Making Recycled Plastic

Find innovative production technology for making recycled plastic and connect directly with world-leading specialists

The ubiquitous plastic shopping bag was first designed as a reusable carrier. Its inventor, Sten Gustaf Thulin, will have been appalled to see his creation turn into a single-use object. But this disposable tendency is common to all plastic materials, from screw taps to milk carton lining. With plastic recycling equipment, however, plastic waste can be reprocessed and given a second lease of life.

Stories about recycled plastic

Select your recycled plastic process

Tell us about your production challenge

Treat polyolefins with heat to depolymerize the plastic material

Plastics are synthetic organic polymers than be broken into the basic monomers and reconstructed into new material. The most widespread type of plastics, polyolefins, can be chemically depolymerized at high temperatures.

Heat the polymers to 380-480°C in a fluid bed heater until the chains start cracking and turn into gas. The monomer vapor is collected in a condenser and returned to liquid. Use catalysts like kaolin, quartz, or zeolite to improve heat transfer and decrease the temperature required for cracking.

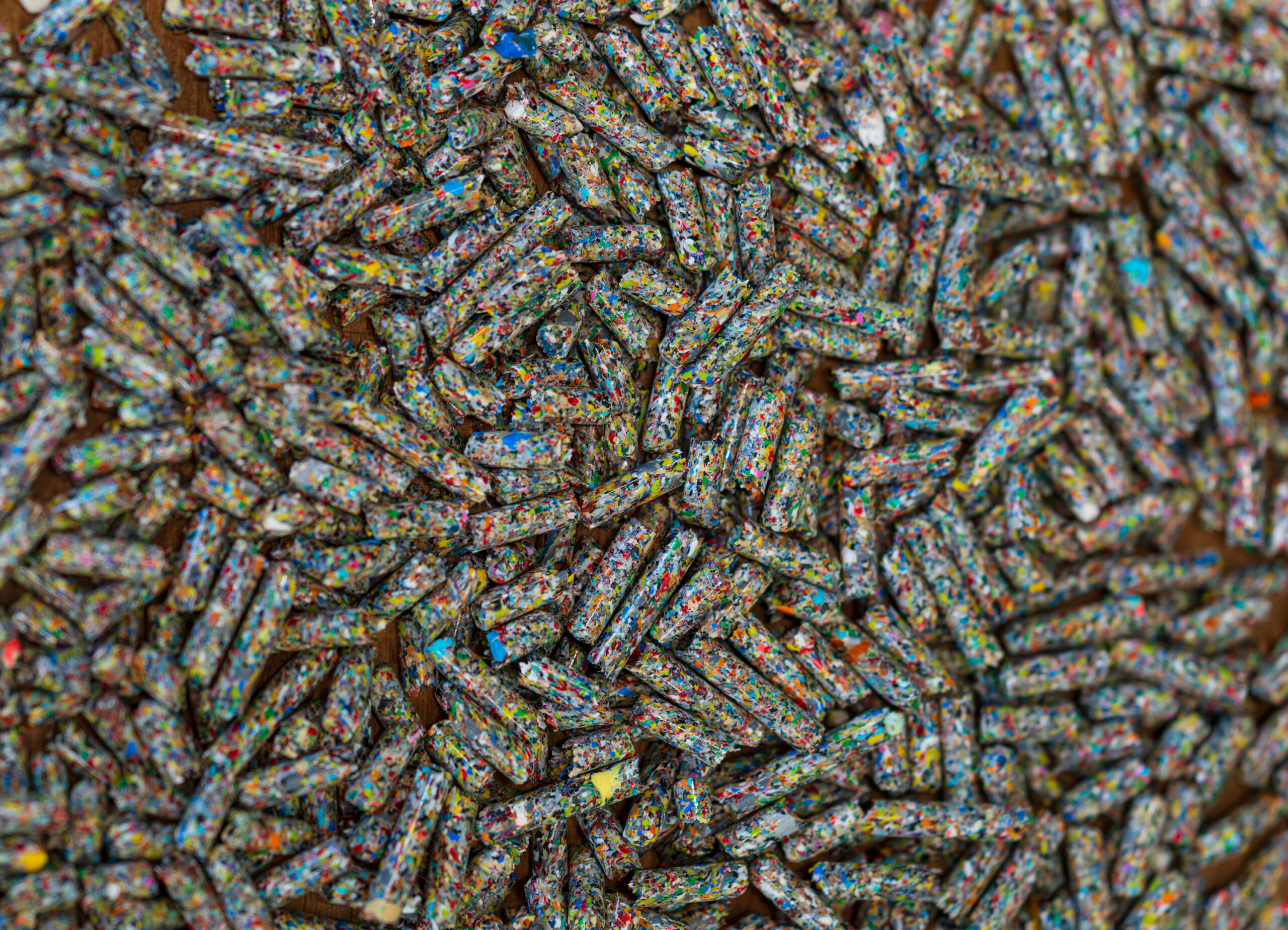

Mix additives in the recycling system to produce plastic pellets

The clean monomers are ready to be refabricated into new plastic material. Melt the material through an extruder to produce plastic pellets.

Depending on the intended use of the end product, the raw material feed can be compounded with other additives such as fire-retardants, impact-absorbers, or colorings. Pellets from recycled plastic are a suitable base to manufacture masterbatches for the industry.

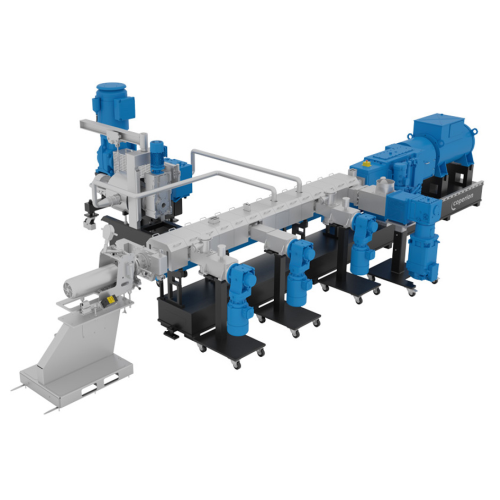

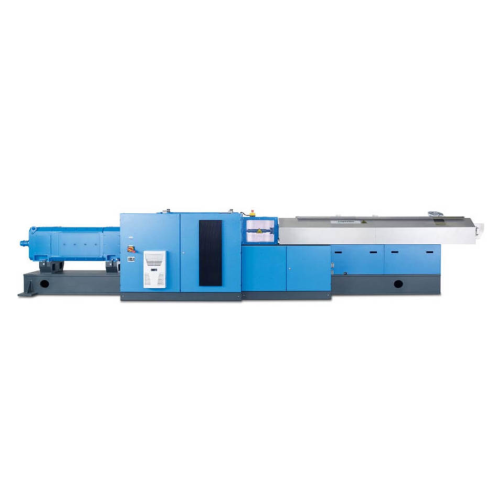

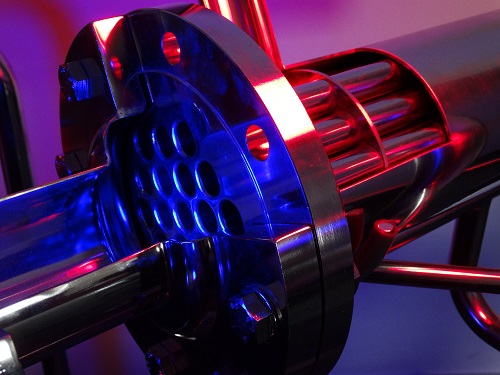

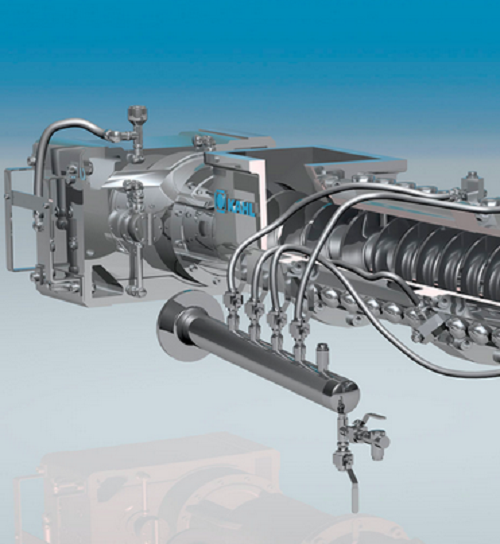

Use a twin-screw extruder for tighter control over the pelletizing process

Polymer modelling of plastics follows a similar sequence whether it is manufactured through a single-screw or twin-screw extruder. However, a co-rotating twin screw extruder allows greater control over the plasticating process.

As the feed material travels along the screw, friction forces and heat transfer from the barrel begin melting it. This process accumulates in a melt pool nearer to the inner barrel, where the polymer is subjected to increasing pressure and flows out through the die.

Separate the feed with specialized plastic waste processing equipment

Plastic types, for example HDPE, PVC and PET, all behave in different ways when subjected to mechanical and chemical processing. Separate the primary material into the right streams to prevent contamination down the plastic recycling production line.

A sink-float separator classifies the pieces by density. High-density plastic polymers sink when conveyed to a water-filled tank, whereas low-density pieces float. An alternative method is an optic scanner that sorts plastic pieces according to their capacity to absorb light.

Grind the plastic to improve the recycling process

Resize the feed material into uniform dimensions to prepare it for processing. Grind the plastic into flakes or filaments by passing the pieces through a shredder.

Besides making the stream more workable, reducing the size of the stream makes it easier to pick out impurities during the washing line stage. Contaminants such as metals or adhesive chemicals could compromise the quality of the final product. But resizing the feed material facilitates the segregation of valuable plastic from undesired particles.

Processing steps involved in recycled plastic making

Which recycled plastic technology do you need?

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Industrial strand pelletizer for polymer processing

Optimize polymer pellet production with precision engineering, ensuri...

Filtration compounder for polymer recycling

Streamline your recycling process by integrating filtration and compounding in...

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Automated sorting robot for material recovery facilities

Enhance your material recovery operations with AI-driven precisi...

Density separator for recycling applications

Efficiently separate light and heavy materials with minimal density differenc...

Sliding belt conveyor for sorting light, voluminous materials

Efficiently sort and convey light, voluminous materials wi...

Occ screen for separating large cardboard

Efficiently separate large cardboard from mixed waste streams to streamline your...

Integrated optical sorting unit for lightweight materials

Optimize your processing of lightweight materials by achieving...

Optimize optical sorter performance

Enhance your optical sorting line capacity and material purity with advanced air displa...

Air drum separator for heavy and light material separation

Effectively separate heavy and light materials with minimal e...

Optical analytics tool for material flow and composition

Optimize your waste management with real-time data analysis and ...

Belt feeder for waste sorting applications

Efficiently handle diverse waste streams and optimize resource recovery with a ...

Chain belt conveyor for waste paper and industrial waste

Optimize your waste processing with a robust chain belt conveyor...

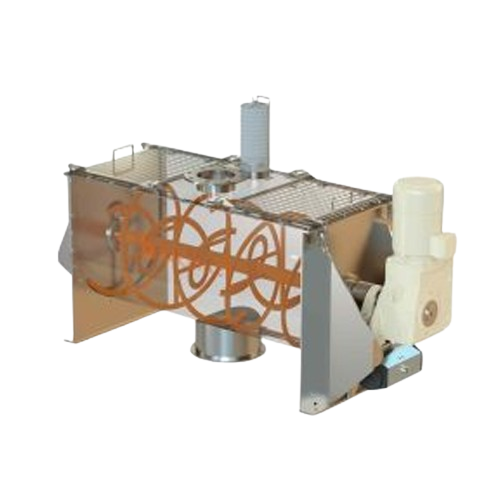

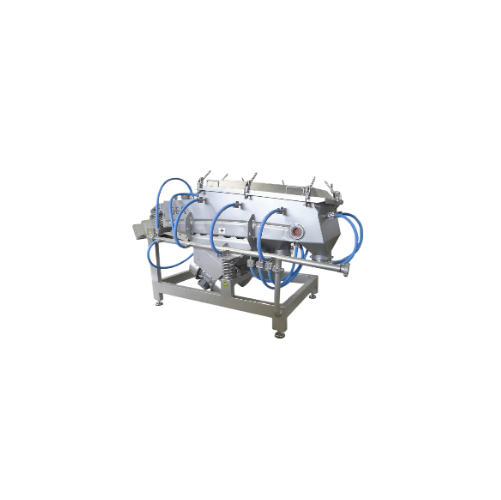

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

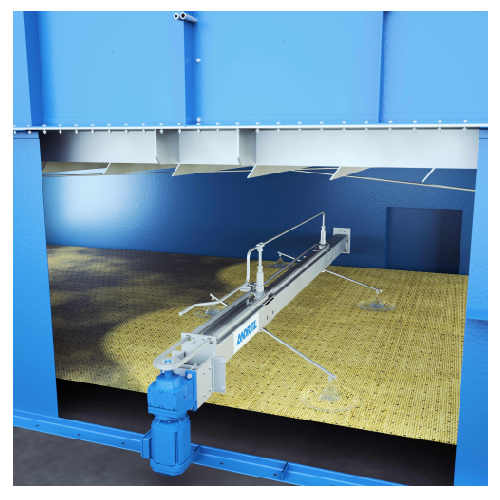

Belt dryer cleaning system

Maximize drying efficiency and product quality with an advanced belt-washing system designed to e...

Powder hopper loaders for free-flowing materials

Efficiently transport free-flowing powders, including PVC and polyethylen...

Industrial shredder for recycling and waste management

Efficiently transform challenging waste streams into valuable raw ...

Continuous loss-in-weight blender for extrusion applications

Ensure precise ingredient ratios for extrusion processes wi...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

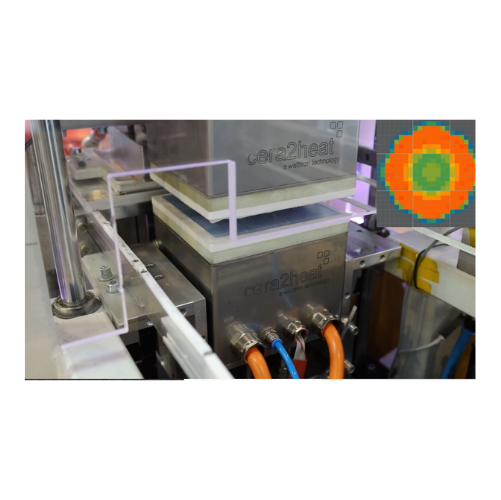

Heating system for sustainable moulded pulp packaging

Maximize material efficiency and sustainability by ensuring consist...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

Complete pellet line

Large industries are shifting towards more environment-friendly technology, such as recycling wastes and...

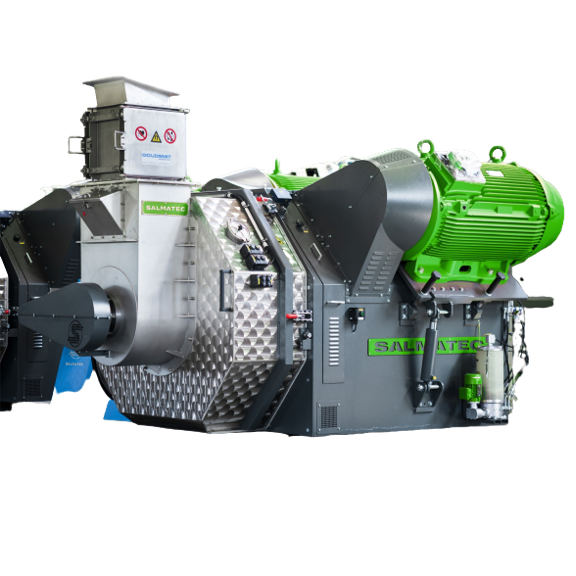

Industrial pellet mill

At the industrial level, the application areas of pellets range widely in fields such as feeds, biomas...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products acro...

Pellet hardness tester

Control the quality of your pelletizing processes using a pellet hardness tester. Pellet hardness is o...

Hygienic FIBC handling line

There are many considerations when handling FIBC’s (Flexible Intermediate Bulk Containers)...

Solid biomass screening and crushing equipment

Biomass fuels come in many forms and often include impurities that can dama...

Robot palletizer

Palletize up to 1,800 large industrial bags per hour at a multi-pick-up configuration.

Pusher centrifuge

Pusher centrifuges are continuously operating filter centrifuges and can have several basket stages dependi...

Reclaim crusher

Waste products and rejected materials are inevitably generated from any gypsum products manufacturing process....

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...