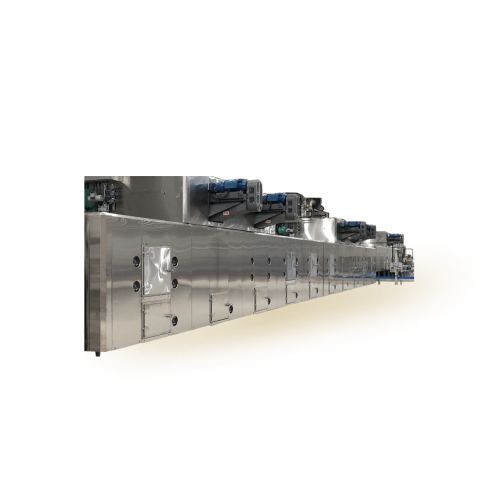

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that efficiently combines baking and drying in one streamlined unit, perfect for high-speed production lines demanding precision heat transfer and air circulation control.

Bakes and Dries Snacks and Bakery Products

The Convection Oven with Integrated Dryer Zone from Reading Bakery Systems is designed to streamline your baking and drying operations, particularly suited for snacks and bakery products. This innovative equipment combines a convection oven and a drying zone to enhance space efficiency, using independent control systems to optimize baking profiles. The system processes a range of end-products, including pretzels, chocolate chip cookies, and tortilla chips, through its flexible heat transfer modes. It features PLC-controlled systems for automated monitoring and adjustments, reducing energy usage with its variable-speed motor design. Built under SafeShield standards, it ensures high safety and sanitation. Customize your configurations with options for gas or electric heat, and benefit from seamless integration into your existing production line, aiding continuous and high-speed operations.

Benefits

- Enhances production efficiency by combining baking and drying processes in a single footprint.

- Reduces operational costs with independent control systems for precise temperature and air flow management.

- Supports a wide range of products and formulations, increasing your product line flexibility.

- Ensures safe and sanitary operations with enclosed design and SafeShield standards.

- Minimizes energy consumption with optimized heat transfer and air circulation systems.

- Applications

- Cookies, Biscuits, Snacks, Pet food, Chips, Expanded snacks, Crackers, Granola, Fried potato snacks, Bakery products

- End products

- Salted crackers, Dog biscuits, Granola bars, Chocolate chip cookies, Breadsticks, Rice cakes, Tortilla chips, Potato rings, Gluten-free biscuits, Pretzels

- Steps before

- Mixing, Dough Handling, Dough Forming

- Steps after

- Cooling, Packing

- Input ingredients

- dough, pretzel dough, snack dough, cracker dough, cookie dough, biscuit dough, pet food mix, granola mix

- Output ingredients

- baked pretzels, snacks, crackers, cookies, biscuits, baked granola, baked pet food, stackable chips, expanded snacks, popped snacks, fried potato rings

- Market info

- Reading Bakery Systems is renowned for its expertise in designing and manufacturing innovative industrial bakery equipment, particularly for snack food production, combining advanced technology and industry knowledge to enhance productivity and quality.

- Heat transfer modes

- Flexible

- Installation type

- Factory built sections

- Oven heat type

- Gas or electric

- Control system

- Feedback based

- Oven and dryer control

- Independently controlled and monitored

- Automation

- Feedback based control system

- Flexibility

- Modular design

- Heat Transfer Modes

- Flexible

- Installation Time

- Quick and easy

- Profile Control

- Optimal baking profile

- Separation Process

- Baking, Drying

- Heat Configuration

- Gas or electric

- Control System

- Feedback based

- Conversion Capability

- Gas to electric

- Cleanability

- High

- Biological compatibility

- Yes

- Product size compatibility

- Variable

- Batch vs. continuous

- Batch or Inline

- Machine Footprint

- Space-saving design

- Modular Design

- Flexible installation

- Heat Transfer Modes

- Convection

- Control Panel Type

- Feedback-based control system

- Heating System

- Gas or Electric

- Air Circulation System

- Forced air plenum

- Operation

- Enclosed operation

- Feed/Discharge Method

- Conveyors

- Baking and Drying Separation

- Independently controlled modules

- Control panel type

- Feedback-based control system

- Customization of heat

- Gas or electric heat options

- Installation

- Factory built sections for quick installation