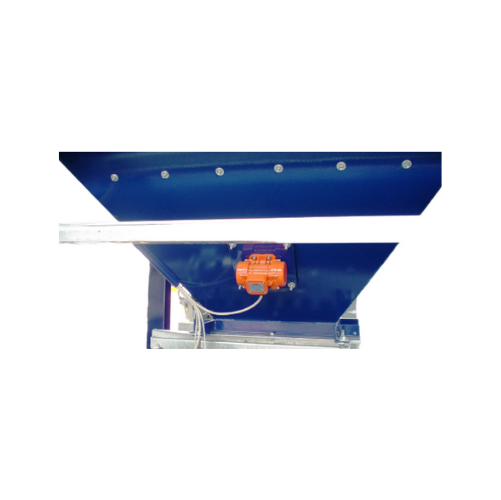

Industrial electric vibrator for bulk solids discharging

Enhance material flow efficiency and ensure consistent output across various production lines with industrial vibrators designed for robust performance in demanding environments.

Enhances Material Flow and Facilitates Vibrating Operations

The MVE External Electric Motovibrators from WAMGROUP are designed to optimize material movement and enhance vibrating operations across diverse industrial applications. Equipped with an advanced electric motor within a robust, FMEA-designed cast casing, these motovibrators provide centrifugal force ranging from 20 to 26,000 kg through 2, 4, 6, or 8 pole configurations. Commonly used in industries such as construction, pharmaceuticals, and waste management, the MVE facilitates efficient conveying, screening, sizing, and compacting of materials like cement, detergents, and granular biomass.

Available in multiple voltages to accommodate global electric standards, MVEs are ATEX ExII3D and ETL, Class II, Division 2 certified, ensuring safe operation in environments with flammable dust. Integration into existing systems is seamless, with PLC control options for enhanced automation and remote monitoring. Designed to be energy-efficient, they minimize power consumption, contributing to sustainable operations. Offered in stainless steel for increased chemical resistance, these motovibrators are ideal for both dry and wet processing environments. Optional features such as PTC thermistors and stainless steel covers enhance performance and durability, while customization support is available to tailor equipment to specific operational needs.

Benefits

- Enhances productivity by improving material discharge flow, reducing blockages and downtime.

- Certified for hazardous environments, ensuring safe operation with flammable dust present.

- Accommodates global power requirements with multiple voltage options, streamlining international integration.

- Provides robust performance with minimal energy consumption through optimized motor control.

- Customizable to specific application needs, increasing flexibility and operational efficiency.

- Applications

- Lime, Aluminium, Gas, Municipal waste, Grain, Biogas, Soap, Pesticides, Minerals, Cement, Detergents, Glass, Spices, Biomass, Industrial solid waste, Rubber, Cocoa, Animal feed, Ceramics, Sugar, Building materials, Pet food, Varnish, Meat processing, Oil, Fertilizer, Shot blasting, Plastics, Sand, Wood, Pharmaceuticals, Paint, Coffee, Flour, Gypsum, Concrete

- End products

- Biogas energy, Sausage, Wood pellets, Sandblasted metal components, Shot peened surfaces, Wheat flour, Hydrated lime, Aluminum sheets, Rubber sheets, Cattle feed, Wall paint, Plywood, Laundry detergent, Plaster of paris, Ceramic tiles, Kibble, Instant coffee powder, Portland cement, Recycled paper, Petroleum, Plastic pellets, Prefabricated wall panels, Ground spices, Metal scraps, Ammonium nitrate, Granulated sugar, Polyurethane varnish, Liquid soap, Wheat grains, Insecticidal powder, Natural gas, Quartz, Chocolate bars, Recycled glass, Tablets, Ready-mix concrete

- Steps before

- Grinding, Sizing, Mixing, Purification, Material Crushing

- Steps after

- Conveying, Screening, Compacting, Material Discharge, Loading

- Input ingredients

- bulk solids, material to be discharged, material to be compacted, material to be screened, material to be conveyed

- Output ingredients

- discharged bulk solids, compacted material, screened material, conveyed material

- Market info

- WAMGROUP is known for its expertise in manufacturing bulk material handling and processing equipment, including screw conveyors, dust collectors, and valve systems, with a strong reputation for innovation, quality, and global market presence.

- Centrifugal force

- 20 ~ 26, 000 kg

- Motor type

- Single phase, Three-phase, DC

- Poles

- 2, 4, 6, 8

- Casing design

- FMEA-designed cast casing

- Insulating materials

- Class F

- Voltage compatibility

- Multiple voltages worldwide

- PTC option

- Standard from size 60

- Accessory options

- Split covers, Stainless steel covers

- Movement type

- Circular, Linear

- Type of Movement

- Circular / Linear

- Centrifugal Force Range

- 20 ~ 26, 000 kg

- Pole Configuration

- 2, 4, 6, 8 poles

- Voltage Compatibility

- Single phase / Three-phase / DC

- Environmental Certification

- ATEX ExII3D and ETL, Class II, Division 2

- Application Usage

- Flow aids, material discharge, conveying, screening, sizing, compacting

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- ATEX certification

- ExII3D

- ETL certification

- Class II, Division 2

- Centrifugal Force

- 20 ~ 26, 000 kg

- Motor Type

- Single phase, Three-phase, DC

- Number of Poles

- 2, 4, 6, 8

- Casing Design

- FMEA-designed sturdy cast casing

- Poles

- 2, 4, 6, 8

- Motor Type

- Single Phase, Three-Phase, DC

- Casing Material

- FMEA-designed Cast Casing

- Cover Options

- Split Covers, Stainless Steel (on request from size 60)

- PTC Thermistor

- Standard from size 60, available on request for smaller sizes