Making Textured Vegetable Protein

Find innovative production technology for making textured vegetable protein and connect directly with world-leading specialists

Vegan meat alternatives and plant-based foods have rapidly grown in popularity over the last decade. Many people are switching to meat substitute food products. Your body does not discriminate between proteins and calories coming from meats and those coming from plants. From a nutritional point of view, they all have the same value. But chewing on a portion of veggie pumpkin protein does not feel the same as a cut of meat - the texture is completely different.

Select your textured vegetable protein process

Tell us about your production challenge

It’s the fibers, stupid

What gives meat products their bite

The tastes and consistency that you pick up in meat are determined by the fibers in the natural muscle. The structure of fibers, their water content, and the formation of connective tissue are all analyzed by your tongue which it then interprets as qualities of tenderness, juiciness, freshness.

The primary sensory experience of eating meat comes from the interplay between fiber properties that are released by chewing.

Making textured vegetable protein

Food scientists are developing new ways of re-creating meat muscle fibers using plants.

Textured vegetable protein (TVP) is plant protein formed into structures that mimic the fibrous character of meats and seafood. To achieve this, you need to mill the protein into a flour and mix it with water at high temperatures in an extruder. The thermomechanical energy alters the structure of the proteins allowing you to remodel them into chunks or fiber-like arrangements.

Try a meatless meatloaf

Using multiple sources of plant-based protein

TVP techniques experiment with a variety of plants from soy protein to peas, sunflower to potato. Different sources produce different textures, colors, and tastes and flavors matching a range of meat or fish products.

Apart from the base plant, your final TVP combination will also be determined by the protein intensity in the mix. An isolate base has a high protein content while a meal is considered a low-share type. The middle way is a protein concentrate.

Animal, vegetable, or integral? TVP blends make more sense for food industry

TVP products are ready for the pan and various brands are making meat analogs to produce non-meat versions of eats like burgers, dim sim or meat pies. But food producers are increasingly integrating TVP products with minced meat mixes.

Supplementing recipes with TVP meat extenders reduces environmental and economic costs associated with meat processing without giving up the consistency of natural meat fibers.

Processing steps involved in textured Vegetable Protein making

Which textured vegetable protein technology do you need?

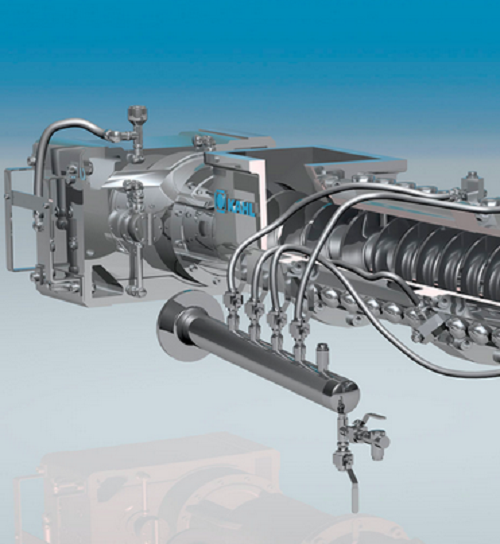

Extruder for large-scale production of TVP

Shaped and filled extruded products are extremely popular with consumers, but c...

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

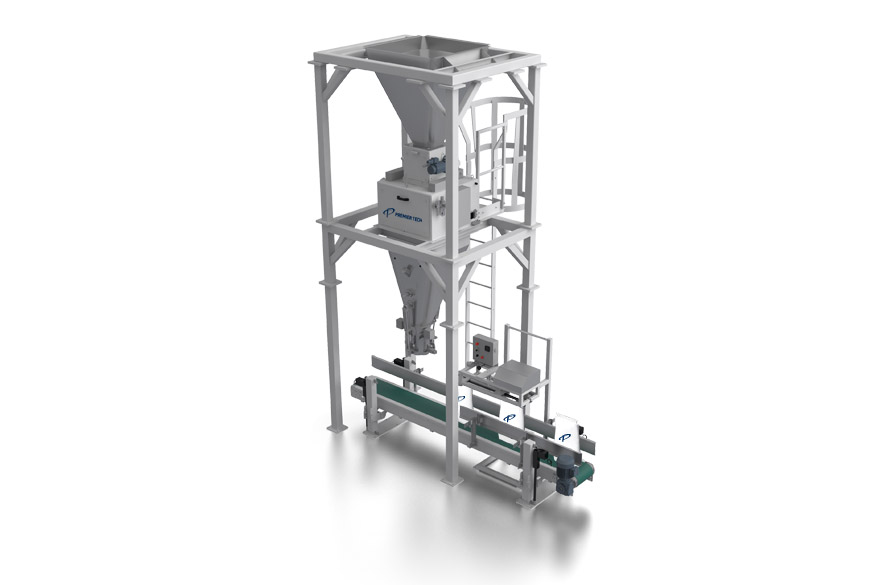

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Organic soybean feed extruder

Soybeans are an essential ingredient in the creation of protein-rich animal feed. To achieve h...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Industrial sauce pan

For the small and medium food industry, economical use of time, space and human resources is critical wh...

Manual bagger with gross weigher

This is a manual bagging set with an electronic gross weighing system to meet international...

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...

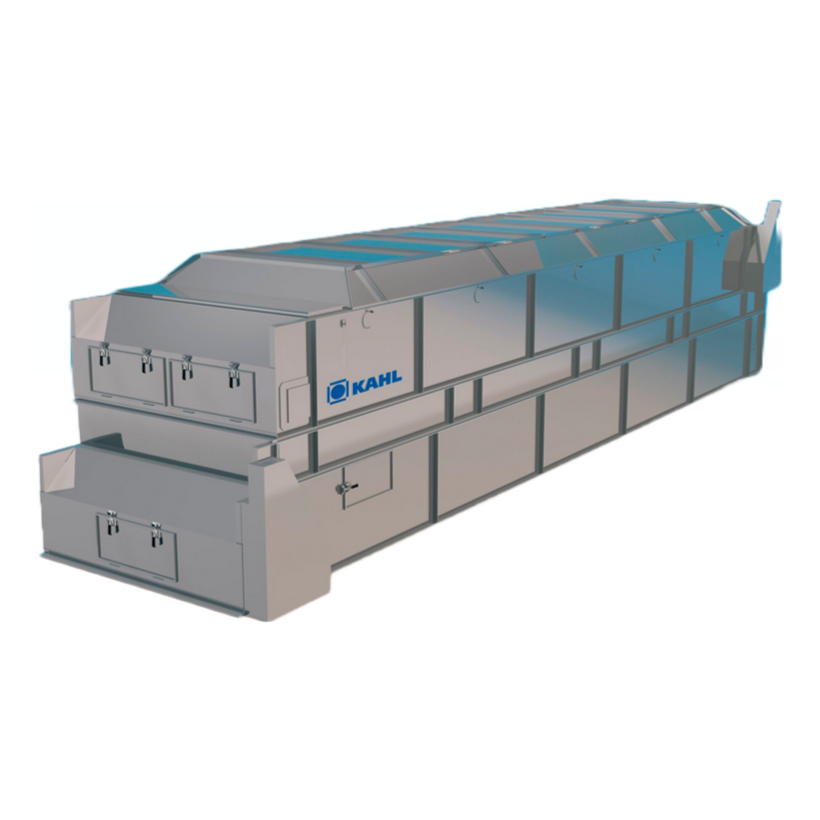

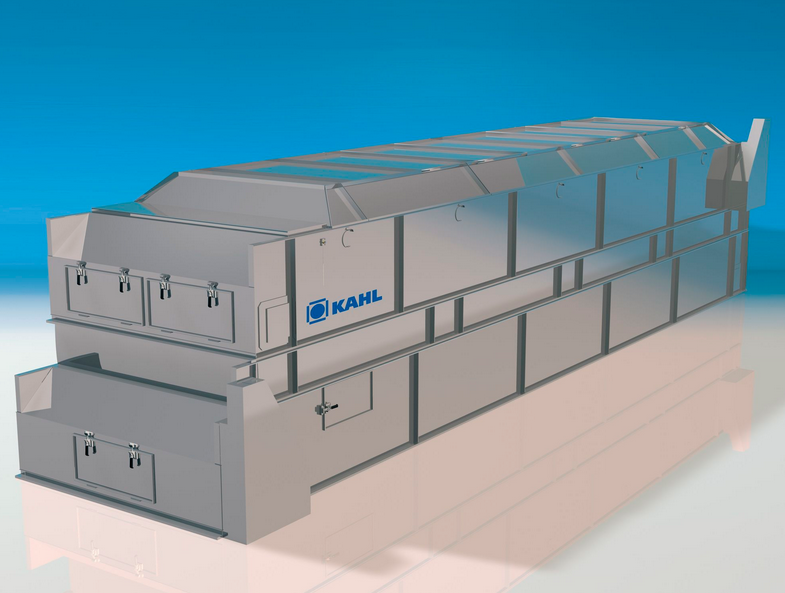

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...