Chemical Processing Technology

Find innovative chemicals equipment and connect directly with world-leading technology suppliers

Due to their potential hazardous nature, chemicals are classified for proper identification and safety during production. Chemical classification depends on their properties, structures and functions. In the chemical industry, you can regard them as basic chemicals such as acids, chemical products to produce plastic materials and finished chemicals for use in cosmetology. As a manufacturer or engineer, you want to know their reactivity when using chemical processing equipment.

Innovative technologies for processing chemicals

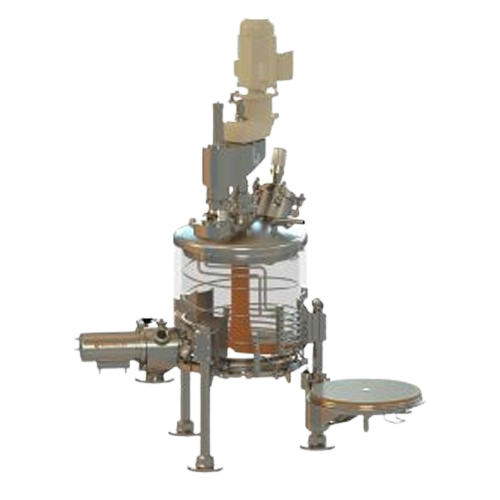

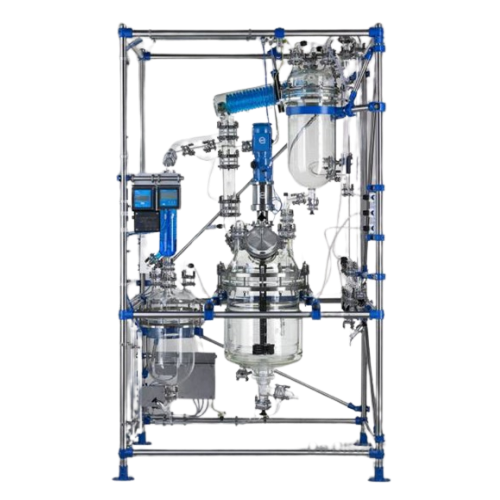

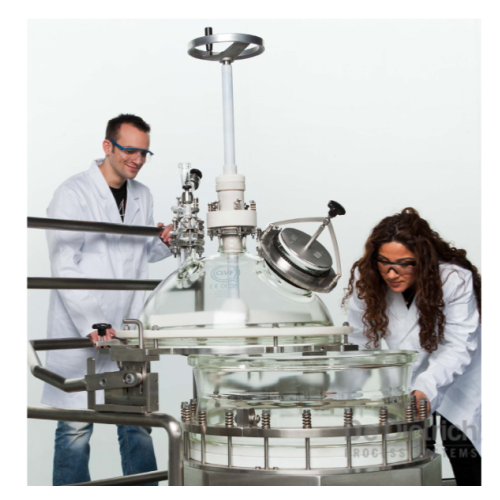

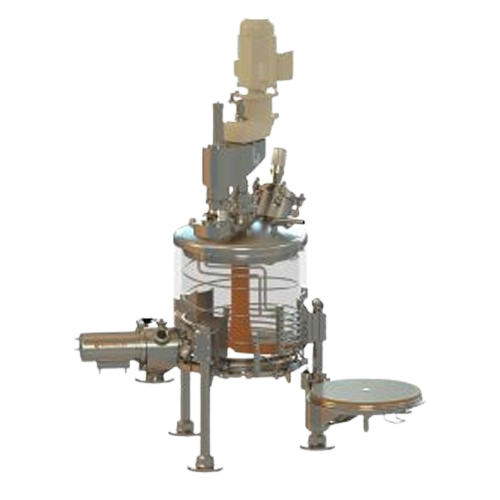

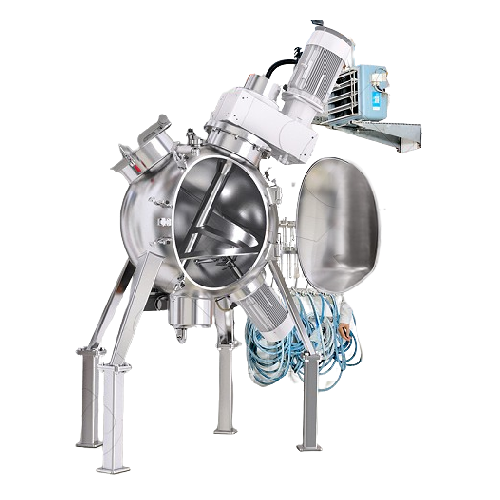

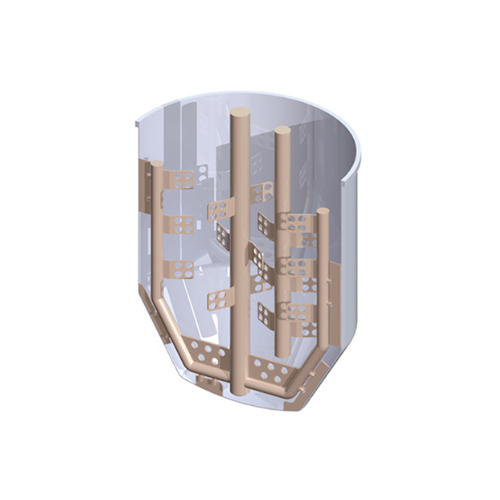

150l jacketed glass reactor for chemical synthesis

Achieve precise control over complex chemical processes with this sing...

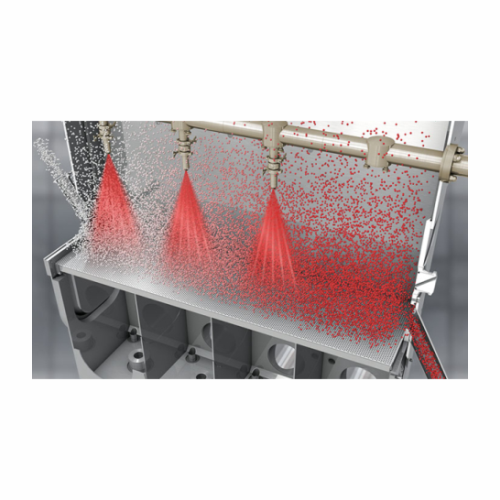

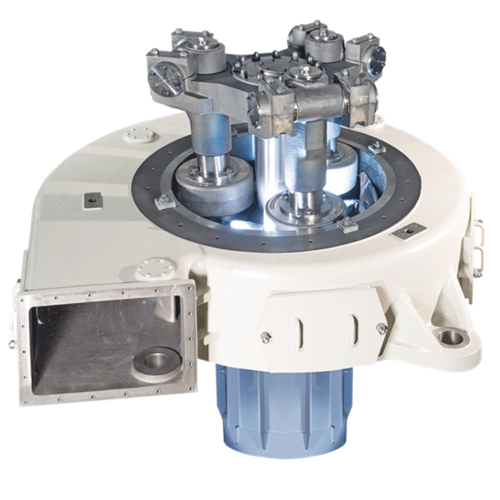

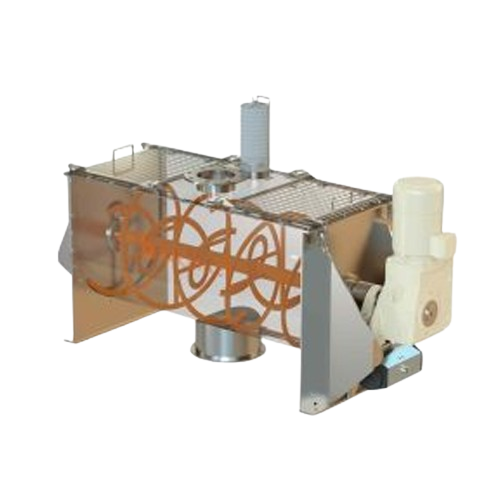

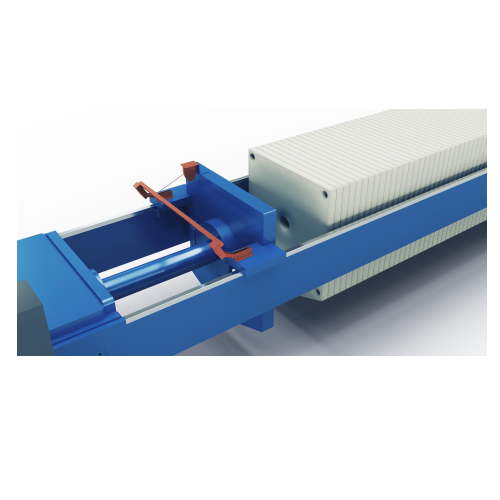

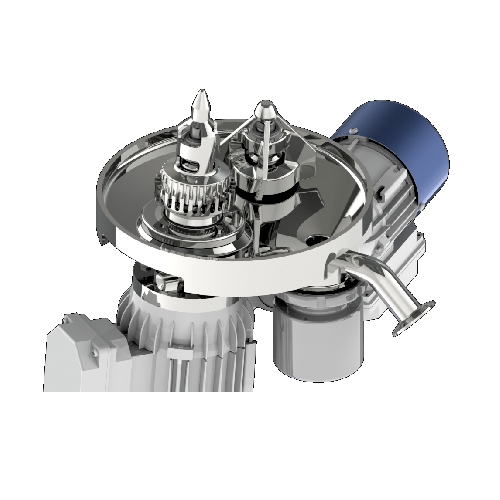

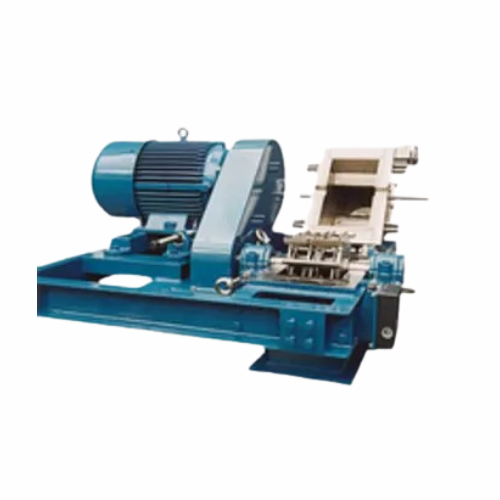

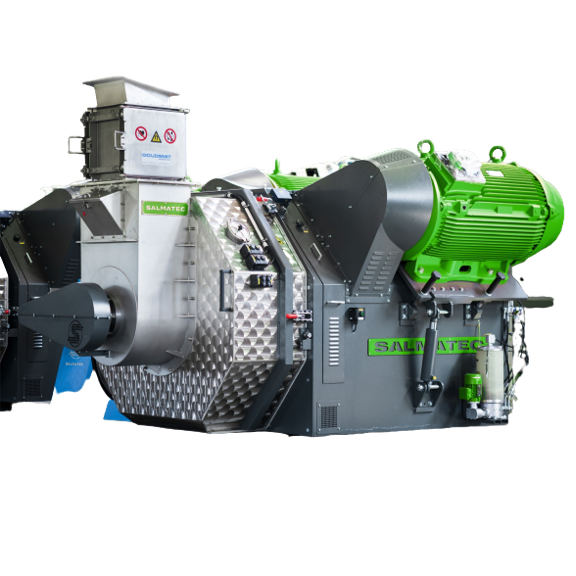

Basket mill for paint and varnish production

Achieve optimal particle size and product consistency with this advanced bask...

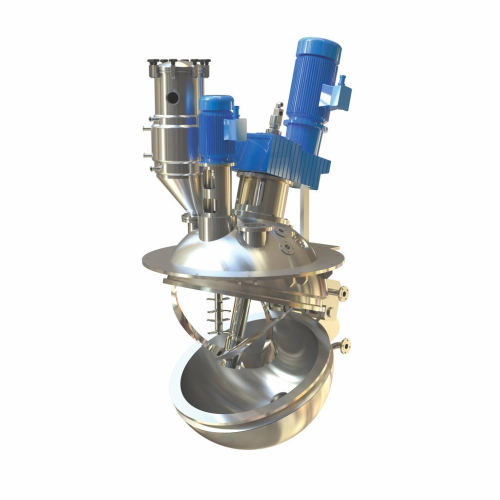

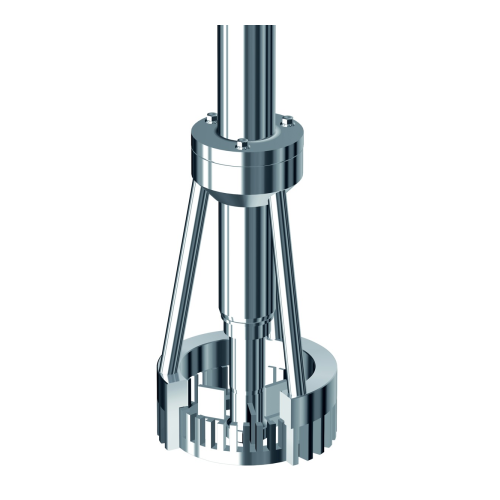

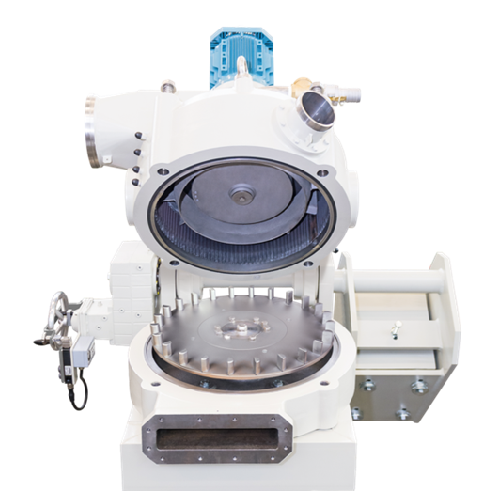

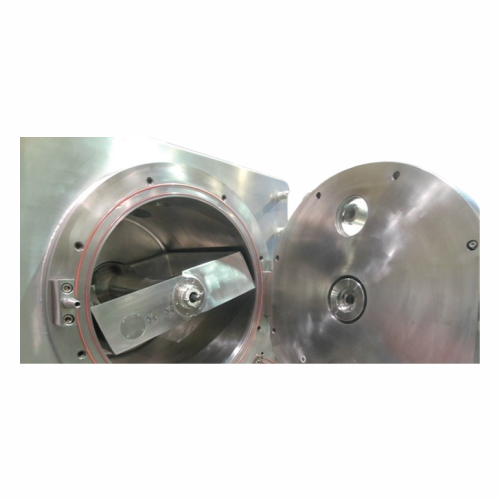

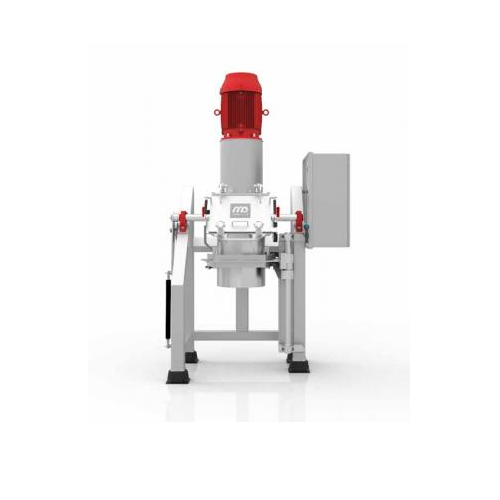

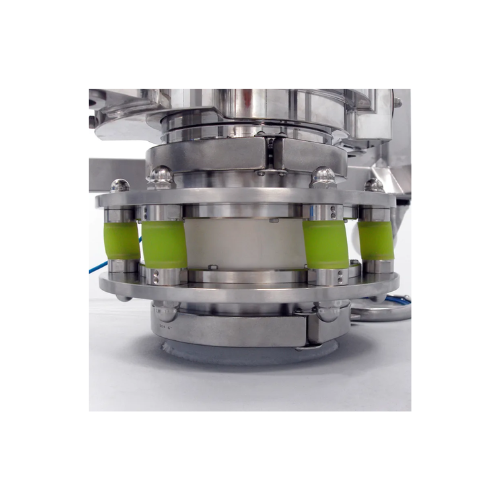

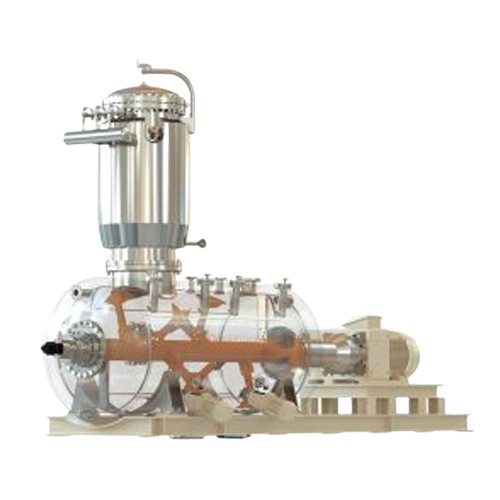

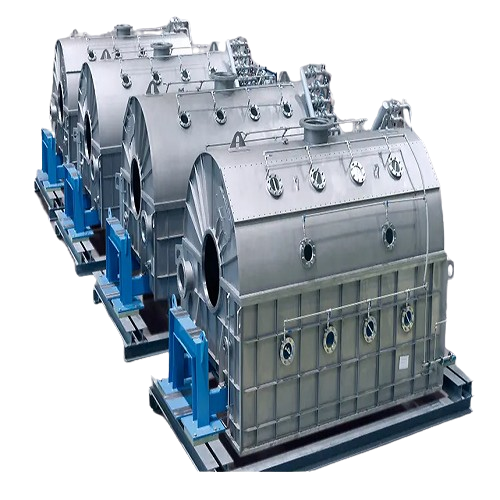

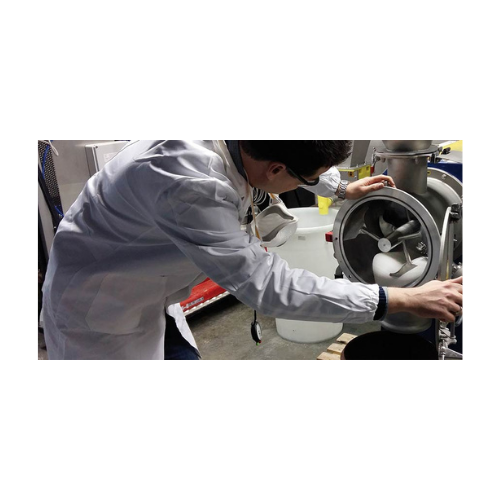

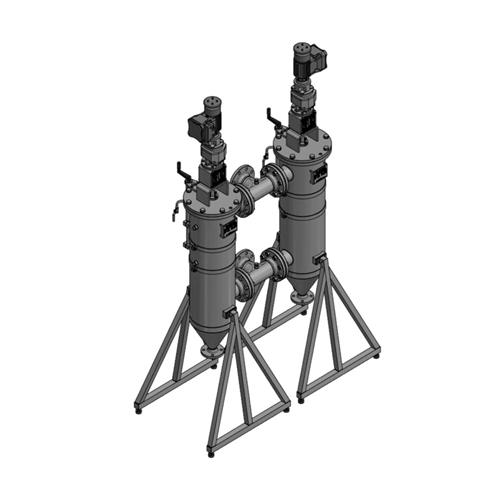

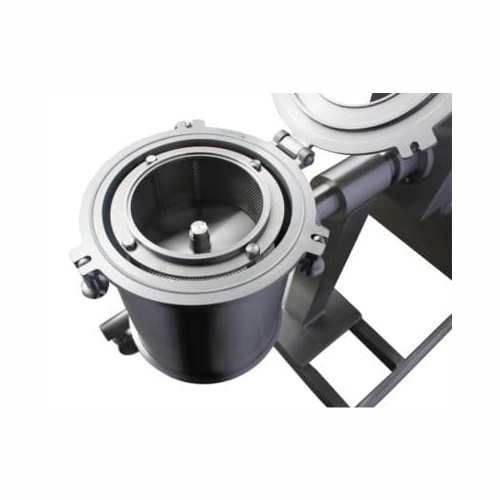

Agitated nutsche filter for solid-liquid separation

Ensure high-purity solid-liquid separation with minimized contaminati...

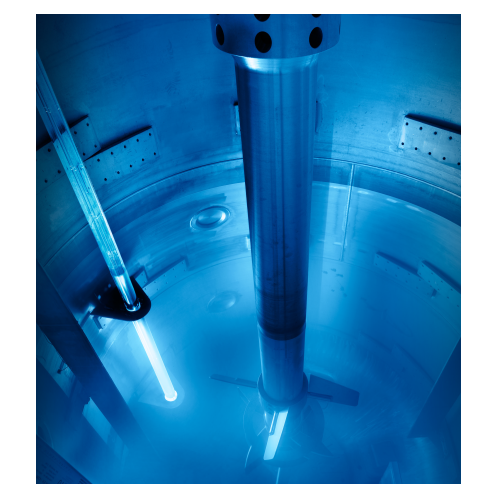

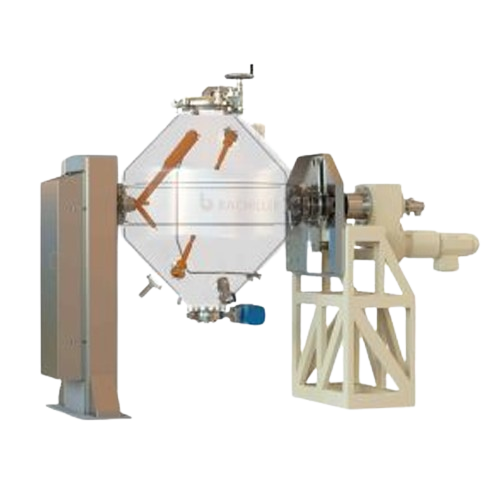

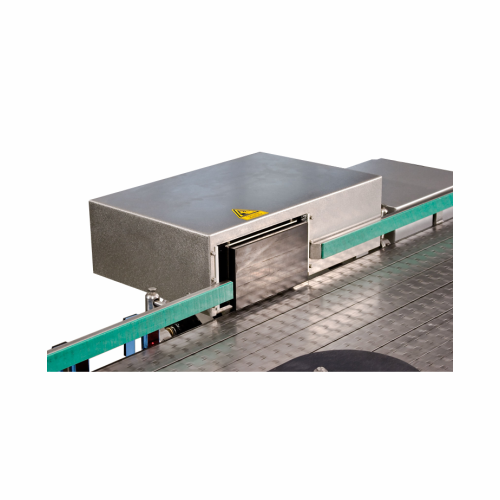

Agitator bead mill reactor for molecular synthesis by mechanochemistry in continuous flow

To achieve cleaner, safer,...

Stories about chemicals

Discover the best mix for your blending application

Powder and liquid, a delicate equilibrium in paint production

Saying goodbye to lumps in battery coating paste

Material discharge should be no burning issue for battery manufacturers

Building a sustainable future by recycling lithium-ion batteries

What is adhesive resin?

What are you making?

Benzene

Biocides

Buffer solutions

Bulk chemicals

Automotive paints

Carbon capture

Baking soda

Asphalt

Automotive coatings

Automotive catalysts

Zeolite catalysts

Wood varnish

Wood coatings

Wax emulsions

Water-based paints

Wall paint

Varnishes

Uv-curable inks

Toluene

Thinners

Thin film coatings

Surfactants

Surface coating

Superabsorbents

Sulfuric acid

Stearic acid

Specialty chemicals

Sodium sulfate

Sodium chloride

Sodium carbonate

Sodium bicarbonate

Silica gel

Ship paints

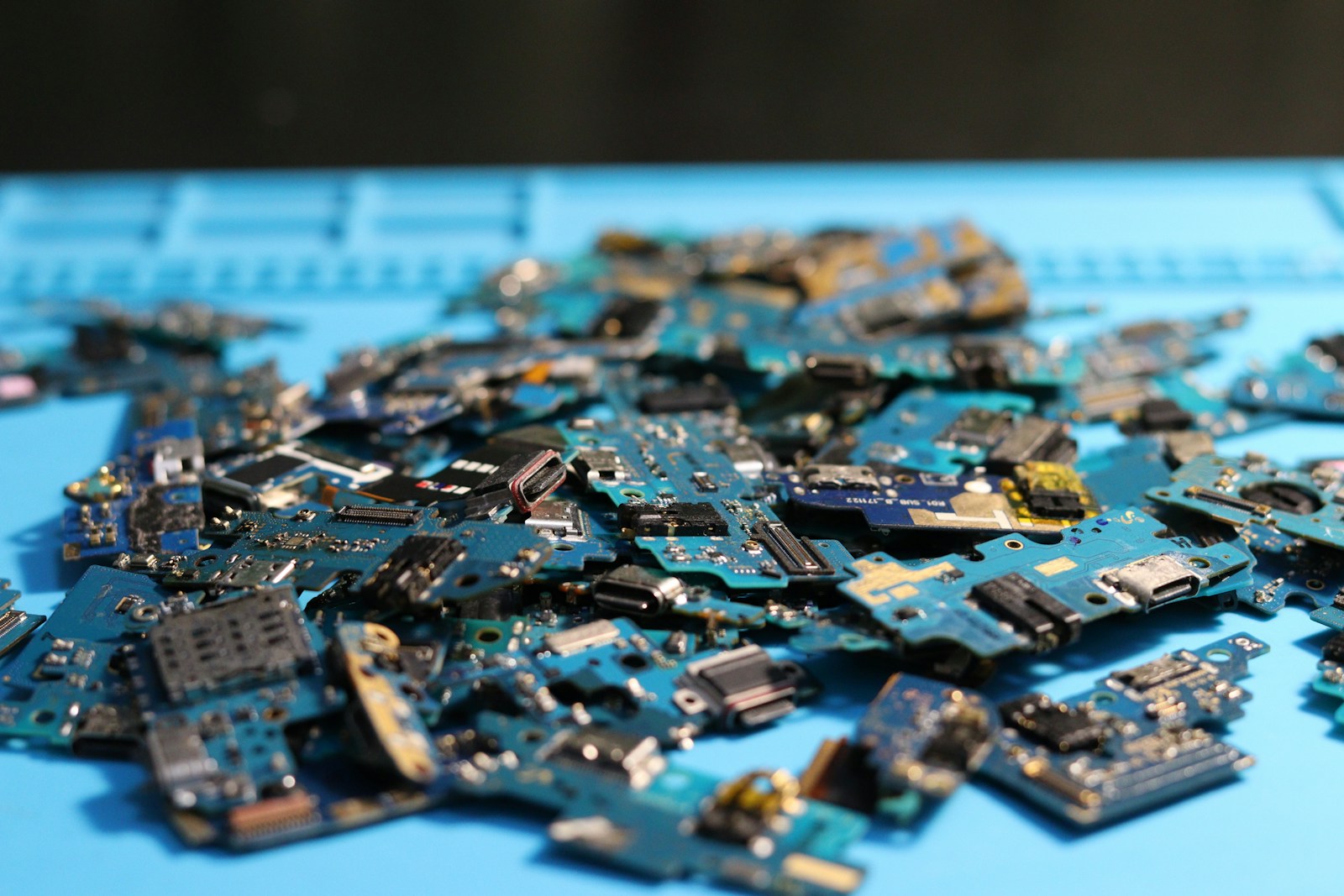

Semiconductors

Reagents

Radiochemistry

Rodenticides

Road marking paints

Protective coatings

Propylene

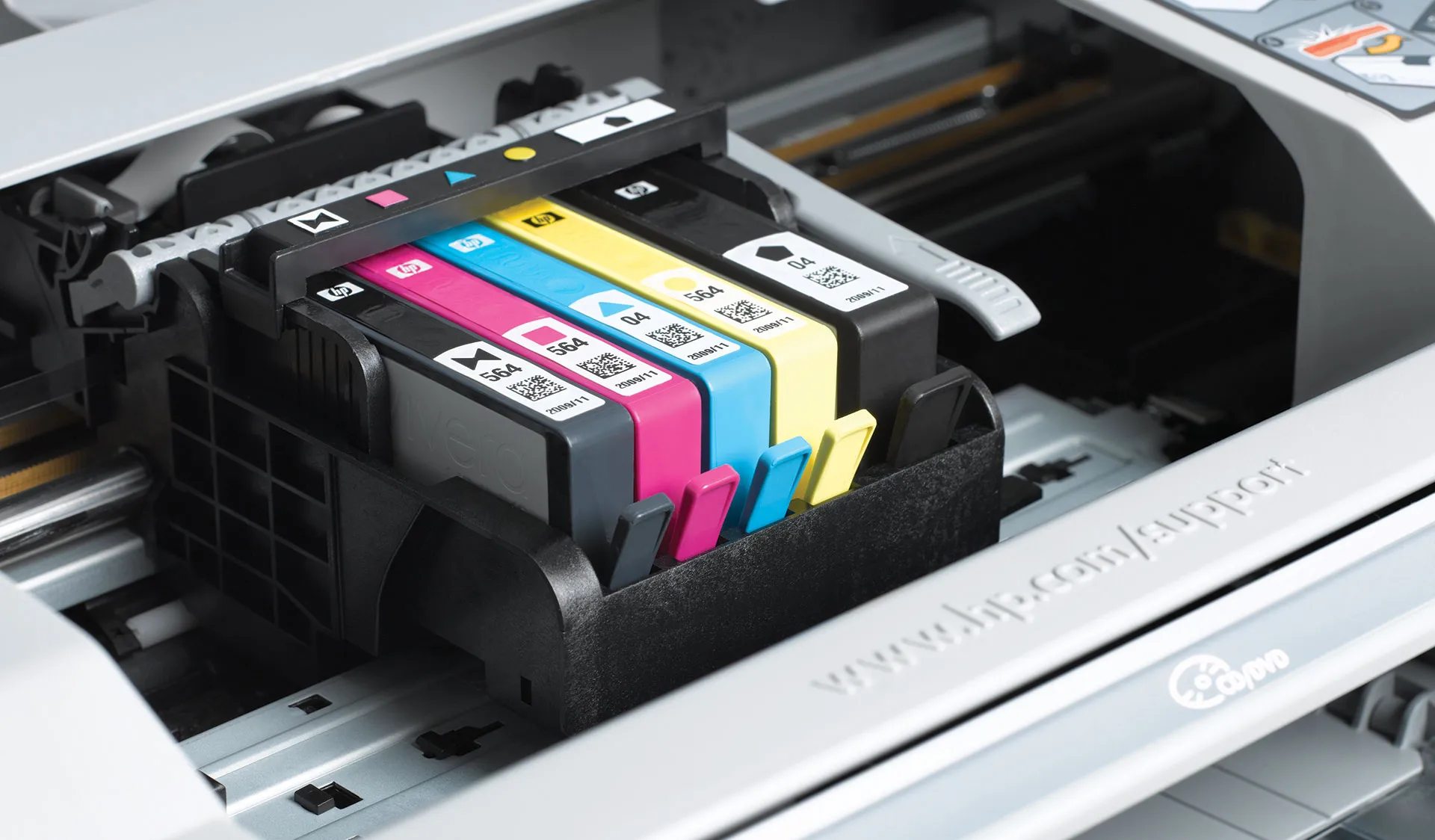

Printer ink

Primers

Precast concrete

Refrigerants

Cartridges

Powder coating

Portland cement

Polymer dispersions

Polishing agents

Polyurethane varnish

Polyurethane coatings

Polymer emulsions

Platinum catalysts

Plasticizers

Plasterboard

Plaster

Plaster of paris

Phosphoric acid

Petrochemicals

Pesticide

Paraffin wax

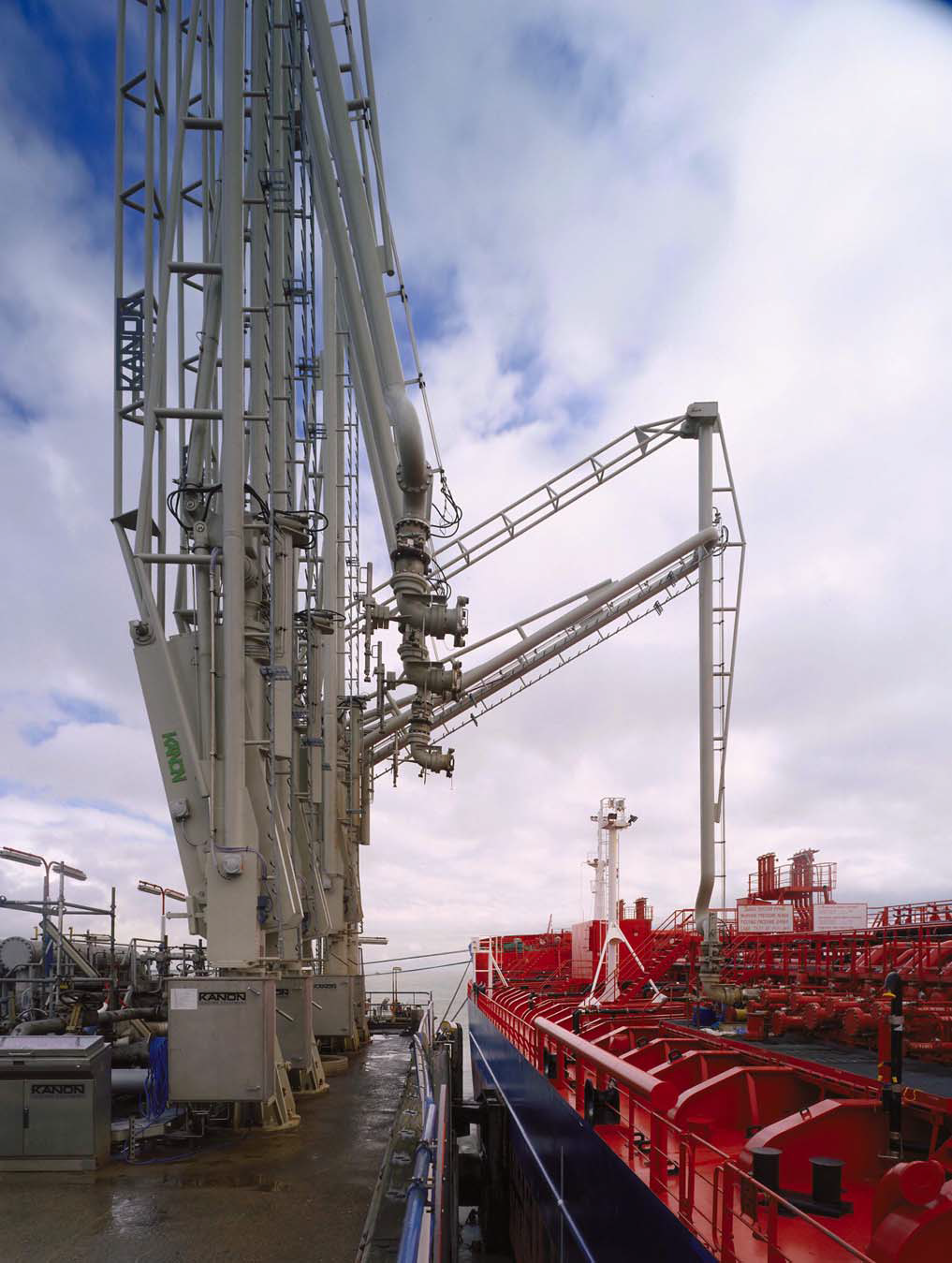

Marine applications

Organic chemicals

Organic acids

Lubricants

Natural paints

Nitric acid

Nitrogen

Nanoparticles

Lignin

Motor oil

Mosquito repellent

Lactic acid

Lacquers

Mineral oils

Methanol

Metal salts

Intermediates

Insecticides

Inorganic chemicals

Glyphosate herbicides

Inkjet printer cartridges

Green chemistry

Grease

Industrial products

Glyphosate

Glycerol

Gloss varnish

Hydrogen peroxide

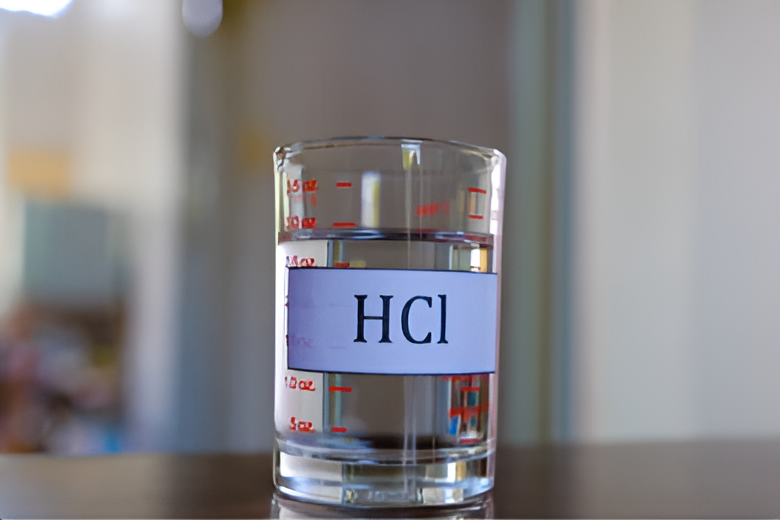

Hydrochloric acid

Hydrocarbons

Hydraulic oil

Fungicides

Herbicides

Epoxy resin

Epoxy coatings

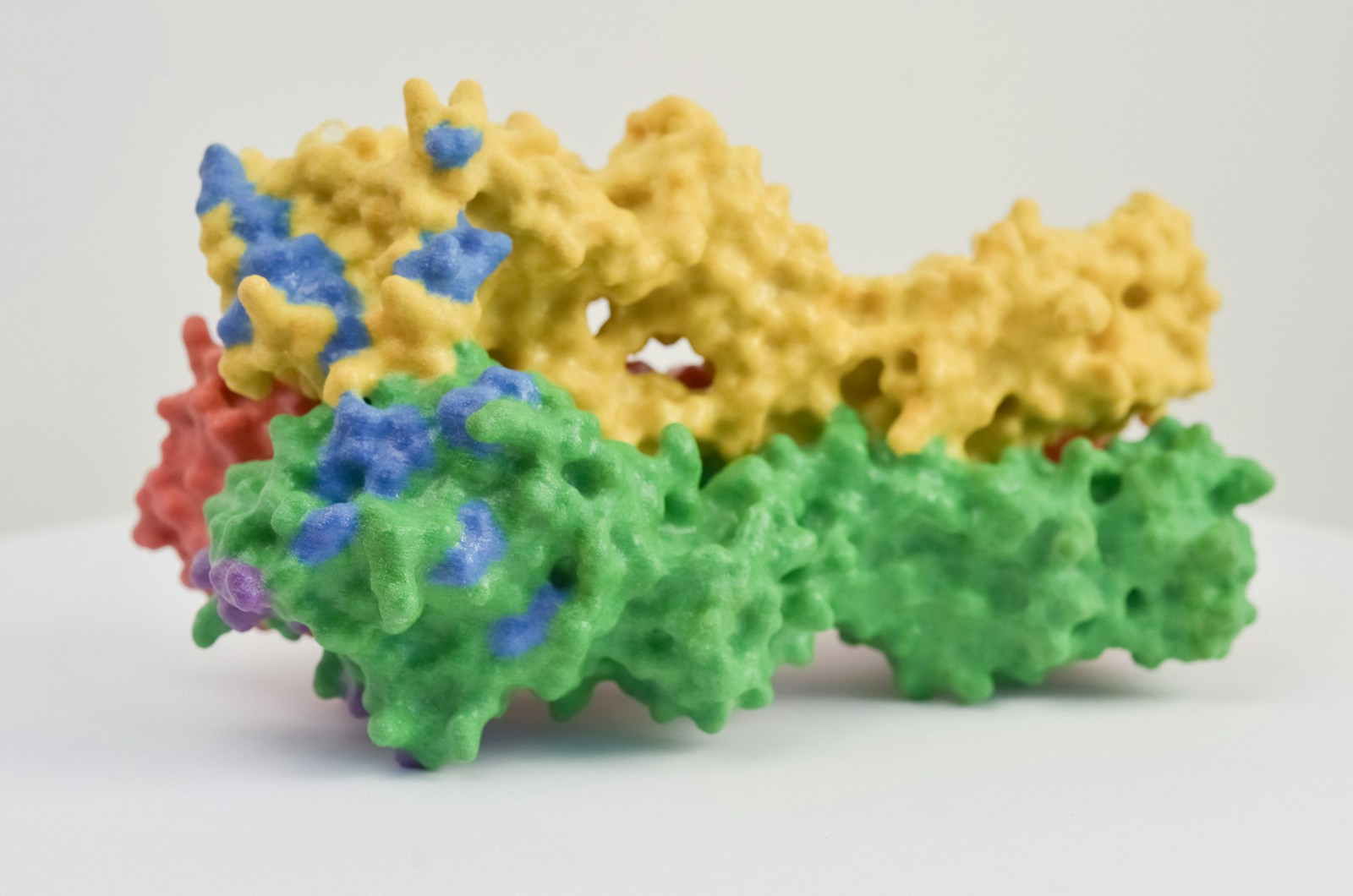

Enzymes

Enzyme catalysts

Fragrance compounds

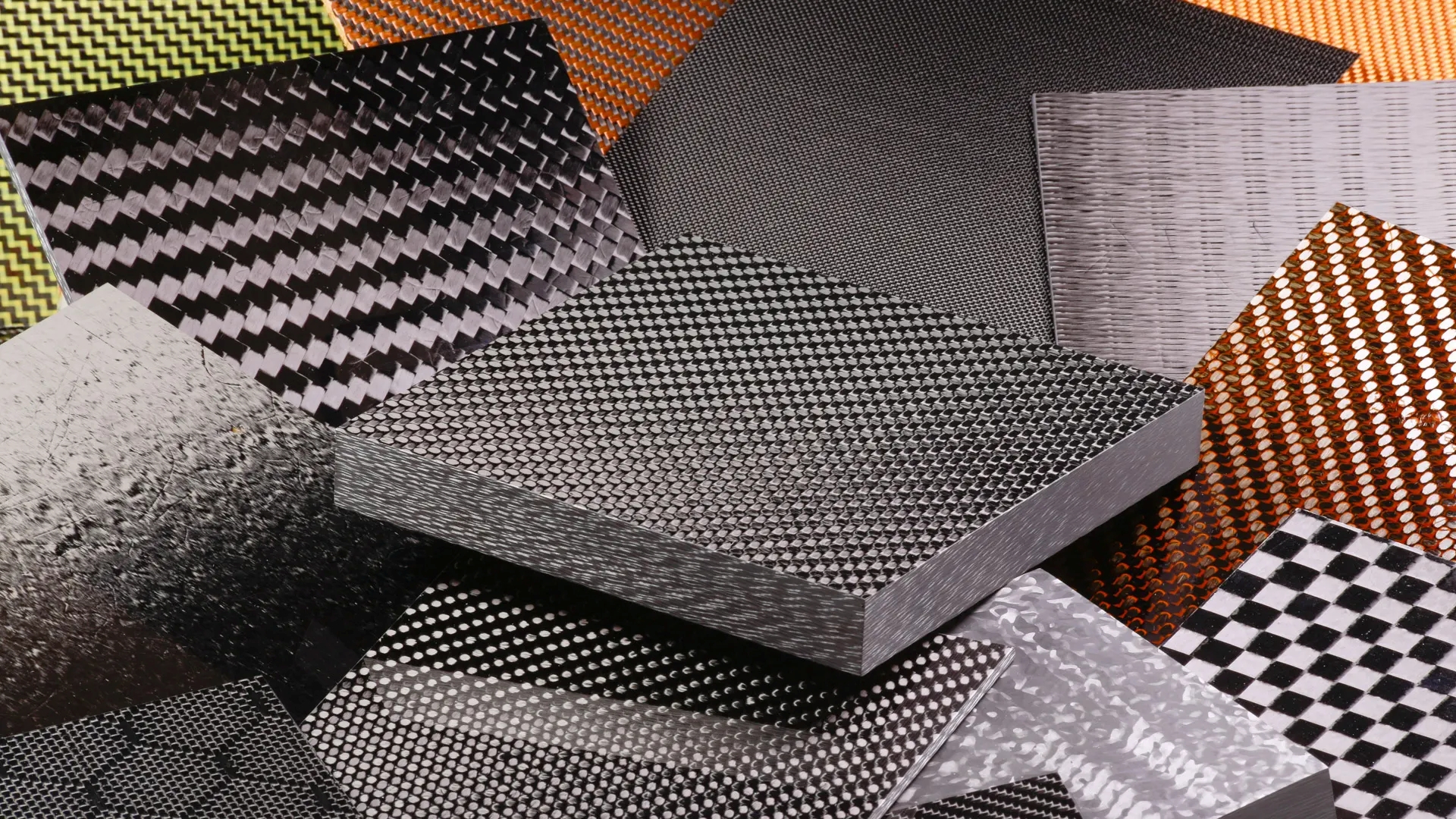

Engineering materials

Engine oils

Foam

Emulsion paints

Emulsifiers

Electronic materials

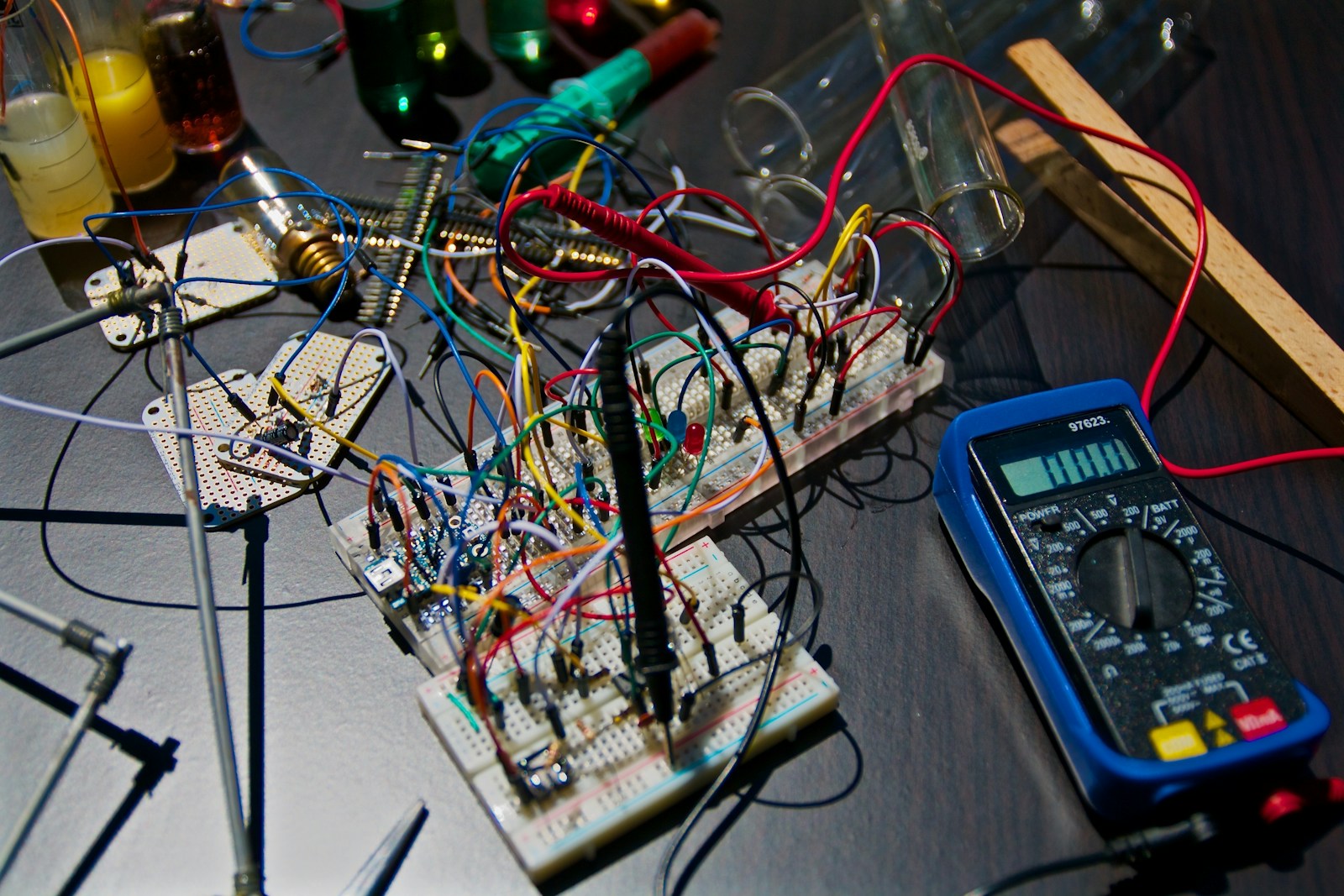

Electrochemistry

Flame retardants

Drywall

Drymix building materials

Fine chemicals

Disinfectant wipes

Digital printing inks

Face masks

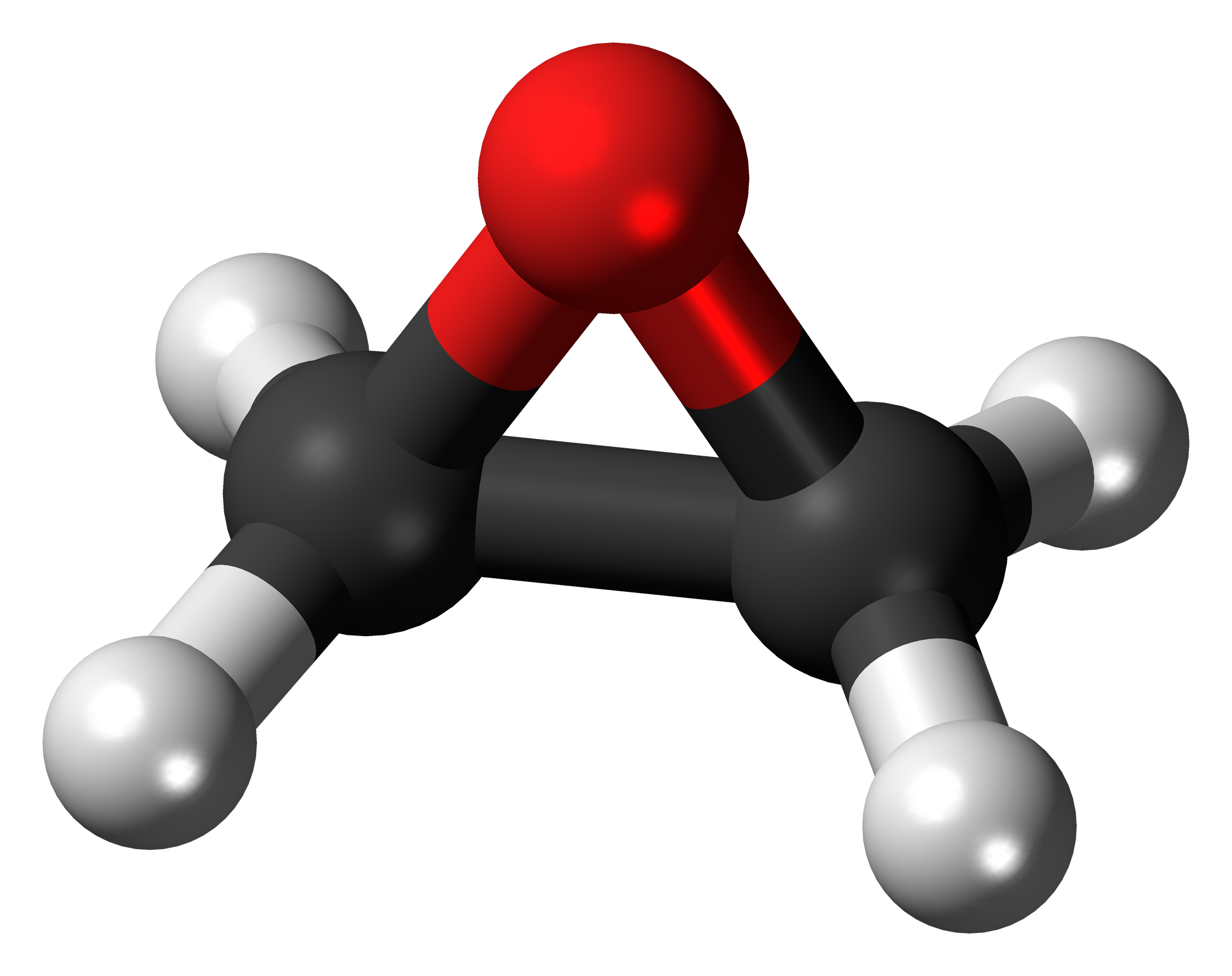

Ethylene oxide

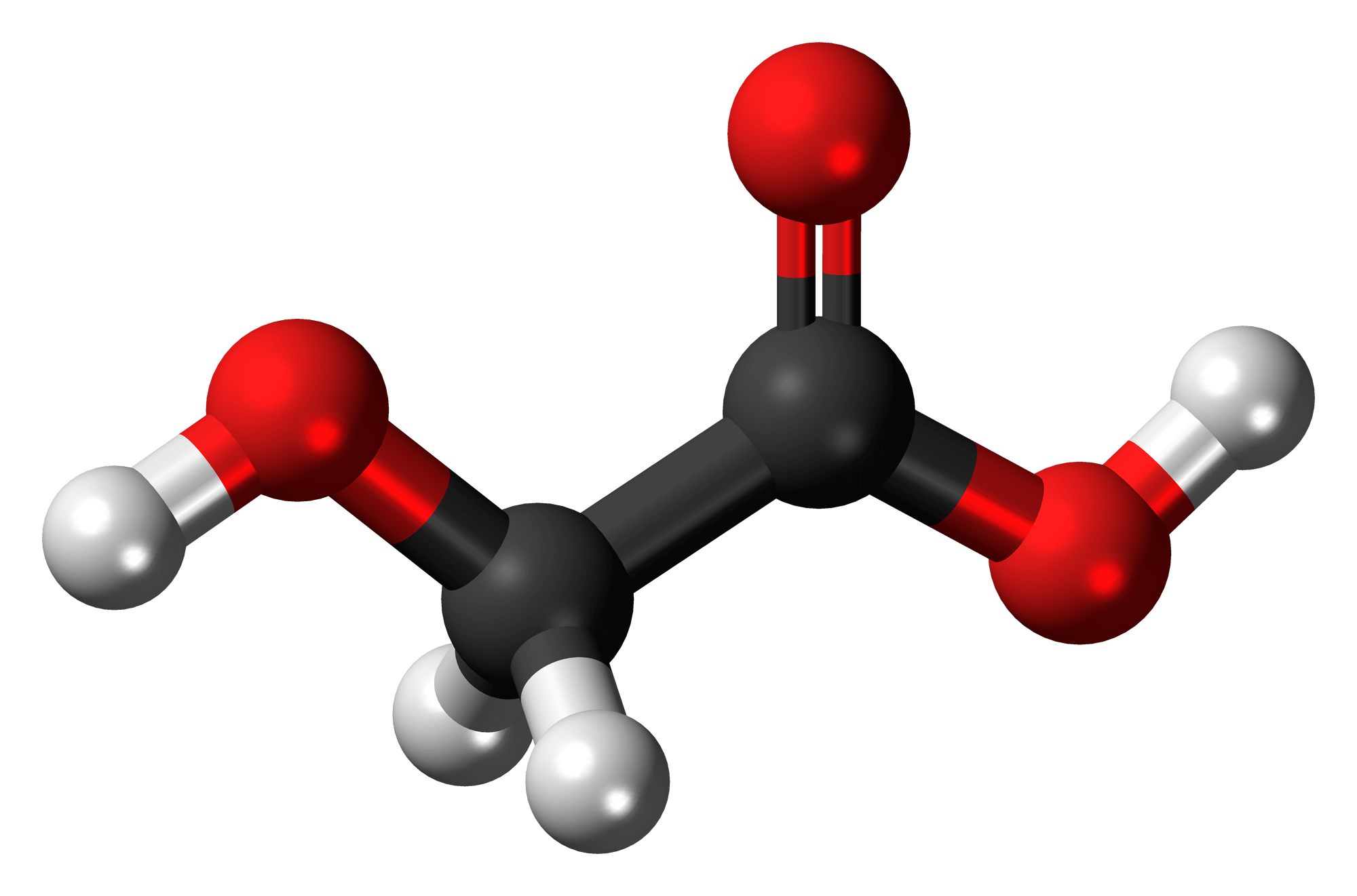

Ethylene glycol

Anti-friction coatings

Anti-corrosion coatings

Anhydrous pastes

Ammonium nitrate

Ammonia

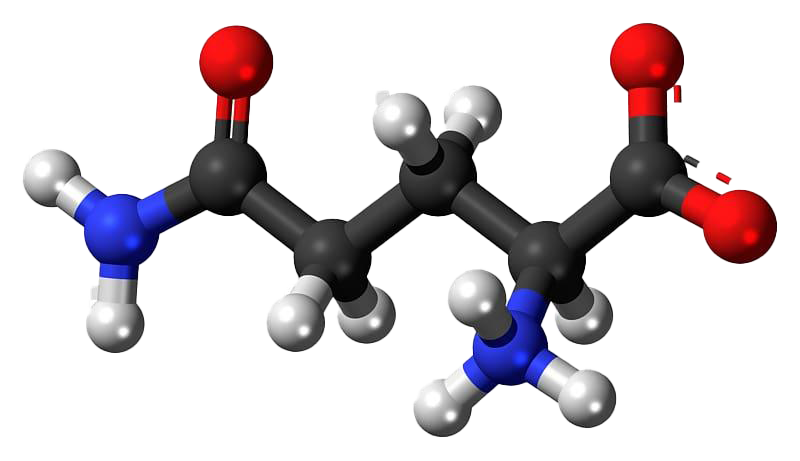

Amino acids

Alumina

Copper sulfate

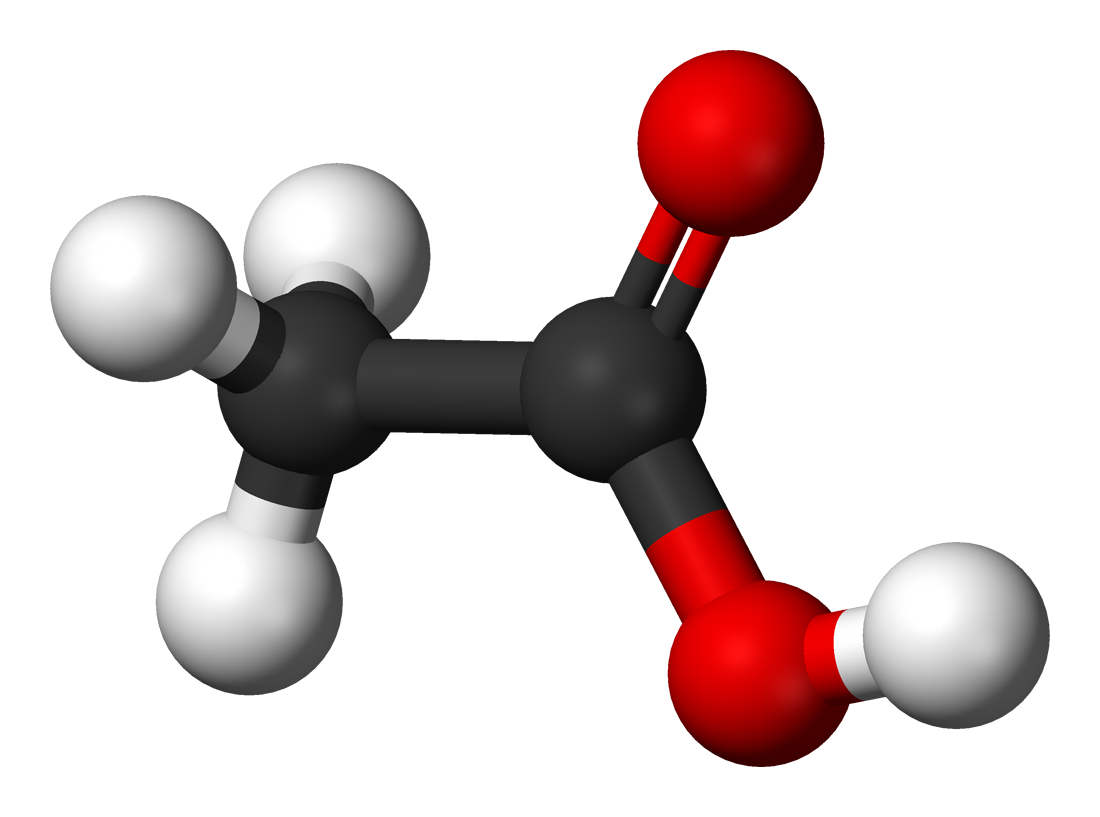

Acetic acid

Agrochemicals

Construction materials

Construction chemicals

Conductive inks

Conductive coatings

Concrete mixtures

Concrete

Colorants

Coil coatings

Clinker

Citric acid

Cigars

Cigarettes

Chemistry

Chemical solvents

Chemical reagents

Chemical intermediates

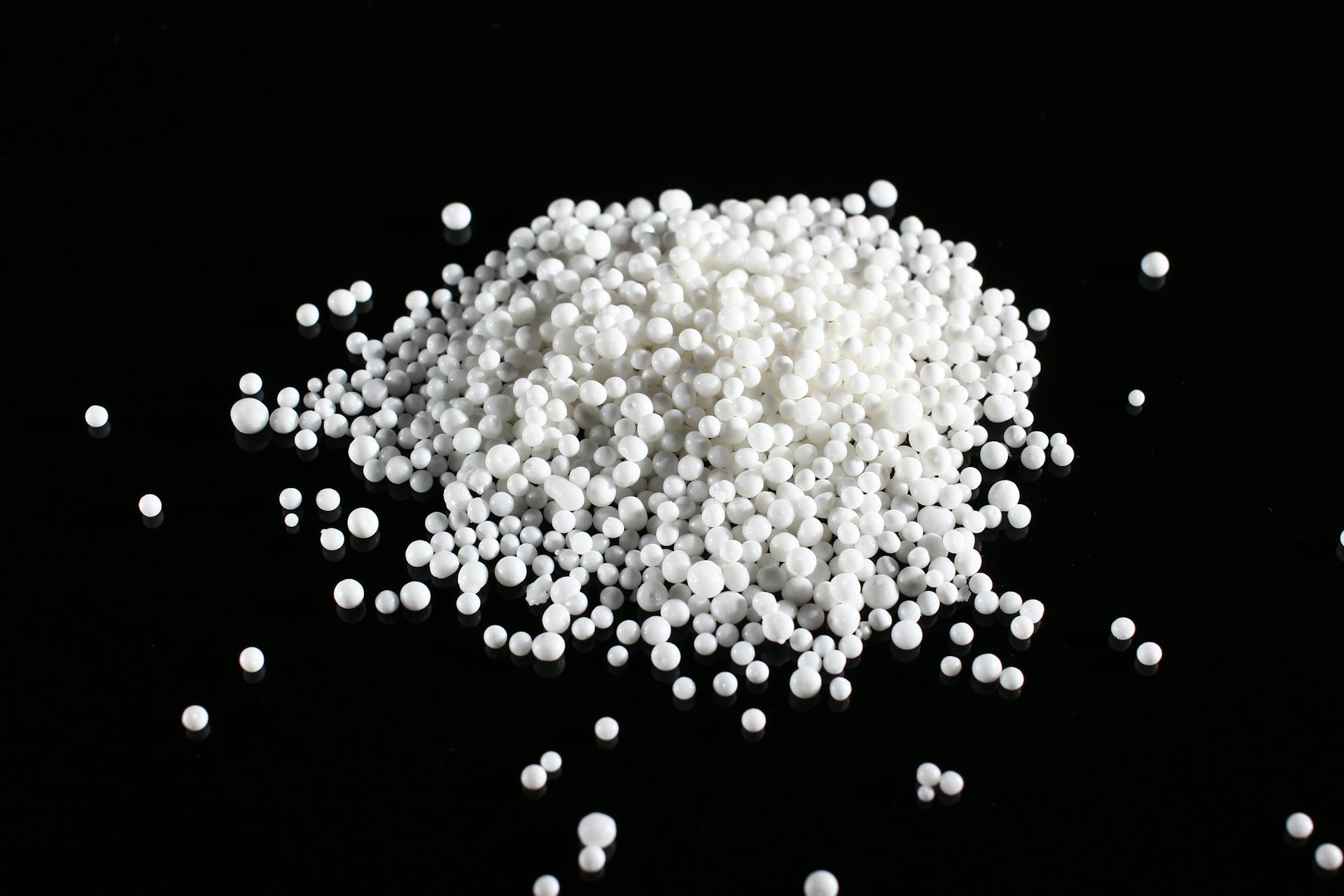

Chemical granules

Chemical emulsions

Chemical catalysts

Chemical additives

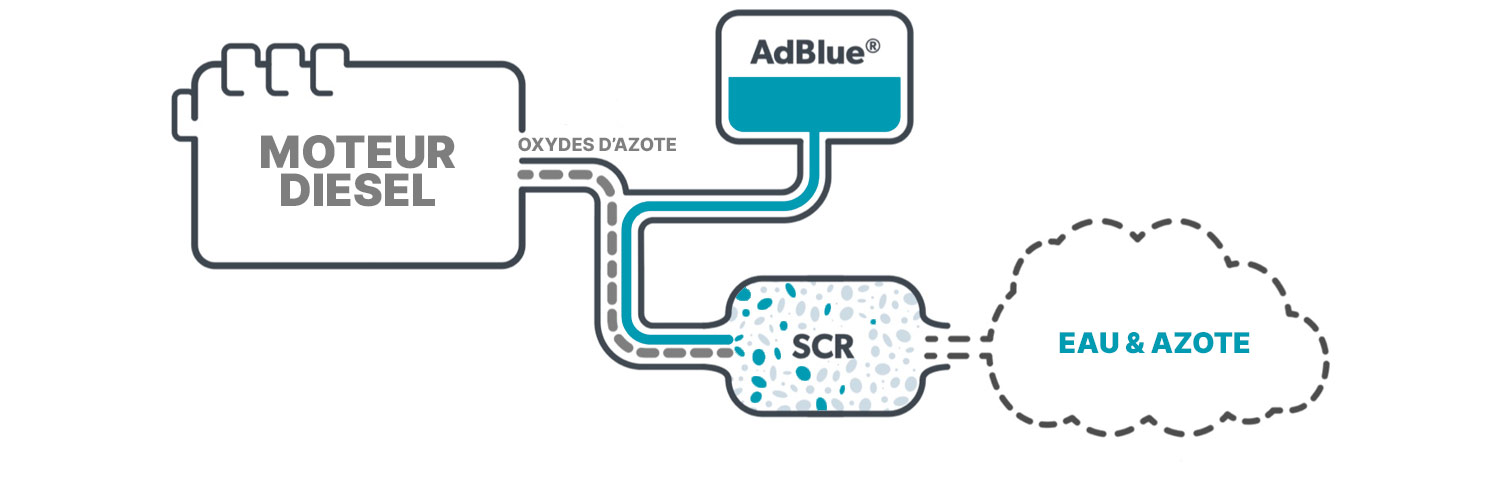

Adblue

Solvents

Sand

Glass

Solid-state batteries

Lithium-ion batteries

Sulphur

Glycerine

Oleochemicals

Aluminium oxide

Cement

Hydrogen

Masterbatches

Silicone

Bioplastics

Synthetic rubber

Latex

Ink

Toner

Dyes

Carbon black

Paint

Synthetic resin

Glue

Phosphorus fertilizer

Nitrogen fertilizer

Powder detergent

Liquid detergents

Dishwasher tablets

Laundry detergent

Tell us about your production challenge

Chemical process equipment is vast and requires proper selection

Chemicals are often toxic and require extra care for operators (according to acceptable operator exposure level – AOEL), as well as waste water cleaning systems. In this sense, chemical process technology has made production of chemicals easy and less hazardous. When producing chemicals, keeping potential risk in check is mandatory to protect the environment and human health. So using personal protective equipment isn’t all that you need when using the chemical process equipment. Make sure to take account of chemical reaction kinetics and equipment design by doing thorough investigation of the process. The scarcity of raw materials may be a challenge to manufacturers, who also need to mind strict industry regulations. One of them is the US Toxic Substance Control Act (TSCA), which prohibits the export of five specific mercury compounds.

Chemical reactors, the key equipment to produce chemicals

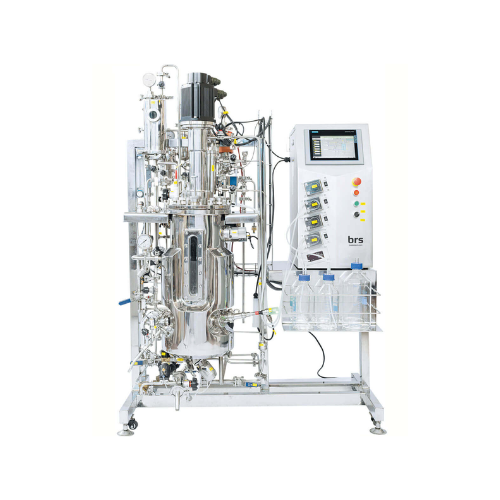

Chemical reactors are key to producing chemicals. They have a design and configuration that provides proper environment such as temperature and presence of a catalyst for the chemicals reaction to take place. There are two main types of chemical reactors: the batch reactor and the continuous reactor. The former usually makes products with different reactants, as in production of colorants and drugs in the pharmaceutical industry. The latter consistently produces ammonia and other chemicals in large quantities.

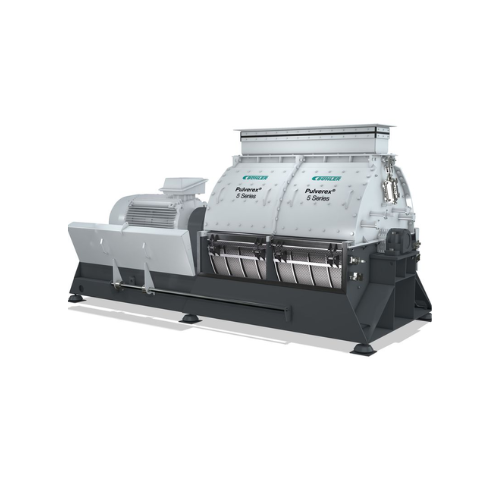

Dry milling is also one of the core processes in manufacturing chemical products, as it controls particle size and removes excess moisture from products. It is advisable to dry at a low temperature because very high temperatures can melt products. You need to monitor the flow of production from the upstream production process (sourcing of raw materials) to the downstream activities, such as purification of chemicals into finished products. This is to ensure good product quality and improve profitability.

Some chemical products and their industrial applications

Industries that use big processing plants buy chemical products in order to make intermediate products. Chemical products like toners, dyes, nitrogen fertilizer, synthetic resins, glue, glycerin, fine chemicals and others work as ingredients of these finished products. The materials and the manufacturing process depend on the industry and final consumer of the products. You can use glycerin in the pharmaceutical industry, for foods and soaps. Also, synthetic resins have wide application in the plastic industry. To provide colors to materials in the textile industry, use dyes. The automotive and furniture industries use adhesives in production.

EU regulations moving towards green chemistry

The release of chemicals, whether in liquid, solid or gas states, can pollute the underground water, soil and air, which in turn poses health risks to humans. To tackle this, the European Union has put in place strategies to ensure the minimal usage and production of harmful chemicals. The strict EU’s regulations aim to put chemical exposure to check from production level to disposal level. They intend to achieve this by phasing out the use of highly toxic chemicals like mercury chloride except their use is essential and promoting green chemistry for sustainability. For example, instead of producing mercury-based batteries, there are alternatives like alkaline.

Which chemicals technology do you need?

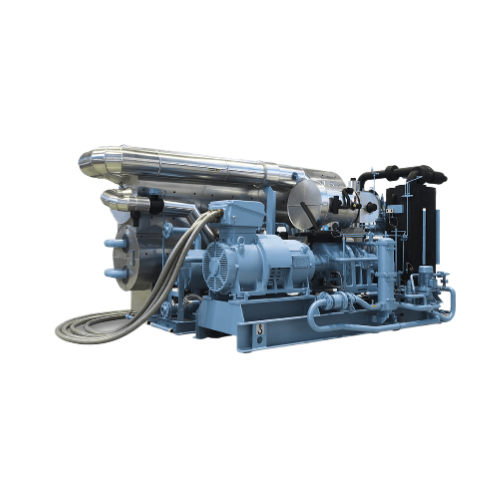

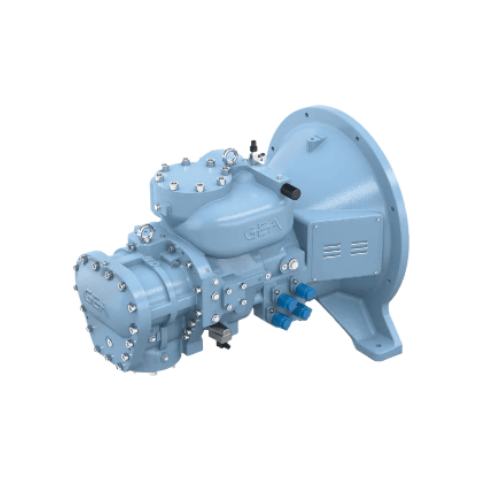

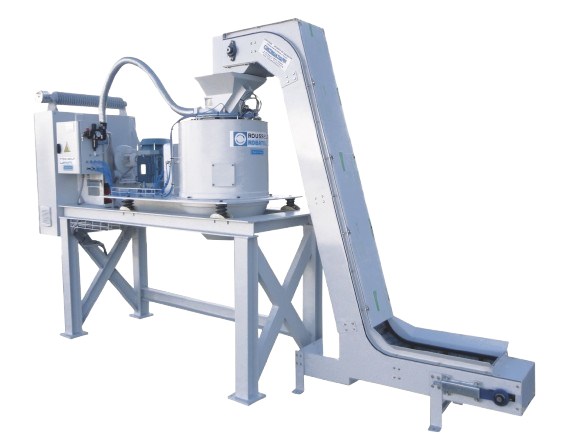

Centrifugal separator for chemicals and minerals

Achieve precise separation of liquids and slurries with this high-speed c...

Solid-wall bowl separator for chemical products

Optimize your separation and clarification processes with this high-speed,...

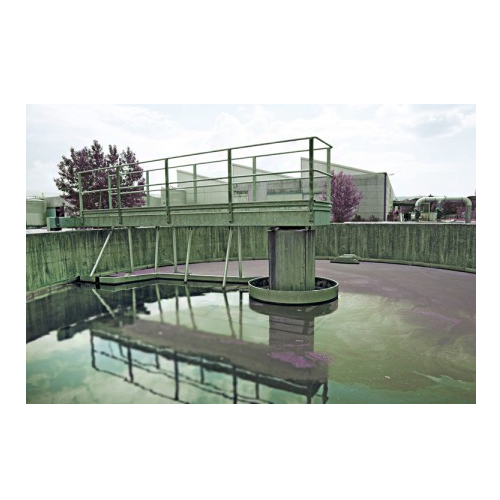

Clarifiers for biochemical separation

Achieve seamless liquid-solid separation with high-speed disk-type clarifiers, ensuri...

Nozzle separators for chemicals and minerals

Optimize your chemical and mineral processing with precise, continuous separa...

Separators for biochemicals

Achieve precise separation and purification of complex biochemical mixtures with self-cleaning c...

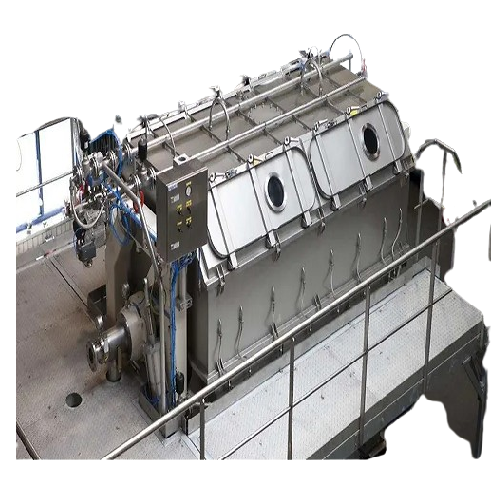

Horizontal batch centrifuge for chemical industry

Optimize your solid-liquid separation with a centrifuge designed for pr...

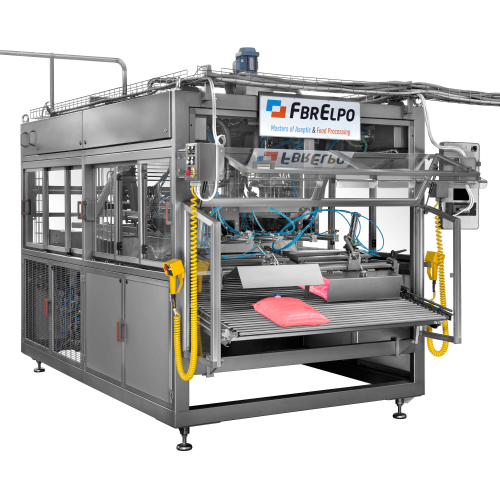

Chub packing system for chemical emulsions

Effectively pack and fill chemical emulsions with precision to enhance the safe...

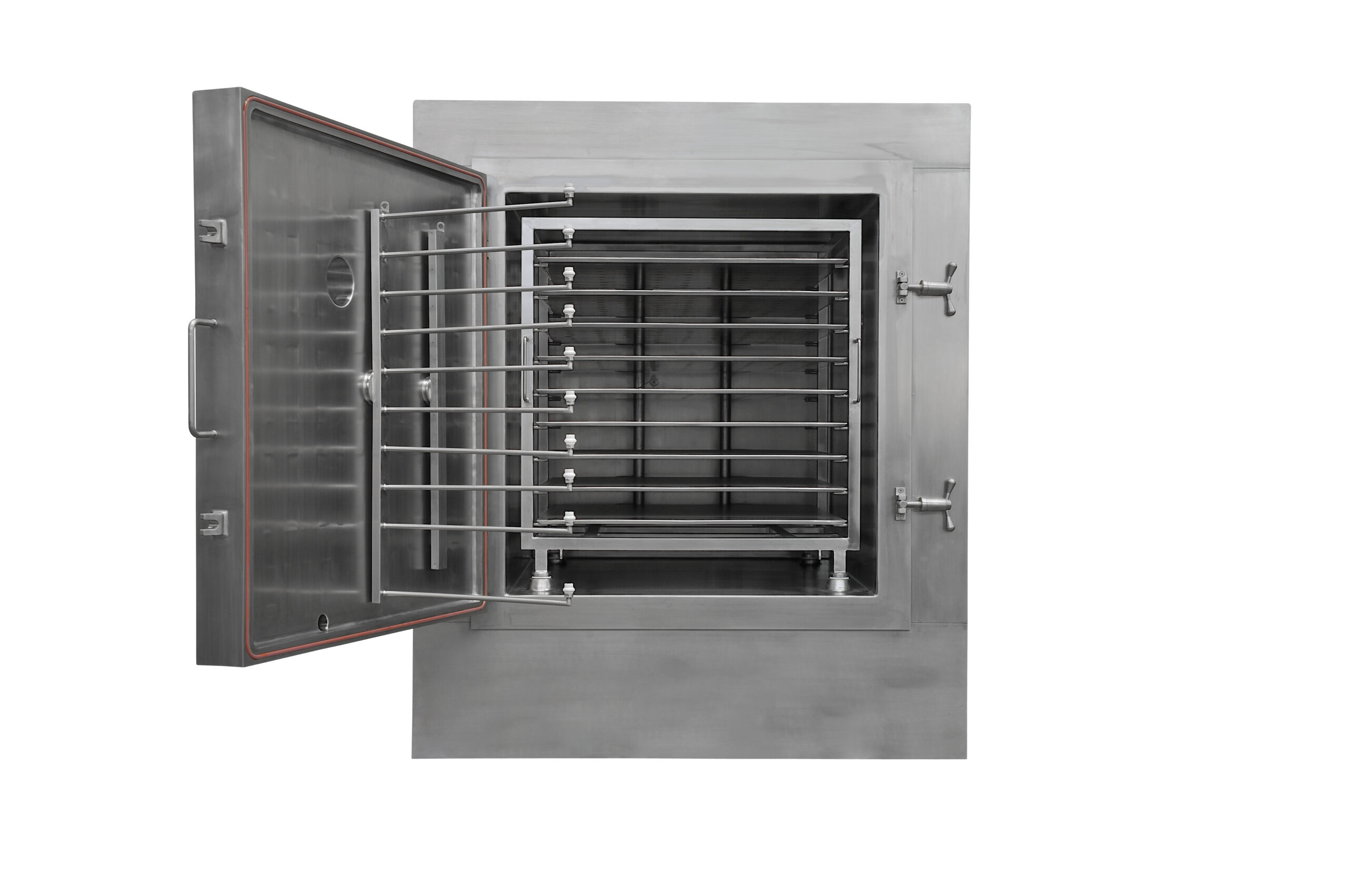

Agitated nutsche filter dryers for chemical synthesis

Enhance your production efficiency by integrating a system that com...

Perforated disc mill for food and chemical processing

Streamline your processing workflow with a versatile solution that ...

Laboratory chemically resistant dry scroll vacuum pump

Ensure efficient handling of aggressive or corrosive substances wi...

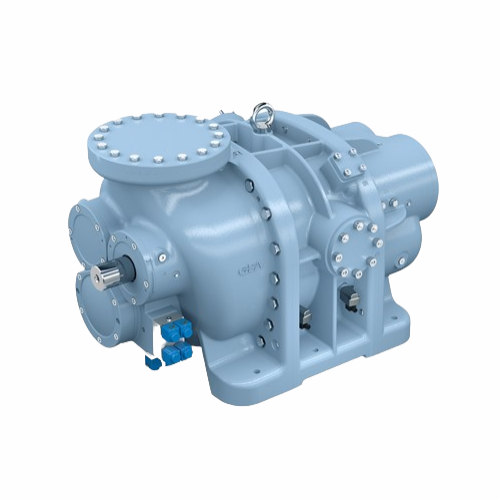

Chemically resistant dry scroll vacuum pump

Effortlessly manage aggressive substances and achieve reliable vacuum conditio...

Vacuum paddle dryer for chemical and pharmaceutical applications

Achieve precise moisture control and efficient drying i...

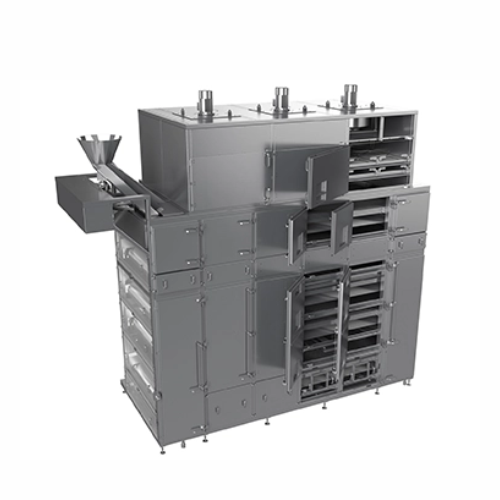

Continuous granulation dryer for chemical and polysaccharide applications

Enhance your production with precise drying ...

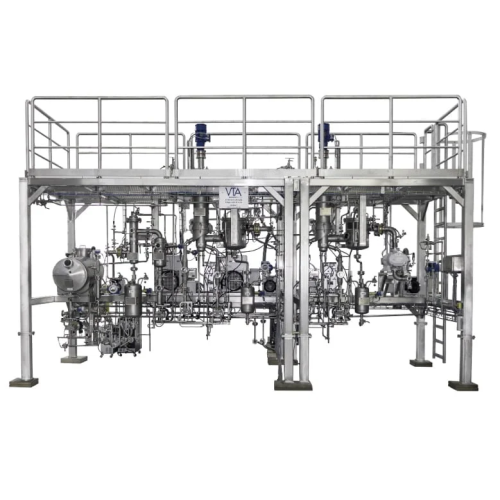

Highly scalable reactors for chemical synthesis

Optimize your production line with versatile reactors designed for seamles...

Tablet pressing system for solid chemicals and cosmetic products

Optimize your tableting process for diverse solid produ...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

Chemical filter dryer for fine chemical production

When processing chemical intermediates, precise filtration and drying ...

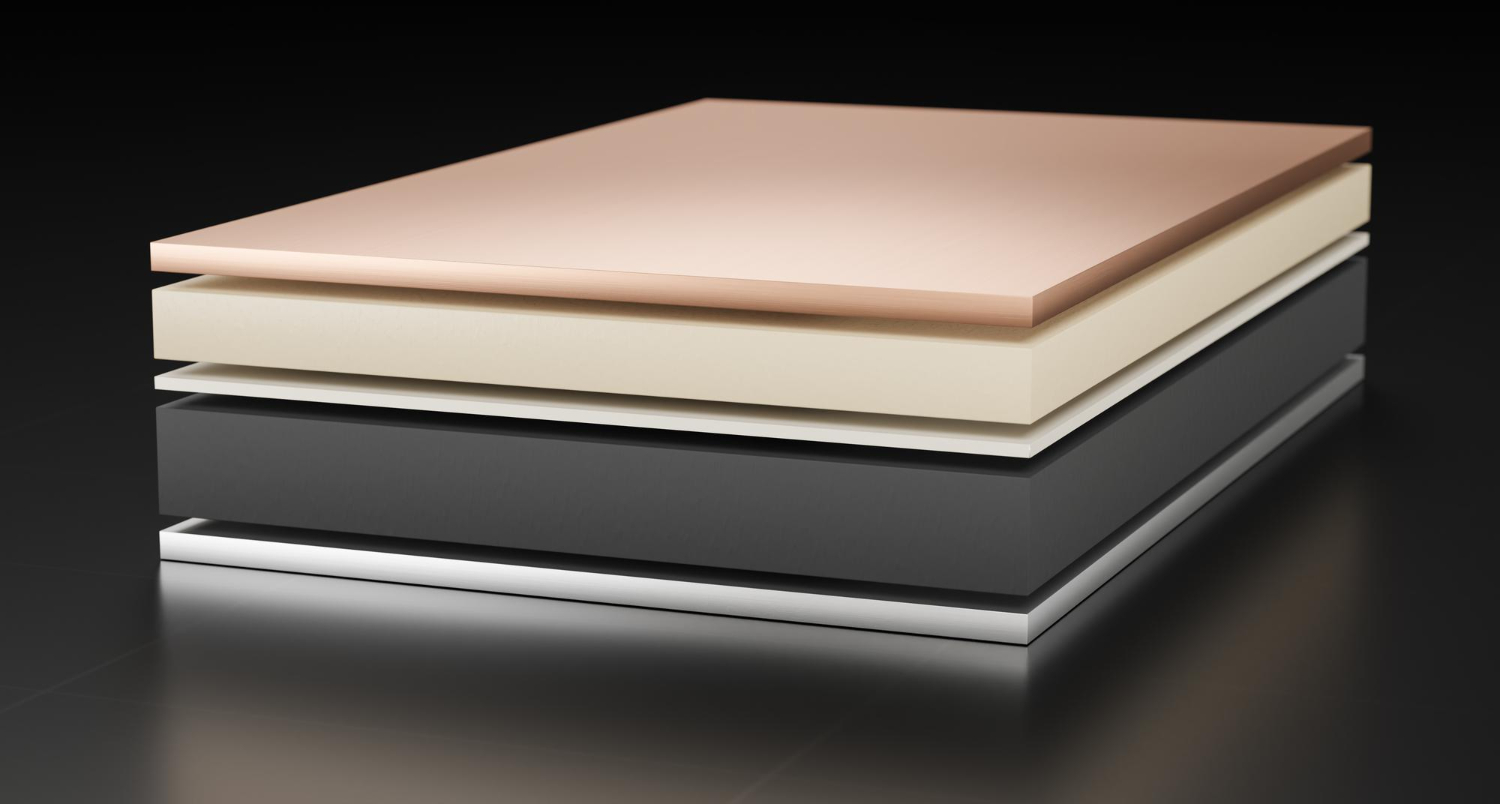

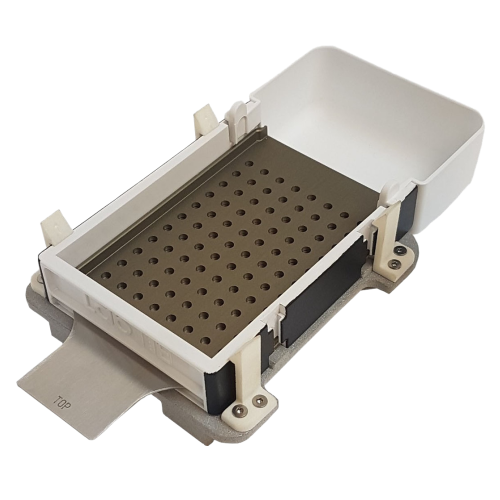

Multilayer filter plates for pharmaceutical and chemical applications

Achieve efficient filtration and separation in yo...

Vertical pilot plant centrifuge for chemical industry

Optimize your lab and pilot plant operations with this mobile centr...

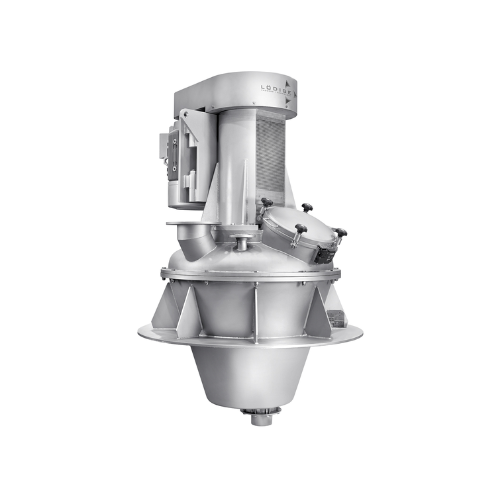

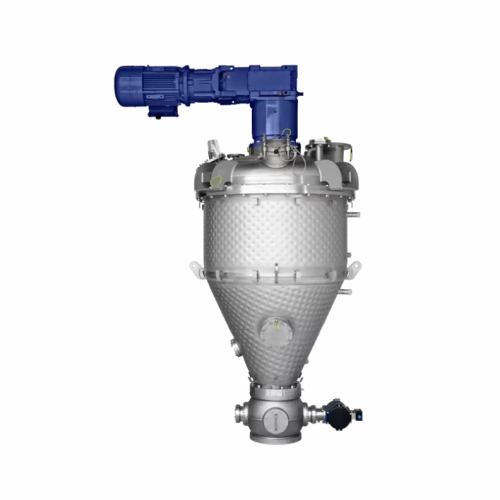

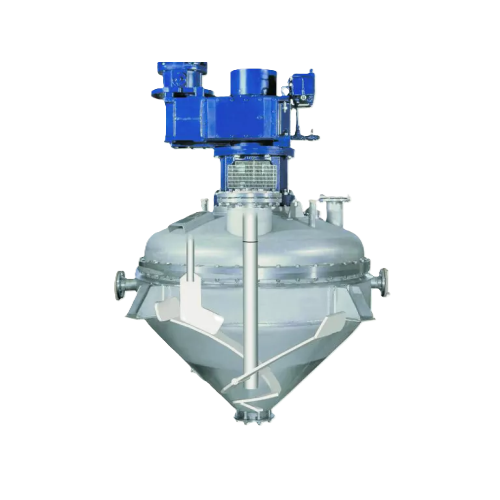

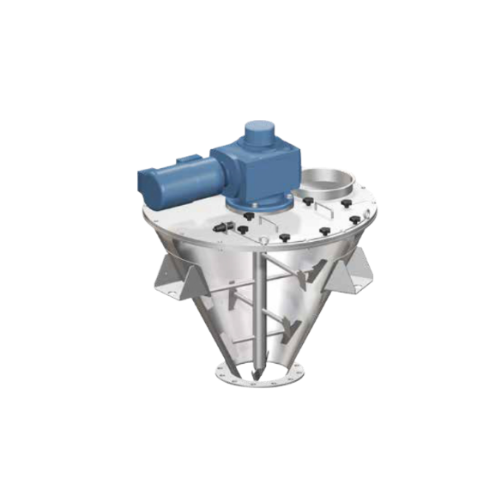

Conical screw mixer for pharmaceutical and chemical industries

Optimize mixing precision and efficiency with a conical s...

Horizontal pilot plant centrifuge for chemical processing

Enhance your R&D and pilot-scale processes with a centrif...

Top discharge centrifuge for chemical manufacturing

Achieve precise filtration and separation with top discharge centrifu...

Vertical peeler centrifuge for chemical industry

Maximize throughput in continuous chemical processes with a versatile ver...

Horizontal peeler centrifuge for chemical applications

Achieve high-throughput product separation and purification with p...

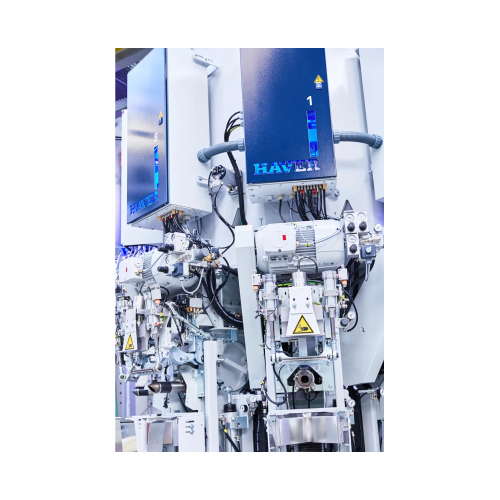

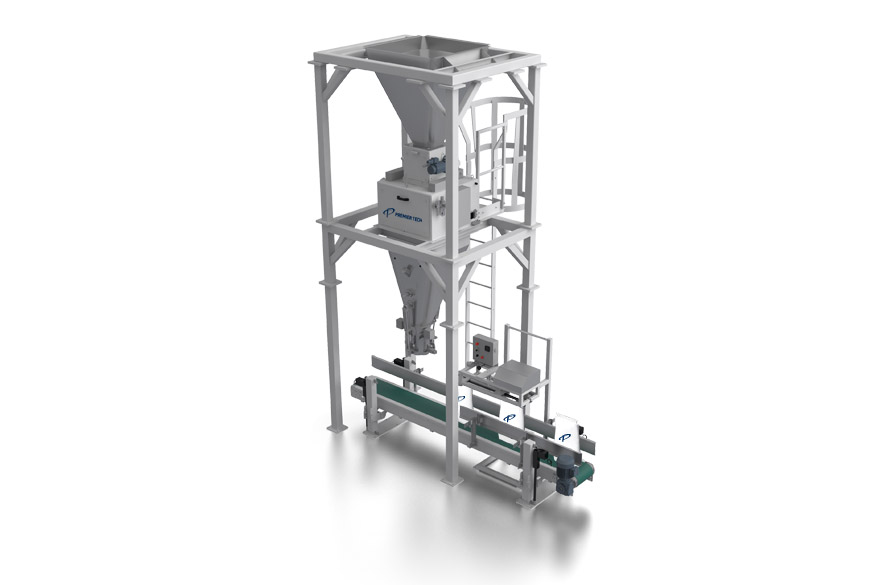

Valve bag filling system for cement and chemicals

Optimize your material handling with precision filling and sealing, ens...

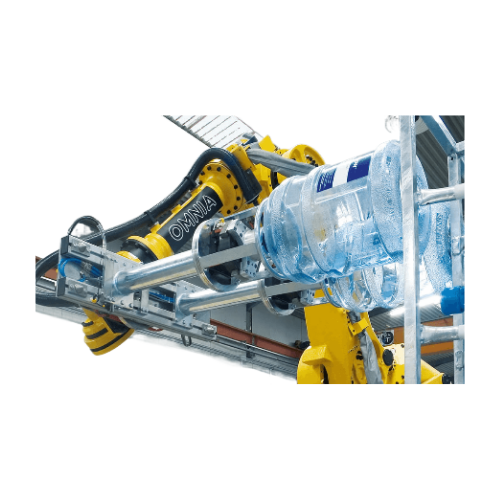

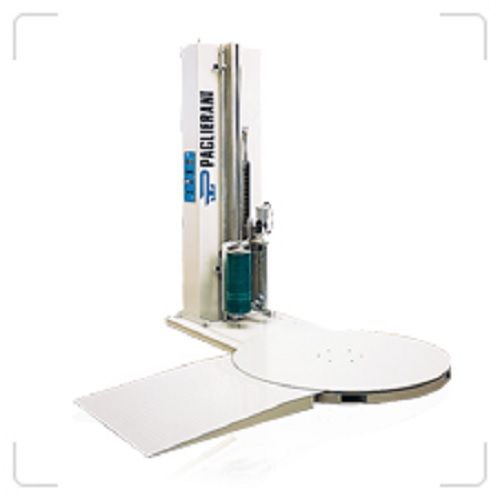

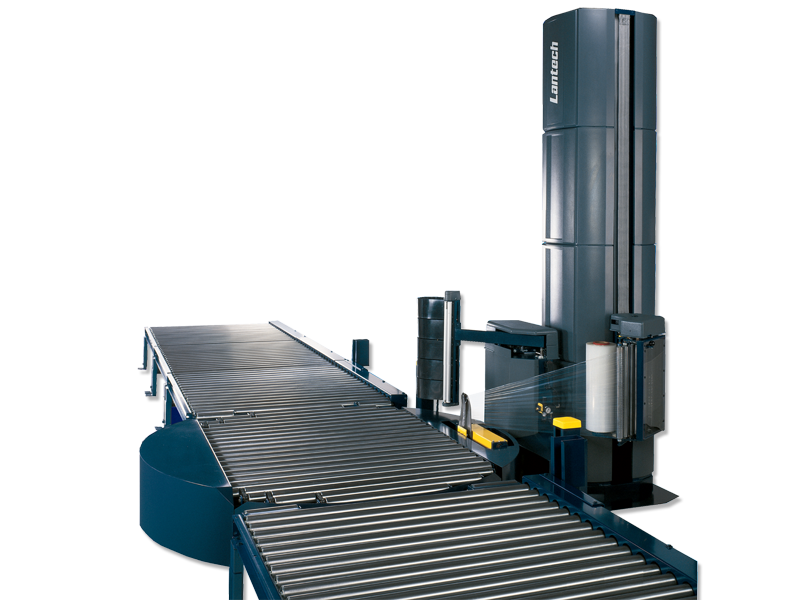

Rotating packaging system for cement and chemicals

Streamline your packaging line with a high-speed, rotating solution th...

Laboratory filter-reactor for chemical synthesis and extraction

Optimize your chemical processes with a versatile filter...

Nutsche filter dryer for pharmaceutical and chemical industries

Achieve precise filtration and efficient drying in one s...

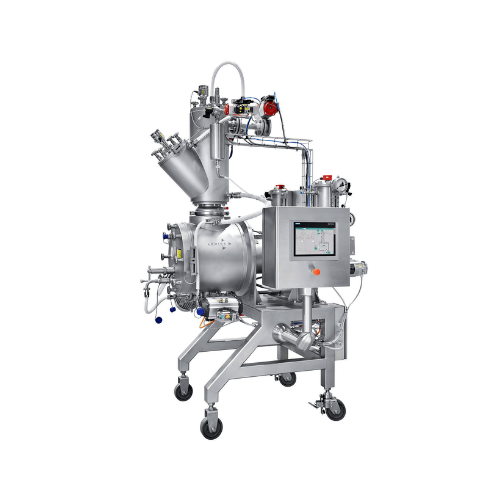

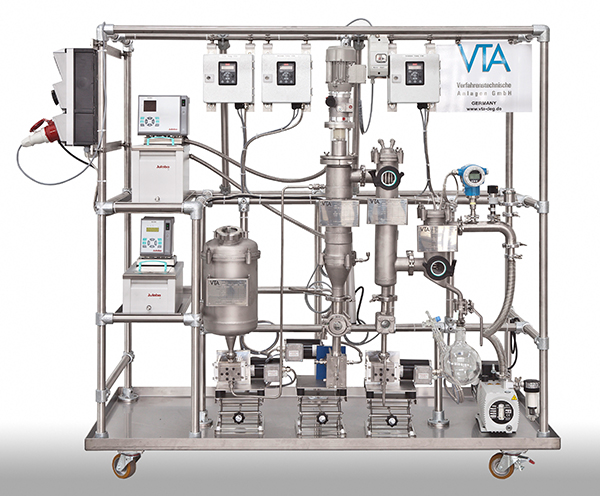

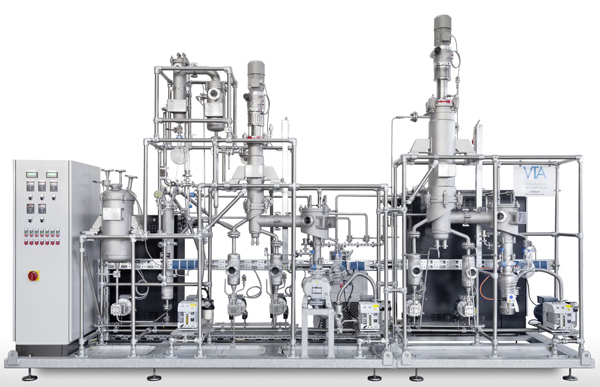

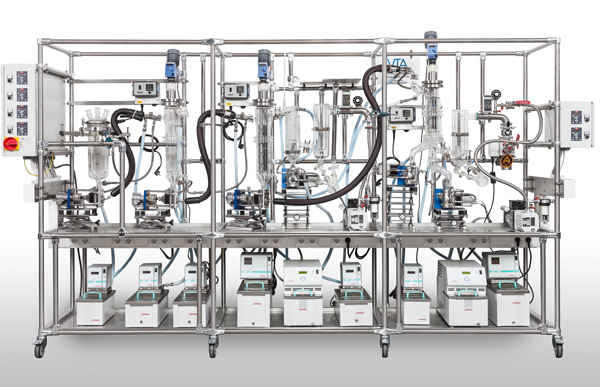

Chemical and pharmaceutical solid-liquid separation pilot plant

Optimize your pilot-scale production of pharmaceuticals ...

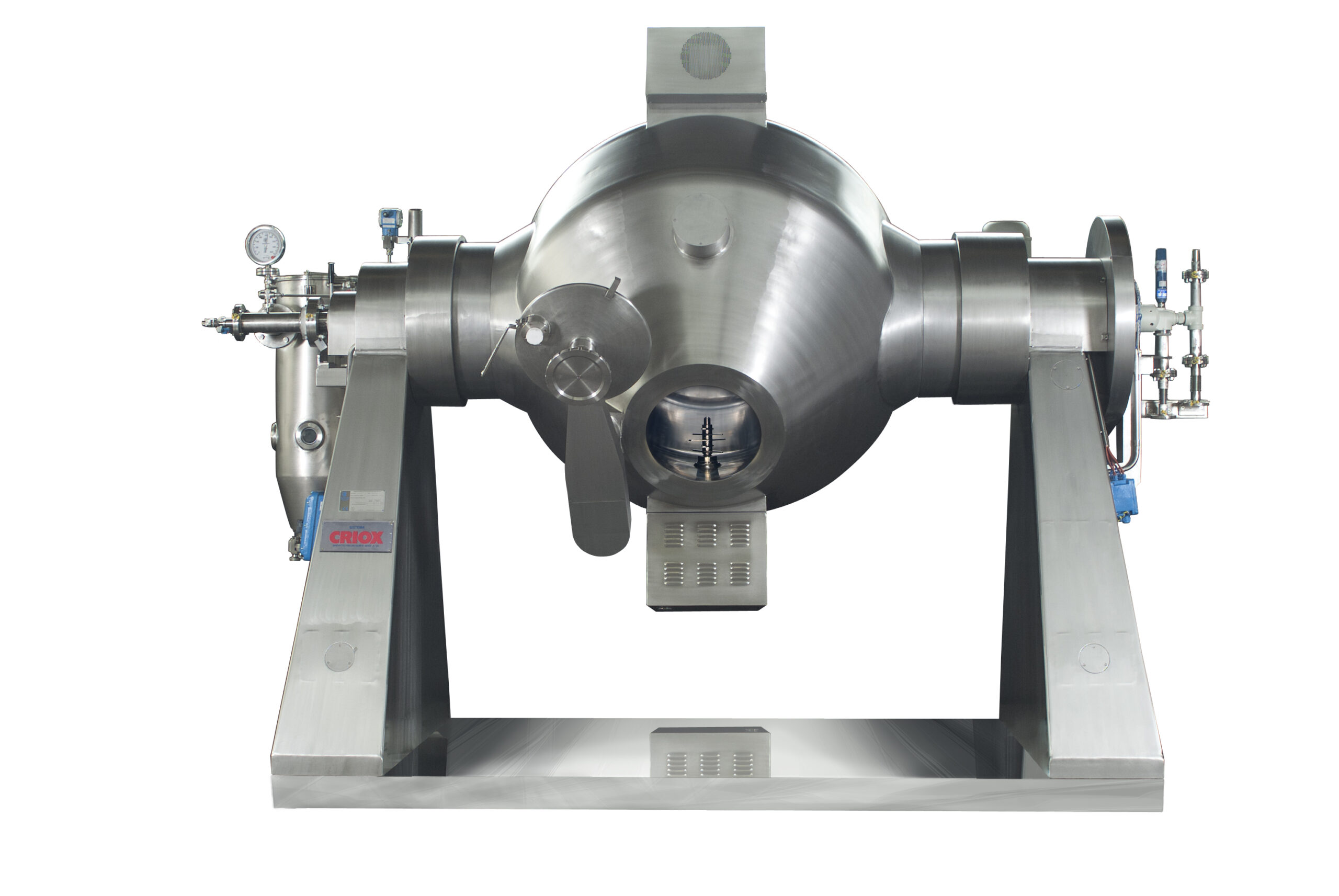

Spherical vacuum dryer for Apis and fine chemicals

Achieve precise moisture control and efficient drying for APIs and fin...

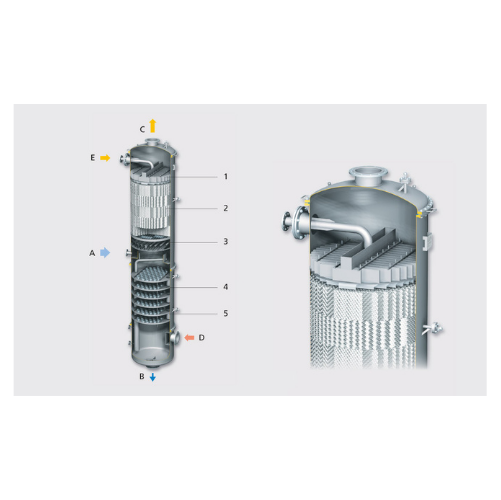

Glass lined columns for chemical plants

Optimize your chemical processing with glass-lined columns, designed to ensure maxi...

Fluid bed granulation system for food and chemical industries

Achieve efficient granulation and drying of liquids with c...

Fluid bed granulator for food and chemical industries

Ensure consistent particle size and moisture control in your produc...

Spouted bed processing for food, feed, and fine chemicals

Tackle the challenge of processing temperature-sensitive and s...

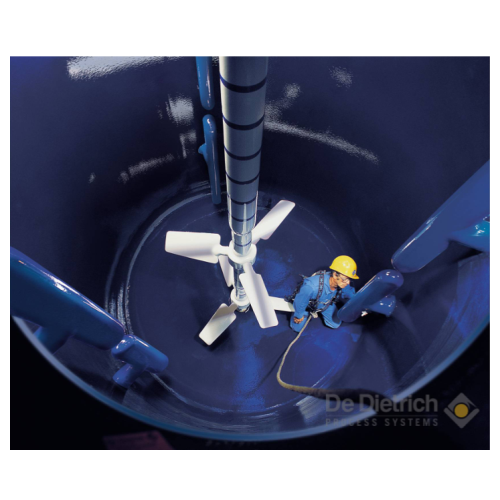

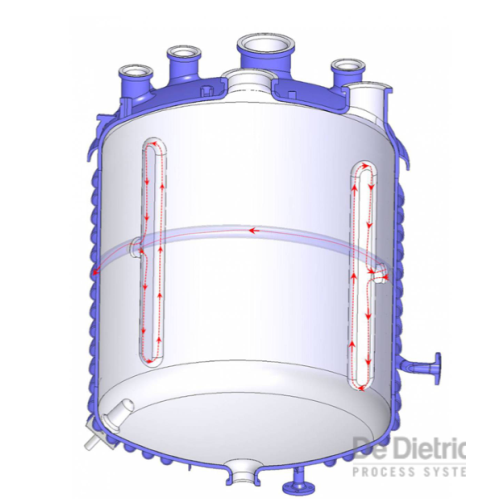

Asme glass-lined reactors for chemical processing

Optimize your chemical processes with high-pressure, corrosion-resistan...

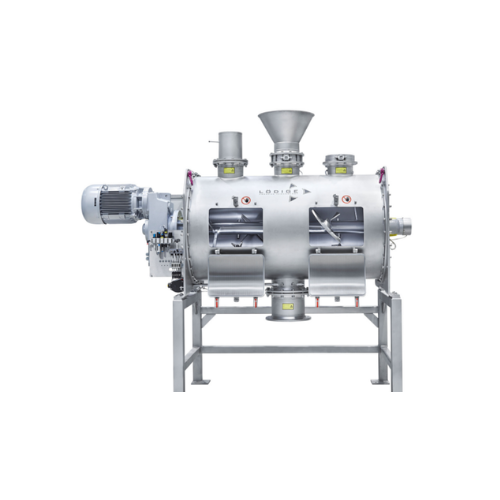

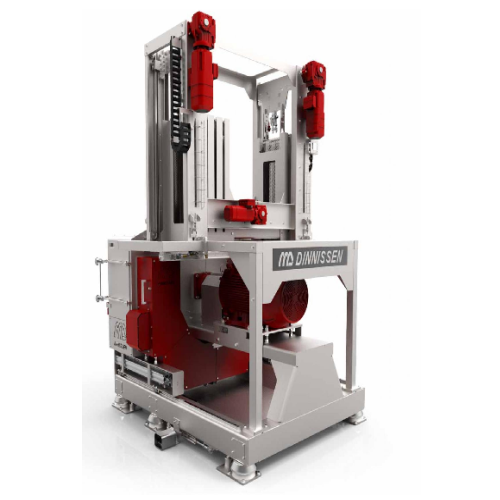

Single shaft batch mixer for chemical and pharmaceutical applications

Optimize mixing efficiency with rapid batch proce...

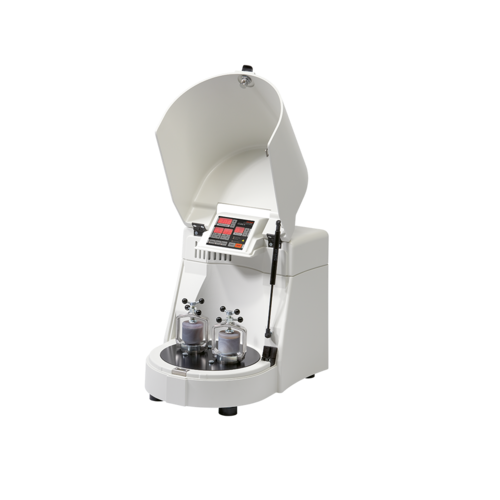

Tapped density tester for pharmaceutical and chemical powders

Ensure precise density measurements for pharmaceuticals an...

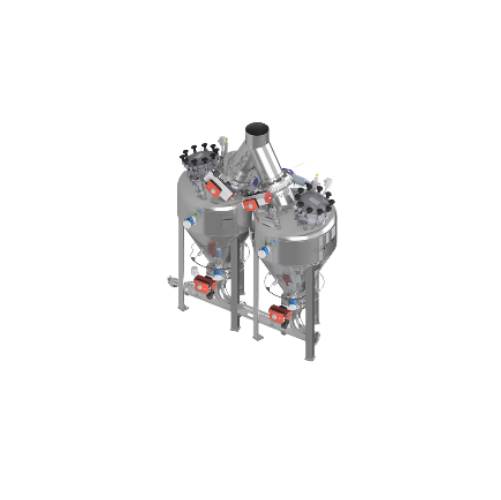

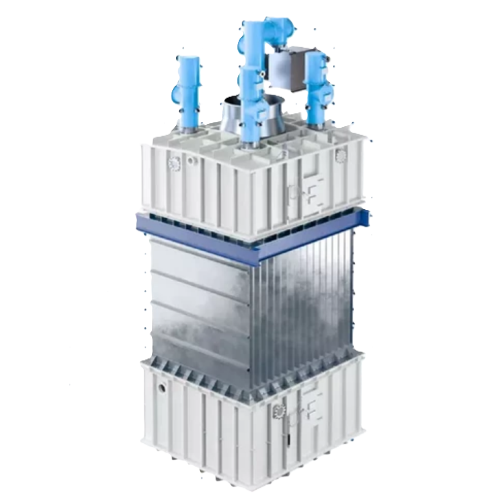

Industrial storage tanks for chemical and cosmetic industries

Need reliable storage that withstands aggressive chemical ...

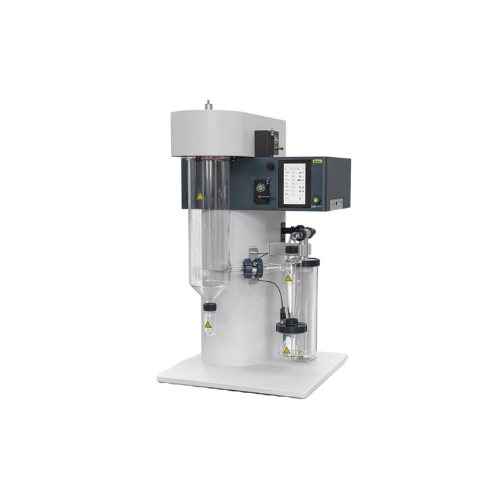

Industrial photochemical reactors for multiphase reactions

Optimize multiphase chemical reactions with light-activated p...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

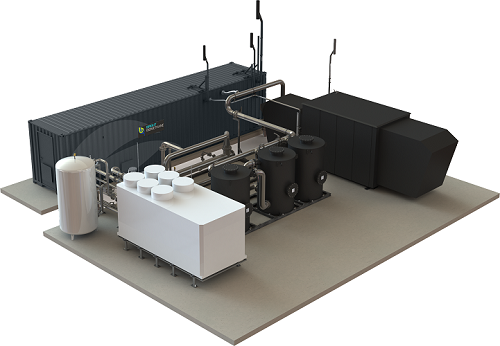

Chemical-physical treatment plants for water treatment

Optimize your water and wastewater treatment processes with system...

Industrial roto-flash dryer for chemical applications

Achieve uniform moisture and particle size in demanding drying proc...

Industrial universal reactor for large-scale chemical synthesis

For chemical producers scaling past laboratory setups, t...

Evaporative crystallizers for chemical processing

Optimize your crystallization process with state-of-the-art evaporative...

Glass nutsche filter for fine chemical and pharmaceutical filtration

For precise separation and filtration in R&D ...

Pilot scale filter-dryer for pharmaceutical and chemical batches

Streamline small-batch production with a mobile filter-...

Microwave-enhanced filter dryer for chemical and pharmaceutical applications

Achieve rapid drying and efficient separa...

Mobile powder transfer system for pharmaceuticals and chemicals

Efficiently transfer and charge powders into various ves...

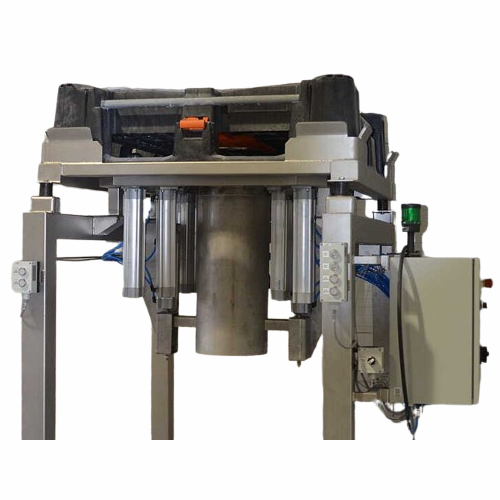

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Oil neutralizing technology for chemical refining

Achieve optimal purity and yield in oil processing with precise control...

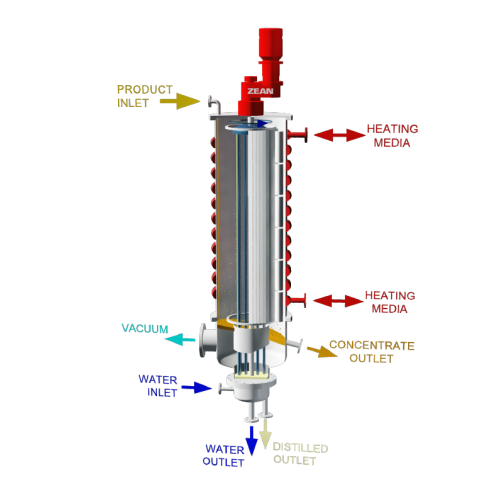

Vacuum concentrator for juice and chemical processing

Reduce energy and concentration costs significantly while enhancing...

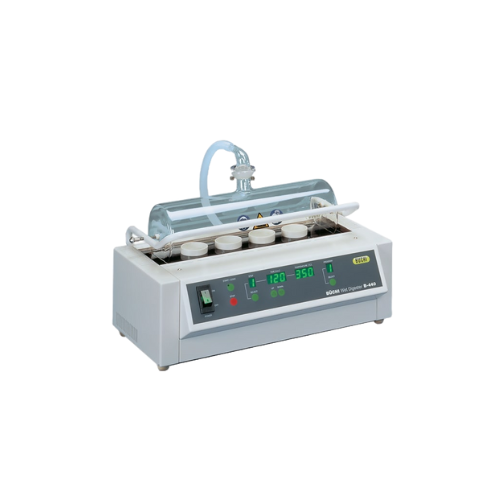

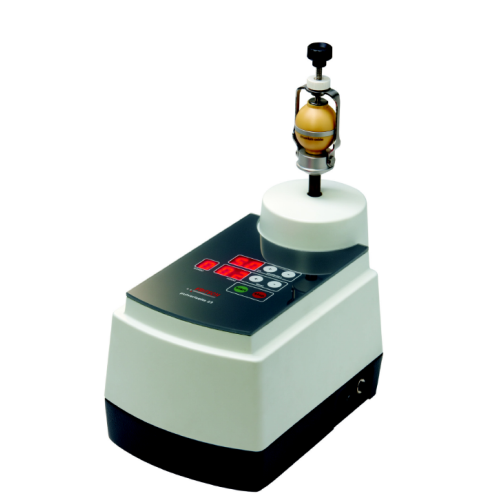

Infrared speeddigester for nitrogen determination and chemical oxygen demand

Effortlessly enhance your laboratory thro...

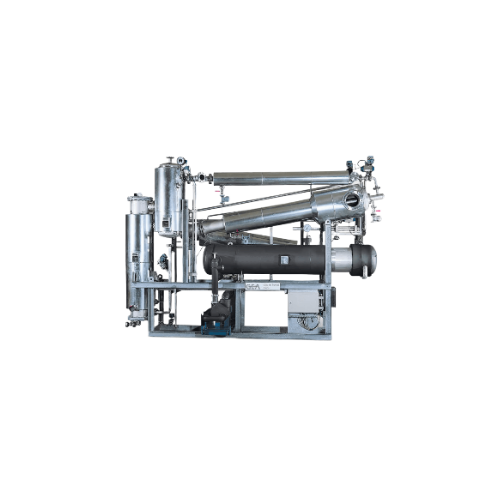

Hydrocarbon recovery unit for chemical plants

Maximize your hydrocarbon capture and reuse with an advanced recovery unit t...

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

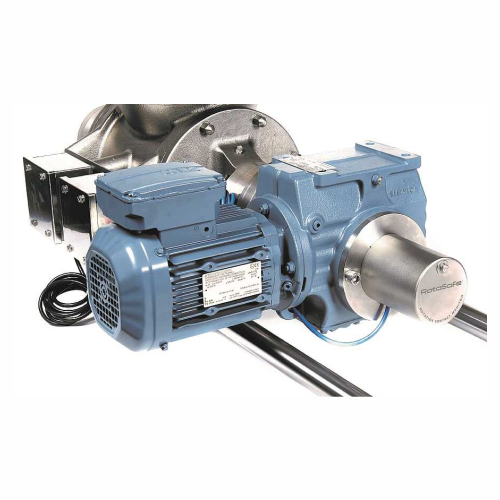

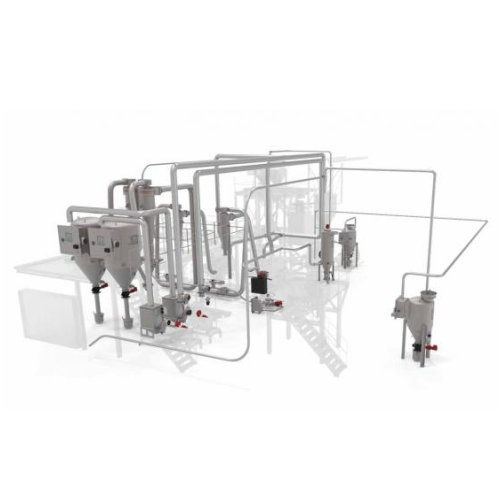

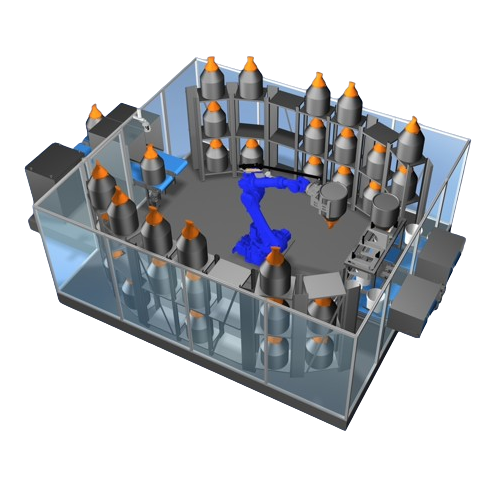

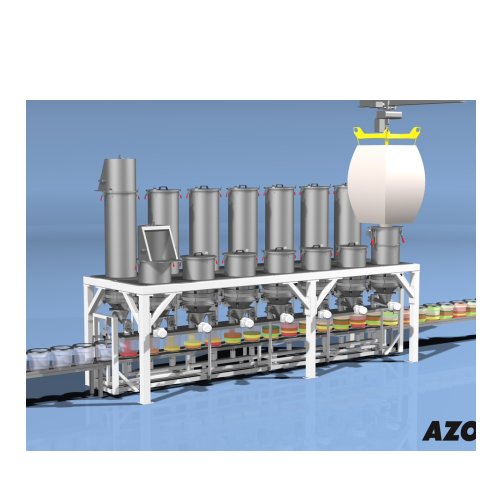

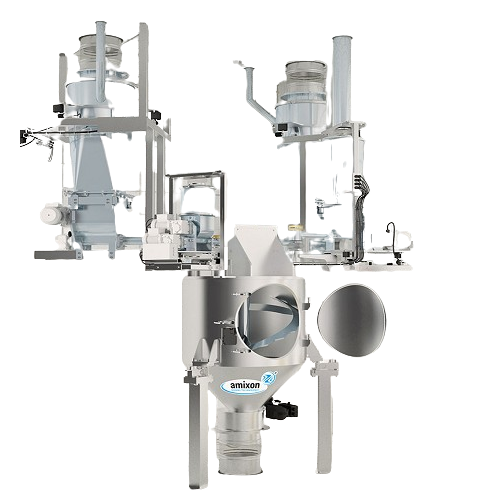

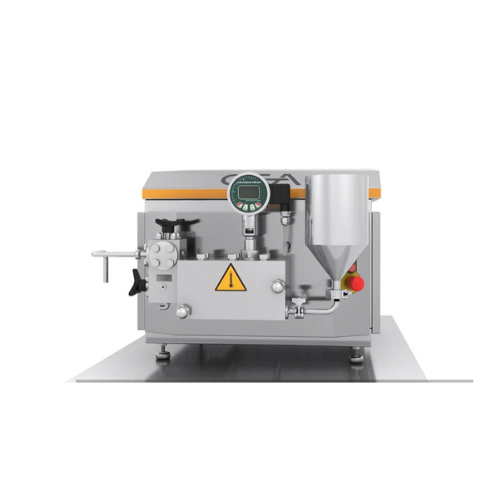

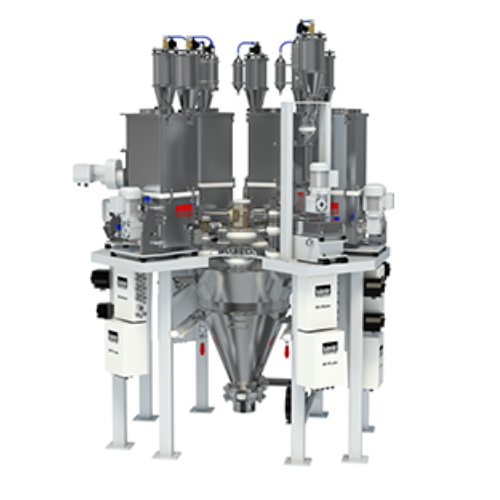

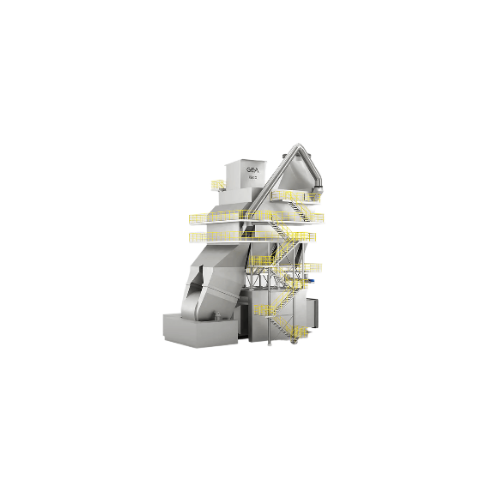

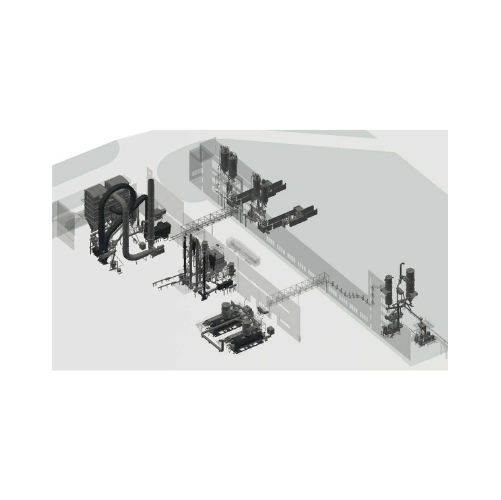

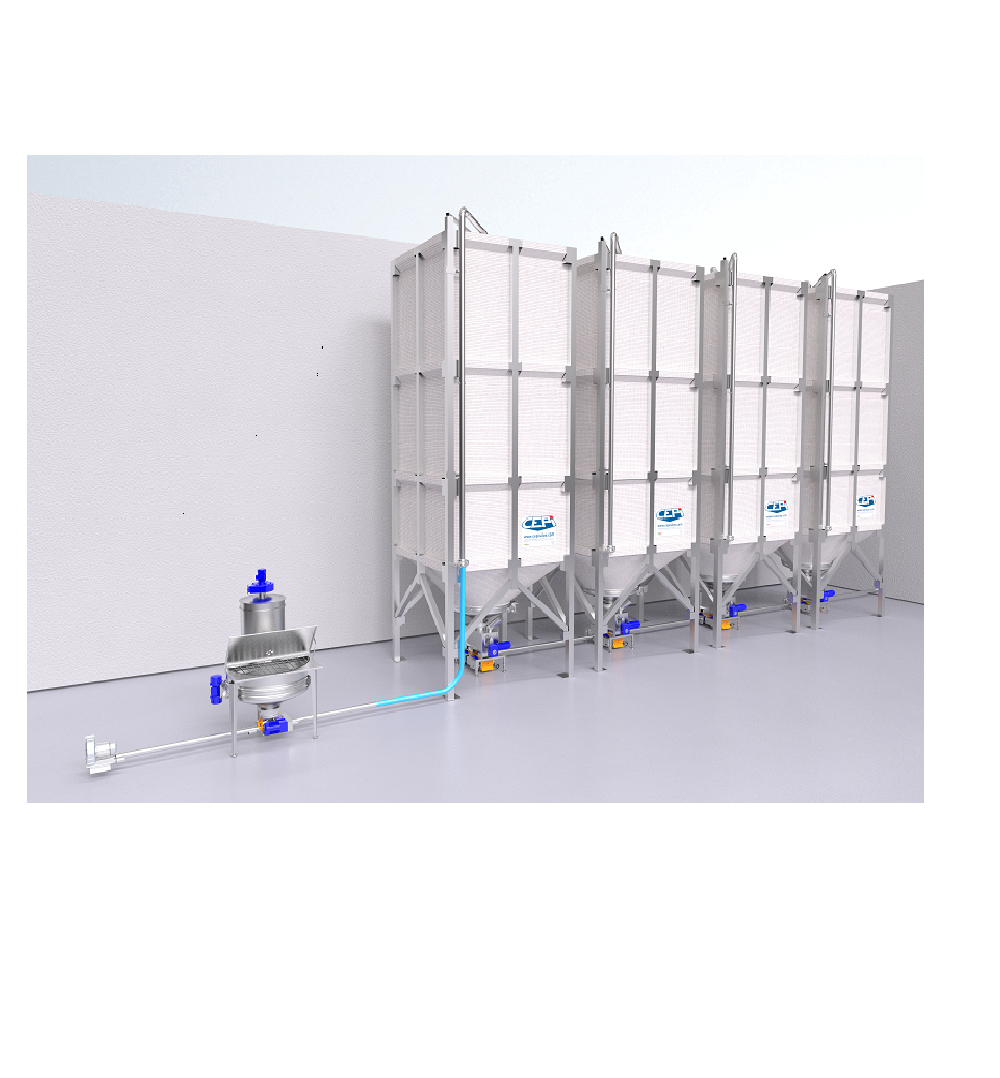

Fine chemical powder system

Optimize your powder processing with a solution tailored to handle complex feeding, conveying, a...

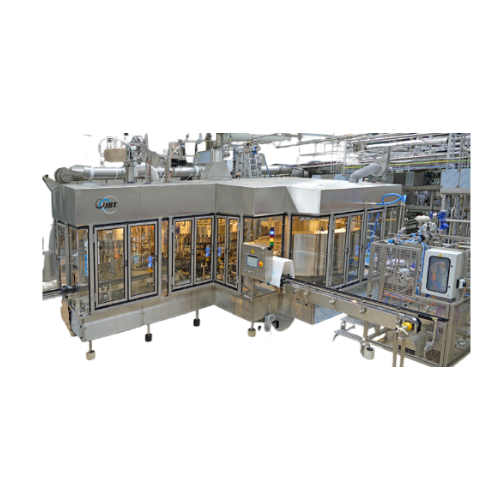

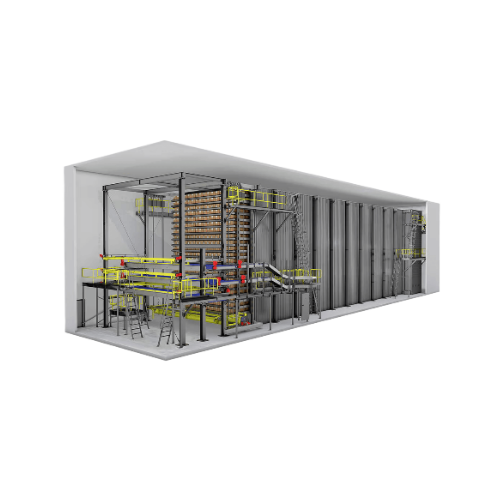

Cleanroom enclosure system for pharmaceutical and chemical industries

Ensure sterile environments with this customizabl...

Roller compactor for pharmaceutical and chemical industries

Optimize your powder processing with precision compaction an...

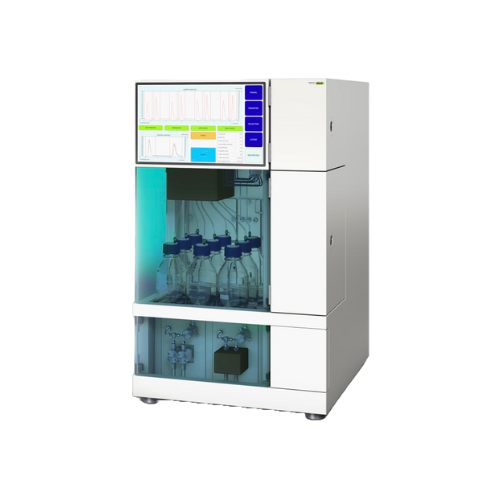

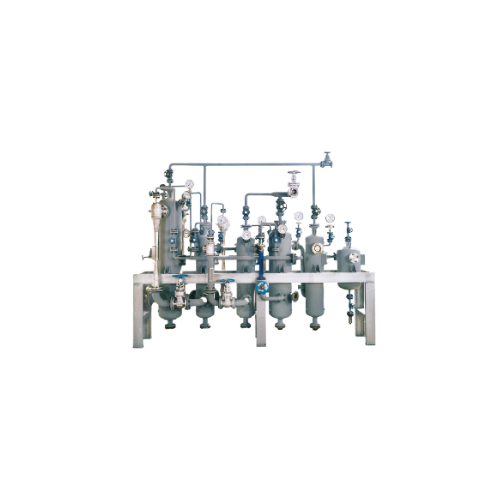

Industrial ion exchange system for chemical purification

Ensure precise ion removal and high-purity output in your produc...

Solidification drum for chemical and pharmaceutical products

Convert molten materials into easily manageable flakes effi...

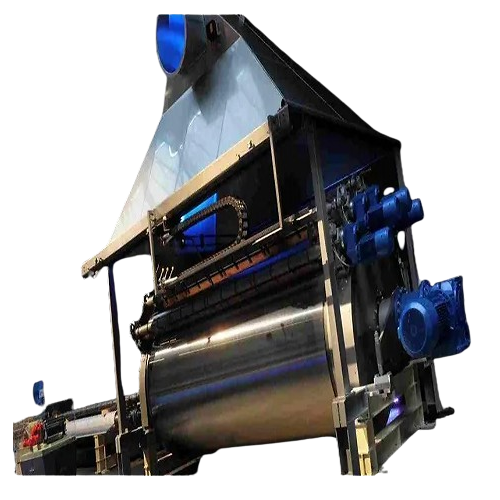

Contact drum dryer for industrial food and chemical processing

Optimize your drying process with a contact drum dryer th...

Industrial grater and shredder for pharmaceutical and chemical applications

Optimize your production line with a versa...

Industrial roller compaction for chemical applications

Enhance material flow and density with advanced roller compaction ...

Moist granulation system for pharmaceutical and chemical industries

Transform powdered materials into uniform granules ...

50l stainless steel dual-jacketed reactor for chemical processes

Optimize your laboratory’s efficiency with a dual...

150l jacketed glass reactor for chemical synthesis

Achieve precise control over complex chemical processes with this sing...

20l jacketed glass reactor for controlled chemical reactions

Optimize your chemical synthesis with precise temperature c...

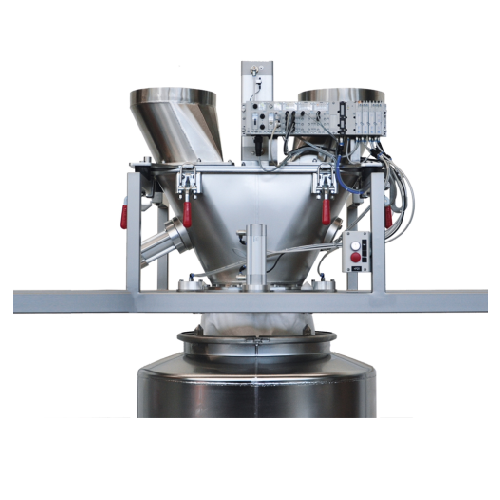

Automatic chemical mixing system for postharvest treatment

Achieve precise chemical dosing and mixing for postharvest tr...

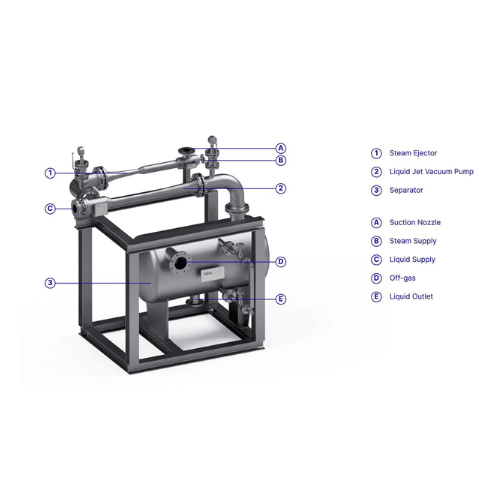

Steam jet liquid ejector vacuum system for chemical applications

Achieve reliable vacuum under challenging conditions wi...

High corrosion-resistant vacuum systems for chemical industries

These high corrosion-resistant vacuum systems are design...

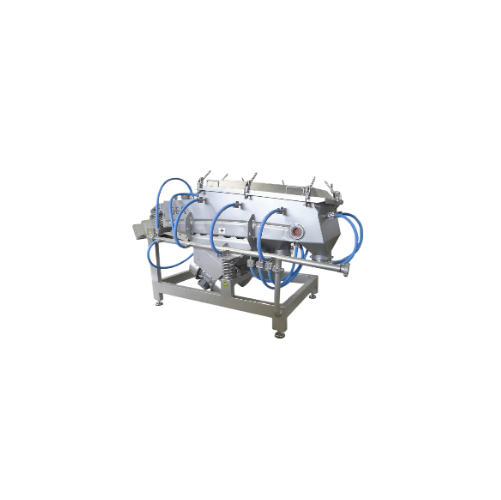

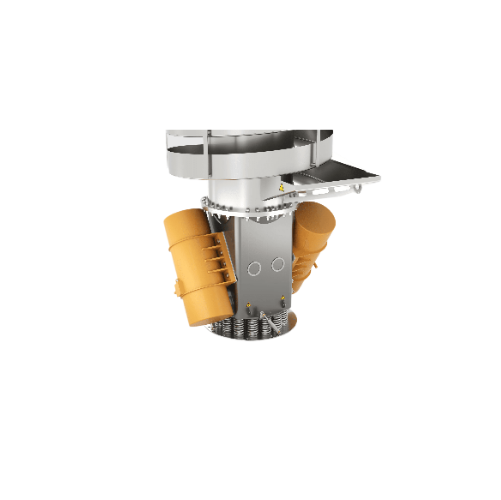

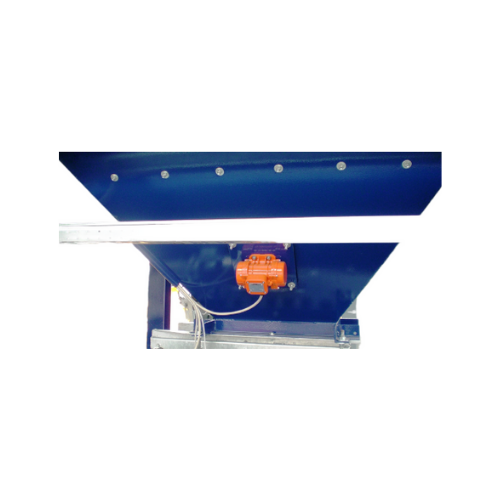

Vibrating sifter for chemical applications

Achieve precise particle separation with this vibrating sifter, ensuring optima...

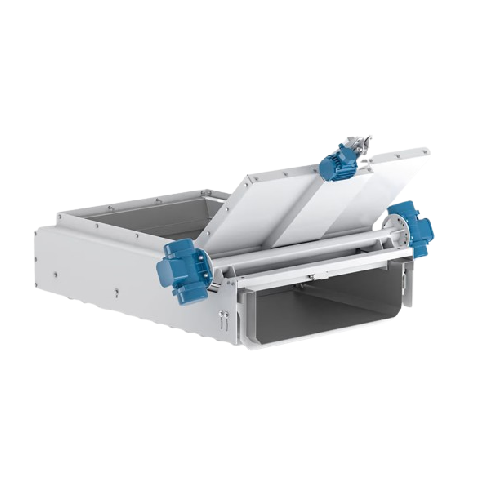

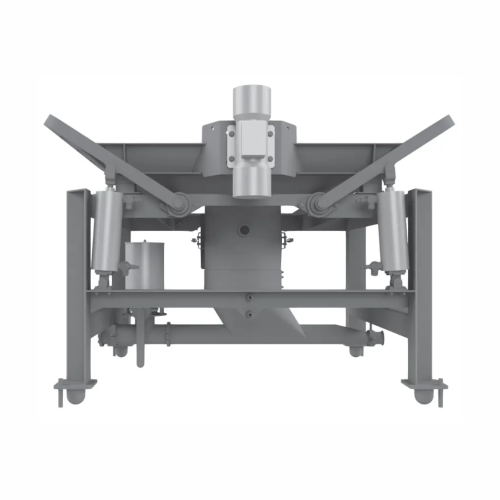

Vibration table for food, feed, and chemical industries

Optimize your production line with a versatile vibration table de...

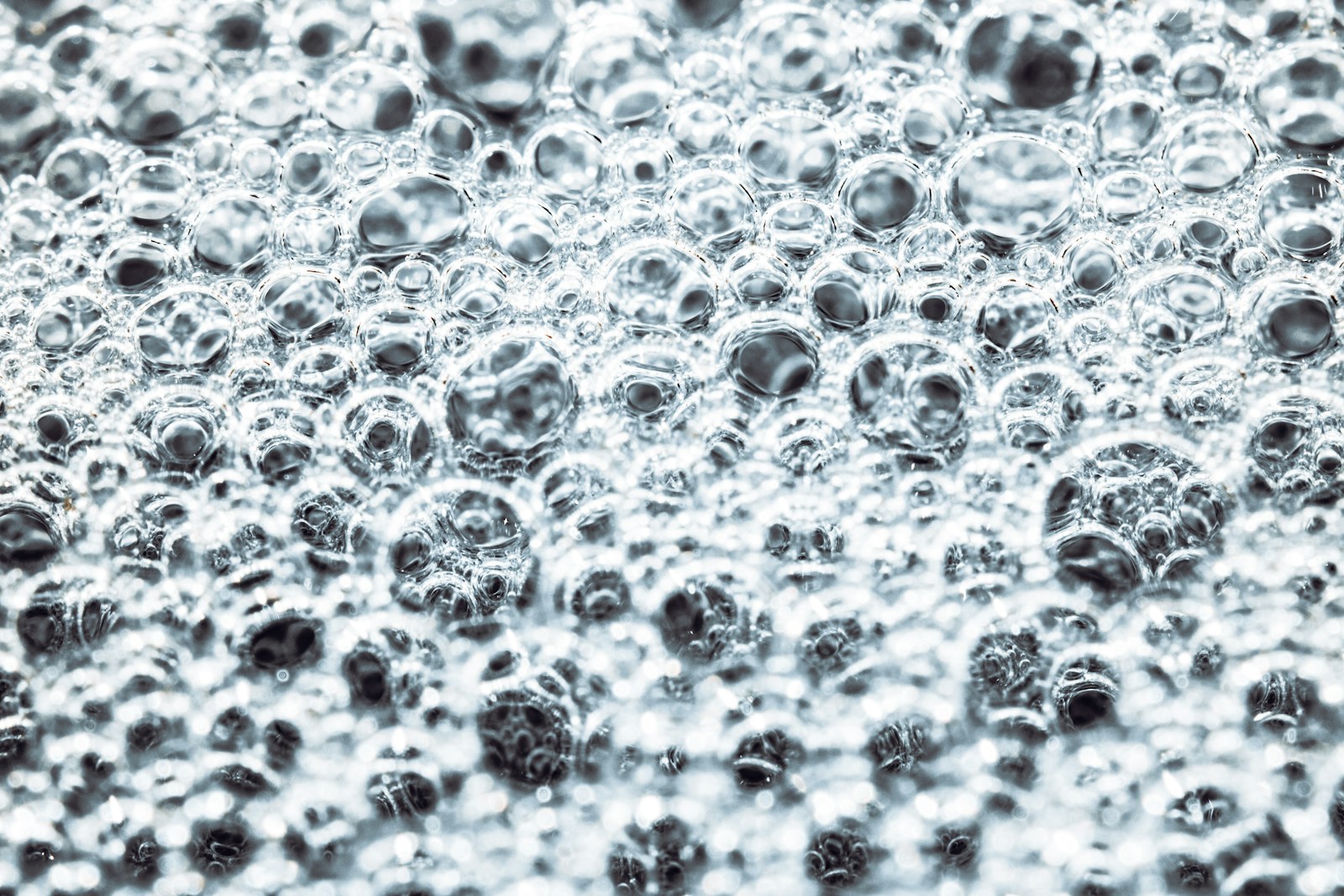

Bubble column reactors for chemical reactions

Enhance gas-liquid interactions with bubble column reactors designed for eff...

Melt crystallization for high purity chemical products

Achieve ultra-pure products with minimal energy by integrating mel...

Compact and laboratory gas scrubbers for chemical emission control

For efficient gas treatment and emission control in ...

Powder separation cyclone for food and chemical industries

Optimize your powder production with advanced cyclone technol...

Spray cooler for food and chemical industry applications

Achieve precise particle size control and encapsulation for melt...

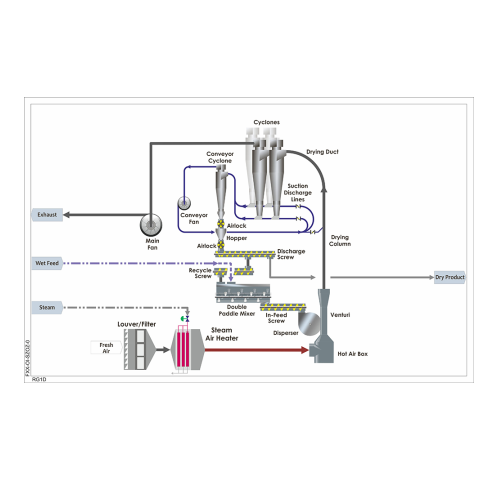

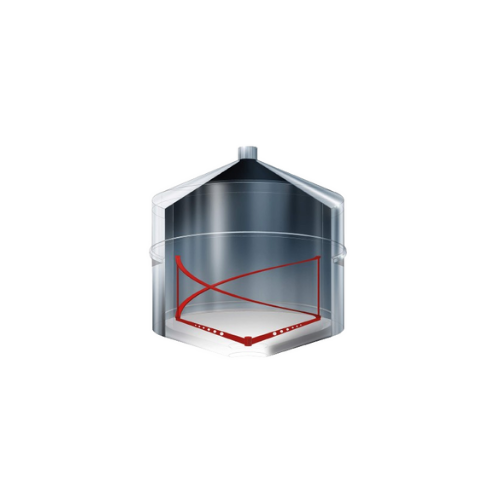

Conventional spray drying for chemical industry

Achieve optimal particle size uniformity in food powders with precision at...

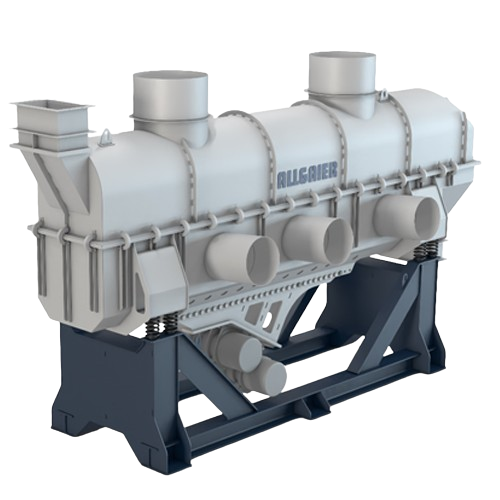

Fluid bed drying system for wet powder chemicals

Achieve efficient large-scale drying and cooling of wet powder chemicals ...

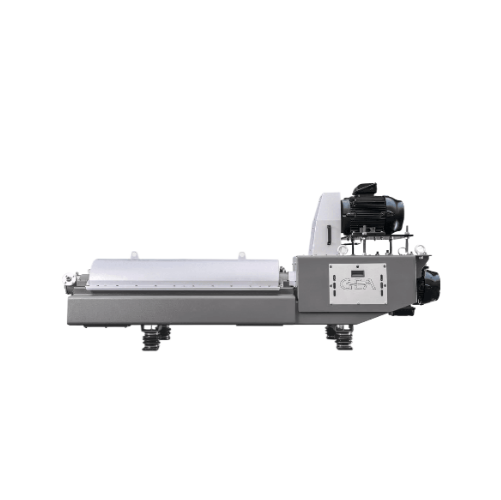

2-phase separating decanter for chemical and mineral processing

Ensure precise separation and optimal moisture control i...

Dewatering decanter for chemical and mineral processing

Maximize efficiency in liquid-solid separation, ensuring optimal ...

Decanter centrifuge for chemical and mineral processing

Optimize dewatering and clarification efficiencies in your proces...

Chemical and mineral processing centrifuge

Optimize your chemical and mineral extraction processes with this high-performa...

Chemical and mineral processing decanter centrifuge

Achieve efficient clarification and dewatering of complex mixtures in...

Clarifying decanter for chemical processing

Optimize your clarification and dewatering processes with a versatile decanter...

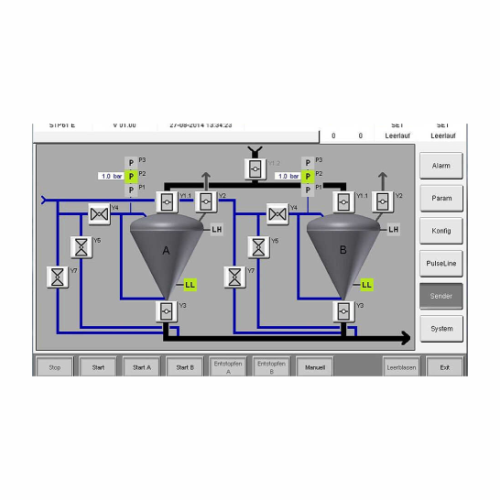

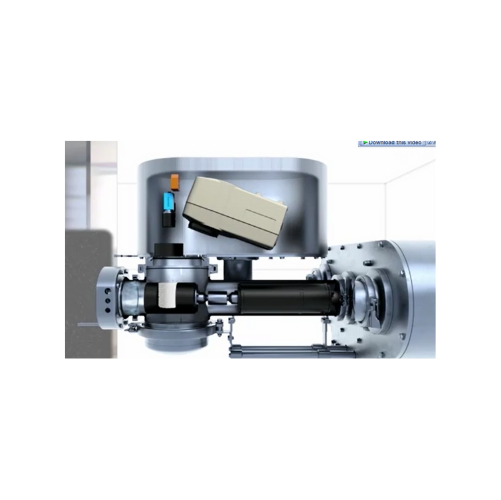

Autonomous process control for petrochemical and food industries

Streamline your production with autonomous control syst...

Special chemical plant safety systems

Ensure operational safety and regulatory compliance in chemical processing with advan...

Multipurpose mixing equipment for chemical and pharmaceutical production

Achieve unparalleled flexibility with modular,...

High-shear batch disperser for chemical and food industries

Achieve unmatched dispersion and emulsification precision wi...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Explosion-proof dissolver for chemical processing

Ensure safe and efficient dispersion in volatile environments with this...

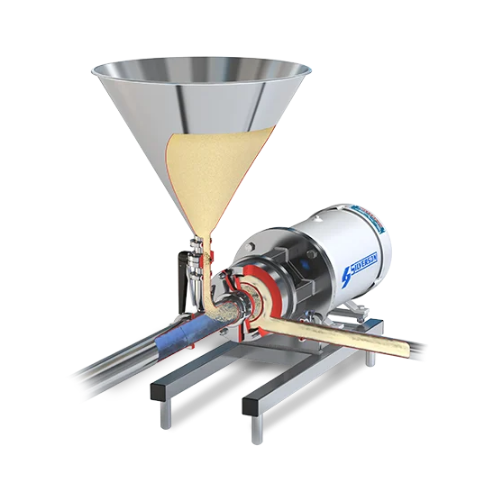

Solid-liquid in-line mixer for chemical product manufacturing

Effortlessly integrate and disperse high-solids content in...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

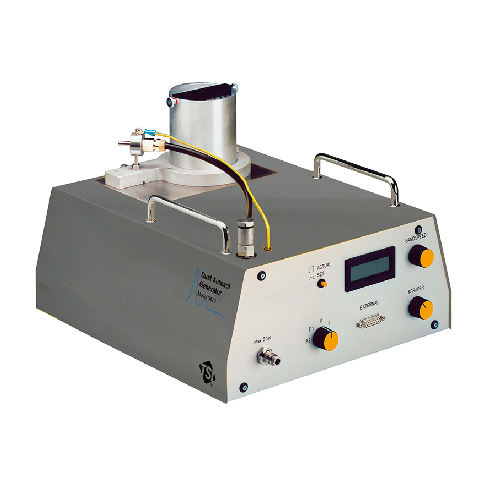

Advanced particle size separation for chemical analysis

Achieve precise particle separation with cutting-edge impactor te...

Handheld raman analyzer for chemical identification

Quickly identify hazardous substances in the field with a touchless, ...

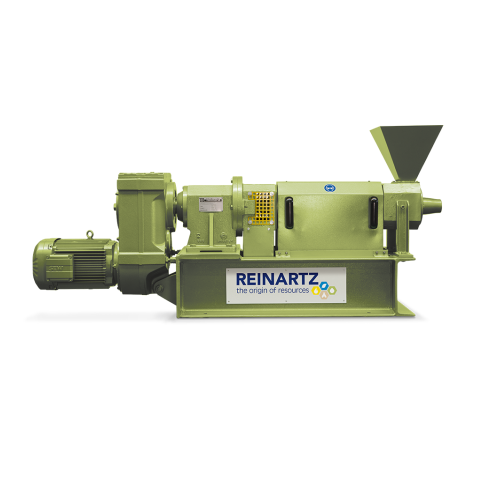

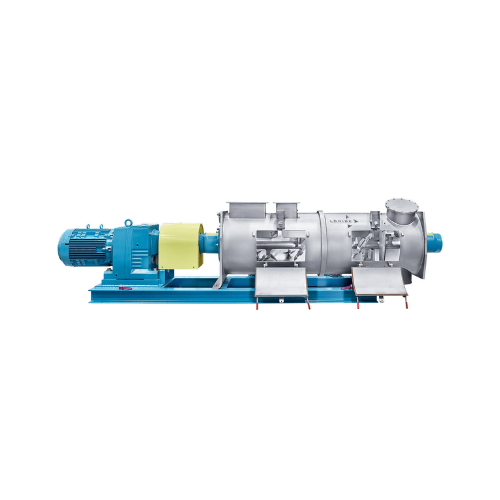

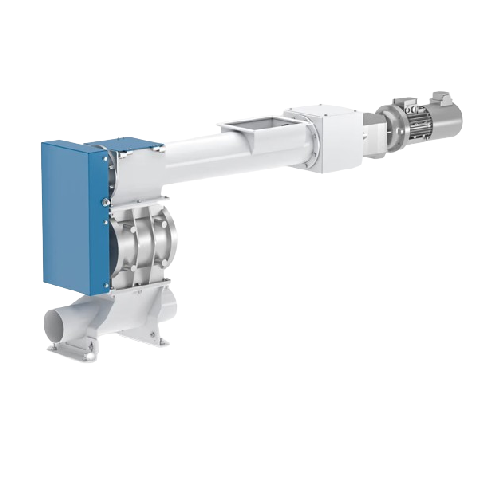

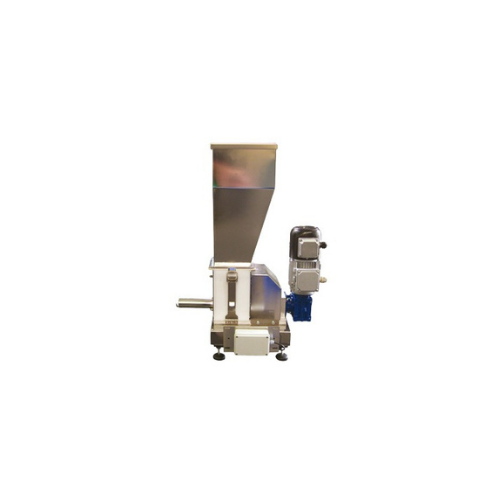

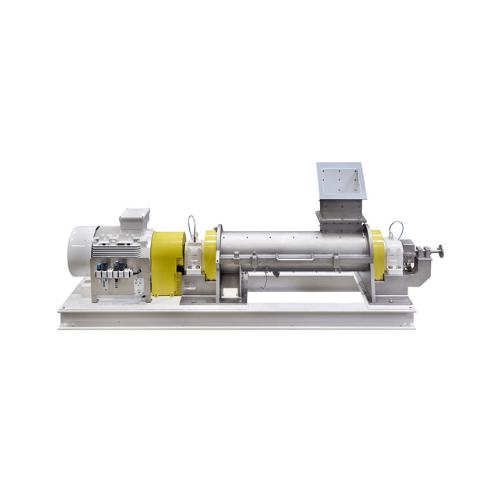

Single screw extruder for chemical catalysts and sealants

Optimize material ingestion and processing with a versatile si...

High-pressure hydrogenation reactor for chemical labs

Achieve precise high-temperature hydrogenation with integrated on-d...

High-capacity industrial sifter for chemical and food processing

Achieve unparalleled screening precision and efficiency...

Medium torque mixer for chemical processing

Achieve optimal mixing efficiency and process consistency in demanding applica...

Medium torque top entering mixer for chemical processing

Achieve consistent mixing results with a versatile, high-torque ...

Refrigerated vacuum cold trap for chemical vapor applications

Efficiently trap corrosive vapors and eliminate the need f...

Net-gas medicine storage cabinet for volatile chemicals

Ensure safe and efficient storage of volatile chemical agents wit...

Fume hood with pipes for chemical laboratories

Ensure maximum safety and efficiency in your laboratory by effectively exha...

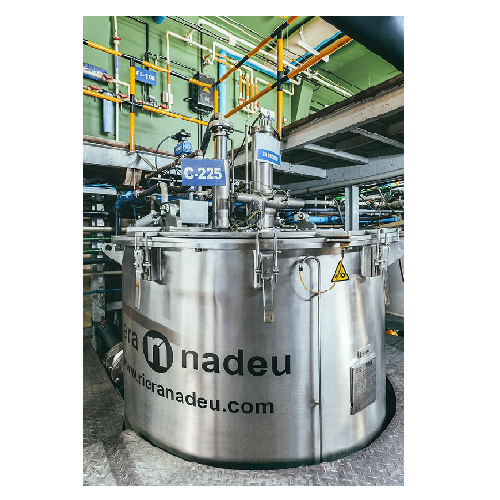

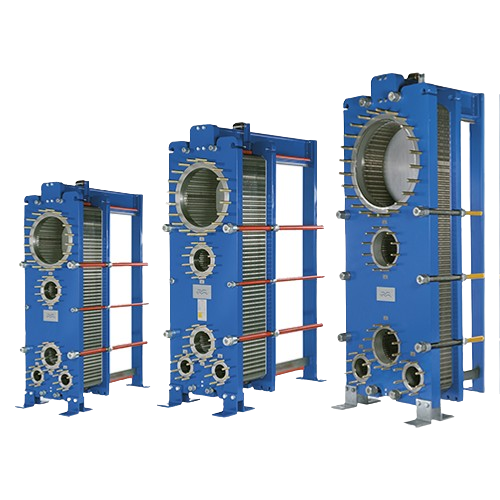

Process tanks for pharmaceutical and chemical industries

Optimize your thermal control and process efficiency with versat...

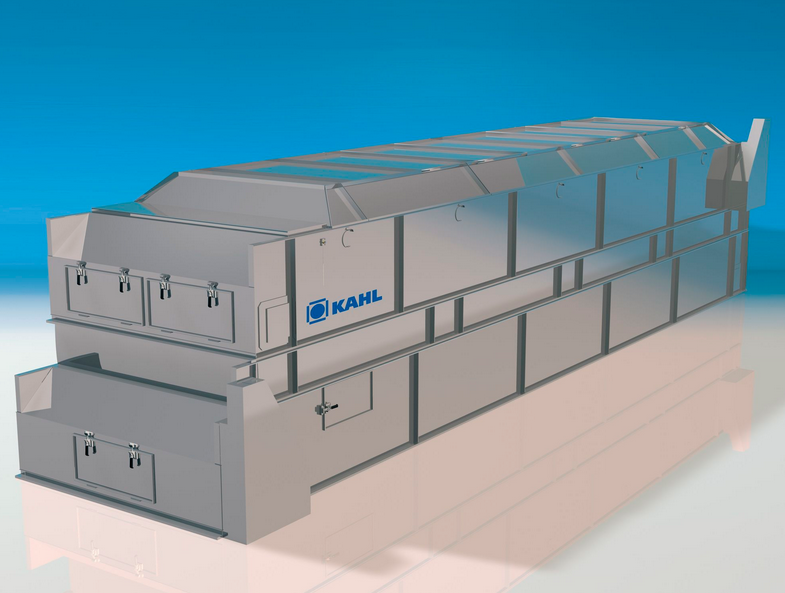

Continuous hot air conveying dryer for chemical and pharmaceutical industries

Ensure rapid moisture removal with high-...

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Horizontal disc bead mill for liquid chemicals

Processing toxic chemicals requires high compliance with safety standards a...

Inline solid-liquid mixer for chemicals and paints

Incorporating solids into liquids is a critical process in producing p...

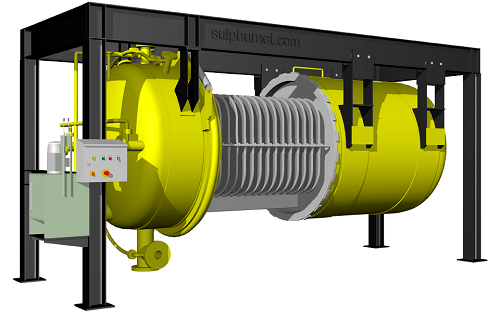

Industrial leaf filter for chemicals

In recent years the removal of sulphur has received increasing attention because of sa...

Horizontal chemical scraper centrifuge

For slurries difficult to discharge, a scraper can improve process reliability, effi...

Centrifugal Partition Chromatography System for Purification and Separation

Traditional chromatography methods for nat...

Versatile Semi-Automatic Laboratory Centrifuge

In research and pilot-scale production, reliable separation is needed for d...

Pilot-Scale Centrifuges for Process Development

Scaling up from laboratory experiments to industrial production requires r...

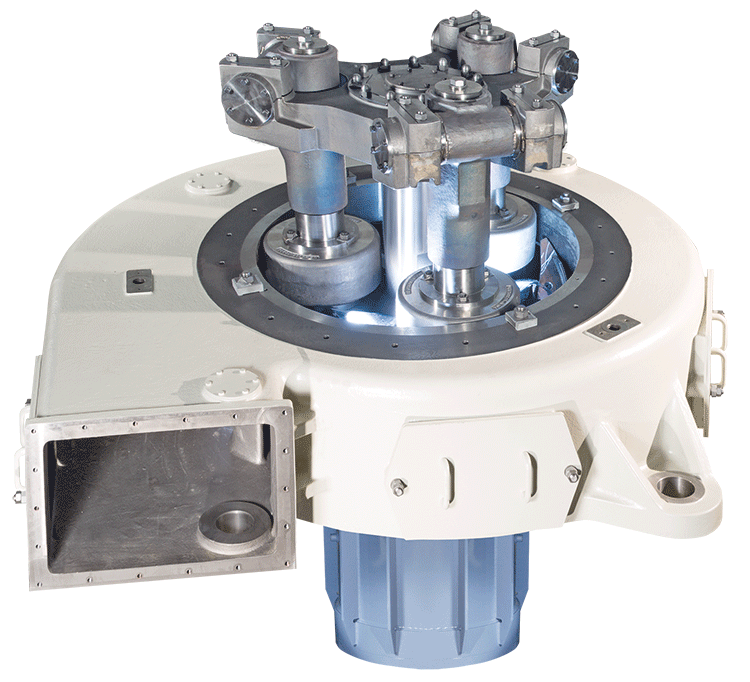

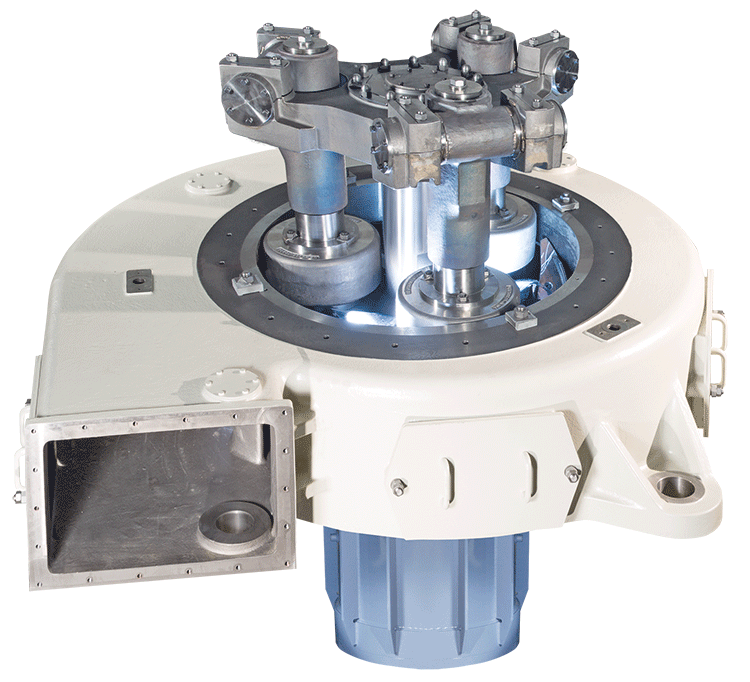

Pusher Centrifuge for Continuous Solid-Liquid Separation

When processing bulk solids, maintaining high throughput while c...

Continuous Multistage Centrifugal Extractor

When working with complex liquid-liquid separations, when handling pharmaceuti...

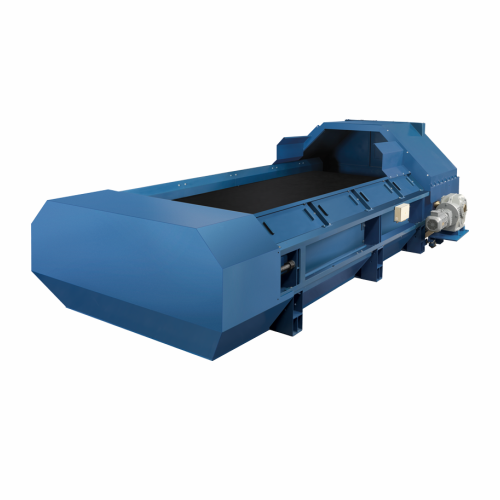

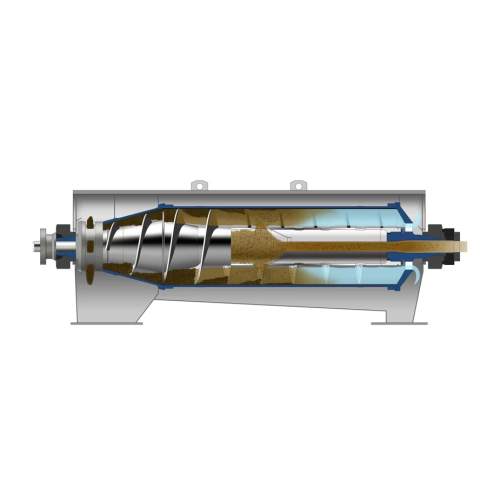

Decanter (Scroll) Centrifuge for Continuous Slurry Processing

For industries dealing with slurries, fine particles, and ...

Monostage Centrifugal Extractor for Solvent Recovery and Purification

When separating immiscible liquids, speed and pre...

Mixer-Settler for Solvent Extraction and Purification

For solvent extraction processes requiring longer residence times, ...

Clarifiers for pilot and lab scale applications

Ensure efficient separation and clarification at the pilot or lab scale wi...

Nozzle separators for starch recovery

Optimize your starch recovery process with our nozzle separators—designed to deliver ...

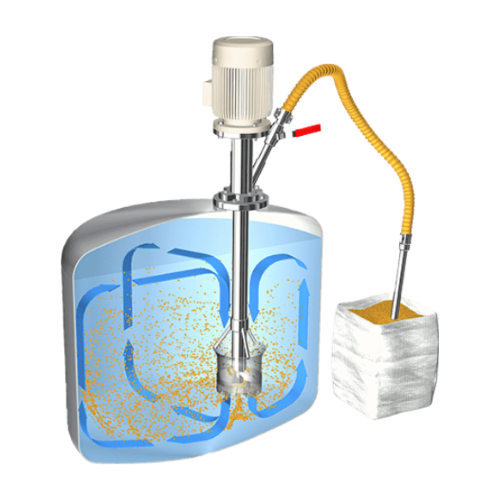

Liquid jet mixer for homogeneous tank mixing

Achieve efficient and consistent mixing in large storage tanks with this adva...

Dual camera system for spray dryer monitoring

Enhance safety and operational efficiency in your drying process by combinin...

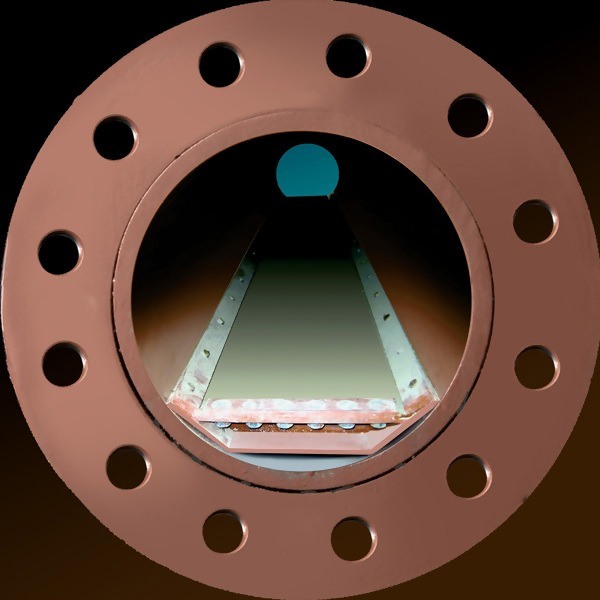

Sanitary cover for visual inspection

Ensure optimal hygiene and easy access in your production line with a transparent cove...

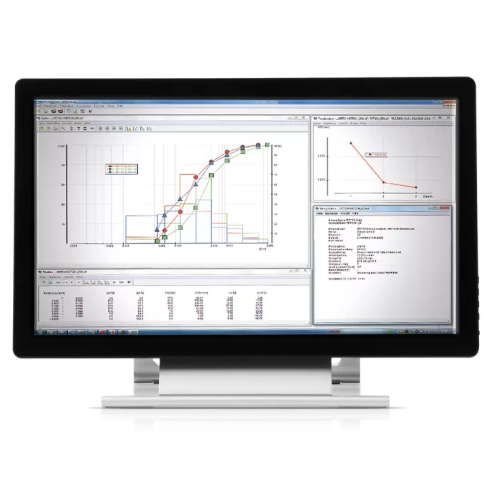

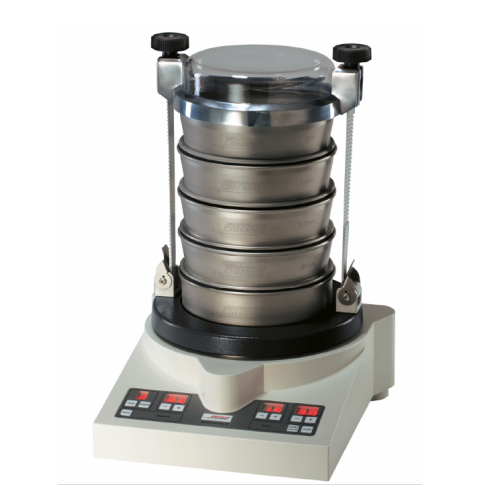

Sieve analysis software for automated evaluation

Streamline your sieving processes with automated data evaluation and prec...

batch centrifuge for solid-liquid separation

Achieve precise solid-liquid separation in high-demand environments with a ma...

Vertical batch centrifuge for solid-liquid separation

Optimize your solid-liquid separation process with high-speed centr...

Continuous filtering centrifuge for solid-liquid separation

Effortlessly separate and filter crystalline or fibrous susp...

Mortar grinder for reproducible sample preparation

Achieve precise and consistent material preparation with this mortar g...

Planetary ball mills for fine grinding of materials

Optimize particle size and surface area in your samples with high-ene...

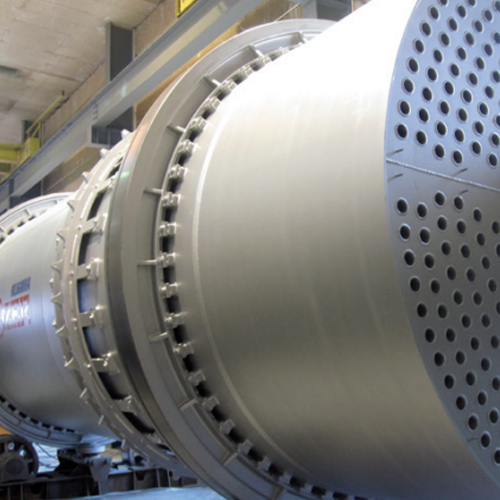

Drum mills for fine grinding of large volumes

Achieve consistent and precise pulverization of large sample volumes with dr...

Laboratory sieve shaker for accurate particle size analysis

Streamline your material testing with a robust vibratory sie...

Air jet sieving system for powdered materials

Optimize particle distribution with precision air jet sieving, designed to e...

Cryogenic ball grinder for laboratory use

Achieve precise temperature-controlled grinding with advanced cryogenic technolo...

Laboratory mixer mill for small volume grinding

Designed for rapid homogenization and size reduction, this versatile mixer...

Ultrafine grinding solution for nanoparticles

Achieve ultrafine particle sizes with high-speed precision, ideal for labora...

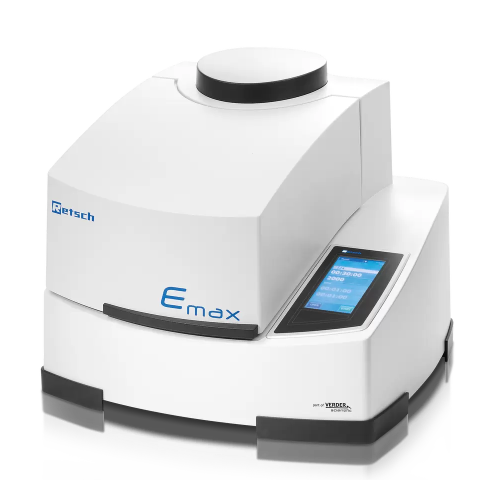

High energy untra fine ball mill

Achieve ultra-fine particle sizes rapidly with this high energy milling solution, designed ...

Cold press for extracting vegetable oils

Efficiently extract high-quality oils from diverse seeds while preserving vital nu...

Fluid bed dryer for bulk material laboratory drying

Efficiently dry and mix organic and inorganic materials with precise ...

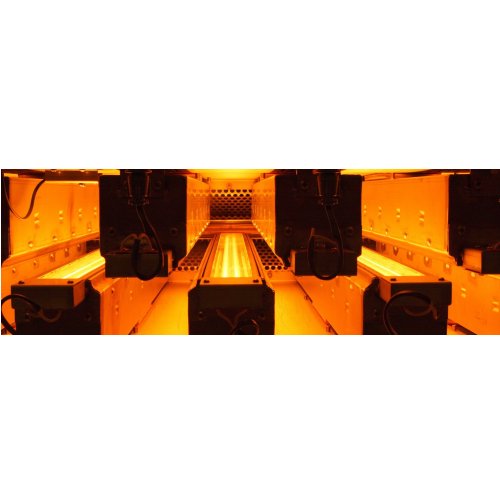

Industrial continuous heat treatment for dry ingredients

Optimize your production line with a continuous system that ensu...

Chub packer for resin bolt packages

Optimize high-speed packaging of liquid resin products with precise filling and wrappin...

Rotary continuous aerosol product filler

Achieve precise aerosol filling with high-speed efficiency, designed for operation...

Industrial powder security screening and de-agglomeration

Ensure product purity by efficiently screening and de-agglomer...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Lab-scale milling and processing platform

Effortlessly transition from lab-scale research to full production with a versat...

Atex compliant milling equipment for explosive atmospheres

Ensure operator safety and process integrity with milling equ...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

Deagglomeration and delumping system

Ensure product integrity and streamline operations by effectively breaking down agglom...

Laboratory nutsche filter dryer for solid-liquid separation

Optimize your lab processes with a versatile benchtop filter...

Pilot scale nutsche filter dryer for solid-liquid separation

Achieve maximum product recovery and consistent quality wit...

Nutsche filter dryer system for small scale batches

Efficiently tackle filtration and drying challenges with a compact, m...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Perforated disc mill for pre-comminution and mashing

Achieve precise granulating and mashing of diverse materials with th...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Horizontal colloid mill for precise grinding

Achieve precise particle size reduction and reproducible results with our adv...

Multistage mixer for emulsions and dispersions

Enhance your production with a versatile multistage mixer that ensures opti...

Multistage mixers for emulsions and dispersions

Experience efficient emulsification and dispersion processes with this ver...

Vacuum cold trap for efficient purging and drying

Optimize your laboratory’s efficiency by integrating high-perform...

Pressure control monitor for laboratory vacuum systems

Effortlessly maintain precise vacuum pressure in your lab operatio...

Explosion-proof rotary vane vacuum pump

Ensure safety and efficiency in flammable environments with this explosion-proof va...

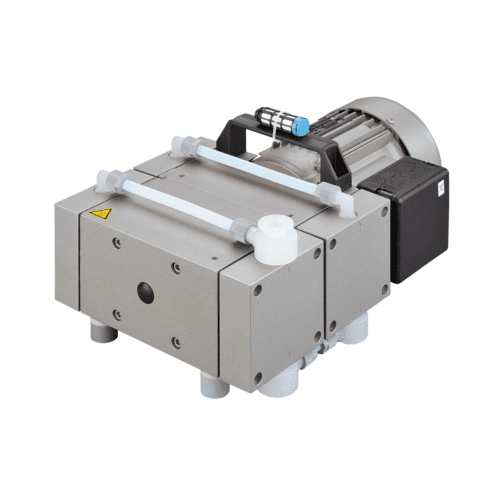

High-capacity oil-free diaphragm vacuum pump

Achieve cleaner operations and reduce maintenance costs with this high-capaci...

Fraction finder for optimized fractional distillation

Achieve unparalleled precision in your distillation process with a ...

Deep water bucket bath for lab heating applications

Achieve precise temperature control and uniform heating for delicate ...

Digital vapor temperature monitor for fractional distillation

Achieve precise temperature monitoring during fractional d...

2-stage rotary vane vacuum pump for laboratory applications

Ensure reliable and efficient vacuum conditions for distilla...

Bag inserter for drums

Effortlessly streamline your packaging process by automatically inserting custom-made bags into drums,...

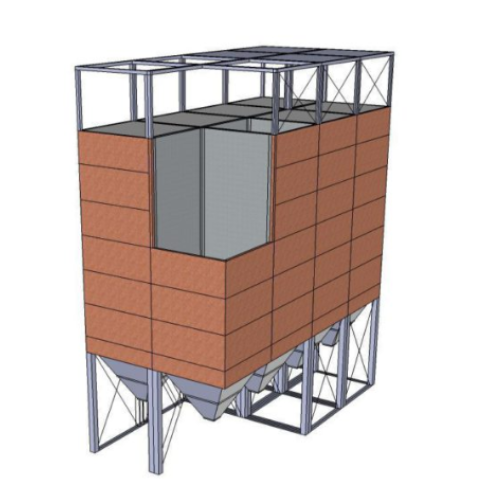

Square silo for bulk goods storage

Maximize your storage efficiency by 25% with square silos, uniquely designed for effecti...

Vertical mixers for animal feed industry

Efficiently combine a variety of powdered and raw materials with precision, ensuri...

Screw conveyors for grain processing and feed mills

Optimize your production line with versatile screw conveyors, designe...

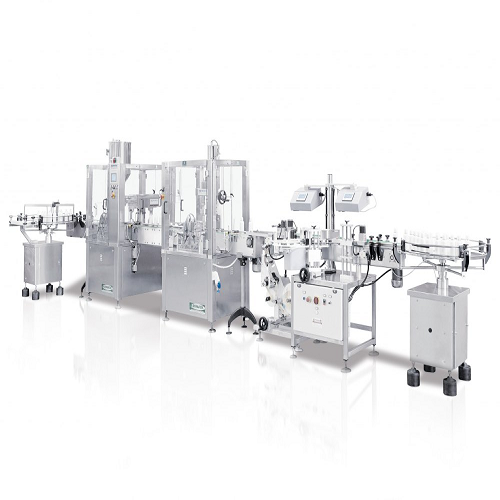

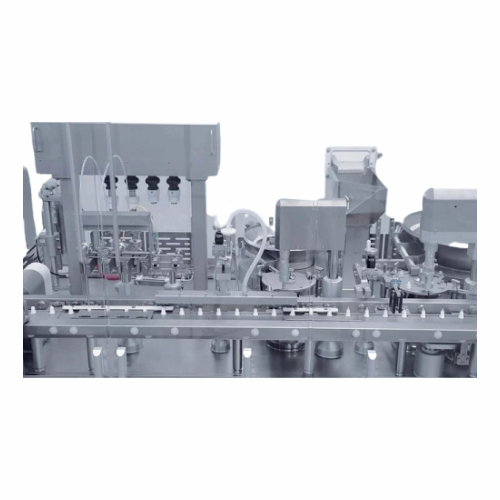

Gravimetric filling and capping system for chlorine solutions

Optimize your filling and capping processes for chlorinate...

Hig Speed Tube Cartoner

Achieve seamless integration into your high-speed packaging line with a cartoning solution that ensur...

Cartoning solution for tube applications

Streamline your cartoning operations with a machine designed for flexible size cha...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Accurate powder filling solution

When precision is paramount, this solution offers exceptional accuracy, filling powders up ...

Impact classifier mill for fine grinding of brittle materials

Achieve precise particle size distribution with advanced g...

Pendulum mill for fine grinding and drying

Achieve efficient and precise grinding for soft to medium-hard materials while ...

Pem electrolyzers for efficient hydrogen production

Transform fluctuating renewable energy into storable, high-purity hyd...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

Unloader for non-free-flowing materials in flat bottom silos

Facing challenges unloading non-free-flowing materials? Thi...

Lab powder dispenser for precision measurements

Effortlessly streamline your lab’s powder dispensing tasks with a ve...

Unloader for conical bottom silos

Eliminate product flow challenges effortlessly with this hydraulic-driven unloader, ensur...

Flake ice maker for food processing applications

Ensure optimal product preservation and temperature control with precisio...

Laser diffraction particle size analyzer

Achieve precise particle size analysis with laser diffraction technology, ensuring...

Nanoparticle size analyzer

Master precise nanoparticle and zeta potential analysis with dynamic light scattering technology,...

Gas pycnometer for precise density determination

Achieve accurate and reliable density measurements for a diverse range of...

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Single-use mixing solutions for downstream processes

Designed for safe and efficient one-time use, this mixing solution e...

Syringe filters for liquid and gas samples

Ensure particle-free liquid and gas samples with high-precision filtration, ide...

Intermediate bulk containers for powder and materials handling

Optimize your material handling processes with containers...

Sesame peeling system

Enhance your seed processing with a sesame peeling system that reduces water usage and eliminates chemi...

Powder handling system for industrial applications

Overcome powder flow issues and enhance production efficiency with adv...

Ibc cleaning equipment for hygienic powder handling

Optimize cleaning efficiency and maintain hygiene standards with a ve...

Hygienic mixer for batch operation

Achieve consistent and precise mix quality across diverse powders and granules with this...

Ploughshare mixer for batch operation

Achieve superior mixing quality with a system designed for rapid batch operations. Ex...

Continuous ploughshare mixer for diverse industrial applications

Enhance mixing efficiency and achieve precise particle ...

Wet mixer for viscous and paste-like products

Achieve high-quality mixing of medium to highly viscous products with precis...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

Batch mixer for powdery, granular, and fibrous materials

Achieve precise consistency and high batch reproducibility in yo...

Cryogenic cooling system for meat mixing

Efficiently manage heat during meat mixing to enhance product quality and ensure s...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Volumetric filler for liquid and viscous products

Achieve precise and adaptable filling for a wide variety of liquid and ...

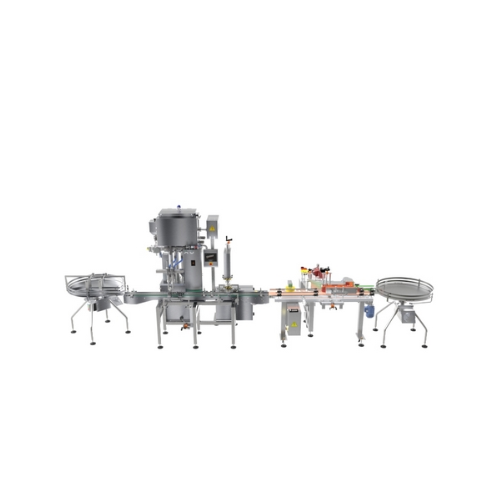

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Industrial water treatment system

Ensure your beverage production maintains optimal purity and taste with tailored water tr...

Uvc surface disinfection for food packaging and tools

Achieve fast and effective UVC disinfection of food products and pa...

Ion exchange for chloride and potassium removal in kraft mills

Optimize your kraft mill operations by efficiently removi...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Micro bubble foaming system for aerated products

Enhance the consistency and quality of your foamed products with precise ...

Laboratory mixer for homogenizing and mixing samples

Achieve precise sample preparation and efficient mixing with this ve...

Laboratory dispersion reactor for 2l mixing and reaction processes

Streamline your laboratory processes with a versatil...

In-line disperser for high-volume liquid processing

Streamline your emulsification process with powerful rotor-stator hom...

Powder induction system for high solid concentrations

Optimize your production line with this advanced system designed to...

Easyclean design disperser for batch processing

Achieve precise homogenization and emulsification with a versatile dispers...

Scalable laboratory reactor for mixing and dispersing

Optimize laboratory-scale production with a versatile reactor desig...

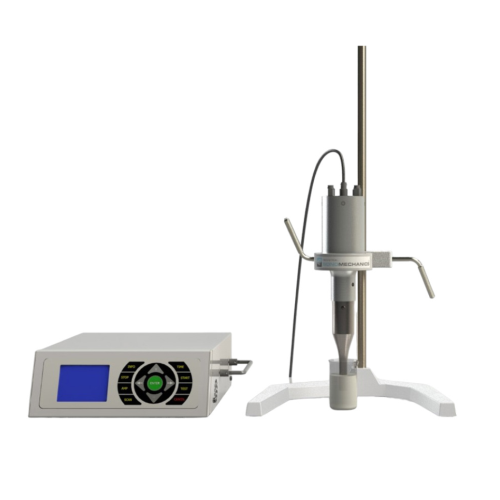

Ultrasonic liquid processor for feasibility testing and procedure optimization

Optimize your liquid formulations by en...

Vibrating control screeners for high volume screening and sifting

Ensure precise material separation with a solution de...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Heavy duty lump breaker for coarse and pre-grinding

Achieve consistent particle size reduction with this heavy-duty solut...

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

High-speed centrifugal sifter for food and pharma applications

Optimize your powder processing with a high-speed centrif...

High shear plough mixer for powders, granules, and pastes

Achieve rapid and efficient blending with high shear mixers de...

Homogenous blending solution for powders and granules

Achieve precise, homogenous blending of challenging materials like ...

Tumbler screener for multi-deck screening in powders and granules

Achieve precise separation and de-dusting of powders ...

Stand dispersing unit for pilot plant applications

Achieve precise particle size reduction and efficient mixing with this...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

Tank bottom mixer for high viscosity applications

Achieve seamless emulsification and homogenization of high-viscosity pr...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

Bin tumbler for efficient mixing

Achieve precise blending and homogenizing of powders and granules with dual-inclination des...

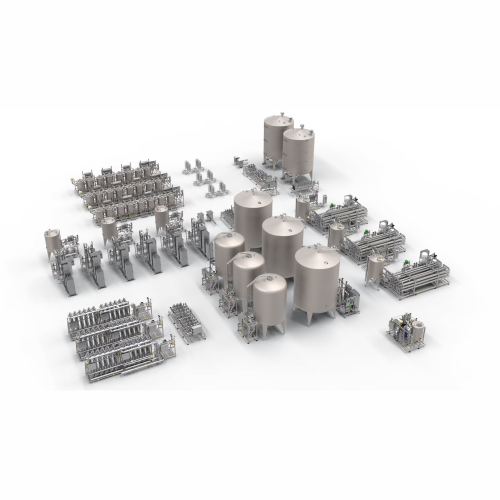

Turnkey resin synthesis plant system

Streamline resin production with a comprehensive turnkey system designed to efficientl...

High-pressure homogenizers for liquid products

Achieve consistent emulsions and stable dispersions with high-pressure homo...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

High-pressure homogenizers for dairy and juice processing

Ensure superior texture and stability in your liquid formulati...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Vacuum dryers for powders and bulk solids

Achieve precise drying and mixing of sensitive materials with advanced vacuum te...

High shear impact mixer for agglomeration and dispersion

Achieve precise homogeneity and efficient agglomeration with a h...

Continuous mixing for fine and cohesive powders

Achieve unparalleled mixing precision for cohesive powders while reducing ...

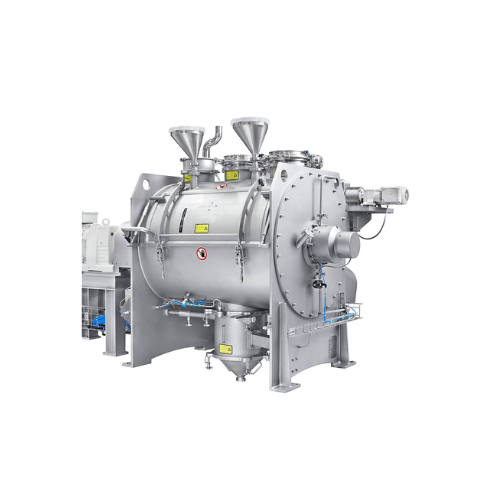

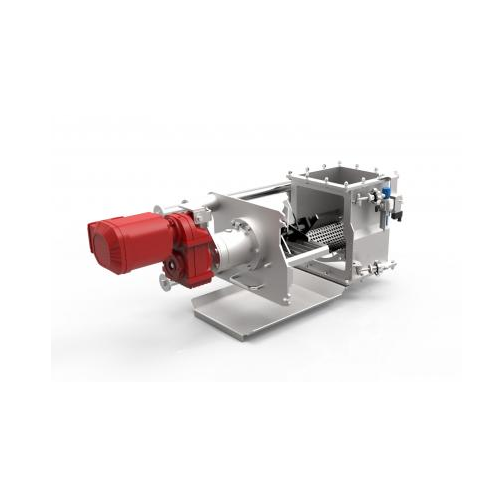

Mixer/extruder for viscous pastes and plastic masses

Achieve seamless mixing, kneading, and extrusion of viscous material...

Batch mixer for segregative, free-flowing powders and pastes

Achieve precise and gentle batch mixing for delicate produc...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Vacuum dryer for powders and granules

Achieve precise moisture control for sensitive materials with a versatile vacuum dryi...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab mixer for powder formulations

Achieve precise particle mixing and coating with this stand-alone high-shear lab mixer, d...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Containment solutions for hazardous material processing

Ensure safe and efficient processing of hazardous materials with ...

Gear pelletizer for stable cylindrical pellets

Achieve uniform pellet size and stability in your production line with a lo...

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

Conical paddle vacuum dryer for powders and granules

Achieve efficient drying of sensitive materials with this versatile ...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Roller press for fine-grained material compaction

Achieve optimal density and stability in your solid press agglomerates ...

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Ultra-fine powder grinding with jet mills

Achieve unparalleled fineness and purity in powder production with cutting-edge ...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Ultrafine grinding mill for calcium carbonate slurries

Achieve precise particle size distribution in your mineral slurrie...

Dry grinding mill for superfine products

Achieve high fineness in your comminution processes with this advanced dry grindin...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Classifier mill for ultrafine grinding

Achieve precise particle size distribution and contamination-free processing with th...

Air classifier for classifying industrial minerals

Achieve precise particle separation with advanced air classifiers, par...

Air classifier for fine to medium-fine separation

Reduce energy consumption and wear while achieving high precision in th...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

Industrial liquid mixers for continuous slurry movement

Ensure uniform slurry consistency with precision-engineered liqui...

Immersion mill for pail and drum-sized batches

Streamline your production with a versatile solution that efficiently handl...

Drum mixer for dispersions & agitations

Achieve seamless fluid formulation and agitation with a compact, high-speed drum mi...

Immersion mill for particle reduction

Achieve streamlined particle size reduction and enhanced mixture homogeneity with imm...

Immersion mill for lab to production scaling

Achieve consistent quality from lab to production with precision milling, mix...

Immersion mill with sweep blade for high-viscosity products

Optimize your production line with this immersion mill desig...

Beer production filtration system

Enhance your beverage production with cutting-edge filtration systems designed to maintai...

Filtration system for Cip cleaning in food production

Optimize your cleaning processes with a state-of-the-art filtration...

Self-cleaning filter for industrial and hygienic applications

Ensure continuous operation and minimal waste in your liqu...

Stainless cartridge filters for industrial applications

Achieve precise fine filtration and maximize efficiency in liquid...

Magnetic bag filter unit for heating and cooling systems

Efficiently remove magnetic and non-magnetic particles to enhanc...

Vacuum pan dryer for heat-sensitive pasty products

When dealing with highly viscous, heat-sensitive products, efficient m...

Vertical vacuum dryer for heat sensitive products

Achieve optimal drying and mixing for your heat-sensitive and shear-sen...

Containment system for filter dryers

Ensure safe handling and containment of hazardous materials during sampling and discha...

Filter dryer with containment system for hazardous materials

Ensure operator safety and product integrity during hazardo...

Pharmaceutical filter dryer

Achieve precise moisture control and efficient drying of sensitive materials with this advanced ...

Horizontal vacuum paddle dryer for bulk production facilities

Achieve precise moisture control in powders with a versati...

Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive ...

Pilot plant filter dryer for small scale production

Optimize filtration and drying processes in your pilot plant with a v...

Pilot unit filter dryer for laboratory applications

Efficiently manage filtration and drying processes with precise tempe...

Sterilizable filter dryer for pharmaceutical applications

Ensure full sterility and efficient moisture removal in critic...

Vertical pilot plant centrifuge for pharmaceutical applications

Ensure precise separation and optimal scaling in your la...

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Conical screw vacuum dryer for hazardous and temperature-sensitive products

When you need precise moisture control for...

Vacuum drying solution for filter cake or viscous materials

When faced with the challenge of drying filter cake or trans...

Cylindro conical mixer for batch mixing

Maximize mixing efficiency in compact spaces with this versatile solution, ideal fo...

Laboratory system for drying and mixing processes

Enhance your R&D capabilities with precise drying and mixing contr...

Pilot plant conical screw dryer

Optimize drying efficiency with this versatile pilot plant solution, ideal for simulating an...

Inverting filter centrifuge for difficult-to-filter products

Designed for challenging filtration tasks, this centrifuge ...

Inverting filter centrifuge for high-potent Api products

Achieve optimal separation and reduce residual moisture with pre...

Separation of cutting fluids from metal chips

Enhance your production line efficiency by effectively separating cutting fl...

Top discharge centrifuge for pharmaceutical production

Optimize your product yield and quality with precise filtration an...

Vertical peeler centrifuge for gypsum dewatering

Effectively dewater gypsum with minimum residual moisture and optimized w...

Classifying centrifuge for wet classification of fine particles

Ensure precise particle classification in continuous pro...

Coating centrifuge for small parts with oil and adhesives

Optimize your coating processes with a centrifuge designed to ...

Pharmaceutical horizontal peeler centrifuge

Optimize product consistency and purity with precise separation and filtration...

Automated empty bag depalletizer

Enhance your packing efficiency by seamlessly depalletizing and feeding empty bags into you...

Continuous kneader for viscous applications

For engineers tackling high-viscosity challenges, this continuous kneader stre...

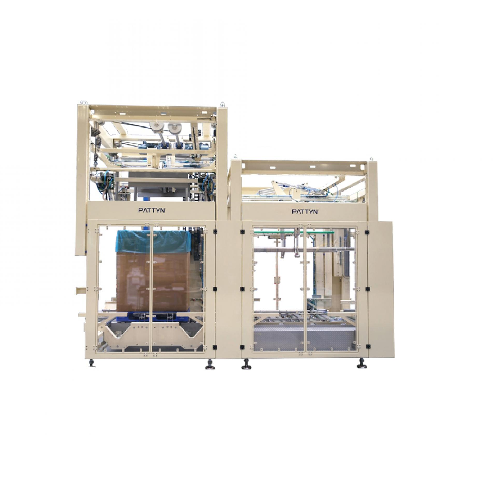

Stationary entry packaging system for valve bags

Optimize your packaging workflow with a high-speed, modular filling syste...

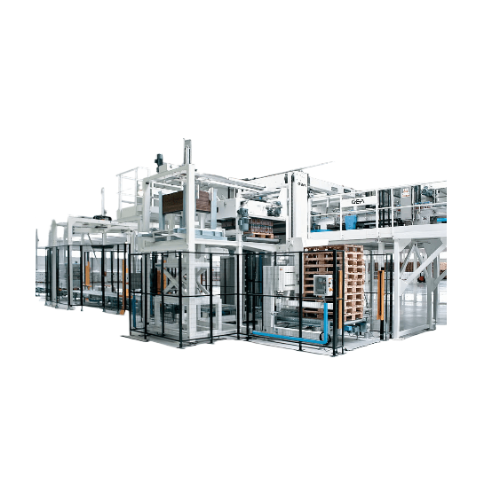

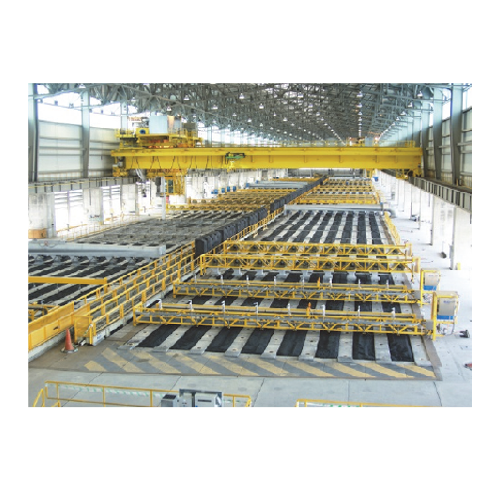

Integrated packaging system for cement and building materials

Streamline your packing operations with a fully enclosed s...

Integrated packaging system for valve and Ffs bags

Streamline your packaging operations with a versatile system designed ...

Integrated packaging system for valve and tubular film bags

Achieve precision and efficiency in your packaging line with...

Fully automatic bag applicator for valve bags

Maximize your packaging line efficiency with a high-speed system that seamle...

Rotating packaging system for bulk materials

Optimize your bulk material packaging with high-speed, precise rotary packers...

Apron extractor weigh feeder for large-scale material extraction

Achieve precise material dosing and metering under chal...

Vacuum belt filters for solid-liquid separation

Ensure high-efficiency solid-liquid separation and maximize filtrate recov...

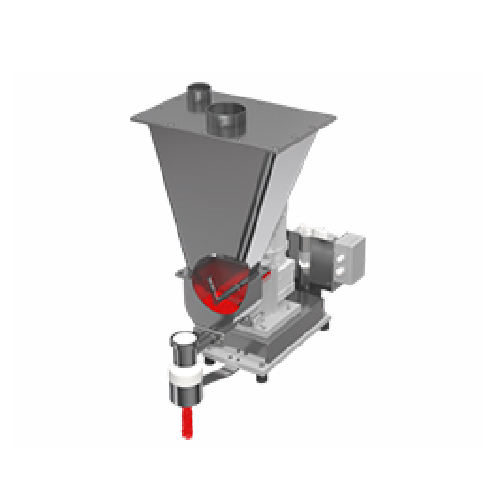

Double-stage rotary weigh feeder for precise powder dosing

Ensure consistent dosing and precise weighing of challenging ...

Laboratory z-arm kneader for high-viscosity materials

Ideal for R&D, this advanced Z-arm kneader efficiently handles...

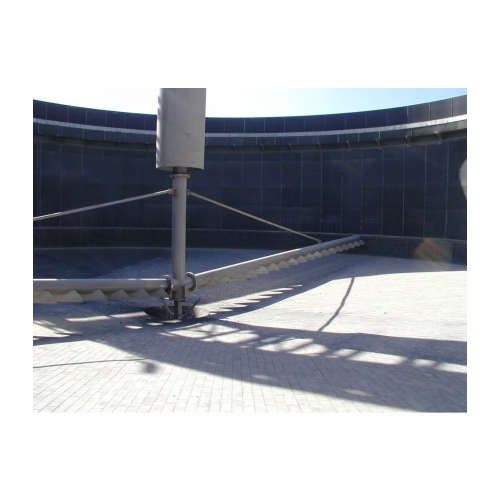

Industrial scraper for settling processes

Efficiently manage continuous sludge removal and sedimentation within your clari...

Sealless top-entry industrial mixer

Engineered for diverse industrial applications, this sealless top-entry mixer offers su...

Side entry mixer for industrial fluid mixing

Optimize your fluid mixing processes with high-speed side entry mixers, desig...

Universal industrial agitator for various fluid mixing needs

Optimize your production with an industrial agitator design...

Vacuum table filters for liquid-solid separation

Optimize your liquid-solid separation with vacuum table filters, designed...

High-speed industrial belt feeder for granular materials

Achieve precise and consistent material dosing in high-flow envi...

High-performance cartoning system for pharmaceutical products

Optimize your packaging line with a flexible cartoning sol...

Ultra-hygienic vacuum conveyor for pharmaceutical industry

Optimize powder transfer with ultra-hygienic vacuum conveying...

Ultra-hygienic vacuum conveyor for pharmaceutical and food industries

Streamline material handling with this ultra-hygi...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Pre-breaker for initial material size reduction

Efficiently prepare your bulk materials for further processing by swiftly ...

Laboratory and pilot scale blending module

Efficiently integrate multiple blending functions on a single drive for streaml...

Dust control sack tip station for bag unloading

Ensure efficient powder unloading and minimize dust emissions in your prod...

Silicone dust caps for dust-tight powder transfer

Achieve dust-tight containment and efficient powder transfer with flexi...

Rotary crushing valve for lump breaking

When handling bulk solids, effective pre-breaking and sizing are crucial to ensure ...

High-accuracy rotary dosing valve for fine material feeding

Ensure precise dosage of fine powders and granules, enhancin...

Split butterfly valve for sterile powder transfer

Ensure safe and sterile transfer of powders with unparalleled containme...

Industrial bin blenders for uniform batch production

Optimize your blending process by achieving uniform mixtures with in...

Stainless steel drums for powder storage

For high-value powder storage, these stainless steel drums offer reliable containm...

Conical mill for particle size reduction

Achieve precise particle size control and reduce thermal stress on materials with ...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

Industrial lump breaker for compact material deagglomeration

Efficiently deagglomerate compacted materials to enhance fl...

Over-driven conical mills for precise particle size reduction

Achieve consistent particle size reduction with minimal he...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

Dust-control sack tip station for industrial loading

Ensure seamless and safe unloading of powders with an integrated dus...

Drum tippers for precise and safe drum handling

Streamline your operations by eliminating manual lifting and aligning proc...

Industrial drum tumblers for uniform batch processing

Achieve precise mix uniformity in your batches with drum tumblers, ...

Industrial container lifting system

Optimize your production line with a versatile lifting solution designed to safely hand...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

Din standard glass-lined reactors

Streamline your chemical reactions with these DIN standard glass-lined reactors, designed...

Industrial continuous distillation system

Enhance product purity and efficiency with a robust continuous distillation syst...

Lab nutsche filter for small scale filtration

Efficiently manage filtration and drying needs in fine chemical and pharmace...

Acid recovery system for industrial waste acids

Optimize your production with an innovative acid recovery system that tran...

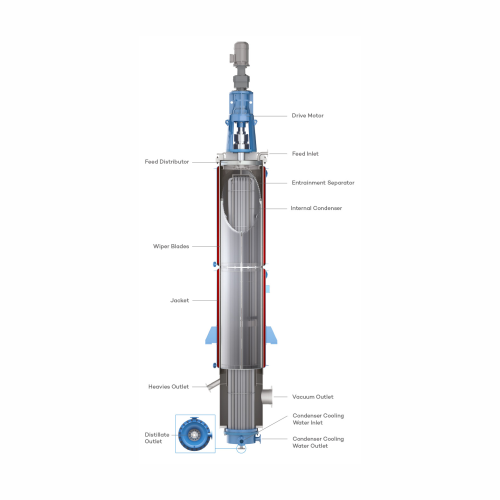

Wiped film evaporator for high boiling point materials

For challenging separations of high boiling, viscous, or heat-sens...

Packed and tray columns for distillation, absorption, and extraction

Enhance your production line with columns designed...

Centrifugal disc filter for solid-liquid separation

Optimize solid-liquid separation in your processing line with an adva...

Rotary vacuum paddle dryer for pharmaceutical ingredients

Ensure precise moisture control and efficient drying for sensi...

Vacuum paddle dryer for active pharmaceutical ingredients

For precise moisture control and contamination-free conditions...

Vertical conical dryer for pharmaceutical ingredients

Optimize drying and mixing processes for high-value substances with...

Glass-lined mixing systems for pharmaceutical industry

Achieve consistent mixing and thorough agitation for complex formu...

Fluid bed and spouted bed systems for granulation and coating

Optimize your production line with cutting-edge fluid bed ...

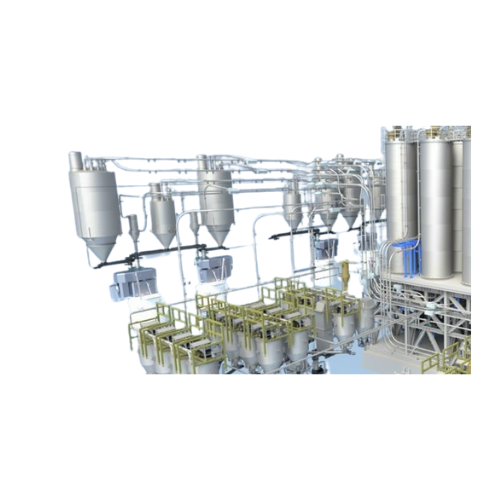

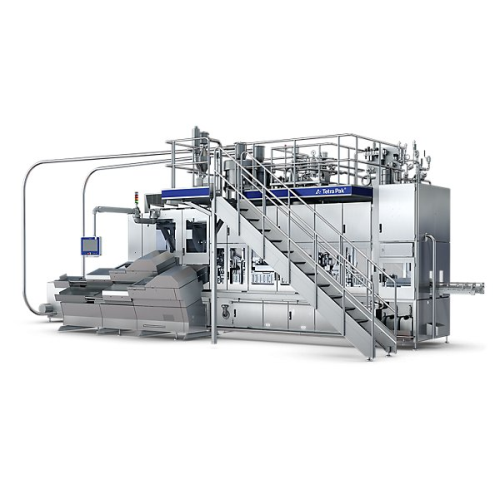

Integrated production system for food processing

Optimize your food production line with this versatile system, designed t...

Emulsifying plant for pasty and liquid products

Optimize your production line with seamless emulsification processes, desi...

Vacuum pneumatic conveying for infant nutrition

Ensure efficient handling of delicate powders with a versatile vacuum pneu...

High-precision volumetric feeder for bulk materials

Achieve precise bulk material flow with a solution that ensures consi...

Mini batch blender for pharmaceutical solids

Achieve precise mixing homogeneity with the mini batch blender, perfect for l...

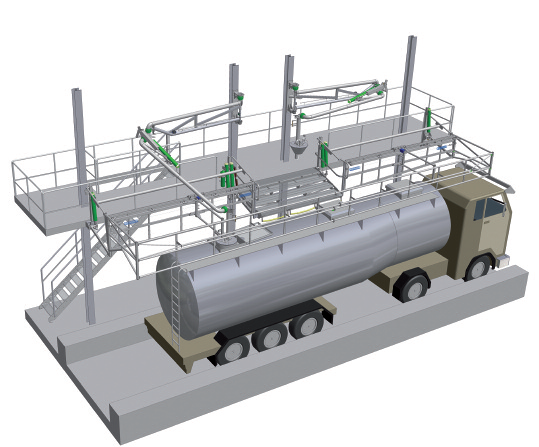

Pneumatic truck unloading for bulk tankers

Efficiently unload bulk materials from trucks with minimal dust emissions while...

Heavy duty rotary valves for powder handling

Ensure precise material flow and safety in harsh processing environments with...

Contact detection system for rotary valves

Prevent product contamination and equipment damage with instant contact detecti...

Sack tipping station for dust-free bulk material handling

Efficiently manage bulk materials while minimizing dust exposu...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Hygienic flexible sleeves for tri-clamp connections

Ensure seamless, contamination-free transitions between processing st...

Continuous inline mixing for late product differentiation

Achieve seamless product differentiation with compact inline m...

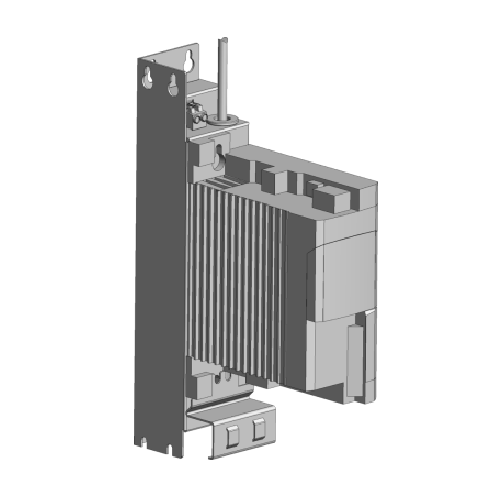

Conveying controller for dense phase conveying

Streamline your dense phase conveying operations with precise control and m...

Dense phase pneumatic conveying system for powder transfer

Ensure gentle and efficient material transport with minimal m...

Pneumatic dilute phase conveying system for powders and bulk materials

Optimize your production line’s efficiency...

Double shaft powder batch mixer

Achieve high homogeneity and gentle handling with a double shaft mixer designed for efficien...

Quick-clean hygienic rotary valves

Ensure seamless cleaning and minimal downtime in your production line with rotary valves...

High-precision gravimetric feeders for industrial bulk solids

Achieve unparalleled accuracy in your production line with...

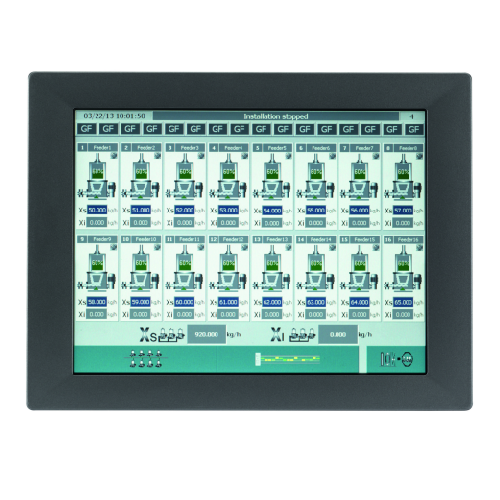

Universal controller for feeders in powder handling applications

Simplify and enhance your powder handling with precise ...

Deagglomerator for consistent particle size reduction

Struggling with inconsistent particle sizes or unwanted lumps in yo...

Continuous mixer for homogeneous blending

Achieve consistent product quality with precise mixing and blending, ideal for a...

Laboratory mixer for r&d and small batch production

Achieve superior mixing precision for R&D and pilot production w...

Hygienic flexible sleeves for food and pharmaceutical use

Say goodbye to contamination risks with this tool-free, quick-...

Big bag unloader for industrial bulk materials

Efficiently handle bulk materials with this modular unloading system, desig...

Bin aeration system for silo and hopper material flow

Optimize the flow of your stored powders and granules with an effic...

Centrifugal sifter for bulk solids and powders

Achieve precise particle separation and enhance product quality with a solu...

Continuous powder mixer for industrial applications

Achieve precise and efficient integration of powders, granules, and l...

Heavy duty blowing seals for abrasive products

For operations dealing with abrasive materials under high pressure, these r...

Vibratory sieve shaker for precise particle size distribution

Achieve precise particle size distribution with advanced v...

Jaw crusher for pre-crushing hard and brittle materials

Optimize your material processing with a robust jaw crusher desig...

Laboratory knife mill for fast comminution

Achieve rapid and precise sample preparation with this versatile knife mill, de...

Laboratory mortar grinder for wet and dry grinding

Ensure precise blending of fine powders, pastes, and creams with contr...

Particle sizing for powders and suspensions

Optimize particle shape and size analysis with rapid, reproducible results for...

Laboratory vibratory feeder for uniform material feed

Achieve precise, uniform feeding of fine powders and granules in la...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

High shear granulation mixing system

Optimize your powder granulation process with a system designed for precise control ov...

High shear granulator for wet granulation of powders

Achieve consistent granule density and size with a high shear granul...

High shear lab granulation system for powder processing

Achieve precise granulation and consistent mixing of powders with...

Pilot Gmp spray dryer system for small-scale manufacturing

For precise control in spray drying, streamline your small-sc...

Benchtop spray dryer for drug discovery

Optimize your formulation development with a compact spray dryer that streamlines t...

Fluid bed granulator for industrial granulation

Optimize your production efficiency with versatile fluid bed granulation, ...

Laboratory scale fluid bed system for granulation and coating

For precise formulation and optimization, this fluid bed s...

Development fluid bed system for feasibility studies

Explore precise granulation and coating capabilities for small batch...

Precision feedstocks for biomass energy production

Optimize your biomass conversion with precision-sized feedstocks desig...

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

High-performance decanter centrifuge for industrial separation

Optimize your production with a centrifuge solution that ...

Aseptic filler for bag-in-box packaging

Achieve unparalleled product safety and quality in liquid packaging with our advanc...

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Fluid bed processor for granulation and coating

Fluid bed processors offer efficient granulation and coating, streamlining...

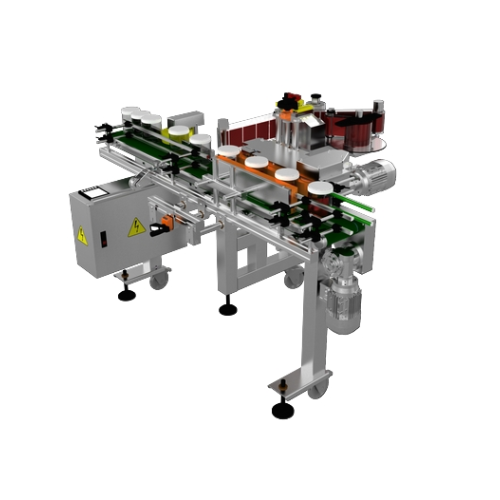

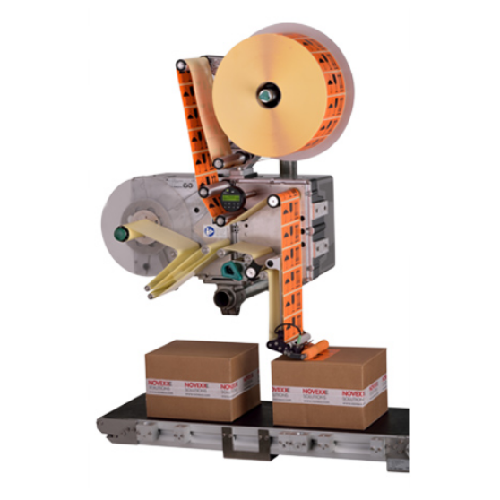

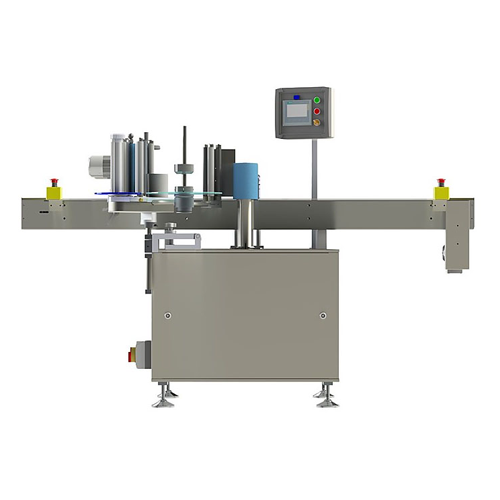

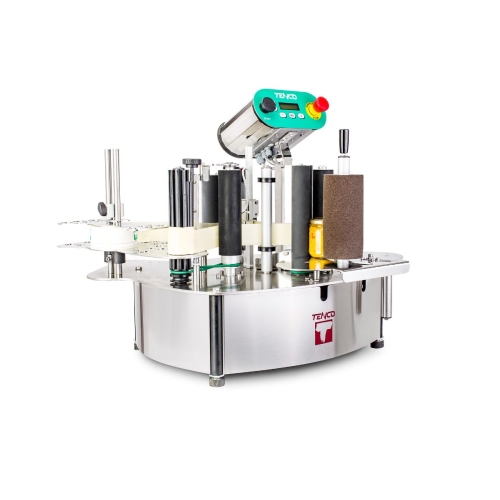

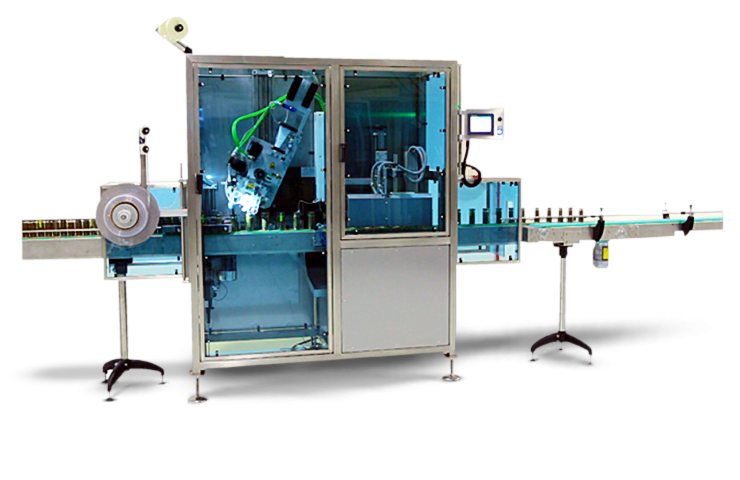

Self-adhesive labeling system for unstable cylindrical containers

Ensure precise labeling of unstable cylindrical conta...

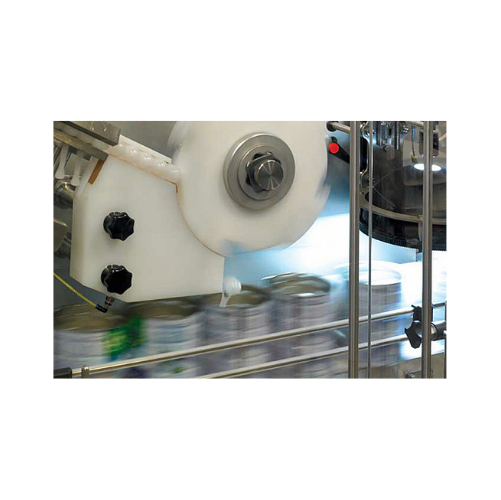

High speed wraparound label applicator for cylindrical containers

Experience efficient high-speed labelling for cylindr...

Multiformat high-speed labelling for self-adhesive labels

Achieve precision labelling on diverse container formats with ...

Self-adhesive labeling for multi-format containers

Ensure precision on diverse container shapes with a high-speed, self-a...

Linear self-adhesive labeller for cylindrical and flat containers

Optimize your labelling process with precision applic...

Cold glue label applicator for pre-cut labels

Optimize your packaging line with high-speed labeling for a variety of conta...

Rotary hot melt labeller for pre-cut labels

Achieve precise high-speed labelling of diverse containers with enhanced adhes...

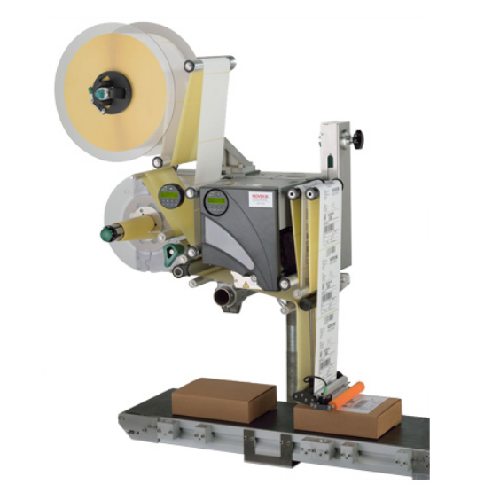

High-speed labeling heads for industrial applications

Enhance your production line efficiency with high-speed labeling he...

Double cone mixer for free flowing powders and granules

Achieve uniform blending of powders and granules with precision, ...

V-mixer for solid bulk material blending

Achieve precise and uniform mixing of sensitive powders with gentle treatment, ide...

Double roll crusher for laboratory applications

Optimize material processing with a double roll crusher designed for preci...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Consumables for elemental analyzers

Optimize your laboratory’s elemental analysis with high-quality consumables desig...

Carbon/hydrogen/sulfur analyzer for organic sample analysis

Ensure precise elemental analysis of carbon, hydrogen, and s...

Clinical analyser liquid waste treatment system

Effectively manage and treat hazardous liquid waste from clinical analyser...

Portable process development unit for gas-liquid reactions

Optimize your gas-liquid reaction processes with a versatile,...

Pilot plant for highly viscous applications

Perfect for R&D, this pilot plant efficiently handles complex mixing and ...

Vacuum dryer for free-flowing and pasty solids

Achieve precise drying and mixing with this vacuum dryer, optimizing heat t...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Vertical pharma vacuum blender for bulk solids

Optimize your mixing of fine chemicals and pharmaceutical powders with high...

Automated bolting system for electric vehicle production

Enhance your production line with a multi-direct bolting system ...

Automatic bolting system for car underbody assembly

Achieve precise underbody bolting in car assembly lines with a fully ...

Automotive system leak testing solution

Ensure the integrity and safety of your vehicle systems with precise leak testing, ...

Roll support dryers for web transportation

Eliminate web curl issues and enhance drying precision for diverse materials wi...

High-pressure catalytic system for air pollution control

Enhance your exhaust management with a high-pressure catalytic s...

Low-pressure catalytic system for Voc removal

Efficiently remove volatile organic compounds while reducing energy consumpt...

Evaporative gas cooling system for industrial gases

Optimize exhaust gas management with precision cooling and conditioni...

Industrial liquid distillation for solvent recovery

Optimize your solvent separation and purification process with advanc...

Wet scrubbers for acid gas absorption

Effectively capture and neutralize harmful acid gases with advanced wet scrubbers, en...

Automatic bolting station for industrial assembly

Elevate your production line with a modular bolting station designed to...

Compact laboratory mixer for high-shear granulation

Streamline your R&D processes with advanced mixing and granulati...

Pilot single-pot processor for granulation and drying

For efficient pilot production, streamline your mixing, granulating...

Versatile entry-level mixer granulator

Solve complex mixing and granulating challenges with this compact solution, offering...

High-capacity universal mixer for industrial applications

Optimize your batch processing with a versatile high-speed mix...

Single-pot processor for wet granulation and vacuum drying

Achieve efficient mixing, granulation, and swift vacuum dryin...

Fluid bed processor for large batch spray granulation

Optimize your production with precision granulation, drying, and co...

Midilab for efficient laboratory-scale product development

Streamline your laboratory and pilot-scale production process...

Industrial shredder for diverse material reduction

Achieve precise and efficient material resizing for diverse applicatio...

Industrial vibrating sifters for granular material separation

Achieve precise particle separation and ensure product pur...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Batch mixer for powder and grain processing

Achieve ultra-fast, homogenous mixing in just 20 to 50 seconds with this versa...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

Product handling system for big bags and containers

Optimize your production line with a comprehensive system for transpo...

Industrial pulper for fresh produce

Achieve ultra-fine purees and pastes with this high-speed industrial pulper, designed t...

Industrial roller mill for grain size reduction

Achieve precise grain size reduction with minimal heat generation and opti...

Rotary drum sifter for pellets and chunks

Achieve precise particle separation and minimize product loss with a rotary drum...

Hammer mill with automatic screen exchange

Optimize your milling operations with a high-speed solution that ensures seamle...

Fast screen exchange grinding solution for medium-hard products

Maximize your milling efficiency with a solution that al...

High-care big bag filling system for hygienic environments

Ensure precise hygienic filling of Big Bags in high-care envi...

Mechanical horizontal conveyor for powders and granulates

Efficiently handle and transport your delicate powders and gra...

Vertical transport for bulk goods

Efficiently move bulk goods vertically with minimal energy usage, ensuring seamless integ...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

Industrial mixer for moisture conditioning

Ensure precise moisture levels and homogeneous mixtures for complex extrusion p...

Big bag conditioning system for compact materials

Struggling with clumped materials during unloading? This system expertl...

Industrial breaker for reducing large lumps and agglomerates

Efficiently break down challenging materials with a robust ...

Centrifugal mill for fine grinding in industrial processes

Achieve exceptional fineness without overheating your materia...

Industrial centrifugal sifter for solid particulate materials

Quickly and accurately sift a wide range of powders and gr...

Bag emptying system for bulk material handling

Streamline your material processing operations with a versatile solution de...

Hygienic industrial grinder for food and pharma applications

Achieve optimal hygiene and efficiency in your grinding pro...

Liquid dosing system for powders and granulates

Achieve precise liquid addition with this dosing system, ideal for integra...

Drum and container emptying system

Ensure safety and efficiency when handling and emptying drums or containers, whether dea...

Evaporation plant for liquid mixtures

Achieve precise thermal separation of multi-component liquid mixtures, optimizing con...

Extraction plant for natural essences and active ingredients

Optimize your extraction processes with a versatile system ...

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Bag-in-box filling system for packaging efficiency

Streamline your packaging process by integrating filling and boxing in...

Ceramic ultrafiltration for treating oily emulsions

Optimize your oily emulsion treatment process with advanced ceramic u...

Crossflow filtration with ceramic membranes for wines

Enhance filtration efficiency and durability with ceramic membranes...

Rotary vacuum filters for wine and lees filtration

Achieve high-precision liquid filtration and separation with continuou...

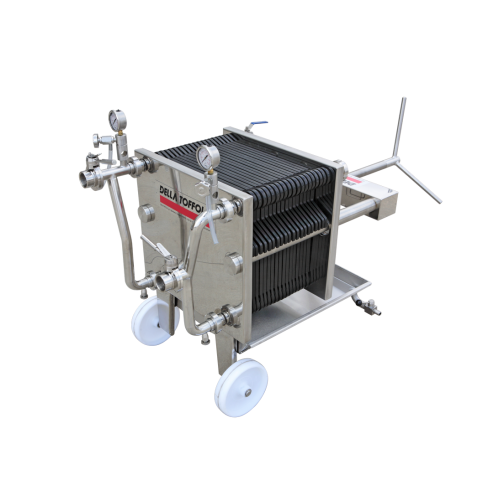

Industrial plate filter press for winemaking

Efficiently separate liquids from solids to recover valuable liquid component...

Industrial sheet filters for diverse liquid filtration applications

Achieve precise liquid filtration with adaptable sh...

Biological water treatment systems

Maximize efficiency in water treatment with advanced biological systems designed to seam...

Industrial crossflow filters with ceramic membranes

Achieve precise filtration with robust ceramic membranes, ideal for h...

Crossflow filter for clarified and unclarified wines

Optimize your filtration process with ceramic membrane technology th...

Ceramic membrane crossflow filters for wine clarification

Enhance filtration efficiency with ceramic membranes offering ...

Temperature control systems for winemaking

Achieve precise temperature regulation in fermentation and storage processes wi...

Roll linear labelling machines for bottling and packaging

Achieve precise and efficient labeling with roll linear labell...

Stabilizer dissolution system for beverage industry

Efficiently dissolve and homogenize stabilizers like pectin or CMC in...

Press-on capping system for bottles

Ensure precise and secure closure of various bottle types with our versatile press-on c...

Dissolution and batching system for minor ingredients

Efficiently manage minor ingredients with a system designed for pre...

Spray dryers for lithium iron phosphate powder production