Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with precise gas flushing technology, ensuring consistent quality from packaging to delivery.

Extends Shelf Life of Perishable Products

Viking Masek’s Modified Atmosphere Packaging (MAP) Solutions utilize nitrogen gas flushing and specialized packaging materials to extend the freshness and shelf life of perishable goods. Designed for seamless integration into various production lines, these solutions are ideal for applications ranging from food and beverages to medical devices, ensuring products like ground coffee, frozen strawberries, and surgical supplies maintain their quality. With both continuous and intermittent operation modes, Viking Masek’s MAP equipment handles a wide range of product types, including solids, powders, and liquids. Its PLC-controlled system enhances automation and remote monitoring capabilities, allowing for efficient control and integration within existing packaging lines. For energy-conscious operations, the system’s optimized configuration reduces waste and energy consumption. Available in corrosion-resistant materials, the equipment complies with relevant industry standards, offering reliable performance in varied industrial environments. Customization options and engineering support allow tailoring to specific operational requirements, making it a versatile choice for diverse manufacturing needs.

Benefits

- Enhances product freshness and longevity, reducing waste and spoilage costs.

- Supports diverse product types, ensuring flexible application across multiple industries.

- Seamlessly integrates into existing lines, optimizing production efficiency.

- Minimizes energy consumption through efficient nitrogen flushing processes.

- Ensures compliance with industry standards, maintaining product quality and safety.

- Applications

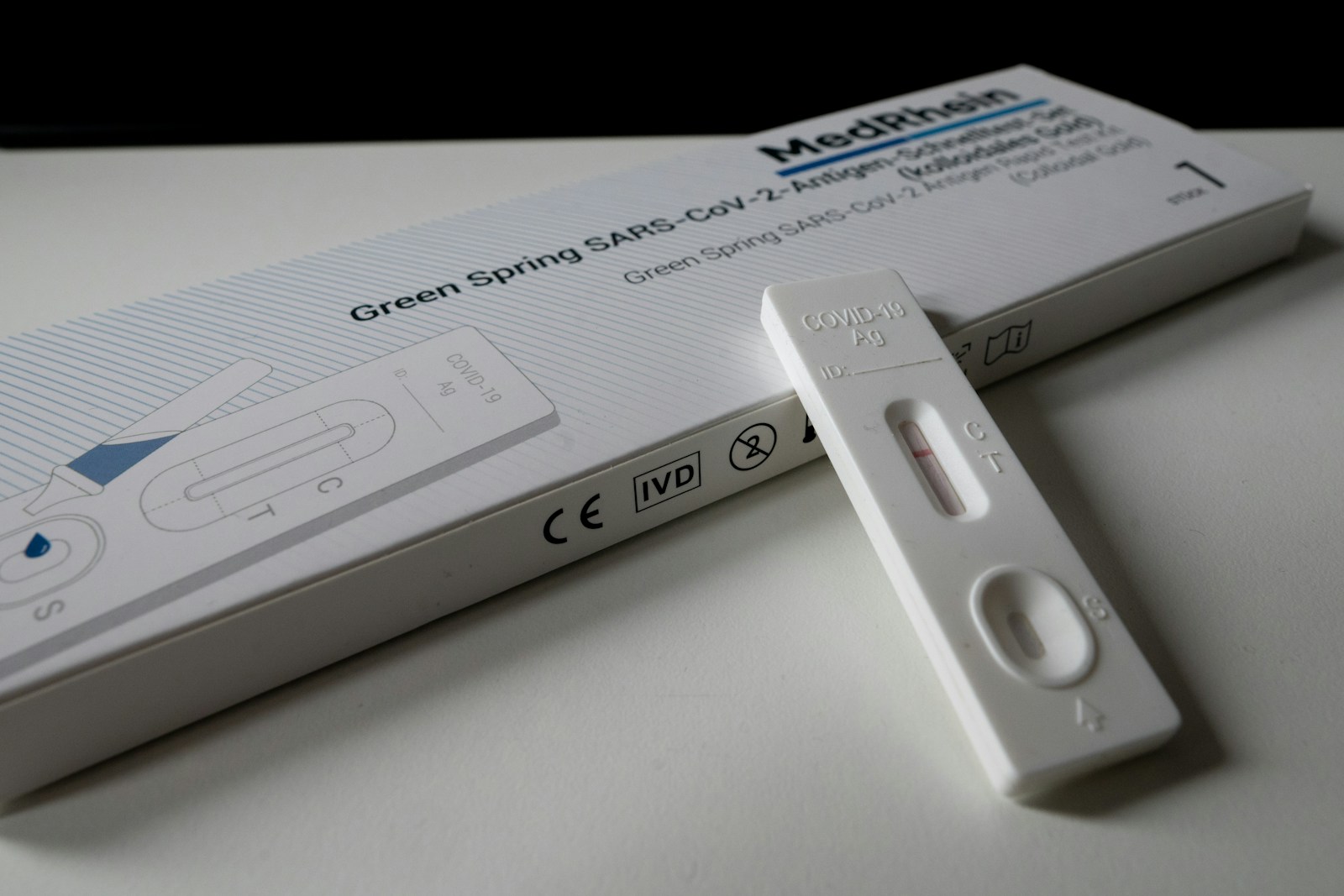

- Treats, Medical devices, Snacks, Bakery, Cheese, Organic foods, Medical testing kits, Fish, Liquids, Food, Fresh fruit, Non-food products, Individual quick frozen (iqf) products, Beans, Supplies, Pills, Cannabis, Capsules, Candy, Pasta, Pet food, Nuts, Natural, Rice, Health, Cereal, Beverage, Meat, Coffee, Medical products, Vegetables, Poultry, Powders

- End products

- Dog biscuits, Spaghetti, Vitamin tablets, Potato chips, Baking soda, Jasmine rice, Salmon fillets, Chicken breasts, Orange juice, Croissants, Covid-19 test kits, Bandages, Cheddar cheese, Frozen strawberries, Cornflakes, Syringes, Milk, Cat food, Black beans, Ground coffee, Almonds, Carrots, Cannabis oil, Apples, Organic baby food, Ibuprofen capsules, Chocolate bars, Salami, Automotive parts

- Steps before

- Product Preparation, Sorting, Cleaning, Weighing

- Steps after

- Sealing, Labeling, Cartoning, Palletizing

- Input ingredients

- perishable products, food, beverages, coffee, cannabis, individual quick frozen (IQF) items, powders, cereal, nuts, snacks, fresh fruit, vegetables, liquids, meat, poultry, fish, pet food, treats, candy, pasta, beans, rice, natural foods, organic foods, cheese, bakery items, health products, medical devices, pills, capsules, medical testing kits, non-food products

- Output ingredients

- packaged perishable products, extended shelf life products, fresh packaged food, stabilized packaged goods, shelf-stable items

- Market info

- Viking Masek is known for manufacturing innovative packaging machinery. They specialize in automated packaging solutions, including vertical and horizontal form-fill-seal machines, and are reputed for quality, flexibility, and custom-engineered solutions for various industries.

- Automation

- PLC-controlled

- Filling method

- Nitrogen gas flushing

- Bag type

- Premade Pouch / Pillow / Doypack / Stick Pack

- Capacity

- Modified Atmosphere Packaging (MAP) technologies for extended shelf life

- Oxygen scavenger

- Integrated unit

- Shelf life extension

- Ensures freshness as packaged

- Packaging process integration

- Added at key points

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- Energy efficiency

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Perishability risk

- High

- Discharge method

- Endload / Wraparound / Topload

- Control panel type

- PLC / HMI

- Bag type

- Standcap / Premade Pouch

- Control panel type

- Auto / Manual with User Interface