Making Plant-Based Meat

Find innovative production technology for making plant-based meat and connect directly with world-leading specialists

With consumerism comes great responsibility. More and more are switching their diet towards vegan and vegetarian alternatives, varying from dairy to meat. As more plant-based meat technologies are being invented, the production is rising in popularity. Ever wondered which challenges come with that?

Stories about plant-based meat

#Changemaker: developing your recipe to success in the vegan market

Innovator or perfector – what kind of plant-based food maker are you?

#Changemaker: The tastiest part of chicken is plant science

#Changemaker: The plant-based burger made of lentils you didn't know you needed!

#Changemaker: Chickpea protein for your plant-based food product!

#Changemaker: Fava bean umami extract for your vegan diet!

#Changemaker: Vegan bacon is a co-man love match

Select your plant-based meat process

Tell us about your production challenge

The secret lies in the mixing!

The main ingredients in plant-based meat production process are protein-rich plants like soybeans which are then cooked and processed into meat shape. While the general production of plant-based meat alternatives (PBMA) involves many processing stages, the (pre-)mixing stage is amongst the most challenging step. The base mix of PBMA often contains over 30 different ingredients with different physical properties in terms of density, size, moisture, etc.

This makes mixing quite challenging as continuous production processes can be disturbed by frequent recipe changes. As a solution, makers can use special plant-based meat technologies such as continuous mixing systems which focus on batch production and intend to reduce any disturbances in the mixing process.

Newest plant-based meat technologies

The ‘Extrudable Fat Technology’ is a plant based food technology that focuses on mimicking animal fat which enables a more authentic fat texture, also known as marbling. For this, fat is run through an extruder and then combined with protein. Despite the production pressures and temperature, this allows both components to be physically linked together instead of the fat turning liquid, as it would have normally.

Another effective way of making plant-based meat is by producing TVP (Textured Vegetable Protein). TVP per se was commonly produced with Low Moisture Extrusion Cooking (LMEC) processes and has been used as a meat substitute since the 1960’s, so technically it is not new. New techniques are now using High Moisture Extrusion Cooking (HMEC) and offer a better fibrous consistency and texture, more effectively replicating the structure, texture and overall feeling of meat.

It all depends on the consumer

While it is known that plant based protein alternatives are a lot friendlier for the environment and reducing our footprint, a common point for discussion or rejection from consumers is the taste, texture and appearance of many vegan meat substitutes. These three criteria make the biggest challenge for producers. With advanced plant-based food products, there is a hopeful outlook on continuous positive developments. Especially with the rise of popular alternatives such as “impossible foods” & “beyond Meat”. Consumers used to believe that protein could only come from real meat. However, there are now an incredible amount of alternative protein choices on the market. Some of which even contain higher protein content than actual meat. You can now get all the protein you need in the form of meat substitutes such as meatless steaks, nuggets, burgers, sausages and more.

Processing steps involved in plant-based meat making

Which plant-based meat technology do you need?

Clarifiers for plant protein recovery

Maximize protein yield and minimize waste with advanced clarification technology desi...

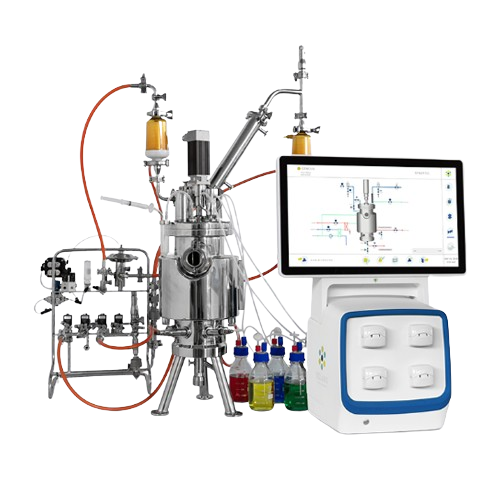

Industrial bioreactor for microbial food production

Enhance microbial food production with advanced bioreactor systems de...

Piping solutions for breweries cold block area

Efficiently distribute and regulate media within your brewing process, ensu...

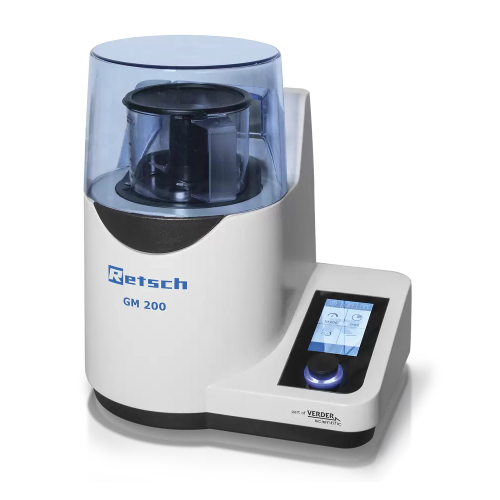

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Flexible powder recipe formulation system

Streamline your batch production with efficient, dust-tight formulation and blen...

Tray diverter for packaging line efficiency

Optimize your packaging line with an advanced tray diverter designed to stream...

Low-pressure forming solution for plant-based products

Achieve a handcrafted look and precise texture retention for plant...

Sausage linking system for consistent weight and length control

Achieve precision in sausage production with high-speed ...

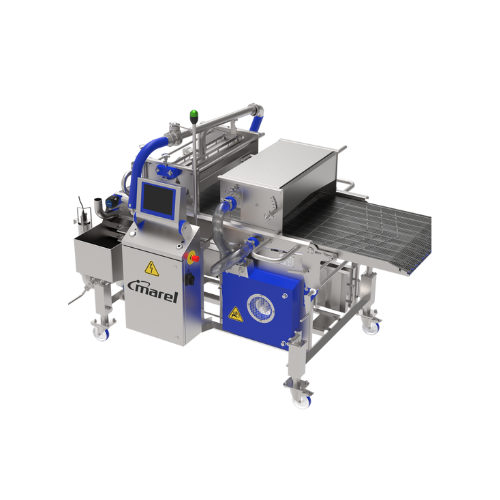

Batter applicator for plant-based products

Achieve flawless coating with precision technology that ensures complete wet an...

Cooled grinder for meat processing

Enhance meat processing efficiency with a cooled grinder that maintains optimal temperat...

Cluster cutter for green bean processing

Efficiently streamline your green bean and vegetable processing with advanced snip...

Combination cooker-cooler for pasta production

Streamline your production with a machine that efficiently cooks and cools ...

Rice cooking system for low-moisture processing

Achieve fully cooked, low-moisture rice with precise control over absorpti...

High torque twin screw extruder for industrial applications

Enhance your production capabilities with advanced twin scre...

Vertical packaging for fresh produce

Streamline your fresh produce packaging with high-speed vertical form fill seal machin...

Mixer/extruder for viscous pastes and plastic masses

Achieve seamless mixing, kneading, and extrusion of viscous material...

Lab mixer for high-accuracy powder and paste mixing

Achieve precise mixing of powders and pastes with a gentle convective...

Vacuum filler for medium-scale sausage production

Achieve precise portion control and optimal hygiene with a versatile fi...

Manual forming unit for burger patties

Produce up to 30 perfectly shaped burger patties per minute with consistent quality ...

Emulsifying plant for pasty and liquid products

Optimize your production line with seamless emulsification processes, desi...

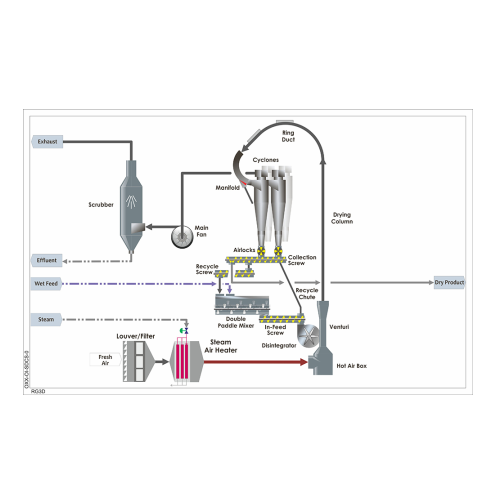

Pea fiber drying solutions for food or feed applications

Ensure top-tier product quality with precise drying of pea fiber...

Continuous vacuum dryer for protein products

Achieve precise moisture control and maintain product functionality with low-...

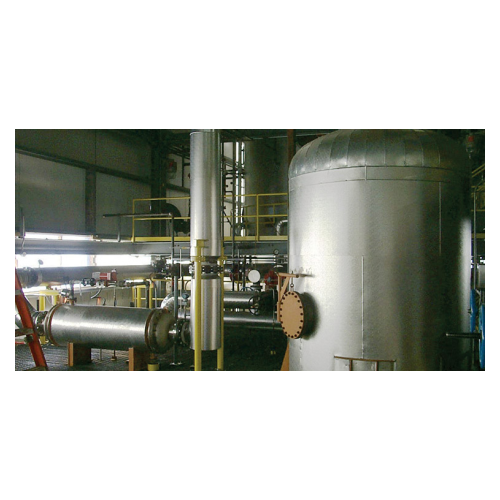

Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process whi...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Scraped surface heat exchanger for viscous liquids

Optimize heating and cooling of viscous liquids efficiently with conti...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Industrial fume scrubber for safety compliance

Enhance workplace safety by efficiently neutralizing hazardous fumes and va...

Industrial fat extraction system for food and feed analysis

Optimize your laboratory workflow with a versatile fat extra...

Acid hydrolysis system for total fat determination

Streamline your laboratory workflow with a powerful hydrolysis system ...

Modular cooling die for texturised plant proteins

Engineered for lab-scale extrusion, this modular cooling solution tailo...

Flour and dough analyzer

Enhance your dough and flour testing with precise rheological analysis, ensuring optimal water absor...

Flour and dough analyzer for quality control

Ensure precise flour and dough quality analysis with dependable standards com...

Ultrasonic slicer for precise food cutting

Achieve perfectly portioned bakery and food products with precision ultrasonic ...

Open flame grill marking system

Enhance your food products’ visual appeal with precision grill marking, ensuring consi...

Double-shaft paddle mixer for homogeneous raw masses

Optimize your mixing efficiency with a dual-shaft system designed fo...

Viscous coating applicator for poultry, meat & seafood

Effortlessly apply even viscous coatings like tempura or marinades...

Self-priming side channel pump for high gas content media

When handling media with high gas content, achieving efficient...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

Industrial bucket elevator for efficient product conveyance

Enhance production efficiency by elevating and transferring ...

Twin-shaft mixer for meat mix preparation

Achieve consistent texture and flavor in your meat and plant-based products with...

Brine preparation system for marination processes

Ensure consistent and high-quality brine and marinade mixtures with a s...

Industrial fryer for pork, poultry, and seafood

Enhance your production line with a fryer that ensures consistent, high-qu...

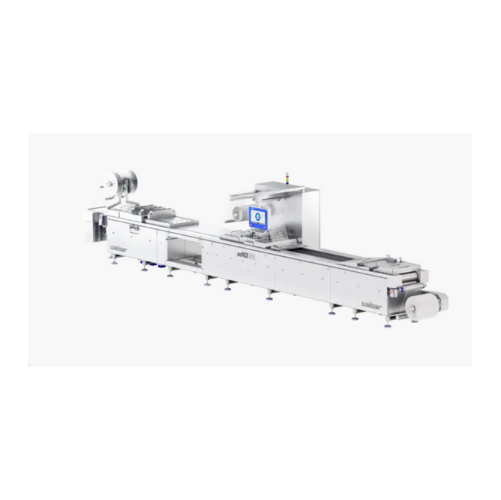

Thermoforming packaging for food products

Enhance your packaging operations with advanced thermoforming technology, perfec...

Single-screw cooking extruder for high-value food products

Transform raw materials into diverse, high-value products wit...

Sterilization of concentrated food products using direct steam

Achieve rapid and efficient sterilization with direct ste...

Cold block process technology for breweries

Optimize your fermentation and storage with integrated cold block process tech...

Thermoforming packaging solution for medium production volumes

Optimize your medium-volume packing with a compact thermo...

Grinding and separating solution for meat processing

Optimize your meat and plant-based production lines by integrating a...

Stuffing feeding device for extruders

Efficiently feed cohesive or lightweight powders into extruders to enhance product qu...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

Industrial-scale bioreactors for large-scale biomanufacturing

When producing at large volumes, efficient and reliable bi...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Autoclavable photobioreactor for microalgae and bacteria cultivation

Optimize the growth of phototrophic organisms with...

Benchtop Sip fermenter for bioprocessing applications

Optimize your bioprocesses with precise control over fermentation a...

Autoclavable fermenters for small scale bioprocessing

Optimize your bioprocesses with configurable fermenters offering pr...

Automated mayonnaise and dressing production line

Ensure the consistent quality of your mayonnaise, dressings, and sauces...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

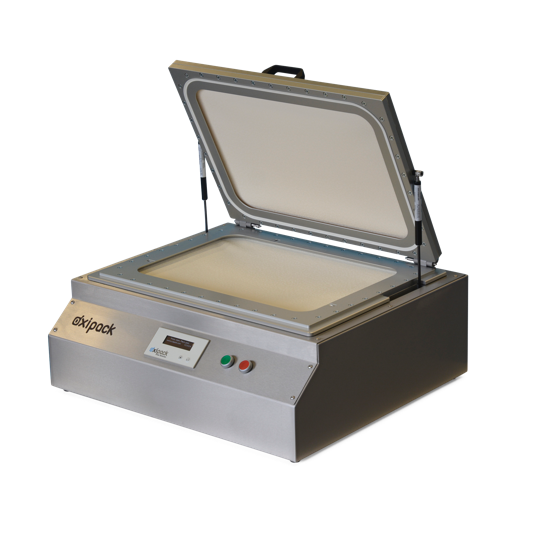

Tray sealer for food production

Companies in food industry know how essential packaging is in keeping food fresh and ensurin...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

Tray former for various tray formats including trays with corner constructions

If you are looking to increase your sup...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

Organic soybean feed extruder

Soybeans are an essential ingredient in the creation of protein-rich animal feed. To achieve h...

Industrial thermoformer for food production

The primary purpose and aim of food packaging are to protect all food products...

Form fill seal thermoforming machine

As the name suggests, a Form Fill Seal machine is one that forms, fills, and seals a p...

Skin packaging machine

Skin packaging is when a product is placed on a tray or a paperboard with a thin layer of plastic plac...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

X-ray inspection system for processed meat products

When dealing with the poultry industry, the Dual X-ray inspection sys...

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Complete cutting, mixing, emulsifying and heating system

From laboratory scale to large volume food or cosmetic productio...