Vacuum sequencing blower for industrial conveying systems

For manufacturers handling bulk materials like powders and granules, this vacuum sequencing blower streamlines conveyance, ensuring efficient and continuous material transfer while maintaining product integrity across demanding industrial processes.

Efficiently Conveys and Sequences Materials

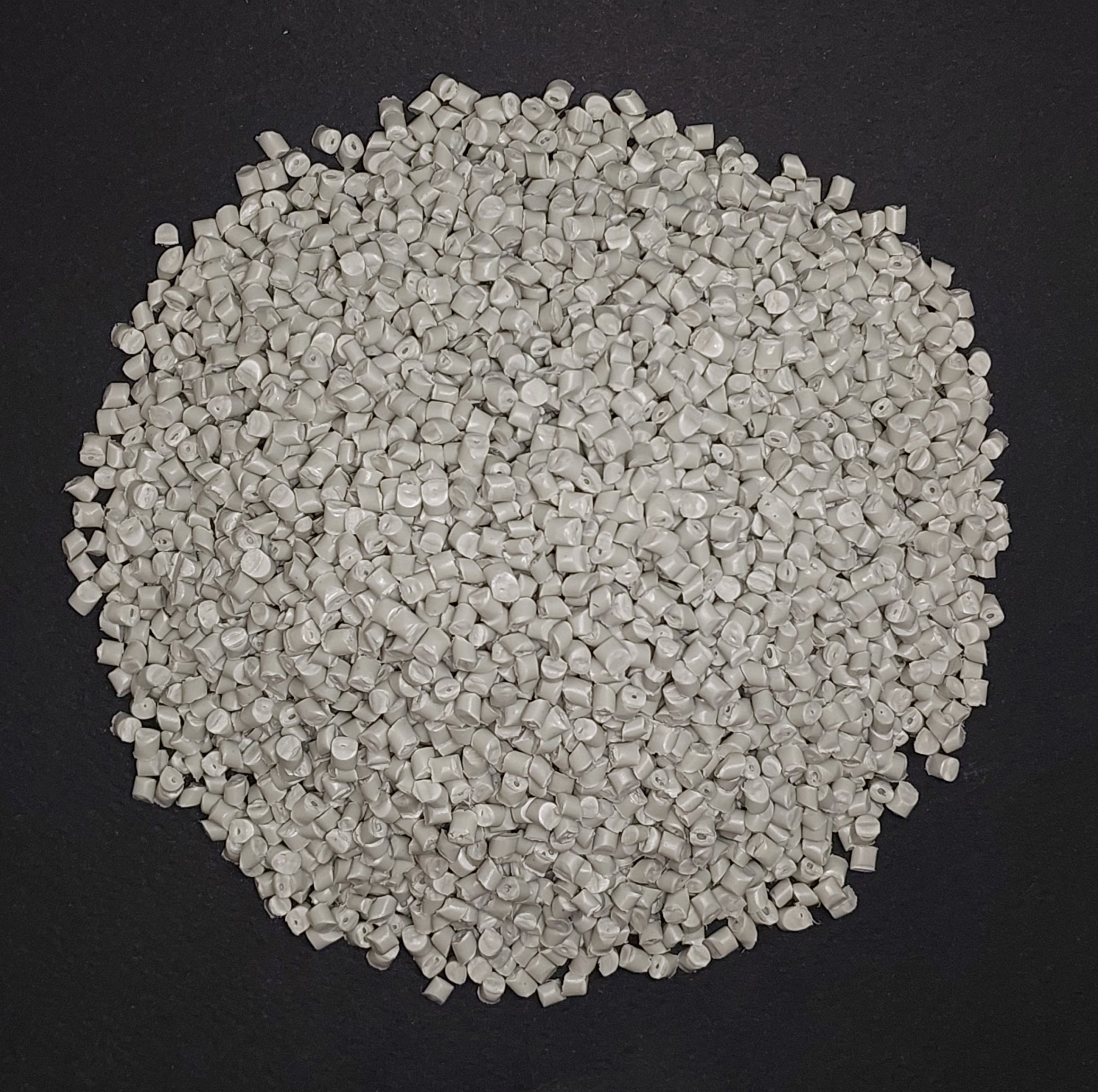

The Series 2400 Positive Displacement Vacuum Sequencing Blower from Coperion K-Tron is tailored for seamless integration into high-speed, automated production lines. It incorporates a microprocessor or PLC controller for precise operation in continuous vacuum sequencing conveying systems. Engineered for handling granules, powders, and gases, it efficiently serves the demanding environments of plastics, chemicals, food, pet food, minerals, and nonwovens industries. With its positive displacement technology, this blower accommodates 50 mm to 100 mm systems, offering variable motor power between 4 to 18.5 kW. Its heavy-duty construction includes a totally enclosed drive guard, vibration mounting pads, and a chamber-absorptive type discharge silencer, ensuring durability and minimal operational noise. Easy-to-read gauges and air-actuated vacuum breaker valves enhance control and reliability, while its compatibility with various materials ensures versatility across applications such as polyethylene pellets, lithium-ion battery materials, and superabsorbent polymers.

Benefits

- Optimizes material flow and processing efficiency with seamless plc-controlled integration.

- Accommodates diverse material types, enhancing versatility across multiple industries.

- Minimizes operational noise and prolongs equipment lifespan with vibration damping and discharge silencing.

- Supports high-speed, continuous operations, reducing production cycle times.

- Customizable motor power options optimize energy use and handling capacity.

- Applications

- Chemicals, Food, Nonwovens, Pet food, Plastics, Minerals

- End products

- Cement particles, Polyethylene pellets, Lithium-ion battery materials, Cornflakes, Polypropylene granules, Dog kibble, Superabsorbent polymers (sap), Pvc compounds, Plant-based protein powders, Calcium carbonate powder

- Steps before

- Material Loading, Feeding, Ingredient Blending

- Steps after

- Material Unloading, Packing, Storage

- Input ingredients

- bulk solids, raw materials, plastics, chemicals, food ingredients, minerals, nonwoven materials

- Output ingredients

- conveyed materials, processed bulk materials, sequenced vacuum transport

- Market info

- Coperion is known for its expertise in manufacturing industrial compounding and extrusion equipment, bulk materials handling systems, and services for various industries, such as plastics, chemicals, and food processing, with a strong reputation for innovative engineering solutions and customer support.

- Automation

- PLC-controlled

- Capacity

- 50–2000 kg/h

- Conveying system size

- 50 mm (2 in) to 100 mm (4 in)

- Power

- 4 to 18.5 kW (5 to 25 HP)

- Vacuum rating

- up to 338 mbar (g) (10 in Hg)

- Blower type

- Positive displacement blower

- Motor mount frame type

- IEC or NEMA

- Drive guard type

- Totally enclosed

- Gauge type

- Liquid filled

- Discharge silencer type

- Chamber-absorptive

- Vacuum breaker valve

- Air-actuated

- Relief valve type

- Mechanical vacuum

- Mounting pads

- Vibration

- Working mechanism

- Positive displacement blower

- Integrated steps

- Continuous sequencing conveying

- Automation level

- Microprocessor or PLC controlled

- Maximum vacuum

- 338 mbar (g) / 10 in Hg

- Conveying system size

- 50 mm (2 in) to 100 mm (4 in)

- Blower power range

- 4 to 18.5 kW / 5 to 25 HP

- Vibration control

- Vibration mounting pads

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Air-actuated vacuum breaker valve

- Motor mount frame

- IEC or NEMA

- Blower base

- Heavy-duty

- Drive guard

- Totally enclosed

- Gauge type

- Liquid filled

- Silencer type

- Chamber-absorptive type discharge silencer

- Vibration protection

- Vibration mounting pads

- Control Type

- Microprocessor/PLC

- Motor Mount Frame

- IEC or NEMA

- Drive Guard

- Totally enclosed

- Vacuum Breaker Valve Type

- Air-actuated

- Vibration Isolation

- Vibration mounting pads