Pea fiber drying solutions for food or feed applications

Ensure top-tier product quality with precise drying of pea fiber, critical for maintaining nutritional and sensory profiles in plant-based foods and animal feeds, while optimizing energy efficiency through advanced ring dryer configurations.

Dries and Concentrates Pea Fiber for Production

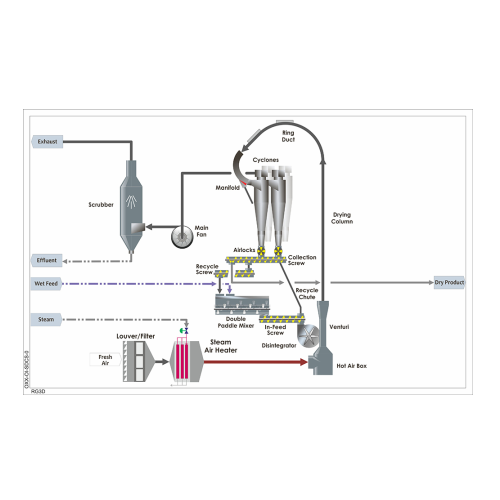

The Feed-Type Ring Dryer from Dedert Corporation revolutionizes the drying process for pea processing applications. This equipment is distinguished by its short residence time and centrifugal classification manifold, significantly enhancing dryer efficiency while maintaining product quality. Ideal for plant-based protein producers and food ingredient manufacturers, it processes pea fiber, starch, and solubles into high-value isolates and concentrates, suitable for a variety of end products including nutritional supplements and livestock feed mixes. The OC Ring Dryer configuration ensures pea fiber retains its nutritional integrity in food applications, while the PGR solution optimizes energy recovery for animal feed production. Engineered for continuous, high-speed operation, this dryer integrates seamlessly into existing production lines, utilizing ambient air in a 1-pass configuration to prevent contamination. Dedert’s design minimizes energy use through a gas-heated evaporator, ensuring both environmental and economic efficiency, making it a vital component for enhancing processing capacity and product quality.

Benefits

- Enhances product quality by minimizing exposure to high temperatures.

- Increases energy efficiency with partial gas recycle for reduced operating costs.

- Integrates seamlessly into existing production lines for uninterrupted processing.

- Maintains nutritional integrity in food applications with clean air drying.

- Reduces emissions and environmental impact through advanced energy-recovery design.

- Applications

- Grains, Animal feed, Chemical, Plant-based protein, Food ingredients, Starch, Biofuel

- End products

- Nutritional supplements, Nut-free snacks, Pea protein concentrate, Pea protein isolate, Plant-based meat alternatives, Bakery ingredients, Pet food, Gluten-free breads, Pea fiber, Pea starch, Livestock feed mixes, Ready-to-eat meals, Lactose-free drinks, Protein bars

- Steps before

- Wet Fractionation, Concentration

- Steps after

- Packing, Quality Control

- Input ingredients

- Yellow Peas, Chickpeas, Peas

- Output ingredients

- High-Value Protein Concentrate, Protein Isolate, Pea Fiber, Pea Starch, Pea Solubles

- Market info

- Dedert is known for its expertise in designing and supplying advanced drying and evaporation technologies, serving the chemical, food, and other processing industries with innovative and efficient engineered-to-order solutions.

- Dryer Configuration

- Open-Circuit (OC) / Partial Gas Recycle (PGR)

- Drying Time

- Short residence time

- Temperature Control

- Low temperature environment

- Heat Source

- Indirect heating / Steam-heating

- Recirculation Method

- Partial Gas Recycle (PGR)

- Exhaust Stream Handling

- Exhaust recirculation with Gas Heated Evaporator (GHE)

- Energy Recovery

- Energy recovery through GHE

- Drying Medium

- Ambient fresh air

- Drying Efficiency

- Maximum dryer efficiency via centrifugal classification manifold

- Product Quality Control

- Prevents discoloration and off-tastes

- Working mechanism

- Ring Dryer

- Integrated steps

- Drying, solids recycle

- Batch vs. continuous operation

- Continuous

- Automation level

- Variable, may include PLC

- Energy efficiency

- PGR for improved efficiency

- Cleaning method

- CIP / Open-Circuit for food

- Heat source

- Indirect or steam heating

- Contamination prevention

- Ambient fresh air, 1-pass configuration

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customizable based on application

- Dryer type

- OC Ring Dryer / PGR Ring Dryer

- Discharge method

- Ring Dryer with centrifugal classification manifold

- Feed type

- Solid recycling to a high-temperature feed zone

- Control panel type

- PLC-controlled

- Heating method

- Indirect / Steam-heating

- Cooling method

- Optional Fluid Bed Cooler

- Heating source configuration

- Indirect heating / Steam-heating

- Dryer type

- OC Ring Dryer / PGR Ring Dryer

- Gas flow configuration

- Open-Circuit / Partial Gas Recycle