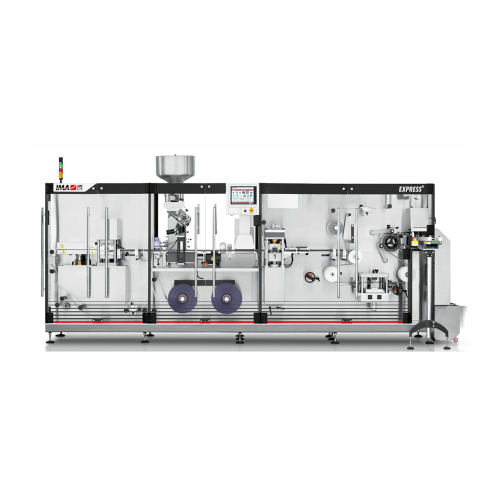

Blister packaging system for tablets and capsules

Designed for seamless 24/7 production, this blister packaging machine effortlessly manages thermoforming and aluminum materials, making it ideal for medium-sized batch processing of tablets and capsules.

Forms and Seals Blisters for Pharmaceuticals

The EXPRESS N from IMA PG is a robust blister packaging machine designed for the pharmaceutical industry, excelling in medium-size production batches for tablets and capsules. It features a flat forming and flat sealing system, ensuring a continuous high-speed operation with up to 240 blisters per minute. Each servo-driven station enhances precision and efficiency, while the machine’s balcony construction allows easy access for maintenance and quick, tool-less size changeovers. With capabilities to handle thermoforming materials and aluminum, it offers seamless integration into existing production lines with optional downstream automation. EXPRESS N is CE certified and built in accordance with GMP standards, ensuring reliability and compliance for your pharmaceutical packaging needs. Energy consumption is minimized, supporting 24×7 production while incorporating remote diagnostics for optimal operational oversight.

Benefits

- Maximizes production efficiency with continuous, high-speed blister packaging.

- Minimizes energy consumption for cost-effective 24x7 operation.

- Facilitates quick, tool-less changeovers to reduce downtime and enhance flexibility.

- Ensures compliance with GMP standards for pharmaceutical applications.

- Provides remote diagnostic capability for proactive maintenance and reduced operational interruptions.

- Applications

- Capsules, Pharmaceutical tablets

- End products

- Ibuprofen tablets, Vitamin d capsules, Probiotic capsules, Fish oil capsules, Aspirin tablets, Paracetamol tablets

- Steps before

- Tablet Production, Capsule Manufacturing, Thermoforming Material Preparation, Aluminum Material Preparation

- Steps after

- Blister Packing, Inspection, Labeling, Cartoning, Distribution

- Input ingredients

- tablets, capsules, thermoforming materials, aluminum

- Output ingredients

- blisters

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Blister Dimensions

- 30-100 mm (W) x 52-222 mm (L) x 3-12 mm (D)

- Production Output

- Up to 240 blisters/min

- Automation

- Servo controlled operations

- Changeover time

- Quick, tool-less changeover of size parts

- Cleaning method

- Easy access facilitates effortless cleaning

- Energy consumption

- Reduced to a minimum

- Working Mechanism

- Flat forming and flat sealing

- Automation Level

- Servo-driven

- Batch Size

- Medium size production batches

- Changeover Time

- Quick, tool-less

- Operational Efficiency

- 24x7 production capability

- Compliance

- CE certified, built as per GMP guidelines

- Energy Efficiency

- Reduced energy consumption

- Diagnostic Management

- Remote possibilities

- Blister dimensions

- 30-100 mm (W) x 52-222 mm (L) x 3-12 mm (D)

- Construction style

- Balcony construction

- Forming and sealing method

- Flat forming and flat sealing

- Material reel holders

- Forming Material Reel Holders

- Feeding station

- Feeding station

- Sealing and cooling station

- Sealing and cooling station

- Coding station

- Coding station

- Cutting station

- Cutting station

- Blister outfeed

- Blister Outfeed

- Control panel type

- Servo controlled

- Changeover method

- Quick, tool-less changeover

- Automation integration

- Possibility of downstream automation

- Diagnostic Management

- Remote diagnostics management