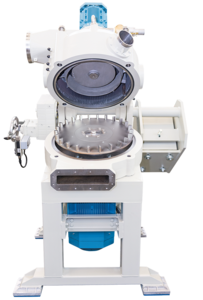

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain and serves as a usable material in the manufacturing of rubber products such as conveyor belts. The main challenge in recycling tires for recovered carbon black of versatile use is refining the pyrolyzed tire materials from various feedstocks to achieve consistent fineness. Typically, an efficient grinding, milling, and classifying system are required to ensure the desired fineness of rCB and increase its value.

Classifier mill for superfine grinding and classifying process

The Impact Classifier Mill ICX by NEUMAN & ESSER is suited for dry grinding by combining extra-fine grinding with high-precision classification in a single assembly. During grinding, rapidly moving grinding tools convey feed materials into the liner at variable speeds and crush them. The integrated classifier separates coarse particles carried via airflow. Coarse materials rejected from the classifier re-enters the grinding zone for further reduction. The ICX can achieve particle size top cut from 5 µm to 50 µm. It also enables high throughput rates with high energy efficiency and the capability to process mill capacities ranging from 10 kg/hr to 20,000 kg/hr.

The direct drive uses a VFD-controlled motor; this avoids using a gearbox and oil supply in the rotor. As a result, the ICX can provide easy operation, low maintenance, and low energy consumption by using this design.

When grinding potentially explosive dust such as carbon black, a pressure shock-resistant classifier mill is pressure-resistant up to 11 bar. The NEA ICX is also compatible, and other ATEX-compliant systems can be attached to it.

Benefits

- Good particle size distribution and top cuts

- Durable mill casing with long service life

- Additional available options: tailor-made wear protection, customized grinding tools and classifier wheel type, and belt-drive

- Low noise and vibrations