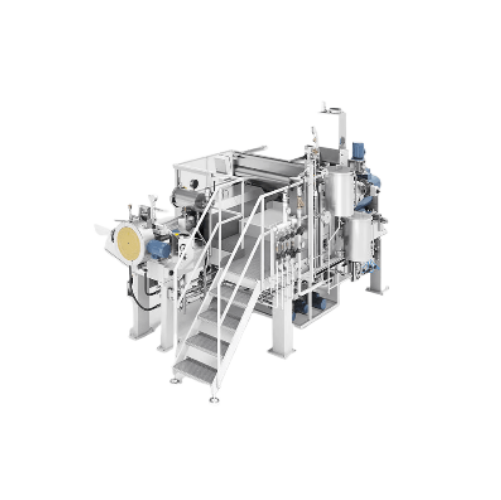

Single-screw cooking extruder for high-value food products

Transform raw materials into diverse, high-value products with a versatile single-screw extruder, ensuring precise cooking and mixing for innovative food applications.

Processes and Transforms Raw Ingredients into Finished Products

The GEA xTru Cooker is a single-screw cooking extruder engineered by GEA for precise and efficient processing. It converts raw ingredients into high-value products through a robust cooking and extruding process. This machine is ideal for manufacturing instant noodles, textured vegetable proteins, and plant-based meat alternatives. It operates continuously with high speed, utilizing a single fluid heating system for stable temperature control, which enhances energy efficiency. Designed with hygiene and safety in mind, it features stainless steel components for easy cleaning and complies with EN60204-1 safety standards. Capable of integrating seamlessly into existing production lines, the GEA xTru Cooker provides advanced control and customization options, ensuring consistent product quality and operational efficiency.

Benefits

- Enhances production efficiency with continuous, high-speed operation.

- Optimizes energy use with stable, single fluid temperature control.

- Ensures product safety and quality with easy-to-clean stainless steel construction.

- Increases operational safety through compliance with EN60204-1 standards.

- Facilitates diverse product development with customizable kneading and shear profiles.

- Applications

- Alternative proteins, Snacks, Noodles, Protein products, Novel foods

- End products

- Soy protein isolates, Plant-based meat alternatives, Potato-based snacks, Textured vegetable protein (tvp), Ramen noodles, Pea protein nuggets, Chickpea protein products, Vegan burger patties, Instant noodles, Extruded corn snacks

- Steps before

- Flour hydration, Mixing, Material preparation

- Steps after

- Packing, Quality control, Storage

- Input ingredients

- flour, raw materials

- Output ingredients

- high added value products, processed noodles, chewier noodle texture

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Temperature Range

- Up to high temperatures

- Kneading/Shear Profiles

- Specific profiles for long residence time

- Heating System

- Single fluid, super-heated water

- Material

- Stainless steel for product contact parts

- Cooling Control

- Chilled water

- Working mechanism

- Single-screw extrusion

- Heating system

- Super-heated water jackets

- Cooling system

- Chilled water control

- Kneading/shear profile

- Specific profile for optimal cooking

- Automation level

- PLC-controlled

- Cleaning method

- Manual / CIP capability

- Changeover time

- Efficient disassembly for cleaning

- Batch vs. continuous operation

- Continuous

- Corrosive resistance (e.g. acids)

- Induction-hardened stainless steel

- Control panel type

- PLC control

- Integration possibilities

- SCADA integration

- Heating system

- Electric resistance heated

- Kneading/shear profiles

- Customizable

- Temperature control

- Chilled water regulation

- Cooking screw configuration

- Adjustable