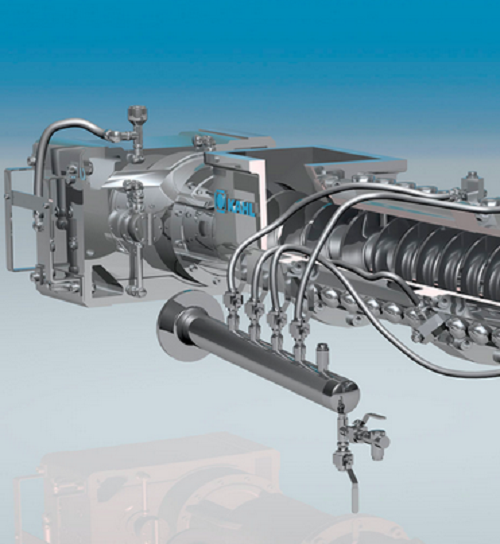

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozzle geometry and pressure and temperature characteristics of substrates as they are propelled through a screw-style mixing machine. Precise control of pressure at the point of extrusion is essential to predictable, desirable results.

Product shaping with easy start-up and less waste

Amandus Kahl’s Extruder OE series is an extruder line that works on the same principle as the successful annular gap expander design. A conical stop restricts the flow out of a tube as materials are driven through it by a rotating shaft. The stop is moved towards and away from the tube, creating an adjustable-sized gap through which material leaves the line. Controlling the size of this gap relative to the material throughput determines the pressure under which the material is extruded and influences many of the product’s final characteristics.

Heating or cooling jackets can be added to these units for monitoring temperature and pressure. Precisely controlled product extrusion is thus achieved by applying Amandus Kahl’s patented gap control technology from the annular gap expanders to this more straightforward machine.

Benefits

- Proven design form an industry leader

- Production capacity from 200 Kg/h to 8 Ton/h

- Less sensitive process and less wasted product than traditional extruders

- Does not require liquid additions at start up and can be started with an “open die” configuration