Tablet Making Equipment

Find innovative tablets equipment and connect directly with world-leading technology suppliers

Among all dosage forms in use today, tablets constitute the most common one. They are pharmaceutical solid dosage forms containing active ingredients and excipients such as diluents, binders, glidants, and lubricants. Using tablet making equipment, these solid dosage forms are made by compression of granules or powder blends and then shaped by molding.

Top picks for tablet manufacturing equipment

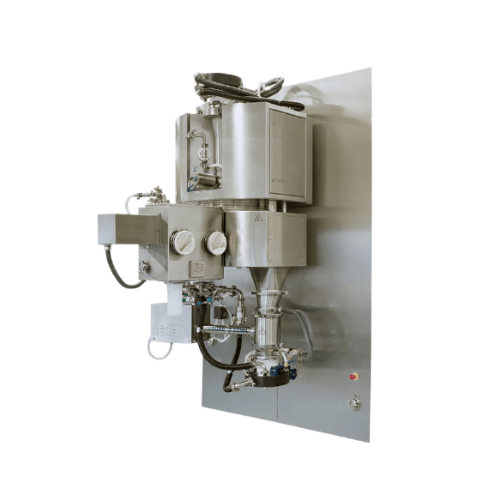

Laboratory fluid-bed dryer and tablet coater

Experience seamless transition from laboratory to production scale with a ver...

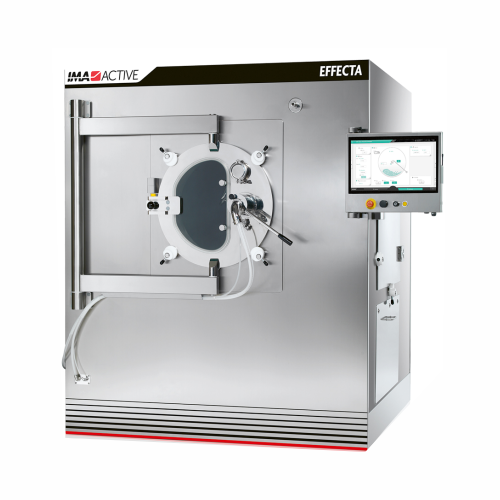

Energy-efficient film coating machine for pharmaceutical tablets

Tablet coating involves applying a thin layer of coatin...

Benchtop tablet press

For lab work or small-scale production, a purpose-designed tablet press that meets your exact requireme...

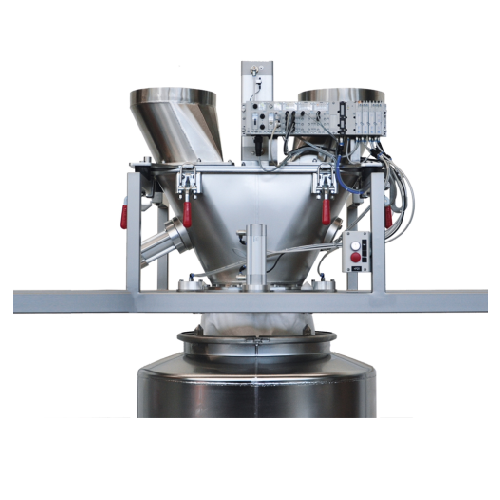

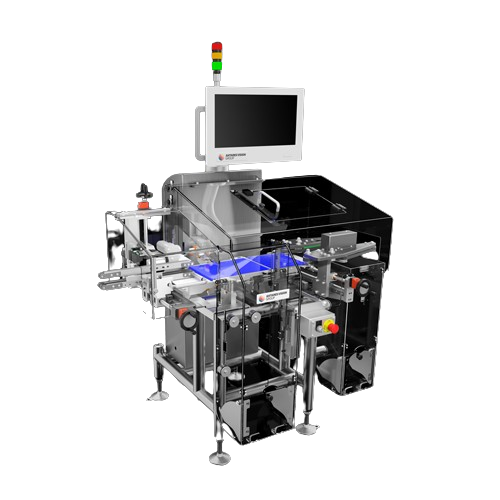

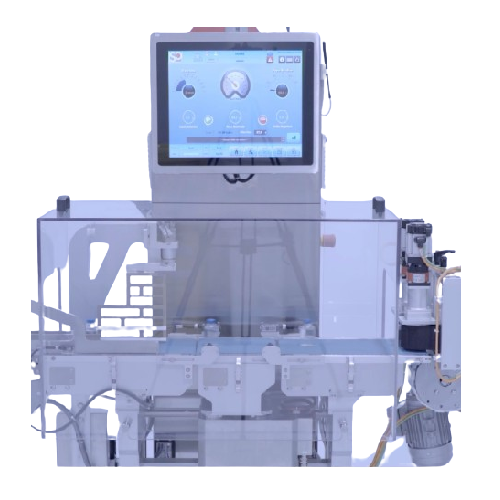

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

Stories about tablets

Scientifically tested continuous drying for your tablets

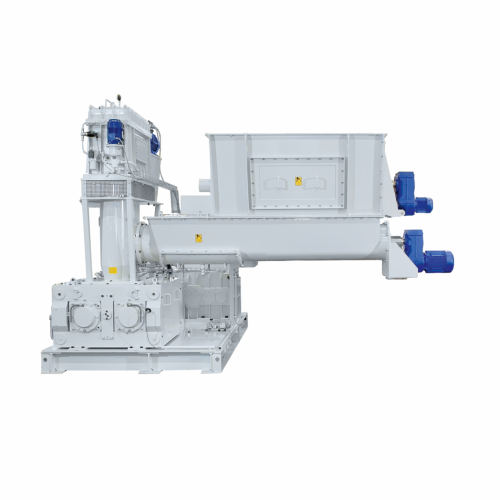

Aim your safety standards high, while granulating dry

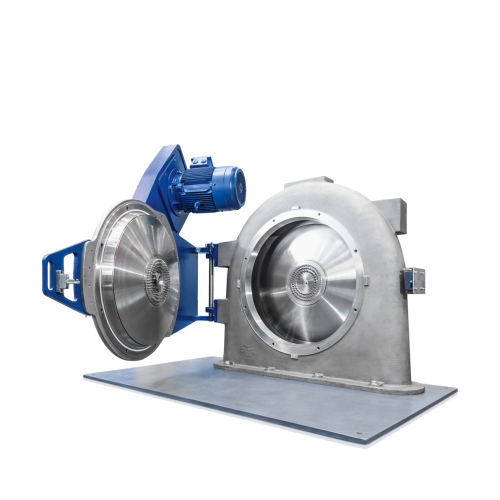

Discover the best mix for your blending application

Coat-astrophe averted: a sprightly spin on tablet efficiency

Lean into efficiency with inclined tablet discharging

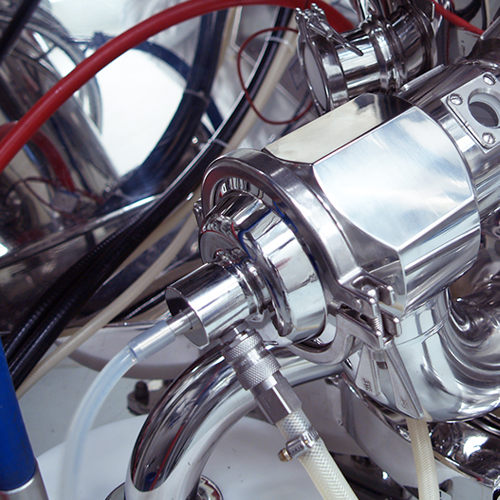

Wet milling: The revolution in the API production

The sweet world of pharmaceutical tablets - The trifecta for achieving coating uniformity

Closing the containment loop in HPAPI manufacturing

#Changemaker: Ready to protect your pharmaceutical products from moisture?

How reliable imaging plays an important role in capsule visual inspection

Chewable or regular aspirin: what is the difference?

Making chewable multivitamin tablets for kids

Keeping pharmaceuticals moisture free

#Changemaker: Keep track of your medicine every day with FabriSol sticker

#Changemaker: Turning grass into pharmaceutical packaging

Select your tablets process

What are you making?

Antihistamine tablets

Antibiotic tablets

Sugar-coated tablets

Sustained-release tablets

Pharmaceutical pills

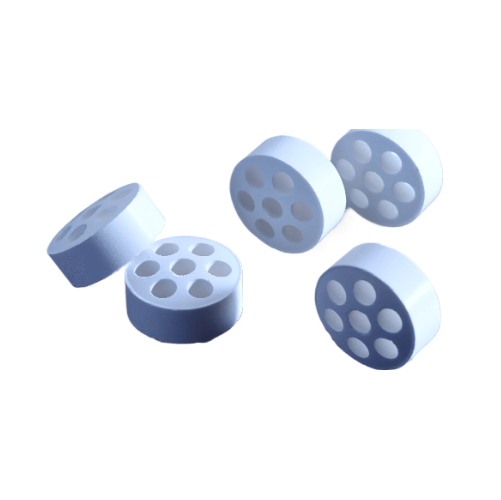

Micro-tablets

Immediate-release tablets

Er tablets

Antacid tablets

Analgesic tablets

Coated tablets

Pharmaceutical granules

Multi-layer tablets

Microtablets

Uncoated tablets

Enteric Coated Tablets

Veterinary tablets

Chewable tablets

Effervescent tablets

Tell us about your production challenge

Originally only manufactured in discoid shape, tablet today also come in triangular, rectangular, round, oval, oblong, or cylindrical varieties. Colors can vary to distinguish different medicines, and tablets are often stamped with symbols, letters, and numbers, enabling them to be identified.

According to their route of administration and the method of manufacture, it is possible to classify tablets into chewable tablets, effervescent tablets and multi-layer tablets, to name a few. Still, the compressed tablet remains the most popular dosage form nowadays.

Production processes involved in making pharmaceutical tablets

In the pharmaceutical industry, the methods used for tablet making can be classified as granulation (wet granulation and dry granulation) and direct compression.

Wet granulation vs. dry granulation

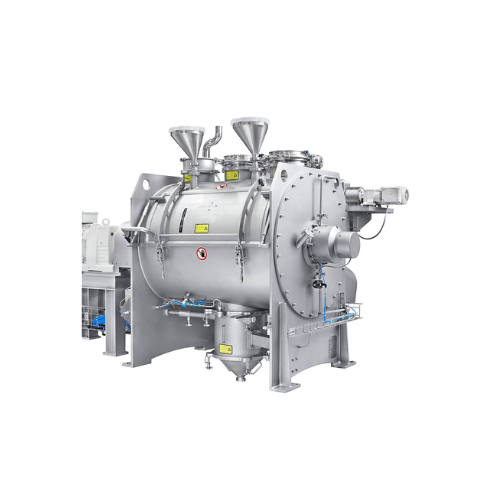

Granulation is a complex multi-stage process in which small powder particles are combined together to form agglomerates called granules.

The main difference between wet granulation and dry granulation is that wet granulation involves a granulating fluid like water, isopropanol, ethanol, or mixtures thereof. In contrast, dry granulation is the formation of granules without using any liquid solution.

Dry granulation can be accomplished with two methods, slugging and roller compaction, and it is used above all for those tablet ingredients that are sensitive to moisture or are unable to withstand elevated temperatures.

In wet granulation, powder particles are bound together using liquid solutions to achieve particle enlargement. The granulating fluid should be volatile to be easily removed by drying and should be non-toxic.

Tablet making equipment for direct compression

Direct compression refers to a process in which powdered APIs are mixed with excipients and lubricants without involving granulation steps. It has grown in popularity because it provides the shortest, cheapest, and most effective way to produce tablets while minimizing processing time, steps, and equipment required. This tablet production method is suitable for moisture and heat-sensitive API ingredients. Direct compression requires a tablet press in which the upper and lower punches are pressed together within the die hole and compress the tablet until it is formed.

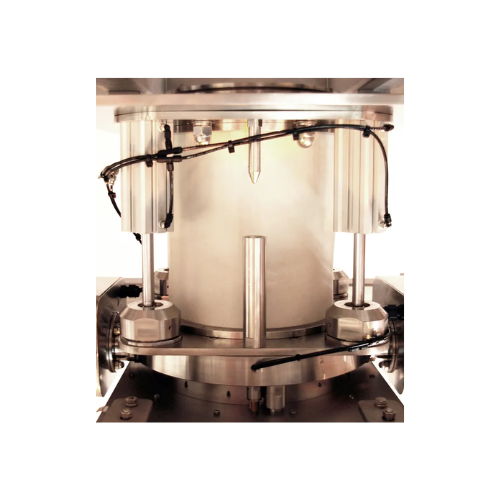

The tablet equipment used for compression is the single punch tablet press and the rotary tablet press. The difference is that the single punch tablet press has two punches (upper and lower), but it uses only the upper one for compression. The rotary press has multiple punches and uses both the upper and the lower ones to compress the granules.

Uncoated tablets vs. coated tablets. When is a tablet coating machine needed?

Have you ever wondered why some tablets are coated and others are not?

Let’s start by understanding the difference, although the name already says it all. Uncoated tablets are simply made by compressing the granules with no coating added afterward. They don’t taste good and are harder to swallow, especially for children. This can be an excellent reason to use a coating; for instance, tablets are coated to mask an unpleasant taste.

An example of coated tablets is enteric coated tablets. The enteric coating is necessary when the tablet’s active ingredient is acid sensitive. Using tablet coating equipment that applies a polymer barrier to the tablet makes it possible to protect it from stomach acidity. This involves spraying the film-forming material onto the tablet surface as the tablets rotate in the pan.

Keep your tablet safe by choosing suitable packaging

Solid dosage forms such as tablets are commonly packed in blister packs. This type of packaging assures the integrity of each dose since each cavity is separate, so if one of their seals is breached, this doesn’t compromise the quality of the whole product

The main aim of pharmaceutical packaging, like all others, is usually to protect products from any physical and biological damage and from external conditions that can alter the property of the product inside.

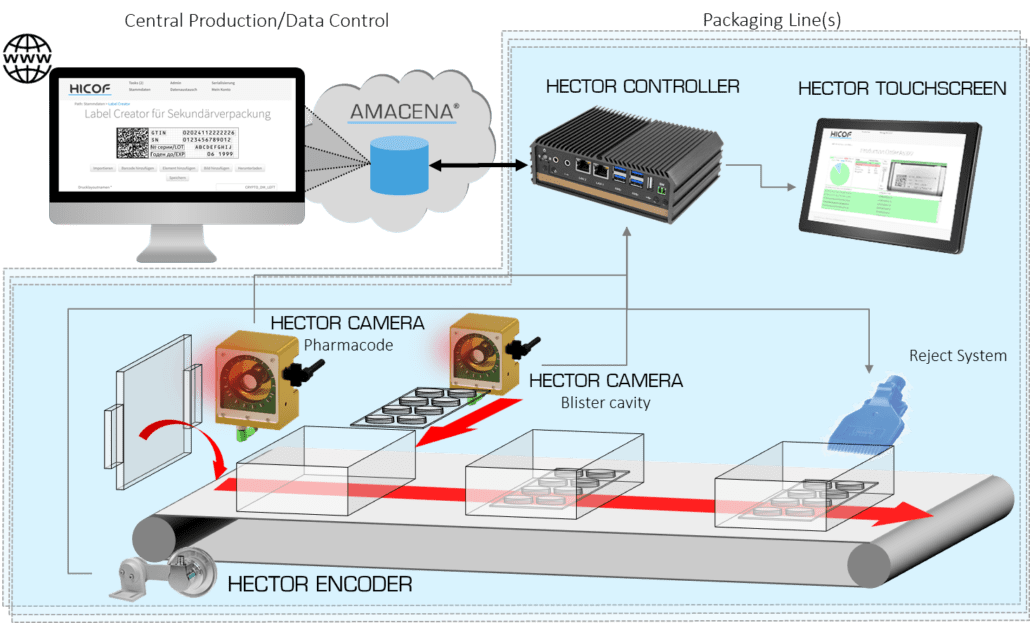

The importance of serialization in the pharmaceutical industry

When it comes to informing the buyer, medical packaging must provide correct information about product name, ingredients, use, and dose, to mention a few. This way, consumers are more aware of product origin or manufacture. To be able to access all this information, product traceability needs to be provided.

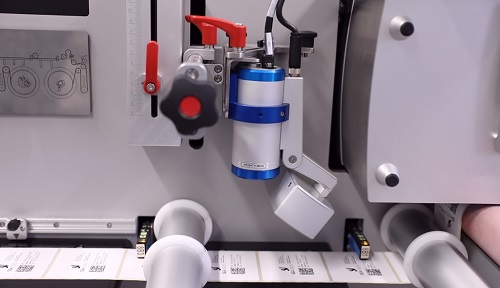

The most commonly used standard to facilitate traceability on drug units is serialization. A barcode needs to be printed on a different level of drug packaging (primary, secondary, and tertiary). With the help of this printed symbol, it is easier to track and trace the origin of a drug and reduce the chance of counterfeit products.

Tablet Making Equipment in Action

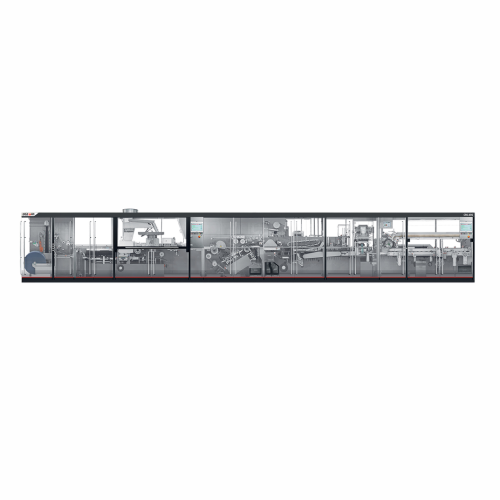

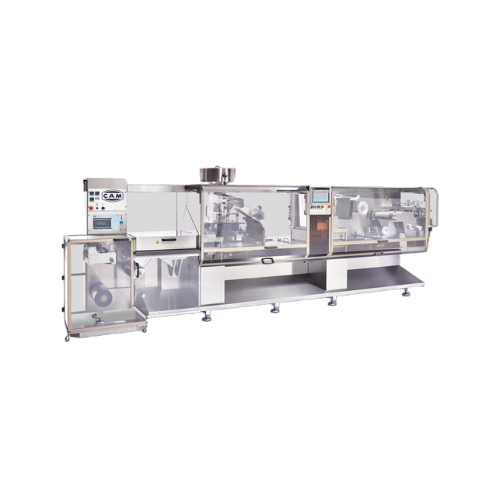

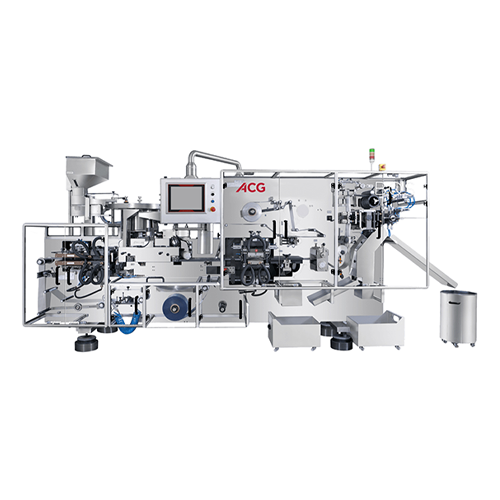

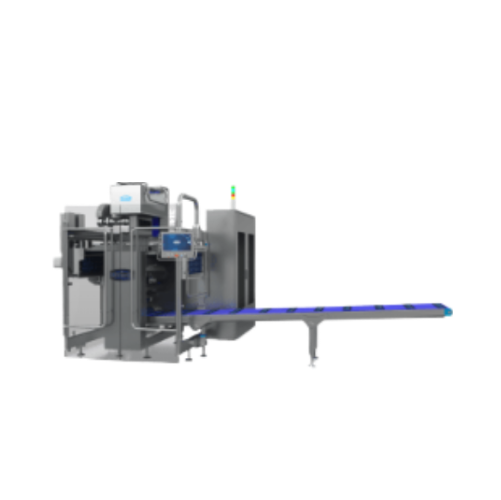

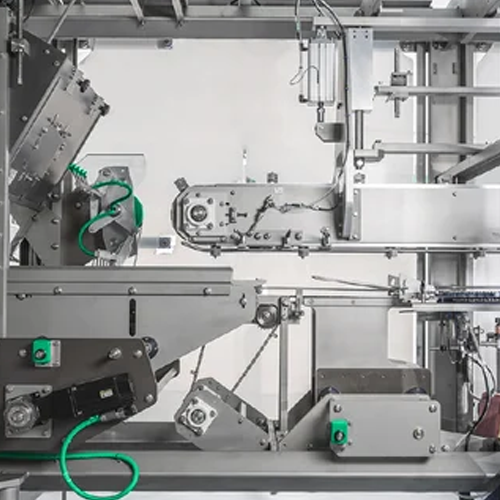

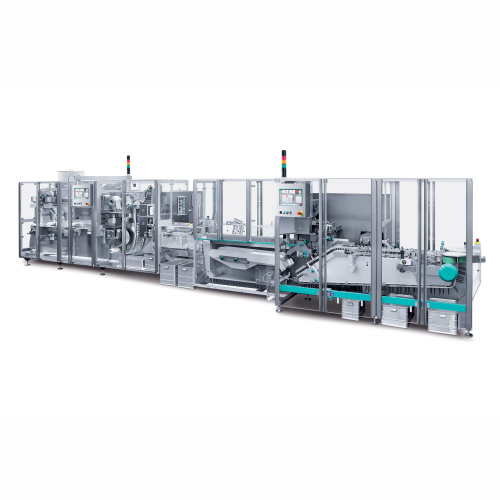

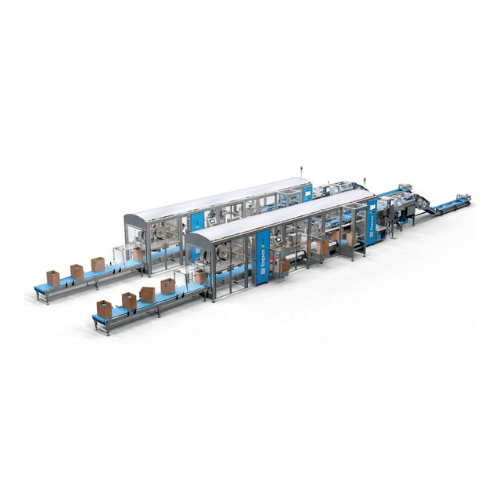

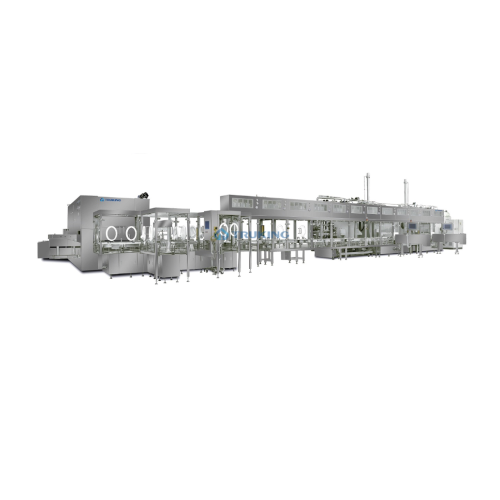

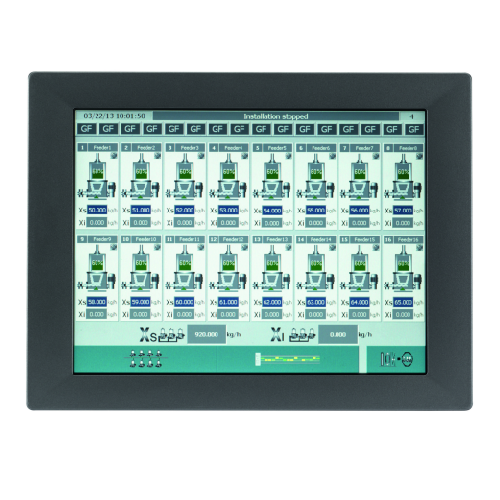

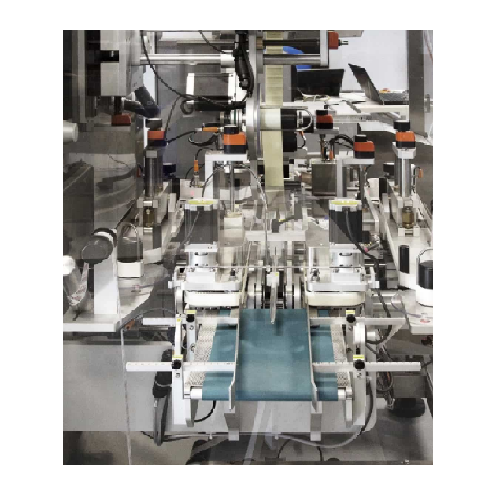

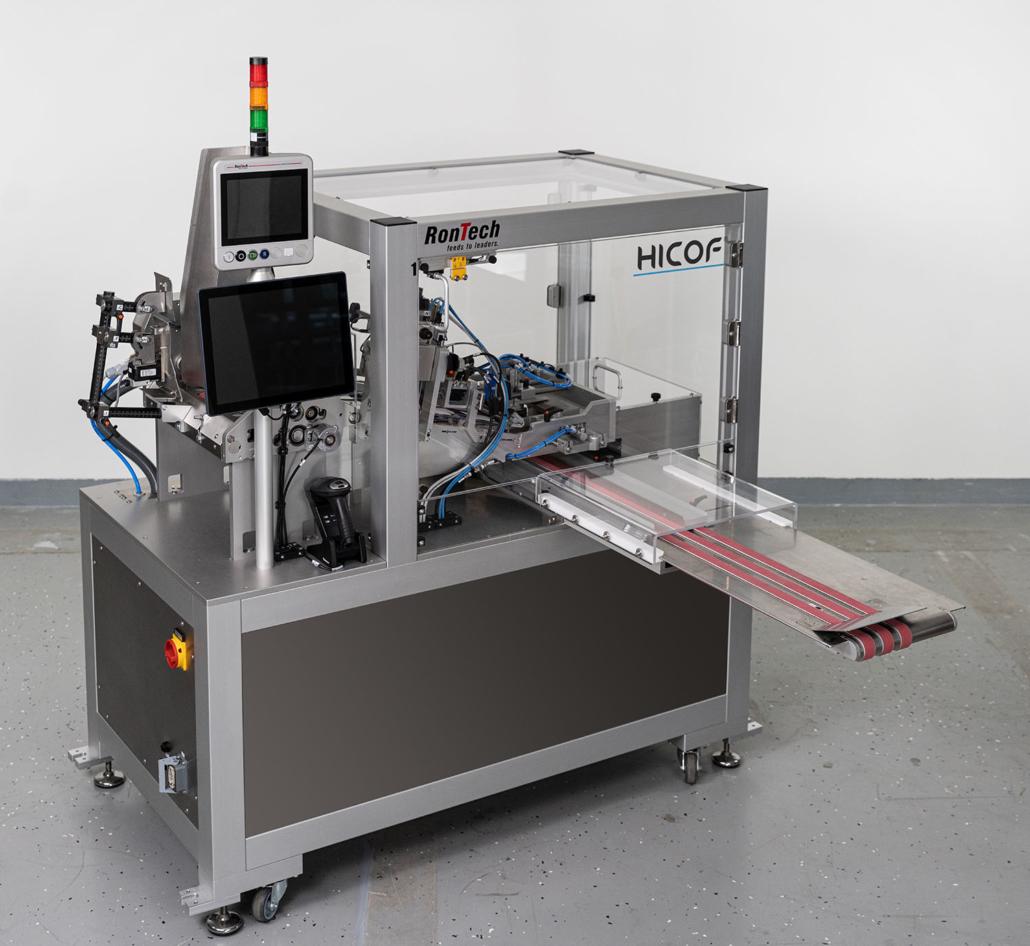

Tablet press - automated line

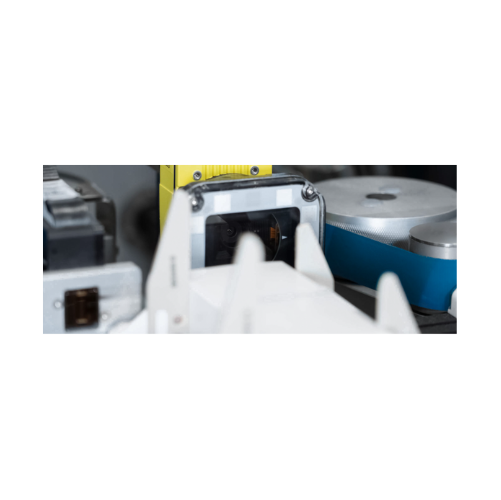

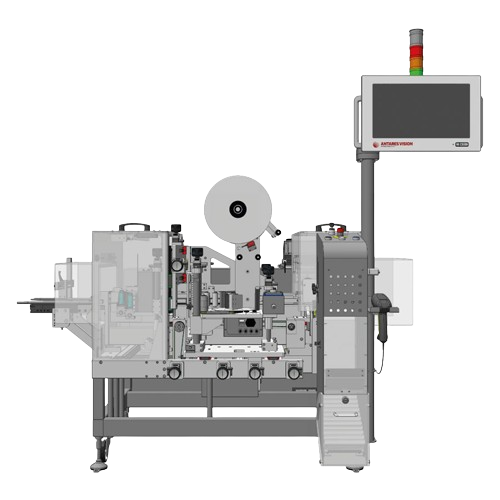

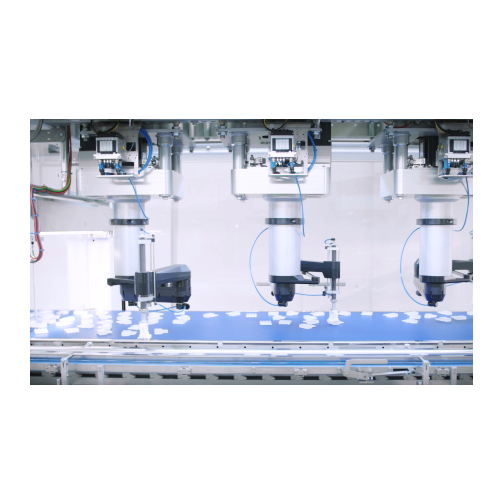

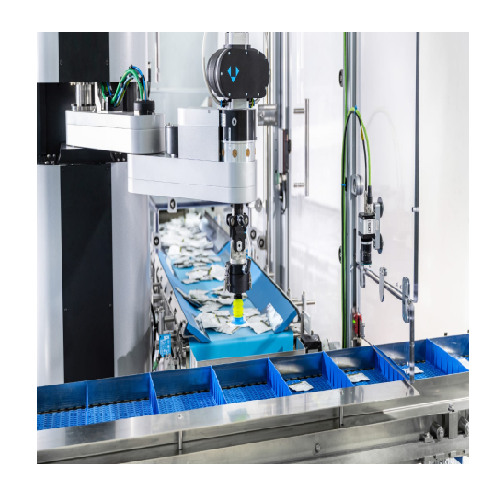

Tablet visual inspection

Which tablets technology do you need?

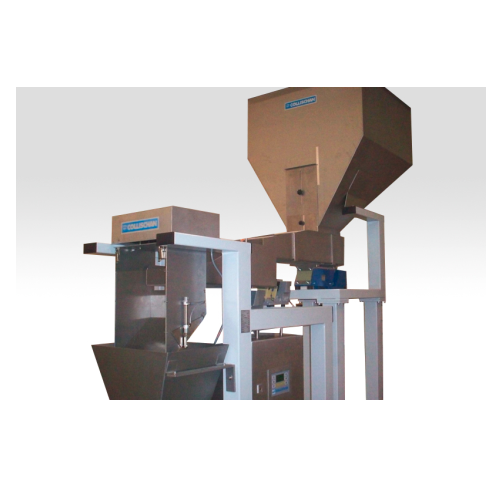

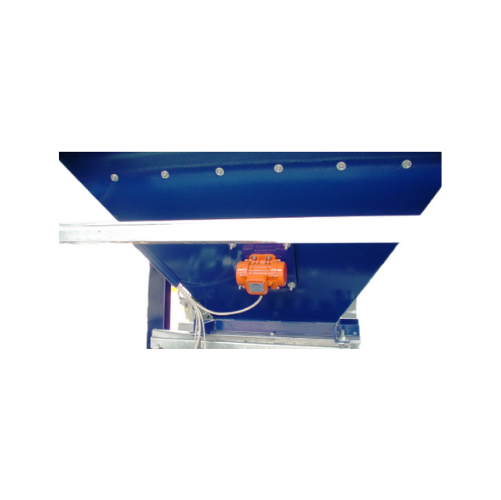

Dosing system for chocolate tablets

Enhance your confectionery production with a versatile solution for precise dosing and ...

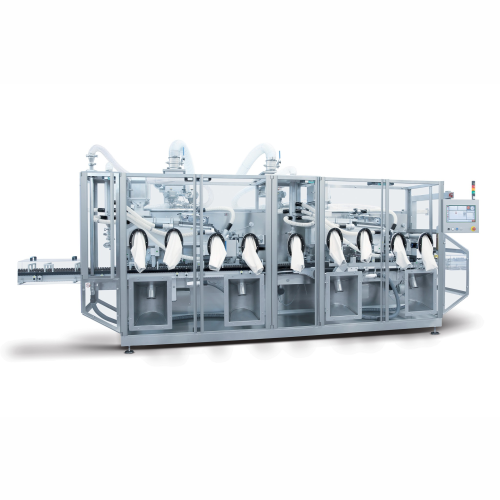

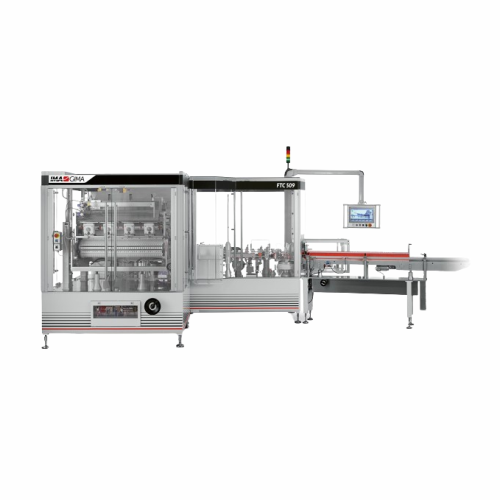

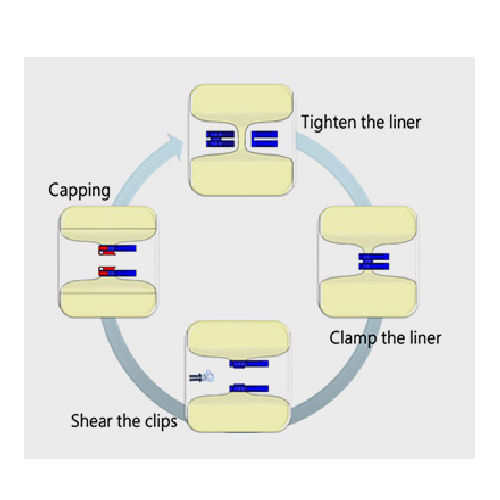

Rigid tube filling and capping system for tablets

Streamline your tablet production with an efficient solution that preci...

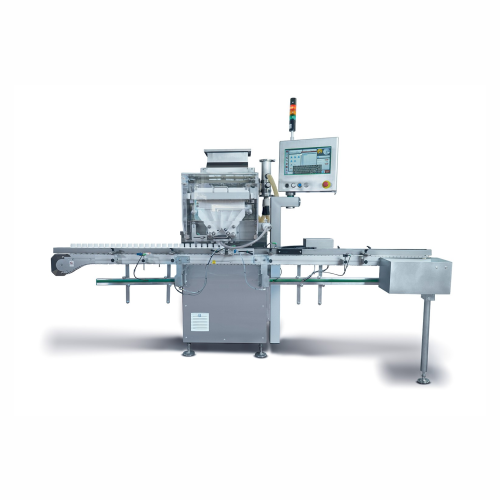

Tablet and capsule counting system

Need precise counting and filling of solid doses like tablets and capsules in your produ...

Counting and capping solution for tablets and capsules

Streamline your tablet and capsule production with a high-speed so...

Pharmaceutical metal detector for tablets and capsules

Ensure contaminant-free tablets and capsules with advanced detecti...

Fold wrapping solution for round pharma tablets

Ensure precise and gentle packaging of round tablets with our innovative f...

Tablet coater for pharmaceutical applications

Achieve uniform tablet coatings with exceptional efficiency and reduced proc...

Laboratory tablet coater for pharmaceuticals

Achieve consistent and efficient coating of tablets with this innovative coat...

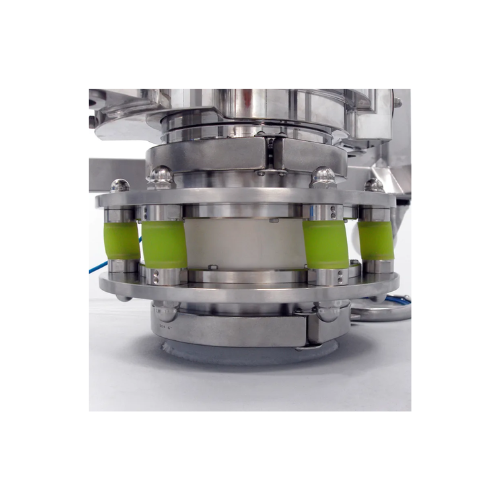

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

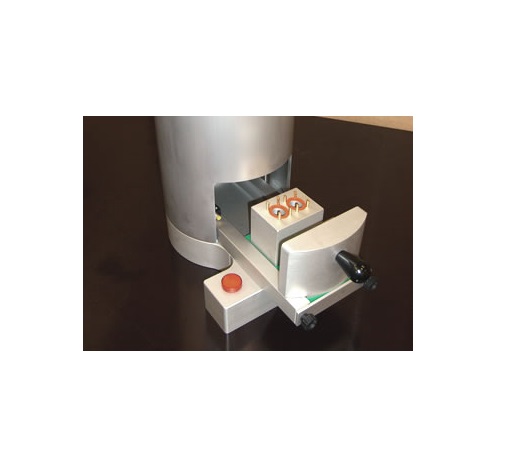

Dust-tight dispenser for metal detector test tablets

Ensure seamless integration of test tablets in high-containment envi...

Vertical vibratory tablet deduster for pharmaceutical tablets

Ensure optimal cleanliness and quality assurance for table...

Tablet deduster with upward conveying

Ensure consistent dedusting and deburring of tablets and capsules while maintaining h...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety ...

High-containment tablet deduster

Ensure optimal purity and safety in pharmaceutical production with high-containment dedusti...

2-way diverter for tablet and capsule filling

Ensure precision in tablet and capsule filling with seamless batch switching...

Tablet and capsule diverter

Streamline your tablet and capsule production with precise container filling and flexible config...

Table top tablet and capsule counter

Effortlessly ensure precise tablet and capsule counts with solutions that seamlessly i...

Tablet elevator for pharmaceutical applications

Ideal for efficient transport and elevation of delicate pharmaceutical tab...

Electronic tablet counter for tablets and capsules

Optimize your production line with precise counting solutions for a wi...

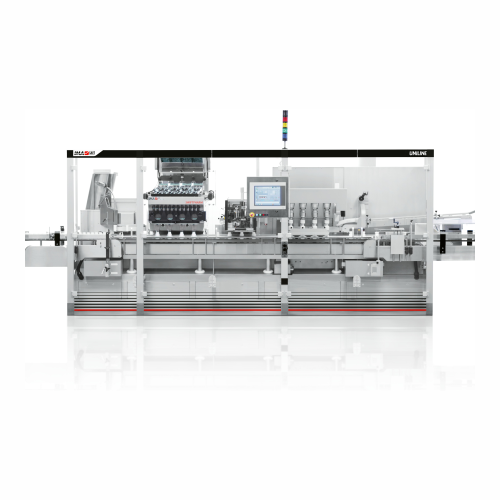

Integrated counting system for tablets and capsules

Streamline your packaging line with a highly versatile system that se...

High-precision slat counter for tablet bottling

Optimize your tablet bottling with a low-energy, high-speed counter design...

Industrial tablet coating solution

Achieve precise film and sugar coatings on a versatile range of tablet and pellet forms,...

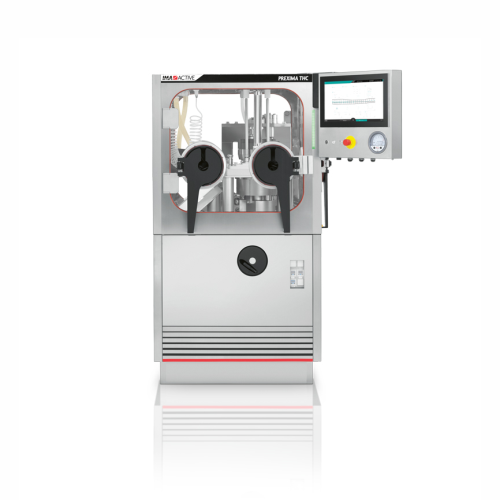

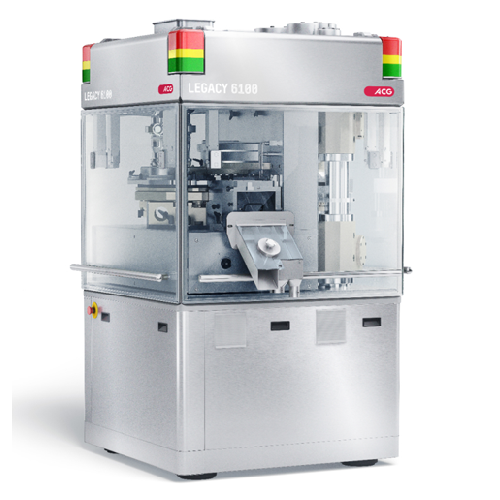

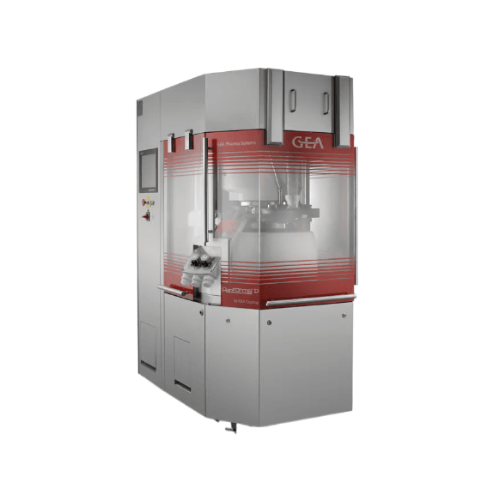

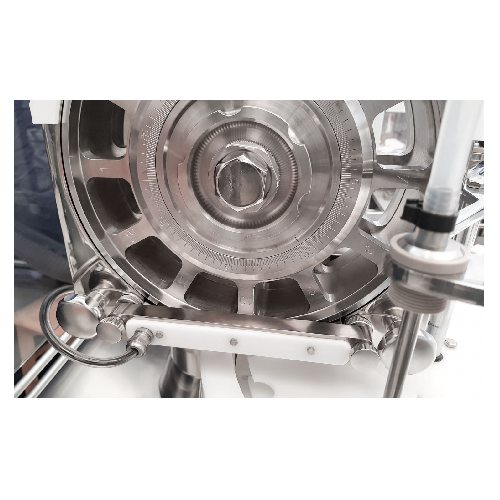

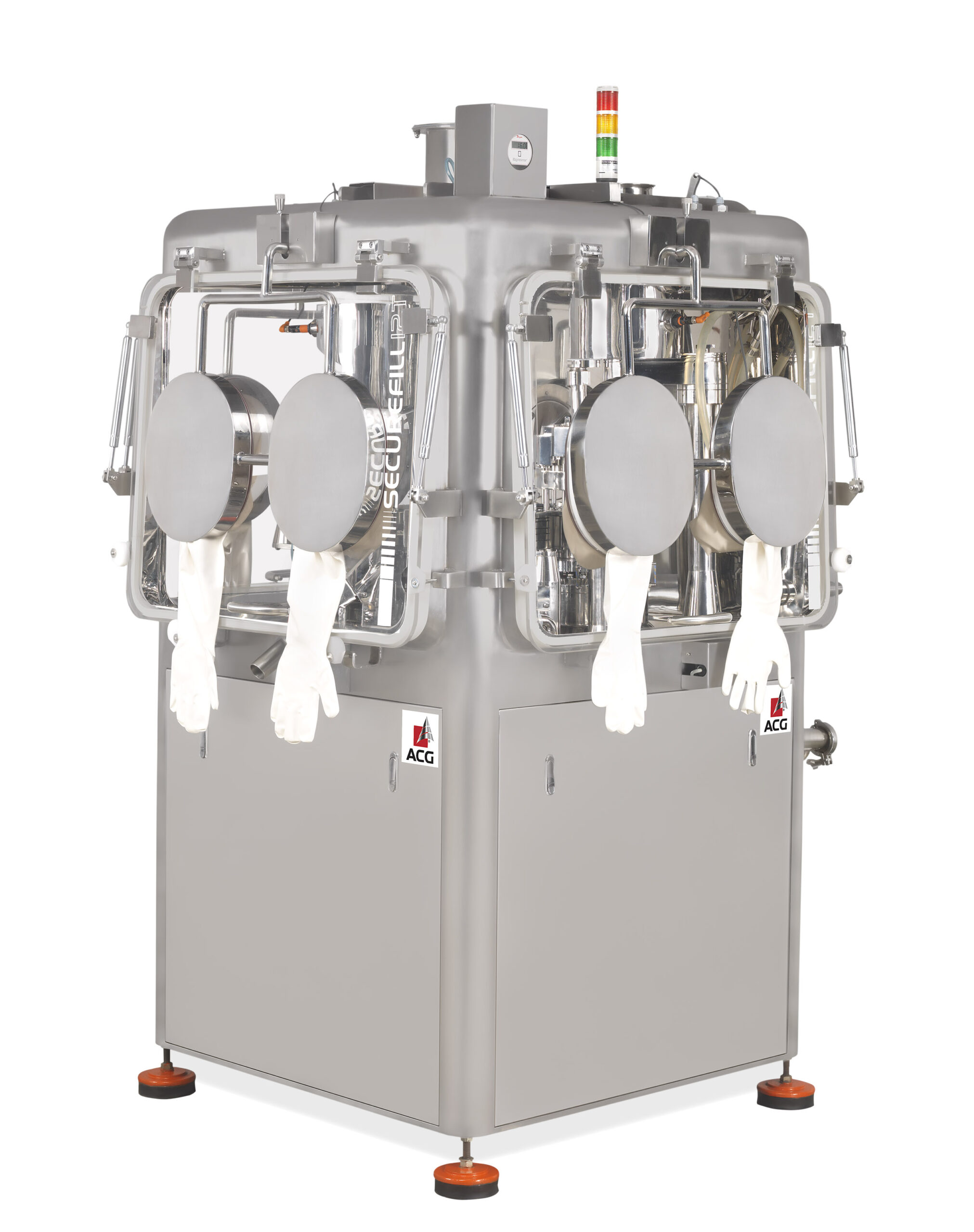

Tablet press for high containment environments

For handling potent compounds without compromising safety, a high-containme...

Integrated counting system for tablet and capsule bottling

Optimize your production line with a compact solution designe...

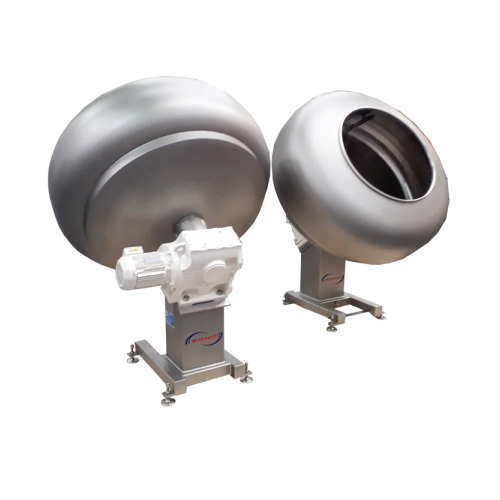

Tablet film and sugar coating pan

Achieve uniform coating while minimizing operator exposure to potent substances, ensuring...

Continuous coater for tablet coating

Achieve seamless tablet coating with continuous processing, enhancing efficiency and r...

Tablet coating pan for pharmaceutical and nutraceutical industries

Enhance coating efficiency with a versatile solution...

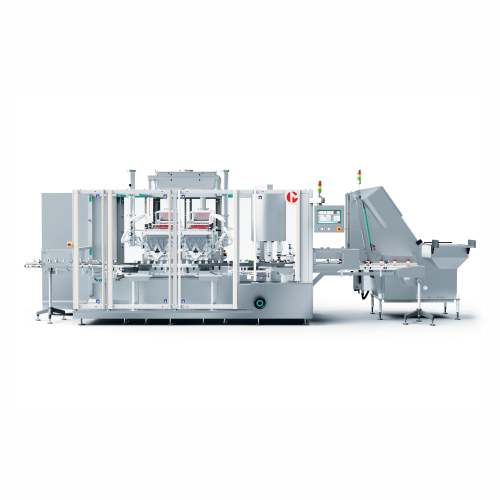

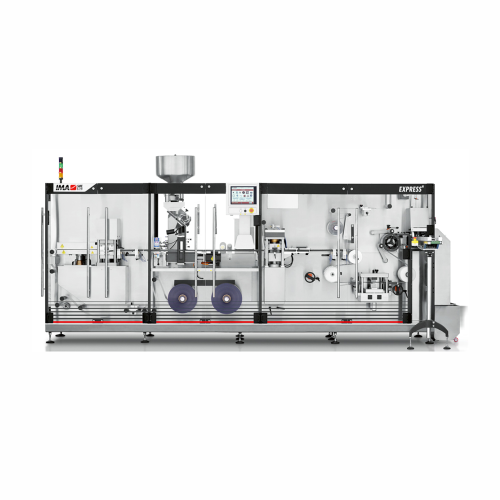

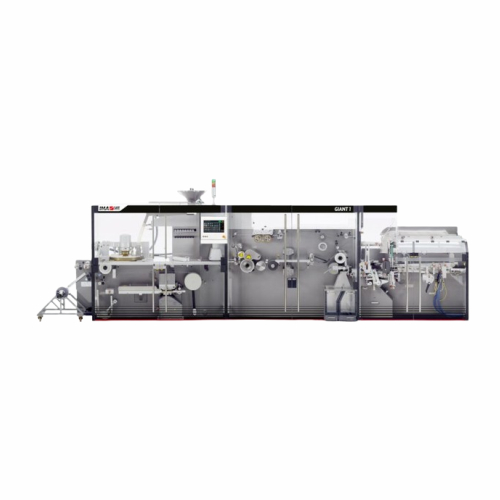

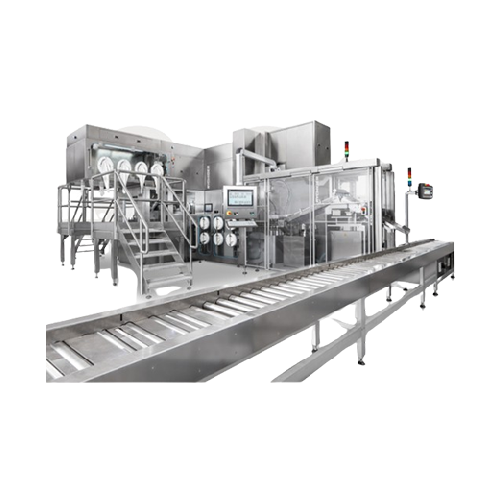

Blister packaging system for tablets and capsules

Designed for seamless 24/7 production, this blister packaging machine e...

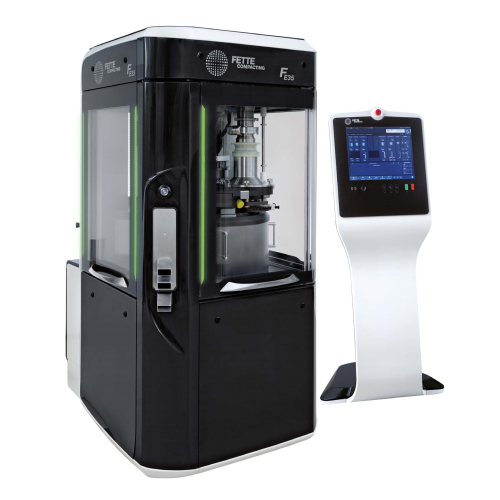

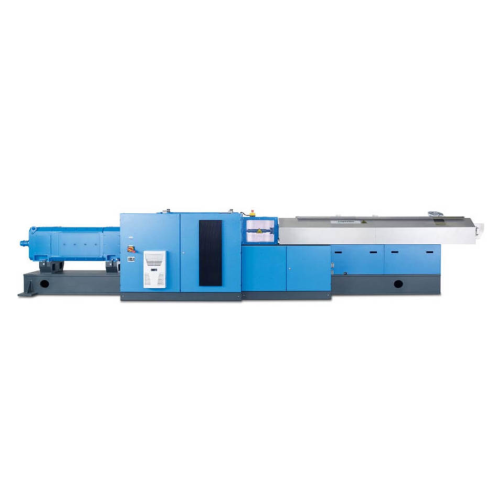

Tablet press for high-quality pharmaceutical tablets

Ensure optimal tablet quality and yield with an advanced compression...

Tablet pressing system for solid chemicals and cosmetic products

Optimize your tableting process for diverse solid produ...

Automated coating pan for pharmaceutical tablets

Enhance your tablet production with a fully automated system that ensures...

Tablet blister wallet packaging line

Enhance packaging efficiency with a high-speed line that integrates blister packaging ...

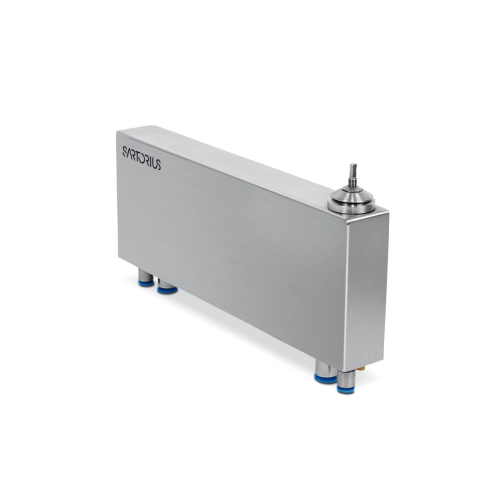

Weighing system for 100% inspection of capsules and tablets

Ensure precise quality control with a format-free system tha...

In-process weighing system for capsules and tablets

Ensure precise dosing and consistent quality with a format-free syste...

Capsule filling system for powder, pellets, and tablets

Optimize capsule production with rapid dosing changes, minimizing...

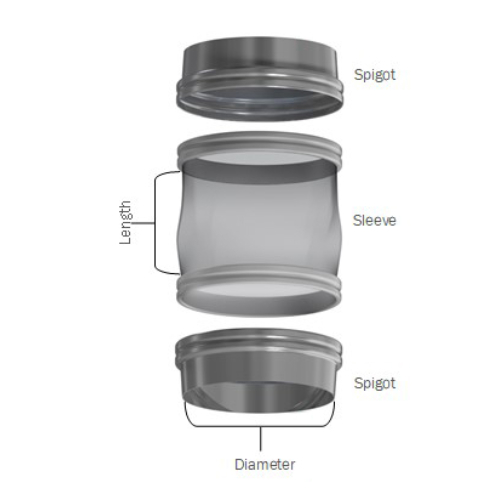

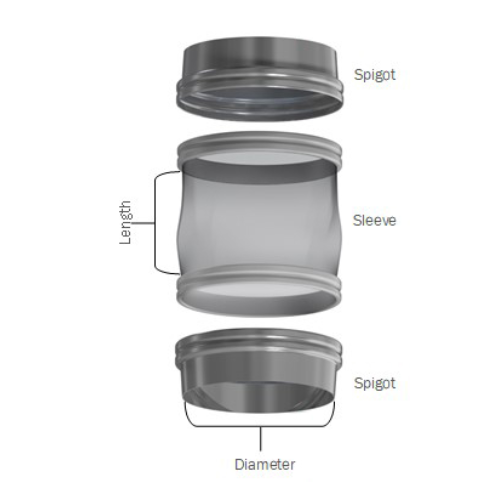

Tablet storage and transport containers

Ensure the safe and gentle handling of tablets during storage and transport, minimi...

Tablet coater for precision pan coating

Achieve precise coating control for pharmaceuticals and nutraceuticals, accommodati...

Ibc tablet bins for pharmaceutical storage and handling

Efficiently manage pharmaceutical tablet processes with adaptable...

Integrated plenum tablet coater

Achieve consistent and high-quality coatings on tablets with advanced airflow management, ef...

Tablet coating system for laboratory development

Optimize your tablet formulation development with a versatile coating sys...

Laboratory development coating system for tablet coating

Efficiently manage small-scale batch coating with versatile, ful...

Portable pan coater for pilot scale tablet coating

Achieve uniform tablet coating with interchangeable pans and anti-mark...

Tablet coating system for aqueous, solvent, and sugar films

Achieve precision coating with flexible application capabili...

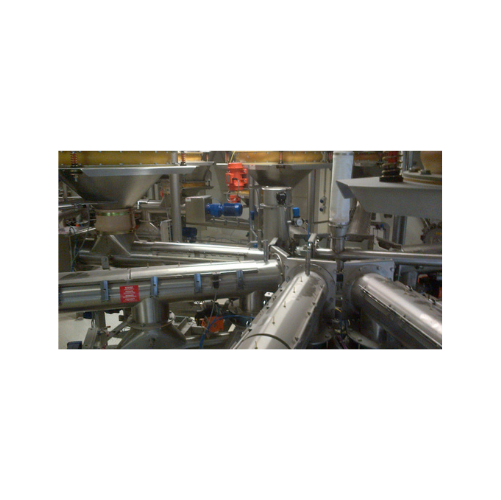

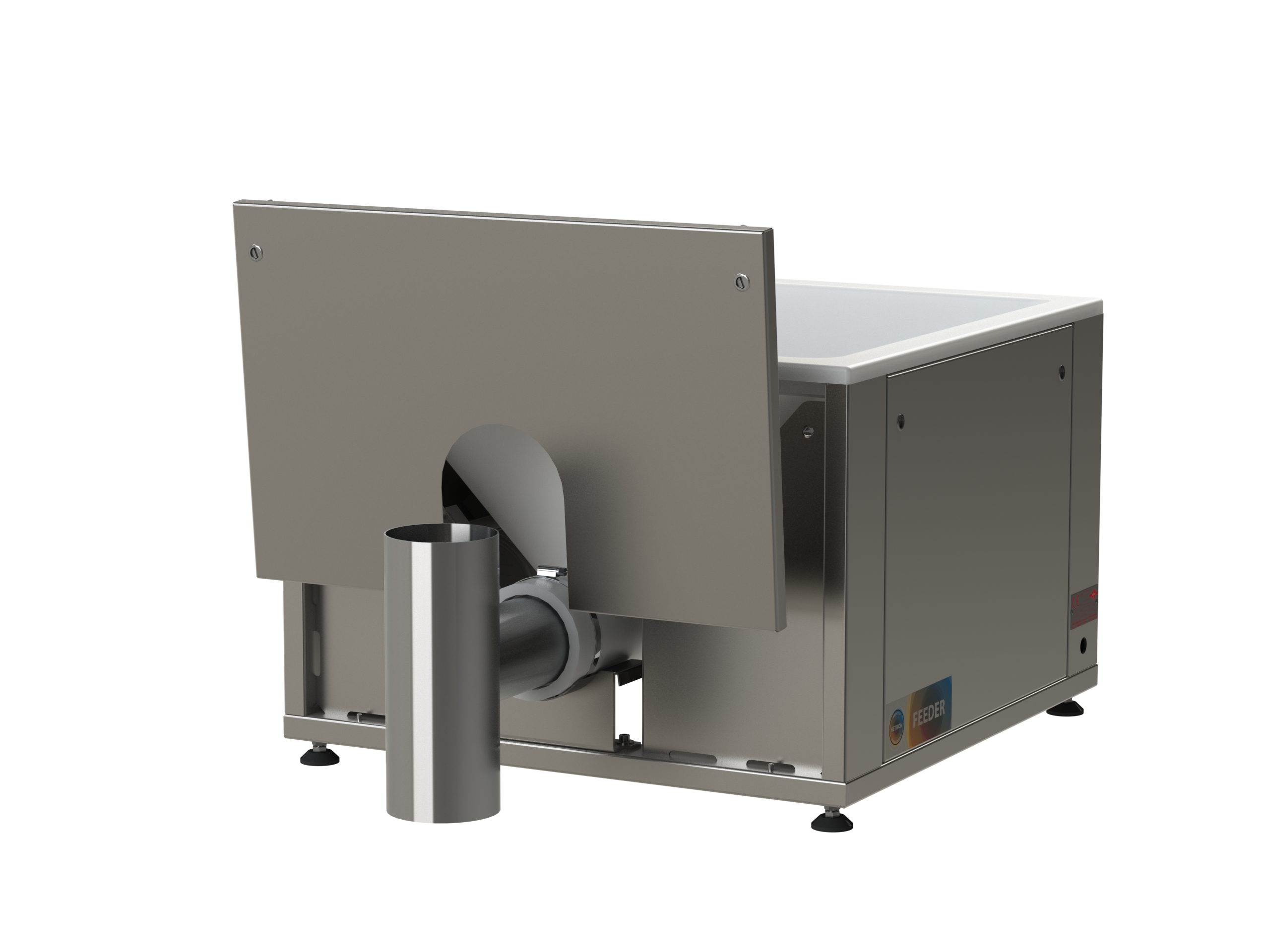

Continuous direct compression system for tablet production

Achieve seamless continuous direct compression by integrating...

High-capacity tablet press for pharmaceutical production

Achieve precise compression and consistent tablet density with a...

Industrial tablet press for high output production

Achieve precise control and efficient production with advanced rotary ...

High performance tablet press for large batches

For manufacturers aiming to boost tablet production without sacrificing pr...

Tablet coating solution

Achieve precise tablet coating with uniformity and efficiency, tailored for diverse tablet types, ens...

GMP automatic tablet hardness tester

Ensure precise control over tablet quality with a fully automated tester that seamless...

Tablet hardness tester

Ensure consistent tablet quality by precisely measuring hardness, thickness, diameter, and weight with...

Tablet hardness and combination tester

Ensure consistent tablet hardness and precision across multiple parameters with this...

Tablet hardness tester for pharmaceutical quality control

Ensure precise tablet hardness measurement to enhance pharmace...

Polishing drum for coated tablets

Enhance the surface quality of coated tablets with this polishing drum, perfect for achie...

Automated calibration tool for tablet hardness testers

Streamline your tablet hardness testing with a tool that automates...

pharmaceutical-tablet hardness testing system

Ensure consistent tablet quality and compliance with pharmacopeia standards ...

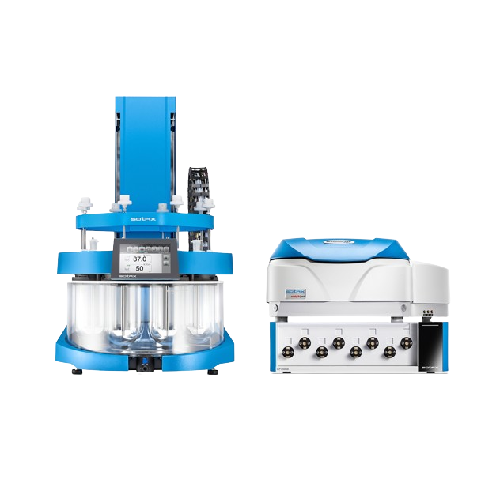

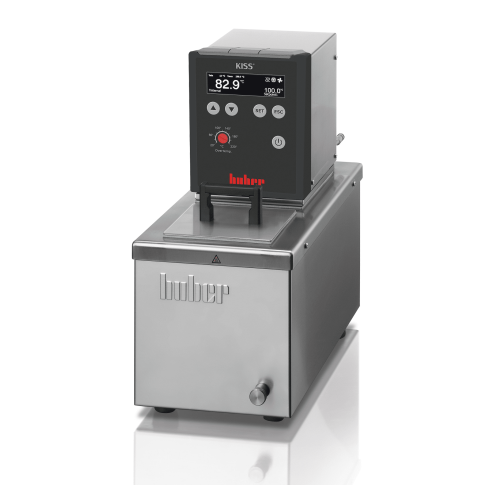

Automated disintegration tester for tablets

Efficiently determine tablet disintegration times with advanced waterbath tech...

Laboratory fluid-bed dryer and tablet coater

Experience seamless transition from laboratory to production scale with a ver...

Linear tablet and capsule counter

Ensure precise and efficient bottle filling with a cutting-edge counting system that guar...

Integrated bottling center for pharmaceutical tablets and capsules

Enhance your production line with versatile bottling...

Mini laboratory mixer for tabletops

Optimize your lab’s mixing precision with this compact tabletop bin mixer, design...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Counting system for tablets and capsules

Effortlessly count a variety of tablets, capsules, and dragées with precision, ens...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

High-speed strip packaging for tablets and capsules

Optimize your high-speed pouching operations with precise four-side s...

High speed strip packaging for tablets and capsules

Ensure precise packaging of pharmaceutical tablets and capsules with ...

Small batch tablet and pellet coating solution

Optimize your small batch coating and drying processes with a versatile ben...

Tablet press for multi-layer and dry-coated tablets

Optimize your tablet production with high-speed multi-layer pressing ...

Tablet coating system for pharmaceuticals and supplements

Enhance tablet coating efficiency with flexible, replaceable p...

Efficient blister packing for pharmaceutical tablets

Streamline your production with a blister packing machine that enhan...

Single rotary tablet press for small and medium-batch production

Optimize your tablet production with precision compress...

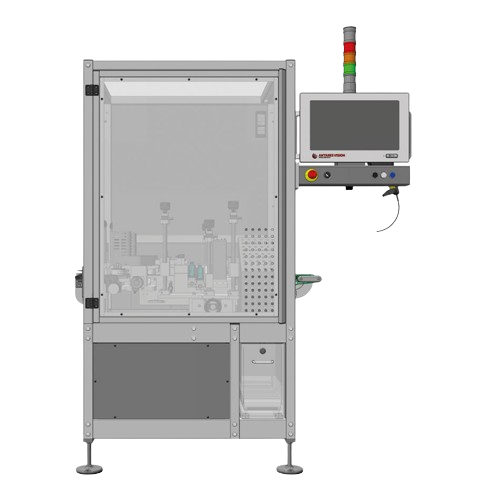

Tablet and capsule visual inspection system

Achieve unparalleled precision in tablet and capsule inspection with a high-sp...

Tablet coating for r&d and small-scale production

Achieve precise, efficient tablet coating with a compact, versatile mac...

Containment tablet coater for high-potency drugs

Ensure operator safety while achieving precise tablet coating on high-pot...

Tablet coating system for high-capacity operations

Streamline your tablet production with a coater that maximizes through...

Tablet coater for batch sizes up to 250 liters

Enhance your tablet production process with high-speed coating solutions de...

Containment tablet coater for high-potency pharmaceuticals

Ensure operator safety and maintain stringent OEB 4 complianc...

Double rotary press for high-volume tablet compression

Achieve high-speed, precision tablet compression with a machine th...

Single rotary tablet press

Streamline your tablet production with enhanced efficiency and precision, ensuring consistent tab...

Tabletop blister packaging for clinical trials

For R&D facilities conducting clinical trials or feasibility studies, ...

Rotary blister packaging for tablets and capsules

Optimize your blister packaging with high-performance rotary forming an...

Metal contamination detection for tablets and capsules

Ensure product integrity by detecting and separating metal particl...

Next generation tablet compression unit

Meet the demands of modern tablet production with advanced modular design, ensuring...

High-output tablet press for pharmaceutical production

Achieve high-speed, continuous production of precise and consisten...

Rotary tablet press for pharmaceutical industries

Optimize your tablet production with swift format changeovers and bi-la...

Rotary tablet press for small to medium scale production

Optimize your tablet production with a versatile rotary press, o...

Pharmaceutical tablet coating system

Achieve precise and efficient coating of pharmaceutical tablets to enhance product sta...

Rotary tablet press for abrasive powders

Achieve precise tablet sizing and bilayer production, even with abrasive powders, ...

Heavy-duty tablet press for single & double-layer tablets

Maximize your tablet production with a high-speed solution cap...

Rotary tablet press for large volume industrial tablets

Optimize your high-volume tablet production with a fully automati...

Double-sized bi-layer tablet press

Achieve high-volume production with precision using a double-sized bi-layer tablet press...

Tablet compression module for high containment applications

Quickly switch between tablet batches without compromising s...

Medium-volume rotary tablet press for pharmaceuticals

Optimize tablet production with high-throughput and rapid changeove...

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying des...

Calendering solution for laboratory production of films, tapes, and tablets

When rapid production of high-quality film...

Pharmaceutical metal detector for tablet presses and capsule filling

Detect and eliminate metal contaminants in high-sp...

Tablet compression technology for pharmaceutical production

Enhance your production capabilities with advanced tablet co...

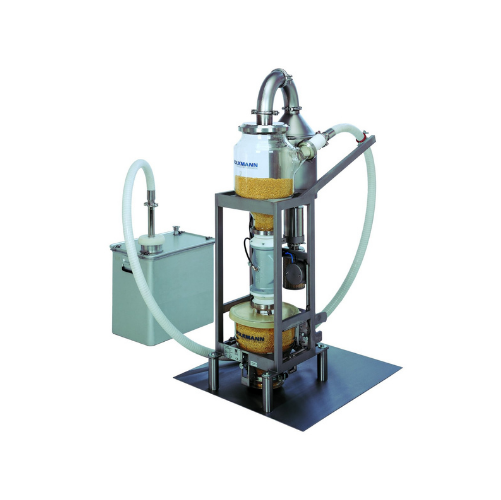

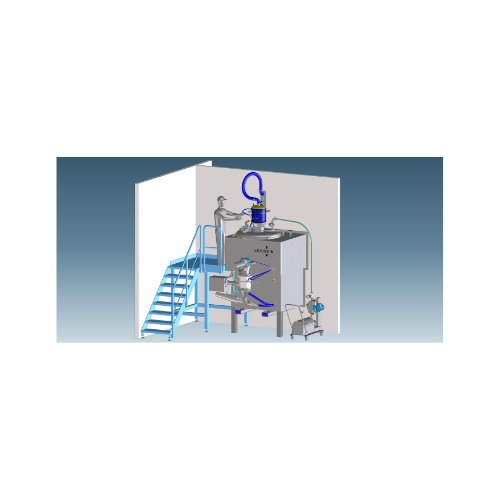

Wet granulation system for pharmaceutical tablets

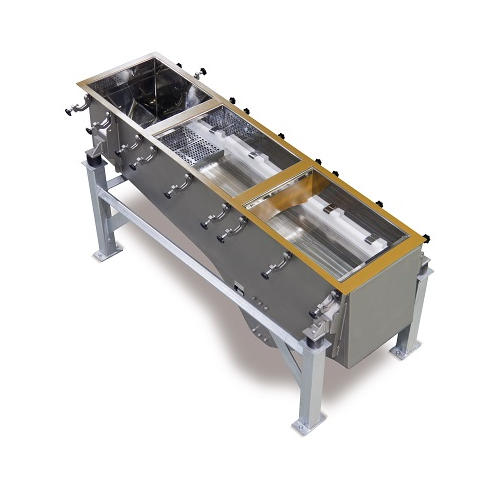

Optimize your tablet production with precise particle size reduction an...

Tablet de-dusting system for pharmaceuticals

Ensure the highest quality of your tablets by effectively removing excess pow...

Tablet coating system

Achieve precise and uniform coating on pharmaceutical tablets with this scalable system, designed for o...

Online tablet counter inspection system

Ensure product integrity by precisely inspecting and rejecting defective tablets an...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

Bathless disintegration apparatus for tablet and capsule testing

Achieve rapid and precise disintegration testing of tab...

Manual tablet disintegration tester

Ensure precise and reliable disintegration testing of pharmaceutical tablets, capsules,...

Tablet friability tester

Ensure your tablets meet rigorous quality standards by accurately measuring friability and abrasion,...

Multi-parameter tablet hardness tester for laboratories

Optimize your tablet production line with a versatile tester that...

Automatic counting and capping system for tablets and capsules

Ensure precise tablet and capsule counting and seamless c...

Grain dispenser for decoration of chocolate tablets

Elevate your confectionery with precise grain decoration, enhancing t...

H-track ink printing solution for tablets and capsules

Ensure precise ink printing on tablets and capsules with high-spee...

Flatbed laser drilling for tablet manufacturing

Optimize your tablet production with high-speed laser drilling, ensuring p...

Uv laser writer for tablets and capsules

Achieve precise laser marking on tablets and capsules with high-speed production, ...

High-speed tablet ink printer

Achieve precise and high-speed printing on tablets and capsules for streamlined production and...

High-speed tablet laser drilling system

Achieve precise, high-speed drilling of solid dosage forms with a system capable of...

Uv laser writer for high-speed tablet marking

Achieve precise and rapid marking of pharmaceutical and nutraceutical tablet...

Lab laser drilling for tablet manufacturing

Achieve precise drilling in pharmaceutical tablets with advanced laser detecti...

Tablet and capsule ink print and laser marking system

Streamline tablet and capsule identification with a high-speed syst...

Tablet and capsule ink printer

Achieve precise and high-speed printing on tablets and capsules, ensuring clear product ident...

Precision laser drilling for osmotic controlled release tablets

Enhance tablet precision and control drug release with h...

Uv laser marker for tablets and capsules

Achieve precise laser marking on tablets and capsules at high speeds while maintai...

Tablet and capsule ink printing and laser writing solution

Maximize efficiency in marking and coding with a high-speed s...

Energy-efficient film coating machine for pharmaceutical tablets

Tablet coating involves applying a thin layer of coatin...

Pharmaceutical tablet coating machine

Tablet coating requires spraying, mixing, and drying procedures that must be carried ...

Vision inspection system for tablets and capsules

Pharmaceuticals and healthcare product manufacturers dealing with oral ...

Inspection system for tablets chemical composition

The packaging of pharmaceuticals and oral solid products such as table...

Eccentric press for refill tablets

Hundreds of different refill tablets, of various shapes or sizes, are on the market toda...

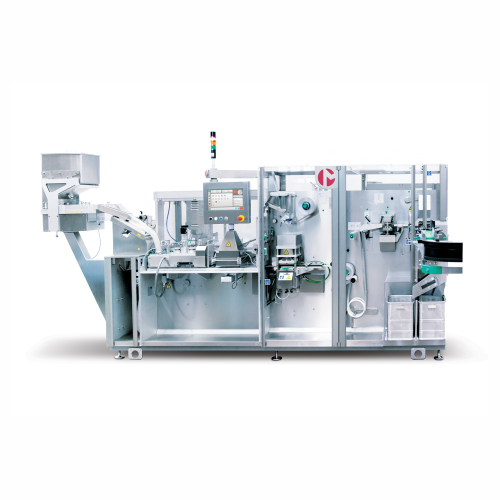

Automatic medical forming and sealing blister machine for packing capsules and tablets

Product safety is very importa...

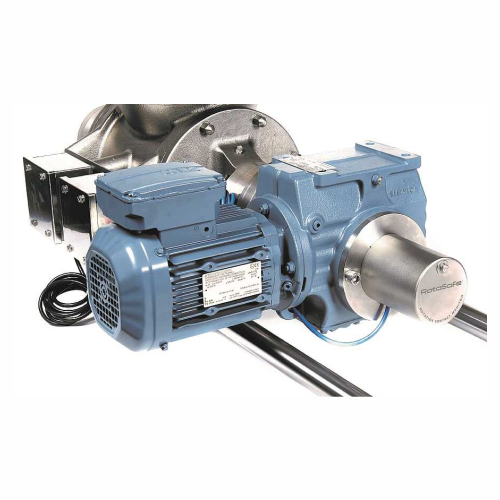

Lifter and De-duster for Tablets

The use of several different tools for lifting, de-dusting, and polishing in the pharmaceut...

High Speed Visual Inspection System for Tablets

In order to ensure quality and standard specifications of tablets, capsule...

Industrial scale tablet coater

During the coating process, tablets pass many stages that can make them wet and sticky or cra...

Tablet coater for laboratory scale

Tablet coating can be applied for adding colours or glosses, or based around sugar in or...

Tablet counting machine

Production of pharmaceutical solid dosage forms usually require complete accuracy, flexibility, and c...

High Speed Double-Sided Tablet Press

To achieve as much as double the output of single-sided tablet press, the upper and lo...

Laboratory Tablet Press

Pharmaceutical research and development projects may require small samples of high quality tablets fo...

High Speed Tablet Press

High speed pharmaceutical tablet presses convert powder to tablets. The operations should be quick an...

High Speed Containment Tablet Press

High speed containment presses make pharmaceutical tablets in closed environments with ...

Metal detector for tablets and capsules

Identification of metallic contaminants is a vital part of pharmaceutical quality c...

Dust-tight metal detector for tablets

For FDA-compliant production of tablets, the elimination of airborne dust containing ...

Wash-in-Place metal detector for tablets

Where hygiene and decontamination are vital, traditional pharmaceutical metal dete...

Benchtop tablet press

For lab work or small-scale production, a purpose-designed tablet press that meets your exact requireme...

Economic tablet press

Successful pharmaceutical manufacturers know that high quality, reliable equipment is essential in orde...

Single rotary tablet press

Creating batches of consistent high quality pharmaceutical grade tablets from your powdered ingre...

Automatic tablet coater for lab scale

The ability to coat tablets in an even and controlled way is an important stage in th...

Tablet auto coater for lab scale

Many pharmaceutical doses in tablet form require a coating before they are ready for use. T...

Single and double layer tablet press

High performance tablet presses that are capable of producing both single and double-l...

Lab scale single layer tablet press

Automated pressing of tablets saves time and improves quality. In R&D or laboratory...

Single layer tablet press

High performance tablet presses for the modern production environment need to be fast, accurate an...

Rotary tablet press

For pharmaceutical tablet producers looking to reduce waste, costs and increase production volume, a hig...

Waste minimization weight sorter for tablets & capsules

For medium scale production, you can improve line efficiency and ...

High capacity weight sorter for tablets & capsules

By employing a weight sorter that is fully flexible and able to ha...

Benchtop weight sorter for tablets & capsules

For laboratory pharmaceutical R&D work or use in clinical trials, a...

Versatile weight sorter for tablets & capsules

Saving costs and improved production efficiencies are possible by opti...

R&D electronic counter for capsules and tablets

This machine has been designed to offer an ever-precise and reliable count...

Strip packaging machine for effervescent tablets

Pack your effervescent tablets with extreme precision and care at a speed...

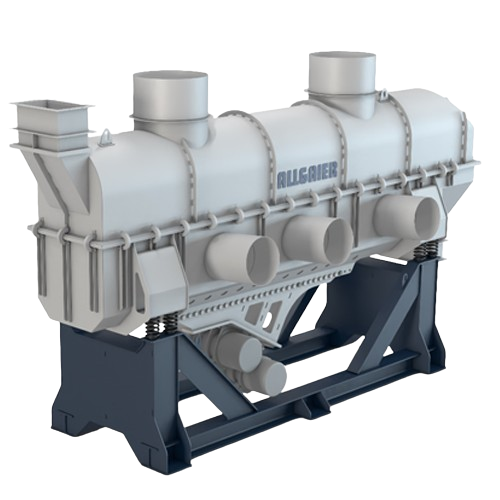

Vibratory sieve shaker for particle size determination

Achieve precise particle size analysis with rapid, reproducible re...

Sample dividing solutions for laboratory applications

Streamline your lab’s precision in sample preparation with so...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

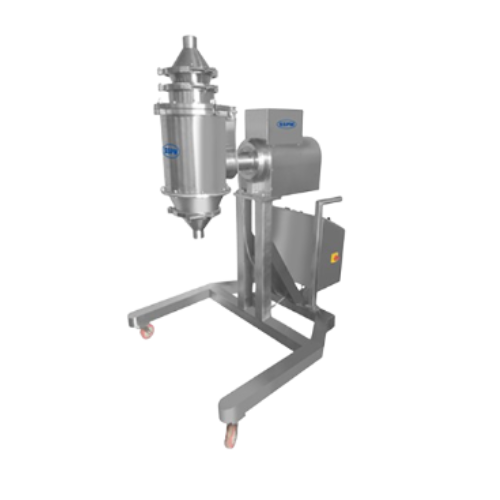

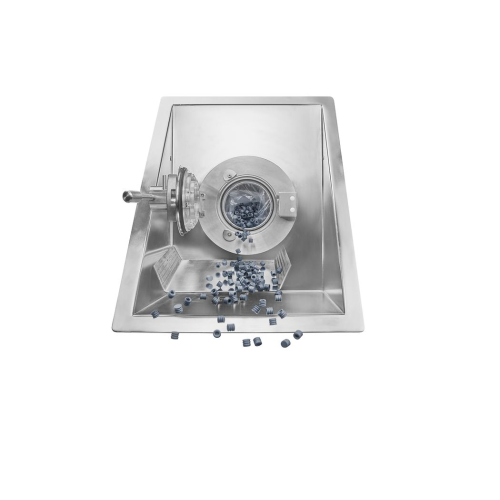

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Atex compliant milling equipment for explosive atmospheres

Ensure operator safety and process integrity with milling equ...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Precise dosing technology for praline and chocolate production

Streamline the production of pralines, chocolate bars, an...

Buttercream filling applicator for chocolates

Enhance your confectionery process with precision dosing and moulding to cre...

Dosing system for kügel chocolate moulds

Automate your chocolate production with precision dosing, seamlessly integrating m...

Chocolate filling application system for manons

Efficiently apply a variety of fillings, from delicate buttercream to rich...

In vitro dissolution and flux measurement platform

Optimize drug formulation by accurately assessing dissolution, solubil...

Flow through dissolution system for drug products

Capture real-time dissolution behavior with high-resolution imaging, pr...

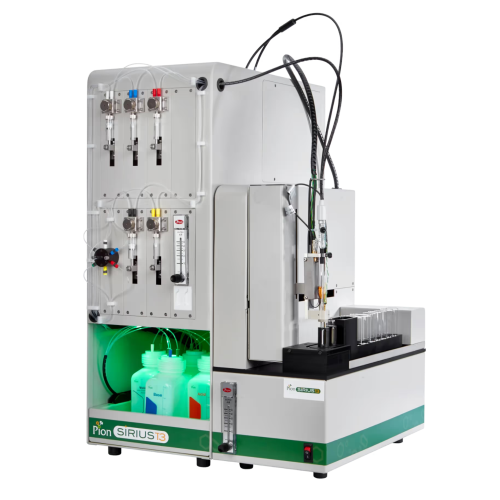

Automated platform for determination of physicochemical properties

Optimize your compound screening process with a full...

In-vitro dissolution-absorption assessment

Optimize drug formulation tests by combining dissolution and absorption measure...

Uv monitoring system for small volume dissolution studies

Efficiently monitor small-volume dissolution processes in real...

Case packer for pharmaceutical and healthcare products

Streamline your packaging line with a versatile case packer design...

Intermediate bulk containers for powder and materials handling

Optimize your material handling processes with containers...

Blister thermoforming for Pvc/alu

Effortlessly mold and seal blister packs for a range of solid products, optimizing packag...

Compact strip packaging for solid products

Efficiently package a variety of solid pharmaceutical products with precision a...

Strip packing for solid products

Ensure consistent quality and precision in packaging solid products with this advanced stri...

Electronic counting and filling system for vials

Efficiently streamline the packaging of solid dosage forms with a cutting...

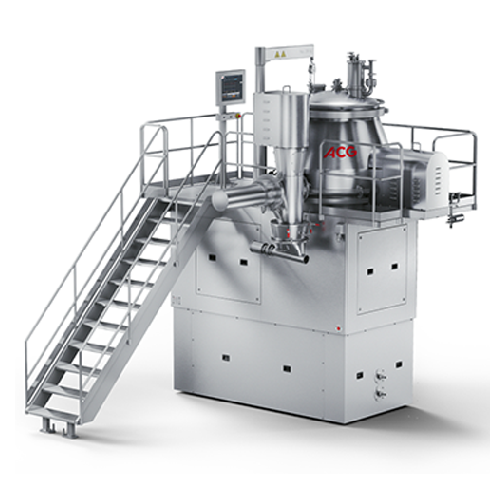

Mixing granulator for pharmaceutical and cosmetic industries

Achieve precise granulation and uniform mixing for high-qua...

Film coater for Otc and food supplements

Achieve optimal film coating for tablets and capsules with precision-engineered so...

Industrial twin screw extruders for high torque and volume applications

Optimize your extrusion processes with high tor...

High torque and volume twin screw extruder

Maximize processing adaptability and efficiency across diverse applications wit...

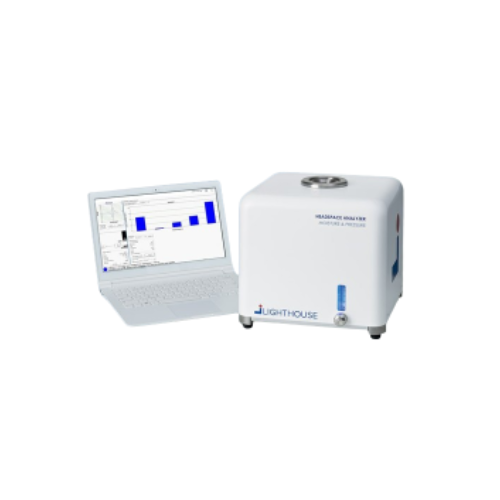

Water activity headspace analyzer for drug product samples

Ensure precise control of moisture levels across the entire p...

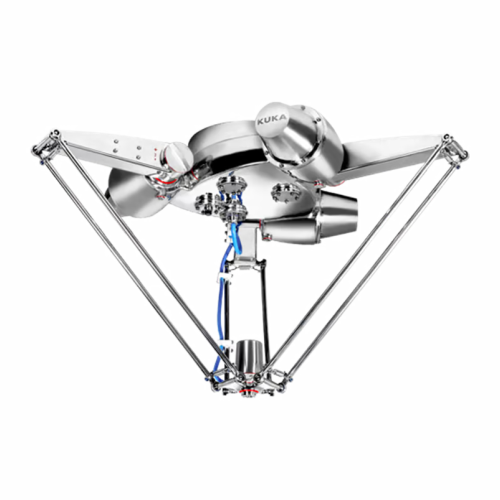

Hygienic design robot for food industry

Optimize your production line with a high-speed, hygienic design robot engineered f...

Capsule polisher for pharmaceutical production

Enhance capsule quality and safety by effectively polishing, dedusting, and...

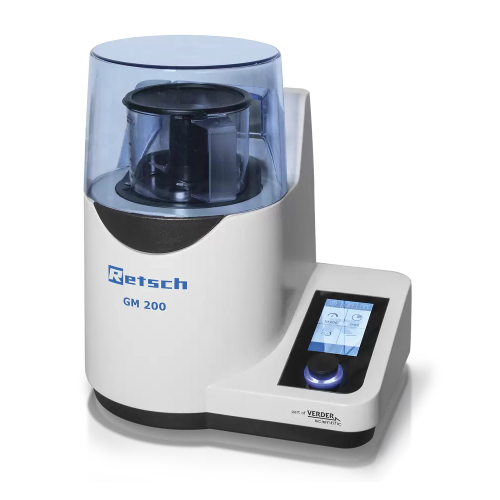

Laboratory mill for dry sample preparation

Achieve precise particle size reduction for pharmaceuticals and fine chemicals ...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

Vertical intermittent motion stick packaging

Experience seamless packing for diverse products, from powders to dense paste...

Medium speed blister packaging solution for pharmaceuticals

Optimize medium-speed tablet blister packaging with seamless...

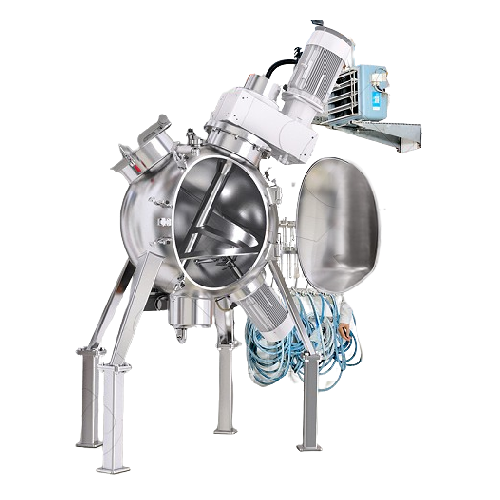

Single-pot granulation processor for pharmaceutical applications

For manufacturers needing precise granulation and dryin...

Fluid bed and coating system for small batch processing

Streamline your R&D process with a modular system that ensur...

Precision weight-checking for pharmaceutical capsules

Ensure exact capsule and tablet dosage with high-speed precision we...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Fluid bed processor for pharmaceutical granulation and drying

Achieve precise drying, granulation, and coating of pharma...

Blister packaging solution for small-medium batches

Achieve unparalleled versatility and efficiency in blister packaging ...

Lifting column for drums and containers

Streamline your production with lifting columns designed for precise handling, blen...

Blister packaging solution for small/medium batches

Achieve high production efficiency with frequent changeovers for your...

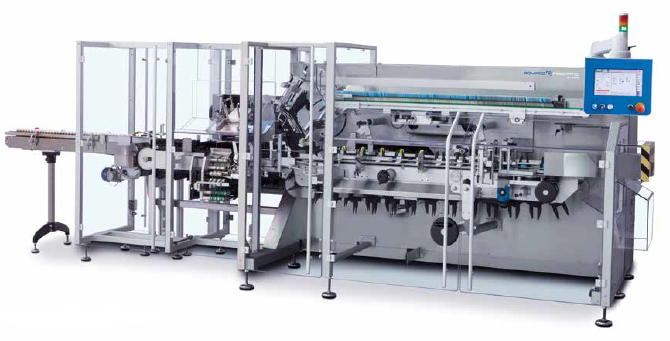

High-speed blister packaging with integrated cartoner

Optimize your blister packaging process with a solution that seamle...

High-speed blister packaging with integrated cartoning

Achieve unmatched efficiency in blister packaging with seamless in...

Thermoforming solution for clinical trials

Designed for precision and flexibility, this compact thermoforming machine stre...

Pressed soup cube bottom fold wrapper

Optimize your packaging line with high-speed wrapping machines designed for precision...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

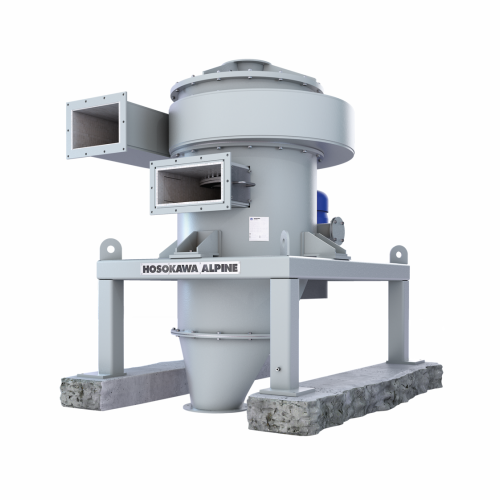

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Mid-capacity film coating solution

Enhance your seed coating and biofuel pellet production with a customizable turn-key sol...

Pharmaceutical metal detectors

Ensure product purity by detecting and eliminating metal contaminants in pharmaceuticals, enh...

High-viscosity continuous industrial kneader for small volumes

Achieve consistent high-viscosity material processing wit...

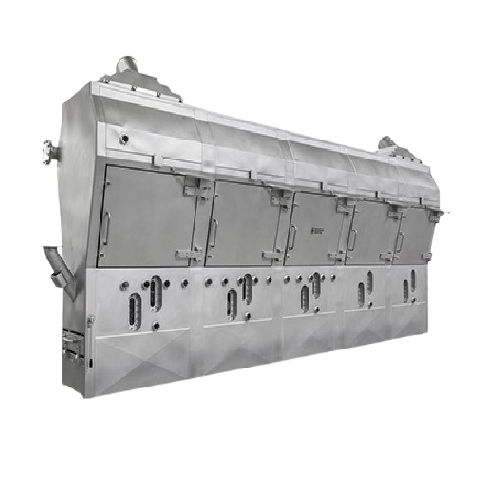

Continuous dryer for large production volumes

Achieve high-speed moisture removal with precision and minimal thermal impac...

Batch drying system for food, pet feed, pharmaceuticals, and more

Optimize your drying needs with precision control for...

Continuous tunnel dryer for food products

Achieve precise moisture removal with adaptable drying technology, ensuring your...

High-performance cartoning system for pharmaceutical products

Optimize your packaging line with a flexible cartoning sol...

Powder dosing for lab and galenics

Ideal for precise dosing needs, this compact lab device streamlines powder filling proce...

High-containment capsule dosing and filling system

Achieve precise dosing and optimal containment for pharmaceutical prod...

Containment capsule filling system for lab and small batch production

Designed to ensure maximum safety in pharmaceutic...

Versatile capsule filler for pharmaceuticals

Effortlessly switch between powder, pellet, and liquid dosing with this adapt...

Ultra-hygienic vacuum conveyor for pharmaceutical industry

Optimize powder transfer with ultra-hygienic vacuum conveying...

Single-color inline digital printer for blister-lidding foils

Streamline your pharmaceutical packaging with precision pr...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Powder flow control system for gravity transfer

Ensure precise dosing and prevent spillage during powder transfers in your...

Waste powder recovery cyclone for pharmaceutical processes

Efficiently recover up to 99.9% of waste powder from oral sol...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

Hygienic vacuum conveyor for pharmaceutical and food industries

Optimize your material handling process with a vacuum co...

High-accuracy rotary dosing valve for fine material feeding

Ensure precise dosage of fine powders and granules, enhancin...

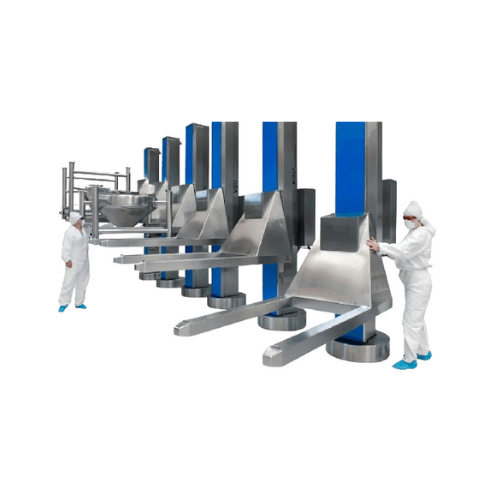

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Pharmaceutical size reduction shredder

Achieve fast, efficient material size reduction with this shredder, enabling seamles...

Ibc tumbler for uniform batch mixing

Achieve consistent and homogenous mixing of powders, granules, and solid products with...

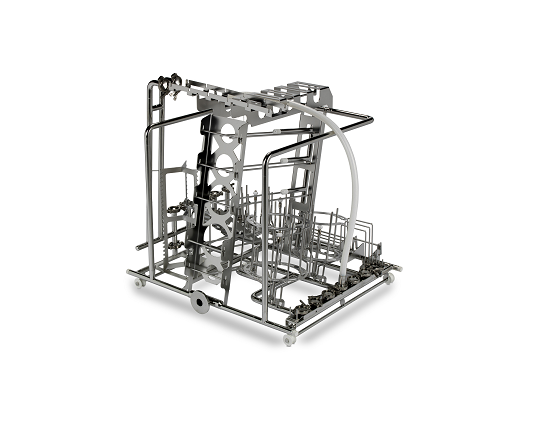

High-capacity cgmp washer/dryer for cleanrooms

Optimize your cleanroom operations with this compact washer/dryer, designed...

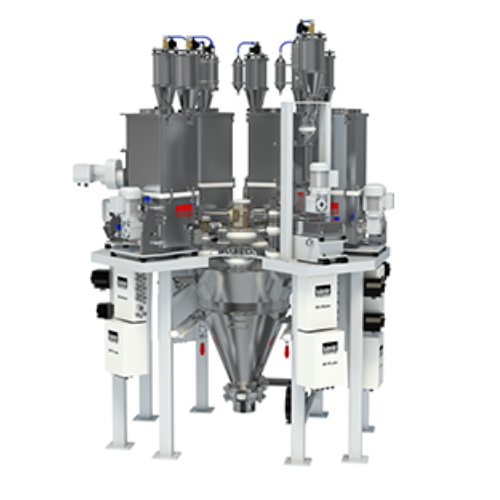

Gravimetric feeders for pharmaceutical applications

Ensure precise ingredient metering in continuous pharmaceutical proce...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Continuous mixer for homogeneous blending

Achieve consistent product quality with precise mixing and blending, ideal for a...

Continuous powder mixer for industrial applications

Achieve precise and efficient integration of powders, granules, and l...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

Laboratory film coating system for development and clinical batches

Achieve precision in tablet coating with a versatil...

Laboratory and pilot scale pan coater

Maximize coating efficiency in tablet production with this advanced pan coater, offer...

High shear granulator for wet granulation of powders

Achieve consistent granule density and size with a high shear granul...

High shear lab granulation system for powder processing

Achieve precise granulation and consistent mixing of powders with...

Mini High shear granulator for wet granulation

Optimize your powder granulation with precision and flexibility, ensuring c...

High shear wet granulation line

Achieve consistent and uniform granules with energy-efficient wet granulation designed to op...

Pilot Gmp spray dryer system for small-scale manufacturing

For precise control in spray drying, streamline your small-sc...

Laboratory fluid bed system for solvent processing

Optimize your laboratory scale operations with a versatile fluid bed s...

Fluid bed granulator for industrial granulation

Optimize your production efficiency with versatile fluid bed granulation, ...

Fluid bed system for granulation and coating

Optimize your production with a multi-purpose fluid bed system designed for e...

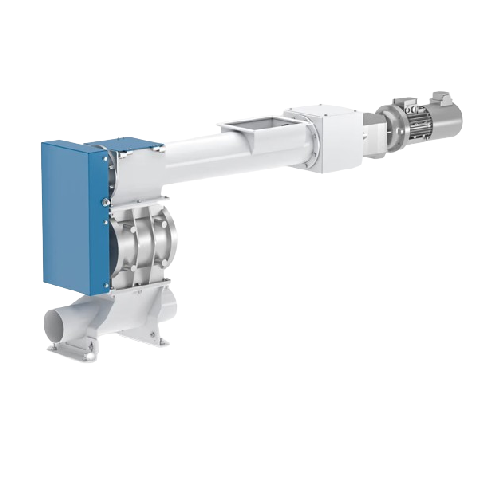

Dry granulation system for powder compaction

Achieve consistent sheet hardness and increased density in powdered materials...

High shear wet granulation system

Experience efficient wet granulation with precise control over granule density and moistu...

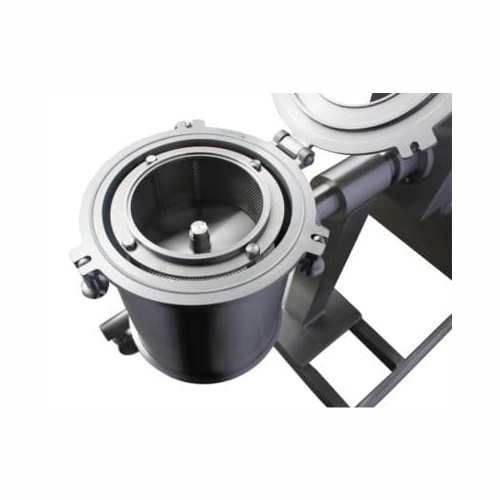

Centrifugal sifter for particle size classification

Achieve precise particle size control with high output efficiency, en...

Pharmaceutical powders and granules dry blending

Achieve uniform blending of diverse powder and granule formulations with ...

Development fluid bed system for feasibility studies

Explore precise granulation and coating capabilities for small batch...

Fluid bed processor for granulation and coating

Fluid bed processors offer efficient granulation and coating, streamlining...

High shear mixer granulator for efficient wet granulation

Achieve consistent and precise granule formation with high she...

Particle sizer for precise sifting

Optimize your production line with high-speed particle sizing, ensuring precise control ...

Pharmaceutical powder blender

Ensure uniform mixing of pharmaceutical powders and granules with advanced blenders designed f...

Tumbling cube mixer for homogeneous blending

Achieve uniform blending with precision using a cube mixer that enhances mixi...

Double cone mixer for free flowing powders and granules

Achieve uniform blending of powders and granules with precision, ...

Drum hoop mixer for uniform three-dimensional mixing

Achieve consistent, homogenous mixing of powders and granules with a...

Laboratory high speed mixer for powders and granules

Achieve homogenous blending of powders and granules efficiently with...

Blister packaging leak tester

Ensure airtight integrity in your blister packaging with precise vacuum and dye penetration te...

Advanced friability and abrasion testing solution

Ensure precise compliance in pharmaceutical tablet testing with this in...

Tapped density tester for pharmaceutical and chemical powders

Ensure precise density measurements for pharmaceuticals an...

Wet granulator for pharmaceutical applications

Achieve precise granule consistency with advanced oscillating rotor technol...

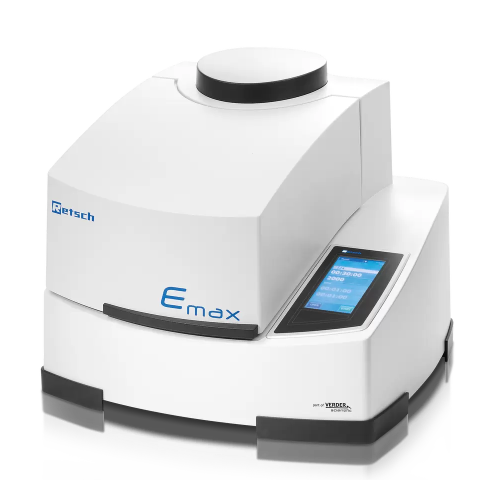

Lab-scale ball mill for crystalline material grinding

Effortlessly grind and mix crystalline materials into fine powders ...

Conical mill for particle size reduction and homogenization

Achieve precise particle size reduction and homogenization w...

Manual disintegration testing for pharmaceuticals

Ensure precise disintegration testing of pharmaceuticals with a compact...

Apparent bulk density tester for granules and powders

Ensure accurate formulation by determining the apparent bulk densit...

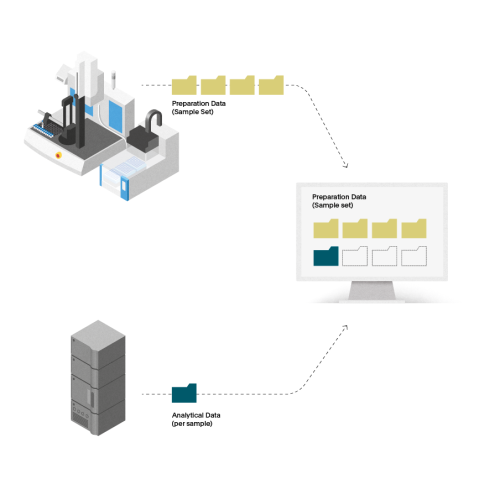

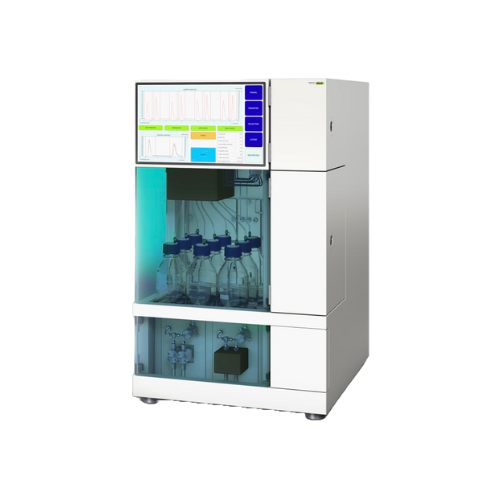

Dissolution testing system with Hplc analysis

Streamline your dissolution testing with integrated HPLC analysis, offering ...

Dissolution testing software for compliance and efficiency

Ensure data integrity and streamline compliance with a robust...

Digital dissolution tester for high volume testing

Optimize high-volume tablet and supplement testing with precise contro...

Automatic dissolution testing for sustained release dosage forms

Effortlessly simulate pH changes for accurate dissoluti...

Dissolution online system for automated Uv-vis analysis

Ensure precise dissolution testing and seamless UV/VIS analysis w...

High volume dissolution tester for pharmaceutical research

Achieve precise dissolution testing of tablets across two bat...

Intermittent stick pack machine for pharma and healthcare

Looking to streamline your packaging operations with high-spee...

High-shear mixer granulator for pharmaceutical production start-up

Effortlessly achieve optimal granule consistency and...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Pharmaceutical high-shear mixer granulator

Enhance your production efficiency with a high-shear mixer granulator, designed...

Pilot single-pot processor for granulation and drying

For efficient pilot production, streamline your mixing, granulating...

Versatile entry-level mixer granulator

Solve complex mixing and granulating challenges with this compact solution, offering...

Laboratory granulator and coating system

Optimize your research with a versatile benchtop unit that combines fluid-bed proc...

Hygienic design dough mixer

Achieve superior dough consistency and safety with our hygienic design mixer, ideal for reducing...

Granulation line for pharmaceutical manufacturing

Enhance your batch production with integrated mixer and fluid-bed techn...

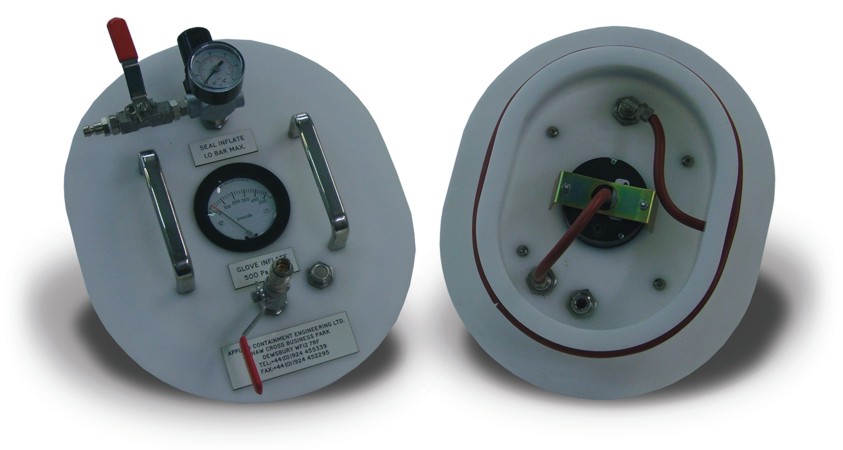

Containment solutions for pharmaceutical production

Enhance operator safety and product integrity with advanced containme...

Single-pot processor for wet granulation and vacuum drying

Achieve efficient mixing, granulation, and swift vacuum dryin...

Laboratory unit for mixing, granulating, and vacuum drying

Achieve precise mixing, granulating, and drying in laboratory...

Industrial dough feeding elevator tipper

Optimize your dough handling process with a robust elevator tipper designed for se...

Fluid bed processor for granulating, drying, and coating in pilot scale

When scaling from laboratory to production, rel...

Midilab for efficient laboratory-scale product development

Streamline your laboratory and pilot-scale production process...

Laboratory coater and fluid bed processor

Optimize your research and development with a versatile benchtop unit that integ...

Industrial elevator tipper for efficient material handling

Optimize your material handling process with a high-performan...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Powder blender for efficient mixing and discharge

Achieve precise mixing and efficient discharge with advanced powder ble...

Benchtop laboratory powder blender

Perfect for R&D labs needing precise, small-batch powder blending and mixing, this ...

Pharmaceutical bottle unscrambler

Streamline your pharmaceutical packaging process by efficiently sorting and aligning bott...

In-motion pharmaceutical bottle filler

Achieve up to 400 bottles per minute with this modular bottle filling solution, desi...

In-motion bottle filling system for pharmaceuticals

Boost your production efficiency with our high-speed bottle filling s...

Surge bins for material handling

Ensure efficient material flow and storage in your production line with surge bins that fea...

Centric pelletizer for direct extrusion

Effortlessly transform materials into uniform granules with our high-speed pelletiz...

Atex compliant isolator for dispensing powder procedures

Ensure safe weighing and transfer of explosive and pharmaceutica...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Vibratory collar for powder flow assistance

Struggling with sticky or poorly flowing powders during discharge? This vibrat...

Dust particulate extraction system

Ensure safe containment and minimize airborne particulates in your production line with ...

Mobile lifter solutions for pharmaceutical handling

Streamline your handling of sensitive materials with versatile mobile...

Lightweight plastic butterfly valve for industrial use

Achieve precise flow control and quick disassembly during pharmace...

Automatic docking system for bulk powder handling

Optimize docking precision and ensure seamless alignment in bulk powder...

Clean room oven for class 100 environments

Achieve precise temperature control and maintain particle integrity in critical...

High speed blister packaging for pharmaceutical industry

Ensure precision and speed in pharmaceutical packaging with a hi...

High speed blister packaging for pharmaceuticals

Need efficient packaging with quick format changeovers for various capsul...

Blister packaging for pharmaceutical products

Facilitate seamless packaging of pharmaceuticals with a solution designed to...

Slat-type counting solution for pharmaceutical applications

Ensure precise tablet counts and efficient packaging with th...

Analyze wet granulation properties for pharmaceutical formulation

Optimize your pharmaceutical and chemical formulation...

Lab scale mixer, extruder & spheronizer for r&d formulation

Optimize and streamline your research and development proces...

Flexible spheronization kit for wet granulation pellets

Achieve precise pellet and granule formation with a versatile ben...

Bench-top mixer and spheronizer for formulation development

Accelerate R&D success by seamlessly integrating mixing...

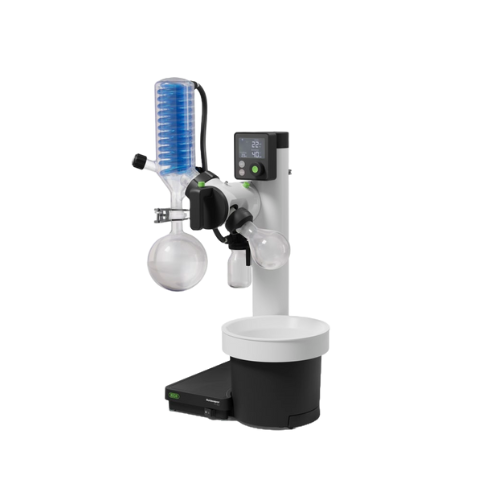

Industrial recirculating chiller for laboratory applications

For consistent distillation results, maintain accurate temp...

Flour handling plant for pasta production

Streamline your production with precision handling and processing of flour for p...

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Laboratory homogenizer for pharmaceutical and biotech applications

Achieve precise homogenization for your laboratory n...

Sampling unit for continuous sampling in industrial processes

The PRS sampling unit ensures precise and uncontaminated s...

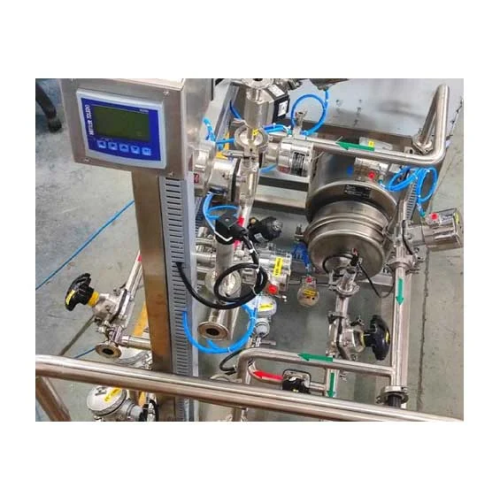

Cip system for process tanks

Ensure high-level cleanliness and compliance in your production line with an efficient in-place...

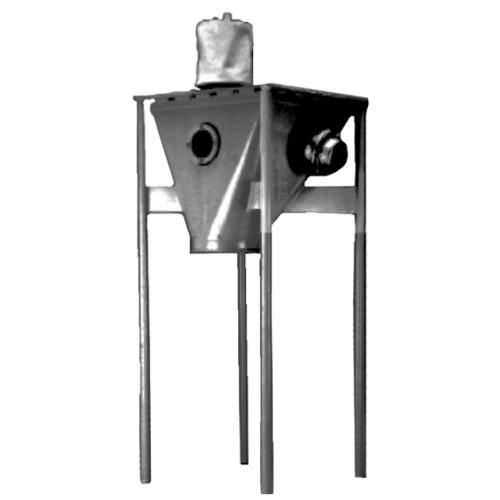

Precise dosing system for bulk materials

Ensure precise bulk material dosing with minimal dust, seamlessly switching betwee...

Accurate dosing for powder products

Ensure precise dosing and consistent flow of bulk powders in your production line to en...

Batch automation system for fast and precise weighing

Achieve unmatched precision and speed in batch processing with this...

Contamination-free docking system for bulk solids

Achieve contamination-free transfer of bulk powders and granules while ...

Flexible isolator for aseptic containment

Ensure sterility and safety with a flexible isolator designed for efficient cont...

Automatic visual inspection for sterile preparations

Ensure the integrity of sterile products with precise visual inspect...

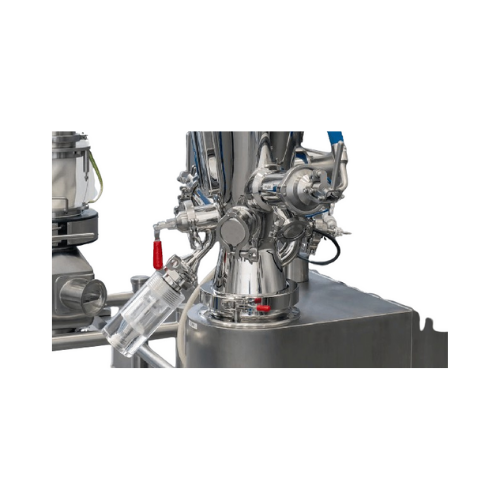

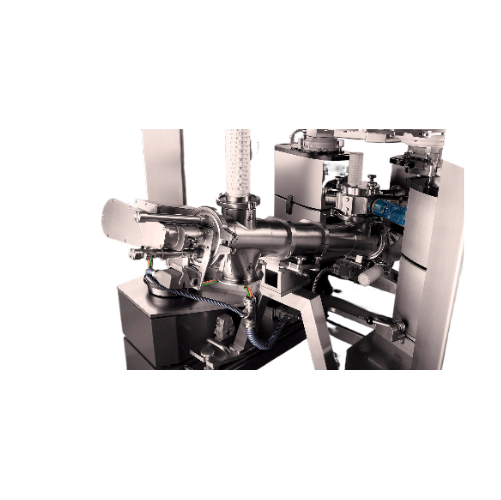

Continuous wet granulation equipment

Achieve optimal particle size and uniformity in pharmaceutical production with our con...

Microspheres process equipment for classification, washing, drying

Achieve high yield production of polymeric microsphe...

Integrated raw & auxiliary material pre-treatment system

Experience dust-free processing with an integrated system design...

High containment isolator for toxic and active drug handling

Ensure safe handling and environmental protection while pro...

Particle size control equipment for pharmaceutical applications

Achieve precise particle size control for diverse materi...

Wet granulating equipment for pharmaceutical industry

Enhance production efficiency and safety in high-potency pharmaceut...

Continuous wet granulation equipment

Optimize your production line with continuous wet granulation, seamlessly transforming...

Roller compactor for pharmaceutical and chemical industries

Optimize your powder processing with precision compaction an...

Pharmaceutical checkweigher for milligram-level accuracy

Ensure precision and compliance in your pharmaceutical packaging...

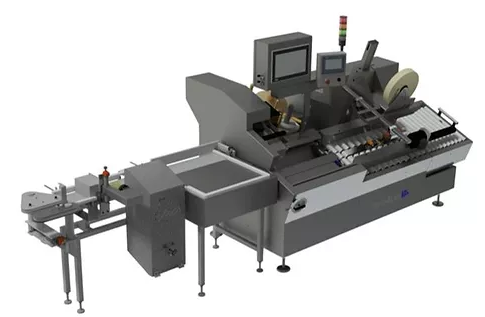

Serialization system for printing and verifying carton codes

Ensure accurate serialization with high-speed printing and ...

Checkweighers for medium and small products

Ensure precise weight control in high-speed production lines with advanced che...

Pillow bag horizontal form-fill-seal solution

Optimize production efficiency with seamless integration of continuous, high...

Vibration batch dryer for difficult solids

Ensure efficient drying of complex solids prone to sticking and shape irregular...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Fluidized bed dryer for industrial materials

Enhance product quality and energy efficiency with fluidized bed dryers, opti...

Pharmaceutical roller compactor for precise granulation

Achieve consistent and high-quality granulation with a solution t...

Pharmaceutical roller compactor for dry granulation

When precision and uniformity in tablet production are crucial, optim...

Dry granulation technology

Achieve precise control over particle size and density with our compacting and granulation soluti...

Moist granulation system for pharmaceutical and chemical industries

Transform powdered materials into uniform granules ...

Pharmaceutical roller compaction solution

Optimize your pharmaceutical tablet production with precision granulation and co...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Pharmaceutical roller compactor for granulation

Achieve precise granulation with streamlined compaction, ensuring consiste...

Bin blender for pharmaceutical powder mixing

Achieve uniform mixing and homogenization of dry powders directly in storage ...

Lifting column for plastic boxes in pharmaceutical processing

Optimize your tablet and powder processing by seamlessly l...

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

Vacuum transfer system with integrated cleaning

Ensure sterile powder handling and contamination-free production with vacu...

Analytical balance for precise laboratory measurements

Achieve unparalleled precision and reliability in your lab’s...

High-shear mixer granulator for small batches

Achieving consistent particle size and mix uniformity in pharmaceutical and ...

High-shear granulator for wet granulation

Achieve precise content uniformity with advanced high-shear granulation, designe...

Intermediate-scale fluid bed system for drying and granulation

Achieve precise drying and granulation with this versatil...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid-bed drying and granulation system

Optimize your production line with high-speed batch processing for efficiently dryi...

Fluid bed granulator for pharmaceutical applications

Optimize your granulation and drying processes with advanced fluid-b...

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear...

High-shear mixer for small batch granulation

Enhance your production efficiency with a high-shear mixer designed for preci...

Liquid filling system for hard capsules

Easily fill two-piece hard capsules with liquids, pastes, and suspensions with prec...

Containment capsule filler for highly potent drugs

Achieve complete operator safety while encapsulating potent pharmaceut...

Containment capsule filling system for highly potent drugs

Ensure operator safety while filling capsules with high-poten...

High-speed capsule filler for large batch production

Achieve higher yields and reduce powder waste with a capsule filling...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Fluid bed dryer with granulation and coating

Enhance your processing efficiency with a versatile system capable of combini...

Fluid bed combo for granulation and coating

Achieve seamless granulation and coating with batch and high-speed operations,...

Fluid bed combo for top-spray granulation and wurster coating

Optimize your batch processing with a versatile system cap...

Fluid bed combo for granulation and coating

Streamline your manufacturing with a versatile fluid bed combo, integrating gr...

Flat-forming blister packager for small production batches

Ideal for pharmaceutical and nutraceutical firms seeking effi...

Containment blister packaging for highly potent Apis

Ensure operator safety during the blister packaging of highly potent...

High-output blister packaging system

Maximize blister packaging efficiency with continuous-motion capabilities, ensuring su...

Blister packaging for solid dosage forms

Optimize your packaging line with high-speed, continuous blister packaging that en...

Capsule band sealer for liquid-filled hard capsules

Seamlessly seal liquid-filled hard capsules to enhance product integr...

Semi-automatic de-blistering solution for Pvc and alu blister packs

Streamline your packaging operations by swiftly rec...

Flat forming and sealing blister packaging solution

Enhance your blister packaging process with a solution that ensures p...

Flat-sealing continuous-motion blister packaging solution

Enhance your blister packaging with precise, high-speed sealin...

Desiccant inserter for pharmaceutical containers

Prevent product degradation by efficiently inserting desiccants into cont...

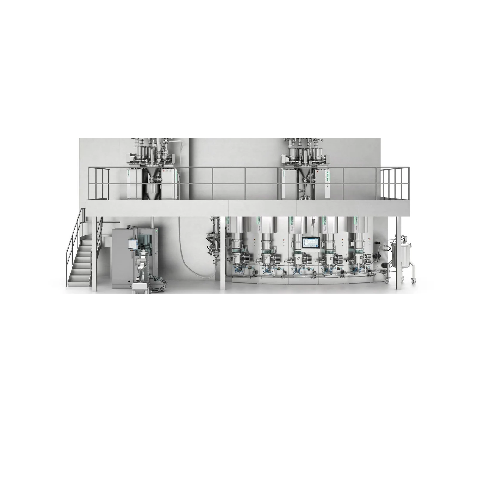

Continuous direct compression line for pharmaceuticals

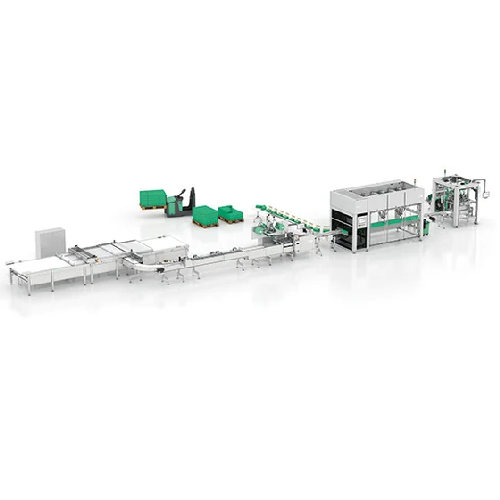

Optimize tablet production with a seamless system combining contin...

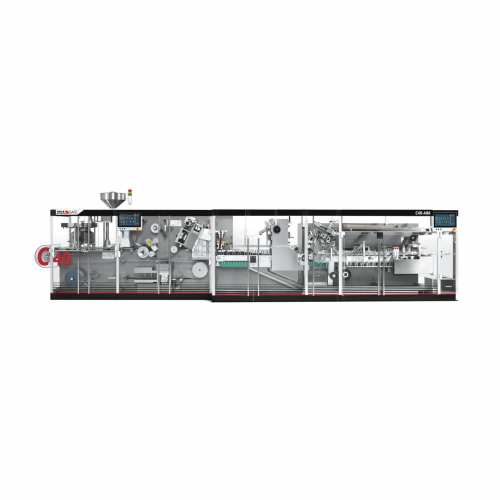

Continuous granulation and compression line for pharmaceuticals

Optimize your pharmaceutical production with a line that...

Pharmaceutical direct compression with linear blending

Streamline your pharmaceutical production with a continuous direct...

Disposable containment system for solid dosage material

Ensure safe and dust-free transfer of hazardous materials with ou...

Direct discharge descender for product handling

Efficiently transport granulated materials without compromising their inte...

Dense phase vacuum conveying system for powder handling

Effortlessly transport delicate powders and fragile granules with...

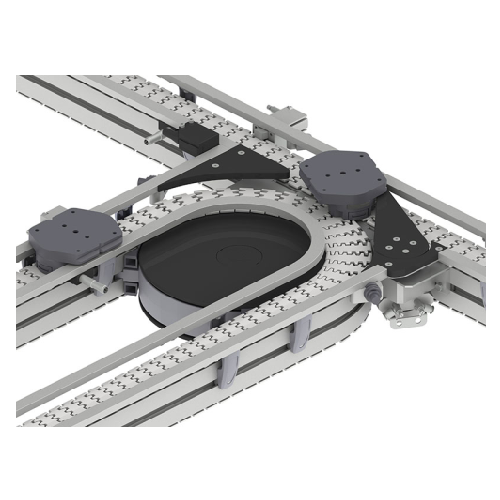

Circular distribution feeder for fragile product handling

Achieve precise dosing and reduced product damage with a versa...

Vibrating feeder for food and pharmaceutical industries

Optimize your production line with precision dosing and gentle ma...

Ibc post hoists for pharmaceutical manufacturing

Ensure precise material handling with advanced lifting solutions designed...

Contained powder sampling system

Ensure contamination-free sampling of active powders with fully contained system integratio...

Intermediate bulk container (ibc) blending for pharmaceutical manufacturing

Streamline your pharmaceutical blending pr...

Pharmaceutical intermediate bulk containers (ibc)

Streamline pharmaceutical production with precise containment and trans...

Continuous granulation and drying system for r&d

Develop precise pharmaceutical granules with this compact system, tailore...

Pharmaceutical r&d granulation system

Optimize your pharmaceutical research with a versatile small-scale granulation system...

Continuous granulation and drying system for pharma production

Achieve precise control over granule quality with a conti...

High shear granulator for pharmaceutical applications

Efficiently transform powders into uniform granules for consistent ...

Pharmaceutical bottom-drive high shear granulator

Achieve optimal granule uniformity and precise control over moisture le...

Integrated small-scale granulation and drying system

Ensure precise granule size and moisture control for enhanced tablet...

Integrated granulation and drying system for pharmaceuticals

Achieve seamless granulation and drying with our fully inte...

Powder feeding behavior characterization solution

Optimize your R&D with precise powder feeding behavior analysis, c...

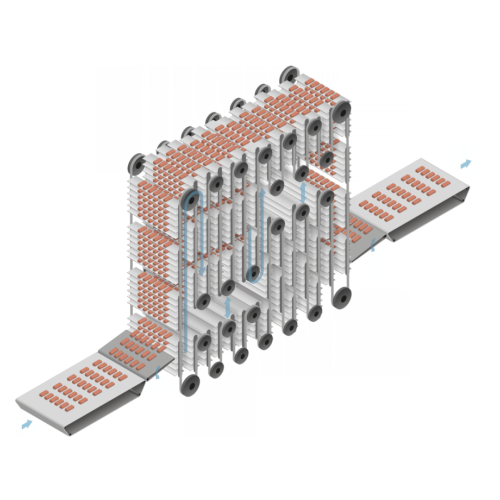

Variable retention time carton freezer

Optimize your production line with a flexible freezing solution that handles multipl...

Palletizer for high-speed pallet loading

Achieve efficient, high-speed palletizing with a system designed for seamless inte...

Fluid bed pellet coating solution

Achieve precise and uniform pellet coating with fluid bed technology for enhanced product...

Pharmaceutical low shear extruder

Optimize your pharmaceutical pellet production with precision-controlled extrusion, ensur...

Pharmaceutical fluid bed processor for r&d

Optimize your pharmaceutical R&D with a versatile fluid bed processor desi...

Single pot processor for granulation and drying

Streamline your pharmaceutical production with an integrated solution that...

Flexstream fluid bed processor for pharmaceutical applications

Addressing the limitations of traditional fluid bed proce...

Static fluid bed dryer for powder and granular materials

Achieve optimal moisture control in powder and granular products...

Fluid bed processing of pharmaceuticals

Enhance your pharmaceutical production with versatile fluid bed processors, enablin...

Pharmaceutical fluid bed r&d processing

Ensure precise formulation and consistency in pharmaceutical and nutraceutical tabl...

Cip for pharmaceutical process plants

Streamline your cleaning processes with integrated CIP systems to ensure precise and ...

Wash-off-line system for pharmaceutical plants

Optimize your production with a versatile wash-off-line system, ensuring pr...

X-ray inspection system for wet environments

Ensure unparalleled product inspection under extreme cleaning conditions with...

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Stainless steel tubular screw conveyor for bulk solids handling

Ensure precise material handling with stainless steel tu...

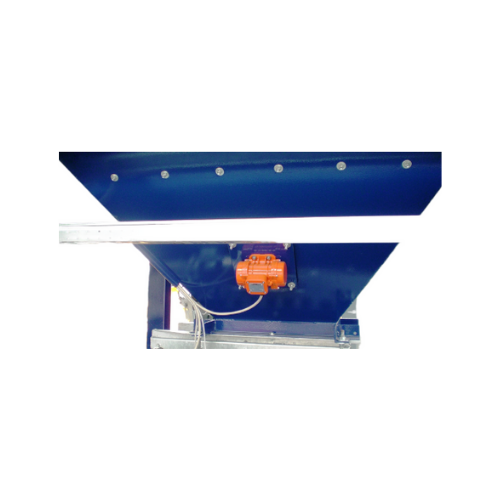

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Drum discharge system for bulk material handling

Achieve precise, gentle transfer of sensitive pharmaceuticals and granula...

Lump breaker for breaking agglomerates and lumps

Effortlessly break down challenging agglomerates and clumps to ensure smo...

Laboratory dedusting systems

Designed for high-containment lab environments, this solution efficiently captures and manages ...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Compact dust extractors for cleanroom applications

Ensure safe and efficient dust extraction in cleanroom environments wi...

Sachet packaging for pharmaceuticals

Streamline your pharmaceutical packaging with high-precision sachet solutions, ensurin...

Stick pack packaging for pharmaceutical products

Enhance your production efficiency with compact stick pack solutions, off...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Stick pack packaging line for pharmaceuticals

Optimize your pharmaceutical production with stick pack packaging lines that...

Cartoning solution for pharmaceutical products

Ensure accurate and efficient packaging of pharmaceutical products with pre...

Gmp contact part washers for pharmaceutical industry

Ensure product integrity and hygiene with specialized washing system...

Sterilizing and depyrogenization tunnel for ampoules

Ensure sterile and pyrogen-free ampoules with precision control in d...

Oral liquid bottle filling & capping system

Streamline your liquid manufacturing processes with precise filling and secure...

Twin-screw extruder for high containment applications

Achieve precise mixing of sensitive compounds with a twin-screw ext...

Table top extruder for customizable extrusion processes

Discover versatile extrusion capabilities for developing complex ...

Compact high-torque extruder for customizable extrusion tasks

Ensure precise control over your extrusion processes with ...

Mini extruder for small batch processing

Ideal for precise control in experimental formulations, this mini extruder streaml...

High-precision feeding system with load cell and weighing electronics

Achieve unparalleled accuracy in dispensing powde...

Isolator high containment for granule production

Ensure high-purity production in pharmaceuticals with controlled granulat...

Quick change volumetric and gravimetric single-screw dosing device

Simplify your dosing process with a quick-change sin...

Checkweigher for pharmaceutical and food industries

Ensure precise weight measurement and reliable product rejection in h...

Cooling conveyor belt for extrudates and granules

Efficiently cool and convey extrudates and granules with precise temper...

Pharmaceutical twin-screw extruder

Optimize your pharmaceutical production with high-speed continuous extrusion that ensure...

Industrial metal detector for food and beverage applications

Ensure your production line is free from metal contaminants...

High speed wrapping solution for pre-formed products

Achieve seamless integration of primary and secondary packaging with...

High-speed wrapping machine for chocolate or compressed powder products

For confectionery and pharmaceutical operations...

High-speed wrapping solution for compressed powder products

Efficiently wrap high-volume compressed powder products with...

Bouillon cube wrapping system

Streamline your packaging line with a high-speed system tailored for compact, compressed produ...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Lab scale roller compactor for dry granulation

Achieve seamless scale-up from lab development to full-scale production wit...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Pilot-scale milling and screening platform

Achieve precise powder consistency and integrity with flexible milling and scre...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Industrial powder milling solution

Achieve precise particle size control and improve material flowability with this advance...

Modular high-speed flow pack wrapper for preformed products

Eliminate packaging line bottlenecks with a versatile high-s...

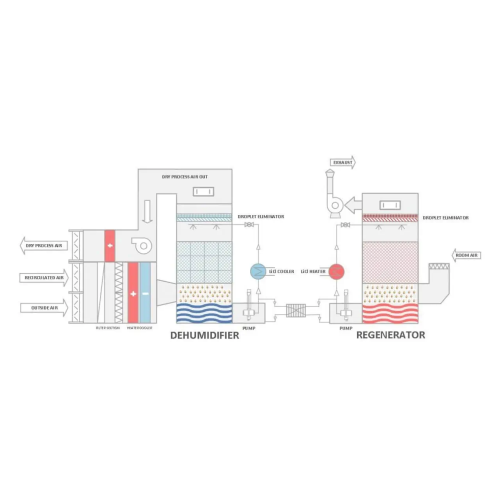

Industrial lithium chloride dehumidifier

Efficiently control air moisture and temperature with a solution that ensures prec...

Sublimation front monitoring system for freeze drying

Ensure precise control over your freeze-drying process with real-ti...

Nut coating machine for snack food processing

Enhance your snack and confectionery production with a nut coating machine t...

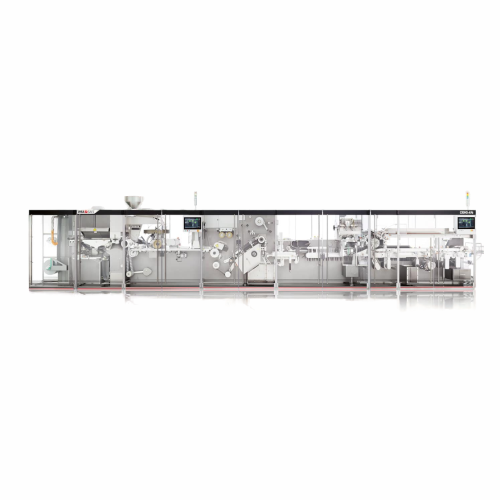

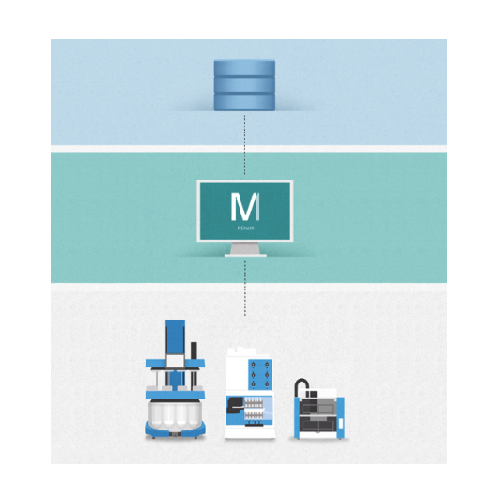

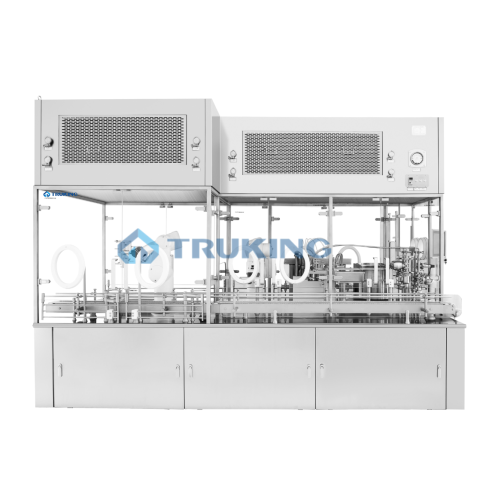

Continuous manufacturing for pharmaceuticals

Achieve precision in oral solid dosage production with seamless continuous pr...

Fluid bed processor for pharmaceutical granulation and coating

Achieve superior granulation and coating of pharmaceutica...

High-shear mixer granulator for pharmaceutical production

Achieve optimal granulation with enhanced mixing efficiency, r...

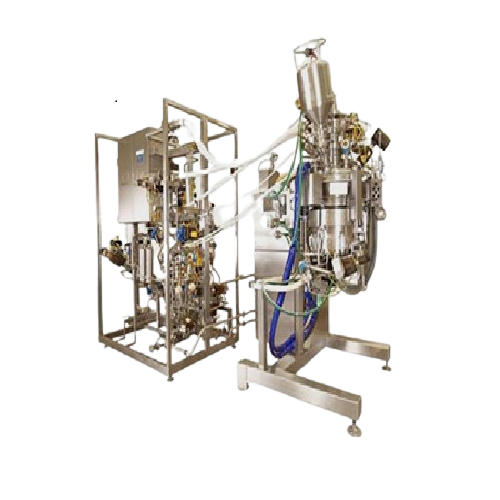

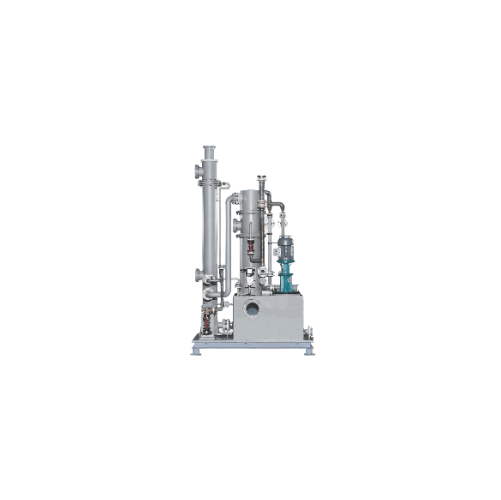

Pure water generation system for pharmaceutical manufacturing

Ensure high-purity water and steam production with precisi...

Nutraceutical products processing and packaging

Streamline your nutraceutical production with versatile equipment capable ...

Pharma r&d equipment for solid dosage forms

Optimize your pharmaceutical production with cutting-edge equipment designed f...

Sanitary separator for food processing applications

Ensure efficient separation and prevent contamination in food product...

Wet granulation process for pharmaceutical applications

Achieve consistent granule size and uniform mixing with advanced ...

Material handling system for granules and powders

Optimize your production with seamless material handling specifically d...

Wet granulation for pharmaceutical products

Achieve seamless integration of sifting and milling with precise powder handli...

Dry granulation roll compactor

Optimize your tablet and capsule formulation by efficiently compacting and granulating powder...

Fluid bed dryer for wet granulation in pharmaceutical industry

Streamline your production with fast, uniform drying and ...

High shear granulator for uniform wet granules

Achieve uniform and homogeneous wet granules with high-speed mixing and aut...

High-speed sifting for safety screening in pharmaceutical production

Achieve precise particle sizing with a high-speed ...

Steam/electrical kettle for wet granulation processes

Achieve precise moisture content and uniformity in your granulation...

Wet granulation co mill for pharmaceutical formulations

Optimize your manufacturing process with precise particle size re...

Bin washing station for pharmaceutical applications

Achieve reliable sanitation and enhanced efficiency with this tailore...

Industrial blender for uniform mixing

Optimize your process with precise mixing and consistent blending, ensuring uniformit...

Wet granulation cleaning system

Ensure optimal cleaning and purification within your production line with a system designed ...

Feeder controller for gravimetric feeders

Optimize your dosing precision and monitoring accuracy with a versatile feeder c...

Speed controller for feeders

Ensure precise material flow by integrating this speed controller, ideal for managing both volu...

Microbatch dosing for precision ingredient measurement

Achieve precise ingredient dosing with our MicroBatch system, desi...

Pharmaceutical sieving equipment for high hygiene standards

Ensure the purity of pharmaceutical powders and granulates w...

Small scale pharmaceutical filler and stoppering system

Optimize your R&D operations with a versatile filling and st...

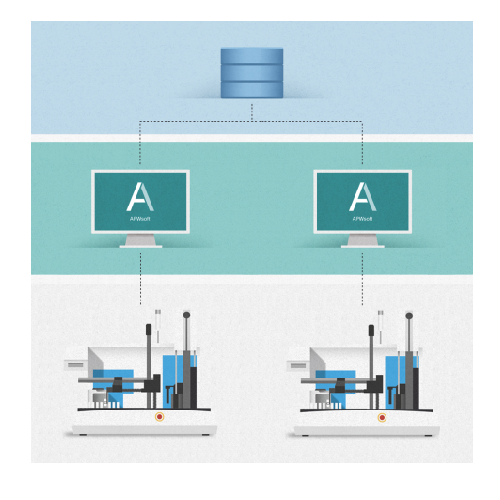

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Automated sample preparation software for pharmaceutical testing

Streamline your laboratory’s sample preparation w...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

Automated flow-through cell dissolution testing system

Enhance precision in dissolution testing with real-time UV-Vis ana...

Flow-through cell dissolution testing with Uv analysis

Effortlessly monitor real-time dissolution with flow-through cell ...

Powder flow tester for pharmaceutical powder flowability

Quickly assess powder flow characteristics to ensure consistent ...

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Manual dissolution tester for pharmaceutical applications

Achieve precise and repeatable sampling in pharmaceutical test...

Automated dissolution sample collection system

Double your testing efficiency with parallel dissolution sampling, ensuring...

Automated dissolution testing with direct Hplc injection

Streamline your lab operations with precise and efficient direct...

Integrated Uv-vis spectrophotometer for dissolution testing

Streamline your dissolution testing with real-time UV-Vis an...

Real-time Uv-vis analysis for dissolution testing

Efficiently perform dual dissolution tests simultaneously, seamlessly i...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Dissolution testing software for pharmaceutical industry

Optimize dissolution testing with advanced software that manages...

Automated sample preparation software

Enhance your laboratory’s efficiency with a software solution that automates sa...

Benchtop dissolution tester for multiple test runs

Streamline your laboratory’s workflow with a fully automated ben...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

Compact wet granulation r&d system

Ensure precise formulation of pharmaceutical powders with a scalable, lab-friendly syste...

High precision pharmaceutical checkweigher

Ensure precise weight compliance in high-speed production lines with this advan...

Automatic blister packaging for pharmaceuticals

Experience precise blister packaging that ensures product integrity and qu...

Pneumatic conveying system for dry bulk powders

Ensure seamless and contamination-free transfer of pharmaceutical powders ...

Industrial vacuum conveying system

Simplify bulk material movement and separation with a versatile vacuum conveying system,...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Rotary transfer system for pharmaceutical product filling

Ensure precise and hygienic filling of diverse pharmaceutical ...

Dual laser capsule marking system

Ensure precise and rapid laser marking of tablets and capsules with a dual-laser system, ...

High-speed laser writer for soft gelatin capsules and caplets

Achieve precise laser marking on up to 300,000 tablets or ...

Combination ink printing and laser writing for high-speed production

Achieve precise ink printing and laser marking at ...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Continuous roller compactor for dry granulation of pharmaceuticals

When making tablets, pharmaceutical manufacturers ne...

Container blender for pharmaceuticals

Manufacturing pharmaceutical solids like tablets requires using a proper blender to b...

Serialization and aggregation inspection system

Including serialization and aggregation inspection systems to packaging li...

Blister inspection system

The pharma and healthcare industries widely use blister thermoforming machines to package a variet...

Semi-automatic forming and sealing blister machine

As a manufacturer of medical device, the packaging is a critical facto...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Particle analysation monitor

Products like granules, tablets and capsules require inspection at numerous steps in the produc...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Granulation line for pharmaceutical solid dosage forms

Granulation is a common technique in production of pharmaceutical ...

Automatic filling line for solid doses

For medium-scale production of solid doses such as tablets, capsules, and softgels t...