Coffee Processing Equipment

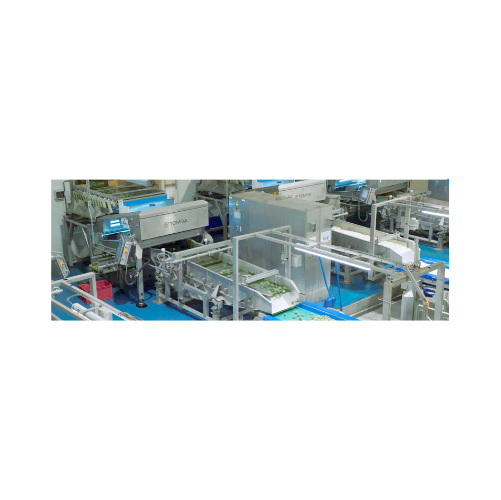

Find innovative coffee equipment and connect directly with world-leading technology suppliers

With over one-third of the population consuming it daily in different forms, coffee is one of the most popular processed beverages worldwide. Not only serving as drinks, but coffee is also often regarded as a culture. Coffee manufacturing is a knowledge-intensive industry. Coffee beans from different regions will reveal different tastes, while the level of caffeine could also be different. When it comes to coffee bean processing, the range of roasts varies from light golden brown all the way to dark. The method of tasting coffee differs between countries, habits, and tools.

Top picks for coffee processing

Automated coffee bean roaster

Optimize your coffee roasting with precision control, ensuring consistent quality in every bat...

Automatic lab roaster for 1 kg coffee batches

Perfect for coffee roasters aiming to refine roast profiles, this lab roaste...

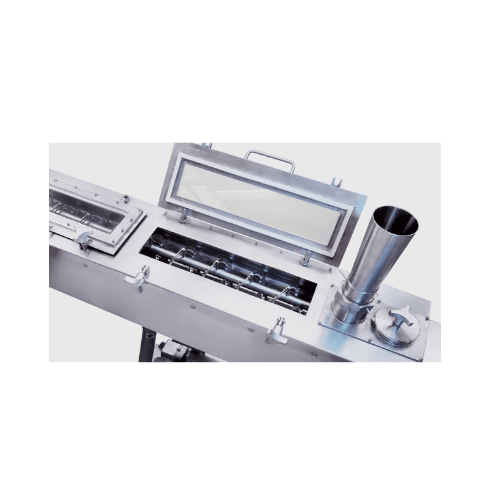

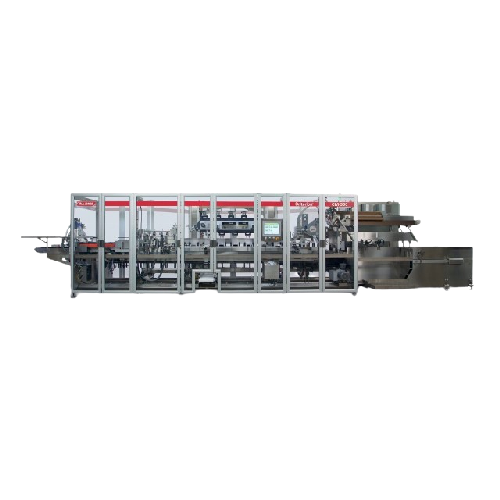

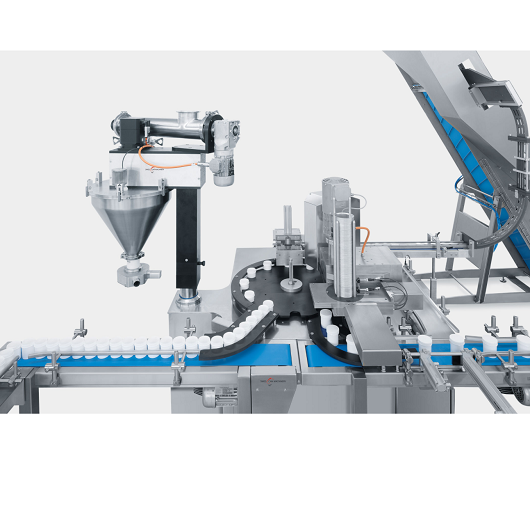

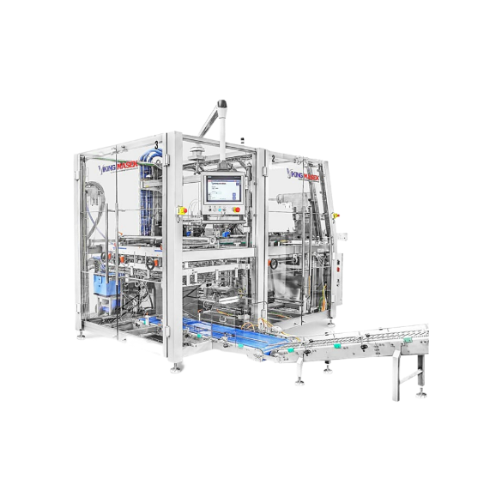

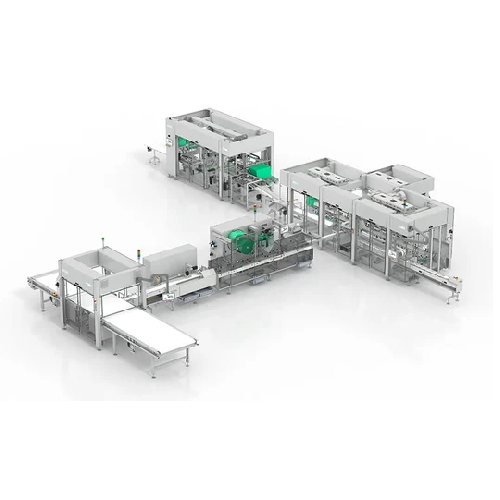

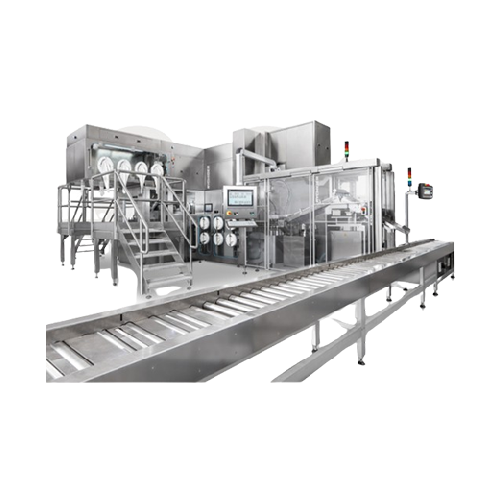

Capsule filling and sealing system for coffee production

Achieve precise coffee capsule production with a machine that se...

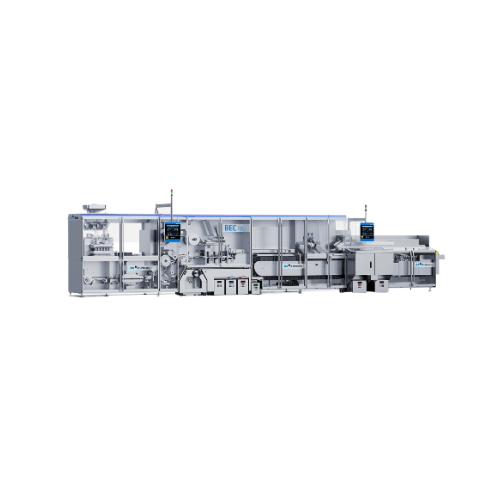

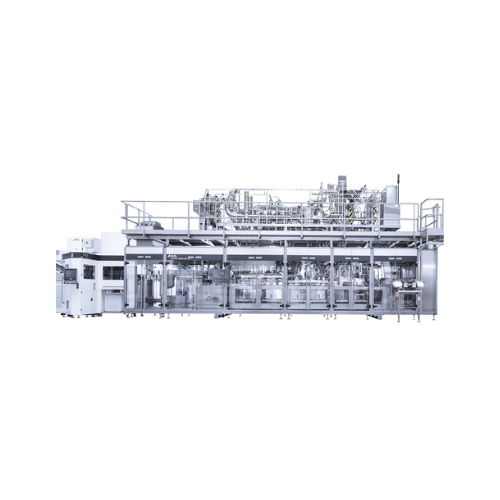

Coffee processing system for integrated coffee production

Enhance your coffee production with a versatile system that in...

Select your coffee process

Tell us about your production challenge

Coffee production is the method of converting raw coffee cherries into the finished coffee beans. There are various ways of processing coffee, which can significantly affect the flavors. In addition, the final format of the coffee products and how people drink their brewed coffee also plays an important role in the taste. A huge increase in demand for high-quality coffee products means that smaller-scale producers can leverage quality and innovation to benefit from this enormous potential.

Coffee processing technologies

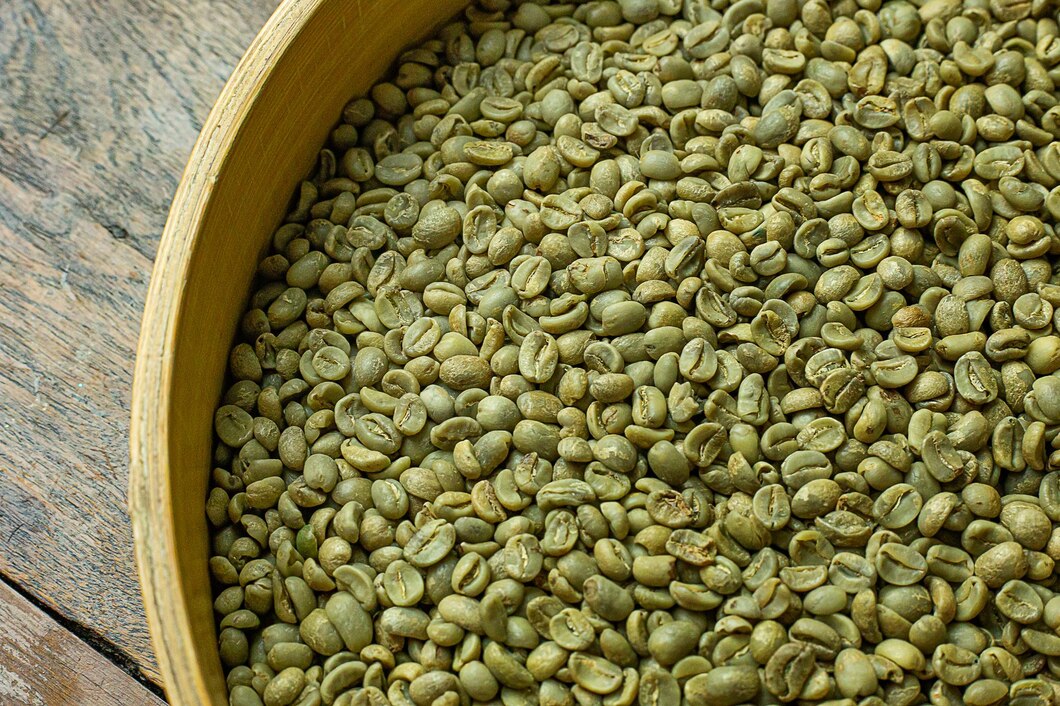

After harvesting, coffee cherries need to be processed in either dry or wet method to have the fruits, known as mucilage, which cover the beans, removed. When the skin is removed to leave only the mucilage, it is referred to as the pulping process.

The beans are then separated by weights and sizes by rotating drums or screening sieves. After the beans are dried and graded, they are ready for roasting. Sometimes, the different beans are blended to create desired taste. When it comes to the wet process, fermentation of the coffee beans in essential. Therefore, specialized coffee fermentation tanks will need to be used to achieve this.

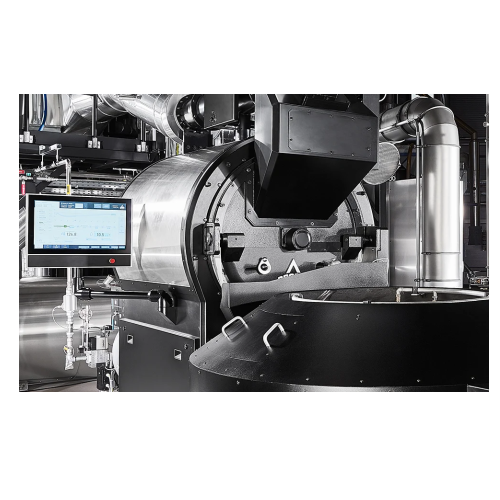

Since coffee’s characteristic flavor and aroma only develops until beans are roasted, roasting is an essential step in the process. After roasting, coffee beans are usually ground in roll mills. The primary goal of grinding is to produce the most taste in a cup of coffee, while the type of grinding determines how fast the coffee can release its flavors.

Producing instant coffee

Instant coffee is made from roasted and ground coffee. The grounded beans are extracted with hot water to retrieve the aroma and the flavor. The coffee extract can then be dried in two different ways: spray drying or freeze drying. In spray drying, the coffee extract is sprayed into a stream of hot water, it dries fast and becomes fine powder when reaching the bottom. In freeze-drying, the coffee extract is frozen to about – 40°C and cut into granules. The quality of the aroma and flavor are protected by the very low temperature and gentle drying conditions. Finally, the granules of instant coffee can be packed into sachets or glass jars.

Sustainable trend in coffee packaging

Due to the raising awareness on climate change and social responsibility, sustainability in the coffee industry has become vital considerations. From the perspective of coffee packaging, there’s a growing trend of using eco-friendly materials. Environmental impacts are eliminated in different stages within the production line. With coffee capsules waste at an all time high, products like biodegradable, dissolvable capsules aim to reduce environmental impact while still offering high quality coffee conveniently at home. Recyclable and biodegradable materials are also widely adopted for coffee bean bags or boxes.

How to pack your beans or coffee powders?

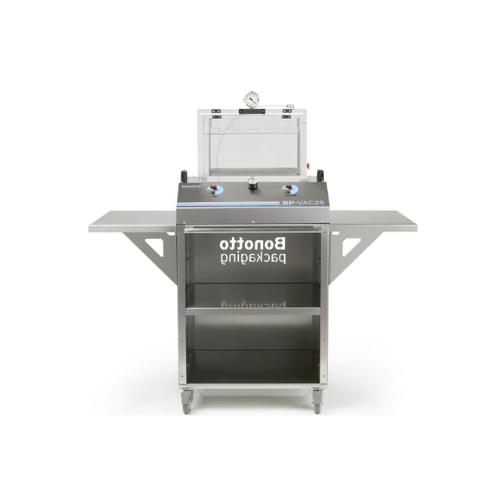

The quality of coffee beans or ground coffee is quickly diminished by oxygen in the air; oxygen breaks down the precious aromas in the coffee, and the flavor becomes flat. To guarantee as far as possible that the flavor of the coffee enjoyed by the consumer is as good as when it left the factory, coffee beans or ground coffee is very often vacuum or soft-vacuum packed, so that no air can get in.

Which coffee technology do you need?

Industrial coffee roaster for mid to large-scale production

Optimize your coffee’s aroma with precision control ov...

P series coffee roasting system

Optimize your roasting precision and flexibility with customizable batch sizes, ideal for ac...

Sample roaster for testing coffee blends

Ideal for coffee innovators, this bench-top roaster enables precise control over t...

Industrial gas roaster for coffee beans

Achieve consistent and flexible coffee roasting with a versatile gas roaster, desig...

Coffee drum roaster px 120 for industrial use

Optimize your coffee roasting with precise control over batch size and heati...

Tangential coffee roaster for diverse roasting profiles

Achieve unparalleled precision and flexibility in coffee roasting...

Large scale coffee drum roaster

Enhance your coffee production with a versatile drum roaster designed for precise control an...

Industrial coffee roaster for large scale production

Enhance your coffee’s aroma and flavor profile with an industr...

Industrial drum roaster for coffee beans

Achieve precise flavor profiles and consistent roasting quality with a flexible dr...

Industrial drum roaster for gourmet coffee

Achieve consistent gourmet coffee flavor profiles with precise heat transfer an...

Centrifugal coffee roaster for uniform roasting

Achieve consistent and precise coffee roasting with advanced centrifugal t...

Commercial coffee grinder for industrial use

Achieve precision in coffee grinding with this solution, offering optimal con...

Sample roaster for green coffee bean quality grading

Achieve precise roasting control and enhance quality assurance with ...

Medium batch coffee roaster for flexible production

For coffee roasters seeking precision and flexibility, this medium ba...

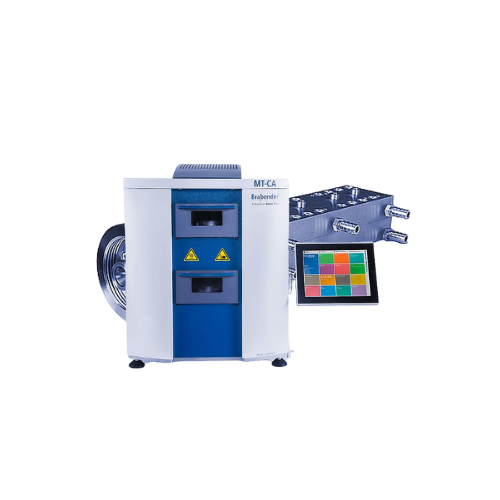

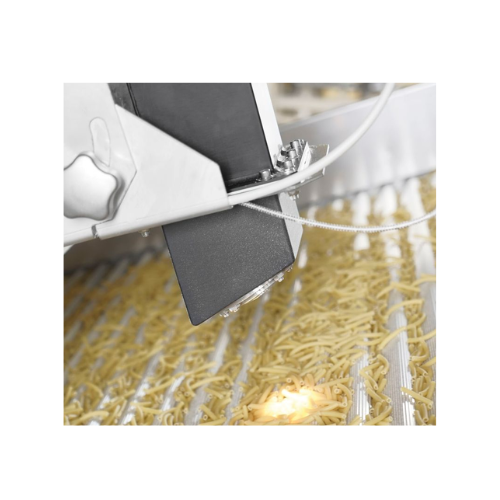

Color measurement tool for ground coffee

Ensure accurate coffee color measurement with a reflection-based system, vital for...

Green coffee preheating system

Optimize your coffee roasting process by utilizing waste heat for preheating, reducing energy...

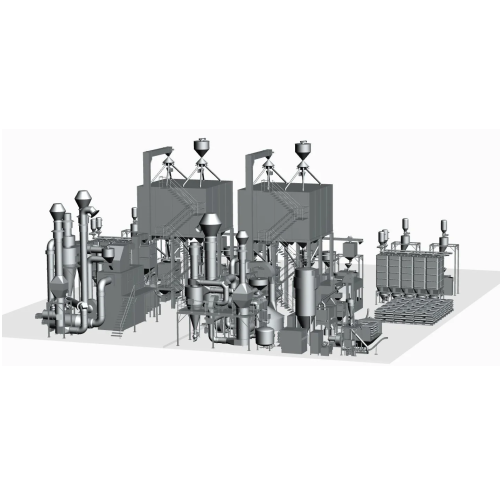

Custom coffee roasting plant solutions

Optimize your coffee production line with scalable plant solutions that integrate se...

Coffee bean and ground coffee filling system

Efficiently fill tins and jars with coffee beans or ground coffee while ensur...

Filling system for ground coffee in tins

Achieve precise weight control and enhanced throughput with a high-speed filling s...

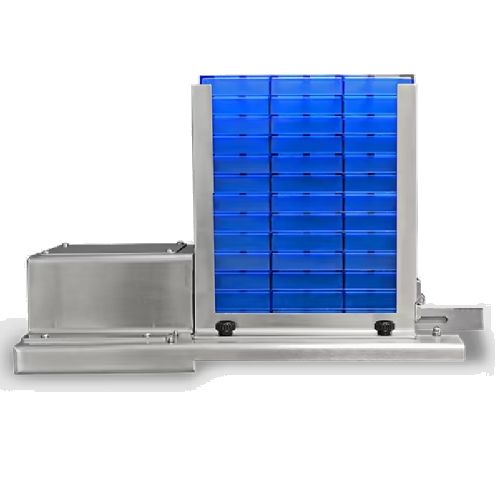

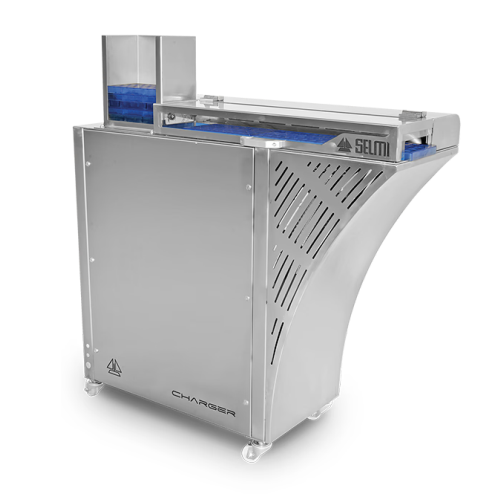

Packaging system for stacked coffee pods

Efficiently package your pods with precise counting and sealing, ensuring optimal ...

System for packaging stacked coffee pods in filter paper

Streamline your pod production with precision bagging and sealin...

Industrial coffee roaster for high-capacity coffee production

Enhance your coffee production line with high-speed roasti...

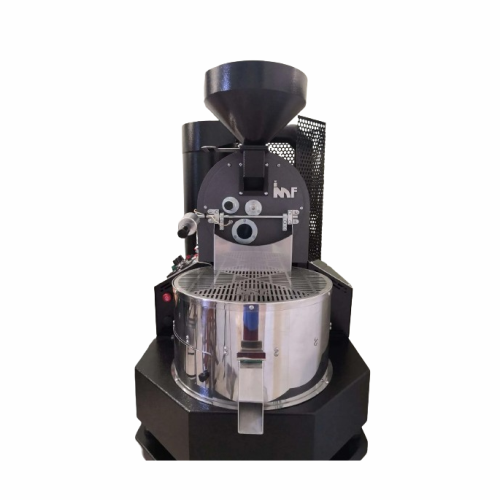

Small batch coffee roaster for specialty coffee shops

Achieve consistent, artisanal coffee roasts with this precision-con...

Automatic coffee roasting system with emission control

Experience precision in coffee roasting with a system designed for...

Industrial coffee roaster 480kg batch capacity

Optimize your coffee production with precision roasting for up to 480 kg pe...

Small-scale coffee roaster for cafes

Elevate your coffee roasting with advanced emission reduction and precise control, des...

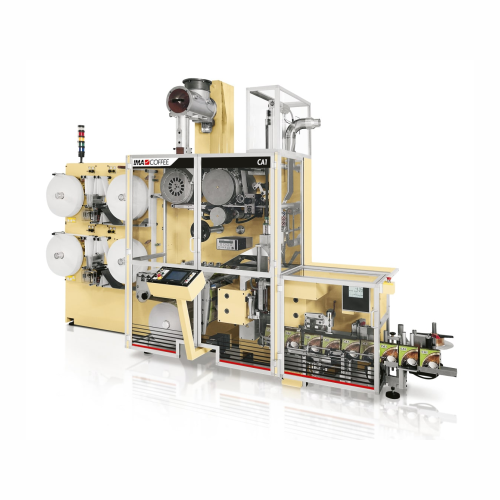

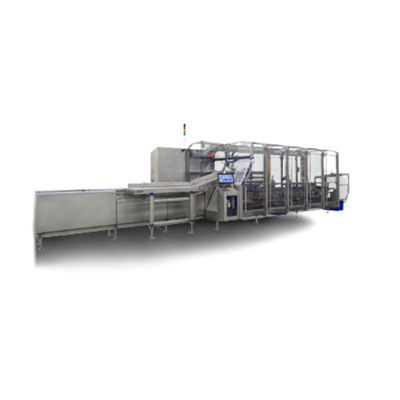

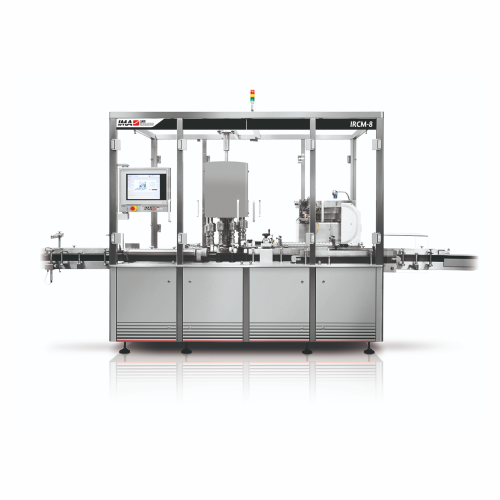

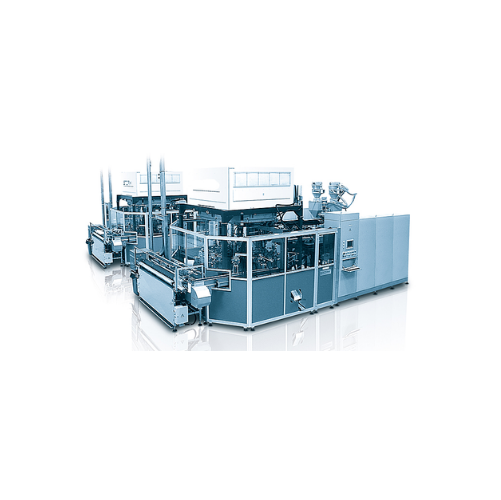

Capsule filling and sealing system for coffee production

Achieve precise coffee capsule production with a machine that se...

Coffee roasting solution for small-scale industrial applications

This innovative roasting solution offers complete contr...

Capsule filling and sealing system for coffee

Optimize your capsule production with a system designed to enhance precision...

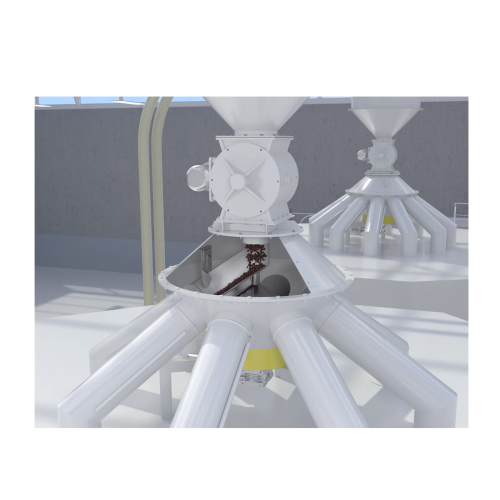

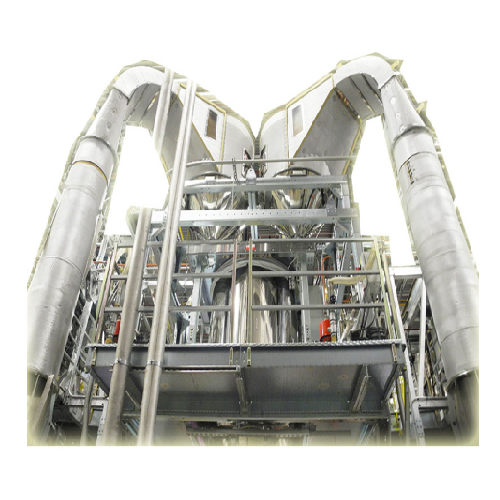

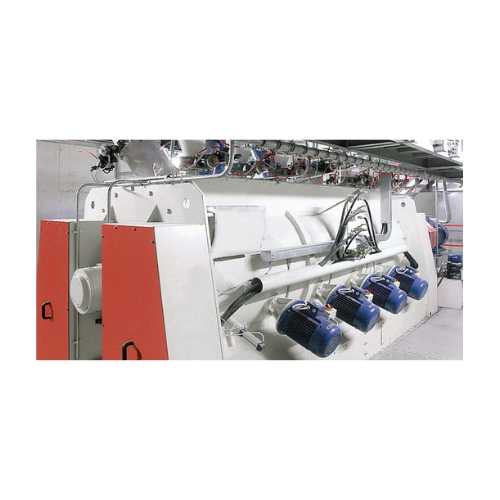

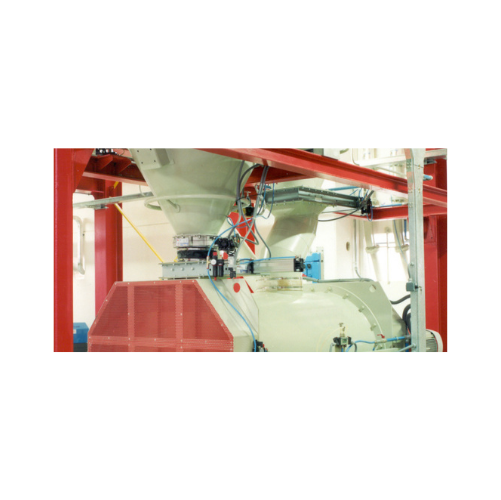

Green coffee intake systems

Streamline your green coffee bean processing with versatile systems that manage intake, conveyin...

Specialty coffee roaster for small batch production

Enhance your coffee roasting precision with advanced heat control and...

Industrial coffee roaster with high energy efficiency

Enhance your coffee roasting efficiency with a modular system desig...

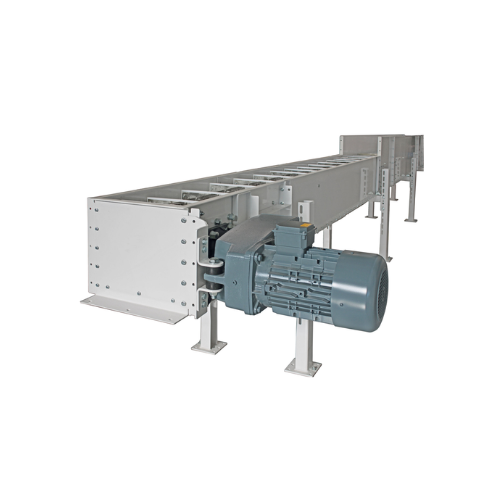

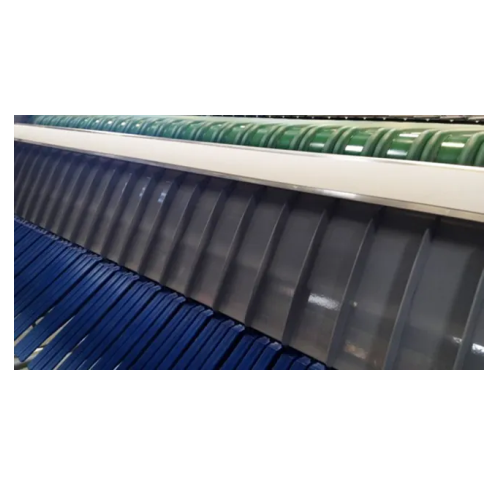

Roasted coffee handling and conveying system

Ensure the gentle handling of roasted coffee with versatile conveying solutio...

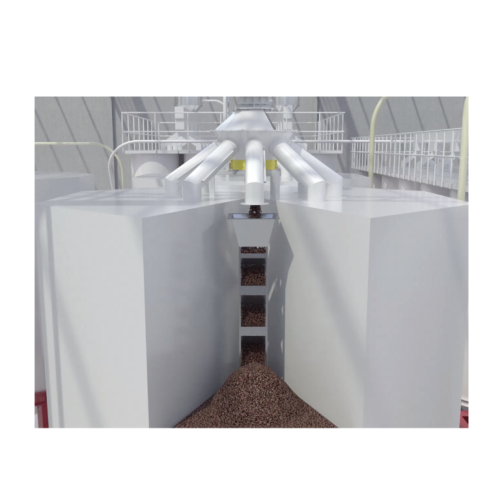

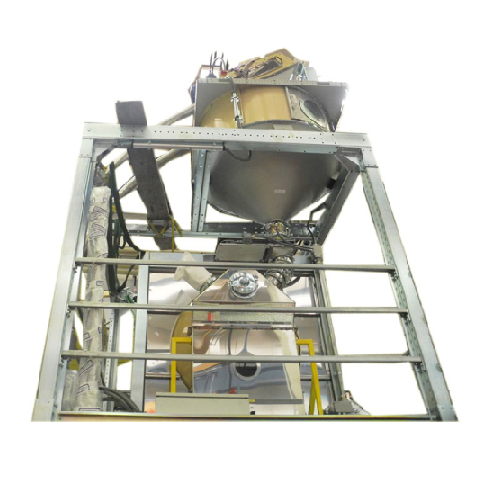

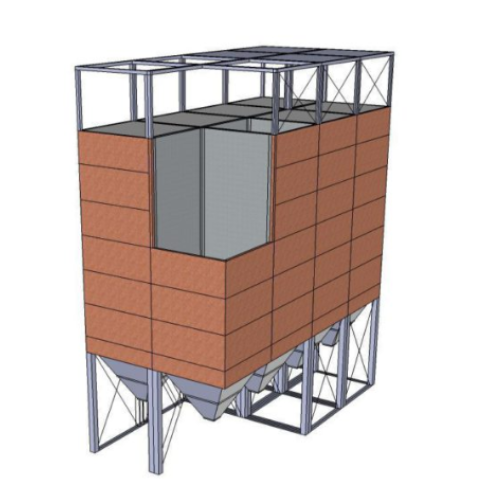

Roasted coffee storage solutions

Ensure the highest integrity of your coffee beans with advanced storage and handling system...

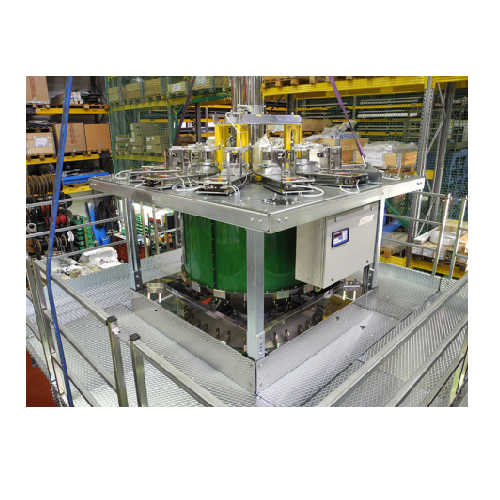

Roasted coffee weighing and blending system

Achieve precision and consistency in your coffee blends with cutting-edge weig...

Capsule filling and sealing system for coffee products

Optimizing the precision of coffee and tea capsule production, thi...

Soft pod packaging solution for coffee

Streamline your coffee production with a compact, high-speed solution that ensures p...

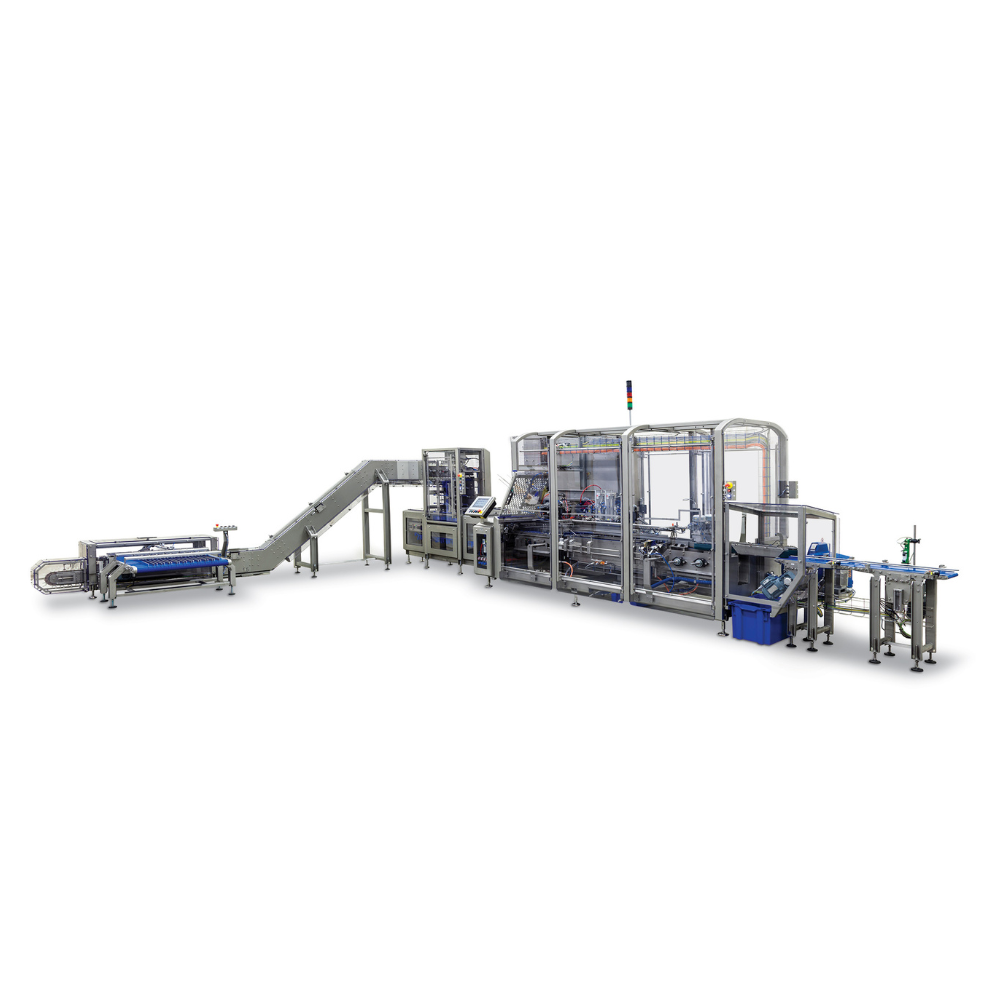

Hard pod packaging system for coffee

Optimize your coffee production with a compact system designed for high-speed packagin...

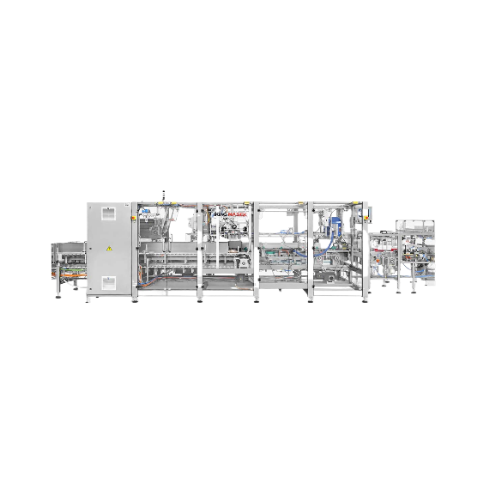

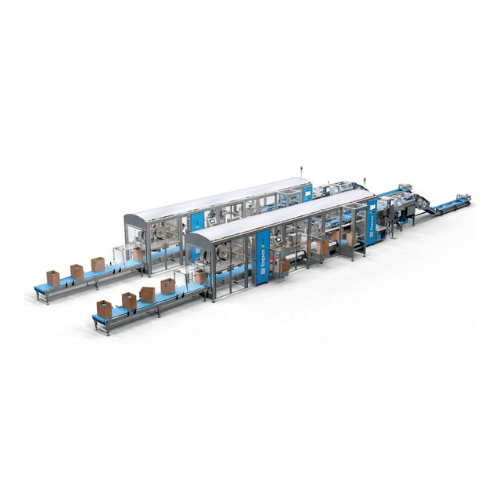

Capsule cartoning for coffee and tea products

Optimize your capsule packaging process with a solution that enhances speed ...

Cartoning system for coffee capsules

Optimize your production line with a space-saving cartoning system designed specifical...

Capsule cartoning system for coffee and tea

Streamline your capsule packaging with a high-speed cartoning solution that ef...

Green coffee cleaning and sorting systems

Optimize your coffee processing by integrating advanced cleaning and sorting sys...

Green coffee handling and conveying systems

Efficiently handle and convey green coffee beans to maintain product integrity...

Green coffee storaging and dosing system

Optimize your coffee production with a flexible and modular solution designed for ...

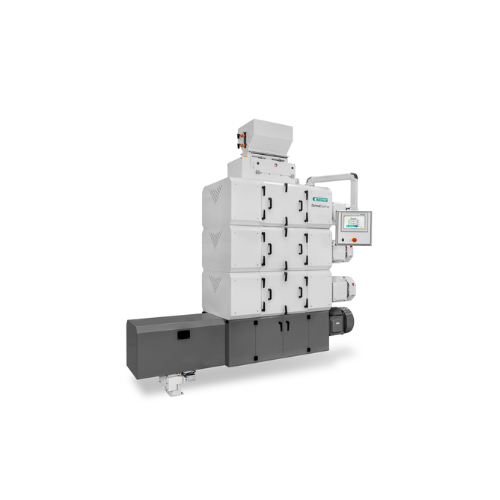

Industrial coffee grinders for optimal particle size

Achieve precise coffee grinding with advanced control over particle ...

Ground coffee handling and conveying system

Enhance your coffee production with precise handling systems that ensure aroma...

Small batch coffee roaster

Achieve consistent flavors and precision in small-batch coffee roasting with this versatile roast...

Industrial coffee roaster for large-scale operations

Elevate your roasting process with a high-capacity solution designed...

Large-scale coffee roaster for wholesale production

Elevate your coffee roasting with precision and efficiency, ensuring ...

Large-scale coffee roaster for specialty coffee production

Elevate your coffee production with a high-capacity roaster d...

Mid-sized coffee roaster for specialty coffee shops

Optimize your coffee roasting process with precision control and vers...

Electrostatic filter for coffee roasting emissions

Mitigate unwanted odors and emissions in coffee roasting with high-eff...

Catalytic emission cleaner for coffee roasters

Optimize your coffee roasting process by effectively reducing emissions wit...

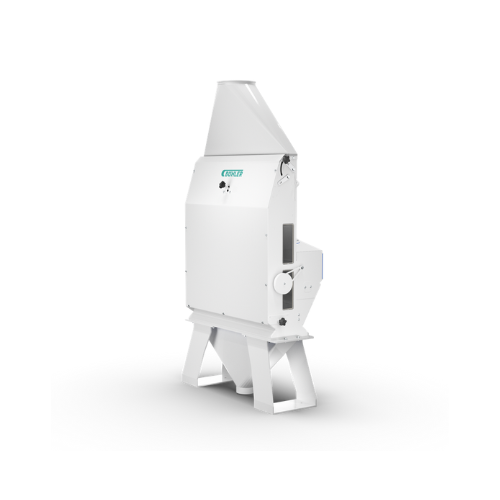

Coffee destoner

Ensure the integrity and quality of your roasted coffee beans by efficiently removing stones and foreign mater...

External cyclone for coffee roasting chaff collection

Simplify your coffee roasting process by efficiently collecting cha...

Green coffee conveyor for efficient coffee roasting operations

Effortlessly streamline your roasting process by automati...

Mixer for blending coffee beans

Achieve precise and consistent coffee blends with a versatile mixer designed for smooth inte...

Sample roaster for coffee beans testing and profiling

Optimize your coffee roasting process with a versatile sample roast...

Modular silo system for coffee bean storage

Optimize your coffee production with a fully customizable modular silo system ...

Industrial coffee roaster for large-scale production

Designed for coffee producers aiming to enhance their roasting capab...

Intermediate coffee roaster for small to middle roasteries

For roasteries expanding production, this versatile roaster o...

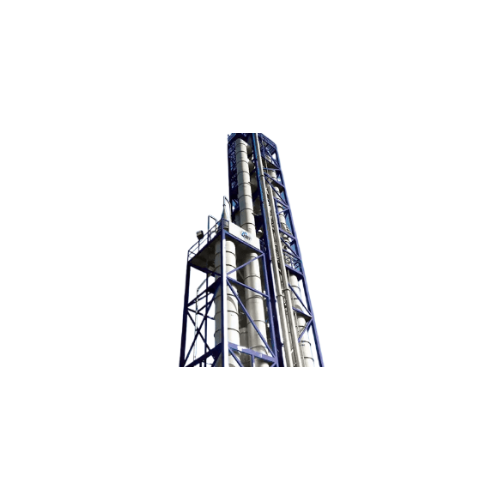

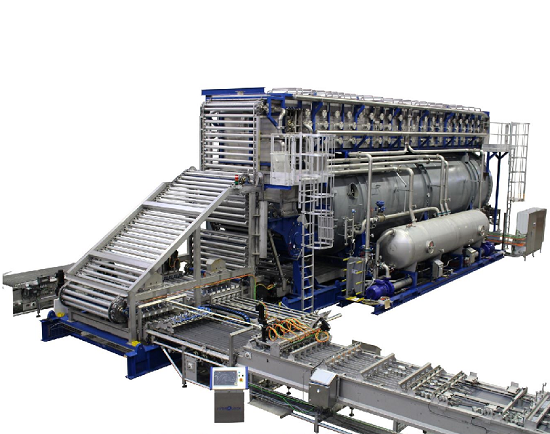

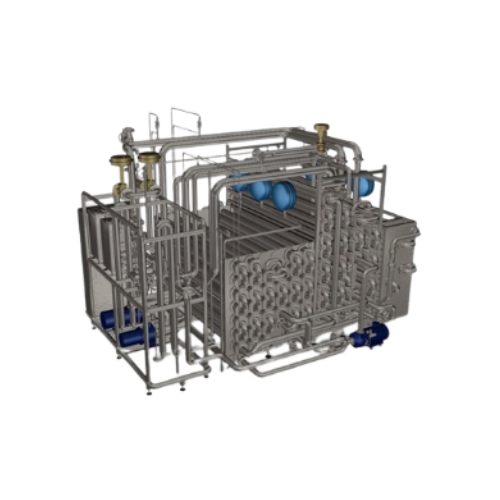

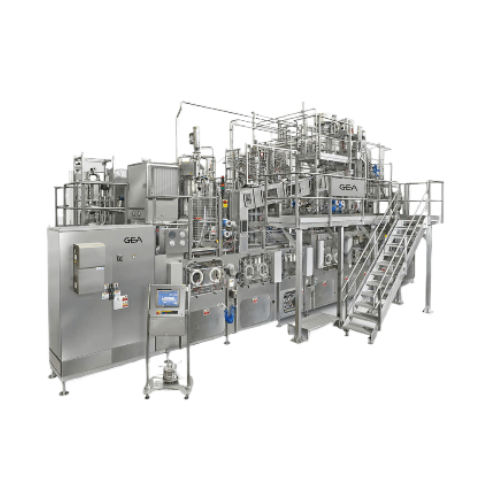

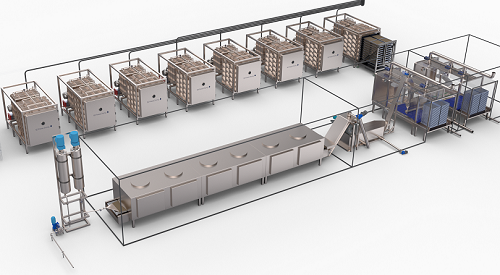

Processing plants for instant coffee production

Achieve optimal flavor retention and cost efficiency in instant coffee pro...

Optical sorter for coffee, grains, nuts, and plastic flakes

Ensure precise defect detection and foreign material removal...

Optical sorter for grains, coffee, nuts, and plastics

Ensure consistent product quality and minimize waste with advanced ...

Industrial coffee roaster

Achieve optimal coffee flavor with precise roasting control and energy efficiency, perfect for pus...

Optical sorter for coffee beans

Achieve precise color differentiation and advanced foreign matter detection, optimizing your...

Industrial coffee grinder for consistent particle sizes

Achieve precise, consistent coffee grinds essential for specializ...

Coffee processing system for integrated coffee production

Enhance your coffee production with a versatile system that in...

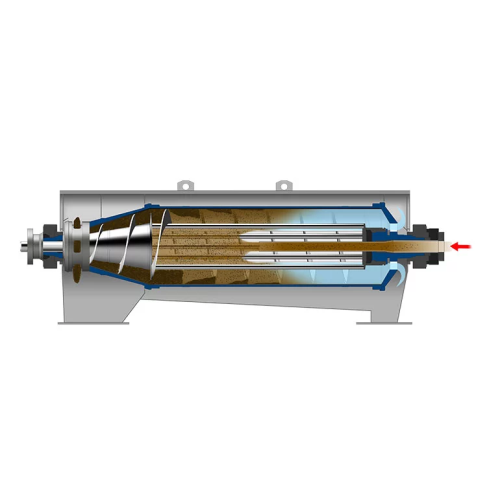

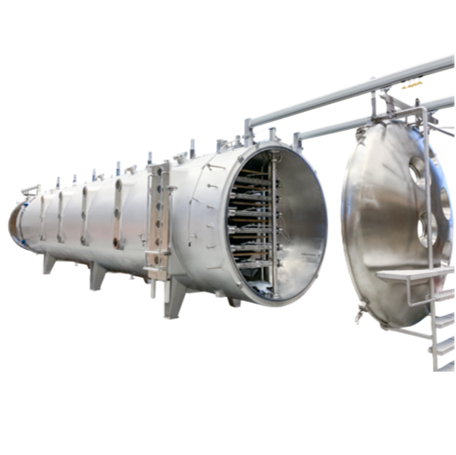

Continuous freeze drying solution for coffee and food pieces

Achieve optimal moisture removal in heat-sensitive products...

Coffee roasting system

Optimize your coffee production from green beans to finely ground espresso with this versatile system,...

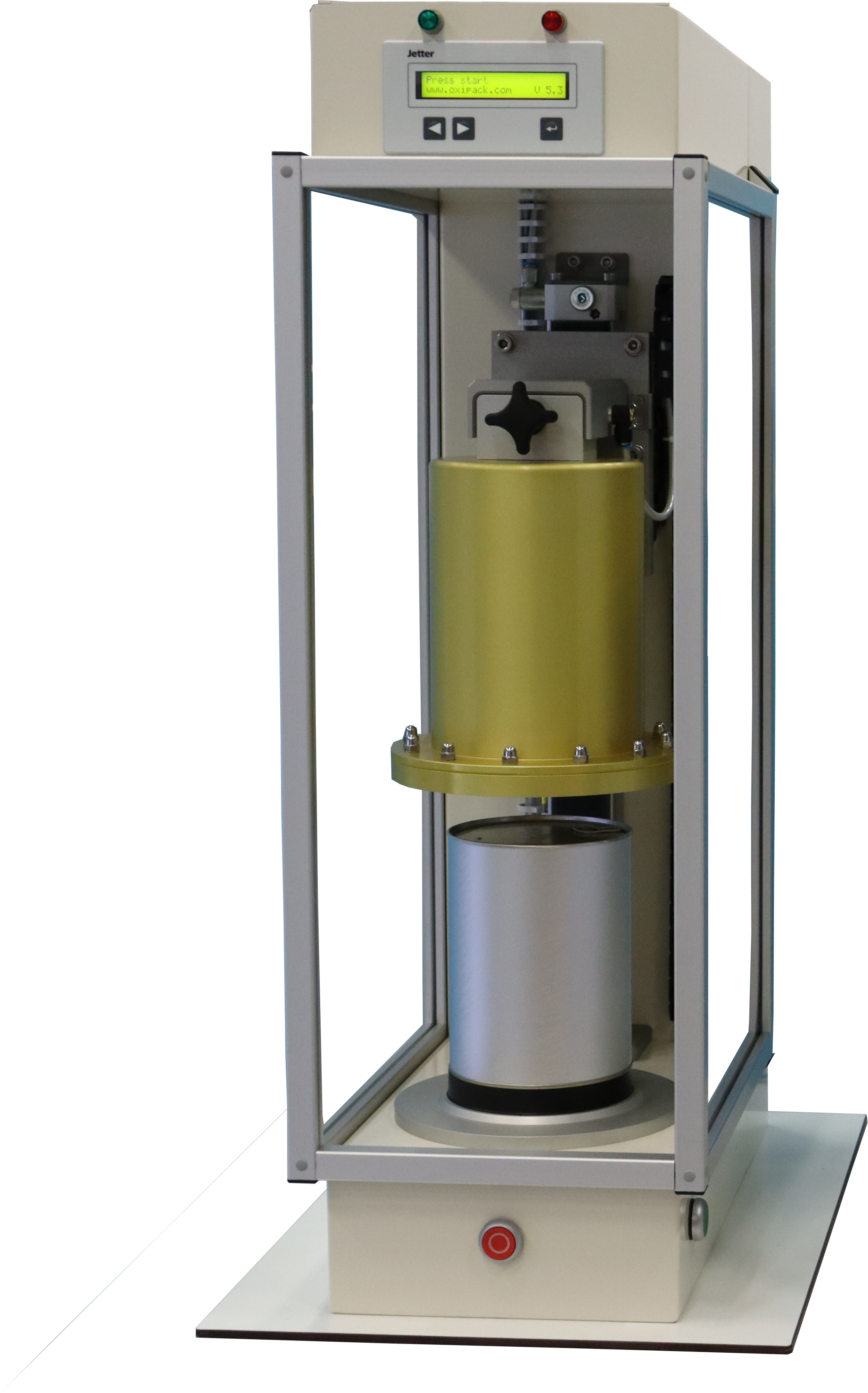

Leak detection unit for coffee pods

Ensure the integrity of your coffee pods with precise leak detection, vital for maintai...

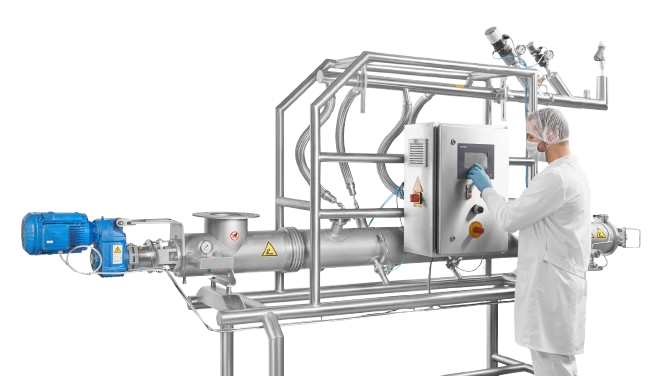

Aroma recovery system for instant coffee processing

Capture and enhance coffee aromas with a specialized system designed ...

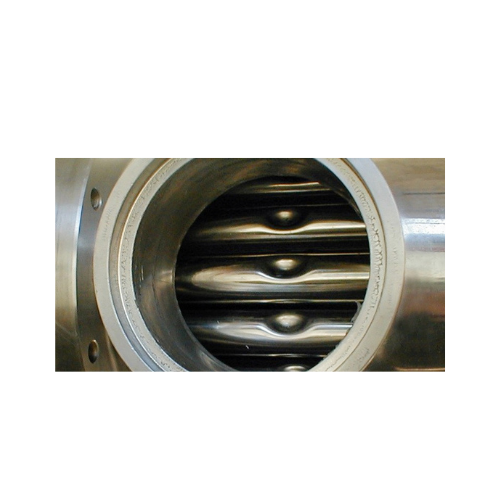

Wet grinding system for coffee flavor preservation

Achieve unparalleled coffee flavor and aroma by integrating a low-temp...

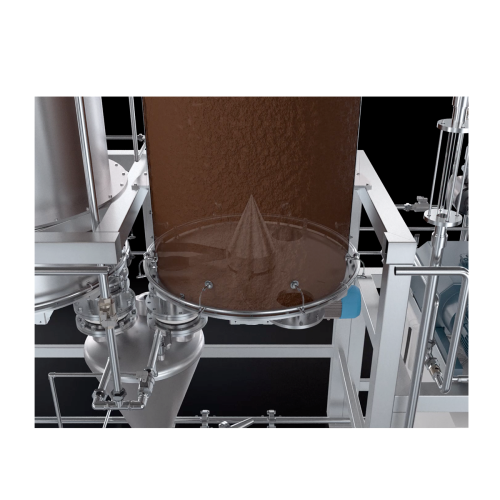

Coffee extractor for optimal flavor preservation

Unlock the potential of your extracts with a continuous system that ensur...

Industrial coffee extraction system for high yields

Maximize coffee yield and quality with precision-controlled extractio...

Aroma analysis for instant coffee processing

Improve flavor preservation by analyzing and optimizing aroma retention at ev...

Automatic pour over coffee brewer

Streamline your pour over coffee experience with precision brewing, ensuring perfect extr...

Rapid cold brew coffee & tea maker with vacuum extraction

Achieve smooth, bold cold brews with less bitterness and enhan...

Automatic pour over coffee maker

Enhance your coffee and tea offerings with seamless brewing precision, optimizing pour-over...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Commercial coffee beans roaster

Maximize your coffee’s flavor profile with precise control over roasting variables, ensuring...

Coffee, dried nuts, and cocoa beans roaster

Achieve precise and customizable roasting for a variety of beans and nuts with...

Industrial roaster for coffee, nuts, and cocoa beans

Optimize your roasting processes with a versatile solution designed ...

Destoner for roasted coffee beans

Ensure your coffee blends are free from impurities and stones with a high-precision desto...

Blender for whole bean roasted coffee

Achieve precise coffee blend consistency and protect delicate roasted beans with an a...

Roasted coffee batch weighing and management system

Optimize your coffee production with our advanced system, designed to...

Rotating sieve for roasted coffee

Optimize your coffee production with a rotating sieve specifically designed to handle del...

Catalytic converter for industrial coffee roasting

Optimize your coffee roasting with precise control and efficiency, ens...

Automatic lab roaster for 1 kg coffee batches

Perfect for coffee roasters aiming to refine roast profiles, this lab roaste...

Automatic roaster for espresso coffee

Optimize your coffee roasting with precision control and uninterrupted processing, th...

Automated coffee bean roaster

Optimize your coffee roasting with precision control, ensuring consistent quality in every bat...

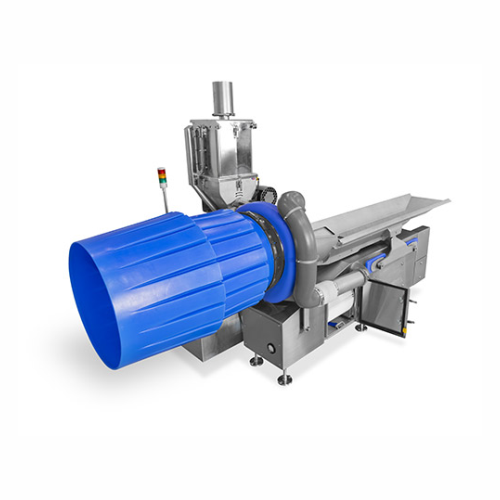

Cleaning system for green coffee beans

Ensure optimal purity in your coffee production with a system designed to remove imp...

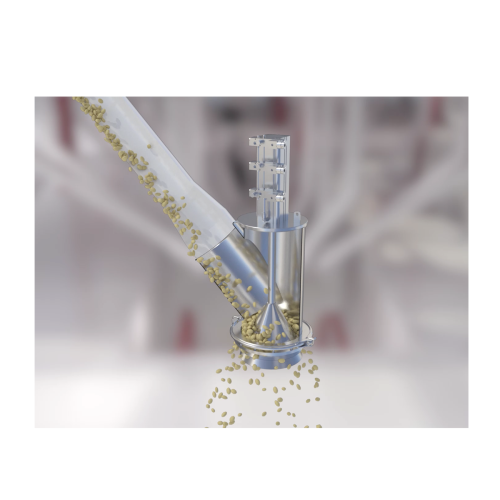

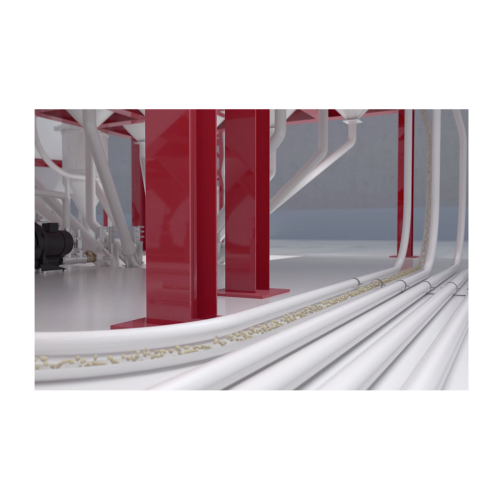

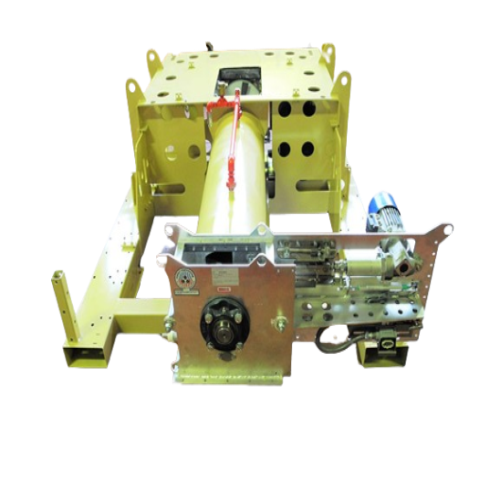

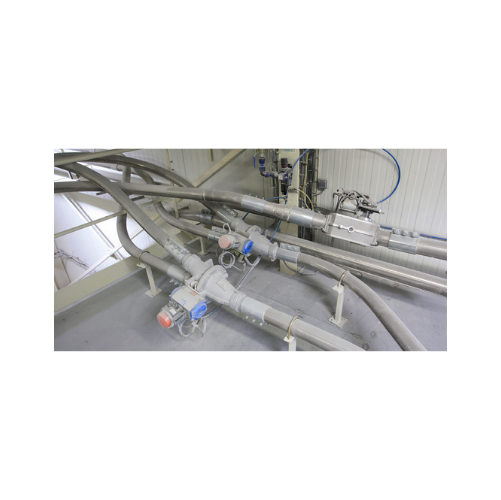

Compression pneumatic line for green coffee handling

Streamline your coffee production with a compression pneumatic line ...

Green coffee decantation cyclone

Optimize your coffee production by effectively separating and collecting granulated materia...

Green coffee unloading and batching system

Streamline your coffee processing with a system that efficiently unloads, clean...

Degassing system for ground coffee

Optimize your coffee production with a robust degassing solution designed to preserve fl...

Industrial coffee grinder for ground coffee production

Enhance your coffee production line with precise grinding capabili...

Chaff conveying system for coffee roasters

Efficiently manage coffee chaff with an integrated solution that transports, co...

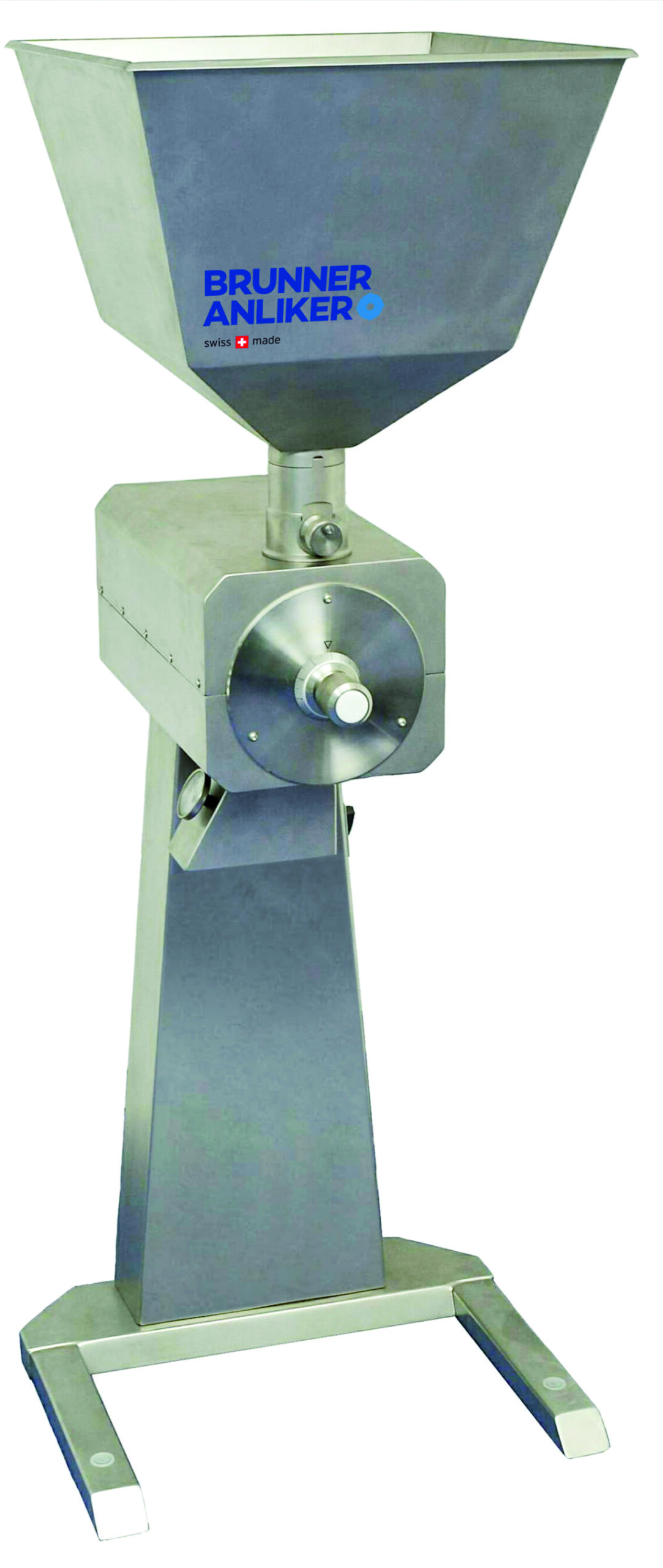

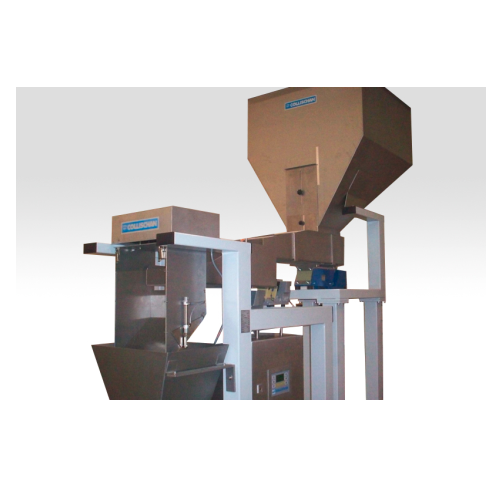

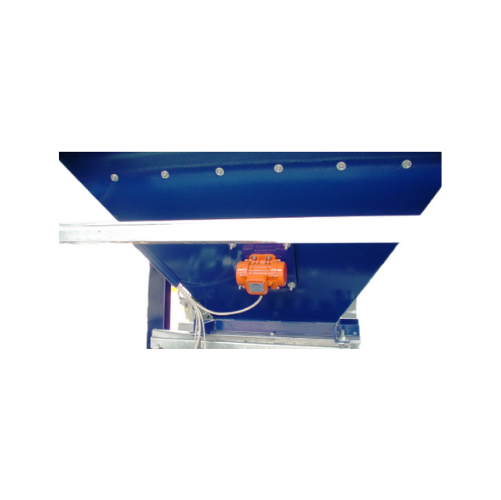

Dosing feeder for coffee production

Streamline your coffee production with precision control, ensuring consistent packing l...

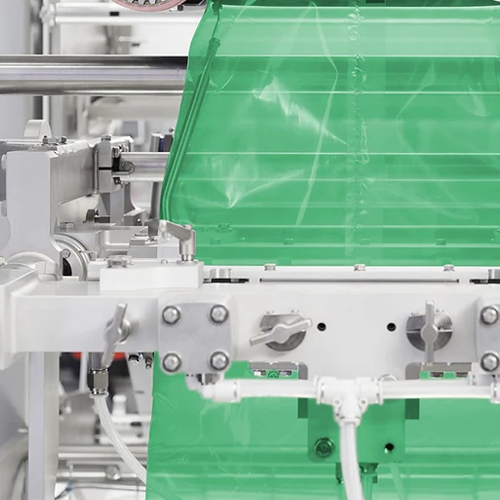

Coffee capsule filling and sealing solution

Optimize your production with a high-speed solution designed to fill and seal ...

Coffee capsule filling and sealing system

Boost capsule production efficiency and reduce downtime with a high-speed system...

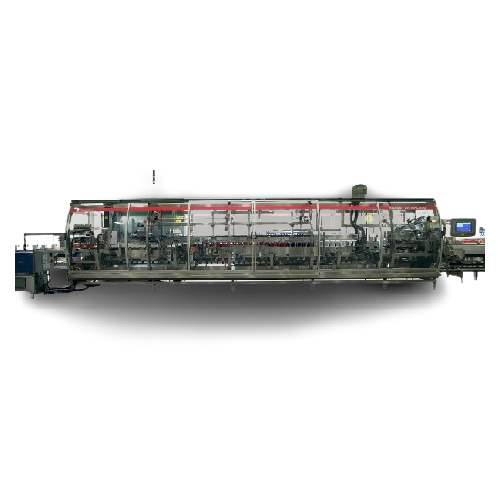

Coffee capsule filling and sealing line

Elevate your capsule production with a high-speed filling and sealing solution that...

Horizontal cartoning system for coffee pods

Enhance your packaging line efficiency with a system designed for gentle handl...

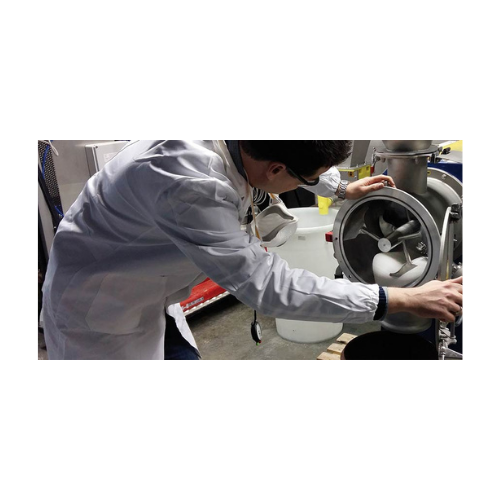

Lab device for testing coffee capsules

Achieve precise testing and reproducibility of coffee capsule parameters crucial for...

Coffee capsule filling and sealing machine

For producers seeking a compact yet powerful machine, this system efficiently f...

High-speed coffee capsule filling and sealing system

Streamline your capsule production with a high-speed solution that e...

Electrical mini coffee roaster

If you are looking to gain full control of the roasting process, obtain 5 – 6 kg / hou...

Roll mill for coffee beans

When you want flexibility to grin beans for filter coffee to Turkish coffee at particle sizes ran...

Coffee capsule packing machine

In the secondary packaging sector, being able to handle different type of capsules and tailor...

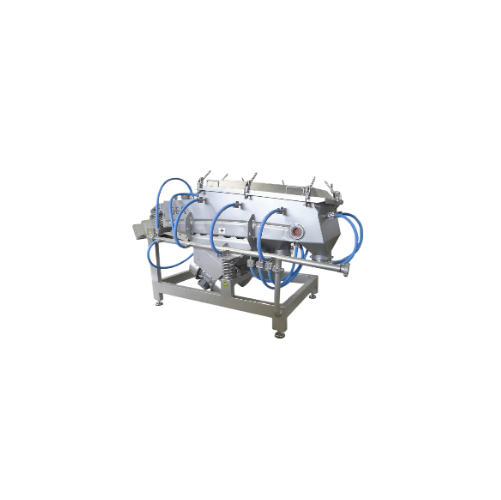

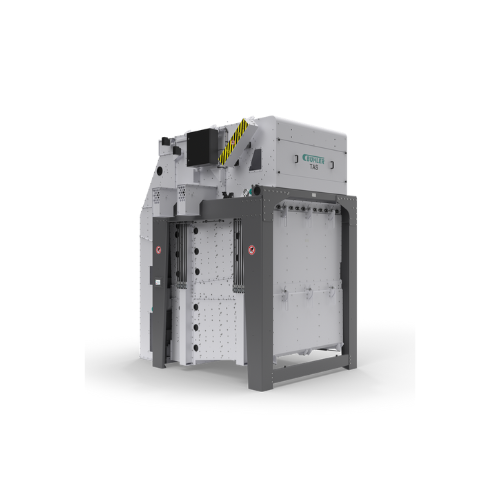

Vibrating screening machine for coffee

Coffee bean separation is one of the important steps during bulk coffee production. ...

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

Gas heated mini coffee roaster

Choose traditional gas heating to take full control of the roasting process and obtain 5 R...

Industrial coffee bean grinder

If you are looking to grind up to 50 kg of fine coffee per our or up to 440kg of medium fine ...

Shop coffee bean grinder

Do you want to grind your beans on-site at your coffee shop, but are you limited for space? Bench-to...

Destoner for coffee beans

When you are roasting and grinding your own coffee beans, destoning is an essential step to gain f...

Hammer mill for coffee beans

Being able to obtain an on-point grinding is easily achievable with these hammer mills, from co...

Stone mill for coffee beans

Traditional milling of coffee beans or seeds, with a stationary bedstone and a turning runner st...

Mortar for coffee pounding

With a pounding capacity of 50 kg/h – 110 lbs/h this mortar for coffee pounding will guaran...

Shop coffee roaster

A roaster for your coffee shop needs to breath coffee roasting tradition and give you hands-on control o...

Industrial coffee roaster

Roast 120 – 3,000 kgs of coffee beans per hour with the latest industrial technologies integ...

Optical coffee roaster

If you want to see or show all the roasting phases and reactions of the coffee beans, an optical coffe...

Industrial coffee beans silo

Silos for the storage of green and roasted coffee beans for your professional roasting environm...

Shop coffee bean silo

Showcase your premium green beans and roasts in traditional shop coffee bean silo’s.

Afterburner for coffee roasting

Afterburners for gas-heated coffee roasters in various levels of performance that fit your s...

Mesh sieves for laboratory particle size analysis

Ensure precise particle size control for a wide range of materials with...

Vibratory feeder for bulk materials and fine powders

Ensure consistent material flow and precise feeding for optimized pr...

Beverage multi-pack cartoner for cans and bottles

Optimize your beverage production line with high-speed, continuous mult...

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

Coating solution for nuts and dried fruits

Easily apply multiple layers of chocolate to nuts, coffee beans, and more, achi...

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

Automatic case packaging for pods in single bags

Optimize your production line by streamlining the packaging of coffee and...

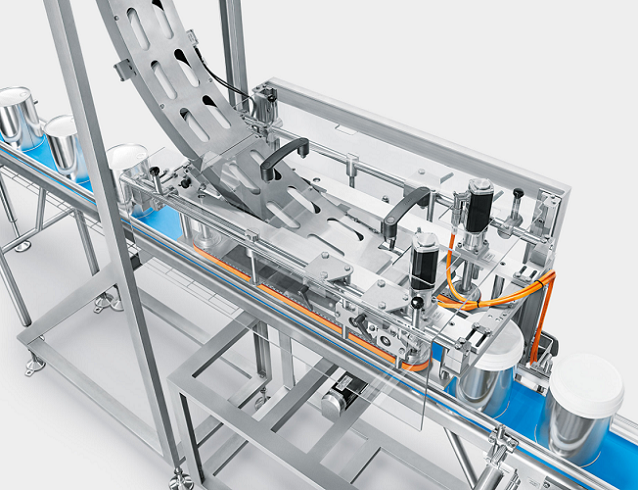

Capsule filling system with in-line weight control

Experience precise capsule filling with high-speed accuracy, designed ...

Automated capsule packaging system

Streamline your high-speed packaging operations with a system designed for precision fil...

Capsule packaging system for individual gusseted bags

Streamline your coffee capsule production with high-speed, precisio...

Filter paper pod production system

Streamline your production of single-serve beverages with precise weight control and sea...

High-capacity filter paper pod production system

Optimize your pod production line with a high-speed solution that ensures...

Pod production system for filter paper pods

Streamline your pod production with a high-speed solution that ensures precise...

High-performance thermoforming tools for packaging

Optimize your packaging production with versatile thermoforming tools,...

Fiber thermoforming system for sustainable packaging

Achieve fast, efficient production of biodegradable fiber packaging ...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

Automatic shop roaster for small and medium roasteries

Enhance your coffee production with advanced roasting technology d...

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

Top loading cartoner for variable box sizes

Achieve precision packaging with a versatile top-loading cartoner that adapts ...

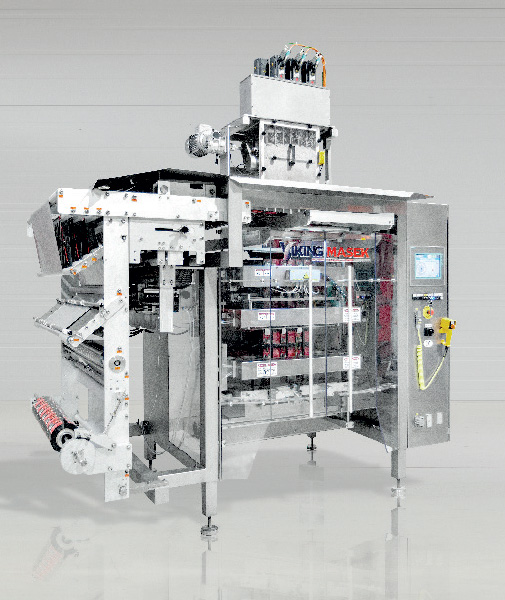

Multilane vertical packaging for stick sachets

Optimize your packaging line with high-speed, multilane machines designed f...

Capsule filling and sealing for lab purposes

Streamline your lab-scale coffee capsule production with a compact solution d...

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

Production system for multi-chamber portion packs

Efficiently produce multi-chamber portion packs with high precision for...

Cryogenic screw conveyor for food processing

Enhance your production line with a cryogenic screw conveyor that simultaneou...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

High intensity scrubber for particle separation and gas absorption

Effectively manage gas emissions and particle separa...

High-capacity tubular screw conveyor for grain transport

Optimize your production flow with a robust solution that ensure...

Trough screw conveyor for grain transport

Streamline your grain processing with a reliable conveyor system that ensures ef...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Aspiration channel for grain cleaning

Achieve superior product quality by efficiently removing light impurities from granul...

Winnowing system for cocoa processing

Achieve precise cocoa separation with a high-efficiency winnowing system designed for...

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, ...

Vacuum dryer cabinet for heat-sensitive products

For manufacturers handling heat-sensitive products, achieving precise moi...

Flour handling plant for pasta production

Streamline your production with precision handling and processing of flour for p...

Raw material handling systems for plastic and pharmaceutical industries

Effortlessly manage and optimize the handling a...

Material handling system for confectionery production

Optimize your production line with a system designed for efficient ...

Moisture analyzer for flour and tobacco

Optimize your moisture measurement process with precision and speed, ensuring quali...

Pressure drum filter for ultra fine-grained products

When traditional filtration methods fall short, ensure ultra-fine pr...

Automated valve manifolds for clean-in-place solutions

Optimize your production efficiency with automated valve manifolds...

Barcode reading and verification system

Ensure every container has the correct product with a cutting-edge scanning system ...

Powder induction system for efficient liquid powder mixing

Achieve precise and dust-free powder incorporation into liqui...

Tube-in-shell heat exchanger for low viscosity products

Enhance your beverage and food processing efficiency with a cutti...

Heat exchanger for dairy and beverage applications

Optimize your liquid product thermal processing by directly regenerati...

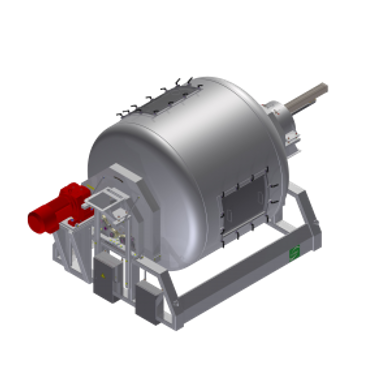

Expandable high pressure processing system

Optimize your production line with an expandable high-pressure processing syste...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Hybrid evaporator for highly viscous tomato concentrate

Achieve superior concentration and energy efficiency with a versa...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Reverse osmosis dealcoholization technology

Elevate your beverage production capabilities with advanced dealcoholization t...

Industrial freeze drying system for high-volume food products

Achieve precise moisture removal and preserve product qual...

Pilot plant freeze dryer for sensitive products

Achieve precise moisture control and nutrient preservation in food and pha...

Carbonated beverage can filler - 4 spout open fill

Optimize canning carbonated beverages while minimizing CO2 loss with t...

Counter pressure bottle filling system for carbonated beverages

Enhance your bottling efficiency with a versatile counte...

X-ray scanner for bulk material inspection

Ensure product safety and minimize downtime by intercepting foreign contaminant...

Stainless steel trough screw conveyor

Ideal for precise handling of powdery and granular materials, this solution ensures m...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

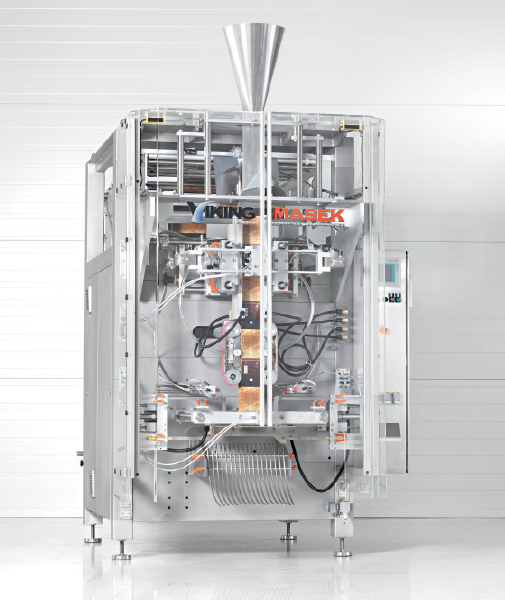

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Blizzard sorter for Iqf fruits and vegetables

Optimize your frozen food production with a compact sorter that seamlessly r...

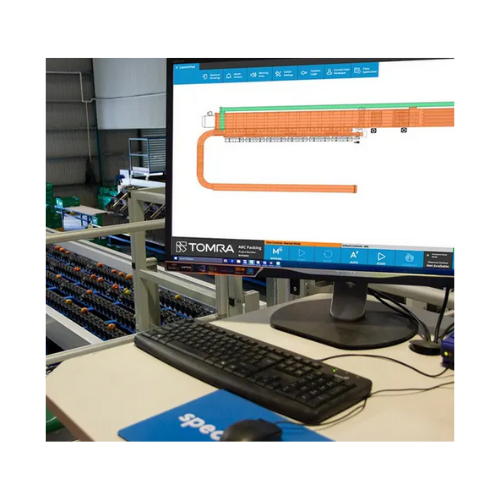

Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and r...

Granule filling sachet machine

Ideal for optimizing packing operations, this granule-filling sachet machine ensures precise ...

Sachet powder filling machine

Optimize your packaging line with this efficient solution for precise powder filling, ensuring...

Continuous freezer for ice cream production

Optimize your ice cream production with precision freezing, mixing, and air in...

Uht processing unit for dairy products

Optimize your liquid food production with continuous, high-capacity UHT treatment th...

Cocoa bean peeling solution

Enhance your cocoa and coffee production with efficient peeling, reducing waste and ensuring hig...

Rising/falling film plate evaporator for heat sensitive products

Efficiently concentrate heat-sensitive liquids with ris...

Ultra high temperature infusion plant for milk processing

Achieve extended shelf life and superior taste in dairy produc...

Sanitary modular bulk silos for efficient storage

Maximize your storage capacity and streamline assembly with a modular s...

Pelletizer for chaff

Transform chaff and agricultural byproducts into valuable energy pellets with precision and efficiency, ...

Tray packer for forming, loading, and sealing

Optimize your production line with a versatile tray packer designed to seaml...

Cartoner for pharmaceutical products

Effortlessly streamline your packaging line with compact cartoning capabilities, ensur...

Sterile filling platform for pharmaceuticals

Achieve precise, high-speed aseptic filling and packaging with advanced compl...

Standardized modular tray former for secondary packaging

Optimize your packaging line efficiency with this modular tray f...

Filling and sealing solution for beverage capsules

Optimize your production with a modular capsule filling and sealing so...

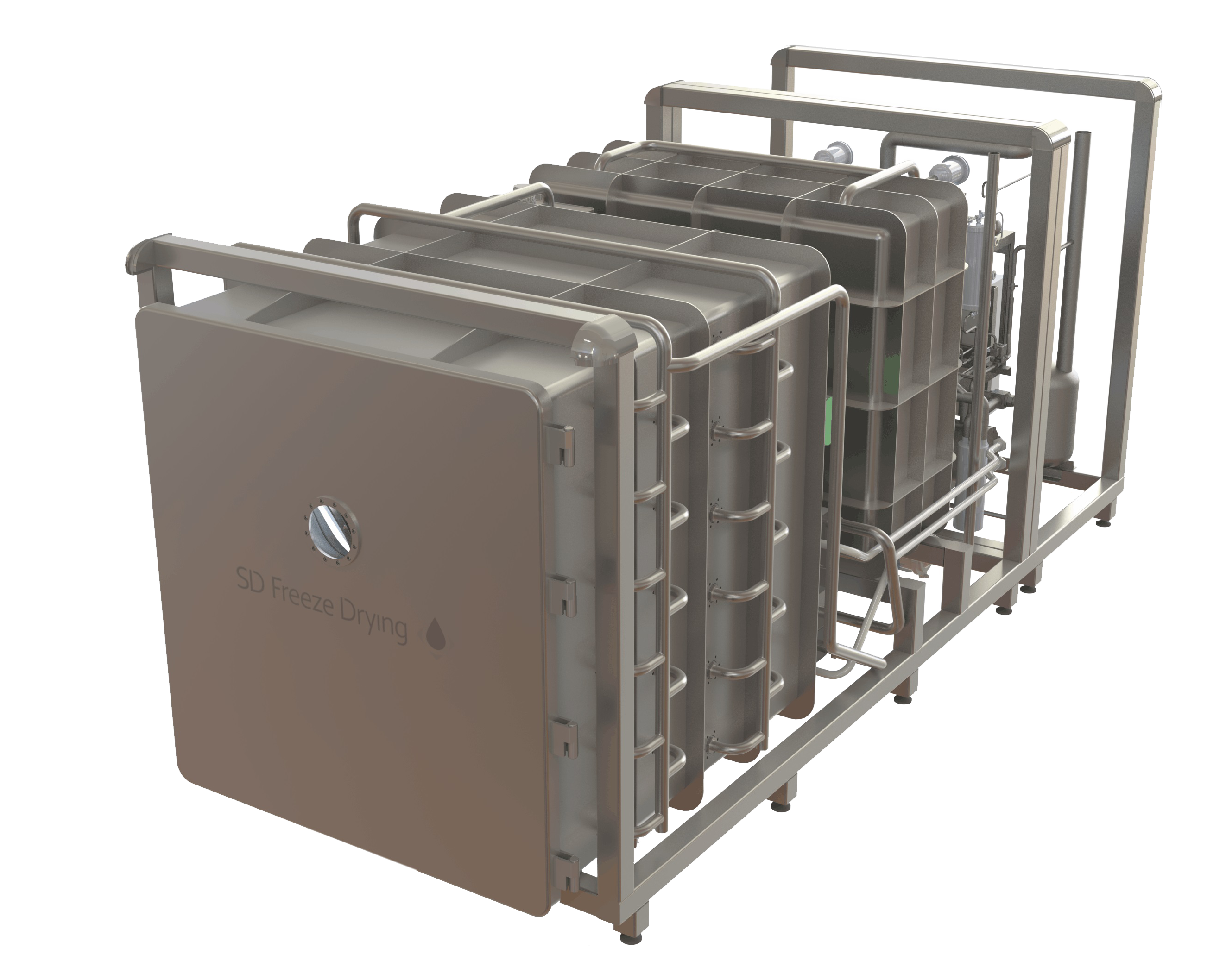

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

Top load Case Packer For Food Products

If you want to pack your food cartons, doy packs and pouches into regular cases, a s...

Horizontal Beverage Can Cartoner

Cans have many advantages over bottles when it comes to packing, for example, your craft be...

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

High-speed Cartoner For Single-Serve Products

Large-volume producers of single-serve packs, such as sugar sticks, instant ...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Leak tester for vacuum packaging

Roasted coffee beans, as well as grounded coffee, rapidly diminish in flavor. The oxyge...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Aseptic FFS machine for UHT products

UHT products (ultra high temperature processing) such as sterilized milk, are products...

Continuous sterilizer for tin cans and jars

A concern in the coffee industry is maintaining the freshness, taste, and qual...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Recirculating batch dryer

Drying can be the most energy and time-consuming process in the food industry. This can have an ef...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

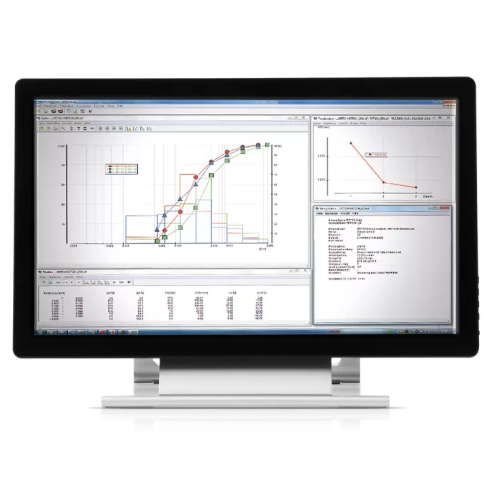

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

Electromagnetic sieve shaker for quality control

Achieve precise particle size distribution with this advanced electromagn...

Perforated plate sieves for particle size determination

Optimize your particle size separation with high-stability stainl...

Vibratory sieve shaker

Enhance your quality control processes with this versatile sieve shaker, designed to efficiently separ...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Box weight checkweigher for bulk bag-in-box applications

Ensure precise weight control in bulk packaging lines with this ...

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

Particle size and shape analyzer

Achieve precise particle size and shape analysis from 0.8 μm to 8 mm with exceptional speed...

Horizontal cartoner for diverse industries

Streamline your packaging process with precise cartoning capabilities, effectiv...

Case packer for pharmaceutical and healthcare products

Streamline your packaging line with a versatile case packer design...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Uht system for aseptic filling of beverages

Ensure microbiological safety and retain natural flavors in your liquid produc...

Cold aseptic filling system for beverages

Ensure microbiological safety and high product quality with a versatile cold ase...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Intermittent motion cartoner for pharma packaging

Streamline your packaging line with versatile cartoning solutions that ...

Labelling solution for cylindrical containers

Achieve precise and efficient labelling for cylindrical containers with a sy...

Linear labelling system for vials and bottles

Streamline your labelling process with a compact solution designed for preci...

Rotary capper for round and irregular shaped containers

Efficiently cap round and irregular containers with precision and...

Compact cartoner for pharma packaging needs

Achieve seamless integration in your production line with a cartoning solution...

High-speed side loading case packer for small dimensions

Optimize your packaging line with a high-speed solution designed...

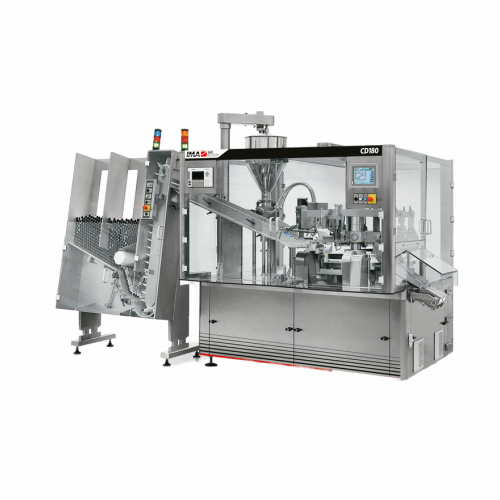

Automatic tubefiller for pharmaceutical tubes

Streamline your tube packaging process with this versatile solution, optimiz...

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrappin...

Horizontal flow wrapper for medium performance level

Offering high-speed, continuous flow wrapping, this versatile machin...

Stand-up pouch making system

Efficiently transform pre-printed reels into customizable stand-up pouches with precise unwindi...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Intermittent motion cartoner for confectionery packaging

For manufacturers needing versatile packaging solutions, this ca...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

Self-cleaning automatic filters for industrial liquids

Ensure reliable filtration of high-contamination liquids while min...

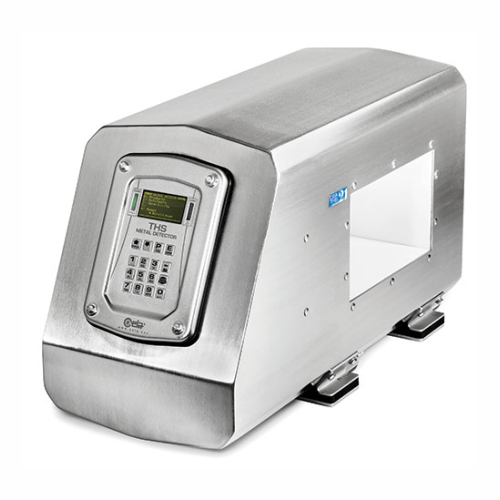

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Linear weigher for dry or frozen free-flowing products

Optimize precision in high-speed weighing tasks with a compact sol...

Decanter centrifuge for soft sediment separation

For operations dealing with soft, easy-flowing sediments, ensuring effici...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

Advanced sludge dewatering for sewage treatment plants

Optimize sludge dewatering with a centrifuge that enhances separat...

Pulsed electric field system for olive oil processing

Enhance extraction efficiency and product quality with this advance...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Static checkweigher for accurate measurement

For those needing unparalleled precision, this static checkweigher ensures ex...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Counting system for tablets and capsules

Effortlessly count a variety of tablets, capsules, and dragées with precision, ens...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Grain scourer for wheat, durum, and rye

Enhance grain processing by efficiently removing impurities like dust, sand, and so...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Optical sorter for grain and seed sorting

Ensure precise defect detection and efficient sorting of grains, pulses, and see...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Vertical conveyor for bulk materials

Optimize your handling of bulk materials with a cost-effective solution that ensures h...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Tubular screw conveyor for grain transport

Efficiently discharge and dose raw materials with high precision, ensuring seam...

Bagging control system for centralized operations

Streamline your bagging operations with a centralized control system, d...

Batch scale for high accuracy weighing of powdery products

Achieve unparalleled precision in powder dosing with our batc...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial cooling die for wet textured proteins

Maximize production efficiency by creating diverse, high-quality protein ...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Trough screw conveyor for transporting grains

Efficiently transport and handle bulk materials like grains and flour with r...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

Small plansifter for grain milling

Optimize your grain milling with a compact plansifter designed for high-speed, precise s...

Vertical grain conveying solution for animal feed and bulk materials

Efficiently transport and elevate various bulk mat...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Dust-free big bag connection system for bulk solids

Eliminate dust and ensure reliable discharge with this vacuum docking...

Cap and fill level inspection system for bottles

Ensure precise cap placement and accurate fill levels in your bottling li...

Solid/liquid extractor for high-yield functional nutrient extraction

Maximize extraction efficiency and elevate product...

8000bph fruit juice filling system

Optimize your beverage production line with a high-speed fruit juice filling system, des...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Single chamber tea bag packer with sealed filter paper

Efficiently pack diverse tea varieties into neatly sealed single c...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

High pressure processing water filtration system

Ensure super clear water after high pressure processing to protect your s...

High pressure processing for diverse food products

Maximize production versatility and ensure product safety with a high-...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Extrusion blow molder for custom bottles

Enhance your production line by creating versatile and customized bottles with sea...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Big bag emptying station for raw materials

Streamline your material handling process by efficiently lifting, emptying, and...

Cold water deaeration system for beverage production

Achieve exceptionally low residual oxygen levels in beverages, ensur...

Tubular heat exchanger for thermal treatment of viscous products

Optimize efficiency in heating, cooling, and pasteuriza...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

Aseptic filling for high and low acid beverages

Ensure aseptic integrity while maximizing operational efficiency with a co...

Hot fill bottling unit for juices and isotonic beverages

Ideal for producers handling delicate or specialty liquids, this...

Level bottle filler for wine and spirits

Achieve consistent fill levels with precision sensor technology, ideal for ensurin...

Volumetric bottle filler for distilled spirits

Ensure precise volume control and compliance with regulatory standards in y...

Counter pressure filler for carbonated beverages

Ensure optimal carbonation and minimal oxygen exposure during bottling, e...

Counter pressure can filler for carbonated beverages

Achieve precise carbonation levels and minimal oxygen exposure in ca...

Counter pressure bottle filler for carbonated beverages

Maintain carbonation levels while filling bottles efficiently, en...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Butterfly valves for powders and granules

Ensure precise flow control and reliable sealing for gravity-fed or pneumatic sy...

Butterfly valves for powder and granular material handling

Experience seamless material control with advanced butterfly ...

Membrane pressure relief valve for silos and bins

Ensure silo safety with our valve that instantly balances internal pres...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Diverter valves for pneumatic conveying lines

Experience precise flow control in pneumatic conveying with diverter valves ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Spring-loaded pressure relief valves for silo overfill protection

Ensure safety and prevent costly overfills with press...

Food-grade tubular screw conveyors

Ensure complete hygiene in your production line with these stainless steel tubular screw...

Food-grade stainless steel tubular screw conveyors

Ensure contamination-free material handling with our tubular screw con...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Blow-through rotary valves for pneumatic conveying

Optimize your pneumatic conveying systems with high-efficiency blow-th...

Rotary ball vibrators for fine powders and granular materials

Ideal for preventing material build-up and blockages, thes...

Rotary ball vibrators for aggregate reclaiming

Enhance efficiency in your production line with a solution that optimizes t...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

Air cannons for resolving bulk material flow issues

Solve bridging and rat-holing issues in bulk material storage with po...

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Pneumatic hammers for bulk solids discharging

Optimize your production efficiency and solve material flow challenges with ...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for bulk solids discharging

Enhance the efficiency of material handling with high-speed, low-noi...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

Continuous impact vibrator for aggregate reclaiming

Tackle material flow challenges head-on by preventing common issues l...

Rotary roller vibrators for concrete compacting and hopper emptying

Achieve higher compaction and efficient emptying wi...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

External electric motovibrators for industrial applications

Optimize material movement and improve discharge efficiency ...

External electric motovibrators for bulk solids conveying

Enhance material flow efficiency and solve challenging dischar...

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output ac...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Silo overfilling safety system

Ensure safe silo filling with our system that prevents overfilling and excess pressurization,...

Micro-batch feeders for powder and granular material

Struggling with clog-prone powders? Gain precise control and consist...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Bin level indicator for bulk solids

Ensure precise material level detection across your production processes, minimizing th...

Electronic pressure meter for silo safety

Ensure the safety of your silos by efficiently monitoring internal pressure chan...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Cushioned pneumatic linear vibrators for bulk solids

Combat material bridging and rat-holing with silent vibratory techno...

Pipe couplings for pneumatic conveying lines

Ensure a secure and quick connection for your pneumatic lines with these pipe...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Anti-wear elbows for pneumatic conveying systems

Reduce wear and extend the lifespan of your pneumatic conveying systems w...

High capacity vertical conveying for flour

For consistent, high-speed handling of delicate and powdery materials, this eng...

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Stand-up pouch filling and sealing system

For packaging lines that demand quick, efficient, and flexible pouching, this hi...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Horizontal flat pouching system for up to 180ml capacity

Optimize your packaging process with a high-speed solution desig...

Horizontal stand-up pouching system for liquids and solids

For producers aiming to optimize efficiency and precision, th...

High-capacity stick pack packaging solution

Enhance your production efficiency by packaging diverse products like powders ...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Industrial airlock for pneumatic systems

Ensure precise air and product separation in your pneumatic systems, maintaining m...

Low temperature food dehydration system for fruit and vegetables

Optimize your food processing with advanced low-tempera...

Advanced fruit sorting platform

Optimize your operations with a cutting-edge sorting solution designed to enhance product in...

Advanced food sorter for tomatoes and peaches

Achieve precise sorting and defect removal for a variety of food products, e...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

Color sorter for small fruits

Optimize your production line with a high-speed color sorting solution that enhances quality c...

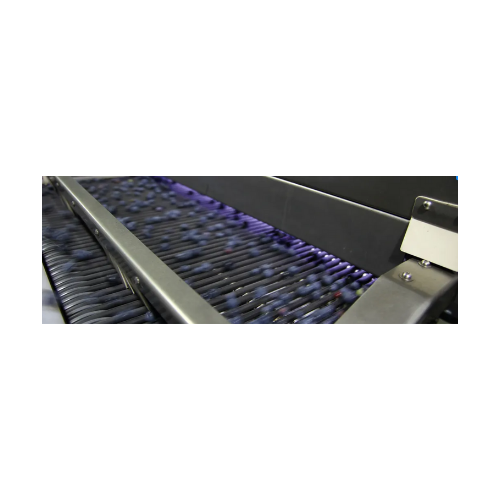

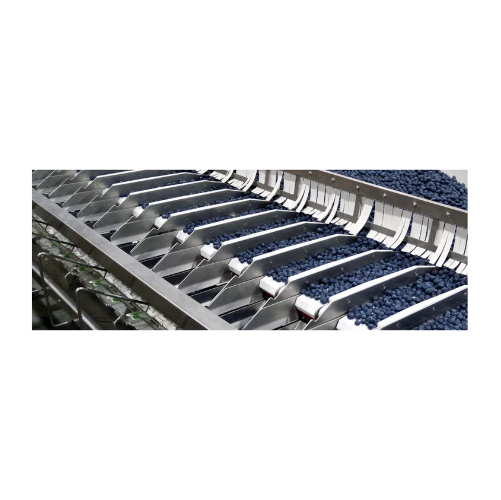

High-speed filling system for cherries and blueberries

Streamline your packaging process with a system designed for rapid...

Industrial steam peeler for potatoes

Optimize peeling efficiency while minimizing waste and energy usage with this high-spe...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

Corn seed sorting solution

Ensure precision in sorting and grading corn with optical and infrared technologies, enhancing pr...

Indirect Uht treatment for dairy products

Ensure your beverages achieve extended shelf life with consistent quality using ...

Continuous freezer for ice cream processing

Achieve exceptional product uniformity and optimal texture with a continuous f...

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high tem...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Uht system for milk and dairy products

Ensure superior product quality and extended shelf-life by utilizing rapid heat trea...

Combi ultra high temperature (uht) processing plant for dairy and beverages

Achieve precise heat treatment for diverse...

Falling film plate evaporators for fruit juice concentration

Achieve precise concentration of liquid products with minim...

Infusion Uht plant for dairy products

Achieve precise thermal treatment with minimal product alteration, enhancing quality ...

Aseptic storage tank for aseptic products

Ensure uninterrupted aseptic product storage with this advanced tank system, des...

Isobaric filler for glass and Pet bottles

Achieve precise liquid filling with enhanced operational flexibility and hygiene...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in ...

Professional chocolate tempering system for artisan chocolatiers

Achieve precise chocolate tempering with quick changeov...

Chocolate tempering solution for small scale production

Efficiently temper chocolate for diverse confectionery creations ...

Chocolate enrobing, moulding, and cooling tunnel

Optimize your chocolate production with this advanced tunnel, designed fo...

Wall chocolate fountain for continuous chocolate flow

Create a mesmerizing ambiance with a seamless chocolate waterfall, ...

Automatic heated mould loader for chocolate production

Streamline your chocolate production with this heated mould loader...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Professional chocolate tempering solution for large workshops

Enhance your chocolate production efficiency with a machin...

Rotary drum mixer for free-flowing materials

Achieve uniform mixing of heavy, free-flowing solids with precise control and...

Modular bulk storage bins for efficient material handling

Maximize your storage efficiency with bolt-together solutions ...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Top loader robots for precision packaging

Optimize packaging operations with versatile robotic top loaders that achieve hi...

Lab punching and sealing system for cleanroom conditions

Test and refine your packaging processes with precision, ensurin...

Production system for molecular diagnostics

Eliminate bottlenecks in molecular diagnostics production with a versatile sys...

Compact case packer for secondary packaging

Optimize your secondary packaging process with a case packer that operates cle...

Sequentially automated case packer for small products

Efficiently pack diverse small products into large cases with preci...

Compact palletizer for food and beverage products

Optimize your end-of-line operations with a space-saving palletizer tha...

Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Gentle mixer for tea blending

The blending process is critical to the flavor quality of tea. But the physical impact of the ...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Freeze drying system for berries and fruit powders

Delicate fruits with high moisture levels, such as berries, risk losin...

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

Multifrequency sieve for separation of difficult particles

Separating particles in difficult-to-process materials for pr...

Screener and separator of dry powder

Many industries require the effective screening and separating of a range of dry powde...

Continuous vacuum belt dryer

For gently drying liquid concentrates into granulates or powders, a vacuum drying solution is t...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...