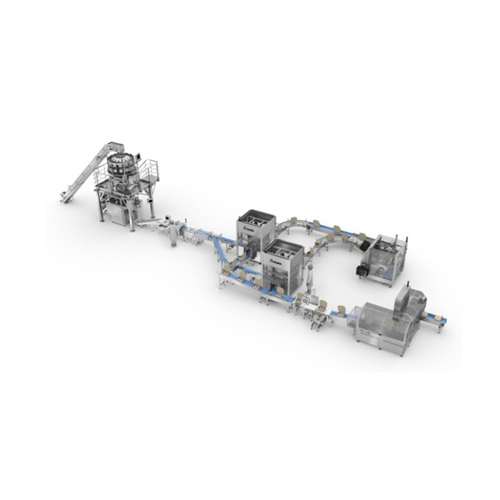

Versatile bakery production line

Enhance your bakery’s versatility with a production line that enables dynamic customi...

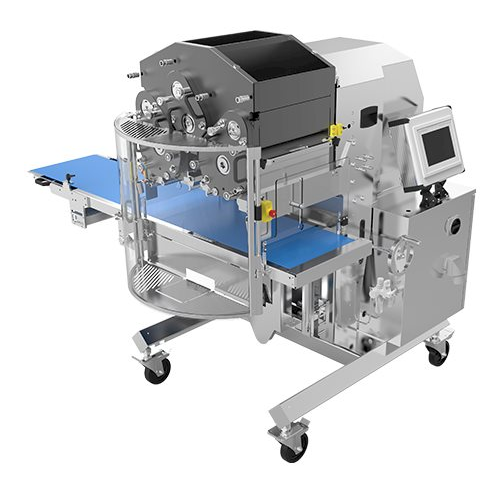

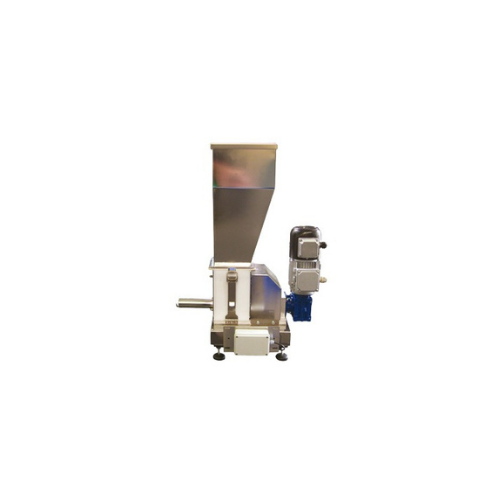

Small-scale depositor and extruder for bakery production

Revolutionize your confectionery and bakery production with a fl...

Compact extruder and depositor for confectionery and bakery production

Streamline your confectionery and bakery product...

Cooling tunnel for chocolate and bakery products

Achieve precise cooling and crystallization for chocolate and confectione...

Chocolate decoration stringer for bakery and confectionery

Elevate your confectionery creations with precision chocolate...

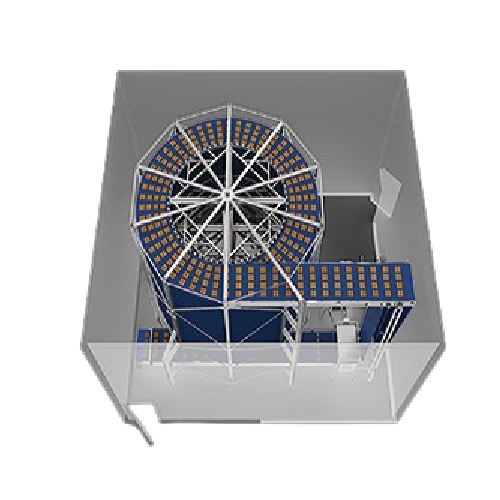

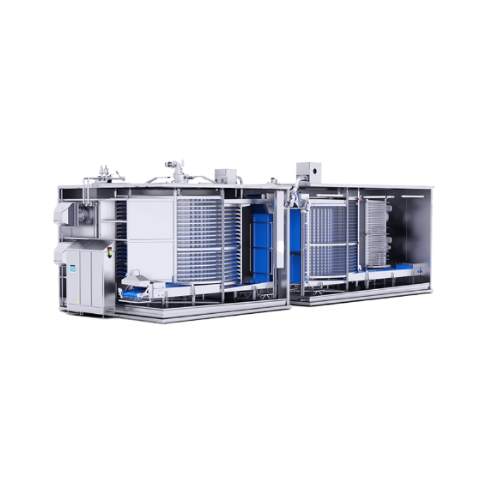

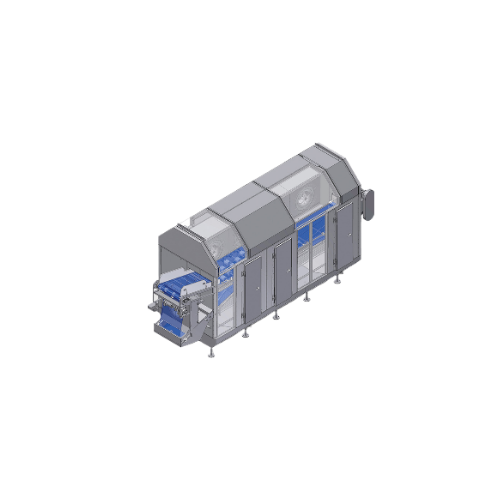

Spiral freezer for bakery and confectionery

Maximize space and efficiency while preserving the quality and freshness of di...

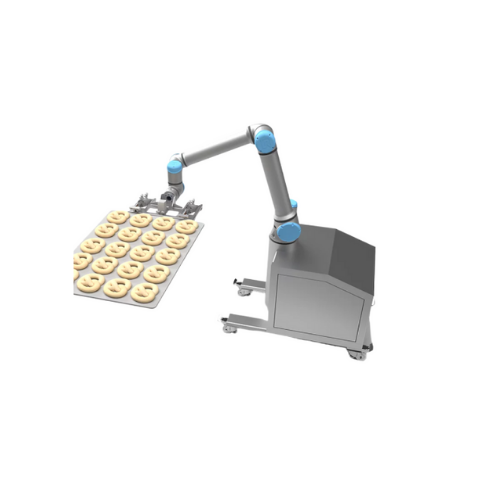

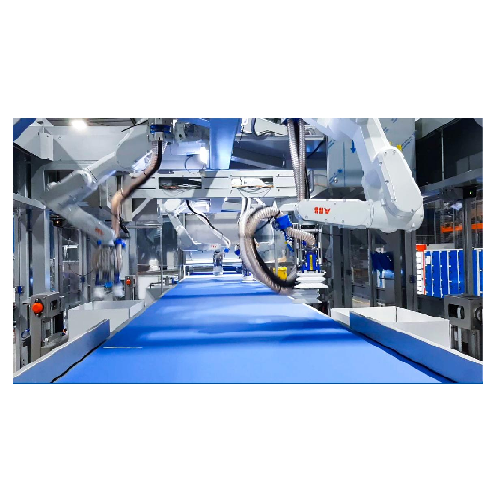

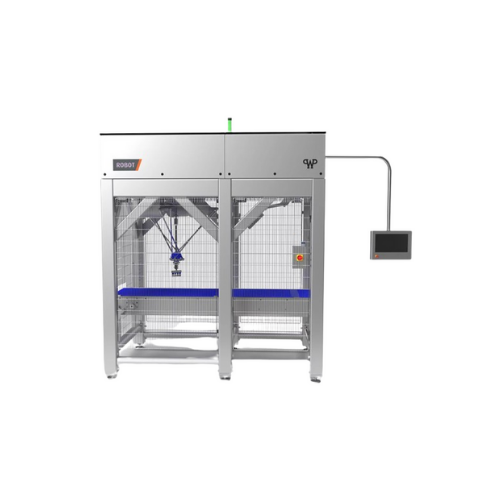

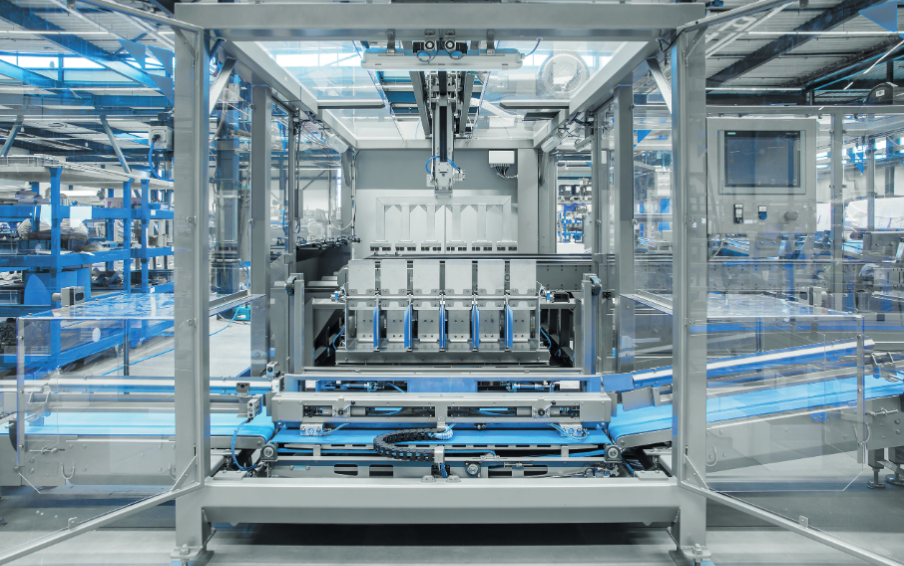

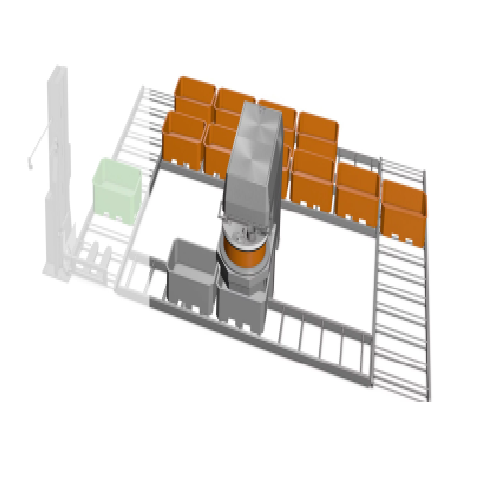

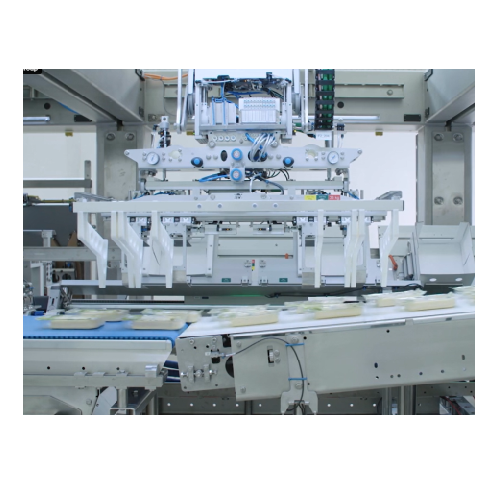

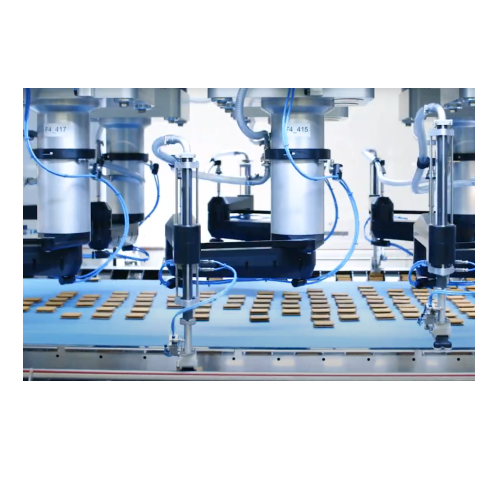

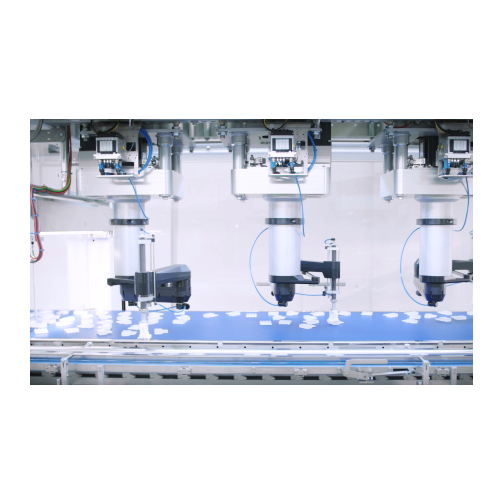

Vision guided robotic pick and place system for bakery settings

For manufacturers tackling high-volume, diverse-sized ba...

Robotic pick and place system for bakery products

Enhance your bakery production line with advanced robotic systems that ...

Infrared baking oven for frozen bakery products

Accelerate your baking process by up to 70% with cutting-edge infrared tec...

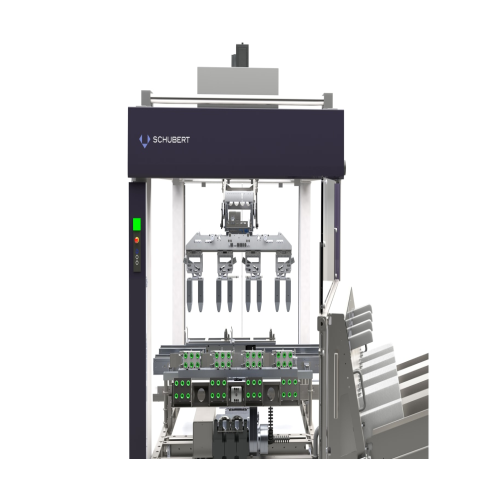

Robotic gripper arm for bakery tray and product handling

Optimize your bakery’s efficiency by automating repetitive...

Industrial lye coating line for bakery products

Streamline your bakery operations with high-speed lye coating technology t...

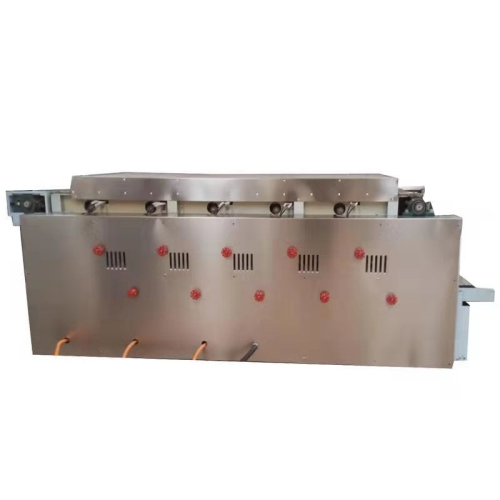

Small batch deep fryer for bakery demonstrations

Achieve consistently low fat absorption and perfect results for small bat...

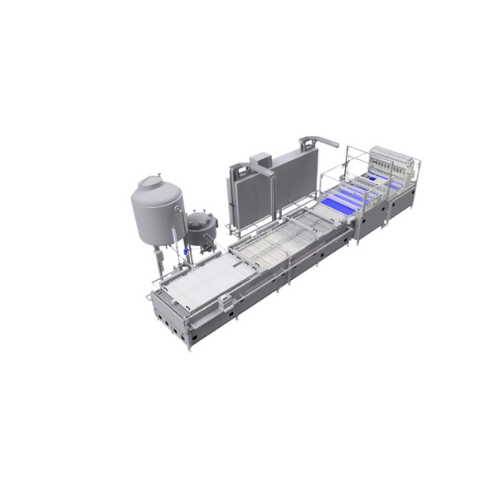

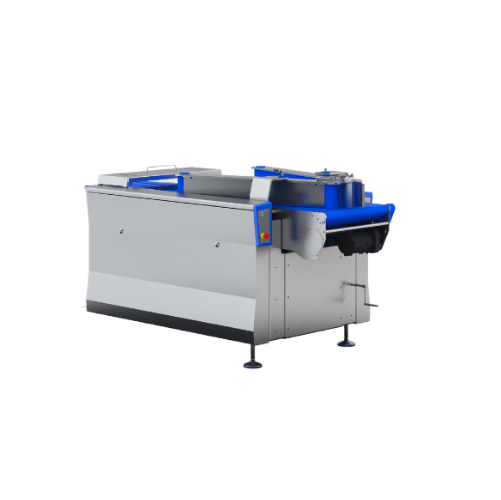

Tray cleaning system for bakery applications

Ensure the highest hygiene standards with a system that efficiently cleans an...

Modular roll line for high-capacity bakery production

Streamline your bakery’s production process with high-speed, ...

Round- and long-moulder for bakery dough production

Achieve precise and consistent bread shaping with a compact solution ...

Three-pocket dough divider for high-output bakery production

Achieve precise dough division effortlessly with this robus...

Multi-deck oven for uniform bakery results

Achieve consistent baking with precision-engineered multi-deck ovens that maste...

Pellet-fired oven for wood-flavored bakery bread

Achieve consistent, flavorful bread with precise temperature control and ...

Automatic tray loading robot for bakery systems

Streamline your bakery’s tray handling by integrating a robotic solu...

Small bakery item baking system

Effortlessly craft artisan-quality bakery items with precision moulding and gentle dough han...

Modular roll baking system for small bakery items

Optimize your bakery production with a modular roll baking system that ...

Bakery refrigeration systems for controlled dough tempering

Achieve consistent bakery quality by precisely controlling y...

Fork mixers for bakery industry

Achieve consistent, high-quality dough mixing with fork mixers designed to enhance tradition...

Planetary mixer for bakery and catering

Streamline your baking operations with a planetary mixer designed for precision mix...

Fixed bowl vertical mixer for bakery and pastry

Optimize dough quality and consistency with a versatile vertical mixer tha...

Vertical mixing solution for bakery and snacking industry

Streamline your dough processing with robust and reliable spir...

Spiral mixers for bakery dough

Transform your bakery production with precise and consistent dough mixing, ensuring every bat...

Industrial dicer for meat and bakery products

Streamline the dicing of meat, bakery items, and snacks with a versatile sol...

Single piston depositors for bakery and food production

Optimize your depositing and filling processes with versatile equ...

High speed pneumatic depositor for bakery applications

When depositing batters, creams, and sauces, achieving consistent ...

Food spraying and flocking system for bakery applications

Enhance your production line with precision spraying and flock...

Multi piston depositors for bakery production

For bakeries seeking precision in depositing and filling, these multi piston...

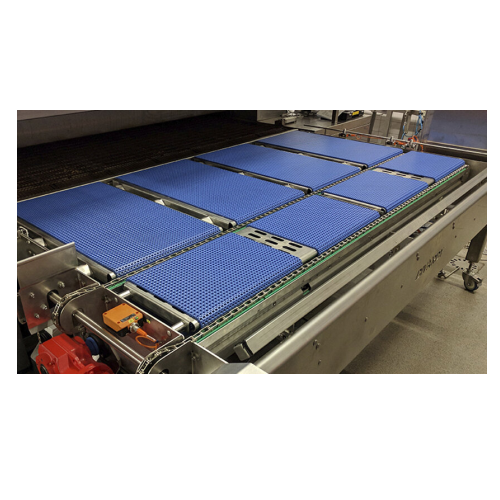

Food and bakery grade conveyors

Achieve consistent product movement and hygiene with our food-grade conveyors, designed to s...

Industrial depositor for large volume bakery products

Achieve precise and high-speed depositing for bakery items with sea...

Pneumatic depositor for bakery batters and fillings

Perfect for high-speed bakeries aiming to enhance efficiency, this se...

Servo multi piston depositor for bakery production

Streamline your bakery production with precise portion control and hig...

Sheetcake icing station for small bakery operations

Streamline your cake finishing process with a compact solution design...

Bakery batter depositor for efficient, consistent depositing

Enhance your bakery production with precision depositing fo...

Portable table top bakery depositor

Optimize your baked goods production with precise portioning and rapid depositing, all ...

Hopper transfer pump for bakery production

Effectively transfer and maintain the integrity of various food products, from ...

Compact bakery depositor for accurate filling

Streamline your bakery production with a compact depositor designed for prec...

Multi piston depositor for automated bakery filling

Optimize your bakery production with precise portioning and filling, ...

Automated syrup sprayer for bakery products

Achieve uniform coating and infusion with precision spraying systems designed ...

Compact bakery depositor for versatile applications

Streamline your bakery production with a high-speed, versatile deposi...

Bakery and food grade conveyor systems

Optimize your bakery and food production with versatile conveyors designed for seaml...

Pneumatic Rp depositor for bakery and food plants

Optimize your production line with a high-speed depositor designed to d...

Industrial food production depositor for bakery applications

Optimize your bakery production with precision depositing a...

Bakery and food grade conveyors

Enhance your bakery and food production with conveyors designed to seamlessly transport and ...

Bakery transfer pump for smooth and chunky products

Ensure consistent product quality with this transfer pump that gently...

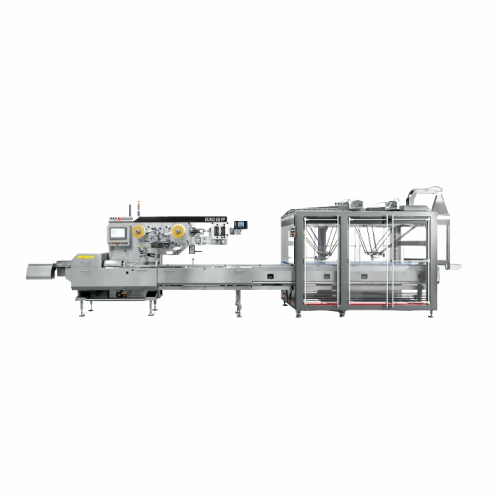

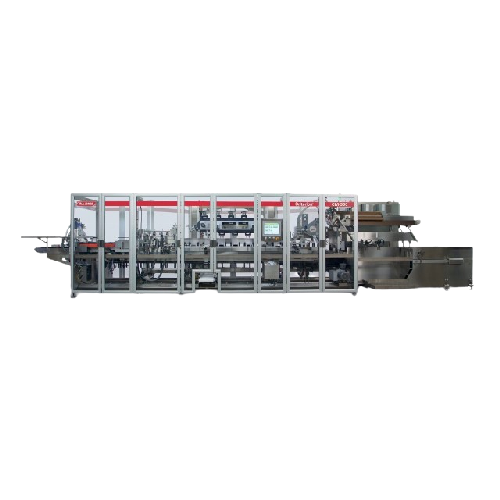

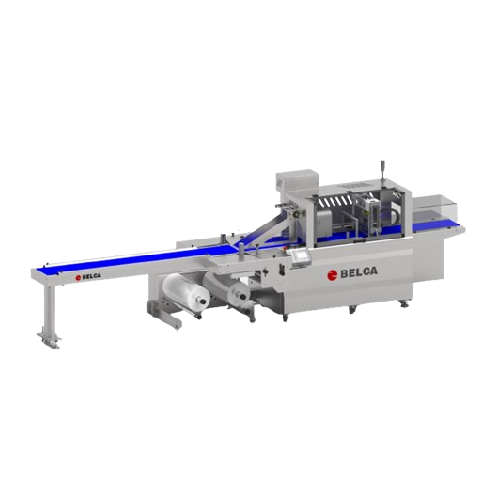

Horizontal flow wrapper for bakery and chocolate

Achieve seamless integration in high-speed production lines with a horizo...

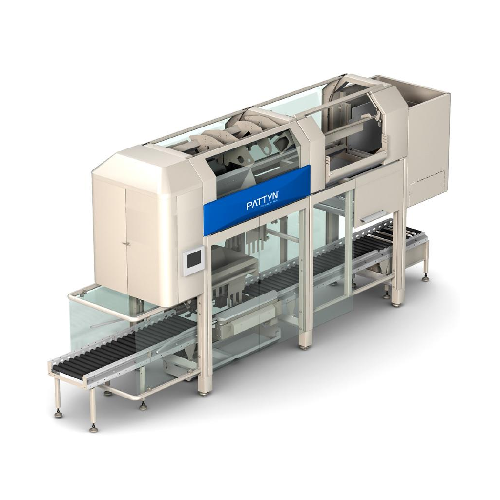

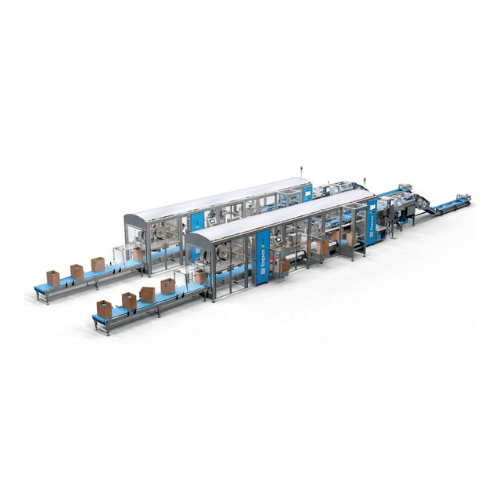

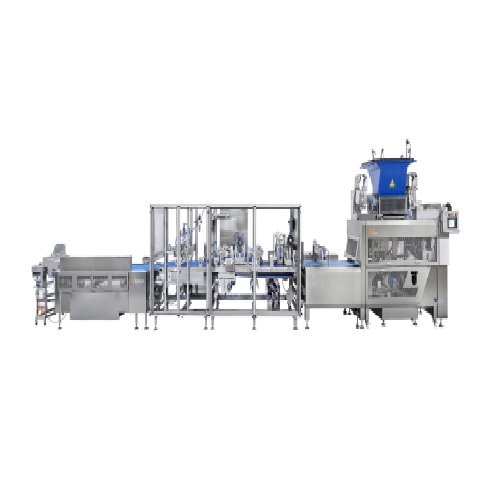

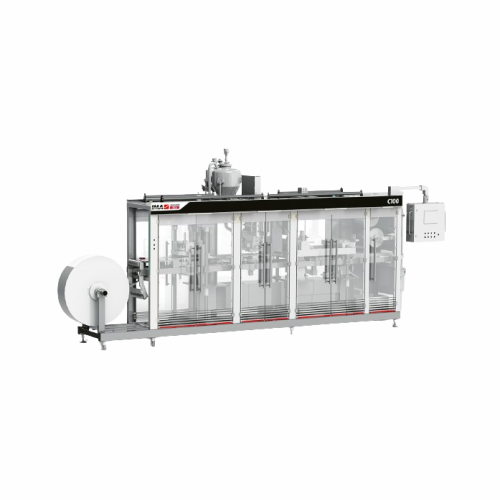

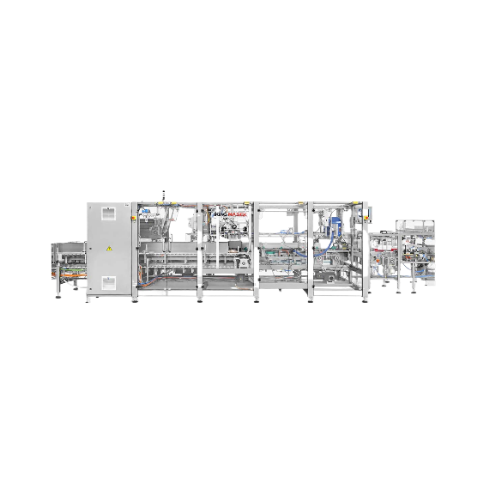

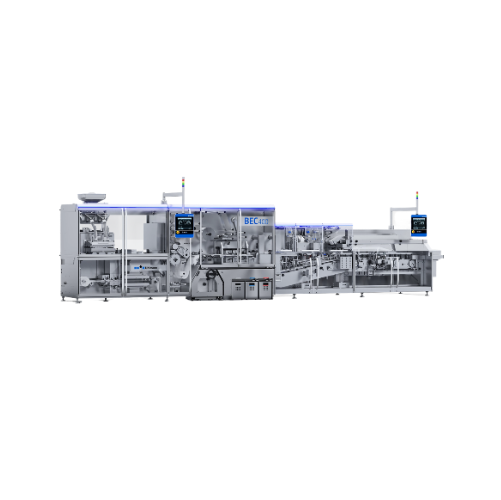

Complete solution for packaging of bakery products

Streamline your bakery’s packaging process with a fully automate...

Commercial bakery equipment for improved baking efficiency

Streamline your baking processes with commercial bakery equip...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Dynamic mixer for bakery and confectionery applications

Enhance product consistency and reduce downtime with this advance...

Static mixer for homogeneous blending of ingredients in bakery and confectionary

Achieve consistent flavor and color i...

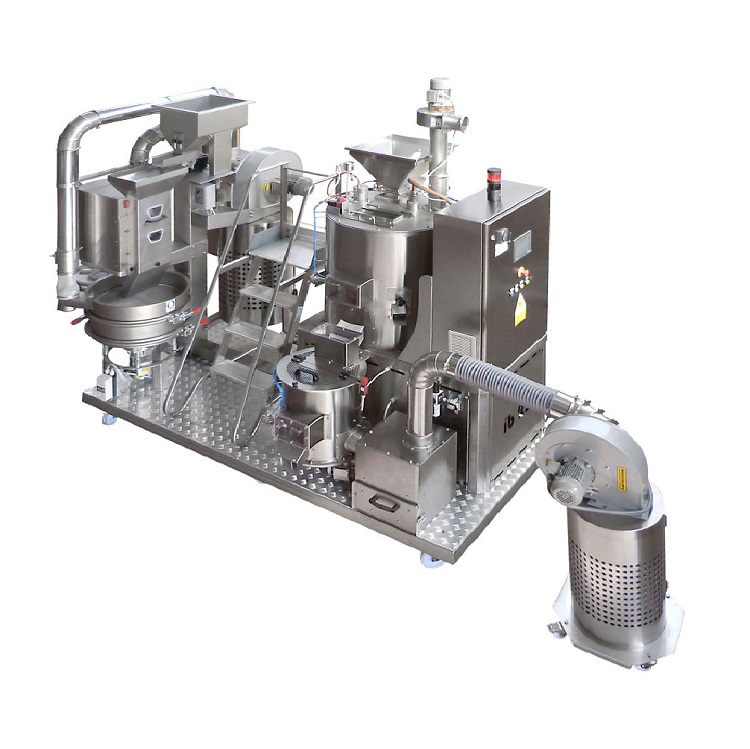

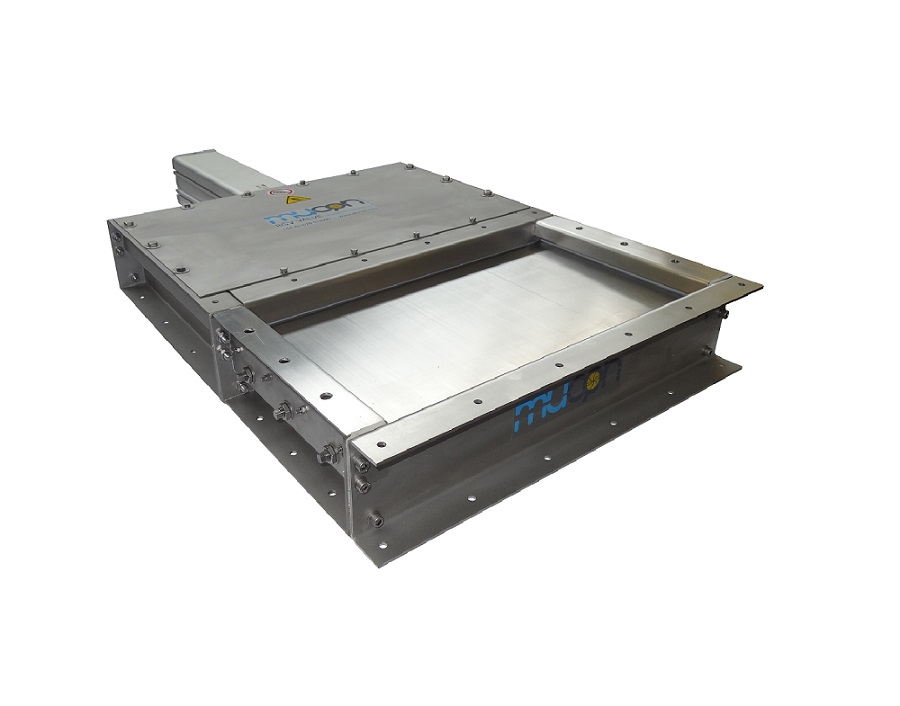

Dry ingredient blending solution for confectionery and bakery products

Achieve seamless integration of dry inclusions i...

Dry and liquid ingredient batch mixer for bakery applications

Achieve homogeneous mixing with precise heat control and e...

Compact continuous aerator for bakery production

Optimize your bakery production with a compact aerator that delivers prec...

Continuous aeration system for bakery products

Optimize your bakery production with precise aeration and mixing, ensuring ...

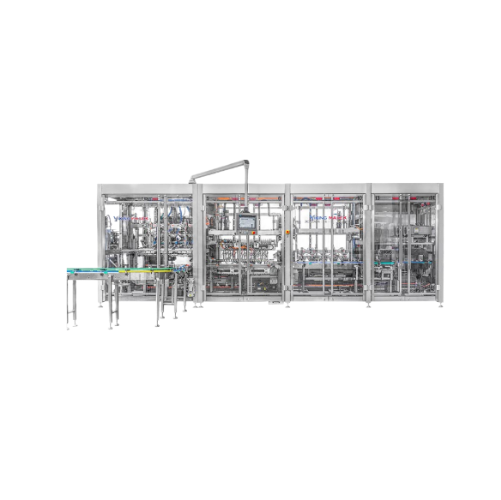

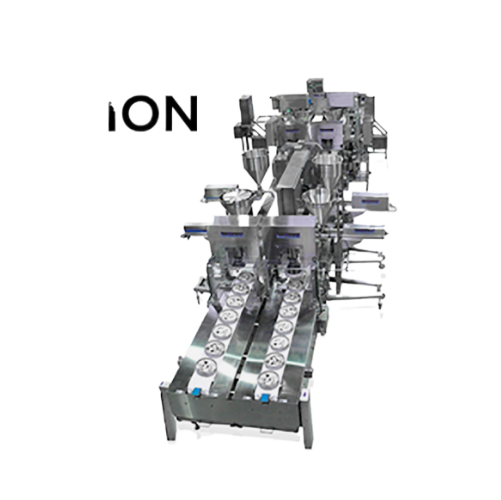

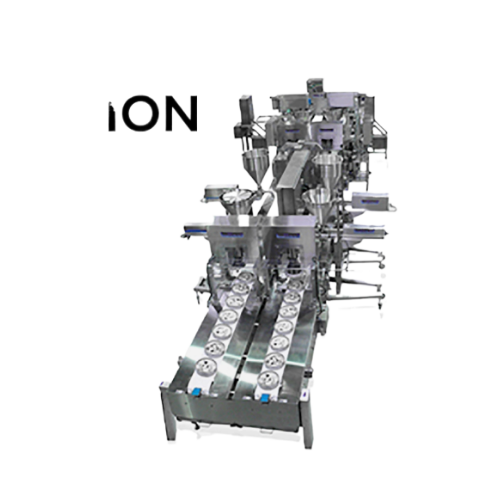

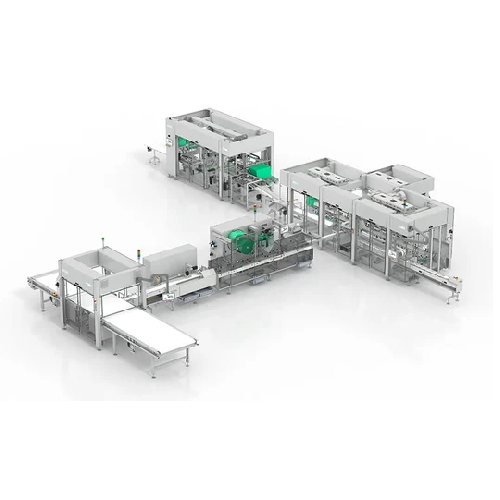

Cupcake production line for automated bakery solutions

Streamline your bakery operations with this comprehensive solution...

Laser-based volume measurement for bakery and solid products

For precision in product quality control, this laser-based ...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Dosing system for bakery and convenience food

Achieve precise dosing and filling of liquids and slurries with this versati...

Dough mixer for high-volume bakery production

Effortlessly handle diverse dough varieties with precision using this mixer,...

Continuous pan cleaner for bakery pans

Efficiently clean and prepare baking pans with precision by leveraging continuous, h...

Bread moulders for bakery production

Efficiently shape various bread types like baguettes and ciabatta, ensuring consistent...

Double sigma arm spiral mixer for bakery applications

Effortlessly tackle high-capacity mixing and kneading with a robust...

Dough chunkers for bakery production

Optimize dough processing by efficiently feeding and dividing dough portions, ensuring...

Dough kibbler for bakery production

Effortlessly transform large batches of dense dough into uniform, manageable pieces wit...

Single sigma arm bakery mixer

Streamline complex mixing tasks with precision using a mixer designed for optimal batch contro...

Pre-dough preparation for bakery products

Streamline your bakery operations with pre-dough preparation, enhancing both dou...

Dough rounders for consistent bakery production

Achieve uniform dough pieces effortlessly with versatile dough rounders, e...

Dough divider for accurate bakery processing

Enhance dough consistency and product uniformity with advanced measurement te...

Cream filling machine for bakery industry

Cream and other fillings in bakery products must be injected in the right volume...

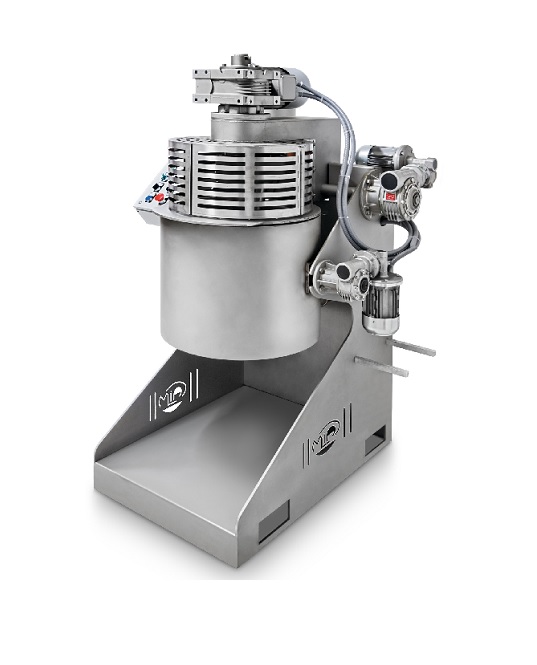

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Mixer for aeration of confectionery and bakery products

Aerated products can be difficult to mix thoroughly without reduc...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

Baguette cutting and sauce filling system

Optimize your bakery production with an innovative system that seamlessly cuts a...

Rotary molder for softdough biscuits and shortbreads

For high output bakeries, achieve precise dough piece formation and ...

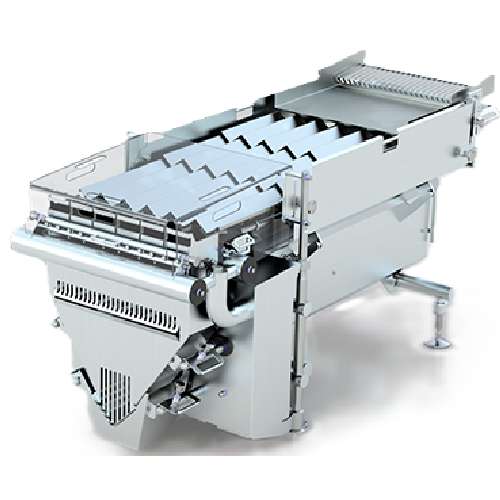

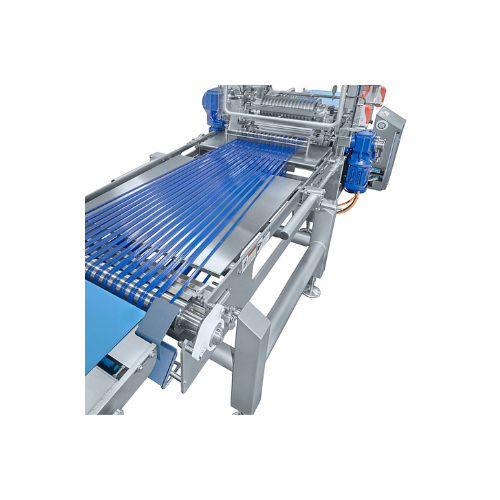

Sheeting lines for biscuit and cracker production

Enhance your bakery production efficiency with advanced sheeting techno...

Cake and pastry depanner

Optimize your bakery’s output with this solution that seamlessly integrates into your production lin...

Layer cake production system

Effortlessly streamline your bakery production with a system designed for precise layering and ...

Lobe depositors and extruders for filled and decorated cookies

Optimize your bakery production with precision depositing...

Rye bread dough depositor

Streamline your bakery production by accurately depositing viscous doughs, tackling sticky and har...

Biscuit sandwiching system

Optimize your biscuit production by seamlessly aligning, overturning, and capping for uniform, hi...

Topping depositor for pizzas and baked goods

Enhance your production line’s efficiency by uniformly adding both dry ...

Volumetric piston depositors for cake and pie fillings

Achieve precise depositing and gentle handling of varied doughs an...

Dough feeding system for biscuits and cookies

Streamline your bakery production with a dough feeding system that efficient...

Industrial pie making systems for high-volume bakeries

Elevate your bakery operations with a versatile solution that seam...

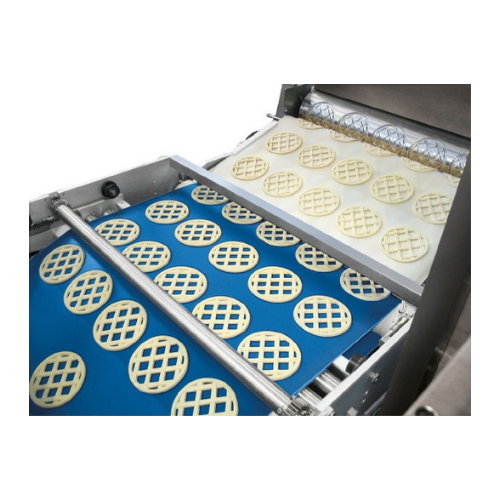

Rotary moulder for pie lids and lattices

Elevate your bakery’s offerings with precise molding and customization for a...

Cakes and pastry side injector

Enhance your bakery production with precision side injection technology that efficiently fill...

Cakes and pastry fill injector

Achieve precise and efficient filling of a variety of bakery products, minimizing waste and d...

Vertical spindle mixer for dough processing

Optimize your dough consistency and quality with this vertical spindle mixer, ...

Cookie dough wirecut machine

Achieve precise control and flexibility in shaping a wide variety of cookies and bars with this...

Rotary moulder for high-definition cookie dough shapes

Efficiently shape intricate dough designs with precision, ensuring...

Precise dough sheet cutting station for bakeries

Efficiently shape and cut dough sheets for diverse snack and bakery produ...

Industrial mixer for various dough types

Efficiently mix a wide range of doughs with precise temperature control to achieve...

Industrial tumble dryer for moisture control in snack production

Ensure precise moisture reduction and optimal air circu...

Instant dough hydration system

Efficiently hydrate dry ingredients instantly with minimal heat increase, streamlining your m...

Servo in-line dough laminator for industrial bakeries

Optimize your snack production with precise dough sheet cutting, st...

Continuous mixer for cookie dough

Achieve consistent dough quality and streamline your production with a continuous mixing ...

Low pressure extruder for pretzel and snack production

Achieve versatile snack production with a low pressure extruder th...

Fried snack extruder for potato rings

Efficiently produce a variety of fried snacks, from potato rings to ethnic noodles, w...

Automated frozen dough production solution

Maximize your frozen dough production with precision control and streamlined ma...

Dough thickness reduction system

Achieve precise dough sheet reduction with controlled thickness to enhance consistency and ...

High pressure extruder for expanded snacks

Enhance your snack production with precise control over texture and shape throu...

Electric oven zones for snack and cookie baking

Optimize your baking line with electric oven zones designed to eliminate e...

Emithermic zone for baking biscuits and cookies

Enhance your baking efficiency and precision with a flexible heat transfer...

Emithermic Xe zone for baking biscuits and crackers

Achieve precise baking and drying for your bakery products with a sys...

Continuous mixer for wheat-based products

Achieve consistent dough quality with minimal variation using a continuous mixer...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Industrial direct drive mixer for dough preparation

Optimize your production line with a robust mixer designed for seamle...

Automated dough handling system for pretzel production

Streamline your dough processing with a system that precisely port...

Vertically feeding system for cookie dough

Optimize your dough handling with a system that ensures seamless and efficient ...

Pie and quiche production line

Optimize your bakery’s capacity with a versatile production line that seamlessly integr...

Croissant production module for pastry make-up lines

Enhance your bakery’s product range with a versatile module de...

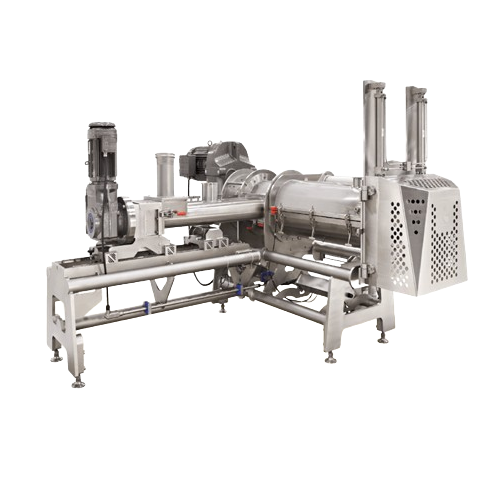

Donut production line for various shapes and sizes

Optimize your bakery’s output with precision-engineered dough pr...

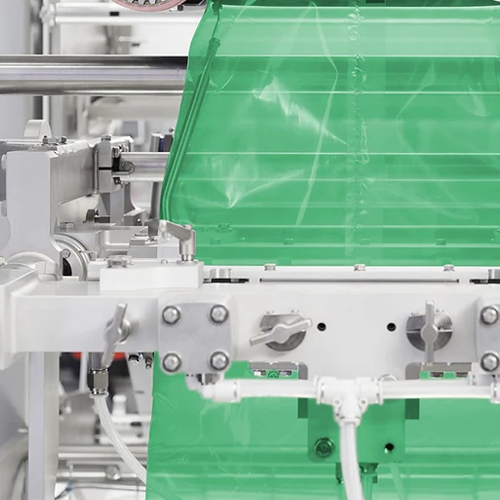

Industrial dough laminator for croissants and pastries

Achieve consistently light and flaky products with precision lamin...

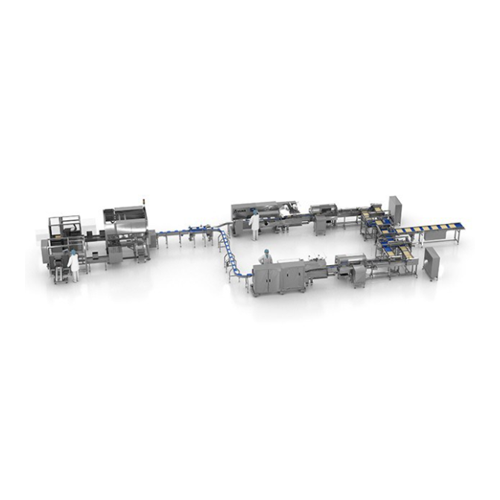

Pastry production line for large-scale bakeries

Streamline your bakery production with a versatile line designed to effici...

Dough laminating equipment for croissants and pastries

Optimize your bakery’s output with our advanced laminating e...

3-roll sheeter for dough forming

Achieve smooth and consistent dough sheeting crucial for high-quality biscuits, cookies, an...

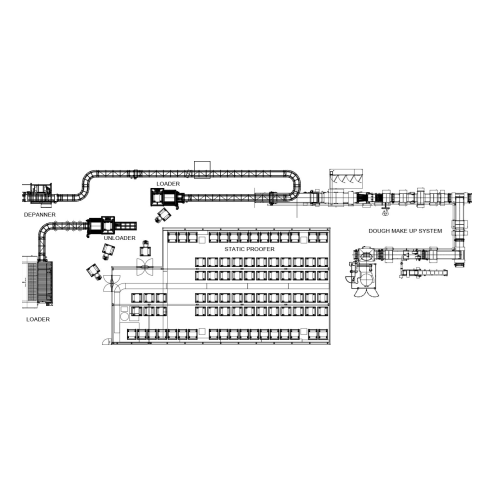

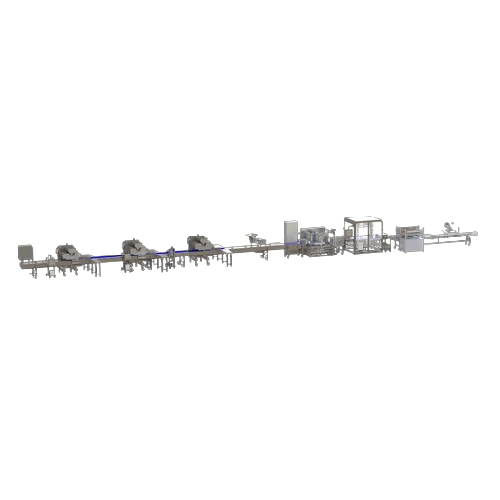

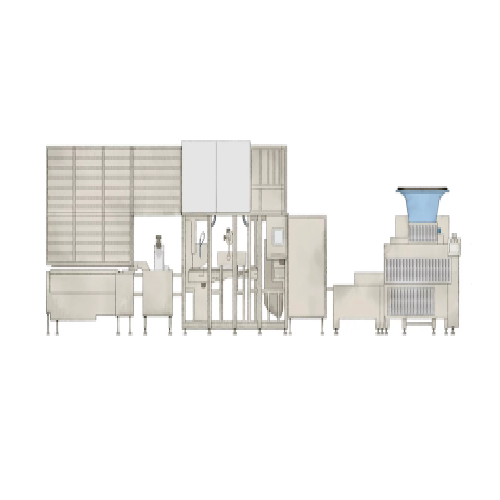

Industrial bread process line

Optimize your bakery operations with a versatile bread processing line, designed to handle a v...

Industrial croissant production line

Streamline your bakery’s operations with a versatile solution capable of produci...

Flatbread sheeting line for consistent dough production

Achieve precision and flexibility in flatbread production with a ...

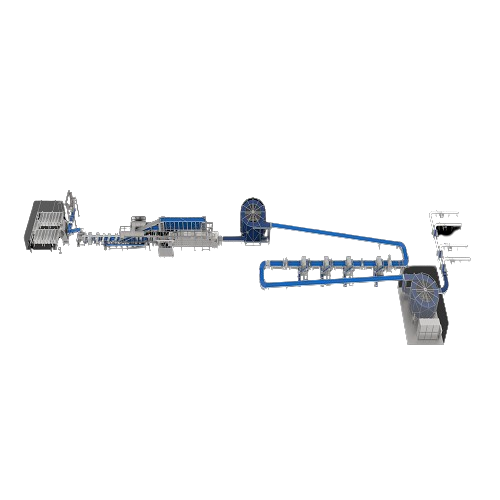

Automated bread production line

Optimize your bakery operations with precision-engineered systems that streamline every stag...

Automatic oven loading and unloading system

Streamline your bakery’s production efficiency with precise and synchron...

Universal pastry production line for industrial baking

Optimize your bakery operations with a versatile line capable of p...

Heating cabinets for chocolate processing

Optimize your confectionery production by maintaining precise temperature contro...

Turbo block flaker for fats

Achieve quick and precise flaking of chocolate, cocoa butter, and fats with high-speed technolog...

Chocolate decoration system for pralines and biscuits

Achieve intricate chocolate patterns and uniform coatings on confec...

Industrial chocolate flaking solution

Optimize your confectionery production with high-speed flaking technology, ensuring p...

Industrial chocolate flakes production equipment for decorative applications

Achieve perfect decorative chocolate curl...

Cooling tunnel for biscuit and chocolate production

Ensure consistent quality control in your confectionery production wi...

Continuous cooler for biscuits and chocolates

Enhance cooling efficiency for your confectionery and bakery production with...

Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities wit...

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Medium duty mixer for breads and pastries

Achieve consistent dough development and uniform mixing for a wide variety of ba...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Slurry mixer for cake batters and premix ingredients

Efficiently mix cake batters and premix ingredients with precision, ...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Continuous mixer for batters and cremes

Achieve consistent texture and uniform cell structure in your cake batters and crèm...

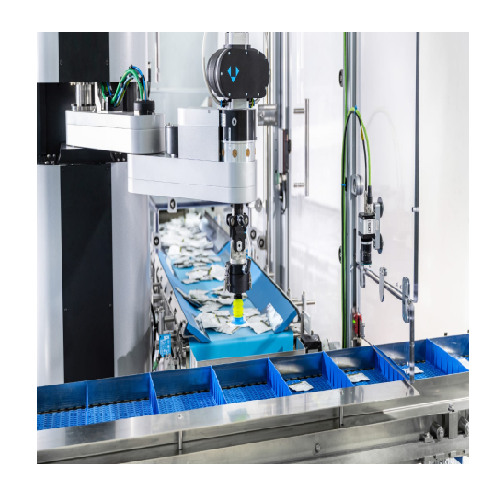

Industrial vision robot for optimized packing

Optimize your bakery production line with a system designed to efficiently p...

Robotic solution for packing frozen bread products

Optimize your frozen bread packing process with high-speed, precise pi...

High-speed baguette case filling station

Effortlessly organize and pack bakery products into cases at high speed, ensuring ...

Vertical form fill seal packaging system

Enhance your packaging line with precision sealing and efficient throughput, ideal...

High-speed camera counting system for accurate product batching

Optimize your production line with a cutting-edge system...

Automated system for placing bags in boxes and crates

Streamline your packaging process with high-speed bag placement tha...

High-speed bag placing system for e-commerce fulfillment centers

Optimize your packaging line with a high-speed system t...

Automated bag sealing for packaging lines

Enhance your packaging efficiency by seamlessly integrating an automated bag sea...

Automated bag folding for packaging

Streamline your packaging operations with a high-speed solution that seamlessly integra...

Automatic bag sealer for varied box sizes

Seamlessly integrate this high-speed bag sealing solution to enhance productivit...

Automatic bag sealing system for packaging operations

Optimize your packaging efficiency with this high-speed sealing sys...

Self-driving transport system for industrial packaging

Streamline internal logistics with a self-navigating vehicle desig...

Compact palletizing solution for limited space

Optimize your space with versatile palletizing that adapts to diverse produ...

Automated paper bag placing system

Efficiently automate the placement of paper bags into totes or boxes with precision and ...

Camera quality control for industrial production

Ensure flawless product quality by integrating a precision optical inspec...

Automatic box loader for fragile products

Ensure precise and gentle handling of delicate bakery goods with a compact case ...

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Compact sealing system for bags and boxes

Achieve seamless, high-speed packaging with a compact solution designed to handl...

Case erecting and bag placing system

Streamline your packaging process with a compact system that integrates case erecting ...

Bag folding solution for high-speed packaging

Effortlessly enhance your packaging line efficiency with this high-speed bag...

Manual bag placing solution for various materials

Increase your efficiency in manual bag placing with an ergonomic soluti...

Automated bag placing solution for industrial packaging

Maximize efficiency with a versatile bag placing system designed ...

Flexible pastry production line

Maximize your bakery’s output with a versatile pastry line that handles everything fro...

Pastry depositor for versatile product shapes

Enhance your bakery’s production with a versatile depositor that effor...

Depositing system for fixed deposited biscuits

Optimize your bakery production with a versatile depositing system designed...

Industrial muffin production line

Maximize your bakery’s efficiency with a high-performance line engineered for preci...

Rotary moulder for shortbread and pie crust production

Achieve precise molding of diverse baked goods with high-speed eff...

Industrial cream doser for pastry applications

Efficiently dose and fill a variety of bakery and confectionery mixtures wi...

Whipping agent solution station for egg solutions

Optimize your production of delicate egg-based foams with a versatile s...

Continuous cooking unit with vacuum for candy production

Achieve precise caramelization and cooking with enhanced flavor ...

Fat melting tank for confectionery production

Melt solid fat blocks efficiently to streamline your caramel, nougat, and ch...

Invert sugar and glucose storage tank

Optimize your sweet and confectionery production by efficiently storing and resting g...

Pressurized buffer tank for aerated products storage

Ensure consistent aeration and product quality with this pressurized...

Dough divider for high water absorption and fermented dough

Achieve uniform dough consistency and precise shaping with a...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Cup filling system for jars and buckets

Optimize your confectionery and bakery filling processes with this high-speed cup f...

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Chocolate tempering solution for industrial production

Achieve consistent chocolate crystallization with a machine that e...

Continuous chocolate mill

Enhance the texture and quality of your chocolate products with this high-speed milling solution, ...

Industrial sugar powder mill

Achieve precise sugar granulation with a high-speed mill designed for continuous production, en...

Steam pipe oven for industrial bakeries

Achieve consistent baking results with efficient heat distribution and steam genera...

Compact tunnel oven for continuous baking

Elevate your culinary production with a tunnel oven designed for precise, contin...

Electrical deck oven for high-efficiency industrial baking

Achieve precise temperature control and energy efficiency in ...

Chocolate cooling tunnel

Enhance your confectionery production with efficient cooling and precise crystallization, critical f...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

Chocolate ball mill for processing chocolate mass

Enhance your confectionery production with precision mixing and uniform...

Industrial chocolate and dough sheeter

Streamline your chocolate and pastry production with robust dough sheeting and rolli...

Conical dough rounder for bakeries

Achieve consistent dough rounding with precision and efficiency, enhancing your bakery’s...

Dough proofing solution for stress-free fermented dough

Ensure stress-free dough handling and optimal fermentation before...

Removable bowl system mixer for dough preparation

Optimize your bakery production with this advanced mixer featuring a re...

Fixed bowl spiral mixer for dough preparation

Ideal for perfecting dough consistency, this spiral mixer offers two-speed o...

Rotary rack oven for bakeries

Efficiently handle diverse baking needs with precise temperature and steam control, ensuring c...

Combinex for baking high-quality breads and pastries

Optimize your bakery or confectionery production with precise temper...

Industrial bread cutter for loaves up to 500 mm

Optimize your bakery’s slicing precision with technology designed to...

Flake ice weighing and batching system for dough processing

Optimize your dough’s freshness and consistency with p...

Automatic box and crate labeler

Achieve precise, high-speed labeling and weighing for various packaging needs, ensuring cons...

Automatic label applicator for food packaging

Enhance your packaging line with precise, high-speed labeling, ensuring your...

Industrial product rework system

Efficiently rework products while minimizing waste with a robust system designed for precis...

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

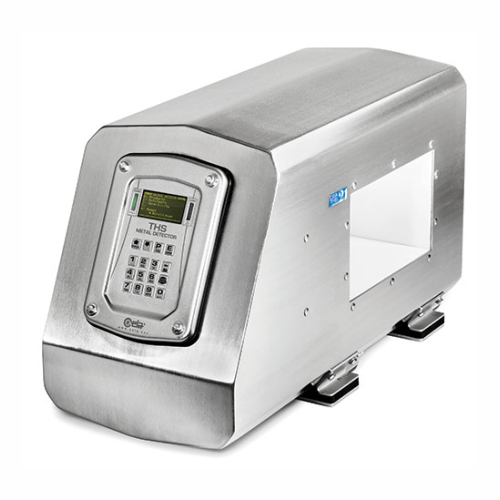

Metal detector for conveyorized applications

Enhance your production line by ensuring product safety with advanced metal d...

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Cryogenic freezer for food processing

Achieve rapid, precise freezing for your diverse food production needs, ensuring qual...

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Cryogenic cooling system for meat mixing

Efficiently manage heat during meat mixing to enhance product quality and ensure s...

Cryogenic chilling systems for bulk food processing

Maintain optimal temperatures during high-volume food processing with...

Cryogenic food freezer

Achieve rapid and precise freezing for diverse food products, ensuring optimal texture and moisture re...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Cryogenic chilling systems for food processing

Efficiently maintain precise temperatures to enhance product quality and sa...

Cryogenic chilling for food processing

Optimize your food production line with cutting-edge cryogenic chilling solutions, d...

Cryogenic chilling for meat mixing and blending

Ensure precise temperature control during mixing and blending to prevent b...

Entry-level food packaging machine for pillow bags

Achieve space-saving packaging versatility with a machine designed for...

Industrial freezing tunnel for food products

Achieve rapid and precise freezing of diverse food products while maintaining...

Stiffening system for meat products

Achieve uniform cooling and extend the shelf life of various food products with precisi...

Industrial thawing systems for meat products

Optimize your food production line with advanced thawing systems designed to ...

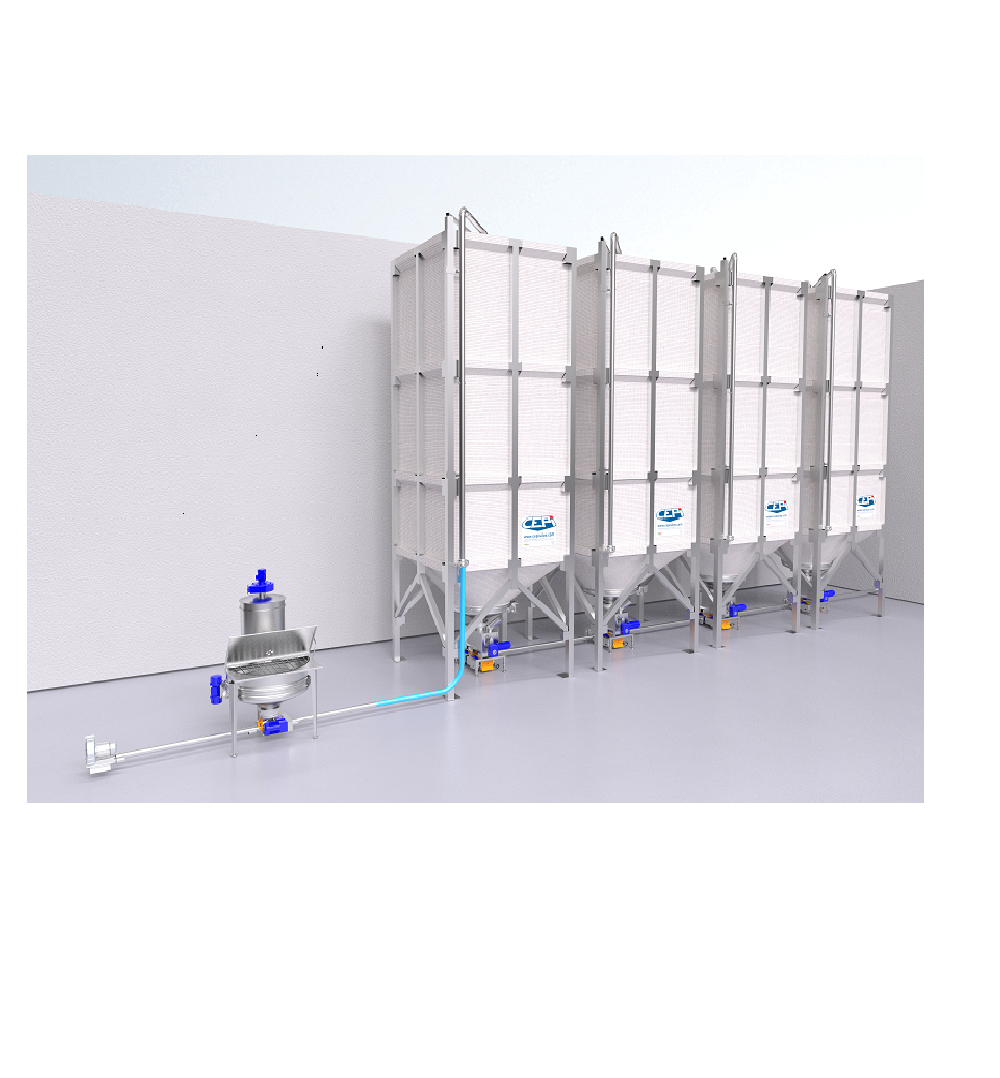

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Manual Cip system for food processing hygiene

Designed for small-scale hygiene needs, this mobile clean-in-place system en...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

Flow wrapper for biscuits in stacks

Optimize your biscuit packaging with a flow wrapper designed to efficiently portion and...

Automatic portion volumetric feeder for biscuits and crackers

Streamline your biscuit and cracker packaging process with...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

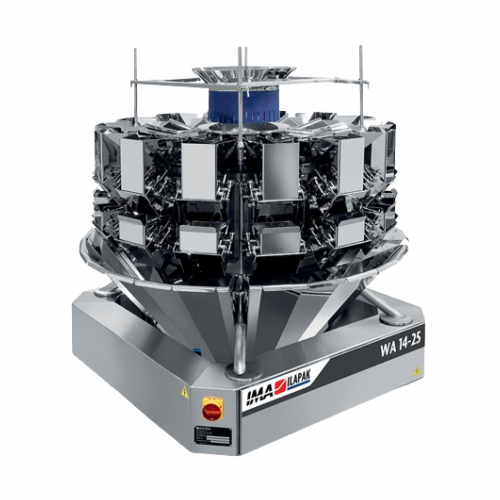

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

High-speed multi-head weigher for confectionery products

Achieve precise measurements and minimize waste in high-speed fo...

Automatic wafer batter preparation system

Optimize wafer production with precision dosing and homogeneous mixing, ensuring...

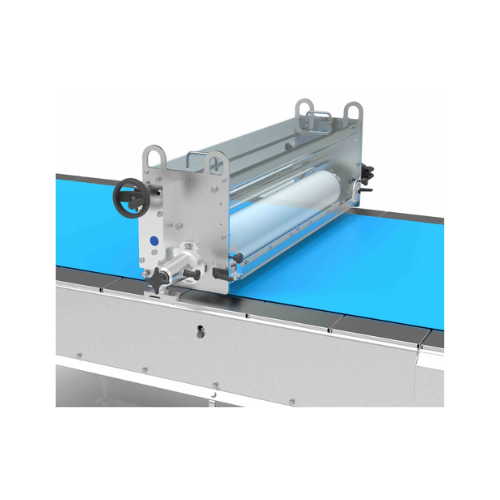

Wafer sheet cream application system

Achieve precision in cream application with high-capacity, continuous film spreading, ...

Automatic wafer baking machine for high-capacity production

Streamline your wafer and snack production with a high-speed...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Sheeting solution for tortillas and chips

Achieve precision sheeting of tortilla chips and taco shells with robust technol...

Multi-purpose oven for prepared foods

Ensure consistent cooking precision with this multi-purpose oven, designed to optimiz...

Industrial bagel boiling system

Ensure consistent bagel quality with high-capacity boiling, coupled with continuous water fi...

Continuous dough dividing and portioning system

Achieve precise dough portions and enhance product quality with high-speed...

Cutting unit for high-yield tin loaves

Experience precision and efficiency in dough portioning with our high-capacity cutti...

High-precision depositing system for fluid and viscous fillings

Achieve precise and efficient dosing for diverse food pr...

Continuous band blade decrusting slicer for bread

Achieve precise decrusting and slicing of various bread loaves with con...

Reciprocating blade slicer for high-speed cutting

Ensure precise, high-speed slicing of bakery products with an industria...

Reciprocating blades slicer for bread

Achieve precise, adjustable slicing for various bread types at medium speeds, enhanci...

High-speed industrial bread slicer

Optimize your bakery’s throughput with a continuous slicing solution designed to h...

Dough divider for industrial baking processes

Optimize your bakery production with precise dough dividing, delivering cons...

Bread moulder for consistent dough shaping

Ensure uniform dough shaping and enhance bread quality with precision moulding,...

Bread dough rounder for consistent shaping

Achieve uniform dough shaping and enhance product consistency for high-speed ba...

Automatic bag closing with metallic clipband

Ensure secure and efficient bag sealing for bakery products at high speeds wi...

Continuous mechanical clipband closing system for bags

Streamline your bakery packaging process with a high-speed clipban...

Continuous flow-wrapping system for high productivity

Optimize your packing line with a high-speed flow-wrapping system d...

Automatic packaging system for preformed bags

Enhance your bakery’s efficiency with advanced preformed bag packaging...

Industrial reciprocating blade slicer for high-speed slicing

Enhance your bakery production line with high-speed slicing...

Pneumatic knife for forming and cutting pasty products

Achieve precision and speed in forming and cutting various pasty p...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Planetary mixer with double tool for pastry dough

Optimize your pastry production with precise mixing capabilities that e...

Automatic mixing and bowl handling system

Enhance your mixing operations with a fully automatic system that streamlines do...

Double jacketed mixer for dough cooling

Achieve consistent dough quality and superior gluten development with precise tempe...

Industrial bowl lifter-tipper

Streamline your bakery production with a solution that simplifies dough handling by seamlessly...

Spiral mixers with bottom discharge system

Ensure consistent dough quality while optimizing space and efficiency with a mi...

Industrial spiral mixer with bottom discharge system

Enhance dough quality and streamline operations with a dual-tool mix...

Rotating cabinet for homogeneous cryogenic cooling

Achieve uniform and efficient cooling or freezing for diverse food pro...

Premium industrial mixer for dough production

Enhance dough production efficiency with a mixer that reduces kneading times...

Thermally controlled pre-dough system

Achieve consistent flavor profiles in bakery products with a system designed for prec...

Rye sourdough production system

Achieve consistent, high-quality rye and wheat sourdough production with a versatile system ...

Sourdough fermentation unit for rye pre-doughs

Optimize your sourdough production with this compact unit, enabling precise...

Wheat and spelt predough production system

Optimize your bakery production with a flexible and mobile compact system desig...

Wheat and spelt pre-dough system

Optimize your bakery production with a flexible system designed for rapid, lump-free mixing...

Planetary stirrer for creamy and foamy masses

Achieve consistent texture and optimal air incorporation in your products wi...

Biscuit depositing system for two-color biscuits

Enhance your bakery line’s efficiency with a high-speed depositing ...

Horizontal flow pack packaging solution

Achieve seamless packaging with versatile flow pack machines, designed to efficient...

Flow pack packaging solution for flexible wrapping material

Optimize your packaging line with this compact flow pack sol...

Horizontal flow pack packaging system for flexible materials

Enhance your packaging line efficiency with a system design...

Biscuit depositing system

Optimize your biscuit production with a high-speed depositing system designed for continuous opera...

Dual-purpose biscuit and jam depositing system

Enhance your production line with a versatile solution that seamlessly depo...

Horizontal packaging system for high-speed operations

Achieve unmatched sealing precision and packaging speed with this h...

Flow pack packaging for irregularly shaped products

Achieve precise packaging for irregularly shaped and delicate items w...

Horizontal flow-pack solution for flexible wrapping material

Simplify your packaging process with a high-speed, three-si...

Planetary cooker for medium-high density mixtures

Achieve smooth, consistent textures with a planetary cooker designed fo...

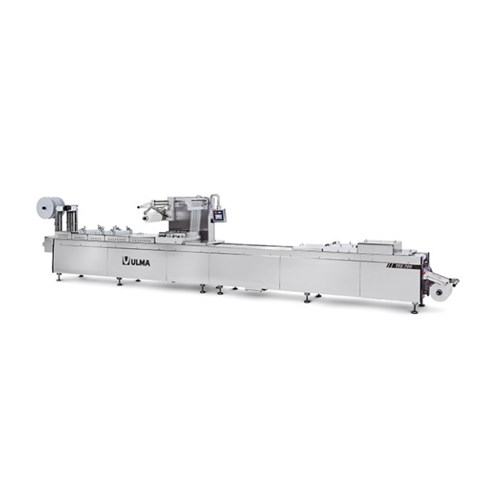

Automated modified atmosphere packaging solution for pre-wrapped trays

Streamline your packaging process with high-spee...

Food counting system for hygienic applications

For food processors needing precise quantity control, this counting system ...

Pallet lift for food processing handling

Enhance your food processing efficiency with a robust pallet lift designed for sea...

Cleaning-in-place system for oils and fats

Streamline your production line by efficiently cleaning oils and fats processin...

Process tanks for oils and fats

Optimize your oil and fat processing with versatile tanks designed for precise emulsificatio...

Scraped surface heat exchanger for oils and fats

Achieve precise crystallization and streamline the production of margarin...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

Industrial sandwich pancake system

Streamline your production with a machine that seamlessly integrates baking, filling, pr...

Enrober for complete dry topping coverage on dough pieces

Ensure consistent, high-speed enrobing of dry toppings on doug...

Smart shaker for dough centering

Achieve perfect dough centering and uniformity with an innovative three-motion shaker that ...

Transversal cutting for confectionery production

Achieve precise and customizable cuts in high-speed confectionery and bak...

Sprinkling unit for confectionery and baked goods

Achieve precise and uniform toppings on baked goods with versatile and ...

Industrial sieving solution for powders and granulates

Ensure top sanitation and food safety in your production line with...

Vibration sprinkler for uniform dough decoration

Elevate your baked goods with precise, uniform decoration using a vibrati...

Hydration solutions for baked goods

Achieve consistent dough quality faster with a system that precisely hydrates and mixes...

Cut-sheet laminator for cracker and biscuit production

Achieve precise dough lamination for consistent quality in cracker...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

High-speed mixer for dough production

Achieve consistent dough quality and streamline your production process with this ver...

Baking oven for molded cones and cups

Effortlessly increase production efficiency with a high-capacity baking oven that del...

Automatic waffle baking oven

Enhance your wafer production with a high-capacity baking oven designed for versatile and effic...

Automatic wafer baking oven

Achieve uniform wafer sheet quality and optimize throughput with this high-speed baking solution...

Chocolate enrober for bars, cookies, and wafers

Ensure consistent and high-quality enrobing for confections with advanced ...

Advanced enrobing line for confectionery

For confectionery producers seeking seamless chocolate coating versatility, our en...

Continuous dough extruder for baked goods

Achieve optimal dough consistency and reduce production time by integrating cont...

Weighing and receiving container for floury products

Achieve precise and consistent ingredient proportions with this syst...

Bagging control system for centralized operations

Streamline your bagging operations with a centralized control system, d...

Gluten-free flour mixing solution

Ensure consistent dough quality and precise analysis in gluten-free production with a rob...

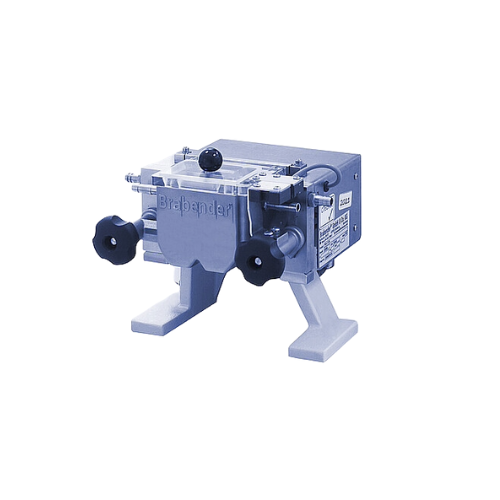

Flour and dough analyzer

Enhance your dough and flour testing with precise rheological analysis, ensuring optimal water absor...

Measuring mixer for flour and dough analysis

Optimize your dough consistency and quality with precise mixing and kneading ...

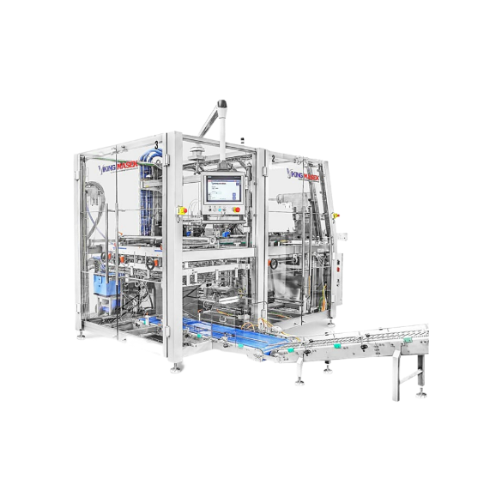

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Case packing system for bags and cases

Streamline your secondary packaging process with a compact, fully integrated system ...

Vision guided robotics case packer

Maximize efficiency with vision-guided robotics for versatile case and tray loading, red...

Vertical packing pattern case packer

Optimize your packaging efficiency with this high-speed case packer designed for seaml...

Wrap around case packer for horizontal and vertical packing patterns

Optimize your palletizing and distribution with a ...

High-speed case packer for snack bags

Optimize your packaging efficiency with a compact solution designed for seamless vert...

Automated retail ready case closer

Optimize your retail packaging process with a solution that seamlessly seals and closes ...

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

Semi-auto case packer for flexible bag collation

Enhance your manual packing speed and flexibility with a semi-automatic s...

Flexible bag case packer with integrated case erector

Streamline your secondary packaging process with an efficient solut...

High-speed vertical and horizontal case packer

Enhance your packaging line efficiency with a versatile case packing soluti...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

Horizontal case packing and tray loading

Enhance your packaging line efficiency with a highly adaptive system that seamless...

Tray erecting system for various tray styles

Effortlessly configure diverse tray styles with an efficient system designed ...

Automatic case forming and sealing solution

Streamline your end-of-line packaging with a solution that forms, folds, and s...

Retail ready packaging system for easy store stocking

Simplify shelf stocking with a sturdily designed packaging system t...

Release agent sprayer for baking trays and moulds

Achieve perfect results in baking by ensuring efficient and uniform gre...

Rotating greaser for baking moulds and trays

Achieve precise greasing with minimal overspray for all your baking moulds an...

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Ultrasonic slicer for cakes and pastries

Achieve precision cuts and superior presentation with this ultrasonic slicer, desi...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Production line for round and square cakes

Streamline your bakery operations with a modular cake production line designed ...

High-volume spraying system for glazes and marmelades

Streamline your glazing process with a system designed to minimize ...

Table top depositor for semi-liquid and solid products

Streamline your bakery operations with a compact solution engineer...

Drizzler for precise food decoration

Transform ordinary dishes into visually stunning creations with a precise drizzling sy...

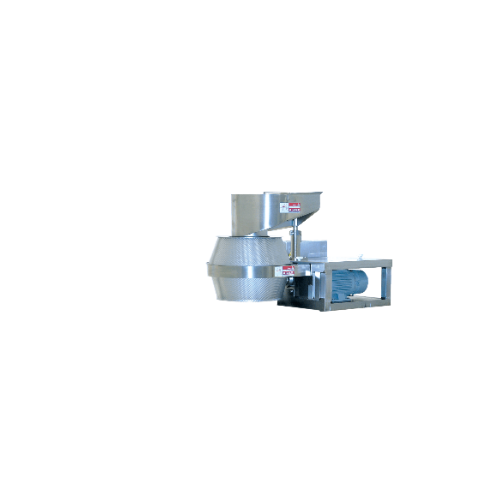

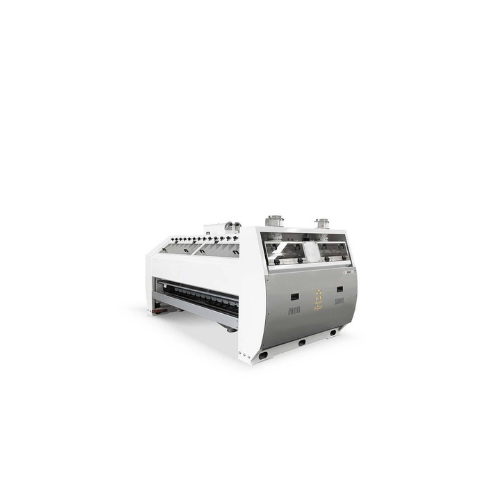

3-roll extruder for heavy dough products

Streamline dough processing for consistent, high-quality confections and baked goo...

Cake batter depositing line

Streamline your production with precise batter depositing and greasing, minimizing waste and opt...

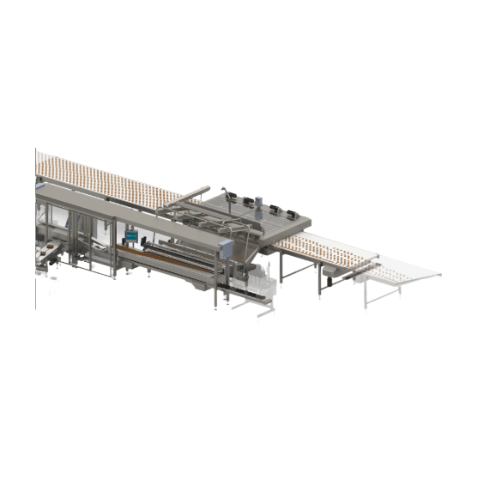

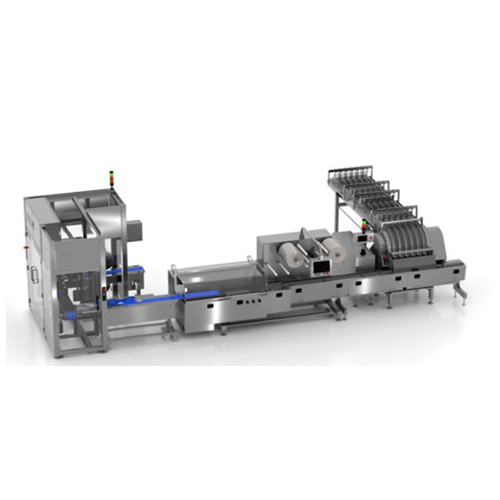

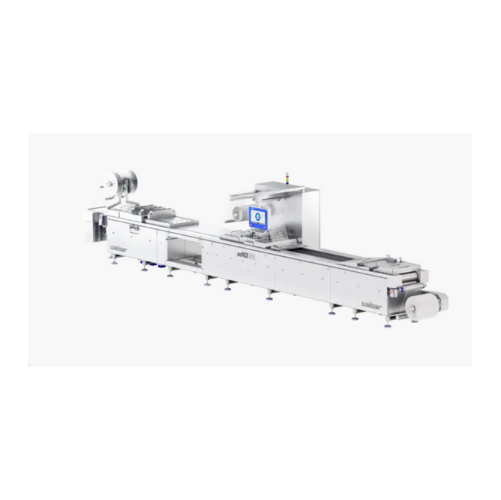

Full production line with depositing and ultrasonic cutting

Streamline your baked goods and dessert production with this...

Water mixing and dosing unit for dough production

Achieve precise dough temperature control effortlessly, ensuring consis...

Tank for jelly and liquid preparations

Optimize your food processing line with a versatile solution that efficiently blends...

Icebox cookies extrusion solution

Streamline your cookie production with a solution that efficiently extrudes, shapes, refr...

Spring roll and samosa pastry sheet production line

Effortlessly streamline your pastry production with this solution, de...

Automatic stamping and aligning system for mooncakes

Elevate your snack production with precision stamping and aligning, ...

Automatic filming and pressing solution for dough products

Streamline your dough processing with this pressing and filmi...

Pita bread production system

Streamline flatbread production by reducing dough resting time with a layered resting conveyor ...

Automatic horizontal cake slicer

Achieve uniform, precise slices with double-blade vibration technology, ensuring each cake ...

Customized puff pastry production line

Streamline your pastry production process with this customizable solution, capable o...

Industrial dough mixer for high capacity food production

Enhance dough consistency and texture with a high-speed industri...

Automatic aligning solution for maamoul and moon cake production

Enhance your production efficiency with a microcomputer...

Pressing and heating system for dough products

Achieve precise control over dough thickness and texture with a semi-automa...

Automatic aligning and rack loading solution for xiao long bao production

Improve efficiency in food production by sea...

Automatic bagel making system

Streamline your bakery production by transforming dough into perfect bagels efficiently, allow...

English muffin production system

Maximize your bakery’s output with our high-speed system designed to efficiently produce co...

Soft bread production system

Optimize your bakery operations by integrating a high-speed system for producing a wide variety...

High-speed bun and roll production system

Optimize your bakery’s output with this high-speed system designed to stre...

Energy-efficient oven monitoring system for bakeries

Optimize your baking operations with a smart oven system that enhanc...

Automated bread and soft roll production system

Streamline your bread and bun production with a system that ensures precis...

Artisan bread production line for high-volume bakeries

Optimize your artisan bakery operations with a production line tha...

High-speed baguette production system

Achieve seamless, high-speed production of artisan baguettes with minimal downtime an...

Swirl bread production system for commercial bakeries

Elevate your bakery’s output with high-speed, efficient produ...

Muffin and cake production line

Enhance your bakery production with a line that meticulously controls every stage, from mixi...

Pie production line for sweet and savory pies

Optimize your pie production efficiency with this integrated system, designe...

Advanced croissant production line

Streamline your bakery operations with a high-speed croissant production line, integrati...

Danish and puff pastry production line

Enhance your pastry production with this integrated solution, designed to optimize t...

Automated sheeting and laminating solution for filled snack bread production

Enhance your bakery line’s efficien...

Pressed pan pizza production system

Elevate your pizza production with a system that enhances flexibility and consistency, ...

Sheeted pizza and flatbread production system

Achieve seamless integration and high-volume production of diverse baked goo...

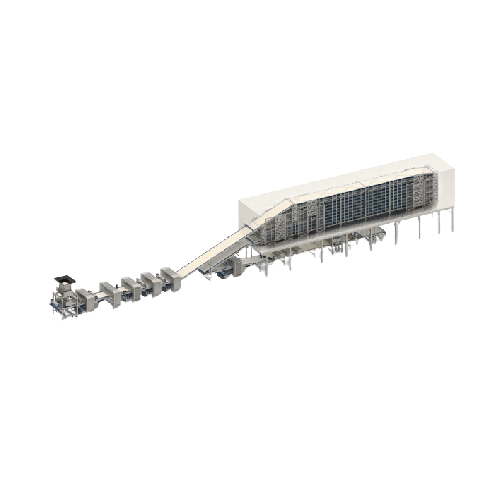

Continuous proofer and oven systems for commercial bakeries

Enhance product consistency and throughput in your bakery op...

Industrial tunnel oven for baking and step proofing

Optimize your production line with modular tunnel ovens and step proo...

Precision dough dividing equipment for bread production

Achieve unmatched precision and speed in your bakery operations w...

Open frame mixer for industrial dough mixing

Streamline your bakery’s mixing process with precision control and enha...

Industrial sheeting and laminating systems for baked goods

Elevate your bakery’s production line with cutting-edge...

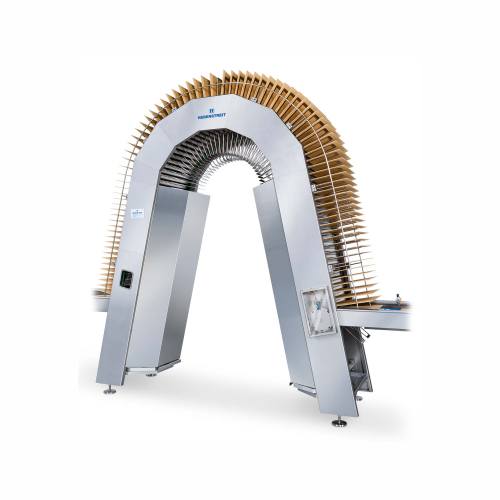

Spiral cooler for industrial baking

Enhance your bakery’s efficiency and product quality with modular cooling solutio...

Ai solutions for pizza production in bakeries

Bring unparalleled precision and efficiency to your bakery with intelligent ...

Industrial cake cutter for round and rectangular cakes

Streamline your cake processing line with high-speed precision cut...

Industrial dough mixing system for bakeries

Enhance your bakery’s efficiency with a system that ensures precise doug...

Chocolate production belt line

Optimize your chocolate and bakery production with a versatile belt line designed for continu...

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

Lab-scale chocolate chip depositor

Enhance your R&D capabilities with precision depositing of chocolate masses, allowi...

Chocolate quality analysis instrument

Ensure the highest quality of your chocolate production by precisely measuring contra...

Laboratory cold-press chocolate shell maker

Enhance your R&D capabilities with a solution that enables precise cold-p...

Advanced chocolate tempering system

Achieve flawless chocolate and confectionery products with precision tempering, ensurin...

Crystallization and aeration unit for fat-based center masses

Efficiently manage the crystallization and aeration of fat...

Energy efficient chocolate tempering solution

Enhance your chocolate products with precise temperature control, reducing e...

Bottom enrober for chocolate and confectionery products

Optimize your production line with precise bottom enrobing, ensur...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Flexible depositor and extruder for small-scale production

Achieve precise multi-mass creations with a compact, versatil...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

High precision depositor for confectionery production

Achieve precision and versatility in your confectionery production ...

Small scale chocolate enrober

Ideal for creative small-scale producers, this enrober allows you to experiment with chocolate...

Energy efficient enrober for chocolate coating

Enhance your production with energy-efficient enrobing that ensures precise...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Industrial chocolate enrober

Achieve exceptional chocolate coating consistency and efficiency with this advanced enrobing te...

Conveyor system for chocolate production lines

Streamline your production flow with this conveyor system, ensuring efficie...

Cooling unit for chocolate mass extrusion

Optimize your chocolate production by precisely cooling chocolate masses during ...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Rotating stencil depositor for confectionery products

Streamline your confectionery operations by precisely depositing in...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

High-speed dough depositor and extruder

Streamline your high-speed dough processing with precise dosing and gentle handling...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Wafer and biscuit feeder for chocolate moulding

Efficiently integrate wafers and biscuits into your chocolate production l...

Chocolate quality measuring instrument

Ensure consistent chocolate quality by accurately measuring contraction, expansion, ...

Compact digital bench weighing scale for food processing

Ensure precise portioning with this compact and durable digital ...

Bi-directional frame scale for industrial weighing

Achieve precise product accumulation and streamlined batch processing ...

Semi-automatic tray sealing solution

Streamline your production line with a versatile tray sealing solution that enhances p...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

Industrial melt tanks for butter and chocolate

Reduce manual labor and elevate safety in your production line with a melt ...

Industrial block melt system for butter and chocolate

Efficiently transition solid blocks of butter, chocolate, or waxes ...

High velocity vertical impingement oven for meat and poultry

Achieve superior cooking uniformity and rapid throughput wi...

Spiral pasteurization system for packaged foods

Enhance product durability and quality with a compact spiral pasteurizatio...

Continuous contact cooker for bottom crust treatment

Enhance dough product integrity with precise bottom heating, ensurin...

Linear convection oven for food processing

Achieve precise cooking and browning of diverse food products simultaneously wh...

Industrial cooker for soups and ready meals

Streamline your cooking operations with a versatile system capable of mixing, ...

Compact spiral freezer for food processing

Enhance your production efficiency and hygiene standards with a compact, self-s...

Spiral freezer for high-capacity food freezing

Enhance your production line by efficiently freezing up to 3,500 kg/hour, o...

Spiral freezer for frozen food production

Optimize your product’s shelf life and quality with advanced freezing tech...

Industrial spiral freezer for high-volume food processing

Optimize your production line with a modular spiral freezer th...

Industrial spiral freezer for high-volume processing

Optimize your high-volume food production with a robust spiral freez...

Crust freezer for delicate and sticky products

For processors handling delicate and sticky items, ensuring product stabili...

Breading line for poultry and seafood products

Elevate your production with high-speed breading lines designed for uniform...

Home style drum breader for meat and poultry

Achieve consistent, high-quality breading on diverse food products with this ...

Preduster for fine-grain coating in food processing

Ensure your products receive a perfect, consistent fine-grain coating...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Frozen food products control system

Ensure optimal freezing precision with a system that continuously monitors product crys...

Oxygen and leakage detection in Map packaging

Ensure enhanced food safety and reduce waste with precise oxygen and leak de...

Automatic tray denesting and erecting system

Streamline your packaging line with precise and efficient tray handling—ensur...

Product distribution system for multiple stencil creamers

Facilitate seamless product flow distribution across multiple ...

Product distribution system for large capacity wrappers

Optimize your high-speed production lines by efficiently distribu...

Robot for picking and placing cookies in wrappers

Boost efficiency and flexibility in your bakery production line with vi...

Robotic pick and place system for cookies

Streamline your bakery production with a flexible robotic system that seamlessly...

Cookie arrangement system for packaging

Enhance your packaging efficiency by seamlessly arranging and loading diverse confe...

Biscuit slug loading system

Enhance your confectionery line with high-speed, precise slug loading that integrates seamlessly...

Automatic loader for irregular shaped cookies

Optimize your bakery line operation by efficiently loading non-uniform cooki...

Product manipulation and stacking systems

Efficiently transition products from flat to stacked on a conveyor while minimiz...

Fifo inflow buffer for efficient production lines

Optimize your production flow with a solution that seamlessly absorbs d...

Product spreader for cooling conveyor

Optimize the cooling process of cream-filled products by gently spreading sandwiches ...