Industrial Milling Equipment

Find innovative milling equipment and connect directly with world-leading technology suppliers

Milling machines are used to reduce the size of material by cutting, crushing, or grinding it. The choice of industrial milling equipment depends on the industry and the materials to work with. Besides, there is a significant difference between those aimed to remove layers from metal or other materials workpieces and those designed to reduce particle size for materials that come in bulk.

Innovative milling solutions

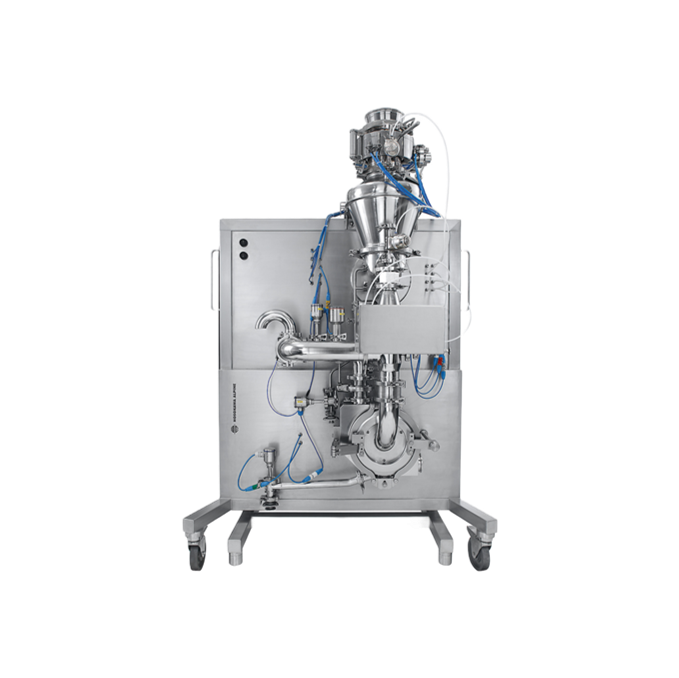

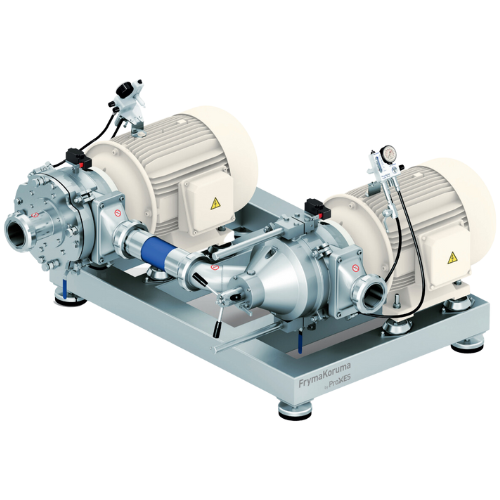

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

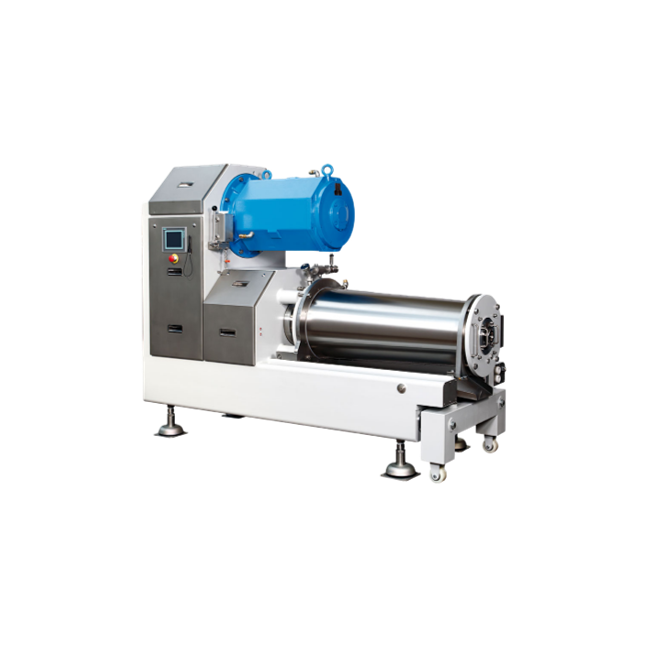

Bead mill for nano-preparation grinding

Achieve precise nano-processing and efficient wet grinding for pharmaceuticals and ...

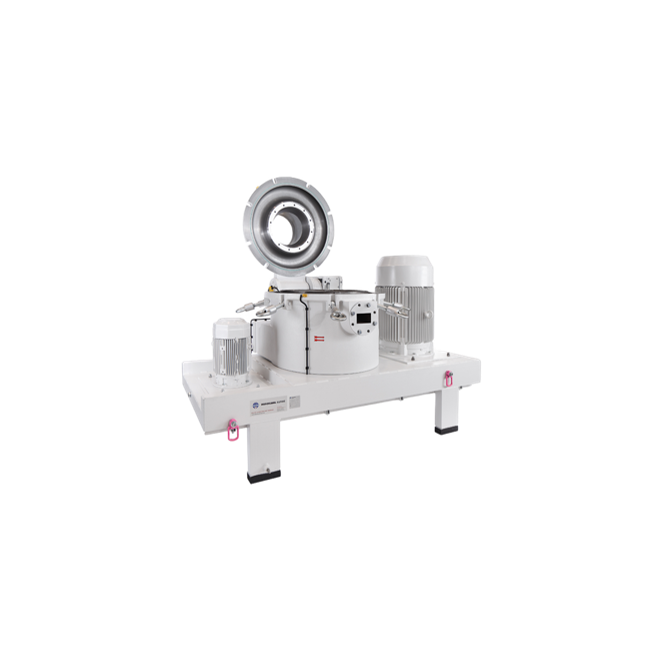

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

Ball mill for chocolate, cocoa, and nut products

Optimize your grinding processes and achieve perfect product consistency ...

Two main types of milling equipment for the metal manufacturing industry

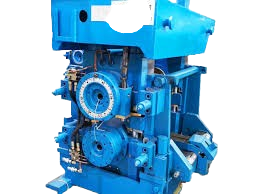

In metal works the mill equipment removes material from a metal piece by cutting or shaping it with rotating multi-point cutters. The orientation of the cutters is what makes these machines different. They can move in a horizontal or vertical axe, giving the name to horizontal milling and vertical milling machines, which are the main configuration of these machines. They are suited to precision work and can be manual, semiautomatic, or fully automatic by computerized numerical control (CNC).

With the milling equipment, you can make plane, two-dimensional and three-dimensional surfaces, for many industrial parts.

High-precision machines need cooling while working

These milling machines are very precise in their cuts and shapes, in addition, they give great surface finish thanks to the speed and other variables. The high speed of the cutting tool and the friction between the tool and the workpiece generate heat, being necessary to use a coolant throughout the entire process.

Nowadays the machining centers are full of CNC milling equipment that are more efficient, highly accurate, and safe to use. They are also great for special designs, dimensions, and materials, for micro machining as well as for large and heavy-duty operations. But you can still find manual and semiautomatic technology for low-complexity shapes.

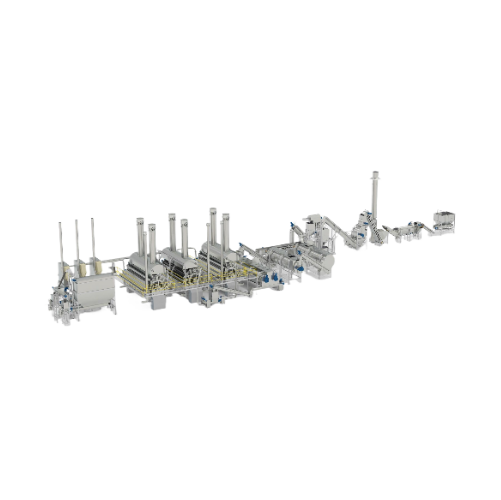

Milling equipment for crushing and grinding bulk material

The milling equipment used for bulk material is designed to crush or grind the different materials to reduce their size in smaller particles, even into powder. You can find milling machines for grains, minerals, wood, composites, and many other materials. Your selection of milling equipment depends on the type of materials you are going to process, and the desired particle size.

Industries such as feed, food, pharmaceuticals, and mining, use mainly hammer mills, roller mills, ball mills, agitated media mills, jet mills, and classifier mills in their processes.

Temperature and speed are important variables to control in the hammer mill

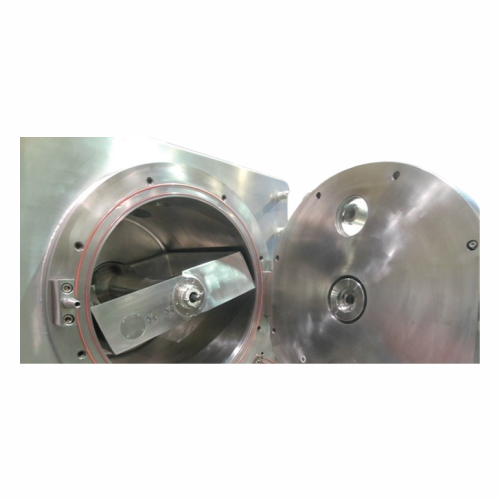

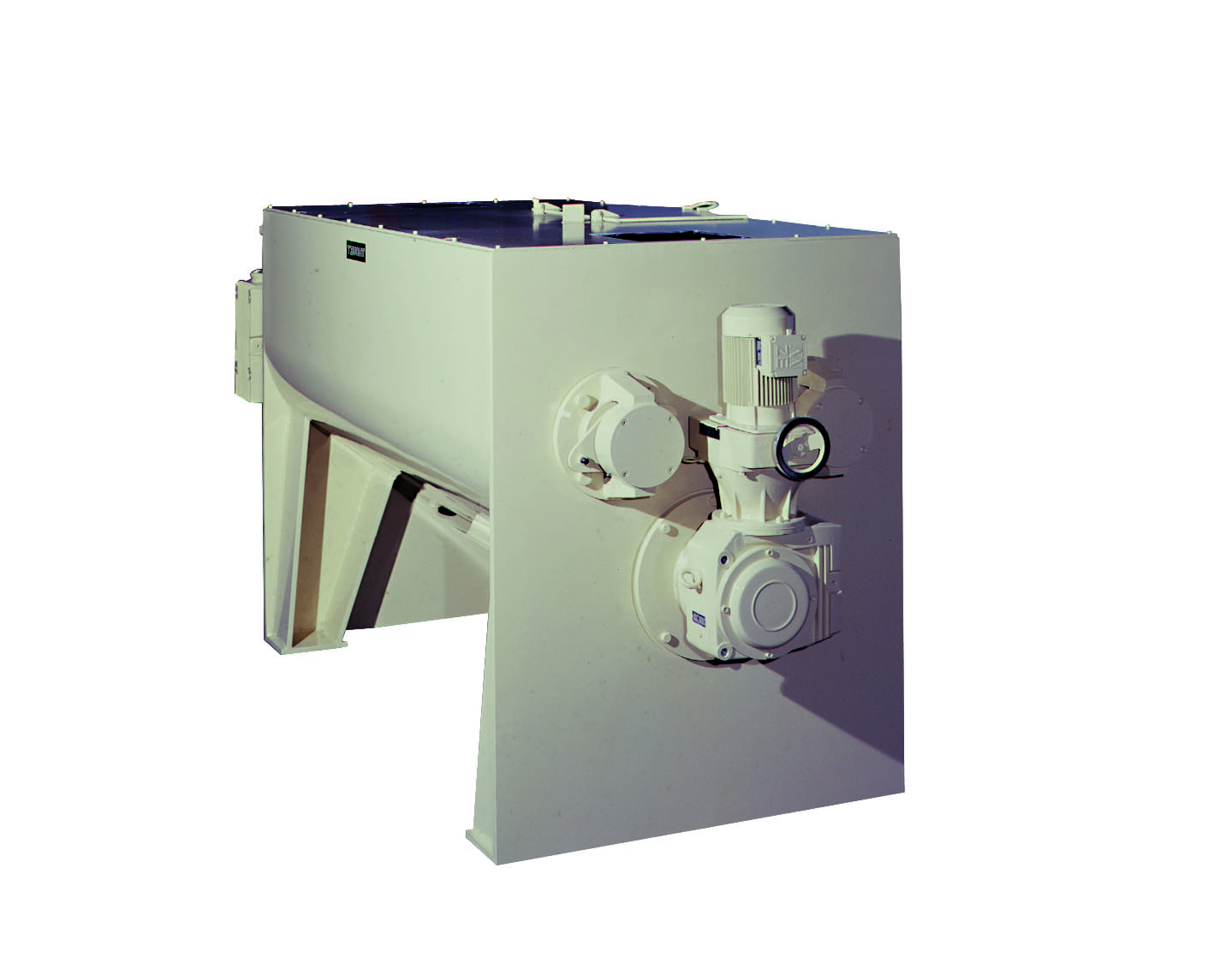

A hammer mill has a horizontal rotor with a shaft that contains hammers, also called blades or knives. These are the elements that crush or grind the bulk material, that rotates with a speed that is settled according to the material that is being processed. This machine also contains a screen that filters the crushed material and ensures that only the particles with the desired size pass through.

The hammer mill needs to have sensors of speed and temperature to keep in good conditions the machine as well as the raw material, moreover to control the variables of the process. Choose a hammer mill with easy access to the chamber to do maintenance and reparations, furthermore replace the hammers frequently to guarantee their sharpness and good state.

This mill equipment is an important part of the process line of feed, food, chemicals, and cosmetics.

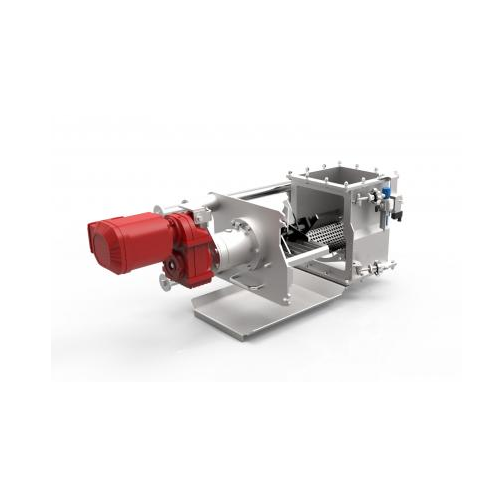

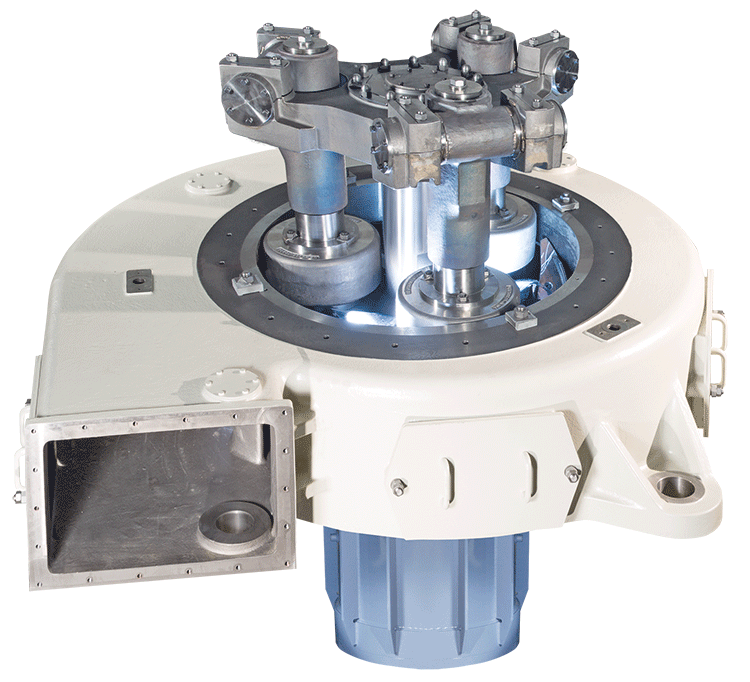

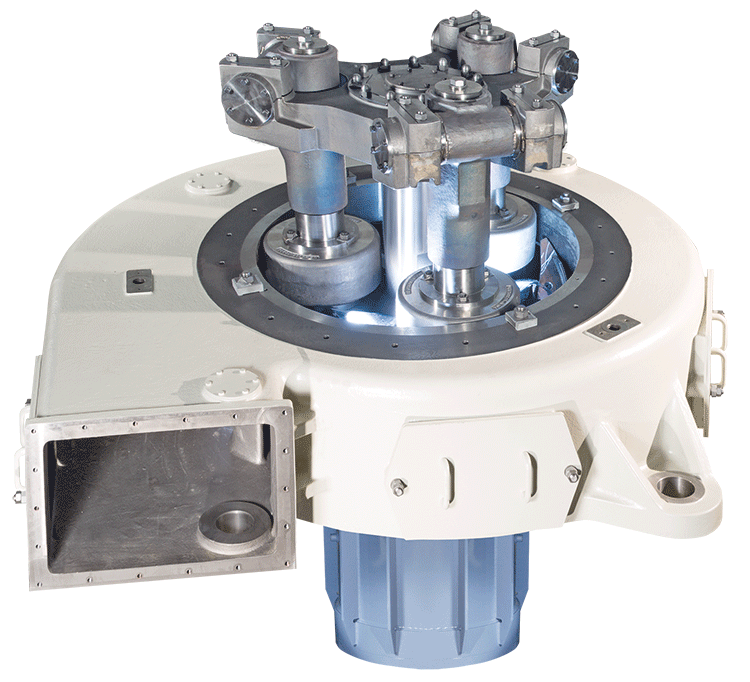

Roller mills need more maintenance but are great for large productions

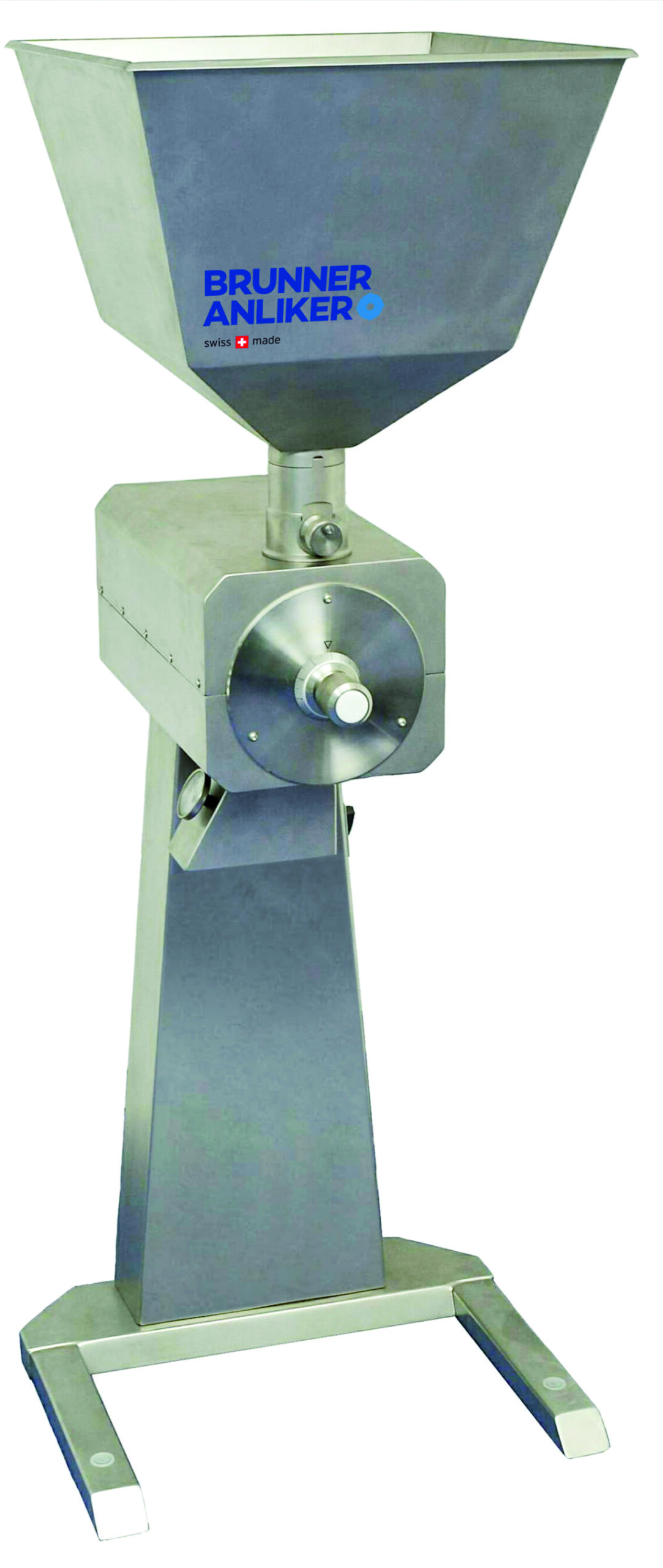

A roller mill has one or more cylindrical rollers or wheels, that rotate to crush or grind the materials by friction. They can be horizontal or vertically oriented. The horizontal roller mills have rollers placed parallel in the horizontal axe, turning in opposite directions and at different speeds, generating pressure and tear between them and the material that passes through. The vertical roller mills have a spinning plate or grinding table with rollers placed in its perimeter, which exerts vertical pressure on the material over the plate.

The roller milling equipment is great to grind grains, cement, clay, rocks, and other minerals. Due to the tear and wear of the rollers, it is important to have regular maintenance and replacement of the rollers, especially if they process abrasive materials. Is also important to adjust the gap between the rollers according to the material and particle size you need.

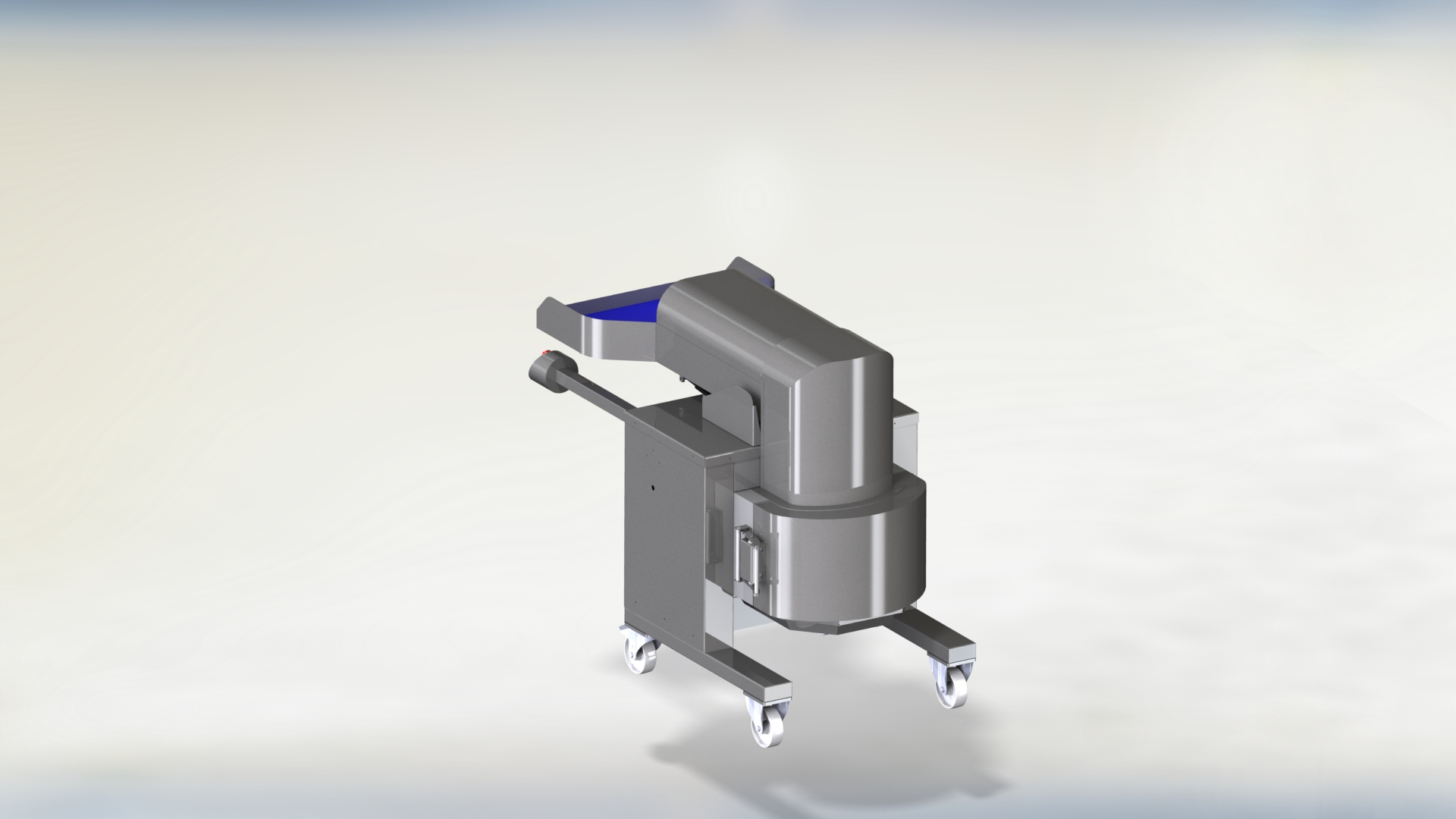

Ball mills should have balls denser and bigger than the material being processed.

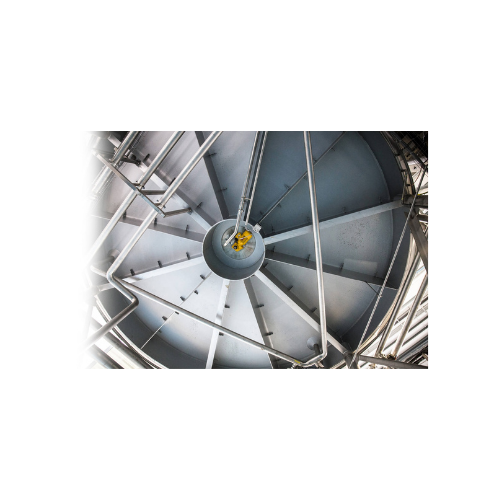

The ball mills have a rotating drum with balls inside that spin around hitting the material as they drop. The impact of the balls against the material reduces the size of the particles. Choose the characteristics of the balls according to the raw material to process, they need to have a bigger size and bigger density than the product being ground. The balls’ material needs to be compatible with the product to avoid contamination, corrosion, or cause an explosion.

This milling equipment is good for turning into powder dry or wet material such as coal, cement, rocks, minerals, ceramics, pigments, and some metals.

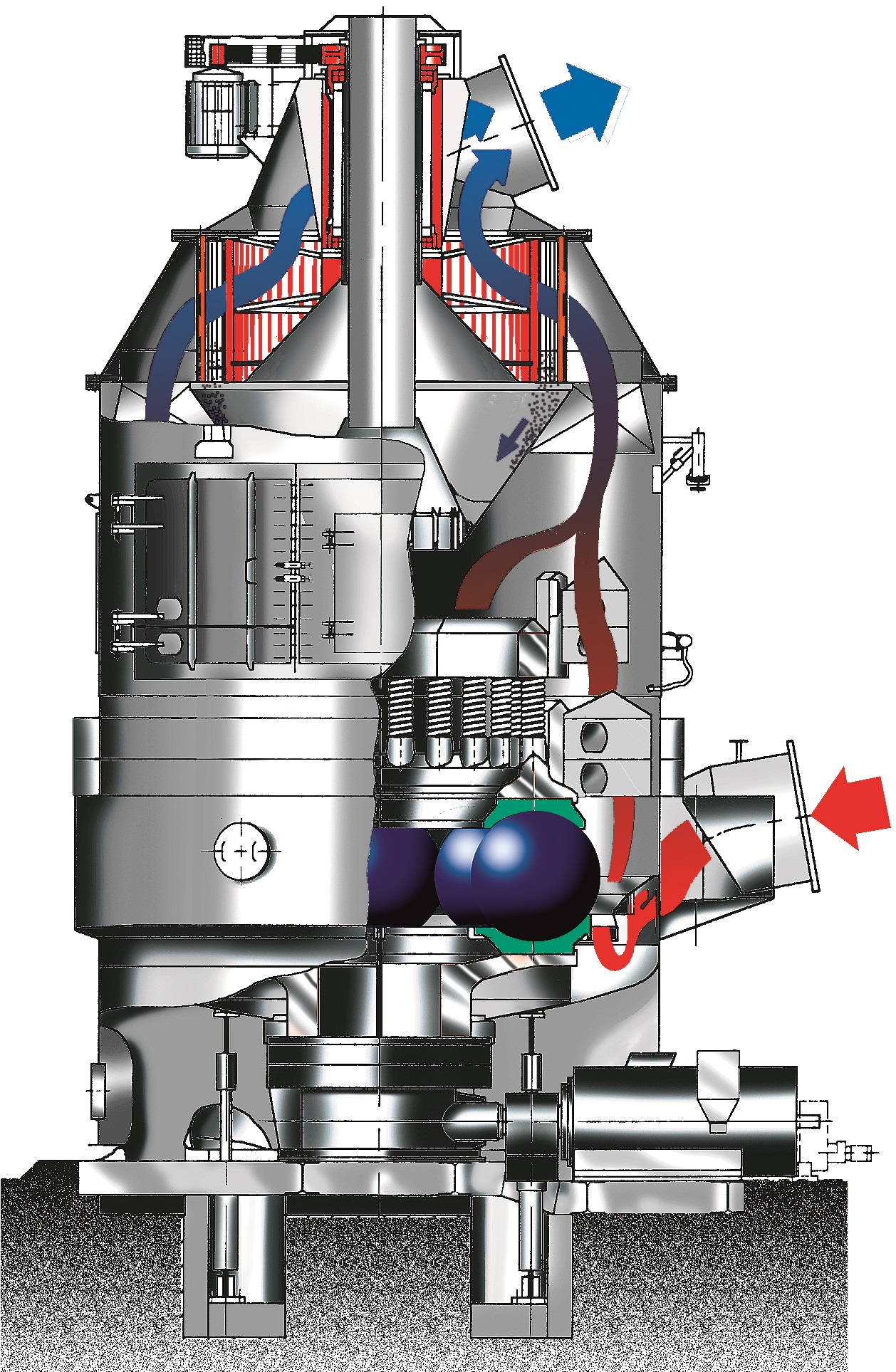

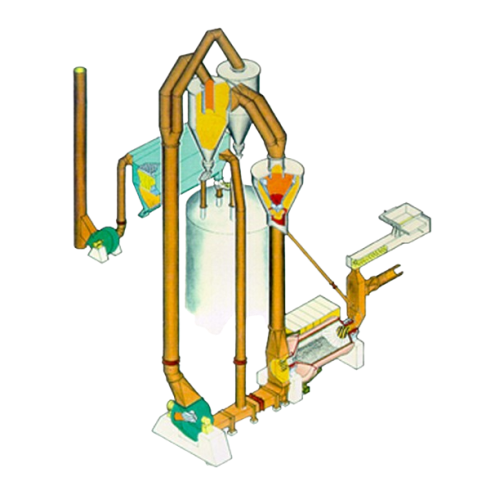

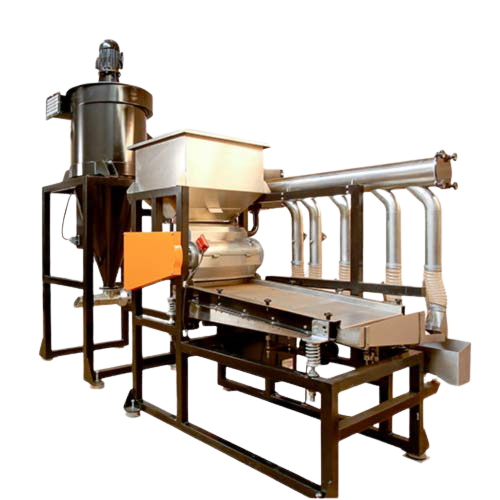

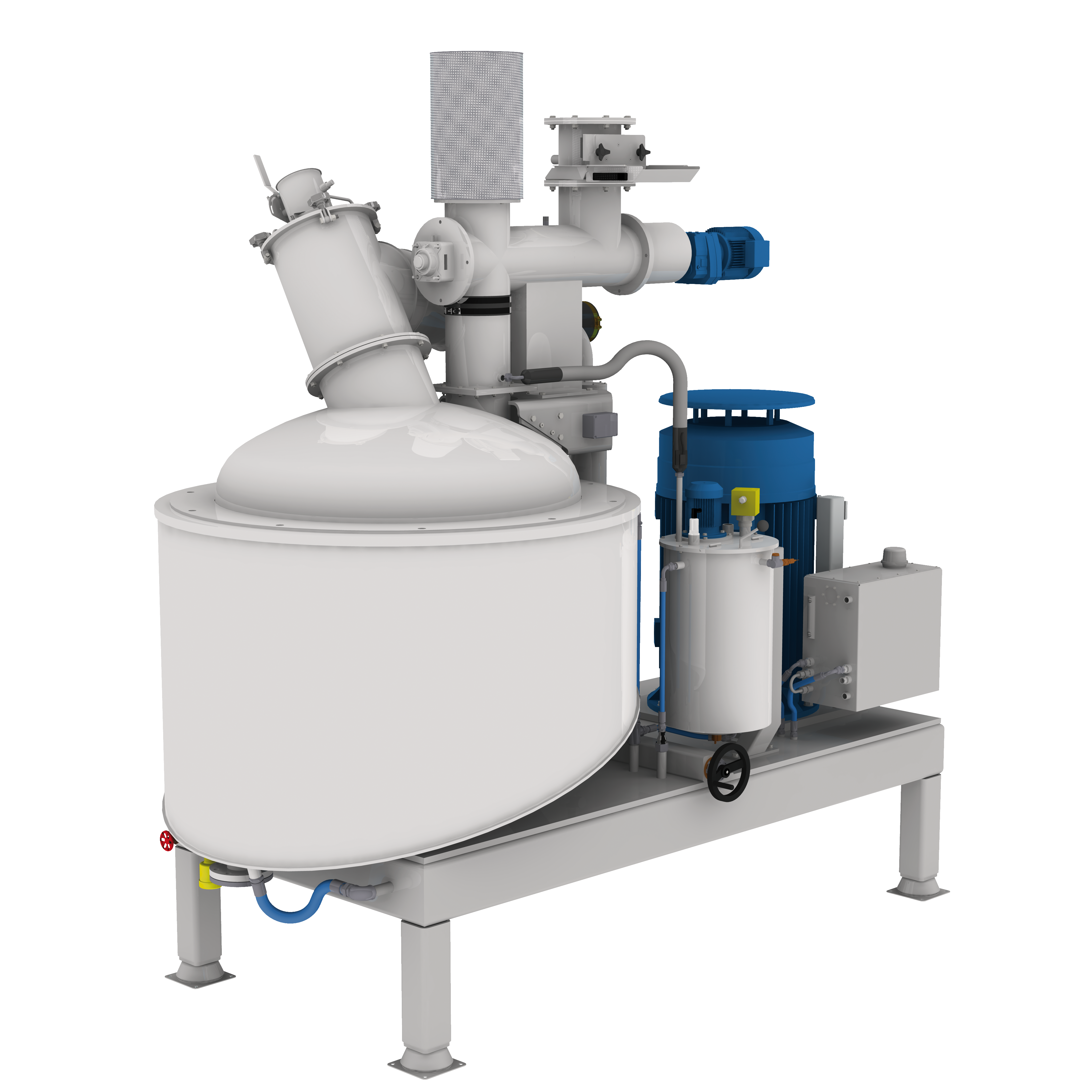

A classifier mill equipment is an impact mill that integrates a particle classifier

The classifier milling system is a mix of an impact mill and a particle classifier. The principle of this milling machine is to reduce the particle size and automatically take out of the grinding zone those particles that have a specific reduced size, the others will come back to the grinding zone until they have the right size. Most of the classifier mills use air to classify the particles.

The classifier milling equipment is commonly used in pharmaceuticals, cosmetics, powder coatings, pigments, and other areas that need fine particles.

What are you making?

Advanced ceramics

Aerospace components

Alfalfa meal

Algae

All-purpose flour

Almond milk

Almonds

Aluminium oxide

Antibiotics

Arborio rice

Bakery flour

Barley

Barley flour

Basmati rice

Bentonite

Bioplastics

Black pepper

Black soldier fly protein

Brewers grain

Carbon black

Cashew milk

Cashews

Catalyst powders

Cement

Chili powder

Chili sauce

Chlorella powder

Chocolate coatings

Chocolate fillings

Chocolate spread

Cocoa beans

Cocoa butter

Cocoa liquor

Cocoa nibs

Cocoa powder

Collagen powder

Compound chocolate

Corn

Corn flakes

Corn flour

Corn grits

Cornmeal

Cottonseed meal

Cricket protein

Curry powder

Decaffeinated coffee

Dispersion paints

Dried distillers grains (DDGS)

Dried meat

Dried oregano

Dry pet food

Durum wheat semolina

Dyes

Excipients

Eyeshadow

Face powder

Feed concentrates

Feed premixes

Filter coffee

Fishmeal powder

Floating pellets

Flour

Fodder

Free-flowing powders

Fruit powder

Fruit puree

Functional flours

Gelatin powder

Gelatine

Ginseng extract

Grated cheese

Green beans

Ground cinnamon

Ground coffee

Gypsum

Halloumi

Hazelnuts

High-potency active pharmaceutical ingredients (hpapis)

Highly Active Pharmaceutical Ingredients

HPMC capsules

Hummus

Hyaluronic acid

Instant coffee

Instant soup

Insulin

Iron

Jam

Jasmine rice

Kaolin

Ketchup

Lavender oil

Lentil flour

Limestone

Lipstick

Liquid Formulations

Lithium-ion batteries

Maize

Malt

Malt extract

Malted barley

Marine algae

Marmalade

Mealworm protein

Meat and bone meal

Metal powder

Metal powders

Metallic powders

Microcrystalline cellulose

Microtablets

Mineral fillers

Multi-layer tablets

Mustard

Nail polish

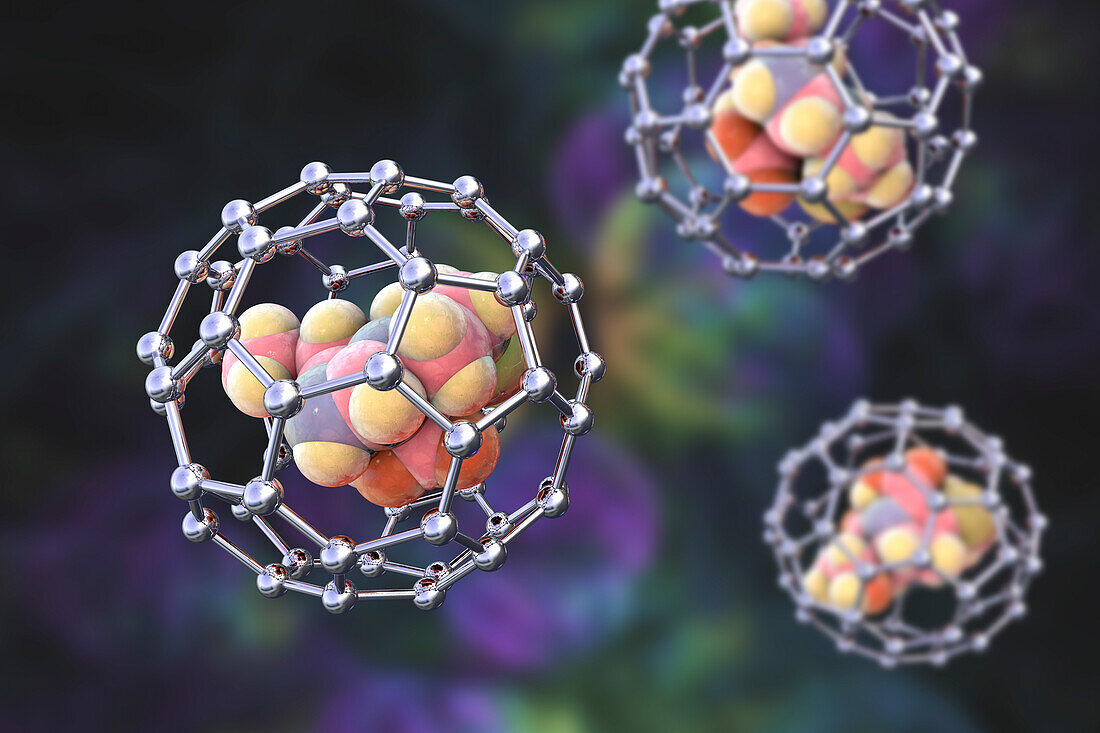

Nanoparticles

Nitrogen fertilizer

Nut butter

Oat bran

Oat flour

Oat milk

Oatmeal

Oatmeal cookies

Ointment

Paint

Paper pulp

Paracetamol

Pea protein isolate

Peanut butter

Peanuts

Pellet fuel

Pelleted feed

Penicillin

Pharmaceutical excipients

Pharmaceutical granules

Pharmaceutical powders

Phosphorus fertilizer

Pistachios

Plant waste

Polymers

Potatoes

Poultry feed

Powder detergent

Protein bars

Protein powder

Pulses

Rice bran

Rice Crispies

Rice flour

Roasted nuts

Rose oil

Rye

Salad dressing

Sea buckthorn oil

Slow sinking pellets

Solid-state batteries

Sorghum

Soy flour

Soy milk

Soybean meal

Soybeans

Spirulina powder

Stock cubes

Straw

Sugar

Sulphur

Synthetic resin

Synthetic rubber

Tahini

Talc

Talc powder

Tea tree oil

Textured Vegetable Protein

Tomato sauce

Toner

Veterinary tablets

Vitamin gummies

Wheat

White cheese

White rice

Wood pellets

Agitated media mills

Ball mills

Bead mills

Beater blade mills

Centrifugal sieving mills

Classifier mills

Colloid mills

Conical mills

Continuous milling solutions

Cracking mills

Cutting mills

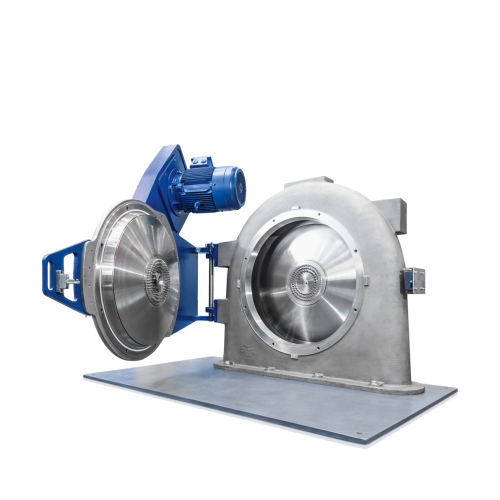

Disc mills

Disk mills

Fine impact mills

Finishing mills

Flaking mills

Grinding mills

Hammer mills

High pressure roller mills

Horizontal bead mills

Immersion mills

Industrial hammer mills

Industrial jet mills

Jet mills

Laboratory mills

Milling beads

Milling equipment

Pellet Mills

Perforated disc mills

Planetary mills

Roller mills

Rotor mills

Size Reduction technologies

Spindle mills

Stone Mills

Table roller mills

Vacuum basket mills

Which milling technology do you need?

Milling system for breweries

Enhance your brewing process with a system that conserves grain husks while optimizing endosper...

Cross beater mill for fine and coarse size reduction

Achieve precise size reduction of medium-hard and brittle materials ...

Ultra centrifugal mill for size reduction of soft and medium-hard materials

Achieve precise particle size reduction an...

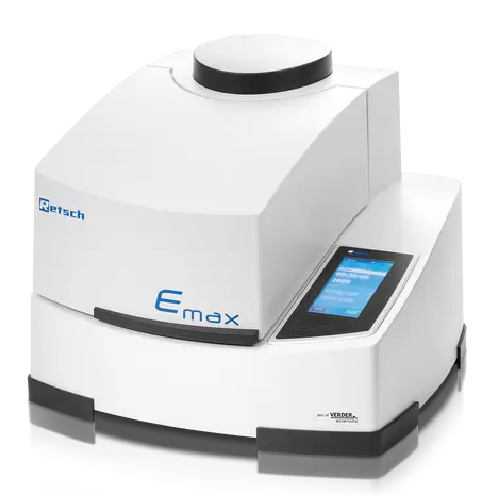

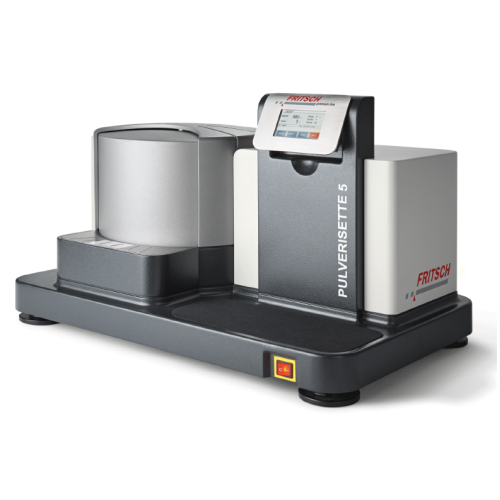

High energy ball mill for ultrafine grinding

Achieve nanoscale precision and unmatched particle uniformity with high-energ...

High-torque cutting mill for tough and fibrous materials

Tackle the toughest materials and ensure consistent particle siz...

Planetary ball mill for high throughput grinding

For precise material engineering, achieve efficient size reduction, homog...

High energy untra fine ball mill

Achieve ultra-fine particle sizes rapidly with this high energy milling solution, designed ...

High efficiency milling solution for pharma and food industries

Achieve precise particle size control and enhance produc...

Conical milling for high-efficiency particle sizing

Maximize efficiency in your production line with conical milling tech...

Production-scale milling and screening system

Achieve precise particle size distribution and high throughput rates with a ...

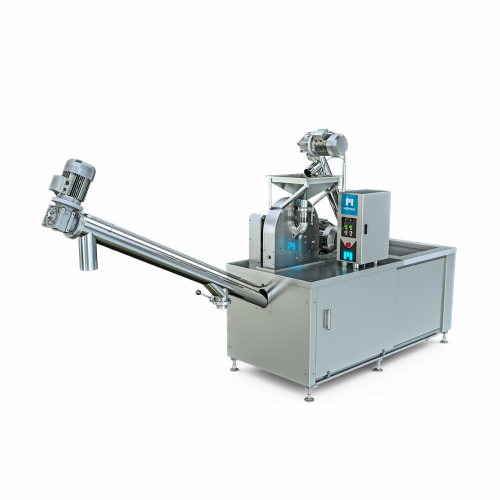

Mid-size milling platform for pilot-scale production

Achieve precise particle size control with this integrated milling s...

Lab-scale milling and processing platform

Effortlessly transition from lab-scale research to full production with a versat...

Conical mill for high-capacity powder milling

Optimize your powder milling process with efficient conical milling systems ...

Atex compliant milling equipment for explosive atmospheres

Ensure operator safety and process integrity with milling equ...

Cone mill for size reduction

Achieve precise particle size reduction and deagglomeration with minimal heat generation, ensur...

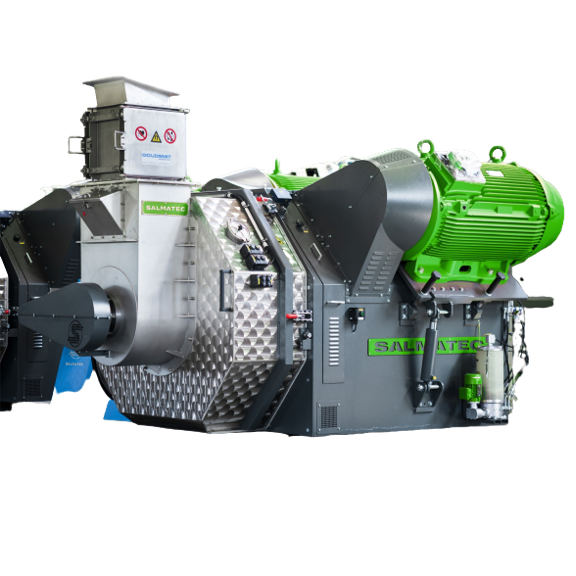

Pellet mill for high efficiency animal feed production

Achieve stable, vibration-free pellet production with enhanced ene...

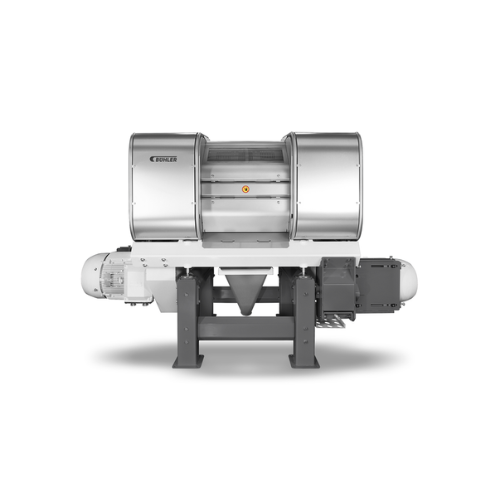

High efficiency roller mill for grain and oilseeds

Optimize your crushing and grinding processes with a versatile roller ...

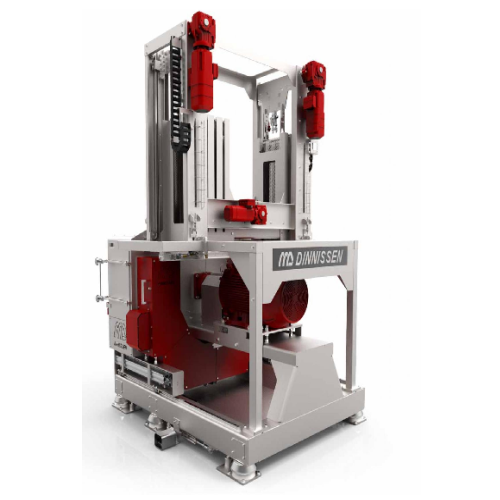

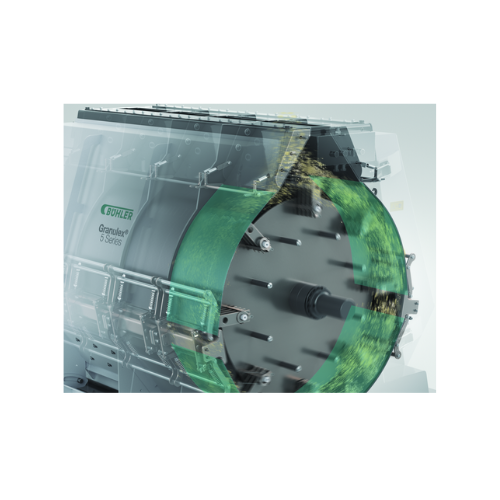

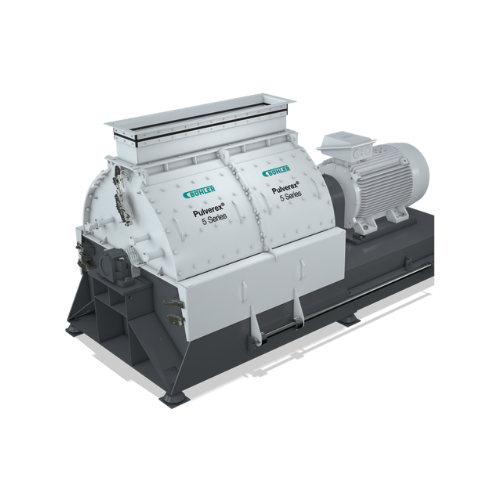

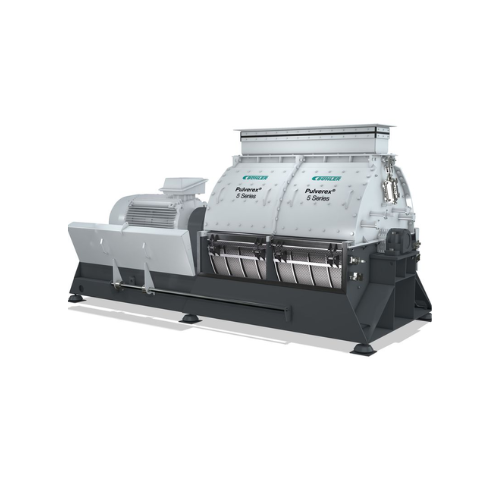

Industrial hammer mill for granulate grinding

Optimize the grinding process in feed production with a high-efficiency solu...

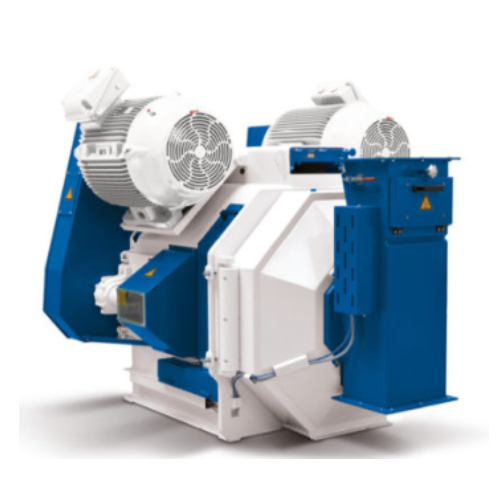

Hammer mill for efficient particle size reduction in feed mills

Optimize your feed milling operations with this hammer m...

Laboratory type ball mill for chocolate and bakery applications

Optimize your R&D processes with precise grinding a...

Industrial sugar powder mill

Achieve precise sugar granulation with a high-speed mill designed for continuous production, en...

Heavy-duty industrial robot for precision milling

Designed for seamless integration in heavy-duty tasks, this robotic sol...

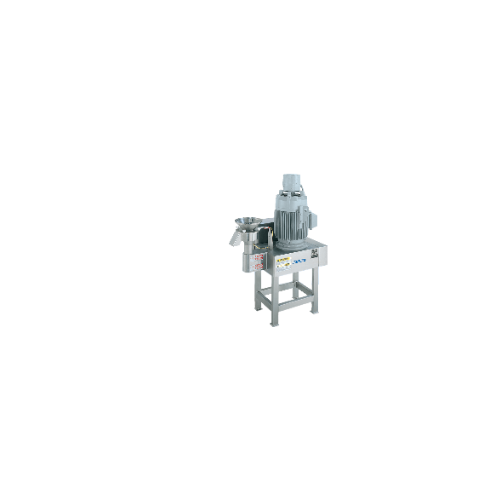

Laboratory mill for dry sample preparation

Achieve precise particle size reduction for pharmaceuticals and fine chemicals ...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

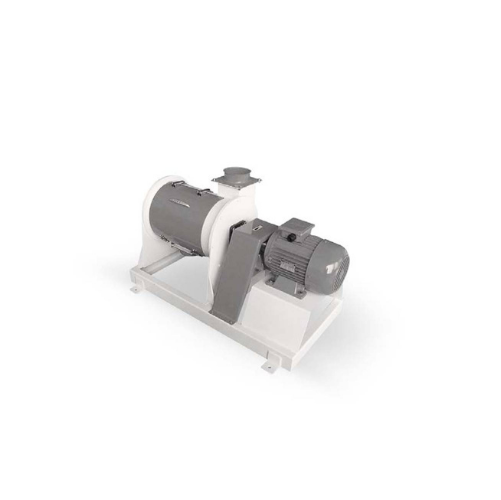

Universal mill for fine grinding in food and pharma industries

Achieve unparalleled particle size reduction with high-pe...

Air classifier mill for ultra-fine powder grinding

Optimize your milling operations with precision particle size control ...

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Cone mill for particle size reduction

For precise particle size reduction, the cone mill offers flexible screening options ...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

Spiral jet mill for ultrafine micronisation

Optimize your powder processing with precision-driven micronisation that ensur...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

High-speed hammer mill for continuous operation

Achieve precise particle size reduction with high-speed hammer milling, id...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Spiral jet mill for superfine powder production

Achieve consistent ultra-fine powder with precise particle size control, c...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Pin mill for fine grinding of sticky materials

Achieve ultra-fine grinding of challenging materials with high speed and pr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

Dry grinding mill for superfine products

Achieve high fineness in your comminution processes with this advanced dry grindin...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

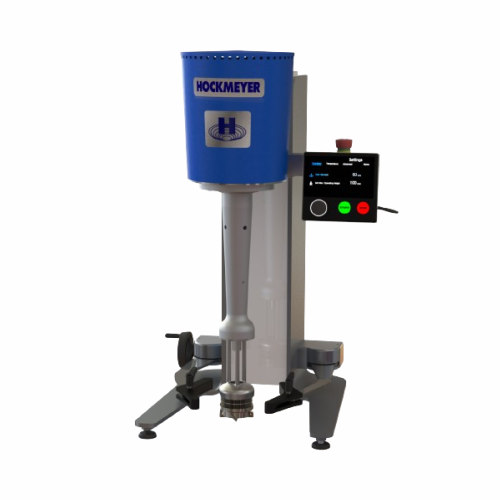

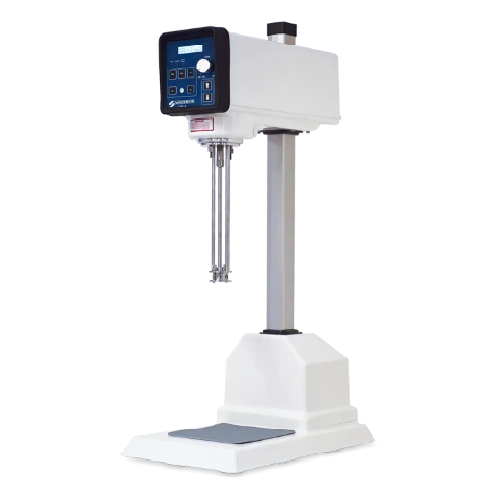

Lab and pilot scale immersion mill

Maximize process efficiency with a compact immersion mill designed for precise milling, ...

Lab-scale disperser and immersion mill

Achieve precise dispersing and milling with rapid changeover capabilities, ideal for...

Laboratory vacuum milling for fine particle size reduction

Streamline your lab and pilot processes with high-speed vacuu...

Vacuum recirculation mill for particle size reduction

Achieve precise particle size reduction and eliminate air entrapmen...

Immersion mill for pail and drum-sized batches

Streamline your production with a versatile solution that efficiently handl...

Immersion mill for particle reduction

Achieve streamlined particle size reduction and enhanced mixture homogeneity with imm...

Immersion mill for lab to production scaling

Achieve consistent quality from lab to production with precision milling, mix...

Nanoparticle production immersion mill

Achieve precise nanoparticle production with immersive milling that enhances materia...

Immersion mill with sweep blade for high-viscosity products

Optimize your production line with this immersion mill desig...

Particle sizing solution for milling and sifting

Streamline your milling and sifting processes with a flexible system desi...

Conical mill for particle size reduction

Achieve precise particle size control and reduce thermal stress on materials with ...

Conical mills for size reduction in pharmaceutical production

Achieve precise particle size control with an innovative m...

Over-driven conical mills for precise particle size reduction

Achieve consistent particle size reduction with minimal he...

High capacity conical mill for powder processing

Optimize your milling process with a versatile solution that ensures prec...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

High-speed cutting mill for versatile material comminution

Efficiently transform diverse materials like plastics, textil...

Cutting mill combination for heterogeneous material reduction

Achieve precise size reduction and material separation in ...

Laboratory knife mill for fast comminution

Achieve rapid and precise sample preparation with this versatile knife mill, de...

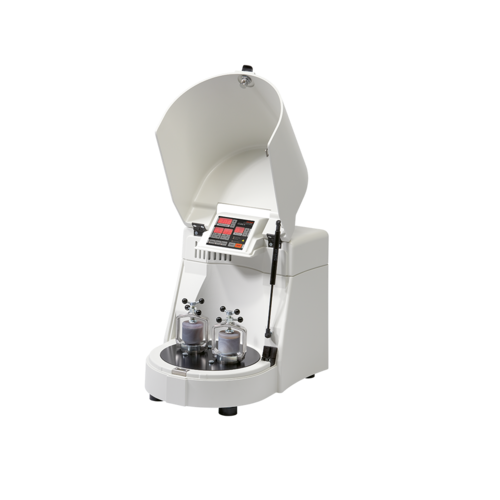

Planetary mill for nano grinding

Achieve precise nano-scale particle production and uniformity for demanding research enviro...

Planetary micro mill for fine comminution

Achieve unparalleled precision in micron-level materials processing with this co...

Variable speed rotor mill for sample preparation

Achieve rapid and precise grinding of various materials with a versatile ...

Vibratory micro mill for fine comminution

Achieve precise particle size reduction and homogeneity for medium-hard to britt...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

Conical screen mills for powder calibrating

Achieve precise particle size distribution for your powders and granules with ...

Conical mill for particle size reduction and homogenization

Achieve precise particle size reduction and homogenization w...

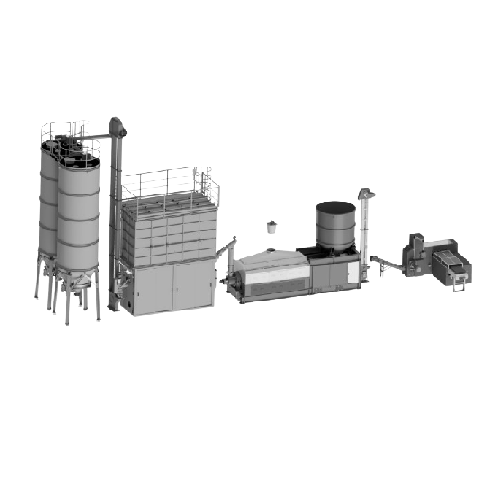

Malt transport and milling system for breweries

Streamline your brewing process with advanced malt transport and milling s...

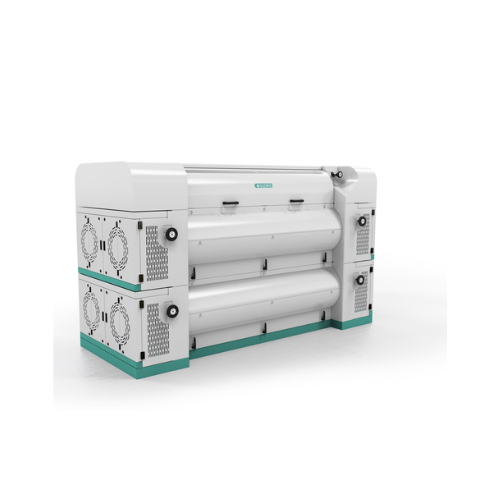

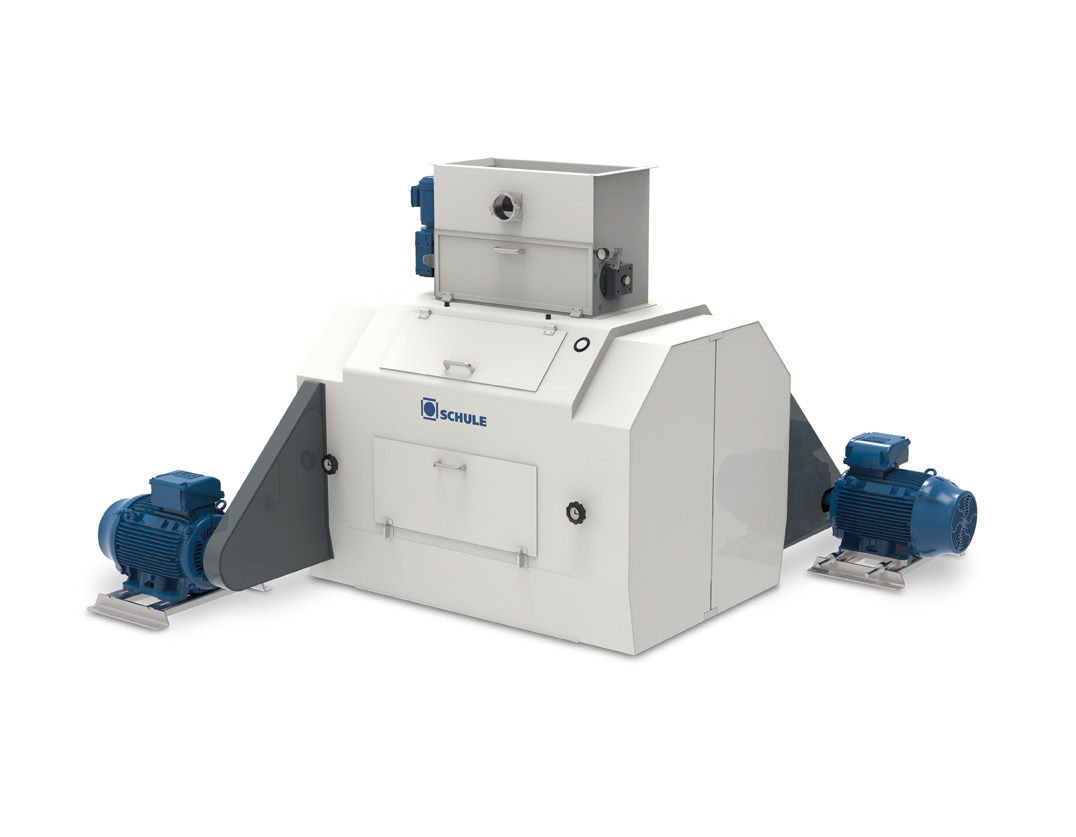

Industrial roller mill for grain size reduction

Achieve precise grain size reduction with minimal heat generation and opti...

Hammer mill with automatic screen exchange

Optimize your milling operations with a high-speed solution that ensures seamle...

Industrial hammer mill for grinding and sifting

Ensure precise particle size reduction and consistent product quality with...

Centrifugal mill for fine grinding in industrial processes

Achieve exceptional fineness without overheating your materia...

Milling flash dryer for fine powder processing

Achieve precise moisture control and prevent agglomeration in your processi...

Efficient barley malt crushing with roller mills

Achieve precise particle size control in your processing line with a robu...

Industrial roller mill for barley malt crushing

Ensure precise barley malt crushing with minimized maintenance for enhance...

Small-scale pellet mill for animal feed production

Achieve precise pellet formulation for diverse feedstocks with an effi...

Pellet mills for feed, plastics, and industrial products

Optimize pelleting output across diverse materials with precisio...

Hammermills for grinding tough products

Optimize particle size reduction with precision-designed hammermills that efficient...

Laboratory cone mill for even grinding

Achieve consistent particle size for laboratory powders with precision calibration a...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

Vertical hammer mill for feed and grain processing

Optimize your milling operations and improve energy efficiency with th...

Industrial three-roll mill for high-quality grinding

Achieve unparalleled precision in grinding and dispersing with our a...

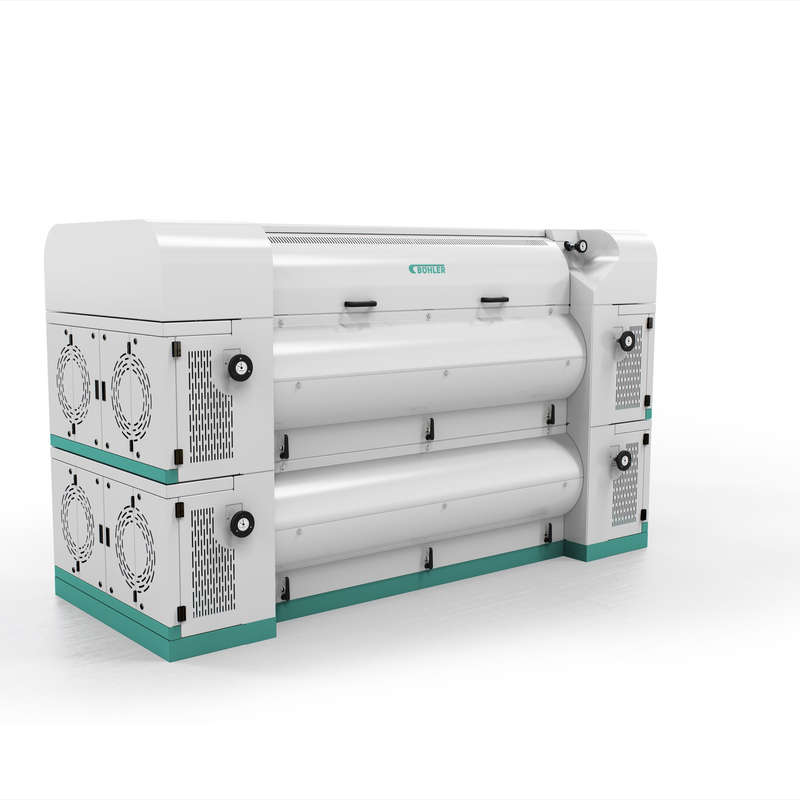

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Grain sifter for milling applications

Optimize your grain processing by efficiently sifting and sorting a variety of produc...

Grist mill for craft and small breweries

For breweries seeking precision grinding, this compact grist mill excels in millin...

Grain purifier for wheat and corn milling

Optimize grain processing with a high-throughput purifier designed to enhance pu...

Flaking mill for grain and cereal production

Achieve consistent flake thickness and high throughput with advanced roller t...

Hammer mill for fine grinding in food and feed industries

Achieve exceptionally fine particle-size distribution with a h...

Ball mill for chocolate, cocoa, and nut products

Optimize your grinding processes and achieve perfect product consistency ...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Grist mill for craft breweries and distilleries

Optimize your brewing and distilling efficiency with a compact, high-speed...

Moisture control system for grain milling

Optimize moisture levels precisely within your grain milling process, ensuring c...

Impact machine for milling applications

Optimize your grain processing with this versatile impact machine, designed to refi...

Horizontal hammer mill for grain processing

Optimize your grinding processes with our horizontal hammer mill, designed to ...

Industrial hammer mill for size reduction in food and feed processing

Achieve precise grinding and milling for diverse ...

High-throughput hammer mill for animal feed production

Ideal for high-throughput operations, this hammer mill ensures pre...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Flaking mill for oilseeds

Achieve consistent, high-throughput flake production with precise thickness control, ideal for enh...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Roller mill for wheat and grain milling

Achieve consistent and high-quality grain milling with this robust, operator-friend...

High-performance cracking mill for oilseeds

Optimize your oilseed processing with a versatile mill designed to enhance eff...

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and m...

High-performance bead mill for wet grinding and dispersing

Optimize your production line with a bead mill designed for e...

Purifier for semolina and middlings in grain mills

Upgrade your milling efficiency with a high-speed purifier that ensure...

Cracking mill for oilseeds and feed processing

Maximize your production efficiency with advanced cracking and milling solu...

Hammer mill for size reduction in food and feed processing

Efficiently tackle size reduction challenges with a versatile...

Hammer mill for animal feed grinding

Achieve precise granulation with high throughput and energy efficiency, while reducing...

Grinding mill for apple and pear mash

Optimize your fruit and vegetable processing with a high-speed, energy-efficient grin...

Grinding mill for apples and pears

Optimize juice yield with tailored grinding for a variety of fruits and vegetables, ensu...

Laboratory grain milling system

Achieve precise grain milling and sample preparation with high-speed capability and gentle t...

Rotary mill for tough and fibrous materials

Achieve precise material reduction with our Rotary Mill, ideal for transformin...

Industrial sample preparation mill

Ensure precise moisture, protein, and fat content analysis with this reliable milling so...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Jet mill for micronizing pharmaceutical powders

Achieve precise particle size reduction with a jet mill that leverages hig...

Mill sifter for precise bulk density and particle size distribution

Achieve precise particle size and uniform bulk dens...

Inline wet mill for mayonnaise emulsions

Eliminate the challenges of achieving stable, uniform emulsions in your sauces and...

Stoneless corn masa mill for snack food processing

Achieve consistent grinding precision while eliminating the hassle of ...

Grist milling unit for breweries and distilleries

Optimize your milling process with a versatile unit capable of handling...

High-performance mill for paint and varnish industry

Achieve superior fine dispersing and grinding efficiency for liquid ...

Milling beads for wet grinding in paint industry

Enhance product uniformity and grinding efficiency with specialized milli...

Vacuum basket mill for high-viscosity product processing

Achieve exceptional fine milling results while preventing air in...

Vacuum basket mill for high viscosity products

Achieve efficient fine grinding of high-viscosity products while minimizing...

Explosion-proof bead mill for industrial grinding applications

For manufacturers seeking precise particle size control, ...

Explosion-proof horizontal bead mill for paint production

Ensure ultra-fine particle size and consistent quality with an...

Explosion-proof horizontal bead mill

For manufacturers seeking precise particle sizing, this explosion-proof bead mill ensu...

Horizontal bead mill for industrial production

Ensure ultra-fine particle size reduction in high-demand processes with thi...

Horizontal bead mill for fine grinding in continuous process

Achieve ultrafine particle dispersion and consistent mixing...

Horizontal bead mill for ultrafine particle grinding

Achieve precision in ultrafine grinding with a system that allows fo...

Horizontal bead mill for industrial nano grinding

Achieve precision in nano-scale grinding with this advanced bead mill, ...

Modular basket mill for industrial dispersion

Effortlessly enhance your production efficiency with this versatile solution...

Industrial basket mill for medium viscosity products

Achieve precise particle size reduction and rapid pigment dispersion...

High-efficiency immersion mill for medium viscosity products

Achieve precise particle size reduction and superior disper...

High-efficient industrial immersion mill

Achieve rapid, efficient dispersion and fine grinding in demanding production envi...

Vacuum basket mill for highly viscous products

Achieve precision in fine milling under vacuum to prevent air inclusions in...

Vacuum basket mill for high-viscosity product milling

Achieve refined particle size and smooth texture in your high-visco...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Explosion-proof basket mill for fine grinding

Achieve efficient and safe fine grinding with this innovative explosion-proo...

Explosion-proof immersion mill for paints and varnishes

Optimize high-performance coatings production with an explosion-p...

Explosion-proof basket mill for large scale production

Enhance your production line with an explosion-proof basket mill t...

Explosion-proof horizontal bead mill for fine grinding

Ensure precise, explosion-proof grinding in hazardous environments...

Laboratory bead mill for sample dispersion

Ensure precise particle size reduction with versatility and ease, enabling effi...

Laboratory and pilot plant horizontal bead mill

Achieve precision milling with minimal product waste, ensuring consistent ...

Nano bead mill for laboratory wet grinding

Achieve ultra-fine particle dispersion and consistent milling results with this...

Corn wet milling plant drying systems

Optimize corn processing efficiency with integrated drying and dewatering systems des...

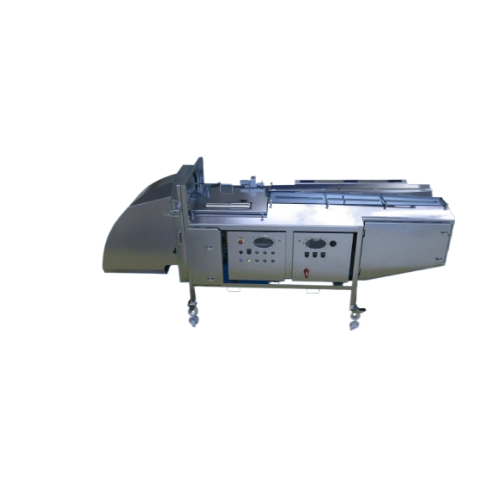

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Vibro bran finisher for milling operations

Optimize your grain processing with an advanced vibratory system designed to en...

Industrial roller mill for high-stability milling

Optimize your milling process with a high-speed roller system designed ...

Double deck roller mill for grain milling

Achieve superior milling results with increased efficiency and hygiene in proces...

Turbo sifter for milling processes

Optimize your milling efficiency with a high-speed turbo sifter designed to precisely se...

Maize flour and semolina milling solution

Efficiently transform corn into diverse food products by combining precision cle...

Hammer mill for grinding dry or low-moisture grains

Efficiently transform dry grains into high-quality feed and flour wit...

Industrial hammer mill for food industry grinding

Efficiently reduce raw material size with high-speed precision grinding...

Hammer mill feeder for controlled grain processing

Optimize your feed production line with precise material control, redu...

Jet milling system for super fine particle size reduction

Achieve ultra-fine particle sizes with precision milling techn...

Atex approved hammer mills for high-capacity particle size reduction

Ensure precise and reliable particle size reductio...

High accuracy hammer milling for precise particle size reduction

Achieve precise particle size control to enhance produc...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Pilot-scale milling and screening platform

Achieve precise powder consistency and integrity with flexible milling and scre...

Industrial powder milling solution

Achieve precise particle size control and improve material flowability with this advance...

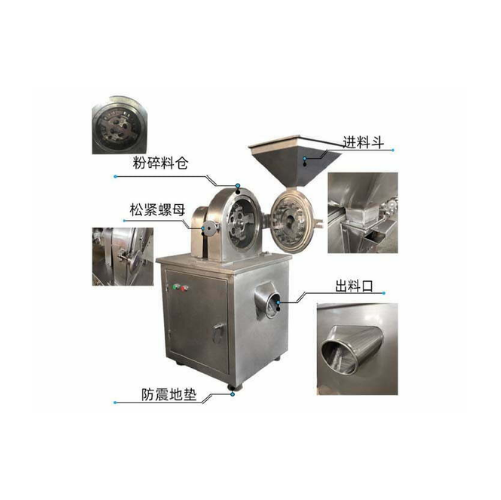

Chili powder milling machine

Transform raw spices into finely milled powders effortlessly with this high-speed grinding solu...

Sub-micron particle size reduction grinding mill

Achieve precise particle size reduction effortlessly with advanced vibrat...

Industrial hammermill for fine grinding applications

Elevate your milling efficiency with hammermills designed for precis...

Colloid mill for particle size reduction and emulsification

Achieve precise particle size reduction and stable emulsions...

Wet granulation co mill for pharmaceutical formulations

Optimize your manufacturing process with precise particle size re...

Lead oxide mill for battery production

Optimize your lead-acid battery production with chainless technology, ensuring consi...

Industrial grinding mill replacement parts service

Optimize production efficiency with high-precision grinding solutions ...

Vertical ring-roll mill for pulverizing minerals

Achieve precise particle size control and efficient material processing w...

Agitator bead mill for flow chemistry

During the early stages of synthesis, generating only limited product quantities can ...

Bead mill for crop protection

To optimize qualities like particle size, distribution, solubility, and miscibility of active ...

Flexible laboratory bead mill for vaccines

For precise, efficient, and reproducible cell disruption, optimization of proce...

Agitator bead mill reactor for molecular synthesis by mechanochemistry in continuous flow

To achieve cleaner, safer,...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Ultra fine bead mill for nanosuspensions

Ensuring the quality, efficiency, and reproducibility of nanosuspensions throughou...

Self-cleaning bead mill for highly viscous materials

To prevent blockages, clogging, and cross-contamination coming from ...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Horizontal disc bead mill for liquid chemicals

Processing toxic chemicals requires high compliance with safety standards a...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Ultrafine bead mill for battery materials

To facilitate the attainment of ultrafine particles and enhance electrode proper...

Flaking roller mill for oats

Consistent flake size is one of the main contributors to processed oat quality. But producing a...

Industrial pellet mill

At the industrial level, the application areas of pellets range widely in fields such as feeds, biomas...

Production scale jet mill

Large volume manufacturers demand the most out of their production process, including powder milli...

Jet mill micronizer

Small scale manufacturers that require effective micronization of powders for their process lines may nee...

Pilot scale jet mill

In a pilot scale level or preliminary study, all the production process steps have to satisfy the small ...

Laboratory jet mill

Manufacturing small quantities of high-value products requires efficient machines that can process these ...

Jet mill for clinical trials

R&D laboratories may need to reduce the size of powder particles in small quantities for cl...

Roll mill for coffee beans

When you want flexibility to grin beans for filter coffee to Turkish coffee at particle sizes ran...

Vertical ball mills for chocolate refining

Powders of extremely high fineness can easily be produced with ball mills and a...

Industrial fine milling equipment for nuts

In a bakery environment fruit jams are often used for the decoration or filling...

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain ...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Horizontal ball mill for chocolate refining

Powders of extremely high fineness can be produced with ball mills and agitate...

Chocolate laboratory ball mill

The ball mills are a type of grinder, with a cylindrical shape, used in the process of grindi...

Batch chocolate machine with vertical ball mill

To mix and refine cocoa liquor, cocoa powder, sugar, and lecithin, several...

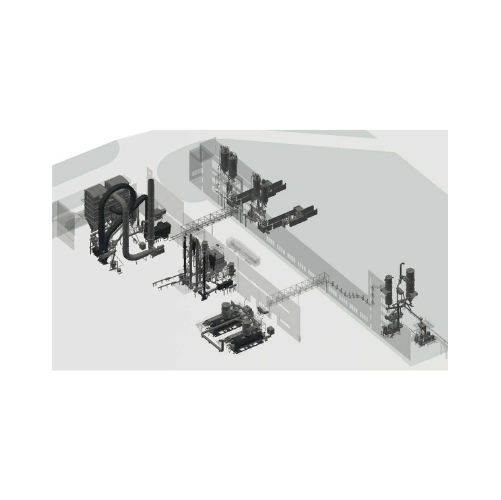

Continuous chocolate line with horizontal ball mills

For mixing and refining cocoa liquor, cocoa powder, sugar, and lecit...

Batch chocolate line with horizontal ball mill

To mix and refine cocoa liquor, cocoa powder, sugar, and lecithin, several ...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Benchtop mill for ointments

Pharmaceutical and cosmetic creams, ointments, gels and pastes can deliver a wide range of activ...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Horizontal rotary ball mill drum

A horizontal rotary ball mill drum can be used for grinding of dry hard materials, such as ...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

Conical mill for drug formulation

The efficient size reduction of granular powders is a key step in many pharmaceutical pro...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Hammer mill for coffee beans

Being able to obtain an on-point grinding is easily achievable with these hammer mills, from co...

Stone mill for coffee beans

Traditional milling of coffee beans or seeds, with a stationary bedstone and a turning runner st...

Vertical agitated dry media mill

A vertical agitated media mill is used for grinding ultrafine particles, in an agitated (or...

Mill for calcining gypsum

Quality of gypsum and stucco products are highly influenced by the quality of the calcining proces...

Versatile stone mill machine

In the food industry, when it comes to milling a wide range of products such as seeds and nuts ...

Craft brewhouse for medium to large breweries

Achieve unparalleled brewing flexibility and efficiency with a brewhouse tha...

Oat milk processing plant

Transform whole oats into creamy, nutritious oat milk with precision, leveraging advanced continuo...

Nuts flour production system

Enhance your nut processing efficiency by transforming whole nuts into fine, consistent flour w...

Laboratory refiner/conche for chocolate processing

For chocolate producers seeking precise control over texture and flavo...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

Single-pot granulation processor for pharmaceutical applications

For manufacturers needing precise granulation and dryin...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

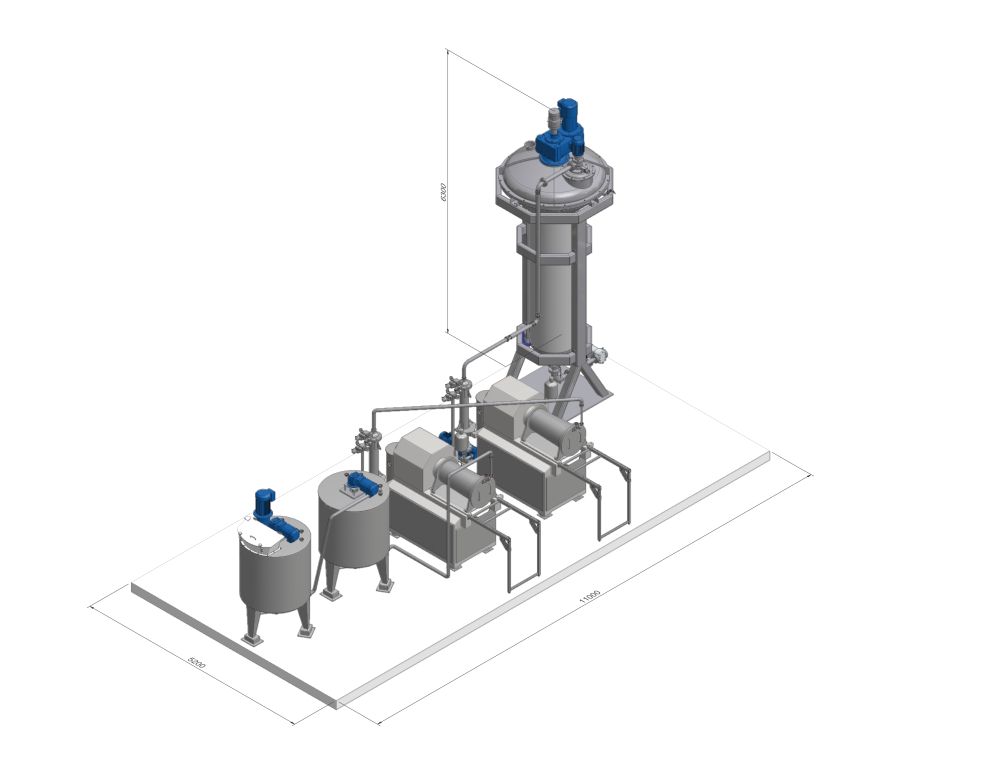

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

Pre-breaker for initial material size reduction

Efficiently prepare your bulk materials for further processing by swiftly ...

Industrial lump breaker for compact material deagglomeration

Efficiently deagglomerate compacted materials to enhance fl...

Pharmaceutical size reduction shredder

Achieve fast, efficient material size reduction with this shredder, enabling seamles...

Rotary vacuum paddle dryer for pharmaceutical ingredients

Ensure precise moisture control and efficient drying for sensi...

Compact machining center for high-precision manufacturing

Achieve unparalleled precision and speed in metal machining wi...

Flex-bräu beer brewing system

Achieve high-efficiency beer production with integrated milling, filtration, and energy-saving...

Fast screen exchange grinding solution for medium-hard products

Maximize your milling efficiency with a solution that al...

Industrial breaker for reducing large lumps and agglomerates

Efficiently break down challenging materials with a robust ...

Hygienic industrial grinder for food and pharma applications

Achieve optimal hygiene and efficiency in your grinding pro...

Oilseed cracking solution

Maximize throughput with precision cracking, ensuring optimal downstream processing for oilseed pr...

High-capacity rice whitener

Achieve uniform whiteness and optimal rice quality effortlessly with advanced vertical whitening...

Sunflower seed dehulling system

Experience efficient dehulling for high-yield sunflower seed processing, enhancing kernel qu...

Automatic rice whitening solution

Need consistent rice whiteness and bran removal without manual intervention? This high-sp...

Vertical rice whitener

Optimize rice and grain outputs with high-yield vertical whitening technology, designed to preserve pr...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Vertical pearler for durum wheat and pulses

Optimize your grain and pulse processing with this high-efficiency pearling te...

Pulverizer for fine grinding applications

Achieve optimal particle size distribution and enhance throughput with this adva...

Bran finisher for wheat and rye

Enhance your milling efficiency by separating finer flour from bran with ease. This compact ...

Grain product plansifter

Optimize your grain processing with a magnetic drive plansifter that efficiently sifts and sorts a d...

Bran finisher for efficient flour and bran separation

Optimize your grain processing efficiency with a solution designed ...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

Flexible isolator for aseptic containment

Ensure sterility and safety with a flexible isolator designed for efficient cont...

Dry granulation technology

Achieve precise control over particle size and density with our compacting and granulation soluti...

Pharmaceutical roller compactor

Achieve consistent granulate quality with optimized compacting processes, ideal for transfor...

Scrap grinding system for reprocessing dry pasta

Efficiently reprocess dry pasta into reusable flour and dough, minimizing...

Wet grinding system for coffee flavor preservation

Achieve unparalleled coffee flavor and aroma by integrating a low-temp...

Laboratory disperser for high-viscosity products

Optimize your laboratory processes with precise mixing and dispersing of ...

Entry-level vacuum dispersion system for laboratory applications

Achieve precise dispersion and milling with this versat...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Dissolver for mixing and processing in lab and pilot plant

Optimize your material dispersion and homogenization processe...

Slicer for food processing applications

Efficiently achieve precise cuts and textures for a variety of food products, enhan...

Industrial mixer for high moisture content products

Optimize the texture and consistency of high-moisture foods with prec...

Industrial drum detacher for semolina and bran separation

Achieve precise separation of semolina and bran with minimal e...

Flour insect control system

Eliminate pest contamination and preserve flour quality with high-speed larva destruction, ensur...

Industrial impact detacher for semolina processing

Optimize your grain processing line with a solution designed to enhanc...

Turnkey potato flake processing line

Effortlessly transform raw potatoes into high-quality flakes with this integrated line...

Tomato squeezer for efficient food processing

Efficiently transform raw tomatoes and other fruits into smooth sauces and p...

Micronization for pharmaceuticals

Achieve ultra-fine particle size reduction for complex materials, essential when precisio...

Dry granulation system for pharmaceutical powders

Streamline your powder processing with a dry granulation system that en...

Sterile lyophilised filler

Achieve precise weighing and contamination-free lyophilisation with our cutting-edge sterile fill...

Spice and pharmaceutical powder grinder

Efficiently transform raw materials into fine powders, ensuring optimal consistency...

Wet granulation system for pharmaceutical tablets

Optimize your tablet production with precise particle size reduction an...

Wet granulation for pharmaceutical products

Achieve seamless integration of sifting and milling with precise powder handli...

Semi-automatic seaweed grinder for efficient algae processing

Optimize seaweed processing with this stainless steel grin...

Compact wet granulation r&d system

Ensure precise formulation of pharmaceutical powders with a scalable, lab-friendly syste...

Industrial grinding solution for hard and abrasive materials

Efficiently grind and mill a spectrum of materials from coa...

Particle size reduction air conveying system

Achieve precise particle size reduction and contamination-free processing for...

Energy efficient grinder for plant-based milk

Buying pre-processed materials, such as flour, and handling and dispersing t...

Complete pellet line

Large industries are shifting towards more environment-friendly technology, such as recycling wastes and...

Grinding and drying of CaCO3

Widely used in the construction industry as filling materials, calcium carbonate is usually mad...

Grinding and drying of bentonite

After crushing and drying mined bentonite, this clay mineral is usually processed through a...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Blending tank for cosmetic powders

The production of high-quality cosmetics powders requires perfect mixing and dispersal o...

Automatic rework system for biscuit and bread scrap

Scraps are an inevitable byproduct of biscuit and bread production. W...

Five deck cocoa bean winnower

Skin and shell removal from cocoa beans is necessary to produce great tasting chocolate. Compl...

Chocolate refiner with chiller

Milled beans need further reduction in particle size before they can be sent to a conche for ...

Chocolate bean to bar line 10kg

Developing new products, producing specialty chocolates, laboratory testing, and in-shop pro...

Chocolate bean to bar line 200kg

Installing a chocolate production line that works efficiently and smoothly can be a dauntin...

Reclaim crusher

Waste products and rejected materials are inevitably generated from any gypsum products manufacturing process....

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

High-pressure homogenizer for small-scale production

Enhance your liquid formulations with precise particle size reductio...

Benchtop homogenizer for r&d labs

Optimize your lab processes with precision particle size reduction and efficient emulsifi...

High pressure homogenizer for cell disruption and nanoemulsions

Achieve precise particle size reduction and enhanced bio...

Laboratory homogenizer for nanoemulsions and dispersions

Elevate your laboratory capabilities with a bench-top homogenize...

Industrial potato flake production line

Maximize yield and quality in potato processing by integrating advanced pre-cleanin...

Stand dispersing unit for pilot plant applications

Achieve precise particle size reduction and efficient mixing with this...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

High-pressure homogenizers for liquid products

Achieve consistent emulsions and stable dispersions with high-pressure homo...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

Precision emulsification equipment for food industry

Achieve precise comminution and emulsification for diverse food text...

Deagglomerator for consistent particle size reduction

Struggling with inconsistent particle sizes or unwanted lumps in yo...

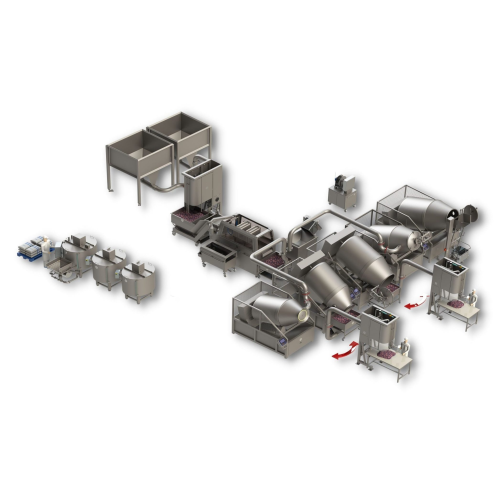

Fully automated meat processing line

Optimize your meat production with a seamlessly integrated line that boosts productivi...

Rotary shear for wood chips and biomass processing

Efficiently transform diverse biomass materials into uniform particles...

Pilot-scale commercial rotary shear for biomass processing

Optimize your biomass processing with efficient particle size...

Micro-scale rotary shear for particle size reduction

Optimize your research with precise particle reduction, ideal for tr...

Particle sizer for precise sifting

Optimize your production line with high-speed particle sizing, ensuring precise control ...

Industrial shredder for diverse material reduction

Achieve precise and efficient material resizing for diverse applicatio...

Industrial pulper for fresh produce

Achieve ultra-fine purees and pastes with this high-speed industrial pulper, designed t...

High-shear processors for uniform nanoparticles

Optimize particle size reduction and achieve uniformity in nanoparticle fo...

Industrial ring dryers for high-capacity drying applications

Maximize drying efficiency for diverse materials with ring ...

Oil and fat refining system

Ensure high-quality oil and fat production by efficiently removing contaminants such as phosphat...

Industrial lump breaker for particle size reduction

Optimize your production line with an advanced solution for efficient...

High containment powder transfer valve

Ensure high containment for potent powders in your production line, reducing contami...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Integrated grinding system for wheat and grain

Optimize your grinding process with a system that delivers consistent parti...

Coffee processing system for integrated coffee production

Enhance your coffee production with a versatile system that in...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial homogenizer for high pressure applications

Achieve consistent product texture and stability for your emulsions...

Modular big bag discharge station for bulk material handling

Streamline your bulk material handling with a customizable ...

Hygienic feeding hopper for bulk solids

Ensure optimal hygiene in your powder and granular processing with a feeder that fa...

Hydro grind reactor for meat, vegetable, and vegan product processing

Achieve precision grinding and emulsification of ...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

High shear emulsifier for hygienic applications

Achieve precise emulsification and consistent mixture quality with enhance...

Dual asymmetric centrifugal mixer for epoxy and slurry mixing

Achieve precise mixing and consistency in your formulation...

Dual asymmetric centrifugal processing system for epoxies and slurries

Streamline complex formulations with a system th...

Marination injecting solution for fresh poultry

Enhance product consistency and maximize yield in your production line wit...

Pharmaceutical r&d granulation system

Optimize your pharmaceutical research with a versatile small-scale granulation system...

Industrial homogenizer for dairy, beverage, and pharmaceutical applications

Enhance your production efficiency with a ...

Pharmaceutical homogenization skid system

Achieve precise particle size reduction and efficient cell rupture with an auton...

Integrated granulation and drying system for pharmaceuticals

Achieve seamless granulation and drying with our fully inte...

High-performance dispersing and mixing solutions

Enhance your mixing and dispersing processes with advanced fluid stream t...

Dissolver for high-viscosity products through floor installation

Optimize production of ultra-high viscosity products wi...

Mixer for high viscosity products

Enhance your production line with a versatile solution designed for precise mixing and di...

High-performance dissolver for large-scale production

Optimize your production line with precision-controlled dispersion ...

Vacuum dispersion system for high-viscosity products

Eliminate air inclusions during production with a modular vacuum sys...

Vacuum dissolver for high viscosity products

Optimize your production with a vacuum dissolver designed to efficiently prev...

Vacuum disperser for high-viscosity products

Optimize high-viscosity product dispersion and prevent air inclusions with a ...

Vacuum dissolver for large batch production

Optimize your mixing processes with a versatile vacuum dissolver designed for ...

High-capacity dissolvers for industrial mixing

Enhance your production line with precision mixing, achieving consistent di...

High shear batch process homogenizer for production

Achieve efficient emulsifying, homogenizing, and dispersing with prec...

High-performance production dissolver for large batches

Achieve precise and repeatable dispersion for complex formulation...

Production dissolver with scraper for high-viscosity products

Efficiently tackle high-viscosity material processing with...

Explosion-proof dissolver for high viscosity products

Optimize your high-viscosity material processing with an explosion-...

ATEX vacuum dissolver for high viscosity products

Ensure safe and efficient dispersion of high-viscosity materials under...

Explosion-proof vacuum dissolver for high viscosity products

Achieve precise dispersion of high-viscosity products under...

Explosion-proof vacuum dissolver for high viscosity applications

For operations requiring precise control in high-viscos...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Vacuum dispersion system for laboratory applications

Achieve precise mixing and homogenization under vacuum conditions, e...

Vacuum dispersion system for single-walled containers

Optimize your production line with an adaptable vacuum dispersion s...

Laboratory vacuum dissolver

Experience precision vacuum processing for your high-viscosity formulations, ensuring optimal di...

Vacuum dissolver for laboratory and pilot plant operations

Perfect for developing intricate formulations, this vacuum di...

Dissolver for high-volume industrial dispersion

Achieve precise and efficient mixing with this dissolver, designed for sea...

Industrial dissolver for high-viscosity materials

Efficiently disperse and mix high-viscosity materials with precision, e...

Vacuum dissolver for highly viscous products

Efficiently mix and disperse high-viscosity substances under vacuum to ensure...

Explosion-proof dissolver for hazardous area mixing

When operating in hazardous environments, maintaining consistent and ...

Explosion-proof dissolvers for laboratory use

Ideal for safely dispersing and mixing chemical substances in potentially ex...

Efficient high-volume dissolver with scraper

For high-viscosity formulations, this advanced dissolver with integrated scra...

Laboratory disperser for small batch processing

Achieve precise dispersion and homogenization of high-viscosity mixtures w...

Flash dryer for corn starch

Reduce energy consumption and maintain product quality with efficient drying solutions designed ...

Wheat processing systems for industrial applications

Maximize efficiency in wheat processing with a system designed for p...

Segment cutter for potatoes and carrots

Achieve precise cuts on vegetables like carrots and potatoes with minimal featherin...

Industrial particle size reduction processor

Optimize your production line with high-capacity, continuous particle size re...

Slicer for elongated products

Effortlessly slice and prepare a wide range of elongated and firm products, transforming your ...

Industrial dicing solution for food products

Enhance processing efficiency with high-speed dicing and slicing solutions, e...

Industrial vegetable protein processor

Achieve precise size reduction and consistent texture in food processing with this h...

Complex preparation system for industrial microsphere production

Achieve precise particle size and uniform drug encapsul...

Electric tomato squeezer for large-scale production

Optimize your tomato processing with this high-capacity electric sque...

Electric tomato squeezer for family and small community use

Ideal for crafting homemade sauces and preserves, this elect...

Lab scale roller compactor for dry granulation

Achieve seamless scale-up from lab development to full-scale production wit...

Pilot to full-scale roller compactor for dry granulation

Easily transition from pilot to full-scale production with this ...

Roller compaction for dry granulation in pharmaceuticals

Ensure consistent granule size and density in your product line ...

Roller compactors for dry granulation

Optimize your powder processing with advanced roller compaction, ensuring consistent ...

Belt dryers for gelatin processing

Efficiently transform liquid gelatin into high-quality solids with precise moisture cont...

Material handling system for granules and powders

Optimize your production with seamless material handling specifically d...

Dry granulation roll compactor

Optimize your tablet and capsule formulation by efficiently compacting and granulating powder...

Industrial blender for uniform mixing

Optimize your process with precise mixing and consistent blending, ensuring uniformit...

Pilot plant homogenizer for immiscible liquids

Streamline your R&D with precise homogenization, allowing you to test ...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

Laboratory scale powder/liquid mixer

Easily integrate powders into complex liquid formulations at a laboratory scale, ensur...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

High shear inline mixer for continuous processing

Effortlessly streamline your mixing process with this solution capable ...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

Pilot scale batch mixer for small scale production

Achieve precise control and consistency in small-scale production with...

High shear batch mixer for industrial mixing

Optimize your production cycle with this high shear batch mixer, designed to ...

Bottom entry mixers for high viscosity products

Optimize your production line with mixers designed to handle both high and...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Turbo separator for Ddg agglomeration

Efficiently eliminate clumping and improve flow in your distillation process, ensurin...

Optimal maintenance solution for industrial weighfeeders

Streamline your processing operations with a solution that minim...

Impact huller for oats

Hulling technology risks breaking oat grains if the system is not adjustable to fragile materials. Agg...

Particle analysation monitor

Products like granules, tablets and capsules require inspection at numerous steps in the produc...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Two Roll chocolate pre-refiner

A pre-refiner is commonly utilized to refine and calibrate the sugar crystals in the chocolat...

Three-Roll chocolate refiner

For mixing, rubbing and fine grinding in the production of chocolate mass, filling materials an...

Five Roll chocolate refiner

When you want to produce high quality traditional chocolate, a 5 Roll Refiner gives you complete...

Mixer and refiner for chocolate compound

Mix cocoa liquor, cocoa powder, sugar, and lecithin in a small scale and refine sm...

Mixer and kneader for sugar based recipes

For the production of chocolate paste based on refined or icing sugar, the decis...

Cocoa liquor grinding line

After roasting and cracking chocolate beans (without husks), the following process is the grindin...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

Cheese grater

Breaking down large blocks into grated, shredded, powdered or planed cheese requires multiple graded discs that ...

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Small capacity chocolate melangeur

In order to produce the finest of chocolate products, you need the cocoa nibs to be grin...

Pelleting press for biomass

Utilization of biomass for energy and other applications requires consistent and reliable compac...

Airshocking hammer

Silos, hoppers, bins, and other containers can build up a layer of powdered product on the internal walls....

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Industrial vegetable cutter

Retaining freshness in cut vegetables, as well as retaining vitamins and nutrients, is a top pri...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

Declumping machine for dried fruit or frozen vegetables

Breaking up dried fruit neatly, without damage, requires gentle a...

Solid biomass screening and crushing equipment

Biomass fuels come in many forms and often include impurities that can dama...

Industrial coffee bean grinder

If you are looking to grind up to 50 kg of fine coffee per our or up to 440kg of medium fine ...

Shop coffee bean grinder

Do you want to grind your beans on-site at your coffee shop, but are you limited for space? Bench-to...

Mortar for coffee pounding

With a pounding capacity of 50 kg/h – 110 lbs/h this mortar for coffee pounding will guaran...