Industrial Conveyor Systems

Find innovative conveying equipment and connect directly with world-leading technology suppliers

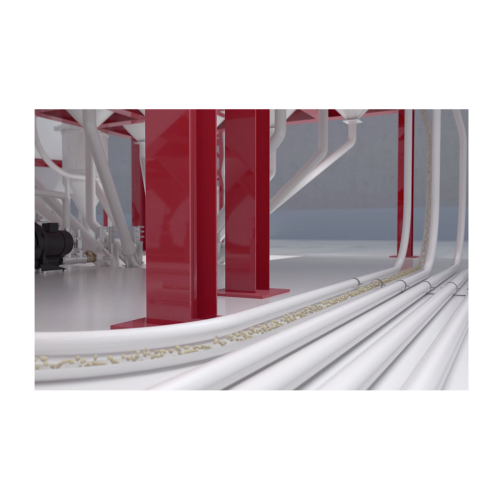

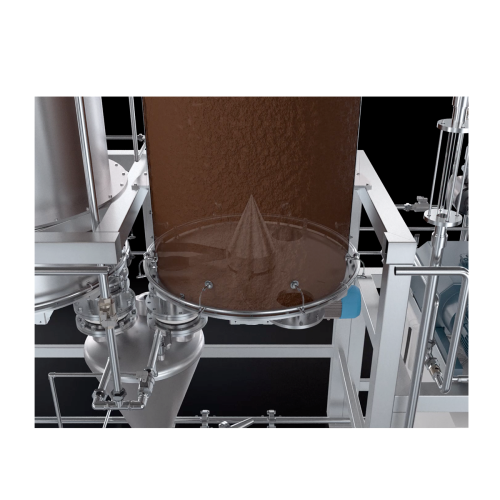

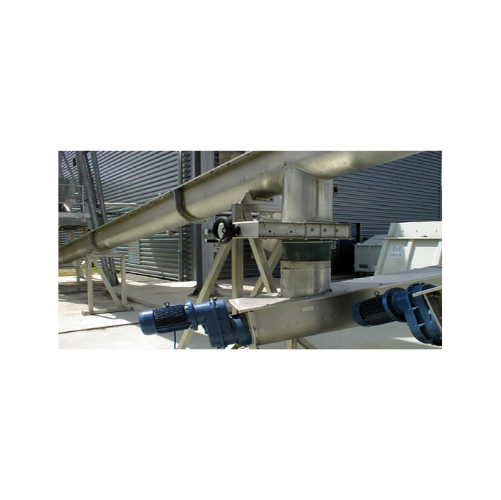

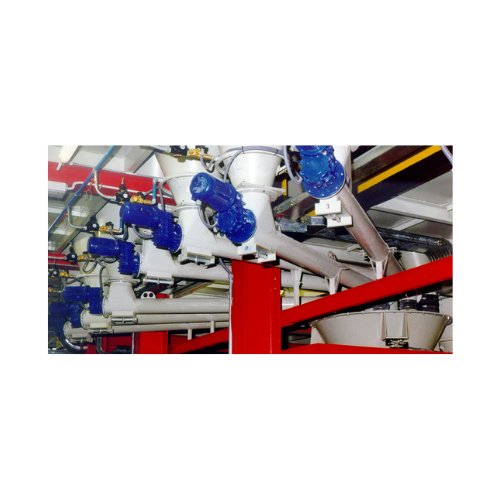

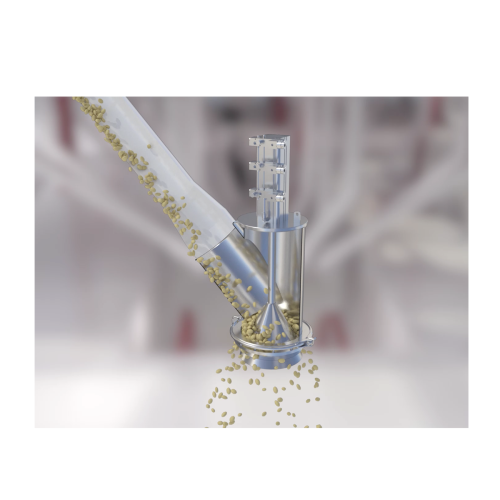

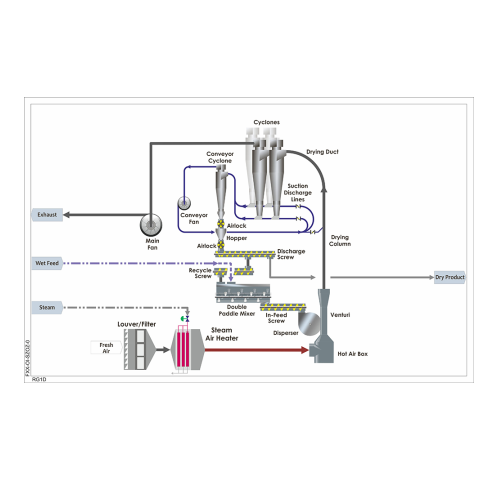

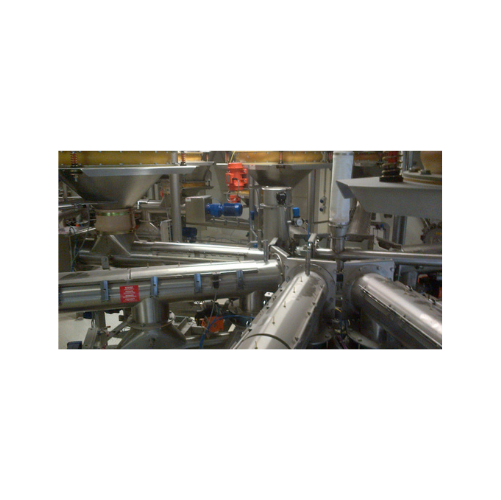

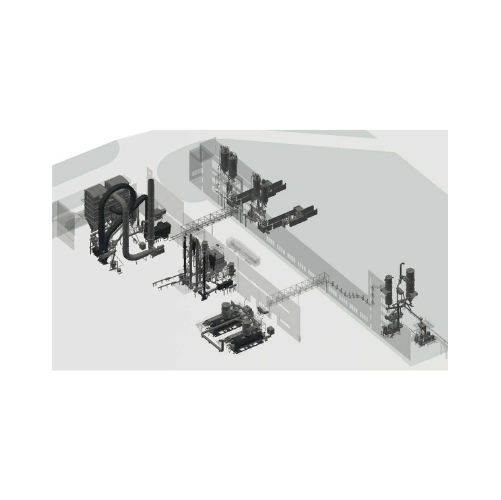

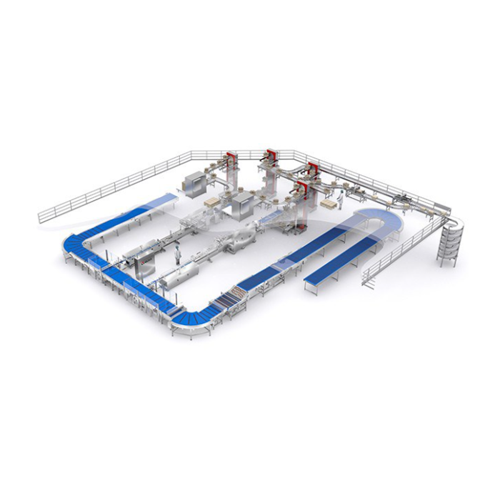

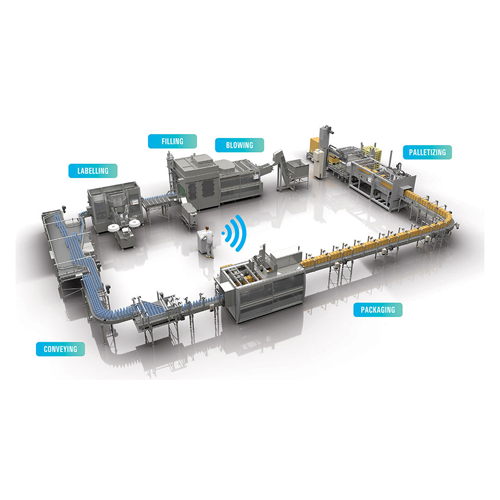

Conveyor systems are used for moving materials from one location to another. Considerations for choosing a suitable industrial conveying system include the nature of the product, its physical state, the desired conveying rate, and sensitivity of the product to heat and mechanical shock. Conveying equipment is used in the food, pharmaceutical, chemical, biomass, and mineral industries to move materials around a warehouse as well as to transport bulk powders, granules, and grains for processing and filling. These types of systems are usually automated and there is a wide variety of solutions to choose when it comes to the type of conveyor. Types include screw, gravity, chain, roller and belt conveyors.

Conveyor systems are an essential part of modern manufacturing. They are used to move materials efficiently and quickly from one location to another. When choosing industrial conveyor technology, there are several factors to consider. One of the most important considerations is the nature of the products being transported. More considerations include the physical state of the material, the desired conveying rate, and the sensitivity to heat and mechanical shock. All of which will play a role in selecting the right conveyor for the job.

This technology is commonly used in industries such as food, pharmaceutical, chemical, and biomass They are used in warehouses and distribution centers to move products around. As well as to transport bulk powders, granules, and grains for processing and filling. With the advent of automated conveyor systems, the handling of materials has become more efficient, saving both time and money.

There are several types of conveyors available. These include roller, chain, screw, gravity, and belt conveyors. Each type has its own advantages and disadvantages. And the selection of the appropriate conveyor system depends on the specifications and throughput of the material to be transported.

Roller conveyors are ideal for moving products with flat or smooth surfaces. while chain conveyors are suited for heavy loads or products that require a more robust design. Overhead conveyors are useful for moving products over longer distances. And gravity conveyors are ideal for situations where items need to be moved continuously or intermittently.

The system design is a crucial consideration when selecting conveying technology. Design should take into account the space and layout of the warehouse. As well as the specific requirements of the material being transported.

What are you making?

Aggregates

Bagels

Baguettes

Crushed stone

Dry pet food

Drymix building materials

Feed concentrates

Floating pellets

Fly ash

Ink

Limestone

Marmalade

Masterbatches

Meat and bone meal

Mineral water

Peanut butter

Pelleted feed

Phosphorus fertilizer

Plant waste

Plasterboard

Port silos

Potato wedges

Salad dressing

Serums

Slow sinking pellets

Synthetic resin

Synthetic rubber

Tomato sauce

Toner

Accumulation conveyors

Belt conveyors

Bottle conveyor systems

Bulk solids conveyors

Chain conveyors

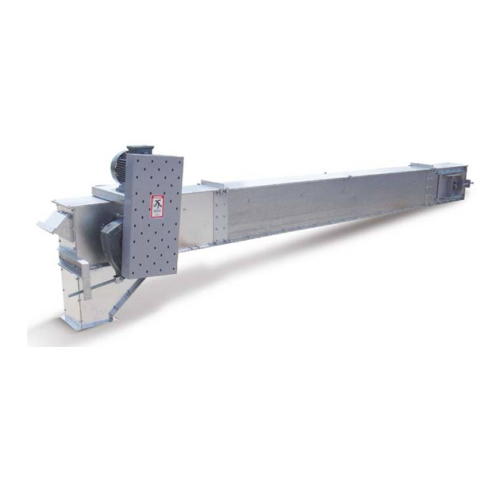

Conveying screws

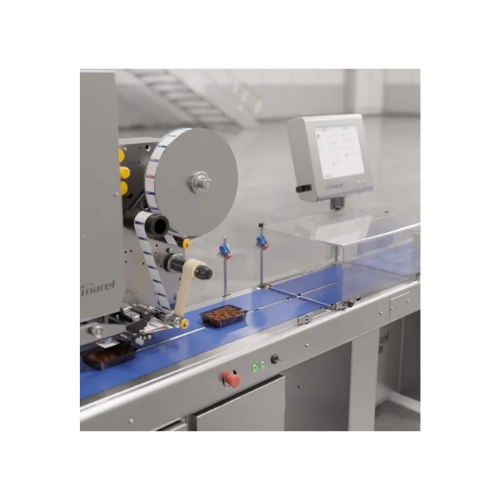

Conveyor belt labellers

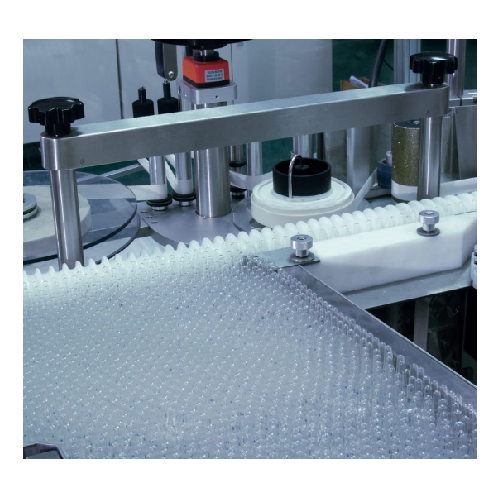

Conveyor belts

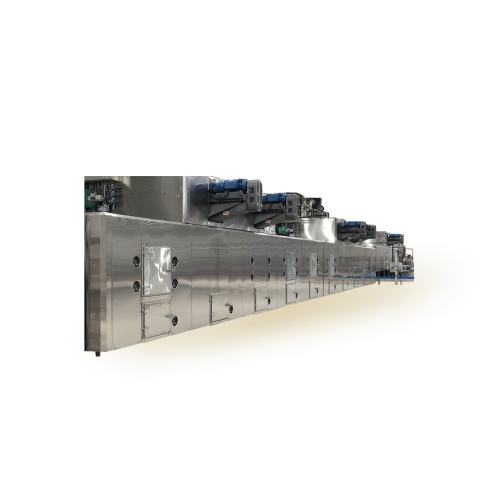

Conveyor dryers

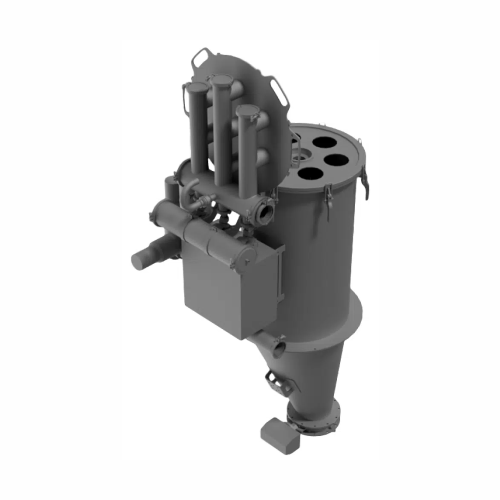

Dense phase conveying systems

Hoists for vacuum conveyors

Horizontal motion conveyors

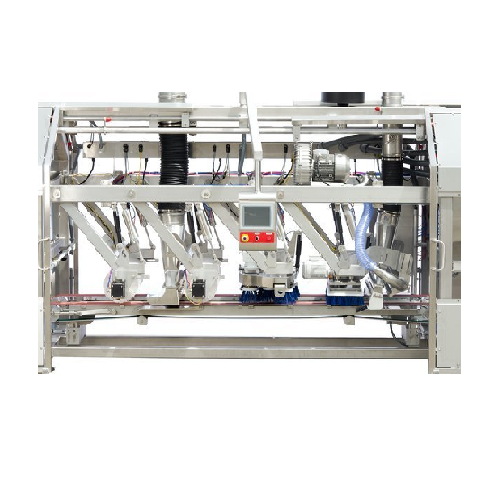

Mechanical conveyors

Modular belt conveyors

Pallet conveyors

Pneumatic conveyors

Pressure conveying systems

Screw conveyors

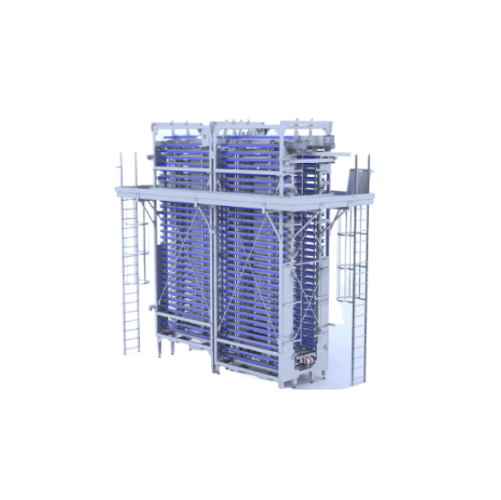

Spiral conveyors

Transfer conveyors

Tubular screw conveyors

Vacuum conveyors

Vertical conveyors

Vibrating conveyors

Which conveying technology do you need?

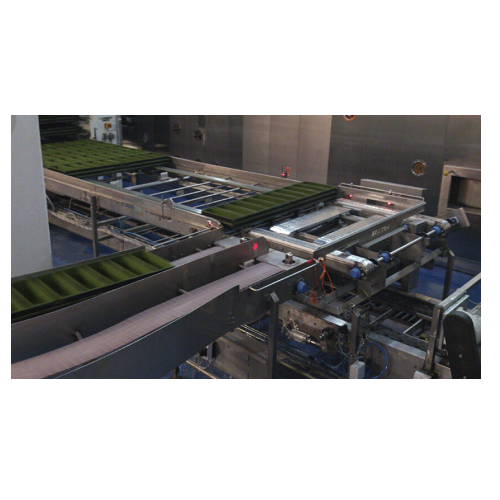

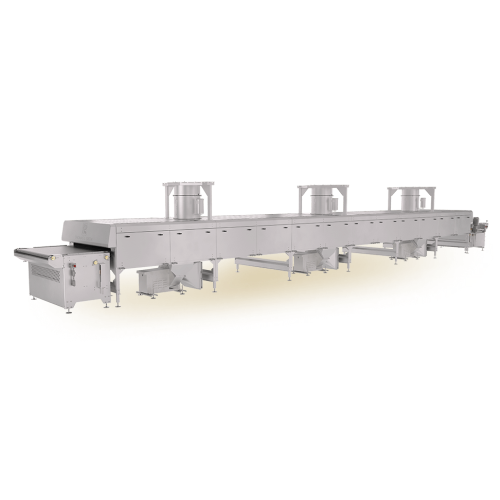

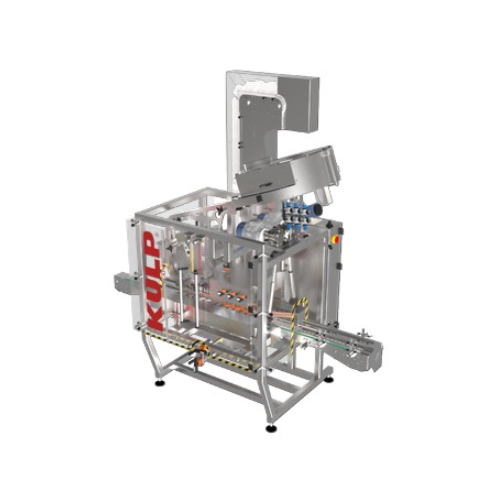

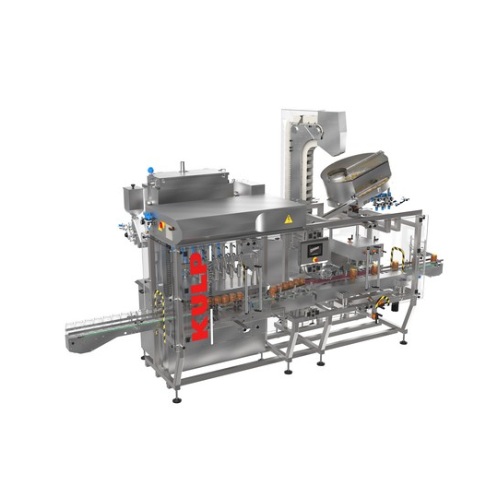

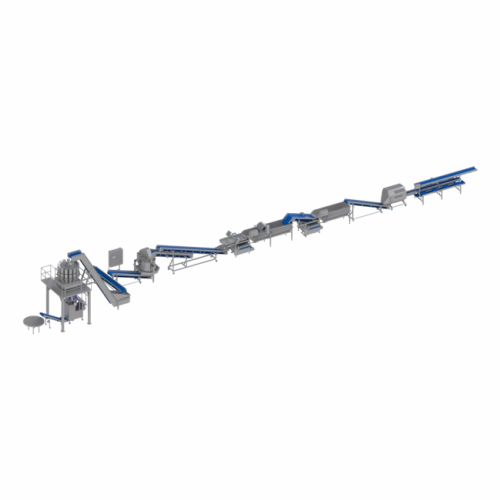

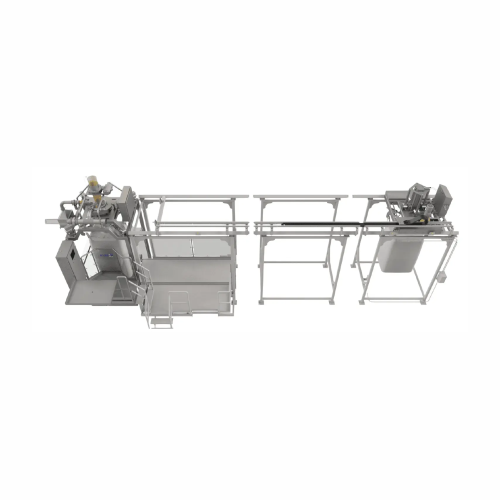

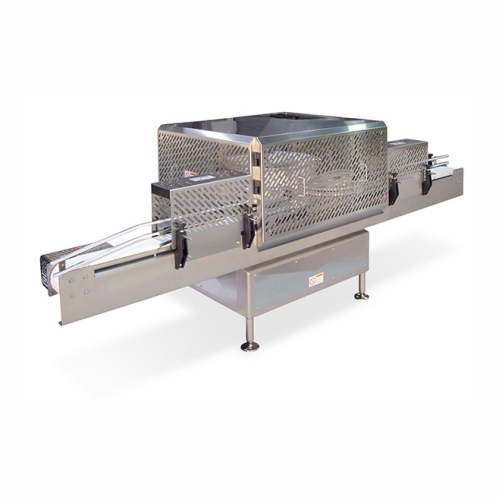

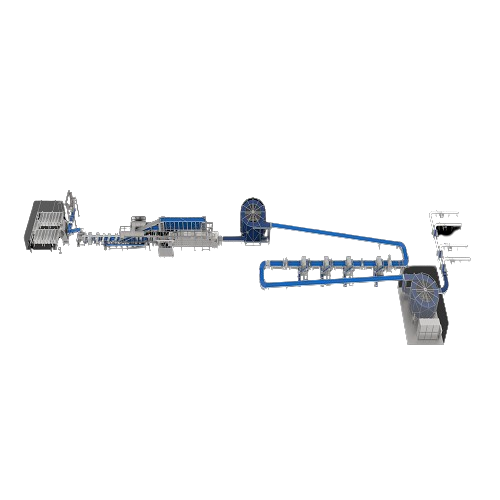

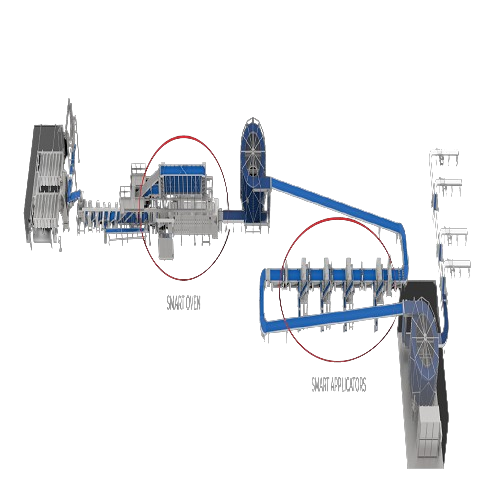

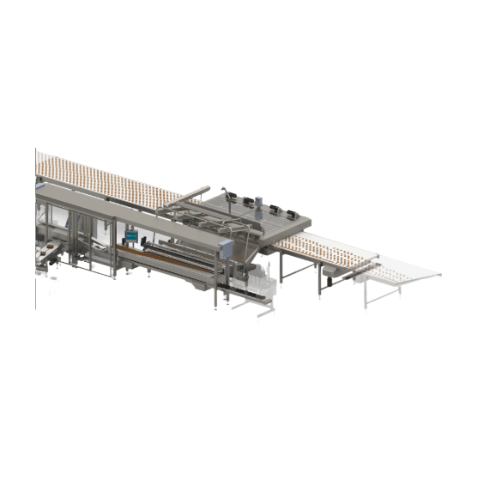

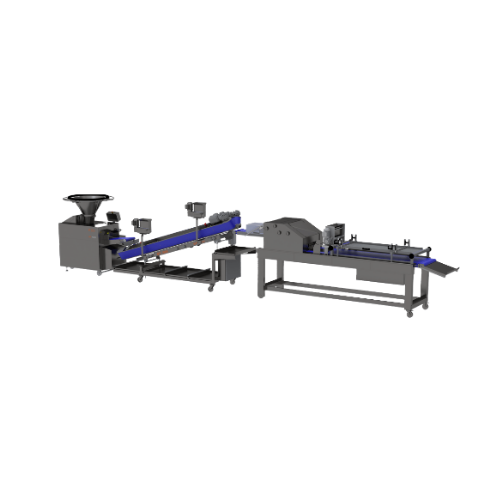

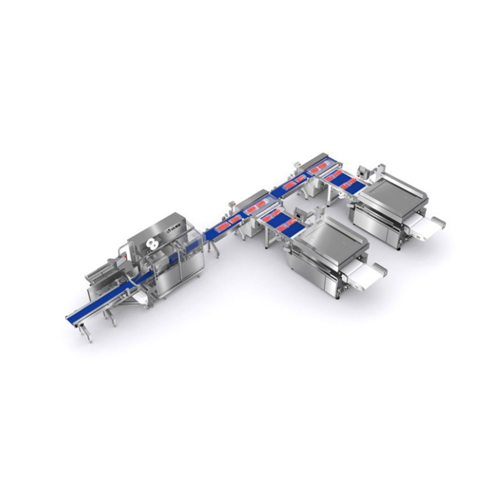

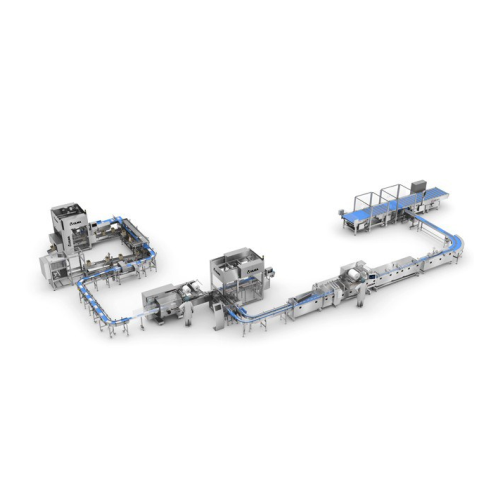

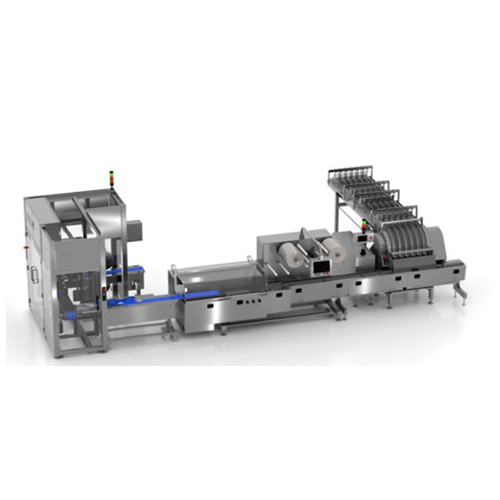

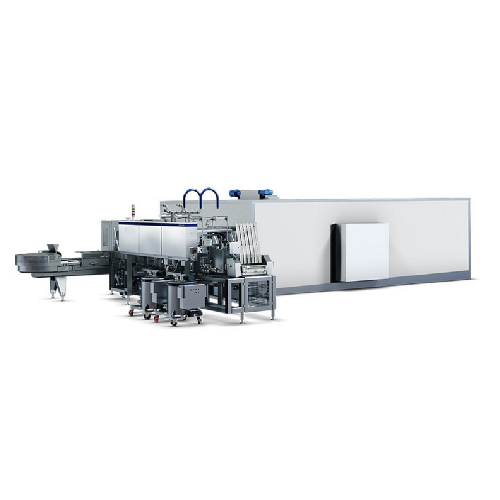

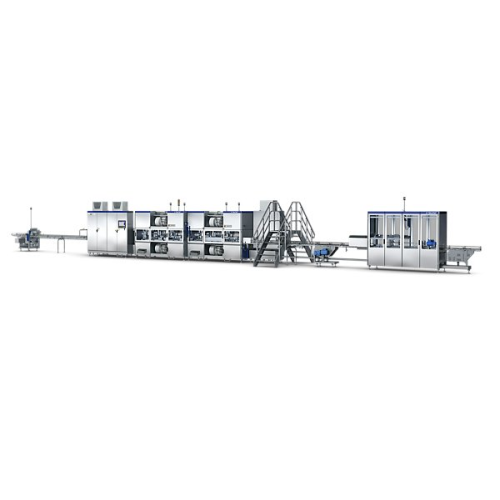

Industrial bakery conveying solutions

Ensure seamless, hygienic transport of bakery goods with precision-engineered conveyi...

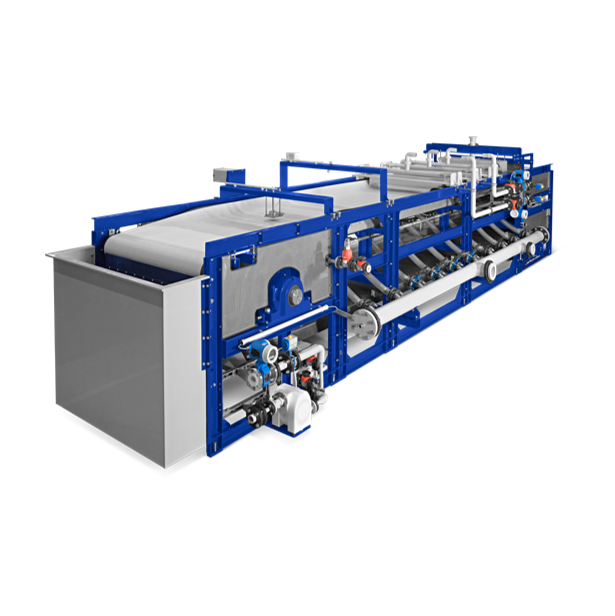

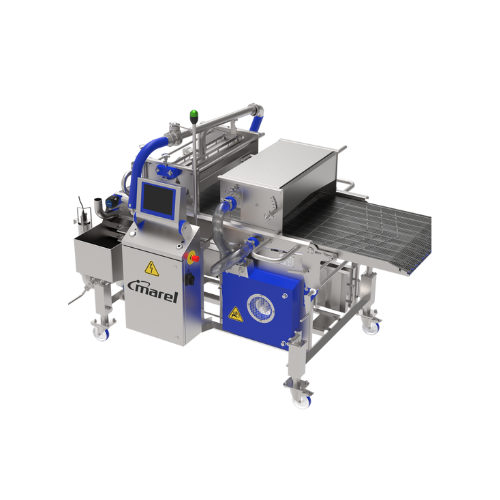

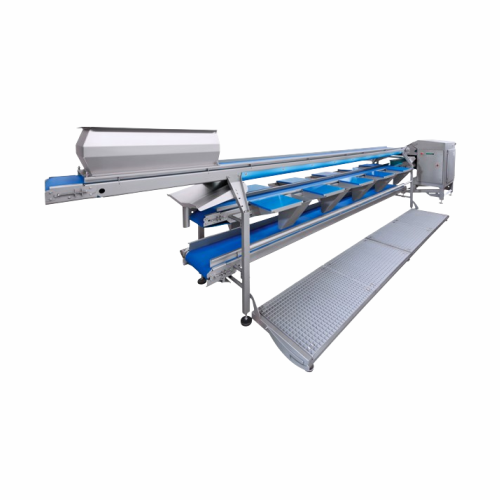

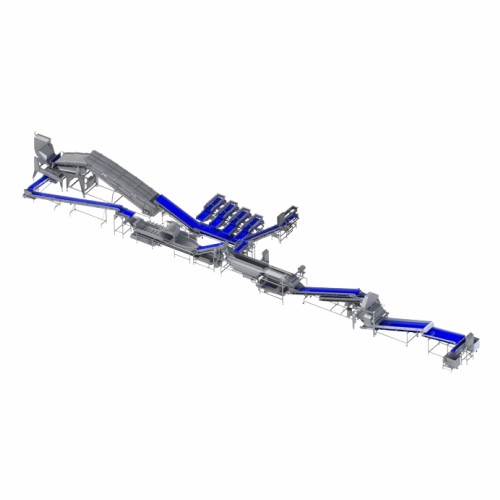

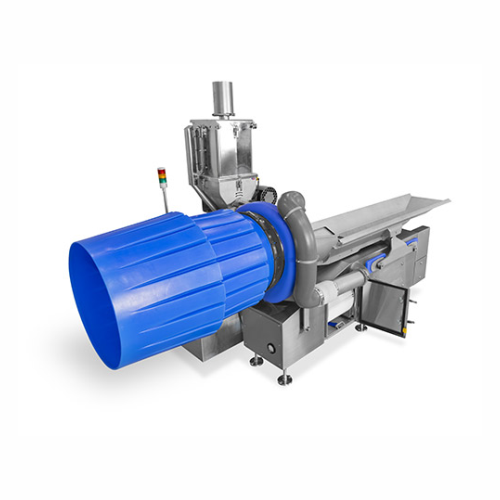

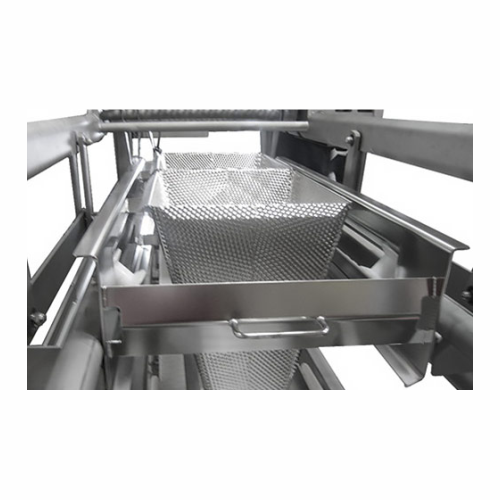

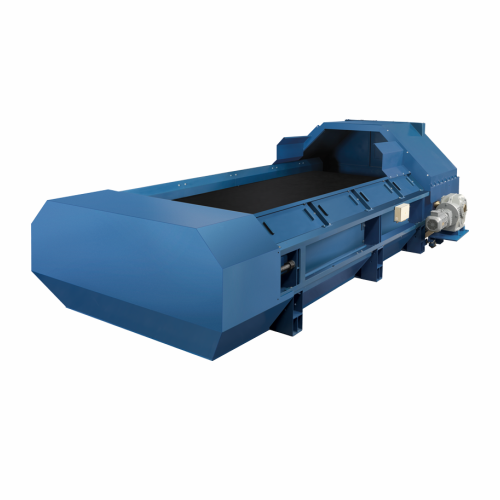

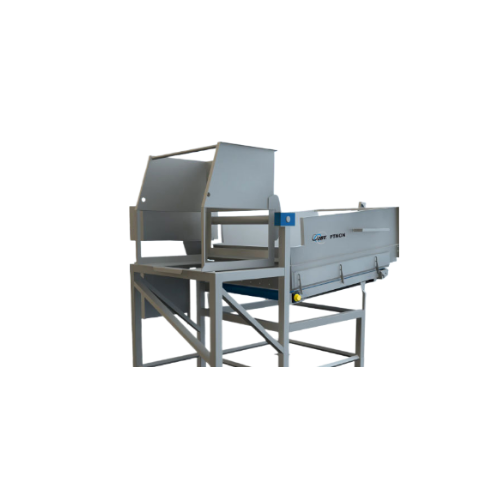

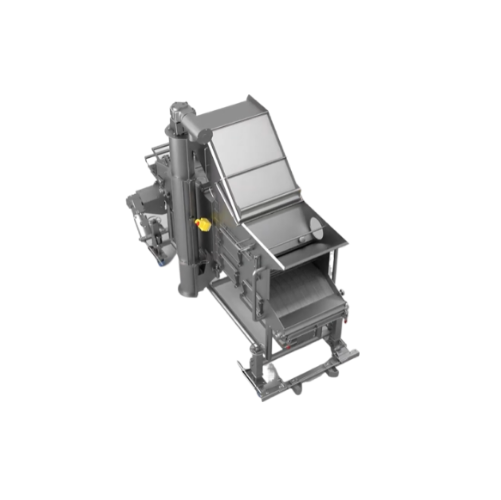

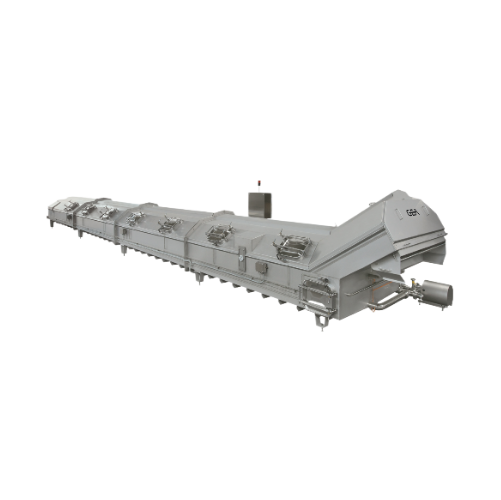

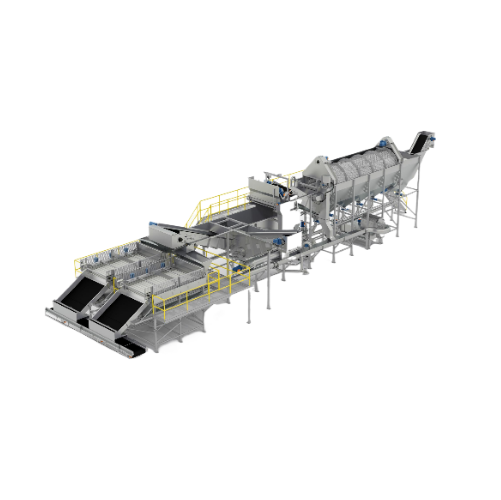

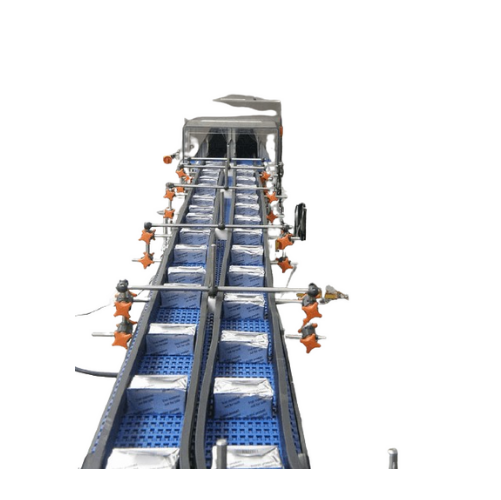

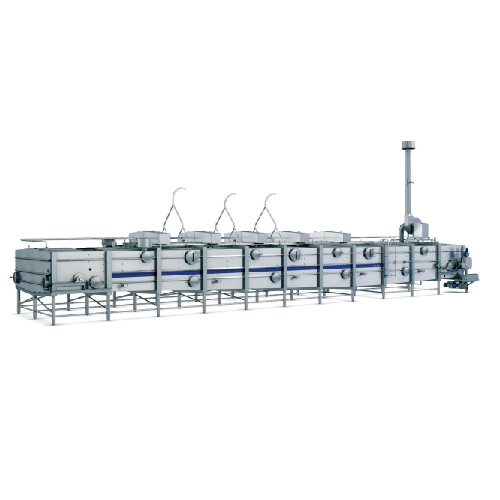

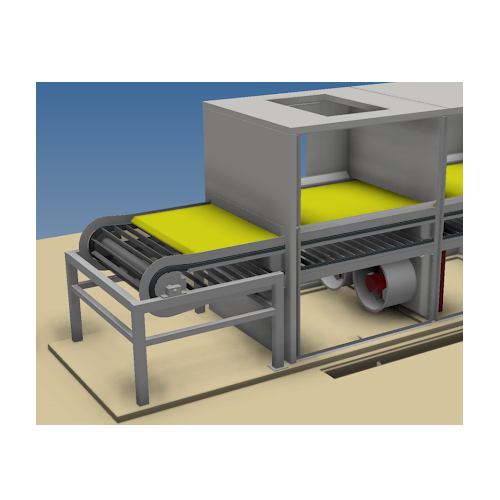

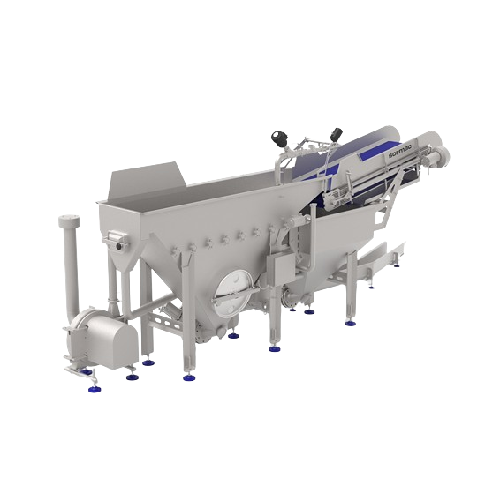

Water bunker belt for pre-cleaning and conveying tuber vegetables

Ensure efficient pre-cleaning and seamless integratio...

Dense phase vacuum conveying for fragile powders

Efficiently convey fragile powders without compromising their integrity, ...

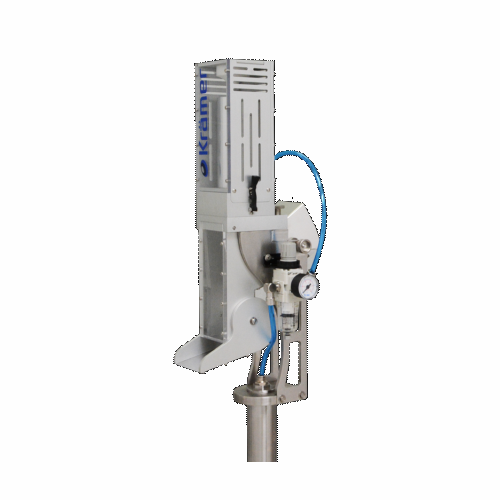

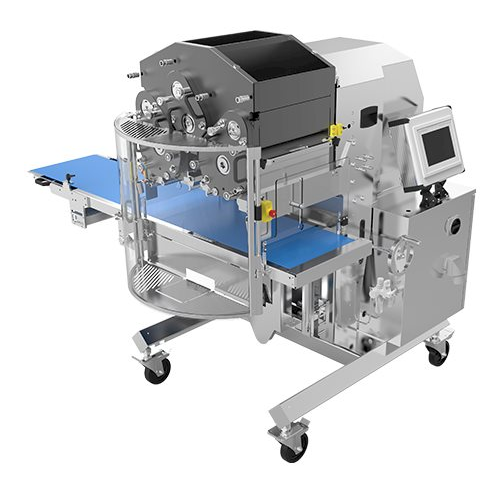

Tablet deduster with upward conveying

Ensure consistent dedusting and deburring of tablets and capsules while maintaining h...

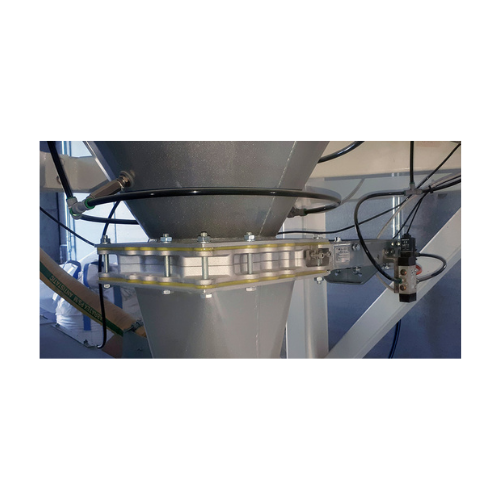

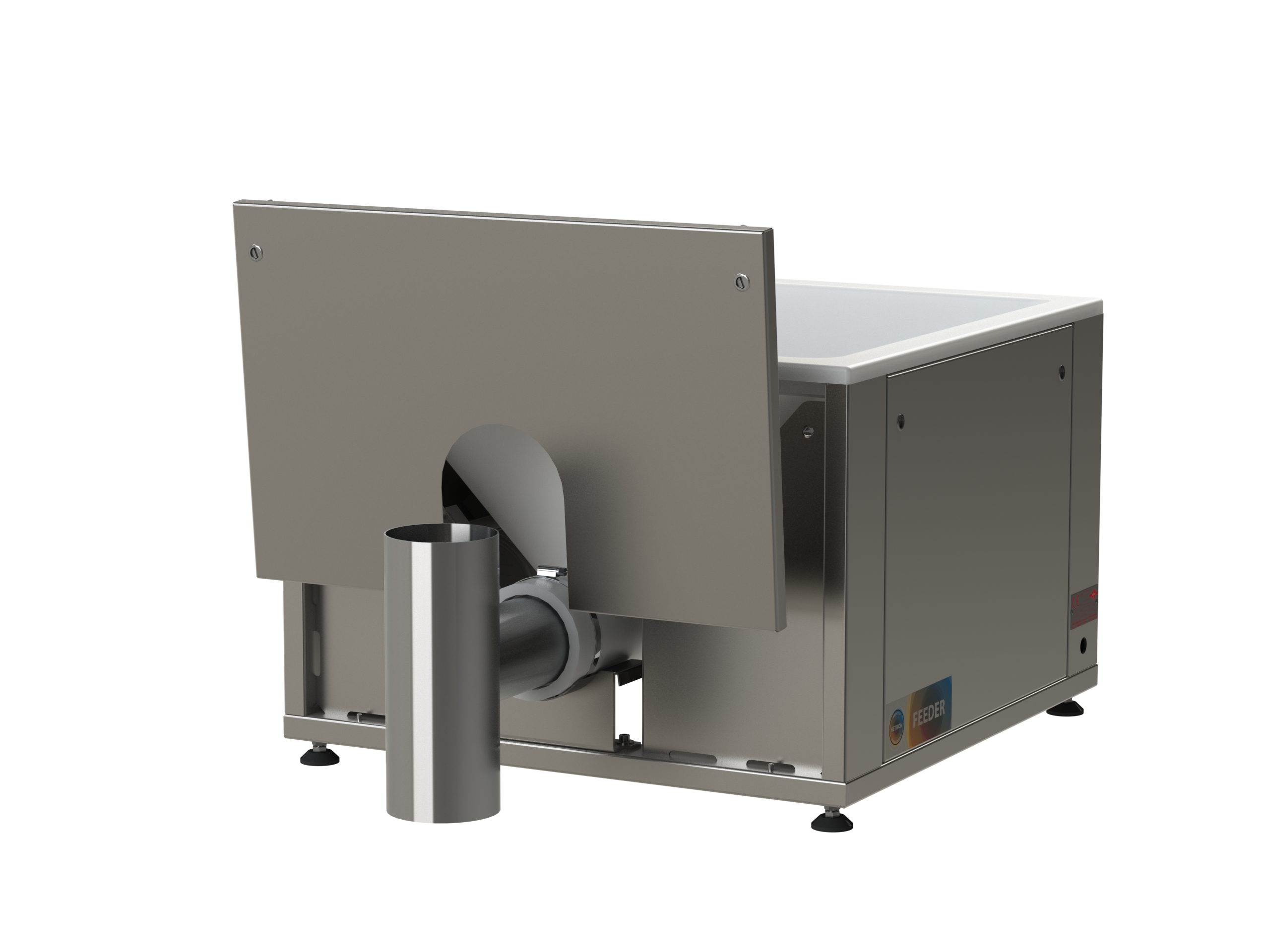

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

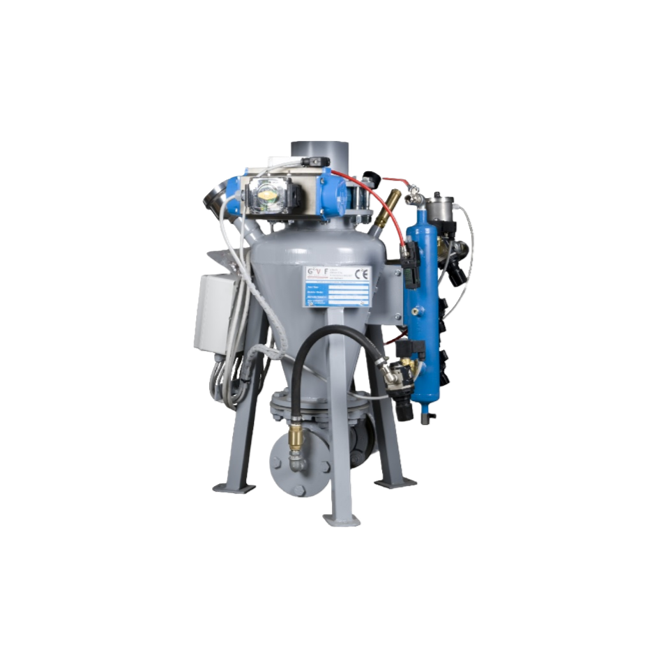

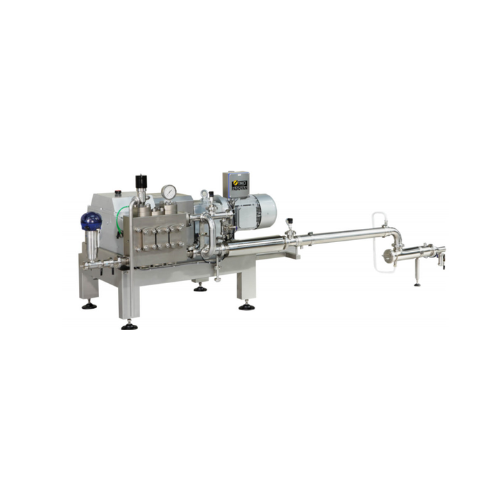

Dense phase pressure conveying system for fragile powders

Ensure gentle handling and long-distance transport of fragile ...

Roasted coffee handling and conveying system

Ensure the gentle handling of roasted coffee with versatile conveying solutio...

Green coffee handling and conveying systems

Efficiently handle and convey green coffee beans to maintain product integrity...

Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma...

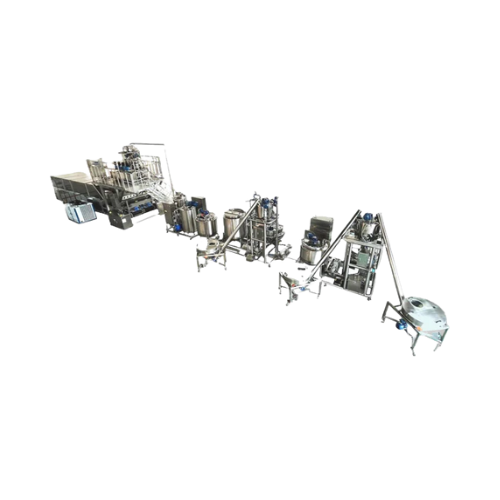

Pneumatic conveying systems for industrial applications

Efficiently transport bulk materials or liquids across your produ...

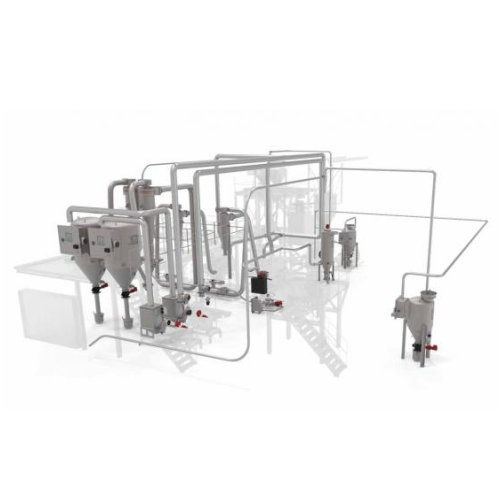

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

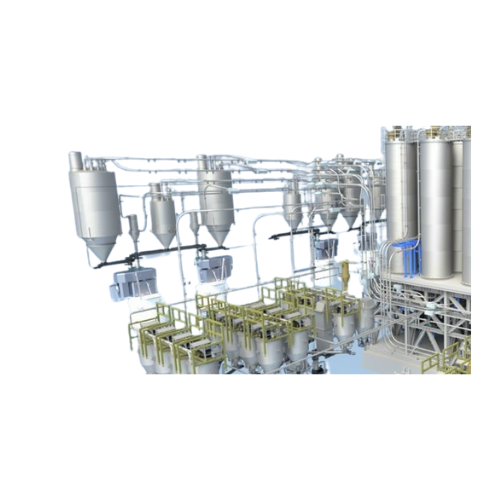

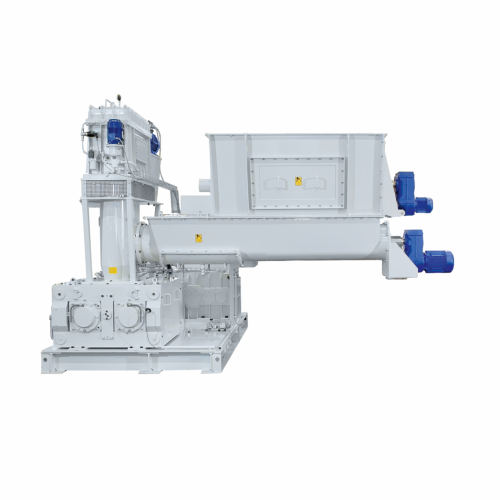

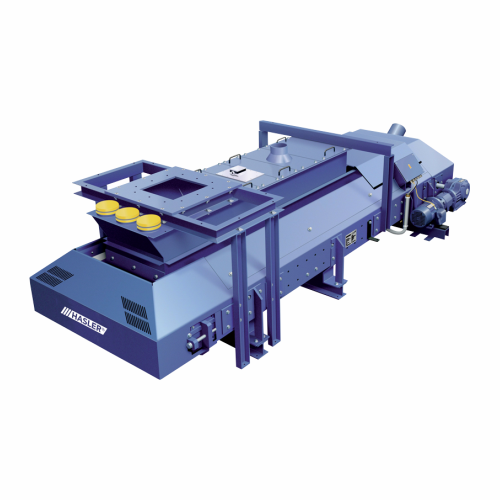

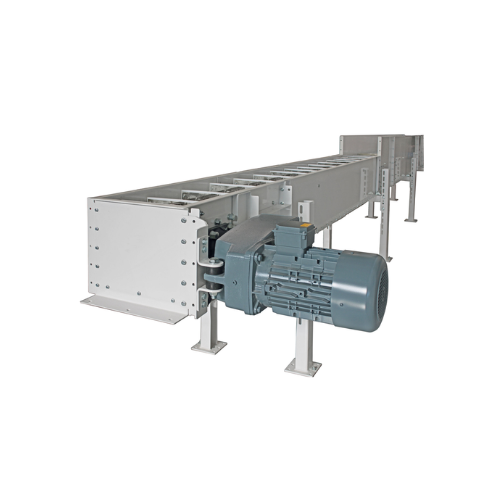

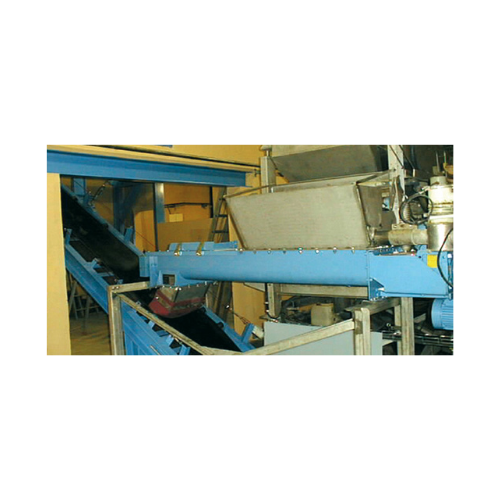

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Vacuum pneumatic conveying for infant nutrition

Ensure efficient handling of delicate powders with a versatile vacuum pneu...

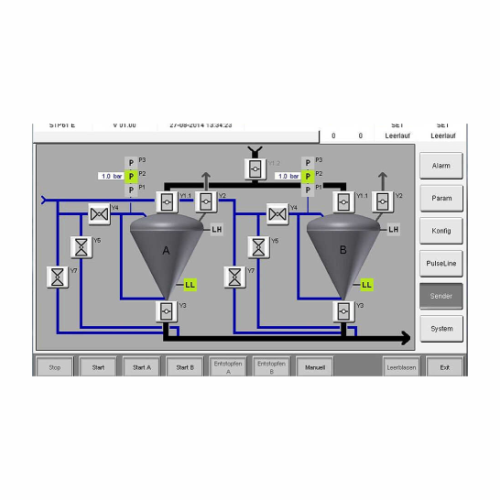

Conveying controller for dense phase conveying

Streamline your dense phase conveying operations with precise control and m...

Dense phase pneumatic conveying system for powder transfer

Ensure gentle and efficient material transport with minimal m...

Pneumatic dilute phase conveying system for powders and bulk materials

Optimize your production line’s efficiency...

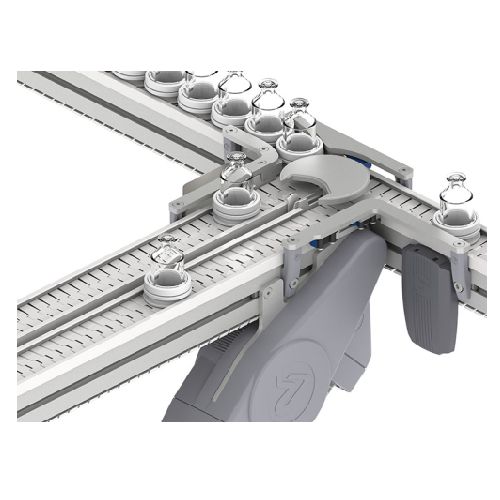

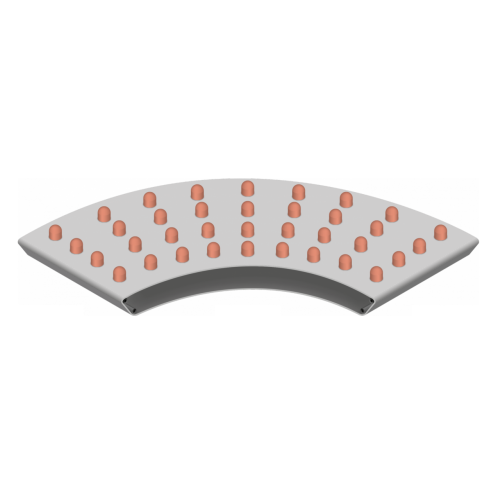

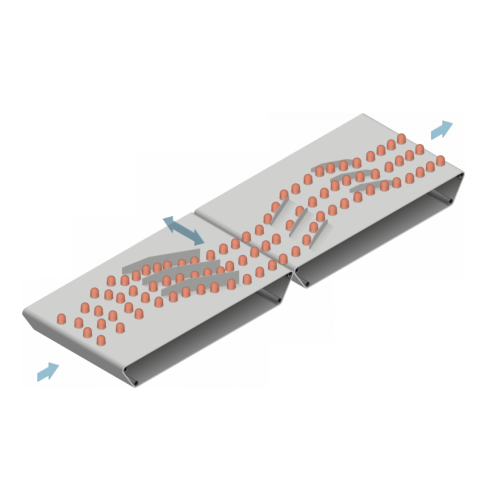

Conveying system for small, fragile products

Optimize your production line with high-capacity conveyors designed for effic...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

Lactose pneumatic conveying solution

Eliminate frequent production halts due to lactose buildup with our conveying solution...

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

Dense-phase powder conveying system

Optimize your powder processing with a system designed to handle abrasive and fragile m...

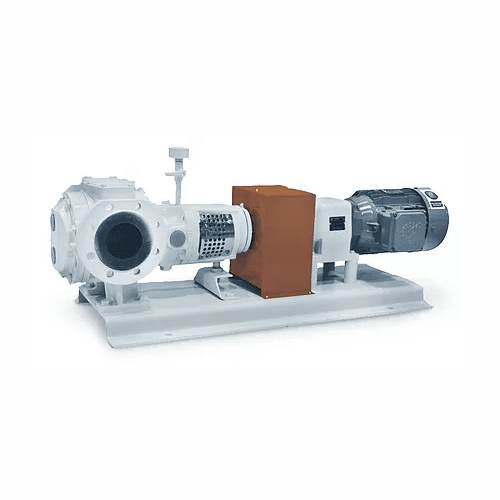

Regenerative vacuum blower for pneumatic conveying

Optimize your material handling with a compact regenerative vacuum blo...

Industrial vacuum blower for continuous pressure conveying

Optimize your production line with reliable vacuum conveying,...

Vacuum sequencing blower for industrial conveying systems

For manufacturers handling bulk materials like powders and gra...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Automatic powder vacuum conveying system for infusion production

Enhance your production line with our vacuum conveying ...

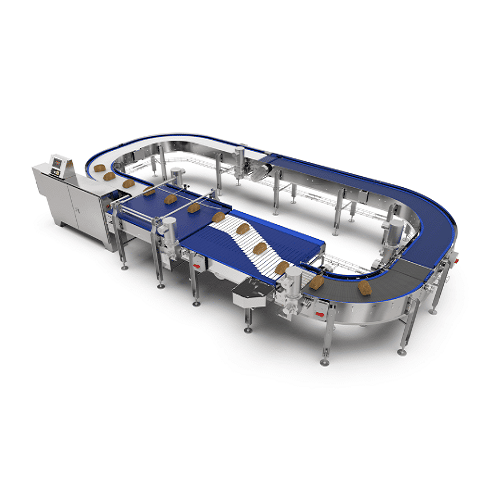

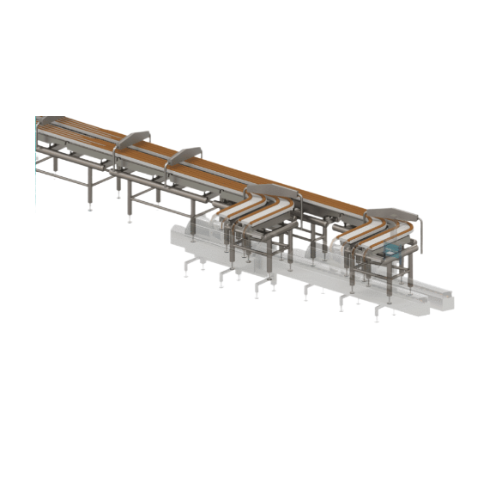

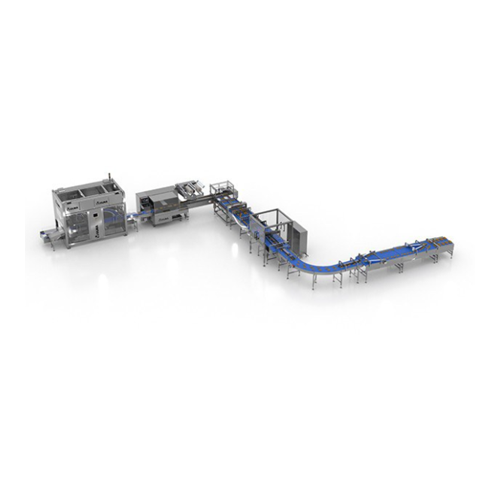

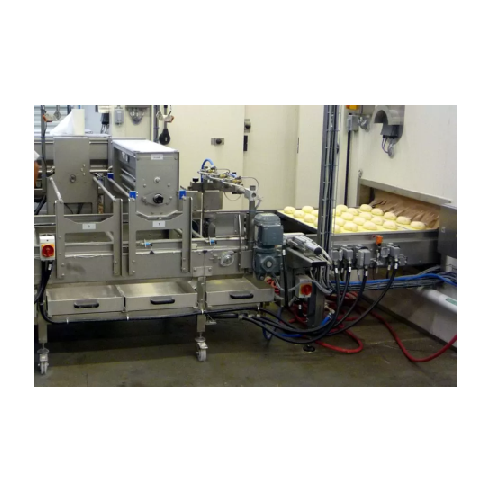

Bakery product conveying solution

Optimize your bakery’s production line by seamlessly transferring diverse products ...

Compressed air loaders for material conveying

Efficiently convey diverse materials with minimal operator intervention, usi...

Automated powder and pellet product conveying system

Optimize your encapsulation process effortlessly with this fully aut...

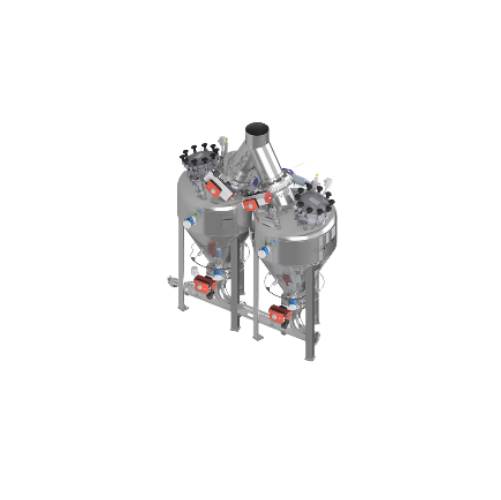

Dense phase vacuum conveying system for powder handling

Effortlessly transport delicate powders and fragile granules with...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Lean phase vacuum conveying system for powder handling

Efficiently transport and separate powders and granules with preci...

Rotary tube selector valve for powder conveying

Streamline your pneumatic transport system with a robust solution that div...

Dense phase pressure conveying system

Efficiently transport high-capacity powders across long distances with precision and ...

Pneumatic conveying diverter valve for abrasive bulk materials

Streamline the flow of abrasive materials in your pneumat...

Industrial diverter valve for pneumatic conveying systems

Optimize your pneumatic conveying system with a versatile two-...

Pneumatic conveying diverter valve for multi-silo feeding

Optimize your pneumatic conveying system by efficiently direct...

Pneumatic conveying systems diverter valve

Effortlessly manage bulk material flow with precision, ensuring seamless transi...

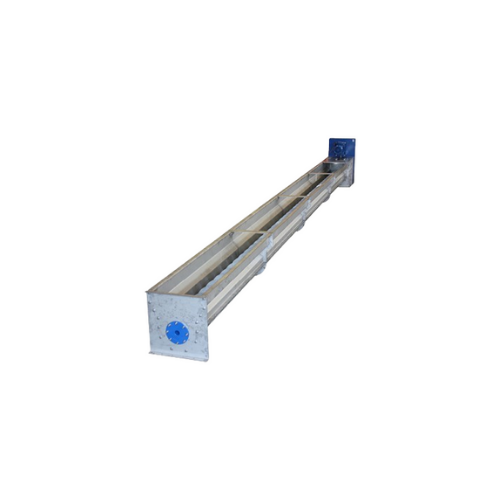

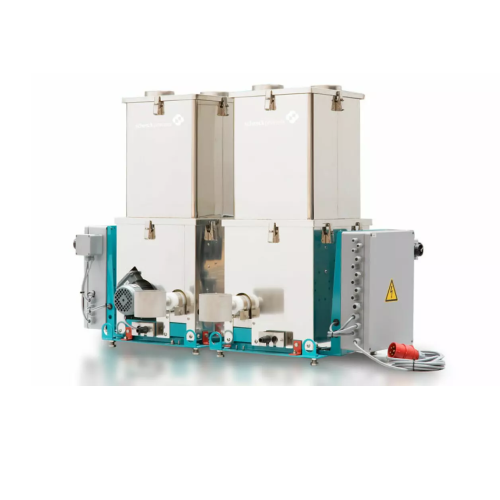

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Industrial conveying system for carbon black and silica

Ensure dust-free conveyance of sensitive materials like carbon bl...

Rotary feeder for bulk material conveying

Enhance your material flow with precise metering and efficient conveying, ensuri...

Bulk solids conveying systems

Efficiently move and manage bulk materials with precision and reliability, ensuring seamless i...

Pneumatic conveying system for bulk solids

Ensure efficient and dust-free transport of bulk materials with a pneumatic con...

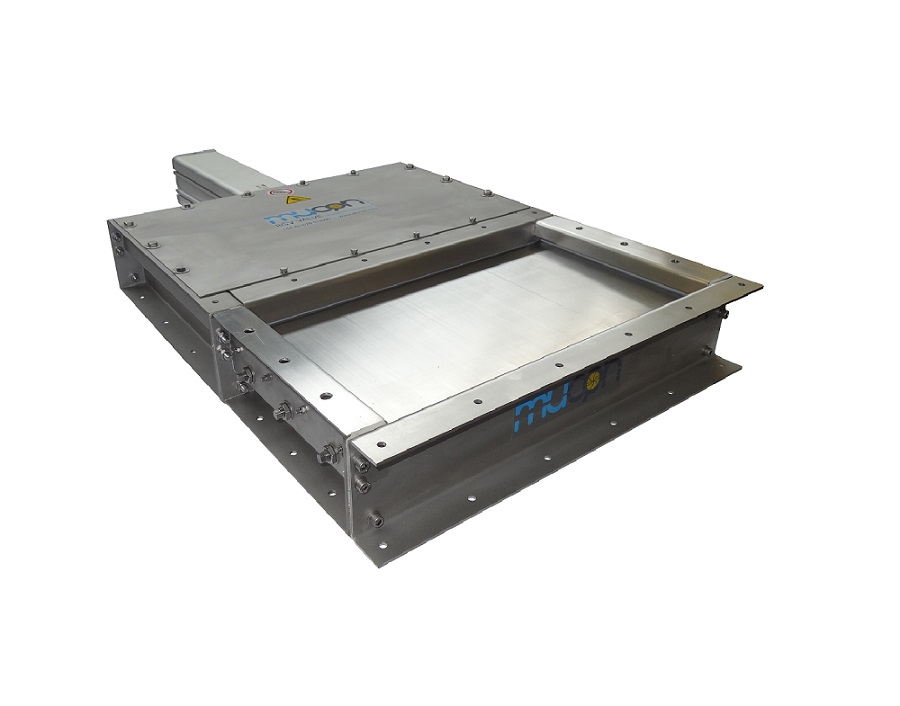

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

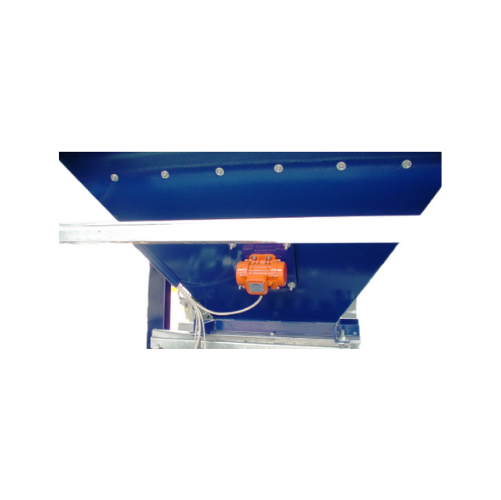

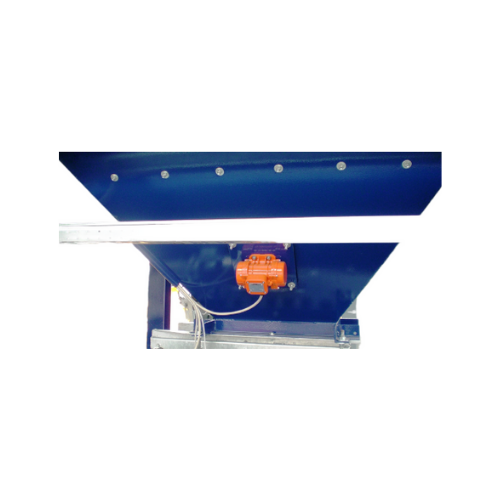

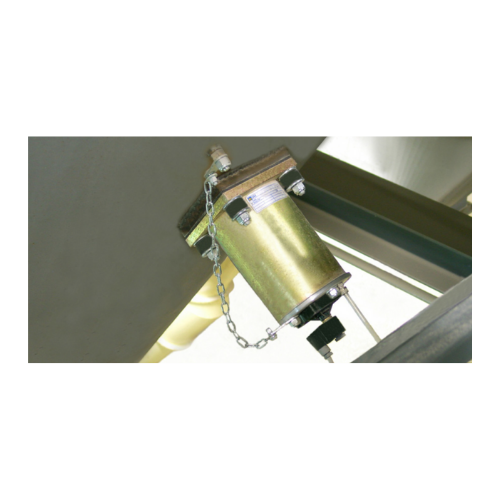

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Pipe couplings for pneumatic conveying lines

Ensure a secure and quick connection for your pneumatic lines with these pipe...

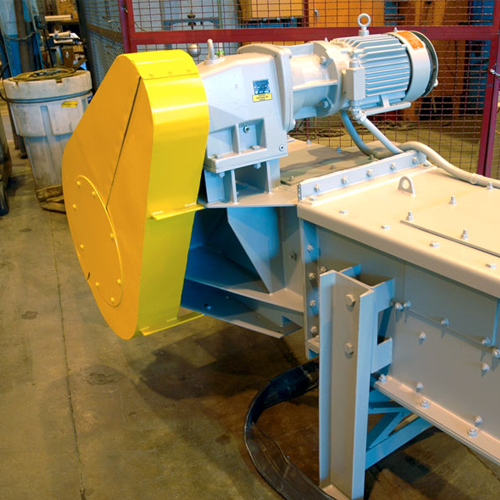

Heavy-duty vertical conveying for aggregates and minerals

Achieve efficient vertical transport of heavy bulk materials w...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

High capacity vertical conveying for grains and cereals

Ensure efficient vertical transport of bulk materials like cereal...

High capacity vertical conveying for flour

For consistent, high-speed handling of delicate and powdery materials, this eng...

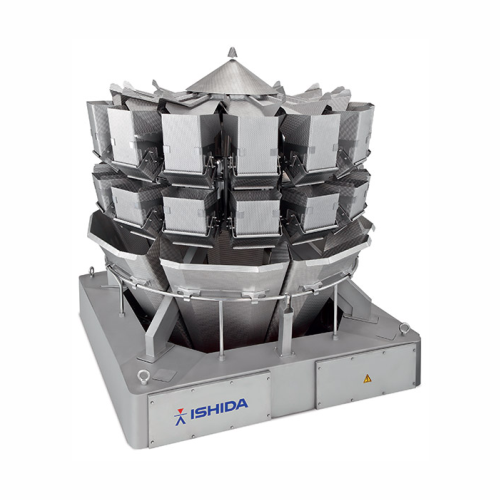

Integrated conveying and weighing system for bulk materials

Achieve precise material management with a solution that sea...

Ecluse for pneumatic conveying systems

Ensure seamless and leak-free material flow in continuous and high-speed operations ...

Pneumatic conveying system for dry bulk powders

Ensure seamless and contamination-free transfer of pharmaceutical powders ...

Chaff conveying system for coffee roasters

Efficiently manage coffee chaff with an integrated solution that transports, co...

Industrial vacuum conveying system

Simplify bulk material movement and separation with a versatile vacuum conveying system,...

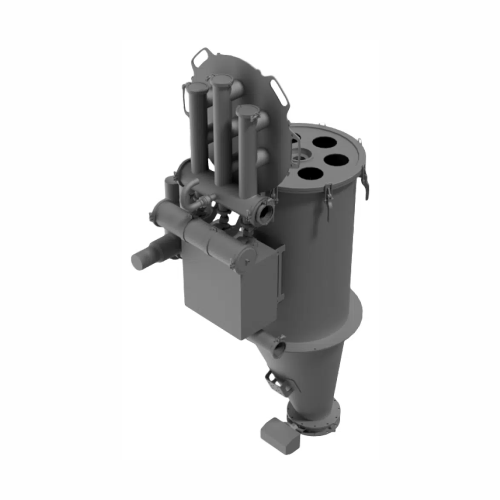

Ash handling pumps for dense phase pneumatic conveying

Efficiently convey various types of ash, including fly ash and was...

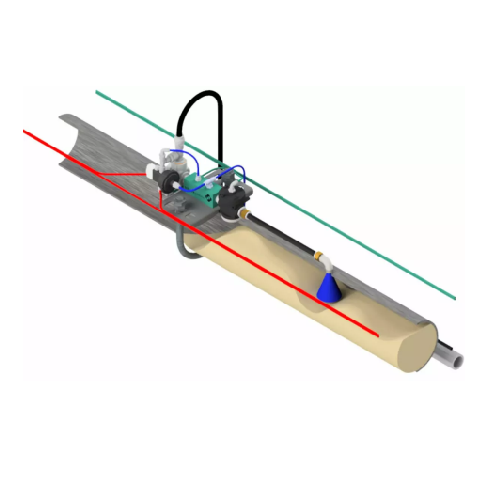

Injected density stabilizer for pneumatic conveying

Optimize your dense phase pneumatic conveying with a stabilizer desig...

Dense phase conveying pumps for bulk material transfer

Optimize your material handling with pneumatic conveying solutions...

Dense phase pneumatic conveying accessories

Optimize material flow and reduce power consumption with dense phase pneumatic...

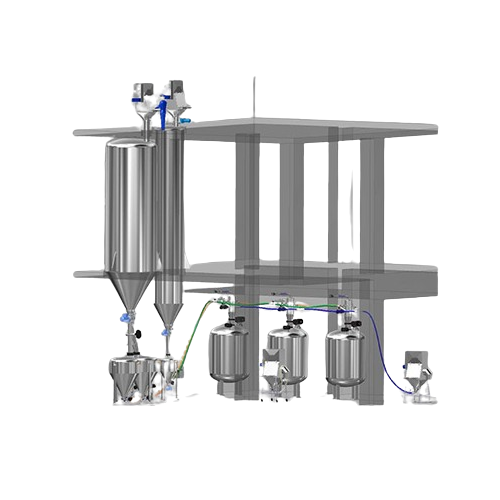

Pneumatic vacuum conveying system for dry raw materials

Optimize efficiency and precision in your bakery operations with ...

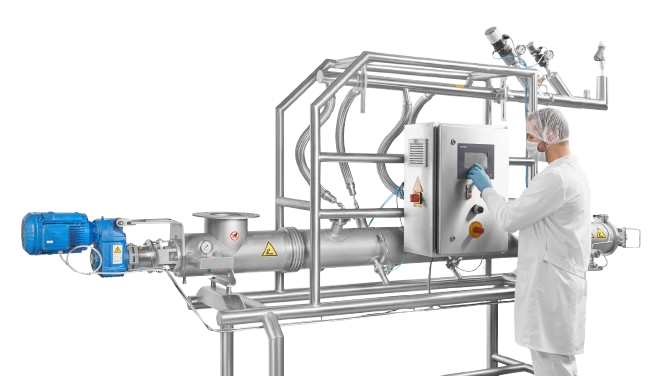

Continuous hot air conveying dryer for chemical and pharmaceutical industries

Ensure rapid moisture removal with high-...

Particle size reduction air conveying system

Achieve precise particle size reduction and contamination-free processing for...

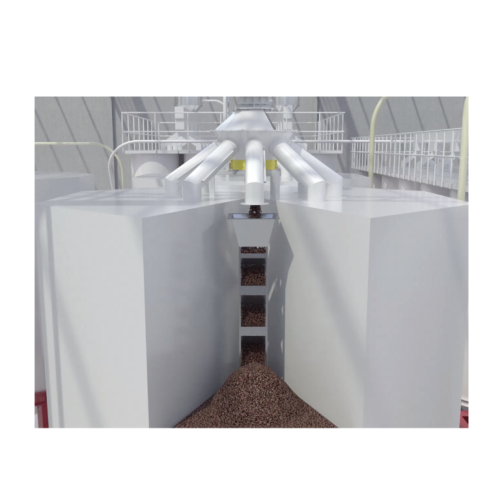

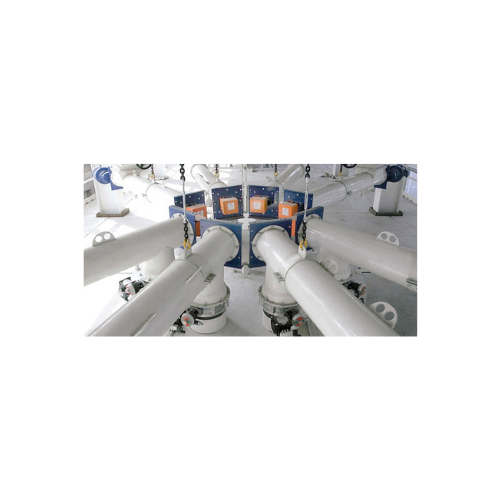

Pneumatic conveying for industrial biomass boilers

Modern boiler plants have a wide variety of conveying needs. While tr...

2-way diverter valves for pneumatic conveying

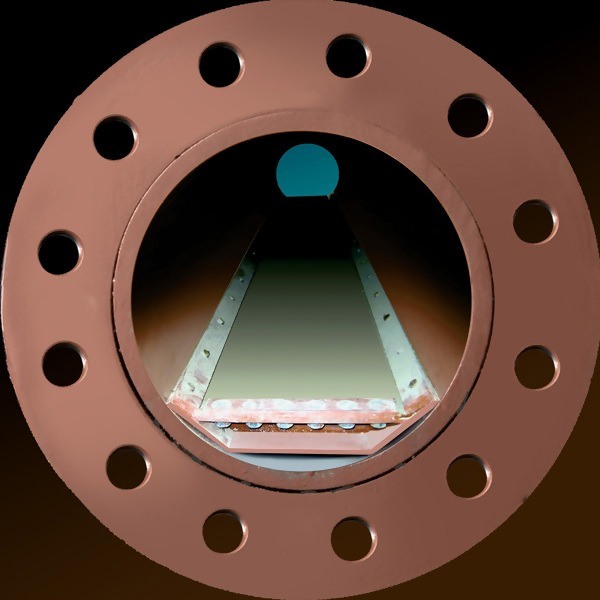

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

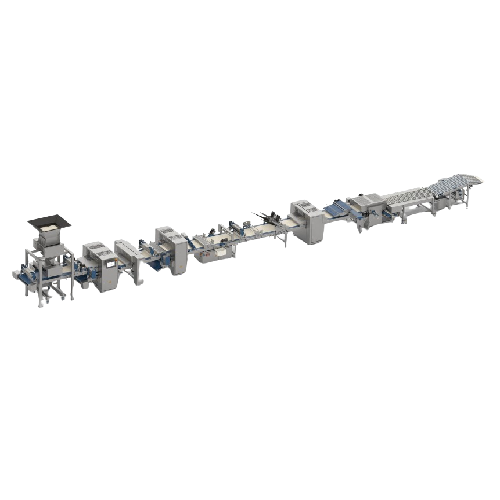

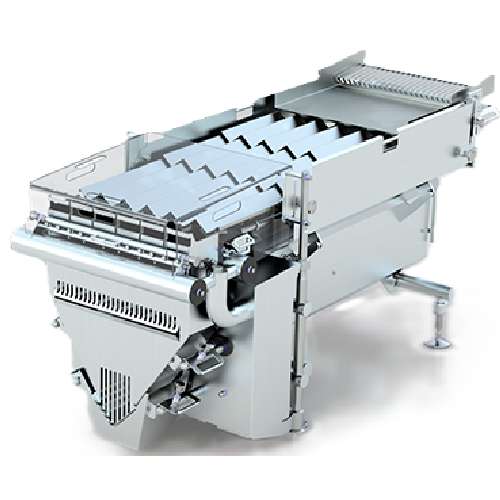

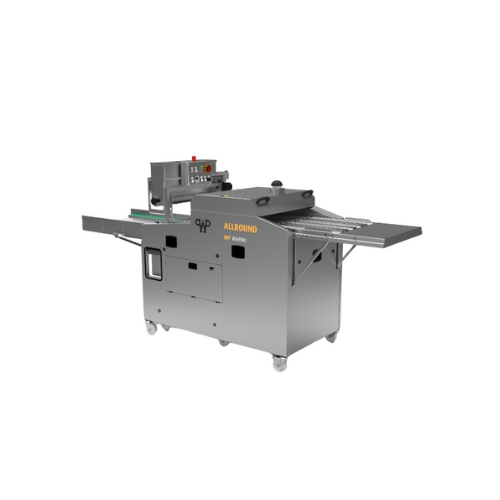

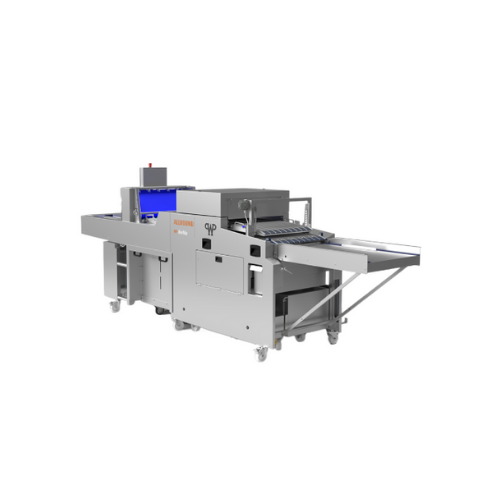

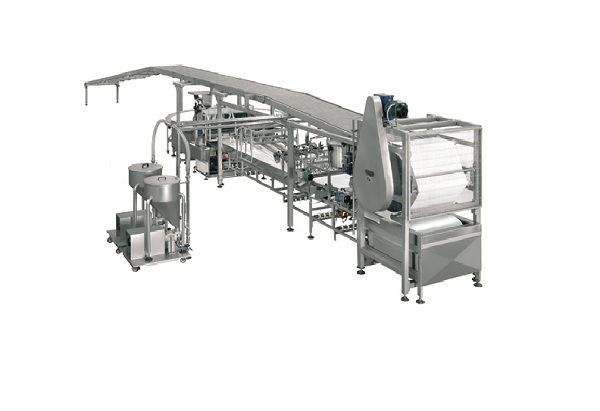

Sheeting lines for biscuit and cracker production

Enhance your bakery production efficiency with advanced sheeting techno...

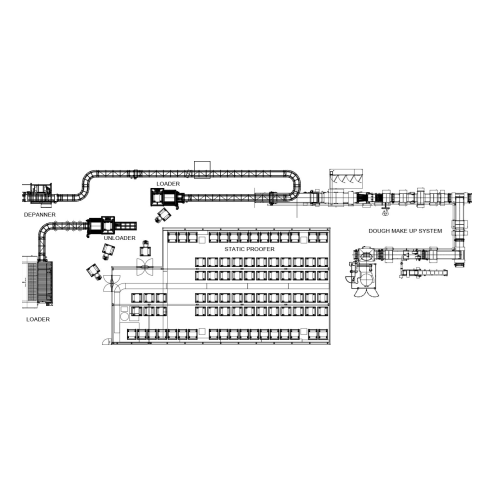

Donut production line for various shapes and sizes

Optimize your bakery’s output with precision-engineered dough pr...

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

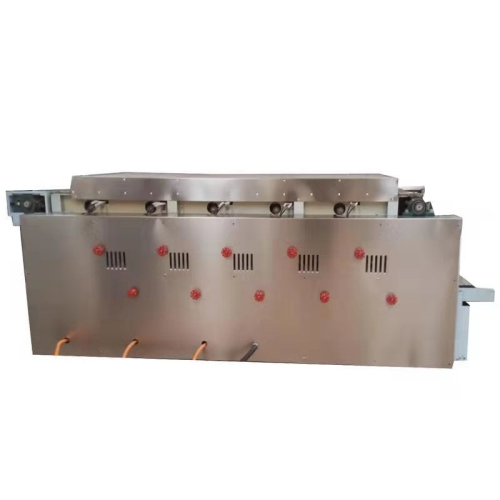

Cooling tunnel for biscuits and chocolates

Ensure product quality and consistency with precision-controlled cooling tunnel...

Cooling tunnel for biscuit and chocolate production

Ensure consistent quality control in your confectionery production wi...

Mechanical conveyors for powder transport

Optimize your powder and granule handling with precise, customizable conveying s...

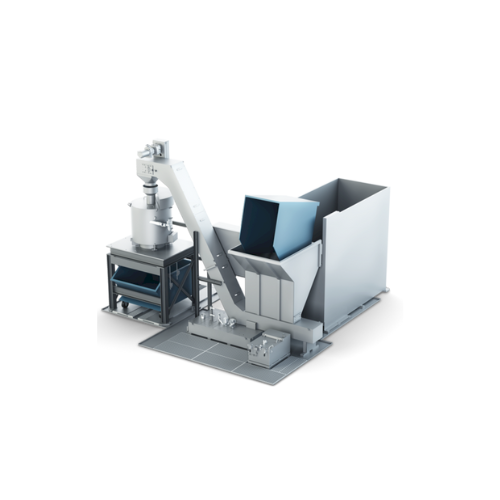

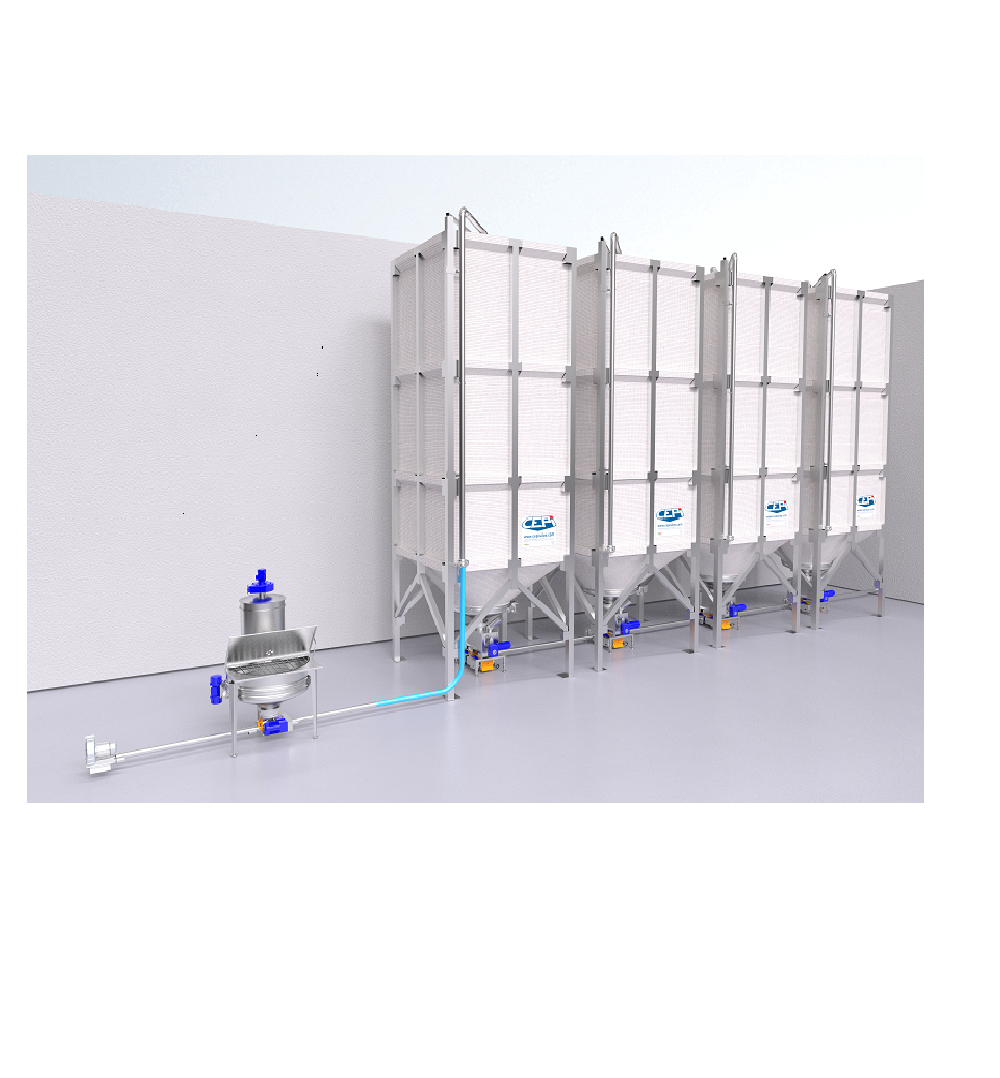

Powder unloading systems for food and dairy applications

Streamline your powder handling with customizable unloading syst...

Bucket elevators for bulk material handling

Efficiently transport and discharge granular and powdered materials with preci...

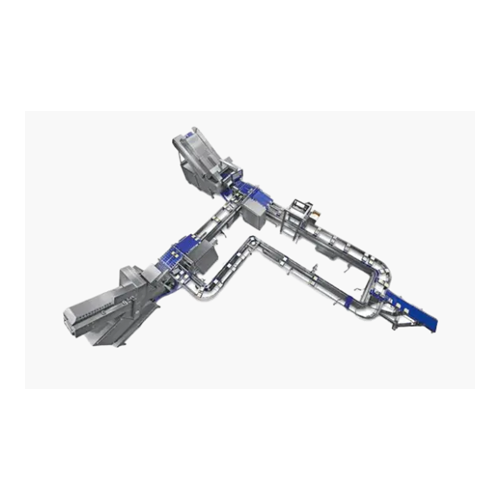

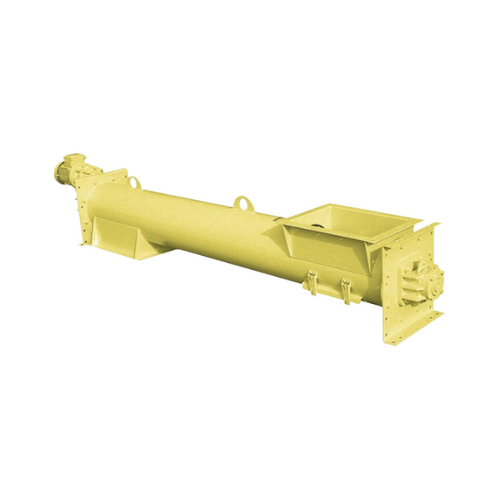

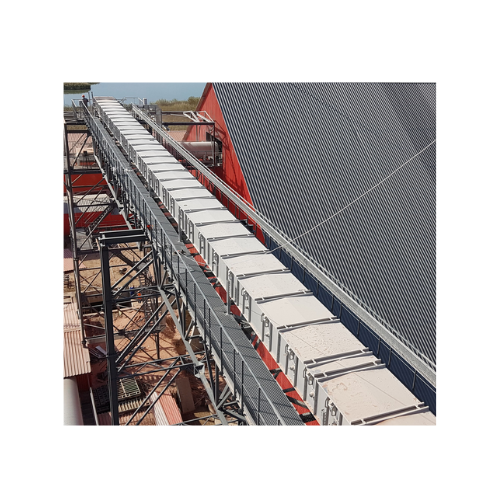

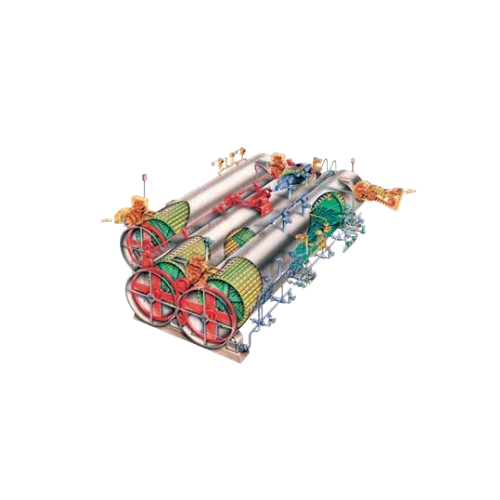

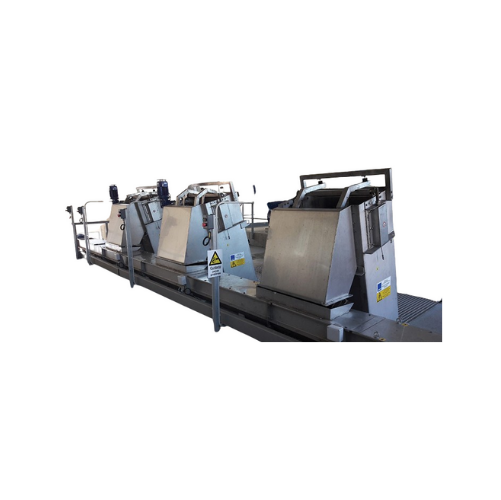

Chain conveyors for long-distance bulk material transport

Efficiently transport challenging bulk materials across long d...

Efficient powder and granulate flight conveyors

Elevate your production efficiency with our cutting-edge flight conveyors,...

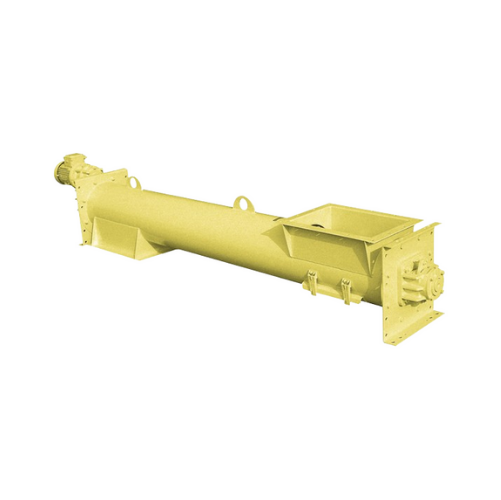

Screw conveyors for grain processing and feed mills

Optimize your production line with versatile screw conveyors, designe...

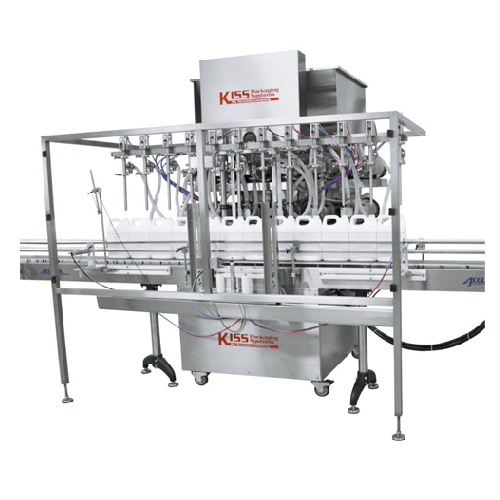

Pick and place cartoning solution for Hdpe bottles

Streamline your packaging process with precise HDPE bottle handling an...

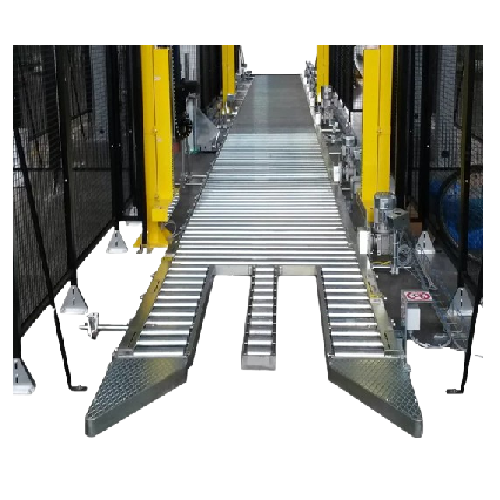

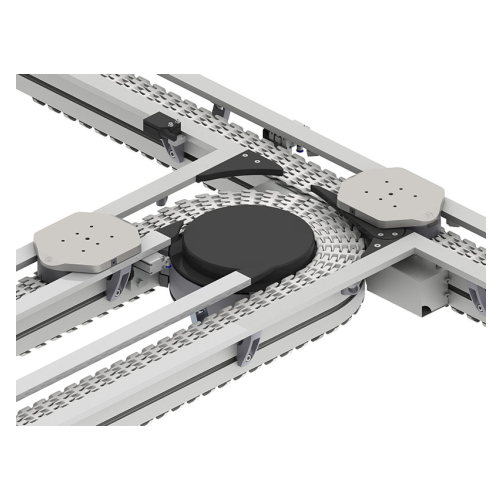

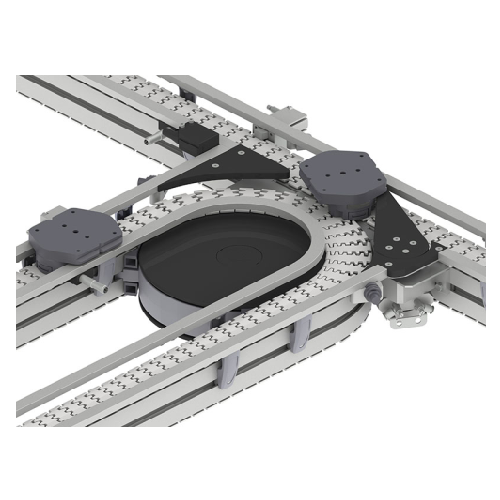

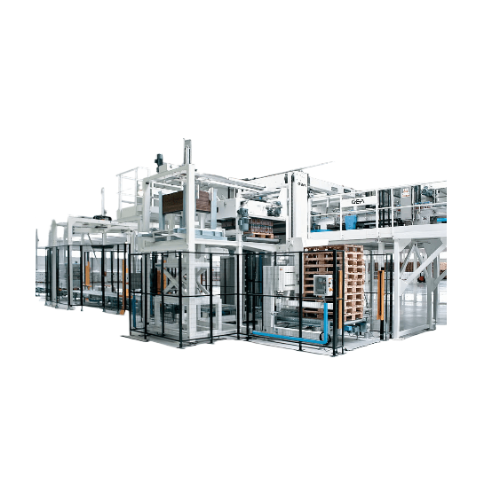

Pallet handling system

Streamline your production line with advanced pallet handling solutions that efficiently automate conv...

Inspection system for glass containers

Ensure precise inspection of liquid, freeze-dried, and powdered products in glass co...

Potato destoner for efficient vegetable processing

Streamline your vegetable processing with a potato destoner that effic...

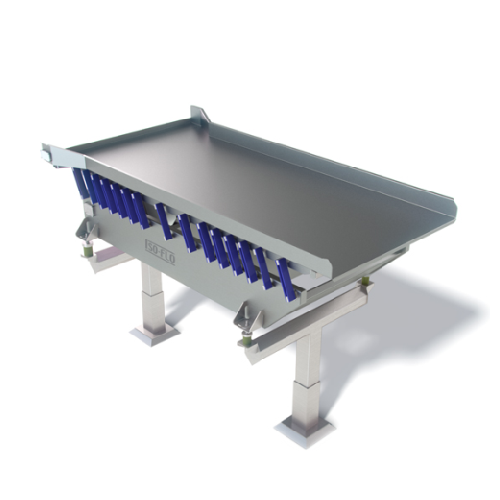

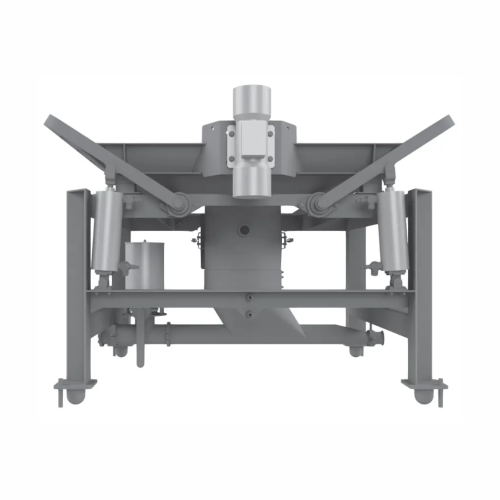

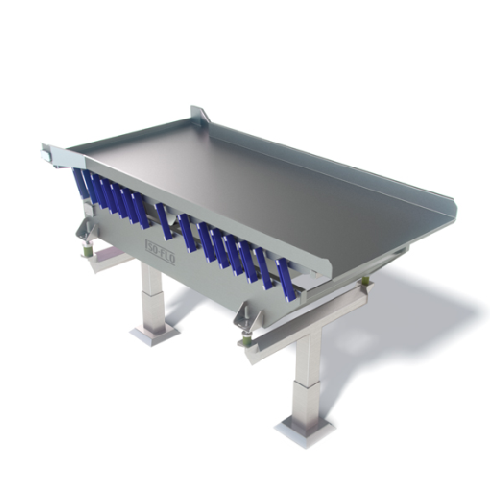

Vibrating sorting table for pre-dewatering

Efficiently streamline your production with a versatile vibrating sorting table...

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

Vertical vibratory tablet deduster for pharmaceutical tablets

Ensure optimal cleanliness and quality assurance for table...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety ...

High-containment tablet deduster

Ensure optimal purity and safety in pharmaceutical production with high-containment dedusti...

Capsule polisher for pharmaceutical production

Enhance capsule quality and safety by effectively polishing, dedusting, and...

Capsule polisher for pharmaceutical capsules

Ensure your capsules are free from dust and perfectly polished with a solutio...

Extruder for pliable mixes in industrial applications

Achieve precision in creating diverse extruded food products with t...

Versatile syrup room systems

Streamline beverage production with a system that expertly handles dissolving, mixing, and past...

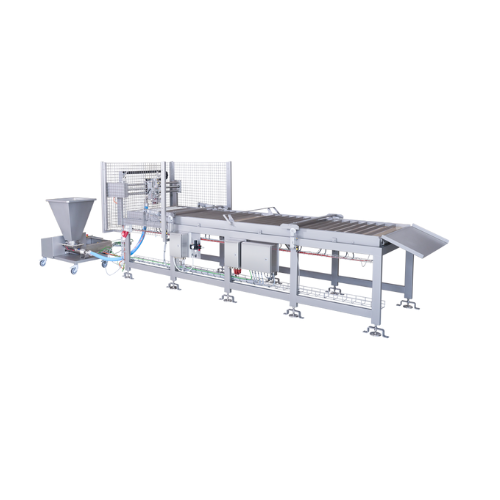

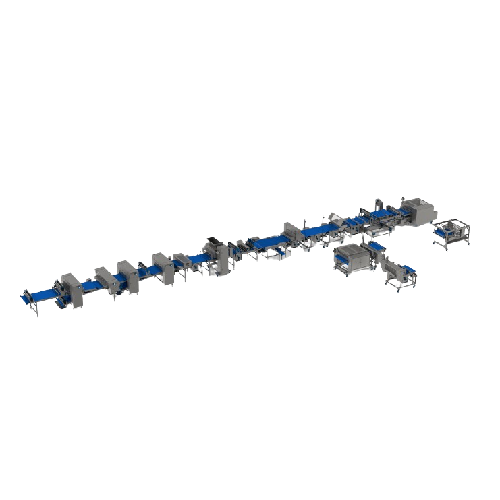

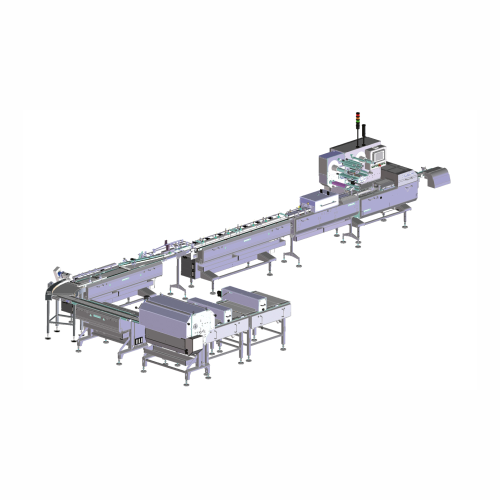

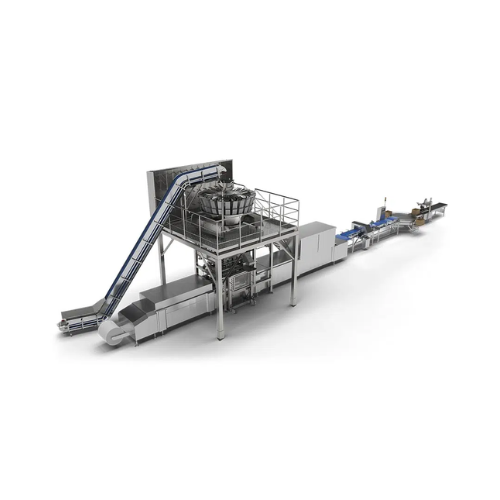

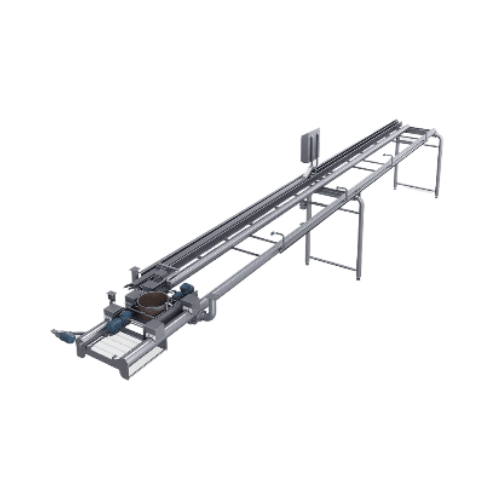

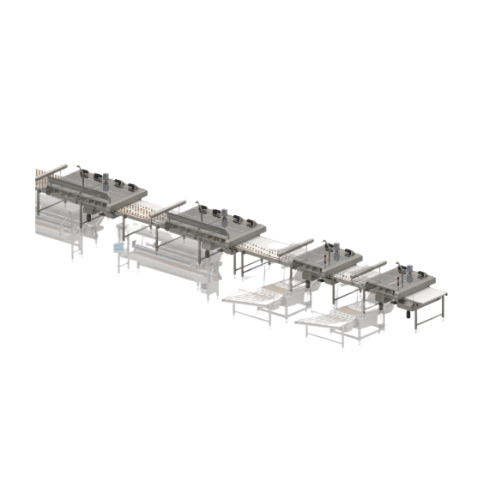

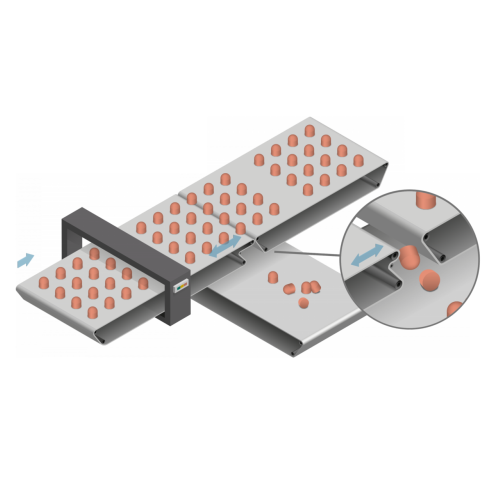

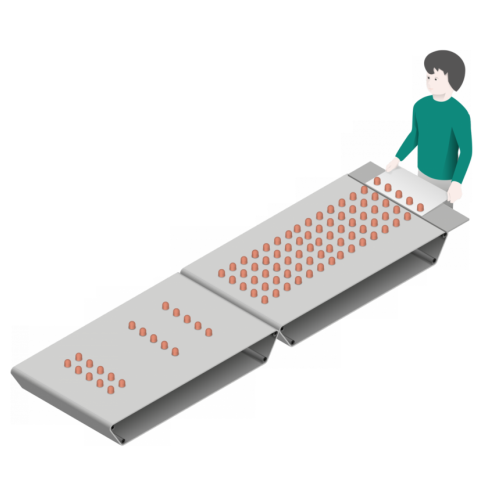

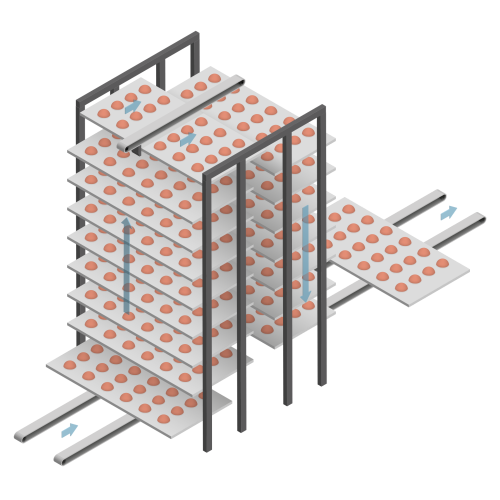

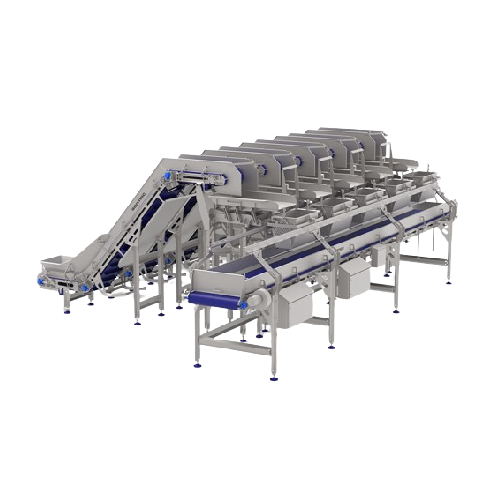

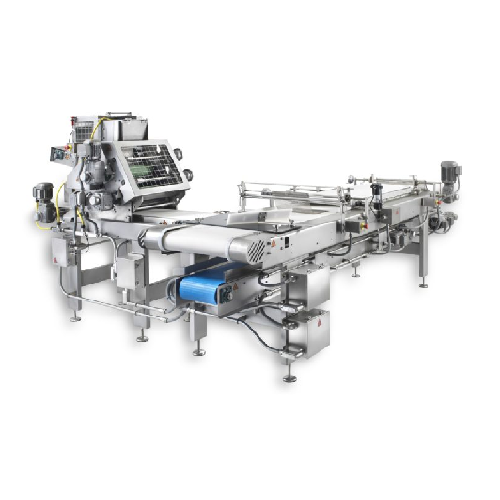

Industrial transfer conveyor system

Efficiently transport and sort diverse food products with precision, ensuring seamless ...

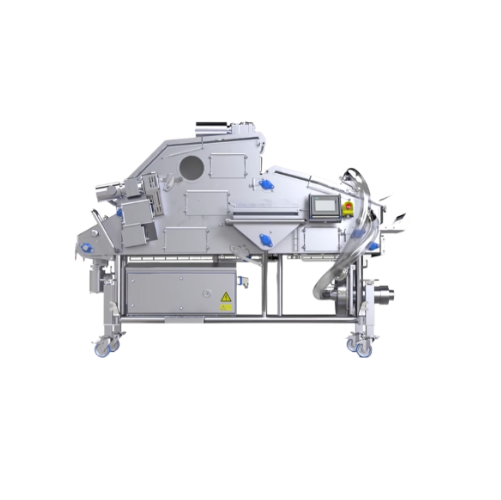

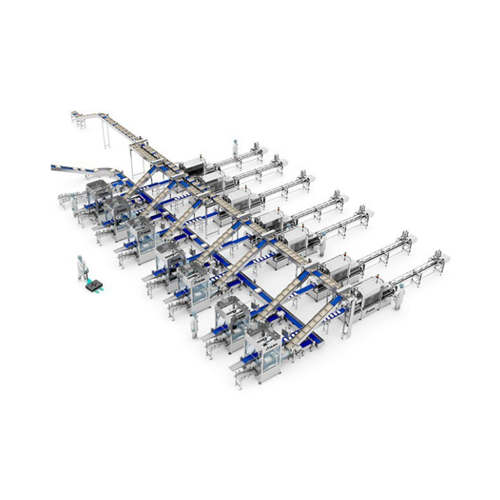

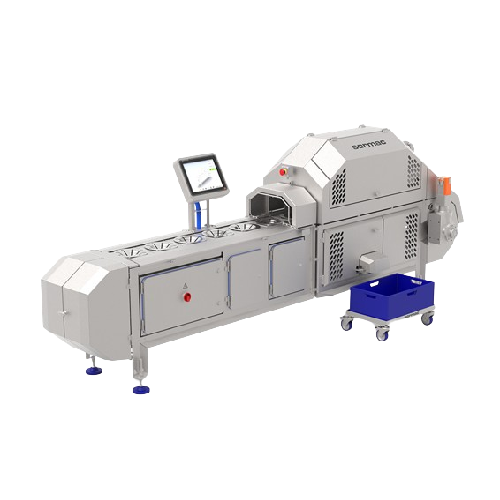

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

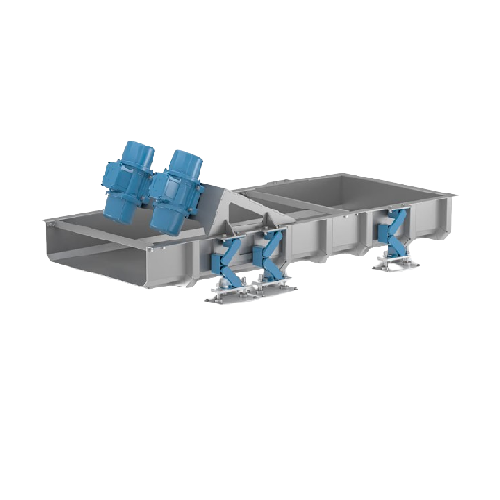

Tackle complex product mixing challenges with a system that seamlessly integr...

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

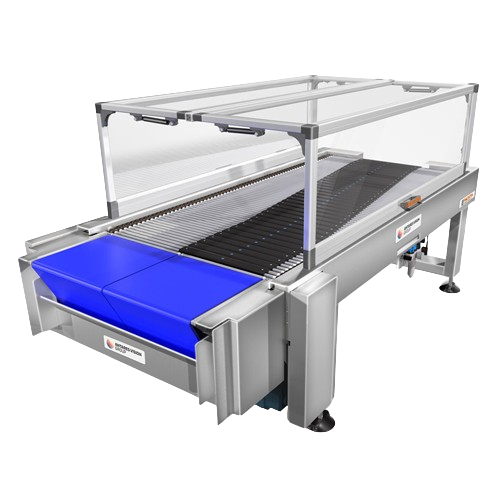

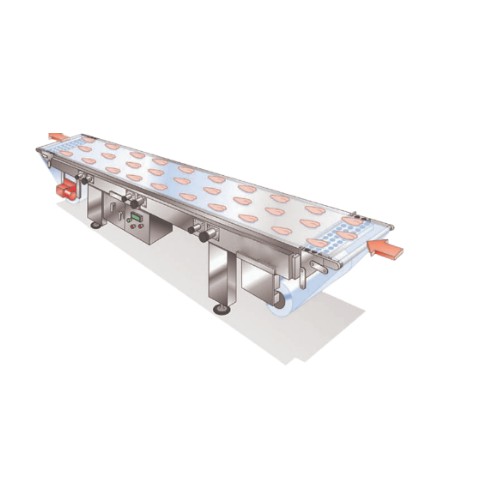

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Commercial meatball roasting tunnel

Achieve consistent roasting of diverse products, from meatballs to grilled tofu, while ...

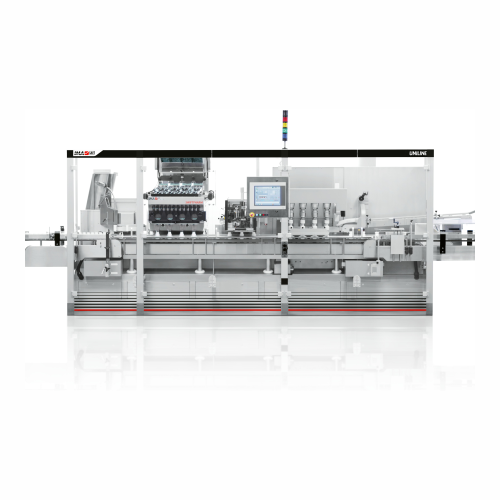

Integrated counting system for tablets and capsules

Streamline your packaging line with a highly versatile system that se...

Green coffee intake systems

Streamline your green coffee bean processing with versatile systems that manage intake, conveyin...

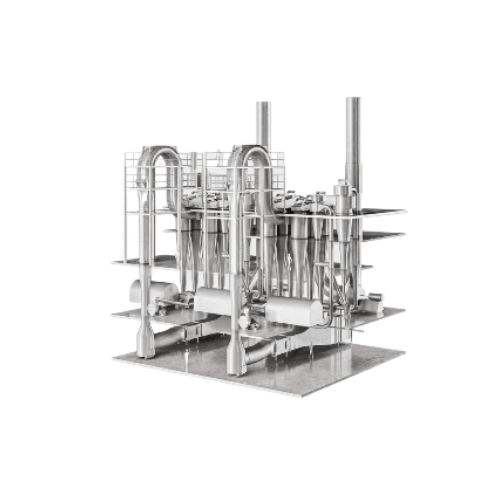

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Belt elevator for seed transport

Optimize your production line with a customizable belt elevator designed to efficiently tra...

Hygienic conveyor belts for food manufacturing

Ensure bacteriological safety and boost productivity with hygienic conveyor...

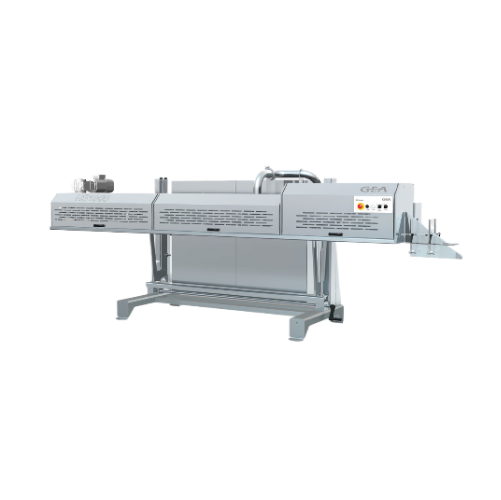

Meat flattener for kebab, schnitzel, or turkey breast

Achieve consistent thickness for optimal cooking with this flattene...

Cream preparation plant for wafer production

Achieve consistent cream texture and optimal weight for perfect wafer product...

Cream preparation plant for homogeneous mixing

Optimize your snack production with precise mixing technology, ensuring con...

Intermediate container for raw material preparation

Streamline your snack and cereal production with this solution that e...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

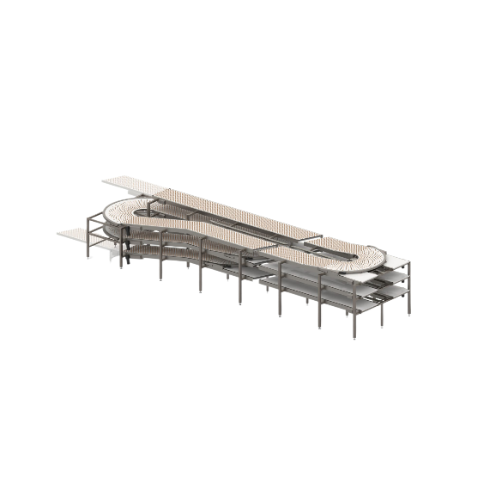

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

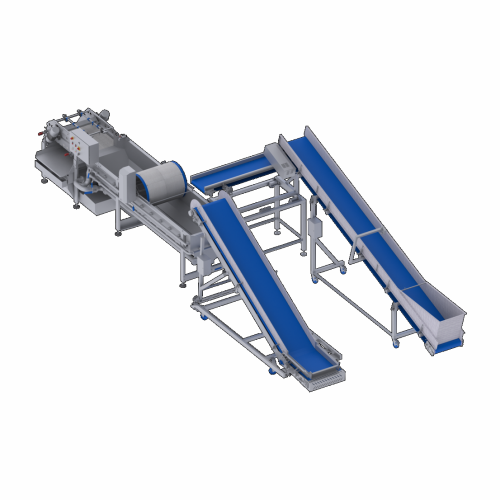

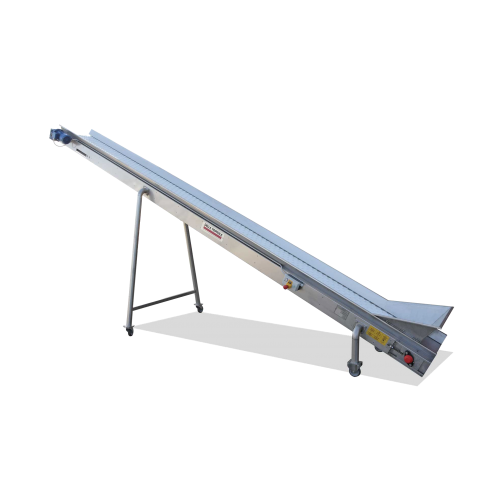

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

High-temperature extractor weigh belt feeder for clinker

Handle hot, abrasive products like clinker seamlessly with a rob...

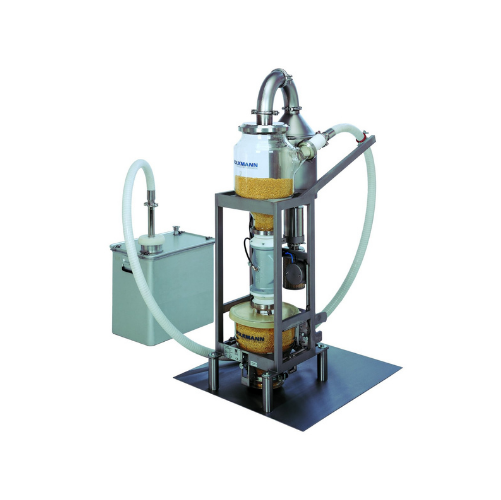

Ultra-hygienic vacuum conveyor for pharmaceutical industry

Optimize powder transfer with ultra-hygienic vacuum conveying...

Vacuum conveyor for hygienic material transfer

For operations demanding swift, dust-free material handling, this solution ...

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Filled capsule conveyor system for pharmaceutical production

Ensure gentle and efficient conveying of filled capsules in...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

Pneumatic truck unloading for bulk tankers

Efficiently unload bulk materials from trucks with minimal dust emissions while...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

Heavy duty blowing seals for abrasive products

For operations dealing with abrasive materials under high pressure, these r...

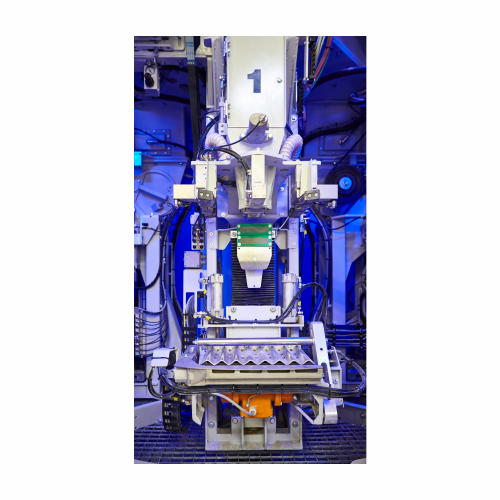

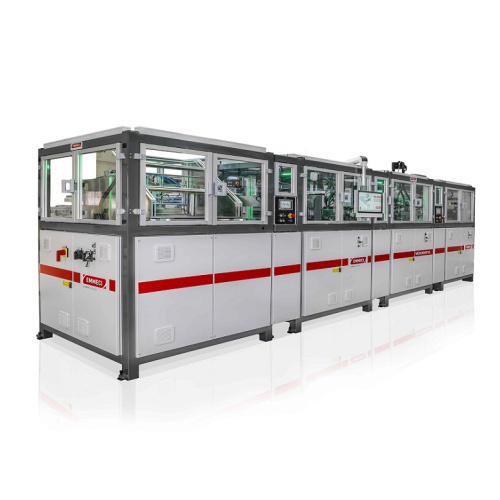

Continuous direct compression system for tablet production

Achieve seamless continuous direct compression by integrating...

Air pelletizer for wood and natural fiber compounds

Optimize your pelletizing process with air-based cooling and conveyin...

Stainless steel tanks with belt conveyors for grapes

Streamline your grape processing with efficiently designed stainless...

Tanks with screw conveyors for grape reception

Optimize grape reception with customizable tanks equipped with screw convey...

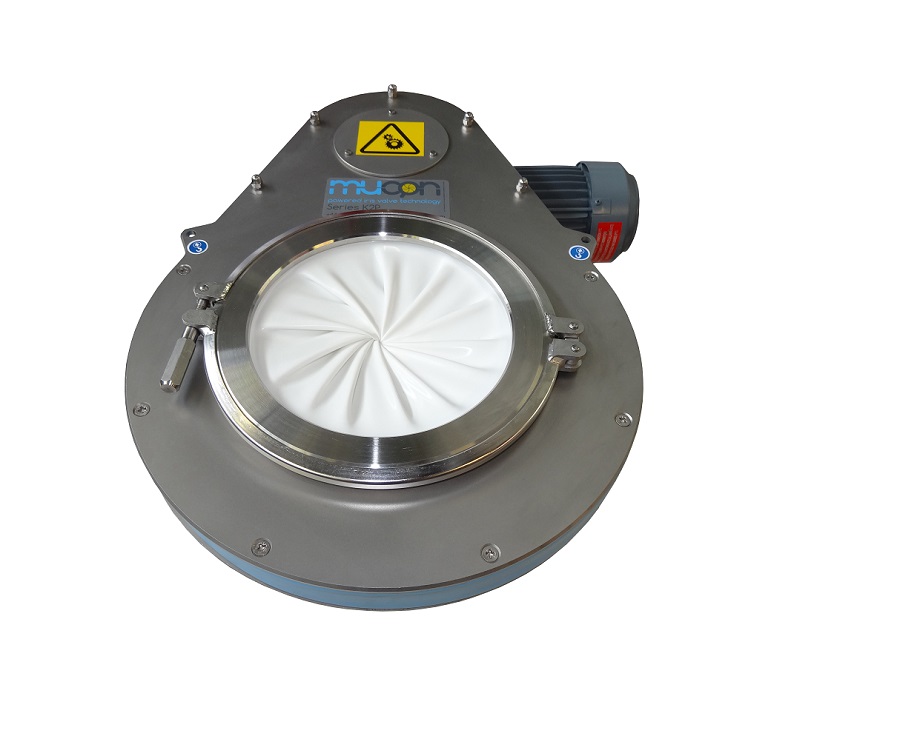

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Supply conveyor with integrated bulb inspection belt

Ensure consistent quality and efficiency in bulb processing with a c...

Sanitary bulk solids receiver for food and pharma

Ensure precise control over bulk solid transfer with a system designed ...

Batch weigh vacuum receiver

Optimize precision in ingredient batching and streamline your production line with advanced vacu...

Feed bins for pre-conditioning materials

Optimize your material flow by pre-conditioning bulk solids for efficient vacuum c...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

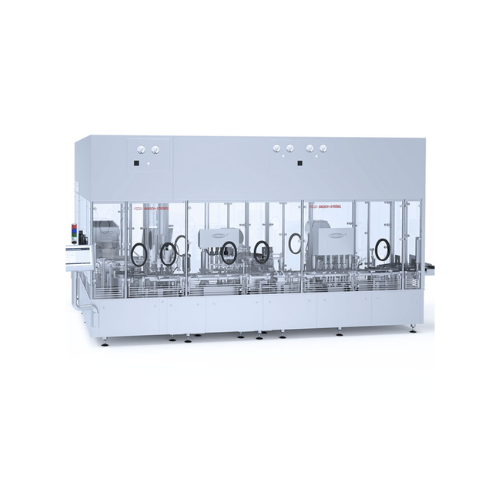

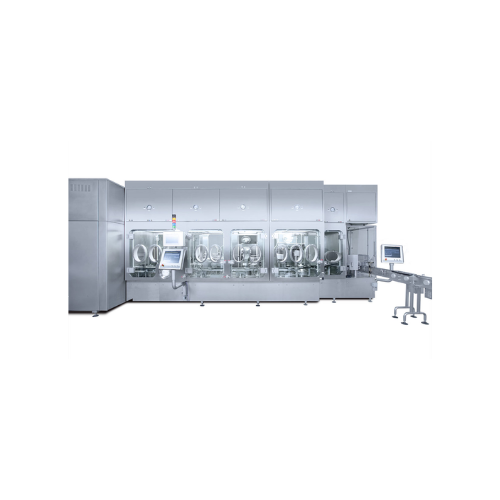

High-throughput aseptic isolator for syringes and vials filling

Streamline your aseptic filling process with a high-spee...

Tube in-feed conveyor for cosmetic packaging lines

Streamline your packaging process with precision by efficiently transf...

Smart shaker for dough centering

Achieve perfect dough centering and uniformity with an innovative three-motion shaker that ...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Horizontal hammer mill for grain processing

Optimize your grinding processes with our horizontal hammer mill, designed to ...

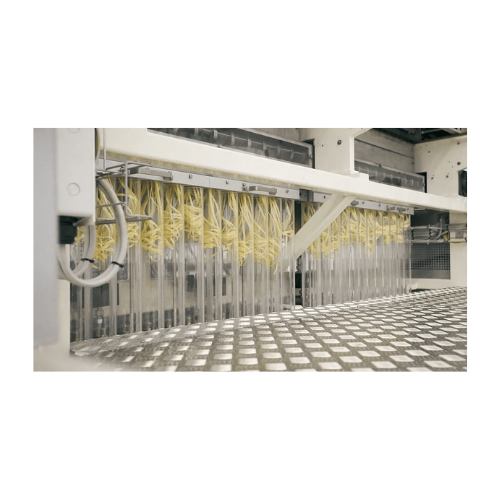

Continuous dough rolling unit for noodles

Ensure your noodle production maintains consistent quality with precise dough th...

Trough screw conveyor for transporting grains

Efficiently transport and handle bulk materials like grains and flour with r...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Compound rolling unit for dough sheets

Achieve unparalleled precision in dough formation with our high-speed compound rolli...

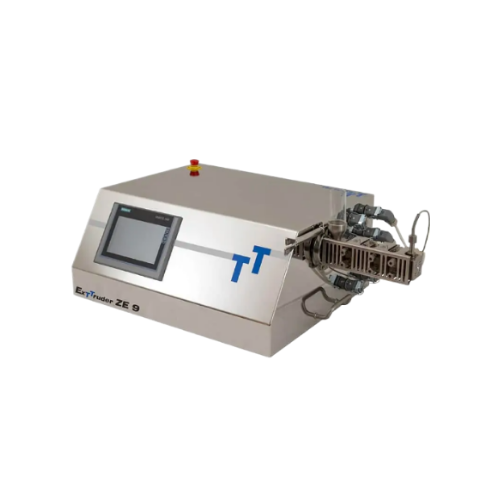

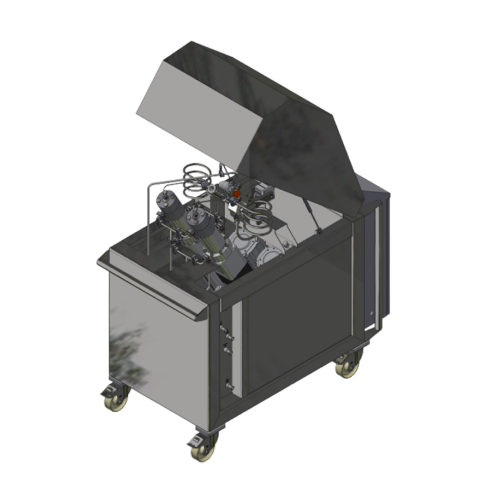

Lab-scale twin screw extruders for material development

Accelerate your formulation testing and material development with...

Conveyor belt for extruded profiles

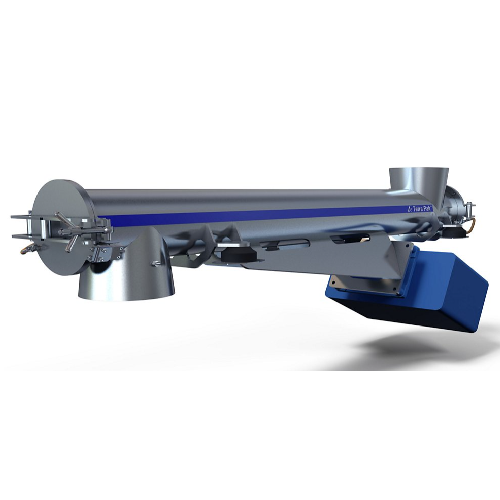

Efficiently transport and convey extruded profiles with precision through adjustable sp...

Chain belt conveyor for waste paper and industrial waste

Optimize your waste processing with a robust chain belt conveyor...

Bag feeding hopper for bulk solids

Optimize your material handling with a robust feeding hopper that seamlessly integrates ...

Precise dosing system for bulk materials

Ensure precise bulk material dosing with minimal dust, seamlessly switching betwee...

Fine chemical powder system

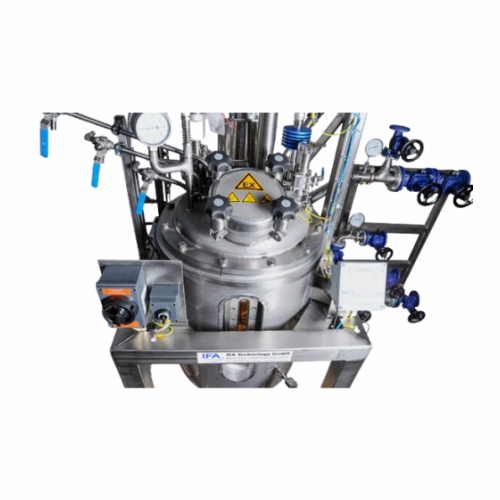

Optimize your powder processing with a solution tailored to handle complex feeding, conveying, a...

Automatic shumai production equipment

Boost your production capacity with high-speed shumai equipment, offering adjustable ...

English muffin production system

Maximize your bakery’s output with our high-speed system designed to efficiently produce co...

Pie production line for sweet and savory pies

Optimize your pie production efficiency with this integrated system, designe...

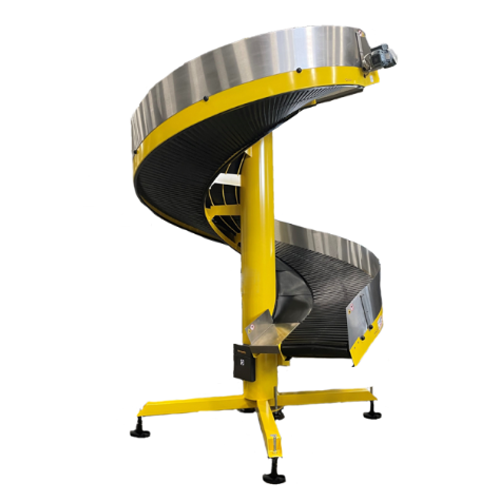

Spiral conveyor for logistics and packaging

Ensure seamless elevation and transportation of diverse products with this ver...

Narrow belt spiral conveyor for small packages

Optimize your production flow with this compact spiral conveyor system, des...

Industrial tunnel oven for baking and step proofing

Optimize your production line with modular tunnel ovens and step proo...

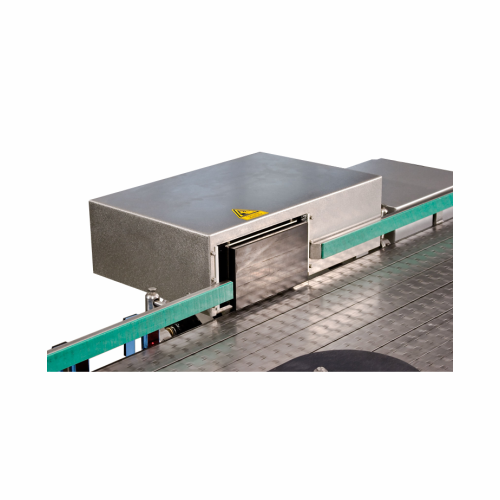

Compact accumulation conveyor for liquid containers

Optimize your space with an ultra-compact conveyor that ensures seaml...

Spiral conveyor for individual bottles and cans

Streamline your production line’s space and layout with a compact co...

Packaging conveyor for efficient bag handling

Simplify your packaging line with a conveyor designed to efficiently transfe...

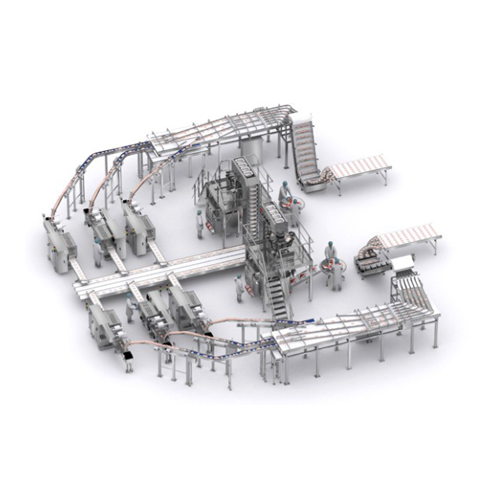

Smart pack conveyor systems for packaging room

Efficiently manage the flow of snack and nut products from packaging to dis...

Conveyors for material handling in food processing

Streamline your snack production line with conveyors designed to effic...

Ergonomic melt systems for solid food and personal care products

Eliminate manual lifting and enhance safety by integrat...

Vegetable and fruit processing skid

Optimize your fruit and vegetable processing with a compact skid that seamlessly integr...

Preparation line for fresh produce

Streamline your fresh-cut processing with this efficient preparation line, facilitating ...

Single pass dryer for fresh produce

Optimize your fresh produce processing with a continuous drying solution that enhances ...

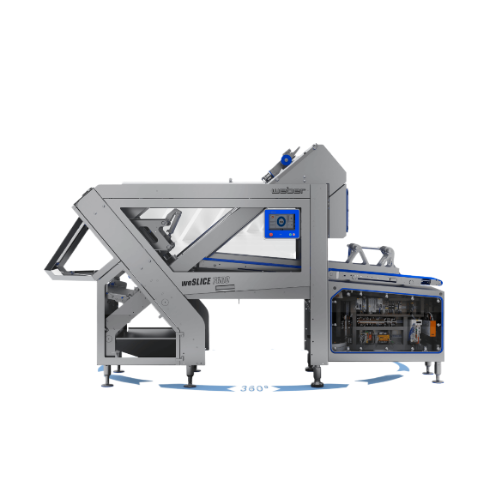

Slicing loader for automatic portion loading

Efficiently manage portion loading with a system designed to balance slicing ...

Continuous raw material distribution screw doser

Optimize your material flow with a screw doser designed for precise and c...

Industrial bucket elevator for efficient product conveyance

Enhance production efficiency by elevating and transferring ...

Silo unloading belt for food industry

Ensure seamless flow and precise control when unloading silos with this automated bel...

Big bag emptying station for raw materials

Streamline your material handling process by efficiently lifting, emptying, and...

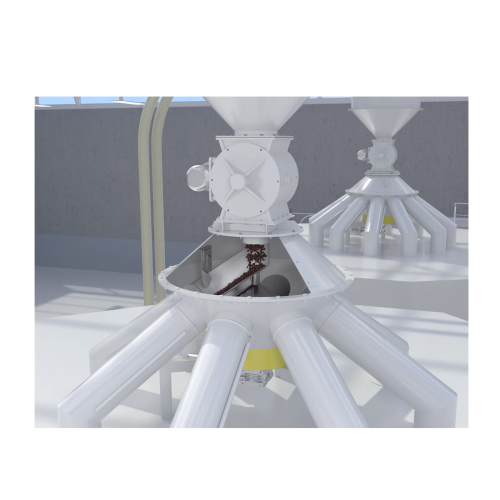

Bulk storage silos for food products

Ensure optimal powder storage and handling with versatile silos designed for efficient...

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

Vibrating conveyor for powder and granule handling

Effortlessly convey and process fragile products with precision, minim...

Industrial spiral cooler for thermal treatment

Improve your final conditioning and packaging process with a spiral cooler ...

Industrial water cooling system for food products

Efficiently cool and convey food products with a system designed for un...

Conveyor cleaning and cooling system for pasta

Efficiently halt cooking processes and eliminate surface starch with a stre...

Integrated small-scale granulation and drying system

Ensure precise granule size and moisture control for enhanced tablet...

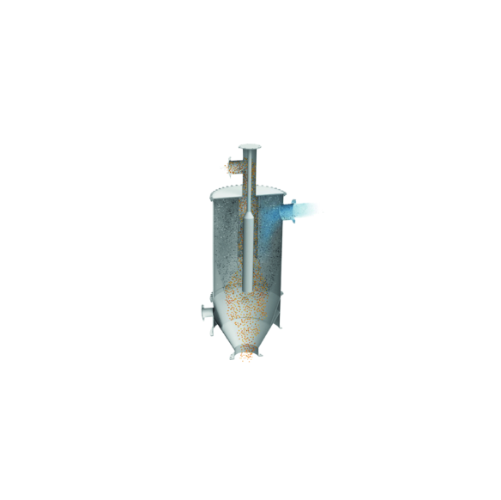

Cyclone separator for pneumatic conveyor systems

Enhance efficiency in pneumatic conveyor systems by effectively separatin...

Automated process controllers for industrial plants

Enhance your production line’s efficiency and adaptability with...

Industrial rotary sifter for bulk materials

Ensure precision and quality in your production line with a robust solution de...

Technical plastics production system

Optimize your production line by integrating a versatile system capable of precise mix...

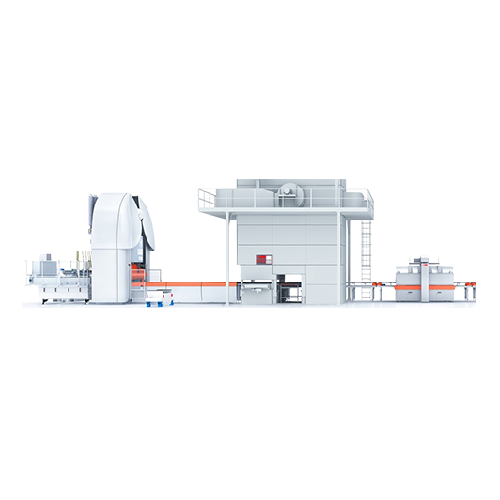

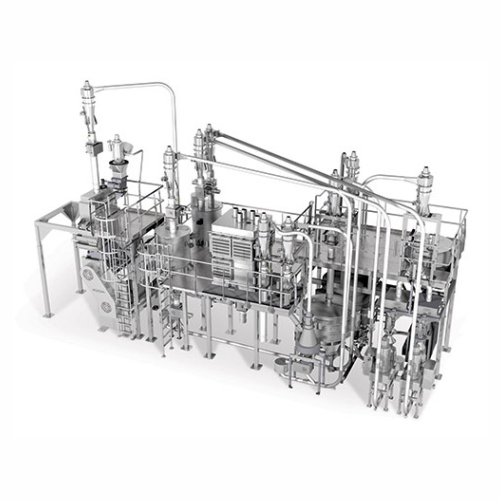

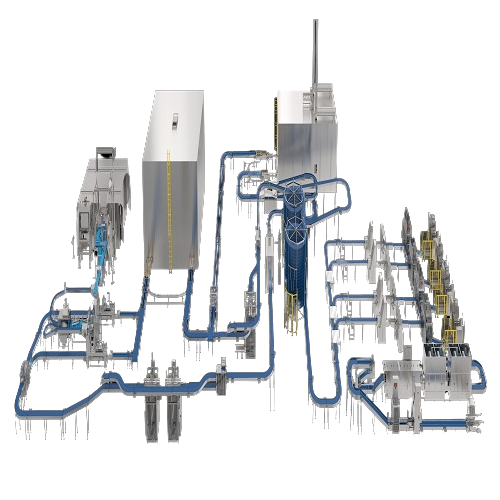

Turnkey plant solutions for industrial applications

Enhance your production line with seamless integration and optimized ...

Negative pressure filter for fine dust particles

Ensure efficient air purification and dust collection in your production ...

Vacuum hopper loader for automatic feeding of powders and pellets

Optimize your material handling with seamless automat...

Short base skirt silo for bulk material storage

Optimize your bulk material handling with adaptable discharge and rapid lo...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

Industrial multi-chamber silos

Optimize spatial efficiency and streamline your production with versatile multi-chamber silos...

Process control for baked goods production

Enhance your production line with precise process control designed to optimize ...

Pta and Pet production systems

Maximize throughput while minimizing dust fines in your production of PTA and PET pellets wit...

Storage silo with long base skirt for processing industry

Optimize your bulk material storage with a silo that offers du...

Sampler for powdered and granular bulk materials

Ensure precise sampling of powdered and granular materials under varied o...

High-efficiency pellet dust separator

Achieve unparalleled separation efficiency in your polymer production line by removin...

Horizontal cooling mixer for industrial applications

Efficient cooling in your production line enhances material quality ...

High-pressure rotary feeder for continuous powder handling

Optimize your production line with reliable powder handling, ...

Advanced degassing and temperature control solution for process silos

Optimize your production line with precise contro...

Rotary feeder for powdered bulk materials

Achieve precise control in feeding and discharging powdered materials with a rot...

Advanced plant engineering services

Optimize your production line with seamless integration of high-efficiency mixing, dosi...

High-pressure rotary feeder for bulk material handling

Manage high-pressure bulk material distribution with precision, en...

Continuous material handling in compounding plants

Enhance your production line efficiency with advanced dosing, mixing, ...

Dispersion paint production systems

Achieve 100% color accuracy and flexible production with our advanced system, ensuring ...

Continuous pneumatic silo air filtering system

Ensure clean and efficient pneumatically conveyed materials by integrating ...

A-type rotary feeder for powder and pelleted bulk materials

Ensure precise feeding and discharging of powdered and pelle...

Battery production facilities with precision weighing

Achieve maximum product purity and precision in your production pro...

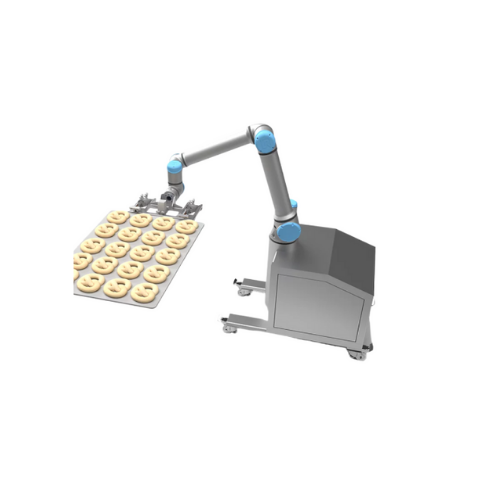

Robotic gripper arm for bakery tray and product handling

Optimize your bakery’s efficiency by automating repetitive...

Modular roll baking system for small bakery items

Optimize your bakery production with a modular roll baking system that ...

Coating and enrobing system for pet foods and treats

Achieve precise coating and flavoring of various food and feed produ...

Automated transport system for cold-cuts in confined spaces

Optimize your production flow by conveying cold cuts efficie...

Biogas plant screw press separators

Maximize your renewable energy output and processing efficiency with cutting-edge solid...

Screw compactor for wastewater treatment

Optimize waste management with a versatile screw compactor designed for efficient ...

Screw screens for solids-liquid separation in waste water

Achieve crucial solids-liquid separation with screw screens de...

Overflow spillway filter for wastewater treatment

Effectively manage overflow wastewater with this advanced filtration sy...

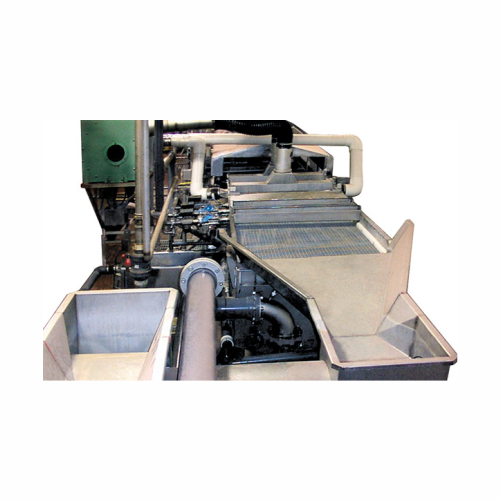

Fine belt screens for wastewater treatment

Efficiently screen and convey solids from wastewater with in-channel fine belt ...

Tapered single shaft screw feeder for flour mills

Ensure consistent material flow and minimal residue with this precise s...

Double dump valves for high temperature granules

Ensure precise material flow and withstand extreme temperatures with thes...

Septage receiving station for septage treatment

Optimize your wastewater management by integrating a station that screens,...

Filler dust feeder for asphalt plants

Ensure consistent asphalt mixture quality by efficiently feeding and conveying hot an...

Tubular screw conveyor for concrete production

Optimize your production line with a versatile solution designed for effici...

Tubular screw conveyor for powdery and granular materials

Optimize your material handling processes with a versatile sol...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Fine drum screens for wastewater treatment

Streamline your wastewater treatment process by seamlessly integrating a rotati...

Shaftless spiral conveyor for difficult waste handling

Efficiently tackle complex waste handling challenges with a design...

Single shaft screw feeders for consistent material feeding

Tackle challenging materials with poor flow characteristics b...

Vertical screw conveyors for sludge handling

Efficiently lift and blend sludge with minimal footprint and costs, while ens...

Vertical screw conveyor for sludge handling

Efficiently raise and blend sludge with minimal footprint and reduced installa...

Horizontal screw press separators for biogas plants

Achieve efficient solids-liquid separation with continuous operation,...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Tubular ribbon flight screw feeder for lime feeding

Experience uniform material flow and precise dosing with this special...

External electric motovibrators for hazardous environments

Ensure safety and efficiency in explosive environments with t...

High-temperature screw conveyors for bulk solids

Designed for extreme conditions, these conveyors handle high-temperature ...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrator for increased safety in hazardous environments

Designed for environments with explosive...

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Vertical conveyor for fine aggregates and minerals

Optimize the handling of abrasive materials with a vertical conveying ...

Cement screw conveyors for concrete batching plants

Ensure precise cement mix delivery with this essential equipment, des...

Cement screw conveyors and feeders for concrete batching plants

Enhance material flow and precision in concrete producti...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Trough screw conveyors for animal by-products

Streamline the processing of animal by-products with reliable conveyors desi...

Screw conveyors for fresh concrete

Ensure uniform and continuous transport of fresh concrete from mixers to molds, minimizi...

Tapered twin shaft screw feeders for bulk solids

Ensure consistent flow and avoid material bridging challenges with a solu...

Tubular trough screw conveyors for gentle powder and granular material handling

Achieve precise powder and granular ma...

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying des...

Powder handling vacuum conveyor system

Streamline your material transfer with a versatile vacuum conveyor system that ensur...

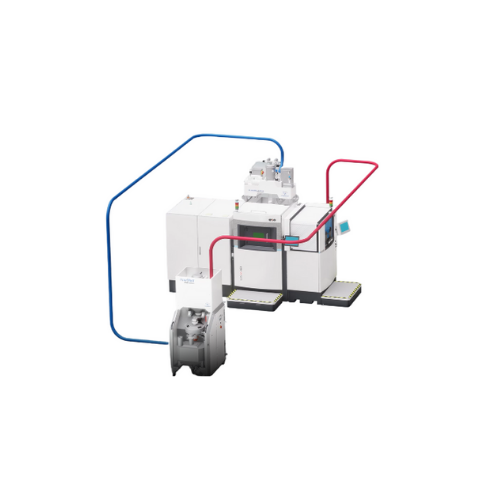

Closed powder handling loop for Eos metal Am printers

Effortlessly manage metal 3D printing powders with a solution that ...

Metal powder recovery system after 3d printing

Effectively reclaim and purify metal powders after 3D printing to enhance c...

Industrial vacuum pumps for efficient powder conveyance

Harness the power of efficient vacuum generation to streamline th...

Containment system for product loading

Ensure safe handling of hazardous materials with this containment system, designed t...

Continuous vacuum conveyors for material flow control

Ensure consistent material transfer and reduce downtime in your pro...

Automatic metal powder filling system for 3d printers

Ensure seamless operation of your 3D printing process with a system...

Docking station for intermediate bulk container (ibc)

Streamline your metal powder management by efficiently connecting a...

Buffer tanks for brewery spent grains

Enhance brewing efficiency by immediately freeing up the lauter tun, allowing for mor...

Steam heated tube bundle dryer

Efficiently achieve precise moisture control and gentle drying for diverse feedstocks with th...

Spent grain conveyor for breweries

Optimize brewery efficiency by transporting wet spent grains effortlessly and securely f...

Wet spent grains pre-dewatering system

Optimize your brewery operations with a dewatering system that efficiently reduces m...

Drying systems for alcohol production

Enhance your spirits production with precise moisture control and nutrient retention,...

Conveyor belts for hot and cold product handling

Efficiently transport hot and cold goods with versatile conveyor solution...

Automated production lines for cakes and cupcakes

Streamline your bakery’s production line with a versatile automat...

Screw feeder for factory filtration systems

Optimize your factory systems with a screw feeder engineered to streamline was...

Industrial airlock for pneumatic systems

Ensure precise air and product separation in your pneumatic systems, maintaining m...

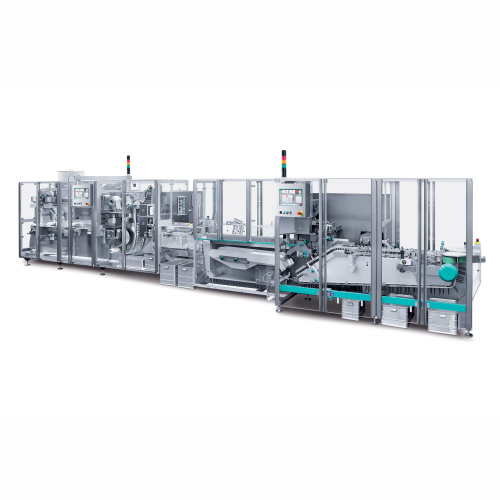

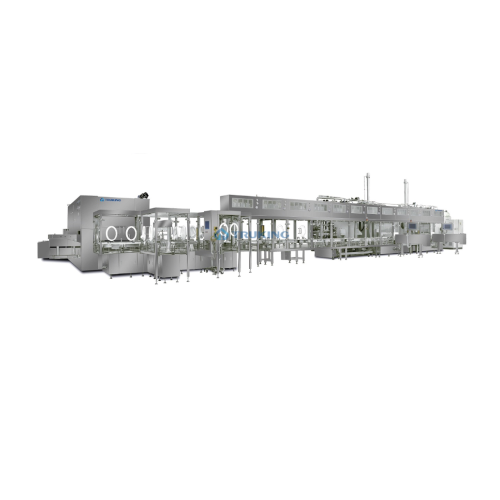

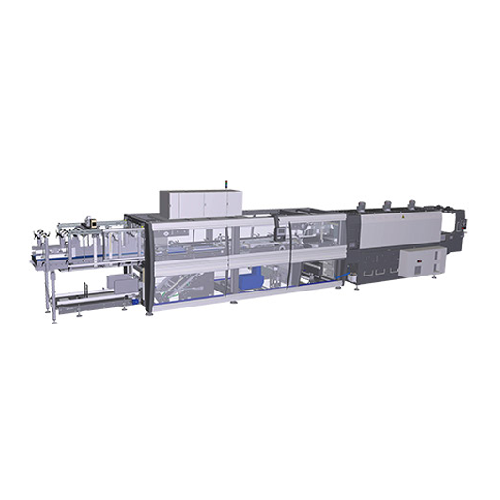

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Table-top mini extruder for precision material processing

Achieve precise control over complex formulations with this fl...

Table top extruder for customizable extrusion processes

Discover versatile extrusion capabilities for developing complex ...

Twin-screw extruder for versatile manufacturing processes

Optimize your production line with a high-capacity extruder th...

Mini extruder for early development phase testing

In early development, tackling limited material availability is crucial...

Mini extruder for small batch processing

Ideal for precise control in experimental formulations, this mini extruder streaml...

Conveyor belt laboratory for cooling extrudates

Achieve precise temperature control for high-temperature extrudates with a...

Cooling conveyor belt for extrudates and granules

Efficiently cool and convey extrudates and granules with precise temper...

Hygienic trough-shaped conveyor belt for vegetable processing

Optimize your vegetable processing line with a hygienic so...

Food production conveyors for efficient material handling

Streamline your food production with versatile conveyors desig...

Continuous sugar dissolver for beverage and food production

Efficiently dissolve crystalline sugar in water up to 65°Bri...

Salt dispenser for cheddar cheese production

Achieve consistent salt concentrations in cheese production with a reliable d...

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this...

Cooking and stretching solution for pasta filata cheese

Streamline your cheese production with precise cooking and stretc...

Pneumatic conveyor for fragile powders

Handle your delicate powders with care, ensuring minimal breakdown while achieving h...

Continuous sugar dissolver for beverage production

Optimize your production line with a system that efficiently dissolves...

Automatic cereal bar production line

Efficiently transform diverse ingredients into consistent, high-quality cereal bars wi...

Commercial momo making equipment

Streamline your dumpling and bun production with equipment designed to enhance precision, f...

Accu-feed system for dry material separation

Boost efficiency by combining storage, feeding, and screening into one space-...

Wet granulation for pharmaceutical products

Achieve seamless integration of sifting and milling with precise powder handli...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Blender for whole bean roasted coffee

Achieve precise coffee blend consistency and protect delicate roasted beans with an a...

High-speed container loading system for granulated bulk materials

Optimize your loading operations with a robust system...

Medium pressure gravimetric feeder for pulverized coal boilers

Achieve precise combustion control and optimize fuel effi...

Drop forged chain for drag chain conveyors

Enhance your material flow efficiency with a robust drop forged chain designed ...

En-masse chain conveyor for bulk material handling

Streamline your bulk material handling with a gentle, efficient system...

Industrial belt and bucket elevators

Optimize your material handling with elevators designed for high-speed conveying and e...

Advanced ceramic tile production line

Elevate your ceramic tile production with an all-encompassing solution that seamlessl...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Automatic rework system for biscuit and bread scrap

Scraps are an inevitable byproduct of biscuit and bread production. W...

Industrial vacuum conveyor

Oftentime utilized as an alternative to mechanical conveyors when a requirement for dust free con...

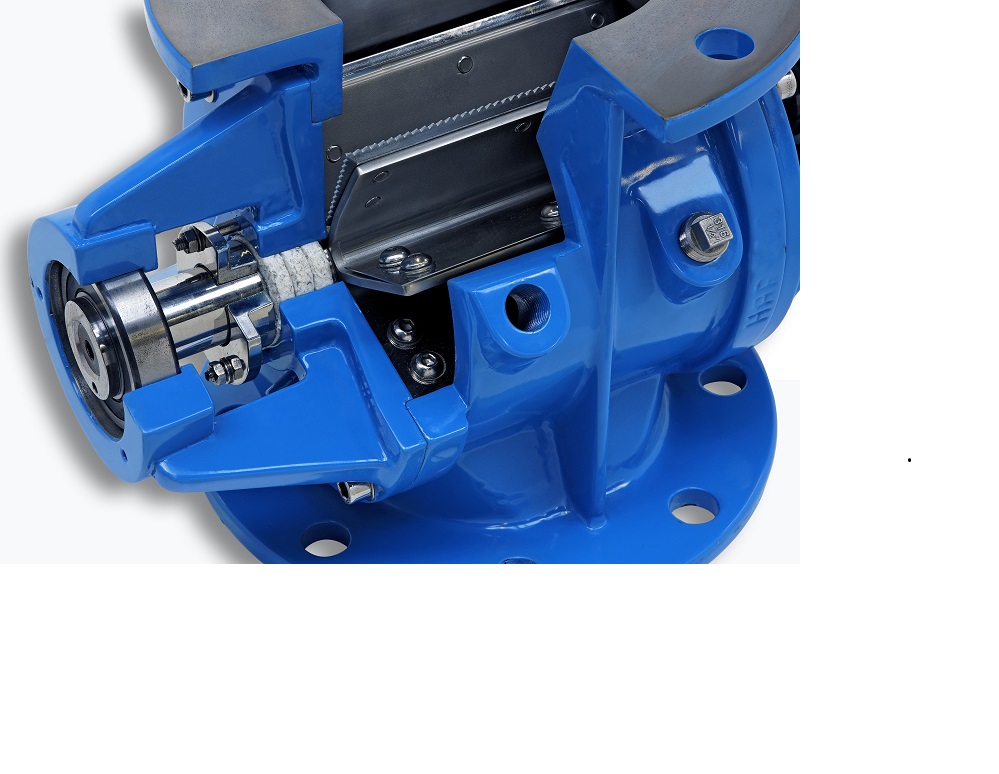

Heavy duty rotary valve

Handling powdered and granulated materials in pneumatic conveying systems requires consistent, safe v...

Special duty horizontal metering valve

Occasionally, there is no suitable standard valve available for a particular conveyi...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

Two-way flap type diverter valve

Routing powder, pellets or granules from a product source to two receiving points must be d...

Dense phase conveyor for abrasive materials

Transporting abrasive materials using pneumatic conveyors can cause excessive ...

Hygienic hand-operated iris valve

Hand-operated valves are required for the walls of clean rooms for glanding around cables...

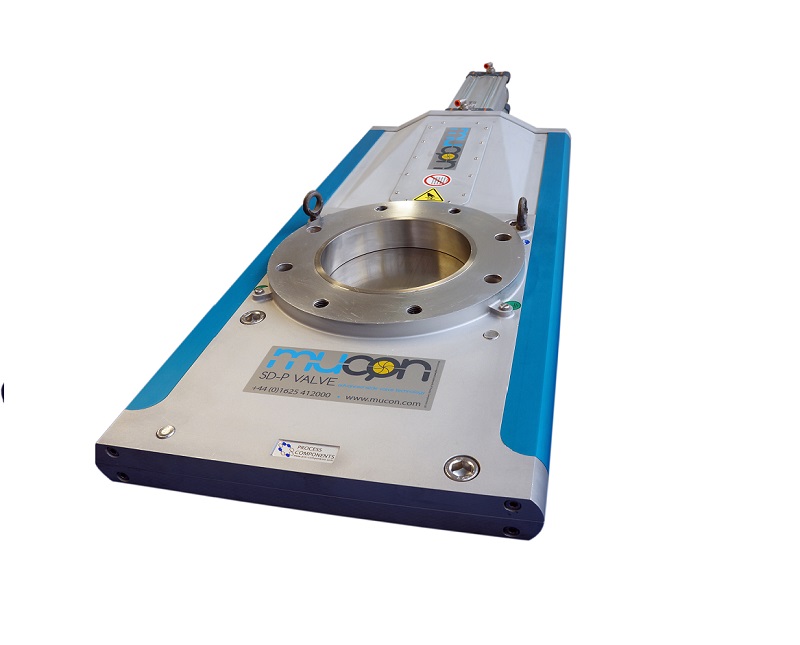

Slide gate valve

In the powder and bulk handling industries, in-line shut off valves are required to provide uninterrupted smo...

Dense phase conveyor for normal wearing materials

Dense phase pneumatic conveying is used for powders, granules, and grai...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Additive and bed material feeding systems

Modern fluidized bed combustion furnaces require consistent and reliable deliver...

Ash handling systems for industrial biomass boilers

The increasing use of solid fuels including biomass for energy conver...

Food vacuum conveyor

Widely used in industries where a high rating in food quality is imperative.

Pipe bend to reduce fines

A specialized pipe elbow for pneumatic conveying systems that virtually eliminates the friction an...

Long distance pneumatic conveyor

Pneumatic conveying of dry bulk materials is a desirable option for many industries because...

Baguette cutting and sauce filling system

Optimize your bakery production with an innovative system that seamlessly cuts a...

Cold block piping solution for breweries

Achieve optimal beverage quality and reduce production costs with this advanced pi...

Cup denester for bakery production

Effortlessly enhance efficiency in bakery production lines by streamlining the process o...

Cake and pastry depanner

Optimize your bakery’s output with this solution that seamlessly integrates into your production lin...

Layer cake production system

Effortlessly streamline your bakery production with a system designed for precise layering and ...

Biscuit sandwiching system

Optimize your biscuit production by seamlessly aligning, overturning, and capping for uniform, hi...

Freezing and cooling systems for bakery products

Enhance your bakery production line with advanced freezing and cooling sy...

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Rotary moulder for high-definition cookie dough shapes

Efficiently shape intricate dough designs with precision, ensuring...

Precise dough sheet cutting station for bakeries

Efficiently shape and cut dough sheets for diverse snack and bakery produ...

Servo in-line dough laminator for industrial bakeries

Optimize your snack production with precise dough sheet cutting, st...

Fried snack extruder for potato rings

Efficiently produce a variety of fried snacks, from potato rings to ethnic noodles, w...

Dough thickness reduction system

Achieve precise dough sheet reduction with controlled thickness to enhance consistency and ...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

Automated dough handling system for pretzel production

Streamline your dough processing with a system that precisely port...

Vertically feeding system for cookie dough

Optimize your dough handling with a system that ensures seamless and efficient ...

Ambient air cooler for bakery products

Efficiently cool fragile baked goods without causing distortion, using ambient air t...

Industrial bread process line

Optimize your bakery operations with a versatile bread processing line, designed to handle a v...

Automated bread production line

Optimize your bakery operations with precision-engineered systems that streamline every stag...

Universal pastry production line for industrial baking

Optimize your bakery operations with a versatile line capable of p...

Mechanized systems for hard cheese molding rooms

Optimize your cheese production with advanced systems designed to streaml...

Mechanical ricotta drainage tunnels

Efficiently manage the draining, drying, and cooling of ricotta and curd with our advan...

Curd drainers and portioners for cheese production

Enhance your cheese production with precise curd draining and portioni...

Turbo block flaker for fats

Achieve quick and precise flaking of chocolate, cocoa butter, and fats with high-speed technolog...

Chocolate enrobing system for industrial production

Effortlessly transition between chocolate types in your high-speed pr...

Industrial chocolate flaking solution

Optimize your confectionery production with high-speed flaking technology, ensuring p...

Chocolate transport system for feeding and packaging

Enhance your chocolate production with a versatile transport system ...

Industrial chocolate flakes production equipment for decorative applications

Achieve perfect decorative chocolate curl...

Continuous cooler for biscuits and chocolates

Enhance cooling efficiency for your confectionery and bakery production with...

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

Industrial chocolate enrobing system for biscuits and fillings

Enhance your production line with this innovative enrobin...

Industrial chocolate flaking system

Achieve precise chocolate flake dimensions effortlessly, enhancing product textures and...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

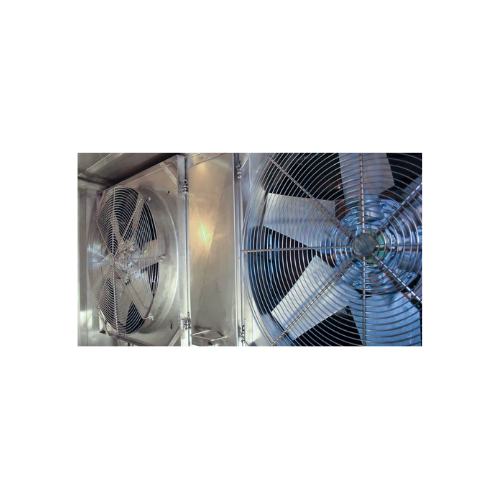

Food processing blower systems

Optimize your production line with precise air handling and moisture control to ensure qualit...

High-speed sandwiching machine for bakery production

Streamline your baking operations with a machine designed to efficie...

Rotary dough feeder for bread and tortilla production

Optimize your dough processing by maintaining dough integrity and e...

Rotary dough feeder for uniform dough blocks

Efficiently feed consistent blocks of dough into your processing line without...

Industrial vision robot for optimized packing

Optimize your bakery production line with a system designed to efficiently p...

Linear belt vibratory weigh filler for solid chocolate

Optimize your chocolate production by minimizing product giveaway ...

Automatic bag inserter for boxes and crates

Optimize your packaging line with a compact solution that seamlessly inserts p...

Product intake solutions for feed processing

Optimize your feed production with efficient material intake systems, ensurin...

Cylindrical storage silos for long-term raw material storage

Efficiently store bulk raw materials for extended periods w...

Inline and continuous weighers for accurate product flow management

Maintain precision and efficiency in your productio...

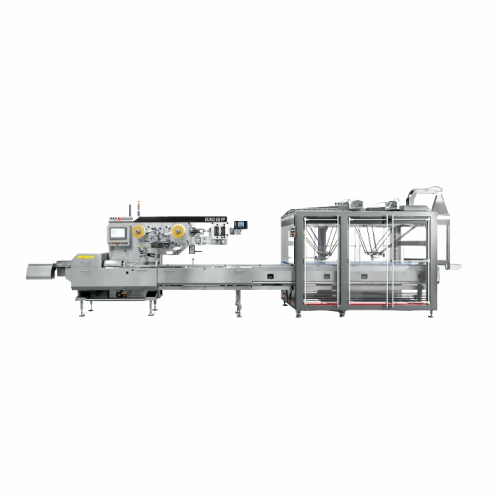

Pod production system for filter paper pods

Streamline your pod production with a high-speed solution that ensures precise...

Unpacker for return bottles

Effortlessly manage return bottle operations with high-speed unpacking solutions that ensure pre...

Automatic bag-in-box packaging system

Optimize your liquid packaging with a precise and seamless workflow, ensuring efficie...

High infeed palletizer for varied product types

Optimize your production line with high infeed palletizers, ensuring seaml...

Automatic case packer for soft pillow bags

Streamline your packaging process with a case packer designed to efficiently ha...

Depalletiser for loose containers and cases

Streamline your production line with a depalletizing solution that ensures pre...

High-speed in-line palletizer for beverage industry

Effortlessly streamline your palletizing processes with a compact, hi...

Robotic palletizer for row gripping

Optimize your palletizing efficiency with a robotic system designed for fast, continuou...

Compact shrink wrapper for medium-speed productions

Optimize your packaging line with this compact shrink wrapper, design...

Depalletizer for cases and crates

Efficiently streamline your high-speed production line by seamlessly transferring cases a...

Laser guided vehicle for pallet handling

Efficiently streamline your internal logistics with cutting-edge laser guidance, e...

Laser guided vehicle for industrial reel handling

Effortlessly manage and transport industrial reels in your facility wit...

Laser guided reach truck for high-density warehousing

Optimize your warehouse operations with an advanced reach truck des...

Hig Speed Tube Cartoner

Achieve seamless integration into your high-speed packaging line with a cartoning solution that ensur...

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Belt loaders for automated food packaging

Streamline your packaging line with precision-engineered belt loaders, designed ...

Mbs belt systems for seamless packaging integration

Optimize your packaging line with a system that seamlessly merges mul...

Automated conveyor systems for food packaging lines

Seamlessly integrate high-speed product transport and handling into y...

High-throughput tube transfer system for lab automation

Streamline laboratory workflows by automating high-throughput tub...

Unloader for conical bottom silos

Eliminate product flow challenges effortlessly with this hydraulic-driven unloader, ensur...

Automated meat portioning line

Optimize your meat production with precise portioning and shaping technology, transforming cy...

Automatic meatball forming machine

Achieve uniform and precise meatball shaping with our high-speed forming machine, design...

Outsert application system for pharma bottles

Effortlessly enhance packaging efficiency in pharmaceutical lines with this ...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Cup filling system for jars and buckets

Optimize your confectionery and bakery filling processes with this high-speed cup f...

Automatic chocolate feeding conveyor

Efficiently connect your chocolate production to wrapping stages with this high-speed ...

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

Almond hulling system for soft and semi-hard shells

Efficiently hull almonds with soft or semi-hard shells to streamline ...

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

Cork feeders for medium to high production rates

Optimize your cork handling process with precision guidance and high-spee...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Pneumatic transport system for long-distance product conveyance

Efficiently convey solid and granular products across lo...

In-line marination system for portion-controlled products

Achieve precise marinating with minimal waste, ensuring consis...

Feeders for cork and synthetic cap orientation

Optimize your bottling operations with precision orientation and feeding sy...

Weigh price labeler for retail food products

Achieve consistent, high-speed labeling and pricing with precision—streamlini...

Sausage linking system for consistent weight and length control

Achieve precision in sausage production with high-speed ...

Automated flake ice storage solution

Streamline your ice management with a solution that eliminates manual handling, enhanc...

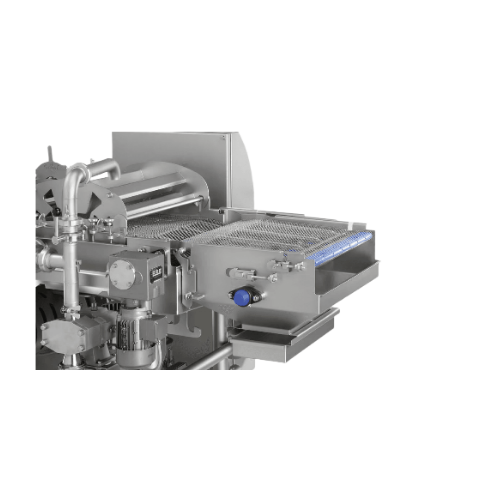

Batter applicator for plant-based products

Achieve flawless coating with precision technology that ensures complete wet an...

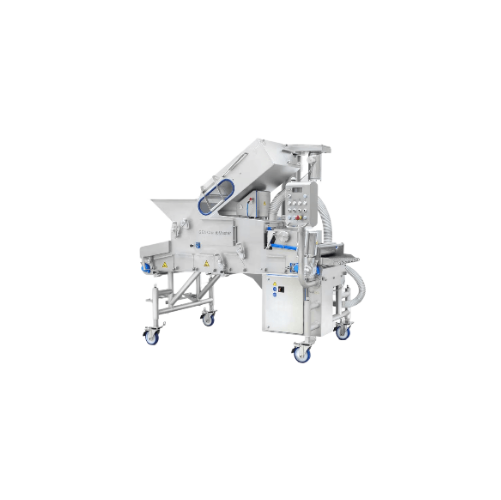

Flour applicator for convenience foods and snacks

Achieve uniformly coated products, such as chicken nuggets and fish fil...

Active tempura applicator for plant-based products

For processors aiming to achieve the perfect batter coating on plant-b...

External washing and drying system for ampoules and vials

Optimize your aseptic processing by seamlessly integrating a c...

Industrial washing and sterilizing system for ampoules and vials

Ensure the highest hygiene standards in your liquid for...

Bottle filler and capper

Achieve precise liquid filling and secure capping with high-speed, intermittent motion, ensuring con...

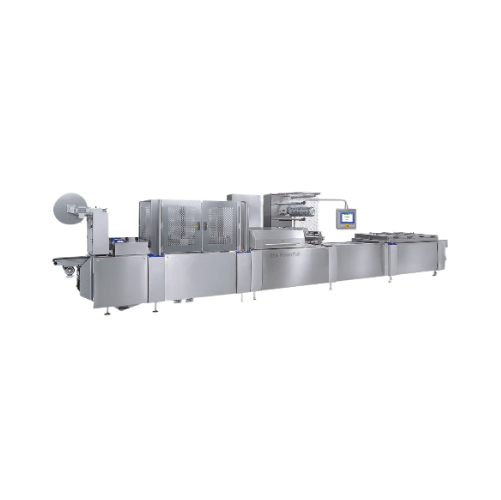

Blister thermoforming solution for pharmaceutical packaging

For high-speed blister packaging of solid dose pharmaceutica...

Rotary drum pasteurizer for pouches

Efficiently pasteurize delicate pouch contents like meats, vegetables, and grains with ...

Chocolate pump for confectionery production

Effortlessly pump and convey a range of chocolate-based products with precisio...

Unsnipped bean remover for green bean processing

Enhance your green bean processing line by seamlessly removing unsnipped ...

Rapid food cooling solution for vegetables and pasta

Efficiently reduce the temperature of particulate foods with rapid p...

Metal detector for conveyorized applications

Enhance your production line by ensuring product safety with advanced metal d...

Conveyorized food metal detector for high-care environments

Ensure food safety with advanced metal detection tailored fo...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

Powder handling systems for battery production

Optimize your battery production with a versatile powder handling system th...

Jar sealing system for plastic and glass containers

Achieve precise and efficient sealing of plastic and glass jars with ...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Continuous inline capping system

Perfect for high-speed operations, this system ensures precise capping of diverse container...

Paste filling system for high viscosity products

Efficiently fill high viscosity products with precision and speed, reduci...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Linear transport system for automotive assembly buffering

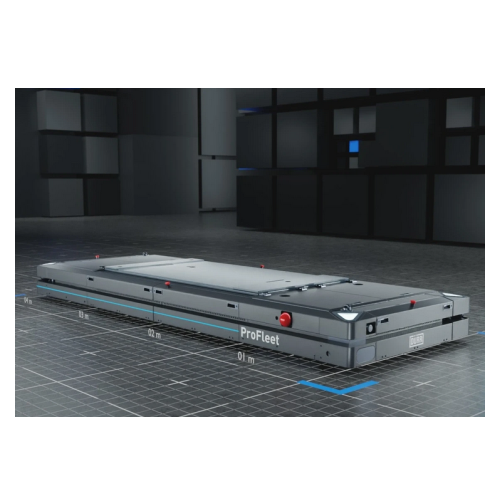

Optimize your assembly line with a smart transport system that...

Industrial shuttle for transporting heavy components

Optimize your production line with a shuttle that handles heavy vehi...

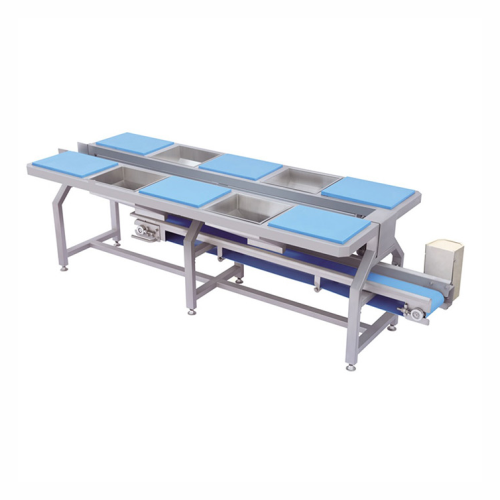

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

Automatic cabbage processing line for industrial shredding

Streamline your cabbage processing and salad preparation with...

Multifunction vegetable fruit slicing solution

Streamline your food processing with a machine that effortlessly slices, di...

Industrial cabbage processing line

Maximize efficiency in cabbage processing with this versatile line, seamlessly integrati...

Inspection table for vegetables and fruits

Streamline your quality control with an efficient inspection table designed for...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

Versatile packer for non-returnable containers

Optimize your bottling line with a flexible solution designed to expertly p...

Container sweep-off depalletiser

Enhance your beverage production line efficiency with a high-performance depalletising solu...

Palletizing grouping system for non-returnable packs

For beverage and packaging lines, precise and rapid palletizing of n...

Crate washer for beverage manufacturers

Ensure thorough cleaning of beverage crates with an advanced washing system featuri...

Automated product change-over system

Maximize your production line efficiency by reducing downtime during product changeove...

Automatic capping system for varied cap types

Enhance your packaging line efficiency with a high-speed capping machine des...

Trimming table for fruit and vegetables

Streamline your pre-processing phase with this trimming table, helping you efficien...

Uvc surface disinfection for food packaging and tools

Achieve fast and effective UVC disinfection of food products and pa...

Washing system for lettuce, vegetables, and fruit

Looking to streamline your vegetable and fruit processing? This versati...

Lettuce processing and packaging line

Maximize throughput with seamless integration of trimming, cutting, washing, and pack...

Processing line for lettuce, vegetables, and fruit

Enhance efficiency and product quality in your production line with a ...

Potato processing line for tubers

For food processors seeking efficiency, this semi-automatic line streamlines peeling, cut...

Automated processing line for lettuce and leafy vegetables

Optimize your salad and leafy greens processing with this ful...

Flexible packaging solution for large food volumes

For high-volume food packaging, achieving consistent bag sizes and red...

Grape destemming solution for efficient fruit processing

Streamline your fruit preparation process with a versatile machi...

Industrial dipping bath for prolonging shelf life of cut fruits and vegetables

Enhance the shelf life and hygiene of y...

Automatic crate weighing system for fresh produce

Streamline your fresh produce processing by precisely weighing and fill...

Washing and grinding system for fruit and vegetables

Efficiently wash and grind fruits and vegetables to streamline your ...

Automatic weighing belt system for mixed products

Achieve precise control and seamless integration of product flows with ...

Convenience avocado processing line

Efficiently halve, pit, and peel avocados while preserving their delicate texture, maxi...

Dust-tight dispenser for metal detector test tablets

Ensure seamless integration of test tablets in high-containment envi...

Empty capsule sorting system

Streamline your capsule production by efficiently removing empty and defective capsules, ensuri...

Fruit bin tipper for processing intake

Efficiently transfer fruits and vegetables from standard bins into your processing l...

2-way diverter for tablet and capsule filling

Ensure precision in tablet and capsule filling with seamless batch switching...

Tablet and capsule diverter

Streamline your tablet and capsule production with precise container filling and flexible config...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

Bulk bag filler with integrated palletizing system

Optimize your powder packaging with a seamless system that fills and a...

Sanitary bulk bag unloader for powdered products

Efficiently manage powder discharge with enhanced dust control and stream...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Curd table for cheese production

Streamline cheese production with effective curd separation, precise salt mixing, and relia...

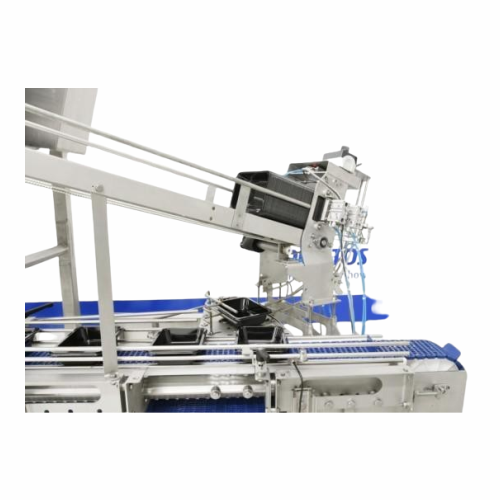

Tray handling equipment for food packaging

Optimize your food production with adaptable tray handling units that streamlin...

High pressure homogenizer for pharma applications

Achieve precise particle size reduction and stability in liquid formula...

Modular stacking and automation for polymer packaging

Addressing the needs of flexible food packaging, this solution offe...

Wine and sparking wine filling system

Achieve precise filling and minimal oxygen pickup for high-value beverages with a rel...

Enclosed film packaging solution

Eliminate the need for corrugated trays and minimize packaging waste with a robust solution...

Pallet stacker/destacker for separator pallets

Optimize your pallet flow with an advanced stacking and destacking system d...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Flexible tunnel pasteurizer for beverage sterilization

Maximize product safety and flexibility in your production line wi...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

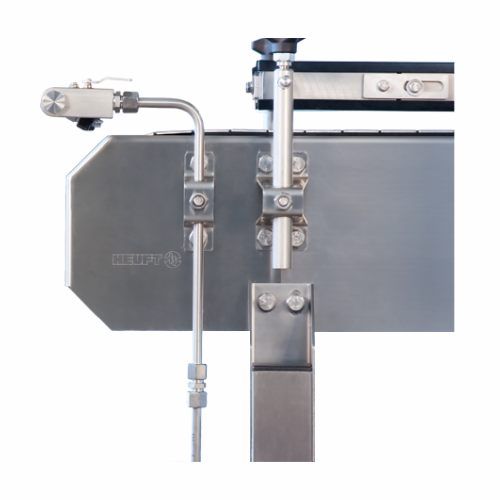

Gentle container conveyor for bottles and cans

Achieve seamless container flow with minimal noise and enhanced precision, ...

Wrap-around packer for cartons and trays

Effortlessly streamline your packaging process with a high-speed solution designed...

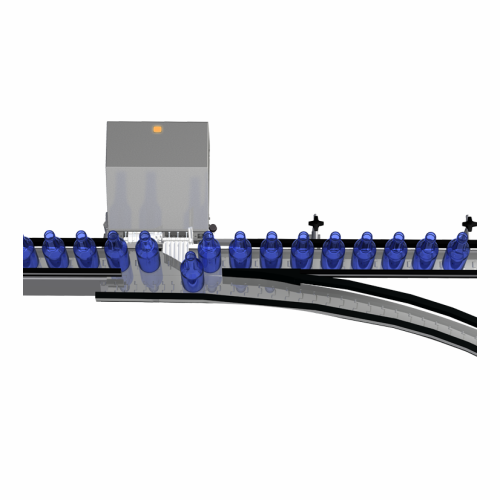

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Sleeving system for leafy greens and cut fruits

Enhance your packaging line with seamless tray sleeving, enabling high-spe...

Micro ingredients loading station for solid additives

Optimize precision dosing and ensure smooth transfer of powdered in...

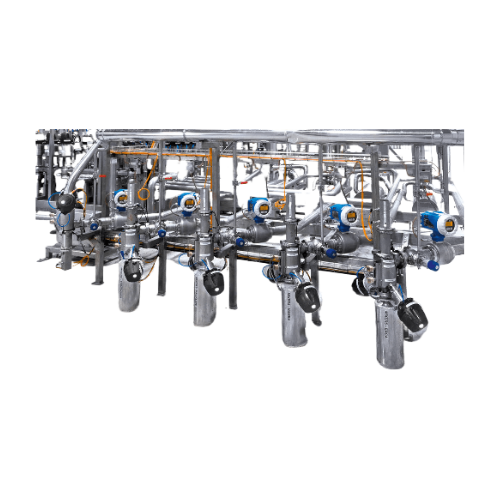

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

Lid applicator for wet wipe packaging

Achieve precise lid placement on flow pack wet wipes with high-speed automation, ensu...

Flexible wrapping system for bathroom tissue and towels

Optimize your wrapping process with a system engineered for high ...

Tablet elevator for pharmaceutical applications

Ideal for efficient transport and elevation of delicate pharmaceutical tab...

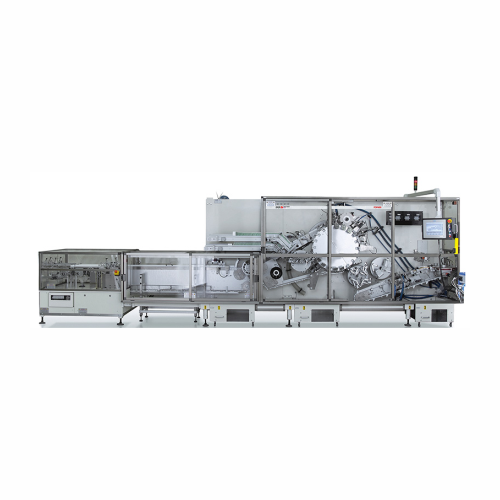

Horizontal cartoning solution for pharmaceutical packaging

Streamline your confectionery packaging with high-speed, cont...

Inline bottle cleaner for pharmaceuticals

Ensure your pill bottles and capsule containers are free from contaminants with ...

Automatic biscuit sandwiching equipment for high-volume production

Optimize your biscuit production line with high-spee...

Cartoning system for triangular cheese portions

Streamline your cheese packaging process with precision-oriented cartoning...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Automatic sandwich biscuit production system

Elevate your biscuit production line with high-speed sandwiching capabilities...

Feeding system for single wrapping lines

Optimize your high-speed wrapping operations by ensuring precise product alignment...

Filling and sealing pre-formed cups solution

Ensure ultra-clean and aseptic processing for pre-formed cups with a fully en...

Flow wrapper for high-speed confectionery packaging

Achieve gentle, high-speed packaging for delicate confectionery items...

Flow wrapping with pick and place robots

Streamline your confectionery and bakery packaging with precision flow wrapping, u...

Automatic portion volumetric feeder for biscuits and crackers

Streamline your biscuit and cracker packaging process with...

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

Roasted coffee storage solutions

Ensure the highest integrity of your coffee beans with advanced storage and handling system...

Roasted coffee weighing and blending system

Achieve precision and consistency in your coffee blends with cutting-edge weig...

Green coffee storaging and dosing system

Optimize your coffee production with a flexible and modular solution designed for ...

High-speed tea bag packaging for naked or heatsealed envelopes

Need to enhance production efficiency in tea packaging? D...

Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrat...

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Customised tank systems for liquid and bulk material storage

Ensure safe and compliant storage of liquids and bulk mater...

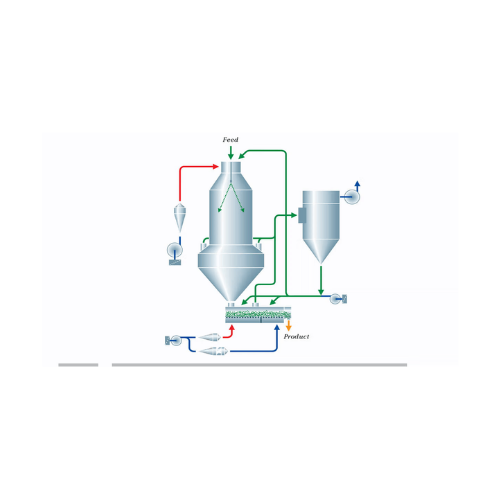

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Ultra-fine dry grinding mill for glass and ceramics

Achieve ultra-fine particle sizes and energy savings with a dry grind...

Air classifier for classifying industrial minerals

Achieve precise particle separation with advanced air classifiers, par...

Single bucket elevator for seed handling

Optimize your seed processing efficiency by seamlessly transporting and splitting ...

Separating packed cheese products from packaging

Efficiently separate individual cheese portions from packaging, reducing ...

Cheese and butter block grinder

Efficiently transform frozen cheese and butter blocks into manageable sizes for continuous p...

Industrial case rejector for faulty packaging

Ensure product integrity by smoothly removing faulty cases from your product...

X-ray assisted empty container inspection system

Detect low-density foreign objects and micro-cracks in empty containers w...

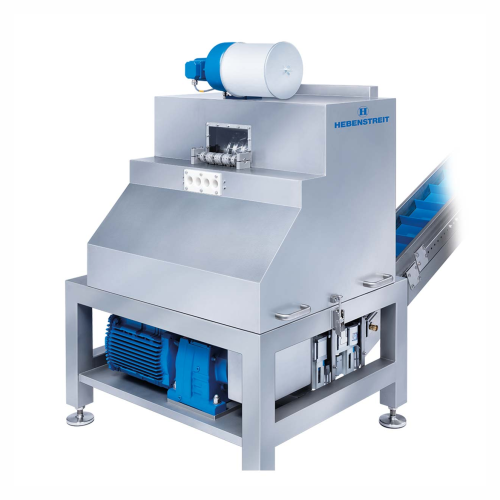

Full container check system for beverage industry

Streamline your quality assurance process with advanced detection techn...

Precision case rejector for faulty packaging

Ensure seamless production flow by reliably removing defective packaging with...

Conveyor system for efficient container transport

Optimize your filling line with a versatile container transport system ...

Conveyor control system for beverage filling lines

Optimize your production line’s efficiency by seamlessly managin...

Curve rejector for beverage containers

Ensure seamless and upright rejection of faulty containers in tight spaces, maintain...

Wafer distribution device for chocolate coating plants

Enhance your chocolate coating operations with precision wafer dis...

Single-screw cooking extruder for snack production

Optimize your snack production with a versatile extruder designed to h...

Contact spreading machine for cream application on wafer sheets

Ensure precise cream application with our specialized co...

Hollow wafer spreading machine for consistent coating

Optimize your snack production with precise spreading—achieve unifo...

Continuous extruded snack dyeing system

Enhance the aesthetics of your extruded snacks with precise and continuous dyeing, ...

Roller embossing system for snack production

Effortlessly shape and press multiple product strands into diverse, precise f...

Kettle fryer for batch potato chips

Ensure consistent quality and precise frying for your kettle-cooked chips with this the...

Conveyor systems for snack production

Streamline your snack production with advanced conveyor systems designed for seamless...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

Potato chip production slicer feeder

Ensure optimal slicing and consistent chip quality with a feeder that delivers a stead...

Batter applicator for poultry and seafood

Achieve consistent, even coating of batters and marinades for a variety of food ...

Advanced breading applicator for meat and vegetables

Achieve uniform coating on diverse products with seamless changeover...

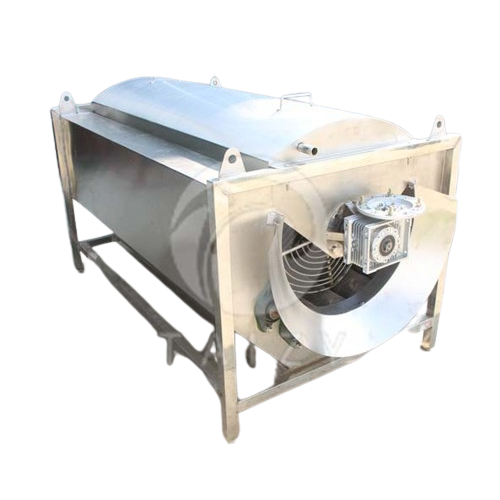

Nut roaster for consistent and high-capacity processing

Achieve uniform roasting and elevate your nut processing with pre...

Sheeting solution for tortillas and chips

Achieve precision sheeting of tortilla chips and taco shells with robust technol...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Nut roasting system

Achieve perfectly roasted and seasoned nuts with precision control over roasting, coating, cooling, and g...

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this...

Industrial nugget former for meat products

Efficiently shape and size a variety of meat and alternative products into nugg...

Potato slice washer for surface starch and fines removal

Ensure optimal cleaning and dewatering of potato slices while si...

Inspection conveyor for potatoes and vegetables

Streamline your defect removal and trimming process with a conveyor system...

Corn masa preparation system

Efficiently transform dry corn into fresh masa in minutes using a continuous process, eliminati...

Versatile dual axis funnel filling system

Eliminate messy spills and maximize efficiency by synchronizing conveyor and tra...

Fabricated chip fryer

Achieve uniformity in stackable snack chips with a fryer that precisely controls temperature and oil le...

Slicer infeed conveyor for potato products

Enhance slicing efficiency by smoothly feeding potatoes into multiple slicers, ...

Fresh produce weighing system

Achieve precise weighing and seamless integration in fresh produce packaging with multihead we...

Corn product moisture conditioning system

Prevent chip blistering and oil absorption by efficiently balancing moisture con...

Impingement oven for meat and baked products

Achieve faster cooking and greater uniformity with advanced airflow technolog...

Ambient air cooling system for food products

Achieve precise cooling control with high-speed ambient air cooling systems, ...

Industrial bagel boiling system

Ensure consistent bagel quality with high-capacity boiling, coupled with continuous water fi...

Valve bag filling system for cement and chemicals

Optimize your material handling with precision filling and sealing, ens...

Rotating packaging system for cement and chemicals

Streamline your packaging line with a high-speed, rotating solution th...

Apron extractor weigh feeder for large-scale material extraction

Achieve precise material dosing and metering under chal...

Weigh belt feeder for low-density materials

Optimize high-volume feeding accuracy for light materials while reducing your ...

Powder belt feeder for accurate powder metering

Achieve precise powder metering with a specialized feeder that maintains d...

Belt feeder for alternative fuels

Maximize fuel efficiency with this belt feeder designed for seamless dosing of alternativ...

High-speed conveyor belt scale for high-flow applications

Achieve precise continuous material flow with a robust belt sc...

Continuous tunneling drying system for industrial applications

Streamline your drying process with precision-controlled ...

High-speed industrial belt feeder for granular materials

Achieve precise and consistent material dosing in high-flow envi...