Plastic Processing Equipment

Find innovative plastics equipment and connect directly with world-leading technology suppliers

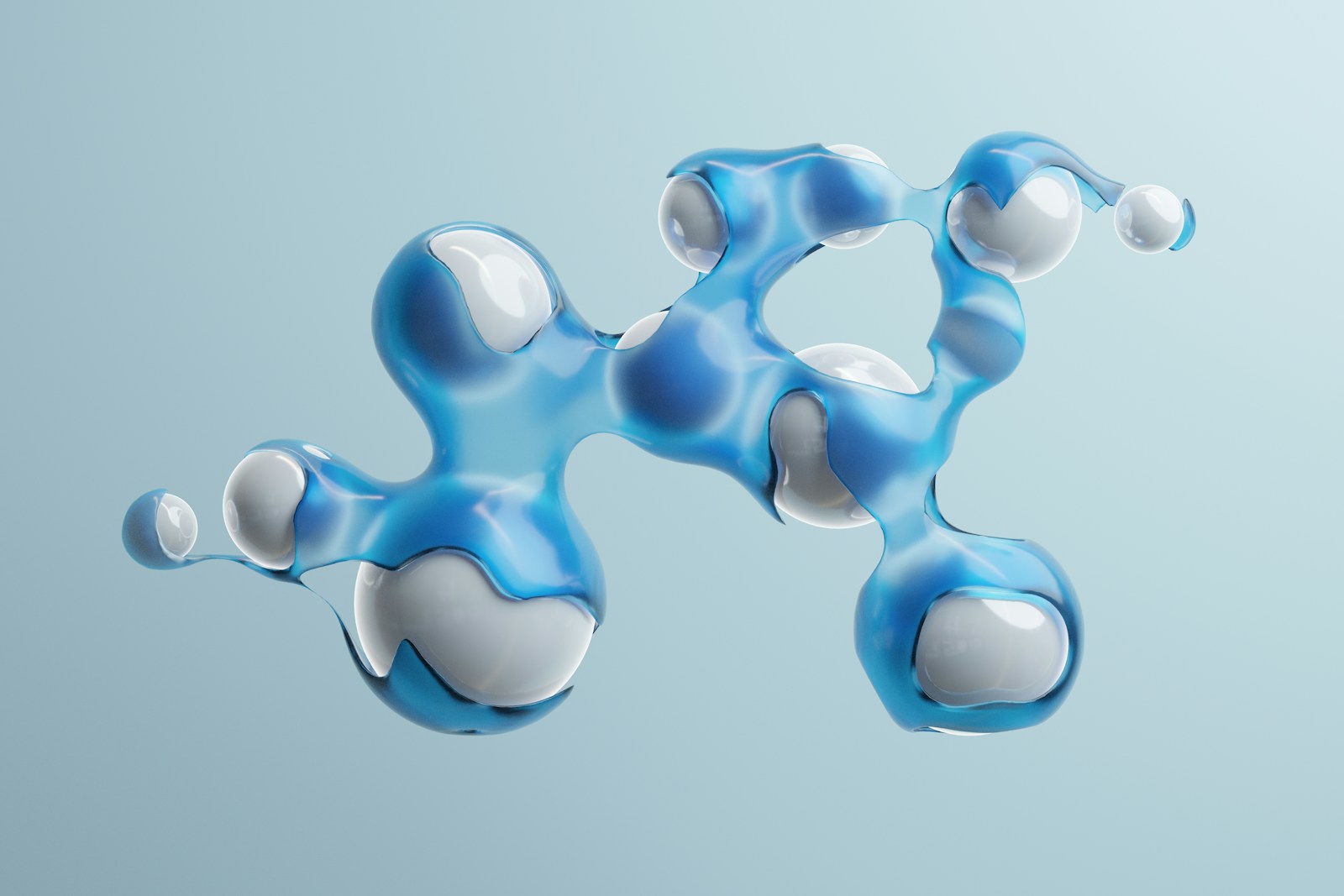

Can it be said that we live in the Plastic age? Basically, yes. From pillows over toothbrushes, and packaging to utensils, plastic is a widely used material in our day-to-day lives. But what is it? Plastics are synthetic or semi-synthetic materials built of polymers that are easily shaped into various structures with the help of plastic processing equipment such as extruders and molders.

Top picks for plastic production

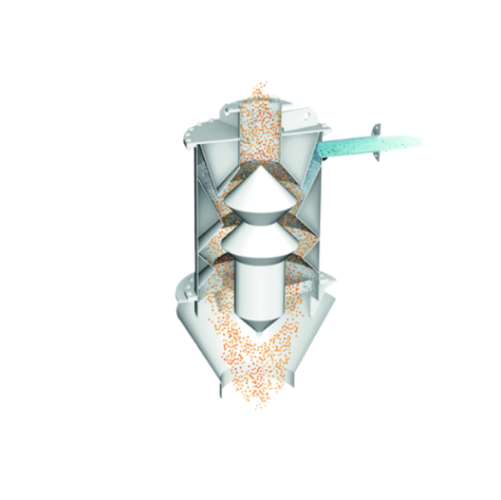

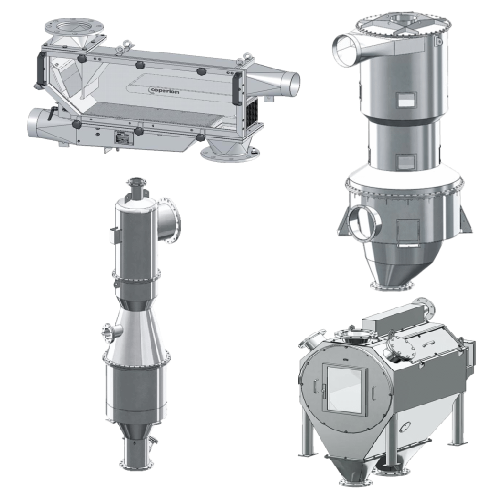

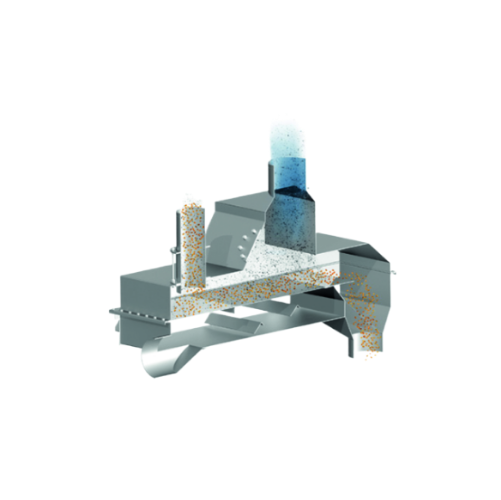

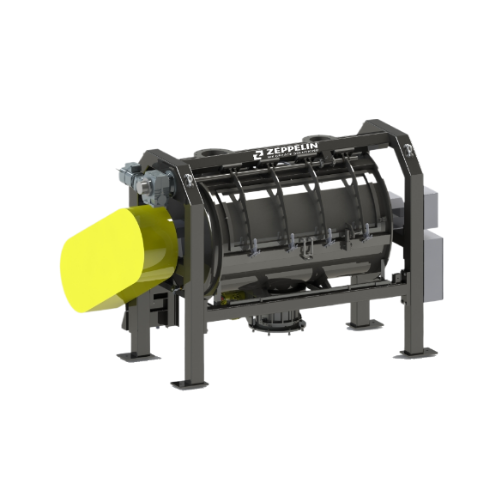

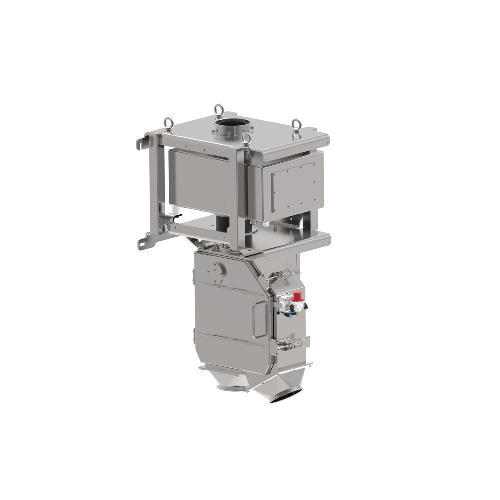

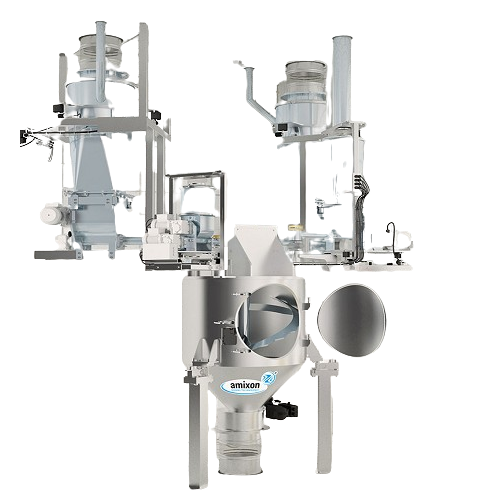

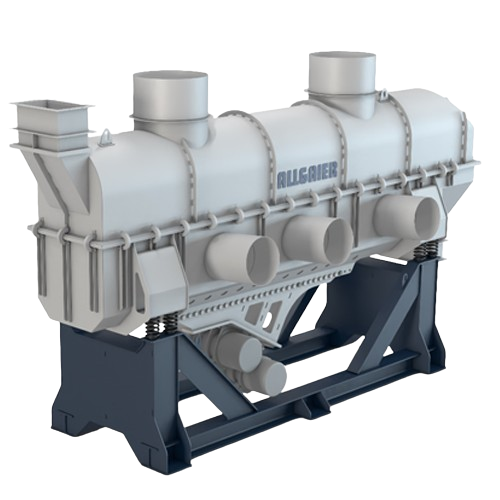

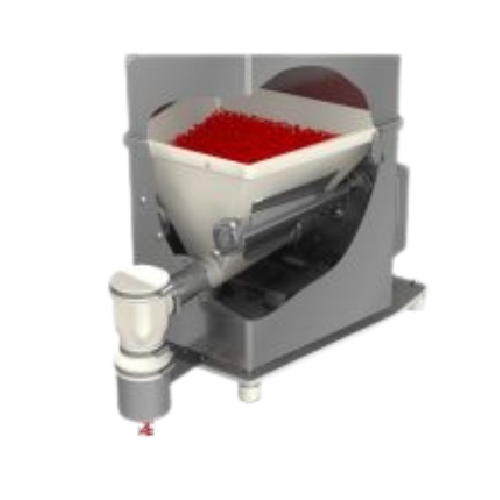

Air separator for polymers and plastics

Ensure high-purity plastic pellets by efficiently separating fine dust and streamer...

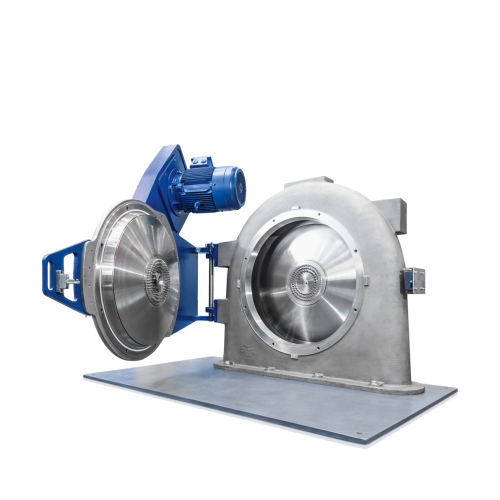

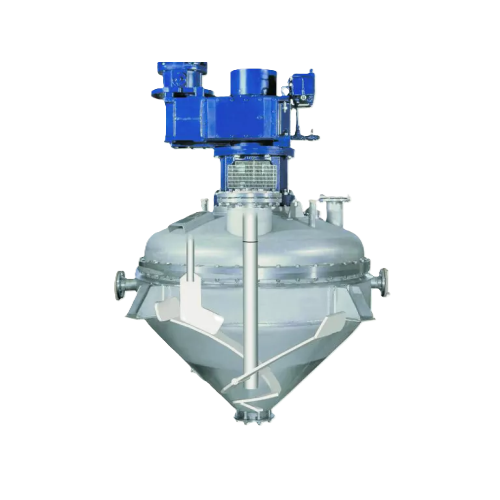

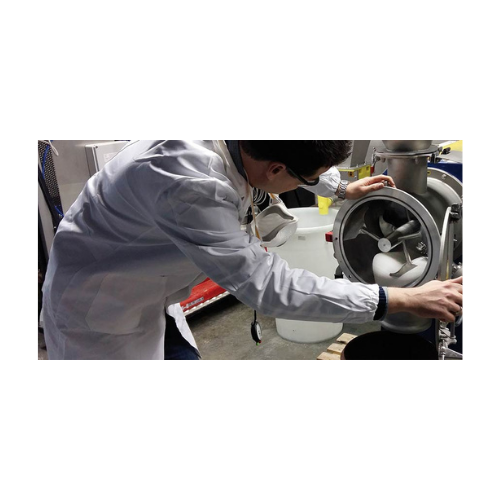

Centrifuge for plastics recycling

Enhance your recycling process with a centrifuge designed to efficiently separate and dew...

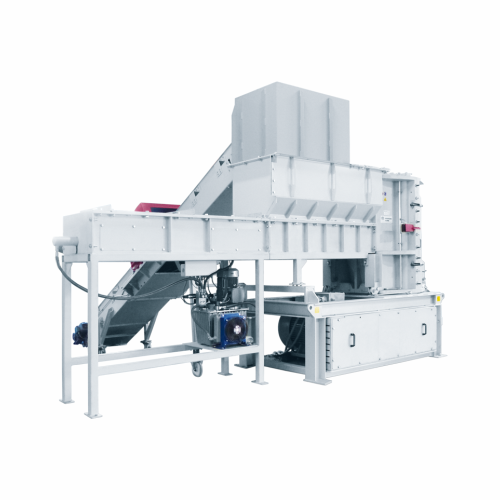

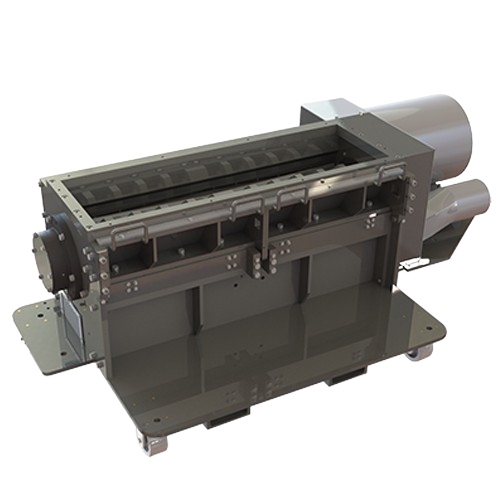

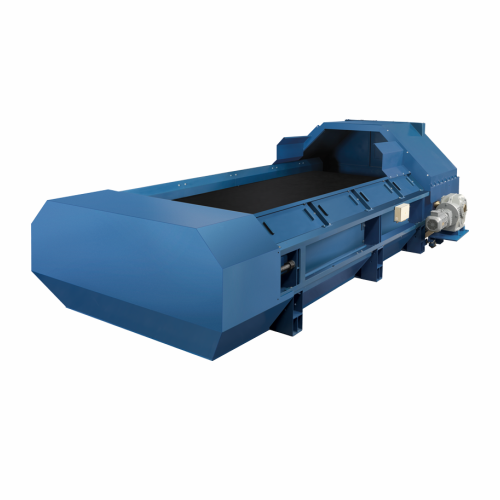

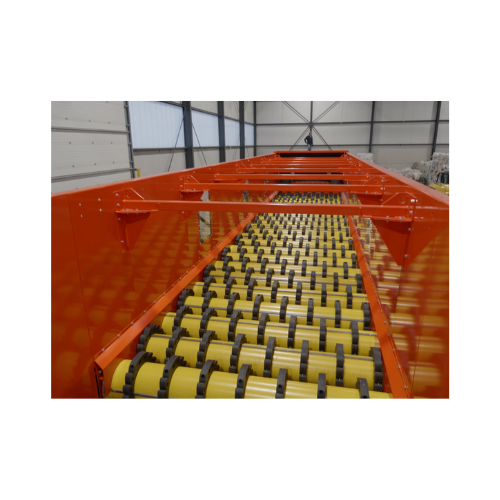

Central granulators for high-volume plastics recycling

Efficiently process large volumes of recycled plastics and industr...

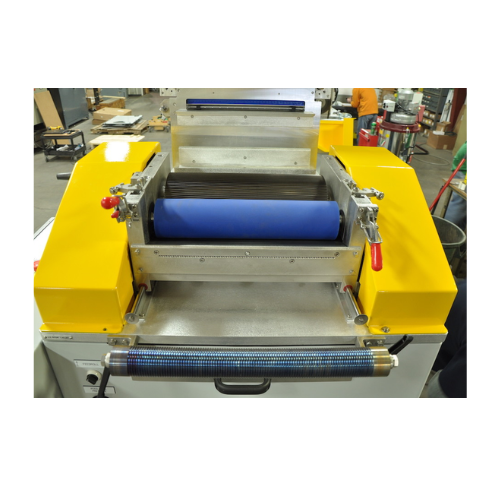

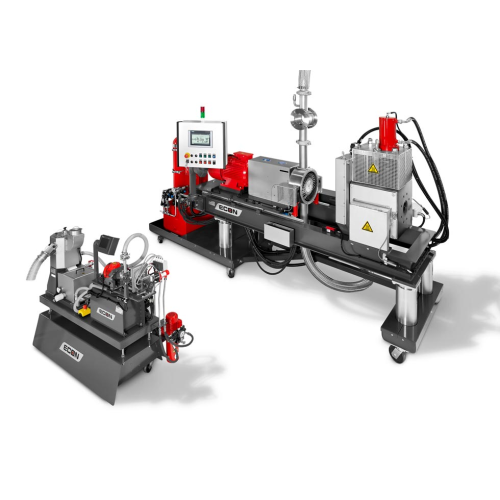

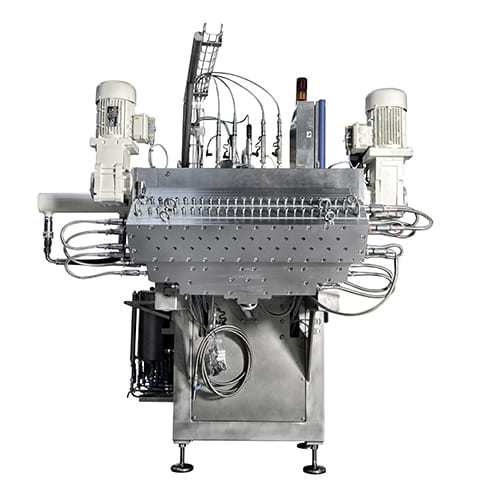

Automatic strand pelletizer for reinforced and filled polymers

Optimize your polymer production with precise pelletizing...

Select your plastics process

What are you making?

Biodegradable polymers

Biodegradable plastics

Biopolymers

Synthetic polymers

Tire treads

Thermoplastics

Textile fibers

Textile

Synthetic fibers

Pvc pipes

Pvc pellets

Rubber tires

Rubber seals

Rubber

Resin

Polyurethane foam

Polypropylene films

Polypropylene containers

Polypropylene

Polyolefins

Polymer resins

Polyethylene film

Polyethylene

Polyester resin

Plastics recycling

Plastic resins

Plastic intermediates

Plastic containers

Mdf boards

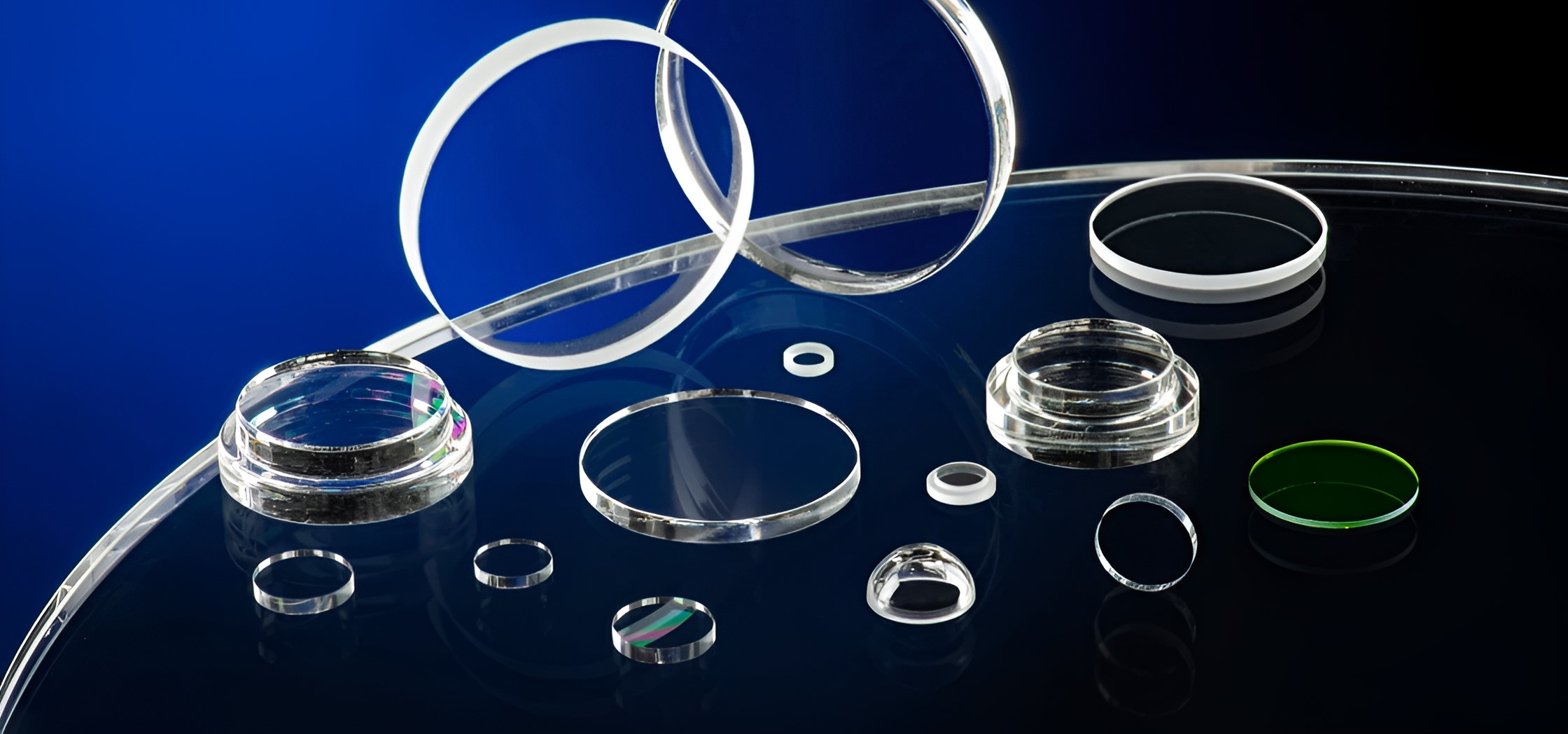

Optical lenses

Nylon pellets

Nylon fibers

Liquid crystal displays

Moped tires

Injection molding

Engineering plastics

Elastomers

Fiberglass

Anti-reflective coated lenses

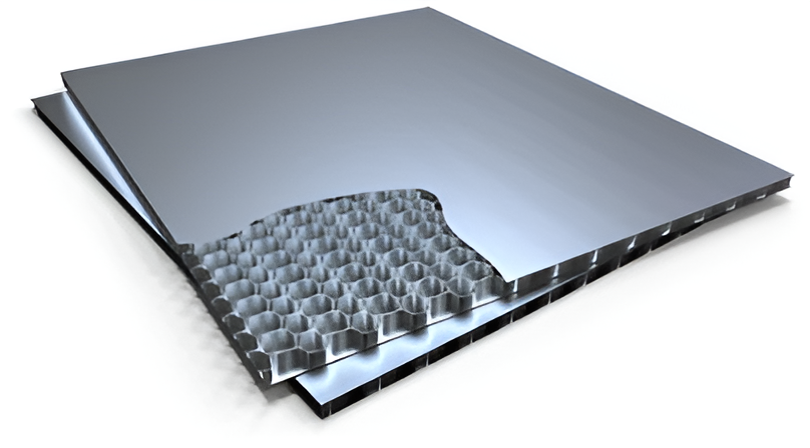

Composite materials

Color masterbatches

Recycled plastic

Masterbatches

Silicone

Polymers

Bioplastics

Synthetic rubber

Latex

Tell us about your production challenge

Making plastics – from crude oil to plastic pellets

Although originally a natural product, nowadays plastic is mostly synthetic and widely produced. The production starts with extracting oil from the underground with the help of pumps that produce between 5 and 40 liters of oil per stroke, which is then transported to an oil refiner through pipelines. The crud oil is poured into preheater, where it is boiled and sent to a furnace. There, according to its molecular weight, oil is separated into several groups of chemicals — petroleum, gasoline, paraffin, etc.

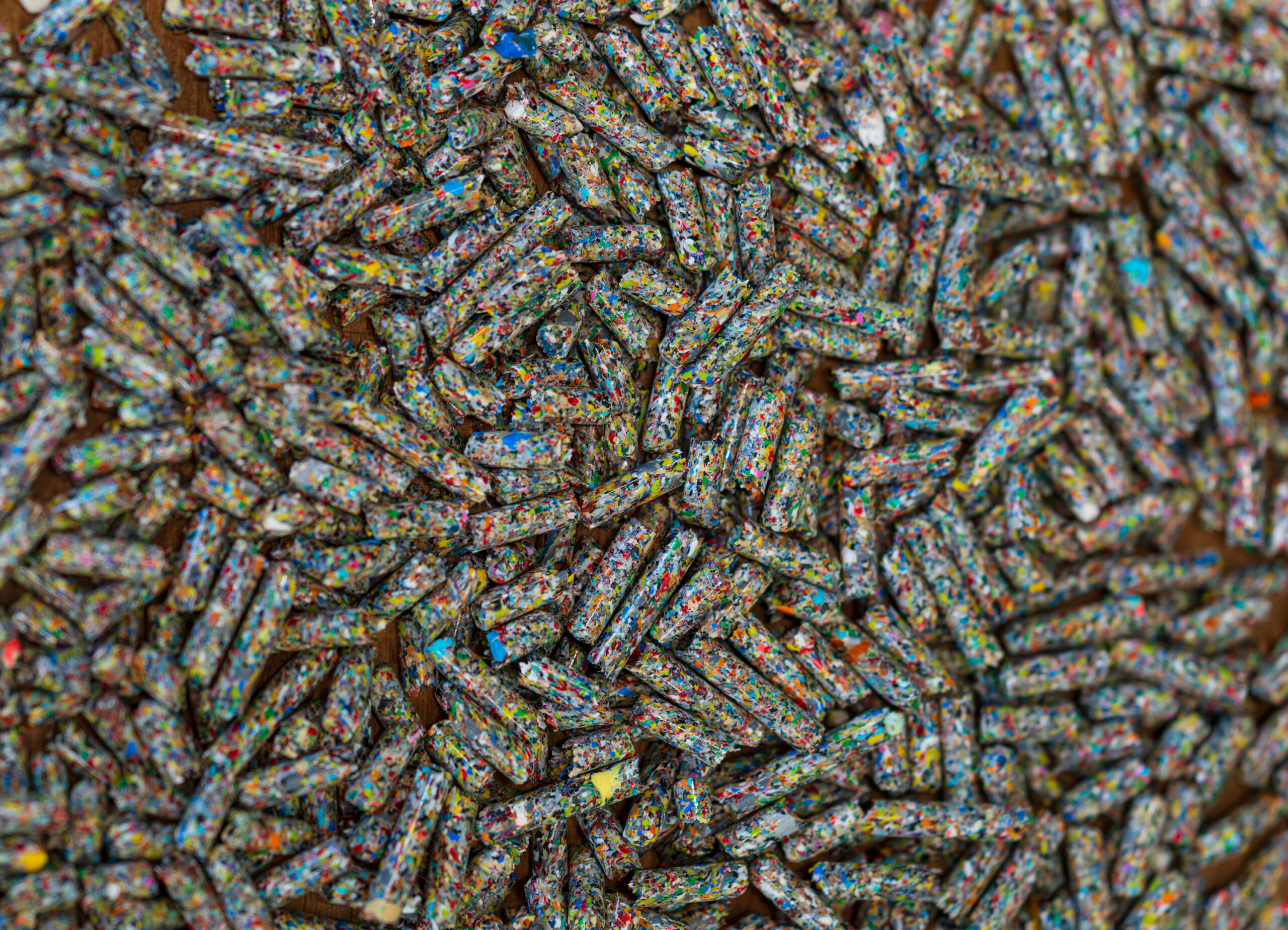

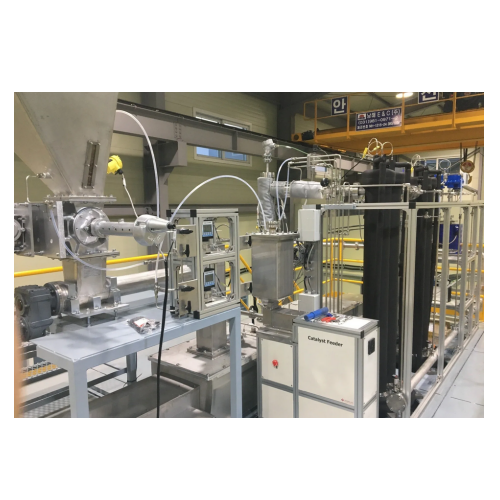

For plastic manufacturing, what’s essential is naphtha. Naphta has to be broken down into smaller units in a cracking process to get ethene. There are two types of cracking processes. Stem cracking is done at high temperatures and pressure, which is not required for catalytic cracking, which uses catalyst instead. Ethene is forwarded into a reaction chamber where the process of polymerization links the hydrocarbon monomers together into thick, viscous substances used to make plastics. The resulting product, polythene, is processed into strings in an extruder before being ground into pellets dispatched to factories to be molded into end products using various plastic machinery.

Plastic processing equipment and transformation of pellets into usable products

Forming usable plastic products, for instance, bottles, hoses, or toys, is executed using various processes: compounding, forming, thermoforming, extrusion and molding. Compounding is the first step – mixing liquids with other ingredients according to the desired recipe in conventional stirred tanks. Other essential plastic processing equipment includes two types of mixers; the workhorse mixer, which applies heat and pressure simultaneously, and the Banbury mixer which reminds of a robust dough mixer with two interrupted spiral rotors.

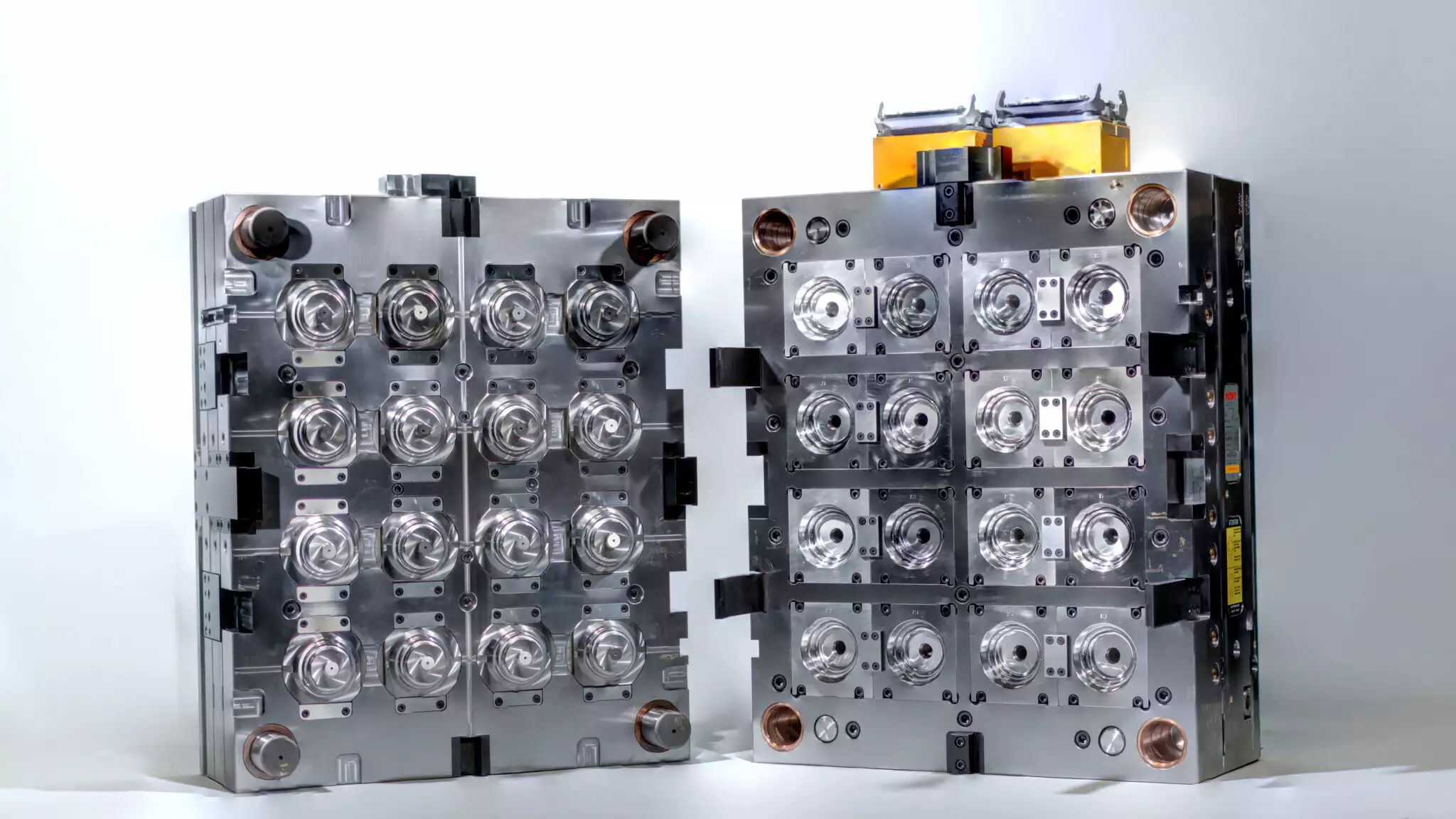

The next step is forming plastics into various shapes by melting, shaping, and solidifying. Extrusion and molding processes create finished or semi-finished products. During extrusion, the melted polymer is continuously forced through an orifice in an extruder for products such as sheets, tubing, and grocery bags. Various types of molding rely on molds to create the desired shape.

To illustrate, rotational molding produces large, hollow products such as kayaks. On the contrary, blow molding is used for small hollow pieces – bottles or fuel tanks. With compression molding, plastic parts can replace metal in the automotive industry. Finally, the most common type, injection molding, has virtually limitless uses with a large production capacity.

Classification of plastics

Plastics are classified according to their unique properties acquired during production processes. The main classification is based on how plastic responds to heat – it is differentiated between thermoplastics and thermosets. Thermoplastics are more common than thermosets. They can be heated without burning, melted, cooled and reheated without losing their properties. On the other hand, thermosets can be heated only, typically during injection molding, once due to irreversible chemical changes.

Any further heating would result in burning. For this reason, thermosets are not recycling-friendly. Further categorization is between amorphous, also known as shapeless, material and semi-crystalline material. While the former gradually softens when exposed to heat, the latter maintains its shape until a certain temperature point, when it rapidly becomes liquid. Finally, according to their monomer composition, plastics can be classified as homopolymers, made of a single type of monomer, or, on the contrary, copolymers.

Bioplastics, biodegradable plastics and recycled plastics – ecological alternatives?

The environmental effects of plastic are a widely known topic. It takes up to 450 years for a plastic bottle and 50 to 80 years for a plastic cup to decompose. Alternatives to traditional plastics are biodegradable, bio-based and recycled plastics. Biodegradable plastics are made of petrochemicals but degraded by microorganisms. However, it can be safely done under warm conditions; otherwise, it degrades into harmful microplastic.

Bioplastic is sourced from renewable natural materials (corn, sugarcane, cellulose), which are compostable. The downside is that using food sources, as well as that, owing to chemical and mechanical differences, can be challenging to recycle. Finally, recycled plastic does not exploit raw material, but it can be used only to produce lower-grade products. Furthermore, it uses energy, water and emits gases. However, it is important to recycle already existing materials as replacing them with mass production of non-reusable lower-quality products is not the ideal solution either.

Green innovations - plastic-eating waxworms

Considering that bioplastics, biodegradable plastics and recycled plastics have downsides, scientists from Canada’s Brandon University have found a unique possible solution. Namely, they discovered that waxworms could live off polyethylene. Their guts contain bacteria that biodegrade plastics and turn them into glycol. In the lab-controlled environment, 60 waxworms can eat more than 30 square centimeters of a plastic bag in less than a week. While it is unrealistic to expect that waxworms can solve the plastic pollution issue, understanding the symbiosis of waxworms and gut bacteria could lead to the development of better plastic biodegradation systems.

Which plastics technology do you need?

Fine cutting mill for soft to medium-hard plastics

Achieve precise size reduction and smooth particle shapes in plastic p...

Centrifuge for plastics recycling

Enhance your recycling process with a centrifuge designed to efficiently separate and dew...

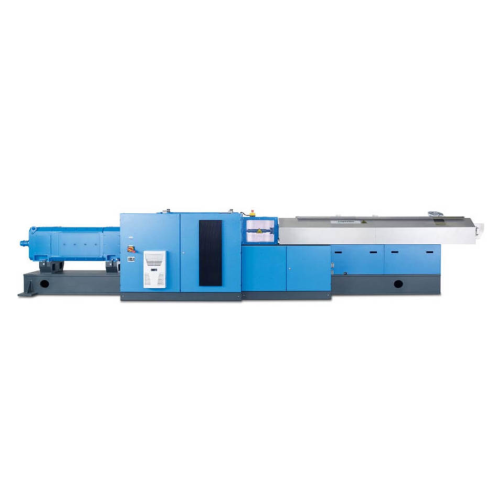

Electric injection molding for precision plastics

Ideal for precision molding, this electric injection system enhances ef...

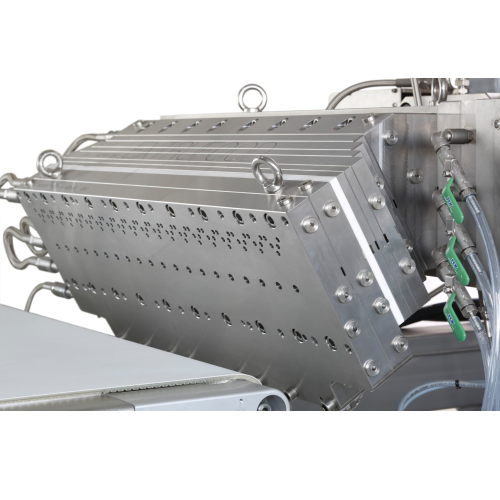

Inline screen changer for thermoplastics

Effortlessly swap filter screens during thermoplastic processing without halting o...

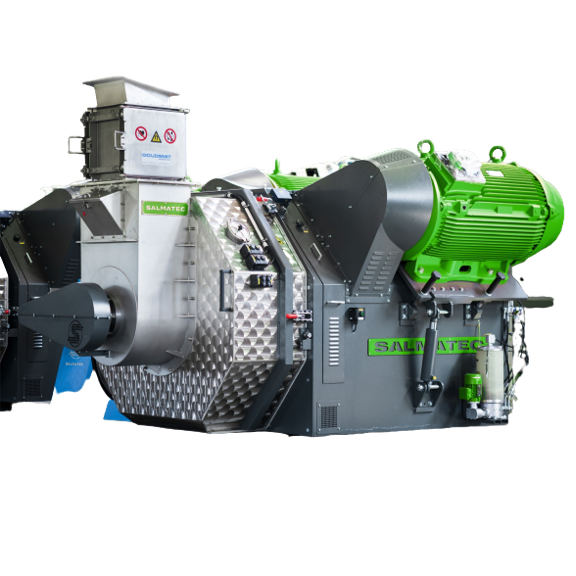

Pellet mills for feed, plastics, and industrial products

Optimize pelleting output across diverse materials with precisio...

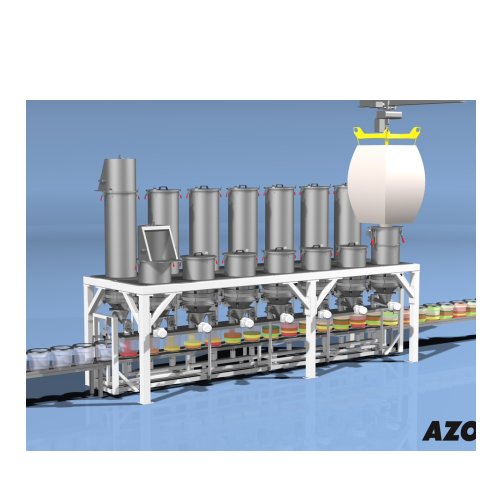

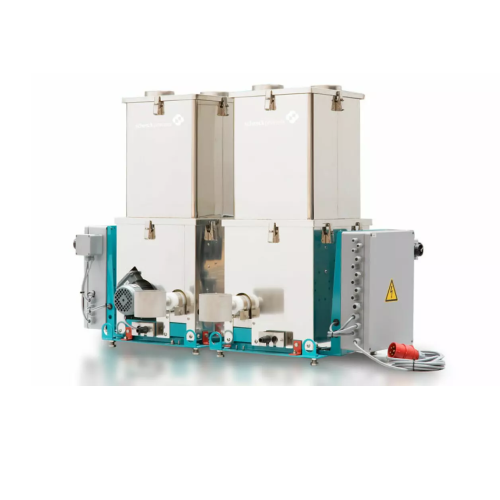

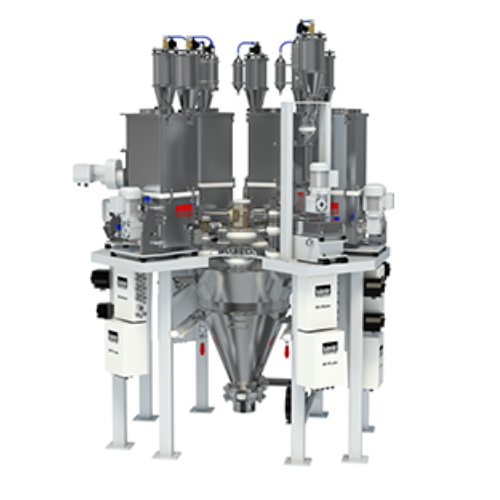

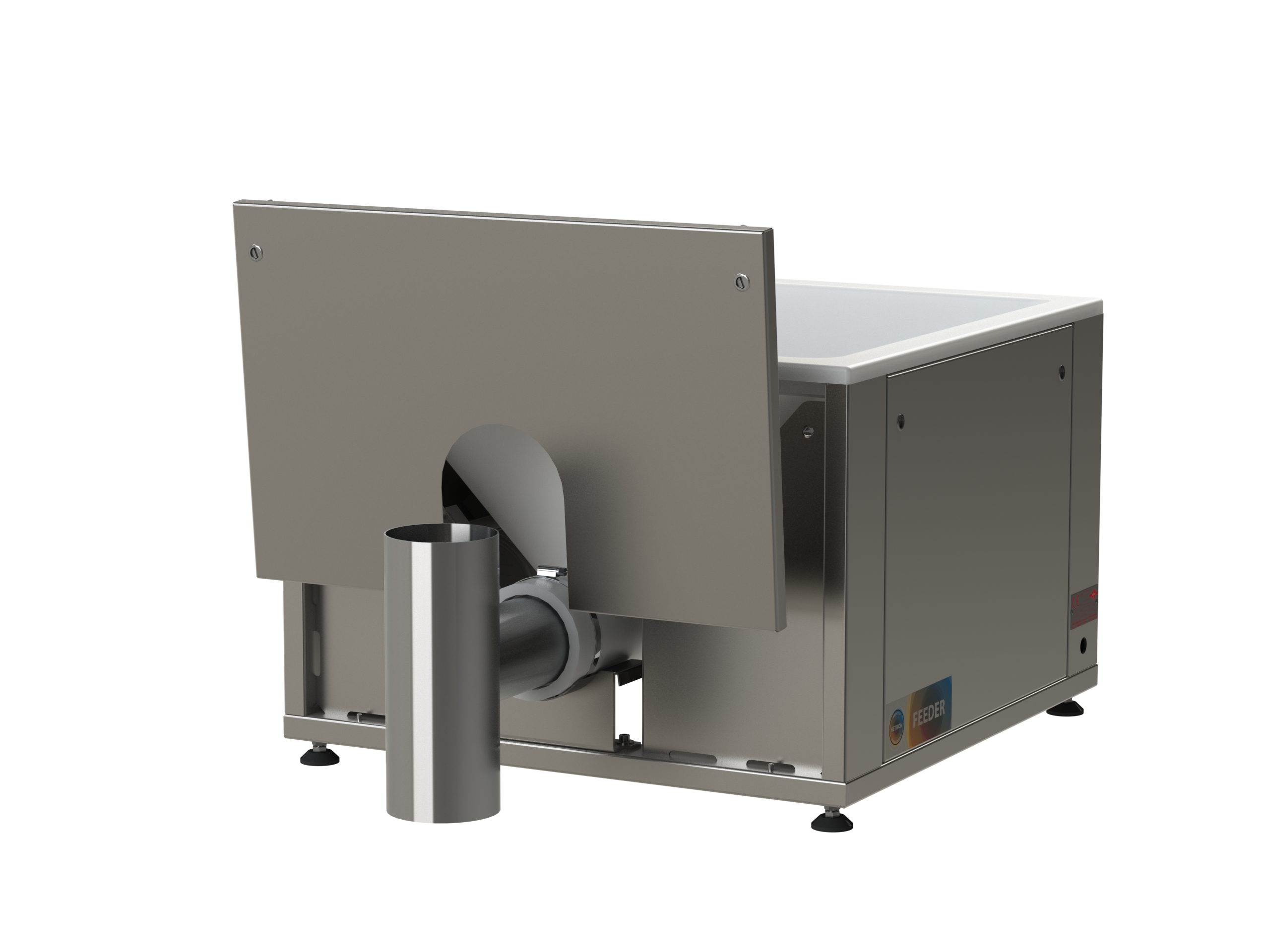

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

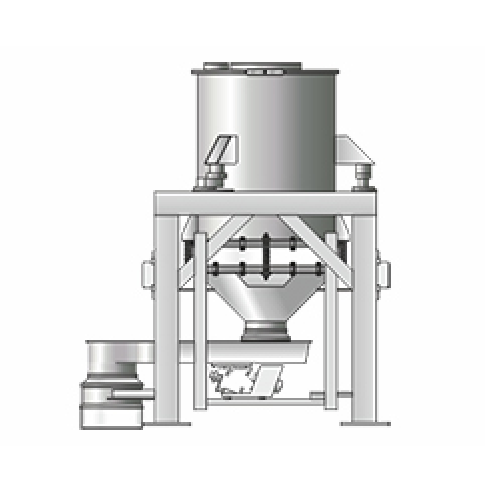

Gravimetric batch blender for plastics compounding

Achieve precise batch blending with high accuracy, ensuring consistenc...

Pelletizer for temperature and shear-sensitive plastics

Optimize your production line efficiency with a pelletizing solut...

Underwater pelletizer for sticky thermoplastics

Enhance pelletizing efficiency for challenging products with optimal therm...

Bench top press for Astm testing of plastics and rubber

Streamline your material testing with precision-controlled bench ...

Optical sorter for grains, coffee, nuts, and plastics

Ensure consistent product quality and minimize waste with advanced ...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

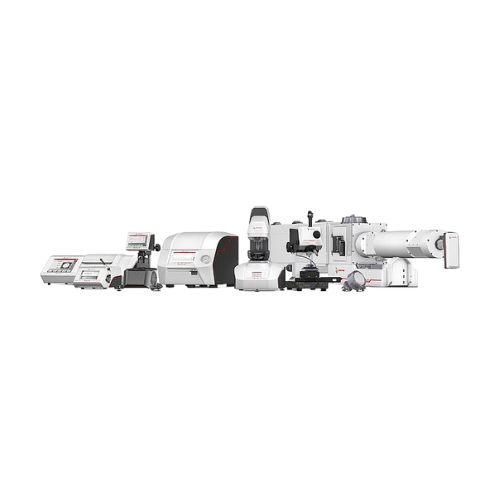

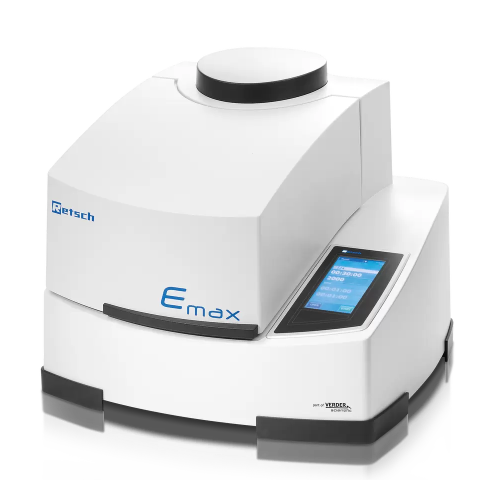

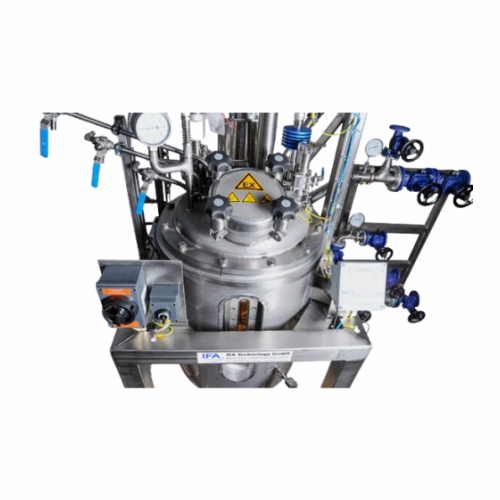

Modular torque rheometer for plastics and plastifiable substances

Optimize your material development and testing with a...

Modular torque rheometer for plastics and rubbers

Optimize your material testing and process development with a versatile...

Micro pelletizer for thermoplastics

Achieve precision in micro pelletizing with a solution engineered to reduce turbulence,...

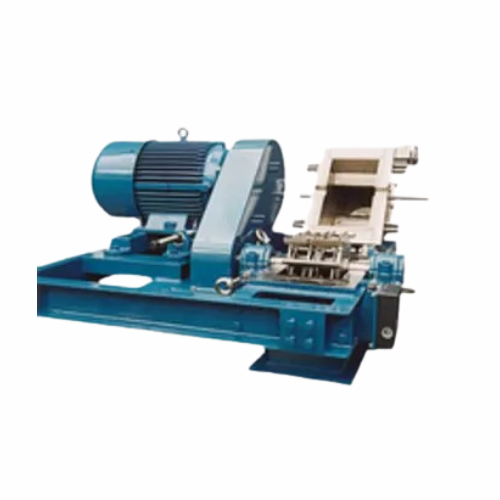

Pultrusion pelletizer for long glass fiber thermoplastics

Engineered to tackle the challenges of cutting and pelletizing...

Central granulators for high-volume plastics recycling

Efficiently process large volumes of recycled plastics and industr...

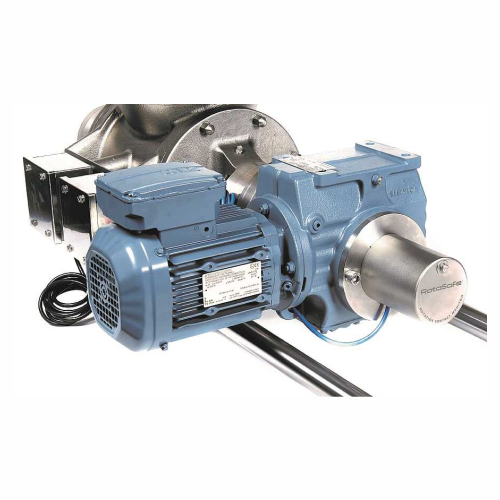

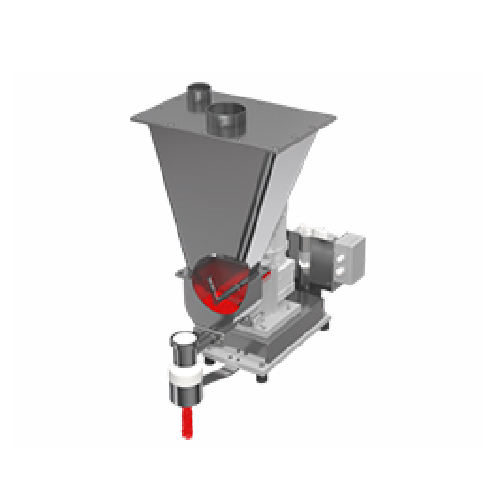

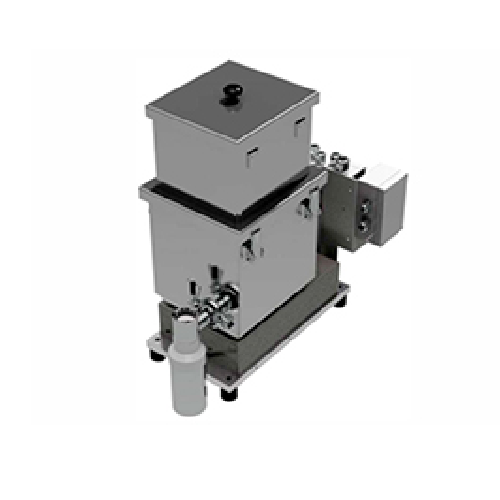

Digital doser system for plastics additive feeding

Achieve precise additive dosing for plastics, ensuring consistent qual...

Steam conditioning plants for polyamide plastics

Enhance the durability and assembly readiness of polyamide components wit...

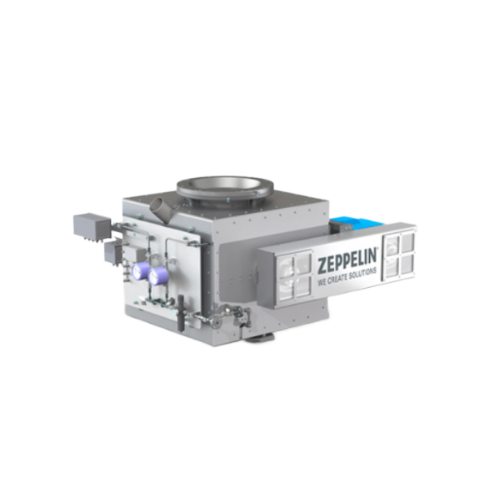

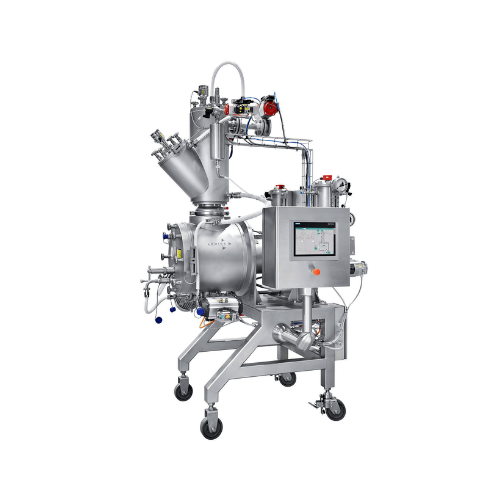

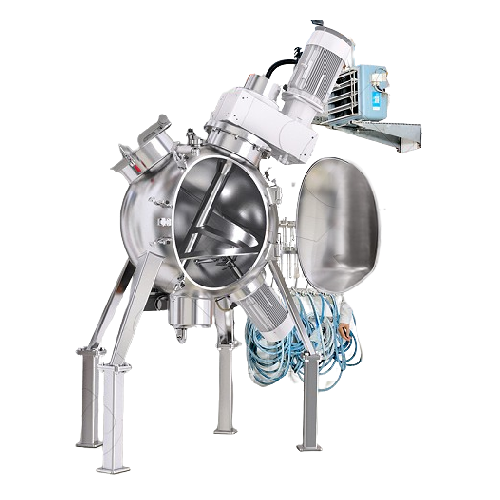

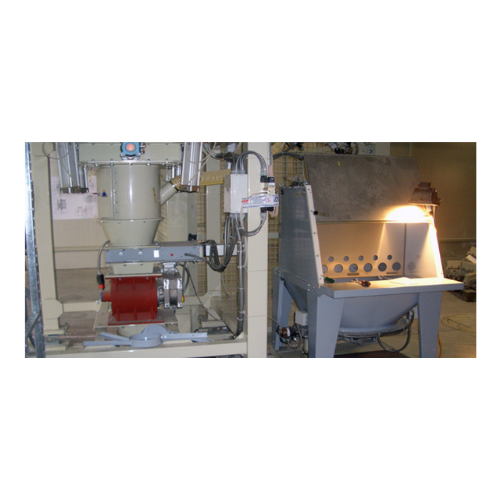

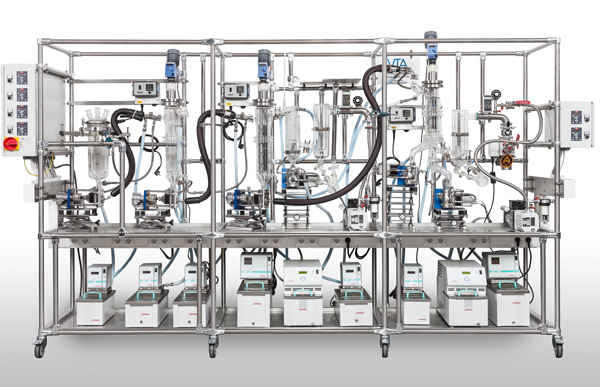

Technical plastics production system

Optimize your production line by integrating a versatile system capable of precise mix...

Air separator for polymers and plastics

Ensure high-purity plastic pellets by efficiently separating fine dust and streamer...

In-line metal detector for plastics processing

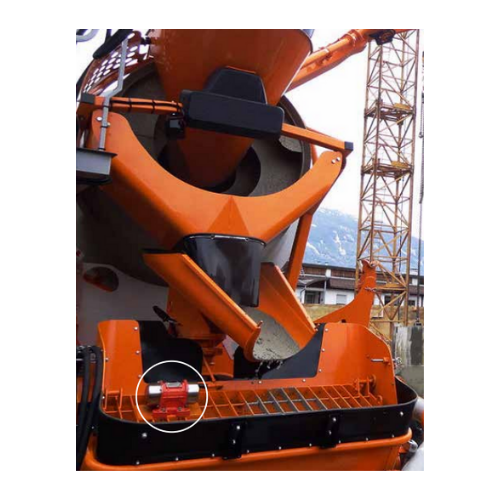

Prevent costly breakdowns in plastics production with an in-line metal dete...

Chute sorting systems for recycling plastics and glass

Streamline your recycling operations by efficiently sorting and pu...

Mobile regrind sorting platform for plastics

Struggling with inconsistent regrind quality? This mobile sorting platform ef...

Tumble dryer for granulated plastics

Vacuum drying at high temperatures is important in the production of granulated plasti...

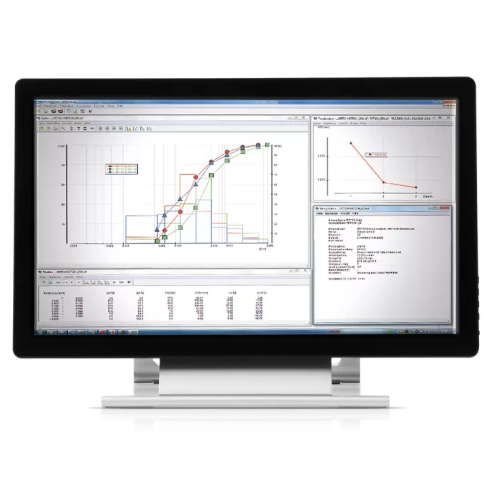

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

High-torque cutting mill for tough and fibrous materials

Tackle the toughest materials and ensure consistent particle siz...

Laboratory sieve shaker for accurate particle size analysis

Streamline your material testing with a robust vibratory sie...

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

Continuous ploughshare mixer for diverse industrial applications

Enhance mixing efficiency and achieve precise particle ...

Vacuum paddle dryer for chemical and pharmaceutical applications

Achieve precise moisture control and efficient drying i...

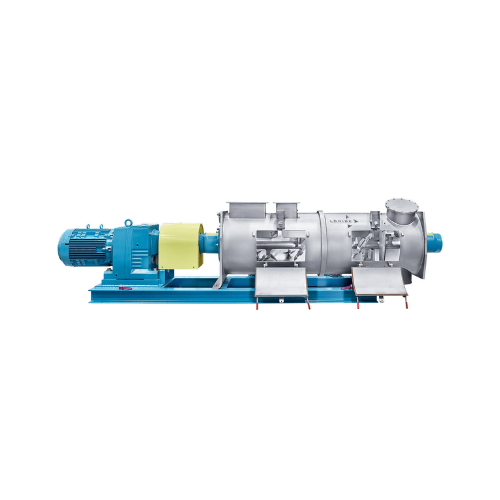

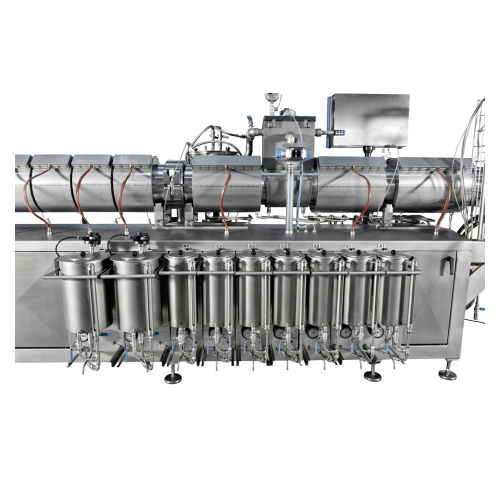

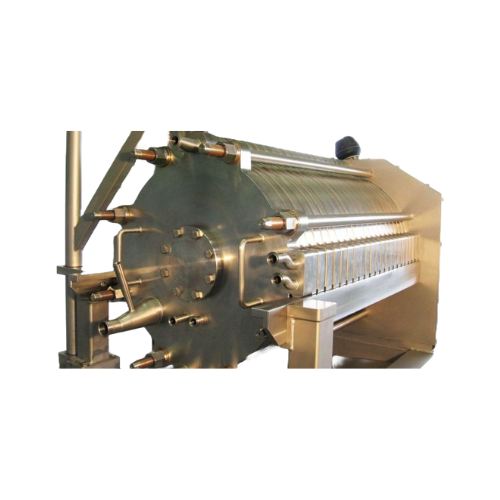

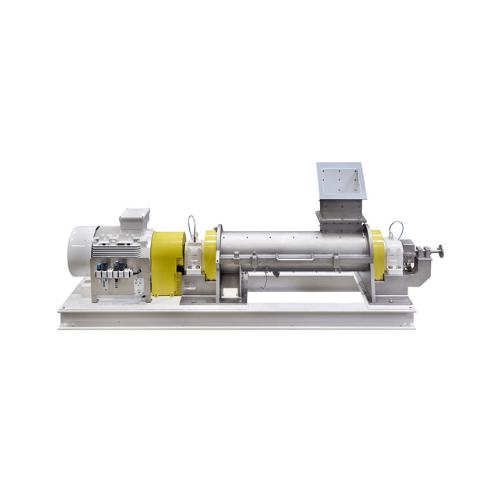

High torque twin screw extruder for industrial applications

Enhance your production capabilities with advanced twin scre...

Industrial twin screw extruders for high torque and volume applications

Optimize your extrusion processes with high tor...

High torque and volume twin screw extruder

Maximize processing adaptability and efficiency across diverse applications wit...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Plastic pellets inspection system

Ensure product quality by accurately detecting impurities and variations in plastic pelle...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

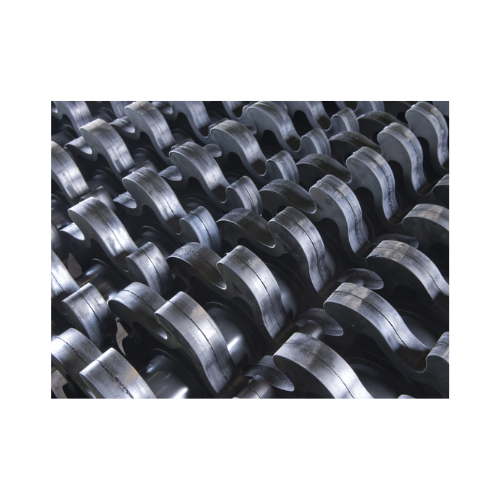

Shredder-granulator for plastic recycling

Simplify your plastic recycling process by integrating shredding and granulating...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Belt feeder for alternative fuels

Maximize fuel efficiency with this belt feeder designed for seamless dosing of alternativ...

Continuous conveyor belt dryer for endless products

Optimize your continuous production line with a high-speed drying sol...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Cutting mill for dry sample comminution

Achieve precise comminution of dry materials, from plastics to dried plants, with e...

High-speed cutting mill for versatile material comminution

Efficiently transform diverse materials like plastics, textil...

Variable speed rotor mill for sample preparation

Achieve rapid and precise grinding of various materials with a versatile ...

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

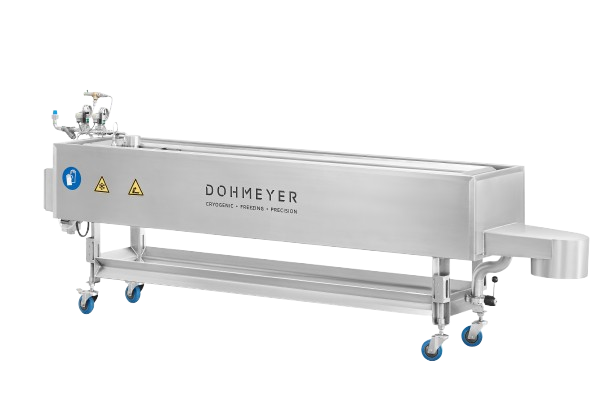

Cooling tunnel for confectionery extrusion

Optimize your production line with a versatile cooling tunnel capable of effici...

Extrusion system for color changing confectionery strands

Easily switch colors in confectionery strands mid-production, ...

High precision dosing system for color, flavor, and acid

Achieve precision and reliability in dosing color, flavor, and a...

Screen changer for extrusion lines

Prevent clogs and maintain quality with this screen changer, designed to filter out soli...

Pyrolysis for biomass conversion

Transform diverse waste materials into valuable bio-commodities and energy through advanced...

Discontinuous screen changer for low viscosity melts

Optimize your filtration process with a discontinuous screen changer...

Continuous screen changer for thermoplastic materials

Eliminate downtime caused by blockages with a continuous screen cha...

Underwater pelletizing system for thermoplastic materials

Optimize your thermoplastic pellet production with a reliable ...

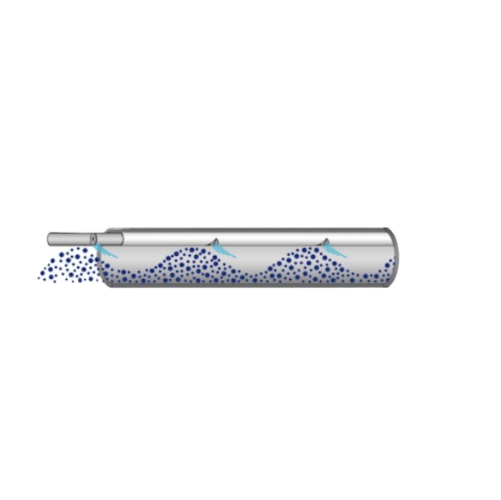

Vibration drying system for pellets

Achieve precise moisture control for pellets with high filler content, enhancing final ...

Versatile entry-level mixer granulator

Solve complex mixing and granulating challenges with this compact solution, offering...

Bulk material mixer for high-speed homogenization

Achieve fast and gentle homogenization of bulk materials with a high-sp...

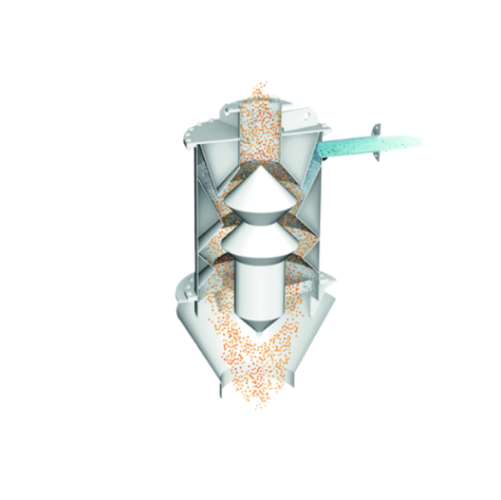

Pellet dedusting elutriators

Achieve superior purity in your production line by effectively removing dust and streamers with...

Industrial smart flow meter

Ensure precise metering and smooth handling of bulk materials with a device that eliminates movi...

Twin screw feeders for difficult bulk materials

For manufacturers handling sticky or fine powders, twin screw feeders ensu...

Industrial vibratory feeder for bulk solids

Ensure precise and gentle handling of delicate bulk materials with a cutting-e...

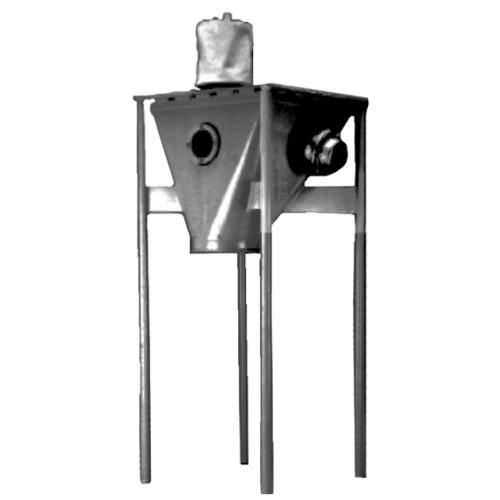

Aerolock surge hopper for precise bulk material management

Optimize your production with a surge hopper designed to ensu...

Feed bins for pre-conditioning materials

Optimize your material flow by pre-conditioning bulk solids for efficient vacuum c...

Scale hopper for bulk material processing

Optimize your bulk material handling with precise control in separation, filling...

Industrial strand pelletizer for polymer processing

Optimize polymer pellet production with precision engineering, ensuri...

Filtration compounder for polymer recycling

Streamline your recycling process by integrating filtration and compounding in...

Laboratory twin screw extruder for small batch processing

Efficiently develop formulations and conduct precise research ...

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Regenerative vacuum blower for pneumatic conveying

Optimize your material handling with a compact regenerative vacuum blo...

Industrial vacuum blower for continuous pressure conveying

Optimize your production line with reliable vacuum conveying,...

Vacuum sequencing blower for industrial conveying systems

For manufacturers handling bulk materials like powders and gra...

High-performance compounding extruder

Achieve precision in compounding and pelletizing with advanced extruders that ensure ...

Hydraulic compression press for Astm plastic sample preparation

Achieve precision in molding and testing with this hydra...

Ashing furnace for complete combustion

Ensure precise sample combustion with a furnace designed for optimal ash analysis, p...

Twin screw compounder for polymer processing

Achieve superior polymer blends with optimized shear forces and consistent ma...

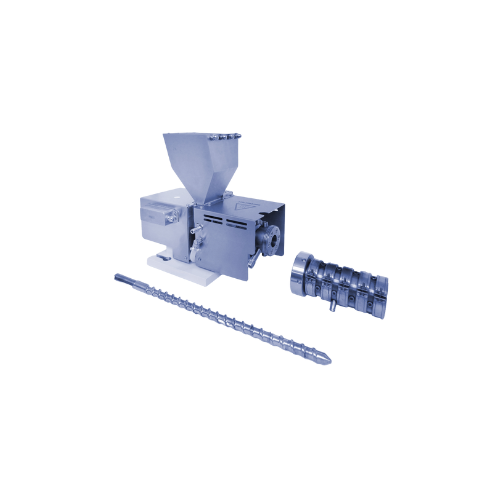

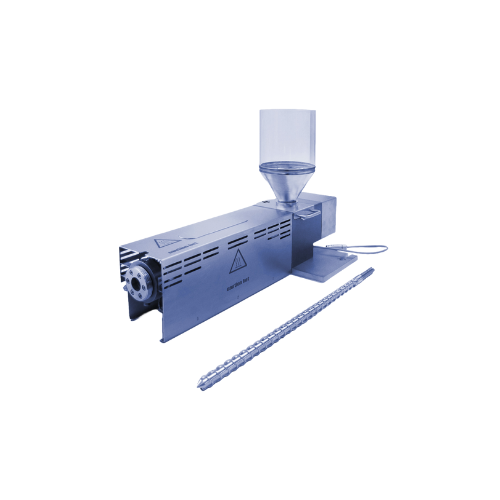

Single-screw extruder for material analysis

Ideal for material testing and development, this single-screw extruder enhance...

Stand-alone extruder for lab-scale testing

Optimize your lab-scale extrusion testing with a compact solution that handles ...

Stand-alone extruder for polymer and food processing

Optimize your extrusion process with a versatile and efficient machi...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Modular torque rheometer for polymer testing

Gain deep insights into the processability and material characteristics of po...

Mini-compounder for laboratory polymer processing

Streamline your polymer development process with a compact compounding ...

Measuring extruder for small sample simulation

Optimize your production process with this precise extruder, designed to si...

Conical twin screw extruder for shear-sensitive materials

Optimize the extrusion process for shear-sensitive materials w...

Lab extruder for elastomer extrudability testing

Optimize your small-scale testing with an innovative extruder designed to...

Polymer testing extruder

Effortlessly evaluate polymer and plastic product properties with precision, ensuring your materials...

Automated polymer melt flow rate measurement system

Achieve precise polymer quality control by continuously analyzing mel...

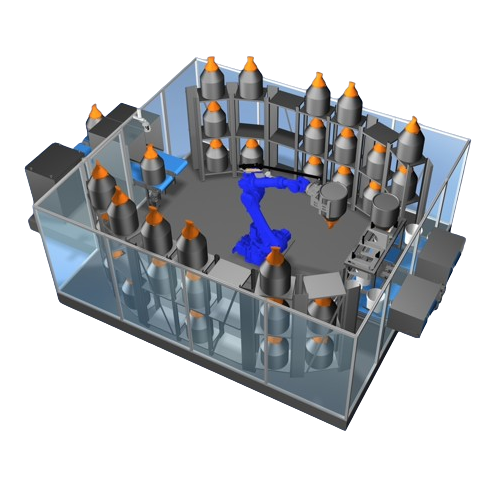

Automated sorting robot for material recovery facilities

Enhance your material recovery operations with AI-driven precisi...

Belt feeder for waste sorting applications

Efficiently handle diverse waste streams and optimize resource recovery with a ...

Chain belt conveyor for waste paper and industrial waste

Optimize your waste processing with a robust chain belt conveyor...

Crossflow filtration for microfine to nanoscale suspensions

Optimize your production line with advanced crossflow filtra...

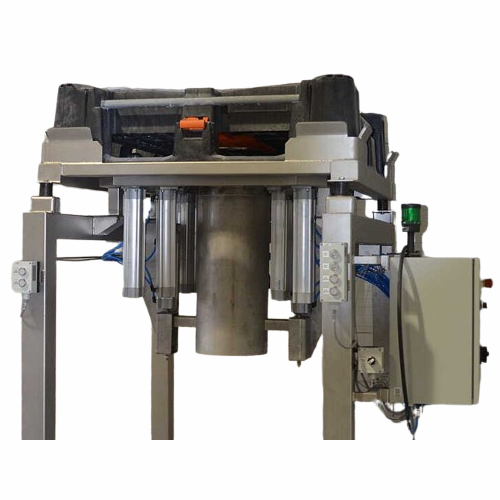

Automatic strand pelletizer for reinforced and filled polymers

Optimize your polymer production with precise pelletizing...

Automatic wet cut strand pelletizer for thermoplastic pellet production

Streamline your polymer pellet production with ...

Strand pelletizer for small production lines

Achieve consistent and precise pellet sizes with our strand pelletizer, ideal...

Industrial water bath for pelletizing processes

Enhance pellet quality and efficiency with a customizable water bath desig...

Advanced vacuum air dryer for pelletizing strands

Efficiently remove residual water from polymer strands with a vacuum ai...

Dx strand pelletizer for plastic pellet production

Reduce operational noise while precision-cutting a wide array of therm...

Bag feeding hopper for bulk solids

Optimize your material handling with a robust feeding hopper that seamlessly integrates ...

Accurate dosing for powder products

Ensure precise dosing and consistent flow of bulk powders in your production line to en...

Robotic dosing system for accurate micro quantities

Achieve precise and reproducible micro dosing of challenging raw mate...

Automatic minor components weighing system

Streamline precision in your production by automating the weighing of minor and...

Automatic Pet preform injection moulding

Optimize your production with high-speed injection molding capable of shaping dive...

Tumbler screening for fine and ultra-fine sieving

For operations demanding precise particle separation, this solution off...

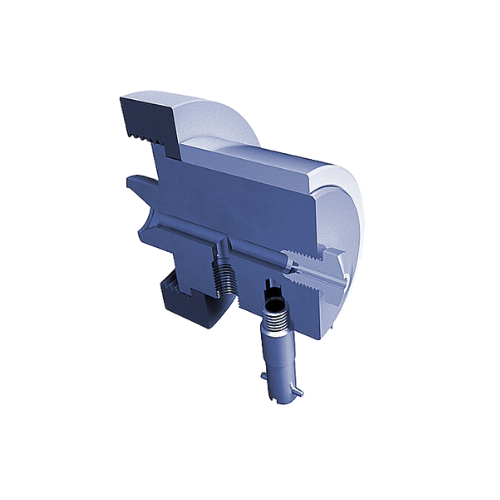

Beside-the-press granulators for injection molding

Optimize your plastic production by efficiently reclaiming resin with ...

Heavy duty granulator for high-capacity size reduction

When tackling high-volume materials, rely on these industrial-grad...

Thermoforming granulators for efficient material processing

Efficiently recycle and optimize your plastic waste by trans...

High efficiency central chiller for industrial cooling

Achieve remarkable energy savings with this modular chiller system...

Powder hopper loaders for free-flowing materials

Efficiently transport free-flowing powders, including PVC and polyethylen...

3.5 Hp air-cooled chiller for industrial cooling

Optimize your production with high-efficiency cooling, essential for main...

Central chiller for consistent process cooling

Optimize your production with modular central chillers offering scalable co...

Industrial shredder for recycling and waste management

Efficiently transform challenging waste streams into valuable raw ...

Stainless steel drying hoppers for plastic processing

Optimize moisture control for thermoplastics with robust drying hop...

Outdoor central chiller for process cooling

For facilities needing reliable process cooling without sacrificing indoor spa...

Continuous loss-in-weight blender for extrusion applications

Ensure precise ingredient ratios for extrusion processes wi...

Desiccant wheel dryer for plastic processing

Optimize drying processes in plastic manufacturing with a system designed for...

Compressed air loaders for material conveying

Efficiently convey diverse materials with minimal operator intervention, usi...

Gravimetric batch blender for injection molding and extrusion

Enhance your polymer blending precision with a solution ta...

Hot air dryers for non-hygroscopic material

Ensure reliable material quality by effectively reducing moisture in non-hygro...

Industrial ring dryer for efficient particle processing

Control particle size and drying efficiency with precise recircul...

Traditionally welded silos for constrained installation sites

Ideal for facilities with limited space, these traditional...

Cyclone separator for pneumatic conveyor systems

Enhance efficiency in pneumatic conveyor systems by effectively separatin...

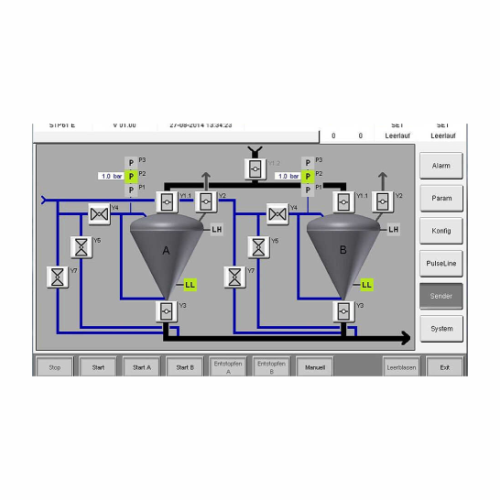

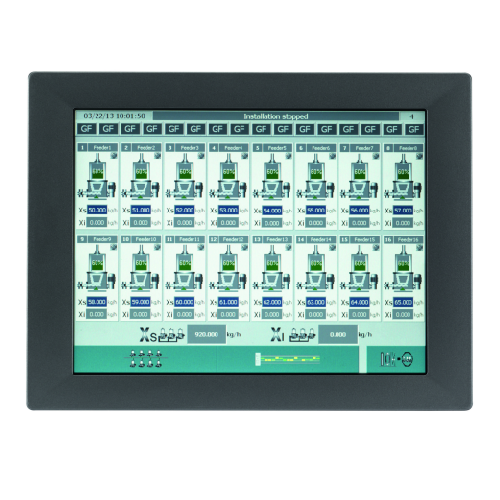

Automated process controllers for industrial plants

Enhance your production line’s efficiency and adaptability with...

Autonomous process control for petrochemical and food industries

Streamline your production with autonomous control syst...

Pneumatic conveying diverter valve for abrasive bulk materials

Streamline the flow of abrasive materials in your pneumat...

Industrial rotary sifter for bulk materials

Ensure precision and quality in your production line with a robust solution de...

Drum screen for streamer and bird’s nest removal in plastic pellets

Ensure the highest quality of plastic pellets by ef...

Pneumatic conveying diverter valve for multi-silo feeding

Optimize your pneumatic conveying system by efficiently direct...

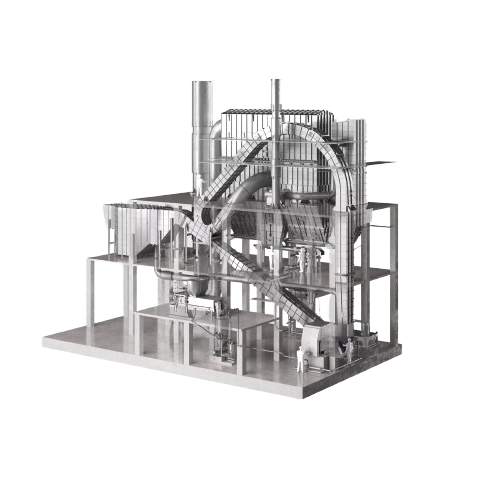

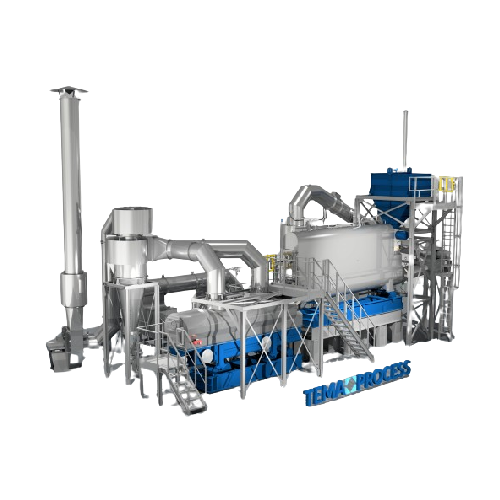

Turnkey plant solutions for industrial applications

Enhance your production line with seamless integration and optimized ...

Negative pressure bin vent filter for dust control

Ensure optimal air quality and operational safety by effectively captu...

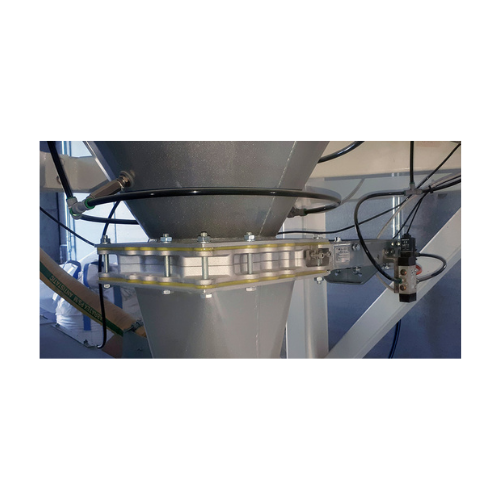

Vibratory bottom discharge system for bulk materials

Ensure consistent flow of challenging bulk materials with a vibrator...

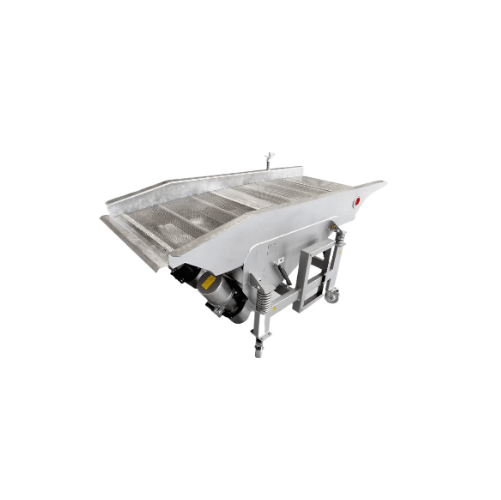

Vibratory pellet separator for dust and streamer removal

Achieve high-efficiency separation of dust and streamers from po...

Pneumatic conveying systems diverter valve

Effortlessly manage bulk material flow with precision, ensuring seamless transi...

Plant refurbishment services for industrial operations

Optimize your existing plant’s performance and extend its li...

Rotary sifter for bulk material preparation

Ensure precise material preparation and protect downstream processes by integr...

Screw belt mixer for dry materials

Achieve uniform mixing of bulk dry materials with variable speed control, ensuring preci...

Vacuum hopper loader for automatic feeding of powders and pellets

Optimize your material handling with seamless automat...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

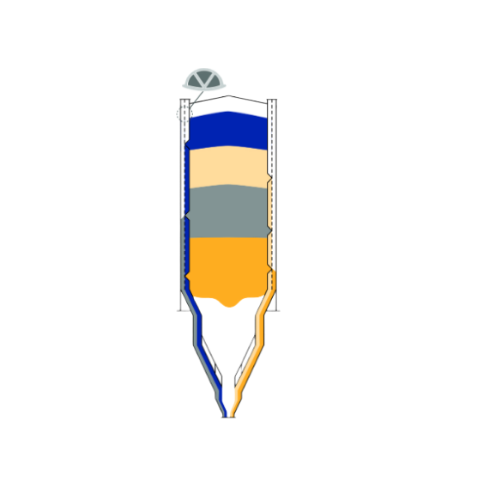

Industrial multi-chamber silos

Optimize spatial efficiency and streamline your production with versatile multi-chamber silos...

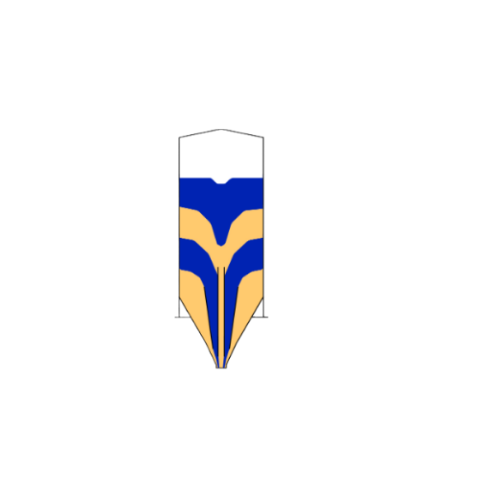

Multi-channel blending silo for free-flowing bulk materials

Achieve precise homogenization and mixing of free-flowing bu...

Blending silo for free-flowing and poorly flowing bulk materials

Achieve precise blending and mixing of diverse bulk mat...

High-speed paddle mixer for food industry blends

Achieve rapid, high-energy blending of varied particulate materials with ...

Prefabricated panel silo construction

Designed for efficient assembly, this silo construction system reduces installation t...

Industrial rotary feeder for powder and agglomerates

Achieve seamless integration in your production line with a robust s...

Process control for baked goods production

Enhance your production line with precise process control designed to optimize ...

Pta and Pet production systems

Maximize throughput while minimizing dust fines in your production of PTA and PET pellets wit...

Bin vent filter with anti-static filter cartridges

Optimize your production line’s air quality by removing fine dus...

Vertical cooler mixer for industrial cooling mixing

Enhance your production line with efficient temperature control and r...

Precise discharge and dosing module for silos and containers

Ensure seamless material flow and accurate dosing with adva...

Industrial discharge and dosing module

Optimize material flow and prevent blockages in silo discharge and dosing processes,...

Liquid additive dosing system for industrial mixers

Achieve unparalleled precision in liquid ingredient integration with ...

Storage silo with long base skirt for processing industry

Optimize your bulk material storage with a silo that offers du...

High precision mixer for metallic powder paints

Achieve unparalleled precision and uniformity in producing high-gloss and ...

Sampler for powdered and granular bulk materials

Ensure precise sampling of powdered and granular materials under varied o...

Gravimetric loading sifter for dust and streamer removal

Optimal for removing dust and streamers, this compact sifter ens...

Sampler for free-flowing granular bulk materials

Efficient and precise sampling of granular bulk materials and coarse powd...

Counterflow separator for polymer pellet cleaning

Achieve unparalleled pellet purity with efficient dust and streamer rem...

Horizontal cooling mixer for industrial applications

Efficient cooling in your production line enhances material quality ...

Horizontal homogenizing mixer for all-purpose applications

Achieve uniformity and consistency in your products with a ve...

Horizontal cooling mixer

Ensure consistent batch temperatures and reduce production costs with this robust cooling mixer, des...

High-pressure rotary feeder for continuous powder handling

Optimize your production line with reliable powder handling, ...

Universal mixer for diverse industrial mixing needs

Achieve precise homogenization and optimal emptying with a versatile ...

Industrial bin vent filter for fine dust particles

Enhance your production line with efficient fine dust filtration to en...

Advanced degassing and temperature control solution for process silos

Optimize your production line with precise contro...

Bin vent filter for dust control in modular systems

Optimize your production line by efficiently controlling dust and fin...

Rotary feeder for powdered bulk materials

Achieve precise control in feeding and discharging powdered materials with a rot...

Advanced plant engineering services

Optimize your production line with seamless integration of high-efficiency mixing, dosi...

Fluidizing bed for bulk material discharge

Optimize your material flow with a fluidizing bed designed for seamless dischar...

Fluidizing bed blending silo for powder mixing

Optimize your batch mixing process with a fluidizing bed blending silo, des...

High intensity industrial mixer

Achieve rapid homogenization and outstanding dispersion with this versatile mixer, designed ...

Bulk materials discharge solution for silos and containers

Ensure reliable material flow with a robust discharge solutio...

Industrial conveying system for carbon black and silica

Ensure dust-free conveyance of sensitive materials like carbon bl...

Blending silo for poorly flowing bulk material

Enhance your bulk material processing with a blending solution that ensures...

High-pressure rotary feeder for powder and agglomerates

Optimize your production line with a high-torque solution that ef...

High-pressure rotary feeder for bulk material handling

Manage high-pressure bulk material distribution with precision, en...

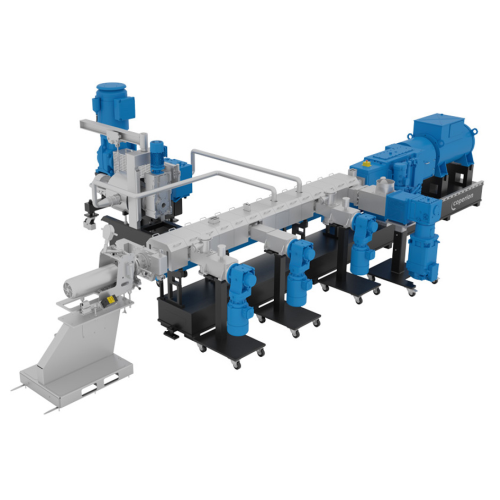

Continuous material handling in compounding plants

Enhance your production line efficiency with advanced dosing, mixing, ...

Turnkey manufacturing and processing systems management

Streamline your production line with comprehensive assembly and c...

Industrial control cabinets and control stations

Streamline your plant operations with customizable control cabinets and s...

Continuous pneumatic silo air filtering system

Ensure clean and efficient pneumatically conveyed materials by integrating ...

A-type rotary feeder for powder and pelleted bulk materials

Ensure precise feeding and discharging of powdered and pelle...

Battery production facilities with precision weighing

Achieve maximum product purity and precision in your production pro...

Twin shaft mixers for fragile and high throughput applications

Maximize mixing efficiency and protect delicate materials...

Continuous single shaft mixer for waste treatment

Achieve consistent mixing homogeneity and prevent dead spots in your pr...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Stainless steel tubular screw conveyor for bulk solids handling

Ensure precise material handling with stainless steel tu...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

High flow rate Fibc discharger

Optimize your bulk material handling with a system designed for efficient and dust-free FIBC ...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

External electric motovibrators for bulk solids conveying

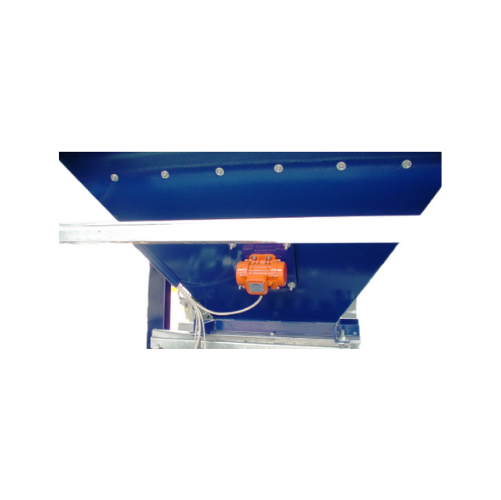

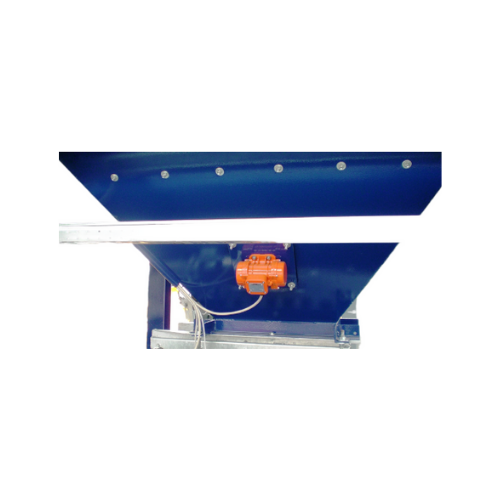

Enhance material flow efficiency and solve challenging dischar...

External electric motovibrator for increased safety in hazardous environments

Designed for environments with explosive...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

High efficiency micro-batch feeder for powdery or granular materials

Achieve precise volumetric feeding and metering of...

Loading bellows for drums and Ibcs

Ensure dust-free loading of bulk solids into confined spaces with compact, pneumatically...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Waste bag compactor for bulk solids

Efficiently compact waste bags to a fraction of their volume, streamlining disposal whi...

Rotary bin discharger for bulk solids

Efficiently manage bulk solids with a rotary bin discharger that minimizes residue an...

Trough screw conveyors for powdery and granular materials

Optimize your material handling process with a flexible screw ...

Industrial tank mixer for high-volume containers

Optimize your mixing processes with a robust solution designed for high-v...

Pneumatic diverting valve for powder and granule transfer

Efficiently redirect bulk materials from one point to another ...

Table top extruder for customizable extrusion processes

Discover versatile extrusion capabilities for developing complex ...

Rewinder for extrudates

Achieve precise winding of extrudates with adjustable tension control, ensuring consistent spooling f...

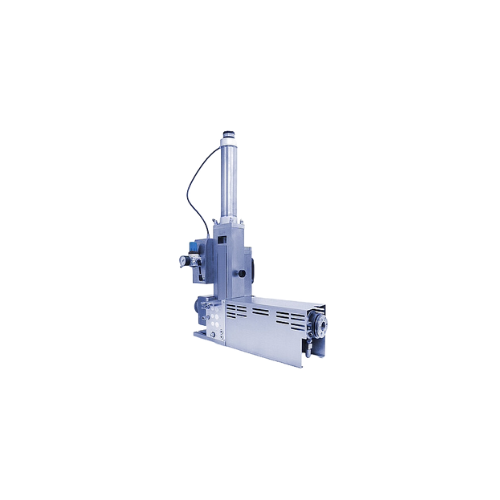

Side feeding device for extruders

Enhance your extrusion process with a side feeding device that gently introduces powders,...

Cooling bath for efficient extrudate processing

Ensure optimal cooling for extrudates to maintain product integrity and en...

Single screw feeders for granules

Optimize the feeding of well-flowing granules with precision and consistency—key for main...

Quick change volumetric and gravimetric single-screw dosing device

Simplify your dosing process with a quick-change sin...

Foil roller for precise extrudate calibration

Achieve uniform film thickness and precise calibration of extrudates with an...

Cooling conveyor belt for extrudates and granules

Efficiently cool and convey extrudates and granules with precise temper...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

Pneumatic inline sifter for dry flowing material

Ensure precise particle segregation and foreign matter removal with this ...

Vibratory finishing and deburring technology

Achieve precise surface finishing and deburring with advanced vibratory motio...

Bin activator for reliable bulk solids discharge

Ensure reliable flow and prevent compaction in your production line with ...

Single screw feeder with stirring agitator for powders and pellets

Ensure consistent mass flow and precise dosing with ...

Dust filter for loss-in-weight feeder refill

Optimize your feeder operations by effectively filtering displaced air and mi...

Bigbag discharge station

Efficiently manage bulk material unloading with this solution, which facilitates seamless dischargin...

Batch ingredient dosing system for high-accuracy weight control

Achieve precise weight measurement for multi-ingredient ...

Loss-in-weight feeder for long and uneven fibers

Optimize feeding precision for challenging materials like long and uneven...

Self-regulating material feeder for recycling lines

Experience enhanced efficiency in recycling operations with a feeder ...

Granulate screening technology for precise particle size separation

Achieve exceptional sorting precision and maintain ...

Vibrating screen for sticky and moist materials

Efficiently tackle the challenges of processing wet and sticky materials w...

Low temperature bath for sample freezing and temperature control

Achieve precise temperature control from -80°C to +100°...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Sorting conveyor systems for recyclables

Efficiently sort and reclaim diverse materials from mixed waste streams with high-...

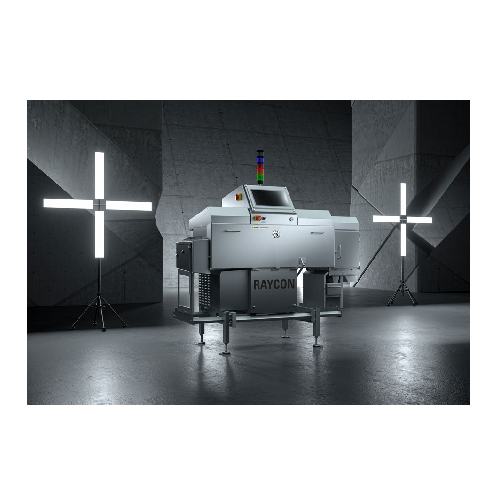

X-ray inspection system for unpackaged bulk products

Ensure product purity and safety in high-speed production lines with...

Mass flow rate feeder for bulk powders

Achieve precise control and consistent material flow in high-speed manufacturing env...

Loss-in-weight feeder for bulk solids

Ensure precise and reliable dosing of bulk solids with a compact feeder that eliminat...

Loss-in-weight feeder for plastic compounding

Achieve precise material flow and improved production efficiency with an ada...

Continuous and batch feeding system for bulk materials

Achieve precise bulk material feeding with seamless integration in...

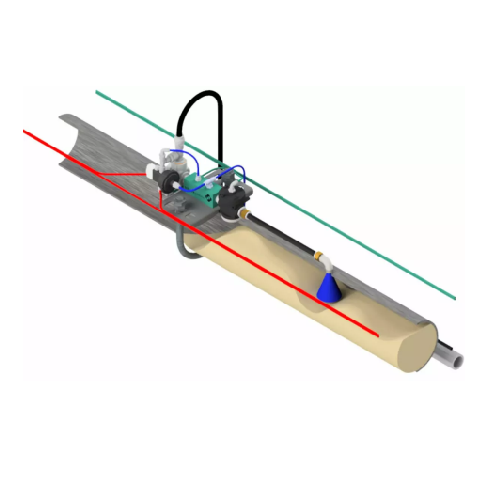

Injected density stabilizer for pneumatic conveying

Optimize your dense phase pneumatic conveying with a stabilizer desig...

Multipurpose feed station for bulk solids

Optimize your production line with a versatile feeding station designed for simu...

Industrial pellet mill

At the industrial level, the application areas of pellets range widely in fields such as feeds, biomas...

Laboratory aerator for food products

Successful innovators in the food, chemicals, and plastics industries need reliable mi...

Macro ingredient dosing system

Traditional dosing systems do not have a very long operational life and are hard and expensiv...

DAF wastewater treatment

The food and beverage industry requires the total removal of suspended solids (TSS), biochemical oxy...

Laboratory granule dedusting analyzer

High quality clean bulk materials are used in many industries including plastics, foo...

Small scale deduster for plastic granules

Industries that use bulk plastics see better product quality and decreased equip...

Deduster for injection moulding

High quality injection molded plastic parts require clean bulk resins free of dust and strea...

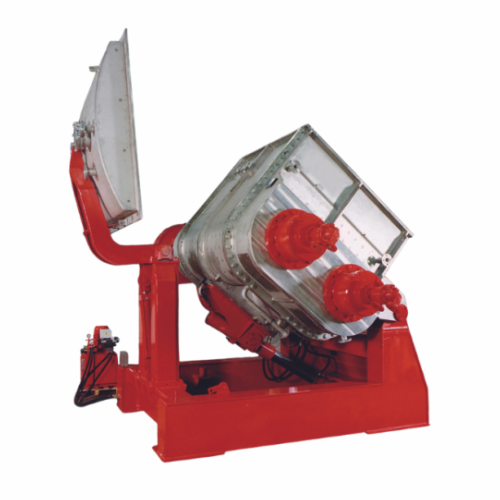

Pusher centrifuge

Pusher centrifuges are continuously operating filter centrifuges and can have several basket stages dependi...

Ultra centrifugal mill for size reduction of soft and medium-hard materials

Achieve precise particle size reduction an...

Cutting mill for soft and medium-hard materials

Efficiently reduce the size of diverse materials with precision cutting an...

Disc mill for industrial laboratory grinding

Streamline your sample preparation with a robust disc mill designed for preci...

Electromagnetic sieve shaker for quality control

Achieve precise particle size distribution with this advanced electromagn...

Mesh sieves for laboratory particle size analysis

Ensure precise particle size control for a wide range of materials with...

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

Pressure and temperature monitoring system for ball mills

Ensure optimal grinding conditions and enhance product quality...

Cryogenic ball grinder for laboratory use

Achieve precise temperature-controlled grinding with advanced cryogenic technolo...

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Pellet press for Xrf analysis

Ensure precise spectral analysis with strong, smooth-surfaced pellets by utilizing adjustable ...

Rotating sample divider for large bulk materials

Achieve precise, dust-free division and volume reduction of bulk material...

High energy untra fine ball mill

Achieve ultra-fine particle sizes rapidly with this high energy milling solution, designed ...

Fluid bed dryer for bulk material laboratory drying

Efficiently dry and mix organic and inorganic materials with precise ...

Sample dividing solutions for laboratory applications

Streamline your lab’s precision in sample preparation with so...

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

Laboratory ploughshare mixer for small-scale production

Achieve precise mixing and granulation for R&D and small-bat...

Ploughshare mixer for batch operation

Achieve superior mixing quality with a system designed for rapid batch operations. Ex...

High-speed mixer for continuous high throughputs

Achieve exceptional homogeneity in mixing liquid and pasty components int...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

Continuous granulation dryer for chemical and polysaccharide applications

Enhance your production with precise drying ...

Laboratory mixer granulator

Achieve high-quality mixtures in R&D and small-batch production with versatile laboratory m...

Cryogenic cooling system for meat mixing

Efficiently manage heat during meat mixing to enhance product quality and ensure s...

4 head sealing system for plastic and glass jars

Achieve precision sealing for jars of various materials with this high-sp...

Collaborative robot for fast and intuitive automation

Accelerate your production line with a versatile and intuitive cobo...

Sanitary bulk bag filling system

Streamline your powder handling process with a system designed to improve stability and acc...

Modular stacking and automation for polymer packaging

Addressing the needs of flexible food packaging, this solution offe...

Thermoforming tools for polymer packaging

Optimize your production line with versatile thermoforming tools that enhance fl...

360° palletizing and depalletizing robot

Optimize your packaging flow with a robot offering seamless 360° operation for pre...

180° palletizing robot for automated palletizing and depalletizing

Optimize your production line with a versatile solut...

Vibrating tumbler screener for dry and wet screening

Achieve efficient dry and wet material separation with a high-capaci...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Rotary unscrambler for plastic bottles

Streamline your bottling process with a solution that efficiently sorts, orients, an...

Automatic filling and sealing solution for medium to large production

Streamline your high-capacity filling and sealing...

Pneumatic conveying systems for industrial applications

Efficiently transport bulk materials or liquids across your produ...

Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrat...

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

Gravimetric dosing systems for precise material measurement

Achieve precise material measurement with gravimetric dosing...

Optical sheet inspection system for industrial manufacturing

Enhance your sheet production quality with accurate defect ...

Customised tank systems for liquid and bulk material storage

Ensure safe and compliant storage of liquids and bulk mater...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Mixer/extruder for viscous pastes and plastic masses

Achieve seamless mixing, kneading, and extrusion of viscous material...

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate produc...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

High-speed pulverizer for carbon black production

Achieve consistent particle size and optimal homogenization with high-s...

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

Classifier mill for ultrafine grinding

Achieve precise particle size distribution and contamination-free processing with th...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...

Continuous kneader for viscous applications

For engineers tackling high-viscosity challenges, this continuous kneader stre...

Stationary entry packaging system for valve bags

Optimize your packaging workflow with a high-speed, modular filling syste...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

Laboratory z-arm kneader for high-viscosity materials

Ideal for R&D, this advanced Z-arm kneader efficiently handles...

Double z-arm industrial extrusion kneader for high-viscosity processes

Optimize high-viscosity material processing with...

High-speed industrial belt feeder for granular materials

Achieve precise and consistent material dosing in high-flow envi...

Vacuum pneumatic conveying for infant nutrition

Ensure efficient handling of delicate powders with a versatile vacuum pneu...

High-precision volumetric feeder for bulk materials

Achieve precise bulk material flow with a solution that ensures consi...

Mini batch blender for pharmaceutical solids

Achieve precise mixing homogeneity with the mini batch blender, perfect for l...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Contact detection system for rotary valves

Prevent product contamination and equipment damage with instant contact detecti...

Sack tipping station for dust-free bulk material handling

Efficiently manage bulk materials while minimizing dust exposu...

Single shaft batch mixer for chemical and pharmaceutical applications

Optimize mixing efficiency with rapid batch proce...

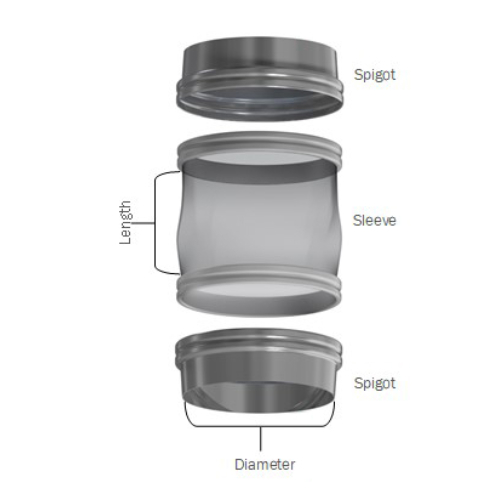

Hygienic flexible sleeves for tri-clamp connections

Ensure seamless, contamination-free transitions between processing st...

Continuous inline mixing for late product differentiation

Achieve seamless product differentiation with compact inline m...

Conveying controller for dense phase conveying

Streamline your dense phase conveying operations with precise control and m...

Dense phase pneumatic conveying system for powder transfer

Ensure gentle and efficient material transport with minimal m...

Pneumatic dilute phase conveying system for powders and bulk materials

Optimize your production line’s efficiency...

Quick-clean hygienic rotary valves

Ensure seamless cleaning and minimal downtime in your production line with rotary valves...

Big bag pallet unloader for bulk products

Efficient and reliable solution for unloading and transporting powders and bulk ...

High-precision gravimetric feeders for industrial bulk solids

Achieve unparalleled accuracy in your production line with...

Deagglomerator for consistent particle size reduction

Struggling with inconsistent particle sizes or unwanted lumps in yo...

Continuous mixer for homogeneous blending

Achieve consistent product quality with precise mixing and blending, ideal for a...

Laboratory mixer for r&d and small batch production

Achieve superior mixing precision for R&D and pilot production w...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

Centrifugal sifter for bulk solids and powders

Achieve precise particle separation and enhance product quality with a solu...

Continuous powder mixer for industrial applications

Achieve precise and efficient integration of powders, granules, and l...

Heavy duty blowing seals for abrasive products

For operations dealing with abrasive materials under high pressure, these r...

Cutting mill combination for heterogeneous material reduction

Achieve precise size reduction and material separation in ...

Particle sizing for powders and suspensions

Optimize particle shape and size analysis with rapid, reproducible results for...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

Lab cooking and forming extruders for r&d

Optimize your R&D processes by testing new recipes and improving formulatio...

Slurry preparation for licorice production

Ensure a continuous and homogeneous feed of licorice slurry to your extruder, o...

Thermogravimetric analyzer for moisture, ash, and volatiles analysis

Streamline your laboratory analysis with this solu...

Thermogravimetric analyzer for ash and moisture content analysis

Optimize your production with precise weight loss analy...

Carbon and sulfur analyzer for organic and inorganic samples

Achieve precise and simultaneous carbon and sulfur analysis...

Carbon and water analysis for lime and gypsum

Achieve precise carbon and water measurement in diverse materials like cemen...

Industrial hydrogenation plant for pharmaceutical raw materials

Optimize your hydrogenation processes with a modular pla...

Laboratory mixer and dryer for solids

Enhance your laboratory capabilities with precision mixing and drying for small batch...

Portable process development unit for gas-liquid reactions

Optimize your gas-liquid reaction processes with a versatile,...

Pilot plant for highly viscous applications

Perfect for R&D, this pilot plant efficiently handles complex mixing and ...

Vacuum dryer for free-flowing and pasty solids

Achieve precise drying and mixing with this vacuum dryer, optimizing heat t...

Air pelletizer for wood and natural fiber compounds

Optimize your pelletizing process with air-based cooling and conveyin...

Pellet dryer for industrial recycling applications

Ensure precise moisture control for recycled plastic pellets and flake...

In situ dry-ice snow generator for food and pharma applications

Achieve precise cooling and deburring with this versatil...

Cryogenic immersion bath for rapid freezing

Achieve rapid and intense cooling by immersing products in liquid nitrogen, id...

High-capacity universal mixer for industrial applications

Optimize your batch processing with a versatile high-speed mix...

Industrial shredder for diverse material reduction

Achieve precise and efficient material resizing for diverse applicatio...

Vertical transport for bulk goods

Efficiently move bulk goods vertically with minimal energy usage, ensuring seamless integ...

Industrial centrifugal sifter for solid particulate materials

Quickly and accurately sift a wide range of powders and gr...

Surge bins for material handling

Ensure efficient material flow and storage in your production line with surge bins that fea...

Batch weigh vacuum receiver

Optimize precision in ingredient batching and streamline your production line with advanced vacu...

Hydrocarbon liquefaction process for plastic waste

Transform plastic waste into valuable liquid hydrocarbons with a conti...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Fully automatic bagging station for granular products

Streamline your packaging line with a high-speed solution designed ...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

Flour handling plant for pasta production

Streamline your production with precision handling and processing of flour for p...

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Rotary mill for tough and fibrous materials

Achieve precise material reduction with our Rotary Mill, ideal for transformin...

Round strand die head for precision extrusion

Achieve precise extrusion control across varied applications with our custom...

Lab- and pilot-scale twin screw extruders

Optimize your material development and testing with versatile extruders, ideal f...

Pelletizer for consistent plastic pellet production

Achieve precise pellet sizes consistently with this flexible solution...

Conveyor belt for extruded profiles

Efficiently transport and convey extruded profiles with precision through adjustable sp...

Polymer extrusion testing extruder

Optimize your polymer and plastic production with precise extrusion testing, simulating ...

Oil absorption testing instrument for carbon black and silica

Accurately measure oil absorption in powders to enhance fo...

Monomer recovery unit

Effectively recover valuable monomers while ensuring high purity and low operating pressures, ideal for...

Troughed belt conveyor for efficient material transport

Effortlessly transport a variety of materials, from glass to muni...

Density separator for recycling applications

Efficiently separate light and heavy materials with minimal density differenc...

Fines starscreen for construction and demolition waste

Efficiently separate construction and demolition waste into valuab...

Glass cleaning system for recycling applications

Optimize glass recycling by efficiently removing contaminants and minimiz...

Industrial balers for recycling applications

Effortlessly transform various waste streams into compact, export-ready bales...

Sliding belt conveyor for sorting light, voluminous materials

Efficiently sort and convey light, voluminous materials wi...

Vibrating feeder for sorting system

Efficiently manage waste streams with a vibrating feeder that optimizes material flow f...

Integrated optical sorting unit for lightweight materials

Optimize your processing of lightweight materials by achieving...

Optimize optical sorter performance

Enhance your optical sorting line capacity and material purity with advanced air displa...

Air drum separator for heavy and light material separation

Effectively separate heavy and light materials with minimal e...

Optical analytics tool for material flow and composition

Optimize your waste management with real-time data analysis and ...

Anti-wrapping starscreen for material sorting

Tackle film, tape, and textile wrapping issues in your sorting process with ...

Commingled material separator

Streamline your recycling operations with precise separation of paper, cans, and glass, reduci...

Film separation system for recycling processes

Facing challenges with film removal in recycling streams? Optimize your pre...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Custom pressure vessels and tanks

For industries demanding precise storage and processing, our tailor-made pressure vessels...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Shell and tube heat exchangers

Efficiently manage heat transfer in your production line with custom-engineered shell and tub...

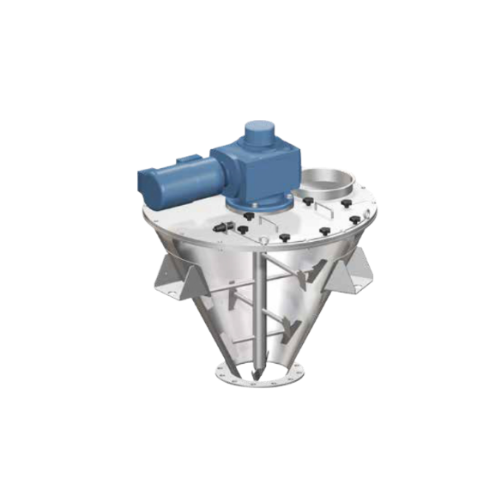

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Vertical conical screw vacuum dryer

Achieve precise moisture control with ultra-vacuum batch drying, ideal for thermo-sensi...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Dust-free big bag connection system for bulk solids

Eliminate dust and ensure reliable discharge with this vacuum docking...

Low temperature bath for precise temperature control

Achieve precise sample freezing from -80°C to 100°C with this low te...

Screen scroll centrifuge for flexible dewatering

Ensure maximum uptime and consistent dewatering performance amidst variab...

Horizontal peeler centrifuge for filtration

Optimize your batch processing with a centrifuge designed for high-speed, effi...

Vertical vacuum dryer and mixing reactor

Achieve precise control over drying and mixing processes with a versatile unit des...

Precision powder mixer for baby formula

Achieve consistent texture and rapid homogenization for sensitive powder blends lik...

Continuous granulator for powdery goods

Achieve uniform particle size and structure with a continuous granulation process t...

Spherical mixer for industrial mixing applications

Experience precise and efficient mixing with this hollow spherical mix...

Vertical twin-shaft mixer for dry, moist, and viscous materials

Achieve consistent mixing and blending of diverse materi...

Conical mixer for dry, moist, and viscous materials

Achieve optimal mixing consistency and precision for diverse material...

Conical vacuum dryer for viscous materials

Achieve precise drying and mixing of moist and viscous materials, ensuring cons...

Container mixer for dry and moist materials

Achieve exceptional mixing quality with variable filling levels, ensuring cons...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Large batch gyraton® mixer for homogenizing moist and poorly flowing materials

Optimize your production line with this...

Automatic plastic injection moulding machine

Enhance your production line with this high-precision injection moulding mach...

Indirect drying drums for solvent-based products

Optimize energy use and safety with our indirect drying drums, ideal for ...

Industrial drum dryer for bulk solids

Optimize your production line with high-throughput drying for varied particle sizes, ...

Flash dryer for high-moisture bulk materials

Tackle high-moisture challenges head-on with rapid drying solutions that effi...

Fluidized bed dryer for industrial materials

Enhance product quality and energy efficiency with fluidized bed dryers, opti...

Industrial auger sack filler for large bags

Designed to efficiently fill large bags and sacks, this advanced filling machi...

Compact marine boiler economizer for auxiliary engines

Efficiently reclaim waste heat from auxiliary engine exhaust to bo...

Oil and gas-fired industrial boiler

Enhance steam production efficiency with a robust three-pass combustion system designed...

High-efficiency brazed plate heat exchanger

Optimize your thermal processes with compact, high-efficiency heat exchangers,...

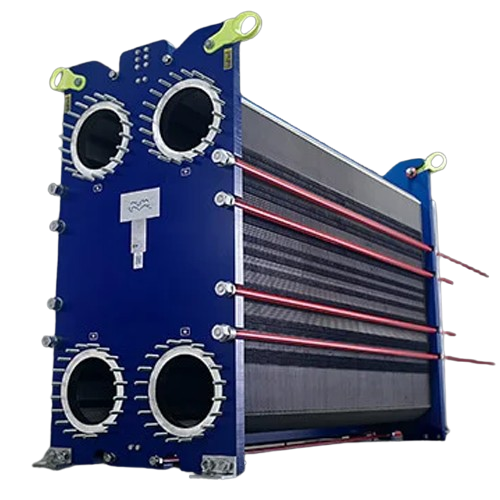

Gasketed plate-and-frame heat exchangers for industrial applications

Optimize your production with precise thermal mana...

Gravimetric batch blender for precise material handling

Achieve precision in blending complex regrind materials and polym...

Positive/negative pressure temperature control unit for cooling circuits

Ensure precise temperature regulation and prev...

Compact water temperature control unit

Achieve precise temperature control in cramped production spaces, enabling consisten...

Water temperature control unit for production applications

Enhance your production efficiency by precisely managing wate...

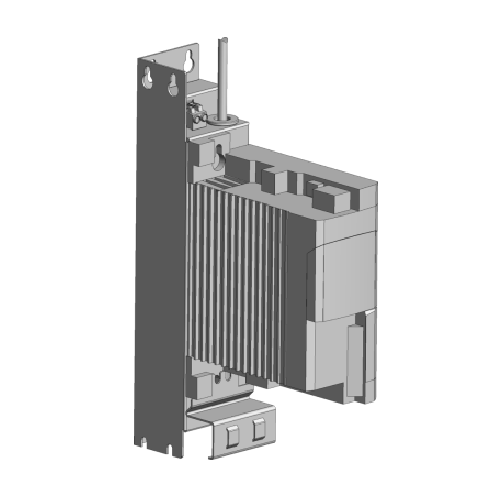

Volumetric additive feeders for injection and extrusion processes

Ensure precise and consistent blending of color conce...

Extrusion control units for high precision manufacturing

Optimize your extrusion process with precision control over thro...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Big bag loading station for bulk product handling

Efficiently manage big bag handling with a system that combines hoistin...

High pressure homogenization for polymer nanodispersions

Effortlessly handle challenging products with fibers or solid pa...

Fluid bed drying system for wet powder chemicals

Achieve efficient large-scale drying and cooling of wet powder chemicals ...

Negative pressure filter for fine dust particles

Ensure efficient air purification and dust collection in your production ...

Short base skirt silo for bulk material storage

Optimize your bulk material handling with adaptable discharge and rapid lo...

Plastic processing systems for high plant availability

Achieve unparalleled throughput and efficiency in your production ...

Industrial fine dust particle ventilation filter

Optimize your production line with a modular filtration system designed t...

High-efficiency pellet dust separator

Achieve unparalleled separation efficiency in your polymer production line by removin...

Rotary feeder for bulk material conveying

Enhance your material flow with precise metering and efficient conveying, ensuri...

Processing vessel for liquid, sauce, or cream products

Efficiently mix and integrate liquid, cream, or slurry products wi...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

High-speed mixer for homogenous mixing of powders and pastes

Achieve rapid and precise mixing with high-speed dispersion...

Industrial rapid turbulent mixer for homogeneous mixing

Achieve unparalleled homogeneity with rapid turbulent mixing, ess...

High-speed mixer for industrial mixing applications

Achieve rapid, consistent mixing and dispersion across diverse materi...

Horizontal shaft mixer for free-flowing materials

Achieve consistent mixing of diverse free-flowing materials with a reli...

Efficient ribbon mixers for precise powder blending

Achieve consistent and uniform blending with this advanced U-Trough m...

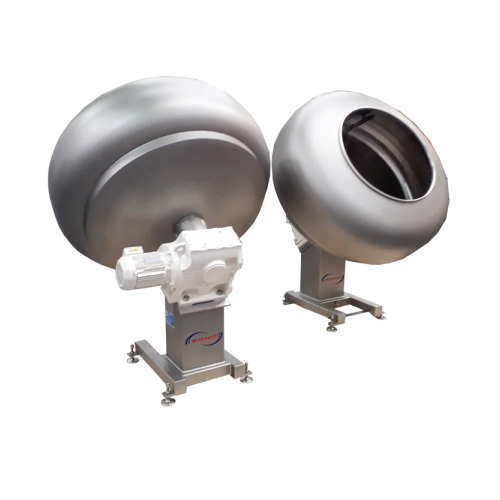

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Industrial coating pan for food and pharmaceutical products

Optimize your production with precision mixing and coating, ...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Laboratory mixers for product development and research

Optimize your R&D efforts with advanced mixing solutions desi...

Industrial blenders for powder and granule mixing

Optimize your production line with advanced mixing solutions designed f...

Pv mixing vessels for industrial hire

Optimize your production mix with vessels that ensure precise blending, heating, and ...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Batch-type single shaft mixer for efficient discharging

Optimize your material mixing and discharging processes with a sy...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

Tanker loading bellow for dust-free bulk solids loading

Optimize tanker loading while minimizing dust emissions with this...

Bulk solids tanker loading bellows

For industries looking to efficiently load dry, non-dusty bulk solids into tankers, thes...

Bulk solids conveying systems

Efficiently move and manage bulk materials with precision and reliability, ensuring seamless i...

Bulk solids discharging and loading solution

Optimize your bulk material handling with equipment that ensures efficient an...

Pneumatic conveying system for bulk solids

Ensure efficient and dust-free transport of bulk materials with a pneumatic con...

Batch-type single shaft mixer for industrial mixing

Achieve precise and uniform mixing with high-speed, single-shaft mixe...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Industrial slide valve for heavy-duty applications

When managing gravity material flow in abrasive environments, achievin...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Membrane pressure relief valve for silo protection

Ensure immediate pressure stabilization in your bulk storage silos wit...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Slide valves for flow interception in powder and granular materials

Effectively manage the flow of powdery and granular...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Double dump valves for high temperature granules

Ensure precise material flow and withstand extreme temperatures with thes...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Dust-free bulk bag filling system

Achieve efficient, dust-free filling of bulk bags with our innovative system, ensuring se...

Manual Fibc bag filling station

Achieve dust-free filling of bulk bags with an efficient system designed to handle compacted...

Manual bag opener for bulk solids discharging

Effortlessly open and empty bags while containing dust emissions, ensuring a...

Tubular ribbon flight screw feeder for lime feeding

Experience uniform material flow and precise dosing with this special...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Continuous impact vibrators for bulk solids discharging

Optimize your discharging process with vibrators that effectively...

Rotary roller vibrators for concrete compacting and hopper emptying

Achieve higher compaction and efficient emptying wi...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Lump breaking feeder valve for bulk material processing

Tackle bulk material flow challenges with a feeder valve engineer...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Aeration pads for powdery material flow in silos

Ensure consistent material flow in your silos and bins with a reliable ae...

Continuous level measurement system for powdery or granular materials

Ensure precise inventory management and enhanced ...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Bin level indicators for powder and granular material

Ensure precise inventory management and prevent overflows in your p...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Pipe couplings for pneumatic conveying lines

Ensure a secure and quick connection for your pneumatic lines with these pipe...

Cushioned pneumatic vibrators for bulk solids conveying

Streamline your material handling with precision vibration contro...

Pneumatic actuators for industrial valves

Optimize valve control in your production line with precision-engineered actuato...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Hand wheel actuators for Vg slide valves

Effortlessly control flow interception in high-demand settings with these hand whe...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Industrial bin activator for smooth material flow

Enhance your material handling process with a solution that ensures con...

Vibratory hopper for bulk solids discharge

Ensure consistent material flow and prevent bridging in storage silos with this...

Bin activator for silo and hopper discharge

Ensure optimal material flow and prevent blockages in your storage systems wit...

Pharmaceutical vacuum conveyors for hygienic transport

Ensure contamination-free transport of sensitive pharmaceuticals a...

Vibratory feeder for dosing powders and bulks

Ensure precise feeding of powders and bulk materials with a system that inte...

Bag rip-and-tip dump stations for bag emptying

Efficiently manage bag emptying operations with advanced dust containment a...

Ibc docking and discharge stations

Ensure seamless material transfer with dust-free docking and effective discharge, mainta...

Explosion-proof dissolver for chemical processing

Ensure safe and efficient dispersion in volatile environments with this...

High-performance dissolver for large-scale production

Optimize your production line with precision-controlled dispersion ...

Vacuum basket mill for high-viscosity product processing

Achieve exceptional fine milling results while preventing air in...

Vacuum dissolver for high viscosity products