Breakfast cereal manufacturing equipment

Find innovative breakfast cereal equipment and connect directly with world-leading technology suppliers

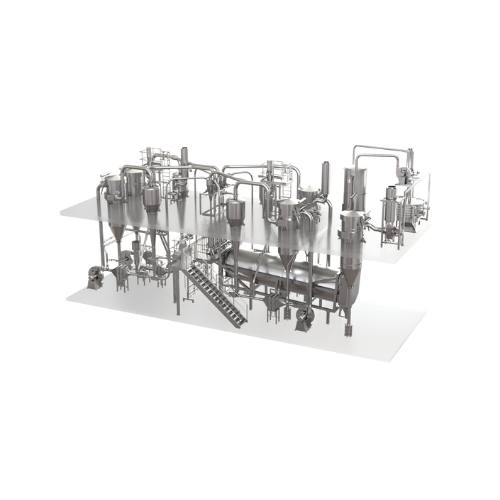

Cereals are also defined as breakfast food made from roasted grain and typically eaten with milk or yogurt. Cereal grain is a small, hard, and dry seed, which mainly harvests for human or animal consumption, like wheat, maize, or rye. Processed from the edible components of the grains, breakfast cereals contain rich nutrients and usually serve as the main course during breakfast meals. Different cereal manufacturing equipment allow various options to appear on the market, ranging from cereals, granola, and muesli. Granola and muesli can be converted into cereal bars. The healthy, on-the-go snack bar shows a growing trend due to its nutrient content and convenience.

Innovative cereal processing solutions

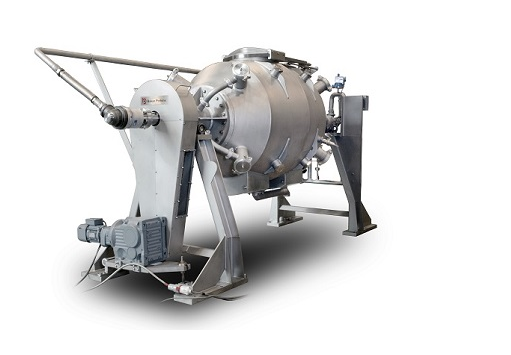

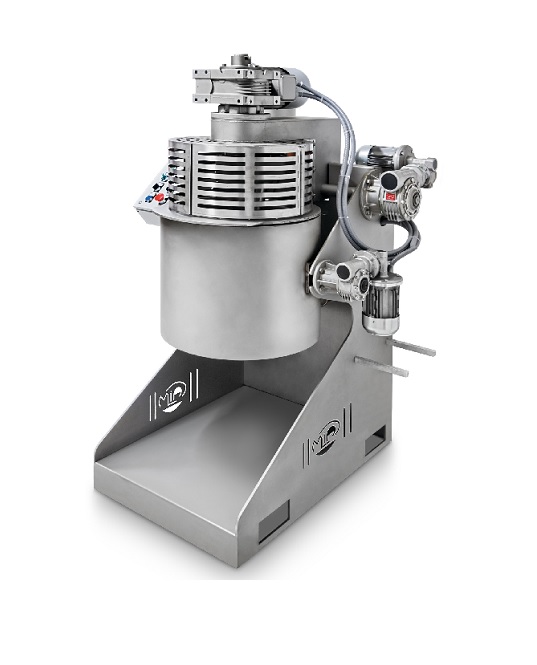

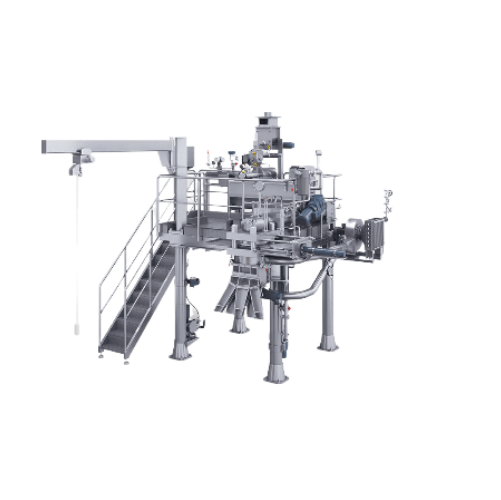

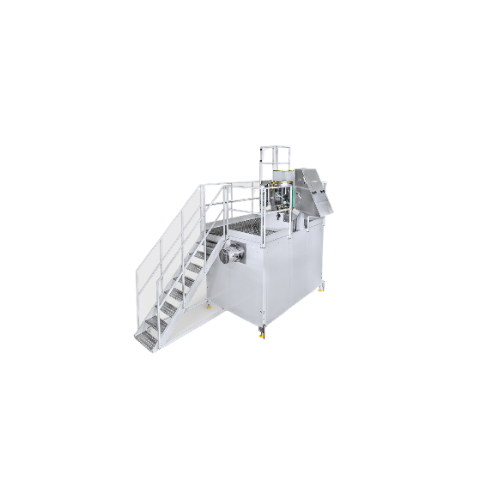

Batch cooker of cereal foods

Controlled steam cooking of whole or milled grain products is the best way to ensure best textu...

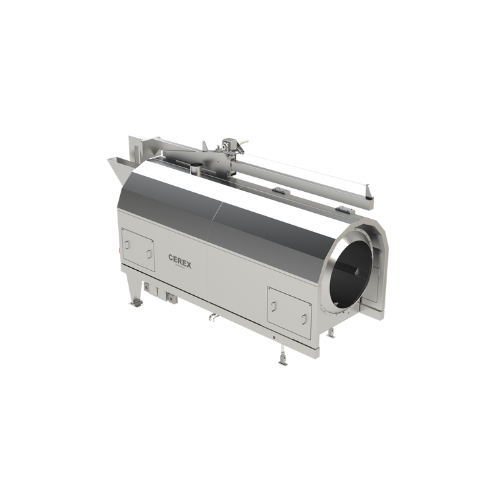

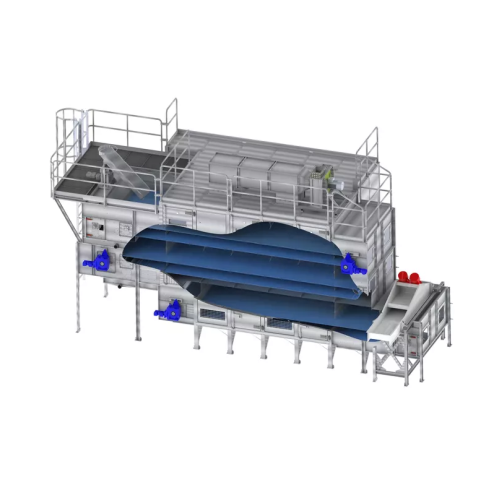

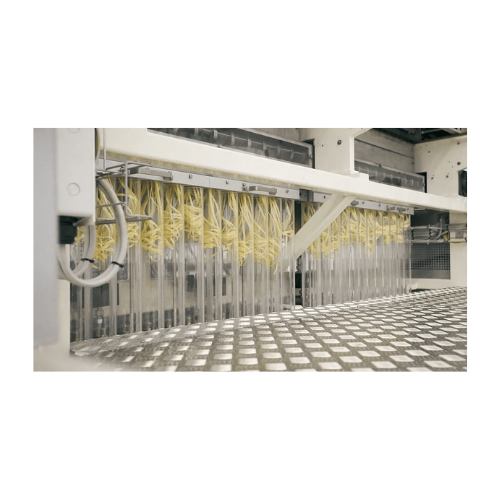

Consistent cereals toaster and dryer

In order to produce the very highest quality flaked cereal, shredded grain or hot air ...

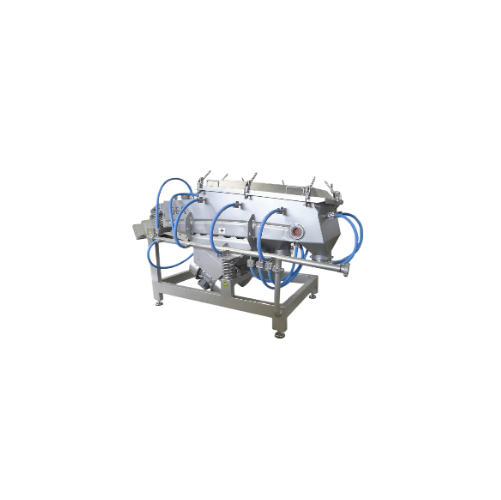

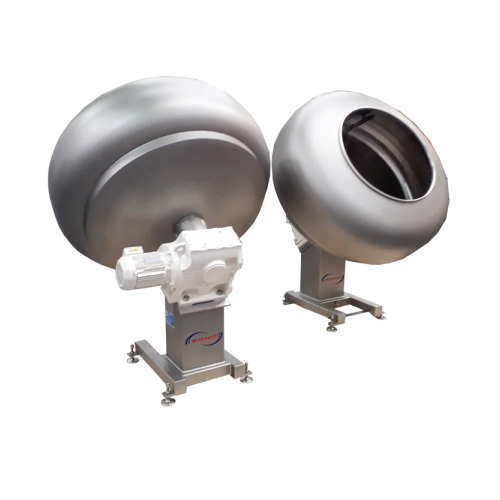

Cooling drum for breakfast cereals production

Ensure even cooling and product separation with optimized airflow for higher...

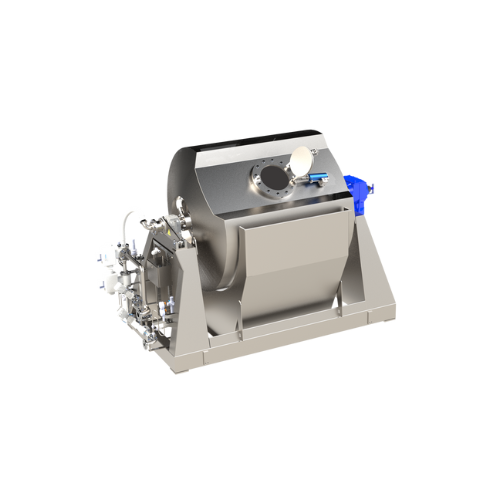

Extruder for large-scale production of breakfast cereals

Shaped and filled extruded breakfast and snack products are extr...

Stories about breakfast cereal

Select your breakfast cereal process

What are you making?

Tell us about your production challenge

Breakfast cereal is one of the most popular meals to eat in the morning around the world. Cereals go through a vast production line. They are usually processed from raw materials such as cereal corn, oats, wheat, and rice. After harvesting, the grains will be crushed to remove the outer layer or ground into flour. To prepare the grains ready to be shaped, they are sent into a rotating pressure cooker and a drying oven. When the grains are grounded into flour, they’ll then be cooked in a cooking extruder, which mixes the flour with other ingredients such as water, vitamins, or flavorings.

After stabilizing the moisture content of the grains, they can be further processed into desired forms ranging from flaked, puffed, shredded, or other special forms of cereals. Granolas and mueslis involve mixing grains with nuts or fruits and cooking them on a conveyor belt through an oven.

Different types of breakfast cereals

Cereals can be made in various forms and shapes through extruders and pellets. Gone are the days when there were only breakfast cornflakes. Nowadays, there are so many different varieties of breakfast cereals. Special forms of cereals, such as circles or shapes of alphabets, can also be achieved by adding a die to the end of the extruder to form a ribbon which will later be cut.

Granolas are processed by baking the grains until crispy, coating them with honey, and sometimes mixed with dried fruits or chocolate chips. On the other hand, muesli keeps the most nutrients since the grains are directly flattened and mixed with dried fruits or other ingredients.

Producing cereal bars and snacks - way more than cornflakes!

In the healthy snacking sector, cereal bars and cereal-based snacks play a large part in the demand for healthier eating due to the nutrient content and convenience factor. To process cereal mix to cereal bars, accurate feeding of major ingredients and molding are quite essential.

First, the cereal mix should be mixed evenly with the binder, which is usually agglutinate syrups. After the mixture is laminated and dried, it can be cut into a bar shape and fed into a flow wrapper for packaging.

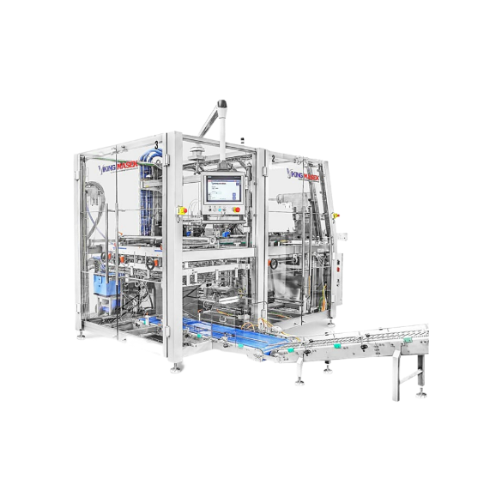

Packing your cereal products

While some cereals, such as shredded wheat, are pretty resistant to moisture and stored directly in cardboard boxes, some cereal products need to be placed in an airtight and waterproof bag to protect them from being damaged. Resealable, flexible, and stand-up pouches have shown a growing trend in cereal packaging. At the same time, as the off-to-go snack bar has become more popular, single-serve packing also shows its potential.

Which breakfast cereal technology do you need?

Nougat and cereal bar forming drum

Streamline your snack production with precision forming of nougat and cereal bars, ensur...

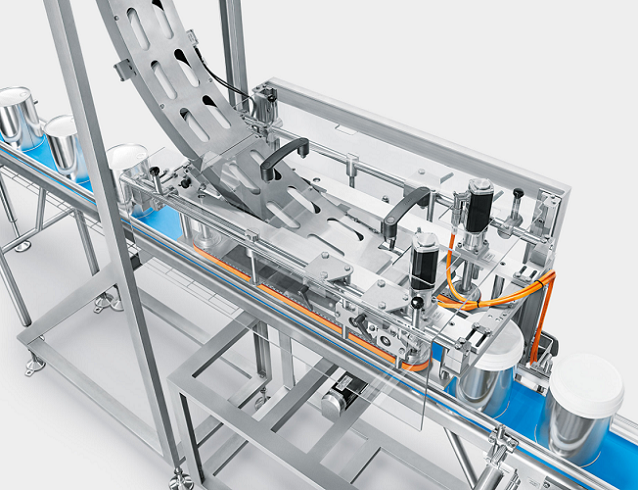

Cereal moulding solution for bars, bites, and clusters

Efficiently shape and form a variety of granola and cereal-based p...

Industrial 2-zone toaster for optimal cereal processing

Achieve precise toasting of cereals and seeds with the 2-zone toa...

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

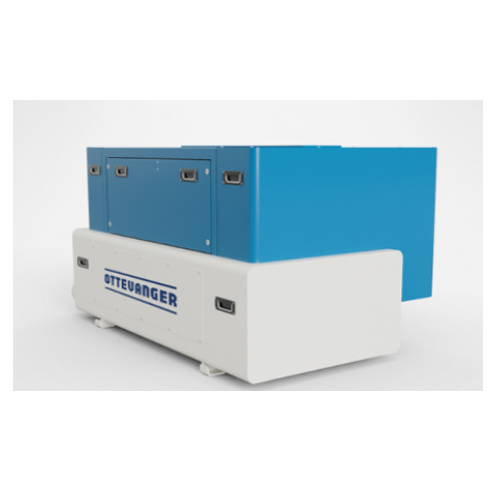

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Grain puffing system for breakfast cereals

Achieve precise and efficient grain expansion in breakfast cereals with this ad...

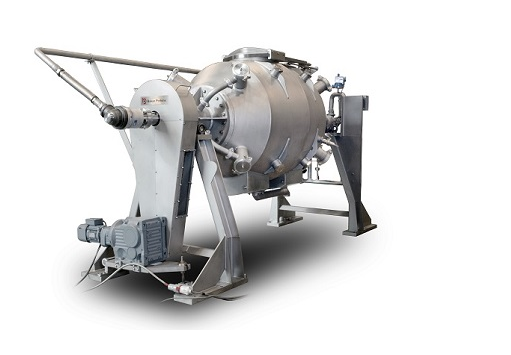

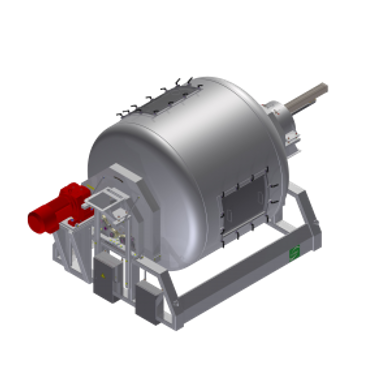

Rotary cooker for uniform steam heating in cereals production

Achieve consistent product quality in high-volume cereal p...

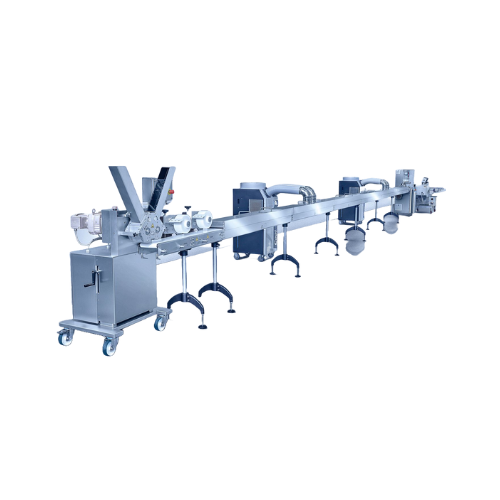

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrati...

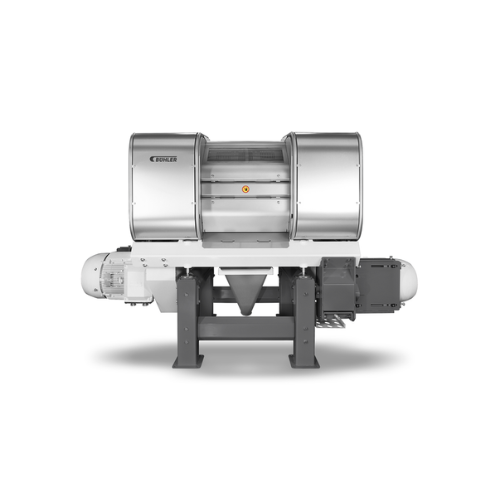

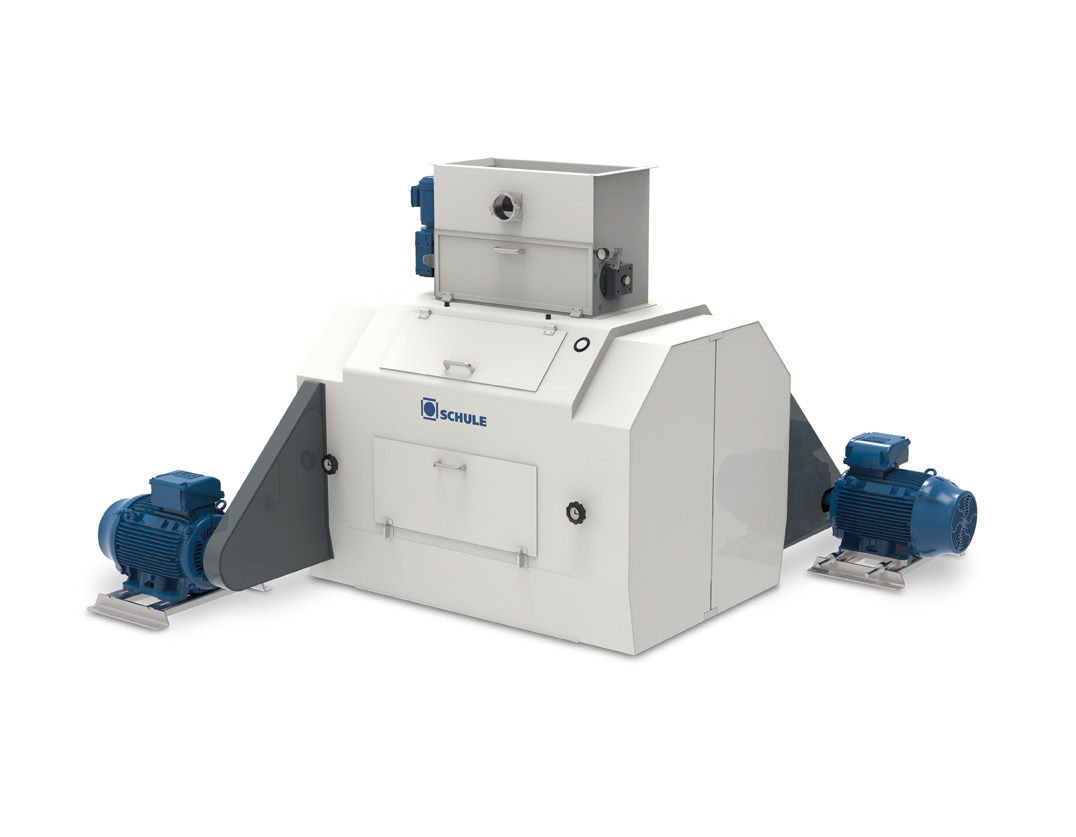

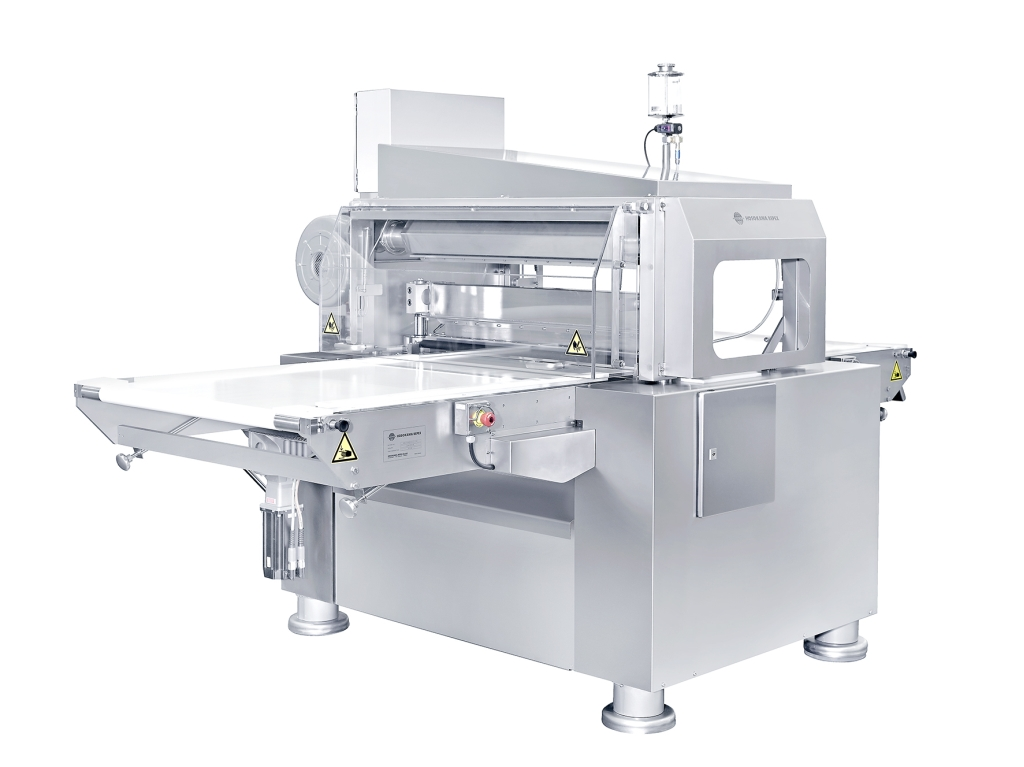

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

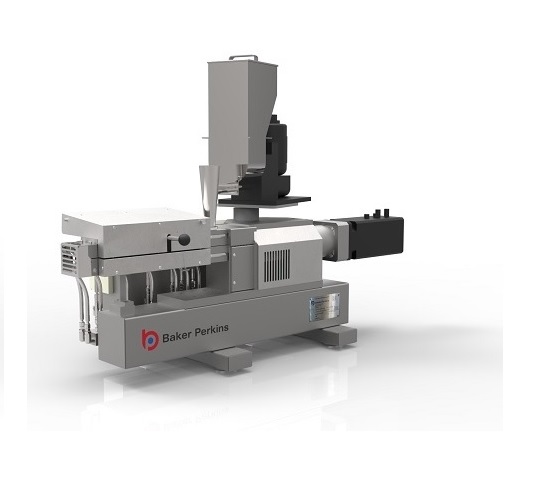

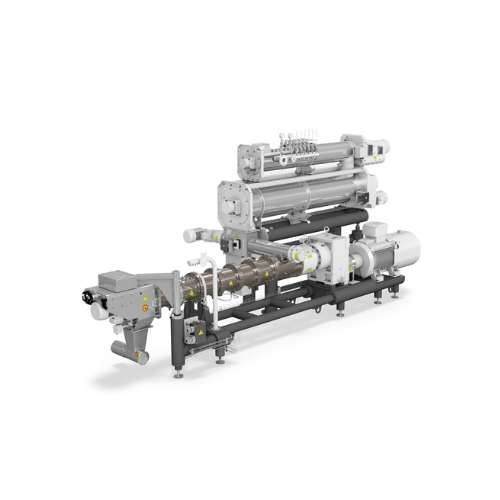

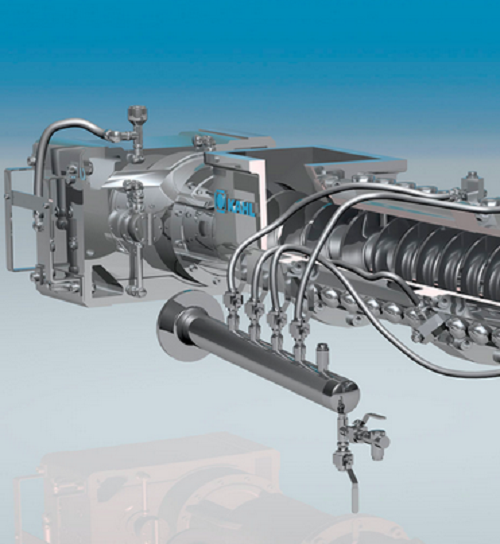

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Fluid-bed toaster for cereal processing

Achieve precise control over texture and taste while reducing operating costs with ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Forming extruders for flaked cereals

Optimize your production line with versatile forming extruders designed for precision ...

High capacity vertical conveying for grains and cereals

Ensure efficient vertical transport of bulk materials like cereal...

Industrial cereal popcorn making solution

Enhance your snack production with a versatile solution designed for creating a ...

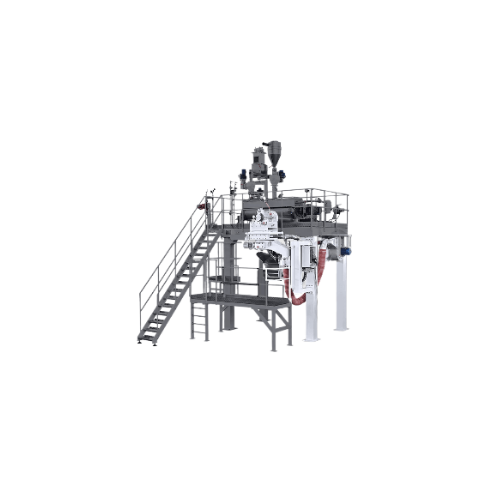

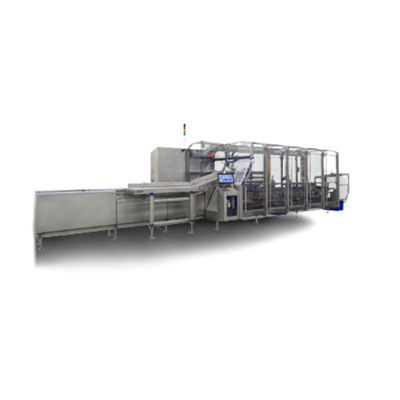

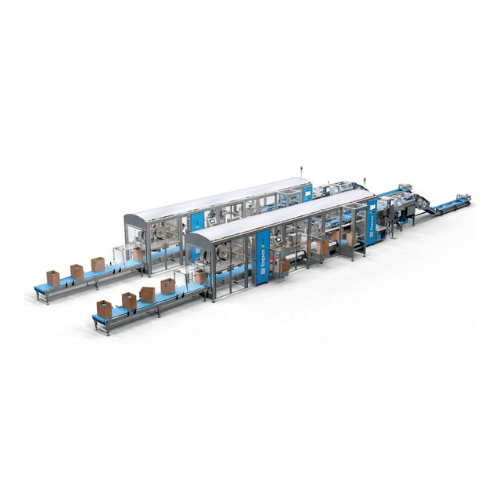

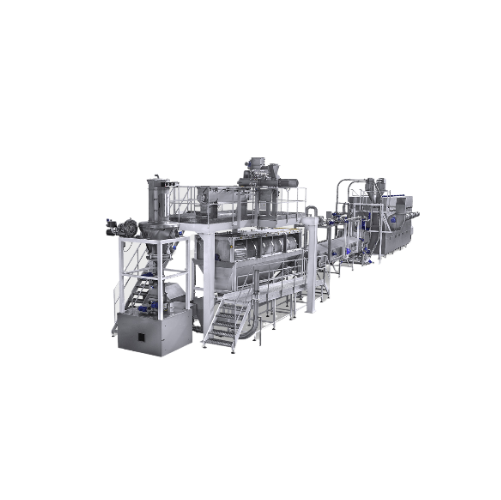

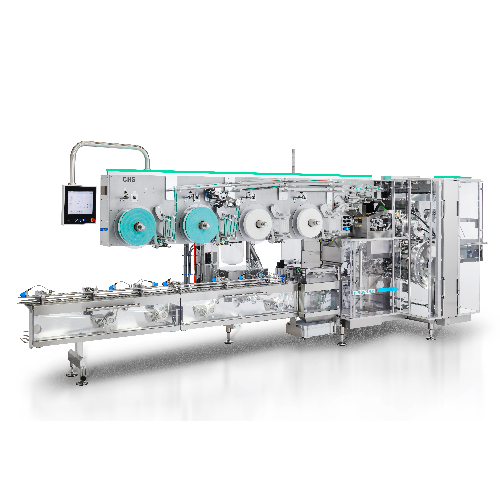

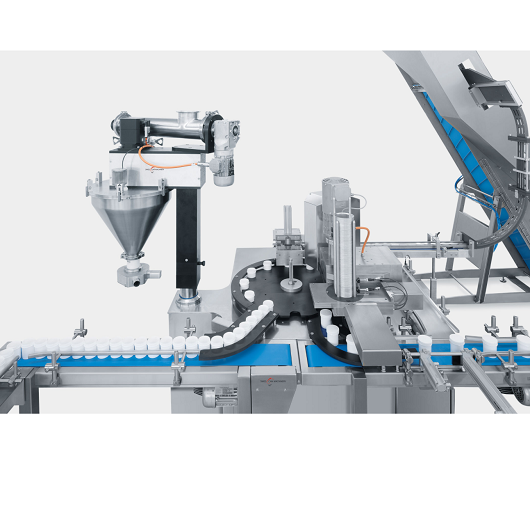

Automatic cereal bar production line

Efficiently transform diverse ingredients into consistent, high-quality cereal bars wi...

Forming solution for candy and cereal bars

Achieve precision in bar production with a system that ensures minimal weight v...

Forming system for cereal bars and nut mixes

Effortlessly transform diverse ingredients like cereals and nuts into precise...

Cooling drum for breakfast cereals production

Ensure even cooling and product separation with optimized airflow for higher...

Infrared dryer for breakfast cereals

Optimize your snack production with precise moisture control, energy-efficient infrare...

Flavouring system for snacks and breakfast cereals

Ensure consistent and homogeneous flavouring in your snack and breakfa...

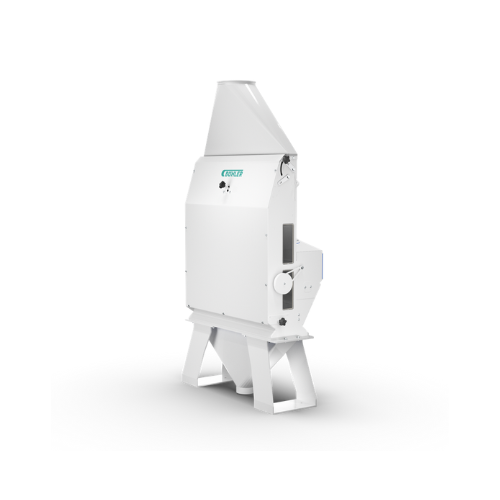

Kiln and cooler for oats and fatty cereals

Grains such as oats and parboiled rice have a high fat content and must be stab...

Benchtop extruder for cereals and snacks

Extruded products are very popular in the breakfast cereal and snack sectors. It i...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

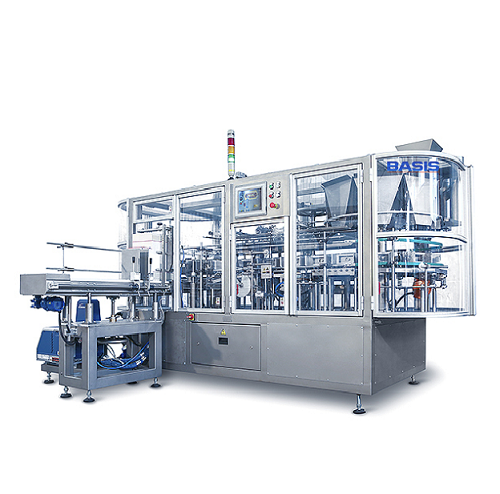

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

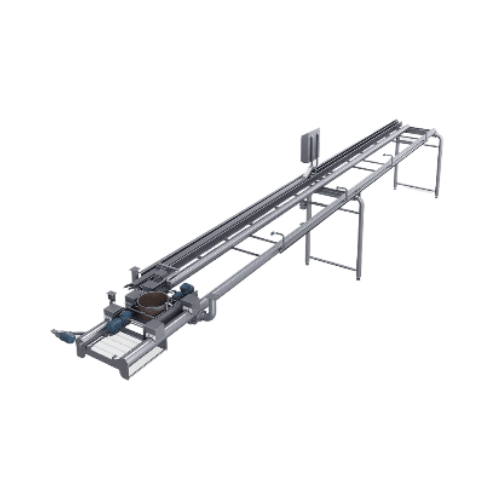

Entry level cereal bar cutting table

The small-scale manual production of crunchy cereal bars, brittles, and similar produc...

Entry level cooker for cereal bar production

The creation of high-quality, flavourful crunch bars, brittles and similar pr...

Batch cooker of cereal foods

Controlled steam cooking of whole or milled grain products is the best way to ensure best textu...

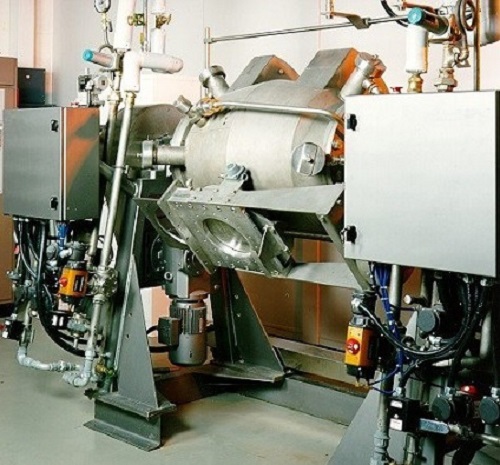

Consistent cereals toaster and dryer

In order to produce the very highest quality flaked cereal, shredded grain or hot air ...

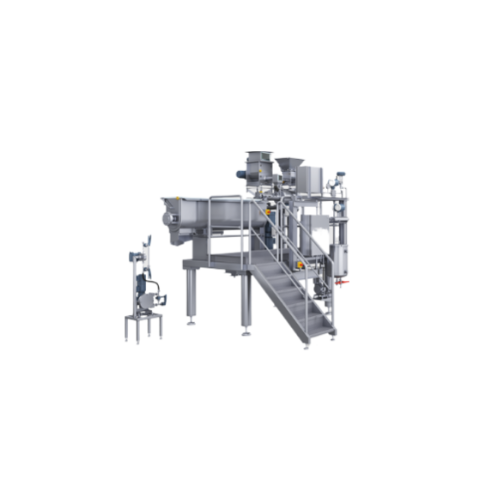

Fully-automated syrup cooker, mixer and coater for cereals

Coating cereal products adds variety, interest and value to b...

Extruder for large-scale production of breakfast cereals

Shaped and filled extruded breakfast and snack products are extr...

Colour-change system for extruded cereals

The traditional approach to multi-coloured extruded breakfast cereal and snack p...

Pilot extruder for cereals and snacks

Small batches of product using high value ingredients are not economical or practical...

Laboratory scale cereal cooker

When developing new breakfast cereal products it is expensive and time-consuming to take your...

Pre-conditioner for breakfast cereals

Extruded breakfast cereal products are a popular and lucrative product class. In case...

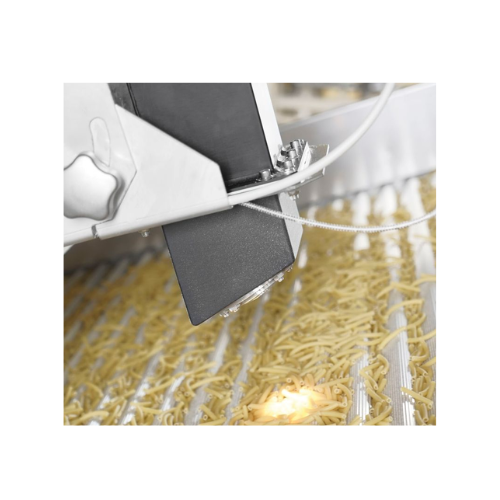

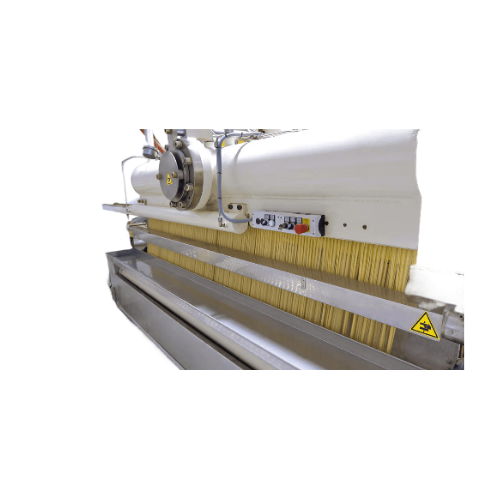

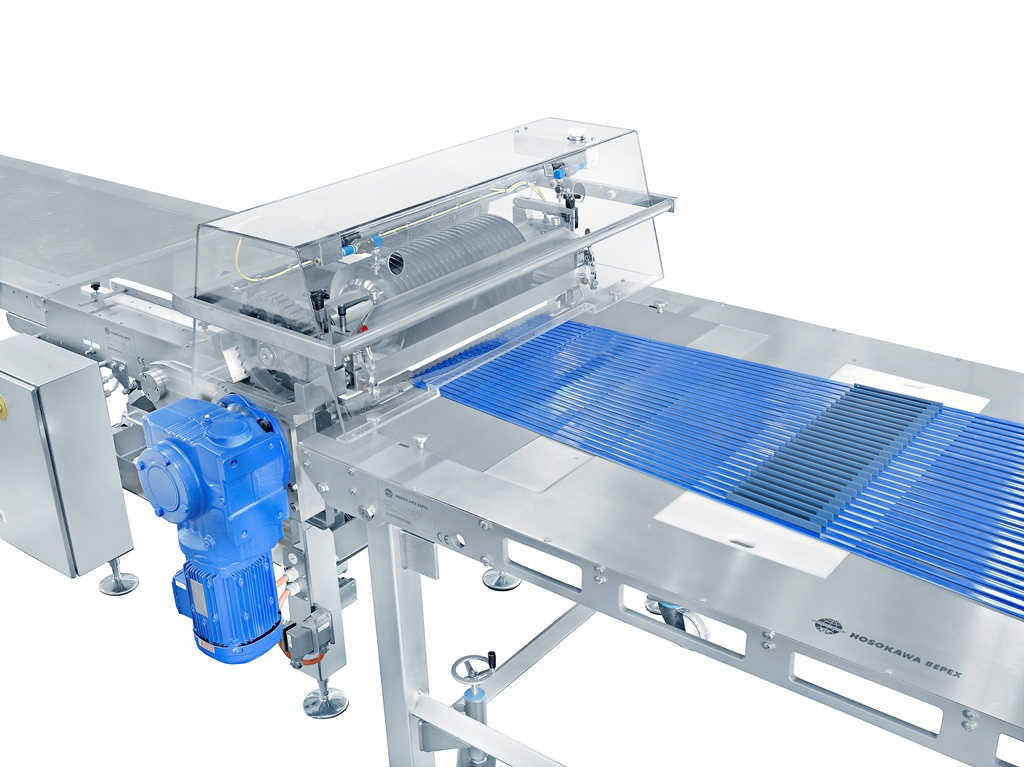

Cooked cereals shredder

By shredding cooked cereals, innovative breakfast and snack products can be created, including single...

Grain flow regulator for roller mills

Achieve consistent grain distribution and safeguard your roller mills from wear and c...

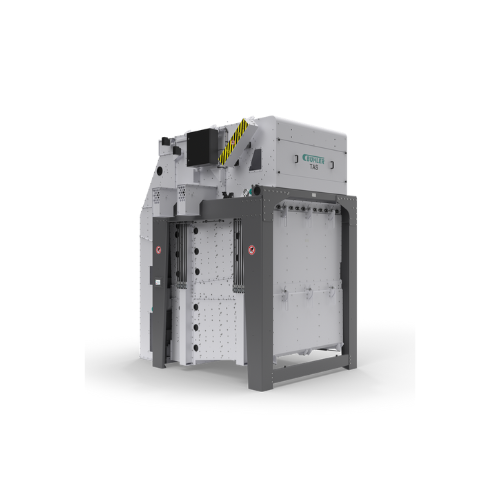

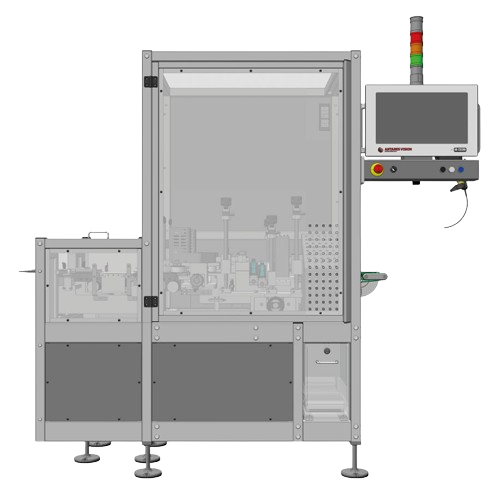

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Conveyor systems for snack production

Streamline your snack production with advanced conveyor systems designed for seamless...

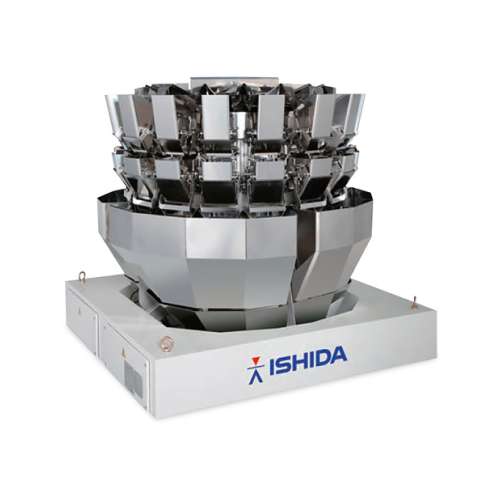

Linear weigher for dry or frozen free-flowing products

Optimize precision in high-speed weighing tasks with a compact sol...

Continuous powder mixer for industrial applications

Achieve precise and efficient integration of powders, granules, and l...

Industrial roller mill for grain size reduction

Achieve precise grain size reduction with minimal heat generation and opti...

Industrial food mixer for high-volume processing

Achieve consistent mixing and precise blending of diverse food ingredient...

Overlapping paddle mixer for precise food processing

For precise and thorough mixing in food processing, this solution en...

Food extruders for pet food production

Achieve precise control in food production with advanced twin screw extruders, desig...

Single-zone toasters for raw grain processing

Optimize your cereal and snack food production by achieving consistent toast...

Granola drying solution

Optimize your granola production with modular drying technology that ensures precise moisture control...

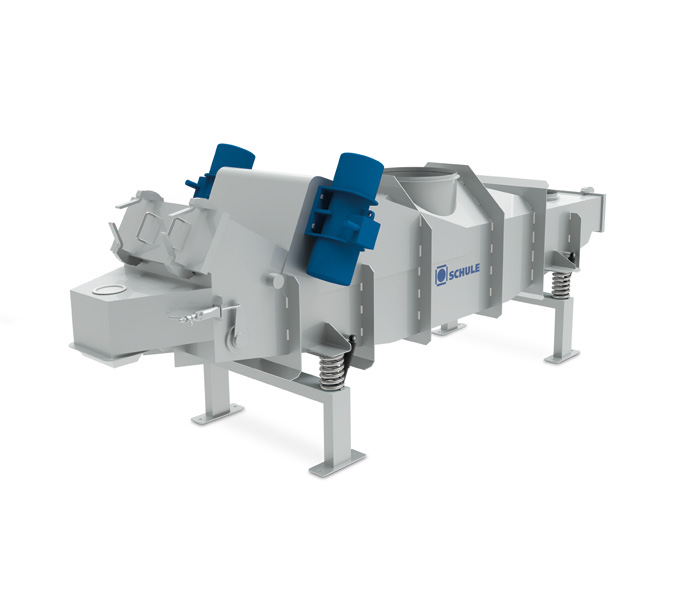

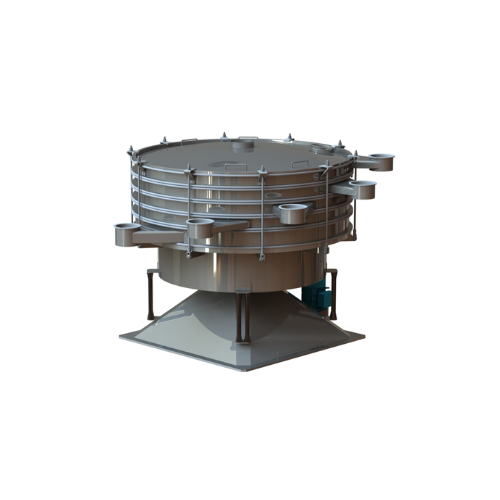

Industrial screeners for grain product processing

Optimize your cereal production line with specialized industrial screen...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

High-performance cracking mill for oilseeds

Optimize your oilseed processing with a versatile mill designed to enhance eff...

Bran finisher for efficient flour and bran separation

Optimize your grain processing efficiency with a solution designed ...

Gluten quality testing solution

Ensure optimal flour quality by rapidly assessing gluten properties, allowing you to refine ...

Mill sifter for precise bulk density and particle size distribution

Achieve precise particle size and uniform bulk dens...

Bar forming line for protein bars

Efficiently form and process a wide range of snack and confectionery bars with our versat...

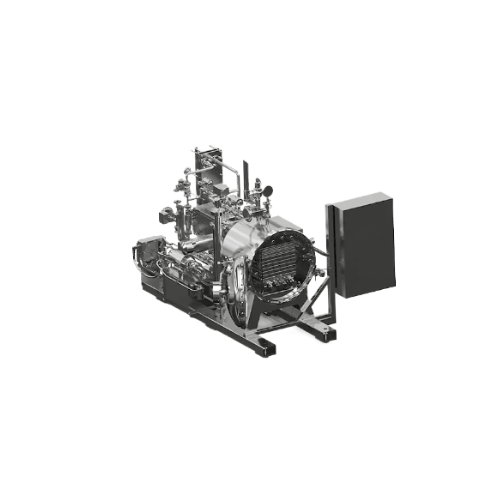

Efficient agitation system for retort packages

Enhance product quality and reduce processing time with this advanced agita...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Packaging system for short-cut pasta and dry granular food

Streamline your packaging process with a versatile system des...

Eco-friendly vertical packaging for pasta

Reduce plastic waste and enhance sustainability in pasta packaging with high-spe...

Industrial predryer for humidity reduction in food processing

Ensure optimal shelf life and prevent product sticking wit...

Industrial pasteurizer for efficient bacterial reduction

Ensure your food products are safe with an industrial pasteurize...

Industrial spiral cooler for thermal treatment

Improve your final conditioning and packaging process with a spiral cooler ...

Long cut pasta packaging solution

Optimize your pasta production line with seamless, high-speed packaging tailored for long...

High-accuracy package weigher for pasta and granular products

Optimize your packaging line with precision weighing and i...

Double sheet forming system for ravioli production

Streamline your production with high-speed forming and sealing, achiev...

Tagliatelle cutting system for pasta production

Enhance your pasta production with efficient, high-speed cutting systems d...

Calibrating rollers for pasta sheet thickness control

Achieve precise pasta sheet thickness control with advanced calibra...

Mixer kneader sheeter for fresh pasta processing

Streamline your pasta and dough production with a single machine that eff...

Kneader sheeter for single sheet pasta production

Achieve consistent and precise dough sheeting with advanced kneader she...

Continuous automatic pasta extruder

This state-of-the-art extruder simplifies your pasta production by seamlessly integrati...

Batch standing mixer for dough preparation

Enhance your mixing precision with a batch standing mixer that optimizes paddle...

Dough distribution system for multiple mixing points

Ensure precise dough allocation across multiple production stages wi...

Industrial screw pump for dosing hard fillings

Enhance precision and efficiency in dosing hard fillings with a robust scre...

Industrial water cooling system for food products

Efficiently cool and convey food products with a system designed for un...

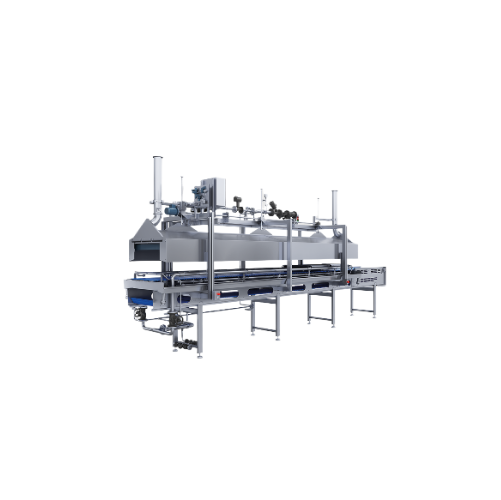

Conveyor cleaning and cooling system for pasta

Efficiently halt cooking processes and eliminate surface starch with a stre...

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing ...

Round die washer for pasta and snack production

Ensure impeccable hygiene with a specialized washer that streamlines die m...

Mini die-washer for pasta industry

Enhance the efficiency of your production line by ensuring thorough cleaning and debris ...

Rotating cutter for short pasta production

Optimize your short pasta production line with a versatile rotating cutter desi...

Single-screw extruder for pre-gelatinized materials

Streamline your production of snack pellets and instant noodles with ...

Membrane mash filter for brewing

Optimize your brewing process with advanced membrane filtration, ensuring maximum yield and...

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

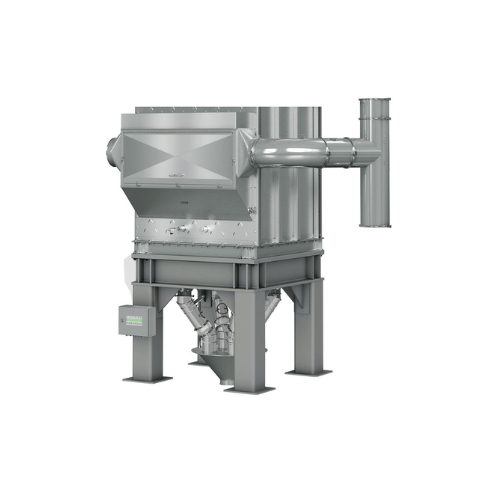

Classifier for flour, semolina, and pulse factories

Optimize grain processing with a high-capacity classification solutio...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

Cold forming extruder for food manufacturing

Achieve precise shape and density control in cereal and snack production by i...

Airflow grain puffing machine

Unlock the potential of versatile snack production with precision-engineered airflow puffing t...

High-capacity pre-cleaner drum for grain silo storage

Optimize your pre-cleaning process with a high-capacity drum that e...

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Chocolate lentil, ball, and egg production system

Achieve consistent and precise shaping of chocolate lentils, balls, and...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Batch mixers for raw material preparation in extrusion processes

Optimize your extrusion process with precise raw materi...

Top load Case Packer For Food Products

If you want to pack your food cartons, doy packs and pouches into regular cases, a s...

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

Fluidized bed drier/cooler for grains

Processed grains absorb moisture throughout the production line. Lowering that water ...

Color sorting machine for grains

Detecting impurities in processed grain becomes more challenging as the output increases. B...

Flexible popped chips machine

Producers of healthy snacks like popped chips, are much more competitive when they are able to...

Fully automated rice cake machine

When investing in a larger scale rice cake machine, marketability should be an important ...

Moulding machine for rolled bread

As great snacks and accompaniments to meals rolled bread is a staple product in commercia...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms ca...

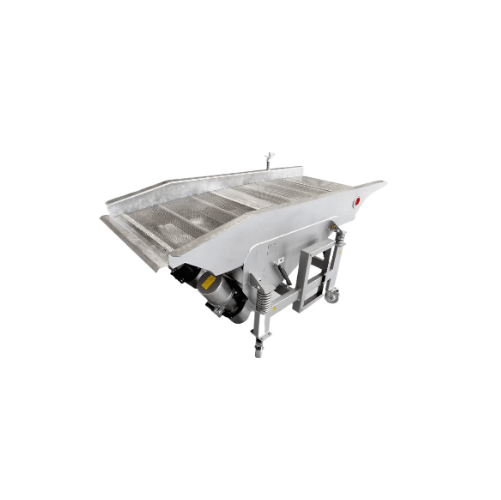

Consistent processor of corn, bran and multigrain

The production of high quality flaked breakfast cereal requires accurat...

Laboratory confectionery depositors

When designing new confectionery products, the ability to experiment on lab-scale equip...

Breaker for baked granola sheets

Once baked in large sheets, granola needs to be processed into a final product. For premium...

Hammer mill for coffee beans

Being able to obtain an on-point grinding is easily achievable with these hammer mills, from co...

Small batch filter press for oil seeds

Getting a high-quality oil filtration can be a challenging task, with a filtration ...

Nut roaster

Nut roaster that guarantees a high-quality roasting of nuts and seeds with a batching capacity of 40 and 120 kg, d...

Cold oil press for seeds

With a cold oil press, you can optimize the process of extracting oil from a wide variety of oil see...

Cryloc rotary screens for grain processing

Efficiently sort and separate fine particles with high precision to enhance pro...

High accuracy micro dosing system

When handling diverse ingredients, precise dosing is crucial to ensuring consistent produ...

Extruders for animal feed production

Optimize nutritional value and ensure efficient processing of animal and aqua feeds wi...

Roasting and pasteurization solution for nuts and seeds

Optimize your product line with seamless blending and pasteurizat...

Vibratory bowl feeder for bulk items

When precision and speed are crucial, ensure your production line efficiently handles ...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

Blending multihead weigher for accurate component mixing

Achieve precise blending in high-speed operations with individua...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

Single-screw extruder for pet food and aqua feed

For producers aiming to diversify their offerings, this single-screw extr...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Moisture control system for grain milling

Optimize moisture levels precisely within your grain milling process, ensuring c...

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Automatic silo scale for grain processing

Enhance your grain handling operations with precision weighing and dosing, ensur...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Compound rolling unit for dough sheets

Achieve unparalleled precision in dough formation with our high-speed compound rolli...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

Air cleaners for grain dust removal

Enhance safety and operational efficiency by effectively removing dust and light partic...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

Standard starch viscometer for gelatinization analysis

Ensure precise gelatinization property measurement with real-time ...

Gluten-free flour mixing solution

Ensure consistent dough quality and precise analysis in gluten-free production with a rob...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

In-line checkweighing and printing system for cartons

Ensure precision and efficiency in your packaging line with a compa...

Preform inspection system for blown containers

Ensure defect-free blown containers and minimize line jams with a robust pr...

Combi x-ray and checkweigher for vertical products

Ensure accurate weight control and safety by detecting foreign bodies ...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Loading box for granular products in production lines

Optimize your production line with a manual-to-continuous loading b...

Vertical packaging system for short-cut pasta and dry granular food

Streamline your packaging operations with a high-sp...

Intermittent motion bulk packaging for pasta and granular products

Optimize your production line with precision packagi...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Industrial cooling system for packaging temperature control

Achieve precise temperature control and maximize energy effi...

Bulk packaging system for long cut pasta

Optimize your bulk packaging of long cut pasta with a high-speed, customizable sol...

High-speed pasta packaging system

Streamline your pasta packaging process with an advanced system that combines precise wei...

High-speed packaging system for long-cut pasta

Achieve seamless high-speed packaging with enhanced accuracy and minimized ...

Extruder for short-cut pasta and lasagna production

Achieve seamless pasta and snack production with an extruder designed...

Double sheet kneader sheeter for fresh pasta processing

Efficiently transform dough into consistent sheets with our machi...

Surface drying system for pasta production

Ensure optimal surface drying of pasta and snacks post-pasteurization, preventi...

Lobe pump for soft fillings

Efficiently dose and feed soft fillings for food products with precision, ensuring smooth integr...

Creamy filling dosing system

Effortlessly dose creamy fillings into your production line with precision, ensuring chunk size...

Pasta folding system for cannelloni production

Streamline your production by precisely folding pasta around filling to cre...

Single sheet former for fresh pasta production

Optimize your production line with a versatile machine designed to precisel...

Pasta sheet forming machine for ravioli and cappelletti

Achieve precision pasta forming with consistent thickness and hig...

Tortellini forming machine

Optimize your tortellini production with a high-speed forming machine that ensures precise thickn...

Long-cut pasta production line

Optimize your long-cut pasta production with a single-tier system designed for precise moistu...

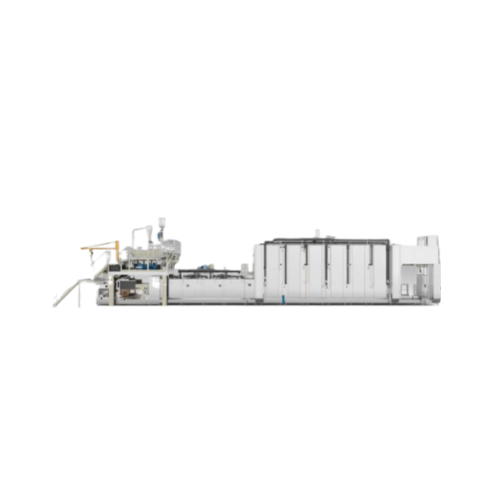

Industrial Long-cut pasta production line

Achieve superior long pasta quality with energy reductions up to 30%, featuring ...

Nest-shaped pasta production line

Streamline your pasta production with a solution designed to retain the integrity of nest...

Couscous production line

Enhance your couscous production with a seamlessly integrated line that ensures precise granule sizi...

Water cooker for fresh pasta processing

Enhance cooking precision and product quality with this water cooker, designed to c...

Industrial water cooker for pasta processing

Enhance your pasta production with precise water cooking, ensuring consistent...

Industrial die washing solution for pasta production

Enhance efficiency in pasta and snack production with a robust die w...

Pasta cutter for short pasta production

Streamline your short pasta production with a versatile cutter designed for rapid f...

Nest-shaped short pasta production line

Optimize your pasta production with a streamlined process that enhances drying effi...

Long-cut multi tier pasta line

Optimize your pasta production with high-speed, multi-tier drying and precise compression, en...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Decanter for plant-based beverage extraction

Ensure high-yield extraction and optimal purity from plant-based ingredients ...

Continuous mash filtration system for breweries

Optimize your production line with continuous mash filtration that revolut...

Automated material flow system for starch processing

Streamline the handling of powdered starches with precise dosing, mi...

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

High intensity preconditioner for textured vegetable proteins

Optimizing your production with precise moisture control a...

Vertical mixing solution for bakery and snacking industry

Streamline your dough processing with robust and reliable spir...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Compact food filling and portioning solution

Ideal for facilities needing precise portioning, this versatile filling machi...

Square plansifter for flour production

Optimize your flour milling process with enhanced sifting and classification, ensuri...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Versatile spray dryer for dairy and plant-based powders

Achieve precise moisture control and optimal powder functionality...

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Gentle mixer for tea blending

The blending process is critical to the flavor quality of tea. But the physical impact of the ...

Flaking roller mill for oats

Consistent flake size is one of the main contributors to processed oat quality. But producing a...

Drum groat cutter for baby oats

Used as food thickeners and toppings, baby oat flakes must adhere to a consistent size. But ...

Table separator for grains

Imprecise sorting of oats and other grains brings down the yield. To avoid wastage, hulled and un...

Gentle polisher for oats

The fine fluff covering oat grains complicates the cleaning of processing equipment. The hair-like f...

Impact huller for oats

Hulling technology risks breaking oat grains if the system is not adjustable to fragile materials. Agg...

Gentle de-awner for grains

Husking is a fundamental step in grain processing, but it lowers the yield if it’s not carefully ...

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

High-speed flow pack wrapping machine for chocolates

Foil flow pack wrapping of chocolate products is an attractive and p...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

Strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other final product sha...

High-speed strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other fina...

Longitudinal strand cutting machine

Cut continuous slabs of your ingredient mix into spaced strands for further processing ...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Hygienic chocolate coating machine

Coat your product with chocolate or caramel. This is a next-generation chocolate coating...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...

Strand forming machine

Form ingredient mixes into strands and slabs for further processing into bars, and other final product...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Convection oven for granola

For high-quality granola products, a perfect bake is required for optimum color, taste, and mout...

Granola batch mixer

The production of granola-based recipes requires careful ingredients handling to ensure optimum quality. ...

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...