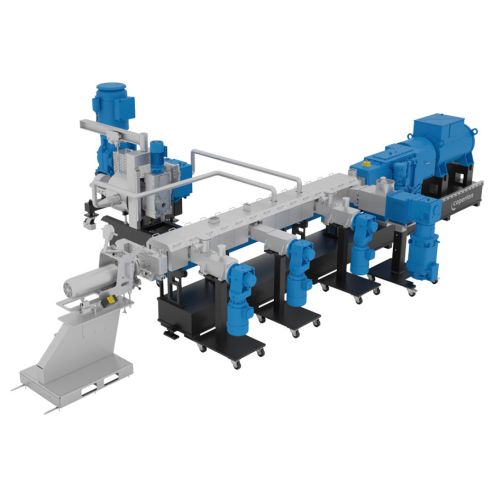

Filtration compounder for polymer recycling

Streamline your recycling process by integrating filtration and compounding in one efficient step, enhancing product quality while cutting energy consumption and emissions.

Streamlines Filtration and Compounding in Recycling

The ZSK FilCo Filtration Compounder by Coperion revolutionizes recycling with a unique system that integrates filtration and compounding into a singular production step. Designed for polymer processors and recyclers, this equipment simplifies the processing of post-consumer recyclate and highly contaminated polymers. Working with the ZSK twin screw extruder, the ZSK FilCo melts, homogenizes, and devolatilizes plastic waste before filtering out contaminants. This processed melt is reintroduced for compounding with various fillers or reinforcing materials, such as glass or carbon fibers.

Applications span across the recycling of diverse plastics, culminating in high-quality products like pelletized plastic recyclate and fiber-reinforced composites. This system notably reduces energy consumption and emissions by over 50% compared to traditional methods, due to its streamlined design that eliminates the need for multiple melting processes. The ZSK FilCo handles solid, granule, and film flake inputs, all while maintaining continuous, high-speed operation. Compact and efficient, it offers consistent quality improvements and reduced thermal stress on polymers, making it a crucial asset for sustainable materials manufacturing.

Benefits

- Lowers energy consumption and emissions by over 50%, promoting efficient and sustainable operations.

- Enhances product quality by reducing thermal stress through single-step melting and compounding.

- Minimizes operational footprint with an integrated system design, saving valuable production space.

- Ensures consistent, high-quality output with accurate gravimetric feeding of additives and fillers.

- Streamlines complex recycling processes into a single, continuous operation, improving throughput.

- Applications

- Polymers, Contaminated polymers, Compounding, Reinforcing materials, Plastics, Fillers, Post-consumer recyclate (pcr), Recycling, Recyclate

- End products

- Recycled polypropylene (pp), Post-consumer recycled polyethylene terephthalate (pcr pet), Glass fiber reinforced plastic materials, Recycled polystyrene (ps), Talc-filled polymers, Recycled polyethylene (pe), Carbon fiber reinforced polymers, Pelletized plastic recyclate, Recycled pc/abs blends, Calcium carbonate (caco3) filled compounds, Wood fiber composites, Recycled polyamide (pa)

- Steps before

- Plastic Waste Collection, Regrind Preparation, Grinding, Shredding

- Steps after

- Pelletizing, Cooling, Packaging, Quality Control

- Input ingredients

- post-consumer recyclate (PCR), highly contaminated polymers, waste plastic, regrind, fiber pellets, film flakes, agglomerate, polymers, PE, PP, PA, PS, PC/ABS

- Output ingredients

- recompounds, pelletized recyclate

- Market info

- Coperion is known for its expertise in manufacturing industrial compounding and extrusion equipment, bulk materials handling systems, and services for various industries, such as plastics, chemicals, and food processing, with a strong reputation for innovative engineering solutions and customer support.

- Filtration and Compounding

- Single-step process

- Energy Consumption Reduction

- Over 50%

- Emissions Reduction

- Over 50%

- Product Quality

- High end

- Melt Homogenization

- Yes

- Devolatilization

- Yes

- Melt Filtration

- Yes

- Automation

- Gravimetric Feeding

- Working mechanism

- Twin screw extrusion

- Integrated steps

- Filtration and compounding

- Energy efficiency

- Reduced by over 50%

- Batch vs. continuous operation

- Continuous

- Automation level

- High-accuracy gravimetric feeding

- Footprint

- Reduced

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- FDA compliance

- Materials for food-grade recycling

- Compact footprint

- Reduced footprint

- Control panel type

- Integrated control panel

- Discharge method

- Reintroduction into extruder

- Control panel type

- PLC-based

- Integration possibilities

- With existing recycling systems

- Space requirement

- Compact footprint