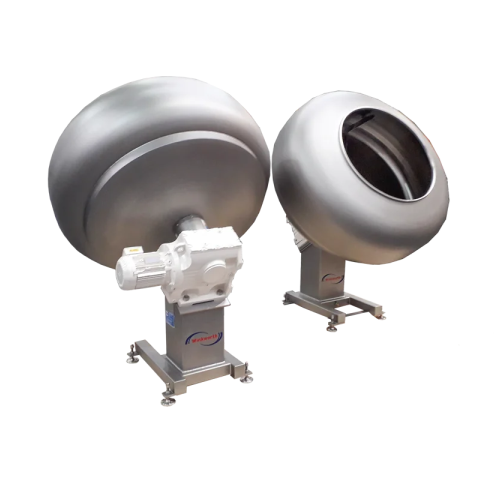

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed for efficient coating of confections and pharmaceutical tablets, delivering precise results with each batch.

Coats and Mixes Solids, Powders, and Granules

The A500 Coating Pan from Winkworth Machinery is engineered for precision and reliability in coating and mixing applications across sectors such as confectionery, pharmaceuticals, and chemicals. With its robust construction, the stainless steel pan ensures optimal performance in batch and continuous processes, whether you’re coating sugar almonds or mixing pharmaceutical granules. Its design includes a fixed angle with a high-tensile output shaft and a 2.2 Kw TEFC IP55 geared motor, providing consistent operation tailored to your production specifications. Capable of handling a variety of solid, powder, and slurry forms, the A500 Coating Pan supports diverse end-products like chocolate bars, medicinal tablets, and rubber granules. Offering options for full automation, variable speed drives, and hygienic design, this equipment integrates seamlessly into your production line with minimal energy consumption. Material options include high-grade stainless steel for enhanced corrosion resistance, ensuring compliance with industry standards and long-term durability. The A500 Coating Pan is easy to maintain, featuring a polished interior and exterior for simple cleaning, while Winkworth’s customization and engineering support ensures that each unit meets your specific operational needs.

Benefits

- Ensures consistent coating quality, enhancing product appearance and uniformity.

- Supports broad material compatibility, reducing equipment changeover in diverse applications.

- Improves production efficiency with fixed speed operation tailored to process needs.

- Lowers maintenance efforts through durable stainless steel components.

- Offers customization flexibility, aligning with specific production requirements.

- Applications

- Vitamins, Agricultural chemicals, Snacks, Granules, Confections, Coated sweets, Pharmaceutical tablets, Solids, Rubber, Chewing gum, Sweets, Plastics, Pharmaceuticals, Metal powders, Nutraceuticals, Confectionery, Cereals, Coating materials, Powders

- End products

- Muesli base flakes, Cornflakes, Agricultural dust control chemicals, Nutraceutical supplements, Medicinal tablets, Metal injection molding powders, Jelly beans, Chocolate-covered nuts, Recycled plastic pellets, Chewing gum pellets, Sugar-coated almonds, Rubber granules, Milk chocolate bars, Vitamin capsules, Fertilizer granules, Sugar dragees

- Steps before

- Mixing, Grinding, Drying, Emulsification, Preparation

- Steps after

- Coating, Packing, Sterilization

- Input ingredients

- Cereals, Chewing Gum, Pharmaceutical ingredients

- Output ingredients

- Coated Sweets, Confectionery, Coated Cereals, Coated Chewing Gum, Pharmaceuticals

- Market info

- Winkworth is known for manufacturing high-quality, engineered-to-order industrial mixing equipment, including mixers and blenders, renowned for their reliability and innovation in the pharmaceutical, food, and chemical industries.

- Material

- 316 and 304 grade stainless steel

- Internal Depth

- 736 mm

- Diameter

- 787 mm

- Working Capacity

- 60 Litres

- Motor Power

- 2.2 Kw

- Voltage

- 230/400V

- Phase and Frequency

- 3Ph/50Hz

- Motor Type

- TEFC IP55 geared motor

- Finish

- Dull polished inside and out

- Drive Base Material

- 304 grade stainless steel, bead blasted

- Speed Control

- Fixed speed

- Batch vs. continuous operation

- Batch

- Automation level

- Manual / PLC

- Cleaning method

- Manual

- Energy efficiency

- High

- Changeover time

- Quick

- Air incorporation control

- Not Applicable

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Internal depth

- 736 mm

- Opening diameter

- 787 mm

- Material

- 304 grade stainless steel

- Contact parts material

- 316 grade stainless steel

- Finish

- Dull polished inside and out, bead blasted finish

- Drive base

- Fabricated stainless steel

- Configuration

- Fixed angle

- Output shaft

- High tensile

- Working capacity

- 60 Litres

- Construction

- Two spun sections with single weld

- Supporting structure

- Stainless steel spider boss and reinforcing back ribs

- Surface finishes

- Bespoke