Capsule Making Equipment

Find innovative capsules equipment and connect directly with world-leading technology suppliers

The most important part of a capsule is its contents. But if the shell is not carefully made, the dosage ingredients inside lose effectiveness. From molding to sizing, capsule manufacturing equipment forms perfectly-matching husks ready for filling. The simplicity of encapsulation revolutionized pharmaceuticals since it was introduced in the 19th century. However, capsules are changing to increase delivery efficiency and reduce the dependency on gelatin.

Innovative Capsule Processing Equipment

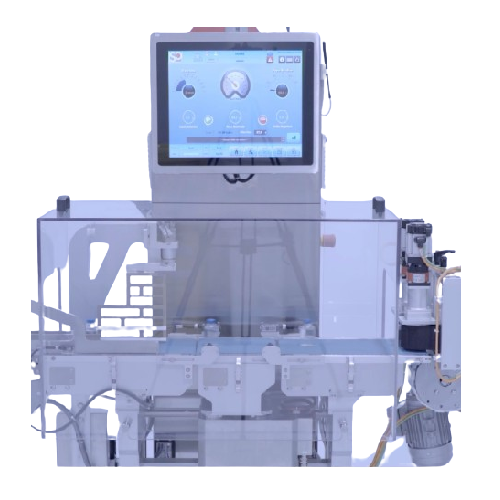

Automatic capsule filler for liquid solutions

Use of liquid filled hard capsules is increasingly popular with today’...

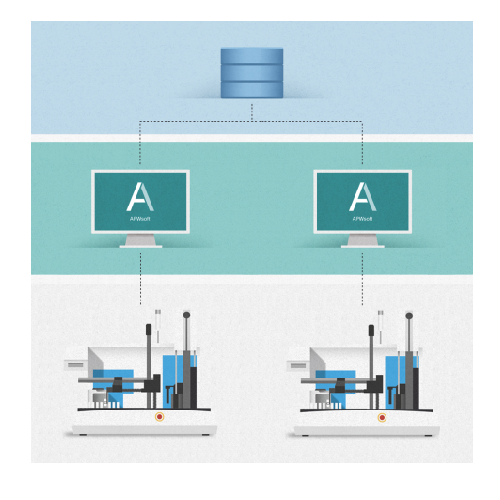

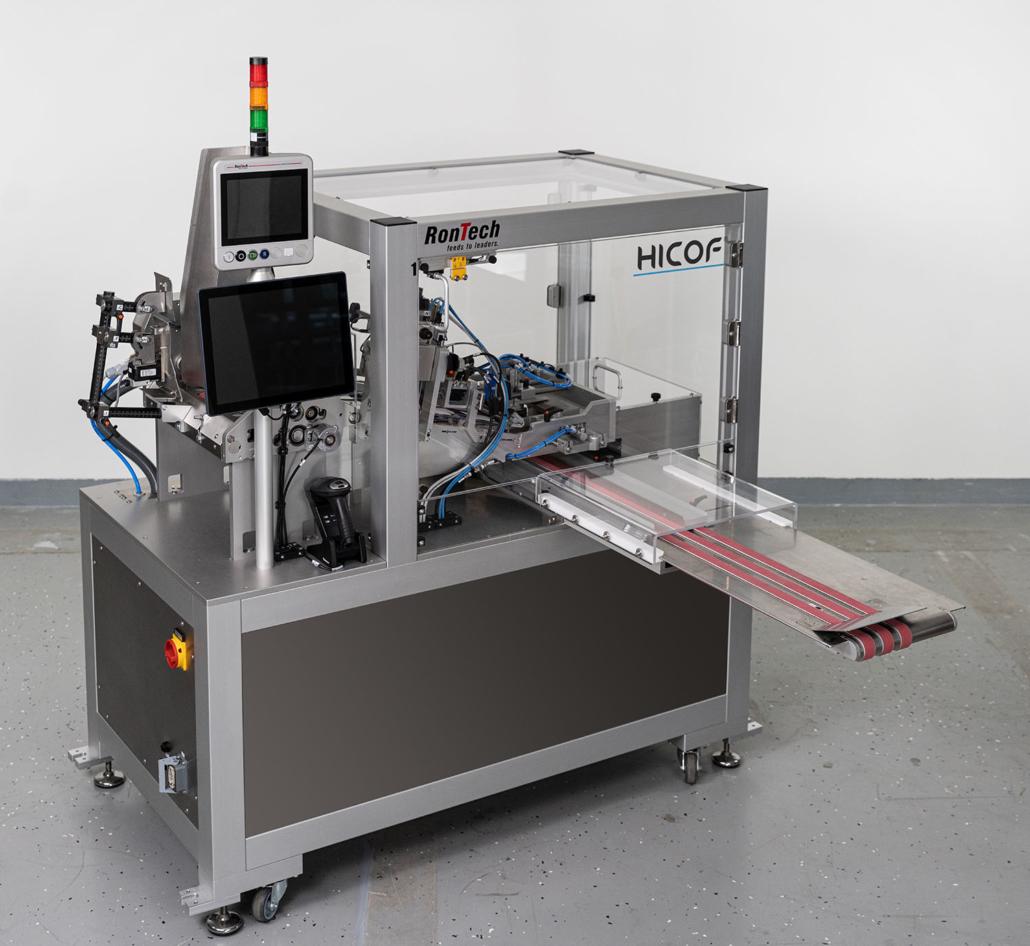

Automatic laboratory capsule filler

Innovators in the highly regulated and highly dynamic pharmaceutical market place need ...

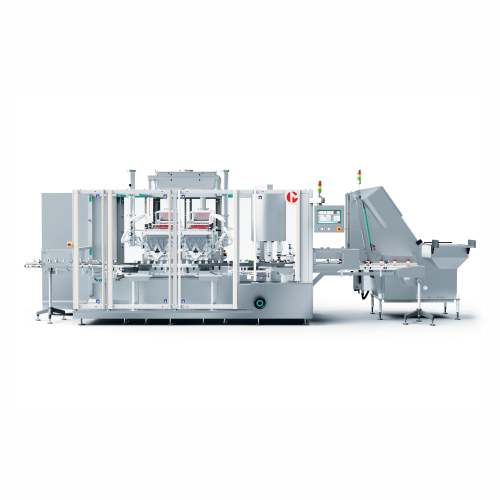

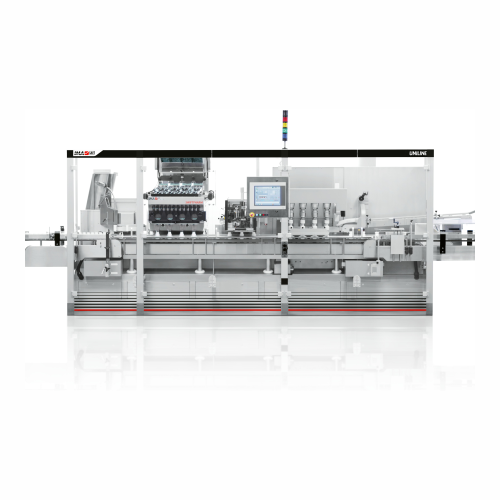

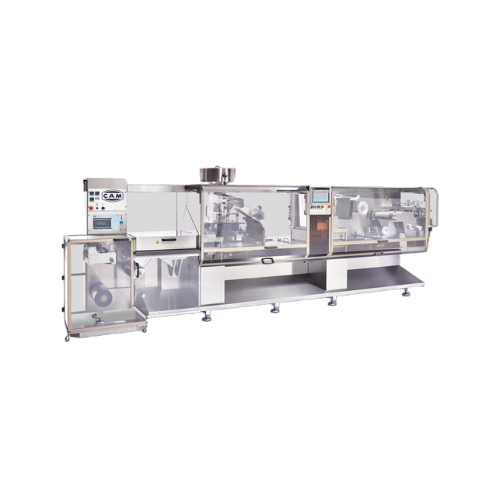

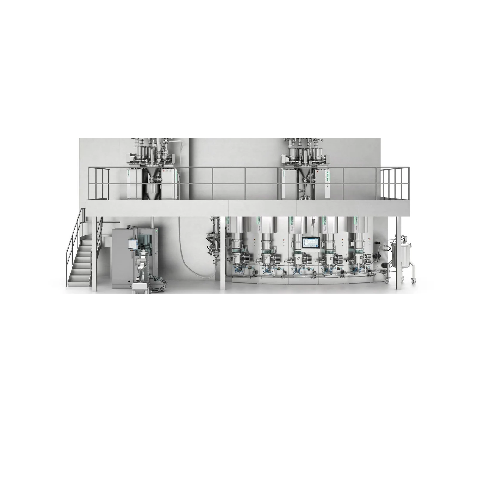

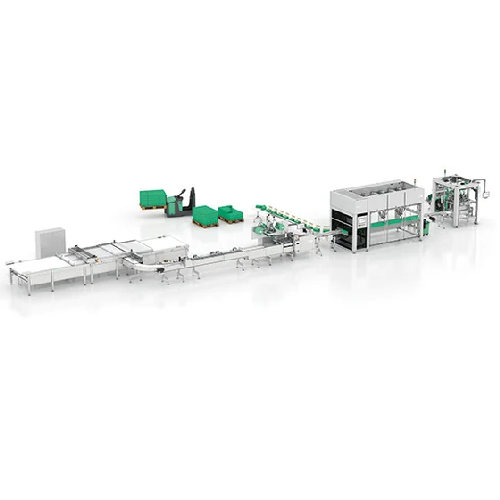

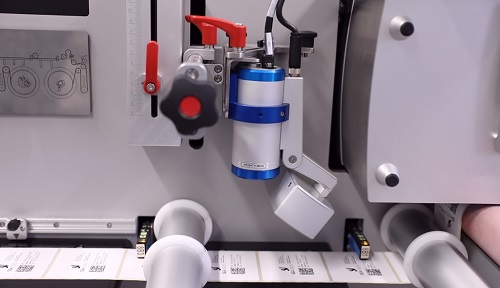

Automated capsule packaging system

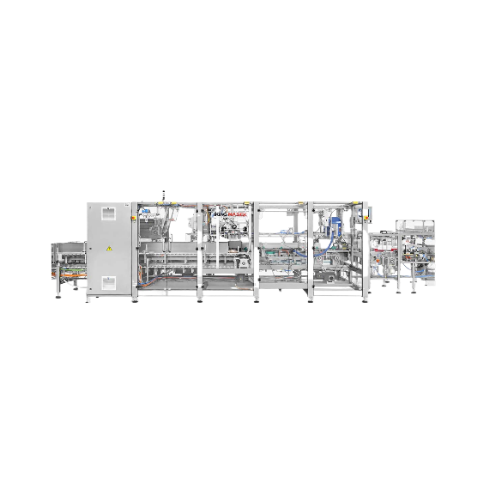

Streamline your high-speed packaging operations with a system designed for precision fil...

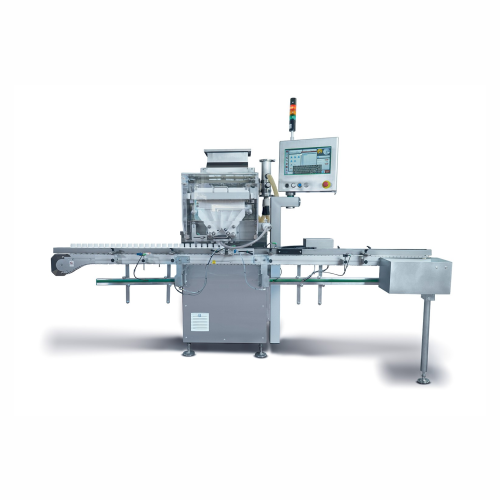

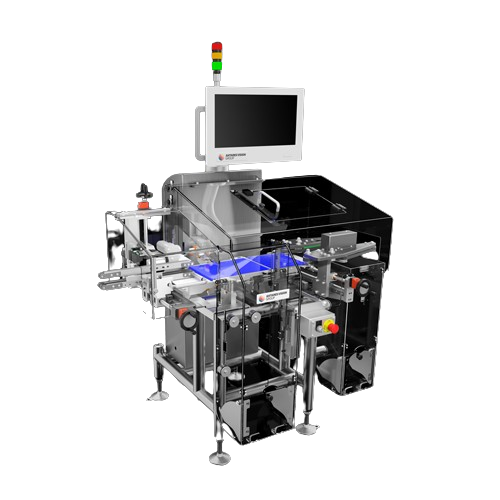

Automatic capsule checkweigher for statistical weight control

Ensure precise weight control of capsules with automatic s...

Stories about capsules

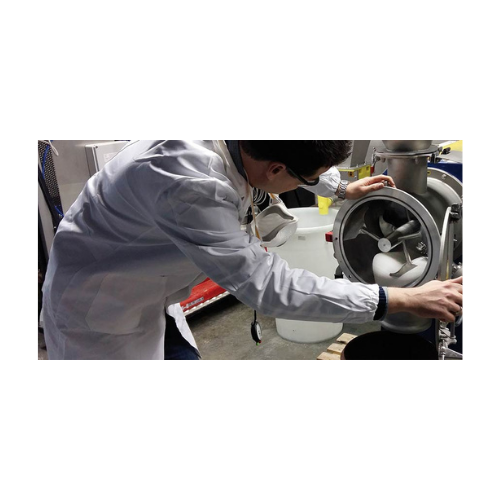

Wet milling: The revolution in the API production

#Changemaker: Ready to protect your pharmaceutical products from moisture?

How reliable imaging plays an important role in capsule visual inspection

Keeping pharmaceuticals moisture free

The rising tide of fish oil supplements

#Changemaker: Keep track of your medicine every day with FabriSol sticker

#Changemaker: Turning grass into pharmaceutical packaging

Select your capsules process

Tell us about your production challenge

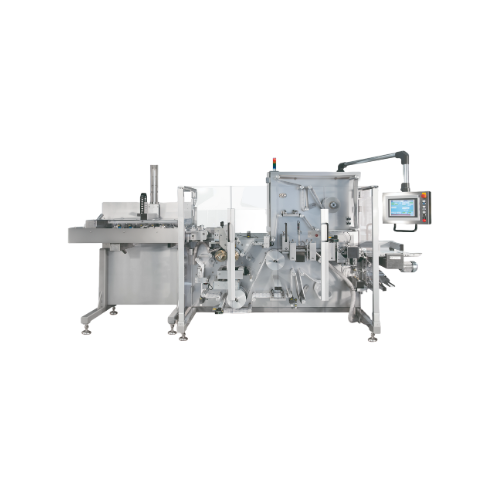

Mold the shells into shape with capsule manufacturing equipment

Capsule shells are composed of the body and the cap that closes the dosage. Capsule manufacturing equipment dips a series of steel pins into a drum filled with the base material. The wet molding pins move to the drying chamber to harden as they spin on their axis to ensure even distribution.

Once the shells are formed, they are stripped off the pins. But they are not yet finished for filling. The empty capsules must first be cut to the correct length and joined in a pre-lock position, ready for encapsulation.

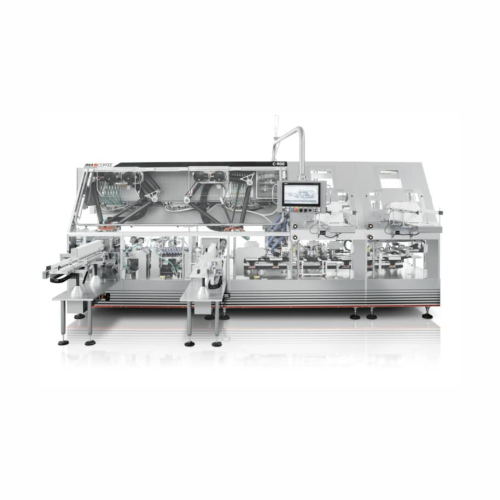

Pair the API with the correct shell before the capsule filling process

Encapsulation technology lines up the capsule bodies on a bed of holders. A stainless steel dosage system pours the formula in the powder tray into the shells. The caps, aligned precisely in their holding section, are ready to be lowered onto the filled capsule bodies. The fins in the body enter the slits of the cap, locking them into position.

The encapsulated ingredients directly impact shell stability. Hygroscopic materials, for example, risk cracking the gelatin capsules. Capsule filling machines must account for the properties of the dosage formula and the materials, thickness, and shelf life of the shells.

Capsule production is either an automatic, semi-automatic or manual process. Manual capsule fillers are still used in smaller production facilities. However, for making large scale pharmaceutical capsules, automation is employed to maximize output and efficiency.

Control the water content in hard gelatin capsules to balance plasticity and containment

The first hard gelatin capsules were filled with pharmaceutical formulas in powder form. But one of the advantages of encapsulation is that it offers flexibility with a range of dosage solutions, from tablets to beads to micro-capsules.

This versatility means that the gelatin shells have to deliver stability. The gelatin mix must allow enough moisture content to create elasticity without altering the properties of the encapsulated APIs.

Insufficient drying temperature leads to undesirable air pockets in soft gelatin capsules

Soft gelatin capsules, also known as softgels, are suitable for non-aqueous solutions such as oil. The active pharmaceutical ingredients are dissolved or suspended into an oil-based form.

One of the challenges in producing softgel capsules is the formation of air bubbles in the gelatin base. This happens when the capsule manufacturing equipment fails to reach the right temperature during the drying stage, and air remains trapped in the mixture. These pockets of unreleased air weaken the structure of the capsule.

HPMC capsules are more suitable hygroscopic fillings

Hypromellose emerged as the plant-sourced alternative to gelatin. But HPMC capsules are less dependent on water content, making them a better solution for hygroscopic ingredients.

However, since Hypromellose has a higher oxygen permeability, the fill ingredients need anti-oxidant additives to compensate. HPMC capsules also require oxygen-resistant packaging, such as aluminum blister configurations.

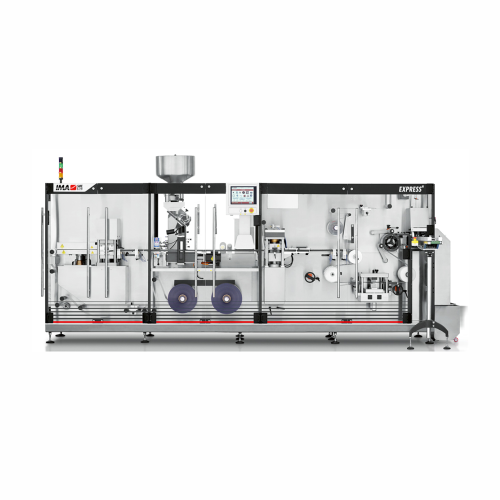

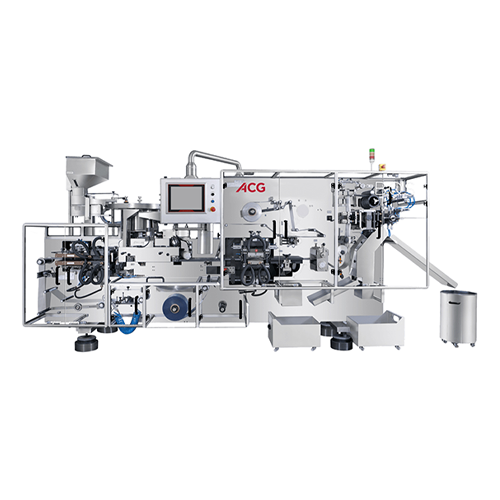

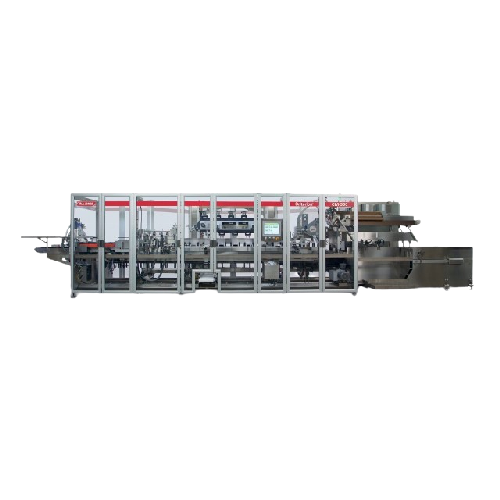

Blister packs offer greater protection for pharmaceutical capsules

The packing solution depends on the type of capsule. Vitamin or food supplement capsules may be bottled in simple containers. However, a desiccant pouch helps to absorb moisture and maintain a controlled environment.

In the case of pharmaceutical capsules, the ingredients demand safer packaging. Blister packs are more secure and are more convenient for dosage control. Complete blister packaging solutions often include coding and die-cutting systems, but simple entry-level batch machines are also available.

Which capsules technology do you need?

Capsule filling system with in-line weight control

Experience precise capsule filling with high-speed accuracy, designed ...

Automated capsule packaging system

Streamline your high-speed packaging operations with a system designed for precision fil...

High throughput capsule filling system

Achieve precise, high-speed capsule filling with versatility, ensuring product integ...

High-speed capsule filling system

Maximize production efficiency with high-speed capsule filling designed for precise dosin...

Capsule filling system for high volume production

Maximize your capsule production efficiency with a system designed to s...

Capsule packaging system for individual gusseted bags

Streamline your coffee capsule production with high-speed, precisio...

Tablet and capsule counting system

Need precise counting and filling of solid doses like tablets and capsules in your produ...

Counting and capping solution for tablets and capsules

Streamline your tablet and capsule production with a high-speed so...

Pharmaceutical metal detector for tablets and capsules

Ensure contaminant-free tablets and capsules with advanced detecti...

High-containment diverter for continuous tablet and capsule filling

Enhance your production line with a versatile solut...

Empty capsule sorting system

Streamline your capsule production by efficiently removing empty and defective capsules, ensuri...

Capsule polisher for pharmaceutical production

Enhance capsule quality and safety by effectively polishing, dedusting, and...

Capsule polisher for pharmaceutical capsules

Ensure your capsules are free from dust and perfectly polished with a solutio...

2-way diverter for tablet and capsule filling

Ensure precision in tablet and capsule filling with seamless batch switching...

Tablet and capsule diverter

Streamline your tablet and capsule production with precise container filling and flexible config...

Automatic capsule filling machines

Efficiently fill capsules with precise doses of powders, liquids, and tablets to enhance...

Table top tablet and capsule counter

Effortlessly ensure precise tablet and capsule counts with solutions that seamlessly i...

Electronic tablet counter for tablets and capsules

Optimize your production line with precise counting solutions for a wi...

Integrated counting system for tablets and capsules

Streamline your packaging line with a highly versatile system that se...

Capsule selection and feeding unit

Enhance your capsule filling process with precise selection and feeding, ensuring only t...

Capsule filler for pharmaceutical applications

Need precise capsule filling for pharmaceuticals and nutraceuticals? This s...

Precision weight-checking for pharmaceutical capsules

Ensure exact capsule and tablet dosage with high-speed precision we...

Integrated counting system for tablet and capsule bottling

Optimize your production line with a compact solution designe...

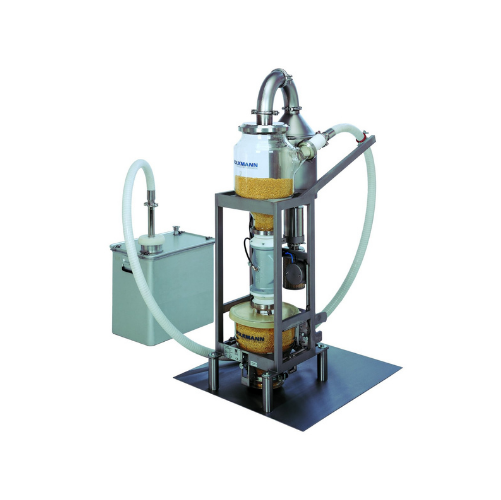

Table-top capsule filler for micro-dosing

Achieve precise micro-dosing for pharmaceutical powders and pellets with a user-...

Capsule banding system for tamper-evident sealing

Ensure tamper-evident integrity for capsules by utilizing a precise ban...

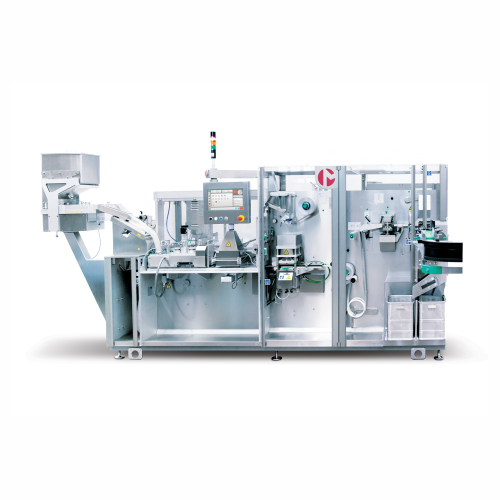

Blister packaging system for tablets and capsules

Designed for seamless 24/7 production, this blister packaging machine e...

Capsule filler for multi-product dosing

Achieve precision and flexibility in capsule filling with a system designed for hig...

Capsule filling and sealing system for coffee production

Achieve precise coffee capsule production with a machine that se...

Capsule filling and sealing system for coffee

Optimize your capsule production with a system designed to enhance precision...

Capsule filling and sealing for lab purposes

Streamline your lab-scale coffee capsule production with a compact solution d...

Capsule filling and sealing system for coffee products

Optimizing the precision of coffee and tea capsule production, thi...

Capsule cartoning for coffee and tea products

Optimize your capsule packaging process with a solution that enhances speed ...

Cartoning system for coffee capsules

Optimize your production line with a space-saving cartoning system designed specifical...

Capsule cartoning system for coffee and tea

Streamline your capsule packaging with a high-speed cartoning solution that ef...

High-speed capsule cartoning solution

Optimize your capsule packaging line with a versatile cartoning machine that accommod...

High-speed capsule weighing system for quality assurance

Ensure precise capsule weight monitoring and sorting with a syst...

Weighing system for 100% inspection of capsules and tablets

Ensure precise quality control with a format-free system tha...

In-process weighing system for capsules and tablets

Ensure precise dosing and consistent quality with a format-free syste...

Commercial capsule filling for small scale production

Efficiently fill and dose capsules with precision, ensuring flawles...

High-containment capsule dosing and filling system

Achieve precise dosing and optimal containment for pharmaceutical prod...

Capsule filling system for powder, pellets, and tablets

Optimize capsule production with rapid dosing changes, minimizing...

Containment capsule filling system for lab and small batch production

Designed to ensure maximum safety in pharmaceutic...

Versatile capsule filler for pharmaceuticals

Effortlessly switch between powder, pellet, and liquid dosing with this adapt...

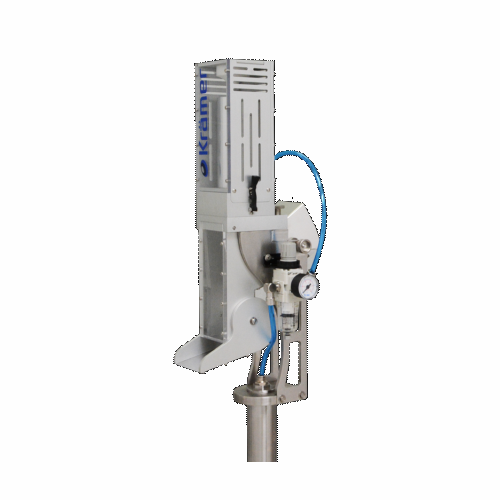

Empty capsule transfer system

Ensure seamless capsule filling operations by eliminating manual handling and preventing produ...

Filled capsule conveyor system for pharmaceutical production

Ensure gentle and efficient conveying of filled capsules in...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

Linear tablet and capsule counter

Ensure precise and efficient bottle filling with a cutting-edge counting system that guar...

Integrated bottling center for pharmaceutical tablets and capsules

Enhance your production line with versatile bottling...

Counting system for tablets and capsules

Effortlessly count a variety of tablets, capsules, and dragées with precision, ens...

High-speed strip packaging for tablets and capsules

Optimize your high-speed pouching operations with precise four-side s...

High speed strip packaging for tablets and capsules

Ensure precise packaging of pharmaceutical tablets and capsules with ...

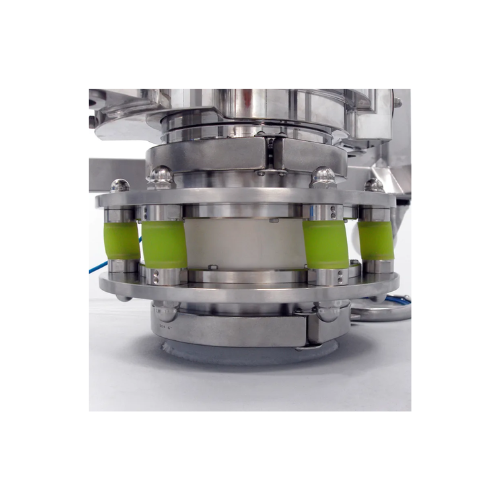

Encapsulation equipment for microbeads and microcapsules

Achieve precise encapsulation of active ingredients and material...

Soft gel encapsulation system

Efficiently produce high-quality soft gel capsules with precision encapsulation, rapid drying,...

Capsule filling solution for small to medium batch sizes

Achieve precise and efficient capsule filling up to 3,400 units ...

Capsule filling system for pharmaceutical production

Efficiently fill and lock capsules of various sizes with exceptional...

Tablet and capsule visual inspection system

Achieve unparalleled precision in tablet and capsule inspection with a high-sp...

Liquid capsule filling for r&d and pilot-scale production

Optimize liquid capsule production with a compact machine that...

Liquid filling system for hard capsules

Easily fill two-piece hard capsules with liquids, pastes, and suspensions with prec...

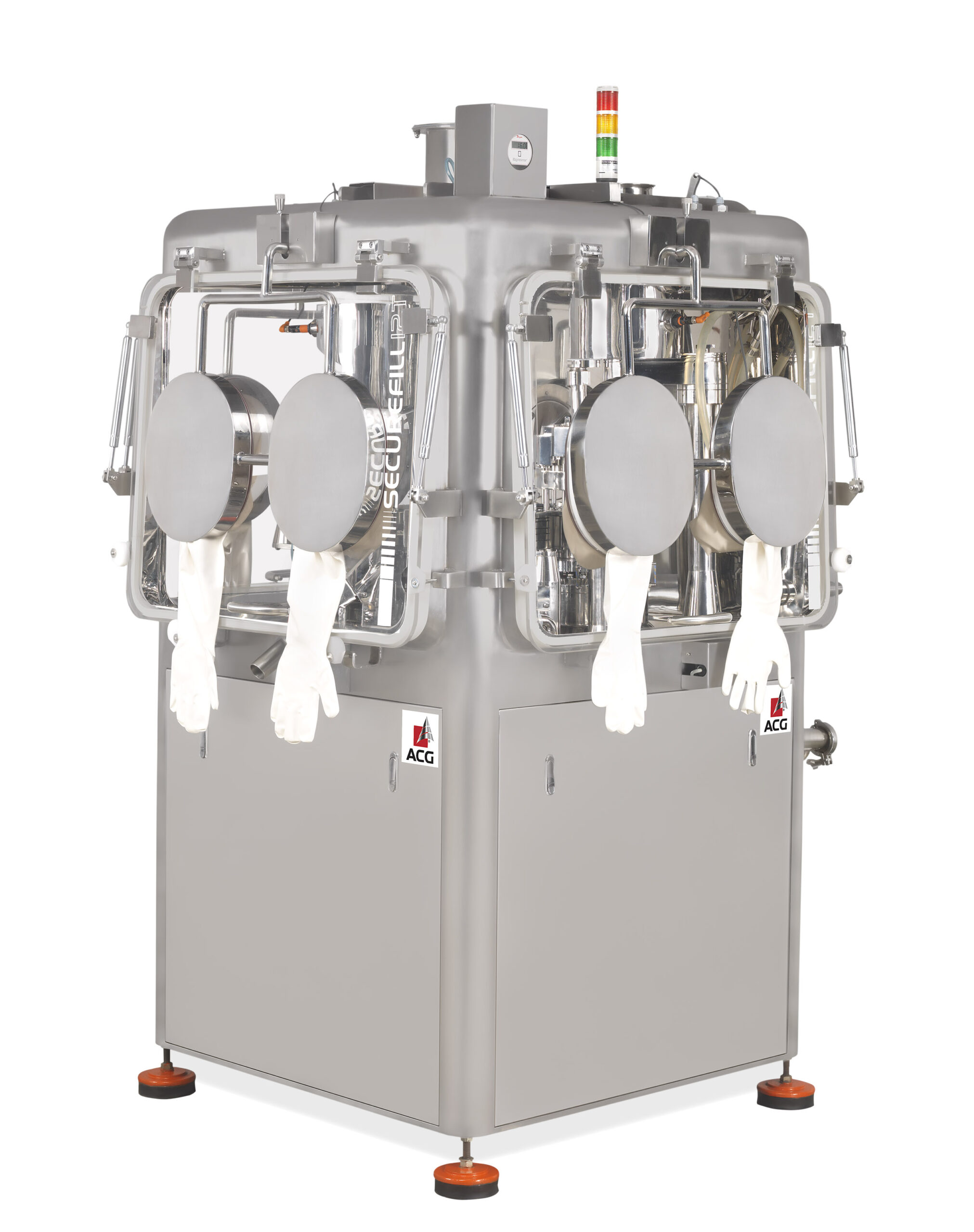

Containment capsule filler for highly potent drugs

Achieve complete operator safety while encapsulating potent pharmaceut...

Containment capsule filling system for highly potent drugs

Ensure operator safety while filling capsules with high-poten...

High-speed capsule filler for large batch production

Achieve higher yields and reduce powder waste with a capsule filling...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Rotary blister packaging for tablets and capsules

Optimize your blister packaging with high-performance rotary forming an...

Capsule band sealer for liquid-filled hard capsules

Seamlessly seal liquid-filled hard capsules to enhance product integr...

Automatic capsule checkweigher for statistical weight control

Ensure precise weight control of capsules with automatic s...

Capsule de-dusting and polishing system

Ensure precision in capsule production with continuous de-dusting and polishing, en...

Empty capsule sorting system for pharmaceutical manufacturing

Expedite your capsule production with a high-speed system ...

Filled capsule elevator for seamless process integration

Efficiently streamline the transfer of filled capsules across va...

Capsule sorter elevator for encapsulation processes

Ensure uninterrupted encapsulation by efficiently removing defective ...

Metal contamination detection for tablets and capsules

Ensure product integrity by detecting and separating metal particl...

Vacuum conveyor for tablets and capsules

Ensure the integrity of your tablets and capsules with gentle vacuum conveying des...

Fully automatic hard capsule filling machine

Enhance pharmaceutical production with precise capsule filling, ensuring opti...

Pharmaceutical metal detector for tablet presses and capsule filling

Detect and eliminate metal contaminants in high-sp...

Manual heat shrink capsule applicator

Quickly and precisely apply shrink capsules to bottlenecks, ensuring perfect adherenc...

Capsule checkweighing system for pharmaceutical production

Ensure every capsule meets your precision weight standards wi...

Capsule filling for nutrition and health products

Optimize your production line with advanced capsule filling capabilitie...

Capsule filling for pharmaceuticals and nutraceuticals

Enhance your capsule production capabilities with modular filling ...

Bathless disintegration apparatus for tablet and capsule testing

Achieve rapid and precise disintegration testing of tab...

Automatic counting and capping system for tablets and capsules

Ensure precise tablet and capsule counting and seamless c...

Coffee capsule filling and sealing solution

Optimize your production with a high-speed solution designed to fill and seal ...

Coffee capsule filling and sealing system

Boost capsule production efficiency and reduce downtime with a high-speed system...

Coffee capsule filling and sealing line

Elevate your capsule production with a high-speed filling and sealing solution that...

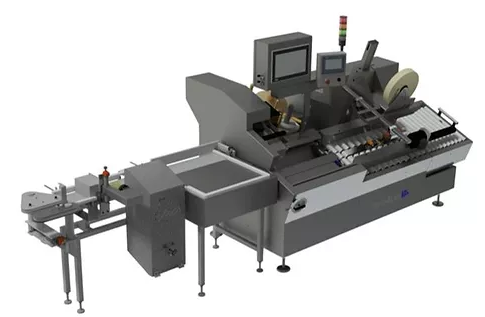

Capsule printer for pharmaceutical applications

Experience precise dual-color printing with high-speed efficiency for caps...

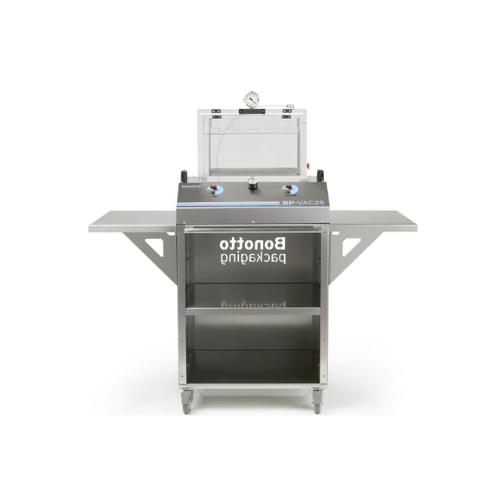

Lab device for testing coffee capsules

Achieve precise testing and reproducibility of coffee capsule parameters crucial for...

Filling and sealing solution for beverage capsules

Optimize your production with a modular capsule filling and sealing so...

Coffee capsule filling and sealing machine

For producers seeking a compact yet powerful machine, this system efficiently f...

High-speed coffee capsule filling and sealing system

Streamline your capsule production with a high-speed solution that e...

Dual laser capsule marking system

Ensure precise and rapid laser marking of tablets and capsules with a dual-laser system, ...

H-track ink printing solution for tablets and capsules

Ensure precise ink printing on tablets and capsules with high-spee...

Uv laser writer for tablets and capsules

Achieve precise laser marking on tablets and capsules with high-speed production, ...

High-speed laser writer for soft gelatin capsules and caplets

Achieve precise laser marking on up to 300,000 tablets or ...

Co2 laser writer for soft gelatin capsules

Achieve precise and efficient laser marking on soft gelatin capsules and caplet...

Tablet and capsule ink print and laser marking system

Streamline tablet and capsule identification with a high-speed syst...

Tablet and capsule ink printer

Achieve precise and high-speed printing on tablets and capsules, ensuring clear product ident...

Uv laser marker for tablets and capsules

Achieve precise laser marking on tablets and capsules at high speeds while maintai...

Co2 laser writer for gelatin capsules

Achieve high-speed laser marking on gelatin capsules and caplets with precision, ensu...

Tablet and capsule ink printing and laser writing solution

Maximize efficiency in marking and coding with a high-speed s...

Coffee capsule packing machine

In the secondary packaging sector, being able to handle different type of capsules and tailor...

Vision inspection system for tablets and capsules

Pharmaceuticals and healthcare product manufacturers dealing with oral ...

Automatic medical forming and sealing blister machine for packing capsules and tablets

Product safety is very importa...

Cold forming aluminum blister machine for capsules

Aluminum blisters are mainly used for packaging products that are sens...

Easy to validate capsule filler

Staying competitive in today’s highly dynamic and highly regulated pharmaceutical prod...

Effective Visual Inspection System for Capsules

The attribute of capsule packing is a critical parameter that controls the...

Metal detector for tablets and capsules

Identification of metallic contaminants is a vital part of pharmaceutical quality c...

Semi-automatic capsule filler

Hard gelatin capsules are a popular format for delivering a wide variety of pharmaceutical dos...

Automatic capsule loader

Capsules are a popular method of dosage delivery for a wide range of compounds. For anything other t...

Electronic capsule counter

For lab work or small batch production, hand counting of solid doses into dispensing containers i...

Laboratory capsule filler for liquid solutions

A recent important change in the industry is the trend toward providing liq...

Automatic laboratory capsule filler

Innovators in the highly regulated and highly dynamic pharmaceutical market place need ...

Automatic capsule filler

Capsule filling should be a worry-step in pharmaceutical and nutraceutical manufacturing. The right...

Industrial capsule checkweigher

Pharmaceutical manufacturing demands the highest quality standards and completely consistent...

Capsule checkweigher

The production of pharmaceutical capsules requires that individual doses are checked for accuracy. In a ...

Laboratory scale soft gelatin capsule machine

Softgel (or soft gelatin) capsules are a very popular method for providing o...

Softgel capsules polisher

The final stage in high quality softgel (or soft gelatin) capsule production is the capsule polish...

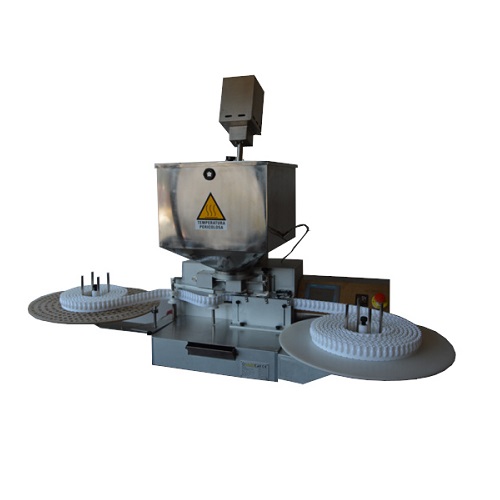

Automatic soft gelatin capsule machines

Soft gelatin (or softgel) capsules have become a popular mode of oral liquid dosing...

Automatic capsule filler for liquid solutions

Use of liquid filled hard capsules is increasingly popular with today’...

Contained capsule filler

For pharmaceutical formulations that are highly active specialized capsule filling equipment is ofte...

High-yield capsule filler

Pharmaceutical manufacturers require maximum yield from their encapsulation process for efficient ...

Microencapsulation system for your drug delivery system

Whether you want to improve the stability of nutrients, protect a...

High capacity capsule filler

In the highest volume pharmaceutical production environments, capsule filling needs to be extre...

Scale up capsule filler

For higher production volumes of pharmaceutical capsules, speed, accuracy and reliability of producti...

Entry level capsule filler

For the production of pharmaceutical doses in capsule form complete accuracy of fill is paramount...

Waste minimization weight sorter for tablets & capsules

For medium scale production, you can improve line efficiency and ...

High capacity weight sorter for tablets & capsules

By employing a weight sorter that is fully flexible and able to ha...

Benchtop weight sorter for tablets & capsules

For laboratory pharmaceutical R&D work or use in clinical trials, a...

Versatile weight sorter for tablets & capsules

Saving costs and improved production efficiencies are possible by opti...

R&D semi-automatic capsule filler

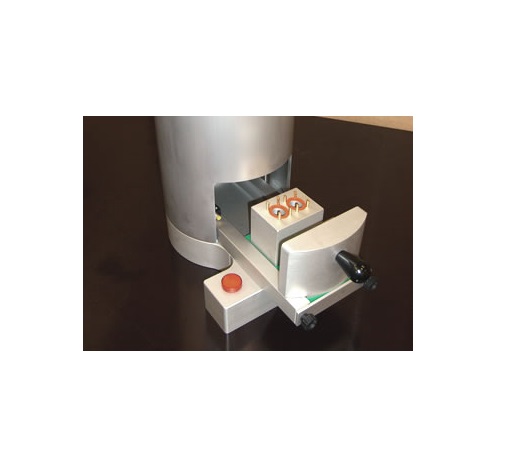

Semi-automatic filling machine suitable to open, fill and close empty hard gelatin capsul...

R&D hard gelatin capsule sealing machine

When encapsulating products at temperatures up to + 80°C, these tend to solidify a...

R&D electronic counter for capsules and tablets

This machine has been designed to offer an ever-precise and reliable count...

R&D automatic capsule filler

Automatic capsule filling machine for powders, pellets, tablets, mini-tablets, capsule in capsu...

R&D capsule orientater

A semi-automatic orienter for capsules with an output speed up to 6000 capsules.

Checkweigher for capsules

The new interactive indicator unit allows for even easier use. High-rigidity weighcells have been ...

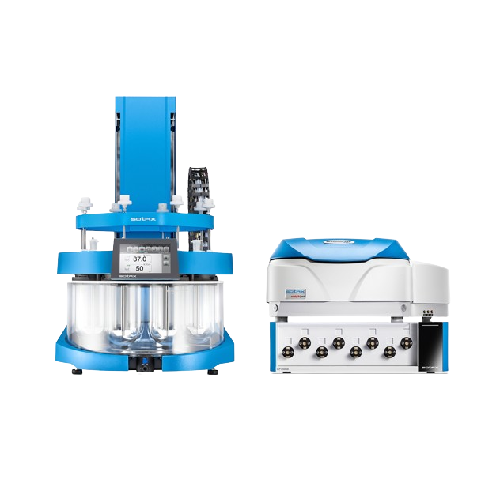

Flow through dissolution system for drug products

Capture real-time dissolution behavior with high-resolution imaging, pr...

Uv monitoring system for small volume dissolution studies

Efficiently monitor small-volume dissolution processes in real...

Vacuum packaging system for high-volume operations

Optimize your packaging line with high-speed vacuum sealing for divers...

Vertical bagging system for four corner seal bags

Optimize your coffee pod and capsule production with a high-speed, cont...

Vertical packaging system for pet food

Streamline your production line with high-speed packaging capabilities, handling var...

System for packaging stacked coffee pods in filter paper

Streamline your pod production with precision bagging and sealin...

Intermediate bulk containers for powder and materials handling

Optimize your material handling processes with containers...

Blister thermoforming for Pvc/alu

Effortlessly mold and seal blister packs for a range of solid products, optimizing packag...

Compact strip packaging for solid products

Efficiently package a variety of solid pharmaceutical products with precision a...

Strip packing for solid products

Ensure consistent quality and precision in packaging solid products with this advanced stri...

Dust-tight dispenser for metal detector test tablets

Ensure seamless integration of test tablets in high-containment envi...

Vertical vibratory tablet deduster for pharmaceutical tablets

Ensure optimal cleanliness and quality assurance for table...

Tablet deduster with upward conveying

Ensure consistent dedusting and deburring of tablets and capsules while maintaining h...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety ...

High-containment tablet deduster

Ensure optimal purity and safety in pharmaceutical production with high-containment dedusti...

Fluid bed and coating system for small batch processing

Streamline your R&D process with a modular system that ensur...

Industrial washing skid for pharmaceutical components

Ensure precise cleaning and drying of pharmaceutical components wit...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Desiccant inserter for pharmaceutical bottles

Ensure your products remain moisture-free and preserved by integrating this ...

Thermoforming solution for clinical trials

Designed for precision and flexibility, this compact thermoforming machine stre...

Pharmaceutical metal detectors

Ensure product purity by detecting and eliminating metal contaminants in pharmaceuticals, enh...

Batch-operated chamber dryer for surface drying

Enhance production efficiency with precise, low-temperature drying and coo...

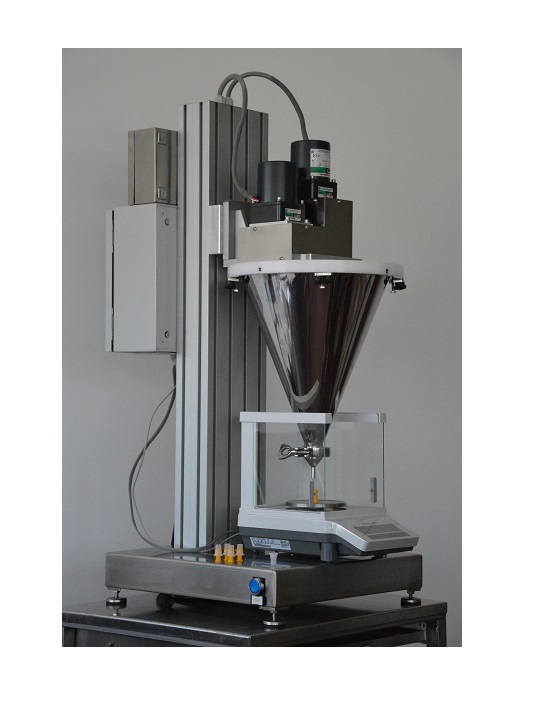

Powder dosing system for development and small batches

Streamline lab-scale pharmaceutical production with a versatile po...

Powder dosing machine for laboratory applications

Achieve precise powder dosing and streamline your R&D processes wi...

Powder dosing for lab and galenics

Ideal for precise dosing needs, this compact lab device streamlines powder filling proce...

Semi-automatic powder dosing system

Achieve precise micro-dosing for pharmaceutical powders with a flexible system ideal fo...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Waste powder recovery cyclone for pharmaceutical processes

Efficiently recover up to 99.9% of waste powder from oral sol...

Tablet storage and transport containers

Ensure the safe and gentle handling of tablets during storage and transport, minimi...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Powder flow control systems for precise gravity transfer

Achieve seamless powder flow control in your production line wit...

Pharmaceutical size reduction shredder

Achieve fast, efficient material size reduction with this shredder, enabling seamles...

Gravimetric feeders for pharmaceutical applications

Ensure precise ingredient metering in continuous pharmaceutical proce...

Fluid bed system for granulation and coating

Optimize your production with a multi-purpose fluid bed system designed for e...

Closed loop granulator for pharmaceutical production

Streamline your production with a fully automated closed-loop system...

High shear mixer granulator for efficient wet granulation

Achieve consistent and precise granule formation with high she...

Particle sizer for precise sifting

Optimize your production line with high-speed particle sizing, ensuring precise control ...

Pharmaceutical bottle unscrambler

Streamline your pharmaceutical packaging process by efficiently sorting and aligning bott...

In-motion pharmaceutical bottle filler

Achieve up to 400 bottles per minute with this modular bottle filling solution, desi...

In-motion bottle filling system for pharmaceuticals

Boost your production efficiency with our high-speed bottle filling s...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

Compact wet glue labeling system for low volume production

Achieve precise, high-quality labeling with compact machinery...

High speed blister packaging for pharmaceutical industry

Ensure precision and speed in pharmaceutical packaging with a hi...

High speed blister packaging for pharmaceuticals

Need efficient packaging with quick format changeovers for various capsul...

Blister packaging for pharmaceutical products

Facilitate seamless packaging of pharmaceuticals with a solution designed to...

Slat-type counting solution for pharmaceutical applications

Ensure precise tablet counts and efficient packaging with th...

Small batch tablet and pellet coating solution

Optimize your small batch coating and drying processes with a versatile ben...

Bead mill for nano-preparation grinding

Achieve precise nano-processing and efficient wet grinding for pharmaceuticals and ...

Softgel pre-dryer tumbler system

Ensure optimal shape and seam formation of softgel capsules with efficient oil removal, pav...

Pharmaceutical checkweigher for milligram-level accuracy

Ensure precision and compliance in your pharmaceutical packaging...

Pillow bag horizontal form-fill-seal solution

Optimize production efficiency with seamless integration of continuous, high...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid-bed drying and granulation system

Optimize your production line with high-speed batch processing for efficiently dryi...

Fluid bed combo for granulation and coating

Streamline your manufacturing with a versatile fluid bed combo, integrating gr...

Flat-forming blister packager for small production batches

Ideal for pharmaceutical and nutraceutical firms seeking effi...

Tabletop blister packaging for clinical trials

For R&D facilities conducting clinical trials or feasibility studies, ...

Containment blister packaging for highly potent Apis

Ensure operator safety during the blister packaging of highly potent...

Blister packaging for solid dosage forms

Optimize your packaging line with high-speed, continuous blister packaging that en...

Semi-automatic de-blistering solution for Pvc and alu blister packs

Streamline your packaging operations by swiftly rec...

Automated powder and pellet product conveying system

Optimize your encapsulation process effortlessly with this fully aut...

Flat forming and sealing blister packaging solution

Enhance your blister packaging process with a solution that ensures p...

Flat-sealing continuous-motion blister packaging solution

Enhance your blister packaging with precise, high-speed sealin...

Disposable containment system for solid dosage material

Ensure safe and dust-free transfer of hazardous materials with ou...

High shear granulator for pharmaceutical applications

Efficiently transform powders into uniform granules for consistent ...

Integrated granulation and drying system for pharmaceuticals

Achieve seamless granulation and drying with our fully inte...

Cip for pharmaceutical process plants

Streamline your cleaning processes with integrated CIP systems to ensure precise and ...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Laboratory dedusting systems

Designed for high-containment lab environments, this solution efficiently captures and manages ...

Gmp contact part washers for pharmaceutical industry

Ensure product integrity and hygiene with specialized washing system...

Mini extruder for early development phase testing

In early development, tackling limited material availability is crucial...

High-precision feeding system with load cell and weighing electronics

Achieve unparalleled accuracy in dispensing powde...

Isolator high containment for granule production

Ensure high-purity production in pharmaceuticals with controlled granulat...

Pharmaceutical twin-screw extruder

Optimize your pharmaceutical production with high-speed continuous extrusion that ensure...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Continuous manufacturing for pharmaceuticals

Achieve precision in oral solid dosage production with seamless continuous pr...

Fluid bed processor for pharmaceutical granulation and coating

Achieve superior granulation and coating of pharmaceutica...

High-shear mixer granulator for pharmaceutical production

Achieve optimal granulation with enhanced mixing efficiency, r...

Pure water generation system for pharmaceutical manufacturing

Ensure high-purity water and steam production with precisi...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Nutraceutical products processing and packaging

Streamline your nutraceutical production with versatile equipment capable ...

Pharma r&d equipment for solid dosage forms

Optimize your pharmaceutical production with cutting-edge equipment designed f...

Wet granulation co mill for pharmaceutical formulations

Optimize your manufacturing process with precise particle size re...

Wet granulation cleaning system

Ensure optimal cleaning and purification within your production line with a system designed ...

Online tablet counter inspection system

Ensure product integrity by precisely inspecting and rejecting defective tablets an...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

Automated flow-through cell dissolution testing system

Enhance precision in dissolution testing with real-time UV-Vis ana...

Manual tablet disintegration tester

Ensure precise and reliable disintegration testing of pharmaceutical tablets, capsules,...

Tablet friability tester

Ensure your tablets meet rigorous quality standards by accurately measuring friability and abrasion,...

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Manual dissolution tester for pharmaceutical applications

Achieve precise and repeatable sampling in pharmaceutical test...

Integrated Uv-vis spectrophotometer for dissolution testing

Streamline your dissolution testing with real-time UV-Vis an...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

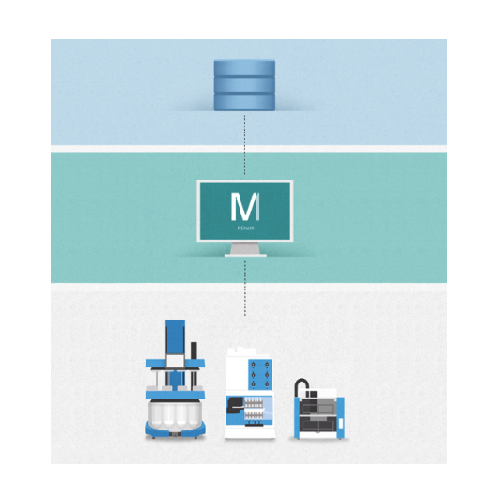

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Dissolution testing software for pharmaceutical industry

Optimize dissolution testing with advanced software that manages...

Automated sample preparation software

Enhance your laboratory’s efficiency with a software solution that automates sa...

High precision pharmaceutical checkweigher

Ensure precise weight compliance in high-speed production lines with this advan...

Automatic blister packaging for pharmaceuticals

Experience precise blister packaging that ensures product integrity and qu...

Horizontal cartoning system for coffee pods

Enhance your packaging line efficiency with a system designed for gentle handl...

High-speed tablet ink printer

Achieve precise and high-speed printing on tablets and capsules for streamlined production and...

Uv laser writer for high-speed tablet marking

Achieve precise and rapid marking of pharmaceutical and nutraceutical tablet...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Inspection system for tablets chemical composition

The packaging of pharmaceuticals and oral solid products such as table...

Blister inspection system

The pharma and healthcare industries widely use blister thermoforming machines to package a variet...

Semi-automatic forming and sealing blister machine

As a manufacturer of medical device, the packaging is a critical facto...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Particle analysation monitor

Products like granules, tablets and capsules require inspection at numerous steps in the produc...

Lifter and De-duster for Tablets

The use of several different tools for lifting, de-dusting, and polishing in the pharmaceut...

High Speed Visual Inspection System for Tablets

In order to ensure quality and standard specifications of tablets, capsule...

Contained Visual Inspection System

In the medicine industry, it is important to ensure there are no defects in tablets or c...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Tablet counting machine

Production of pharmaceutical solid dosage forms usually require complete accuracy, flexibility, and c...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Automatic filling line for solid doses

For medium-scale production of solid doses such as tablets, capsules, and softgels t...

Softgel tumble dryer

Softgel (or soft gelatin) capsules are a very popular means of delivering oral doses in the pharmaceutic...

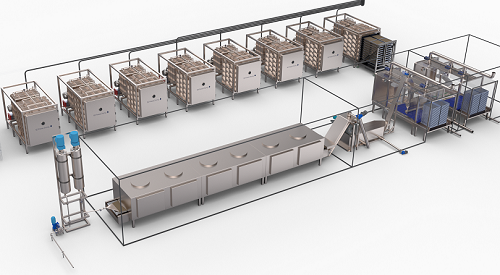

Continuous in-line softgel drying system

High output softgel (or soft gelatin) capsule encapsulating machines can operate b...

Softgel drying tunnel

Softgel capsules require a controlled secondary drying to reduce water content in the capsule to levels...

Gelatin melters and tanks

When producing high quality softgels its important that the gelatin base is processed and stored c...

Compact blister machine

A compact blister machine ideal for packing tablets, capsules, ampoules and syringes and other applic...

Rotating sample divider for large bulk materials

Achieve precise, dust-free division and volume reduction of bulk material...

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

Atex compliant milling equipment for explosive atmospheres

Ensure operator safety and process integrity with milling equ...

Packaging system for stacked coffee pods

Efficiently package your pods with precise counting and sealing, ensuring optimal ...

Automatic case packaging for pods in single bags

Optimize your production line by streamlining the packaging of coffee and...

Filter paper pod production system

Streamline your production of single-serve beverages with precise weight control and sea...

Pod production system for filter paper pods

Streamline your pod production with a high-speed solution that ensures precise...

Label dispenser integration for packaging lines

Streamline labeling operations with precision and flexibility, ensuring yo...

Automated conveyor systems for food packaging lines

Seamlessly integrate high-speed product transport and handling into y...

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Integrity tester for filtration system validation

Ensure precise validation of your filtration systems with highly accura...

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

Water activity headspace analyzer for drug product samples

Ensure precise control of moisture levels across the entire p...

High-performance thermoforming tools for packaging

Optimize your packaging production with versatile thermoforming tools,...

Fiber thermoforming system for sustainable packaging

Achieve fast, efficient production of biodegradable fiber packaging ...

Vertical intermittent motion stick packaging

Experience seamless packing for diverse products, from powders to dense paste...

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

Lifting column for drums and containers

Streamline your production with lifting columns designed for precise handling, blen...

High-speed blister packaging with integrated cartoner

Optimize your blister packaging process with a solution that seamle...

Pharma parts washer for efficient cleaning

Enhance your washing process efficiency with a compact solution designed to sav...

Bin tumbler for efficient mixing

Achieve precise blending and homogenizing of powders and granules with dual-inclination des...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

Side entry mixer for industrial fluid mixing

Optimize your fluid mixing processes with high-speed side entry mixers, desig...

Vacuum conveyor for hygienic material transfer

For operations demanding swift, dust-free material handling, this solution ...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Stainless steel intermediate bulk containers for pharmaceutical use

Ensure safe, efficient transport and handling of po...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

Drum tippers for precise and safe drum handling

Streamline your operations by eliminating manual lifting and aligning proc...

High-capacity cgmp washer/dryer for cleanrooms

Optimize your cleanroom operations with this compact washer/dryer, designed...

Cost-effective rigid-wall isolator for aseptic applications

Ensure sterility and safety with a versatile isolation and d...

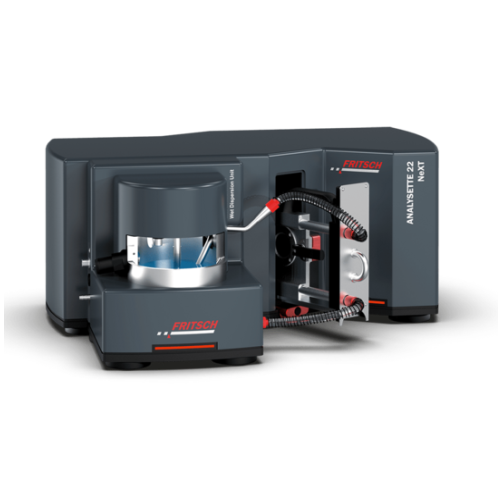

Laser particle sizer for accurate particle size distribution

Achieve precise control over particle size distribution wit...

Laboratory film coating system for development and clinical batches

Achieve precision in tablet coating with a versatil...

Pilot High shear granulator for wet granulation

Achieve consistent particle sizing and superior homogeneity in your powder...

Vacuum transfer system for powders and granules

Effortlessly transfer and manage powders and granules with seamless integr...

Double cone mixer for free flowing powders and granules

Achieve uniform blending of powders and granules with precision, ...

Intermittent stick pack system for pharmaceuticals

Effortlessly streamline your packaging process with a high-speed, mult...

Consumables for elemental analyzers

Optimize your laboratory’s elemental analysis with high-quality consumables desig...

Pharmaceutical granulation line

Streamline your production with an integrated system that combines mixing, granulation, and ...

Laboratory twin screw extruder for small batch processing

Efficiently develop formulations and conduct precise research ...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Static checkweigher for accurate measurement

For those needing unparalleled precision, this static checkweigher ensures ex...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

High containment powder transfer valve

Ensure high containment for potent powders in your production line, reducing contami...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Single use valves for powder transfer

Efficiently transfer powder ingredients with a single-use containment solution, ensur...

Bottle cleaning station for controlled environments

Ensure high-level decontamination of passive units and containers wit...

Single use powder handling bags for pharmaceutical ingredients

Achieve contamination-free powder transfers with ease, ma...

Bulk powder transfer safety device

Ensure stable and secure docking by minimizing equipment damage during powder transfer p...

Self-adhesive labeling system for bottles

Streamline your bottling operations with high-precision labeling that enhances p...

Coffee processing system for integrated coffee production

Enhance your coffee production with a versatile system that in...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Leak detection unit for coffee pods

Ensure the integrity of your coffee pods with precise leak detection, vital for maintai...

Cost-effective dosing container for minor ingredients automation

Optimize your production by streamlining ingredient han...

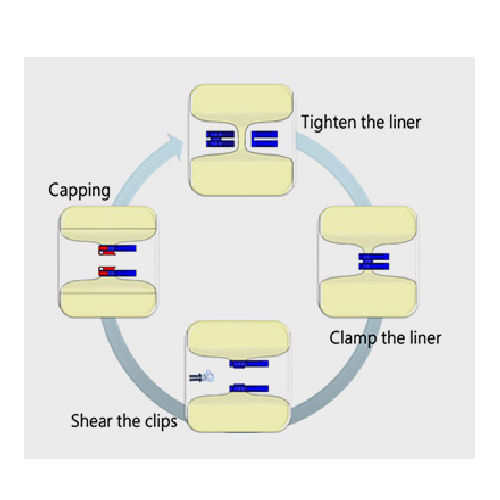

Closure system for aseptic containment

Achieve secure and verifiable seals for sterile pharmaceuticals with advanced closur...

Automatic visual inspection for sterile preparations

Ensure the integrity of sterile products with precise visual inspect...

Particle size control equipment for pharmaceutical applications

Achieve precise particle size control for diverse materi...

Vibration batch dryer for difficult solids

Ensure efficient drying of complex solids prone to sticking and shape irregular...

Dry granulation technology

Achieve precise control over particle size and density with our compacting and granulation soluti...

Pharmaceutical roller compaction solution

Optimize your pharmaceutical tablet production with precision granulation and co...

Vacuum conveyor for powder and granule transfer

Ensure efficient and contamination-free transfer of powders and granules w...

Tube feeder for pharmaceutical and personal care industries

Optimize your production line with this high-speed tube feed...

Moisture analyzer for laboratory samples

Accurate moisture analysis is crucial for ensuring product quality in pharmaceutic...

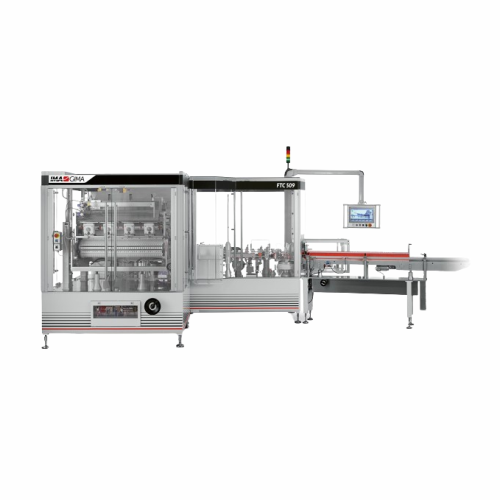

Intermittent motion cartoning machine for blister packs

Optimize your packaging line with a space-efficient cartoning mac...

Desiccant inserter for pharmaceutical containers

Prevent product degradation by efficiently inserting desiccants into cont...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrator for increased safety in hazardous environments

Designed for environments with explosive...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Ibc docking and discharge stations

Ensure seamless material transfer with dust-free docking and effective discharge, mainta...

Industrial container mixing system for high viscosity media

Effortlessly blend high-viscosity liquids and slurries with ...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Supply air filter systems for industrial cleanrooms

Ensure critical air purity and operational safety in sensitive enviro...

Containment single-use filter module

Ensure safe handling of high-potency substances and streamline filtration processes wi...

Industrial chiller systems for processing cooling

Optimize your production line with advanced chiller systems designed to...

Industrial food portioning system

Optimize your production flow with precision portioning equipment designed to handle a di...

Pneumatic diverting valve for powder and granule transfer

Efficiently redirect bulk materials from one point to another ...

Handheld particle counters for cleanroom environment monitoring

Ensure precision in contamination monitoring and quality...

Washing machine for pharmaceutical stoppers and caps

Streamline your aseptic processing with precise washing, sterilizati...

Sterility testing isolator for aseptic environment

Ensure precise sterility testing and prevent contamination with an iso...

Production-level ultrafiltration system for industrial applications

Achieve precise concentration and separation of val...

High-purity nitrogen generator for pharmaceutical and food industries

Achieve ultra-high purity levels in your producti...

Industrial freeze dryer for pharmaceutical applications

Enhance your production line with precision cleaning solutions fo...

Compact high-torque extruder for customizable extrusion tasks

Ensure precise control over your extrusion processes with ...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

Semi-automatic capping machines for versatile applications

Enhance your packaging efficiency with versatile semi-automat...

Saturated steam sterilizer for pharmaceutical production

Ensure sterility for a diverse range of pharmaceutical products ...

Automated visual inspection for pharmaceutical products

Ensure the integrity and safety of your parenteral products with ...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Material lifting system for dust-free transfer in pharma plants

Achieve seamless material transfer with reduced manual h...

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Automated sample preparation software for pharmaceutical testing

Streamline your laboratory’s sample preparation w...

Flow-through cell dissolution testing with Uv analysis

Effortlessly monitor real-time dissolution with flow-through cell ...

Powder flow tester for pharmaceutical powder flowability

Quickly assess powder flow characteristics to ensure consistent ...

Multi-parameter tablet hardness tester for laboratories

Optimize your tablet production line with a versatile tester that...

Automated dissolution testing with direct Hplc injection

Streamline your lab operations with precise and efficient direct...

Real-time Uv-vis analysis for dissolution testing

Efficiently perform dual dissolution tests simultaneously, seamlessly i...

Benchtop dissolution tester for multiple test runs

Streamline your laboratory’s workflow with a fully automated ben...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

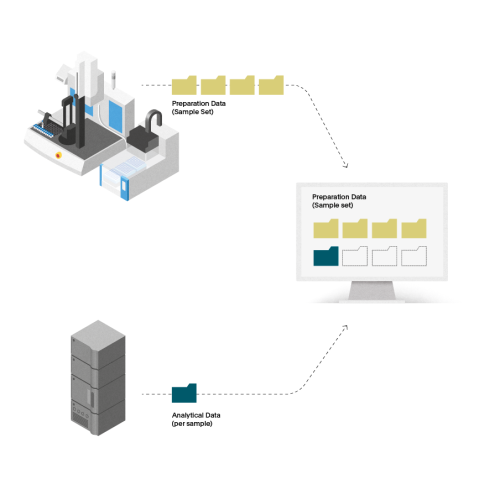

Serialization equipment for cases

Serialization is a multi-stage process that includes printing, inspection, and labeling. ...

Individual item serialization equipment

Traceability is critical to quality assurance in the pharmaceutical sector. But ser...

Flat carton coding machine

The coding process is an essential step in the production line as it can provide trusted supply c...

Software to differentiate between the original pharmaceutical barcode and a reprint

Counterfeit products pose a serio...

Serialized labels inspection and printing station

Labels are a key component in pharmaceutical packaging lines as they in...

Serialization tracking system

To accommodate different products of varied sizes, the pharmaceutical industry requires handli...

Serialization and aggregation system

Manufacturers from the pharmaceutical industry require a variety of cartons, cases and...

Flat carton serialization station

The packaging lines in the pharmaceutical industry handle several flat cartons. Manual pa...

Clinical trial lab sealer for a laminar airflow bench

When running small production for clinical trials, stability studie...

Granulation line for pharmaceutical solid dosage forms

Granulation is a common technique in production of pharmaceutical ...

Fluid bed dryer for pharmaceutical solid dosage form

Fluid bed drying is a pharmaceutical process carried out to reduce t...

Industrial high shear mixer granulator for drug formation

It is rather difficult to successfully produce a pharmaceutica...

Pharmaceutical bottle unscrambler

Pharmaceutical packaging industry requires the ability to quickly manage the process yet ...

Dessicant inserting machine

Desiccant canisters play an important role in the pharmaceutical and nutraceutical industries. T...

Semi-automatic powder dosing machine

Powders or granules are common dose types used in many pharmaceutical and nutraceutica...

Suppository filling machine

Small-to-medium scale production of suppositories using pre-formed shells can be slow where manu...

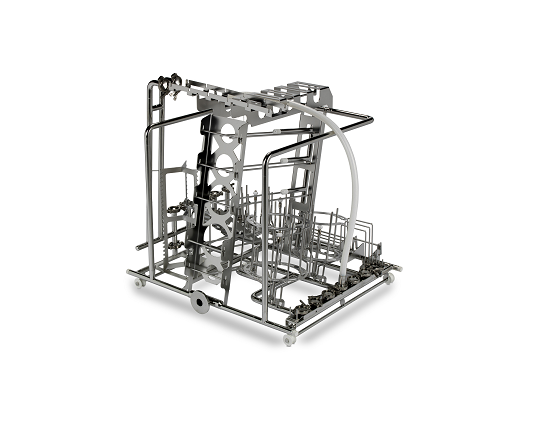

Loading basket for GMP washer

To ensure perfect cleaning of contact parts they must be placed in the GMP washer in such a wa...

Bulk chamber washer

The production of cosmetics, nutraceuticals or unregulated pharmaceuticals often requires the cleaning an...

Entry-level chamber washer

When cleaning smaller products contacting filling or compressing components used in the productio...

Conical mill for drug formulation

The efficient size reduction of granular powders is a key step in many pharmaceutical pro...

Granulation line of mixer and fluid bed dryer

A complete granulation line allows for the mixing and granulation of pharmac...

Fluid bed dryer for production scale

Fluidized bed drying (FBD) is a common process in the pharmaceutical industry for dryi...

Fluid bed dryer for lab scale

Fluidised bed drying (FBD) is a common process in the pharmaceutical industry for drying compo...

Fluid bed dryer and mixer for lab scale

Designed for pharmaceutical R&D, a lab-scale fluid bed dryer and mixer/granulat...

High-shear mixer

For the efficient mixing of larger batches of pharmaceutical compounds and high-shear mixer provides the opti...

Entry-level high-shear mixer for drug formulation

For pilot and lab-scale pharmaceutical formulations, a high-shear granu...

Starch-free depositor for hard candy

Forming hard candies requires careful handling of syrups in order to avoid quality iss...

Thin-film cooker for confectionery products

Producing excellent confectionery products requires high quality cooking. Trad...

Dissolver of confectionery syrups

Many high quality confectionery products require a dissolved syrup as their starting poin...

Automatic weigher and mixer of confectionery ingredients

The production of accurately proportioned and homogenous slurrie...

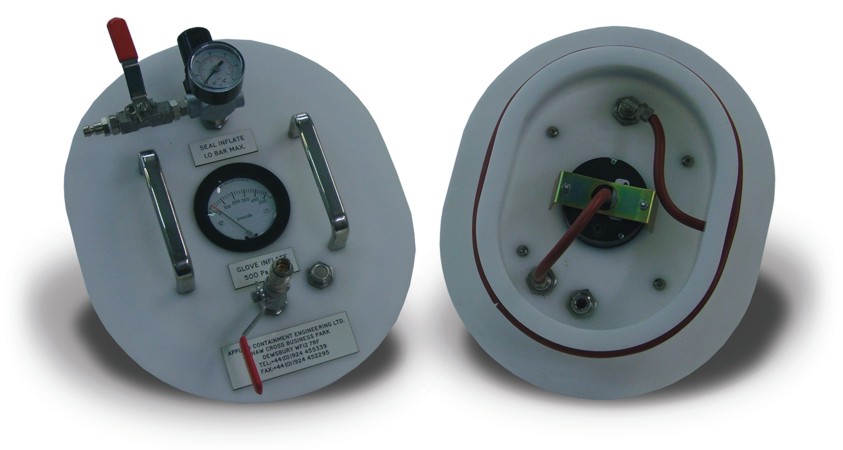

Half-suit tester

Designed to allow operators to perform sterility testing in an aseptic environment providing assurance of mat...

Glove tester

Testing device of the containment capability of gloves, which is as important as the other parts of the integrate...

Negative pressure isolator

Used for products biologically hazardous, that also require minimized cross contamination.

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Laboratory dispersing machine for low-viscous masses

Laboratory mixers have not always been easy to work with. Getting a...

High-speed blister machine

If you are looking for a compact machine that produces blisters with an output of up to 700 blist...

Horizontal intermittent motion cartoner

User-friendly cartooning solution with an intermittent motion for a wide range of p...

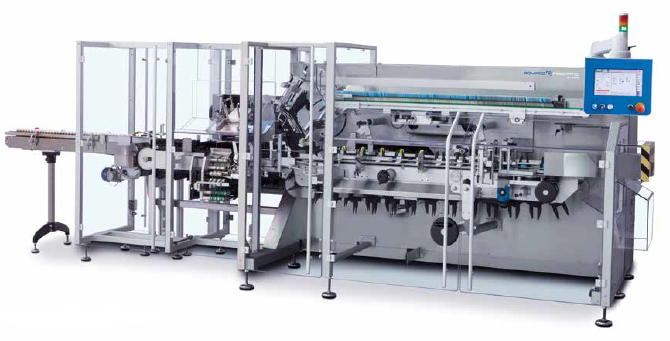

Horizontal continuous motion cartoner

An automatic cartoning machine designed for both high-speed operations and medium pac...

Entry-level blister machine

A start-up solution for contract packing and generics manufacturing with an easy-to-get upgrade ...

Case packer for cartons and bundles

Pack cartons and bundles into RSC (Regular Slotted Case) cases and perform functions li...

Stretch bander

A compact wrapping machine to seal your boxes with a max speed of 50 packs per minute.

Vertical cartoner

A cartoning solution that can be operated in either continuous or intermittent mode depending on the carton...

Aseptic barrier systems

Designed for sterile product and Potent API’s either with low or high OEL requirements.

Restricted-access barrier systems

Create a physical barrier between the operator and the product. More flexible than an iso...

Sterility test isolators

Designed to avoid this risk and protect the product from both the process and externally generated f...

Checkweigher

A check weigher that is equipped with high speed/high accuracy force balance load cell. It meets stringent accura...